| ID |

Date |

Author |

Subject |

|

598

|

Fri Jun 7 22:33:13 2024 |

LB | Run 45 - tests on beam-target overlap |

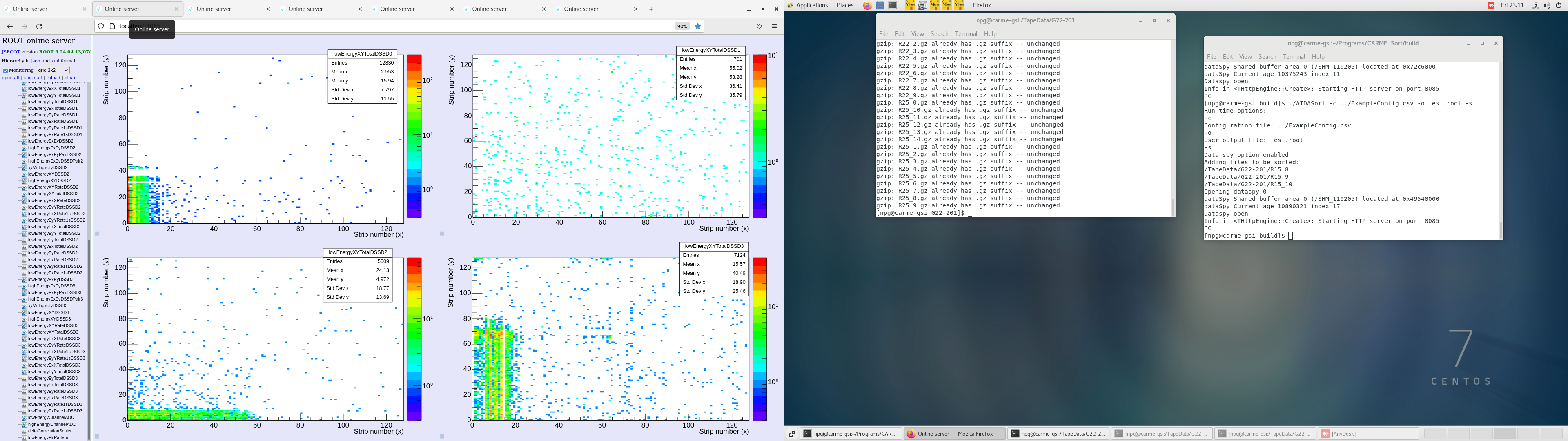

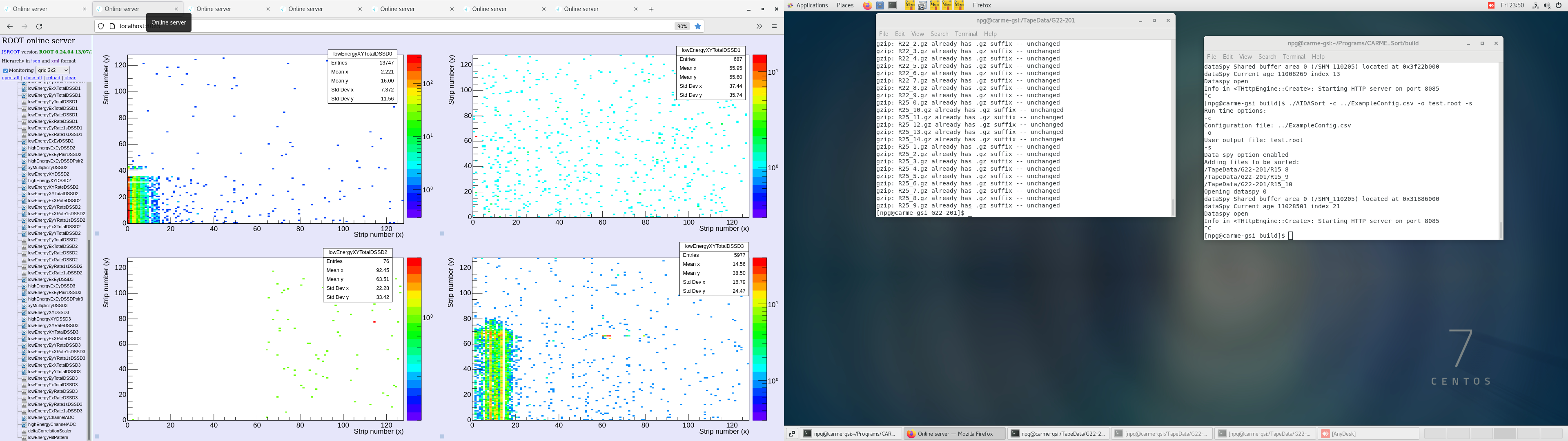

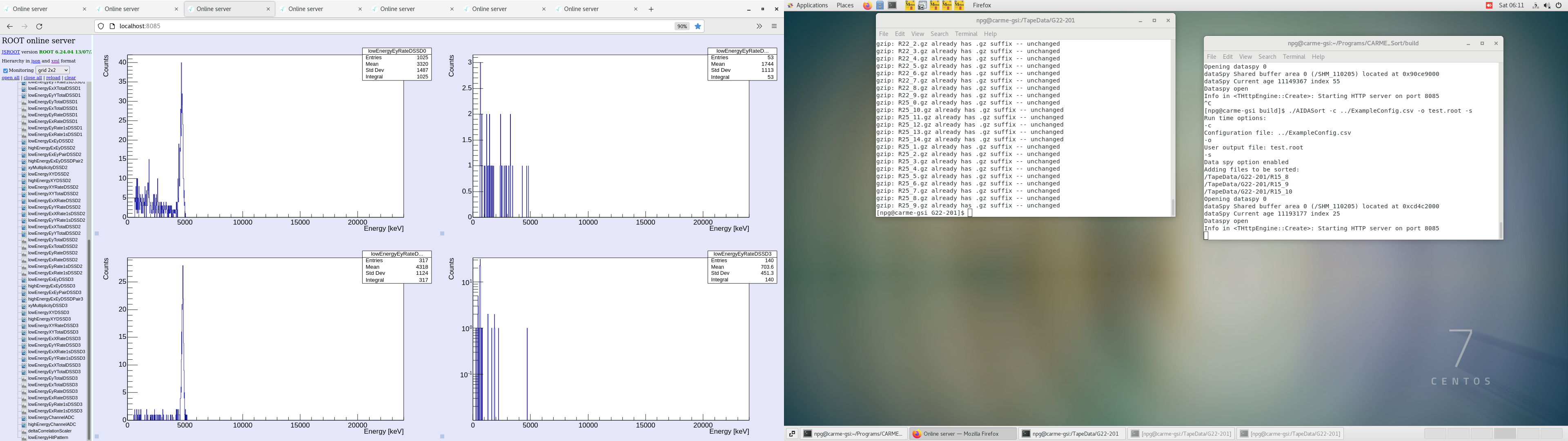

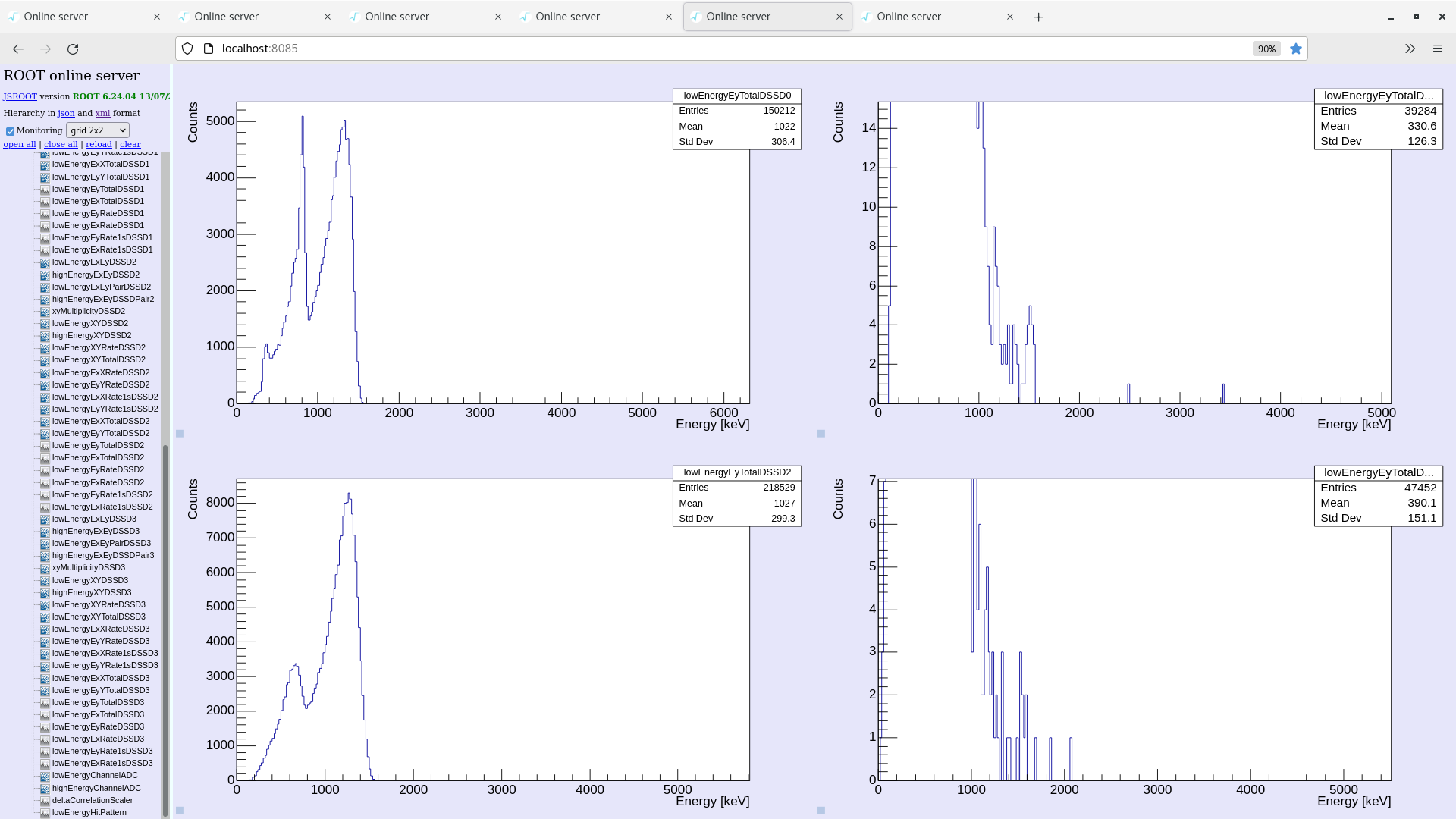

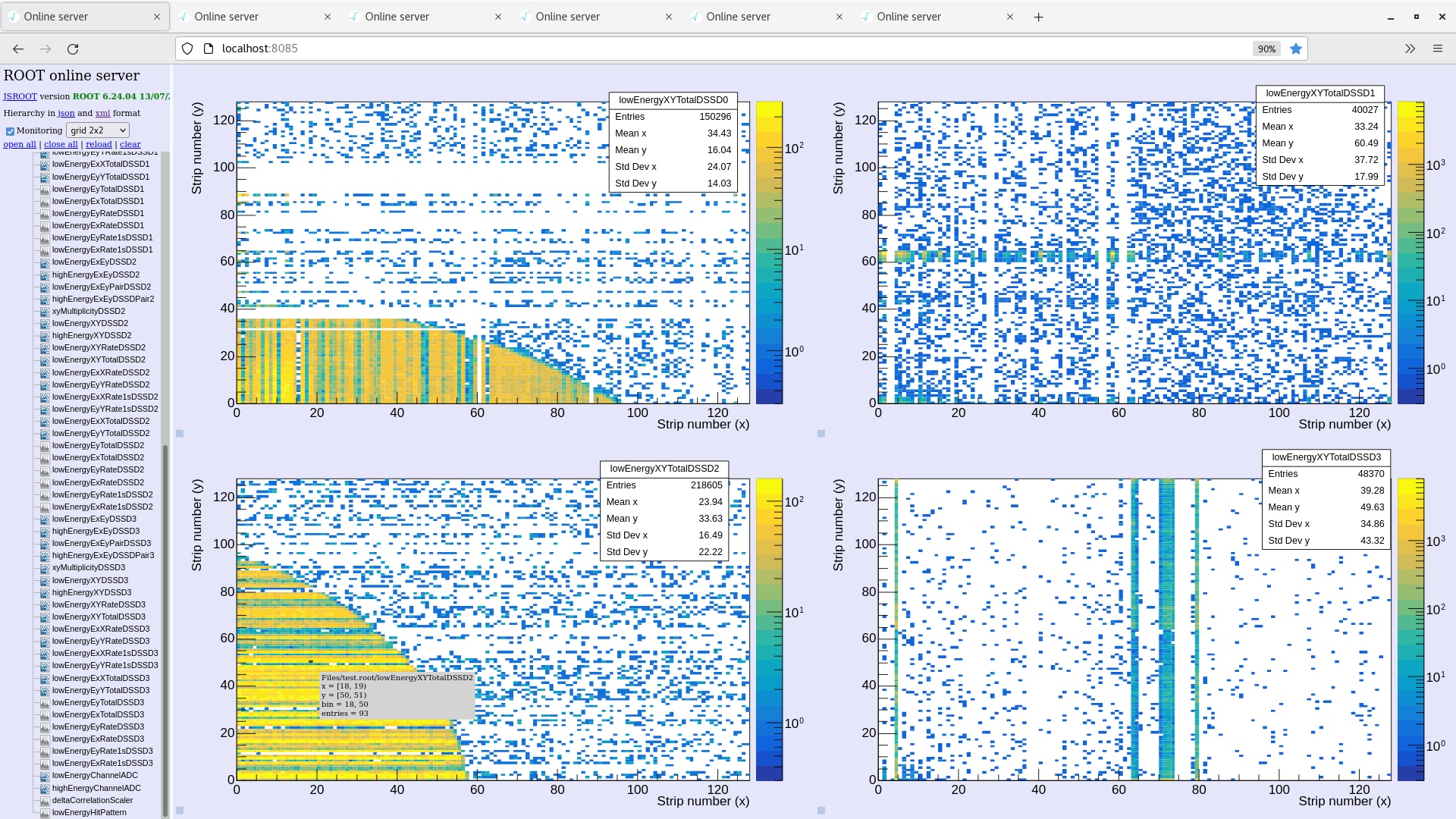

Tried to double check beam-target overlap by changing beam horizontal coordinate.

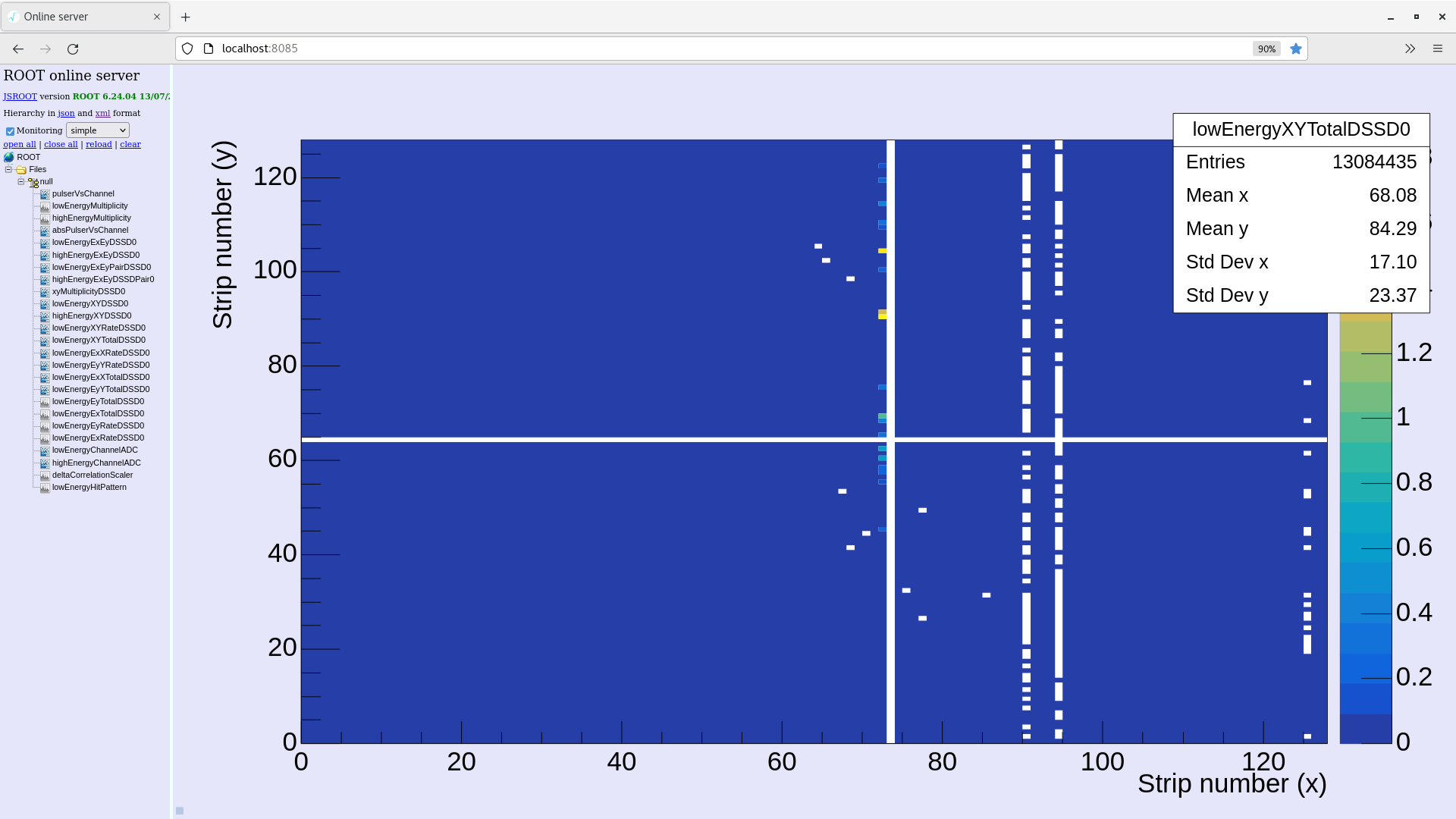

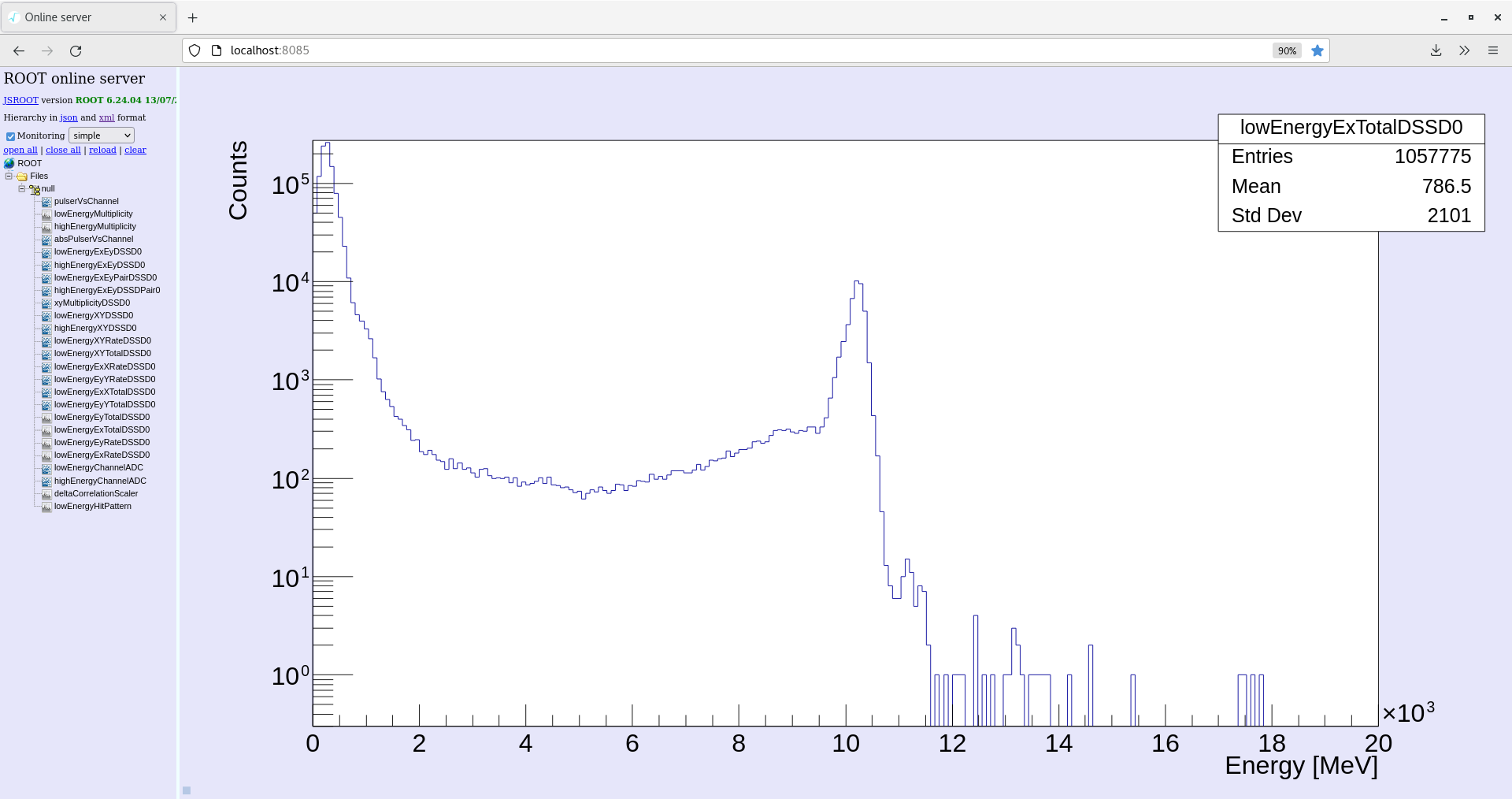

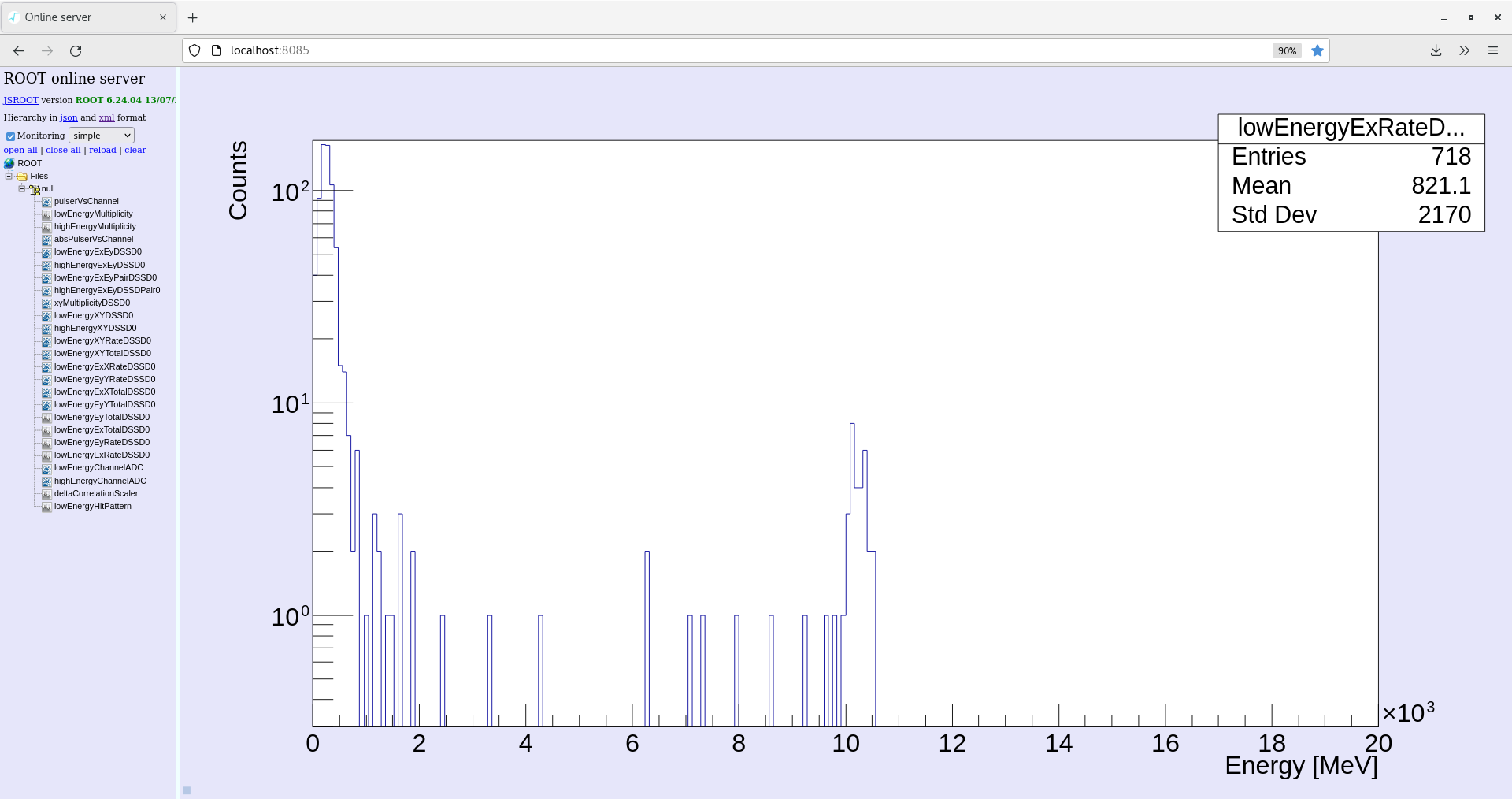

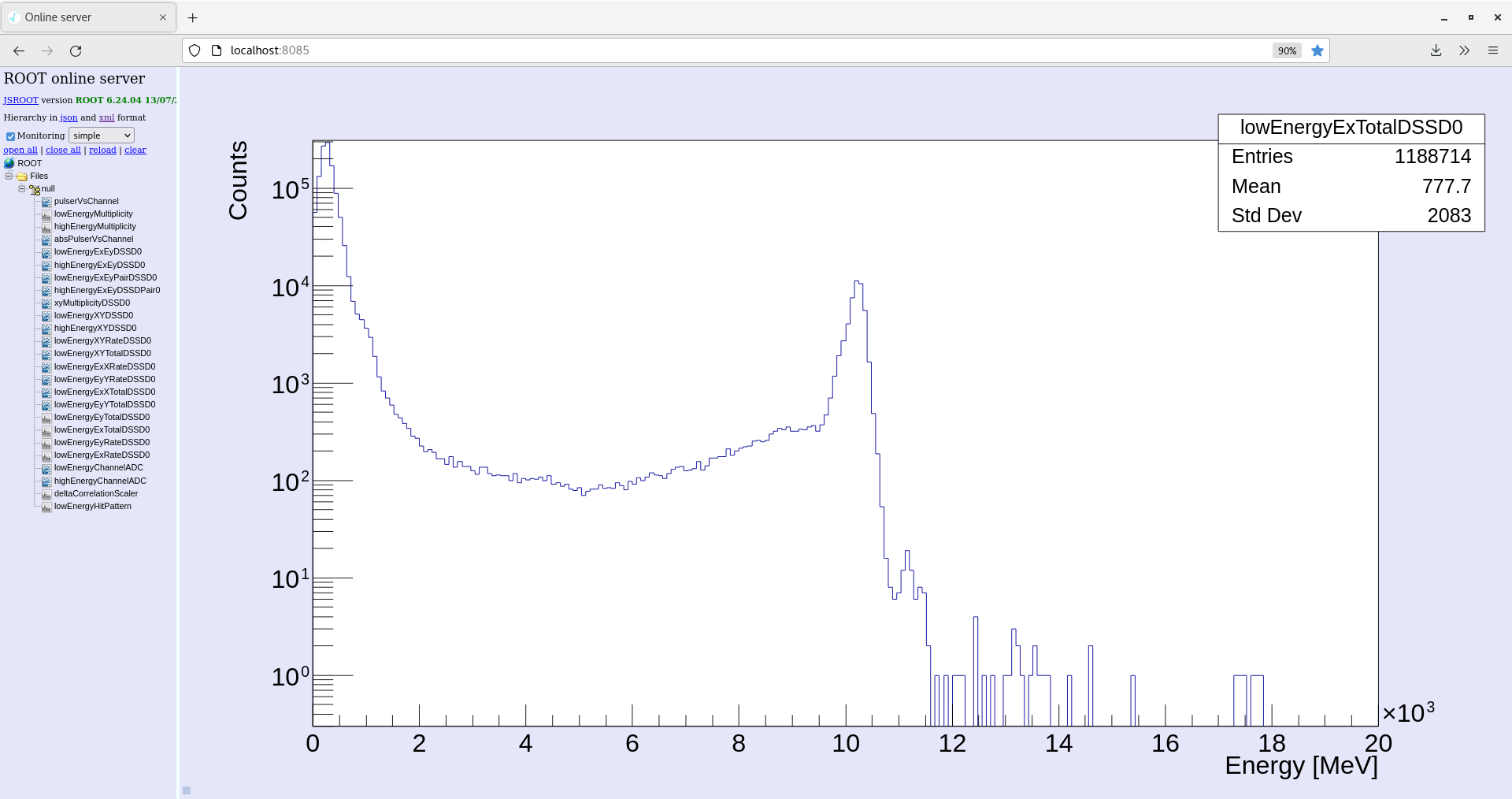

In the tablethe counts in the 4000-5200 keV region in each of the detectors are recorded. Counts were taken for a total time of 5 minutes per beam position. Attached are the xy plots.

I think the tests are inconclusive given that the beam in the first three points were not ideal, with many low intensity injections. Moreover, changing the beam often ends up causing the stats in DSSD0 to rise significantly (consequentely needing to shake the detector to go back to normal operation).

| horizontal |

DSSD0 |

DSSD1 |

DSSD2 |

DSSD3 |

Comments |

| 4.5 mm |

2966 |

60 |

3826 |

1880 |

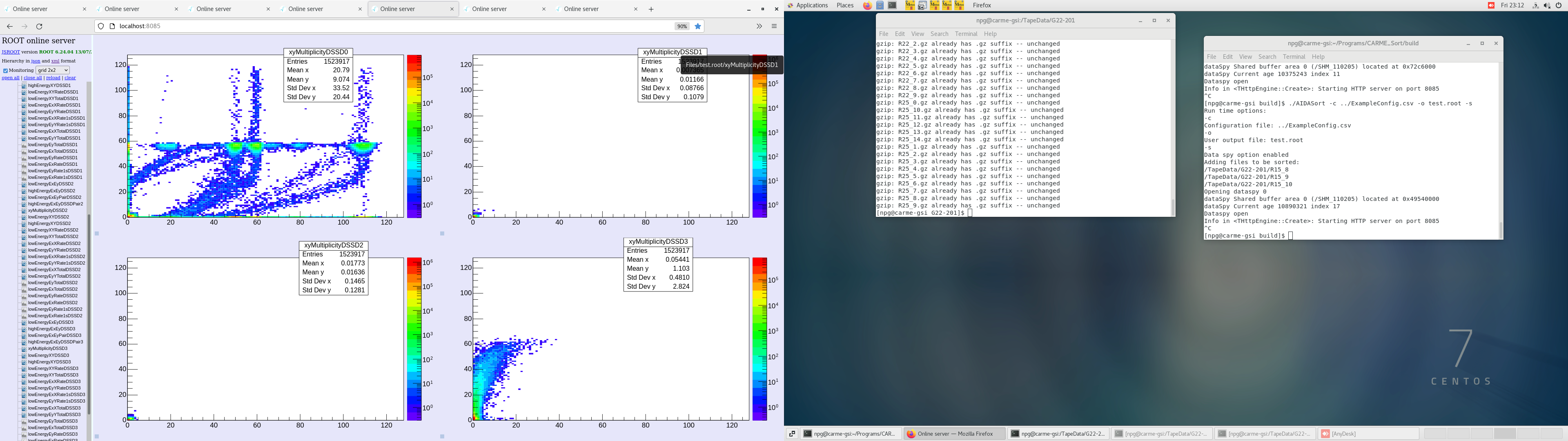

stats went up at the end of the run (attachment 1 is the xy plot, attachment 1 is the multiplicity showing the noise). |

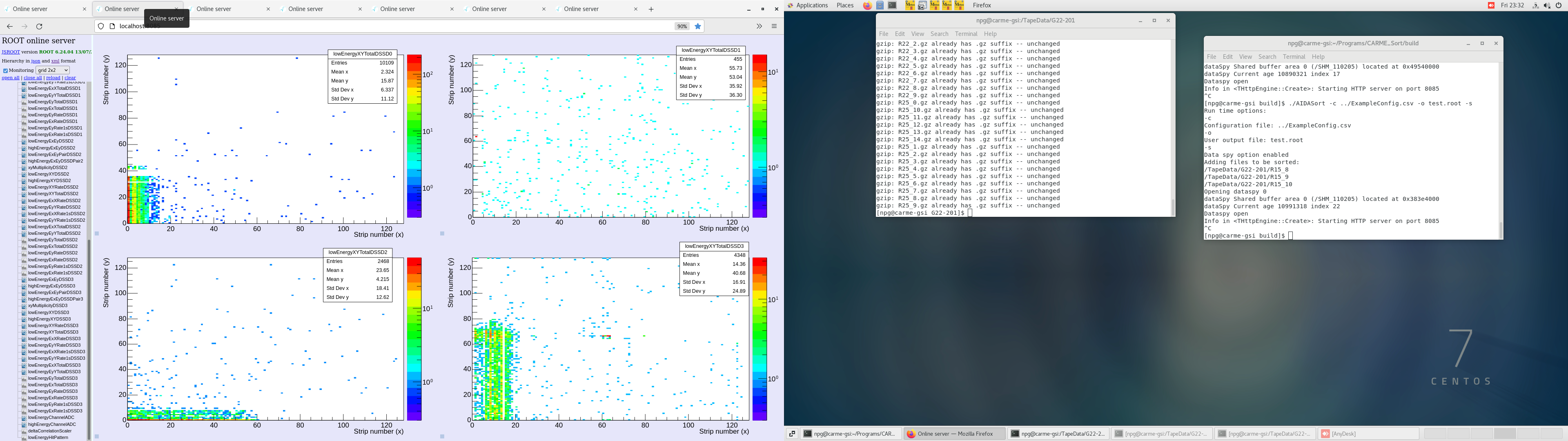

| 5 mm |

3826 |

68 |

1945 |

1719 |

stats ok. Attachment 3 |

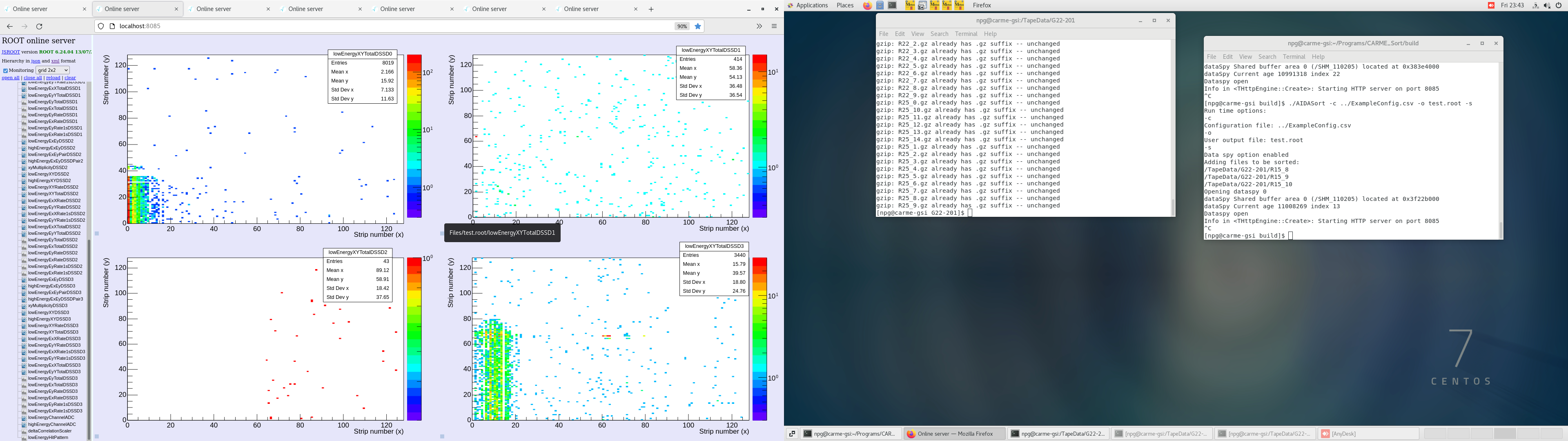

| 5.5 mm |

2443 |

64 |

1 |

1352 |

stats ok. beam bad, called 2222, fixed it. Attachment 4 |

| 5.5 mm good beam |

3587 |

57 |

6 |

2057 |

repeated measurment with good beam. Suspected something wrong with DSSD2 |

| 4.5 mm good beam |

5132 |

64 |

4 |

2153 |

stats bad at the end, confirmed something wrong DSSD2, Jordan did some ASIC check load and made it go back to normal operation. Attachment 5. |

After fixing DSSD2, statsin DSSD0 went up again. Stopped the test after shaking again the detector.

----

I have put back the beam at 4mm horizontal. I switched off the target by moving it to x=-10000--->x=-5000 (previosuly X=-19800). Denisity went down to 5E9. However, I decided under Jordan's suggestion to make another test and I put the target back to x=-19800: interestingly the density went up to 5E12 and start oscillating for a while between 5E12 and 5E11.

I did a 10 minute check of counts in the 4000-5200 keV region with this configuration, then switched off the target and did another 10 minutes test. Results:

| horizontal 4 mm |

DSSD0 |

DSSD1 |

DSSD2 |

DSSD3 |

| target on |

9719 |

163 |

7892 |

5210 |

| targte off |

6579 |

108 |

6092 |

3496 |

|

| Attachment 1: Screenshot_from_2024-06-07_23-11-06.png

|

|

| Attachment 2: Screenshot_from_2024-06-07_23-12-17.png

|

|

| Attachment 3: Screenshot_from_2024-06-07_23-32-22.png

|

|

| Attachment 4: Screenshot_from_2024-06-07_23-43-43.png

|

|

| Attachment 5: Screenshot_from_2024-06-07_23-50-54.png

|

|

|

599

|

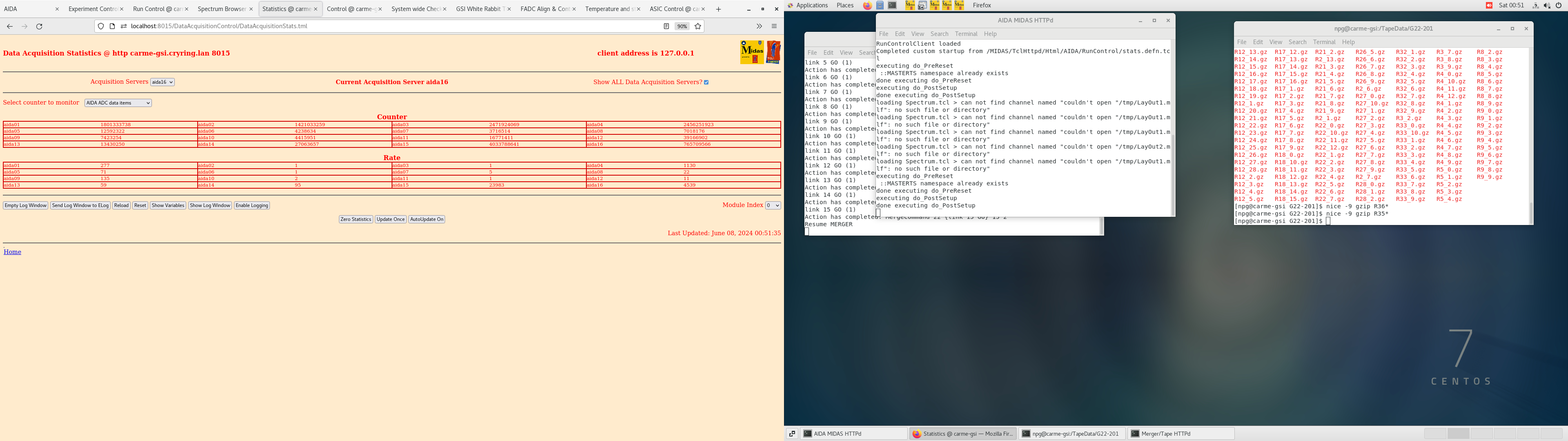

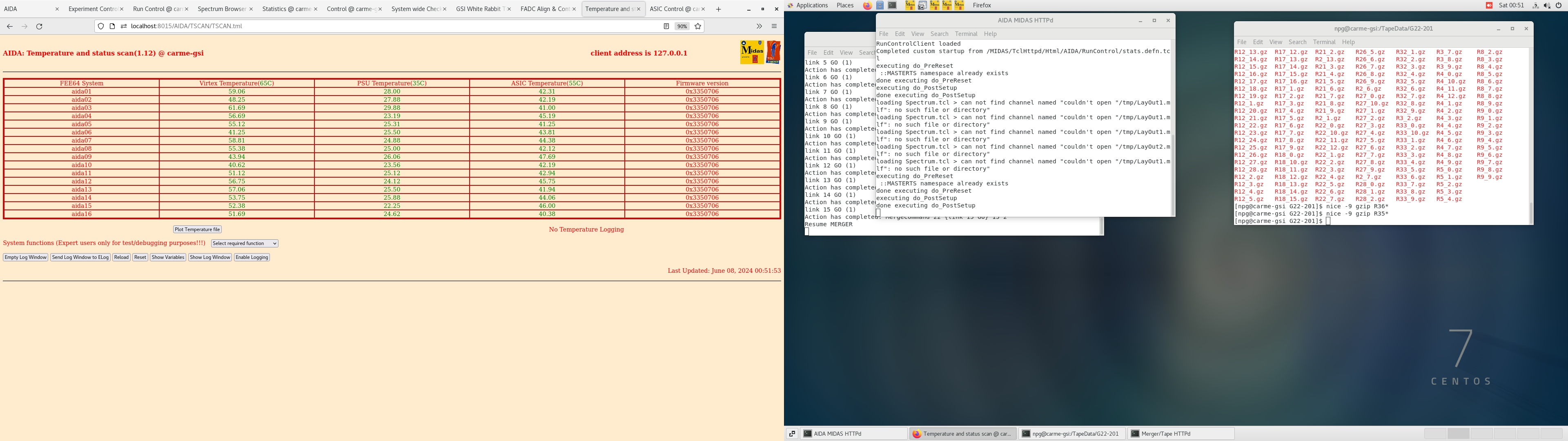

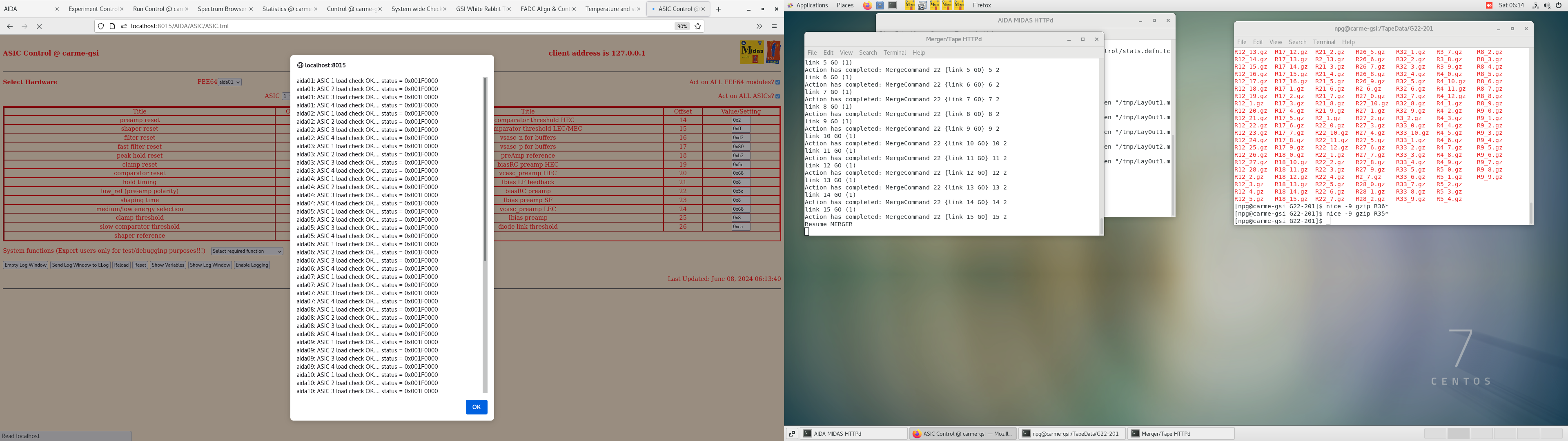

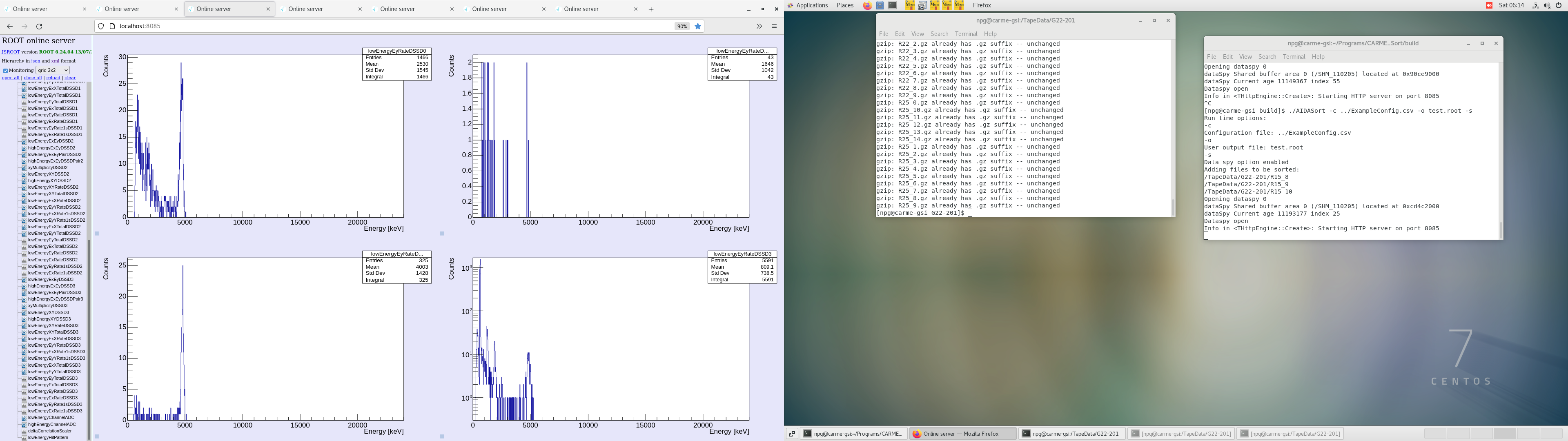

Sat Jun 8 00:14:39 2024 |

LB | Run 46 - background with beam |

RUN 46- started at 00:50

Horizontal beam position = 4.0 mm, vertical beam position = -5.0 mm.

Detectors are Left arm OUT = 36.64, right arm IN = 64.60 mm

Injection at ca. 6E7

Target density 6-7E9

-----

00:51

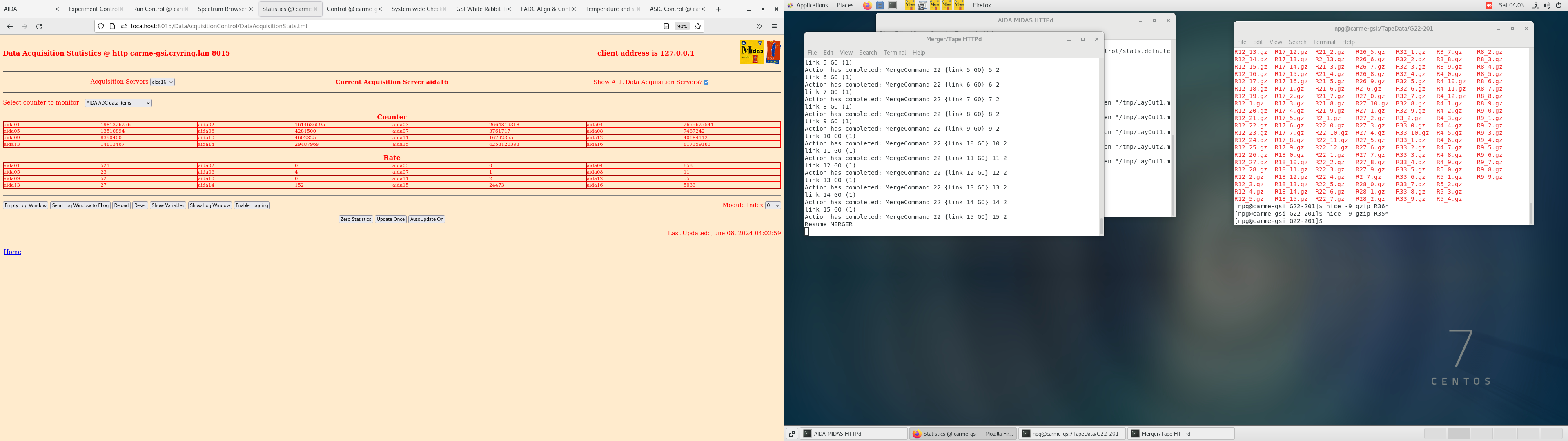

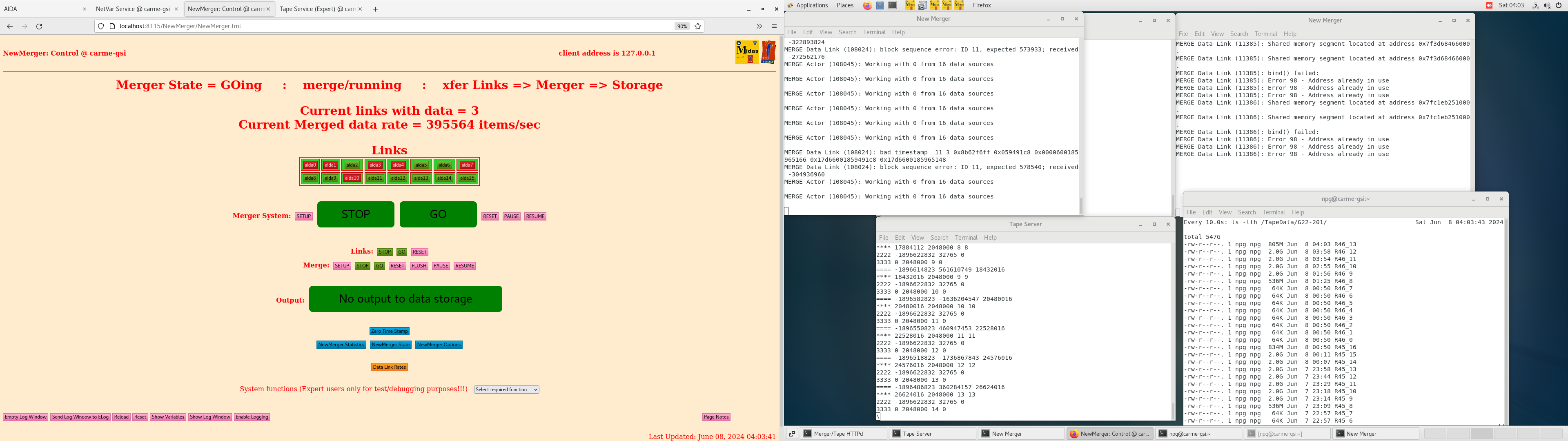

Merger OK, Tape server OK

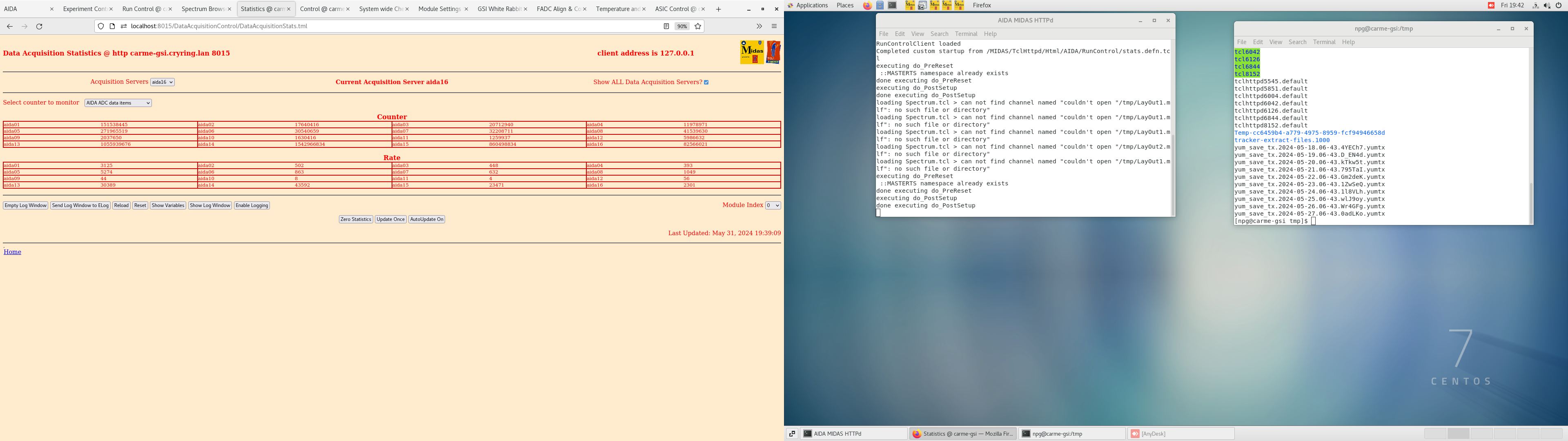

ADC data item statistics looks as before. OK

FEE temperatures look OK

System checks OK

Leakage current stable

Attachments 1-2

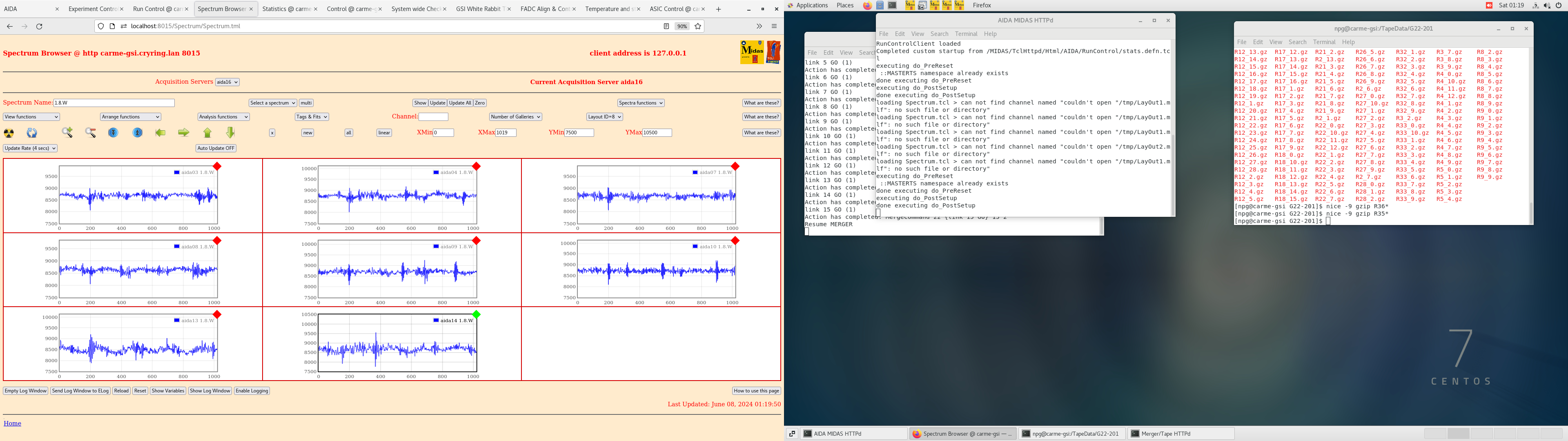

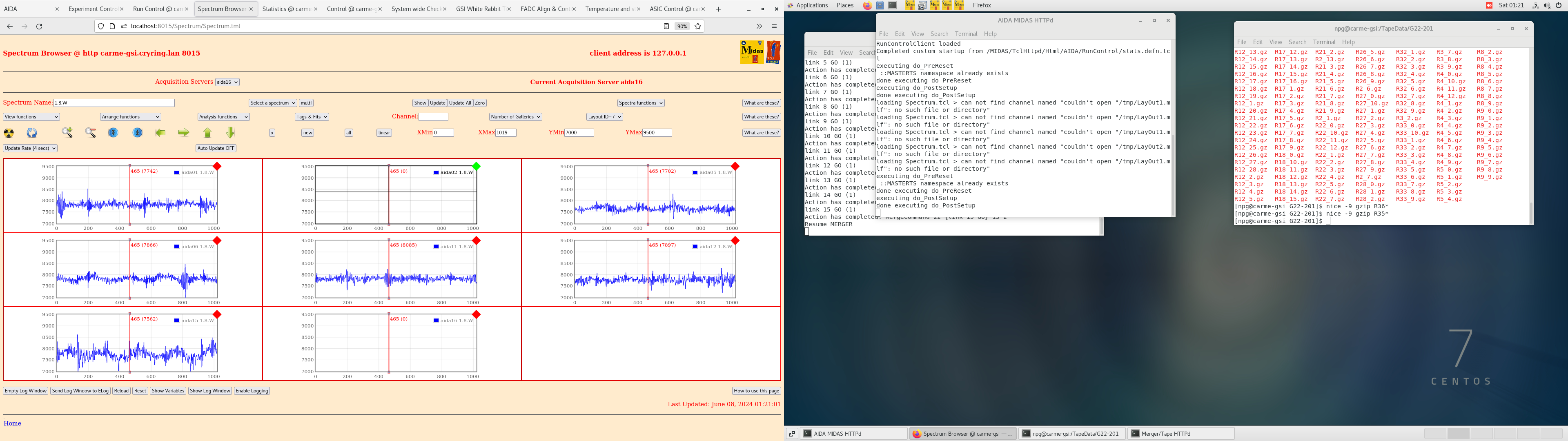

01:19

Attachments 3-4 waveforms. DSSD0 stats fine

01:33

DSSD0 stats fine

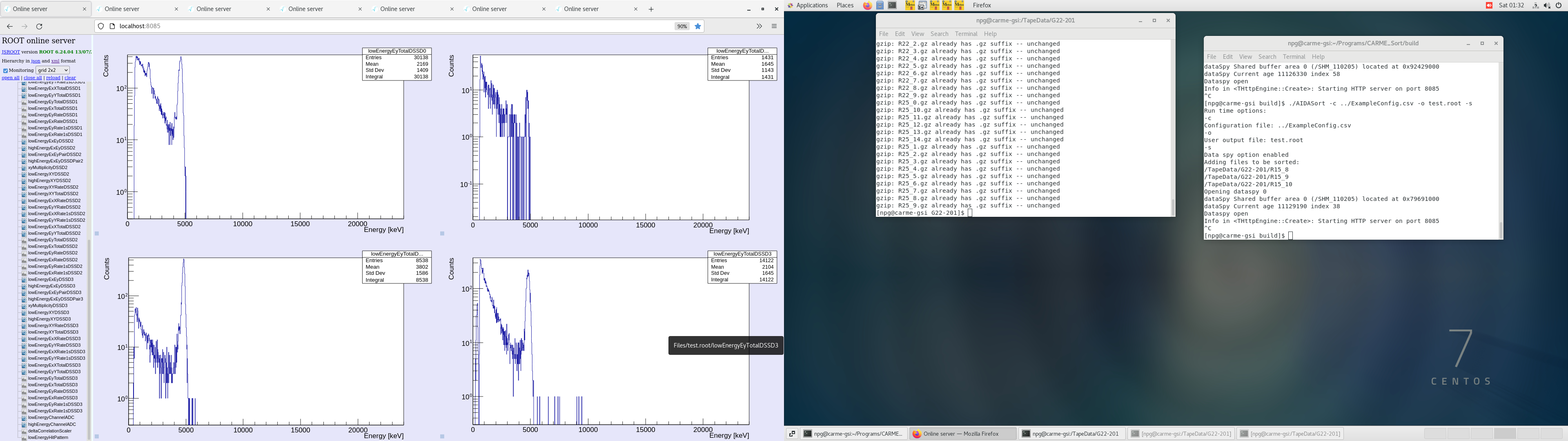

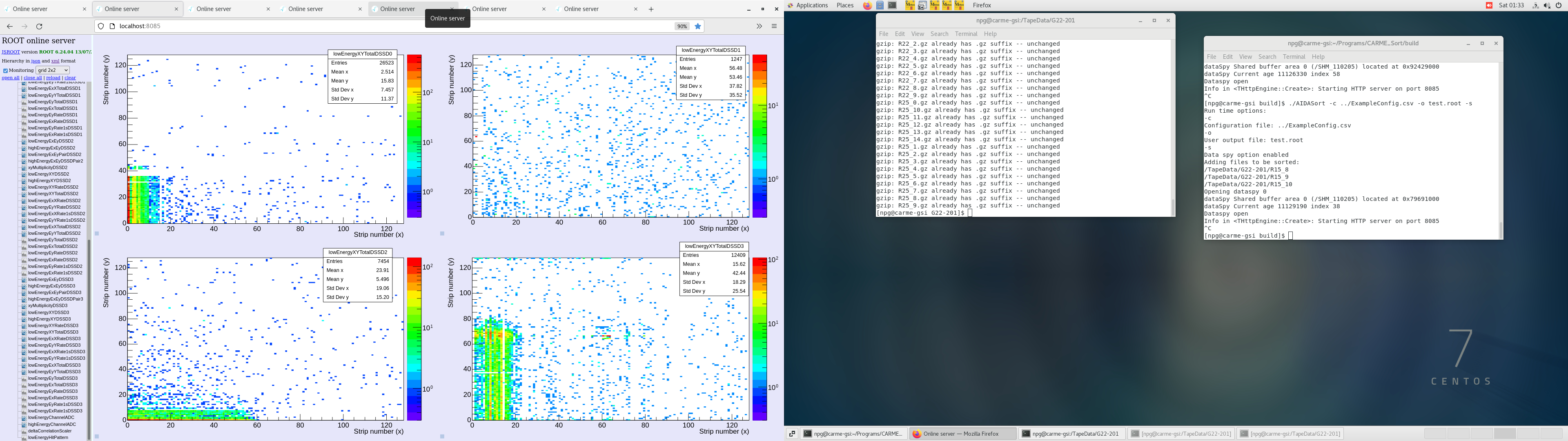

Attachments 5-6 spectra and xy, but I am not sure at which time these are cause I am stupid and apparently the AIDAsort code was not running....

01:56

Restarted the AIDAsort code and noted that stats in DSSD0 were bad again. Another shake. This time no change to the beam on my side.

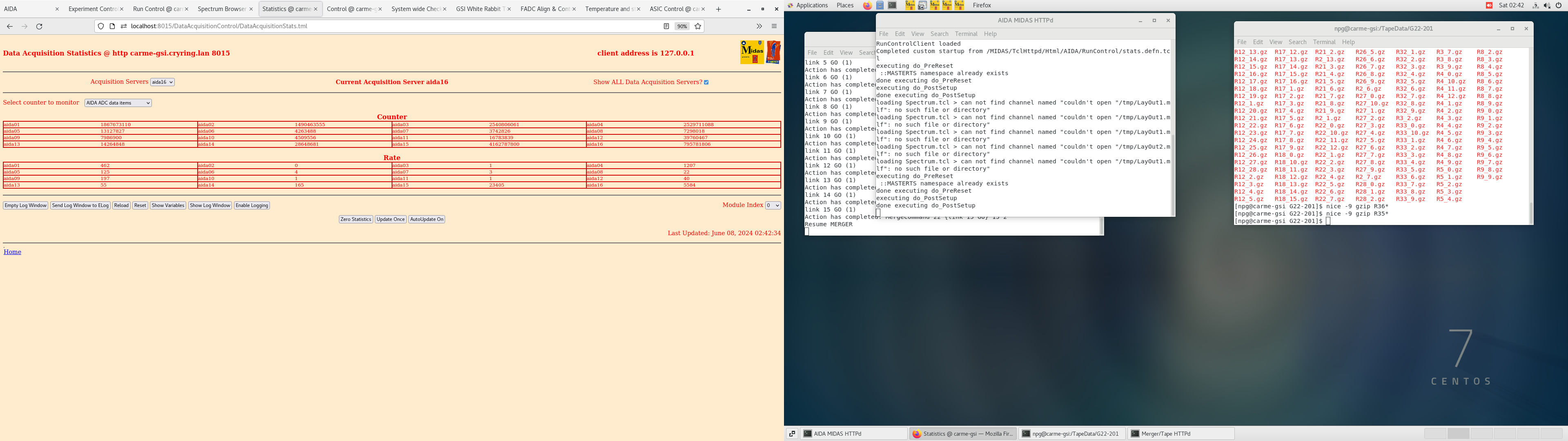

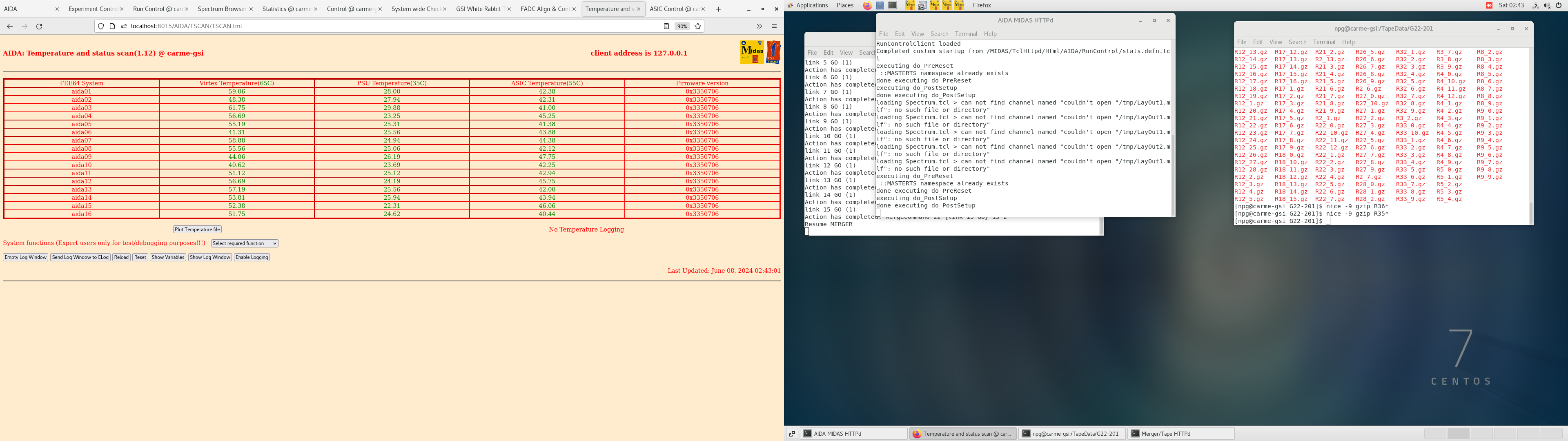

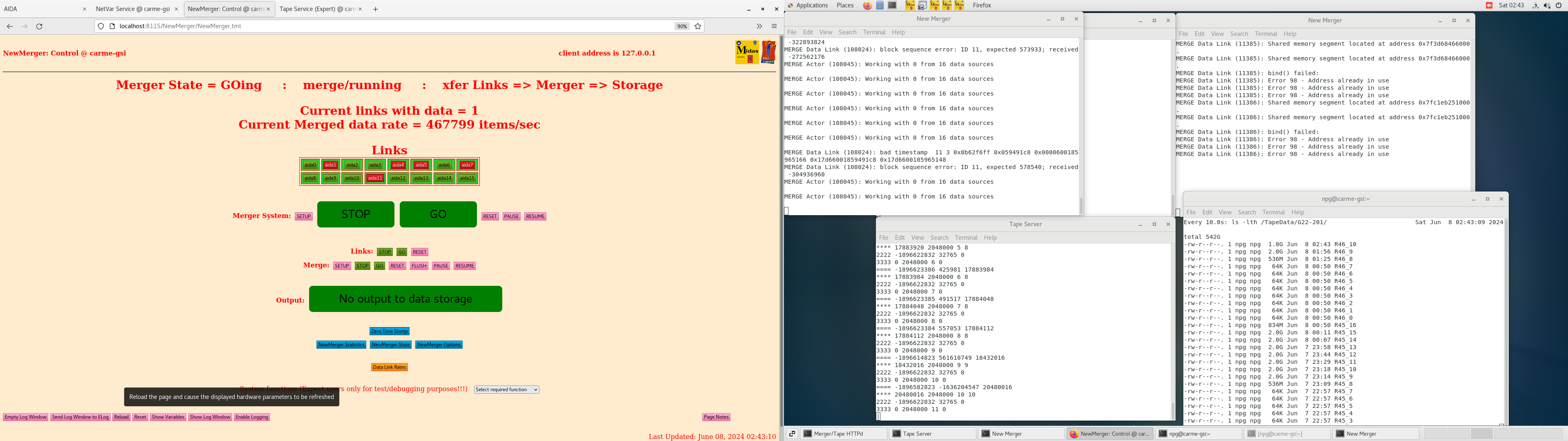

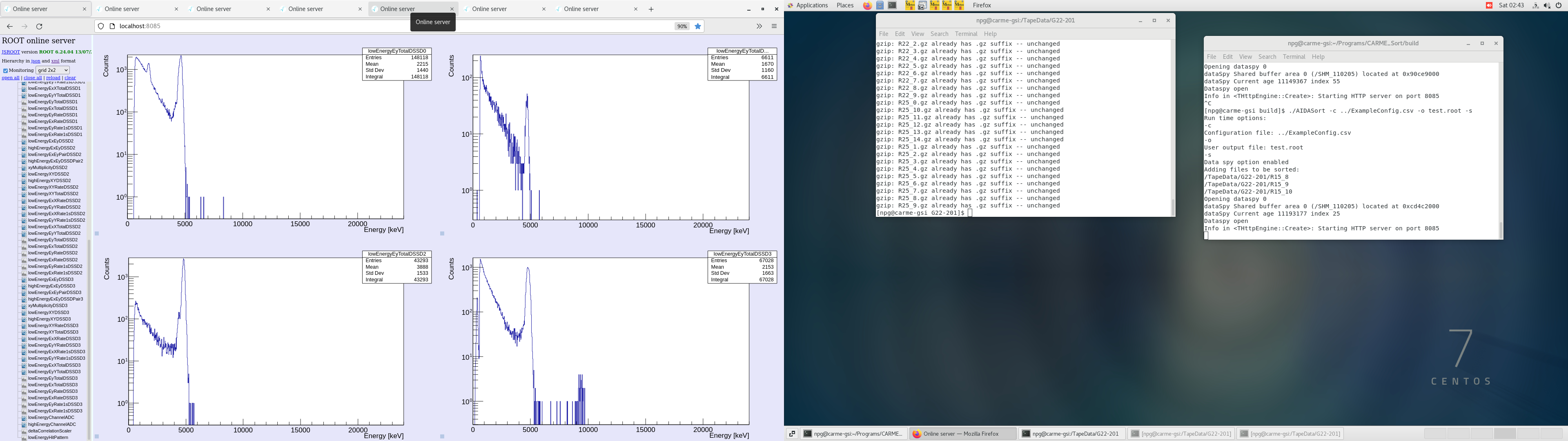

2:43

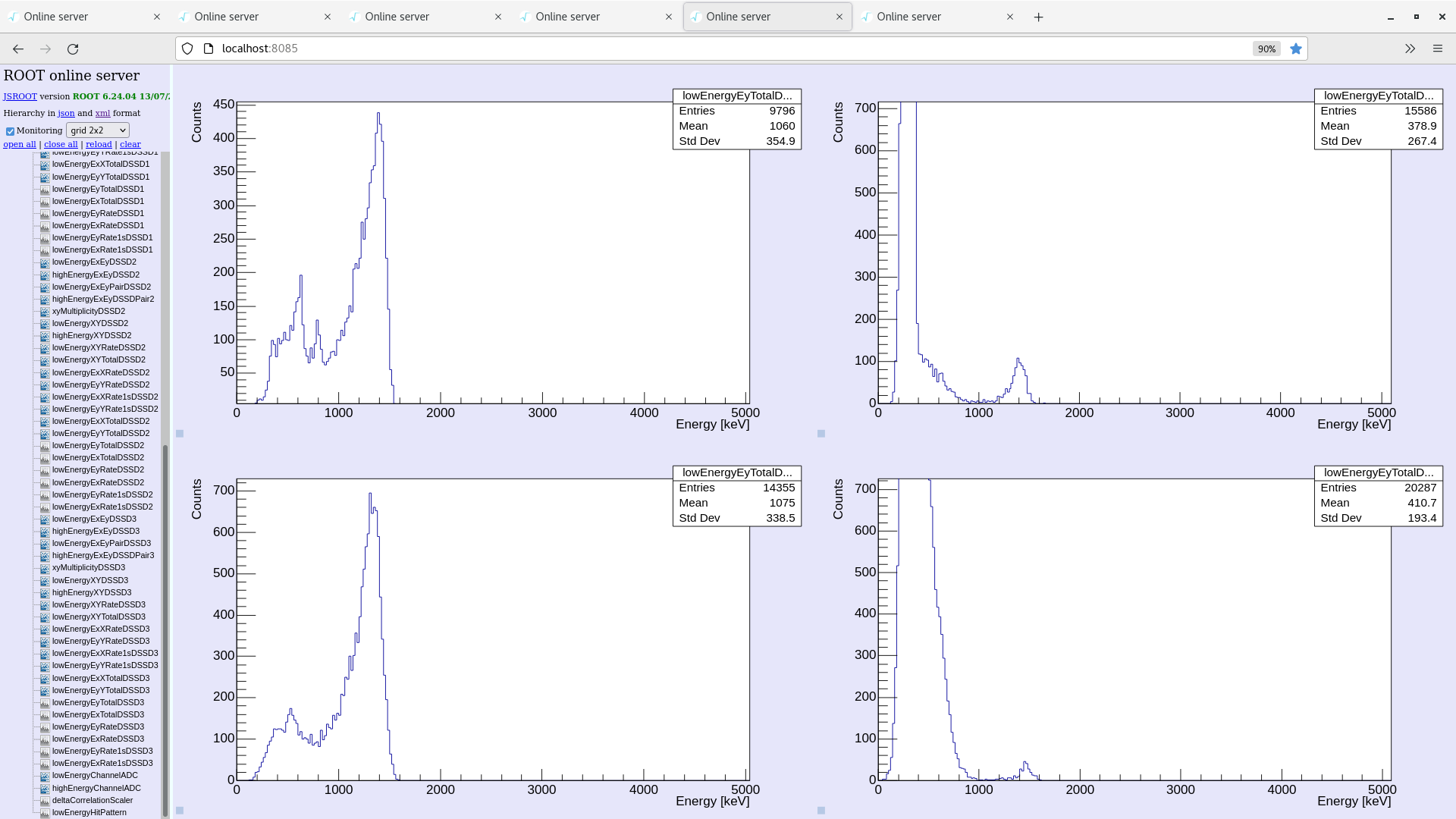

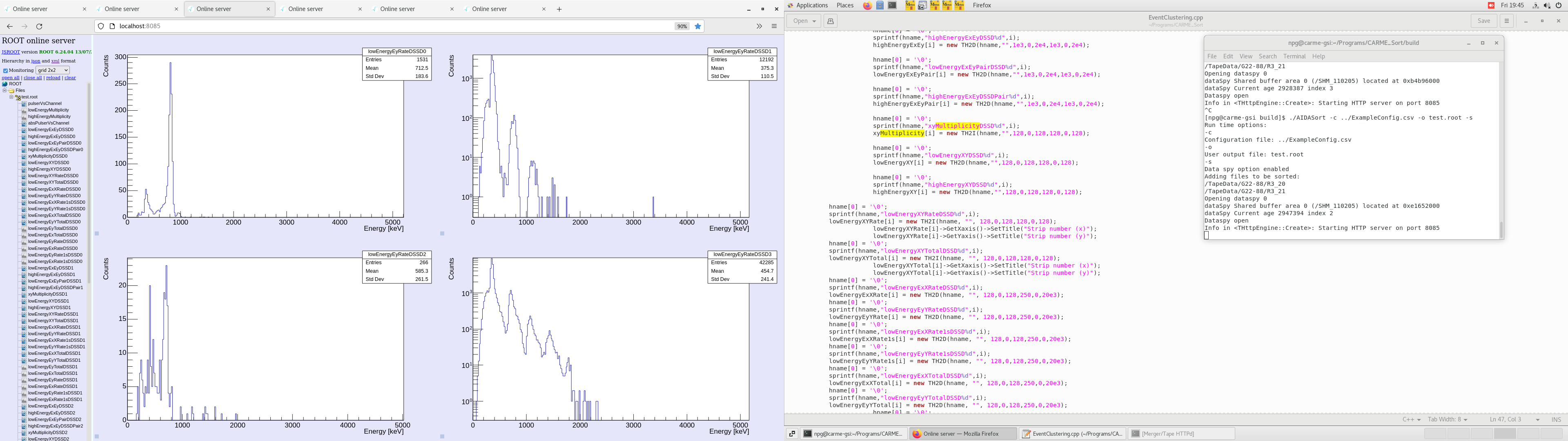

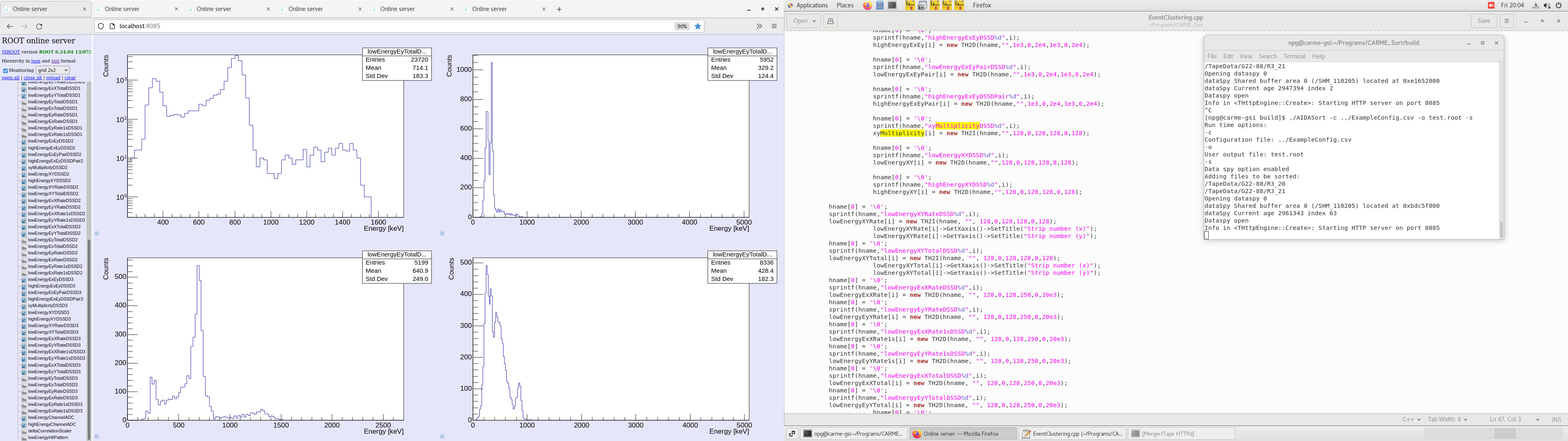

All checks fine. Attachments 7-10 (also spectra)

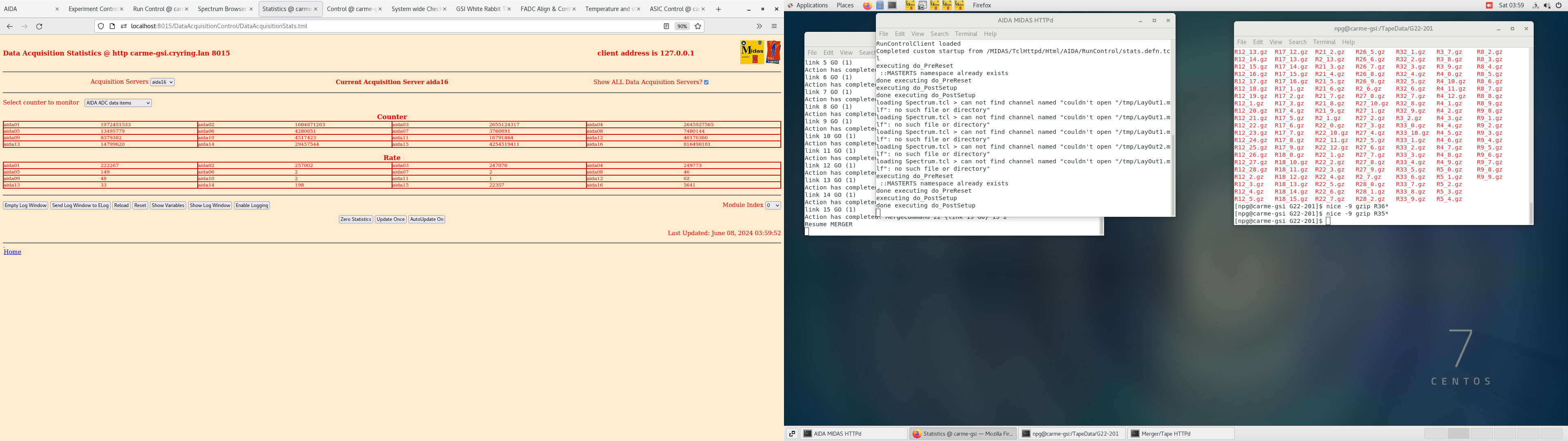

4:01

Notice stats on DSSD0 went bad again. Attachment 11. Gave detector a shake.

Now all system checks OK (Attachements 12-14)

4:19

Just noticed target is oscillating a bit, hitting 1E10. I moved it further in X and Y. Seems to not go below 6E9 in any case.

NOTE: target was on at x=-19899 y=500.

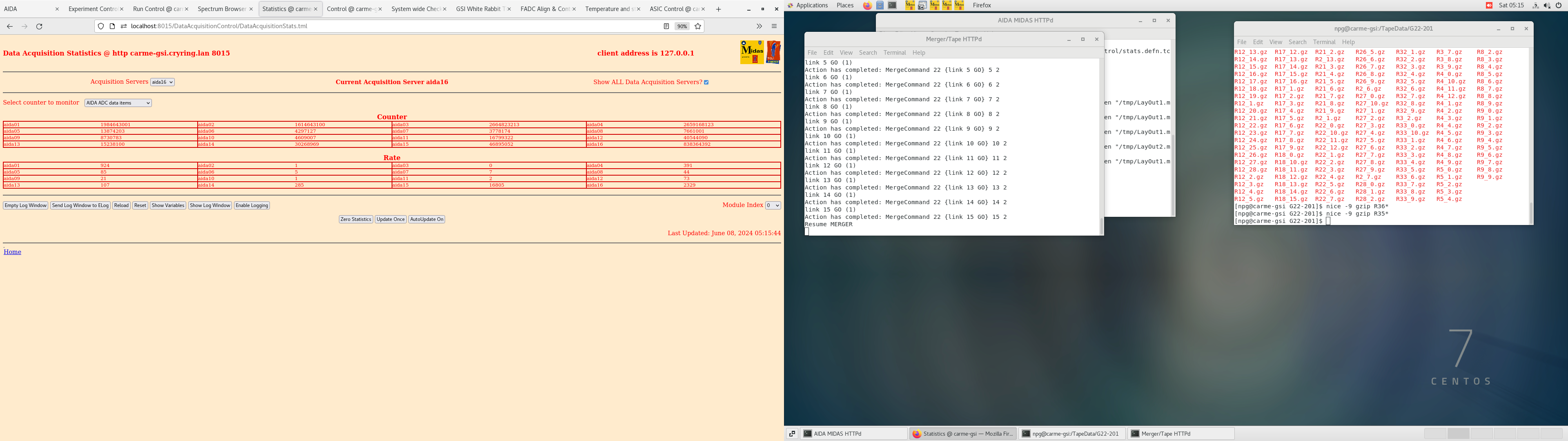

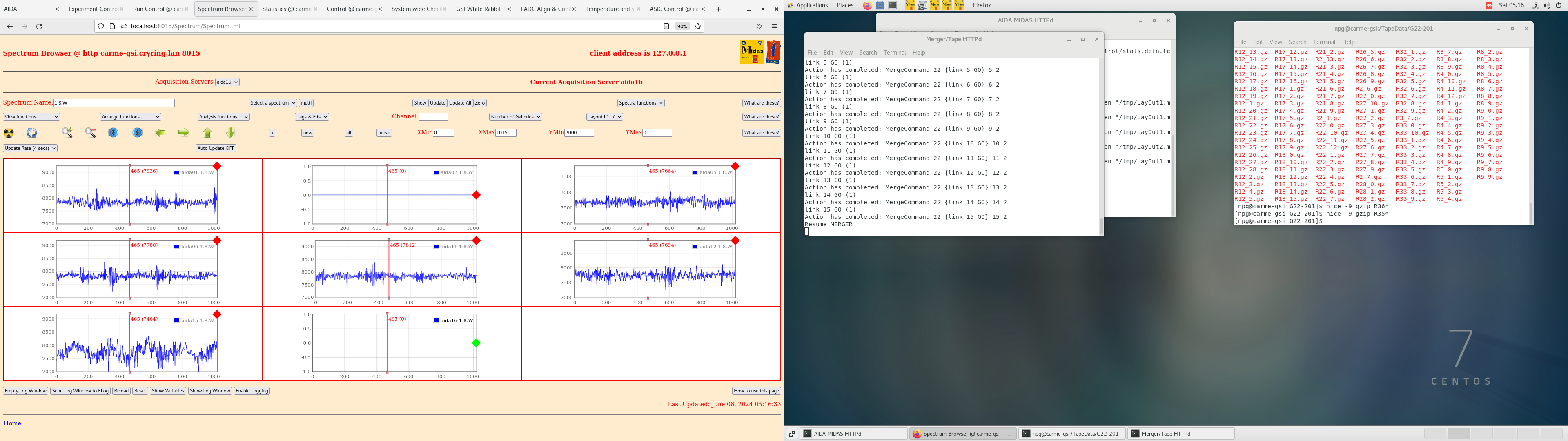

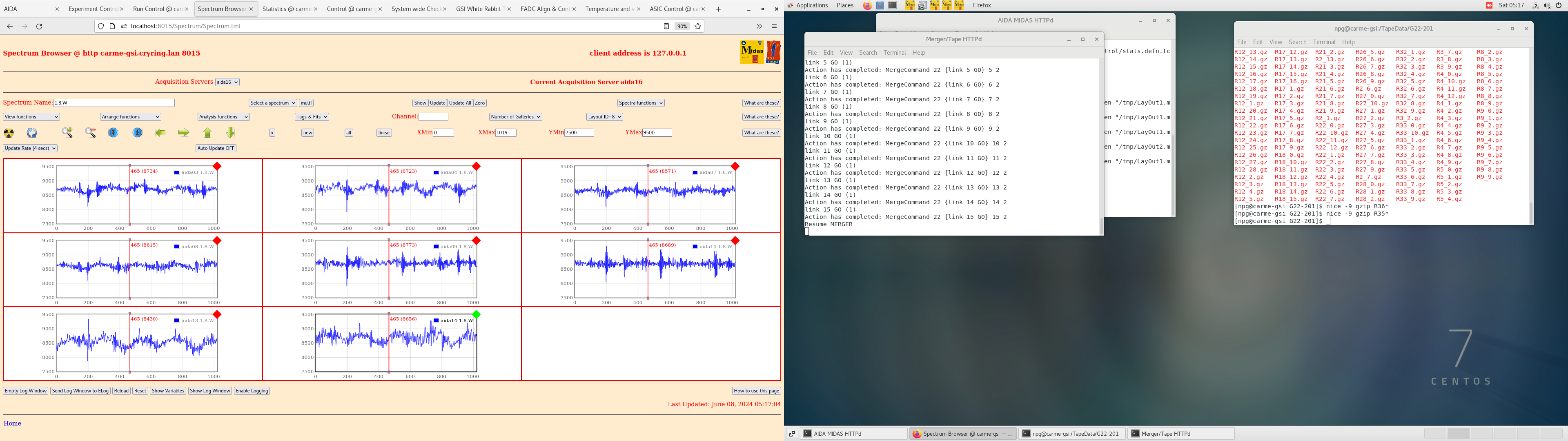

5:17

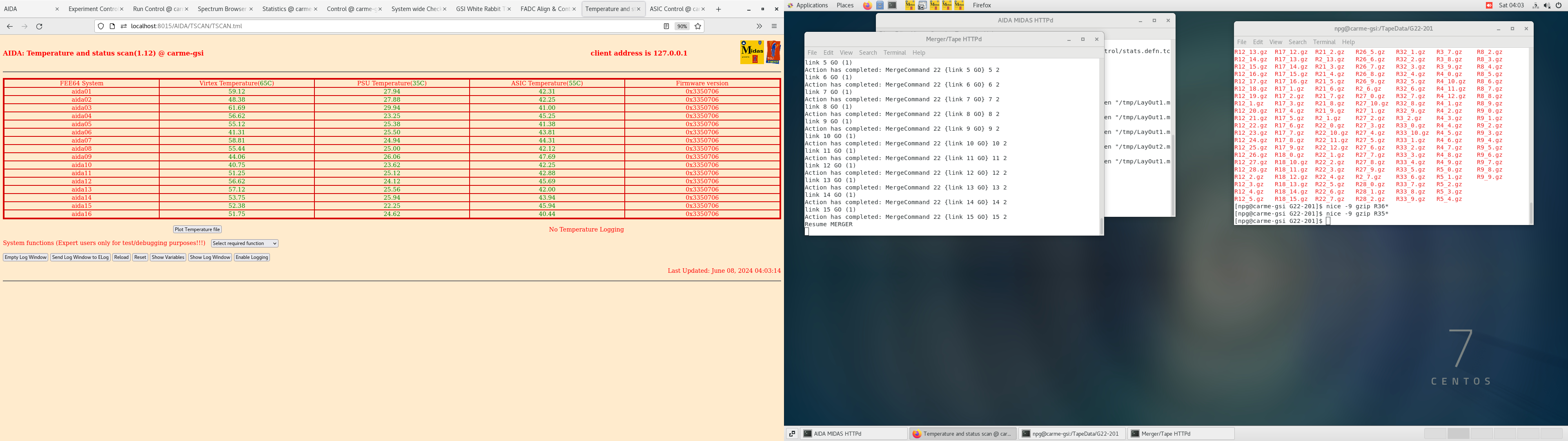

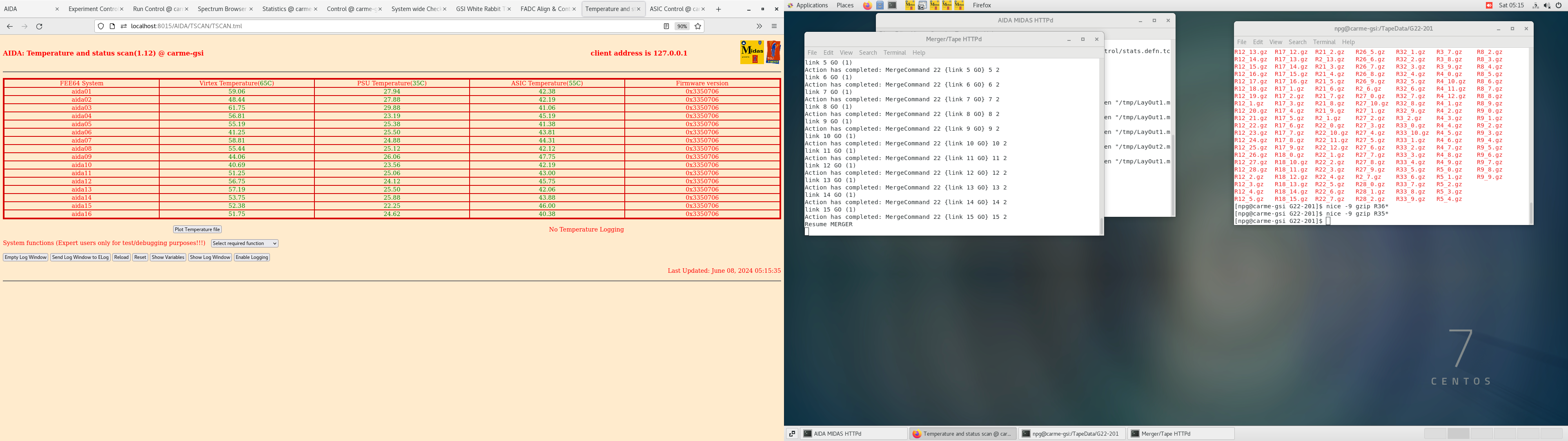

Merger OK, Tape server OK

ADC data item statistics looks as before. OK

FEE temperatures look OK

System checks OK

Leakage current stable

Attachments 15-18 (also waves)

5:53

Notice stats on DSSD0 went bad again. Gave detector a shake.

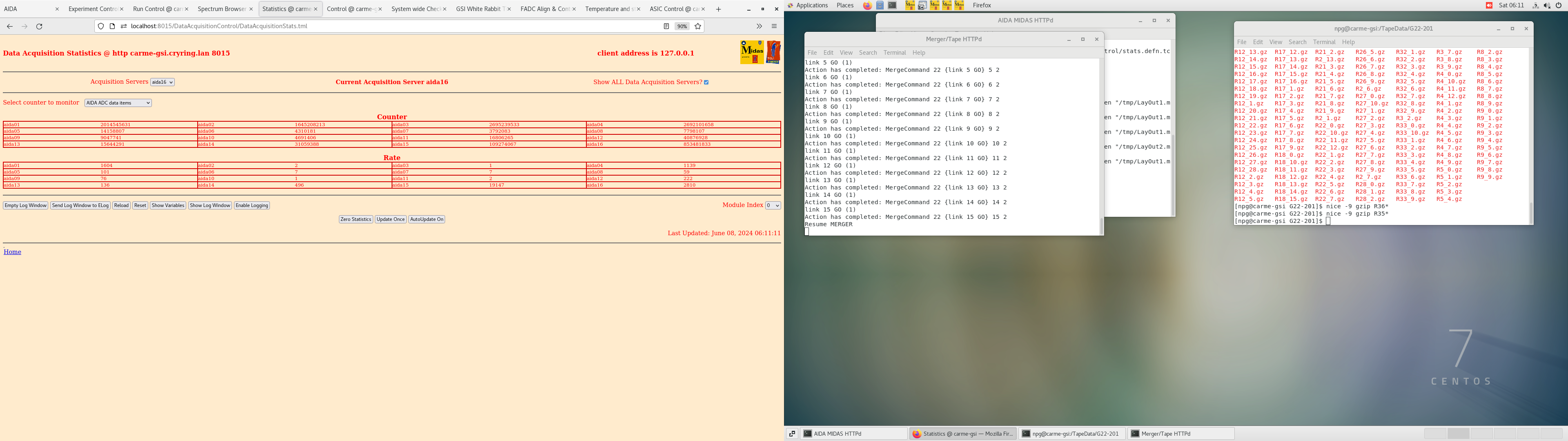

6:10

Stats ok in attachment 19, but

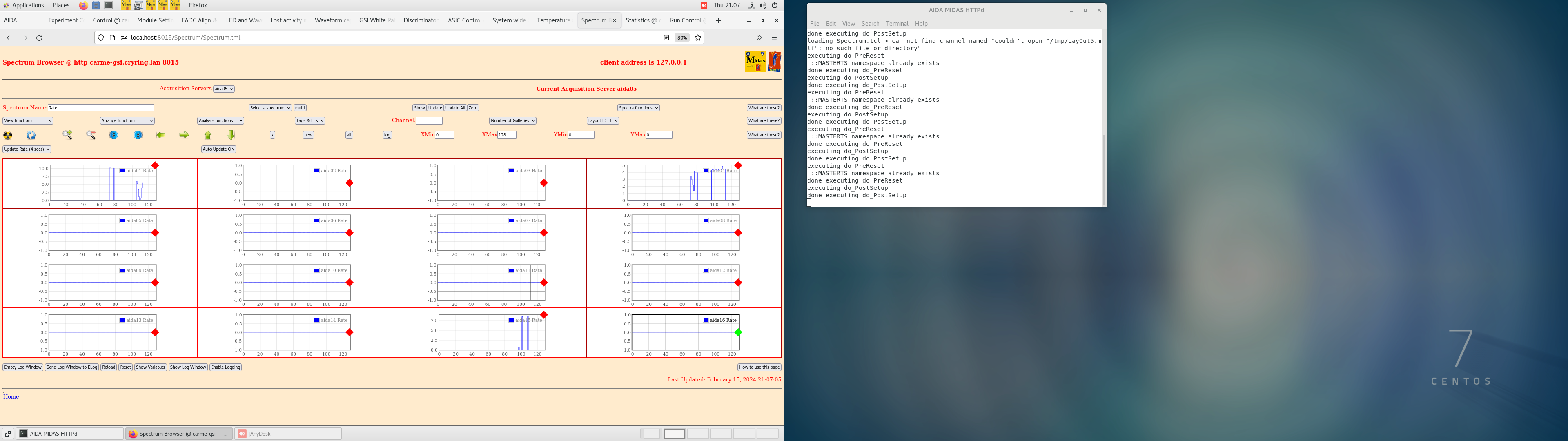

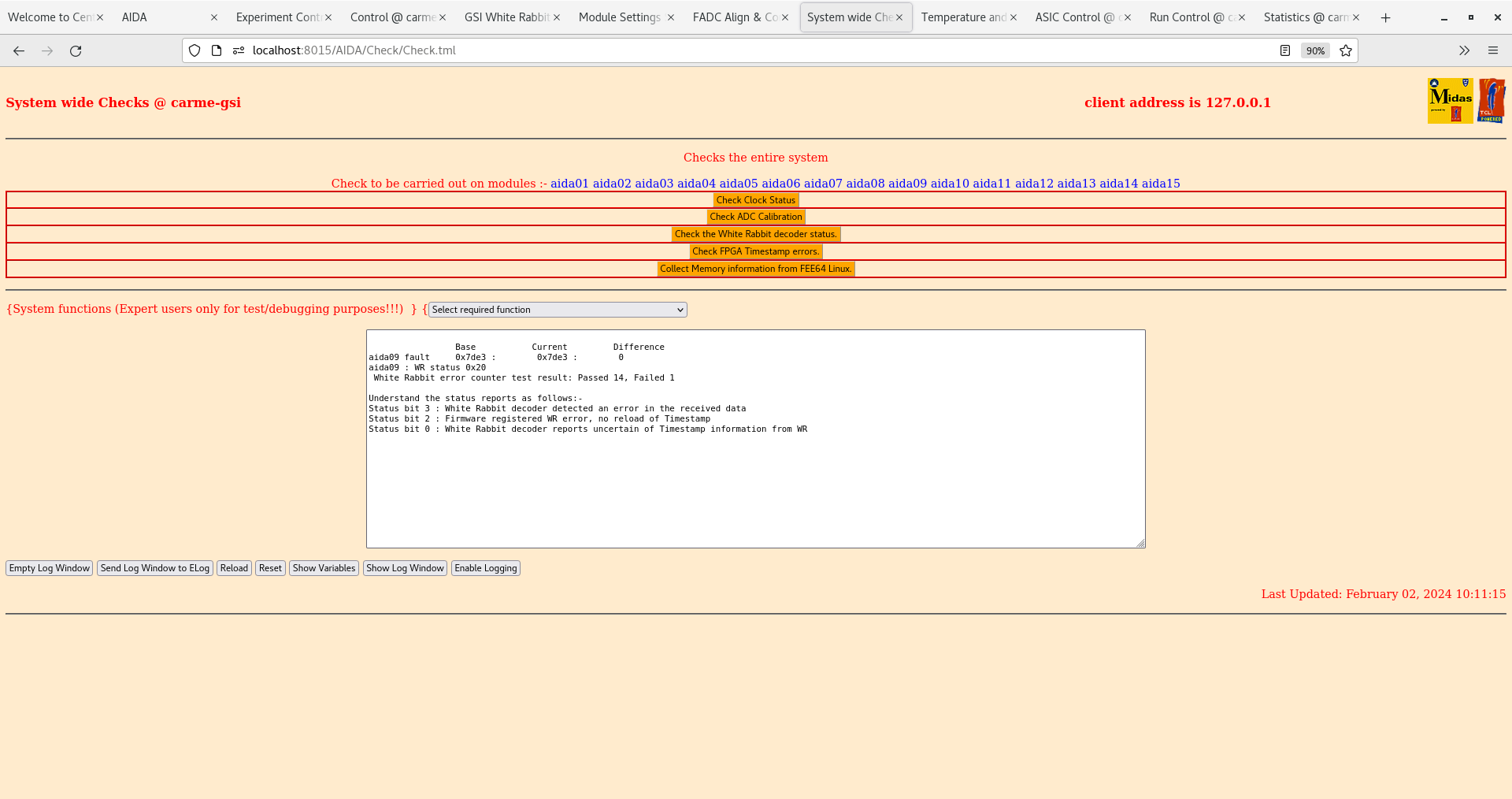

Noticed DSSD3 has started to get only a fate of 140 nstead of previous 5500is (similar to what DSSD2 has done earlier- see previous elog). Attachment 20 for the rates.

I have therefore made the Check ASIC control test from the ASIC control tab- attachment 21 with results.

DSSD3 back to normal operations - attachment 22 |

| Attachment 1: Screenshot_from_2024-06-08_00-51-42.png

|

|

| Attachment 2: Screenshot_from_2024-06-08_00-51-53.png

|

|

| Attachment 3: Screenshot_from_2024-06-08_01-19-58.png

|

|

| Attachment 4: Screenshot_from_2024-06-08_01-21-07.png

|

|

| Attachment 5: Screenshot_from_2024-06-08_01-32-35.png

|

|

| Attachment 6: Screenshot_from_2024-06-08_01-33-28.png

|

|

| Attachment 7: Screenshot_from_2024-06-08_02-42-36.png

|

|

| Attachment 8: Screenshot_from_2024-06-08_02-43-02.png

|

|

| Attachment 9: Screenshot_from_2024-06-08_02-43-12.png

|

|

| Attachment 10: Screenshot_from_2024-06-08_02-43-35.png

|

|

| Attachment 11: Screenshot_from_2024-06-08_03-59-55.png

|

|

| Attachment 12: Screenshot_from_2024-06-08_04-03-02.png

|

|

| Attachment 13: Screenshot_from_2024-06-08_04-03-16.png

|

|

| Attachment 14: Screenshot_from_2024-06-08_04-03-45.png

|

|

| Attachment 15: Screenshot_from_2024-06-08_05-15-37.png

|

|

| Attachment 16: Screenshot_from_2024-06-08_05-15-48.png

|

|

| Attachment 17: Screenshot_from_2024-06-08_05-16-38.png

|

|

| Attachment 18: Screenshot_from_2024-06-08_05-17-07.png

|

|

| Attachment 19: Screenshot_from_2024-06-08_06-11-14.png

|

|

| Attachment 20: Screenshot_from_2024-06-08_06-11-24.png

|

|

| Attachment 21: Screenshot_from_2024-06-08_06-14-01.png

|

|

| Attachment 22: Screenshot_from_2024-06-08_06-14-14.png

|

|

|

699

|

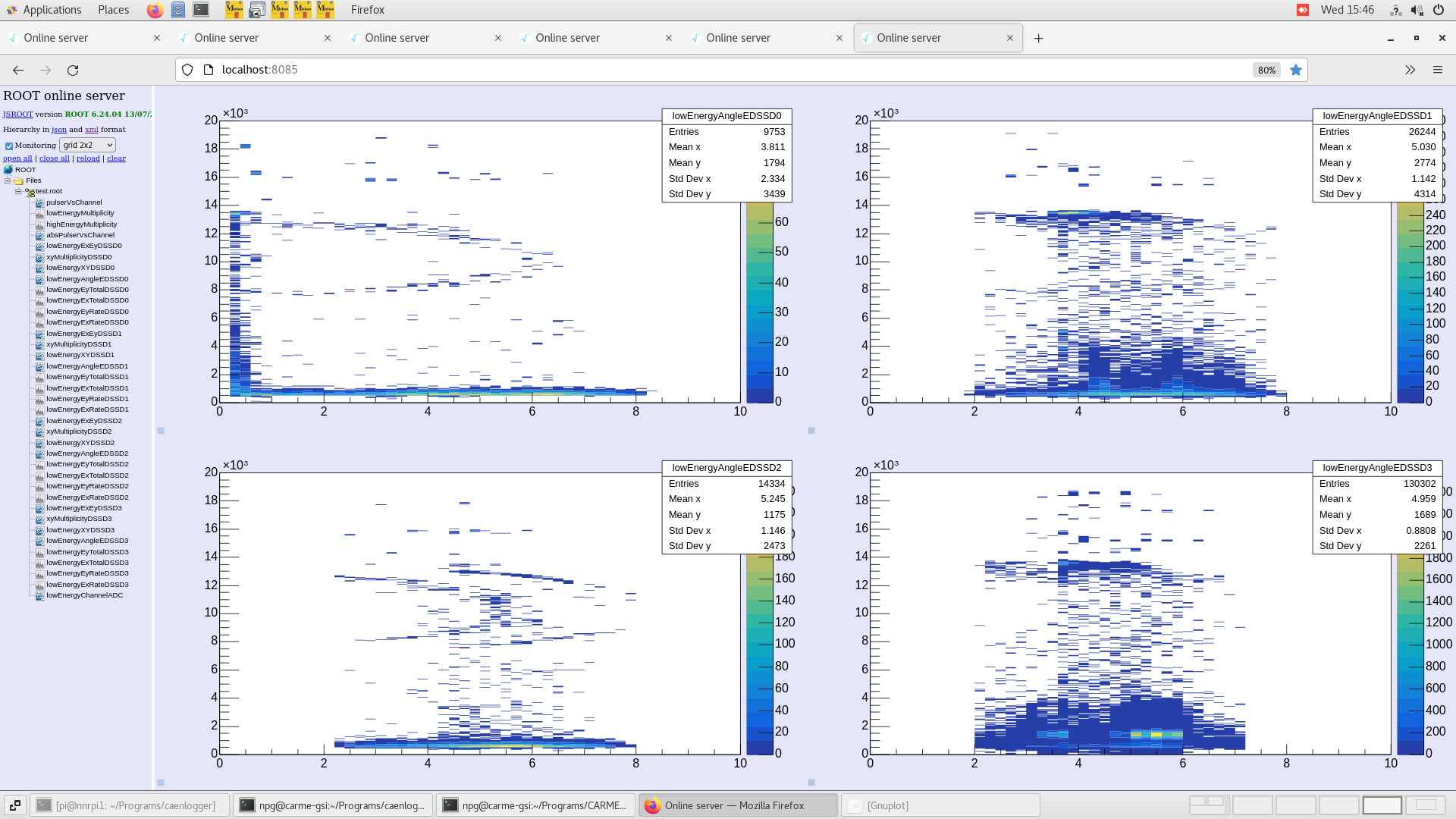

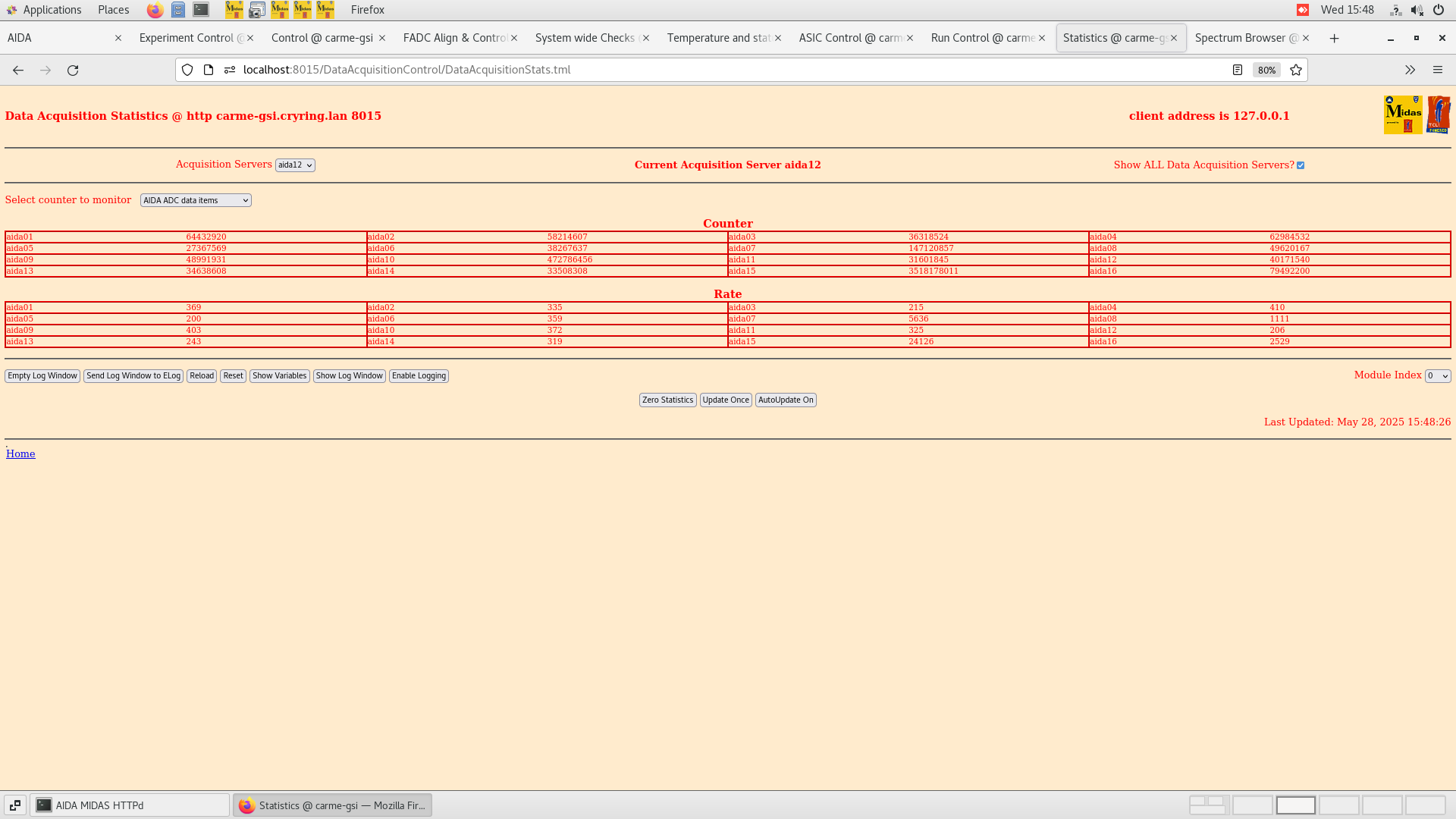

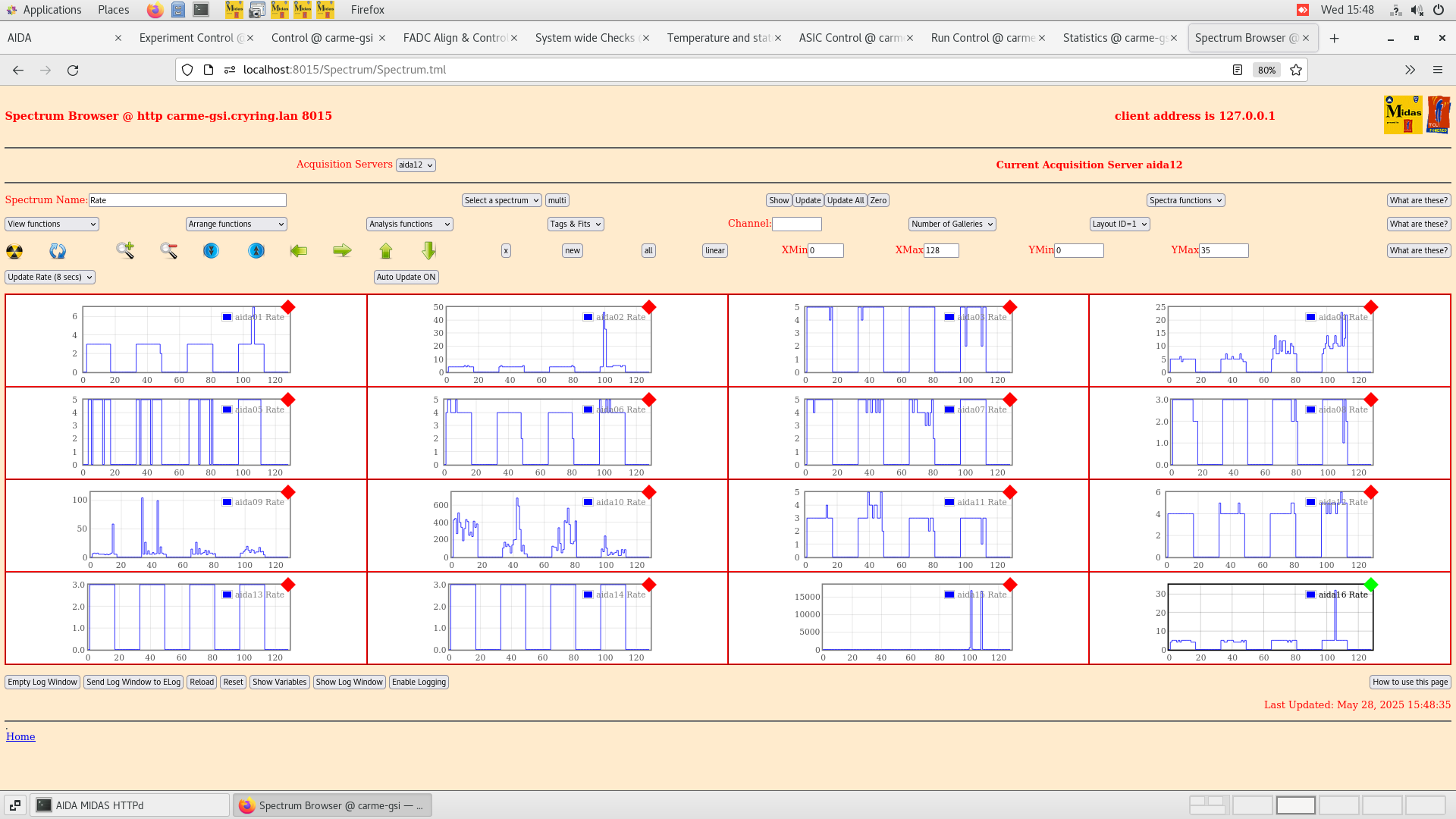

Wed May 28 10:54:14 2025 |

LB | Run 27 |

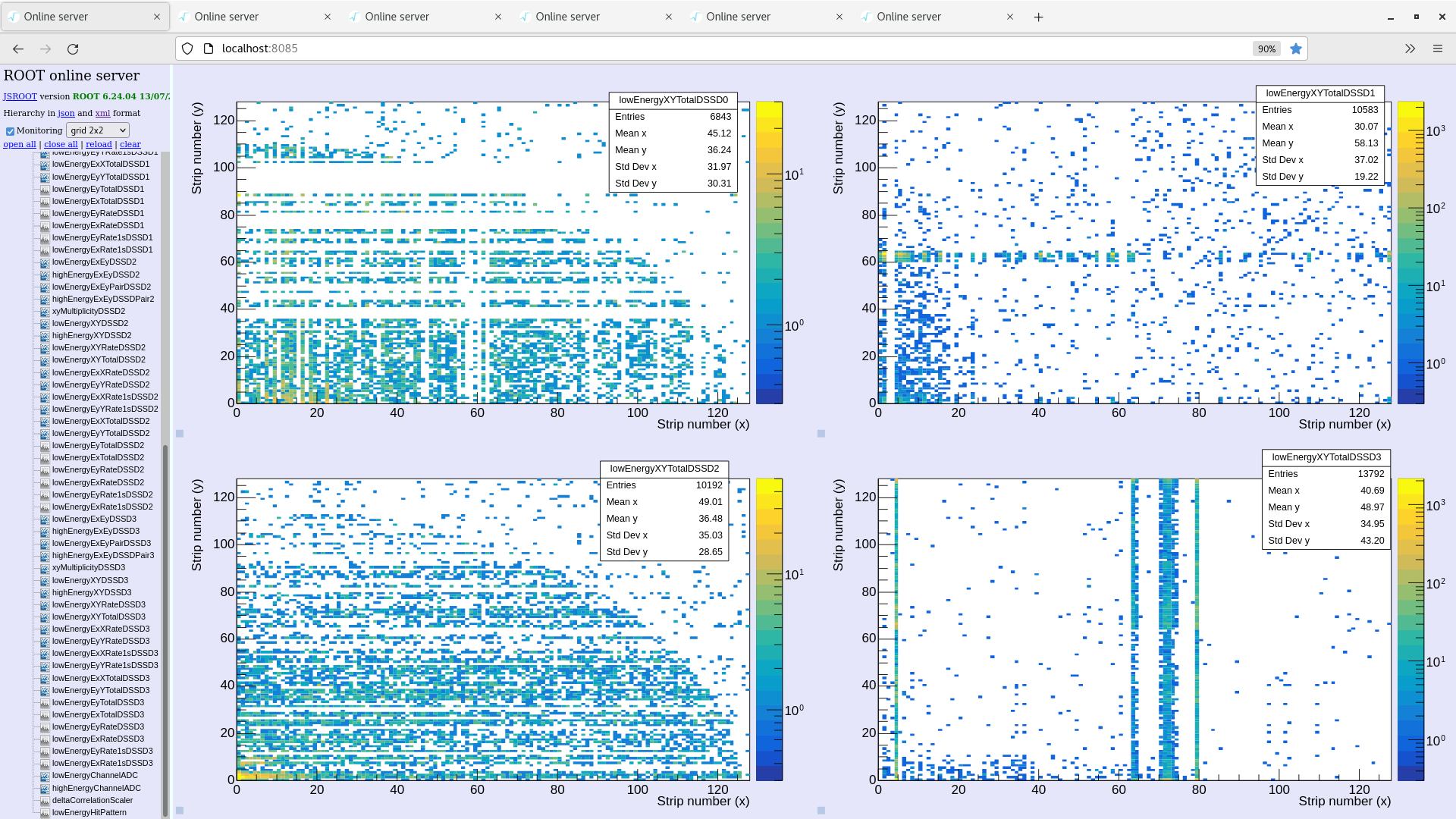

Run 27 running

28/05/2025

(ignore 26 - in-between run)

We start a new run with real data taking condititon: beam is ok, target density is 9.6e11 cm-2, detectors are moving in-out periodically.

Cooler voltage setpoint 1128 V.

Beam energy = 1.99 MeV/u (from HKR) (same as run 25)

Left arm at 18.86 mm

Right arm IN at 83.69 mm (OUT 37.96 mm)

vertical beam position 0.0 mm

horizontal beam position -3.5mm

Beam intensity ~1e+7 particles.

Target density ~9.6e11 at/cm2

Target temperatures: T1=31.5 K T2=35.2 K

Beam cycle set to 10 seconds.

11;57

All checks OK.

Aida10's rates seems low now, but aida07 is instead jumping between 200 and 4000 following beam.

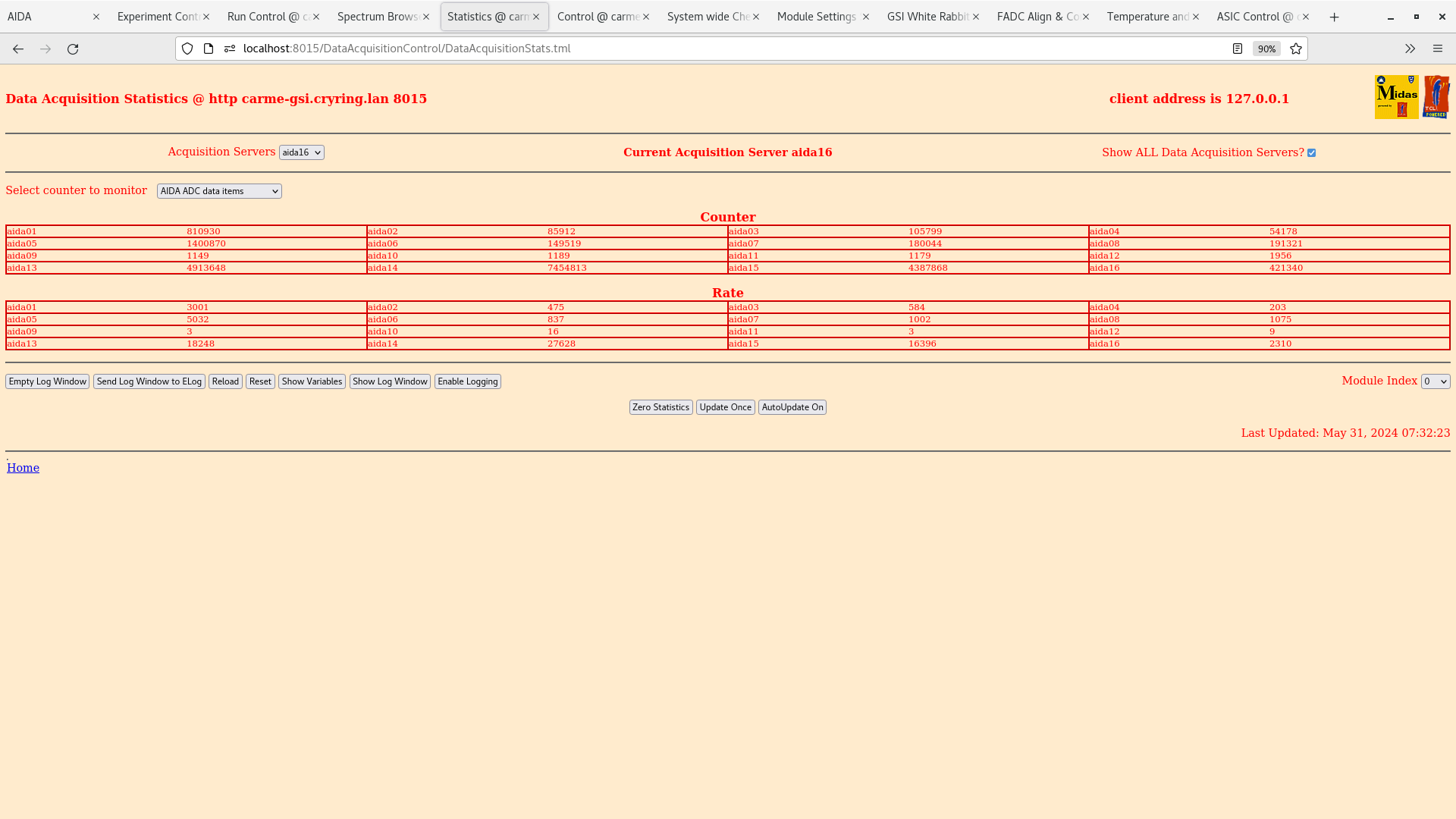

15:45

Root histograms refreshed.

Temps OK - attach

Stats OK - attach

All checks OK

Leakage OK - attach

Base Current Difference

aida01 fault 0x0 : 0x1 : 1

FPGA Timestamp error counter test result: Passed 15, Failed 1

If any of these counts are reported as in error

The ASIC readout system has detected a timeslip.

That is the timestamp read from the time FIFO is not younger than the last

|

| Attachment 1: Screenshot_from_2025-05-28_15-45-13.png

|

|

| Attachment 2: Screenshot_from_2025-05-28_15-46-07.png

|

|

| Attachment 3: Screenshot_from_2025-05-28_15-48-27.png

|

|

| Attachment 4: Screenshot_from_2025-05-28_15-48-38.png

|

|

| Attachment 5: Screenshot_from_2025-05-28_15-49-09.png

|

|

|

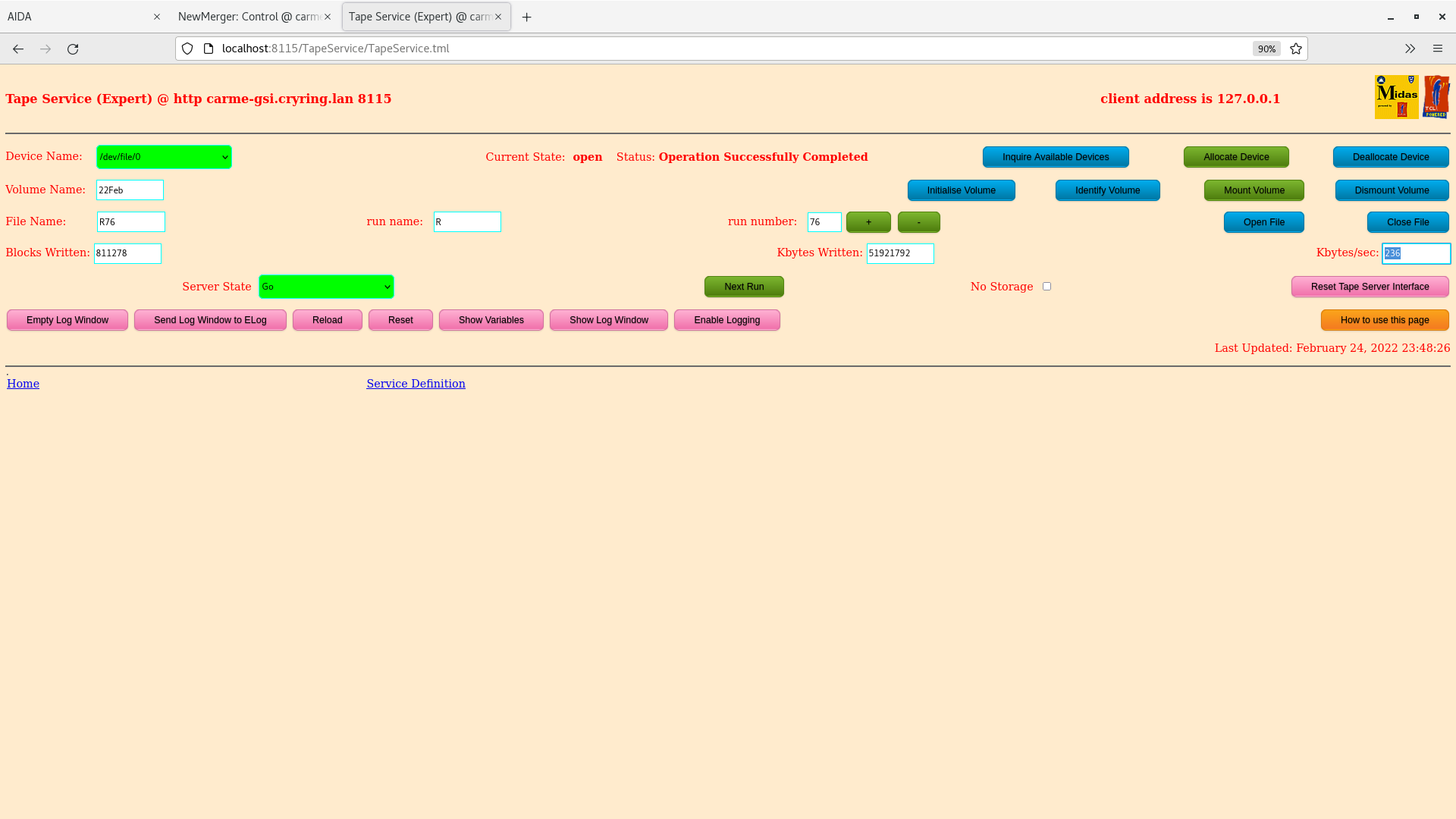

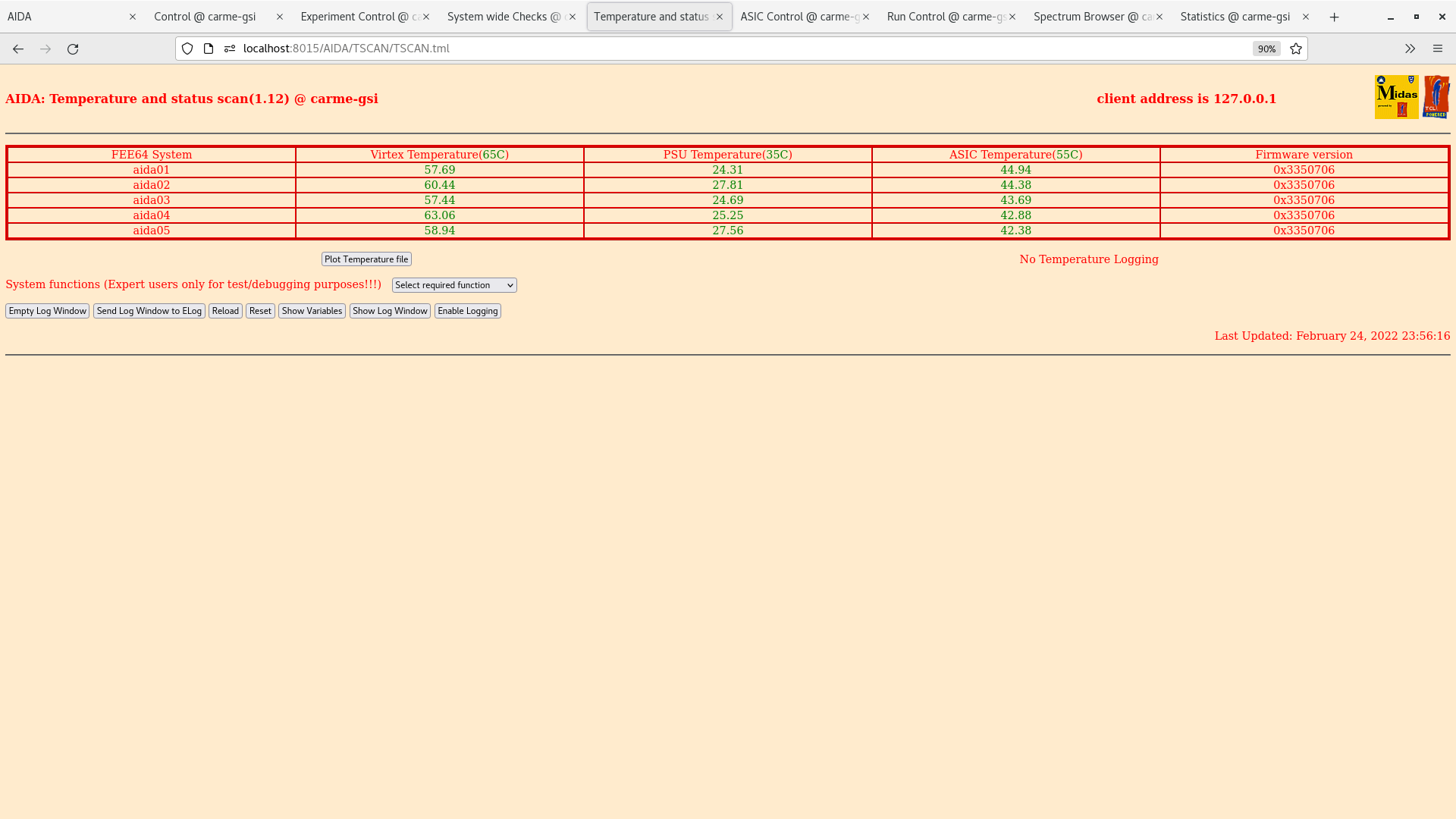

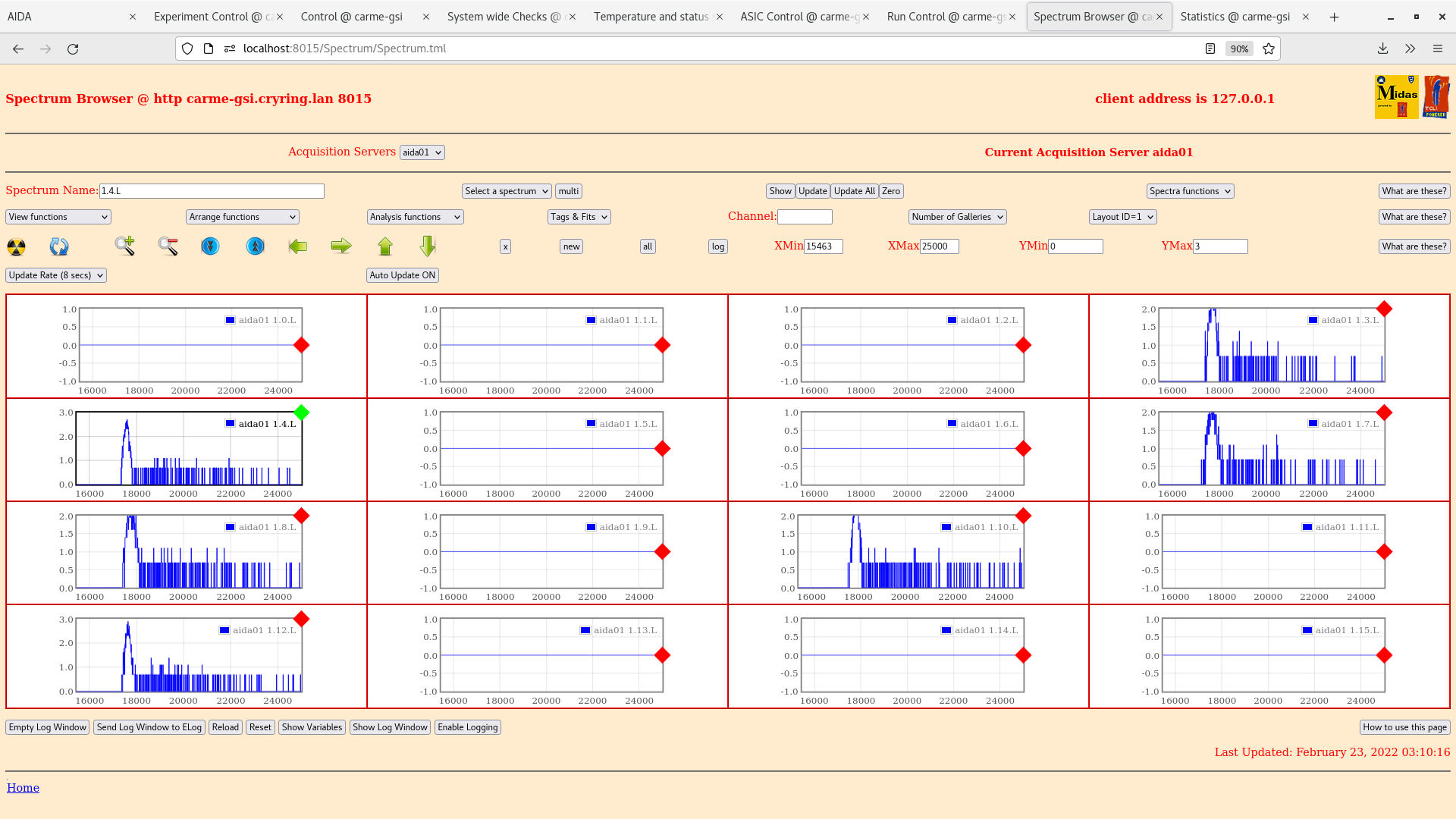

271

|

Thu Feb 24 22:45:08 2022 |

Jordan, George, Rui-Jiu Chen | check |

- Motor fully out position.

SW3

- Merger OK

- Screenshot uploaded

- Data rate : 236 kbytes/s

SW4

- current plot uploaded

SW2

- T OK

- system wide checks OK

- Check statistics tab ok

- Spectra ok

SW5

4 plots uploaded

|

| Attachment 1: Screenshot_from_2022-02-24_23-49-31.png

|

|

| Attachment 2: Screenshot_from_2022-02-24_23-54-01.png

|

|

| Attachment 3: Screenshot_from_2022-02-24_23-54-57.png

|

|

| Attachment 4: Screenshot_from_2022-02-24_23-56-46.png

|

|

| Attachment 5: Screenshot_from_2022-02-24_23-58-18.png

|

|

| Attachment 6: Screenshot_from_2022-02-24_23-59-10.png

|

|

| Attachment 7: Screenshot_from_2022-02-24_23-59-32.png

|

|

| Attachment 8: Screenshot_from_2022-02-25_00-00-48.png

|

|

| Attachment 9: Screenshot_from_2022-02-25_00-02-54.png

|

|

| Attachment 10: Screenshot_from_2022-02-25_00-04-35.png

|

|

| Attachment 11: Screenshot_from_2022-02-25_00-09-26.png

|

|

| Attachment 12: Screenshot_from_2022-02-25_00-11-10.png

|

|

| Attachment 13: Screenshot_from_2022-02-25_00-13-30.png

|

|

| Attachment 14: Screenshot_from_2022-02-25_00-14-11.png

|

|

|

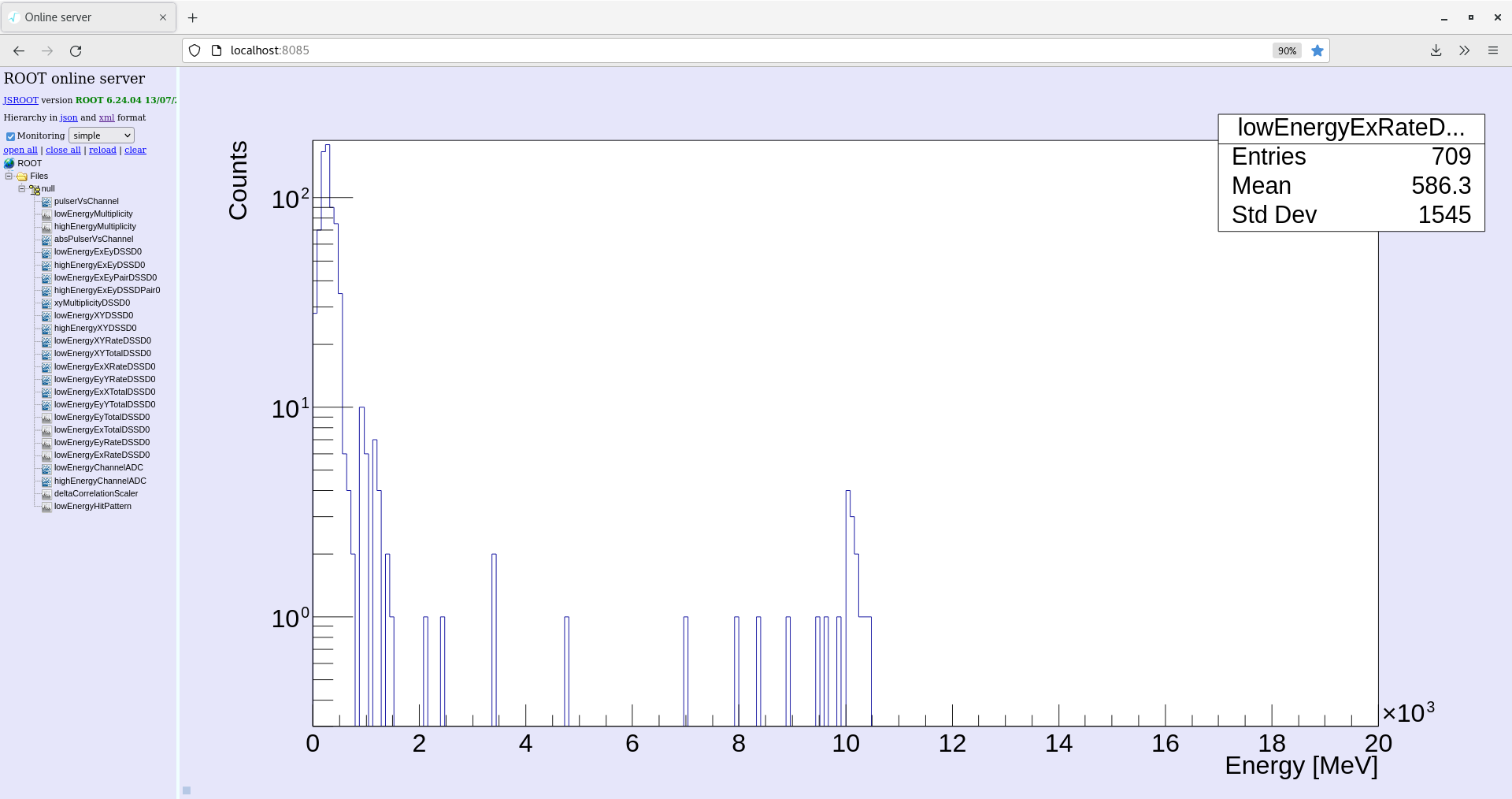

246

|

Wed Feb 23 00:54:17 2022 |

Jordan, George | Current status |

02:04

Temps OK

Data Rate - ~1.1Mb/s

System Check OK

White rabbit diff - 83

Leakage Current - ~3.475uA

YR09 AVG: 7.51E-10mbar

YR10AVG: 1.21E-10mbar

YR07AVG: 1.67E-9mbar

YR08AVG: 1.91E-9mbar |

| Attachment 1: 2022-02-23_02-02-53extotal.png

|

|

| Attachment 2: 2022-02-23_02-02-00lowEnergyXYtot.png

|

|

| Attachment 3: 2022-02-23_01-59-14exRate.png

|

|

|

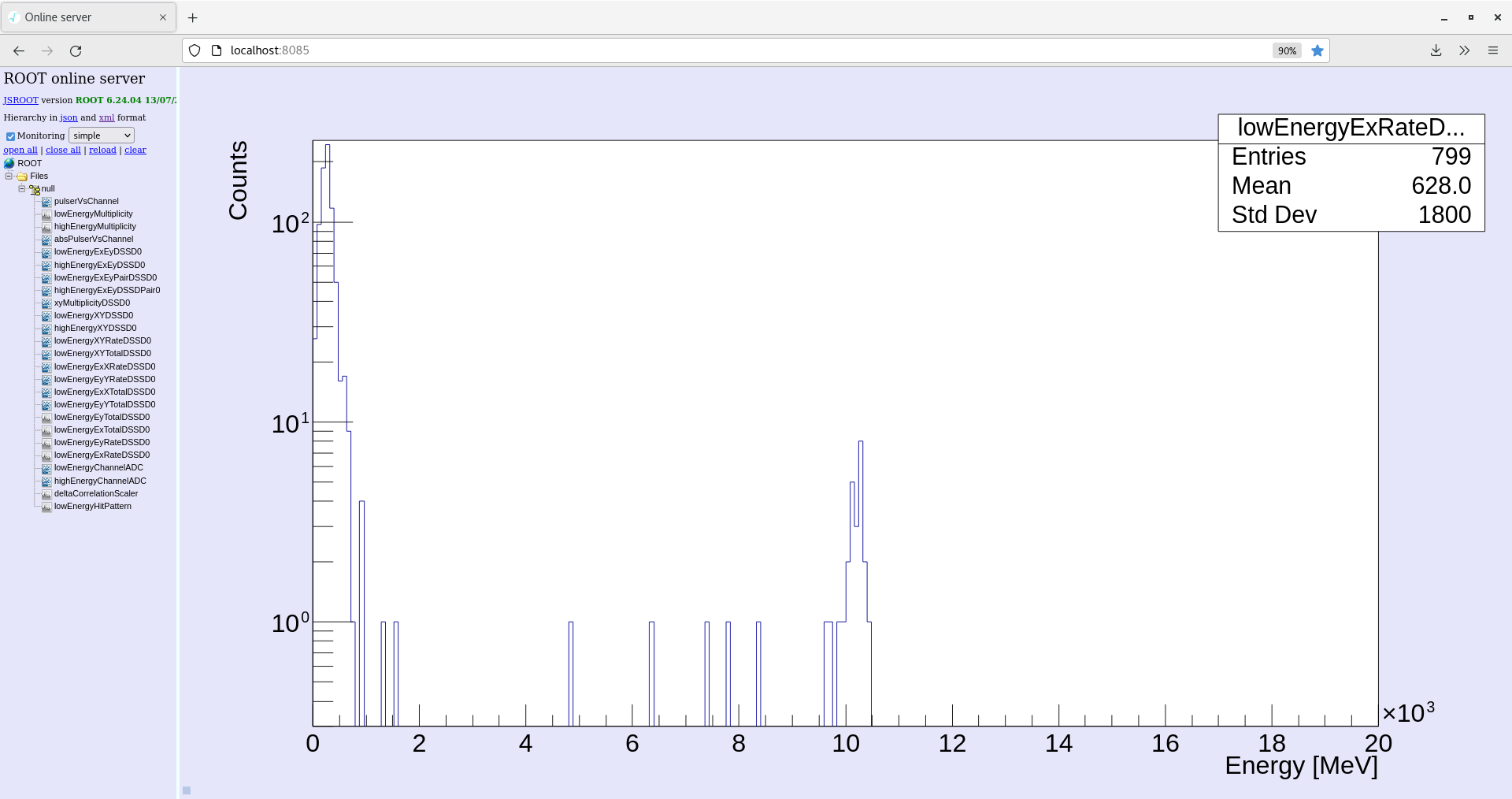

247

|

Wed Feb 23 01:56:59 2022 |

Jordan, George | Current status |

02:56

Temps OK

write speed ~1.2Mb/s

System check OK

White rabbit diff - 89

Leakage Current ~3.472uA

Pressures stable

Beam intensity ~3.0e7

cryostat setpoint 129.2K (unchanged)

AVG Pressures:

YR09: 8.48e-10mbar

YR10: 1.28e-10mbar

YR07: 1.71e-10mbar

YR08: 2.1e-9mbar

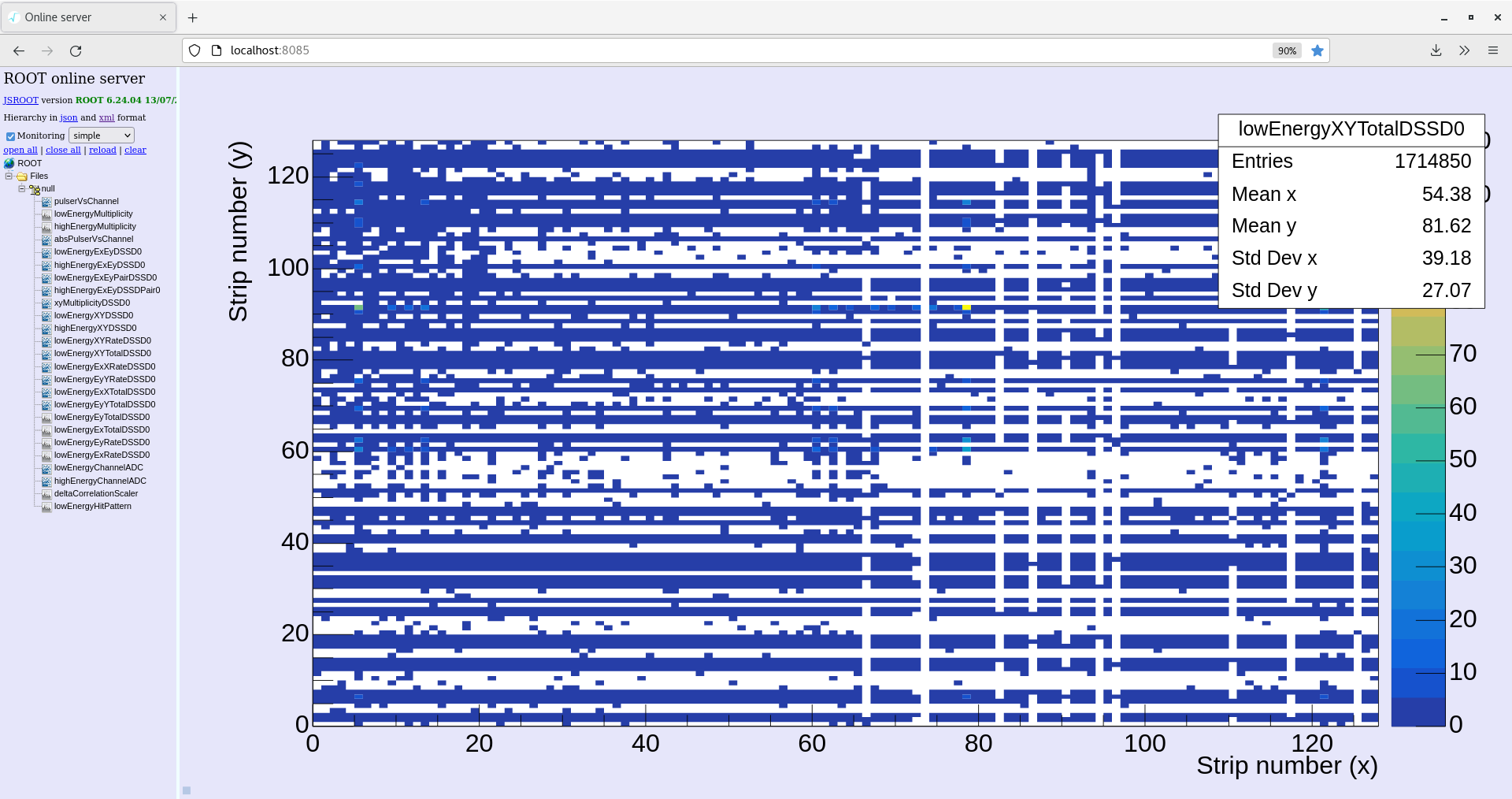

Aida 1 1*L plot attached. Some channels appear missing. Width of rutherford peaks ~280-300 channels. |

| Attachment 1: 2022-02-23_03-01-54xyTotal.png

|

|

| Attachment 2: 2022-02-23_03-00-54exTotal.png

|

|

| Attachment 3: 2022-02-23_03-00-11exRate.png

|

|

| Attachment 4: 2022-02-23_03-10-45-aida1-1*L.png

|

|

|

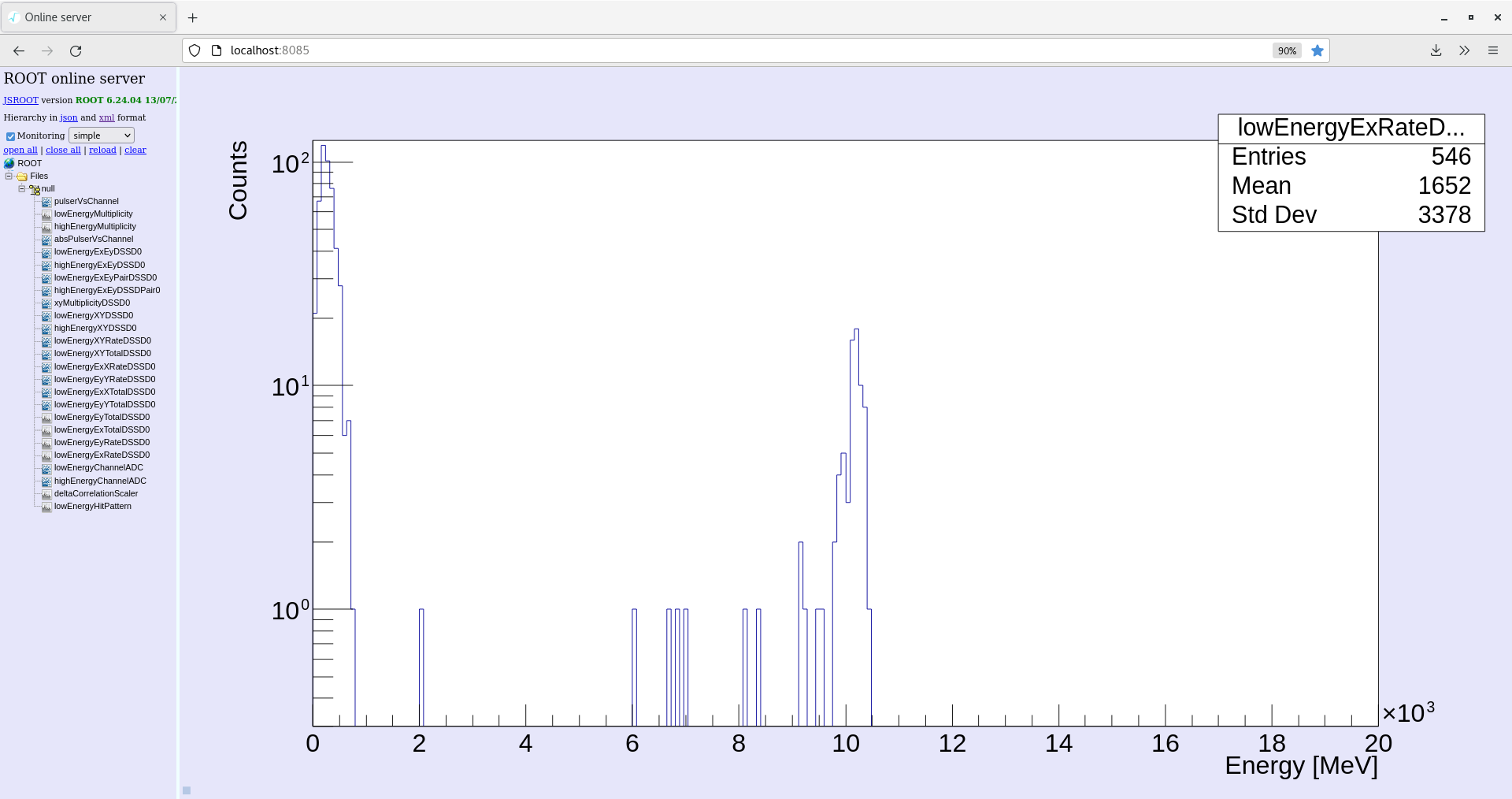

248

|

Wed Feb 23 02:52:09 2022 |

Jordan, George | Current status |

03:52

Temps OK

System Checks OK

White rabbit diff: 90

Data rate: 1.2Mb/s

Leakage Current: 3.474uA

Cryo temp = 129.2K (unchanged)

Pressures stable

AVG Pressures:

YR07: 1.74e-10mbar

YR08: 2.15e-9mbar

YR09: 8.61e-10mbar

YR10: 1.32e-10mbar |

| Attachment 1: 2022-02-23_03-58-03xyTotal.png

|

|

| Attachment 2: 2022-02-23_03-57-34exTotal.png

|

|

| Attachment 3: 2022-02-23_03-56-52exRate.png

|

|

|

249

|

Wed Feb 23 03:52:13 2022 |

Jordan, George | Current status |

04:52

Pressure seems to be climbing a little but still stable (just peaked at end of check)

Temps OK

Write Speed: ~1.0Mb/s

System Checks OK

White Rabbit fail diff: 90

Leakage Current: 3.47uA

Cryo Temp: 129.2K (unchanged)

AVG Pressures:

YR07: 1.79e-10mbar

YR08: 2.3e-9mbar

YR09: 9.46e-10mbar

YR10: 1.41e10mbar

Avg pressures plots for last hour and last 6 hours attached. |

| Attachment 1: 2022-02-23_04-58-19-XYtotal.png

|

|

| Attachment 2: 2022-02-23_04-57-17-Ex-total-hist.png

|

|

| Attachment 3: 2022-02-23_04-56-36-Ex-rate-hist.png

|

|

| Attachment 4: pressures-1hour.jpg

|

|

| Attachment 5: pressure-6hours.jpg

|

|

|

250

|

Wed Feb 23 04:55:48 2022 |

Jordan, George | Current status |

05:55

Temps OK

System Check OK

White Rabbit fail diff: 90

Write Speed: ~1.0Mb/s

Leakage Current: ~3.47uA

Cryo Temp = 129.2K setpoint (unchanged)

Pressures stable

AVG Pressures:

YR07: 1.79e-10mbar

YR08: 2.21e-9mbar

YR09: 8.64e-10mbar

YR10: 1.36e-10mbar |

| Attachment 1: 2022-02-23_06-00-29xyTotal.png

|

|

| Attachment 2: 2022-02-23_05-59-36exRate.png

|

|

| Attachment 3: 2022-02-23_05-59-05exTotal.png

|

|

|

251

|

Wed Feb 23 06:00:25 2022 |

Jordan, George | Current status |

07:00

Pressure Stable

Temps OK

System Check OK

White Rabbit fail diff: 90

Write speed: ~1Mb/s

Leakage Current: 3.47uA

Cryo Temp Setpoint: 129.2K (unchanged)

AVG Pressures:

YR07: 1.66e-10mbar

YR08: 1.93e-9mbar

YR09: 7.63e-10mbar

YR10: 1.26e-10mbar |

| Attachment 1: 2022-02-23_07-06-36exRate.png

|

|

| Attachment 2: 2022-02-23_07-06-11exTotal.png

|

|

| Attachment 3: 2022-02-23_07-05-42xyTotal.png

|

|

|

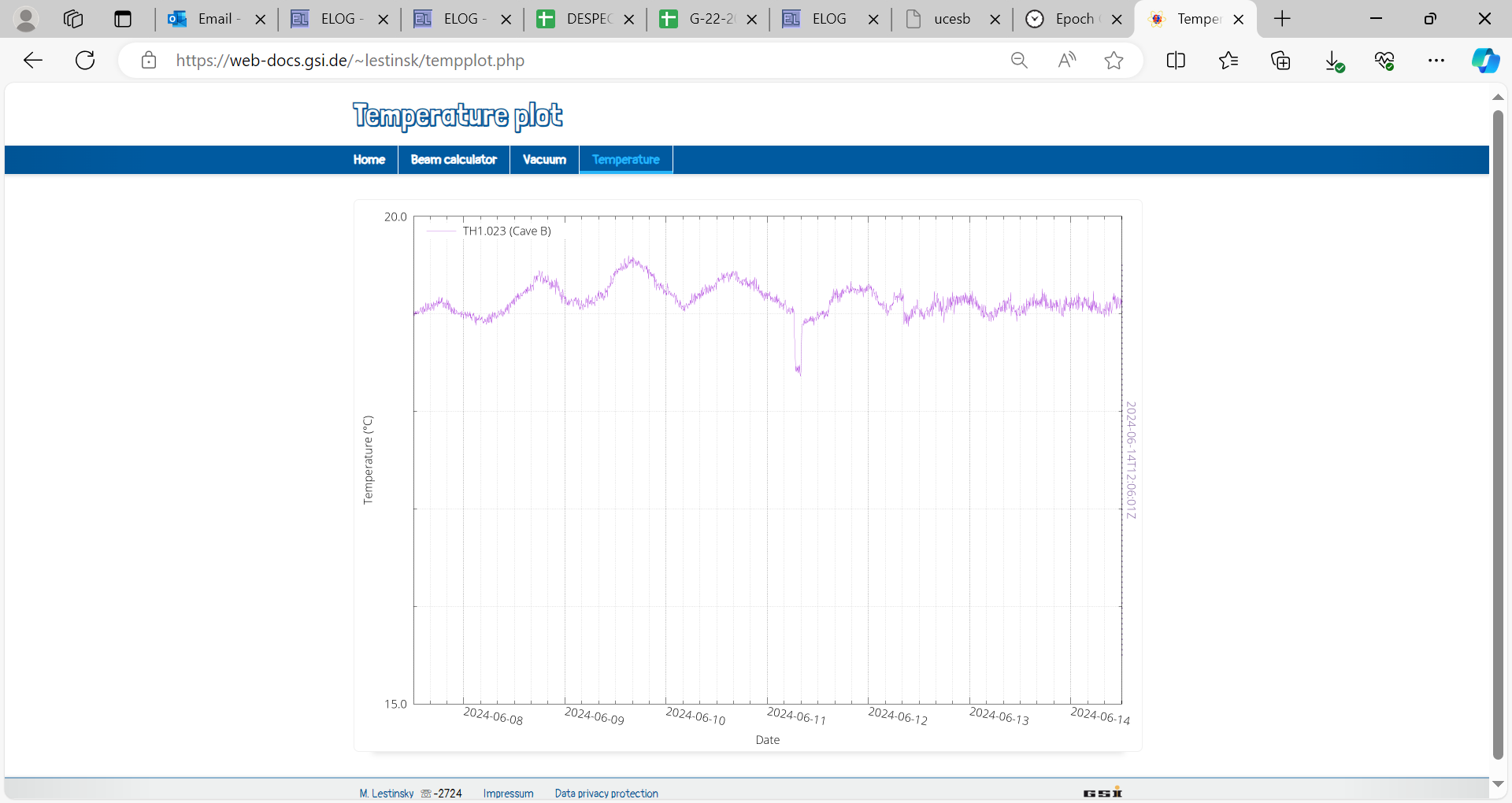

628

|

Fri Jun 14 10:21:24 2024 |

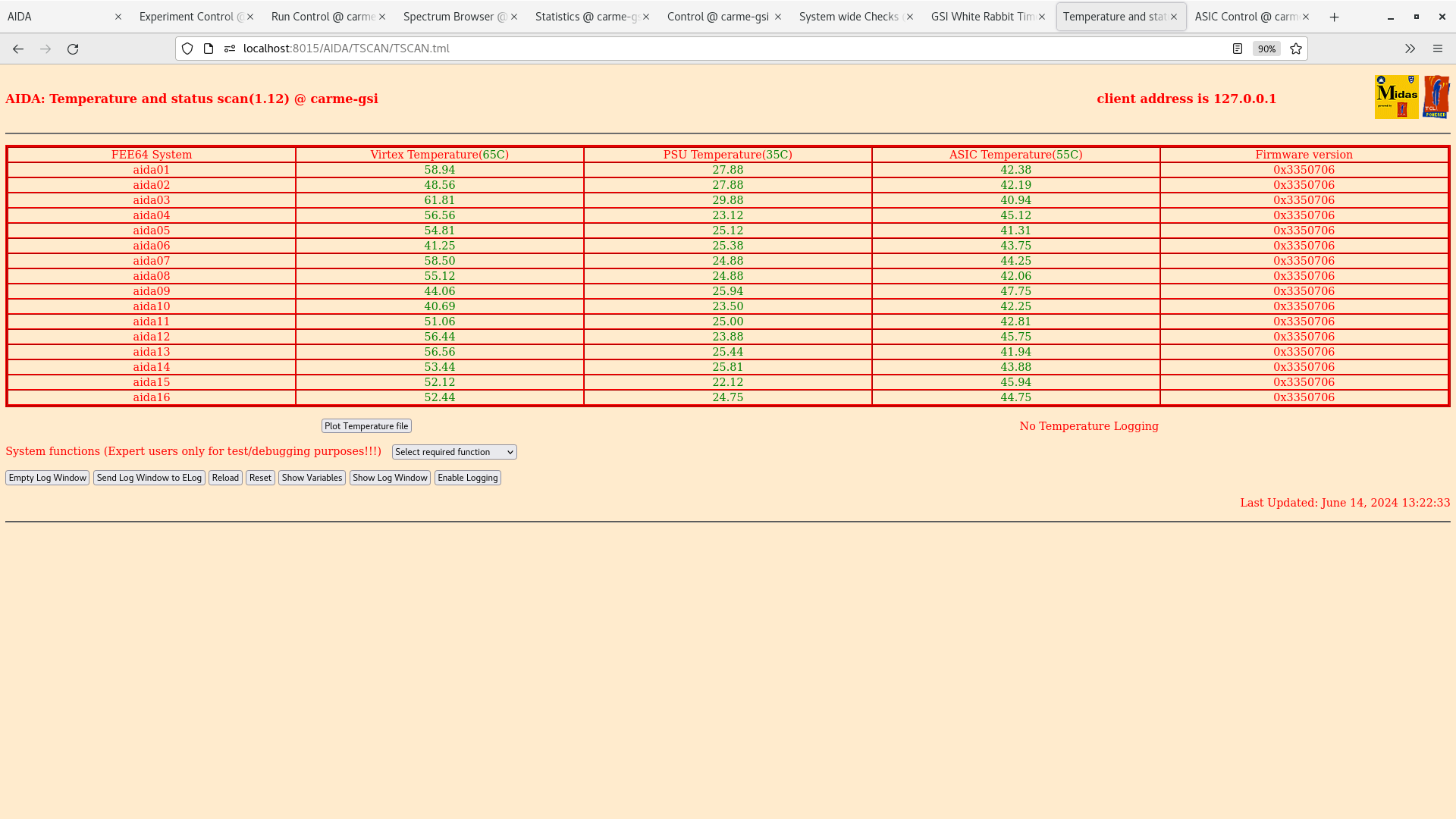

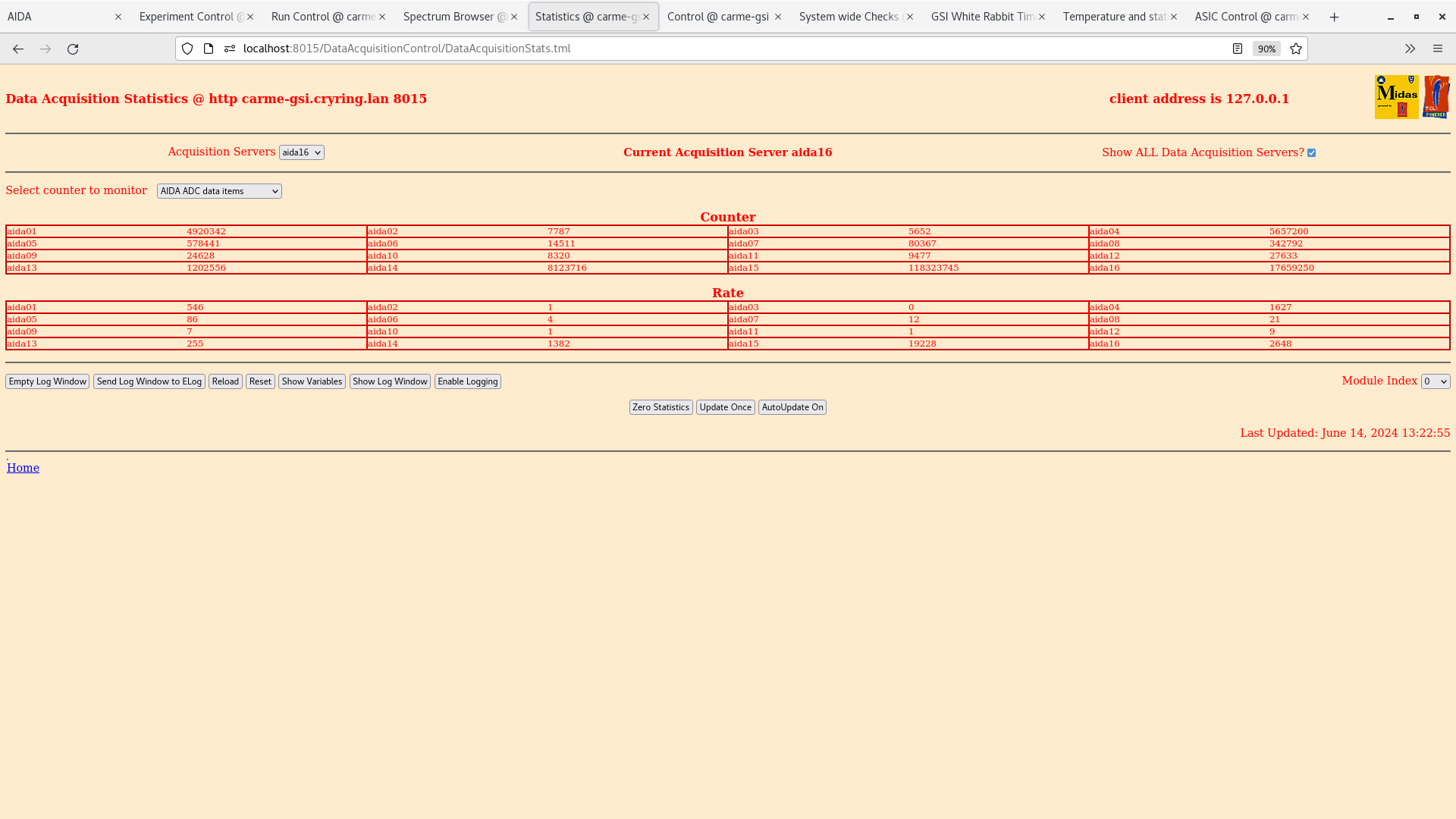

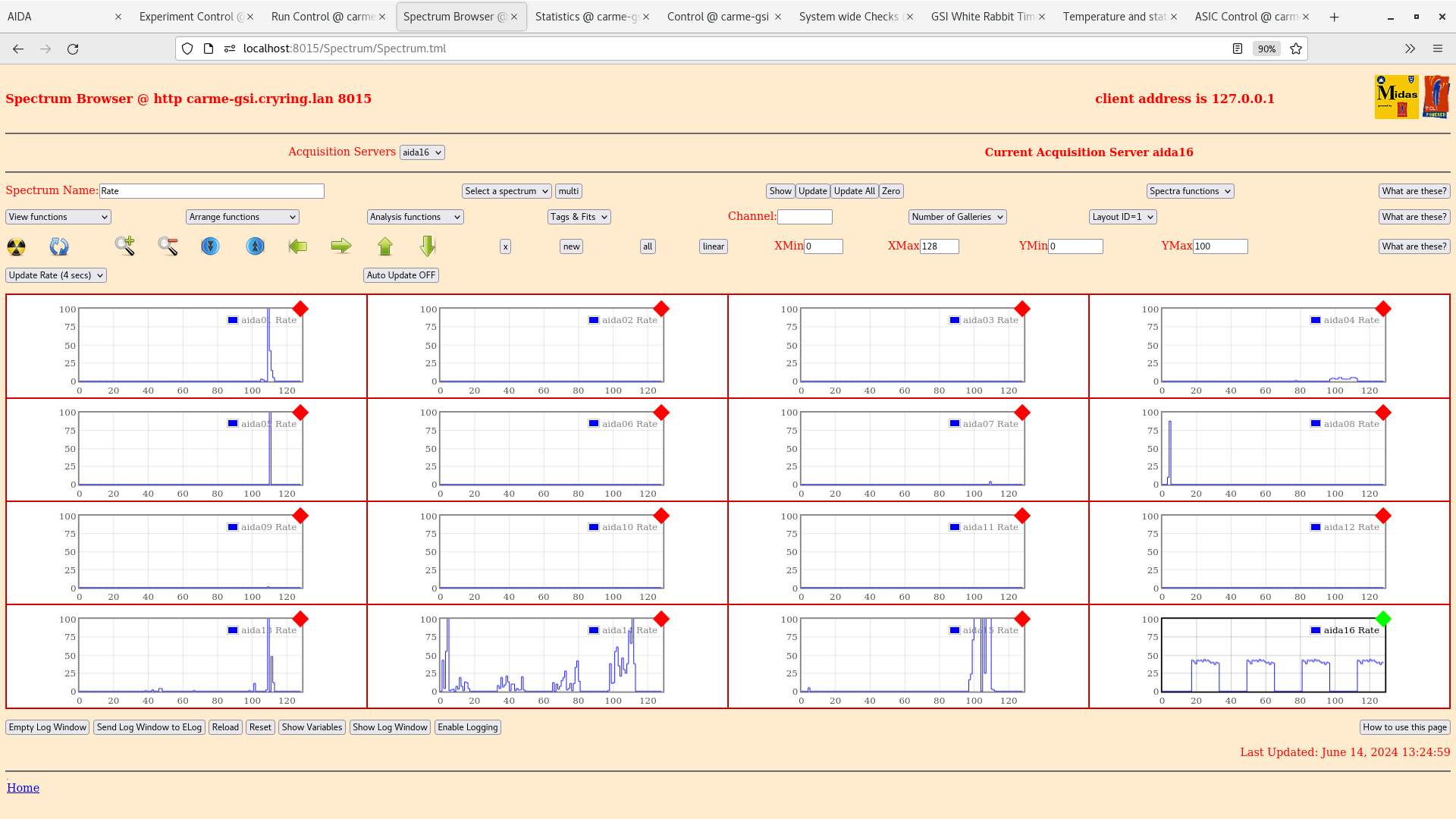

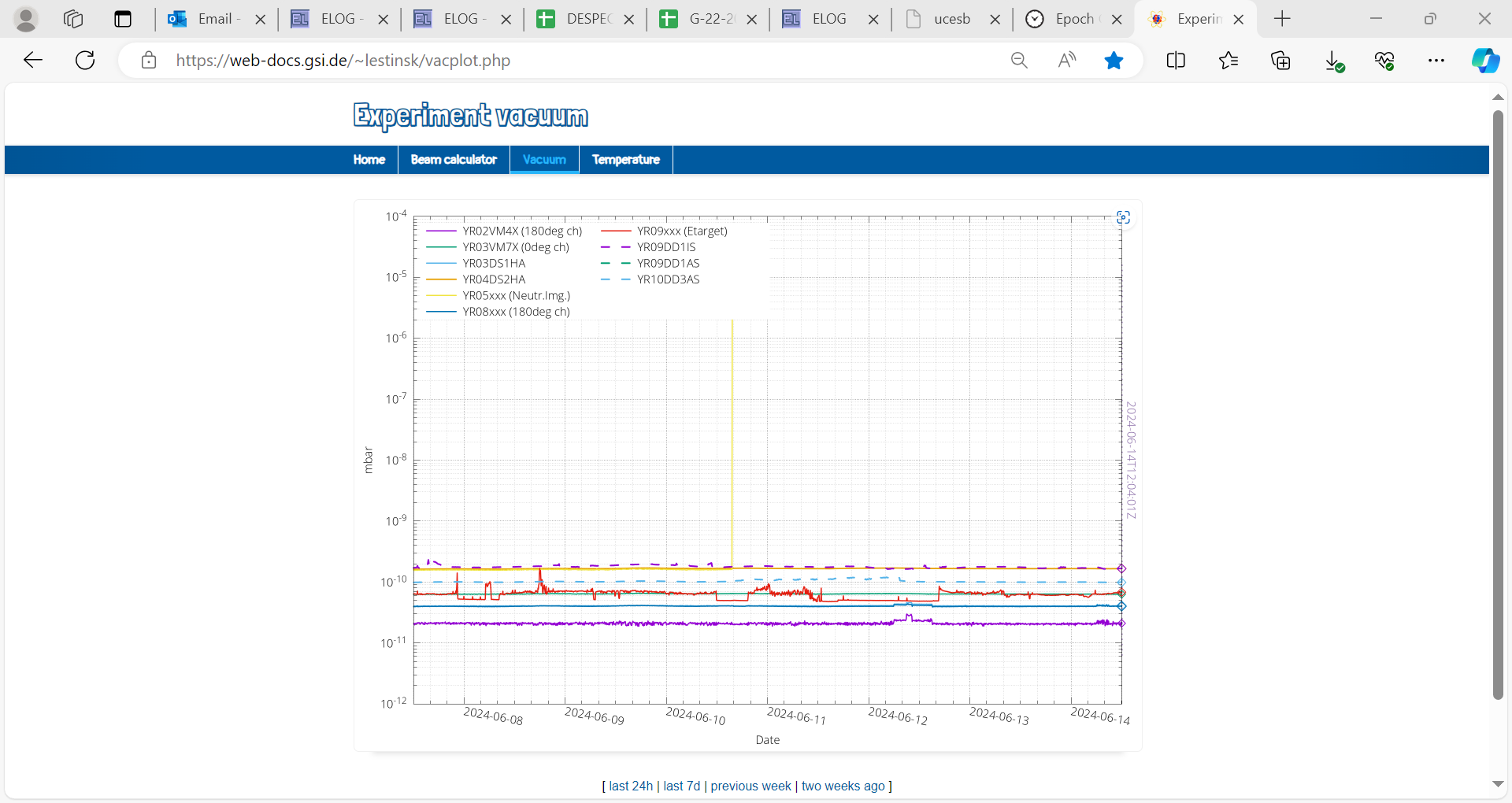

JS, TD | Run 68 |

Frank has been tuning the beam since 08:00

detectors moved fully out

11:20

New run (R68) started at 11:20. Put into no storage mode as rates are high during beam tuning. Cut off the end of last nights run when analysing

System checks OK

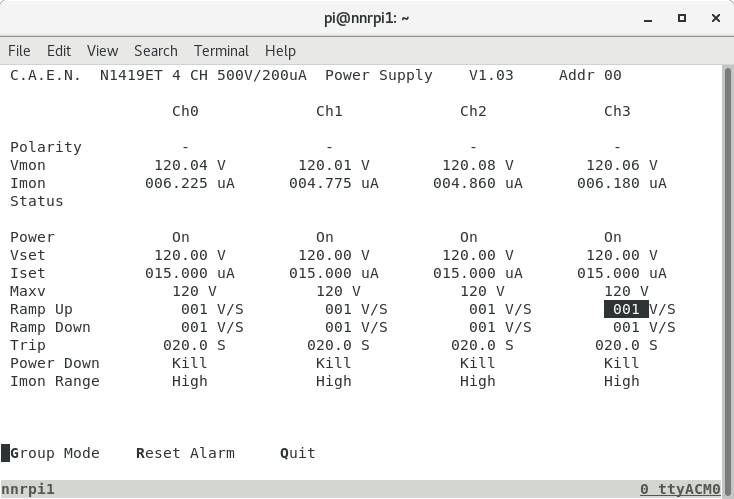

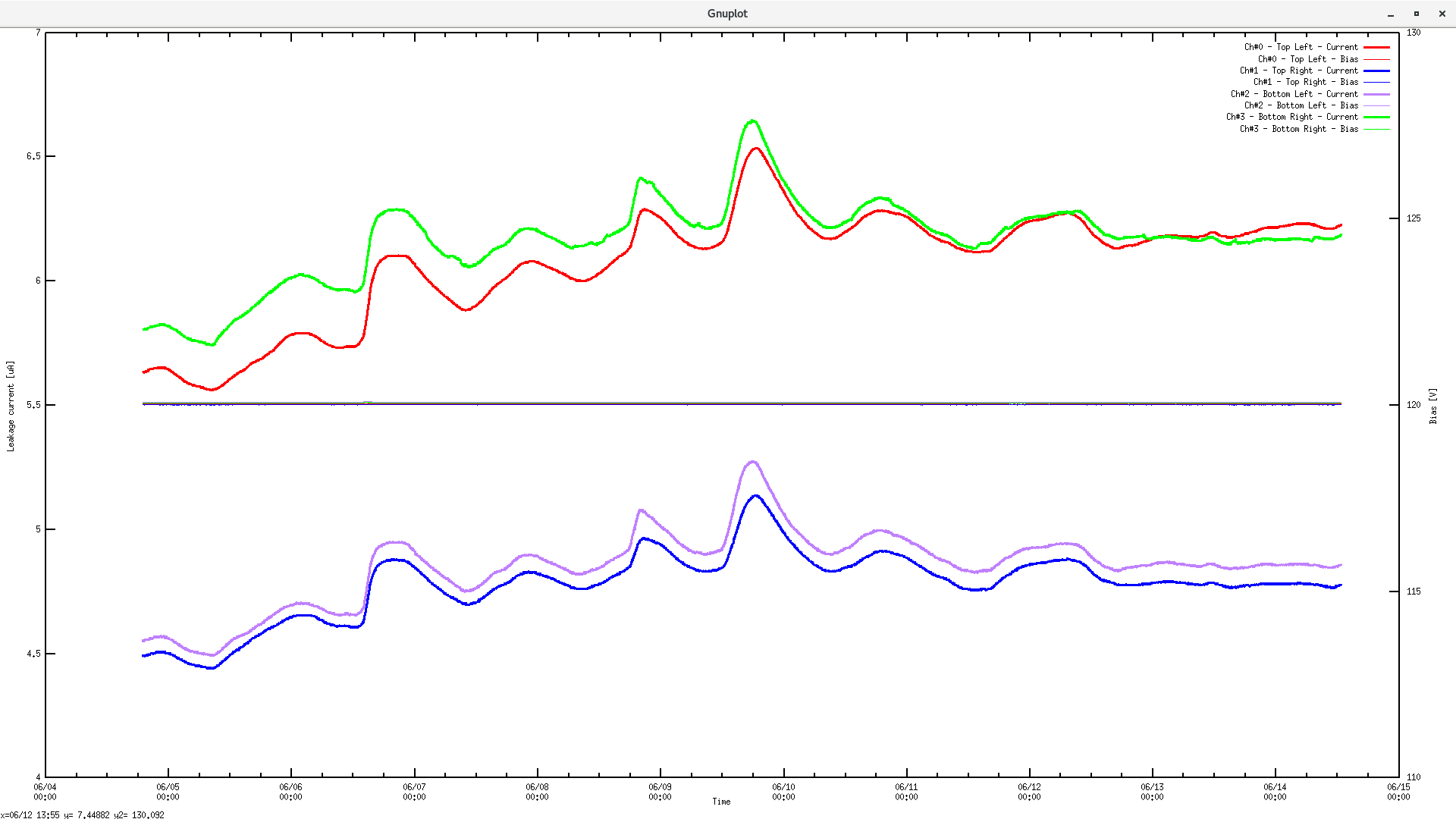

13.20 DSSSD bias & leakage current OK - attachment 1

FEE64 temperatures OK - attachment 2

ADC data item stats - attachment 3

per FEE64 1.8.W spectra - attachments 4-5

per FEE64 Rate spectra - attachment 6

aida16 producing HEC data - Chck ASIC load to fix

TapeServer - no storage mode

13.35 aida01-aida04 c. 250k ADC data items/s - will await completion of current beam/target scan to fix by cycing Left DSSSD motion

14.00 CB cycles Left DSSSD motion to fix aida01-aida04 rate issue

CRYRING vacuum & hall temprature - attachments 7-8

14.28 New run data file G22-201/R69

Beam/target overlap optimised - details to follow |

| Attachment 1: Screenshot_from_2024-06-14_13-22-13.png

|

|

| Attachment 2: Screenshot_from_2024-06-14_13-22-18.png

|

|

| Attachment 3: Screenshot_from_2024-06-14_13-22-37.png

|

|

| Attachment 4: Screenshot_from_2024-06-14_13-22-58.png

|

|

| Attachment 5: Screenshot_from_2024-06-14_13-23-30.png

|

|

| Attachment 6: Screenshot_from_2024-06-14_13-24-08.png

|

|

| Attachment 7: Screenshot_from_2024-06-14_13-25-02.png

|

|

| Attachment 8: vac.PNG

|

|

| Attachment 9: temp.PNG

|

|

|

590

|

Wed Jun 5 08:34:04 2024 |

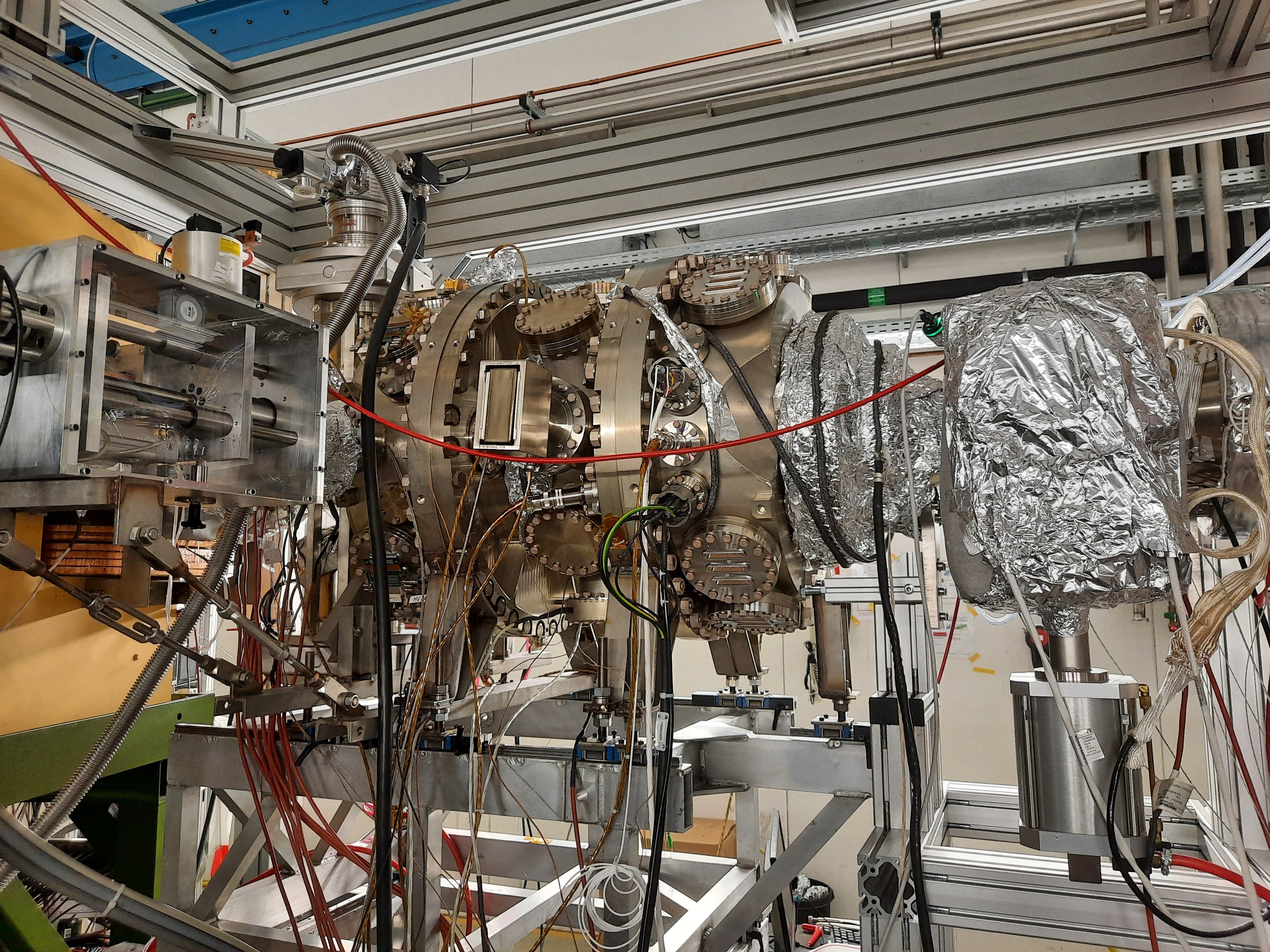

JM. DB, PC | Target nozzle change |

09:30

Target density has not improved despite efforts last night. Mid 10 - low 11 density range. We will try to change the nozzle.

Target nozzle moved to the out position.

HKR allowed access to the cave to turn the compressor off. Target nozzle now warming up.

Internal cave work on changing nozzle expected to start at ~11. In the meantime we will let Wolfgang experiment with the beam settings to try to improve injection intensity.

Detectors have been moved out to fully out position

Run 35 started. |

|

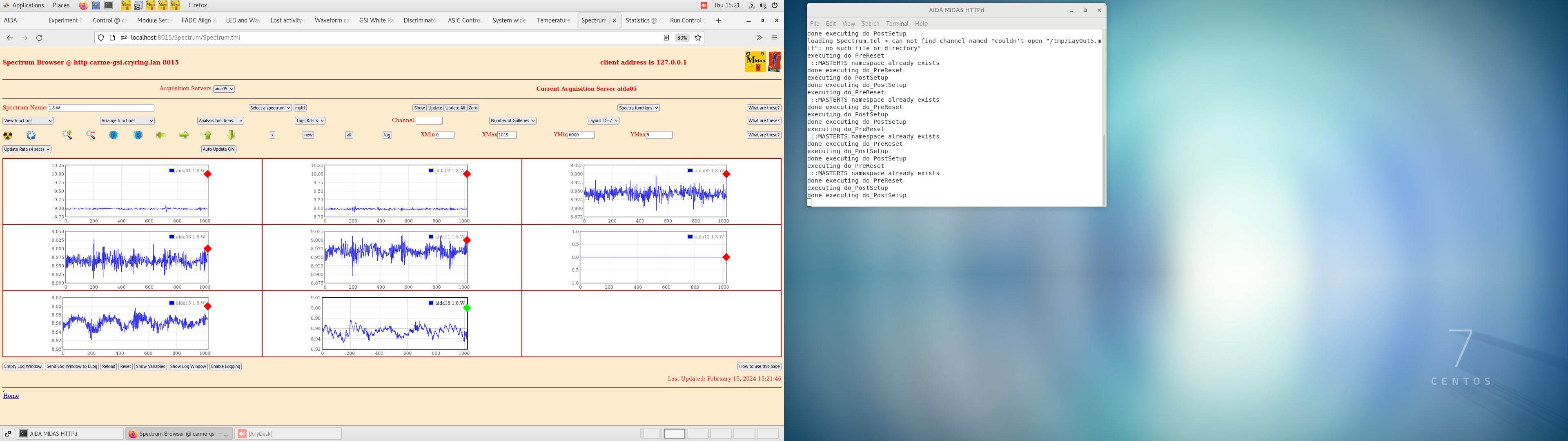

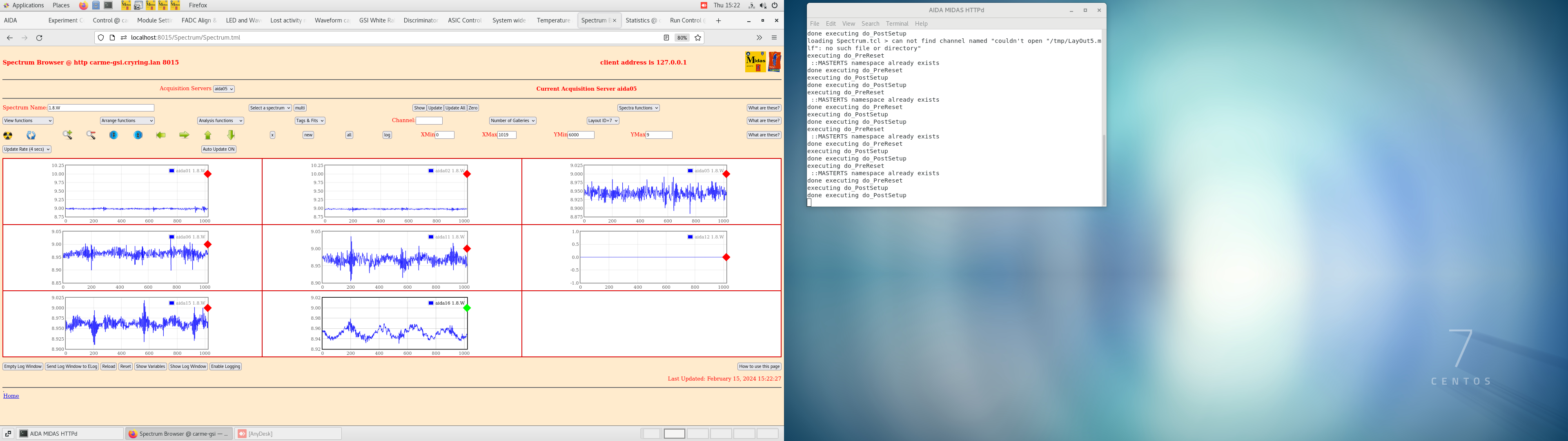

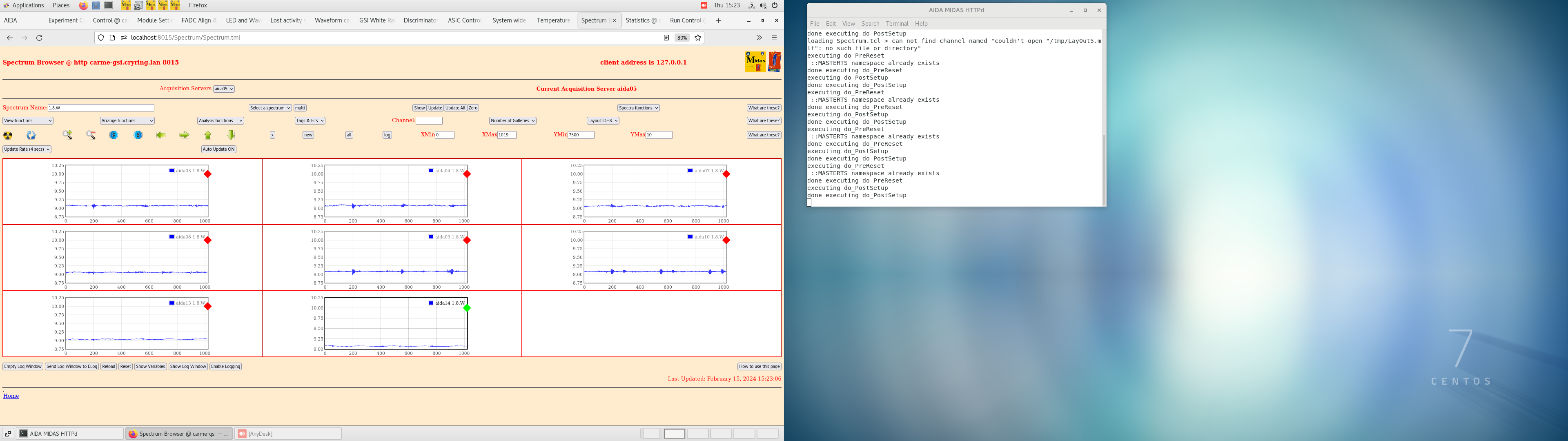

516

|

Thu Feb 15 12:40:52 2024 |

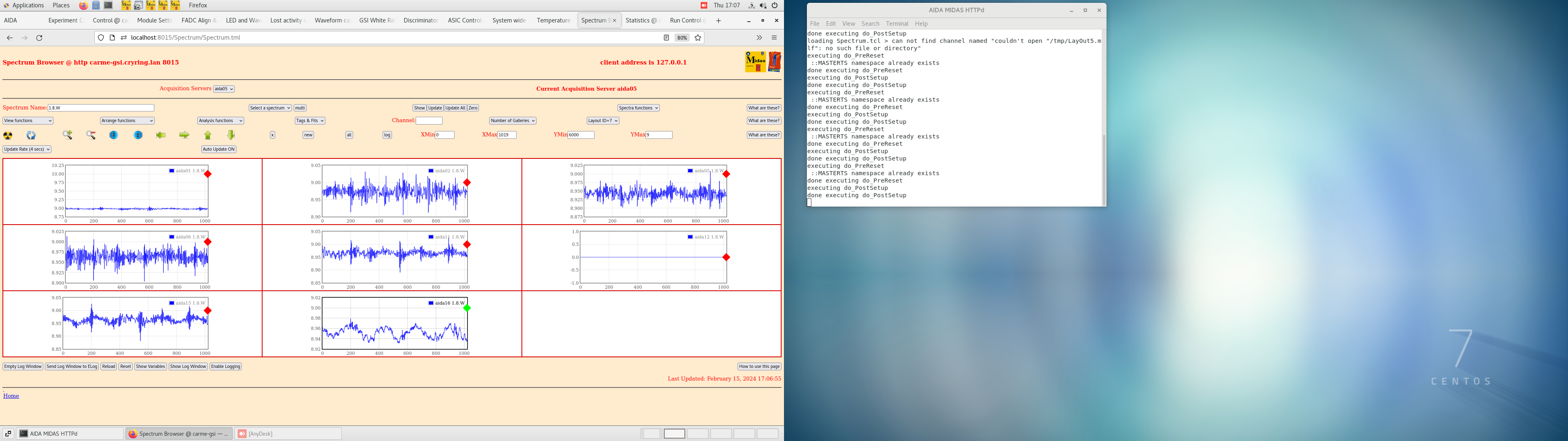

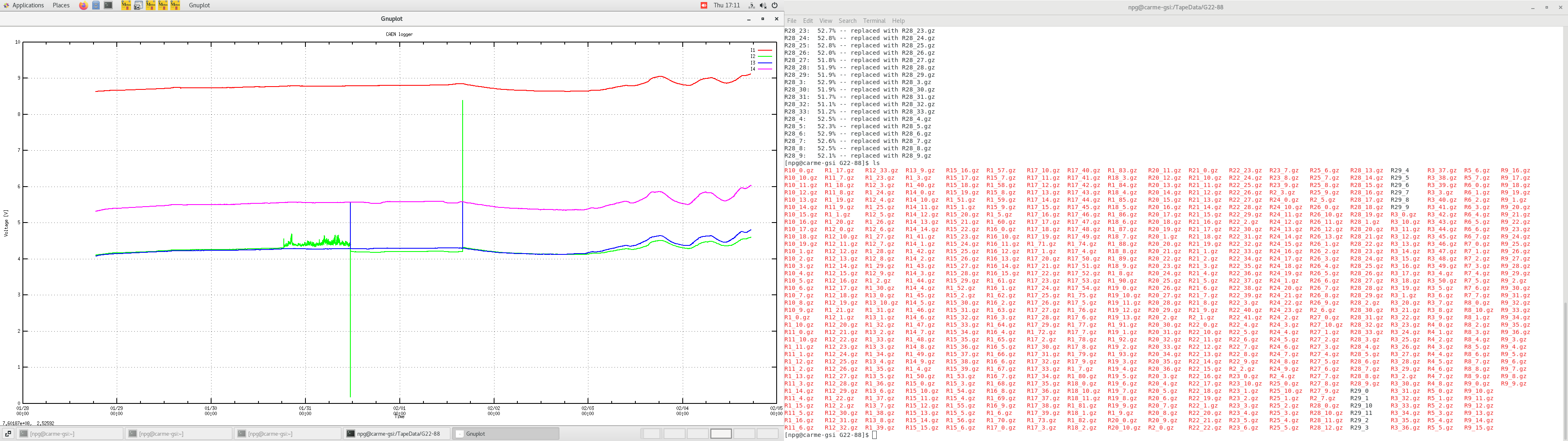

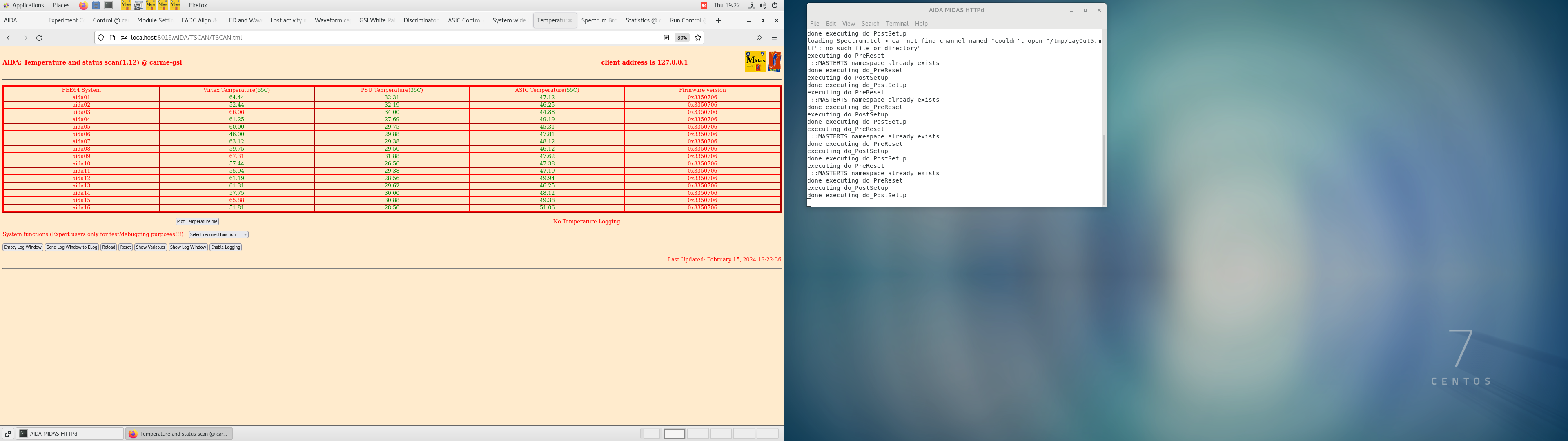

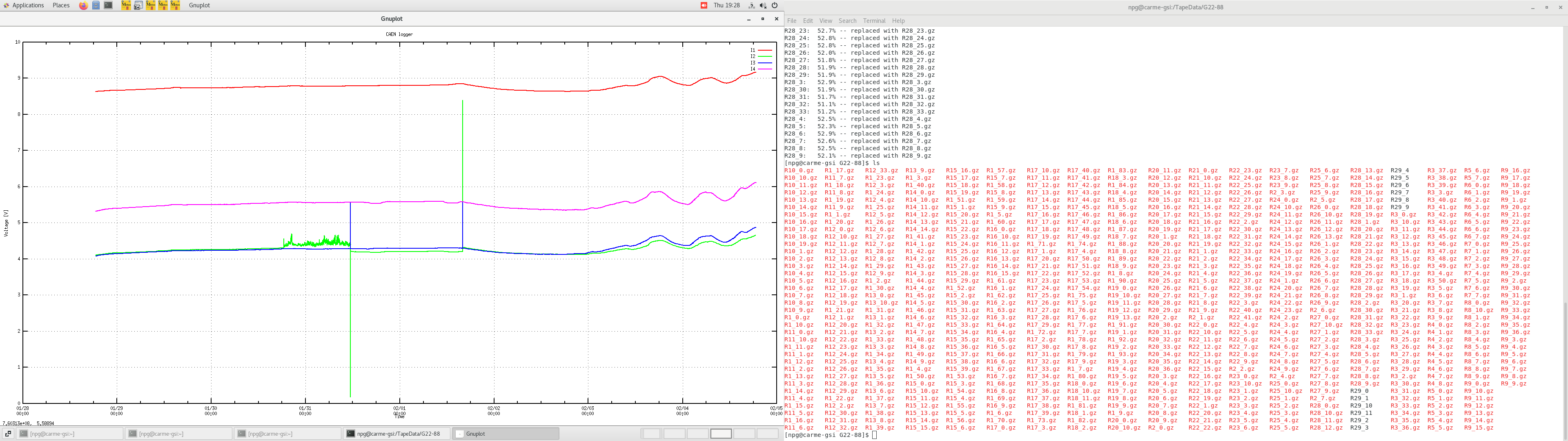

JM. CB, AR, AB | Run30 - uncooled beam on target |

Run started 13:40

Target density 4.3e11, Beam injection is ~1e7, Pressure in the ring is ~1e-10 mbar.

Detectors have been moved IN with servo motors only (left arm pot = 36.5 mm, right arm pot =37.7 mm

Time between injections is 12 seconds. Beam is in the ring for 3 seconds of the cycle.

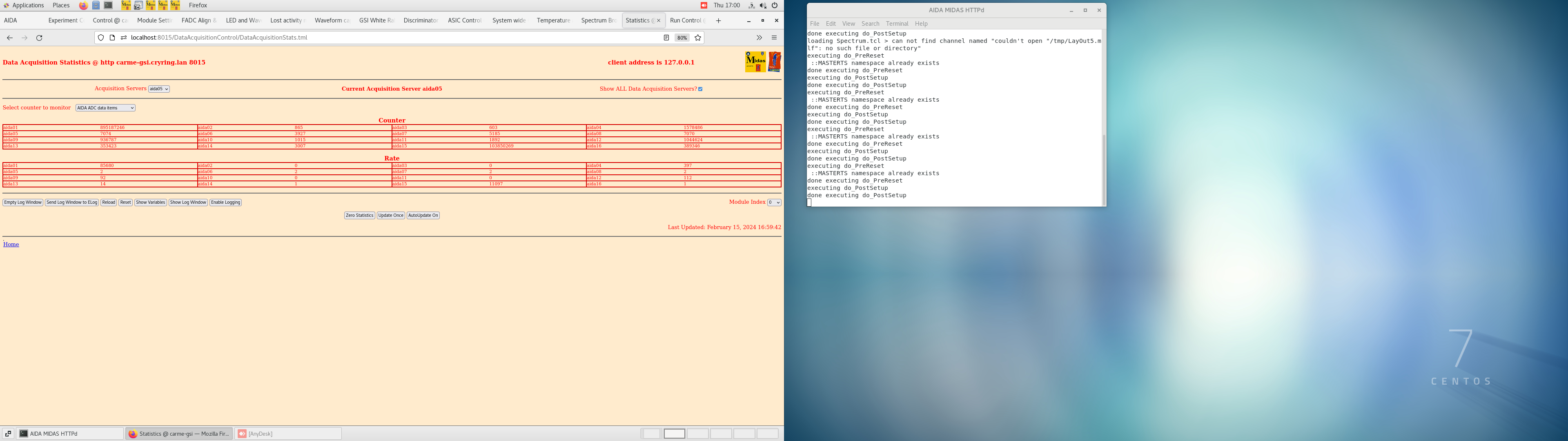

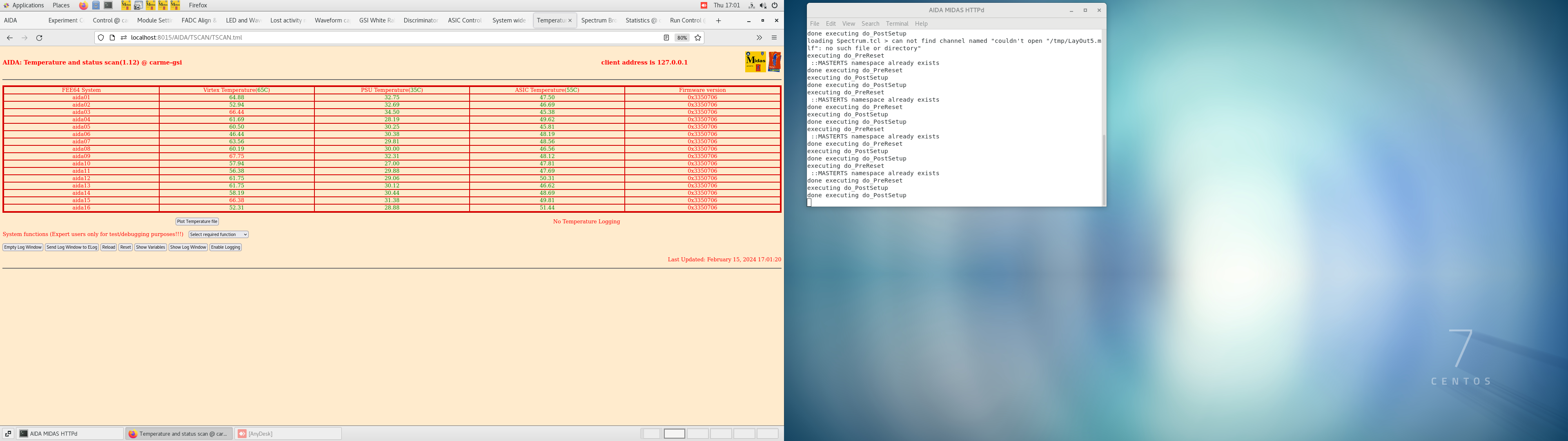

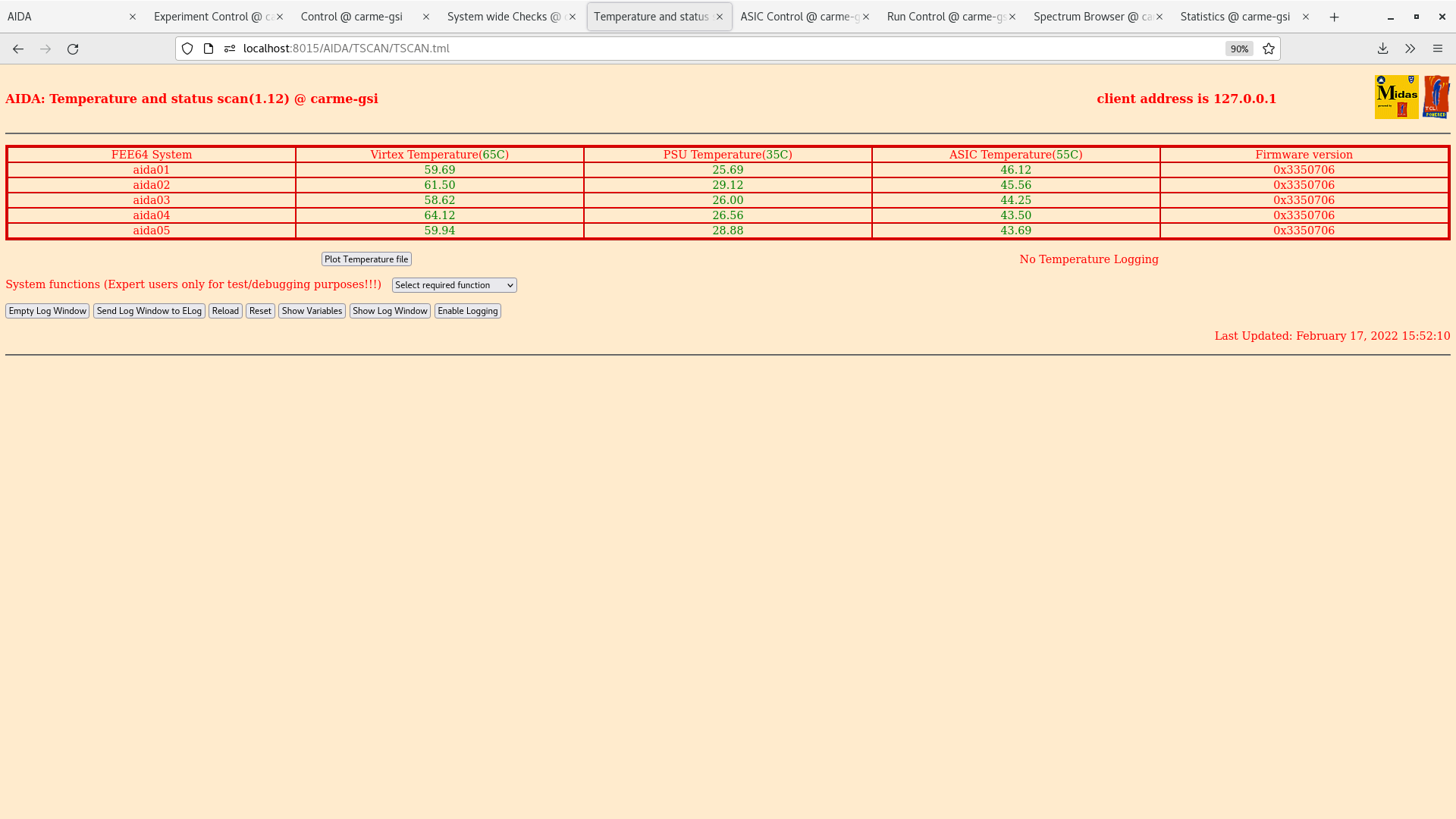

System wide checks OK

Temperatures OK

Leakage current plot attached -> temperature fluctuations (attachment 1)

ADC data items stats (attachment 2)

Merger and tape server OK

All histograms and statistics zero'd

14:17

Cave access required. No beam

15:24

No beam. System wide checks ok. Merger ok.

Attatchment 3: stats

Attatchment 4: Temperatures generally okay, 3 were red before reload, one red after reload.

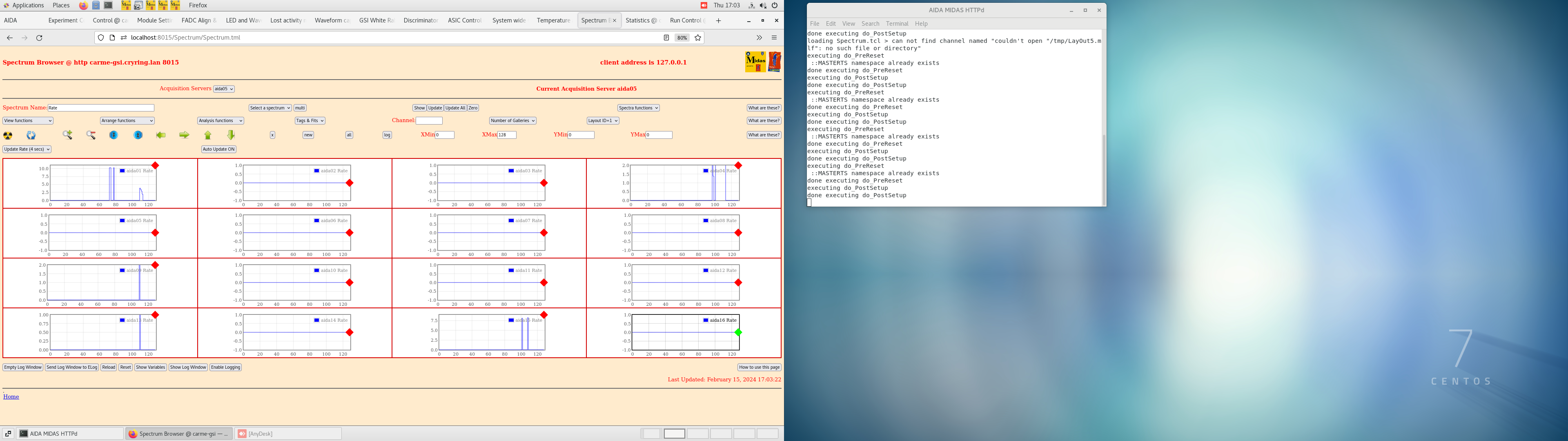

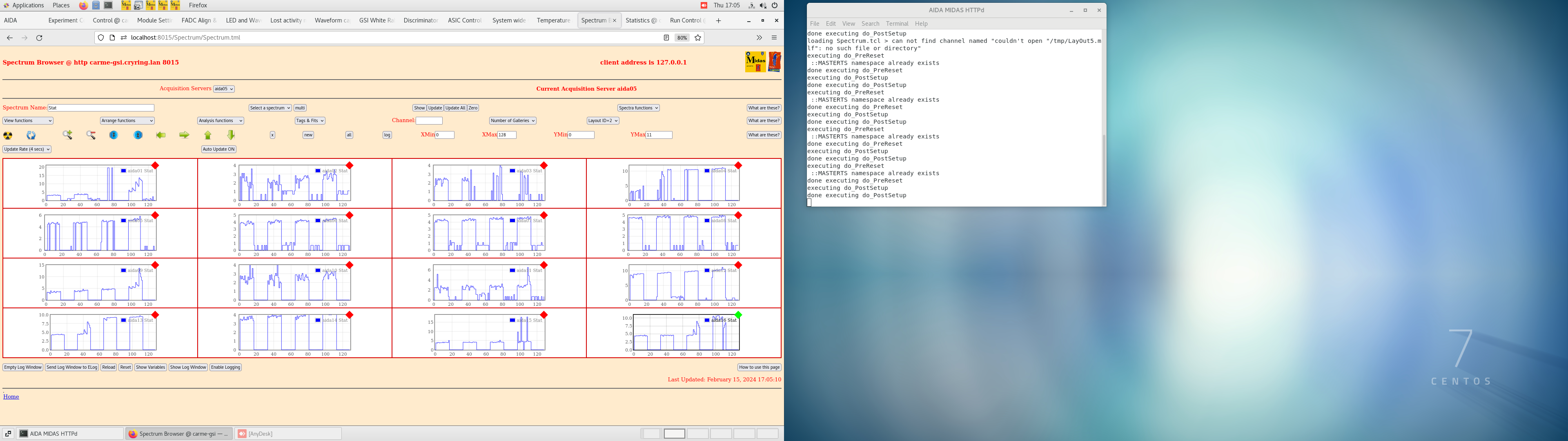

Attatchment 5-8: Waveforms. Layout 7 and 8 look different from yesterday, consistnely different after several reloads.

Attatchment 9: Leakage current

Attatchment 10: LOWENERGYEXEY PLOTS

17:12

Tunning beam. System wide checks ok. Merger ok.

Attatchment 11: stats

Attatchment 12: Temperatures generally okay, 3 were red reloaed and stayed red but not so high.

Attatchment 13-16: Waveforms. Were the same as previous check.

Attatchment 17: Leakage current. They are tunning the beam so its a little bit changed.

19:28

Still hvae unstable noncooled beam, currently being worked on.

Tunning beam. System wide checks ok. Merger ok.

Attatchment 18: Temperatures generally okay, 3 were red reloaed and stayed red but not so high and were slighlty dicrease.

Attatchment 19-22: Waveforms. Were the same as previous check.

Attatchment 23: Leakage current. Slowly increasing from last check in, highest its been but conditions are not great at the moment.

21:10

We did not have any update about the beam. They still work on it.

Tunning beam. System wide checks ok. Merger ok. Stats were ok.

Attatchment 24: Temperatures generally okay, Same 3 were red and they increased a little bit. Nothing too concerning.

Attatchment 25-28: Waveforms. Were the same as previous check.

Attatchment 29: Leakage current. Contining to increase by small amount from last check.

|

| Attachment 1: Screenshot_from_2024-02-15_13-45-42.png

|

|

| Attachment 2: Screenshot_from_2024-02-15_13-48-57.png

|

|

| Attachment 3: Screenshot_from_2024-02-15_15-19-31.png

|

|

| Attachment 4: Screenshot_from_2024-02-15_15-19-55.png

|

|

| Attachment 5: Screenshot_from_2024-02-15_15-21-25.png

|

|

| Attachment 6: Screenshot_from_2024-02-15_15-21-53.png

|

|

| Attachment 7: Screenshot_from_2024-02-15_15-22-32.png

|

|

| Attachment 8: Screenshot_from_2024-02-15_15-23-13.png

|

|

| Attachment 9: Screenshot_from_2024-02-15_15-23-38.png

|

|

| Attachment 10: Screenshot_from_2024-02-15_15-24-02.png

|

|

| Attachment 11: Screenshot_from_2024-02-15_17-00-51.png

|

|

| Attachment 12: Screenshot_from_2024-02-15_17-01-28.png

|

|

| Attachment 13: Screenshot_from_2024-02-15_17-03-31.png

|

|

| Attachment 14: Screenshot_from_2024-02-15_17-05-14.png

|

|

| Attachment 15: Screenshot_from_2024-02-15_17-07-20.png

|

|

| Attachment 16: Screenshot_from_2024-02-15_17-09-17.png

|

|

| Attachment 17: Screenshot_from_2024-02-15_17-11-12.png

|

|

| Attachment 18: Screenshot_from_2024-02-15_19-22-45.png

|

|

| Attachment 19: Screenshot_from_2024-02-15_19-23-53.png

|

|

| Attachment 20: Screenshot_from_2024-02-15_19-24-43.png

|

|

| Attachment 21: Screenshot_from_2024-02-15_19-25-59.png

|

|

| Attachment 22: Screenshot_from_2024-02-15_19-26-38.png

|

|

| Attachment 23: Screenshot_from_2024-02-15_19-28-03.png

|

|

| Attachment 24: Screenshot_from_2024-02-15_21-05-57.png

|

|

| Attachment 25: Screenshot_from_2024-02-15_21-07-39.png

|

|

| Attachment 26: Screenshot_from_2024-02-15_21-08-10.png

|

|

| Attachment 27: Screenshot_from_2024-02-15_21-08-48.png

|

|

| Attachment 28: Screenshot_from_2024-02-15_21-09-29.png

|

|

| Attachment 29: Screenshot_from_2024-02-15_21-10-01.png

|

|

|

205

|

Thu Feb 17 15:09:40 2022 |

JM,CB,SD | Alpha background run44 |

16:09

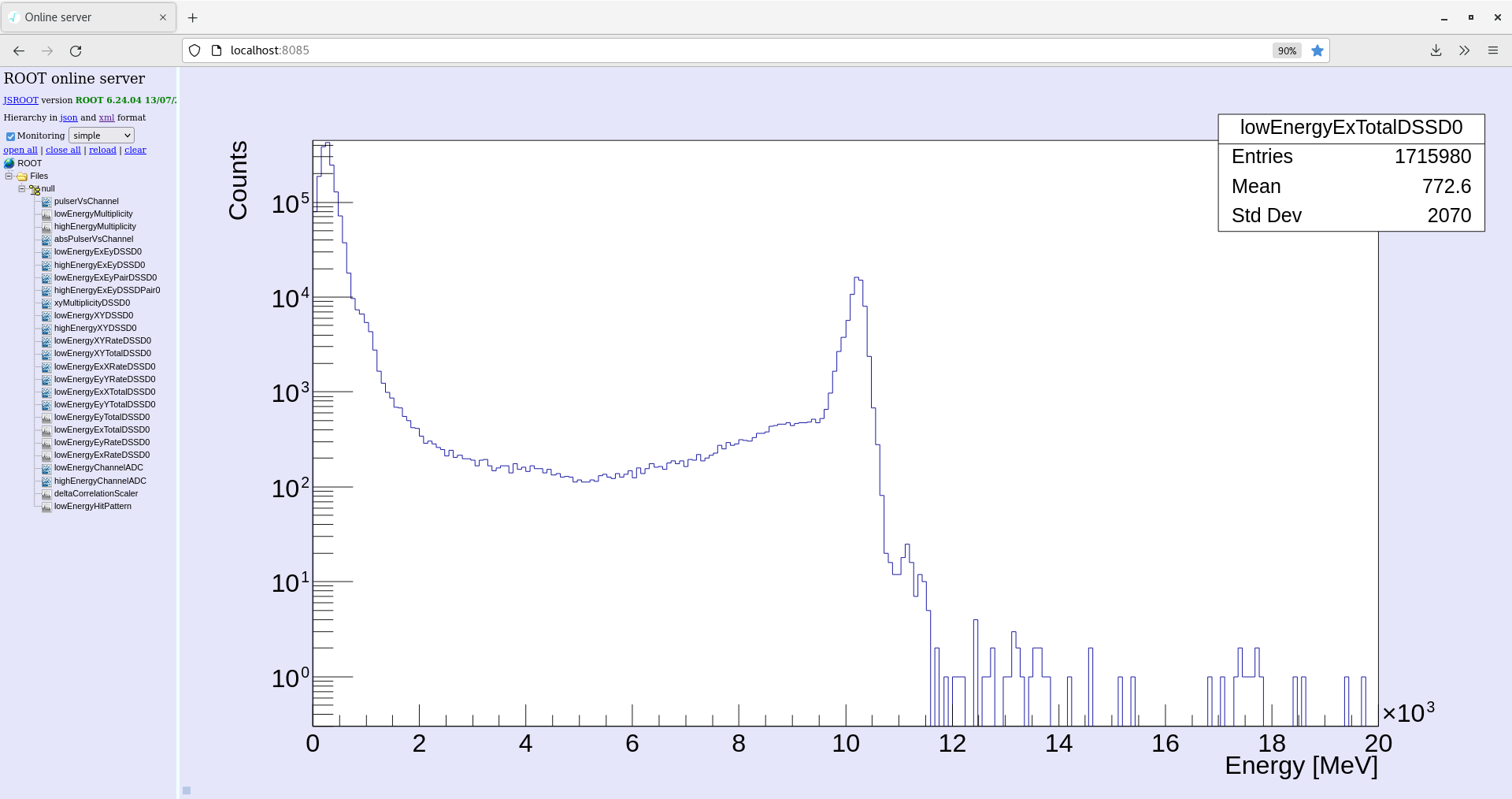

Check Leakage current: (see attachment 1)

Check NewMerger tab: (see attachment 3)

Check Fee temperatures: all green (see attachment 5)

Check statistics tab: ADC data items (see attachment 2)

ADC coincidence-info #8 (see attachment 6)

Good events (see attachment 4)

Check Spectrum Browser tab: (see attachment 10)

Check the following plots:

LowEnergyXYTotalDSSD0 (see attachment 9)

LowEnergyExTotal (see attachment 7)

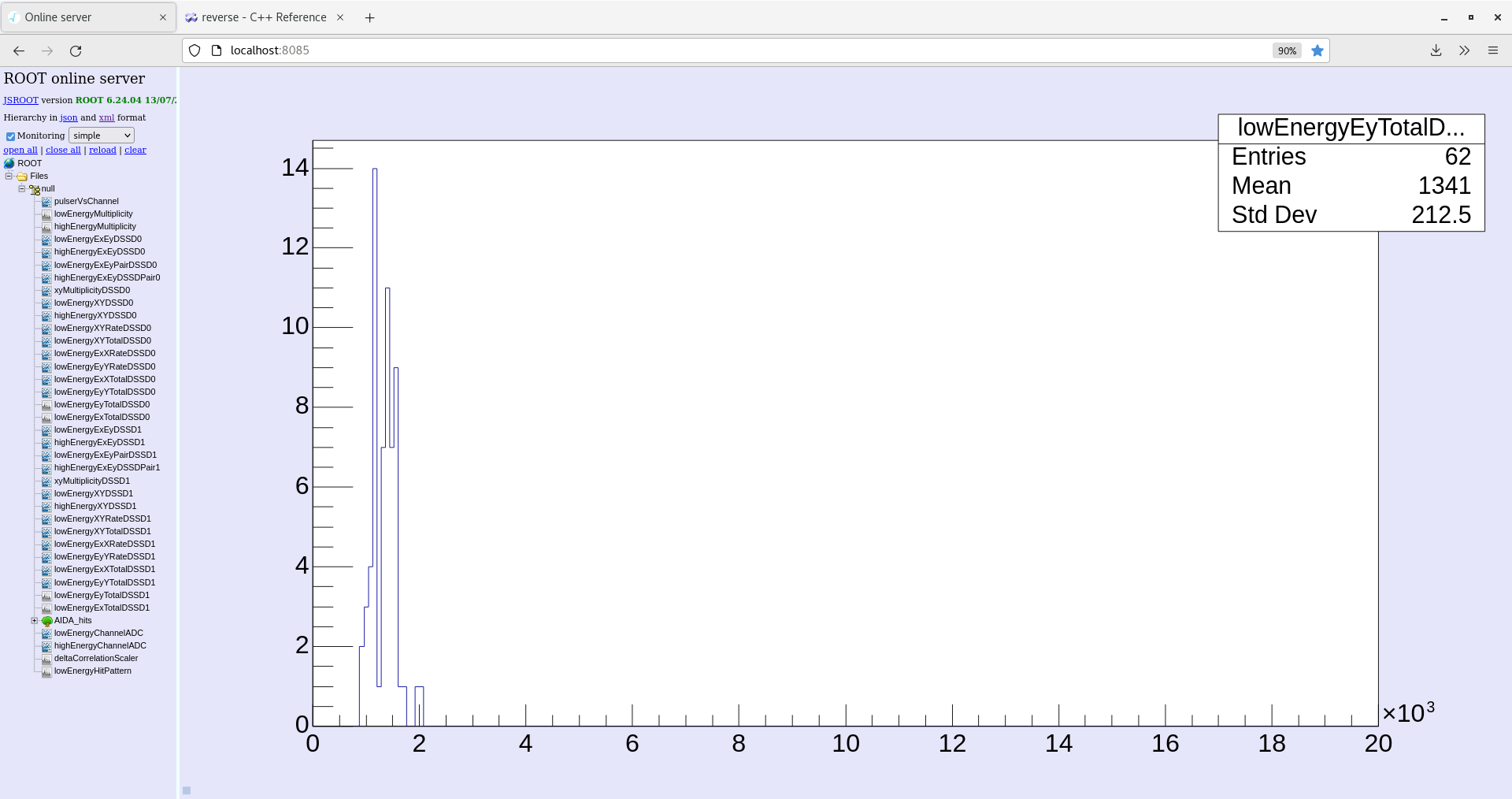

LowEnergyEyTotal (see attachment 8)

Check system wide checks tab: White Rabbit error counter test result: Passed 0, Failed 5 (see attachment 11)

Run stopped for pulser tests 16:13 |

| Attachment 1: 2022-02-17_16-04-11_lowEnergyExTotal.png

|

|

| Attachment 2: 2022-02-17_16-05-03_lowenergyEytotal.png

|

|

| Attachment 3: 2022-02-17_16-03-06_lowEnergyTotalDSSSD.png

|

|

| Attachment 4: 2022-02-17_15-54-12_leakagecurrent.png

|

|

| Attachment 5: 2022-02-17_15-53-25_Merger.png

|

|

| Attachment 6: 2022-02-17_15-52-29_Temperature.png

|

|

| Attachment 7: 2022-02-17_15-50-57_GoodEvents.png

|

|

| Attachment 8: 2022-02-17_15-49-12._AIDA_ADC_dataitems.png

|

|

|

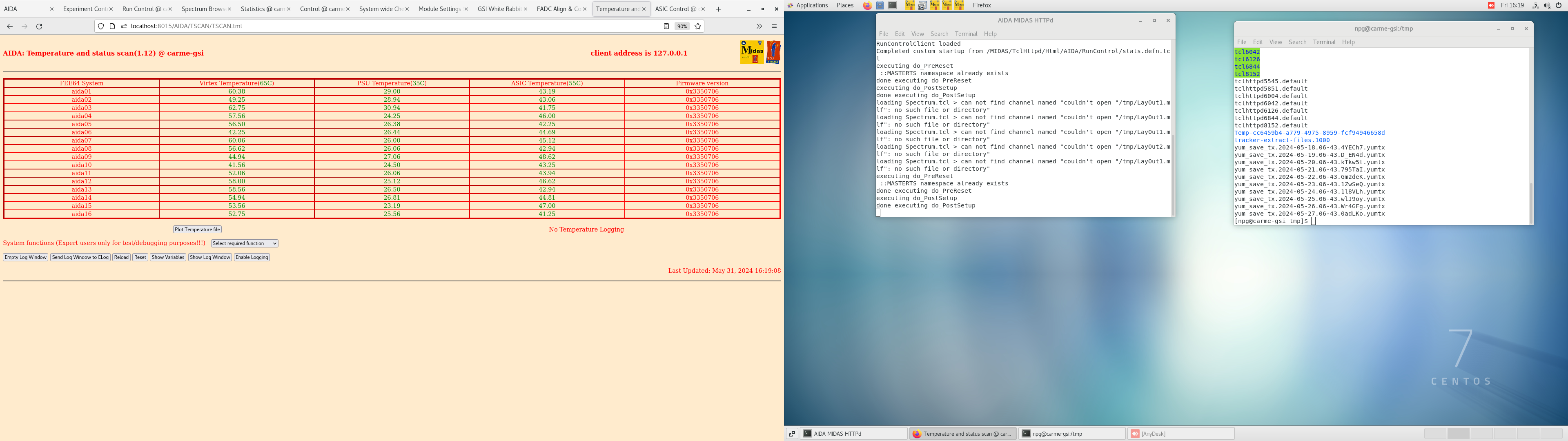

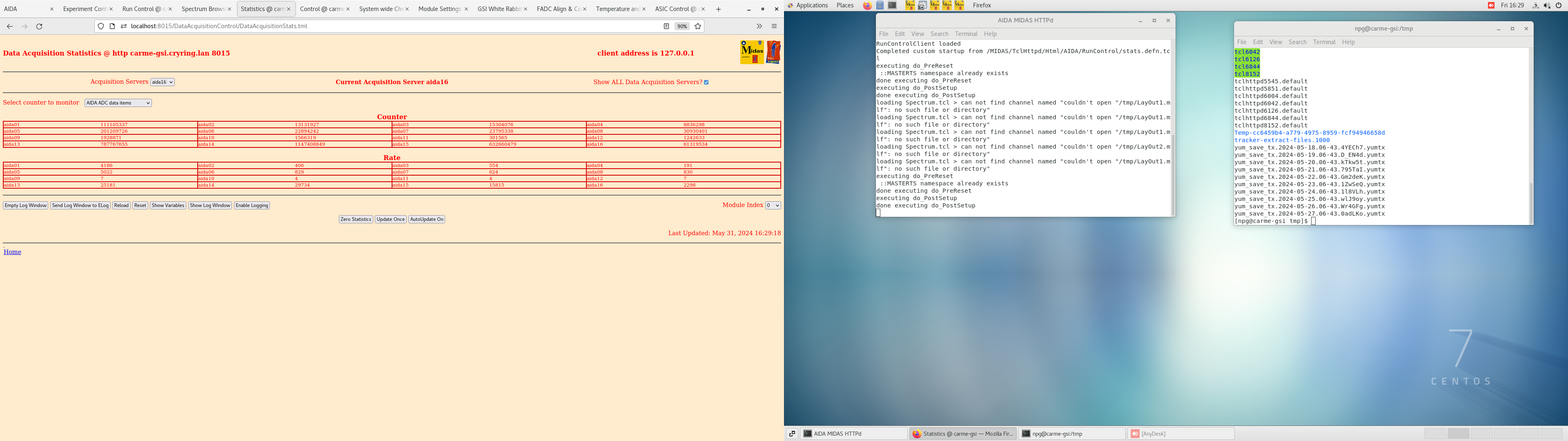

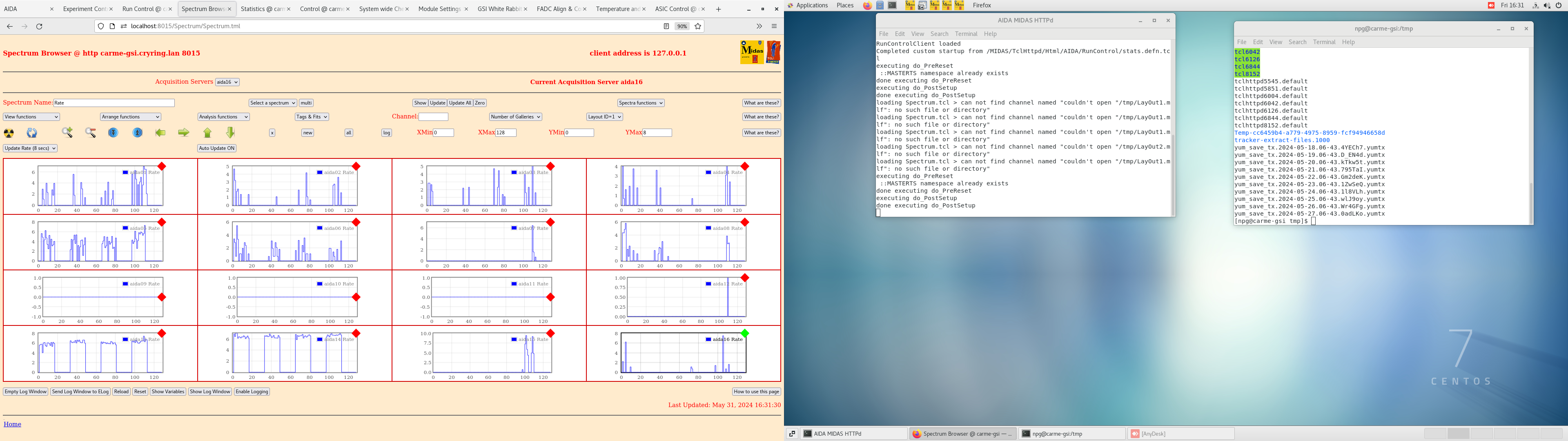

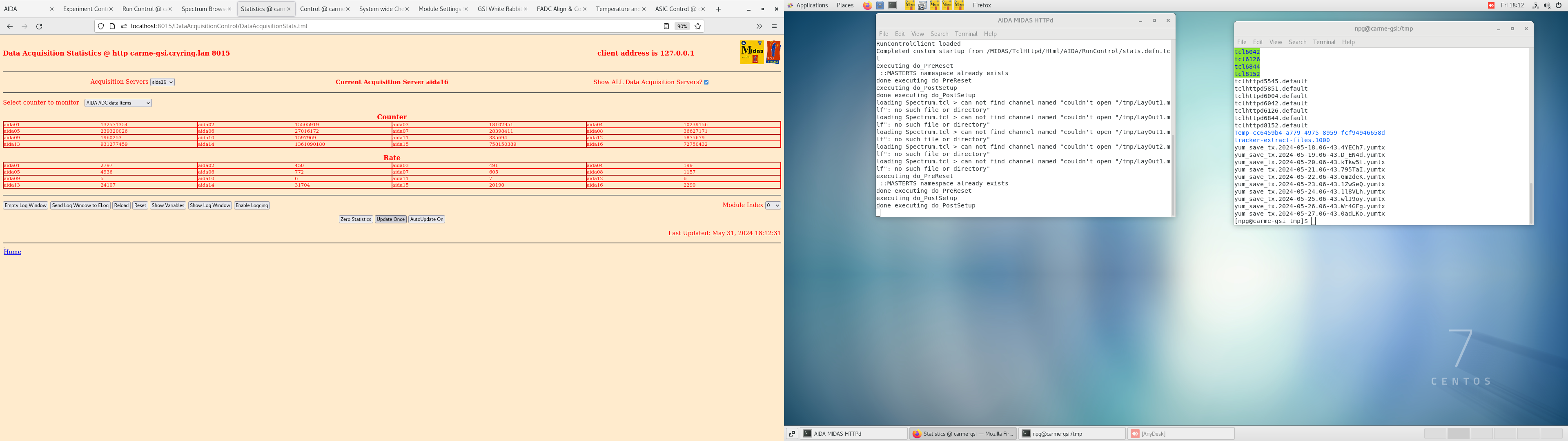

565

|

Fri May 31 06:01:55 2024 |

JM, TY, PW, EM, CB | Run 12 - beam on target |

07:00

Run 12 started. D+ beam is incident on the target at 1.5 MeV

Beam intensity in the ring is ~4e7 particles

Target density shows some fluctuations but is ~1e11 atoms/cm2. Target temp 35K

Detectors are positioned fully out (Left arm 18.86mm and right arm 19.8 mm ) and are not moving

Ring pressure looks OK, YR09 E target sensor seems unaffected by the target currently reads ~5e-11 mbar.

Beam is in the ring for ~15s.

Temps and system checks OK

Leakage current OK

Merger and tape server OK

Horizontal beam position 8 mm and vertical beam position 0mm for overlap with target.

Statistics - attachment 1

Energy histogram - attachment 2

XY plot - attachment 3

We see high rate at 1.5 MeV in left dssds but very little in right dssds. XY plots also show counts are concerntrated in a very circular distribution.

07:15

Gleb has just called and requires access to the cave to check on a turbo pump in the source.

Ring vacuum looks good

Beam will be down for 10-15 minutes only hopefully.

07:45

Beam is back in the ring but injection requires optimisation.

09:00

There are some issues with the source that require a few hours to resolve. Potentially until 7 or 8 pm tonight. We have about an hour before work starts.

We have done a quick test of the motors and moved the left and right arms in using the pnuematic only.

New position left arm = 62.71 mm , right arm = 64.6 mm.

We observed the rates in left detectors went up significantly. In the right detectors we observed little increase.

See attached xy plot - attachment 4

See attached energy histogram - attachment 5

Beam intensity has dropped significantly - below 1e6 particles so even at in positons we see few counts at the moment.

09:25

Source has degraded pretty rapidly so beam will be stopped for now.

Detectors moved back out.

Target nozzle moved from X= -13000, Y=2500 to X= -11000, Y=2500. S1 has dropped to 5e-10 mbar.

Note Gleb mentioned that last night it was likely a large proportion of the ions stored were molecular hydrogen not deuterium.

16:18

Temps and system checks OK

Leakage current OK

Merger and tape server OK

18:10

Temps and system checks OK

Leakage current OK

Merger and tape server OK

19:38

Operators are trying to optimize some beam. For now the beam is lower than it should be probably because is easy to work with the source like that.

Temps and system checks OK

Leakage current OK

Merger and tape server OK

|

| Attachment 1: Screenshot_from_2024-05-31_07-32-33.png

|

|

| Attachment 2: Screenshot_from_2024-05-31_07-33-19.png

|

|

| Attachment 3: Screenshot_from_2024-05-31_07-33-57.png

|

|

| Attachment 4: Screenshot_from_2024-05-31_09-17-08.png

|

|

| Attachment 5: Screenshot_from_2024-05-31_09-21-40.png

|

|

| Attachment 6: Screenshot_from_2024-05-31_16-19-29.png

|

|

| Attachment 7: Screenshot_from_2024-05-31_16-29-22.png

|

|

| Attachment 8: Screenshot_from_2024-05-31_16-31-36.png

|

|

| Attachment 9: Screenshot_from_2024-05-31_18-12-36.png

|

|

| Attachment 10: Screenshot_from_2024-05-31_19-42-42.png

|

|

| Attachment 11: Screenshot_from_2024-05-31_19-45-55.png

|

|

| Attachment 12: Screenshot_from_2024-05-31_20-04-54.png

|

|

|

185

|

Thu Feb 3 22:05:33 2022 |

JM, TD, OH(remotely) | Bias update and grounding |

9:30 Bias remained stable overnight - 60V 2.95 uA.

10:00 No grounding attached initailly. Pulser ON, lots of noise across all ~250-300 kHz across biased detector. Waveforms and histograms saved to /tmp. Pulser width for aida 6 ~300 channels. Aida 7,8 similar, aida 5 producing no ADC data.

11:00 Grounding connected as in elog 181. Rates decreased to ~180-250 kHz. Waveforms and histograms saved to /tmp.

12:00 Bias slowly increased too 100V giving a leakage current of ~3.5 uA which was stable for several hours. Bias varied between 60V and 100V for noise reduction perposes, 80V deemed least noisy at the time, noise still ~180-200 kHz

13:30 New grounding trialled. Bottom detector removed from pulser and grounding loops so that only the biased detector is grounded. Bias set to 80V

14:00 Rates significantly reduced for aida 6,7,8 - aida5 still producing no ADC data. Rates are in range 15-50 kHZ with noisy channels accounting for most of the rates. Waveforms and histograms saved to /tmp. Pulser peak on aida 6 ~300 channels.

16:00 Aida 5 fee investigated to reason it is not producing data. FEE was not properly connected to ERNI connector due to incorrect installation of black adaptor card mount. Adaptor card mount reinstalled and fee remounted. Aida 5 now produces ADC with similar rates to aida6,7,8.

During investigation of aida5, aida4 and 5 were swapped. Config files relating to MAC addresses, polarity etc of FEES has been updated. Elog 175 will be appended to include this swap.

19:00 Bias set to 80V, DAQ running with pulser off to allow for alpha detection overnight. |

|

186

|

Fri Feb 4 09:53:48 2022 |

JM, TD, OH (remotely) | Alpha spectra overnight |

DAQ was left running last night from 19:30. Detector bias 80V with a leakage current ~3.4 uA. Pulser OFF.

Observed alphas in spectra overnightin the 20,000 to 28,000 channel range for the pn side and 36,000 to 44,000 range on the nn side of the detector. Zero energy noise peak is at channel 32000.

Alphas checked for AIDA5 and AIDA6 (pn) with ~150 alphas counted using a range 20,000-26,000/27,000 depending how large the noise peak tail is. Attached spectra show the spectra for the 4 ASICs of AIDA5 and 6. |

| Attachment 1: 2022-02-04_10-04-38aida5-1*L.png

|

|

| Attachment 2: 2022-02-04_10-08-31aida5-2*L.png

|

|

| Attachment 3: 2022-02-04_10-11-34aida5-3*L.png

|

|

| Attachment 4: 2022-02-04_10-15-50aida5-4*L.png

|

|

| Attachment 5: 2022-02-04_10-46-33aida6-2*L.png

|

|

| Attachment 6: 2022-02-04_10-44-10aida6-1*L.png

|

|

| Attachment 7: 2022-02-04_10-48-33aida6-3*L.png

|

|

| Attachment 8: 2022-02-04_10-49-52aida6-4*L.png

|

|

|

167

|

Mon Jan 10 20:52:53 2022 |

JM, TD, OH | Baking tent removed, VI tests |

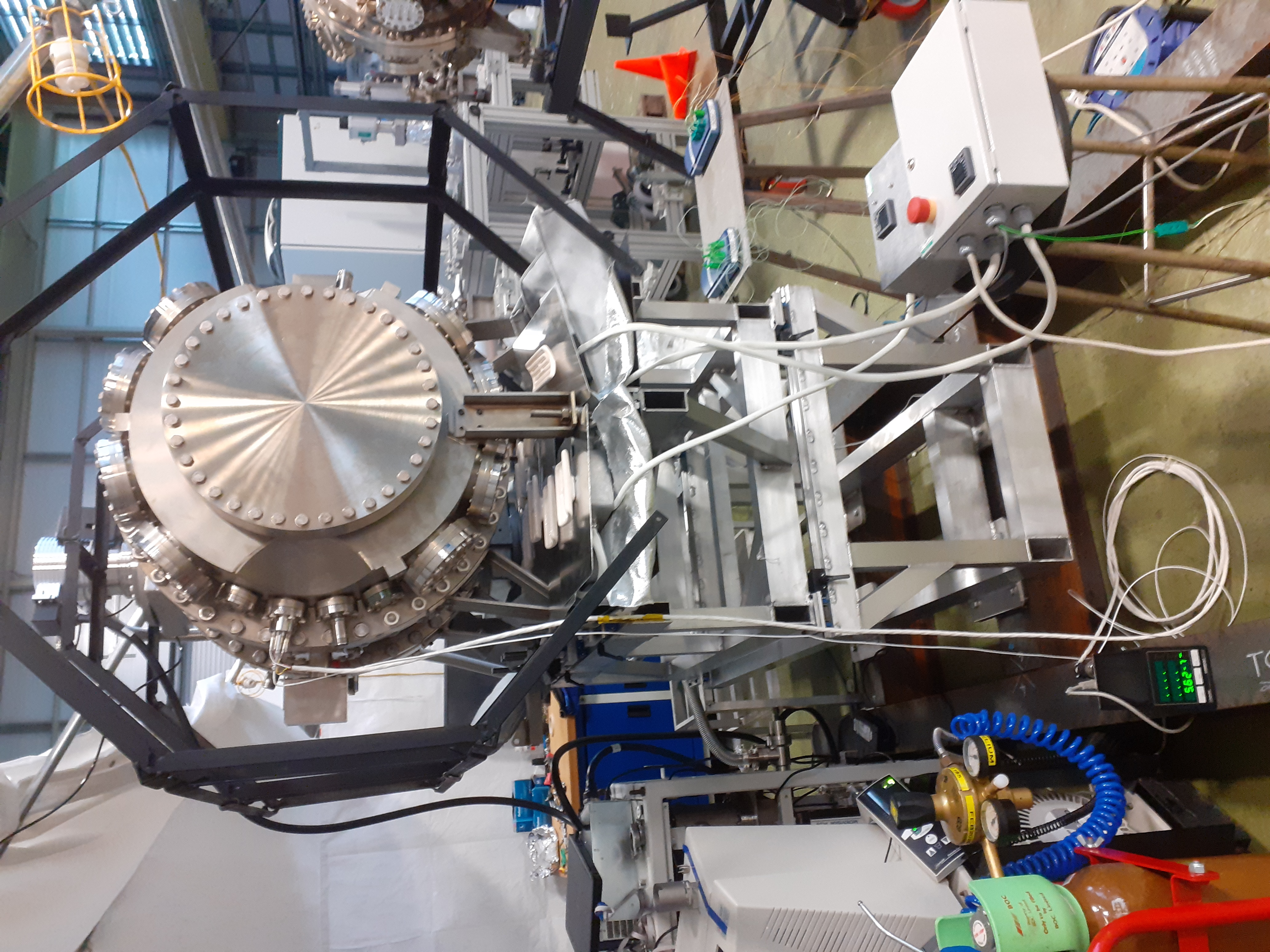

Baking tent, frame and trays fully removed from CARME chamber. Removal of baking frame required removing air lines from upper gate valve and repositioning of vacuum hose connecting turbo pump to backing line and turbo power cable. Some difficulty encountered removing upper baking frame now the target support frame is assembled. Small modification seperating section in two would aid future installation and disammebly.

Baking trays removed with difficulty. Main baking tray bent to extract from the frame -> updated design required for future bakeout cycle.

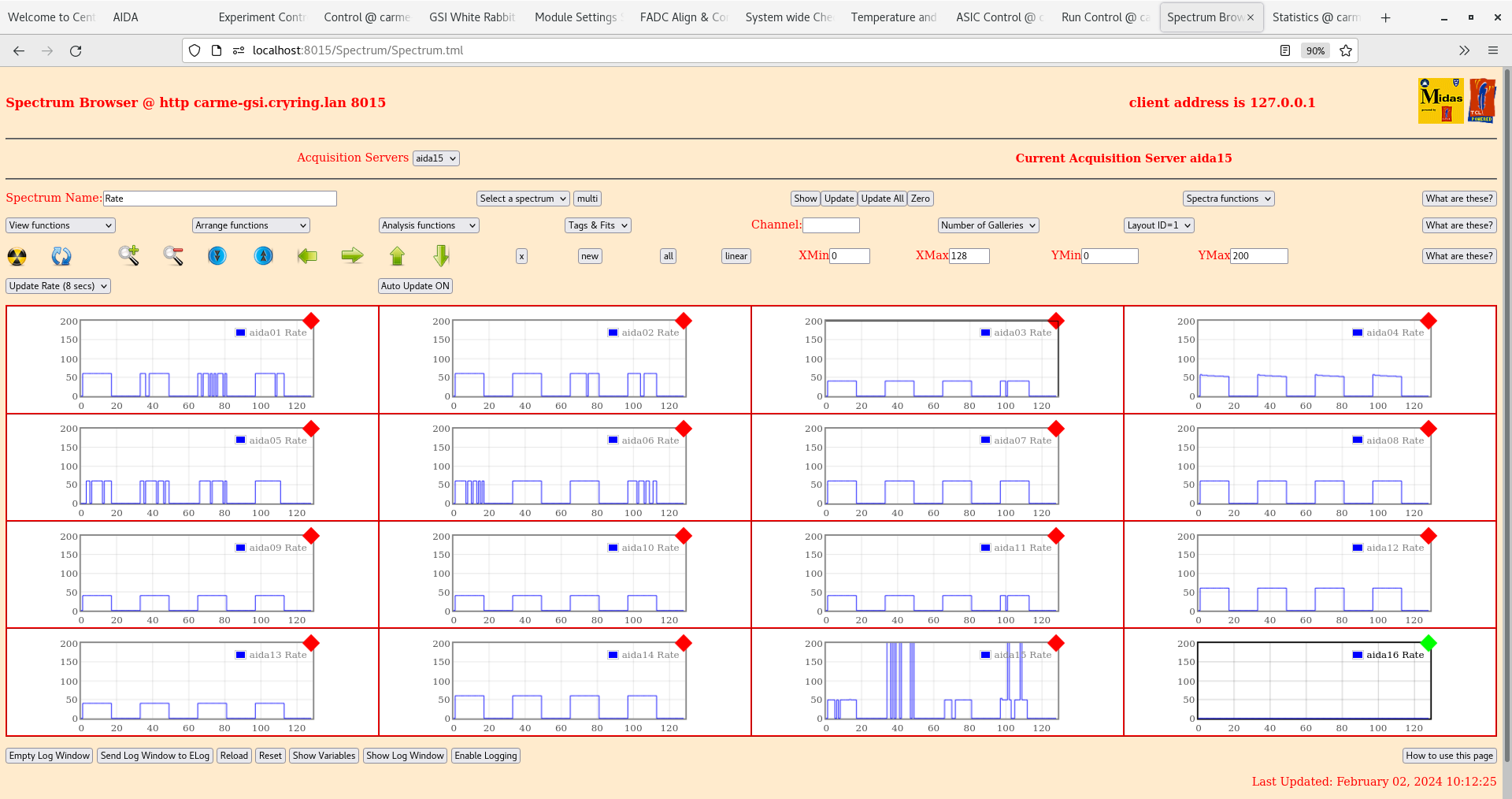

VI tests performed on the upper and lower detectors. Upper detector shows characteristic curve (attached plot), lower detector shows no response to increased voltage. Multimeter used on adapter boards with resistance of ~18.5 kΩ observed between bias pins for the upper detector. Open line seen between bias pins on the lower detector, some connections observed for other pins on the board -> requires further investigation.

NOTE - Channel 0 on bias supply is unstable, should not be used.

Most equipment for installation of FEE's and coolant manifolds found, assembley of FEE holders started. Full list of current swagelock inventory as follows:

| SS-QTM2-D-8M0 MALE QUICK DISCONNECT |

15 |

| SS-8M0-1-6RS MNIFOLD ADAPTOR |

40 |

| NY-8M4-1 ferrule fronts (nylon) |

120 |

| NY-8M3-1 ferrule rears (nylon) |

120 |

| SS-QTM2A-B-8M0 FEMALE QUICK DISCONNECT |

15 |

|

| Attachment 1: 20220110_175547.jpg

|

|

| Attachment 2: 20220110_175811.jpg

|

|

| Attachment 3: vi-curve.png

|

|

|

486

|

Fri Feb 2 08:59:36 2024 |

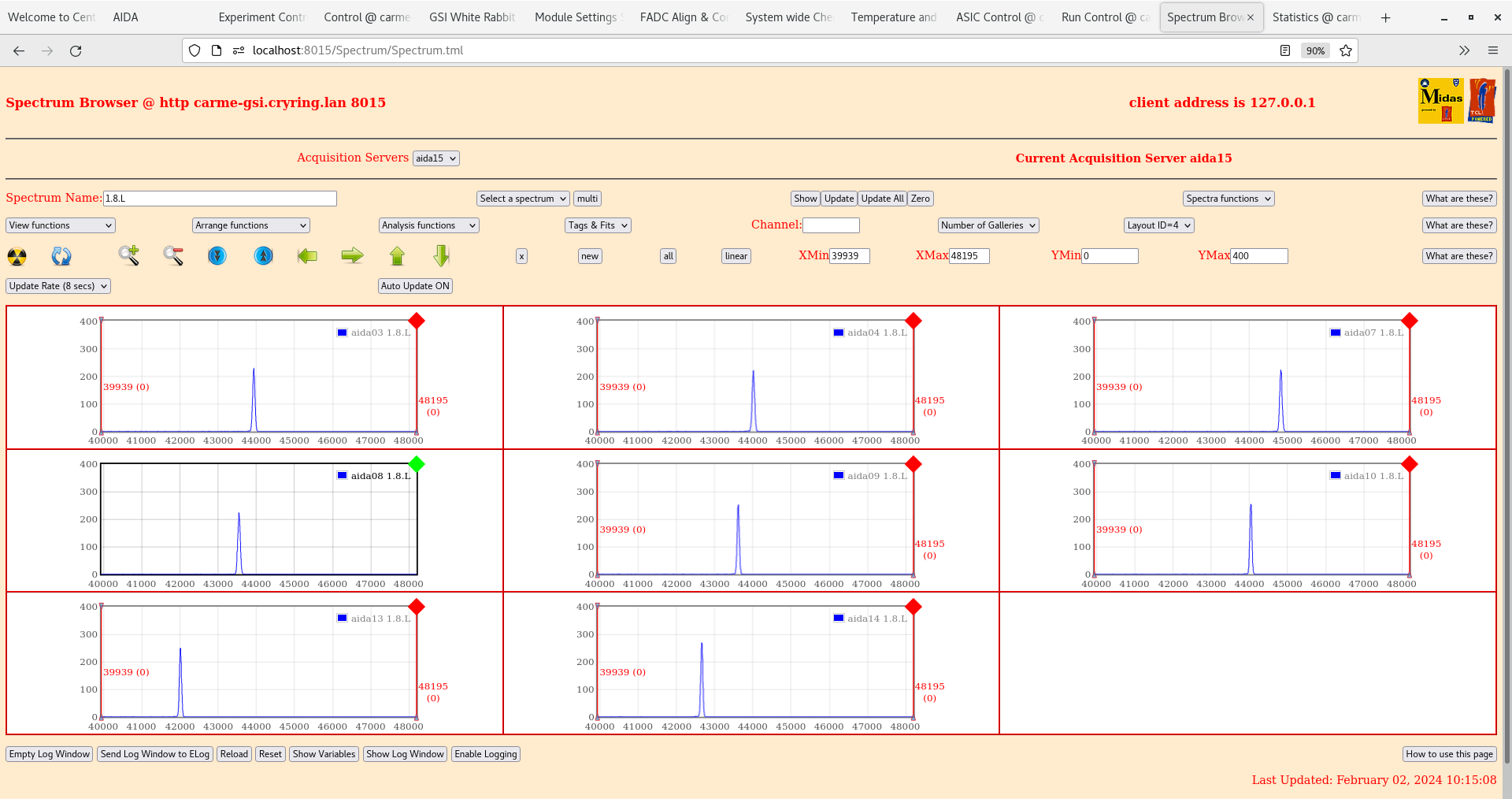

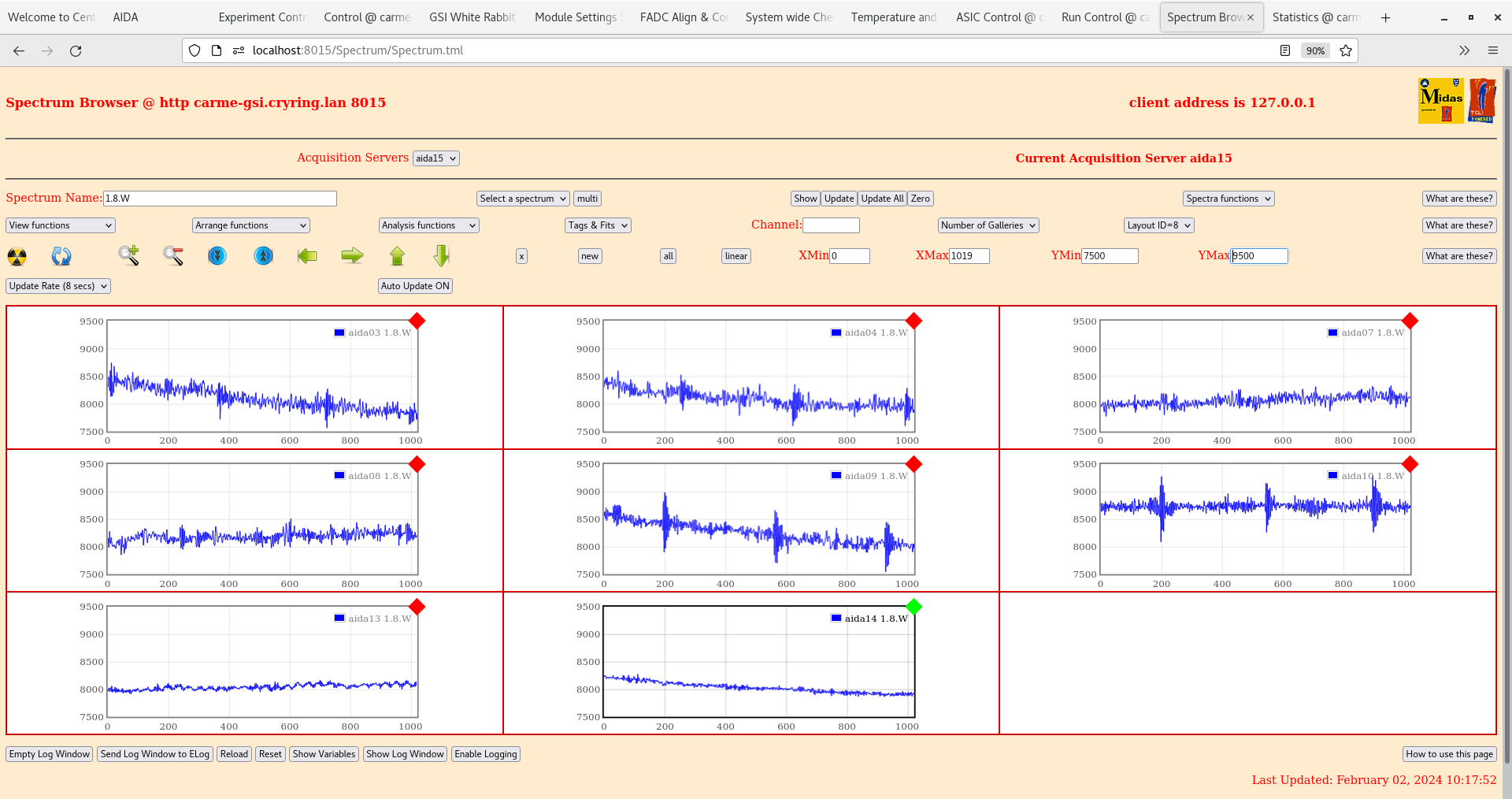

JM, TD, CB | Run1 start - pulser widths spreadsheet |

Current pulser widths excel spreadsheet attached

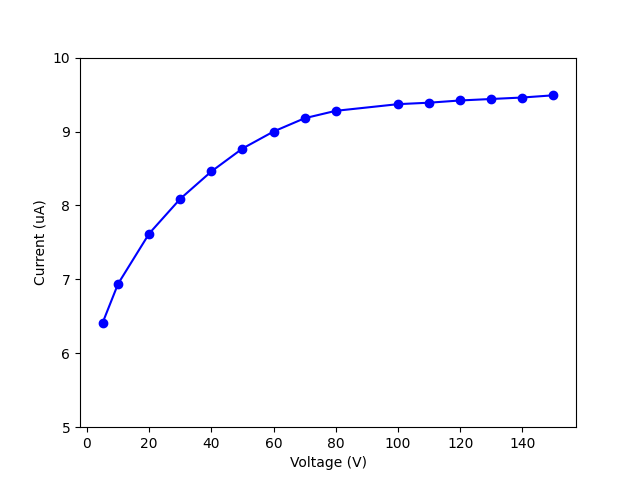

09.58 DSSSD bias OK - attachment 1

Ambient temperature +16.1 deg C FEE64 temps OK - attachment 2

ADC data item stats OK - attachment 3

aida15 asic #2 high rate - asic u/s

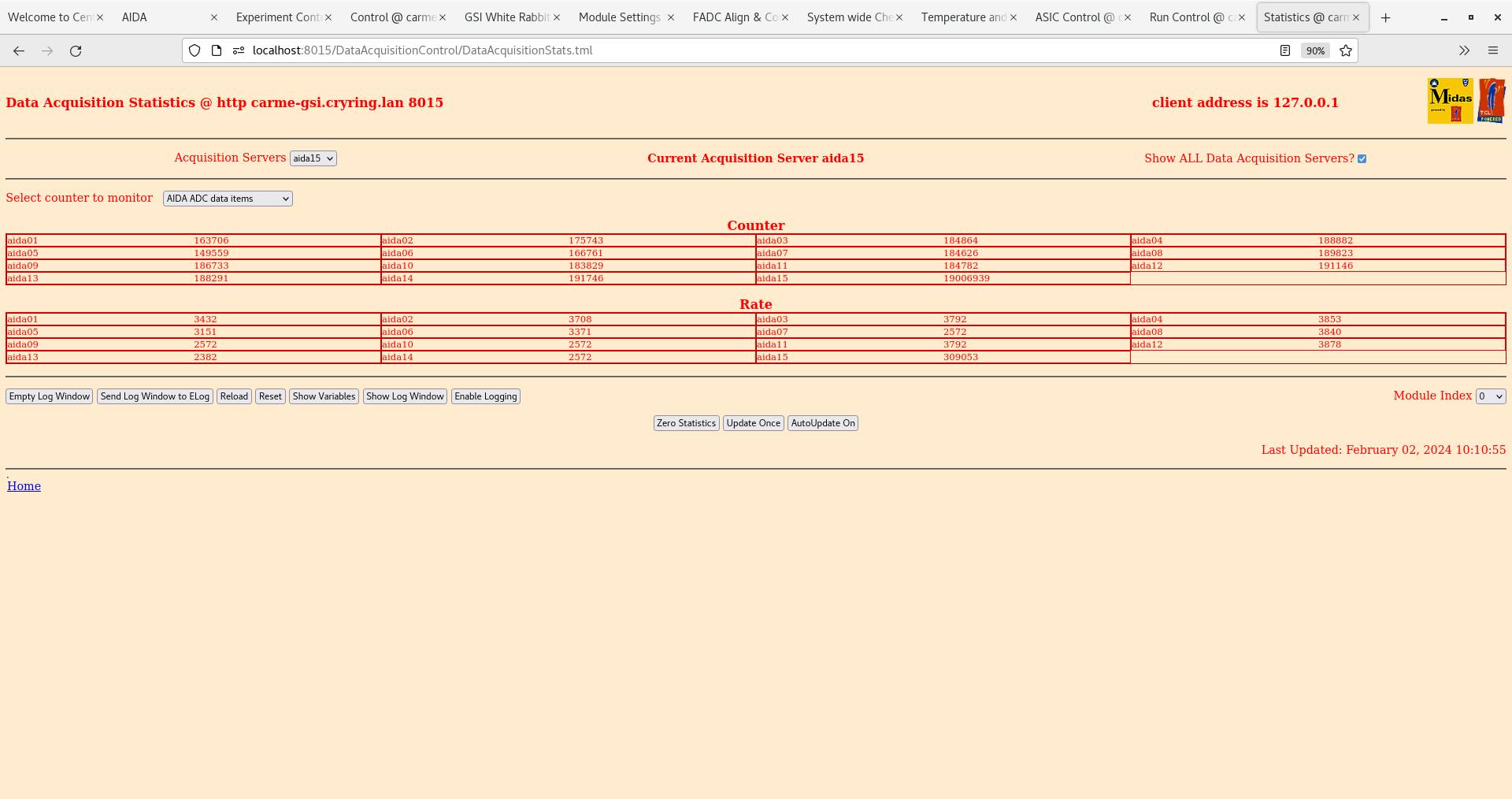

system wide tests OK *except* aida09 - attachments 4-5

aida09 WR status 0x20 aida09 WR timestamp incorrect cf. all other FEE64s

per FEE64 Rate spectra - attachment 6

per FEE64 1.8.L spectra - attachments 7-8

aida14 pulse peak witdh 58 ch FWHM

aida11 pulse peak witdh 48 ch FWHM

per FEE64 1.8.W spetra - 20us FSR - attachments 9-10

12.00

aida09 WR timestamp issue resolved by FEE64 reboot

14.10

Safety pins removed from detector motion system. CB performs one, complete DSSSD movement cycle. Zero all histogram and stats per FEE64 Stat spectra ( log scale ) and

ADC

data item stats for the complete DSSSD movement cycle - attachments 11-12

No change observed in DSSSD leakage currents during DSSSD movement cycle.

15.35

Resolved issue from previous elog. Begin background run writing data to disk.

ASIC check load

Start DAQ G22-88/R1 background alpha

EG&G Ortec 448 Pulser OFF

ASIC settings 2024Jan20-12.02.08

slow comparator 0x64 ( all FEE64s *except aida15 asic #2 0xff )

All histograms set to zero

DSSSD bias OK - attachment 13

FEE64 temps OK - attachment 14

WR timestamps OK - attachment 15

ADC data item stats - attachment 16

aida15 asic #2 u/s - rate c. 250k

ADC data items/s Merger, Tape Server & Merger stats - attachments 17-19

data rate to disk c. 2Mb/s dominated by aida15 asic 2 |

| Attachment 1: Screenshot_from_2024-02-02_09-59-10.png

|

|

| Attachment 2: Screenshot_from_2024-02-02_10-10-46.png

|

|

| Attachment 3: Screenshot_from_2024-02-02_10-10-59.png

|

|

| Attachment 4: Screenshot_from_2024-02-02_10-11-18.png

|

|

| Attachment 5: Screenshot_from_2024-02-02_10-11-37.png

|

|

| Attachment 6: Screenshot_from_2024-02-02_10-12-32.png

|

|

| Attachment 7: Screenshot_from_2024-02-02_10-13-17.png

|

|

| Attachment 8: Screenshot_from_2024-02-02_10-15-11.png

|

|

| Attachment 9: Screenshot_from_2024-02-02_10-16-33.png

|

|

| Attachment 10: Screenshot_from_2024-02-02_10-18-01.png

|

|

| Attachment 11: Screenshot_from_2024-02-02_14-09-42.png

|

|

| Attachment 12: Screenshot_from_2024-02-02_14-09-46.png

|

|

| Attachment 13: Screenshot_from_2024-02-02_15-41-14.png

|

|

| Attachment 14: Screenshot_from_2024-02-02_15-41-35.png

|

|

| Attachment 15: Screenshot_from_2024-02-02_15-42-14.png

|

|

| Attachment 16: Screenshot_from_2024-02-02_15-42-31.png

|

|

| Attachment 17: Screenshot_from_2024-02-02_15-43-02.png

|

|

| Attachment 18: Screenshot_from_2024-02-02_15-43-11.png

|

|

| Attachment 19: Screenshot_from_2024-02-02_15-43-25.png

|

|

| Attachment 20: Pulser-widths-carme-2024.xlsx

|

|

19

|

Wed Sep 23 13:34:32 2020 |

JM, TD | Wednesday 23 September |

Connected Leybold Ionivac IE514 to Leybold Combivac CM52 Vacuum Gauge Controller

Rear panel - power ON

POST checks OK

Change parameters by

select PARA

select <-> to display Sen

select PARA to display S-on

select <-> to display HAnd

select PARA and hold for 7s

select CH to select CH3

select -> hold for 2s

With CARME gate valve closed for c. 24h CARME chamber pressure is 6.43e-5mbar @ 13.34, 6.52e-5mbar @ 14.15

15.45 CARME Leybold turbo restarted

16.06 1.58e-6mbar, 3.5e-5mbar (RGA station), leak rate 3.6e-10 mbar.l/s

16.27 9.44e-7mbar, 3.3e-5mbar (RGA station), leak rate 3.6e-10 mbar.l/s

16.39 7.67e-7mbar

17.00 5.85e-7mbar, 2.5e-5mbar (RGA station), leak rate 2.60e-10 mbar.l/s

17.20 4.83-7mbar, 2.3e-5mbar (RGA station), leak rate 2.17e-10 mbar.l/s

Baking octagon moved into position along with the bottom insulation and heaters

|

| Attachment 1: 20200923_170441.jpg

|

|

| Attachment 2: 20200923_170455.jpg

|

|

| Attachment 3: 20200923_170415.jpg

|

|

| Attachment 4: 20200923_161415.jpg

|

|

| Attachment 5: 20200923_161402.jpg

|

|