| ID |

Date |

Author |

Subject |

|

116

|

Mon Oct 11 11:24:16 2021 |

RSS TD ML | Valve support and cable labeling |

Split funnels were given to Oemer for cleaning. Have received them back after lunch.

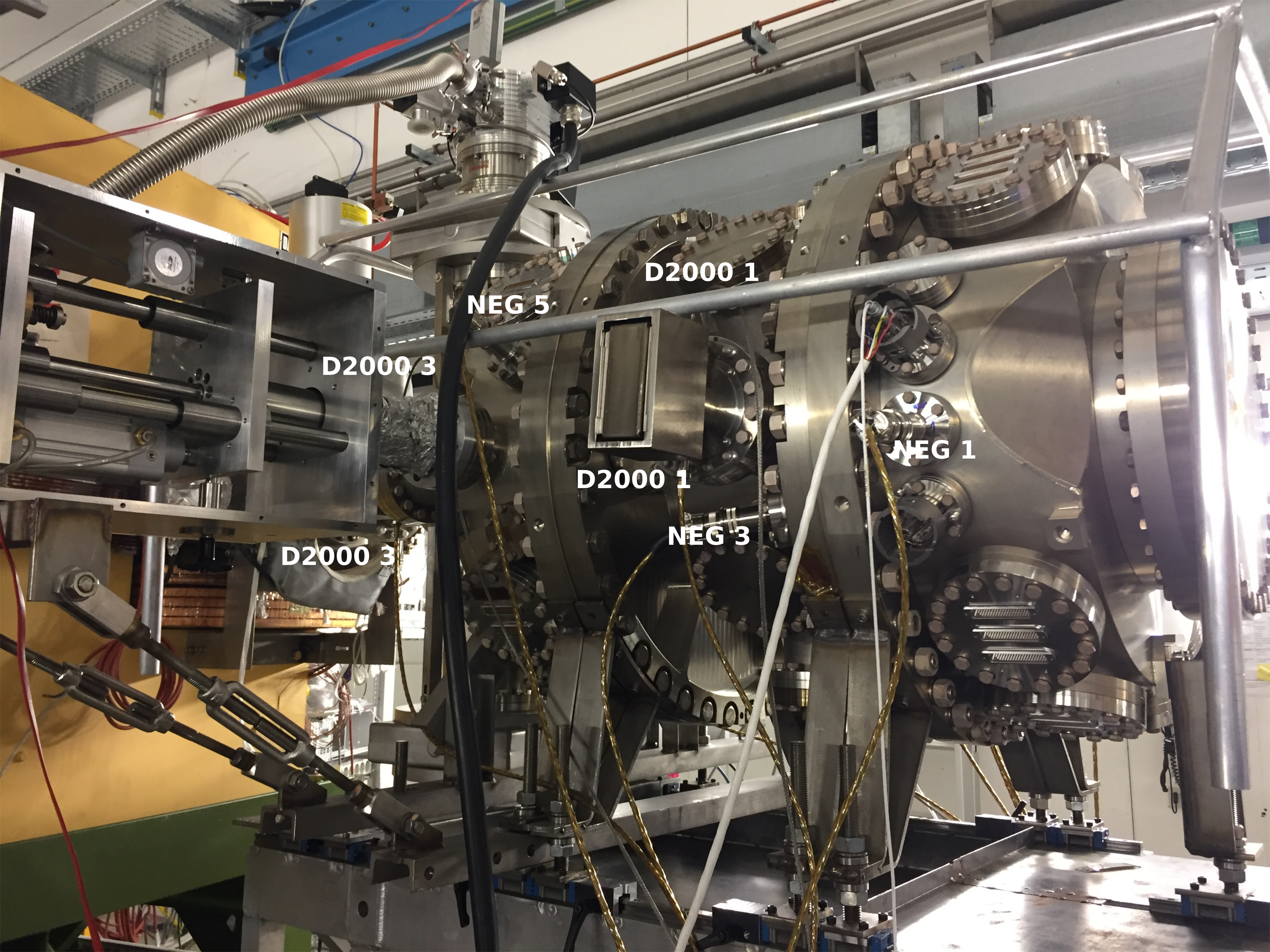

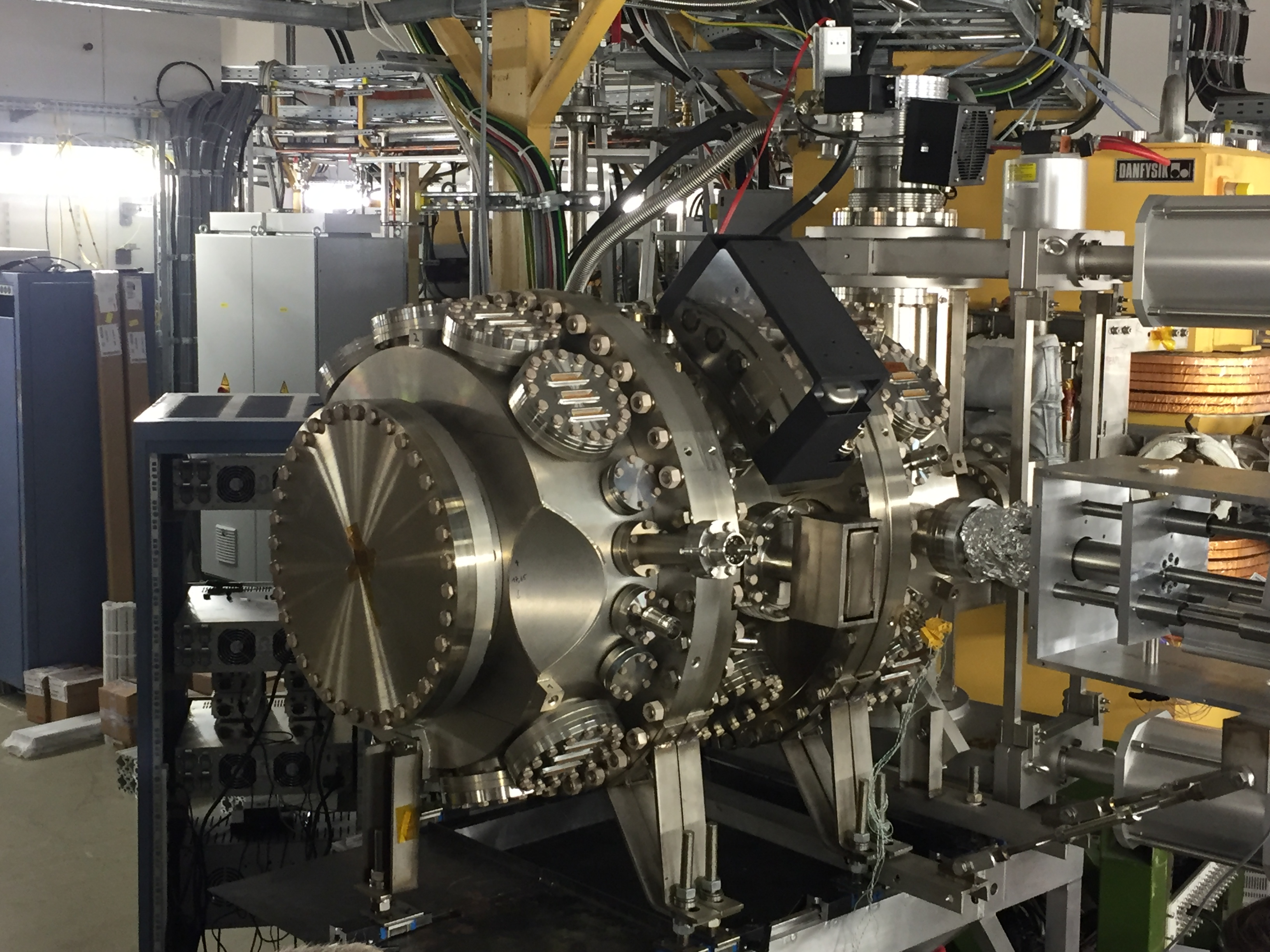

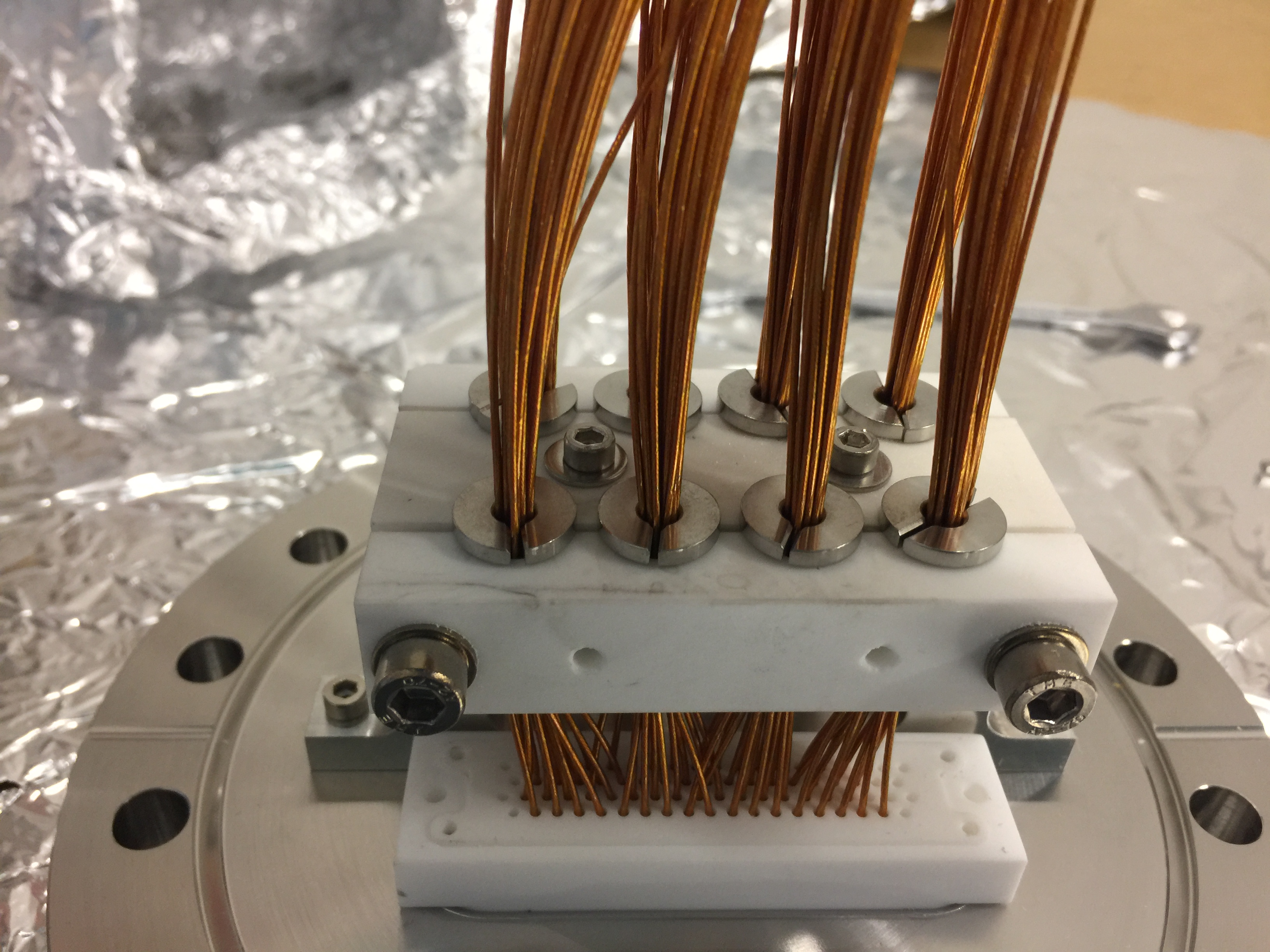

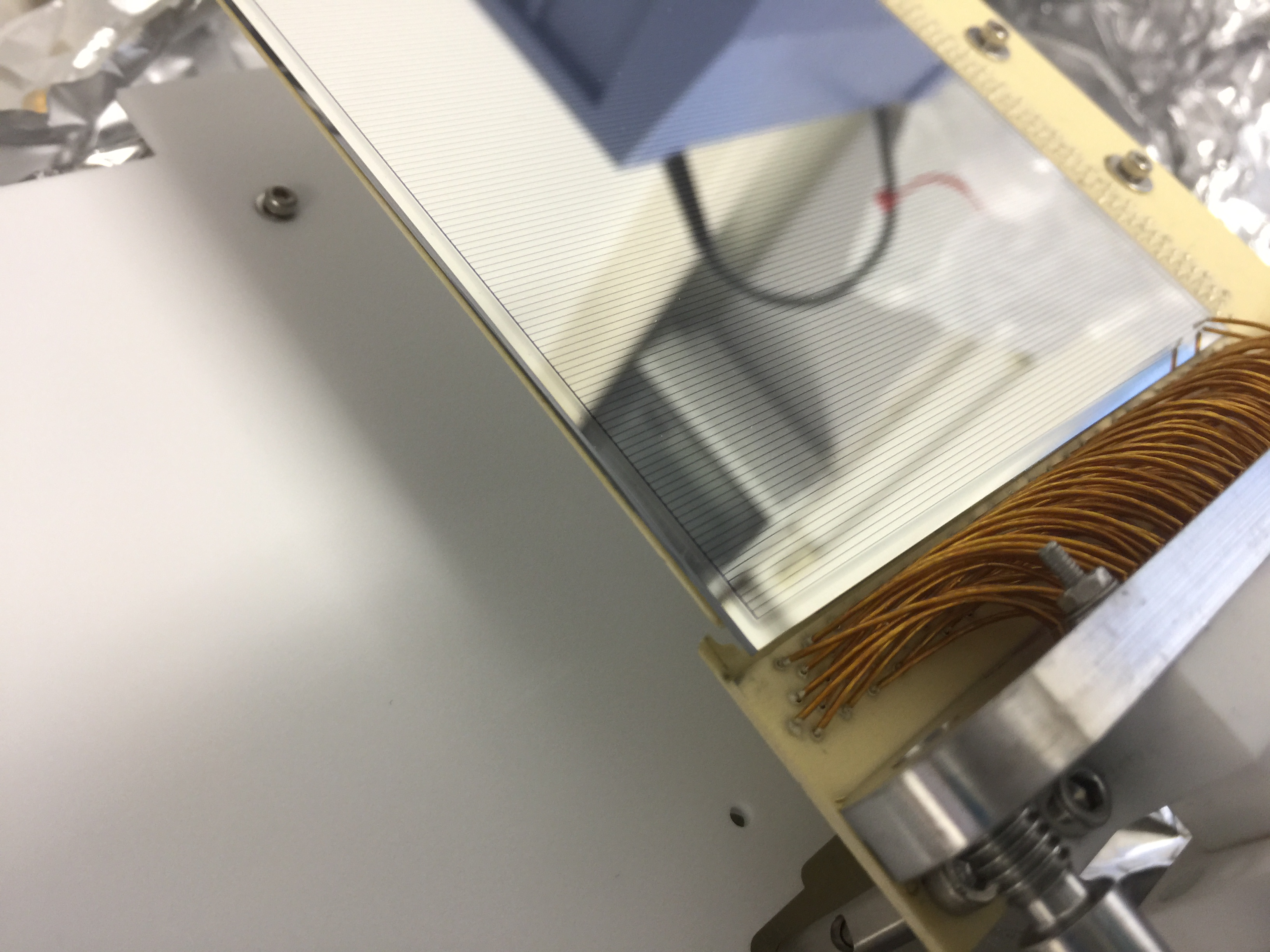

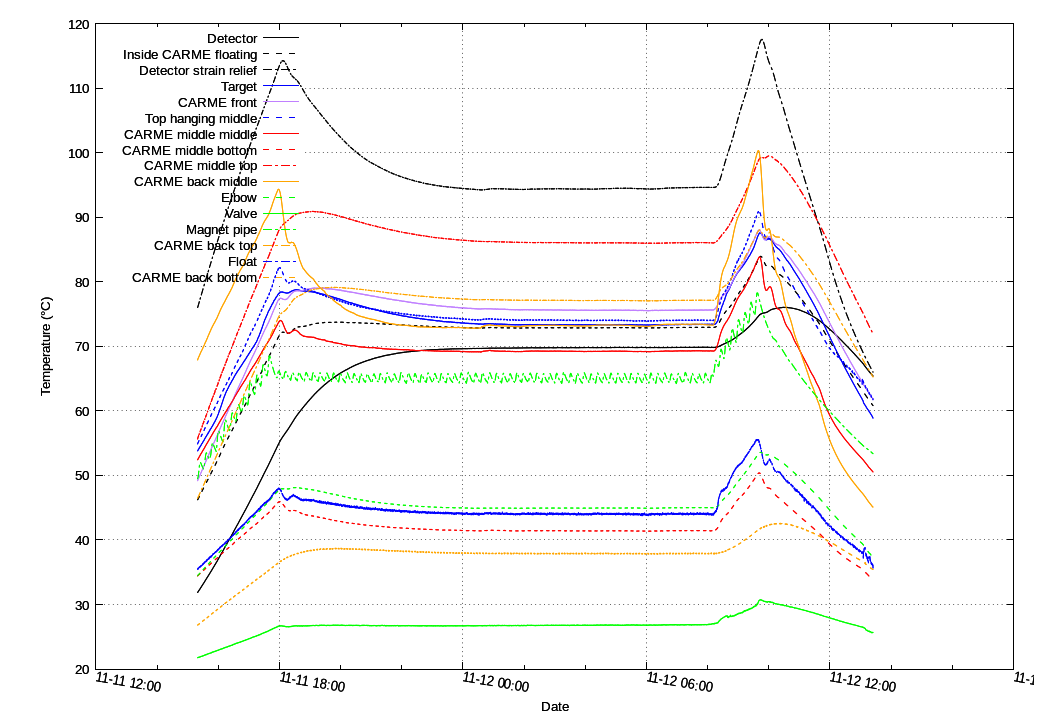

Valve support is installed again (see picture 1).

Ion pump was connected but not activated. Michael will help in doing so. No vacuum support to help will RGA. Will proceed without it.

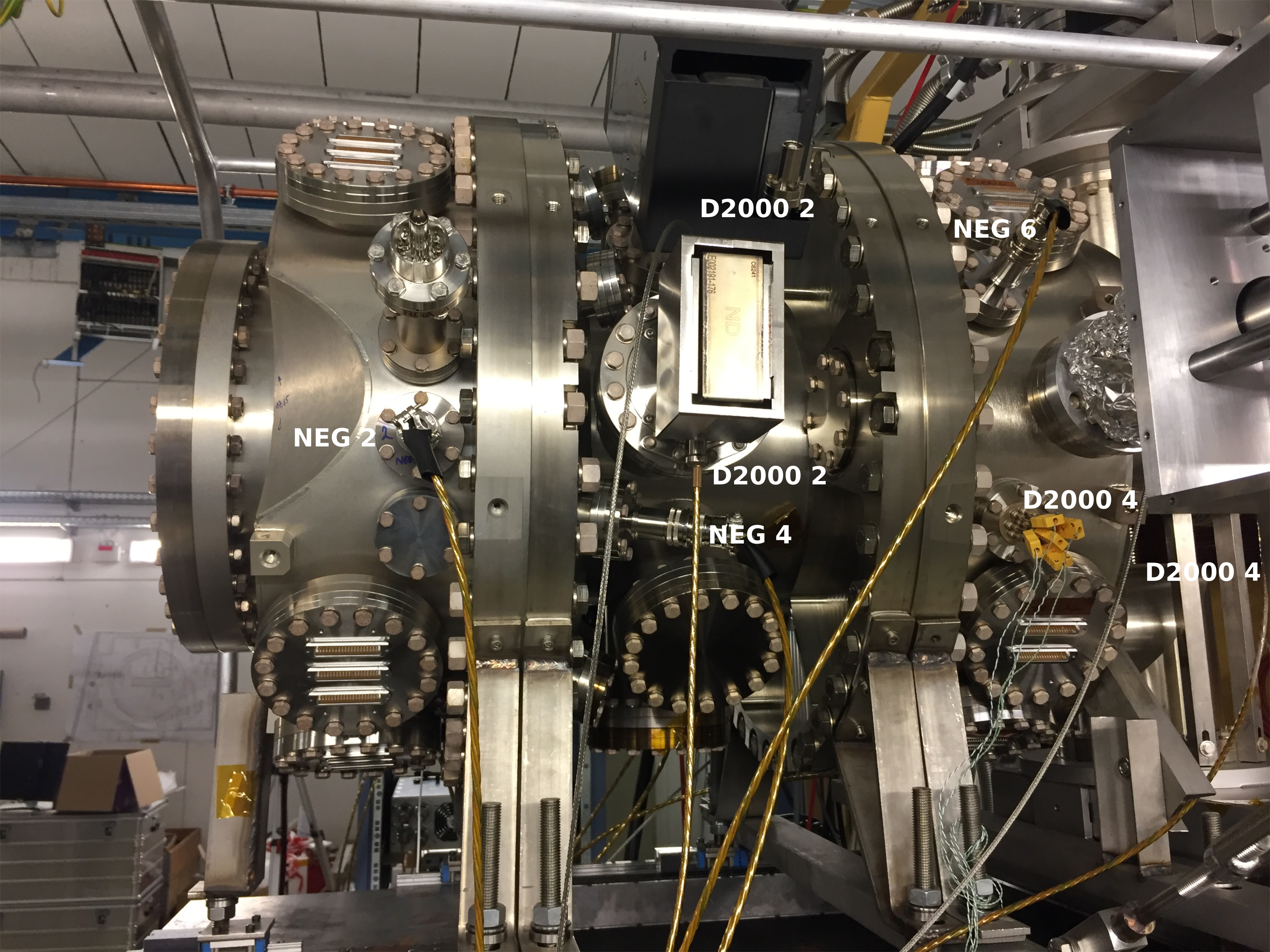

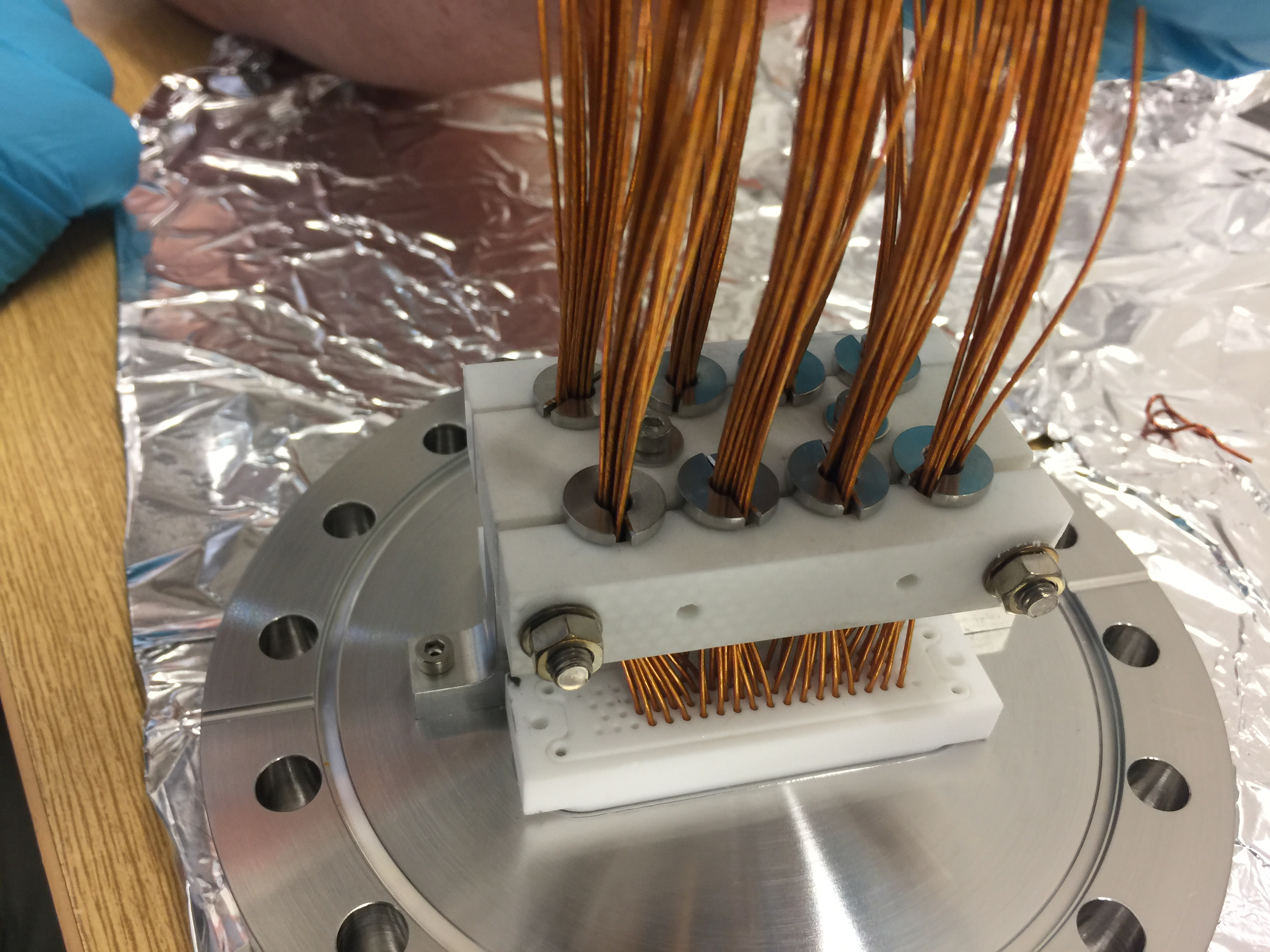

Neg and ion cables were labeled (see pictures 2 and 3).

Chamber was vented using nitrogen.

|

| Attachment 1: IMG_4962.JPG

|

|

| Attachment 2: IMG_4969.JPG.svg

|

|

| Attachment 3: IMG_4968.JPG.svg

|

|

|

117

|

Tue Oct 12 09:22:37 2021 |

RSS TD + OG DR | Motors problem solved |

Neg and ion cables were taken off and were put in the box.

Top support was taken off.

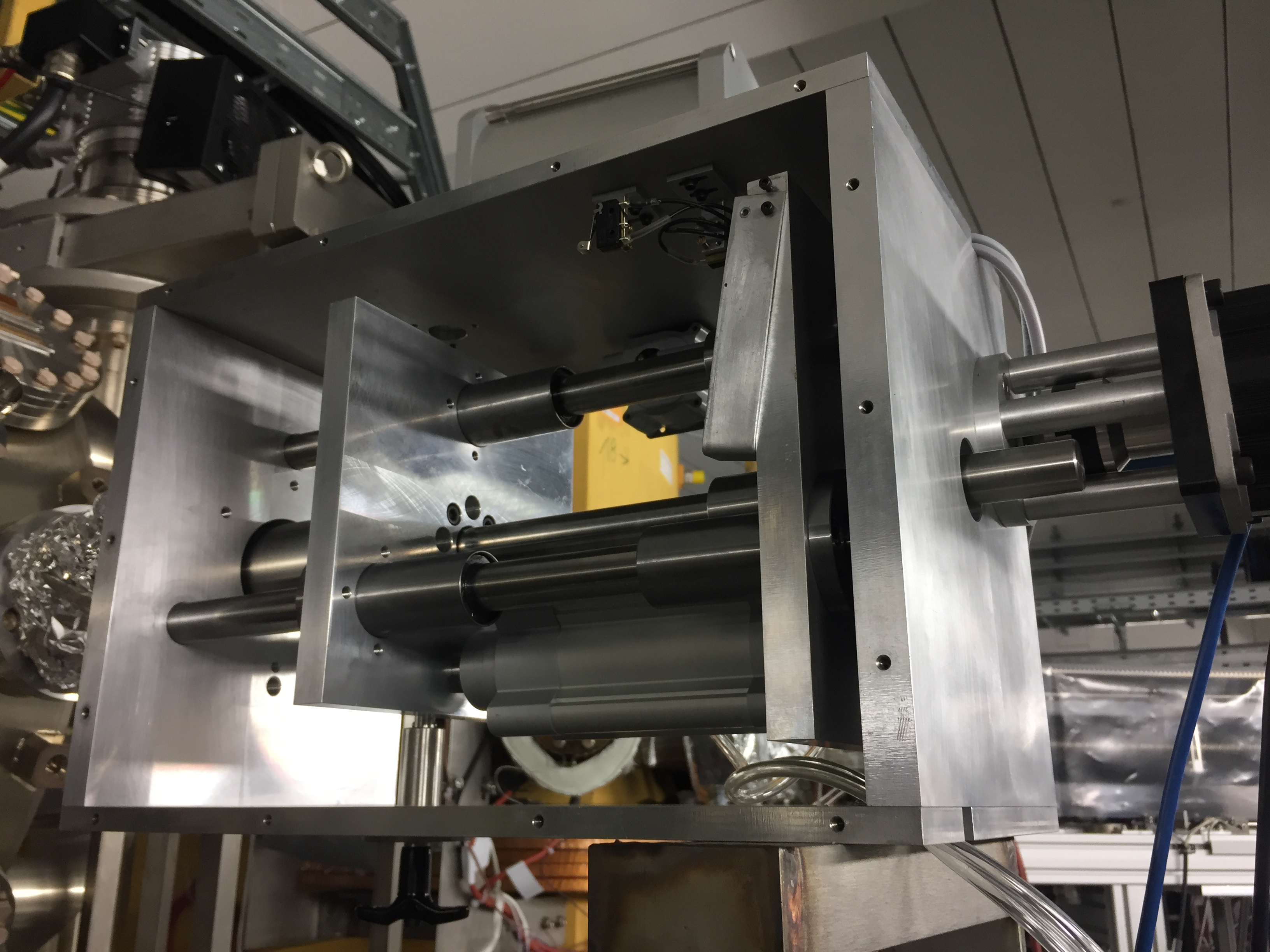

Motors are rotating again. Have to be careful with the position of the limit switches. |

| Attachment 1: IMG_4971.JPG

|

|

| Attachment 2: IMG_4970.JPG

|

|

|

122

|

Wed Oct 13 15:28:22 2021 |

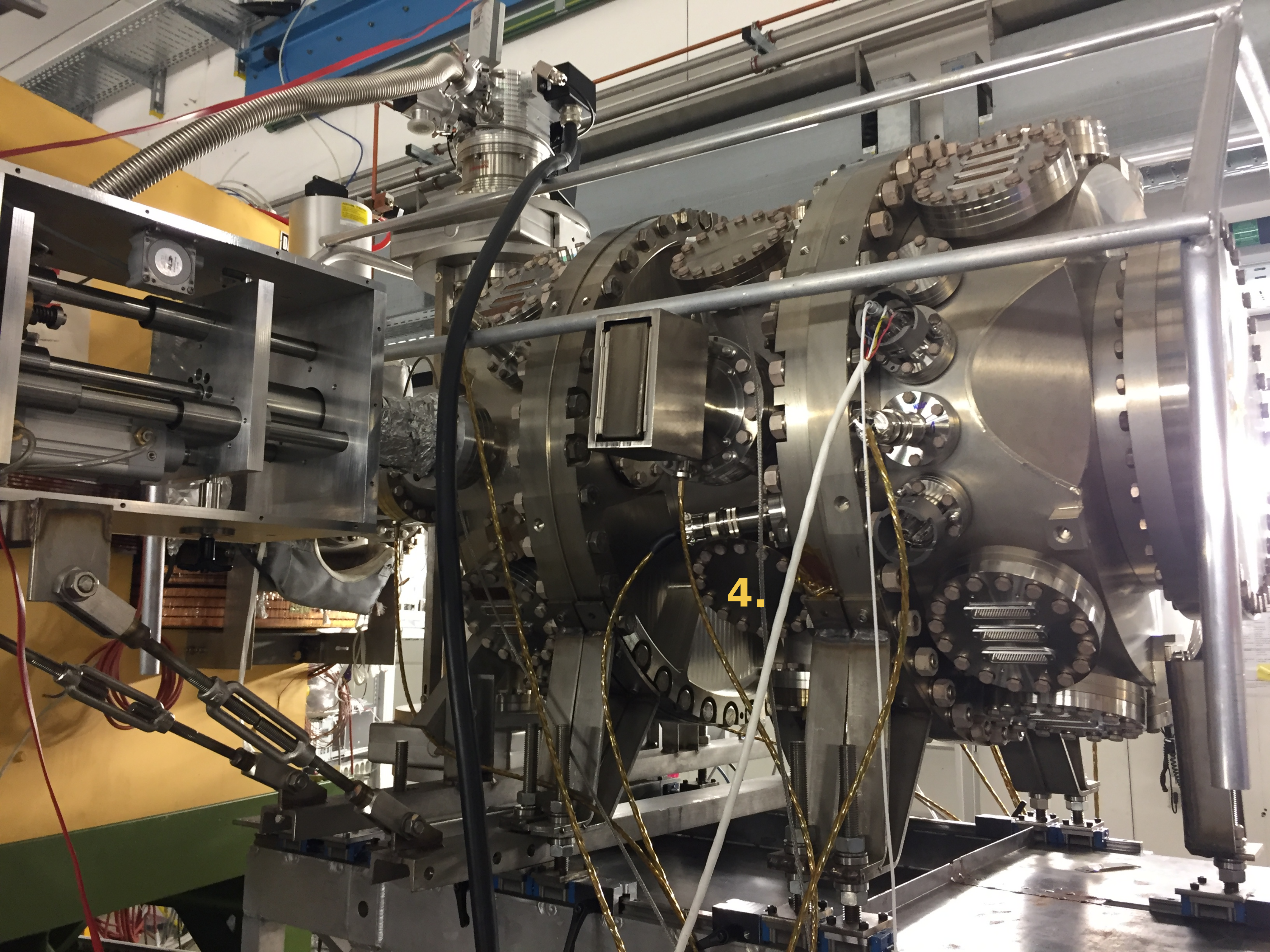

RSS TD + OG | Split funnels |

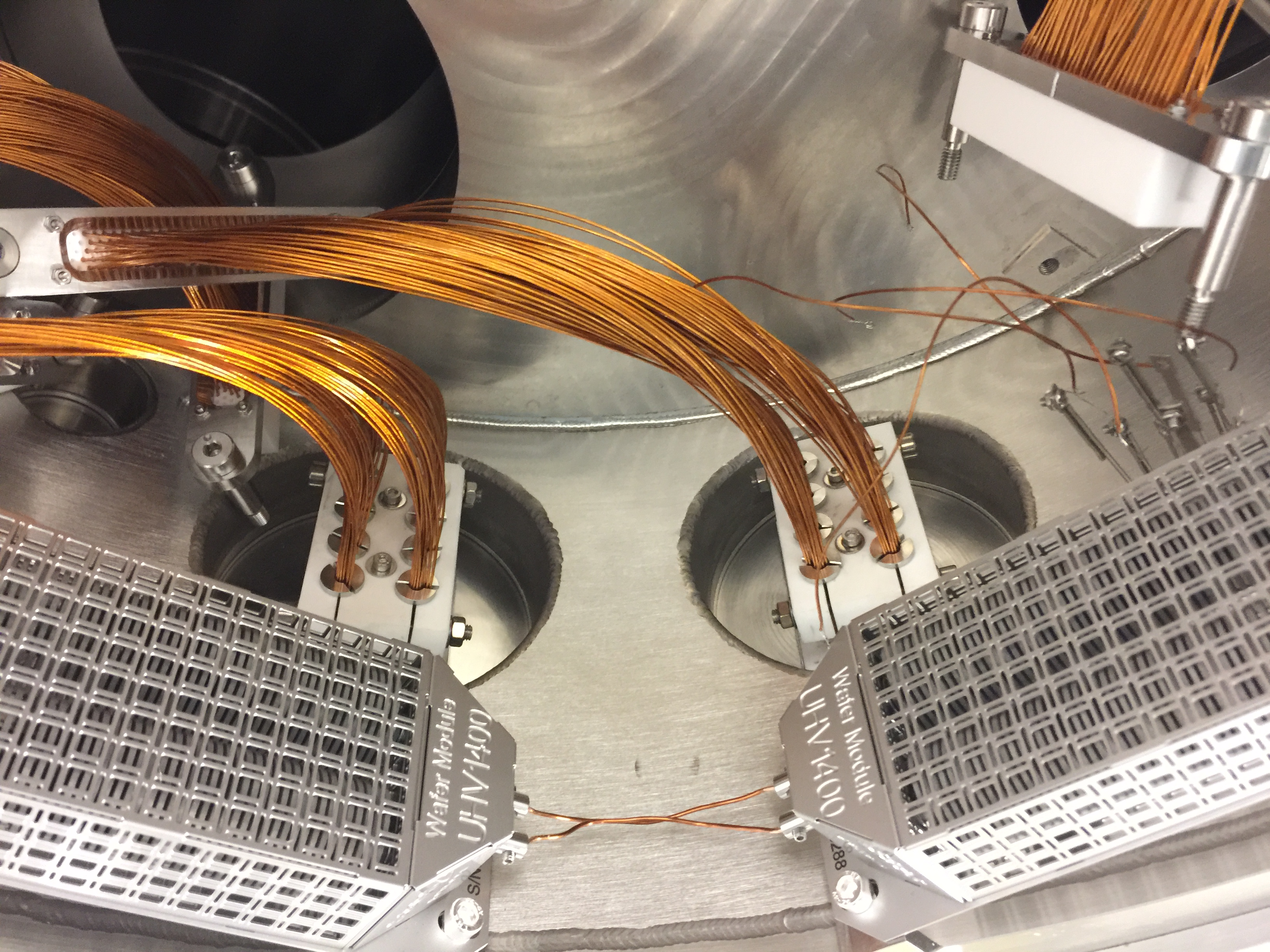

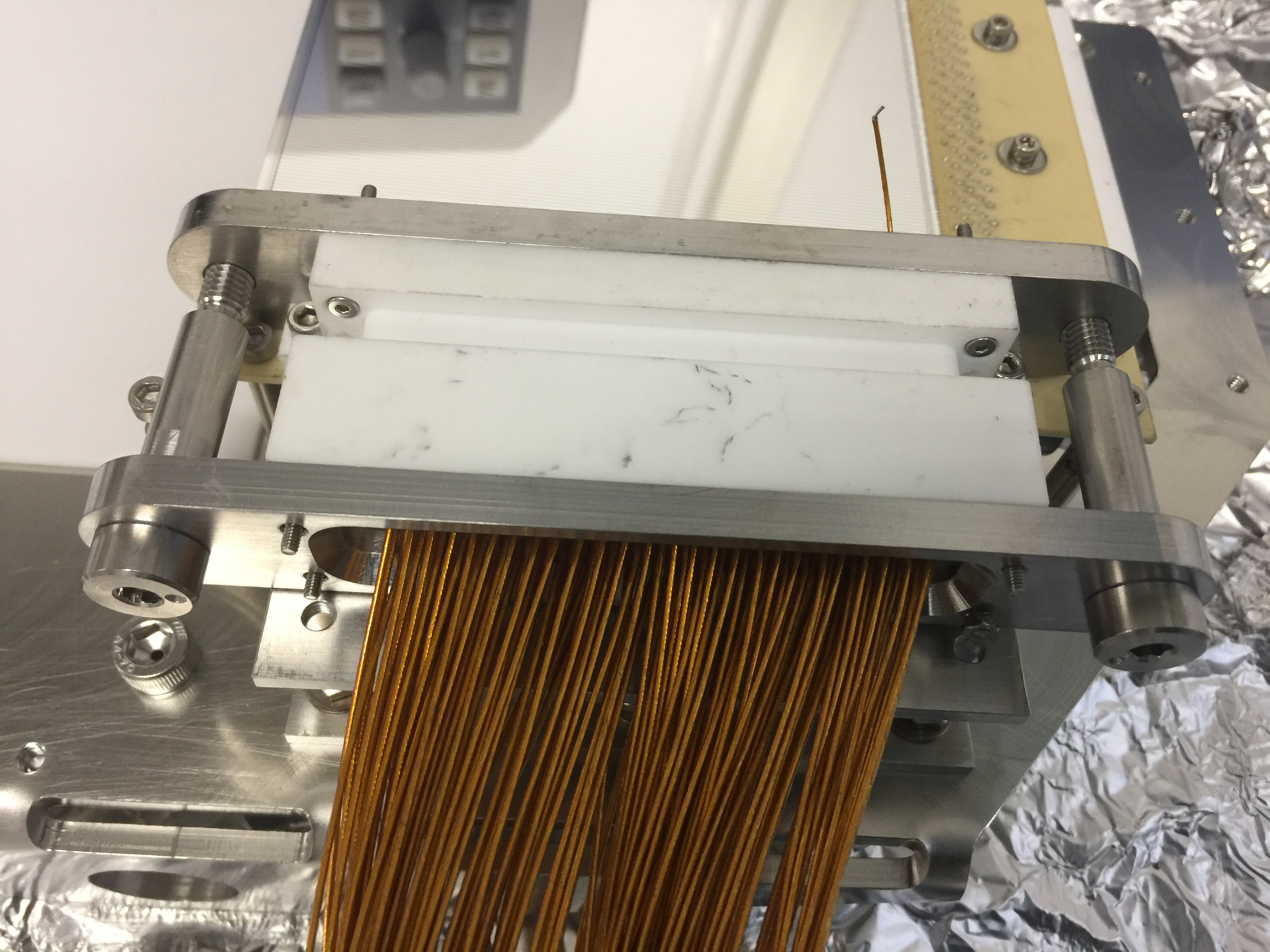

Split funnels installed on 4 (of 8) 2x78 way D connector feed-throughs. |

| Attachment 1: IMG_5038.JPG

|

|

| Attachment 2: IMG_5039.JPG

|

|

| Attachment 3: IMG_5040.JPG

|

|

| Attachment 4: IMG_5041.JPG

|

|

| Attachment 5: IMG_5042.JPG

|

|

| Attachment 6: IMG_5043.JPG

|

|

| Attachment 7: IMG_5044.JPG

|

|

|

150

|

Wed Nov 10 18:38:16 2021 |

RSS TD + ML OG AK NK | CARME wrapped in heating tape |

Heating and electronic experts were in CRYRING and were unhappy with the damaged wire. Heaters were opened by OG, but no damage was found. It is suggested to replace the entire wire and then get it approved by the concerned authority.

To avoid further delays, ML and TD agreed on heating tapes/wires covering the chamber. OG helped in wrapping the heating wire around. Tent is to be built by tomorrow.

MG and RSS tried the magnetic power back off thing which eventually did not work.

AK and NK helped with the power and thermocouple of the heating wire. NK has also covered the pipe and bellows near the magnet with heating jackets.

|

| Attachment 1: IMG_5514(1).JPG

|

.JPG.png)

|

| Attachment 2: IMG_5517(1).JPG

|

.JPG.png)

|

| Attachment 3: IMG_5518.JPG

|

|

| Attachment 4: IMG_5520.JPG

|

|

| Attachment 5: IMG_5521(1).JPG

|

.JPG.png)

|

|

124

|

Fri Oct 15 19:37:12 2021 |

RSS TD + DR | Friday 15 October |

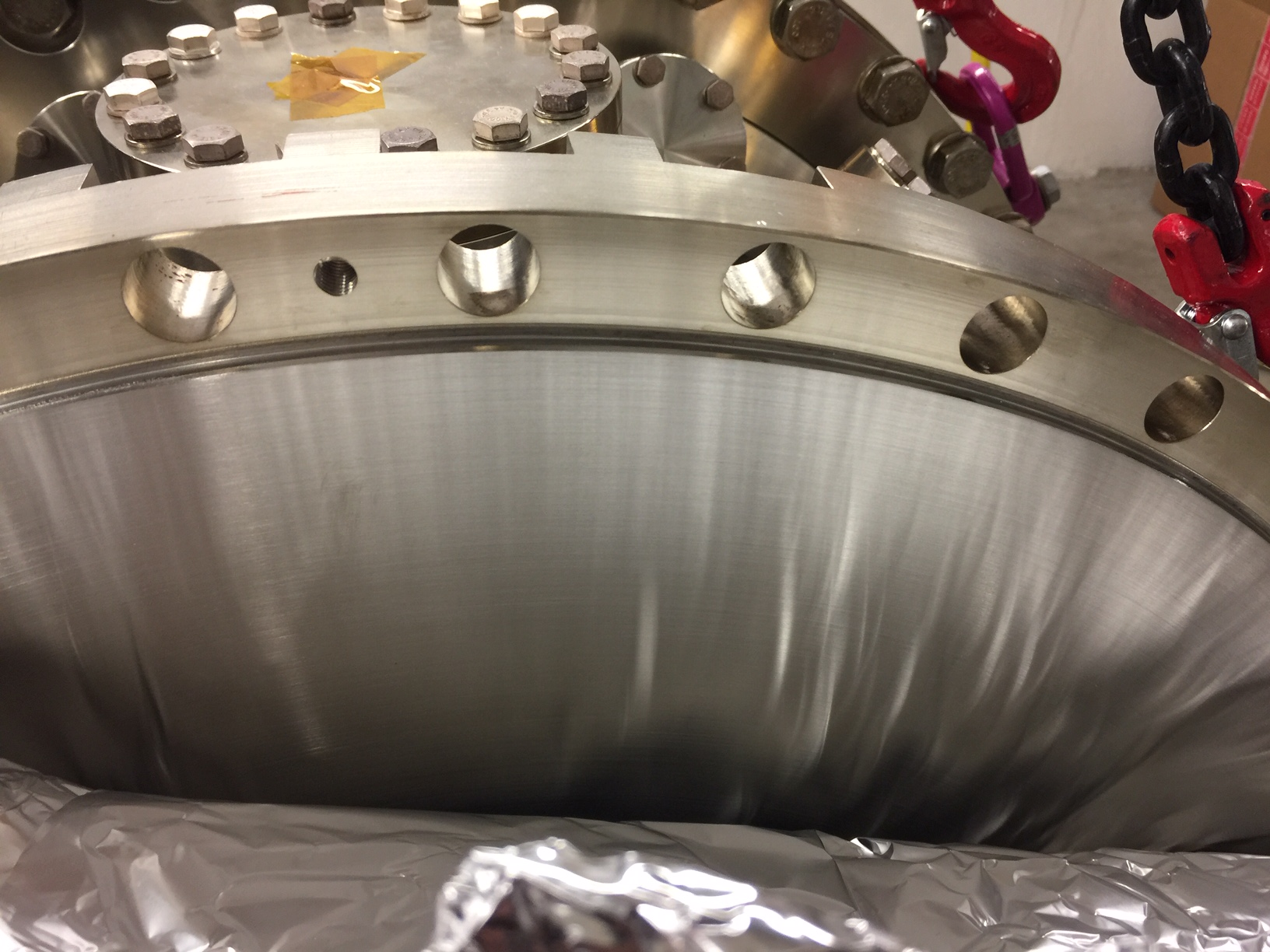

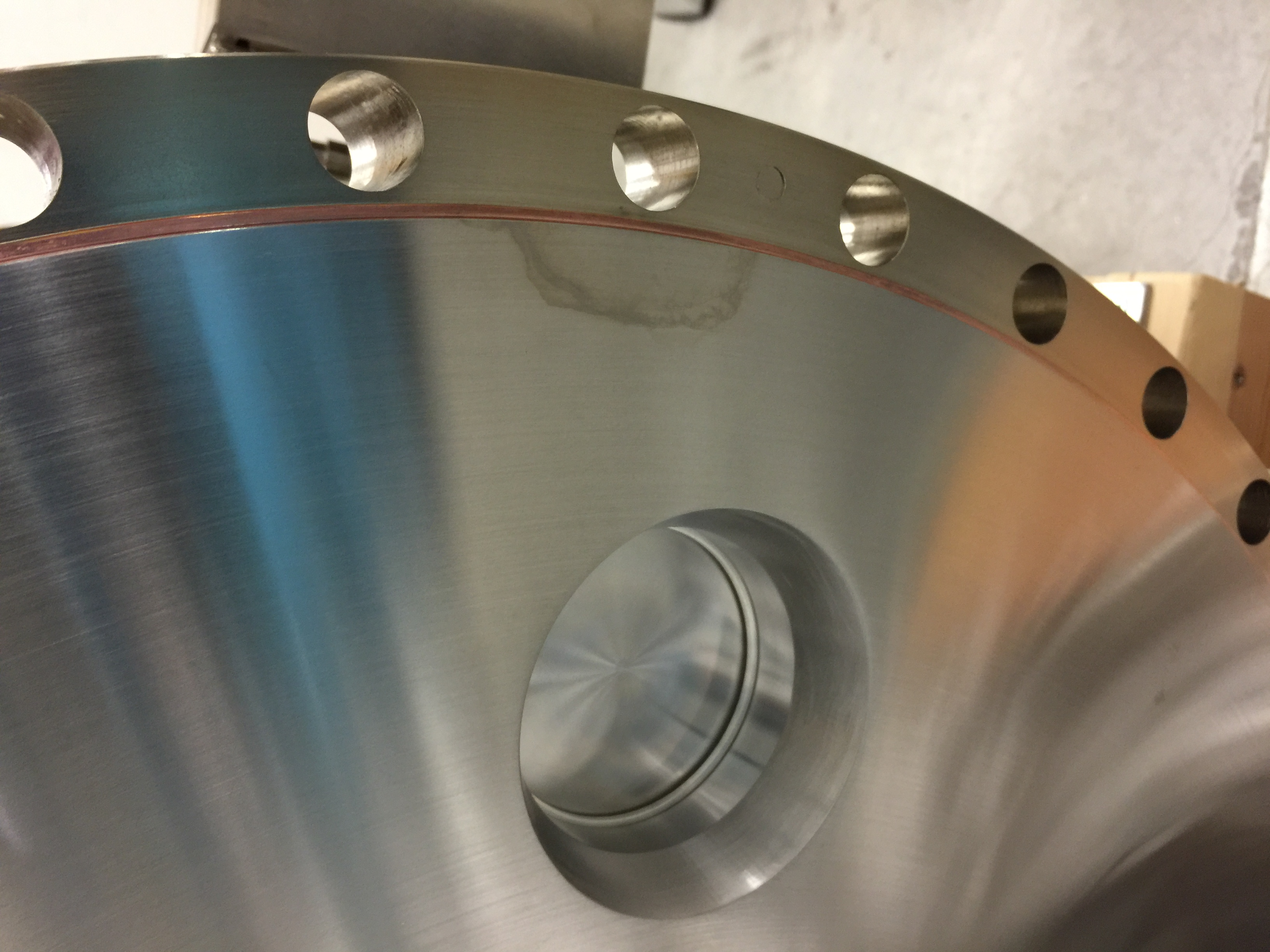

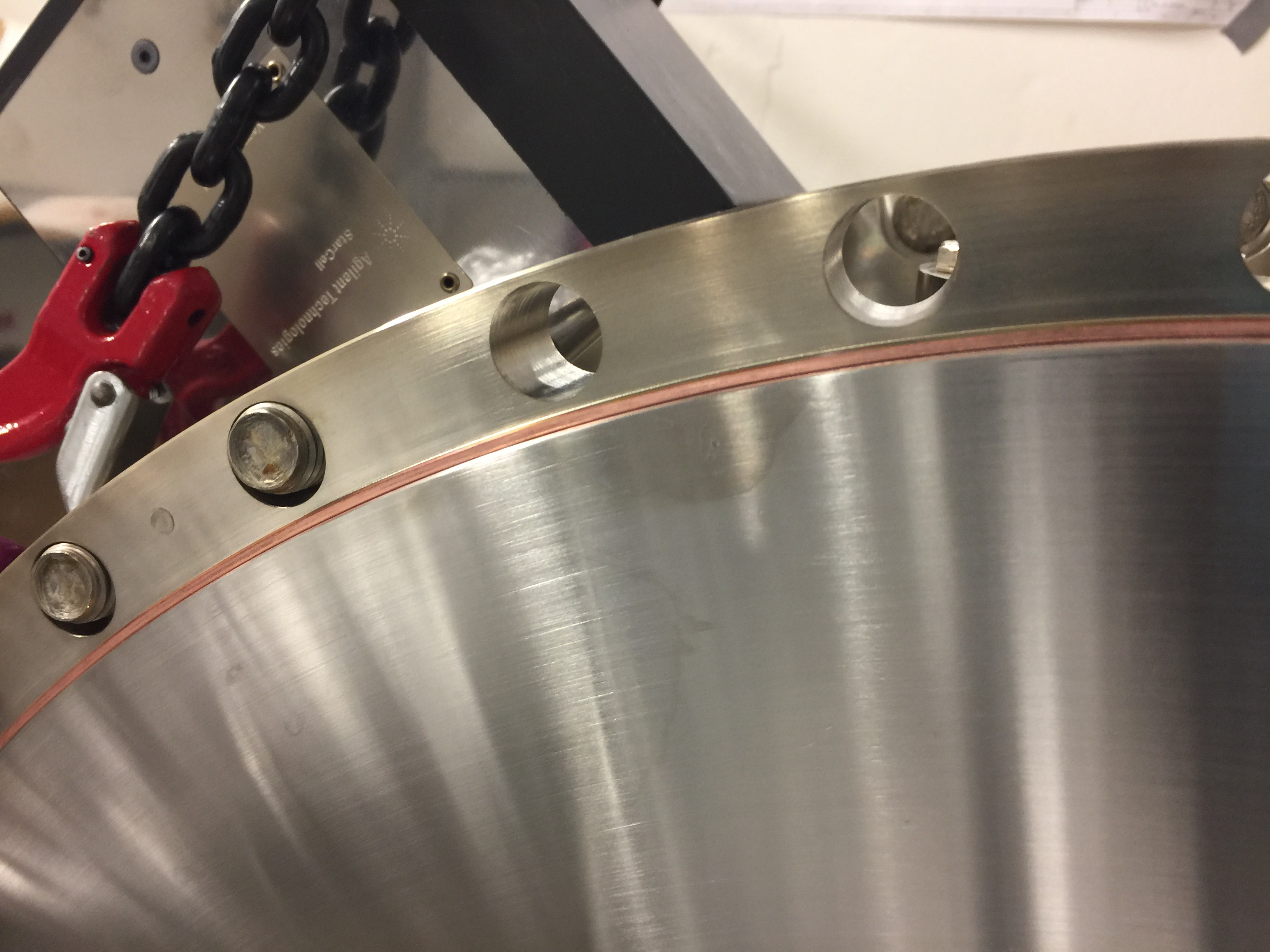

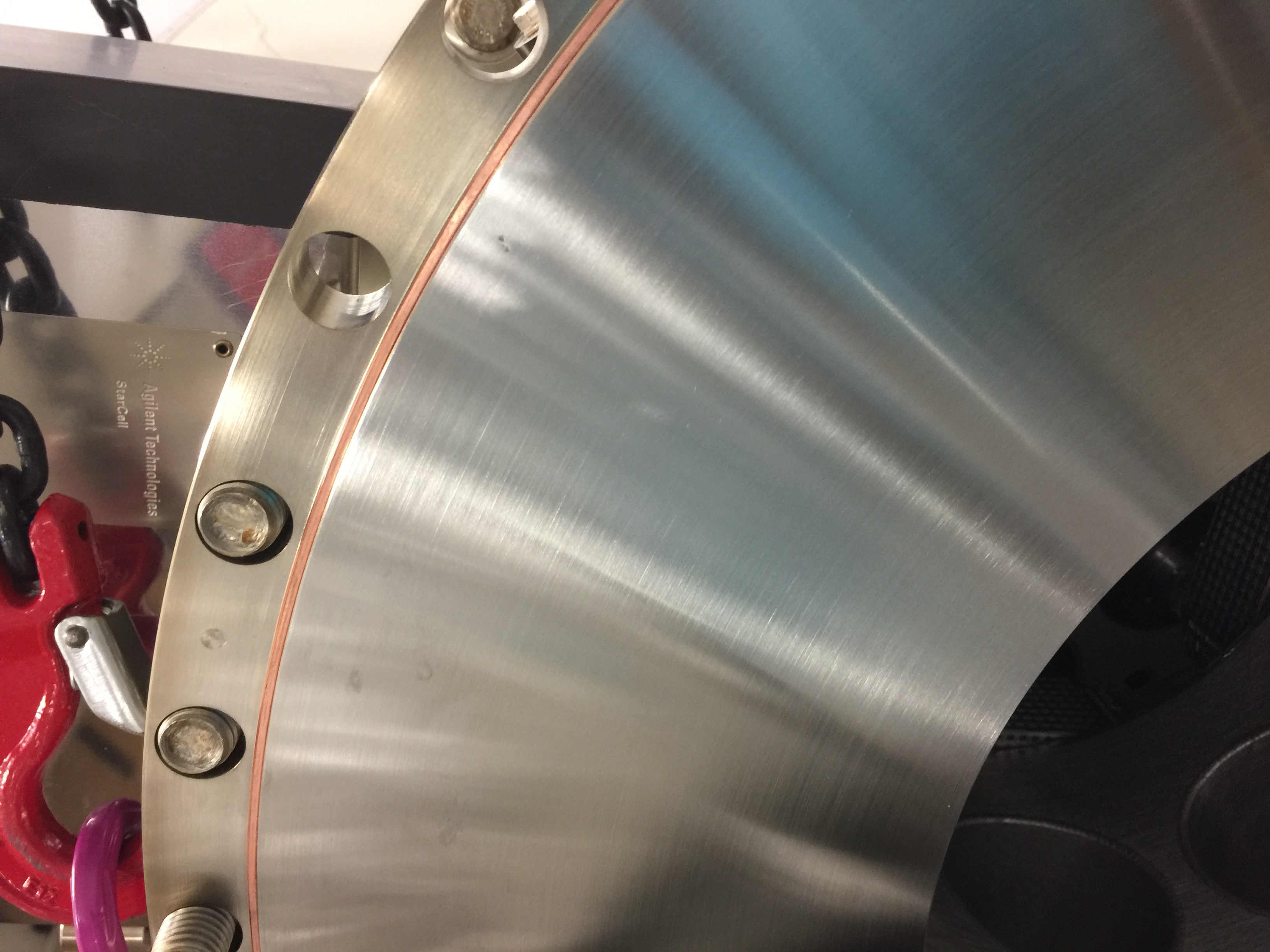

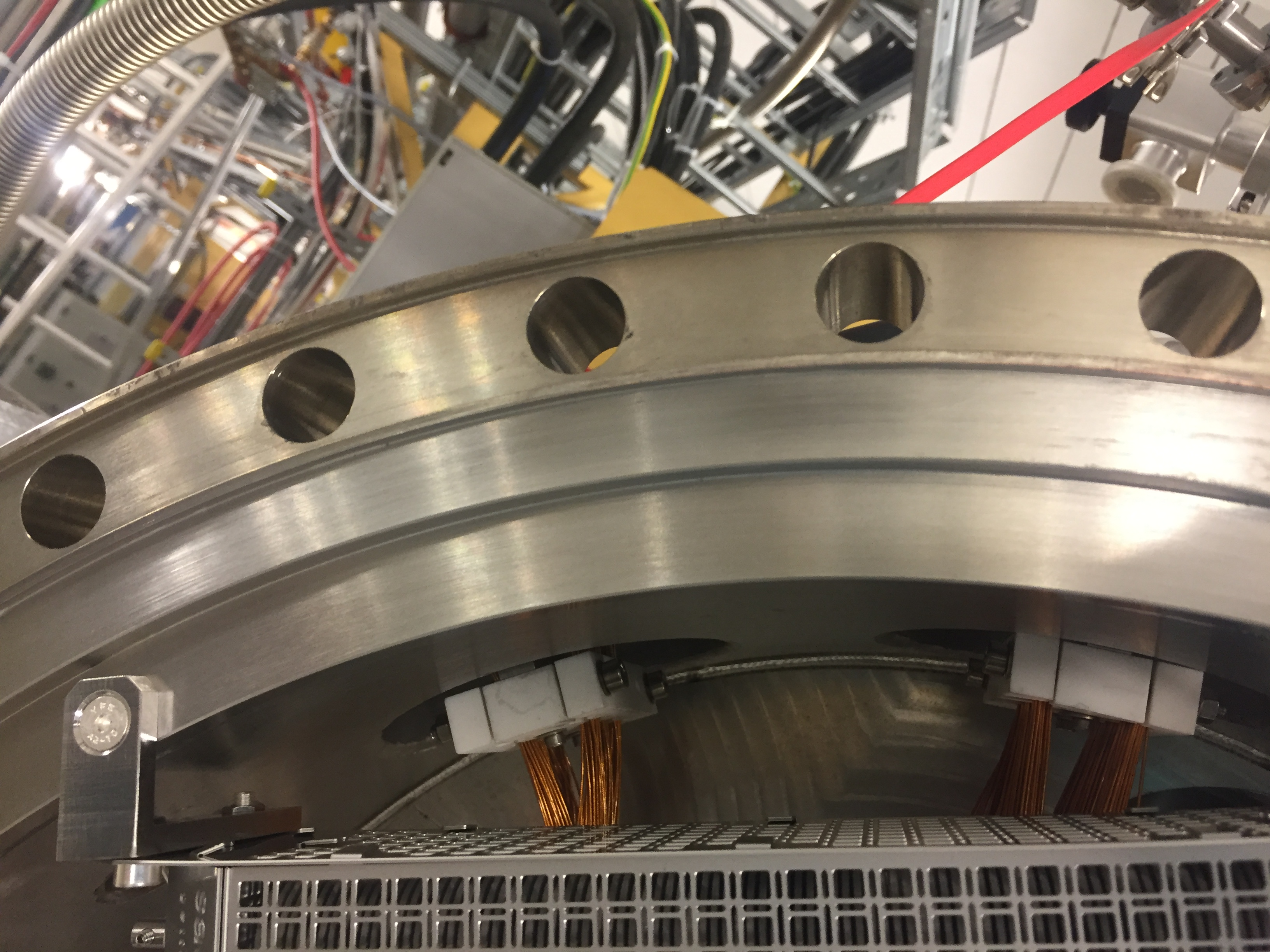

Ring seal is out. See picture 1.

Bellow (towards CARME) was installed in the gas jet chamber. Attached are some pictures. |

| Attachment 1: IMG_5059.JPG

|

|

| Attachment 2: IMG_5060.JPG

|

|

| Attachment 3: IMG_5061.JPG

|

|

| Attachment 4: IMG_5062.JPG

|

|

| Attachment 5: IMG_5064.JPG

|

|

| Attachment 6: IMG_5068.JPG

|

|

| Attachment 7: IMG_5071.JPG

|

|

| Attachment 8: IMG_5073.JPG

|

|

|

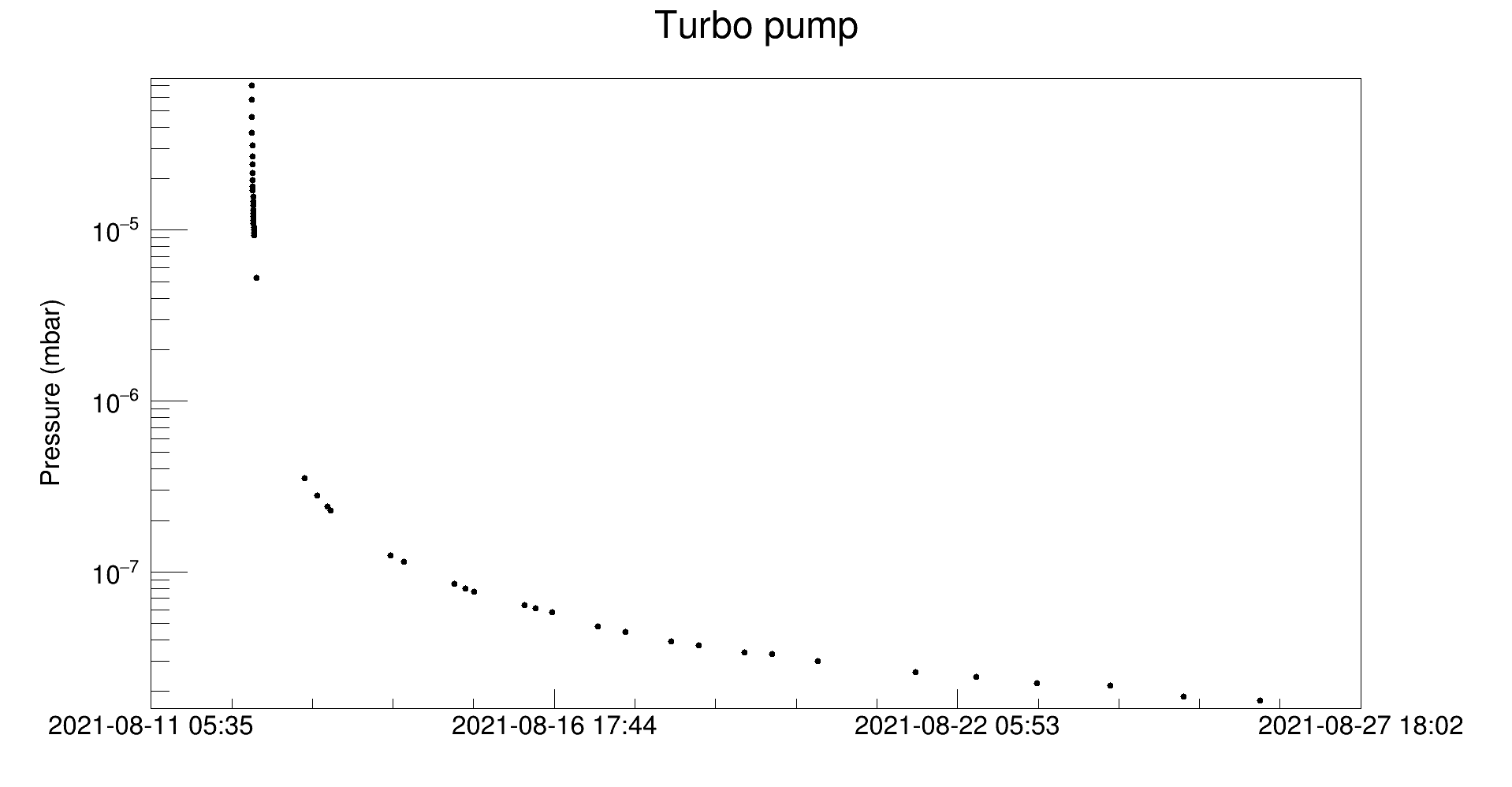

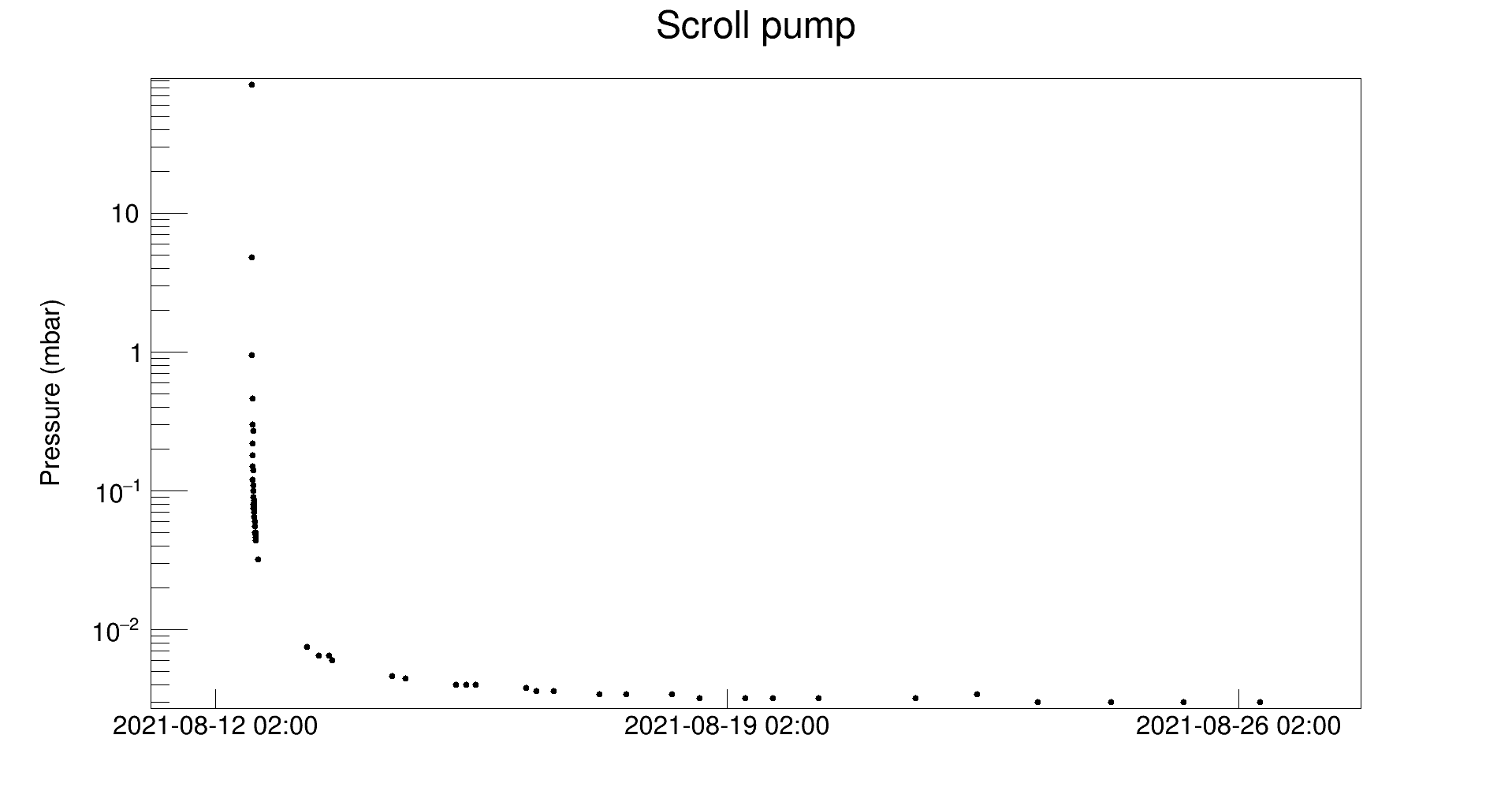

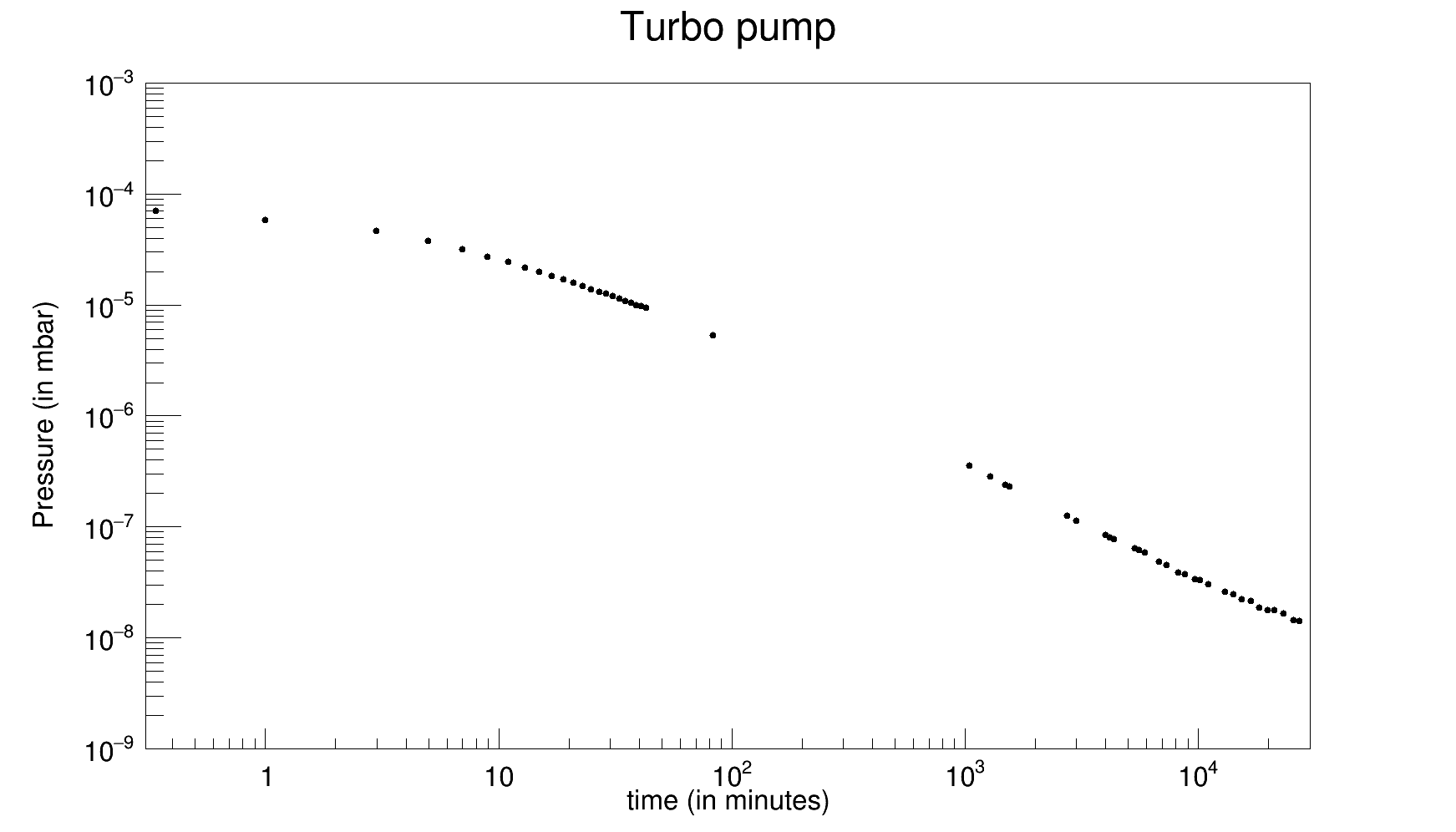

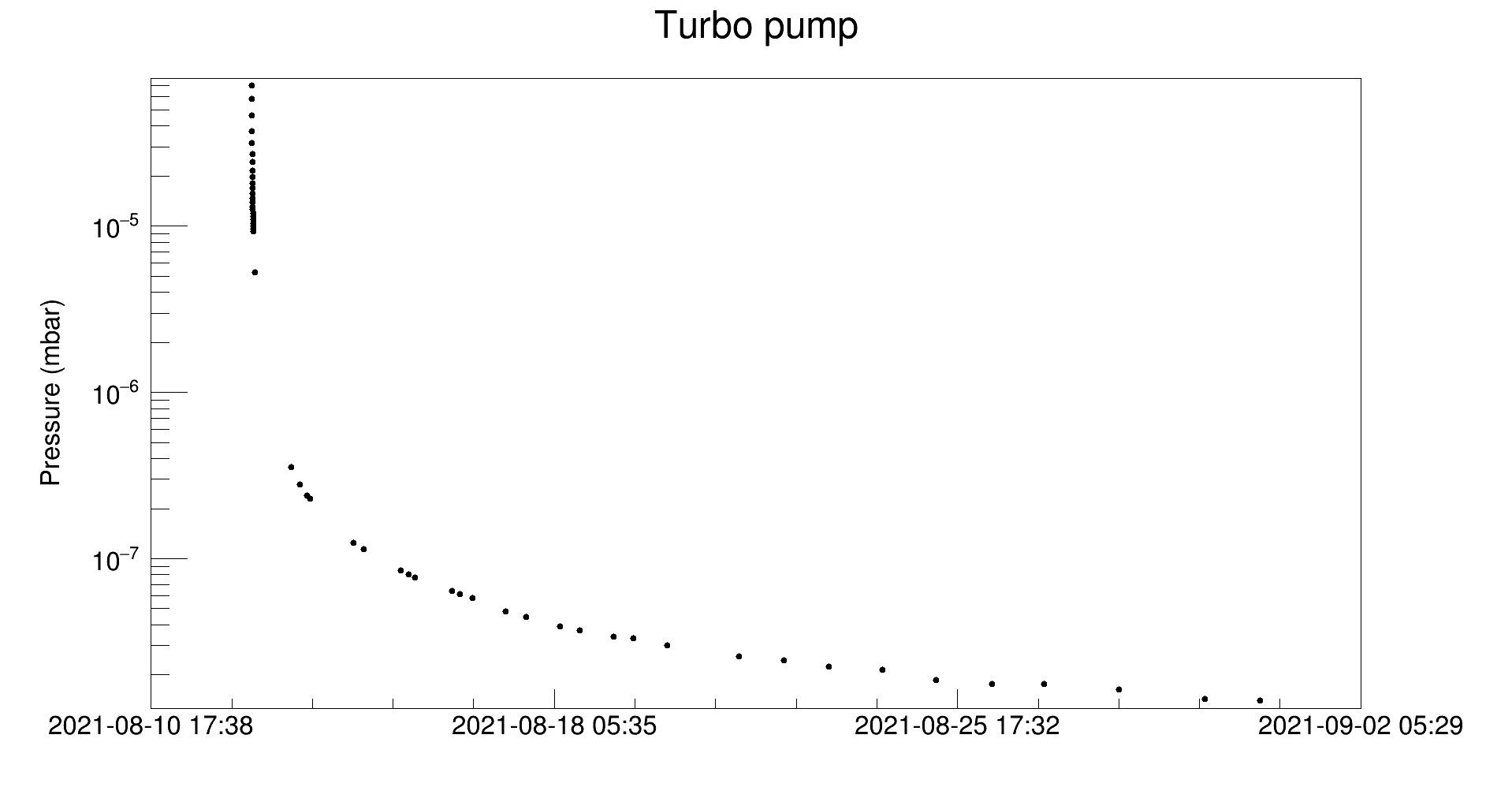

42

|

Fri Aug 13 07:28:37 2021 |

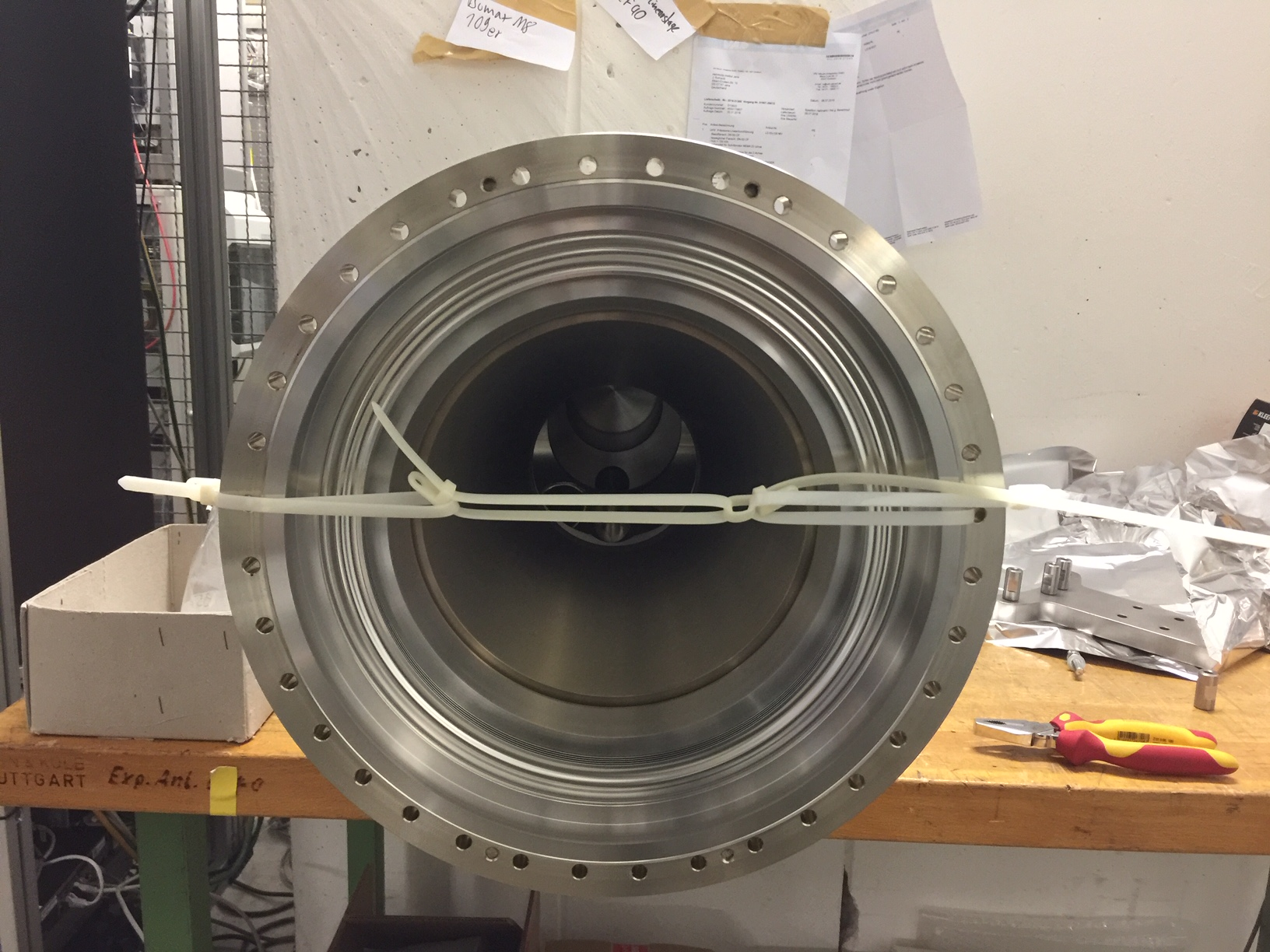

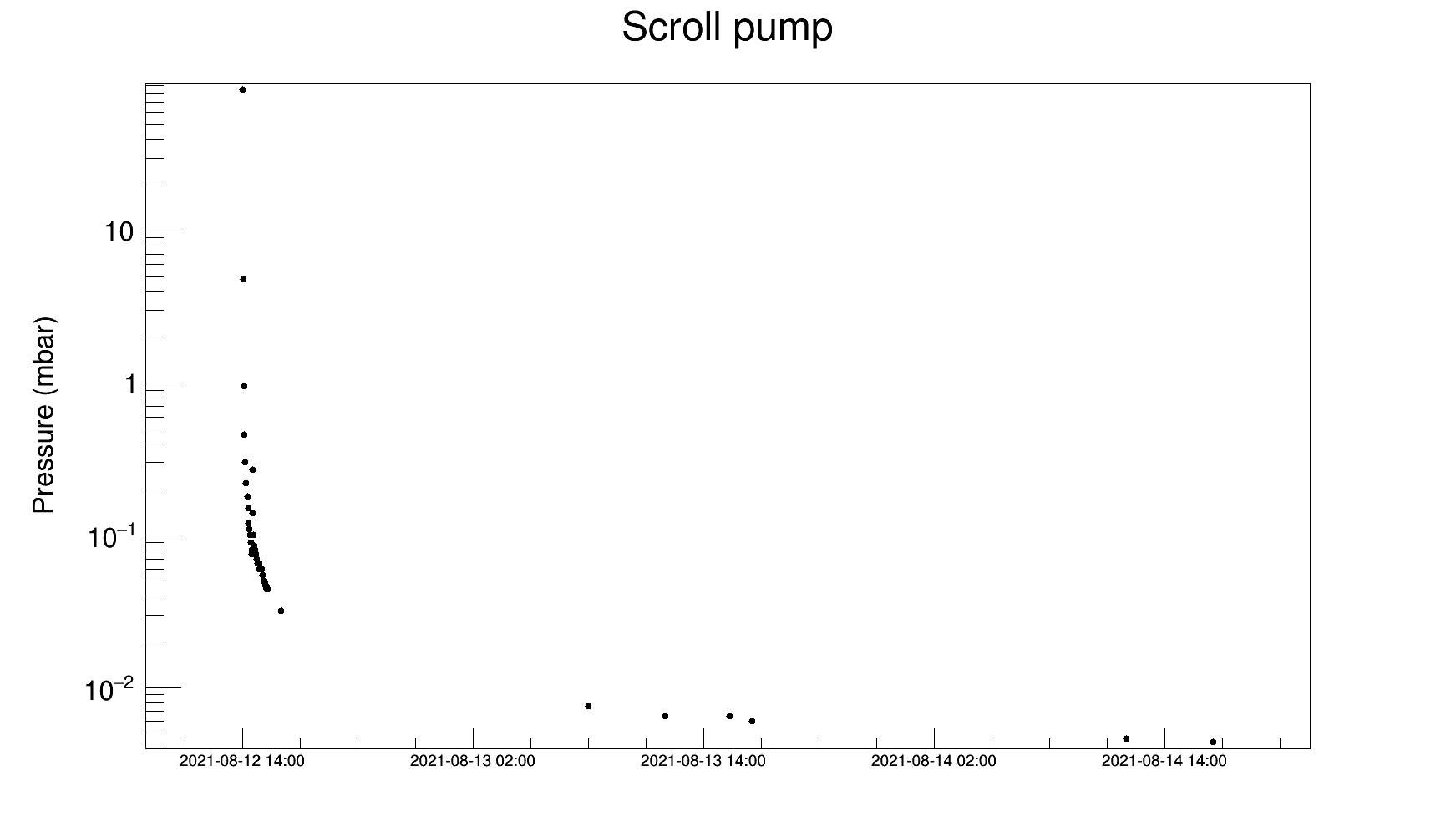

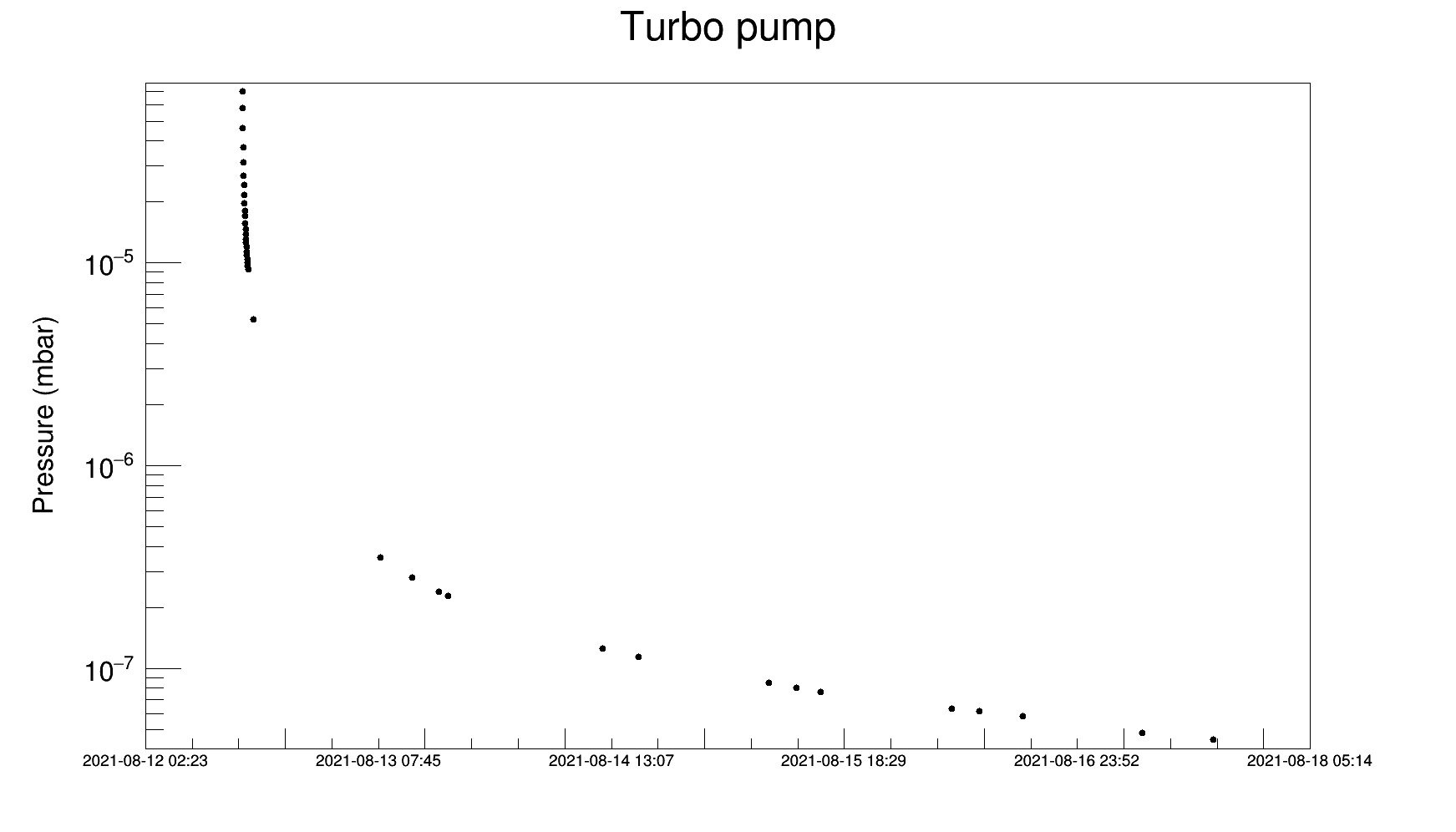

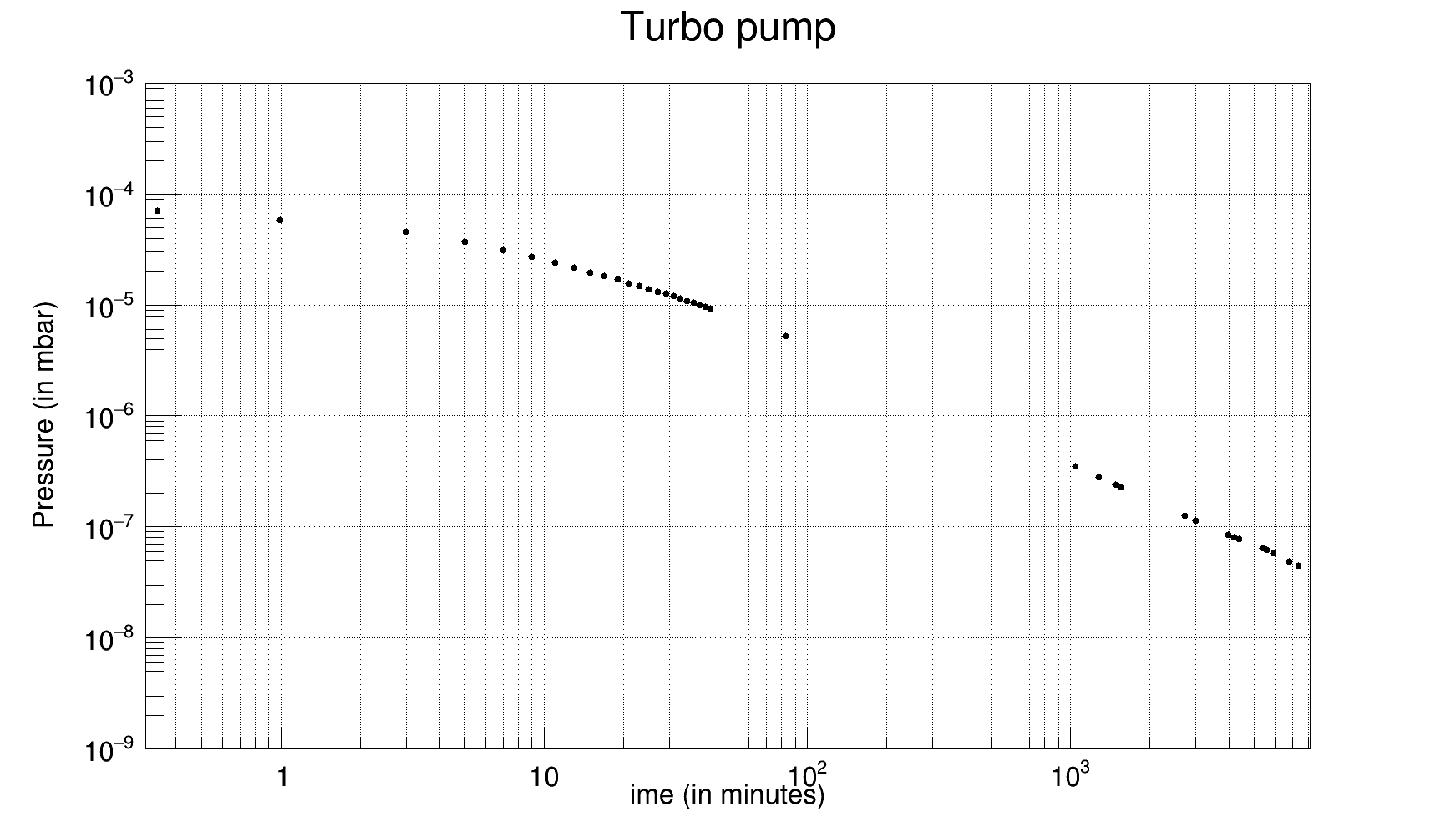

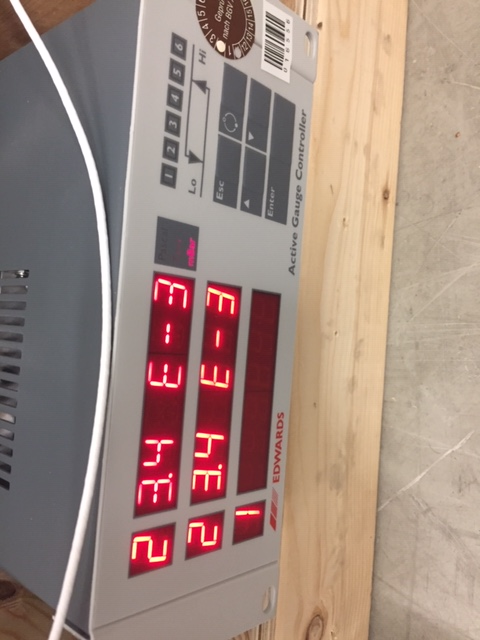

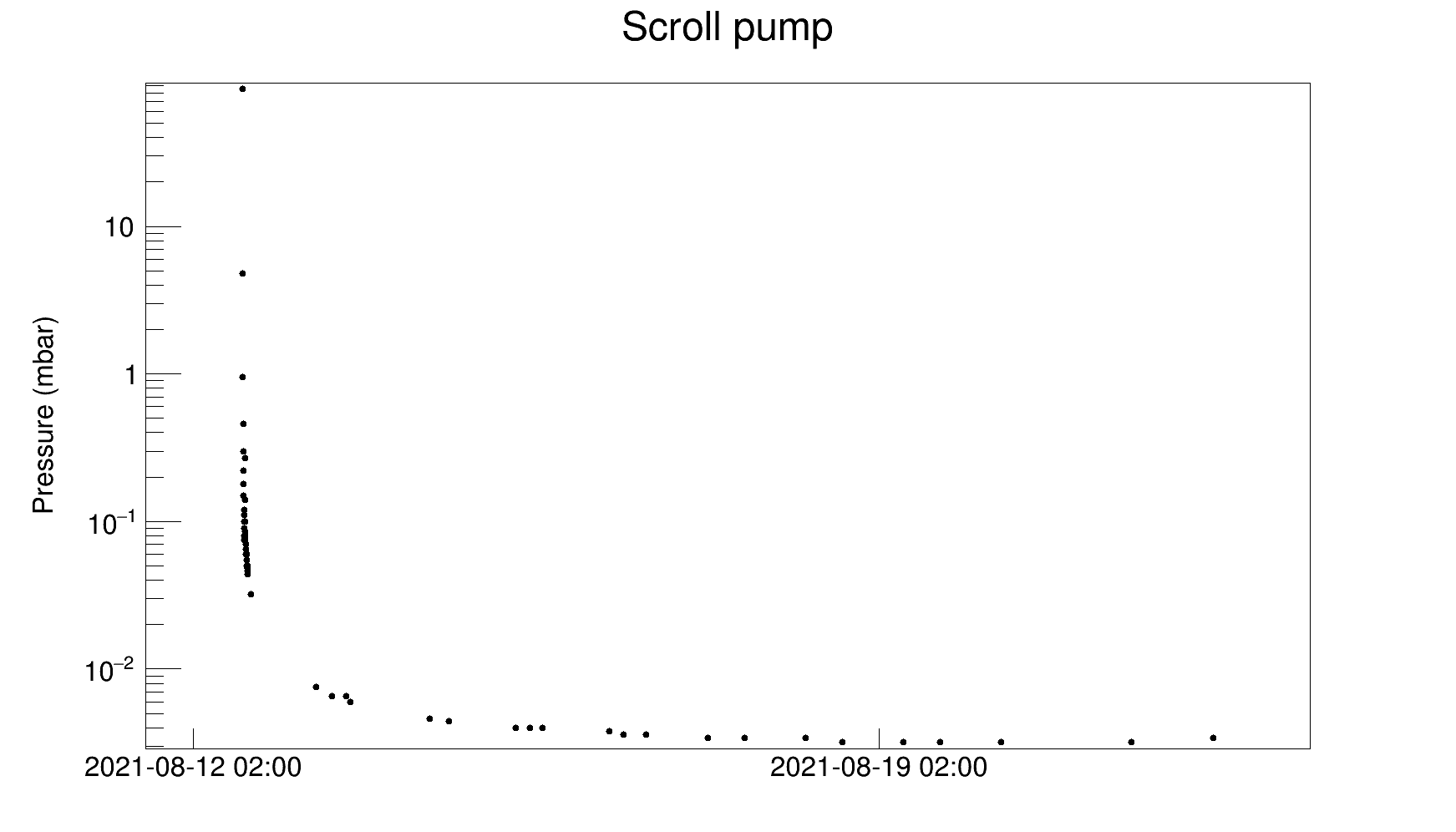

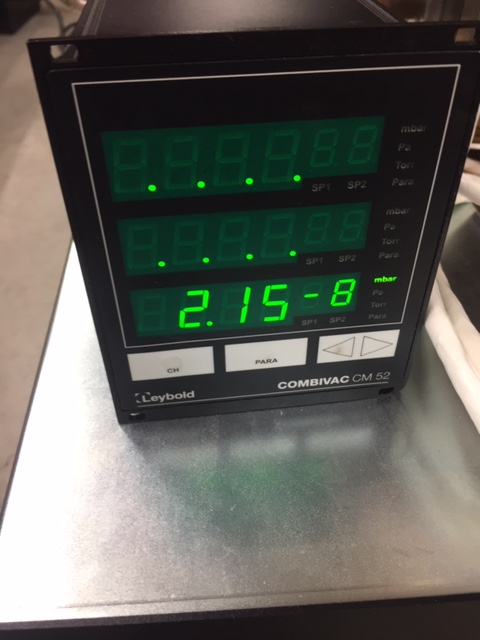

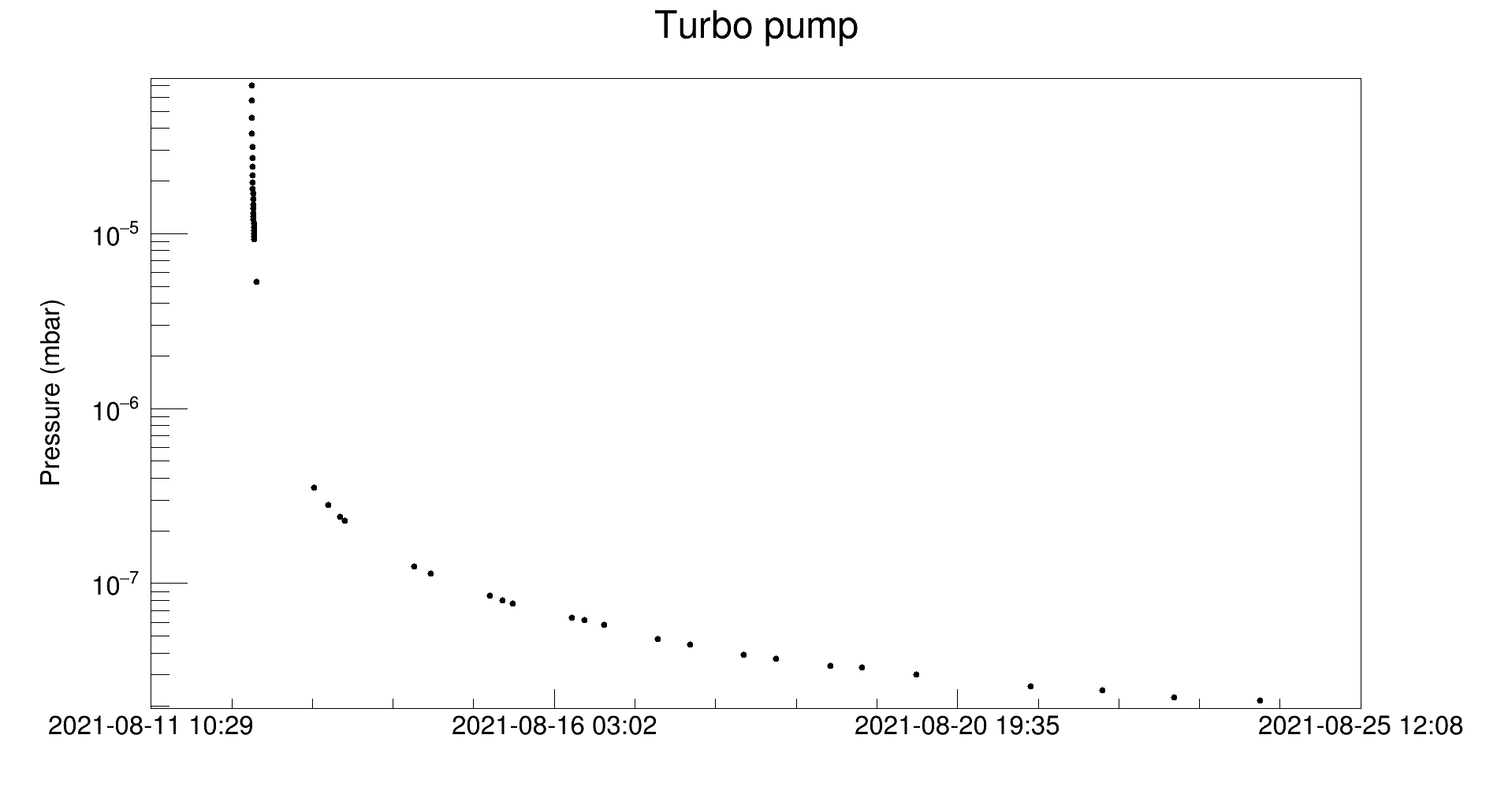

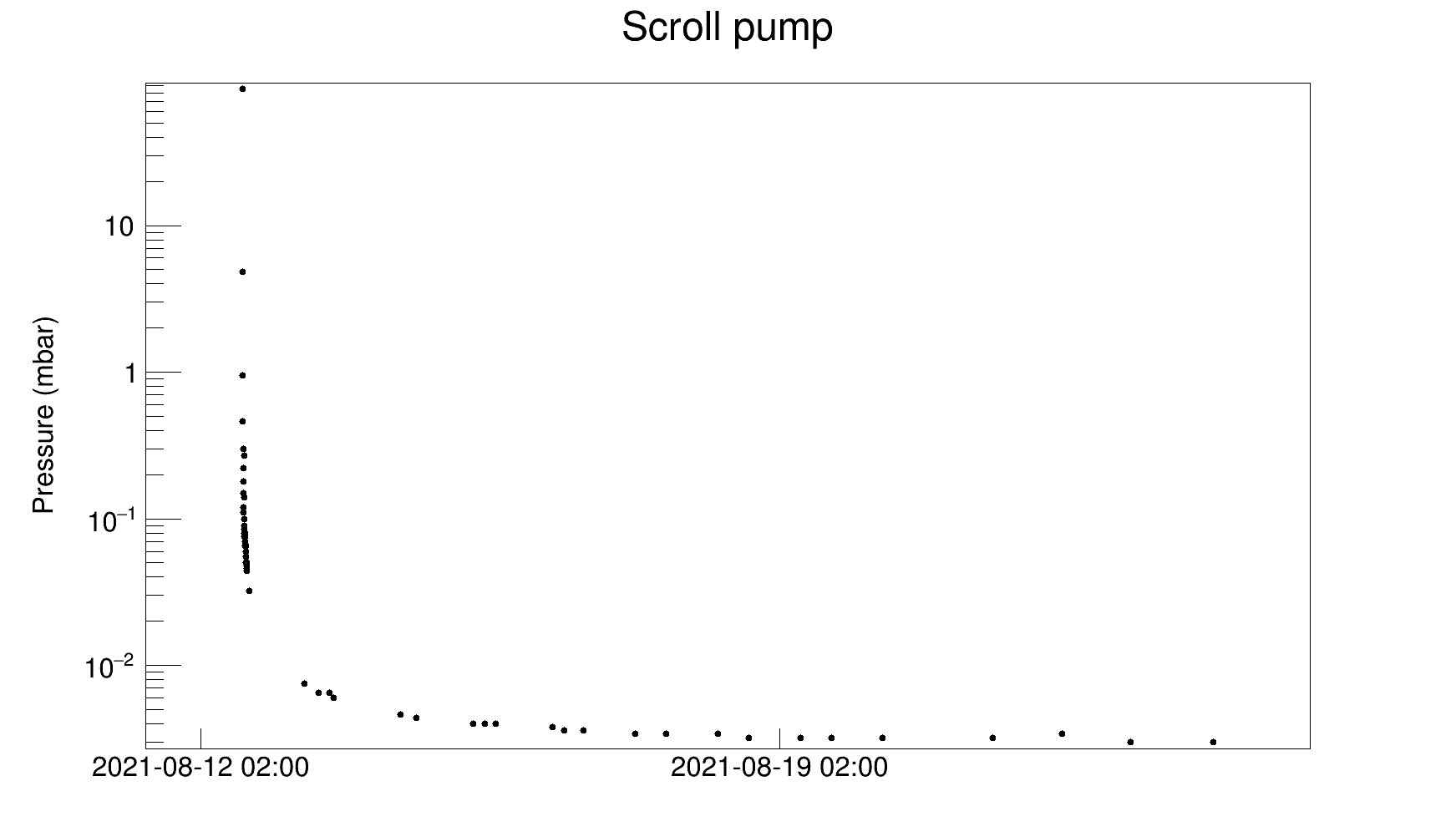

RSS TD | Friday 13-17 August |

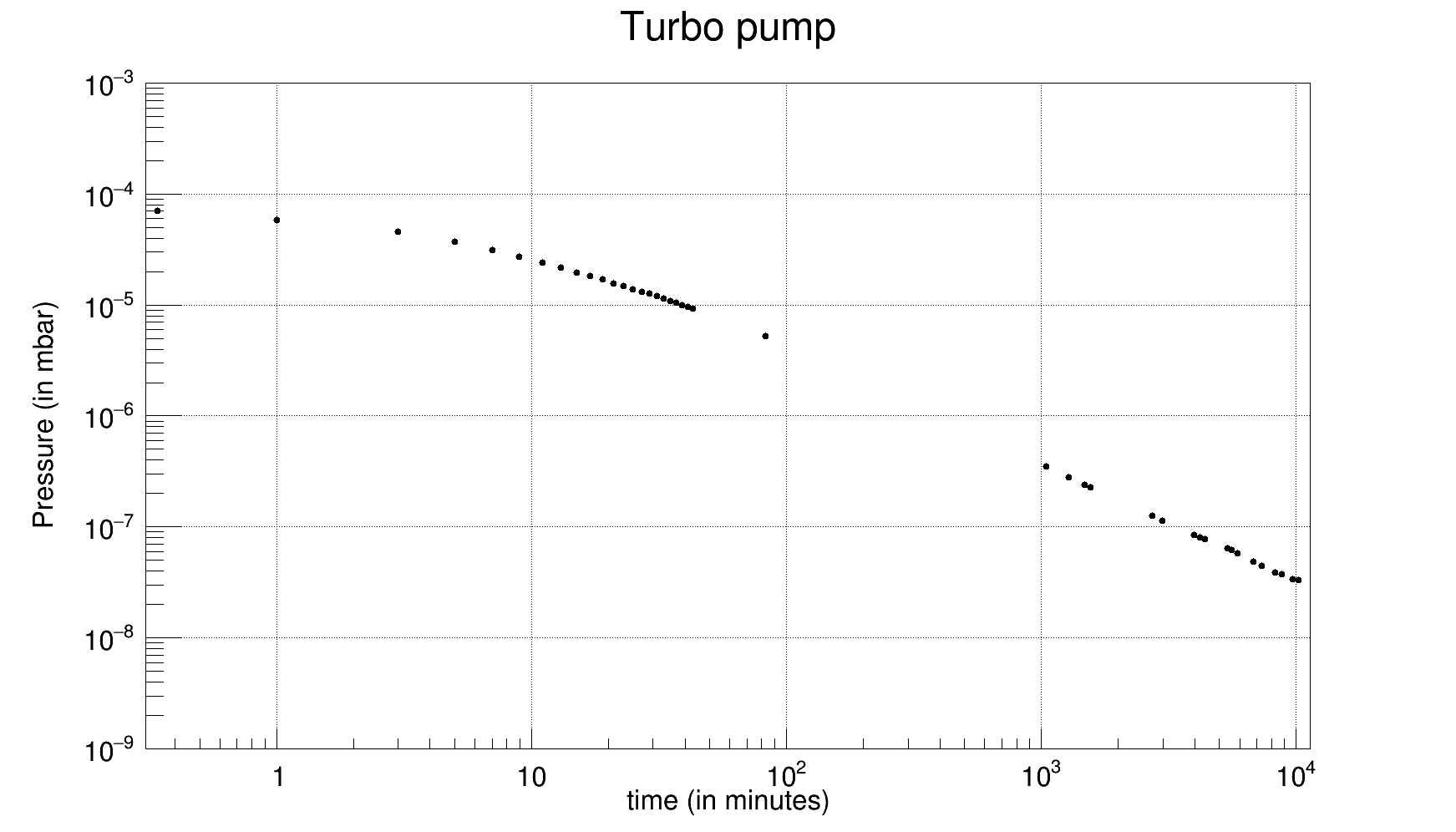

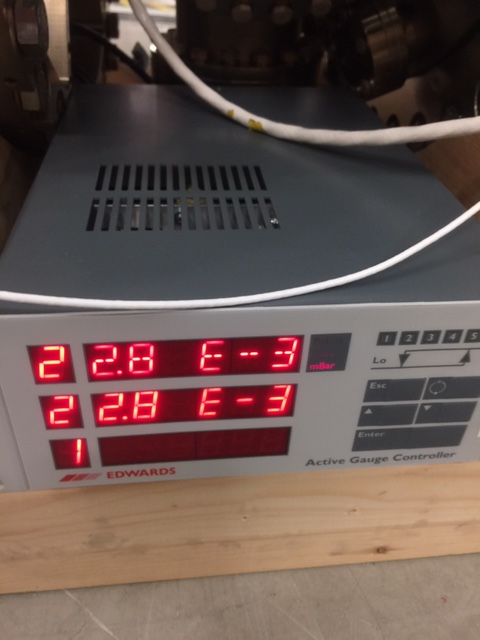

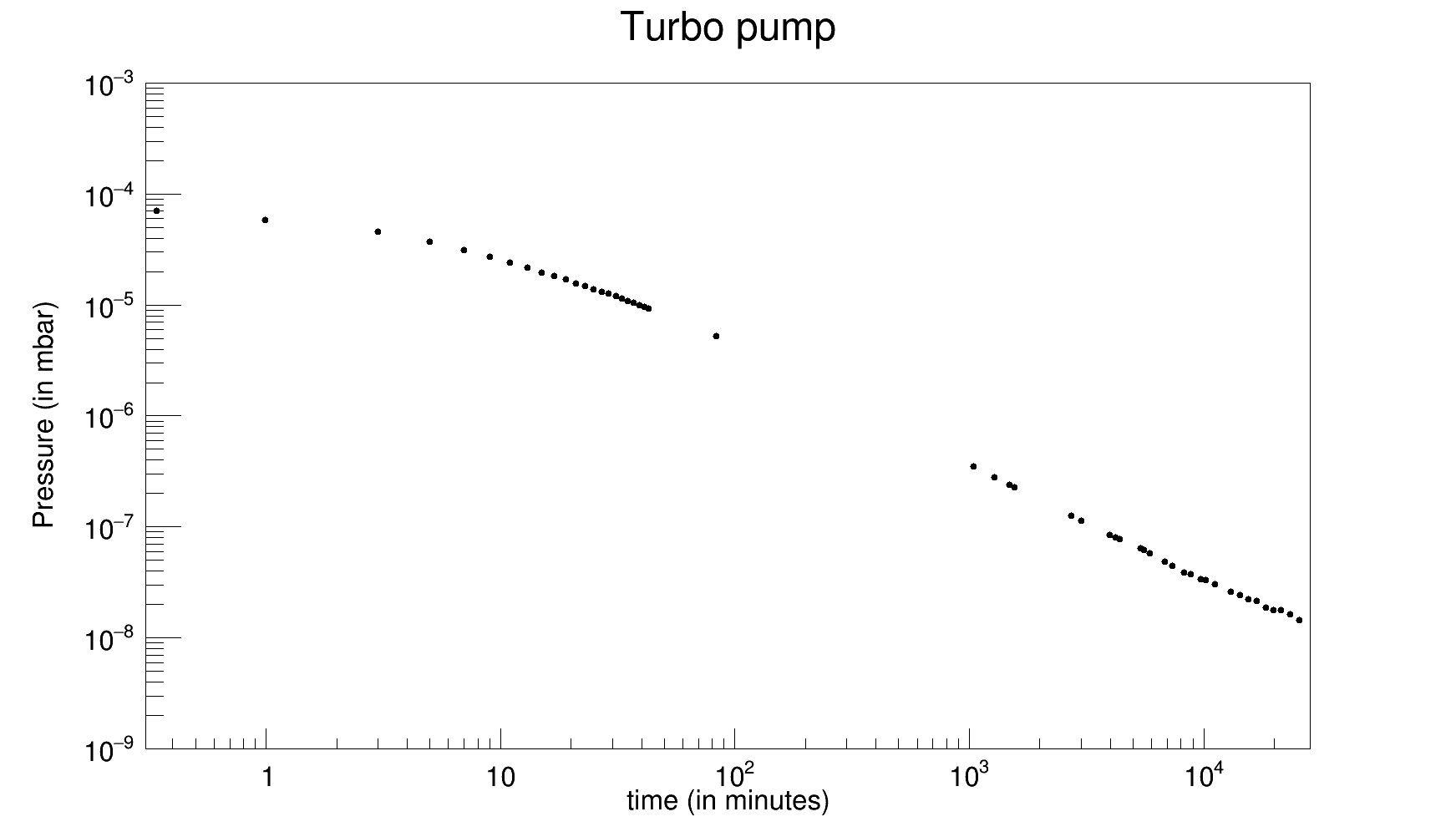

Pirani IE514

mbar mbar

13/8/21 08:00 0.0075 3.53e-7

13/8/21 12:00 0.0065 2.80e-7

13/8/21 15:20 0.0065 2.40e-7

13/8/21 16:30 0.0060 2.29e-7

---------------------------------

14/8/21 12:00 0.0046 1.25e-7

14/8/21 12:00 0.0044 1.14e-7

---------------------------------

15/8/21 09:00 0.0040 8.47e-8

15/8/21 12:30 0.0040 8.00e-8

15/8/21 15:30 0.0040 7.69e-8

---------------------------------

16/8/21 08:00 0.0038 6.36e-8

16/8/21 11:30 0.0036 6.14e-8

16/8/21 17:00 0.0036 5.82e-8

---------------------------------

17/8/21 08:00 0.0034 4.82e-8

17/8/21 17:00 0.0034 4.47e-8 |

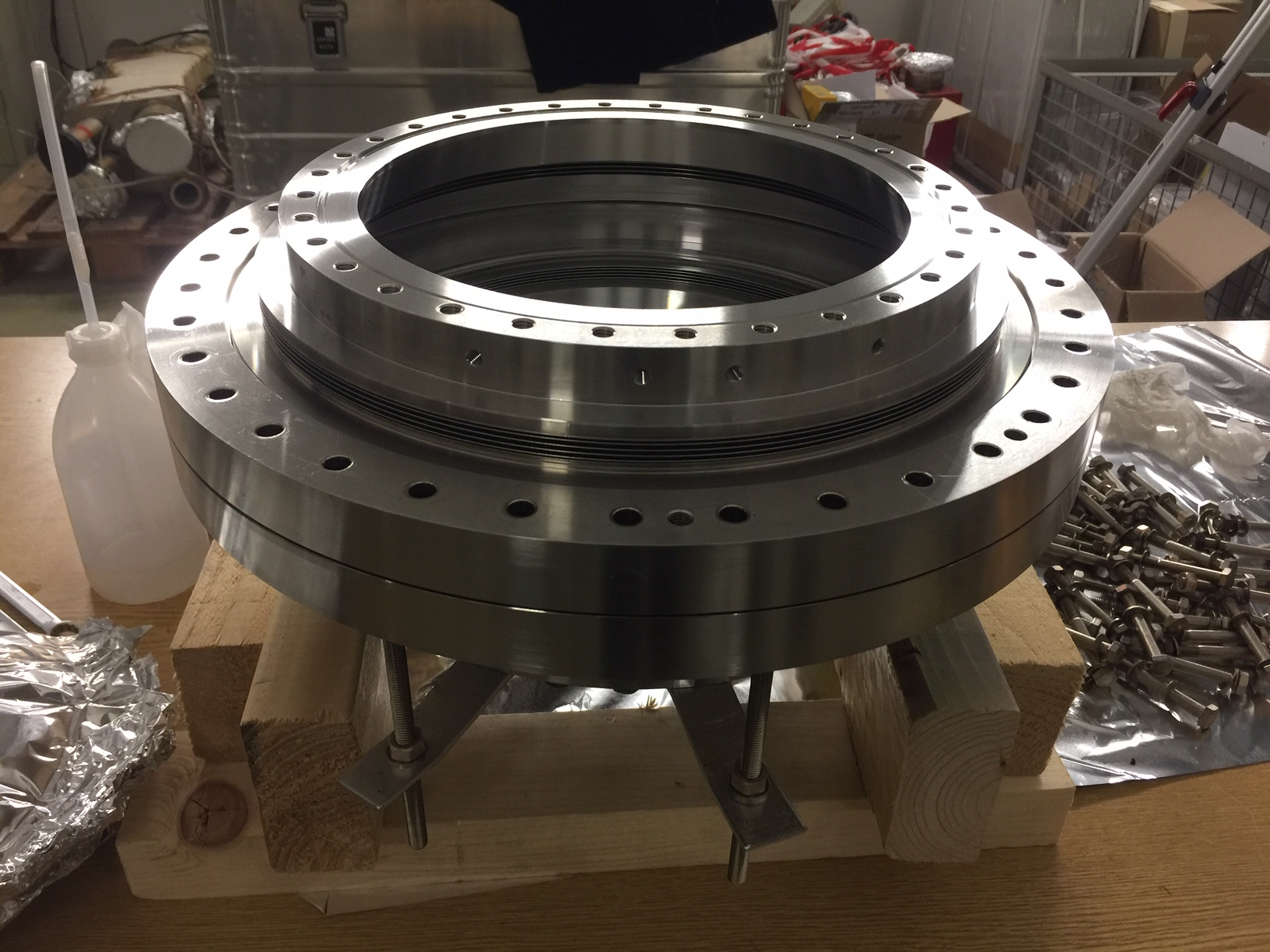

| Attachment 1: IMG_4196.JPG

|

|

| Attachment 2: IMG_4197.JPG

|

|

| Attachment 3: IMG_4198.JPG

|

|

| Attachment 4: scroll_pump_13.08.png

|

|

| Attachment 5: turbo_pump_13.08.png

|

|

| Attachment 6: IMG_4237.JPG

|

|

| Attachment 7: IMG_4238.JPG

|

|

| Attachment 8: turbo_pump_14.08.png

|

|

| Attachment 9: scroll_pump_14.08.png

|

|

| Attachment 10: IMG_4244.JPG

|

|

| Attachment 11: IMG_4245.JPG

|

|

| Attachment 12: turbo_pump_15.08.png

|

|

| Attachment 13: scroll_pump_15.08.png

|

|

| Attachment 14: IMG_4257.JPG

|

|

| Attachment 15: IMG_4258.JPG

|

|

| Attachment 16: turbo_pump_16.08.png

|

|

| Attachment 17: scroll_pump_16.08.png

|

|

| Attachment 18: IMG_4265.JPG

|

|

| Attachment 19: IMG_4266.JPG

|

|

| Attachment 20: turbo_pump_log_scale.png

|

|

| Attachment 21: scroll_pump_17.08.png

|

|

| Attachment 22: turbo_pump_17.08.png

|

|

| Attachment 23: log_scale_17.08.png

|

|

|

43

|

Wed Aug 18 07:07:26 2021 |

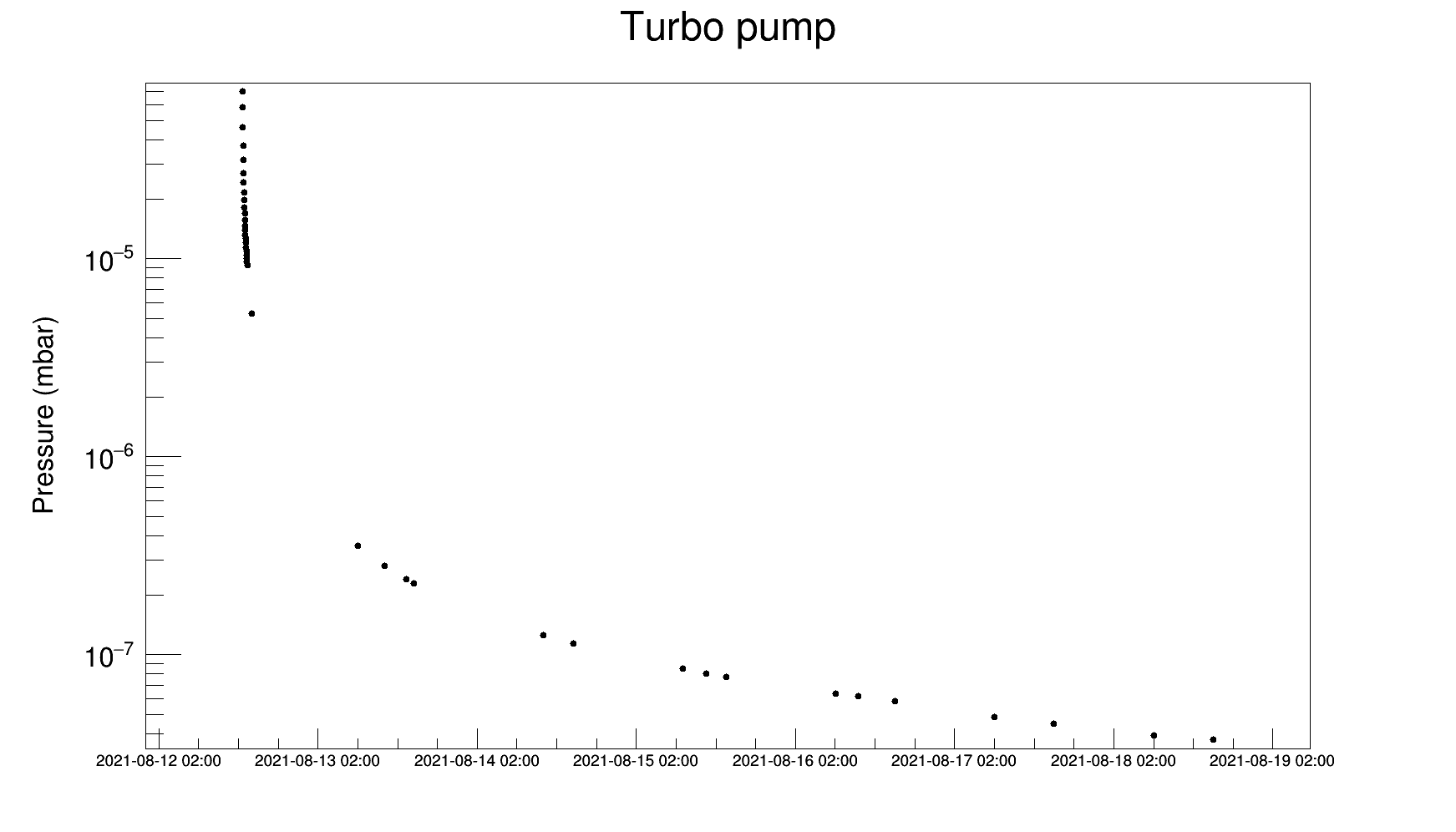

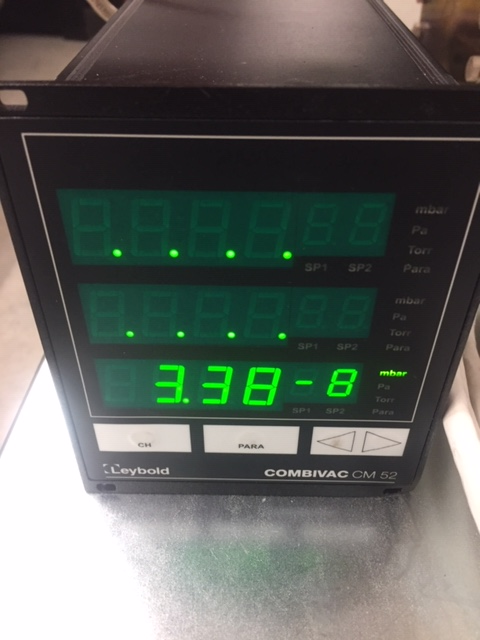

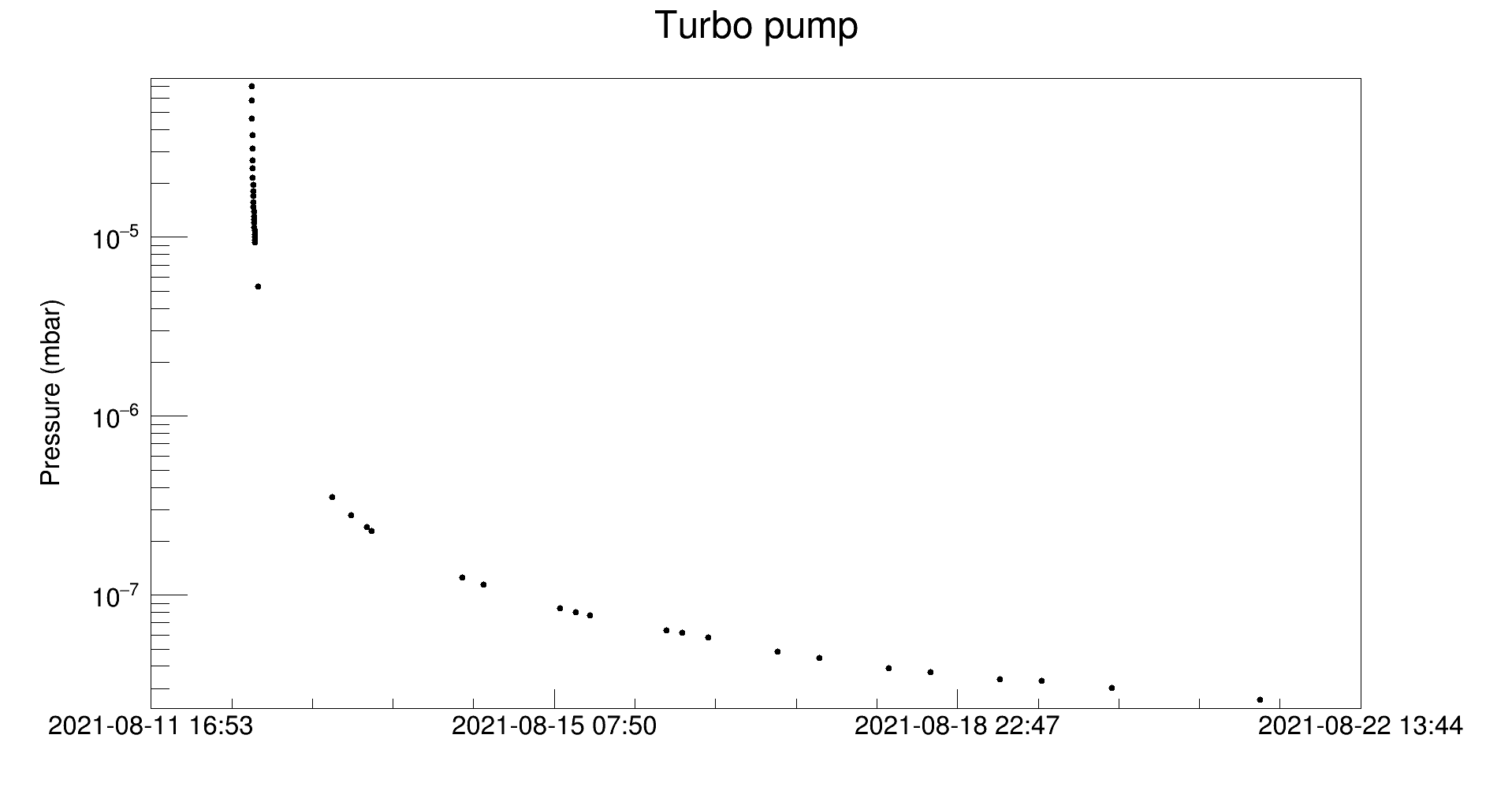

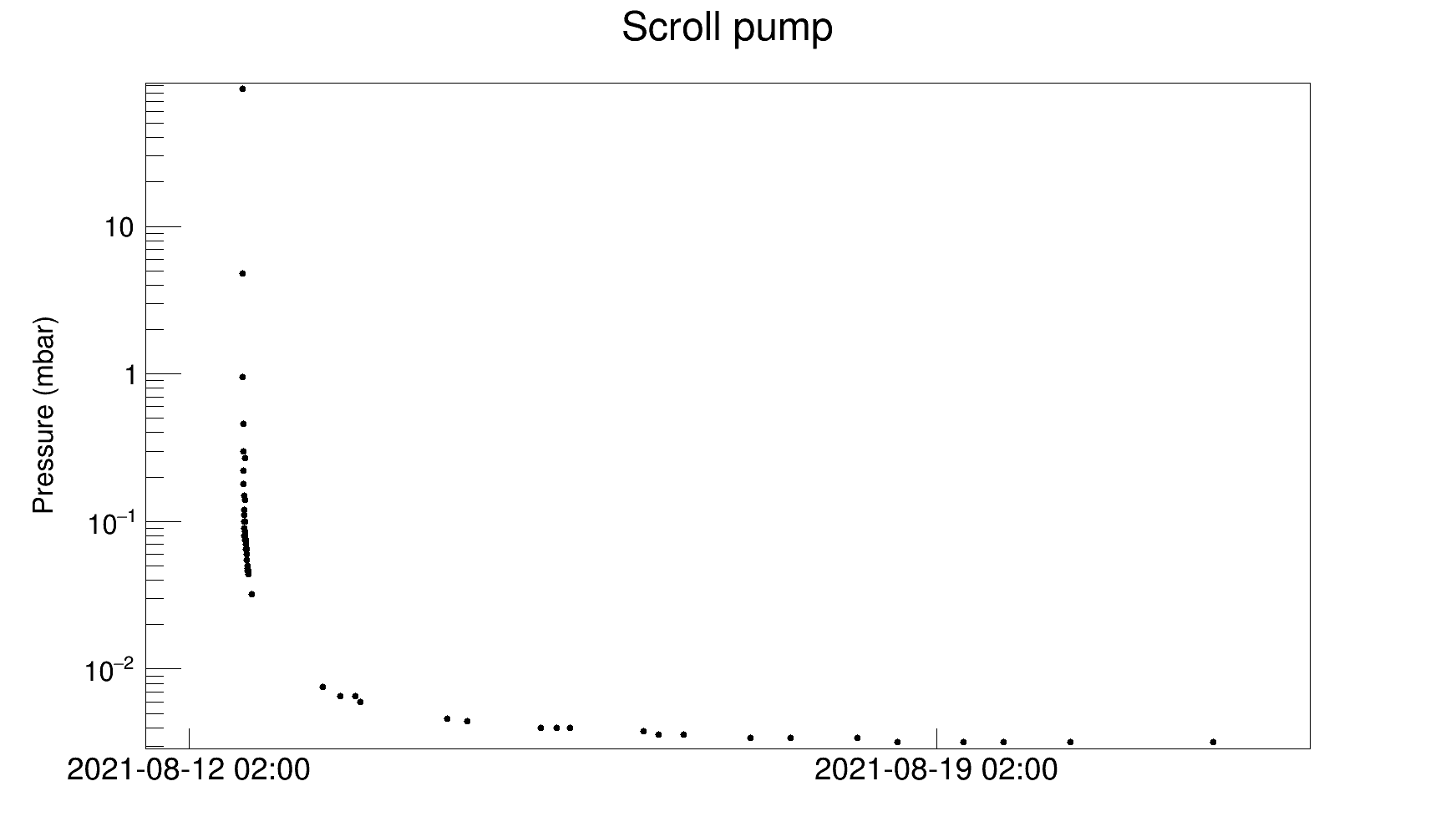

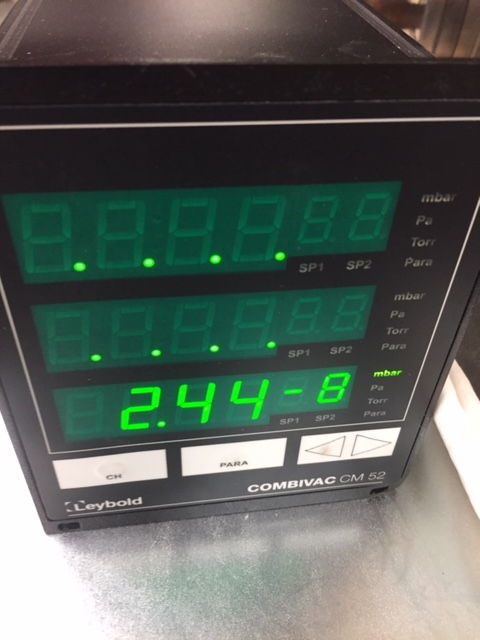

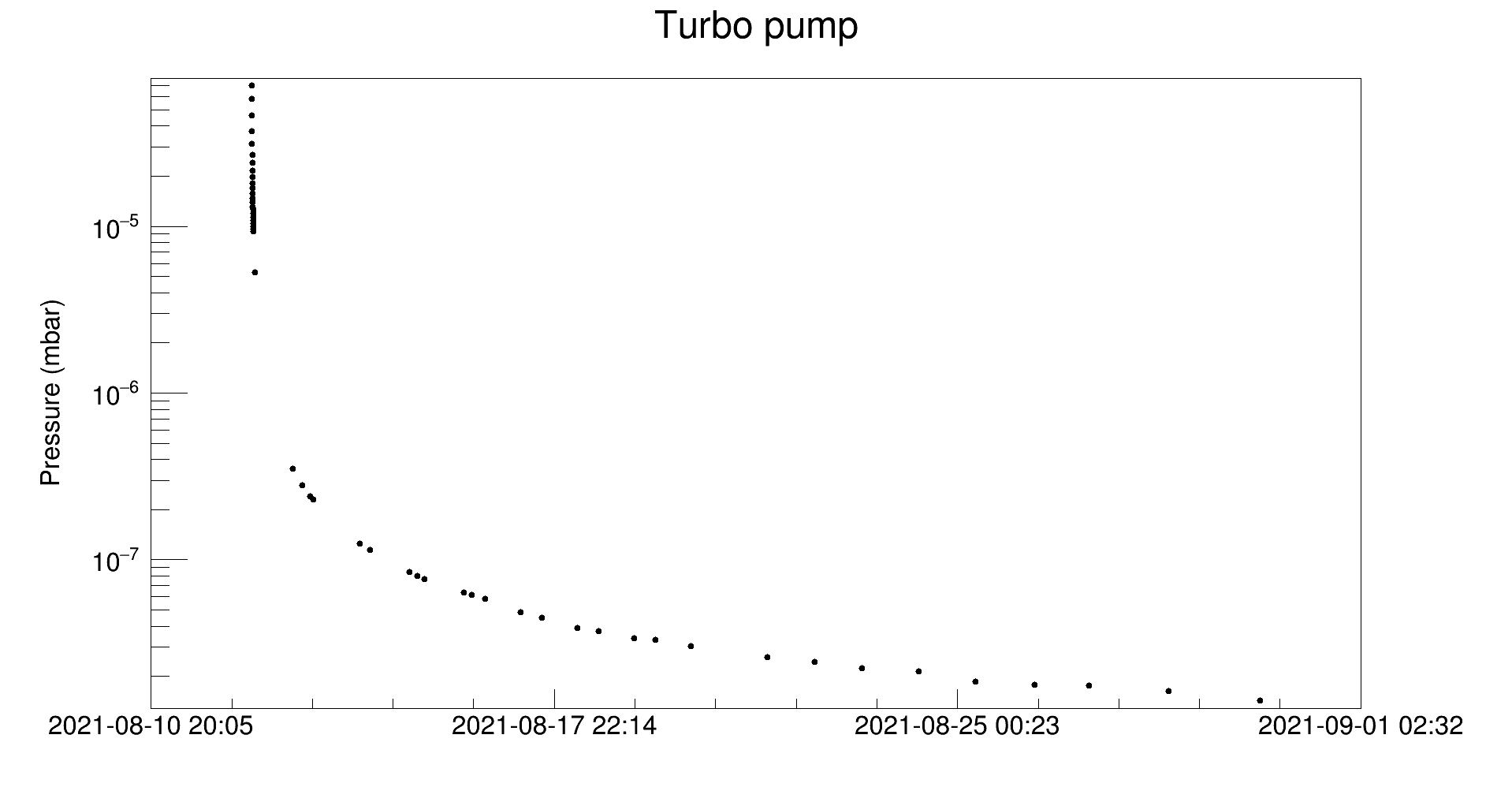

RSS TD | 18-24 August |

Pirani IE514

mbar mbar

18/8/21 08:00 0.0034 3.90e-8

18/8/21 17:00 0.0032 3.72e-8

-------------------------------------------------------------

19/8/21 08:00 0.0032 3.38e-8

19/8/21 17:00 0.0032 3.31e-8

-------------------------------------------------------------

20/8/21 08:00 0.0032 3.02e-8

-------------------------------------------------------------

21/8/21 16:00 0.0032 2.59e-8

-------------------------------------------------------------

22/8/21 12:00 0.0034 2.44e-8

-------------------------------------------------------------

23/8/21 08:00 0.0030 2.23e-8

-------------------------------------------------------------

24/8/21 08:00 0.0030 2.15e-8

|

| Attachment 1: IMG_4273.JPG

|

|

| Attachment 2: IMG_4274.JPG

|

|

| Attachment 3: log_scale_18.08.png

|

|

| Attachment 4: turbo_pump_18.08.png

|

|

| Attachment 5: scroll_pump_18.08.png

|

|

| Attachment 6: IMG_4281.JPG

|

|

| Attachment 7: log_scale_19.08.png

|

|

| Attachment 8: turbo_pump_19.08.png

|

|

| Attachment 9: scroll_pump_19.08.png

|

|

| Attachment 10: IMG_4290.JPG

|

|

| Attachment 11: IMG_4301.JPG

|

|

| Attachment 12: log_scale_21.08.png

|

|

| Attachment 13: turbo_pump_21.08.png

|

|

| Attachment 14: scroll_pump_21.08.png

|

|

| Attachment 15: IMG_4323.JPG

|

|

| Attachment 16: IMG_4324.JPG

|

|

| Attachment 17: log_scale_22.08.png

|

|

| Attachment 18: turbo_pump_22.08.png

|

|

| Attachment 19: scroll_pump_22.08.png

|

|

| Attachment 20: IMG_4339.JPG

|

|

| Attachment 21: IMG_4340.JPG

|

|

| Attachment 22: IMG_4345.JPG

|

|

| Attachment 23: log_scale_24.08.png

|

|

| Attachment 24: turbo_pump_24.08.png

|

|

| Attachment 25: scroll_pump_24.08.png

|

|

|

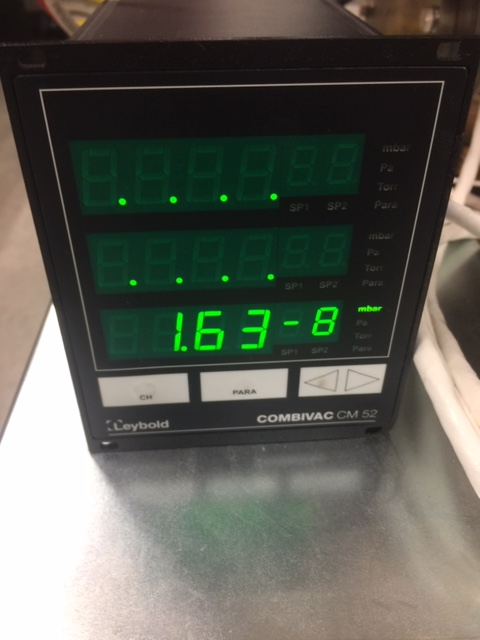

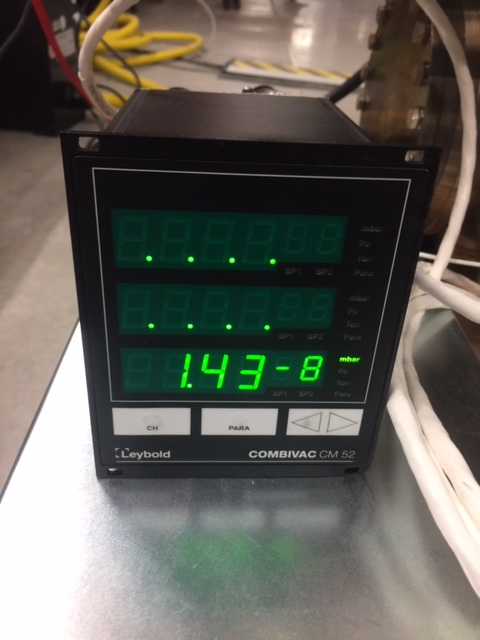

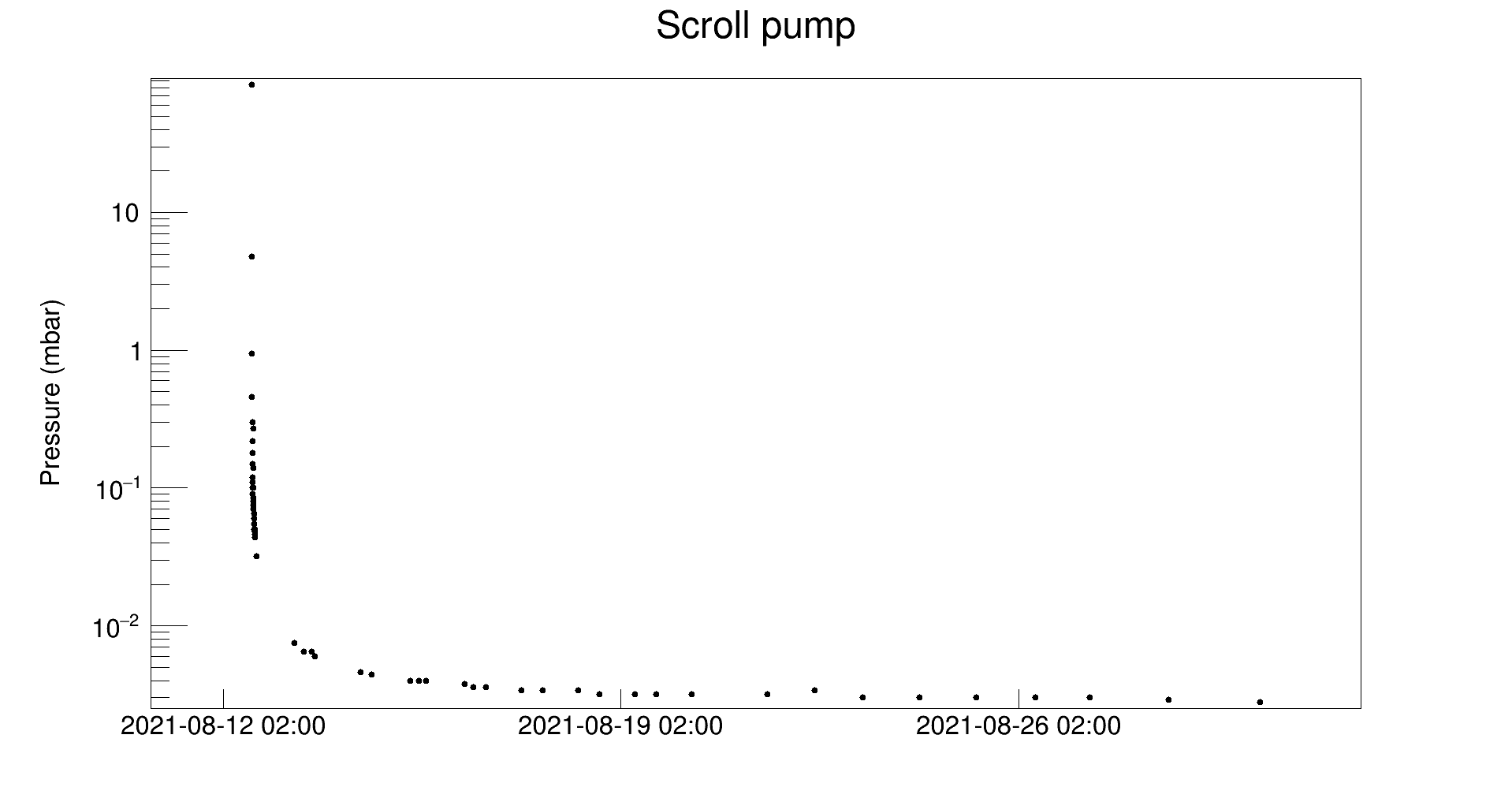

45

|

Wed Aug 25 07:02:41 2021 |

RSS TD | 25-31 August |

Pirani IE514

mbar mbar

25/8/21 08:00 0.0030 1.86e-8

----------------------------------------------------

26/8/21 09:00 0.0030 1.77e-8

----------------------------------------------------

27/8/21 08:00 0.0030 1.76e-8

----------------------------------------------------

28/8/21 17:30 0.0029 1.63e-8

----------------------------------------------------

30/8/21 08:00 0.0028 1.43e-8

----------------------------------------------------

31/8/21 08:30 0.0027 1.40e-8 |

| Attachment 1: IMG_4349.JPG

|

|

| Attachment 2: IMG_4360.JPG

|

|

| Attachment 3: log_scale_26.08.png

|

|

| Attachment 4: turbo_pump_26.08.png

|

|

| Attachment 5: scroll_pump_26.08.png

|

|

| Attachment 6: IMG_4367.JPG

|

|

| Attachment 7: log_scale_27.08.png

|

|

| Attachment 8: IMG_4372.JPG

|

|

| Attachment 9: log_scale_28.08.png

|

|

| Attachment 10: IMG_4426.JPG

|

|

| Attachment 11: IMG_4427.JPG

|

|

| Attachment 12: log_scale_30.08.png

|

|

| Attachment 13: turbo_pump_30.08.png

|

|

| Attachment 14: scroll_pump_30.08.png

|

|

| Attachment 15: log_scale_31.08.png

|

|

| Attachment 16: turbo_pump_31.08.png

|

|

| Attachment 17: scroll_pump_31.08.png

|

|

| Attachment 18: IMG_4445.JPG

|

|

| Attachment 19: IMG_4446.JPG

|

|

|

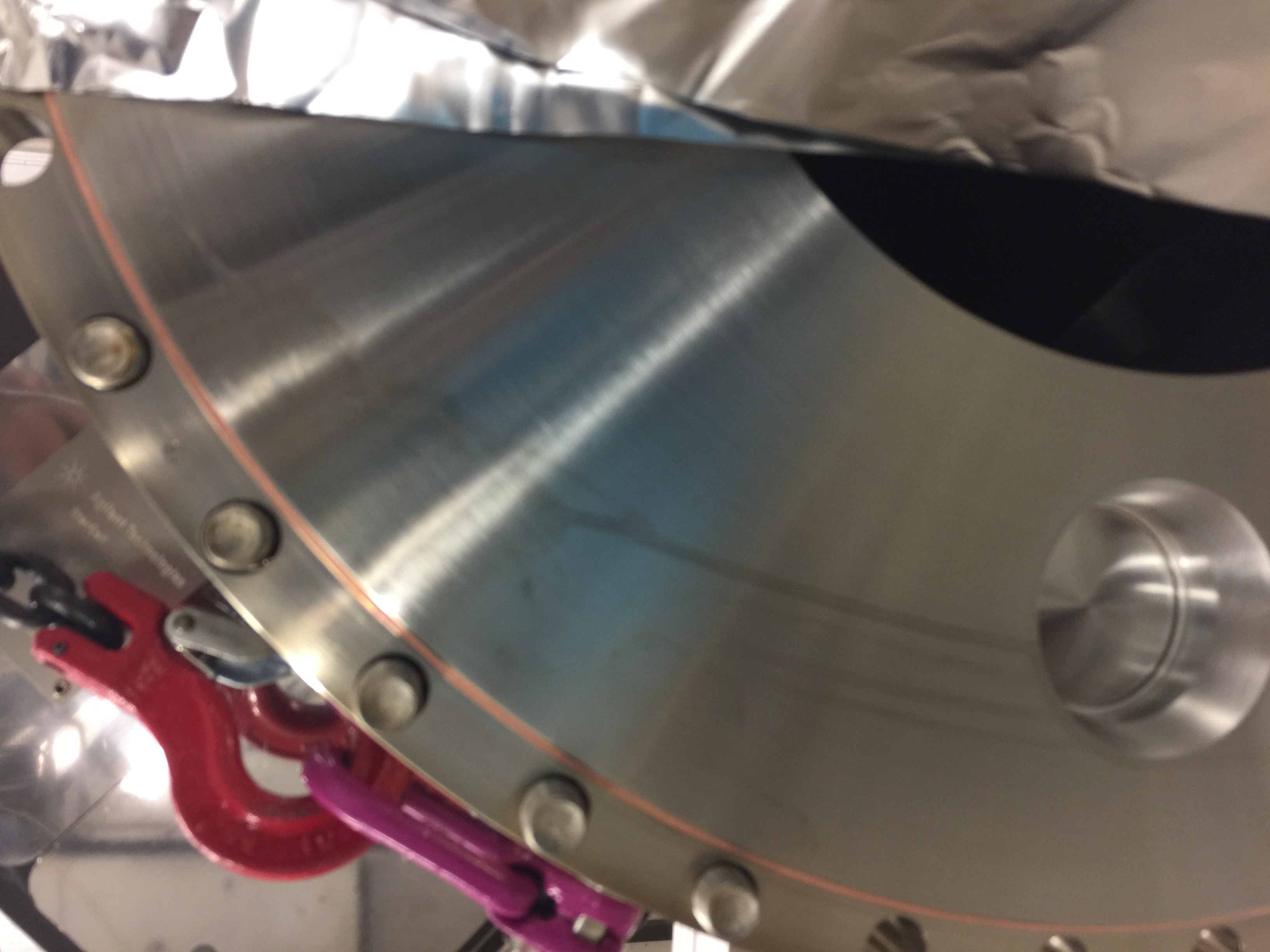

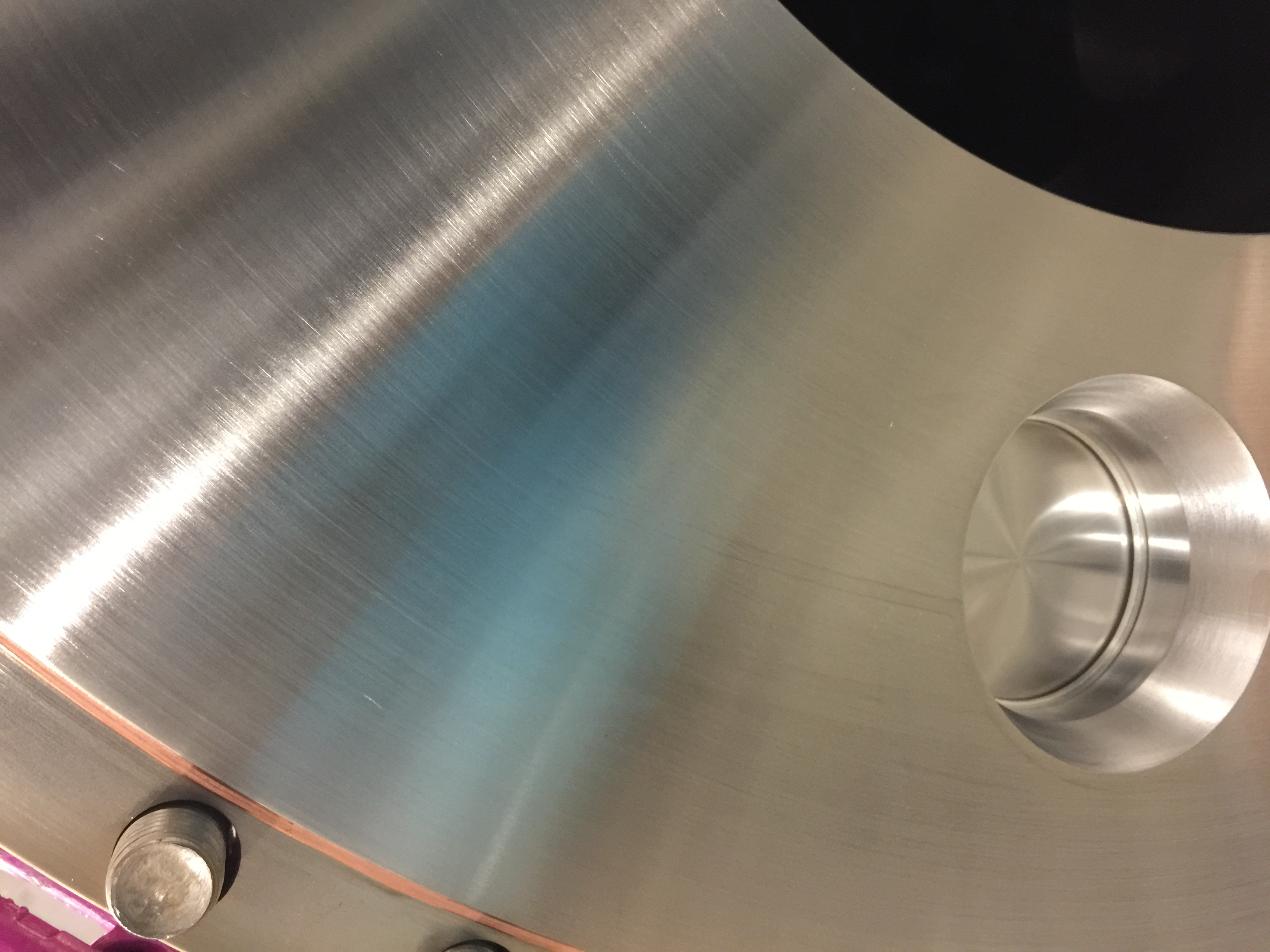

120

|

Wed Oct 13 12:06:09 2021 |

RSS TD | Flanges cleaned |

RSS & TD had some success cleaning the COF600 flange surfaces of the staining and residues observed when the downstream COF600 section was opened yesterday

https://elog.ph.ed.ac.uk/CARME/118

Isopropanol and laboratory tissues were used - most but not all of the staining and the residues were removed. |

| Attachment 1: IMG_5011.JPG

|

|

| Attachment 2: IMG_5012.JPG

|

|

| Attachment 3: IMG_5013.JPG

|

|

| Attachment 4: IMG_5014.JPG

|

|

| Attachment 5: IMG_5015.JPG

|

|

| Attachment 6: IMG_5016.JPG

|

|

| Attachment 7: IMG_5018.JPG

|

|

| Attachment 8: IMG_5019.JPG

|

|

| Attachment 9: IMG_5020.JPG

|

|

| Attachment 10: IMG_5021.JPG

|

|

| Attachment 11: IMG_5022.JPG

|

|

| Attachment 12: IMG_5023.JPG

|

|

|

125

|

Sat Oct 16 17:25:47 2021 |

RSS TD | Broken detectors |

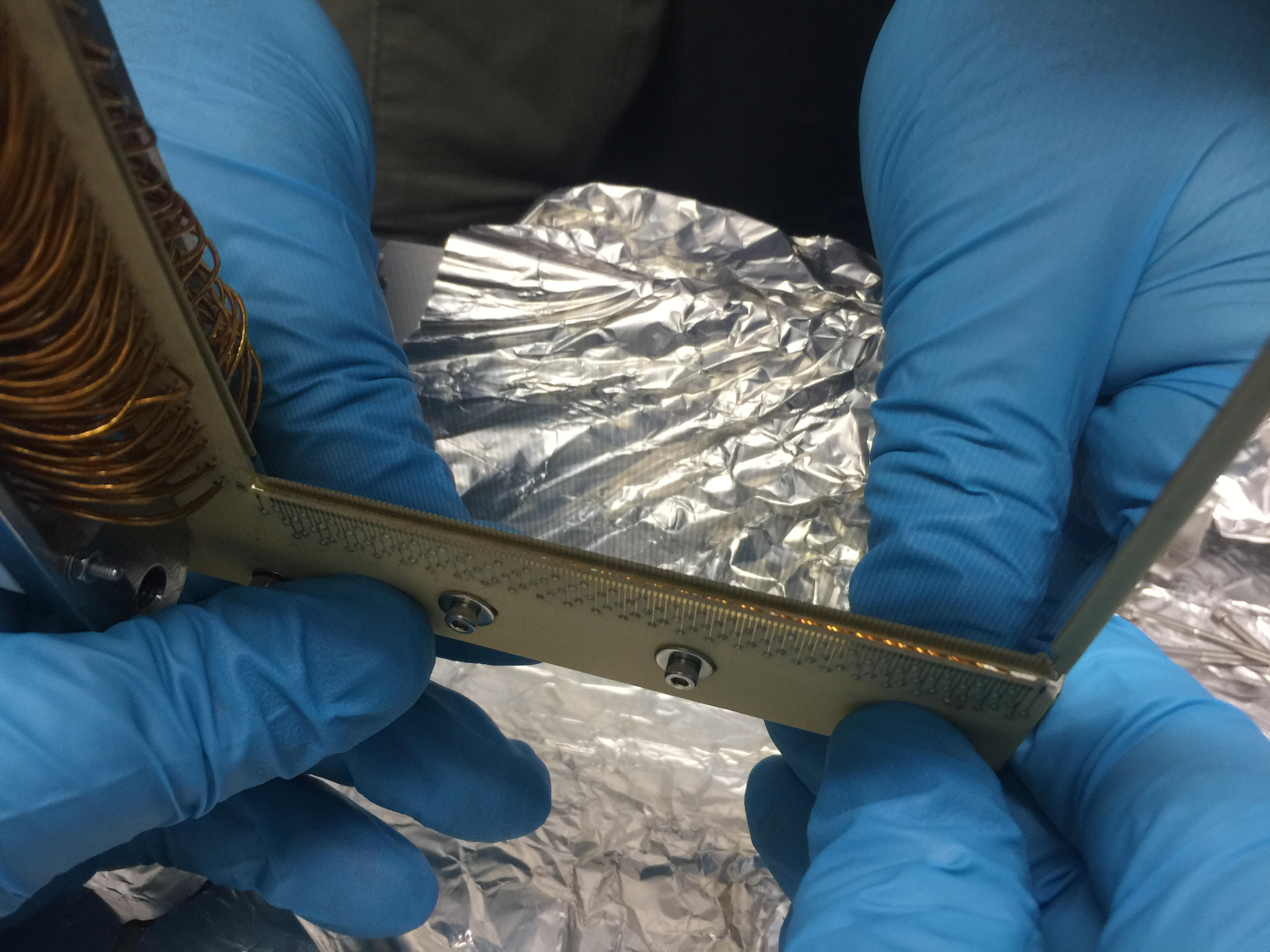

One of the detectors was damaged while mounting (see pictures 1-3).

Second detector was found already damaged when opened (see pictures 4-5). |

| Attachment 1: IMG_5098.JPG

|

|

| Attachment 2: IMG_5097.JPG

|

|

| Attachment 3: IMG_5096.JPG

|

|

| Attachment 4: IMG_5106.JPG

|

|

| Attachment 5: IMG_5105.JPG

|

|

|

287

|

Sat Feb 26 04:36:38 2022 |

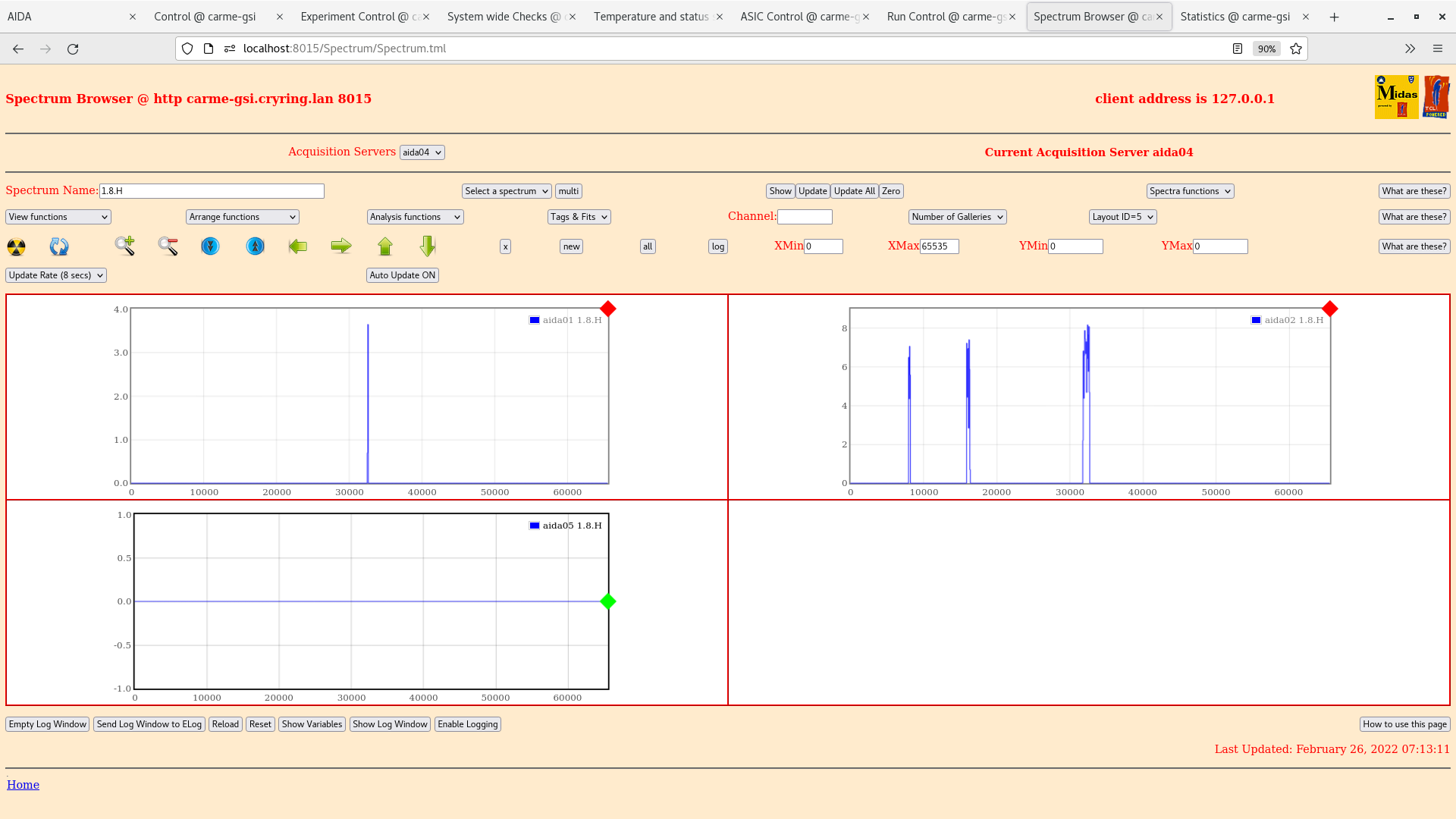

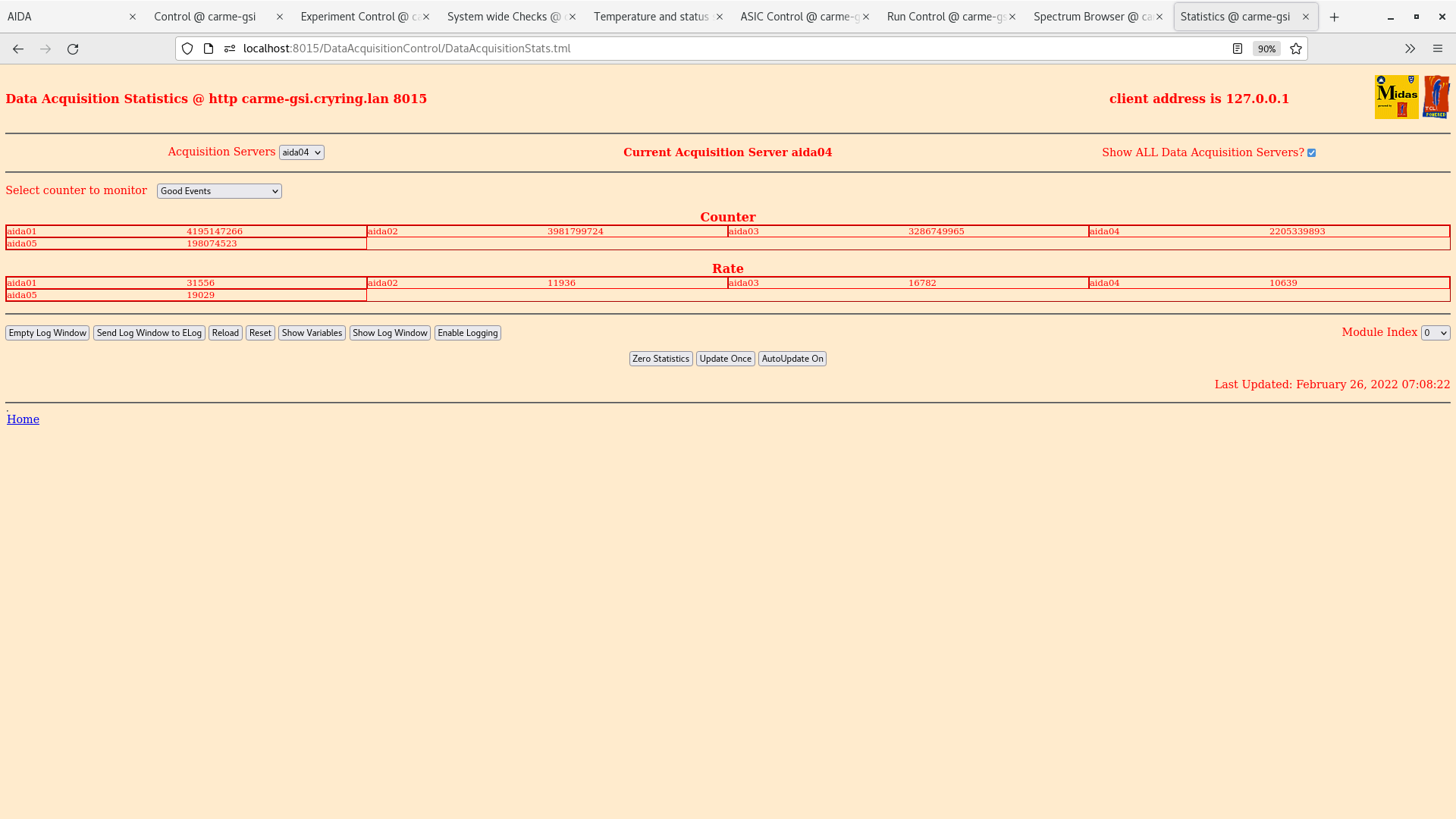

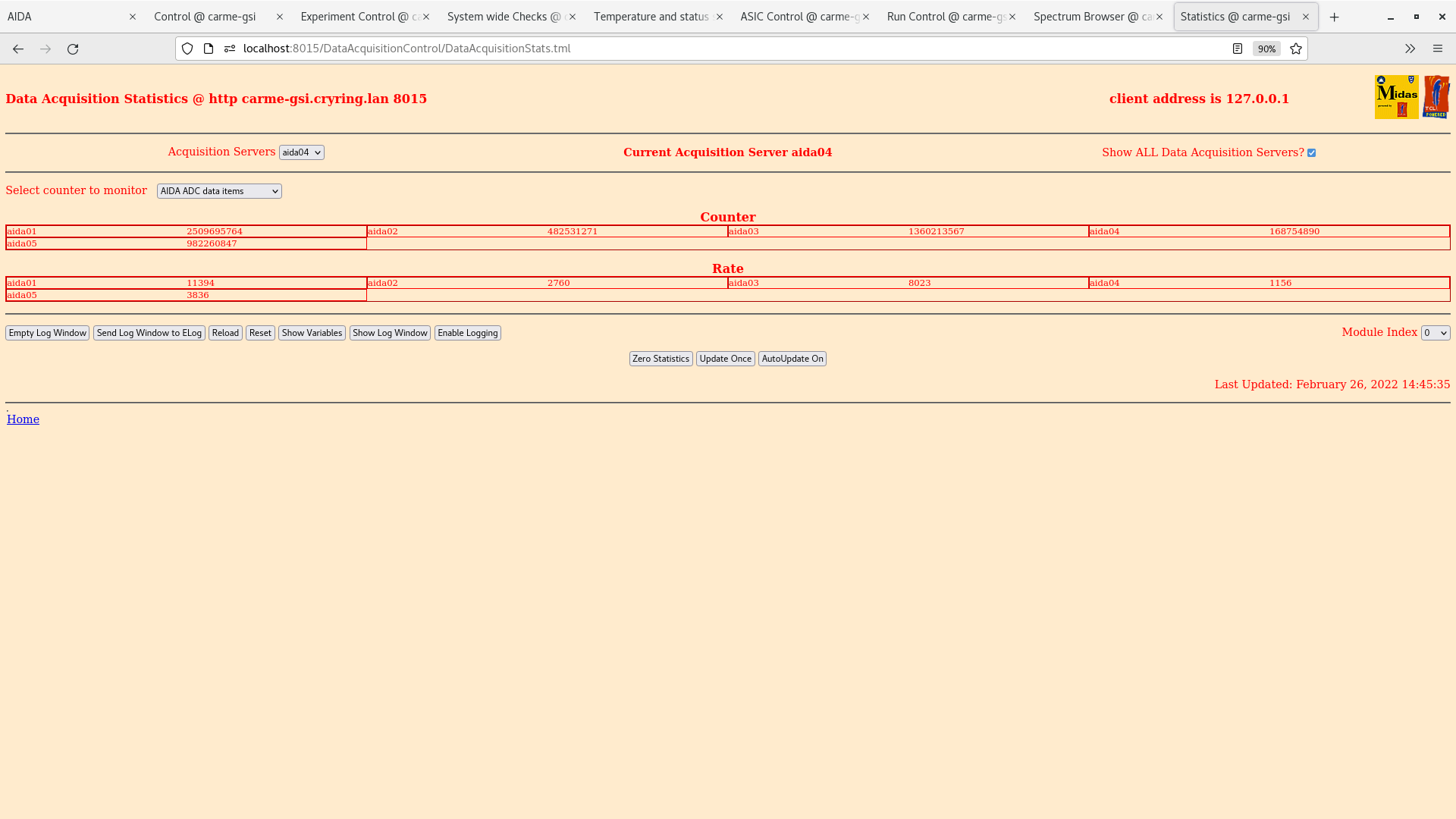

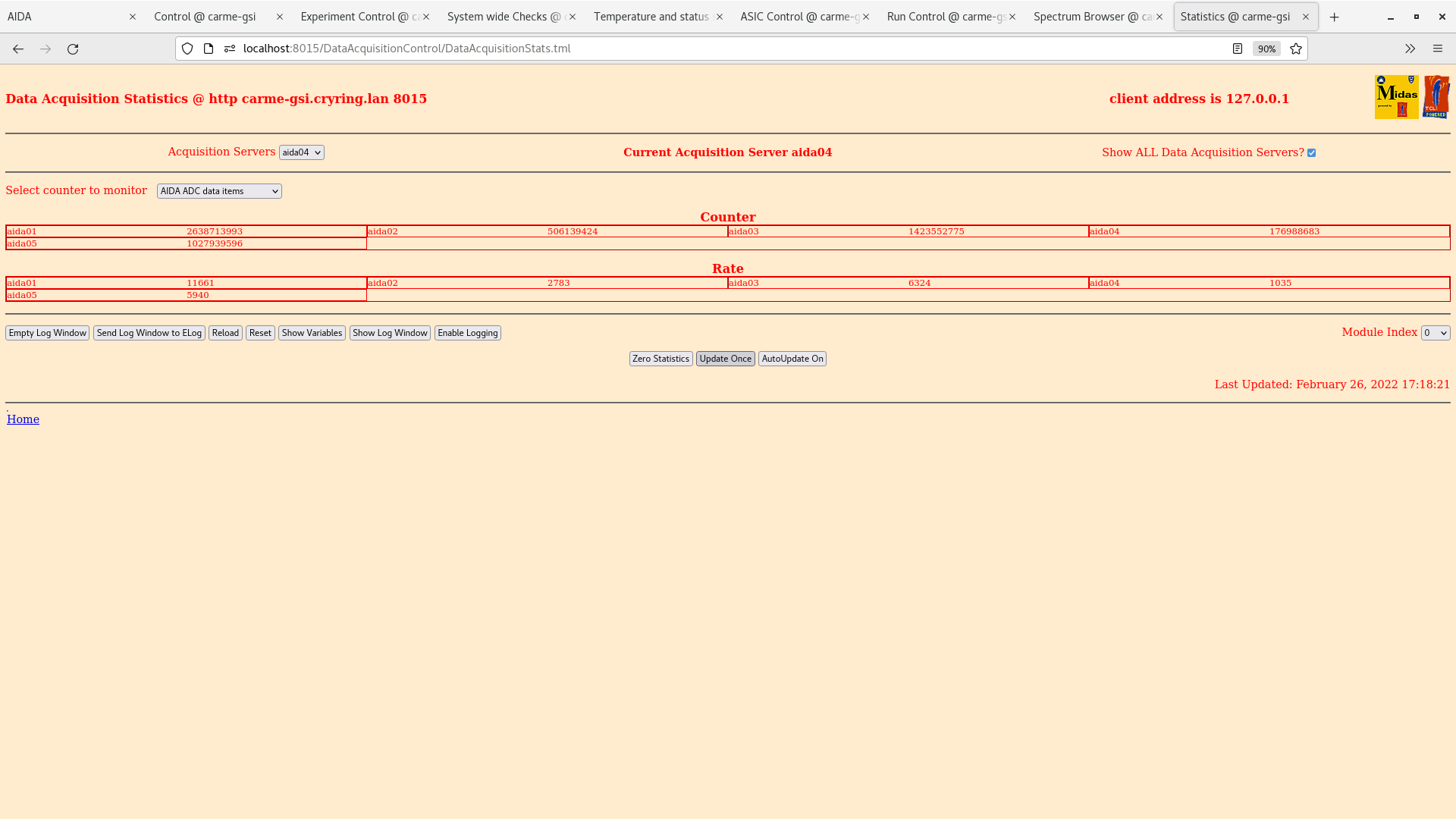

RSS TD | Saturday 26 February 07:00-15:00 |

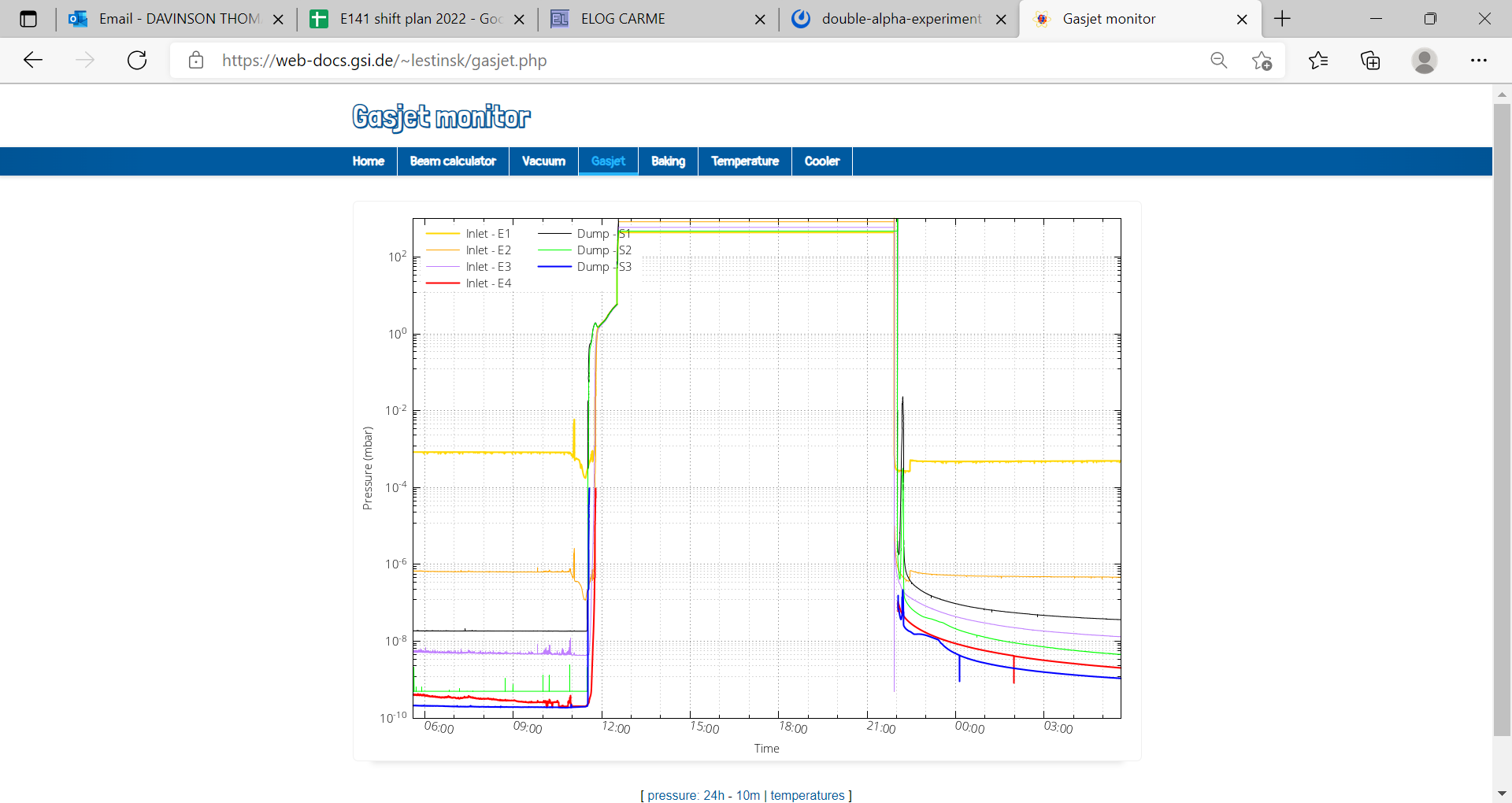

05:36 E4 pressure c. 1.7e-9mbar *not* 3e-10mbar as reported earlier

See attachments 1 & 2

E4 pressure not < 5e-10mbar - wait to startup gas jet target

06:47 RSS & TD on-site

07.00 E4 1.70e-9mbar

S3 9.42e-10mbar

07:00 Checks: all good except for the white rabbit decoder status.

07:15 All histograms cleared in the run control tab.

07.32 E4 1.60e-9mbar

S3 9.00e-10mbar

08:06 E4 1.49e-9mbar

S3 8.59e-10mbar

08:30 E4 1.43e-9mbar

S3 8.34e-10mbar

09:00 E4 1.35e-9mbar

S3 8.03e-10mbar

09:30 E4 1.29e-9mbar

S3 7.70e-10mbar

10:00 E4 1.23e-9mbar

S3 7.49e-10mbar

10:00 Checks: all good except for the white rabbit decoder status.

10:30 E4 1.18e-9mbar

S3 7.22e-10mbar

11:00 E4 1.14e-9mbar

S3 7.02e-10mbar

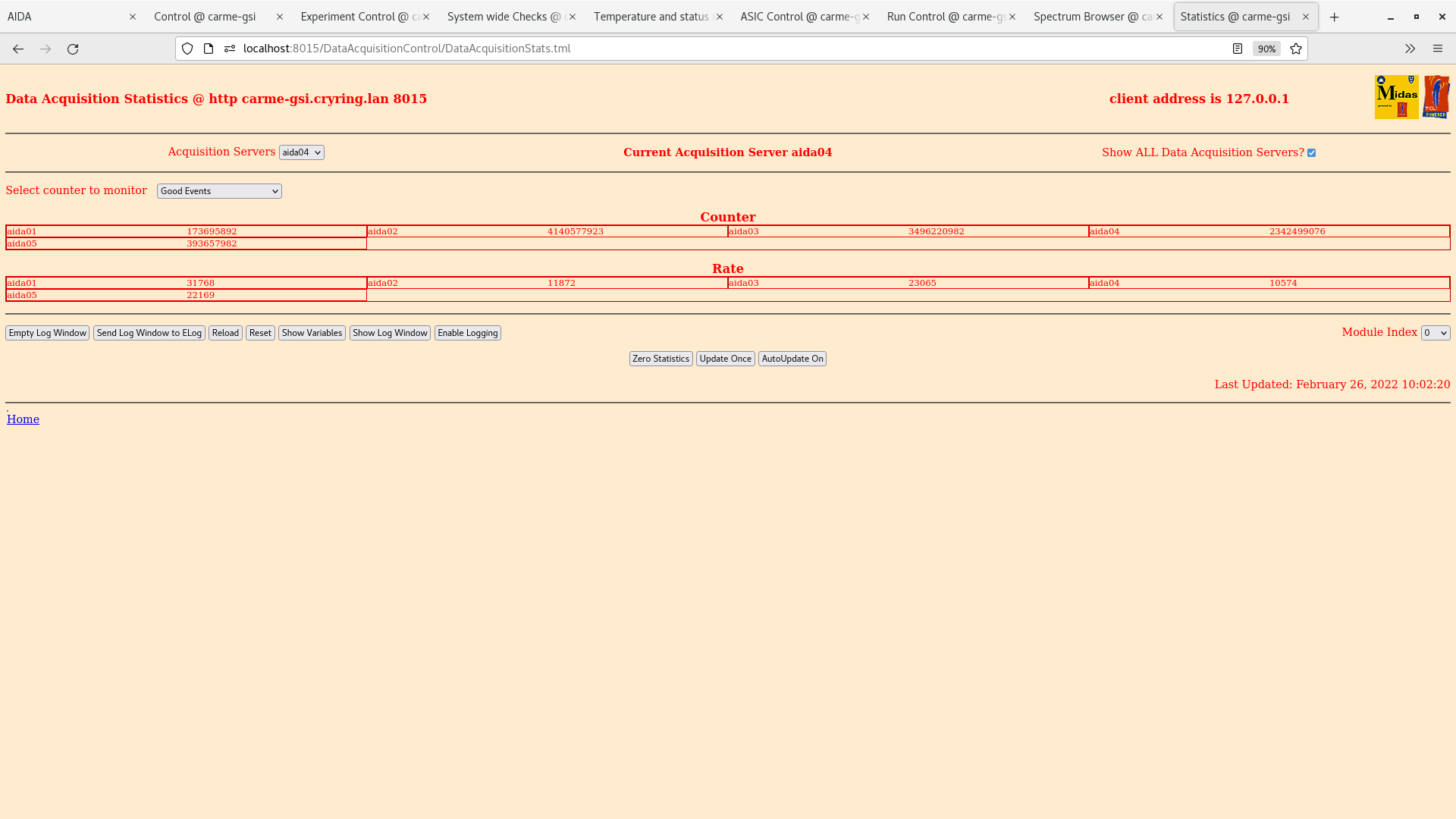

11:20 Compressor was switched on.

11:30 E4 1.10e-9mbar

S3 6.82e-10mbar

12:00 E4 1.35e-9mbar

S3 6.64e-10mbar

12:30 E4 1.23e-9mbar

S3 6.46e-10mbar

14:45 Checks: all good except for the white rabbit decoder status.

17.20 System wide checks OK *except* WR decoder status

Base Current Difference

aida01 fault 0xab60 : 0xab85 : 37

aida02 fault 0x88d3 : 0x88f7 : 36

aida03 fault 0x23aa : 0x23cf : 37

aida04 fault 0x15d7 : 0x15fc : 37

aida05 fault 0x2f03 : 0x2f0e : 11

White Rabbit error counter test result: Passed 0, Failed 5

FEE64 temperatures OK - attachment 26

stats (adc data items) OK - attachment 27

DSSSD bias -100V leakage current -3.31uA |

| Attachment 1: Capture_1.PNG

|

|

| Attachment 2: Capture_2.PNG

|

|

| Attachment 3: 7-spectrum-id8-2022-02-26_07-14-49.png

|

|

| Attachment 4: 7-spectrum-id7-2022-02-26_07-14-12.png

|

|

| Attachment 5: 7-spectrum-42022-02-26_07-13-21.png

|

|

| Attachment 6: 7-spectrum-3-2022-02-26_07-12-50.png

|

|

| Attachment 7: 7-spectrum2-2022-02-26_07-12-02.png

|

|

| Attachment 8: 7-spectrum1-2022-02-26_07-10-55.png

|

|

| Attachment 9: 7-spectrum-2022-02-26_07-10-10.png

|

|

| Attachment 10: 7-correlation-2022-02-26_07-09-11.png

|

|

| Attachment 11: 7-adc-2022-02-26_07-08-53.png

|

|

| Attachment 12: 7-good-events-2022-02-26_07-08-27.png

|

|

| Attachment 13: 10-id2-2022-02-26_10-06-08.png

|

|

| Attachment 14: 10-id1-2022-02-26_10-04-01.png

|

|

| Attachment 15: 10-correlation-2022-02-26_10-03-08.png

|

|

| Attachment 16: 10-adc-2022-02-26_10-02-47.png

|

|

| Attachment 17: 10-good-2022-02-26_10-02-27.png

|

|

| Attachment 18: IMG_7113.JPG

|

|

| Attachment 19: IMG_7112.JPG

|

|

| Attachment 20: IMG_7111.JPG

|

|

| Attachment 21: IMG_7114.JPG

|

|

| Attachment 22: 2-adc-2022-02-26_14-45-37.png

|

|

| Attachment 23: 2-good-2022-02-26_14-45-16.png

|

|

| Attachment 24: 2-correlation-2022-02-26_14-44-56.png

|

|

| Attachment 25: 2-id1-2022-02-26_14-48-13.png

|

|

| Attachment 26: Screenshot_from_2022-02-26_17-18-11.png

|

|

| Attachment 27: Screenshot_from_2022-02-26_17-18-25.png

|

|

|

297

|

Sun Feb 27 06:23:42 2022 |

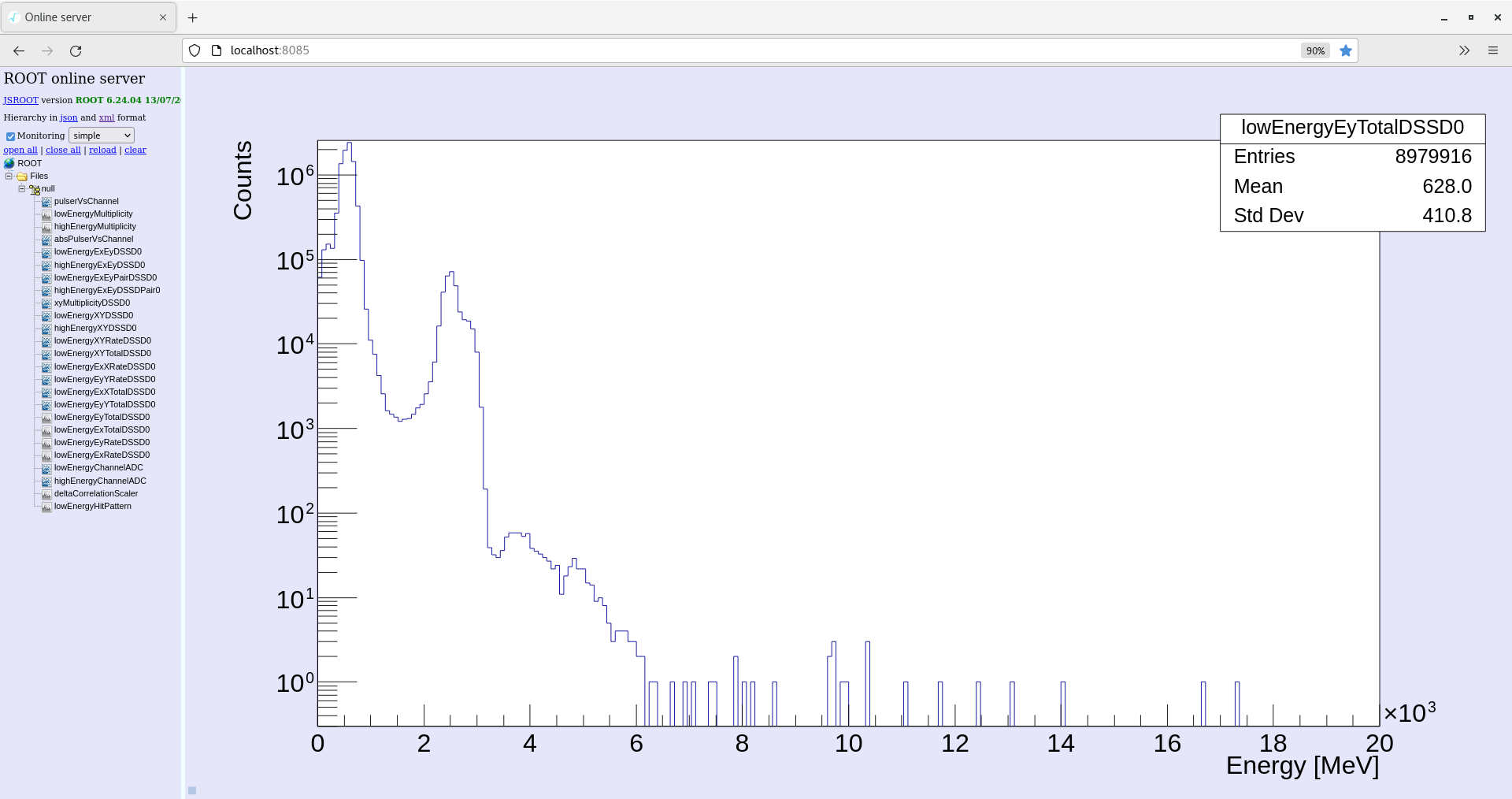

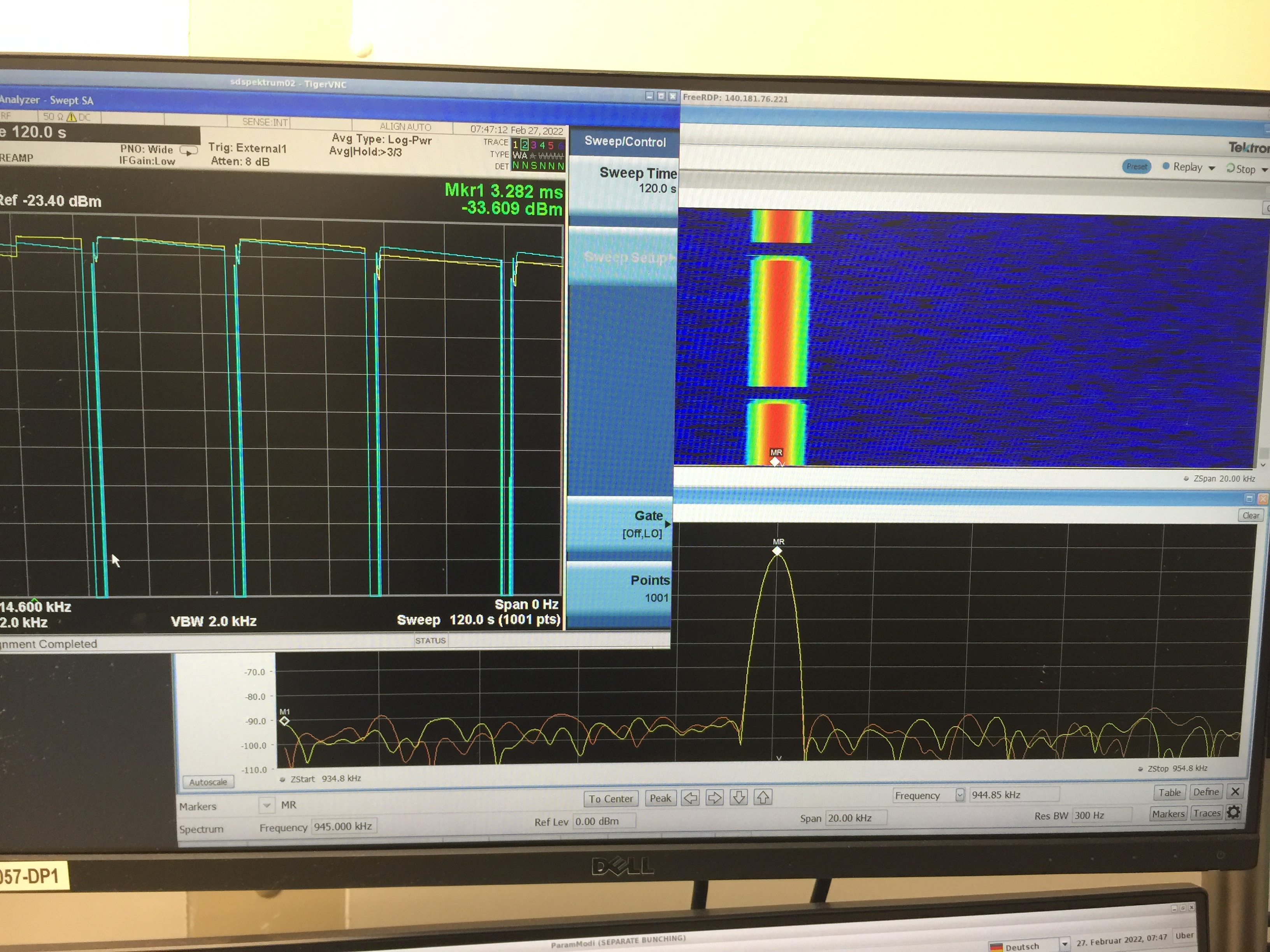

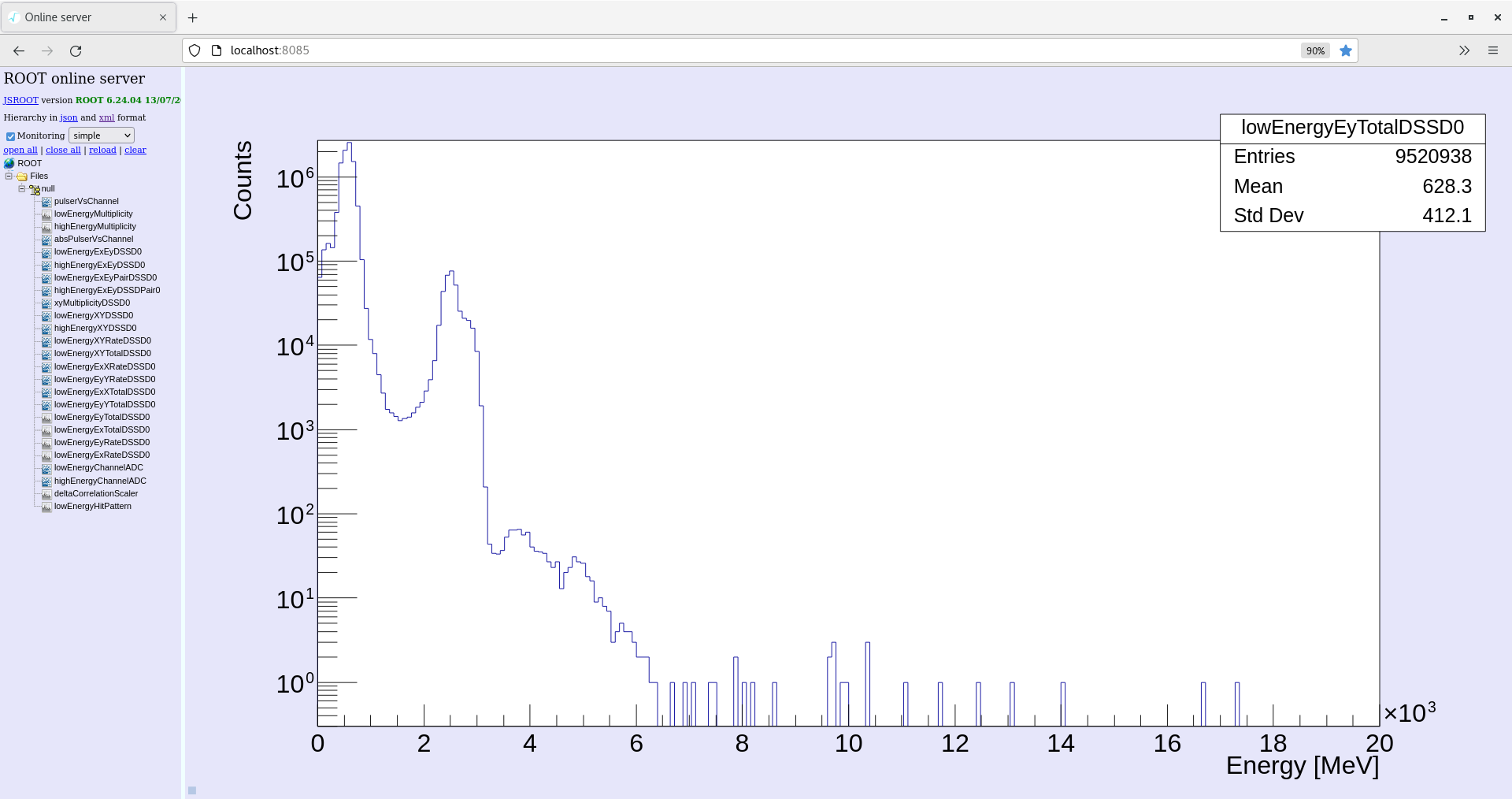

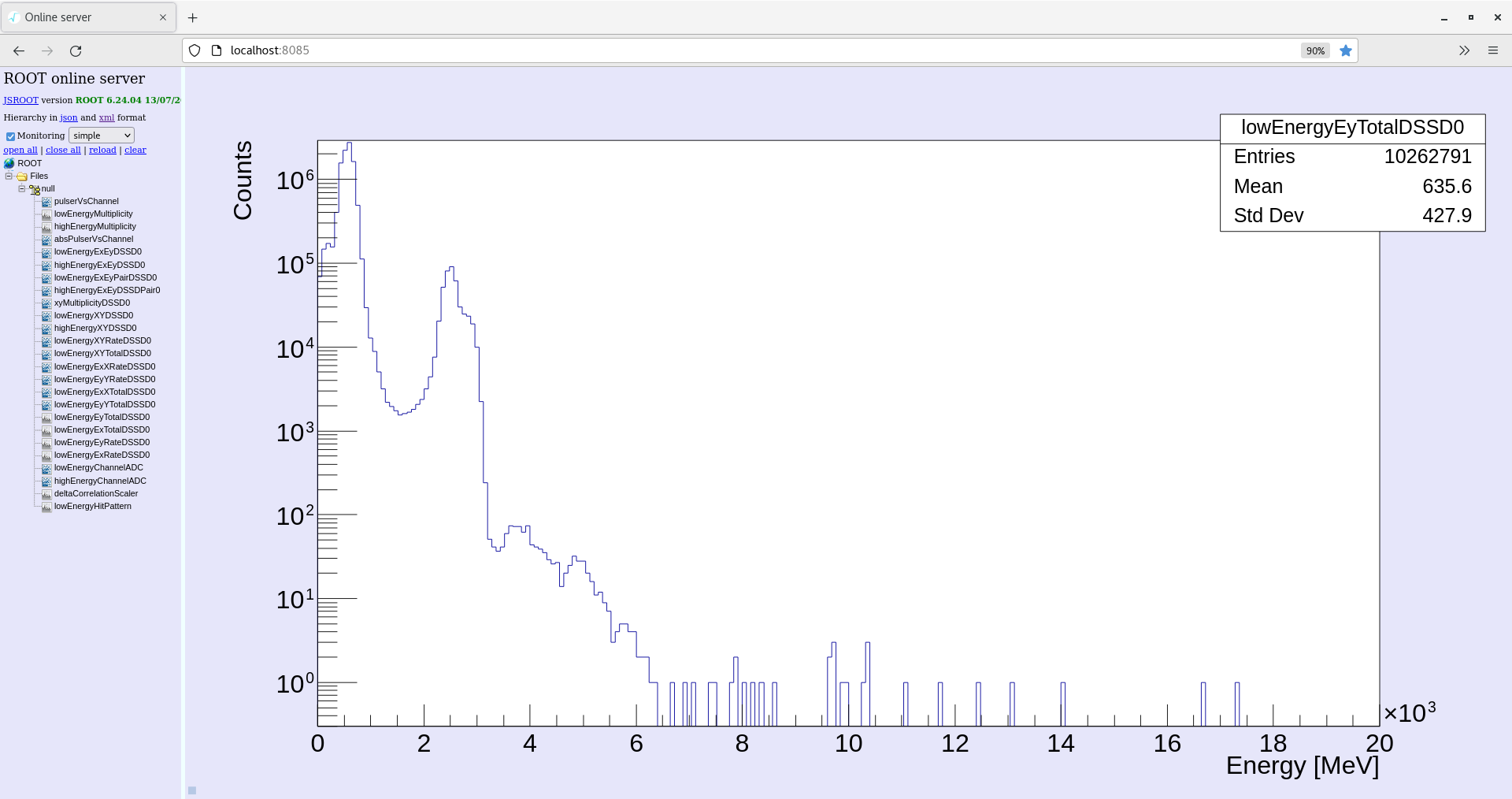

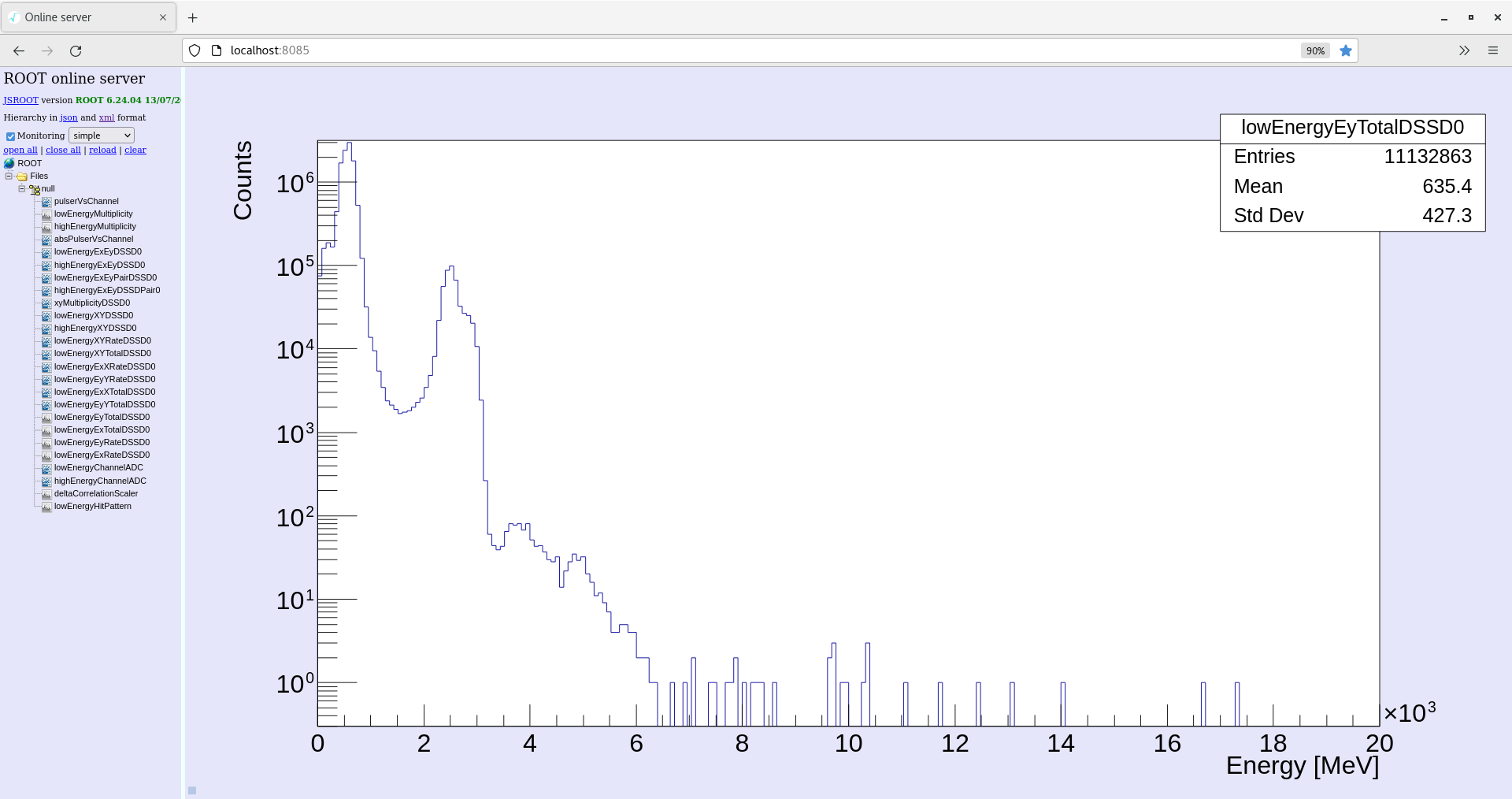

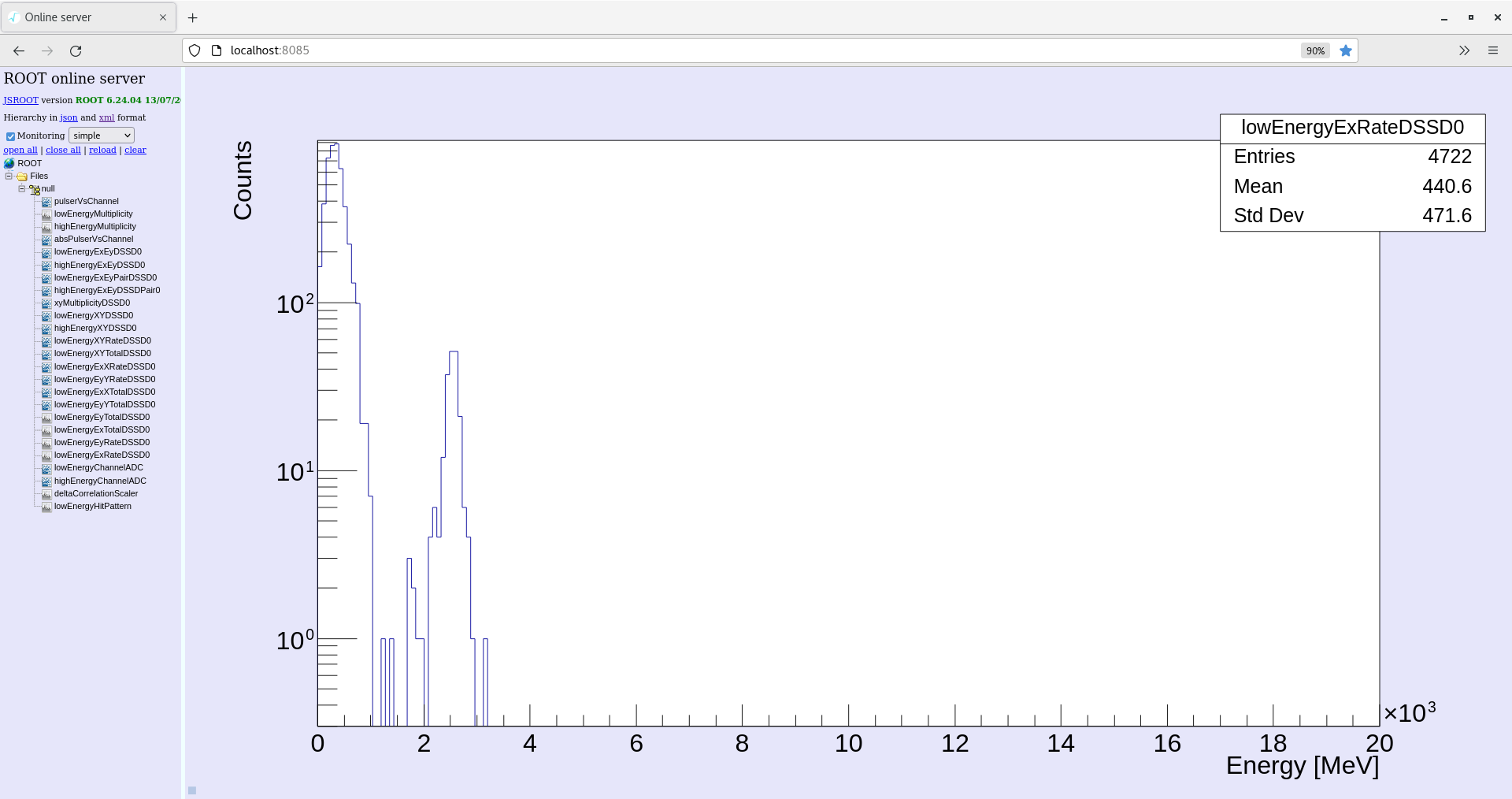

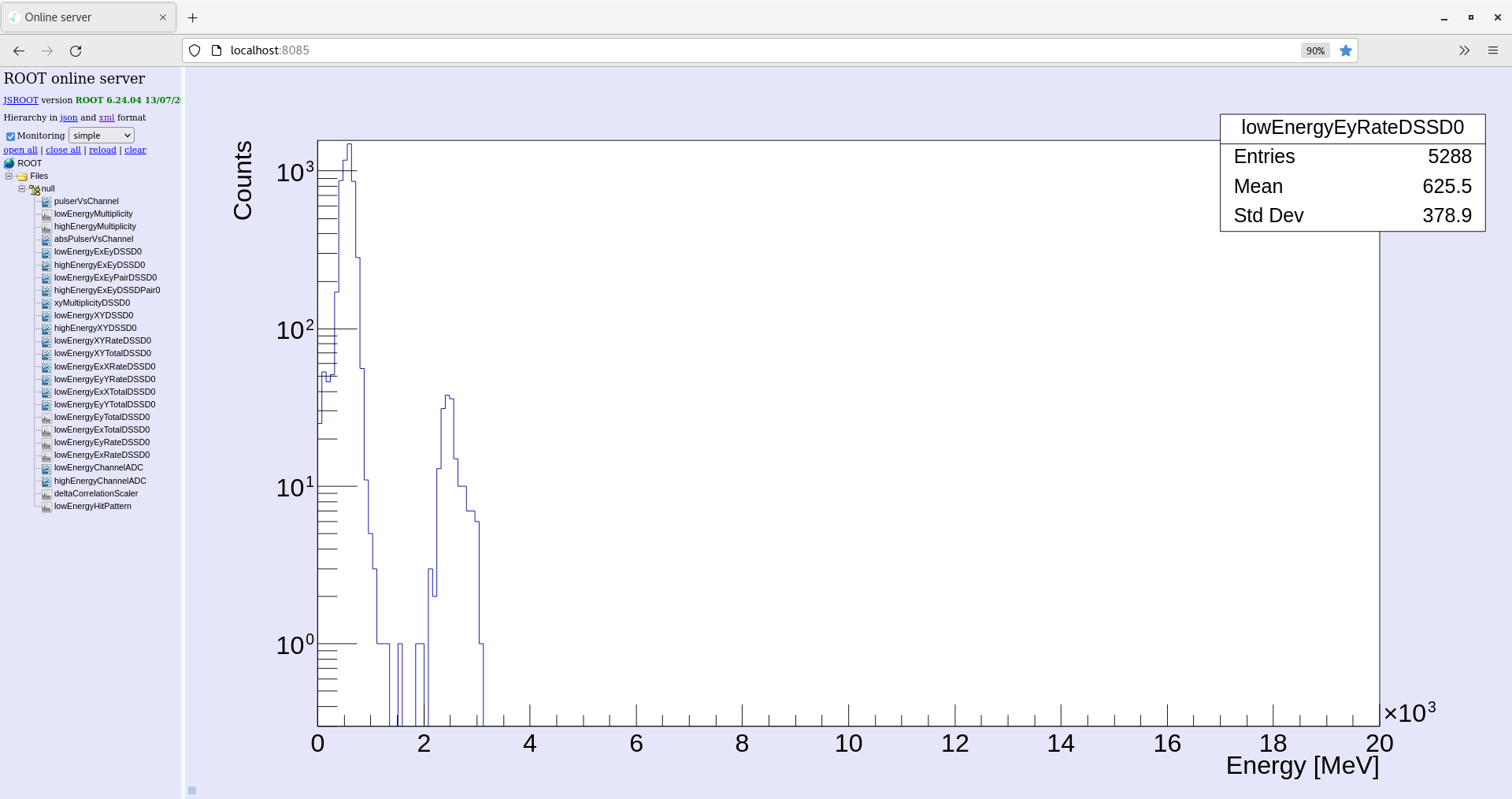

RSS TD | Current status |

Ring current ~6e7 particles/s

Merger, Tape server (WS3): 1414 kB/s writing ok

Leakage current (WS4): 3.44 uA

DAQ (WS2): temperature checked, clock status: ok, adc calibration: ok, white rabbit check: failed

Online monitoring (WS 5): done |

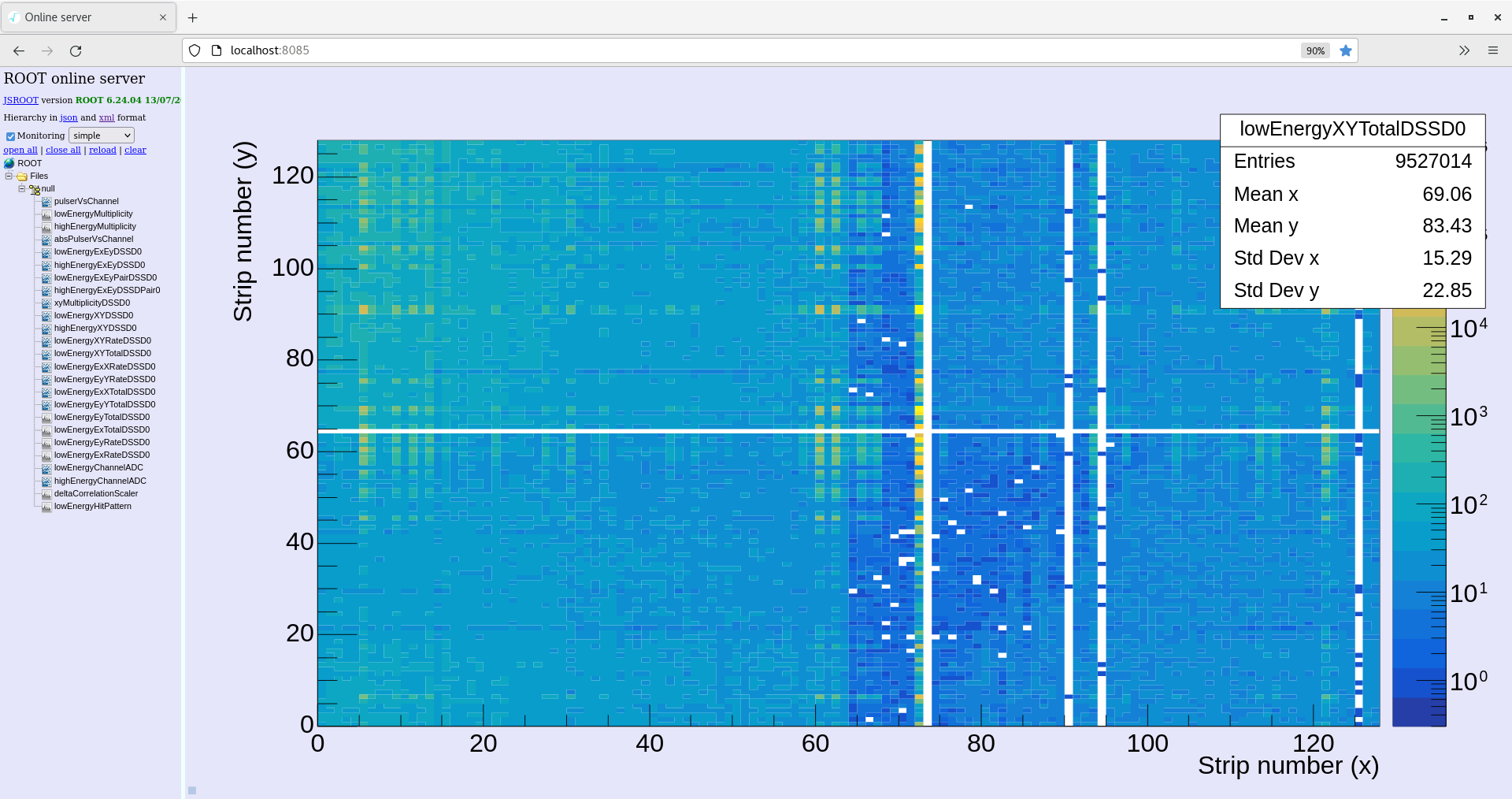

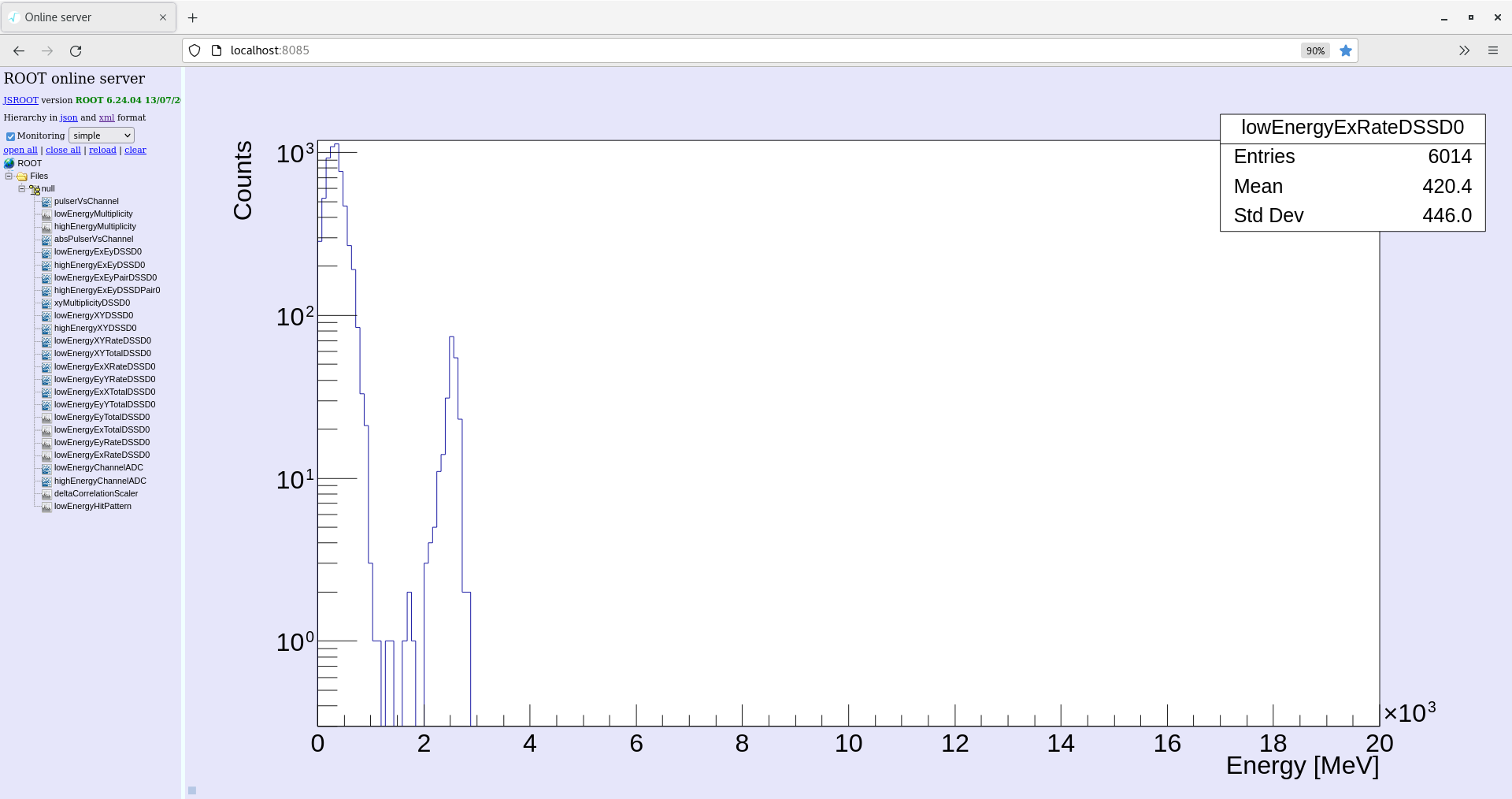

| Attachment 1: 7-ey-2022-02-27_07-30-36.png

|

|

| Attachment 2: 7-ex-2022-02-27_07-30-19.png

|

|

| Attachment 3: 7-xy-total-2022-02-27_07-29-56.png

|

|

| Attachment 4: IMG_7138.JPG

|

|

| Attachment 5: IMG_7137.JPG

|

|

| Attachment 6: IMG_7136.JPG

|

|

|

298

|

Sun Feb 27 06:58:51 2022 |

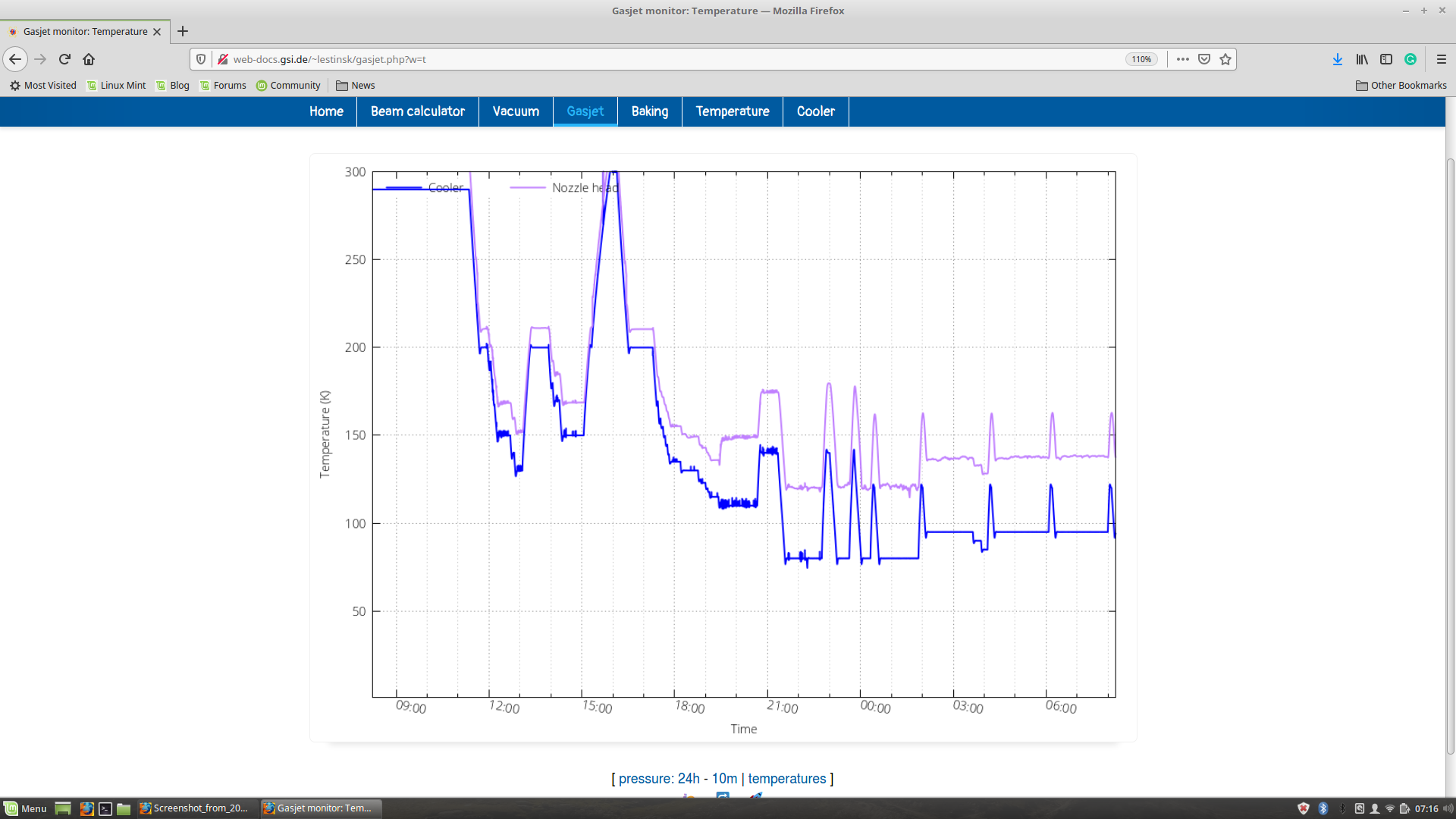

RSS TD | Current status |

7:59: 95K-->120K

8:06: 120K --> 95K

Ring current ~7e7 particles/s

Merger, Tape server (WS3): 1414 kB/s writing ok

Leakage current (WS4): 3.44 uA

DAQ (WS2): temperature checked, clock status: ok, adc calibration: ok, white rabbit check: failed

Online monitoring (WS 5): done |

| Attachment 1: 8-xy-2022-02-27_08-10-15.png

|

|

| Attachment 2: 8-ey-2022-02-27_08-09-46.png

|

|

| Attachment 3: 8-ex-2022-02-27_08-09-29.png

|

|

| Attachment 4: Screenshot_from_2022-02-27_07-16-30.png

|

|

|

299

|

Sun Feb 27 08:00:23 2022 |

RSS TD | Current status |

Ring current ~7.5e7 particles/s

Merger, Tape server (WS3): 1414 kB/s writing ok

Leakage current (WS4): 3.44 uA

DAQ (WS2): temperature checked, clock status: ok, adc calibration: ok, white rabbit check: failed

Online monitoring (WS 5): done |

| Attachment 1: 9-xy-2022-02-27_09-00-57.png

|

|

| Attachment 2: 9-ey-2022-02-27_09-00-03.png

|

|

| Attachment 3: 9-ex-2022-02-27_08-59-48.png

|

|

|

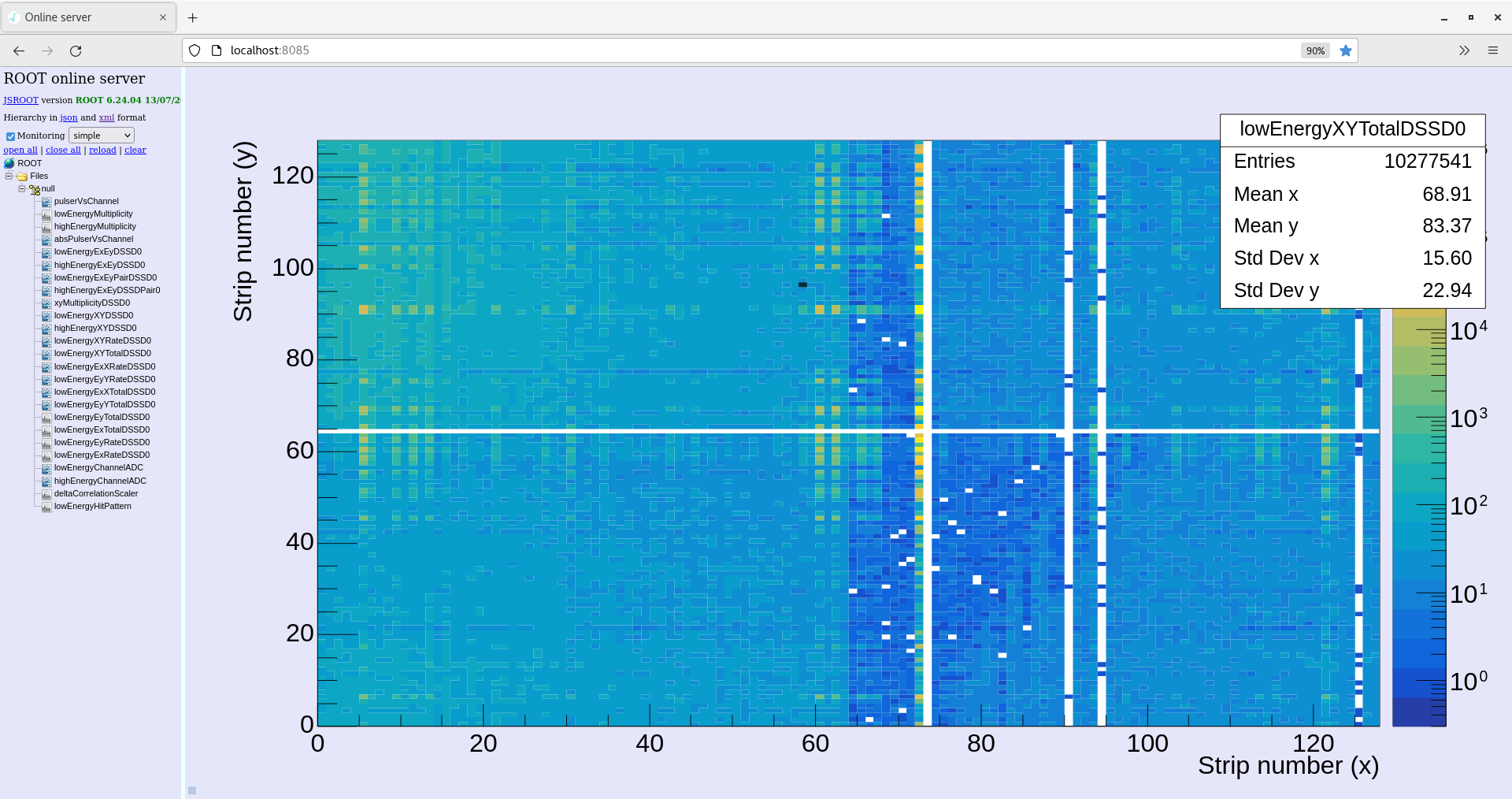

300

|

Sun Feb 27 09:00:09 2022 |

RSS TD | Current status |

10:00: 95K-->120K

10:08: 120K --> 95K

Ring current ~7e7 particles/s

Merger, Tape server (WS3): 1414 kB/s writing ok

Leakage current (WS4): 3.43 uA

DAQ (WS2): temperature checked, clock status: ok, adc calibration: ok, white rabbit check: failed

Online monitoring (WS 5): done |

| Attachment 1: 10-xy-2022-02-27_10-02-27.png

|

|

| Attachment 2: 10-ey-2022-02-27_10-02-04.png

|

|

| Attachment 3: 10-ex-2022-02-27_10-01-46.png

|

|

| Attachment 4: 10-ey-rate-2022-02-27_10-09-54.png

|

|

| Attachment 5: 10-ex-rate-2022-02-27_10-09-33.png

|

|

| Attachment 6: 10-ex-rate-95k-2022-02-27_10-13-33.png

|

|

| Attachment 7: 10-ey-rate-95K-2022-02-27_10-17-09.png

|

|

|

301

|

Sun Feb 27 10:00:07 2022 |

RSS TD | Current status |

Ring current ~9e7 particles/s

Merger, Tape server (WS3): 1414 kB/s writing ok

Leakage current (WS4): 3.43 uA

DAQ (WS2): temperature checked, clock status: ok, adc calibration: ok, white rabbit check: failed

Online monitoring (WS 5): done |

| Attachment 1: 11-xy-2022-02-27_11-01-22.png

|

|

| Attachment 2: 11-ey-rate2022-02-27_11-00-46.png

|

|

| Attachment 3: 11-ex-rate-2022-02-27_11-00-27.png

|

|

|

302

|

Sun Feb 27 11:00:08 2022 |

RSS TD | Current status |

12:00: 95K-->120K

12:07: 120K --> 95K

Ring current ~6e7 particles/s

Merger, Tape server (WS3): 1414 kB/s writing ok

Leakage current (WS4): 3.43 uA

DAQ (WS2): temperature checked, clock status: ok, adc calibration: ok, white rabbit check: failed

Online monitoring (WS 5): done |

| Attachment 1: 12-xy-2022-02-27_12-16-19.png

|

|

| Attachment 2: 12-yrate-2022-02-27_12-15-42.png

|

|

| Attachment 3: 12-xrate-2022-02-27_12-15-03.png

|

|

|

303

|

Sun Feb 27 12:00:13 2022 |

RSS TD | Current status |

Ring current ~7.7e7 particles/s

Merger, Tape server (WS3): 1414 kB/s writing ok

Leakage current (WS4): 3.43 uA

DAQ (WS2): temperature checked, clock status: ok, adc calibration: ok, white rabbit check: failed

Online monitoring (WS 5): done |

| Attachment 1: 13-xy-2022-02-27_13-01-36.png

|

|

| Attachment 2: 13-yrate-2022-02-27_13-01-06.png

|

|

| Attachment 3: 13-xrate-Screenshot_from_2022-02-27_13-00-50.png

|

|

|

305

|

Sun Feb 27 13:34:24 2022 |

RSS TD | Current status |

14:33: 95K-->140K

14:44: 140K --> 95K

Ring current ~6e7 particles/s

Merger, Tape server (WS3): 1414 kB/s writing ok

Leakage current (WS4): 3.43 uA

DAQ (WS2): temperature checked, clock status: ok, adc calibration: ok, white rabbit check: failed

Online monitoring (WS 5): done |

|

154

|

Fri Nov 12 08:54:11 2021 |

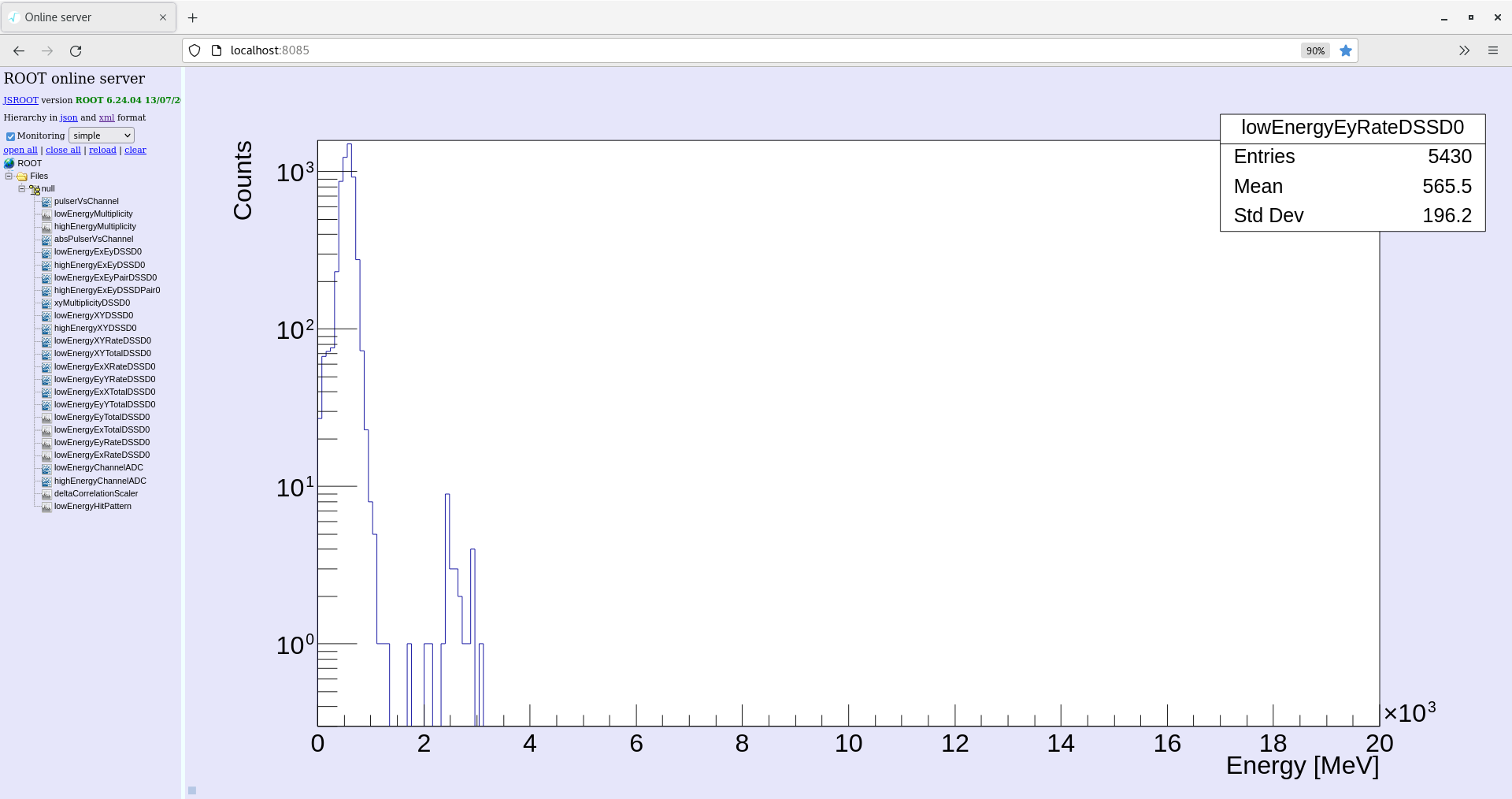

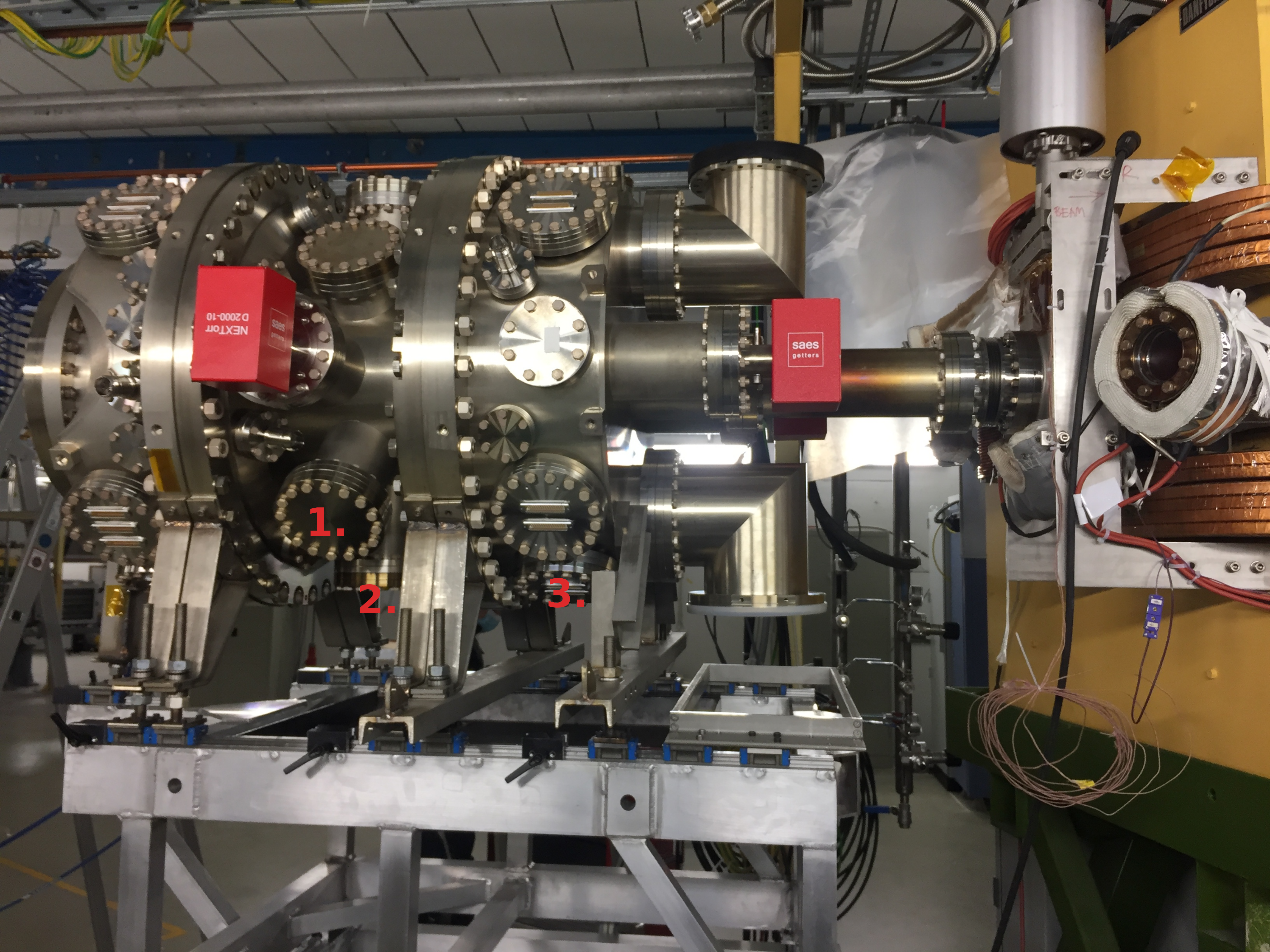

RSS ML + CB (remotely) NK AK NP | First CARME baking attempt |

07:50 Small leaks (near the motors and upper valve) were detected in the tent which were covered with Al foil.

08:10 ML changed the baking temperature to 120 degrees.

09:40 Since the bottom of CARME is cold, due to uneven distribution of heat, baking is stopped.

13:00 Tent was slightly opened from the sides so that the heat can escape.

13:15 NK mounted three 200 W (see red labels in the picture below) and one 40 W (see the yellow label in the picture below) heating jacket on four CF100 flanges. Power cables and thermocouples were taken care of by AK.

14:00 Tent was closed.

14:00-17:00 ML started baking at temperature 80 degrees to check the heat distribution in the tent. Baking was then stopped and will start from Monday.

Attached - thermocouple temperatures (now correct) |

| Attachment 1: Capture.PNG

|

|

| Attachment 2: 200W_heaters.svg

|

|

| Attachment 3: 40W_heater.svg

|

|