| |

ID |

Date |

Author |

Subject |

|

|

430

|

Thu Jul 27 09:43:56 2023 |

RSS | Thermocouples connected -2 |

10:30 IE514 1.80e-08mbar

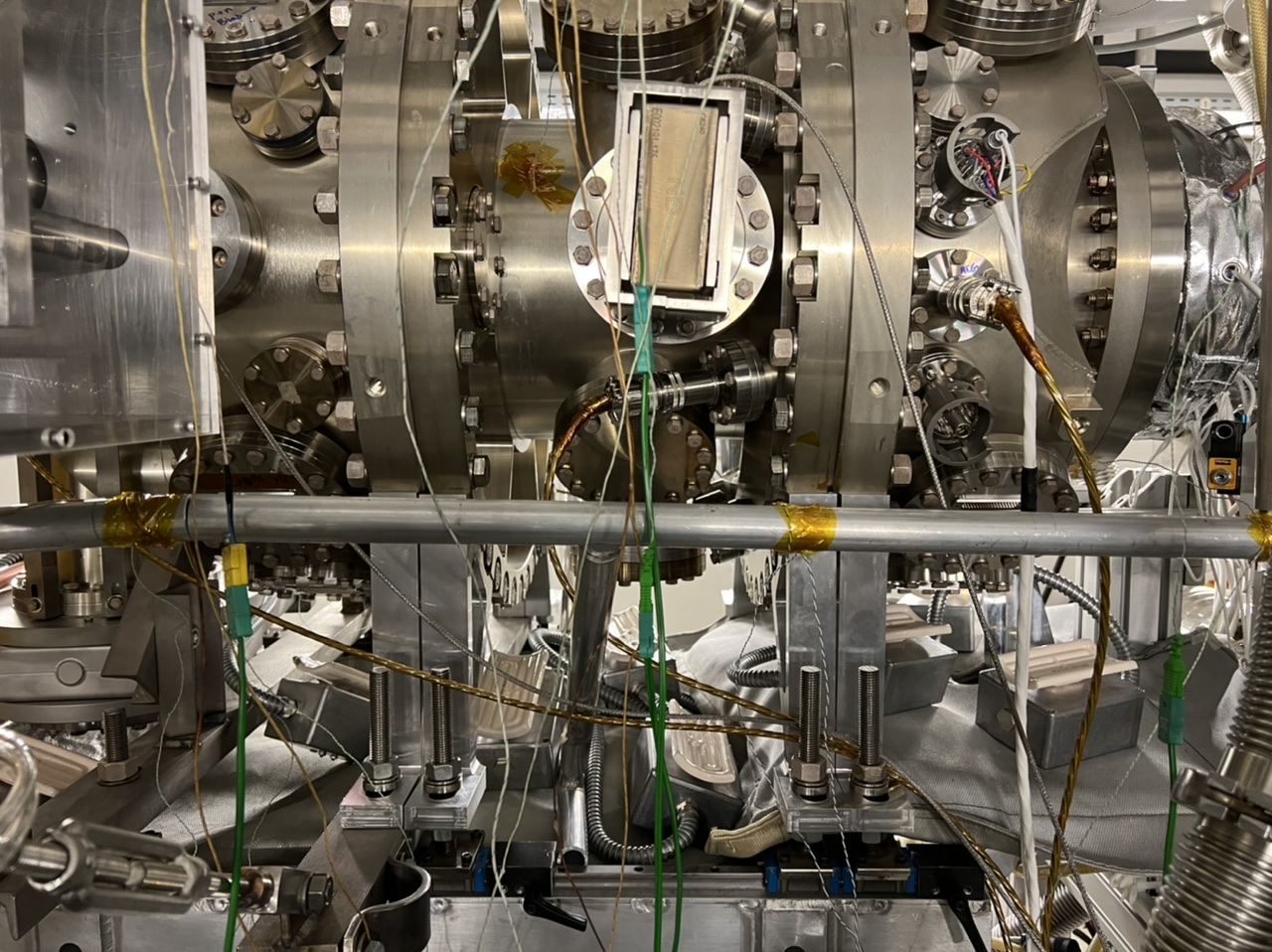

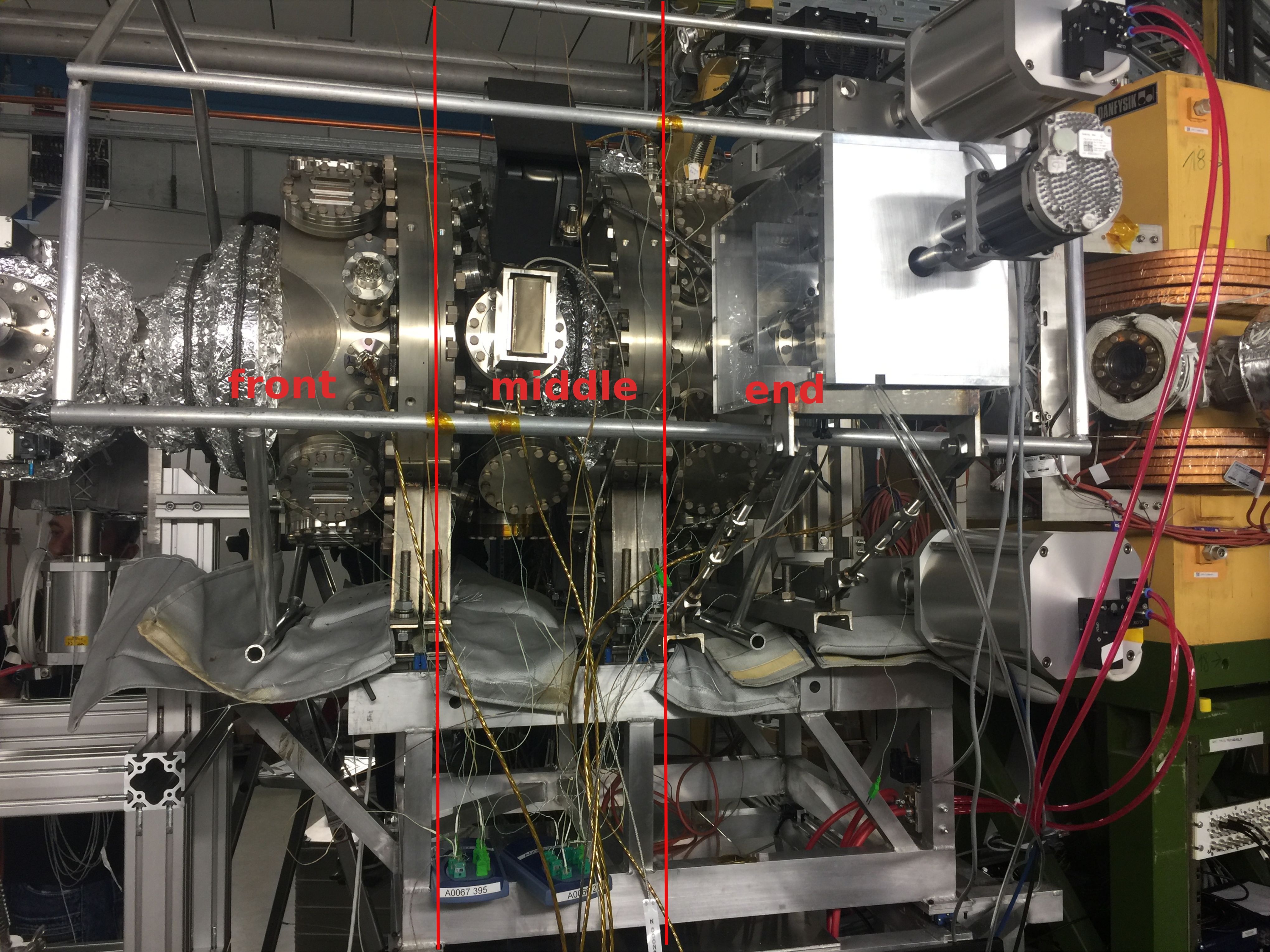

Most of the CARME is covered by the baking tent. The tent needs to be closed and a bit covered from the front (upstream), end (downstream), and bottom side. TCs are labeled with a marker in the sequence 1-1 to 2-8.

1-1 Internal TC 1

1-2 Internal TC 2

1-3 Internal TC 3

1-4 CARME front top

1-5 CARME front bottom

1-6 Top hanging middle

1-7 CARME middle middle

1-8 CARME middle bottom

2-1 CARME middle top

2-2 CARME back middle

2-3 Elbow

2-4 Valve

2-5 Magnet pipe

2-6 CARME back top

2-7 CARME back float

2-8 CARME back bottom

Also, TC extensions would be needed to connect to TC-8 modules. |

| Attachment 1: IMG_9920.jpg

|

|

| Attachment 2: IMG_9919.jpg

|

|

|

|

425

|

Sat Jul 22 09:19:59 2023 |

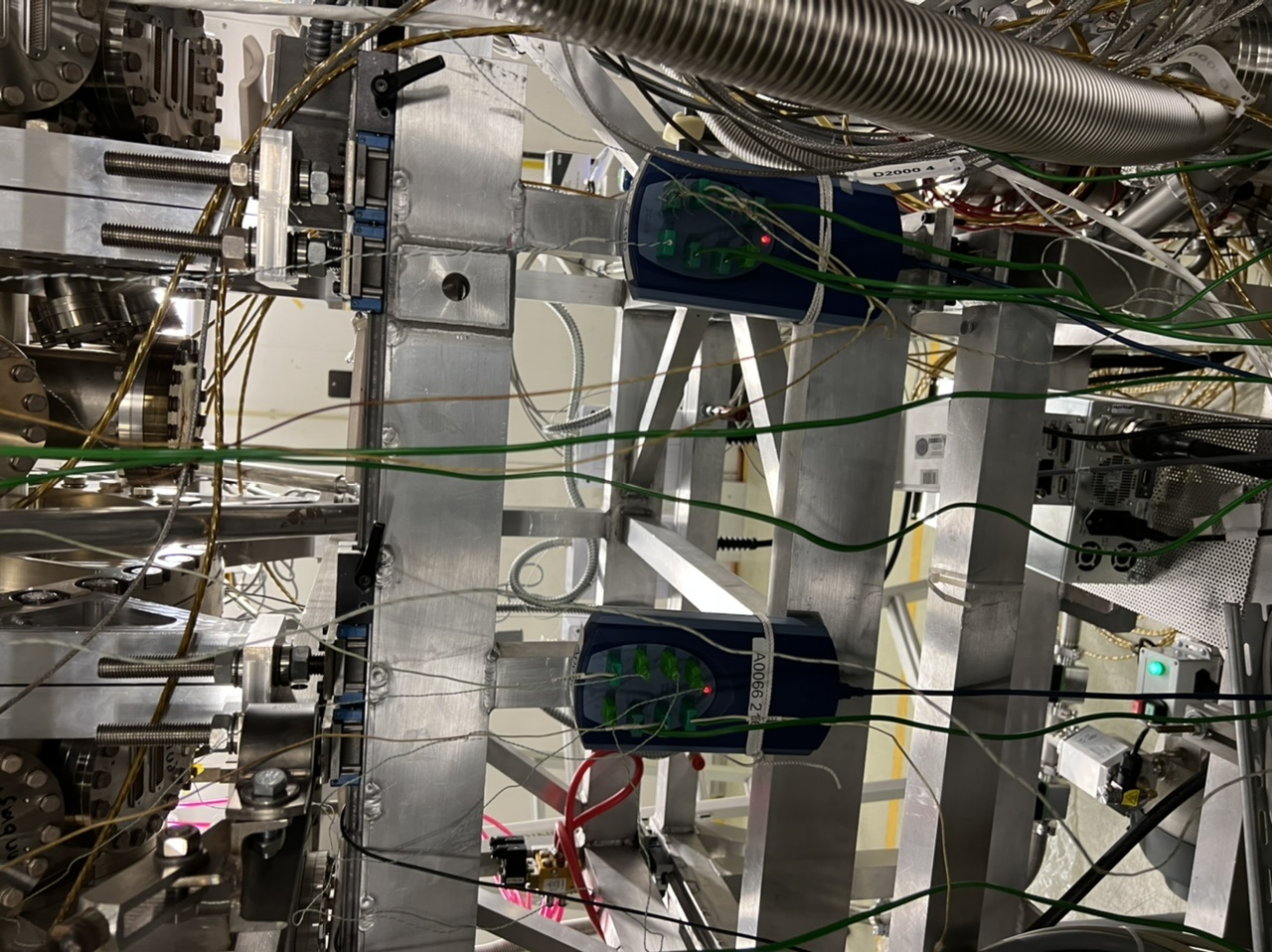

RSS, TD | Thermocouples connected |

10.20 Pirani 1e-03mbar IE514 3.26e-08mbar

12.53 CARME Leybold IE514 gauge OFF

Top right DSSSD bias -20V leakage current -10.51uA

Three internal ThermoCouples (TCs) -labeled 1, 2, and 3 in attachment 1 - were attached and tested on the TC-08 boards. Only 2 showed the ambient temperature, see attachment 3. 1 and 3 showed some strange numbers, see attachments 2 and 4 respectively.

15.28 CARME Leybold IE514 gauge OFF. Top right DSSSD bias -20V leakage current -10.44A

All the TCs are attached to TC-08 modules. See attachments 5-7. Once all TCs were plugged into TC-08 modules, they were fine.

TC-08 A0067

1. Internal TC 1

2. Internal TC 2

3. Internal TC 3

4. CARME front top

5. CARME front bottom

6. Top hanging middle

7. CARME middle middle

8. CARME middle bottom

TC-08 A0066

1. CARME middle top

2. CARME back middle

3. Elbow

4. Valve

5. Magnet pipe

6. CARME back top

7. CARME back float

8. CARME back bottom

Heating Jackets placed beneath the heaters. See attachments 8-10. |

| Attachment 1: 8FE76383-1CCE-45AE-A589-ABD38F1BB304.jpeg

|

|

| Attachment 2: 482F59E4-AC5E-4DEC-8D99-3DE1E9CD77C2.jpeg

|

|

| Attachment 3: 6FAE2064-8F7B-4CF7-ADA2-B89B7DD39FB7.jpeg

|

|

| Attachment 4: F6628AD2-D2B2-4DF3-A2E9-2E56BEFC6D98.jpeg

|

|

| Attachment 5: 8D296DD9-0285-4254-8691-7E2CB42A0623.jpeg

|

|

| Attachment 6: 72C0BF3E-A0C3-496A-A37D-5893C7302462.jpeg

|

|

| Attachment 7: FDF5D49E-FAA2-4CC9-A416-727FDA95E8C3.jpeg

|

|

| Attachment 8: B852C067-86CC-4B9A-9B19-2786C6DF96E6.jpeg

|

|

| Attachment 9: 4DD9700B-B59C-4BE5-99D7-00364C44D590.jpeg

|

|

| Attachment 10: E99CCFF8-3084-426A-AA1D-F992780E7E29.jpeg

|

|

|

|

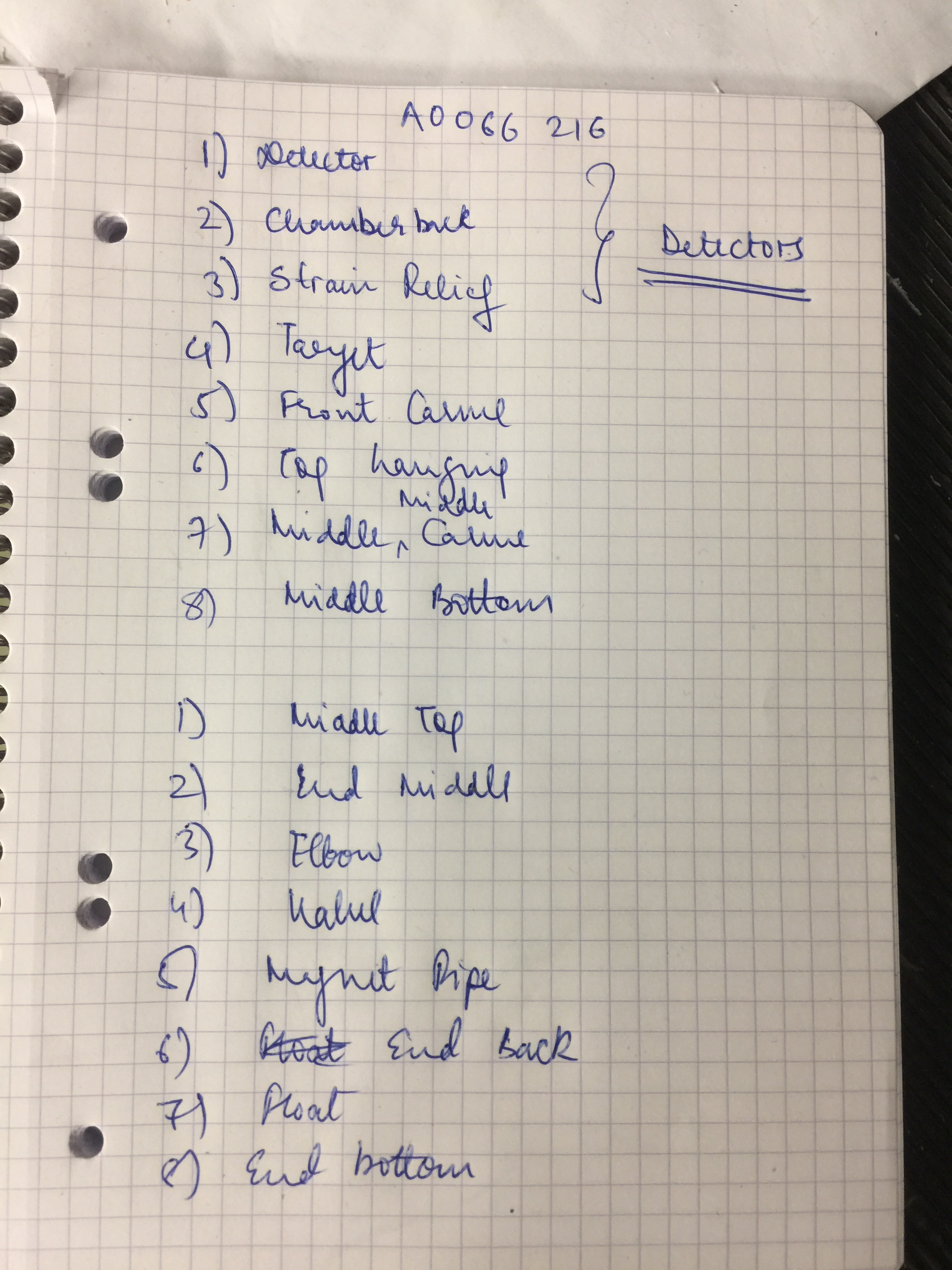

149

|

Wed Nov 10 18:24:12 2021 |

RSS | Thermocouple labelling |

1. Detector

2. Chamber back

3. Strain relief

4. Target

5. Front CARME

6. Top hanging

7. Middle middle CARME

8. Middle bottom

1. Middle top

2. End middle

3. Elbow

4. Valve

5. Magnet pipe

6. End back

7. Float

8. End bottom |

| Attachment 1: labeling.JPG.svg

|

|

| Attachment 2: Labelling.svg

|

|

| Attachment 3: IMG_5512.JPG

|

|

|

|

128

|

Thu Oct 21 20:26:44 2021 |

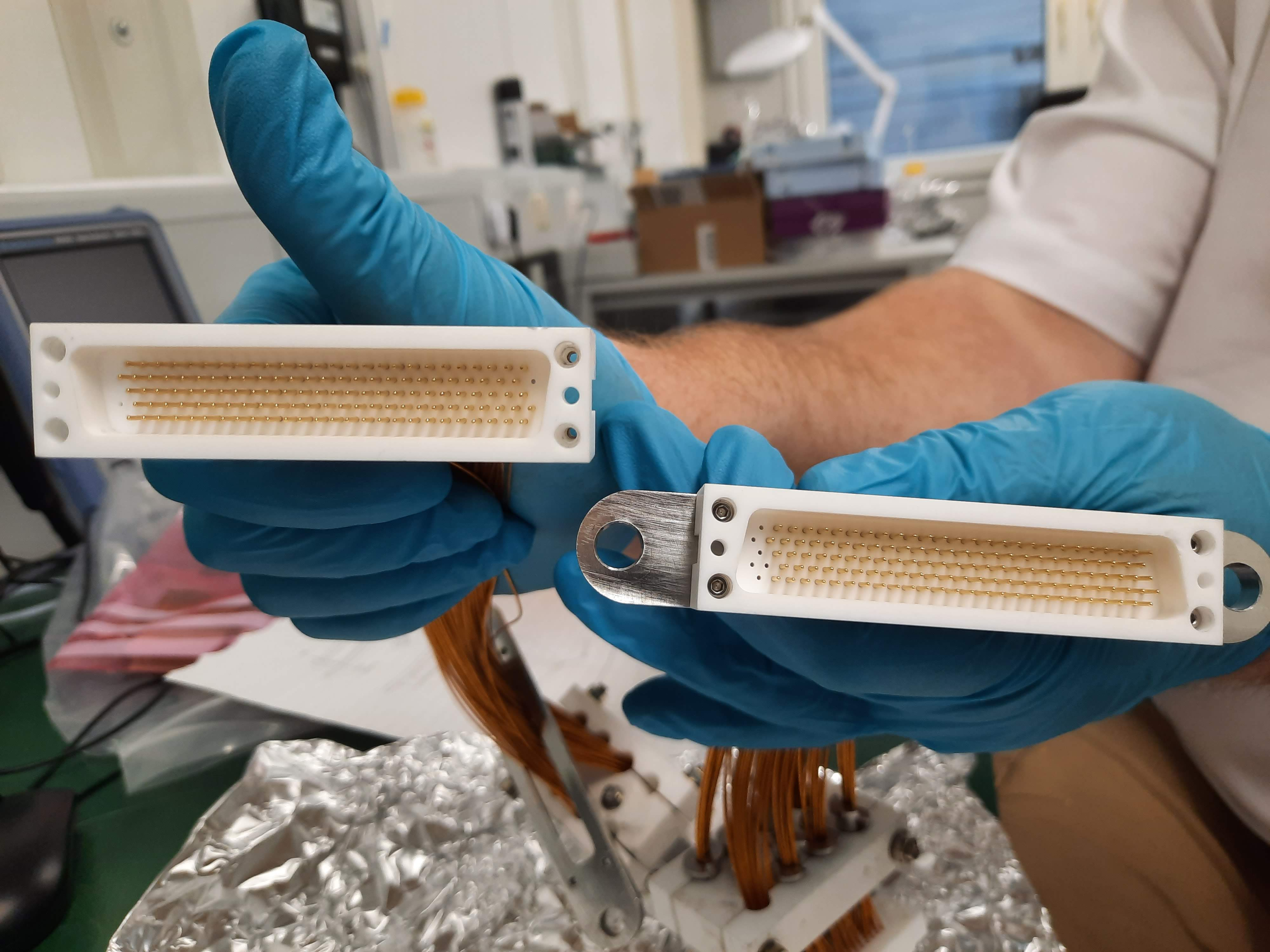

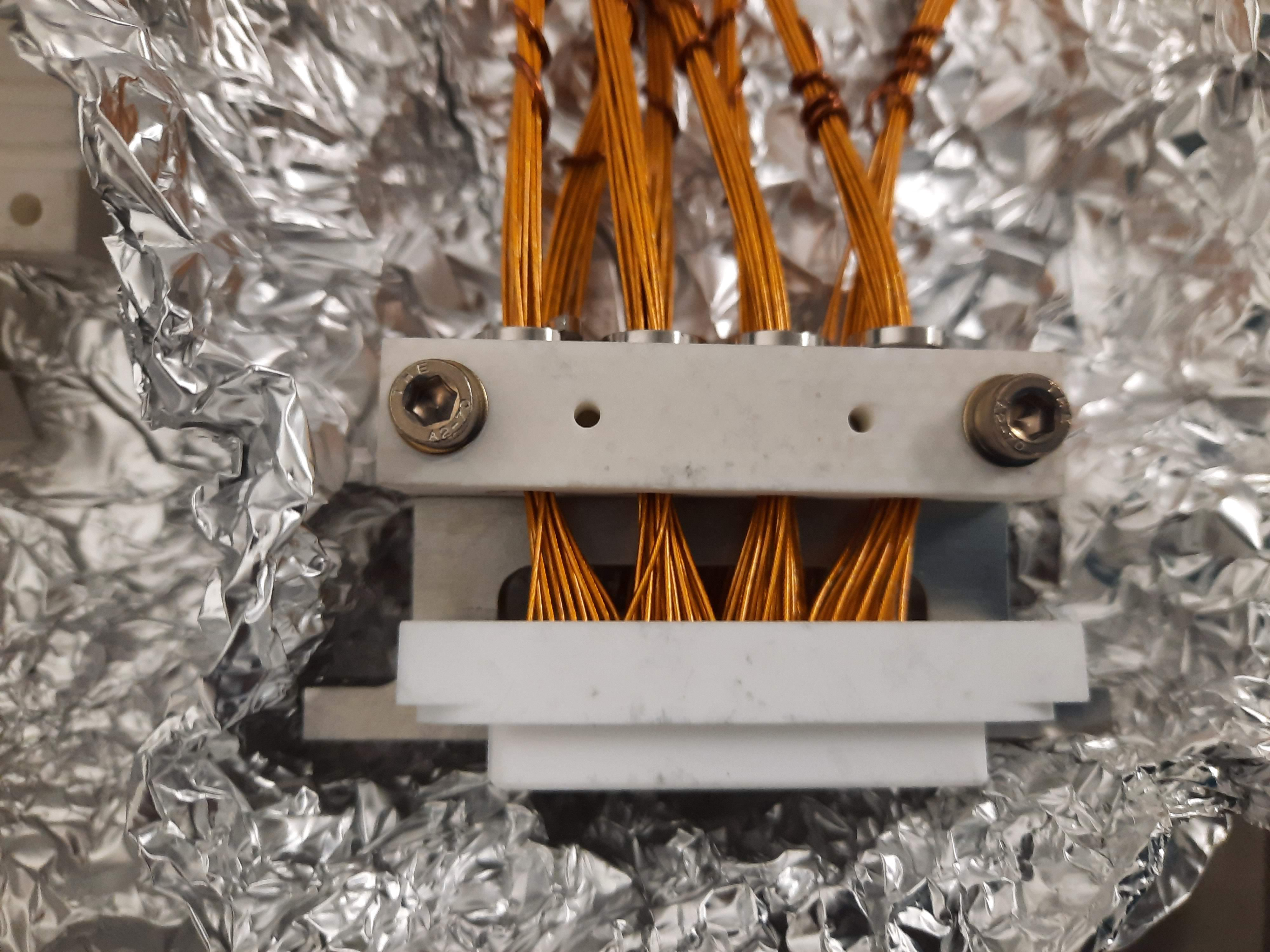

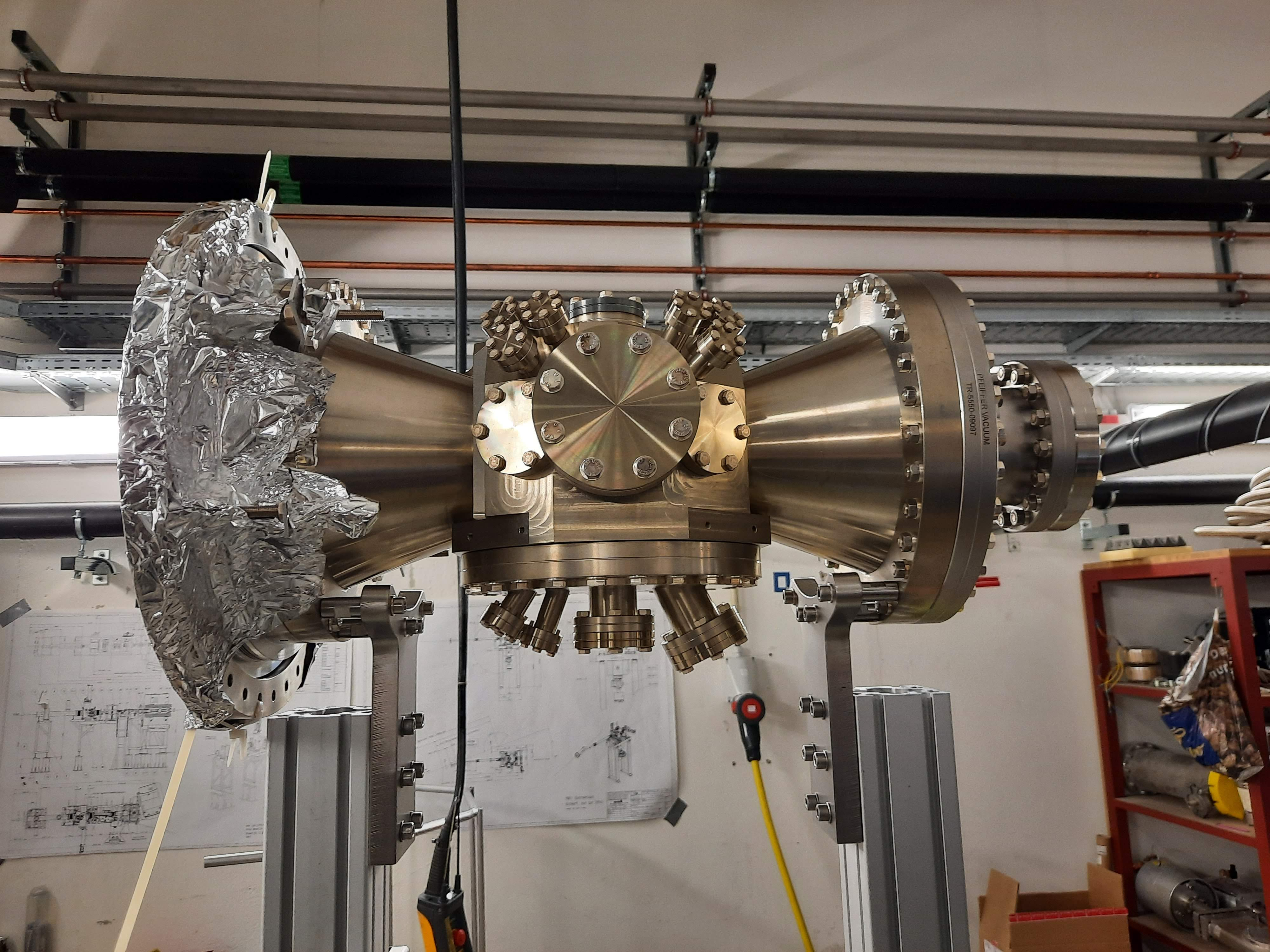

JM TD | Thermocouple and Connector cables |

NEG pump electrical connections tested - all connections sound.

Detector carriers have been redrilled and are currently being cleaned. Carriers were checked within the chamber, mounting much easier with new hole. Distances to NEG feedthroughs and thermocouple feedthrough from the carrier also checked. NEG feedthroughs have sufficient separation now moved, thermocouple required moving to top flange position to avoid collision with carrier.

Longer external thermocouples required for top position to reach TC08's. 3 Longer thermocouples made up using spare wire and connected to feedthrough. All thermocouples checked using baking code - all appear fine. We have 2 long thermocouples for the interaction chamber, 2 for the RE-72's and one for the top of the chamber left. Bellows can be reached by shorter thermocouple. This should be sufficient for baking.

Standoffs job submitted to workshop for production, may be available end of the week depending on schedules of workshop. Clamp guide and hook tools produced.

Cable connectors have started to be seperated and bound into 16 and 17 cable bunches to enable a good fit in strain reliefs. Upon inspection D-connectors were attached upside down and required flipping to correct position (see image - thumbs up indicates correct position). Cables fit through funnel strain reliefs well, other strain reliefs look more difficult - may require more hands to complete. One long connector has criss crossed wires which may not fit in strain reliefs and may require re-wiring a few cables and one long has broken D-connector. Broken ceramic can be replaced with new D-connector and other long connectors are available

Damaged detector removed from carrier and is in its box - awaiting delivery of other detectors.

Interaction chamber mounted on its frame in CRYRING as well

|

| Attachment 1: 20211021_111319.jpg

|

|

| Attachment 2: 20211021_173047.jpg

|

|

| Attachment 3: 20211021_142901.jpg

|

|

| Attachment 4: 20211021_173102.jpg

|

|

| Attachment 5: 20211021_173107.jpg

|

|

| Attachment 6: 20211021_173054.jpg

|

|

| Attachment 7: 20211021_173047.jpg

|

|

| Attachment 8: 20211019_114556.jpg

|

|

| Attachment 9: 20211021_100650.jpg

|

|

| Attachment 10: 20211021_111516.jpg

|

|

|

|

158

|

Thu Nov 18 13:50:51 2021 |

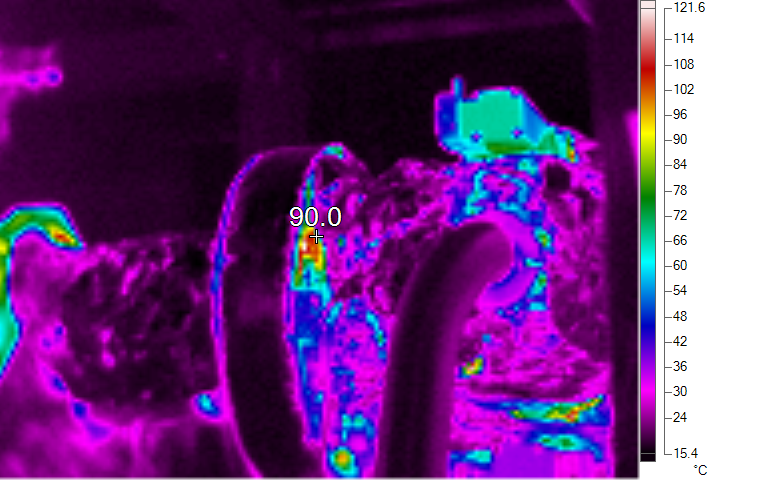

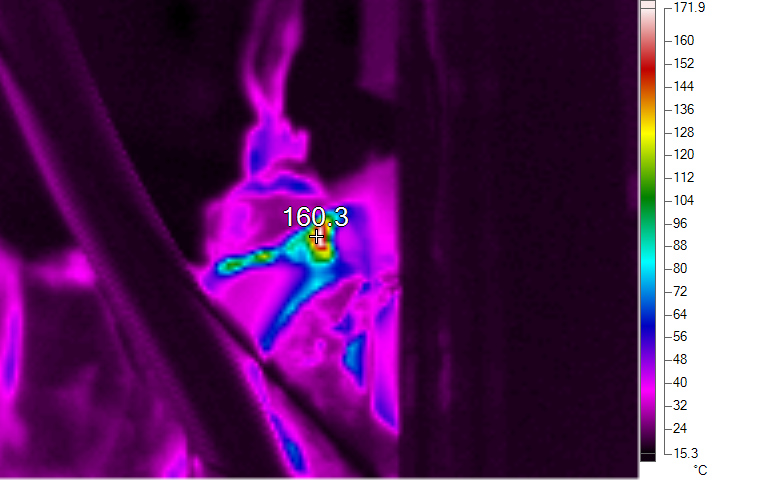

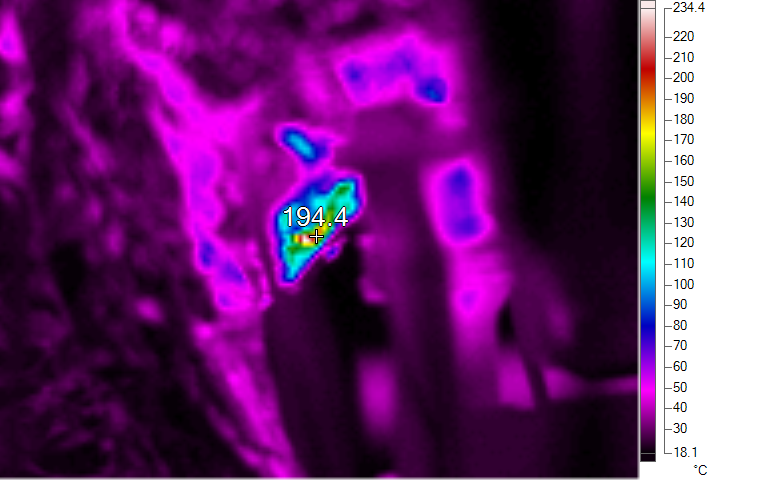

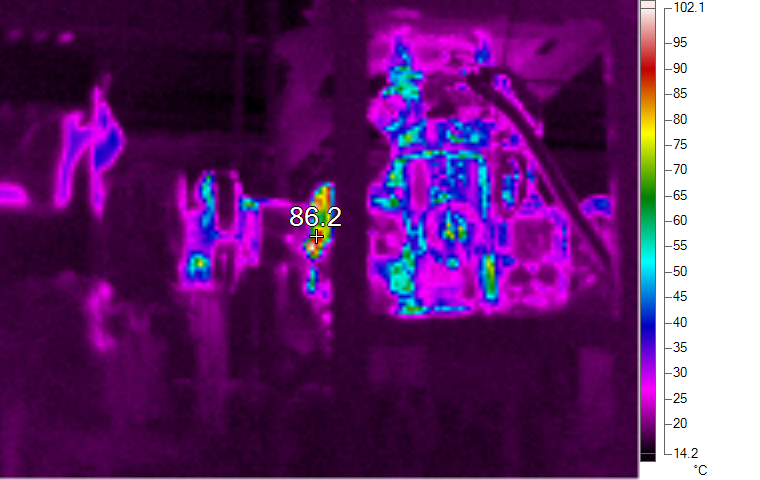

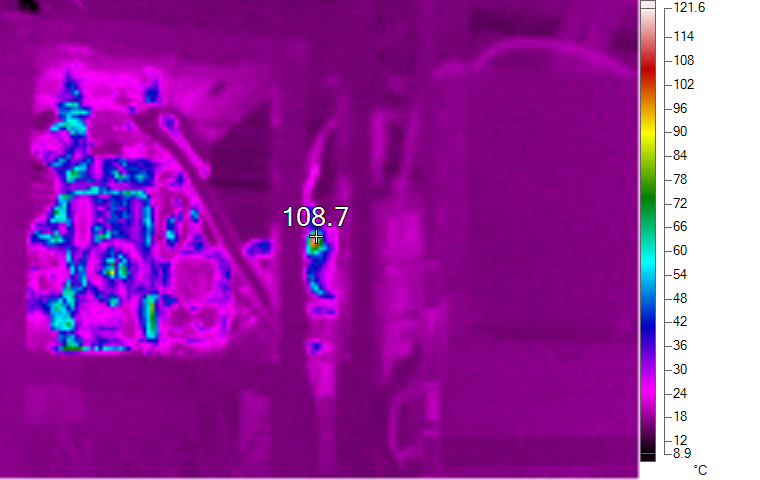

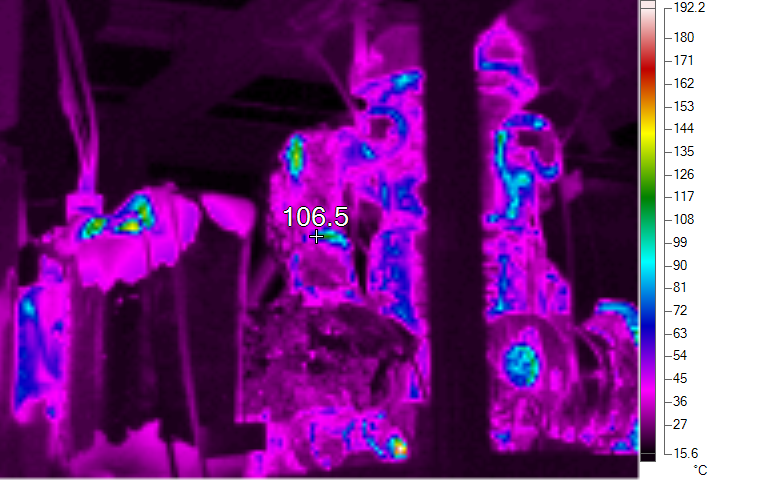

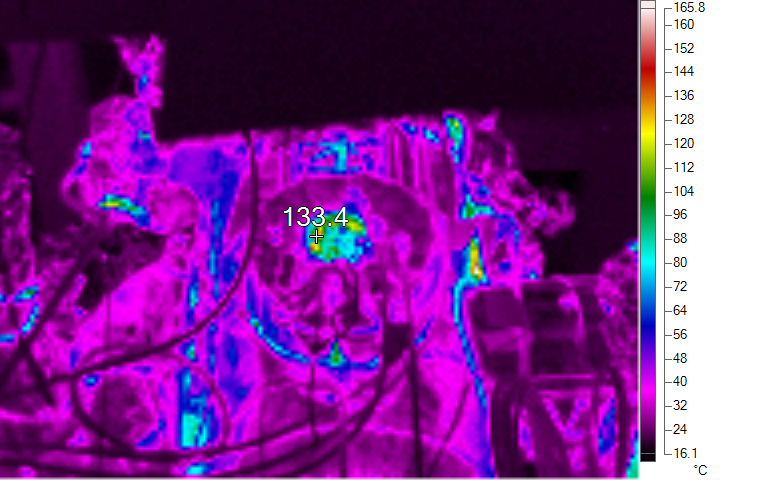

CB RSS | Thermocamera images |

Used thermocamera provided by GSI beam diagnostic division to take some pictures of YR09. See attached.

Due to aluminium outer wrapping some reflections are inevitable, but tried to only take pictures of heat spots that did not disapper from different angles.

Temperature calibration may be not perfectly reliable as well.

1. Gap close to CARME outside motors

2. CARME top valve

3. CARME top valve

4. CARME turbo

5. Interaction chamber looking downstream from outside of ring. Note flexible hose pumping Be window.

6. As 5, from inside the ring.

7. Interaction chamber detail (see top left in picture above)

8. IE514 sensor on interaction chamber bottom

9. YR09 from inside the ring. Note electron target

10. As above, looking further upstream

11. YR09 from inside the ring, looking downstream towards CARME

12. Electron target from inside the ring

13. Electron target from outside the ring. Biggest flange.

14. Interaction chamber from inside the ring |

| Attachment 1: IR000087.png

|

|

| Attachment 2: IR000088.png

|

|

| Attachment 3: IR000089.png

|

|

| Attachment 4: IR000090.png

|

|

| Attachment 5: IR000091.png

|

|

| Attachment 6: IR000092.png

|

|

| Attachment 7: IR000093.png

|

|

| Attachment 8: IR000094.png

|

|

| Attachment 9: IR000096.png

|

|

| Attachment 10: IR000098.png

|

|

| Attachment 11: IR000099.png

|

|

| Attachment 12: IR000101.png

|

|

| Attachment 13: IR000102.png

|

|

| Attachment 14: IR000103.png

|

|

|

|

457

|

Thu Jan 4 13:15:10 2024 |

CB, JM | Tent removed - bias test |

Removed tent, octagon, Neg cables.

Disconnected and removed Baking Pi, TC08, thermocouples.

Tested new rails, plates, fees - it fits. Need to check on the flange next.

Will soon turn off CARME IE514 gauge to bias test the DSSDs.

All four detectors were bias tested using the new flexi-rigid adaptor cards. Note the LK-1 jumper was removed from the adaptor cards so that 'open line' was observed between the bias lemo and the ground. Attachment 1 shows VI curves for all detectors. The maximum leakage current for all detectors appears lower than previous bias tests eg elog 400 -> temperature was ~17C today compared to ~20C for elog 400. We also performed a bias test using the old adaptor cards to see if there was any difference between the old and new cards. No significant difference was observed. For the top left detector we initally observed a significantly large leakage current (4.2 uA at 20V, 8.7 uA at 30V) which had ~1 uA fluctuations. We left for 5 minutes to see if it stabilised and the leakage current suddenly dropped to what is shown in the plot. This leakage current then appeared stable for the rest of the test. Perhaps this effect was observed by Tom but for the top right detector in elog 421?

We plan to connect the bias as we did in the 14N+d measurement so that we can monitor and plot the leakage current over the weekend. |

| Attachment 1: Bias.png

|

|

|

|

87

|

Mon Sep 27 11:09:48 2021 |

CB (remotely) | Temperature vs Pressure plot |

Attached. |

| Attachment 1: Temps.pdf

|

|

|

|

318

|

Mon Feb 28 01:16:02 2022 |

JM, OF | Temperature decrease 115K to 110K |

02:15

Density remains stable at 155 K

Temperature setpoint decreased by 1K. Aim to get to 110 K to see if higher stable density can be achieved.

Spike in YR pressures observed as temperature was decreased, still look OK. Will leave to settle for a while. T = 114K.

Rates remain stable at ~ 10^2 peak height level.

02:33

Pressures stabilised

Setpoint to 113 K.

02:40

No pressure spike observed after decrease

Setpoint to 112 K

02:46

No pressure spike observed after decrease

Setpoint to 111 K

Pressure spike observed in YR pressures (smaller than last) - give time to recover.

03:00

Setpoint to 110 K

No pressure spike observed.

Rutherford rate peak height remains stable at ~ 10^2 . Perhaps peak height minimum is consistently higher than before, difficult to say.

Attachment 1 - 115 K

Attachment 2 - spike 1

Attachment 3 - spike 2

All pressure stable now |

| Attachment 1: 20220228_021455.jpg

|

|

| Attachment 2: 20220228_023832.jpg

|

|

| Attachment 3: 20220228_025416.jpg

|

|

|

|

322

|

Mon Feb 28 05:04:47 2022 |

JM, OF | Temperature cycle to 125K |

06:01

Rutherford rate was decreased compared to previous values. Max rate ~ 50 counts for the peak, average ~20 counts.

Temperature increased to 125 K

No large increase in chamber pressure observed.

06:25

Temperature setpoint back to 110 K.

Rutherford rate has increased, however is quite variable. Peak height 3*10^1 to 10^2 range.

06:54

Setpoint = 110 K

Ruthrford rate has stabilised around 7*10^1 to 10^2 peak height.

Merger OK

Data rate ~ 1300 kb/sec

Leakage current ~ 3.22 uA

Temperatures OK

System checks OK |

| Attachment 1: 2022-02-28_06-30-39-Exrate.png

|

|

|

|

331

|

Mon Feb 28 13:56:02 2022 |

JG, CB | Temperature cycle to 125K |

14:45

Rutherford rate was decreased significantly for longer period.

Temperature increased to 125 K

No large increase in chamber pressure observed.

14:55

Temperature setpoint back to 110 K.

Rutherford rate has increased. Peak height 3*10^1. |

|

|

340

|

Tue Mar 1 04:07:31 2022 |

JM, EM | Temperature cycle |

Have been unable to achieve decent target density with temperature cycling so far. Will attempt to go up to 300 k and back down to around 115 k which proved successful in previous shifts. |

|

|

338

|

Tue Mar 1 03:19:50 2022 |

JM, EM | Temperature Cycle |

04:20

Did another temperature cycle (118 K -> 125 K -> 95 K -> 116 K) trying to improve the pressures at the target and the detector count rate.

Rates are still mostly below 100 counts (Ex rate) and the pressures are still fluctuating by about an order of magnitude (E4: between 1e-9 and 1e-8 mbar). |

|

|

361

|

Wed Mar 2 03:40:40 2022 |

David, George | Temperature Cycle |

04:40

Target density is hovering between 2.0e-8 and 2.3e-8, sometimes dipping below 2.0e-8

We will conduct a temperature walkthrough while there is no beam,

04:40: setpoint 125K

04:46 setpoint 95K

04:56 setpoint 108K

04:59 setpoint 110K

05:00 setpoint 112K (here improved from 110K)

05:03 setpoint 114K

05:08 setpoint 113K

05:11

113K seems good, fluctuating between 2.3e-8 and 3.1e-8

will leave temperature here |

|

|

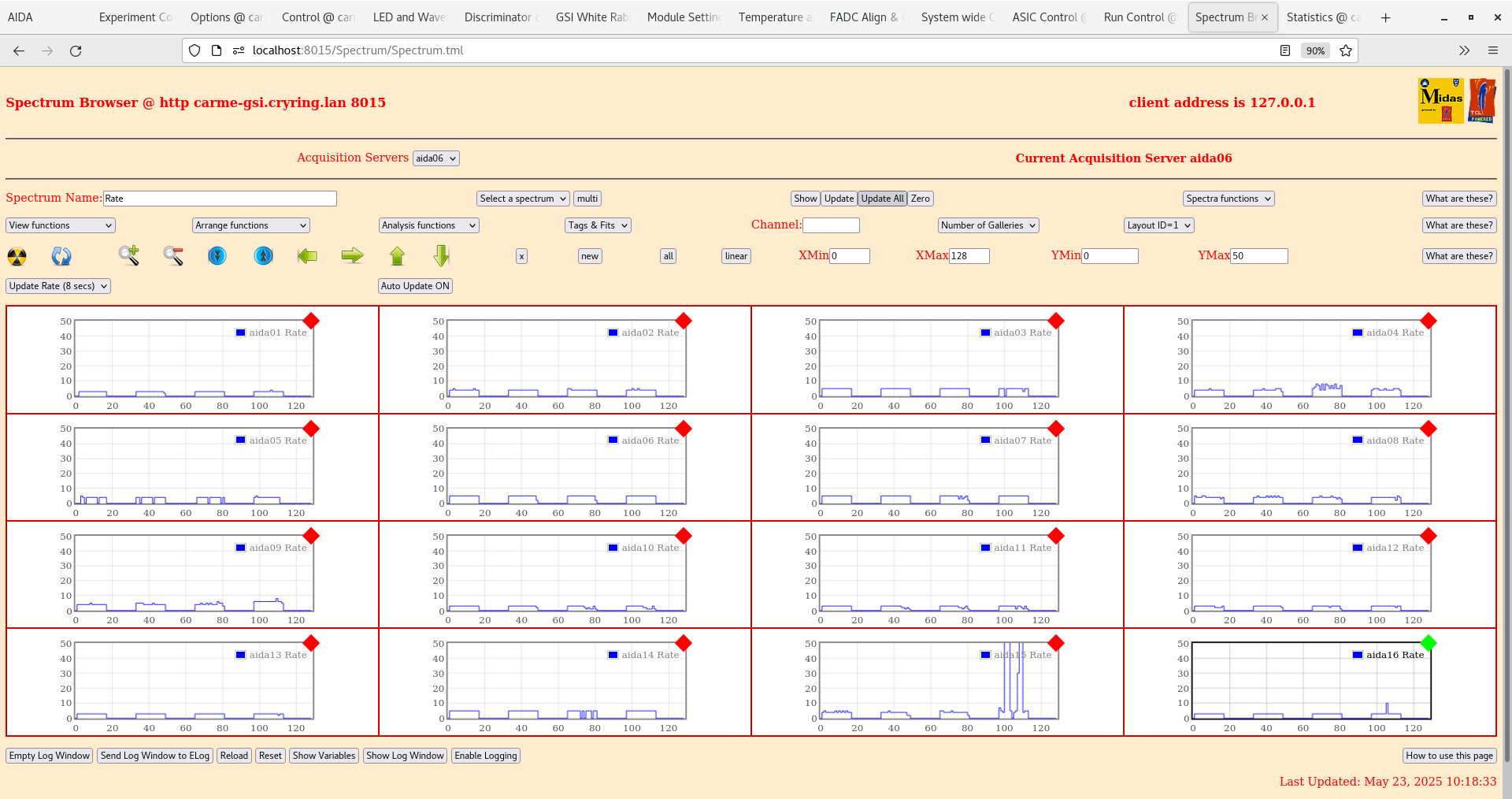

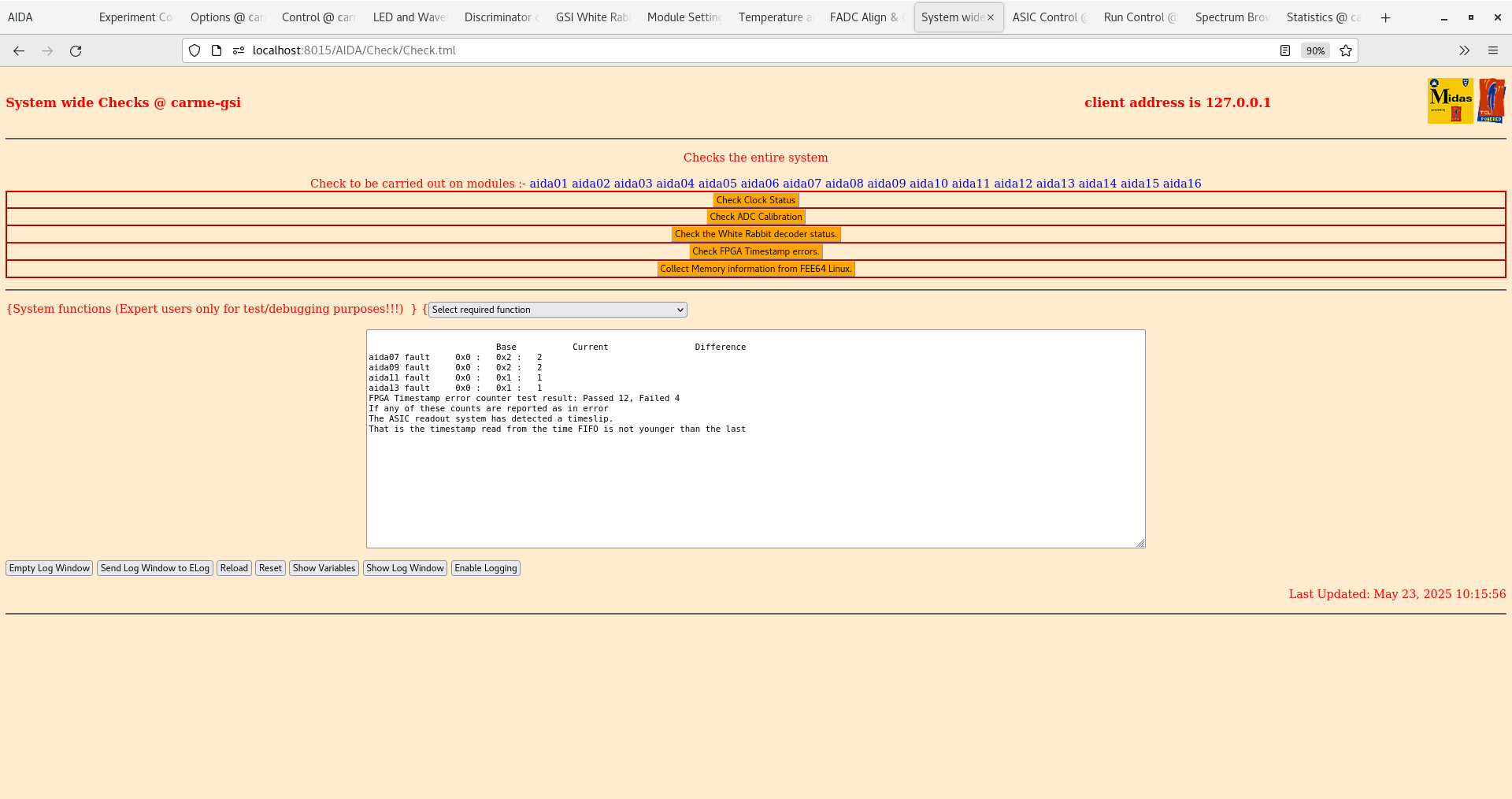

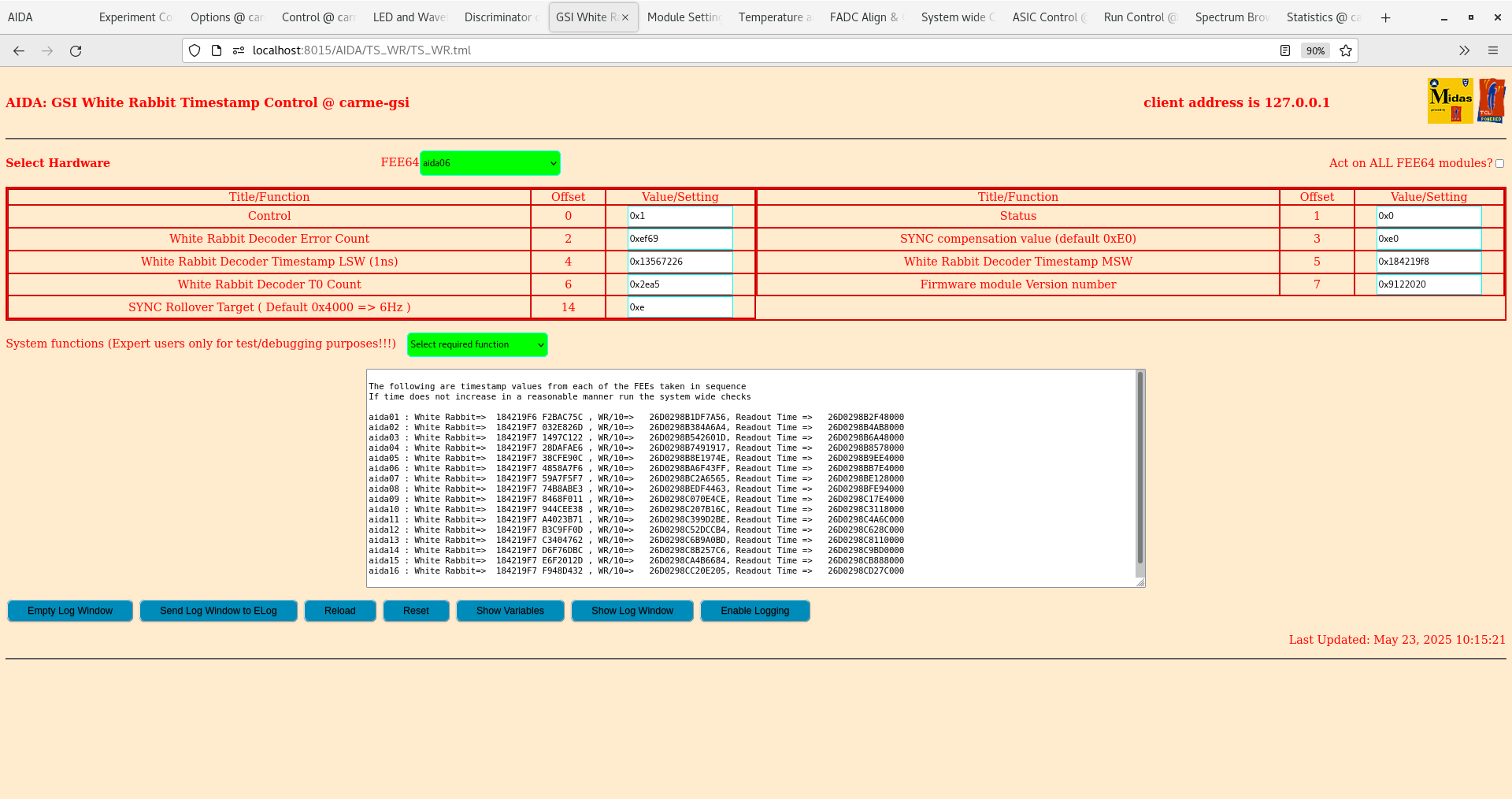

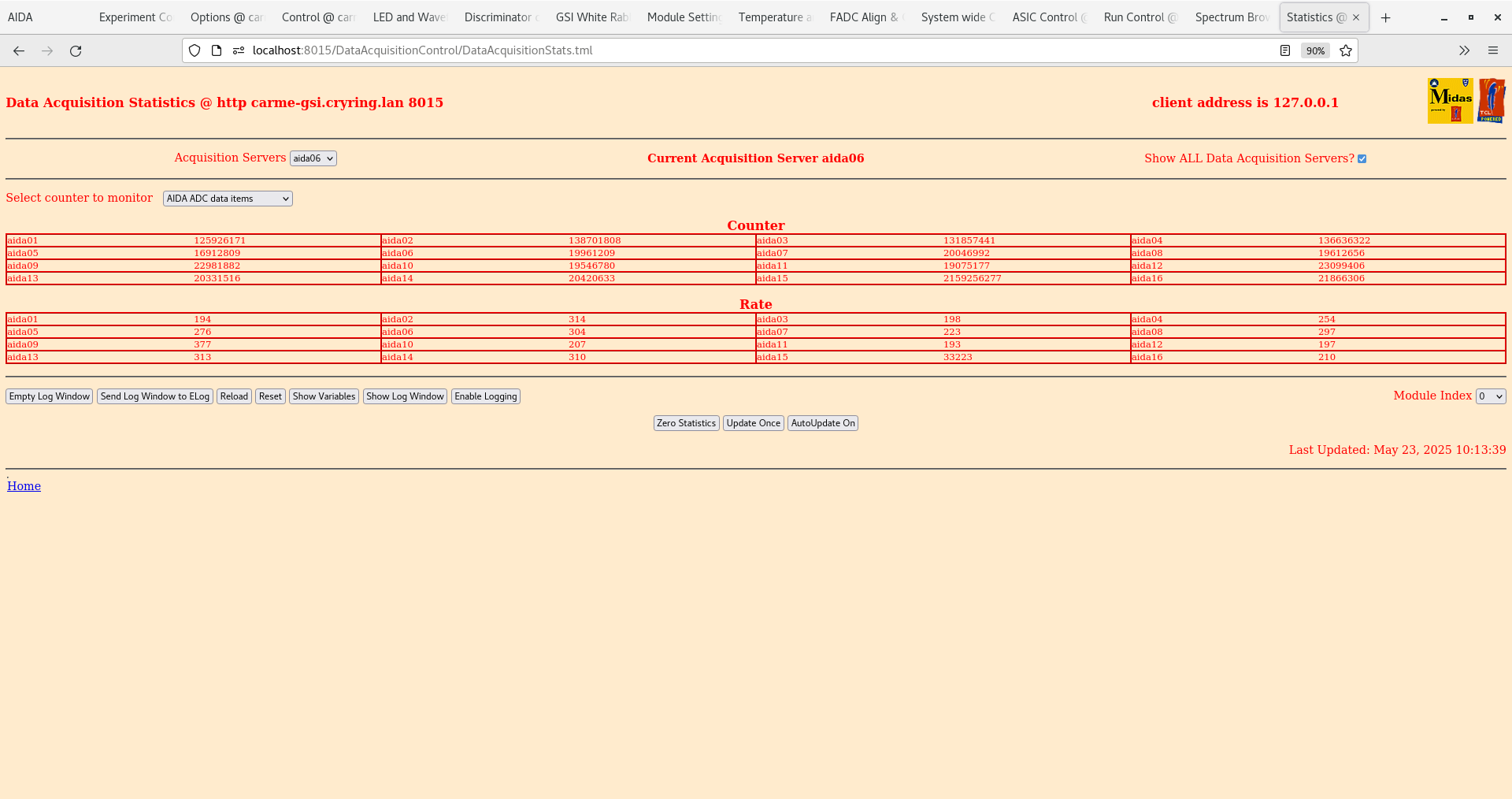

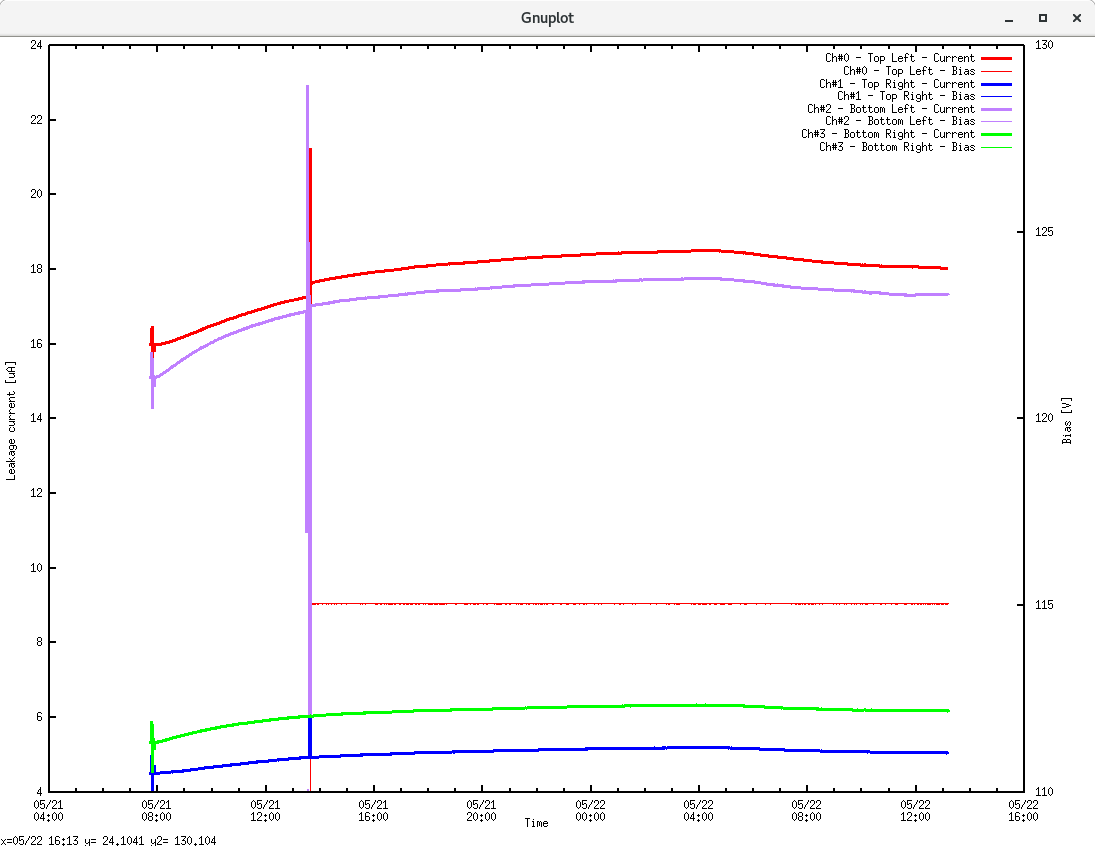

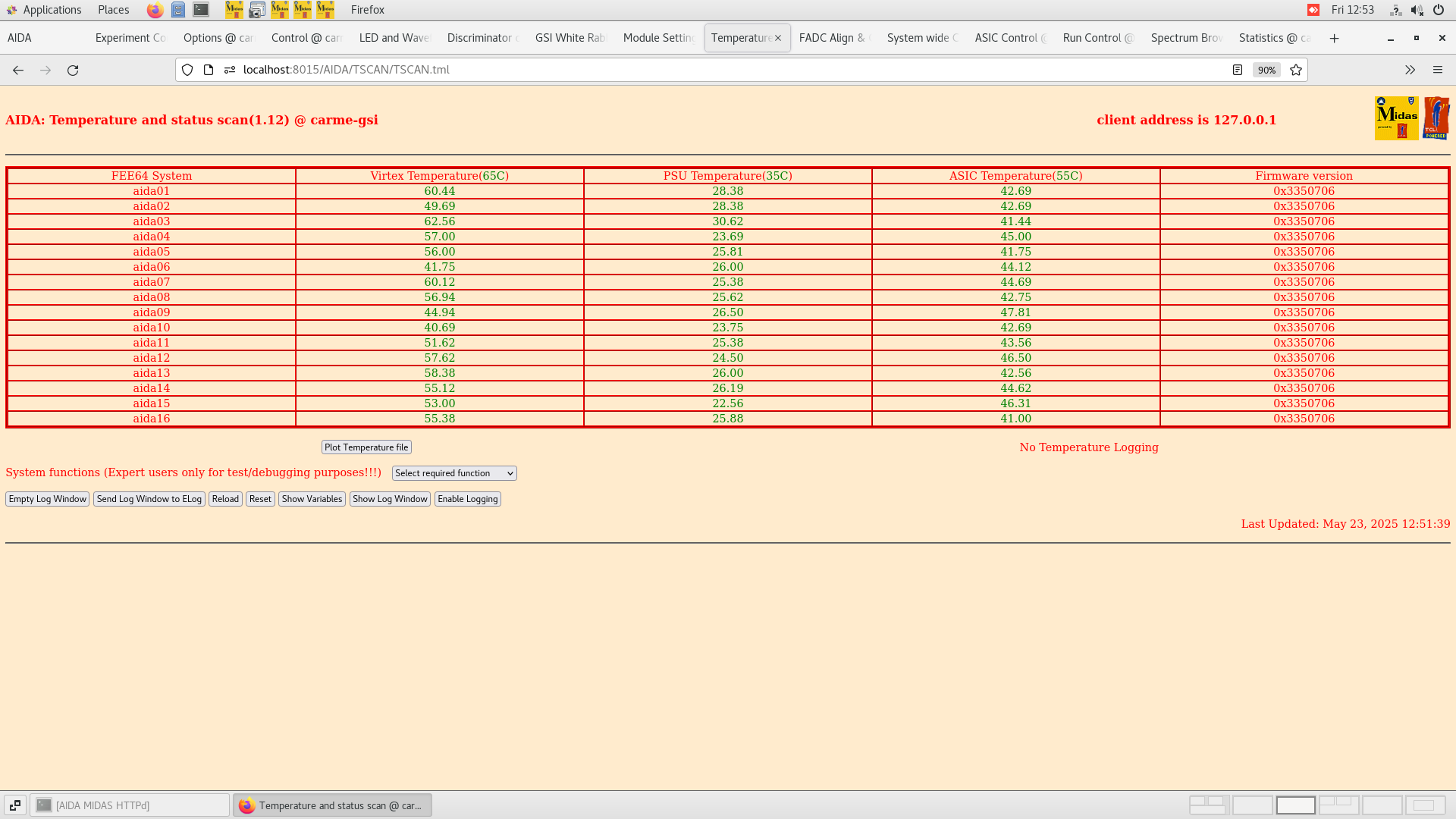

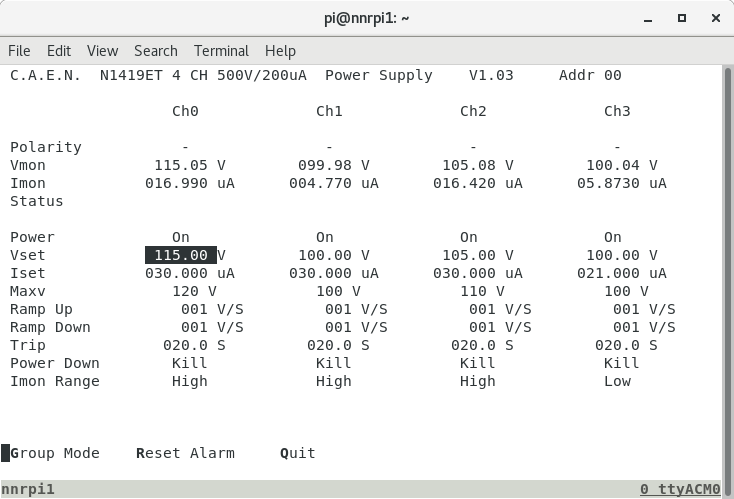

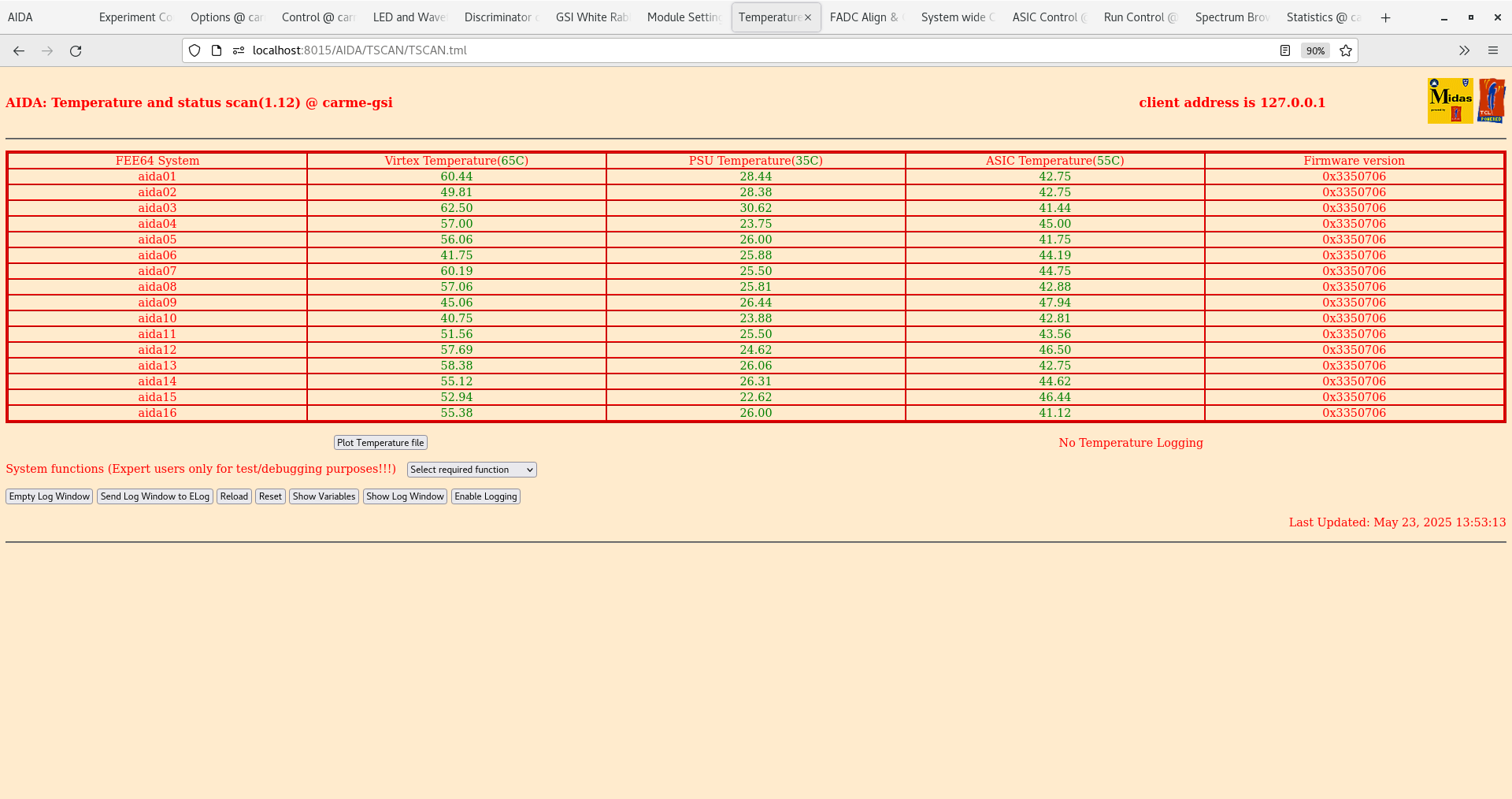

688

|

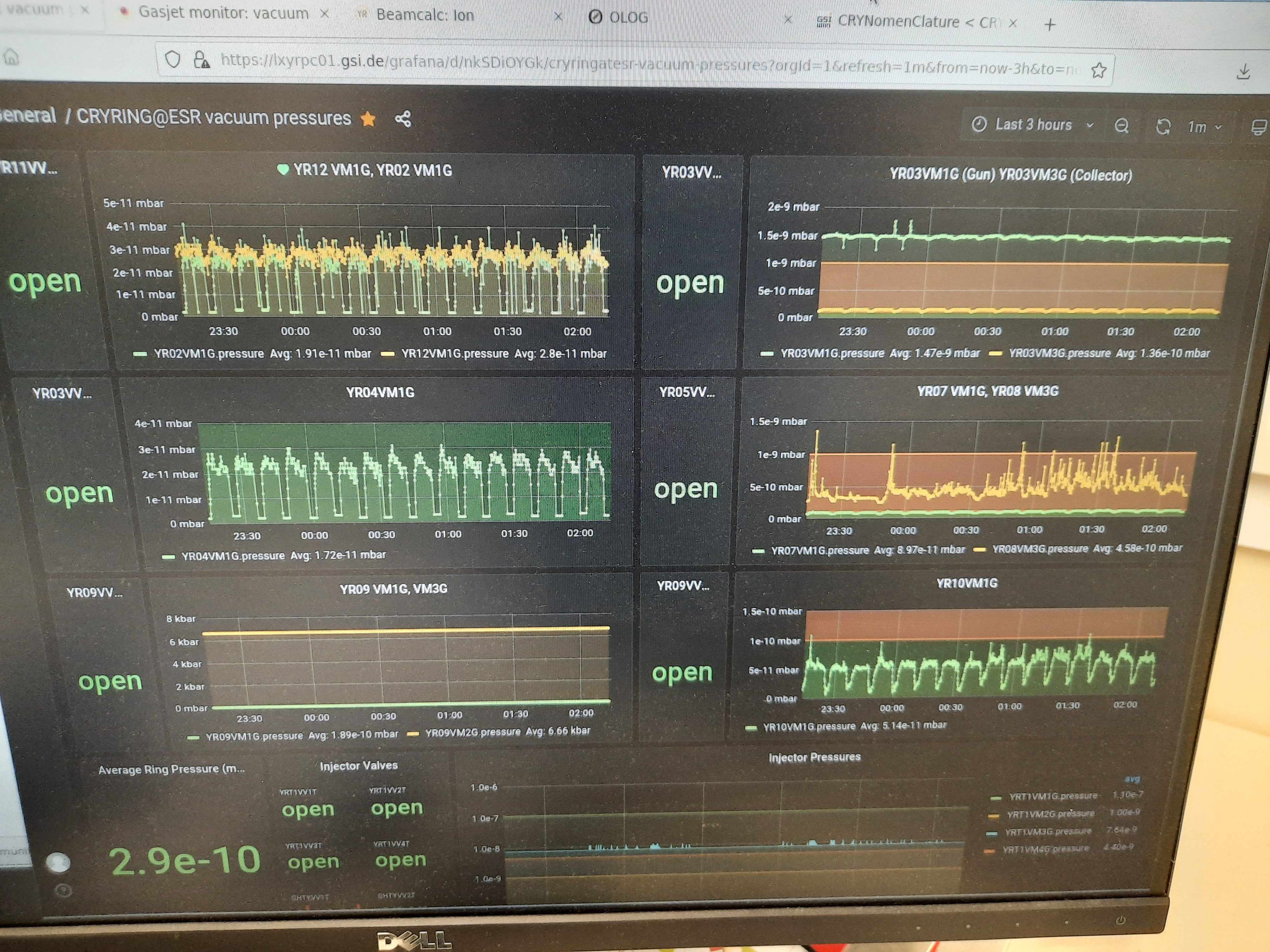

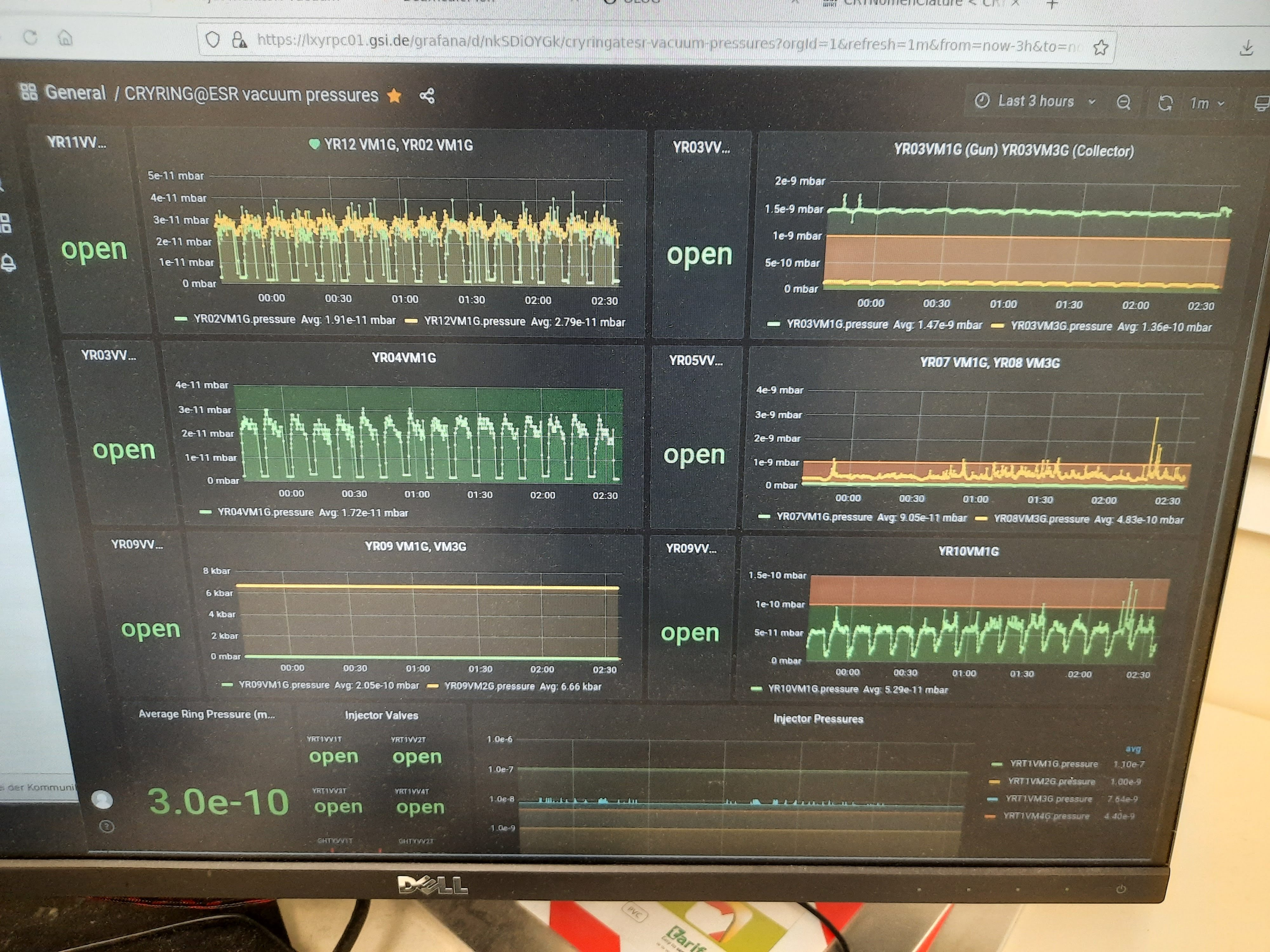

Fri May 23 09:19:40 2025 |

SN, TD | Target wait, switch lithium oven |

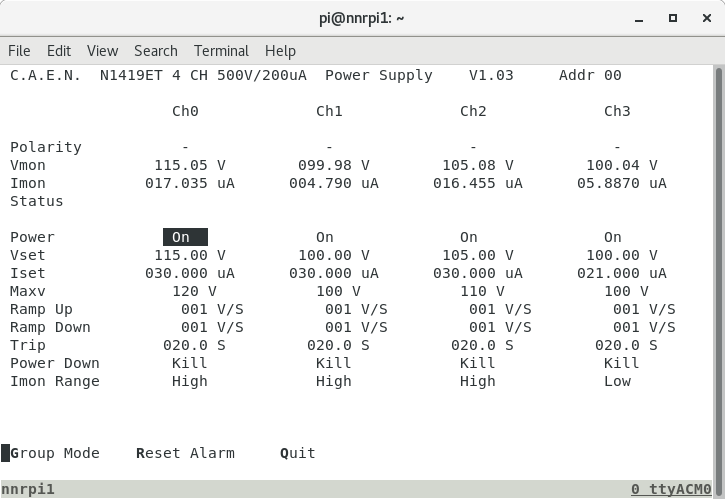

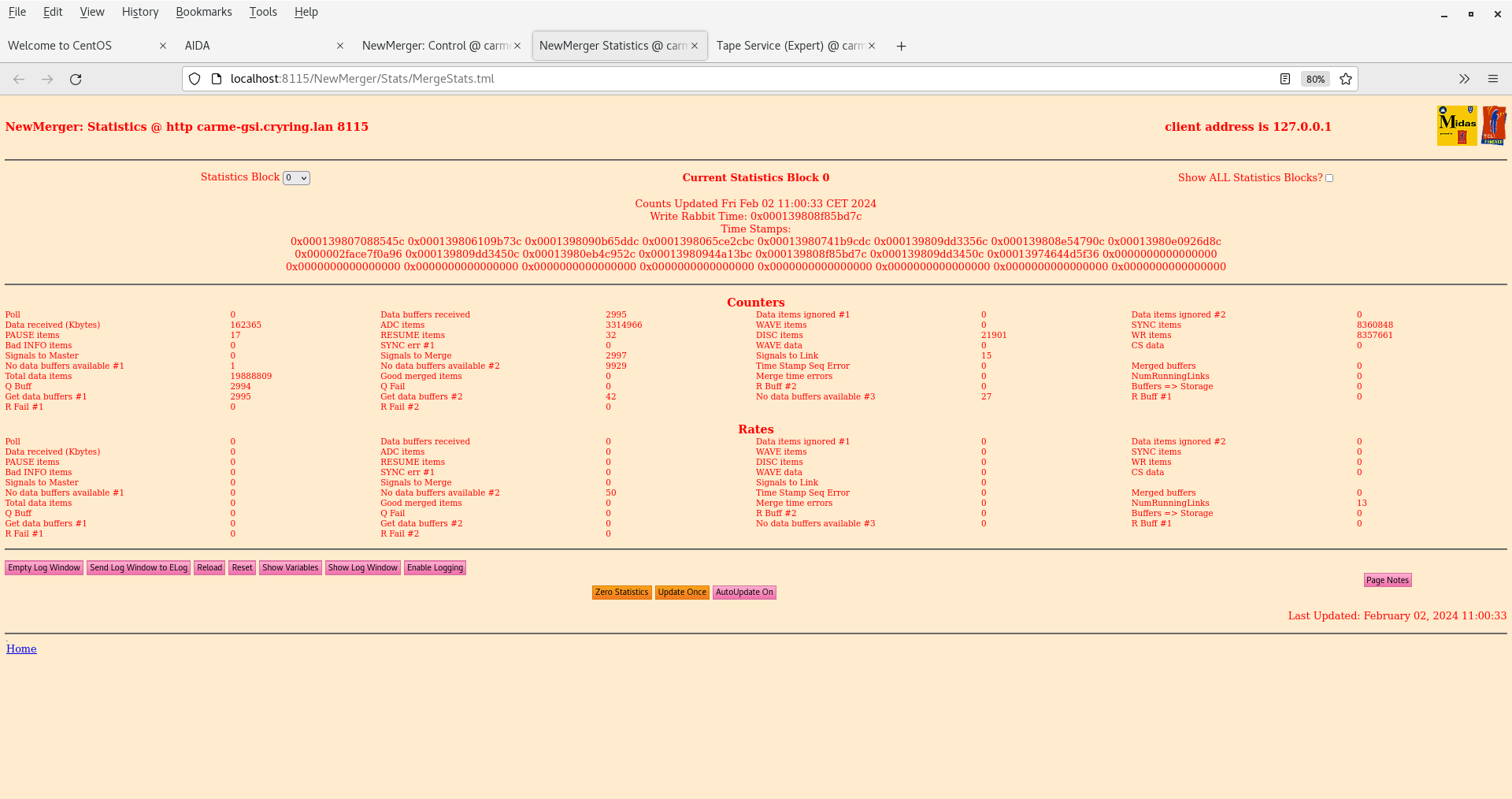

10.12 DAQ, Merger & Tape Server running OK - no storage mode

DSSSD bias leakage current OK - attachments 9-10

CRYRING vacuum & temperature - attachments 11-12

FEE64 temps OK - attachment 8

ADC & DISC data item stats OK - attachments 6-7

per FEE64 Rate spectra - attachments 1 & 5

before and after check ASIC load

WR timestamps OK - attachment 4

System wide checks OK *except* FPGA & WR status - attachments 2-3

10.33 All histograms & stats zero'd

Online analysis restarted

13:56 Checks on temperature status, statistics status and power supply : OK

|

| Attachment 1: Screenshot_from_2025-05-23_10-18-44.png

|

|

| Attachment 2: Screenshot_from_2025-05-23_10-15-58.png

|

|

| Attachment 3: Screenshot_from_2025-05-23_10-15-54.png

|

|

| Attachment 4: Screenshot_from_2025-05-23_10-15-36.png

|

|

| Attachment 5: Screenshot_from_2025-05-23_10-14-27.png

|

|

| Attachment 6: Screenshot_from_2025-05-23_10-13-43.png

|

|

| Attachment 7: Screenshot_from_2025-05-23_10-13-32.png

|

|

| Attachment 8: Screenshot_from_2025-05-23_10-13-21.png

|

|

| Attachment 9: Screenshot_from_2025-05-23_10-12-52.png

|

|

| Attachment 10: Screenshot_from_2025-05-23_10-12-40.png

|

|

| Attachment 11: 1.png

|

|

| Attachment 12: 2.png

|

|

| Attachment 13: Screenshot_from_2025-05-23_12-53-29.png

|

|

| Attachment 14: Screenshot_from_2025-05-23_12-53-24.png

|

|

| Attachment 15: Screenshot_from_2025-05-23_12-50-59.png

|

|

| Attachment 16: Screenshot_from_2025-05-23_13-53-32.png

|

|

| Attachment 17: Screenshot_from_2025-05-23_13-53-16.png

|

|

| Attachment 18: Screenshot_from_2025-05-23_13-52-59.png

|

|

|

|

643

|

Sun Jun 16 22:40:11 2024 |

JM | Target overlap test - R81 |

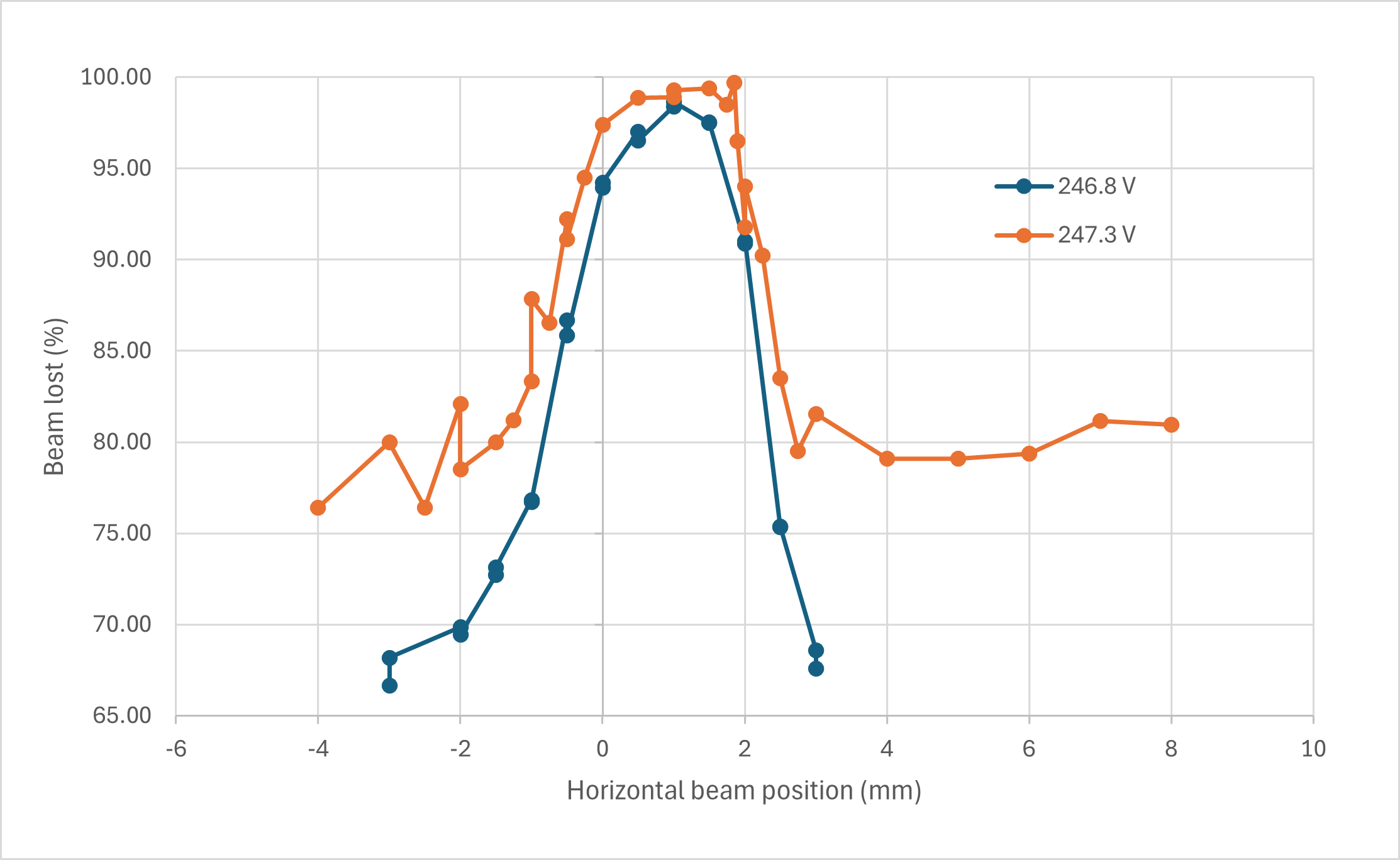

23:10

Beam set to bunched mode to observe beam lifetime.

Electron cooler voltage setpoint kept at 246.8 V. Note this is 0.5 V lower than the previous test where the setpoint was 247.3 V

This corresponds to ~13.5 keV in the beam energy.

Attachment 1 shows target scan. Maximum still observed at a horizontal beam position of 1.0 mm.

Moving 0.5 V up or down does not impact the orbit enough to shift the beam position off the target.

Beam lifetime off target seems larger than previous, perhaps better vacuum conditions?

Back to coasting beam |

| Attachment 1: Beam-overlap-updated2.png

|

|

|

|

618

|

Tue Jun 11 19:44:48 2024 |

OF, SS | Target out and at He |

Target has been moved out and H2 switched off. Changed to He.

Nikos will repair nozzle tomorrow morning. Remote checks until then. |

|

|

590

|

Wed Jun 5 08:34:04 2024 |

JM. DB, PC | Target nozzle change |

09:30

Target density has not improved despite efforts last night. Mid 10 - low 11 density range. We will try to change the nozzle.

Target nozzle moved to the out position.

HKR allowed access to the cave to turn the compressor off. Target nozzle now warming up.

Internal cave work on changing nozzle expected to start at ~11. In the meantime we will let Wolfgang experiment with the beam settings to try to improve injection intensity.

Detectors have been moved out to fully out position

Run 35 started. |

|

|

487

|

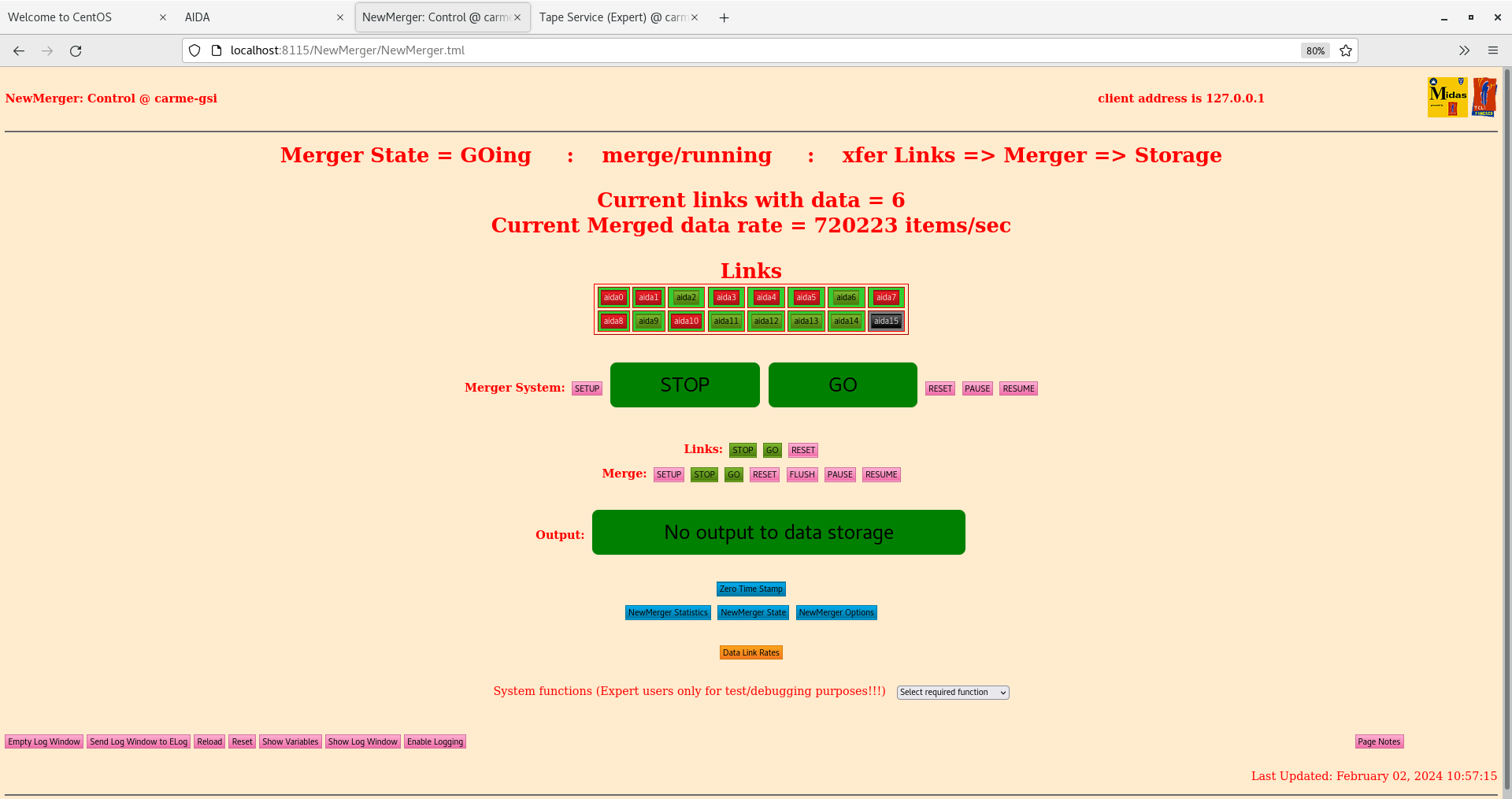

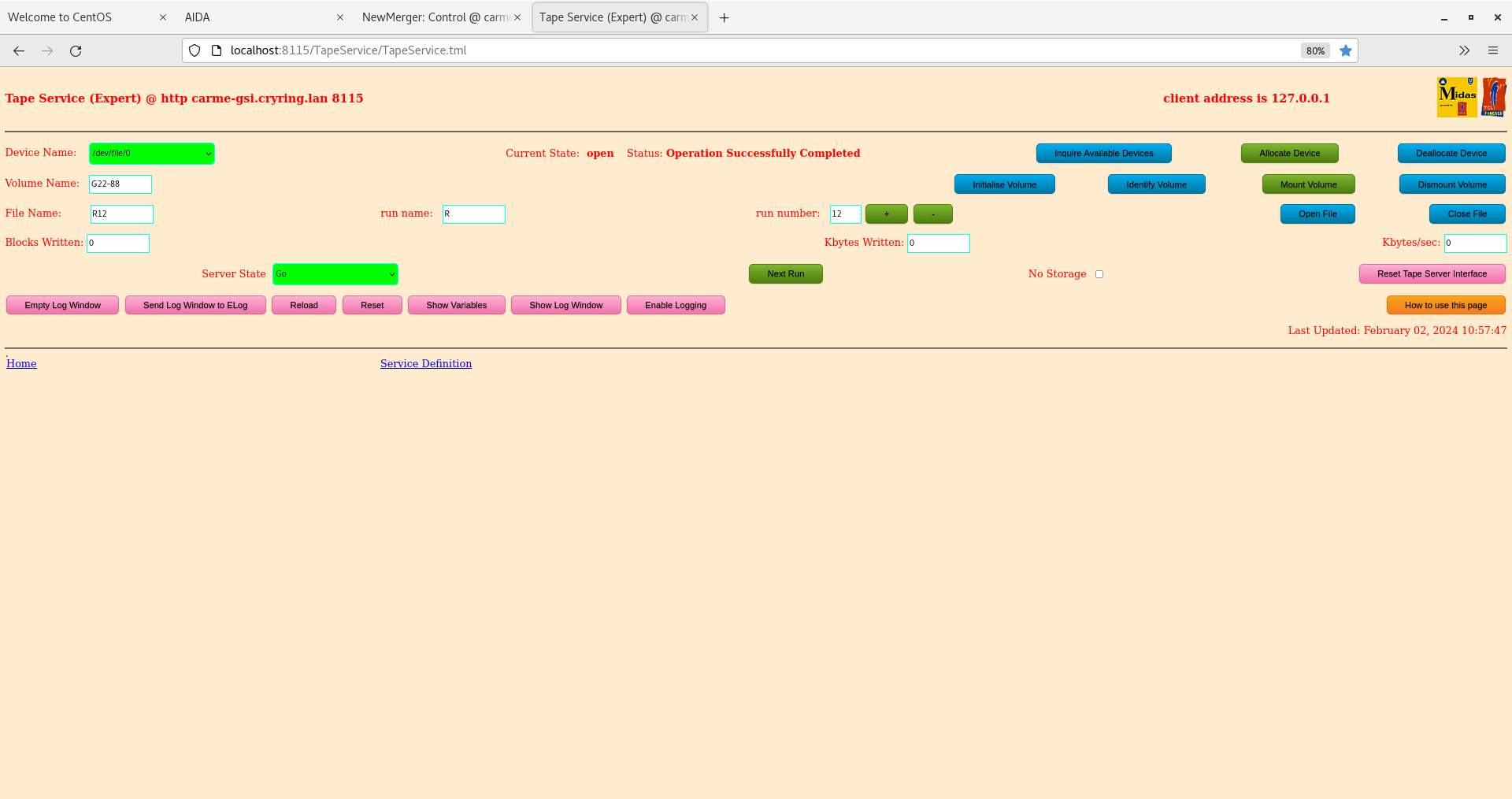

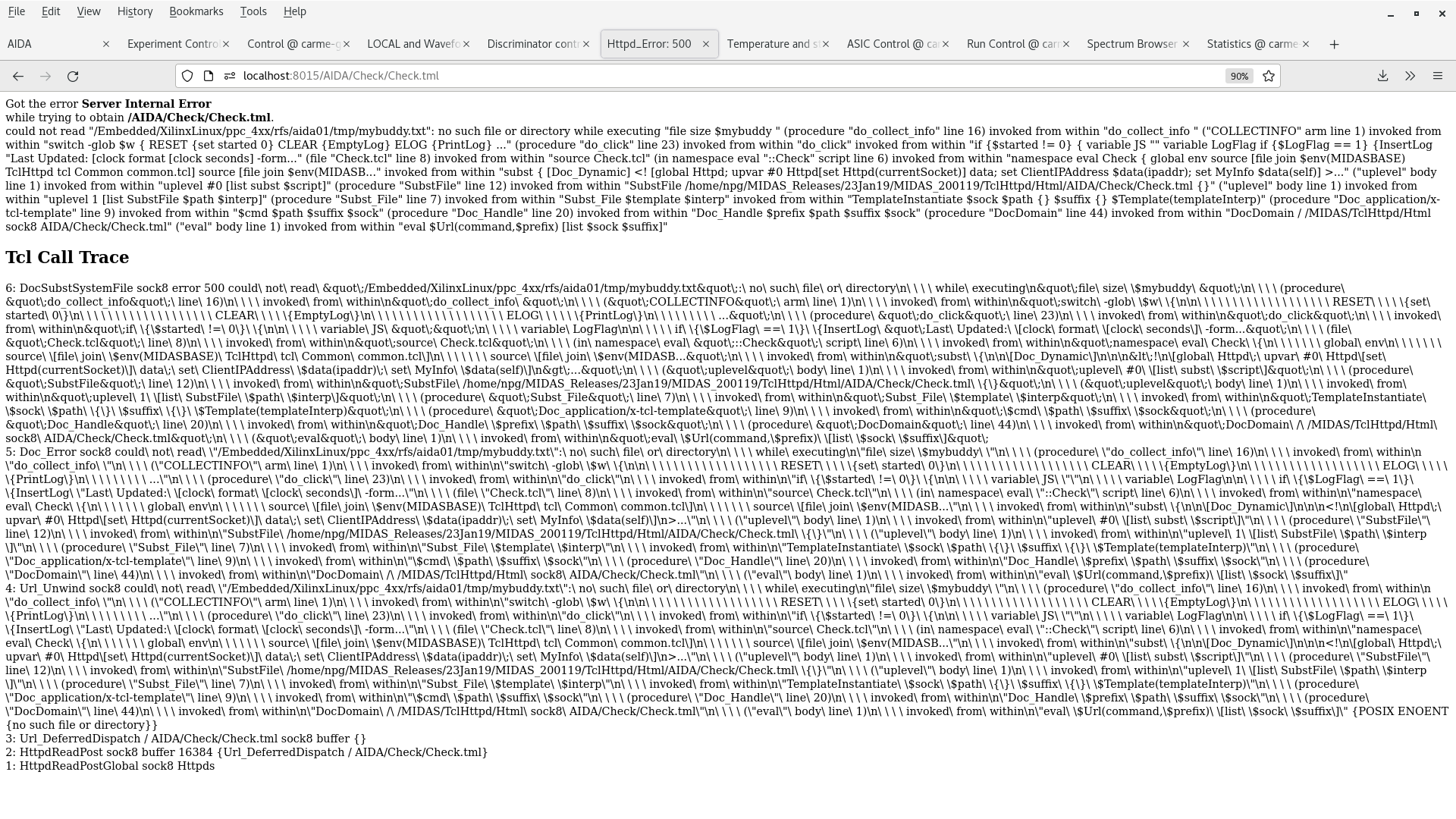

Fri Feb 2 09:58:58 2024 |

TD | TapeServer not writng data to disk - plus fix |

DAQ and NewMerger appear to be cofigured correctly.

Can allocate device, create volume and open file with TapeServer but cannot write data.

See attachmnents 1-3

Noted aida09 WR timestamp issue in attachment 3 - FEE64 Reboot fixed aida09 WR timestamp issue

Restarted DAQ/Merger/TapeServer - still cannot write to disk

14.30 CU provides the following list of NetVar variables used by the Merger

"MERGE_PID"

"MERGE_ID"

"MERGE_Action"

"MERGE_Signal"

"MERGE_Parameter"

"MERGE_Response"

"MERGE_State"

"MERGE_Trace"

"MERGE_Paused"

"MERGE_RunOptions"

"MERGE_HardwareVersion"

"MERGE_LinksAvailable"

"MERGE_TestMode"

"MERGE_PollTicks"

"MERGE_LinksInUse"

"MERGE_LinksAlive"

"MERGE_StatsTime"

"MERGE_Command"

"MERGE_ZeroStats"

"MERGE_SyncStep"

"MERGE_InitialTimeStamp"

"MERGE_LinkState"

"MERGE_LinkStatus"

"MERGE_LinkAlive"

"MERGE_LinkInUse"

15.30 Changed Merger startup and NetVars files ( attachments 6 & 7 )

Change server command line from

./master64 -i 16 -l 16 -p 11001 &

to

./master64 -i 15 -l 15 -p 11001 &

i.e. *exactly* matches number of FEE64s currently in use ( 15x FEE64s, aida01-aida15 )

Change NetVars from

MERGE.LinksInUse string 1%1%1%1%1%1%1%1%1%1%1%1%1%1%1%0%

to

MERGE.LinksInUse string 1%1%1%1%1%1%1%1%1%1%1%1%1%1%1%

i.e. string has 15x 1% strings *not* 15x 1% *plus 1x 0% string

With *both* changes we are now able to write to disk.

N.B. We did not test the above changes individually - it is possible/probable that just one of the changes above fixes the problem. |

| Attachment 1: Screenshot_from_2024-02-02_10-57-18.png

|

|

| Attachment 2: Screenshot_from_2024-02-02_10-57-51.png

|

|

| Attachment 3: Screenshot_from_2024-02-02_10-58-23.png

|

|

| Attachment 4: Screenshot_from_2024-02-02_11-01-22.png

|

|

| Attachment 5: Screenshot_from_2024-02-02_11-18-45.png

|

|

| Attachment 6: NewMerger

|

#!/bin/csh -f

echo "Tidy up"

killall -s9 MERGE

killall -s9 merge64.AD

killall -s9 master64

killall -s9 link64

killall -s9 merge64

killall -s9 statrate64

echo "Starting New Merger"

/bin/echo -e "\033];New Merger\007"

if (! $?MIDASBASE) setenv MIDASBASE /MIDAS

#

#

setenv PATH ${MIDASBASE}/Linux/bin64:${PATH}

setenv LD_LIBRARY_PATH ${MIDASBASE}/TclHttpd/Linux64:${MIDASBASE}/Linux/lib64:${MIDASBASE}/lib_Linux64

netint MERGE_SyncStep 0x0000000

cd ${MIDASBASE}/NewMerger/MergeServer/bin64

./master64 -i 15 -l 15 -p 11001 &

sleep 100000000000

#

echo startup complete

#

|

| Attachment 7: CONTENTS

|

0x0006dead string 0x0000

MERGE.LinksAvailable string 15

Index string MERGE.LinksAvailable&&0x0006dead&&MERGE.RunOptions&&MERGE.LinksInUse

Merge.LinksInUse string 1%1%1%1%1%1%1%1%1%1%1%1%1%1%1%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%

MERGE.LinksInUse string 1%1%1%1%1%1%1%1%1%1%1%1%1%1%1%

MERGE.RunOptions string 3

|

|

|

379

|

Mon Oct 3 16:03:33 2022 |

OH, CB | TTT14 Photos |

Photos of the new TTT14 DSSD delivered to GSI.

Photos of detectors are broken up by photos of SN on box

To big to put on elog. Have uploaded to /Disk/ds-sopa-group/np/GSI/CARME/TTT14_Photos.zip and will change permissions to 777 |

|

|

261

|

Wed Feb 23 20:52:56 2022 |

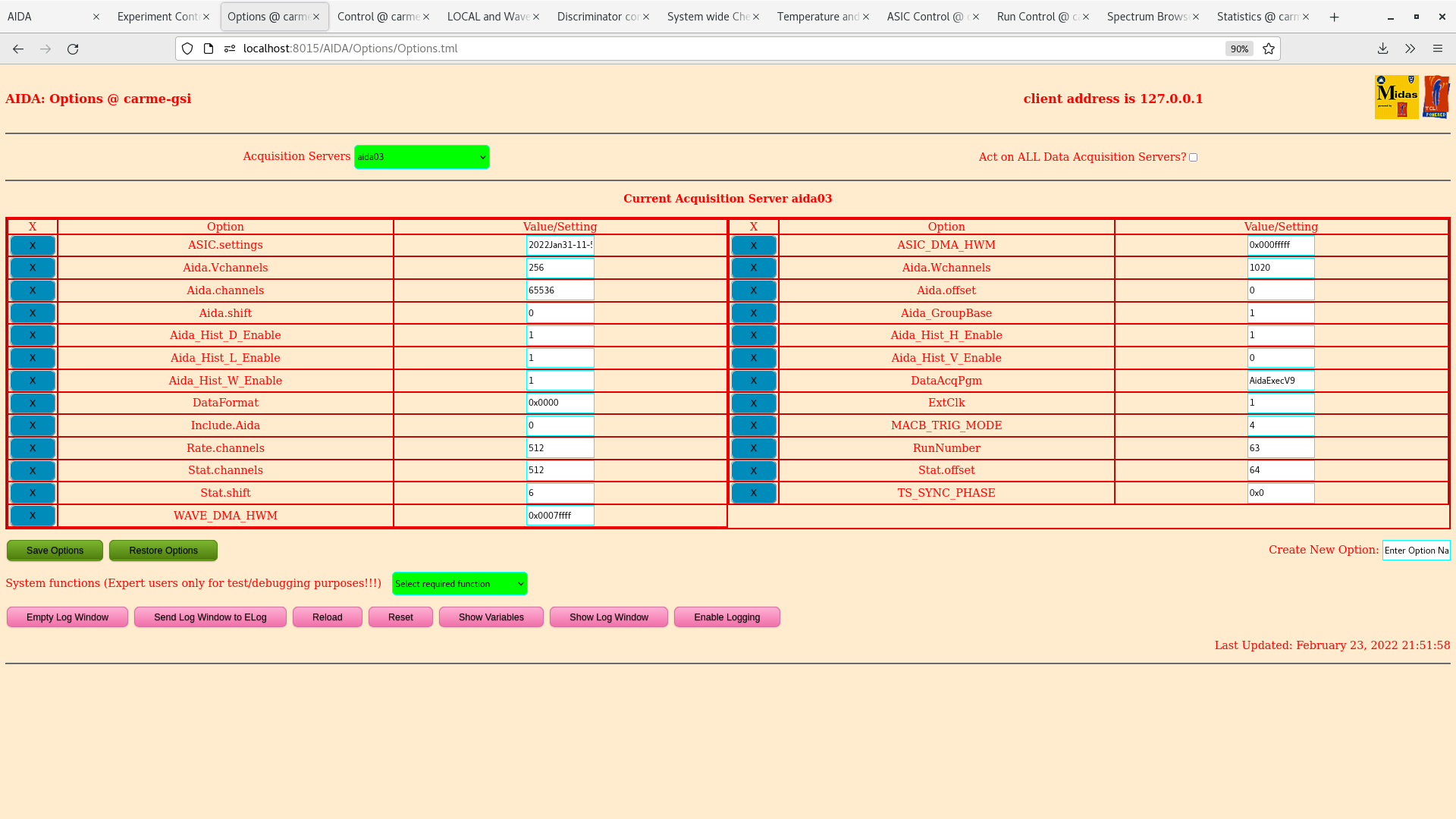

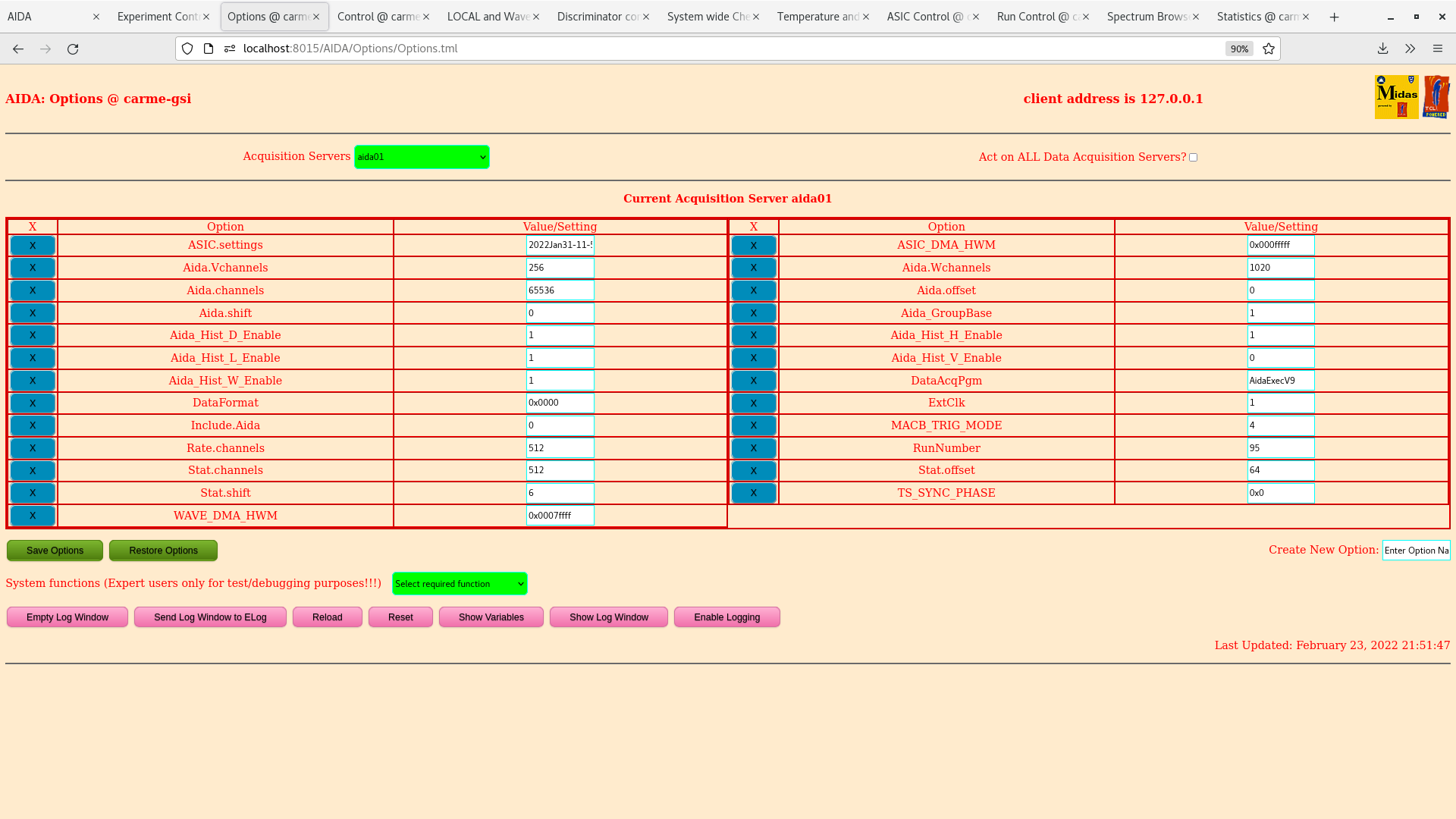

CN, TD | System wide checks |

Attachments 1-5 aida01-aida05 options

System wide checks

Attachment 6 - changes to options files - differences reported but none observed (attachments 1-5)

Attachment 7 - collect memory info from FEE64 Linux

Attachment 8 - collect FPGA timestamp errors

Attachment 9 - WR decoder status

Attachment 10 - ADC calibration

Attachment 11 - Clock status |

| Attachment 1: Screenshot_from_2022-02-23_21-52-10.png

|

|

| Attachment 2: Screenshot_from_2022-02-23_21-52-05.png

|

|

| Attachment 3: Screenshot_from_2022-02-23_21-52-00.png

|

|

| Attachment 4: Screenshot_from_2022-02-23_21-51-55.png

|

|

| Attachment 5: Screenshot_from_2022-02-23_21-51-50.png

|

|

| Attachment 6: Screenshot_from_2022-02-23_21-51-35.png

|

|

| Attachment 7: Screenshot_from_2022-02-23_21-51-20.png

|

|

| Attachment 8: Screenshot_from_2022-02-23_21-51-08.png

|

|

| Attachment 9: Screenshot_from_2022-02-23_21-51-02.png

|

|

| Attachment 10: Screenshot_from_2022-02-23_21-50-56.png

|

|

| Attachment 11: Screenshot_from_2022-02-23_21-50-49.png

|

|