|

|

|

AIDA

GELINA

BRIKEN

nToF

CRIB

ISOLDE

CIRCE

nTOFCapture

DESPEC

DTAS

EDI_PSA

179Ta

CARME

StellarModelling

DCF

K40

MONNET

|

| CARME |

|

|

|

|

Message ID: 53

Entry time: Thu Sep 2 21:04:26 2021

|

| Author: |

CB RSS ML + DR OG |

| Subject: |

Gate valves mounted + pump down |

|

|

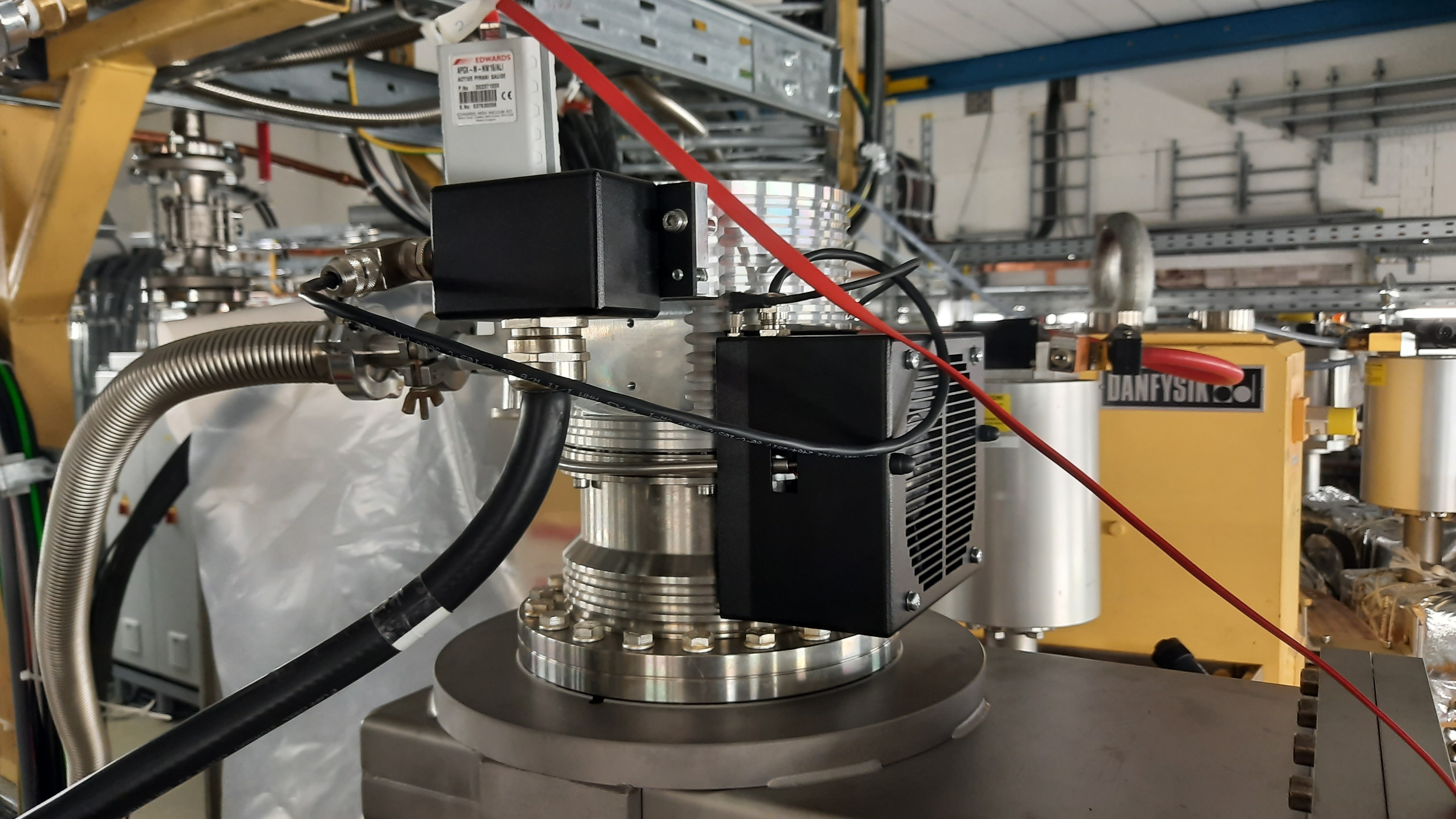

Mounted both gate valves and support. Gate

valves could not be installed one bolt

rotated from 90 degrees as per drawings

due to mechanical conflict with back foot.

Using rotating flanges some small rotation

from 90 was achieved. This may be

sufficient given the reason for the

rotation was to avoid mechanical conflicts

with ring parts that are no longer there.

Valve struts had to be modified as gate

valve is much lower and close to Al frame

than in Daresbury.

ML suggested that the reason for the

change in height mentioned in previous

entry is that the ring gate valve to YR10

is not centered. Solutions will be

considered when the other two setups in

YR09 are mounted and the alignment

situation is more clear

Noted a few blind flanges are bluish,

which indicates SS 304 instead of 316. Did

we get the wrong ones from ITL? Did we

swap them in Daresbury by mistake? Is it

just an odd colour?

Installed turbo pump on top gate valve,

Pirani gauge provided by ABD (where is

ours?) and pumped down.

Reached 10-1 mbar in 10 minutes. Turbo on.

Reached 10-5 mbar on IE514 in 17 more

minutes (where is its manual?)

Will leave pumping overnight. |

|

|

|

|

|

|

|

|

|

|

|

|