| ID |

Date |

Author |

Subject |

|

433

|

Sat Aug 12 11:57:51 2023 |

JM | Updated thermocouple positions and heater channel layouts |

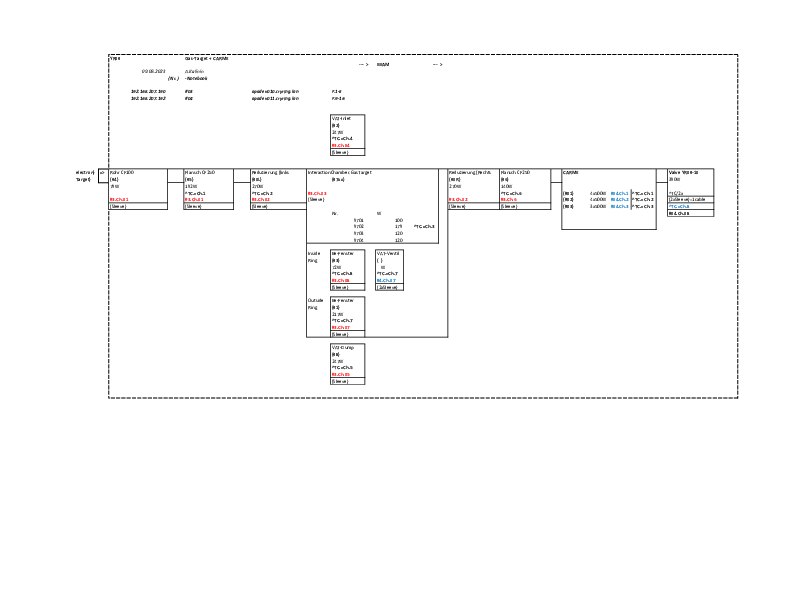

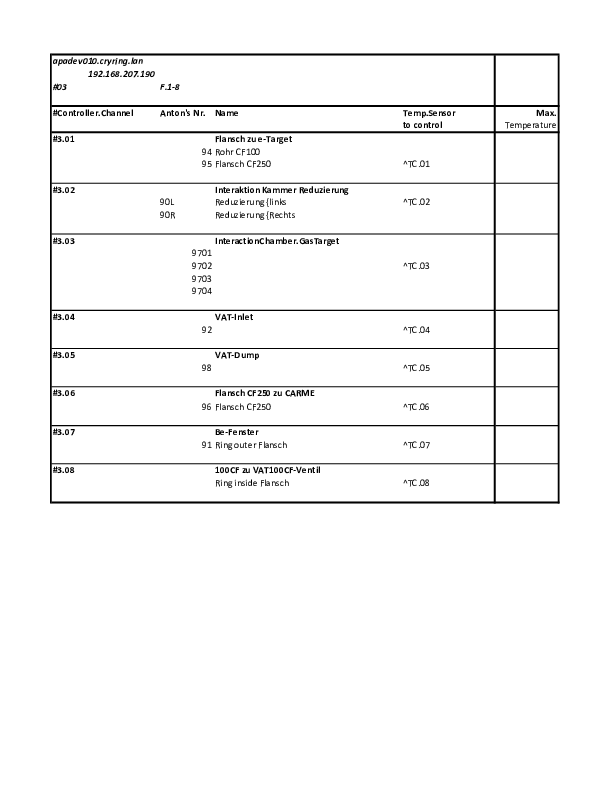

Heater channel layouts for the interaction chamber and carme in attached documents.

Updated thermocouple positions; (front section is closest to gas-target, rear section is moving detector end)

- 1-1 Internal TC 1

- 1-2 Internal TC 2

- 1-3 Internal TC 3

- 1-4 CARME - top of the front section

- 1-5 CARME - bottom of the front section

- 1-6 CARME - top of the mid section

- 1-7 CARME - middle of the mid section

- 1-8 CARME - bottom of the mid section

- 2-1 Float - bottom of mid section

- 2-2 CARME - middle of rear section

- 2-3 Float - middle of the front section

- 2-4 CARME - bottom VAT valve

- 2-5 Float - middle of the rear section

- 2-6 CARME - Top elbow

- 2-7 Float - top of the mid section

- 2-8 CARME - rear beam pipe

Thermocouple posiitons have been updated in the monitoring code, including the averages for the CARME chamber. |

| Attachment 1: Cryring-YR09-CARME-Layout.pdf

|

|

| Attachment 2: Cryring-YR09-CARME-Layout2.pdf

|

|

| Attachment 3: Cryring-YR09-CARME-Layout3.pdf

|

|

| Attachment 4: Cryring-YR09-eTarget-Layout1.pdf

|

|

| Attachment 5: Cryring-YR09-eTarget-Layout2.pdf

|

|

| Attachment 6: Cryring-YR09-eTarget-Layout3.pdf

|

|

|

434

|

Sat Aug 12 15:06:51 2023 |

JM | Initial bakeout tests |

12/08/23

Baking testing. Aim to find relationship between heater temperature setpoint and the temperature of the chamber and floating temperature in the baking volume. Behaviour of the heater tempertures and ability to control the heating is also required. Ambient chamber temperature ~22 C. Interaction chamber temperatures will be raised to the level of the CARME chamber throughout, starting temperature of the interaction chamber with heating off is 28 C. P = 7.5e-9 mbar

CARME thermocouple temperatures can be read from the monitoring code which is currently running in a screen session on the baking pi. Heater temperatures and pressure in YR09 can be read from Grafana.

15:40 CARME heaters turned on, set point 50 C. Ramping is ~ 1C per minute for the heaters.

16:00 Thermocouples inside baking volume show small increases. Setpoint increased to 60 C.

16:10 Setpoint increased to 80 C.

16:30 Setpoint increased to 100 C.

16:45 Setpoint increased to 120 C

17:00 Setpoint raised to 150 C. Average chamber temp ~ 25.2 C, bottom of the chamber is ~28C.

17:45 Setpoint was maintained at 150 C, temperatures of the heaters continued to rise past this setpoint and were floating about 200-230 C with large variations in the temperature. At lower setpoints the heater temperature appeared to rise linearly with the 1 C per minute. I do not believe I currently have control of the heating. Average chamber temp 28.8 C with bottom of the chamber ~35-37 C. Heating has been turned off while I grab some food. P = 1e-8 mbar

Next test will be to try and maintain a consistent heater tempreture for a longer period of time, probabably at a lower set temperture.

13/08/23

10:00 Heater setpoint to 50 C. Will maintain at this level for a while to look at increase in chamber temps and see if heater temp remains stable. P = 8.52e-9 mbar

11:47 Heater temperatures have been constant at ~ 55 C for the last hour. Little heating observed in the chamber, requires much larger temperature to heat the baking volume. Setpoint increased to 100 C.

13:10 Heater temperatures have been constant at ~103 C for the last 40 mins or so and appears stable. Temperatures are rising at a steady rate but temps are still low. Interaction chamber heating jackets activated to be a same temperature as CARME. Will require higher temperatures to heat the baking volume.

16:15 Heater temperaturtes have remained constant at ~103 C. Temps inside the baking volume remain low, Increasing heater temperature to 135 C.

18:30 Heaters temperatures remain stable. Larger fluctations are apparent than at a setpoint of 100C with temps between 140 and 150 C. Chamber temperatures increasing avg is ~ 35C, was aiming for 50C over the weekend. Increasing setpoints to 170 C.

20:50 Heater tempretures are stable. Average chamber temp is ~ 40 C. Interaction chamber heaters set to 40 C to keep constant with CARME. Pressure has increased to 2.9e-8 mbar. Heater power outputs are visible in last image, heaters currently turn on at ~80% max power about twice every 5 mins. I expect temps of 250-300 C are required to obtain significant temp increase up to 100 C on the chamber. Chamber temps appear to be fairly stable at this point, will leave for now and check back in a few hours.

23:00 Heater setpoint temp reduced to 135 C to maintain temperatures inside the baking volume overnight with no increase. Heater power has now reduced to < 50 % full power when the eaters are on. Pressure in the chamber is 4.4e-8 mbar.

I believe I now understand the heating system and plan to increase the chamber temperature throughout the day tomorrow. Aim is to get close to full bakeout temperatures. |

| Attachment 1: 20230813_114600.jpg

|

|

| Attachment 2: 20230813_132550.jpg

|

|

| Attachment 3: 20230813_170829.jpg

|

|

| Attachment 4: 20230813_205613.jpg

|

|

| Attachment 5: 20230813_210238.jpg

|

|

|

435

|

Mon Aug 14 09:22:56 2023 |

JM | Bakeout |

14/08/23

Temperature in the baking volume is ~ 42 C and the pressure is 4.6e-8 mbar. Current heaters set point is 135 C. This will now be increased to 200 C to start increasing the baking temperature more significantly.

Some issues with the interaction chamber heaters were noticed this morning. This included very large increases in temperature despite only small increases in the setpoint. When this occurred the heater channels were simply turned off. Channel 3 on the interaction chamber (main jacket on the centre of the chamber was also observed to smoke slightly). This smoking was seen when the temperature for channel 3 was ~ 70 C.

Changing the settings of these heaters appears to have resolved most of the issues. The heaters now ramp in a much more controlled manner and remain roughly constant at the setpoint value. The interaction chamber heaters were all increased to 70 C with no issues observed. Channel 3 also appears OK.

The CARME heaters settings have also been changed and now the heaters temperature and power output do not oscillate as observed previously. Power output per heater is approximately 15 % of total at heater temperatures of 220 C, and this value remains consistent over time. The temperatures inside the baking volume are now ~ 50 C with the pressure equal to 7e-8 mbar. Heating has not been the priority while investigating the issues observed with the heaters.

As a precaution CARME will now be maintained at the 50C level. The interaction chamber and e-target temperatures have been set to 50 C also. If the system remains stable overnight we will again begin increasing the temperature in the morning.

15/08/23

Temperatures across the whole of YR09 have remained very stable overnight. Temperature of CARME has increased slightly and is now ~ 55 C. Pressure is ~1e-7 mbar. A brief lincrease in pressure was observed yesterday due to the de-gassing of the GSI ion pump on CARME. Plan is to now increase the temperatures of YR09 to the 100 C level

Temperature is ~ 70 C. Heating is slower than expected as I am aiming to minimise thermal gradients across the chamber, which was previously done automatically by our baking code. Current heater temperature values are ~ 320 C. I have increased the temperatures across YR09 to 70 C to match carme . Pressure in CARME is 2.1e-7 mbar.

16/08/23

The temperatures of the CARME heaters were further increased to ~ 420 C to further increase the chamber temperature. Average chamber temperatures of ~93C achieved. Heater temperatures can be pushed to 450C which should allow us to achieve 100 C. Will allow chamber to equillibriate as temperature gradient between top and bottom is quite large.

17/08/23

Baking will be unsupervised over the weekend. To remain safe, the berylium window and the interaction chamber will be kept at a temperature of 50C. Carme will be reduced to ~60C during this period.

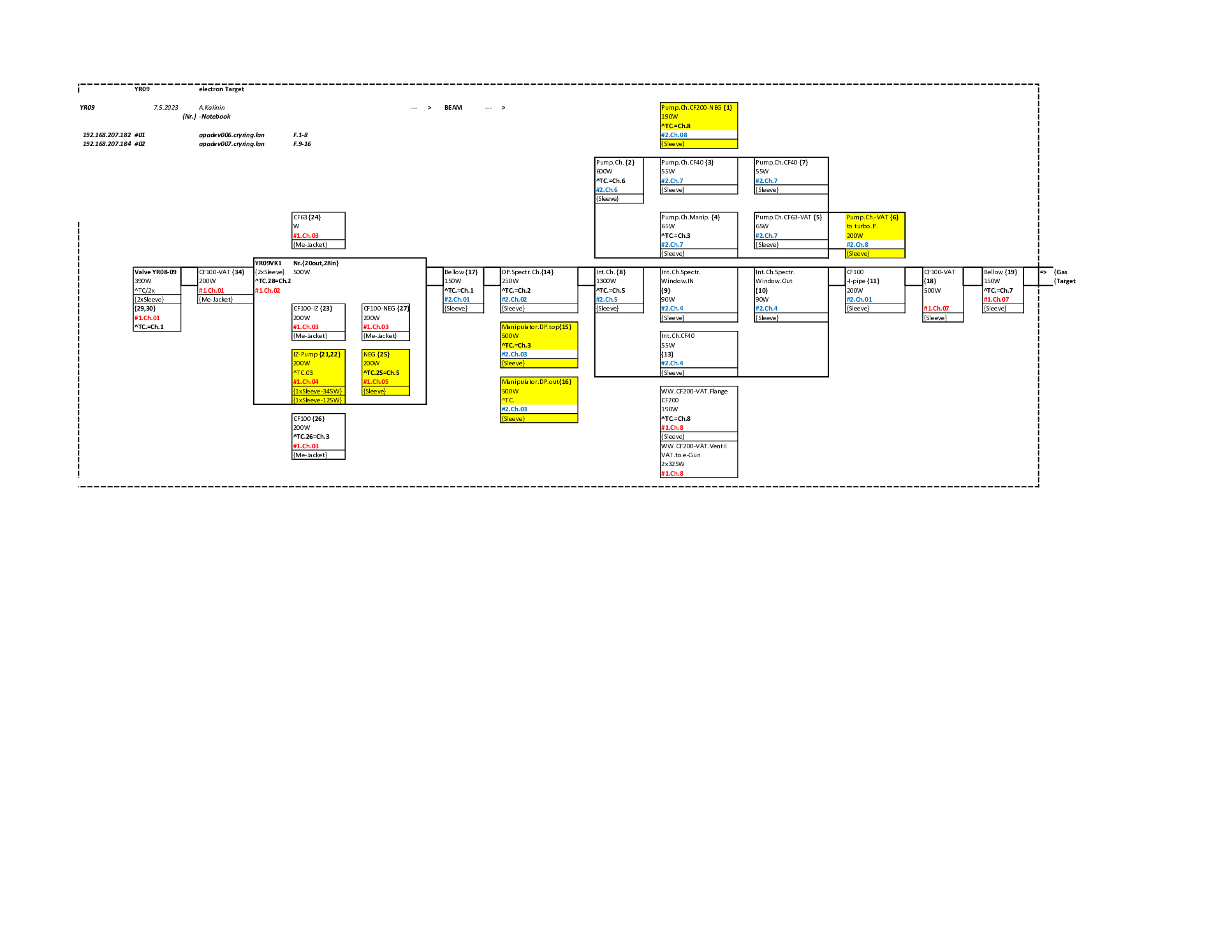

Attached are plots for the bakeout period concerning this week. |

| Attachment 1: 20230814_150430.jpg

|

|

| Attachment 2: 20230815_094400.jpg

|

|

| Attachment 3: Heater-power.png

|

|

| Attachment 4: Heater-ITC-temp.png

|

|

| Attachment 5: Pressure-ITC-temp.png

|

|

|

442

|

Fri Sep 22 12:35:46 2023 |

JM | Bakeout plots |

Attached are plots for the previous bakeout of CARME which may aid in the bakeout to come in the following week.

Plots relate the heater temperatures and heater powers with the chamber temperature (internal floating thermocouple) and pressure inside CARME. |

| Attachment 1: Heater-chamber-temps.png

|

|

| Attachment 2: pressure-chamber-temp.png

|

|

| Attachment 3: Heater-power-chamber-temp.png

|

|

| Attachment 4: Heater-power-temp.png

|

|

|

498

|

Thu Feb 8 11:22:28 2024 |

JM | Shifters instruction 2024 |

EMERGENCY SHUTDOWNS

1. CARME motors: Q key on keyboard while on workspace 1 of appc218 (right of this double-monitor setup)

2. Internal target:

ELOG

Each shift should put all information relating to the shift in ONE elog entry unless a significant change occurs during the shift i.e beam off, target off, run change, detectors out etc.

Elog entry should be named by the shift - morning/afternoon/night followed by the current run number

TO DO FOR THE SHIFTERS - CHECK EVERY HOUR AND POST TO ELOG WITH SCREENSHOTS. ELOG should be updated with current beam energy, injection beam intensity, system checks OK/not, FEE temperature OK/not, Statistics OK/not, Merger OK/not, tape server data rate, Motors OK/not and min/max motors potentiometer value. The time of each update should be noted in the elog. Screenshots of important screens (detailed below) should also be uploaded to the elog.

CARME DAQ

CARME computer has 6 workspaces (WS), two monitors for each WS.

WS1 : left monitor - fee power

right monitor - Detector Bias control, fee power server (just a terminal, do not close)

WS2 : left monitor - DAQ controls

right monitor - DAQ server (just a terminal, do not close)

Most important tabs (DAQ controls)

- Run control : shows daq status, stopped / going

- Fee temperatures : temperatures of fees labelled aida01, aida02, aida03, aida04, aida05, aida06, aida07, aida08, aida09, aida10, aida11, aida12, aida13, aida14, aida15, aida16. Hit reload, temperatures will update and should all be green. 1-2 C above safe limit (top) is OK. More than that - warn expert shifter immediately.

- Statistics : shows the statistics for each fee. Make sure ADC Data Items is selected in the left hand menu. Hit update all (SCREENSHOT once, if no changes record OK in elog)

- System wide checks : checks for the setup. Click on 'Check Clock Status', 'Check ADC Calibration' and 'Check the White rabbit decoder status' to run checks. (SCREENSHOT once, if no changes record OK in elog)

- Spectrum browser : loads histograms for fees and fee channels from preset layouts. select layout from 'layout ID' then restore layout from 'Arrange functions' drop down menu. Check layout 1, Select log scale and change xmax as 128 . This displays the data rate per strip. If any strips are a lot higher than the others, or very different from previous entry, make a note in the ELOG. (SCREENSHOT once, if no changes record OK in elog)

- Asic control : sets asic parameters

WS3 : left monitor - Merge control, Tape server

right monitor - servers (just terminals, do not close) , data being written to file

- Check NewMerger tab. Hit reload button and see if 'current links with data' and 'current merged data rate' are updating. All links should go green, but not necessarily at the same time. Keep hitting refresh until you see all of them going green at least once.

- Data rate, hit reload should be around 100,000. Record data rate in elog

- Check tapeService tab. Hit reload button. Check data rate in Kbytes/sec box. Record data rate to elog. This is where the current run number is displayed

- On the right-hand monitor, bottom right terminal, check the current run fragment (sub-run) is being written and is slowly increasing in size. It refreshed automatically every 5 seconds.

WS4 : Leakage current plot

- Check leakage current plot is stable. Transients will occur during motors movement but baseline current should remain consistent. Make sure it is updating and time is correct. (SCREENSHOT once, record OK in elog if no changes) Check present values on WS2, CAEN window

WS5 : Online data monitoring

- Check the following plots are updating for each DSSD

- LowEnergyXYTotal (right click - col - colz). This shows the total number of events, per pixel, since the code was started / re-started.

- LowEnergyXYRate (right click - col - colz). This shows the rate over the last 20 seconds.

- LowEnergyExRate (double left click. Right click on y axis - Log scale on y). Rate over the last 20 seconds

- LowEnergyExTotal (double left click. Right click on y axis - Log scale on y). This shows the total energy deposited on all X strips since code restart.

- LowEnergyEyTotal (as above). as above, Y strips. (SCREENSHOT of each per DSSD per shift. If significant changes are observed screenshot again)

WS6 : Browser, ELOG

-->IMPORTANT NOTE: MIDAS DAQ can respond slowly. DO NOT try to change tab or give new command while the previous one is being executed. Check activity in right-hand part of tab currently in use. Do not double click on buttons.

Motors computer (Computer to the right)

- Check motors cycle is running. The code will cycle through the loaded motors instructions. When an instruction is being done it is highlighted in bold. Check the bold highlighting cycles through entire set of instructions.

- Check potentiometer is reproducing same max/min values for each cycle of instructions.

- Detectors are on LEFT and RIGHT arm.

- No need for screenshots, but record in the ELOG you checked this.

|

|

533

|

Tue Feb 20 07:50:10 2024 |

JM | DAQ restart |

DAQ restarted. Run46. All appears OK, aida01 shows high rates across ASIC 4 even with no beam which could not be resolved via ASIC control. May suggest some damge.

Merger is running and tape server is writing data to disk. Data rate is about 1300 kB/sec from 800 kb/sec due to increase in aida01 rate.

FEE temps OK

All system checks OK

Detectors moved to IN position (left arm pot = 36.5 mm, right arm =70.49 mm). Target ON.

Lost beam again.

Run 47 started.

|

|

535

|

Tue Feb 20 09:51:37 2024 |

JM | Run 48 beam on target |

Run 48 started |

|

538

|

Tue Feb 20 14:12:32 2024 |

JM | Shutdown |

CARME DAQ shutdown. FEEs turned OFF and all MIDAS server windows closed.

Detector bias turned OFF.

Final leakage current plot - attachment 1 |

| Attachment 1: Screenshot_from_2024-02-20_15-11-40.png

|

|

|

553

|

Mon May 27 15:25:08 2024 |

JM | Startup |

27/05/24

The carme-gsi computer has been moved from the server room into the shifter control room.

Startup of the DAQ looks OK. Settings loaded 2024Apr24

System wide checks OK. Aida16 clock status fails. Aida16 ADC calibration fails. Rest OK.

All FEEs look OK, we again see high rates in aida15 ~ 12k data items/sec, rate in other FEEs is 0.

Testing of the pulser widths has been done. Pulser widths will be uploaded soon.

Background run started. No beam, no target. File G22-201 and R2. Data being written is ~128 kb/s. Run will be left overnight, no night shift.

28/05/24

DAQ continues with alpha background run.

System wide checks OK. Aida16 clock status fails. Aida16 ADC calibration fails. Rest OK. Temps OK

Data can be seen in the spectrum browser on MIDAS. CARME monitoring code was started incorrectly yesterday. It has now be restarted and a small number of events are seen |

|

556

|

Wed May 29 08:10:32 2024 |

JM | Run4 - alpha background |

09:00

R4 alpha background continues, currently R4_12

Temps OK, system checks unchanged from previous status (OK, aida16 clock and ADC issue) |

|

592

|

Wed Jun 5 13:34:02 2024 |

JM | Run 37 - Change in thresholds |

14:20

Target nozzle currently being replaced. No beam

We have decided to switch to 15N beam from now on.

Beam energy for 15N is significantly higher than deuteron beam so we have increased the thresholds (slow comparator) slightly for all detectors to 500 keV (0x32).

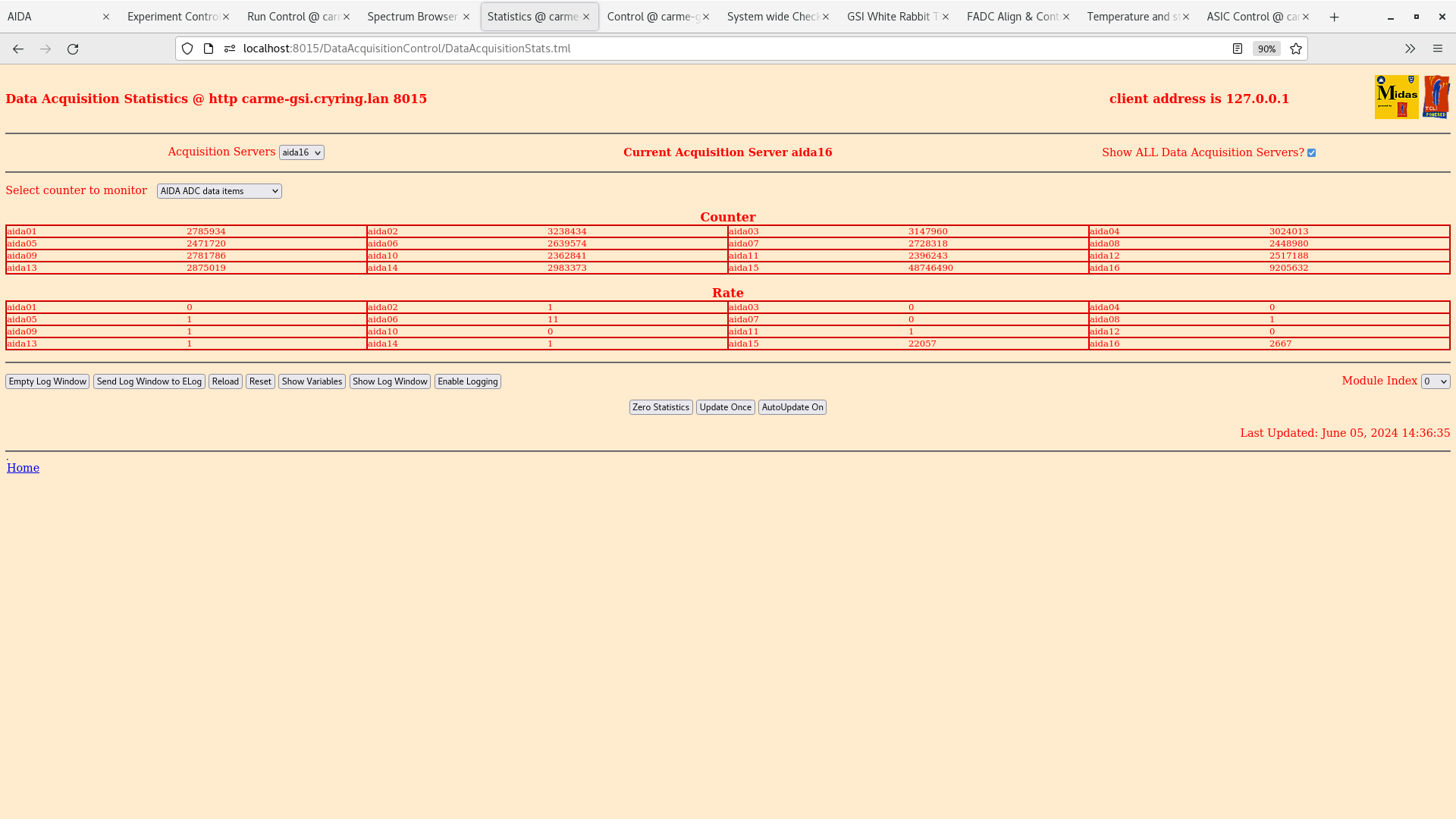

ADC data item rates - attachment 1

Run 37 started. Alpha background

Data rate ~ 200 kb/sec

17:44

All system checks OK

20:00

All system checks OK

23:30

All system checks OK

01:25

All system checks OK

03:25

All system checks OK.

Target is stable at 3.5e11, with T1=29 K

05:30

All system checks OK

Target density has slowly drifted down, and is now 1.2e11 |

| Attachment 1: Screenshot_from_2024-06-05_14-36-44.png

|

|

|

613

|

Mon Jun 10 18:22:47 2024 |

JM | Electron cooler calculations |

Ion beam energy is calculated using Beamcalc (https://web-docs.gsi.de/~lestinsk/beamcalc/electron.php)

Electron current is set to 4.3 mA and can be taken from Grafana

Alpha factor is 50

Ion energy is then adjusted using the cooler voltage

The cooler voltage inserted into BeamCalc is taken from the FC20 voltage divider. However an offset from the space charge correction is required!

This correction is determined experimentally by changing the electron current and finding the cooler voltage which maintains the optimum cooling of the beam.

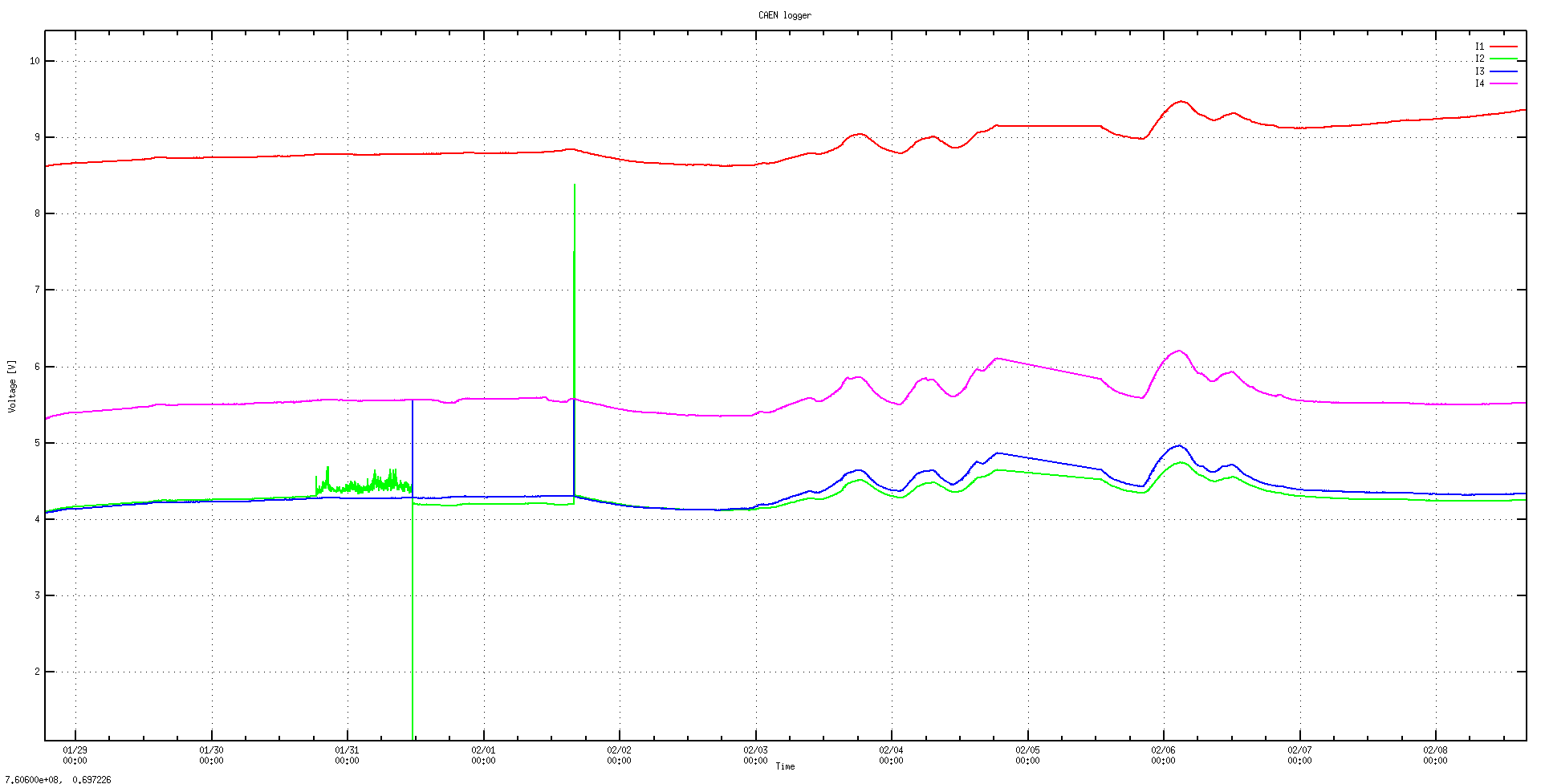

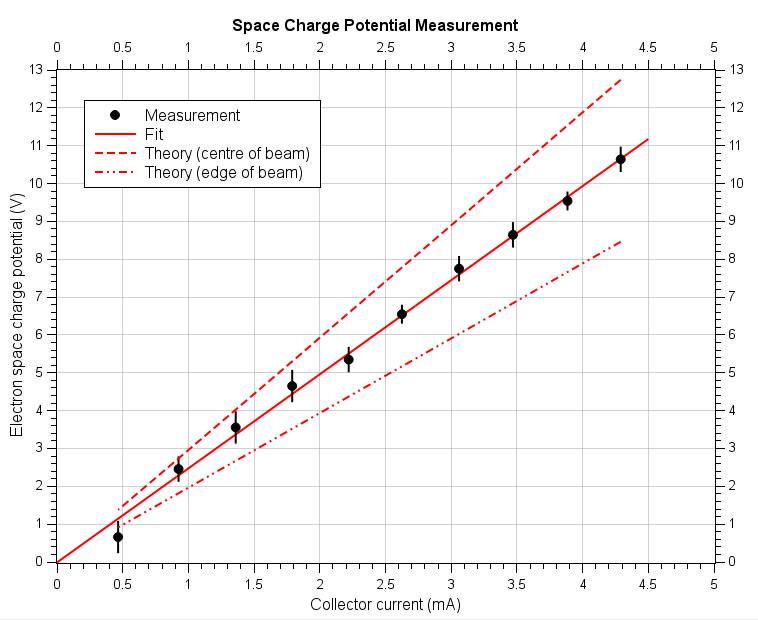

Attachment 1 shows this plot for 15N1+ at ~0.426 MeV/u

Attachment 2 shows this same plot in comparison with BeamCalc

To obtain the correct energy we need to subtract 2V from the voltage used in BeamCalc

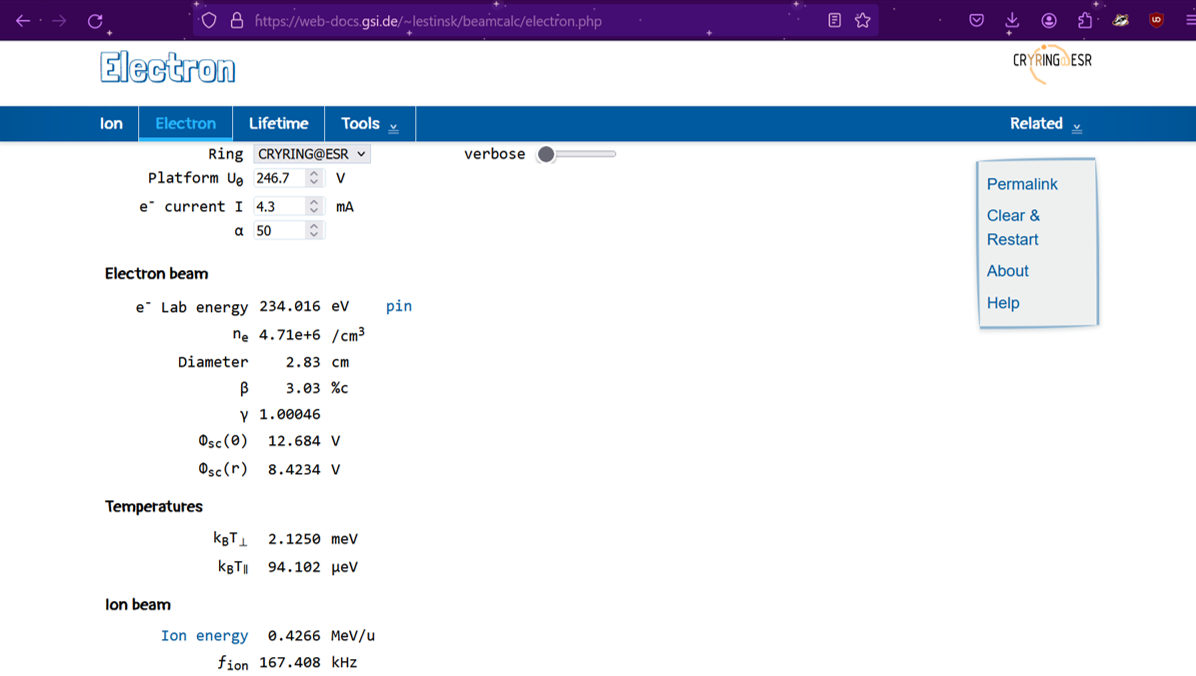

An example is shown in attachment 3

Here to obtain an ion energy of 426.6 keV/u requires a cooler voltage of 246.7 V. But, due to the space charge correction this value should be 244.7 V.

The cooler voltage setpoint should therefore be chosen so that the FC20 voltage divider reads 244.7 V.

The setpoint needs to be ~0.55 V higher than the desired value i.e setpoint of 245.25 V to obtain the required 244.7 V (at least this beamtime it does)

|

| Attachment 1: space-charge-2.png

|

|

| Attachment 2: space-charge-1.png

|

|

| Attachment 3: BeamCalc.png

|

|

|

619

|

Tue Jun 11 20:10:25 2024 |

JM | Run 63 - Beam only background |

21:00

Claude has achieved optimal cooling parameters for the beam

No target and internal work inside the cave tomorrow is required

Run 63 going - beam only background

Right arm at 64.60 mm

Left arm IN at 36.54 mm

MBS fakemotion script running

High rates on top left dssd again. Cycle left servo motor two times resolved issue

Rates OK. Temps OK. |

|

632

|

Fri Jun 14 14:52:02 2024 |

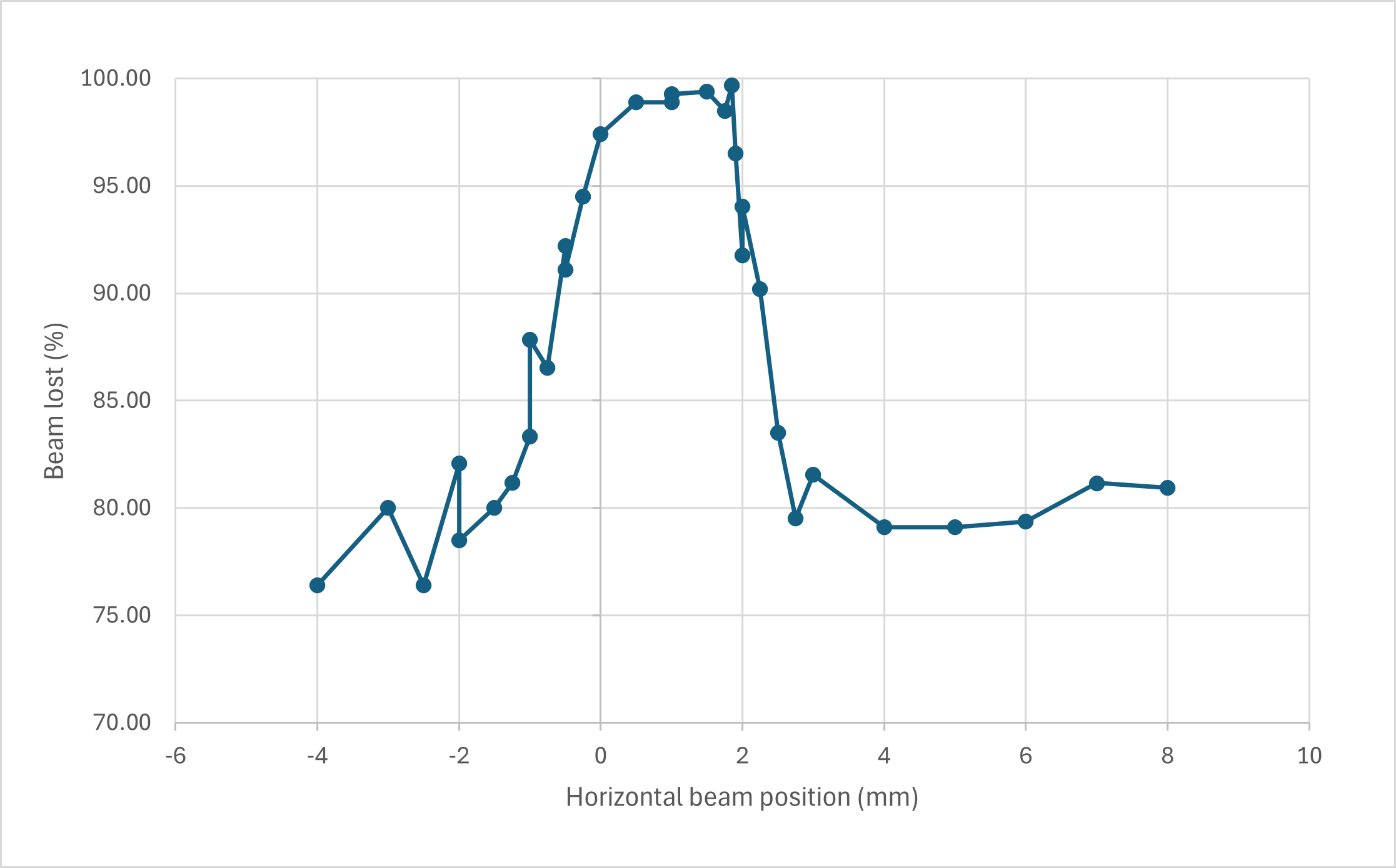

JM | Beam-Target Overlap Scan |

The orbit of the beam in the ring was re-configured so that the beam position is more central.

With the target density at ~6e11 at/cm2 this allowed a target overlap scan using the beam lifetime to be performed.

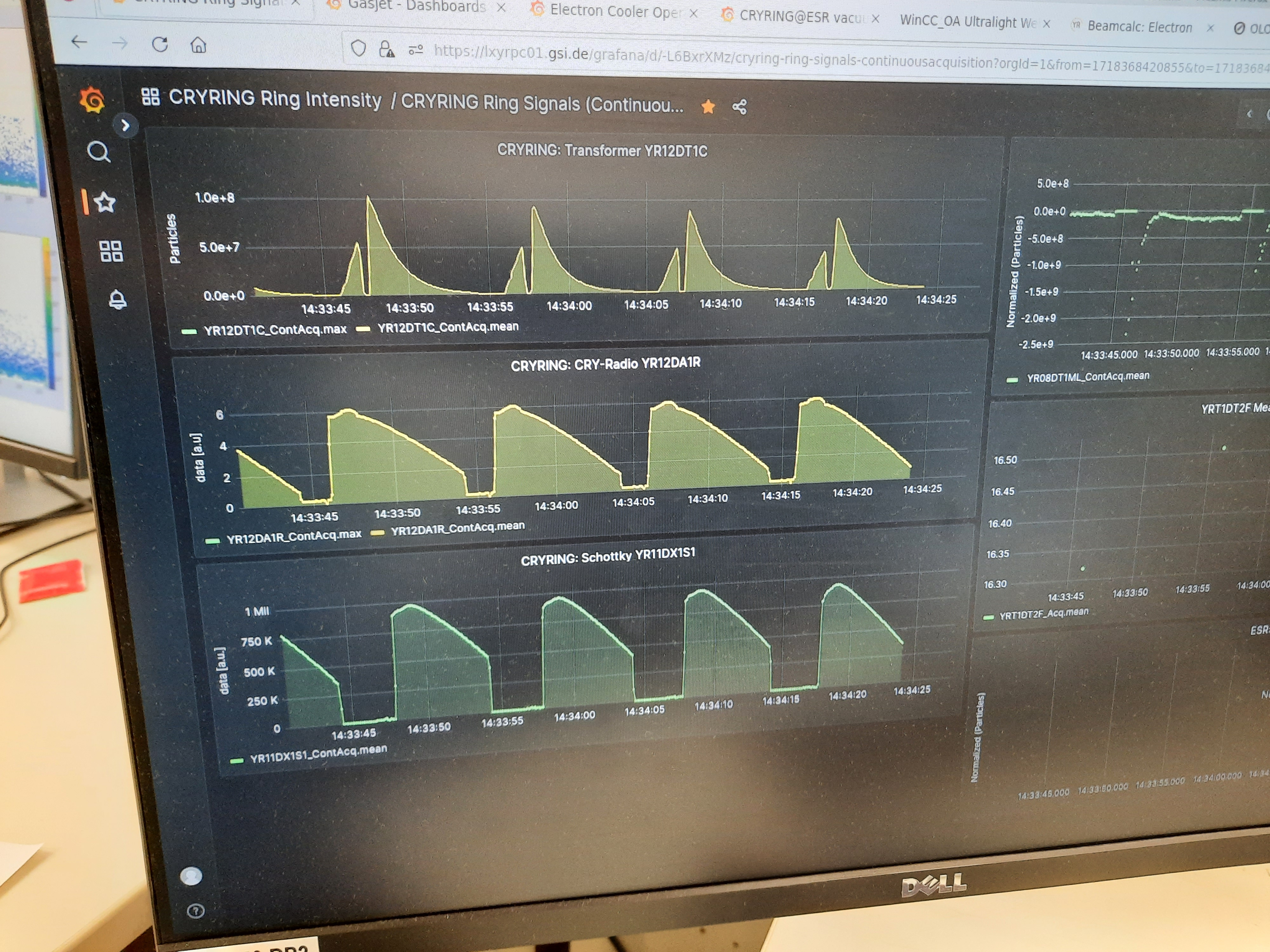

Beam put into bunched mode to allow the number of particles to be observed on Grafana.

The number of particles injected at the start of the cycle was then compared to the number of particles at the end of the cycle to gauge the % of the beam lost.

A flat top region was observed where >99% of the particles in the ring were lost. The centre of this flat top corresponds to a horizontal beam position of 1.0 mm

Attachment 1 - Grafana plot of beam intensity

Attachment 2 - Plot of overlap |

| Attachment 1: 20240614_153532.jpg

|

|

| Attachment 2: Beam-overlap-updated.png

|

|

|

643

|

Sun Jun 16 22:40:11 2024 |

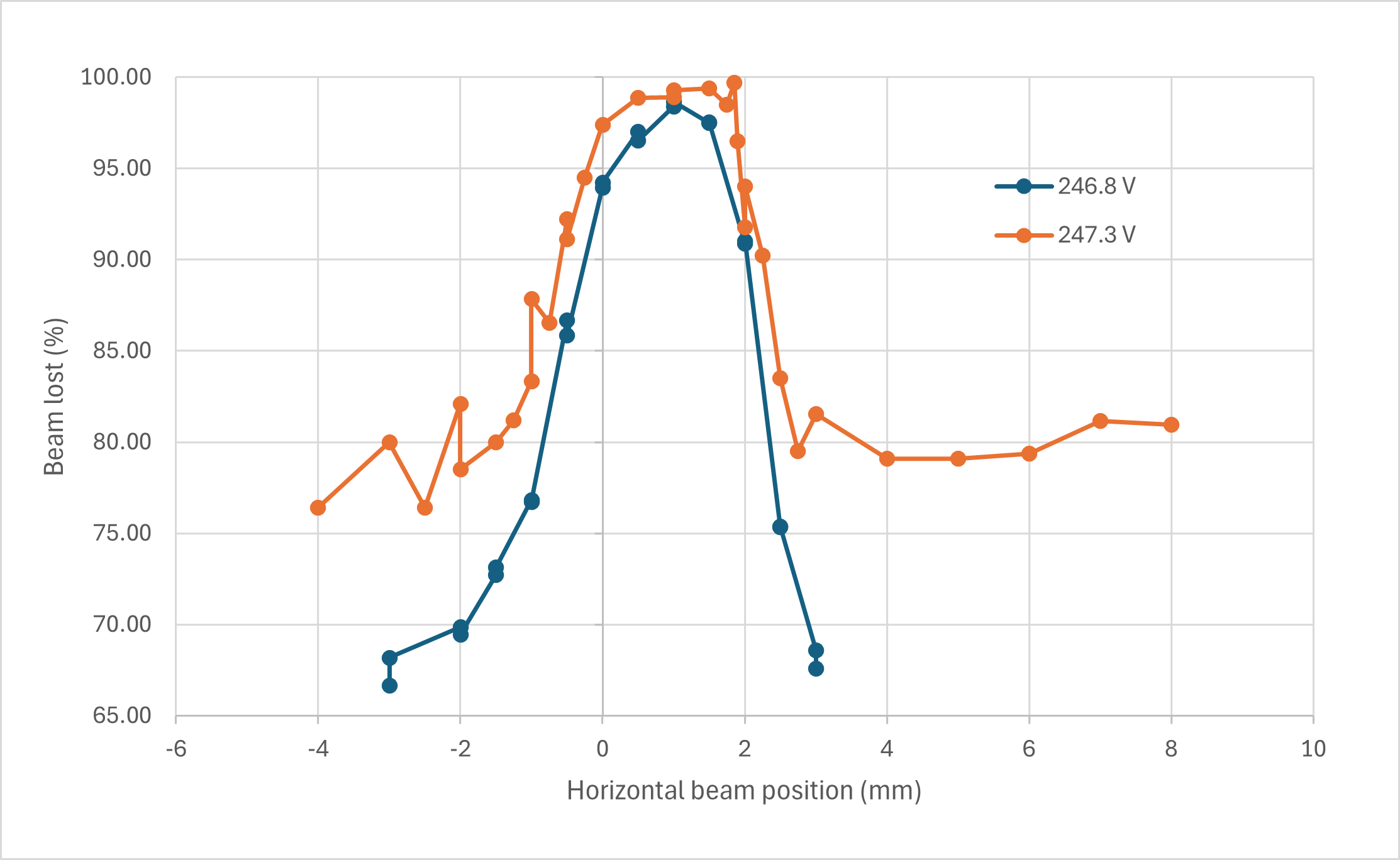

JM | Target overlap test - R81 |

23:10

Beam set to bunched mode to observe beam lifetime.

Electron cooler voltage setpoint kept at 246.8 V. Note this is 0.5 V lower than the previous test where the setpoint was 247.3 V

This corresponds to ~13.5 keV in the beam energy.

Attachment 1 shows target scan. Maximum still observed at a horizontal beam position of 1.0 mm.

Moving 0.5 V up or down does not impact the orbit enough to shift the beam position off the target.

Beam lifetime off target seems larger than previous, perhaps better vacuum conditions?

Back to coasting beam |

| Attachment 1: Beam-overlap-updated2.png

|

|

|

644

|

Sun Jun 16 22:49:22 2024 |

JM | Run 82 |

23:38

Cooler voltage setpoint 247.5 V.

FC20 read value 246.95 V.

Right arm at 64.60 mm

Left arm IN at 36.54 mm

FakeMotion script running

horizontal beam position 1.0 mm

vertical beam position -5mm

Beam intensity 7.0e+7 particles.

Target density ~5e11 at/cm2

Target temperature is 38.6 K. Values of E1 is 820 Hz, 2.7A, 1.7e-1 mbar

All checks OK |

|

645

|

Mon Jun 17 00:05:13 2024 |

JM | Run 83 |

01:00

Cooler voltage setpoint 247.6 V.

FC20 read value 247.05 V.

Right arm at 64.60 mm

Left arm IN at 36.54 mm

FakeMotion script running

horizontal beam position 1.0 mm

vertical beam position -5mm

Beam intensity 7.0e+7 particles.

Target density ~5e11 at/cm2

Target temperature is 38.6 K. Values of E1 is 820 Hz, 2.7A, 1.7e-1 mbar

All checks OK

02:50

Noise increase on dssd top left. Moved servo motor to resolve issue. |

|

646

|

Mon Jun 17 02:05:37 2024 |

JM | Run 84 |

03:00

Cooler voltage setpoint 247.7 V.

FC20 read value 247.15 V.

Right arm at 64.60 mm

Left arm IN at 36.54 mm

FakeMotion script running

horizontal beam position 1.0 mm

vertical beam position -5mm

Beam intensity 7.0e+7 particles.

Target density ~5e11 at/cm2

Target temperature is 38.6 K. Values of E1 is 820 Hz, 2.7A, 1.8e-1 mbar

All checks OK

03:34

Noise increase in top left dssd. Servo motor moved to resolve issue. |

|

647

|

Mon Jun 17 04:01:16 2024 |

JM | Run 85 |

05:00

Cooler voltage setpoint 247.45 V.

FC20 read value 246.9 V.

Right arm at 64.60 mm

Left arm IN at 36.54 mm

FakeMotion script running

horizontal beam position 1.0 mm

vertical beam position -5mm

Beam intensity 7.0e+7 particles.

Target density ~5e11 at/cm2

Target temperature is 38.6 K. Values of E1 is 819 Hz, 2.7A, 1.85e-1 mbar

All checks OK |

|

648

|

Mon Jun 17 05:47:35 2024 |

JM | Run 86 |

06:50

No sign of the resonance during night shift. New run started but when operators are avaiable we will likely move to higher energies to try and observe the (p,a) reaction.

Cooler voltage setpoint 247.8 V.

FC20 read value 247.25 V.

Right arm at 64.60 mm

Left arm IN at 36.54 mm

FakeMotion script running

horizontal beam position 1.0 mm

vertical beam position -5mm

Beam intensity 7.0e+7 particles.

Target density ~5e11 at/cm2 |