| ID |

Date |

Author |

Subject |

|

471

|

Tue Jan 16 16:01:48 2024 |

TD | Change CARMEraspberrypi to nnrpi1 |

Change RPi from CARMEraspberrypi to nnrpi1 to provide carme-gsi access to Rly16 to control USB-controlled ac mains relay.

nnrpi1 is already defined in carme-gsi:/etc/dhcp/dhcpd.conf

Transfer RPi network connection from CRYRING local network to AIDA 24-port network Gbit switch

Change /etc/hostname from

CARMEraspberrypi

to

nnrpi1

Change /etc/hosts from

127.0.0.1 localhost

::1 localhost ip6-localhost ip6-loopback

ff02::1 ip6-allnodes

ff02::2 ip6-allrouters

127.0.1.1 raspberrypi

to

127.0.0.1 localhost

::1 localhost ip6-localhost ip6-loopback

ff02::1 ip6-allnodes

ff02::2 ip6-allrouters

127.0.1.1 nnrpi1

Reboot RPi

Login to RPi and start MIDAS 8015 service

/MIDAS/TclHttpd/linux-arm/TclHttpd-server &

Open new browser tab on carme-gsi

http://nnrpi1:8015/AIDA/Rly16/Rly16.tml |

| Attachment 1: Capture.PNG

|

|

|

33

|

Tue Nov 10 12:25:29 2020 |

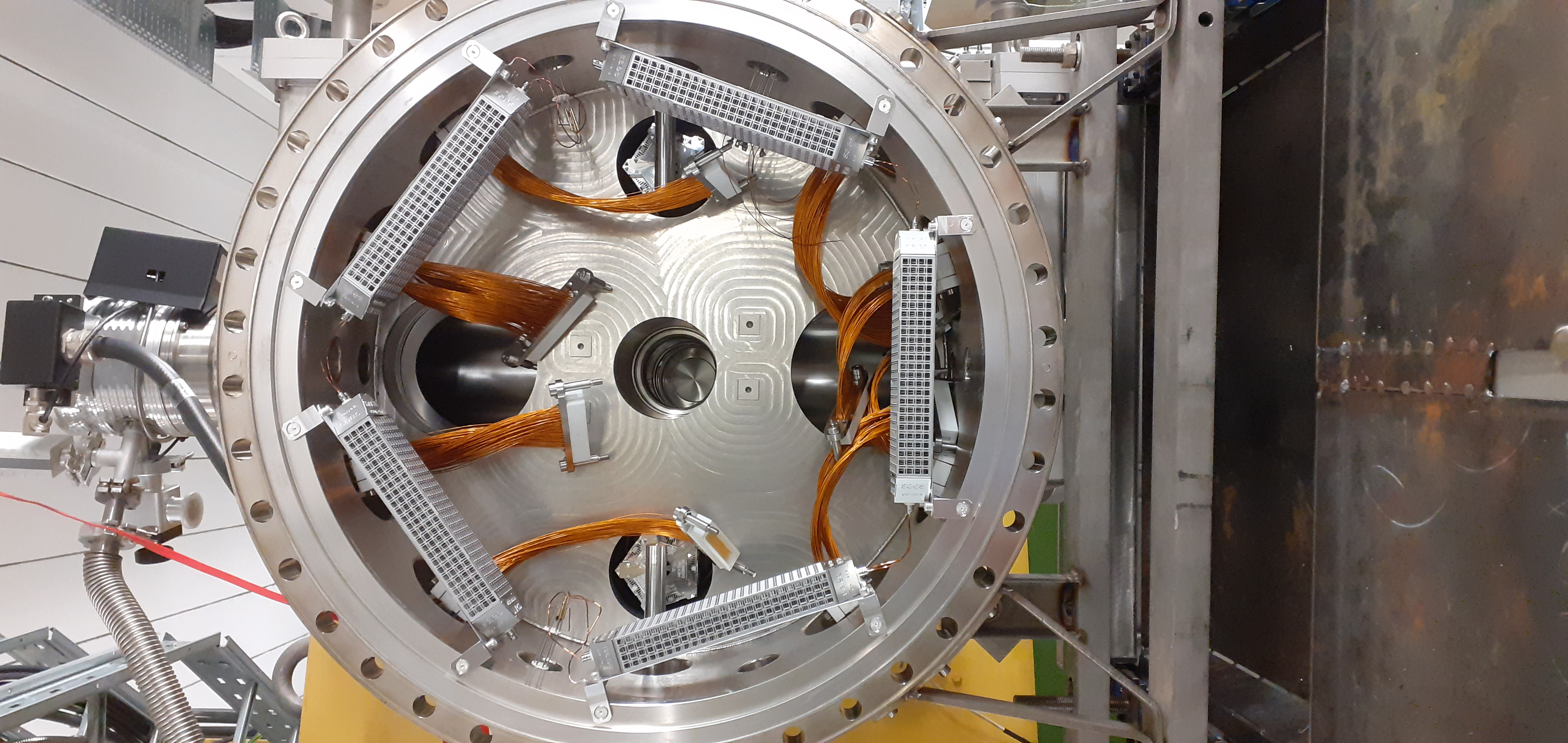

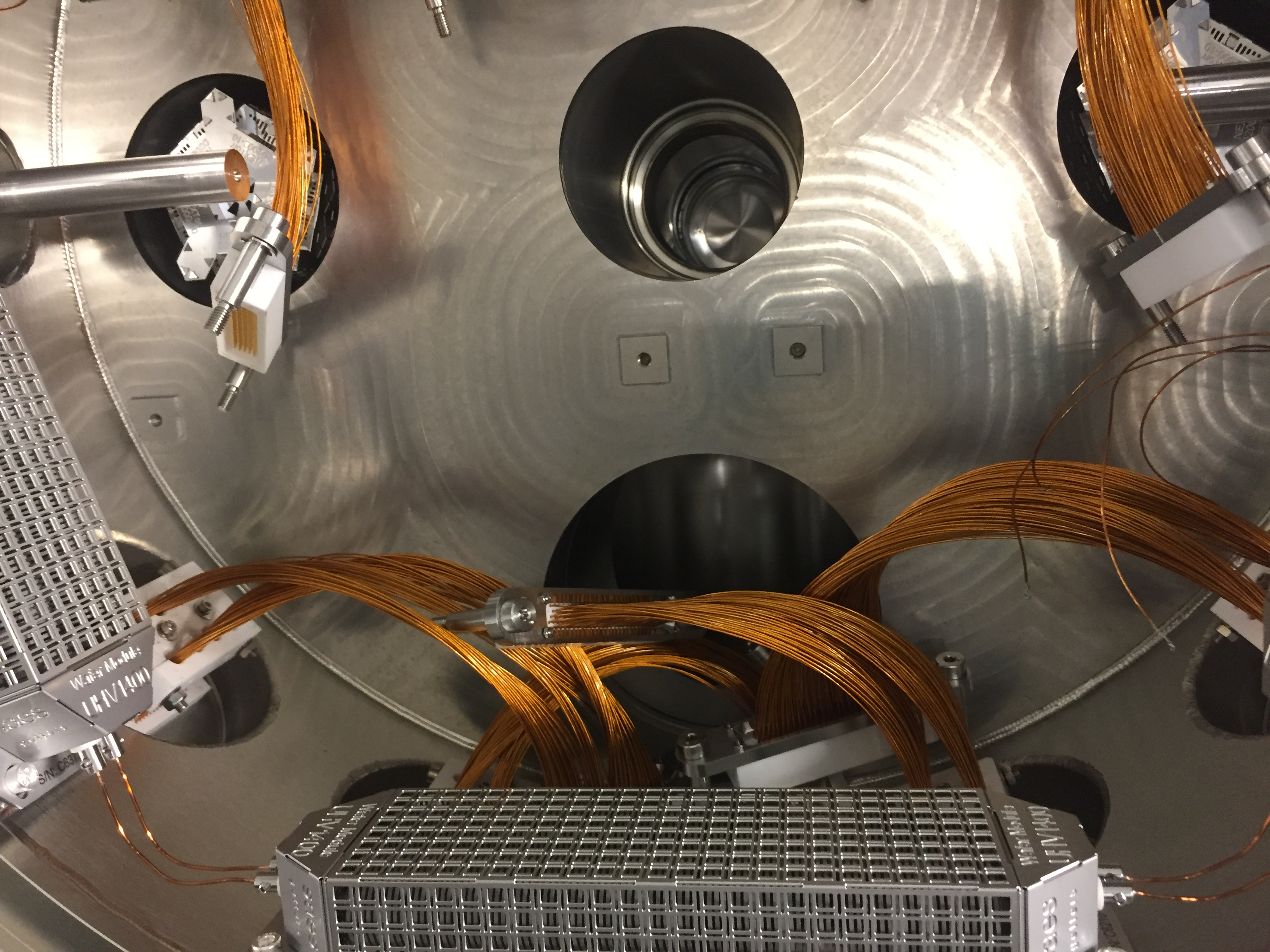

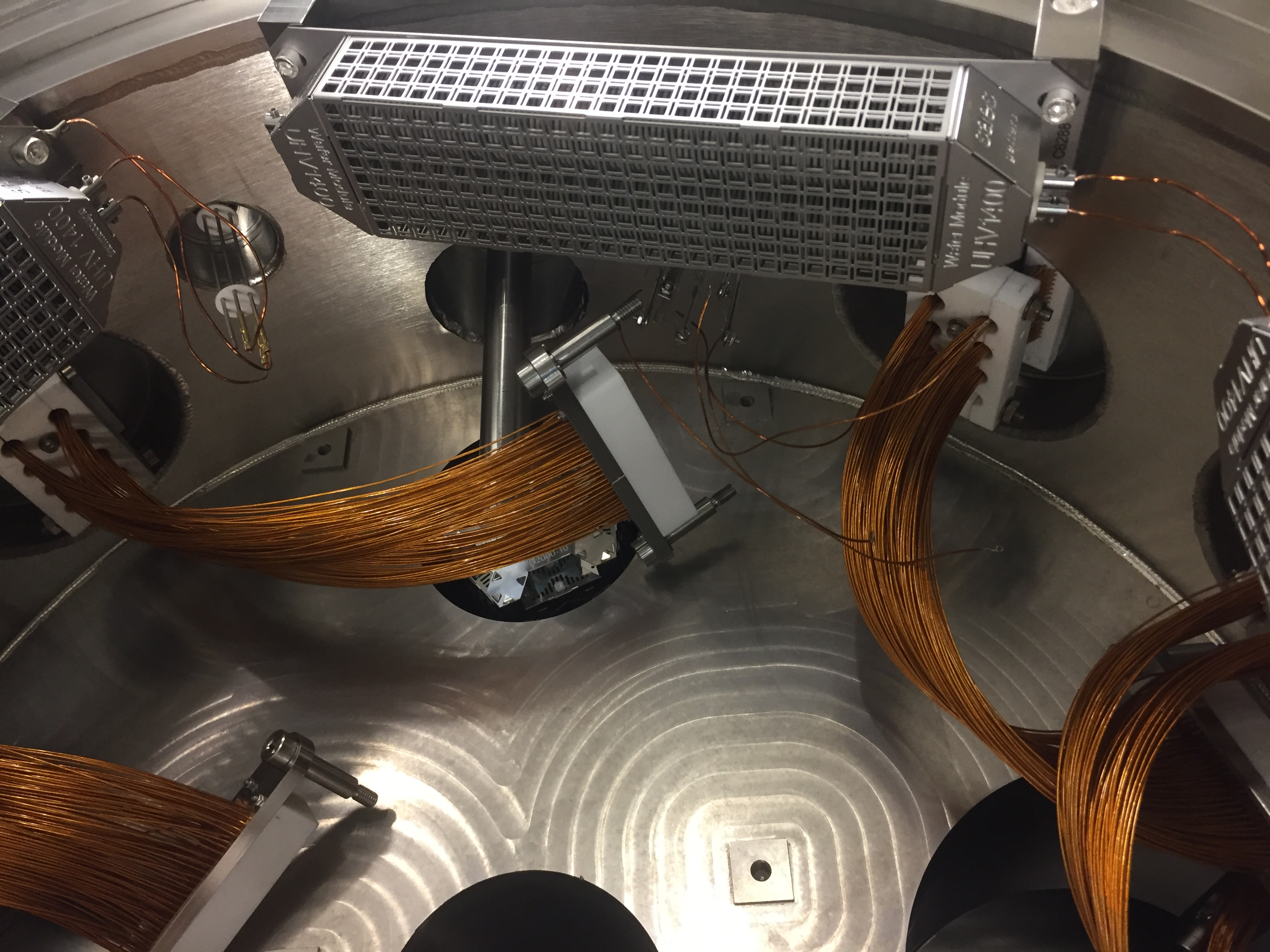

JM | Cable harnesses |

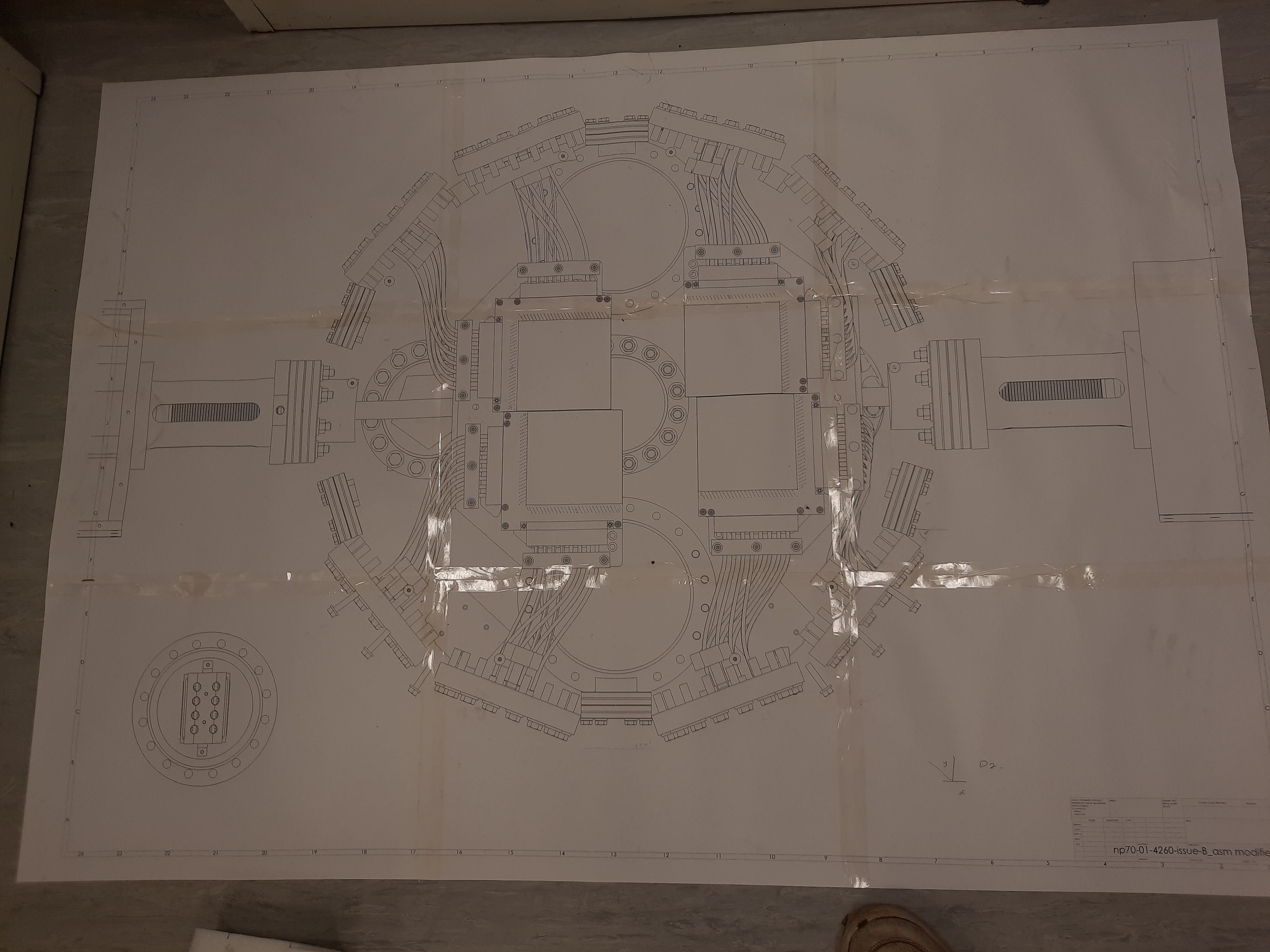

The length of the wire needed was estimated with the aid of a scale image of the detectors in the CARME chamber and foam model pieces. Wire length estimated by simply cutting wire so that it 'fits' the scale model and by taking coordinates of the end points of the longest sections of wire needed on the model and calculating a bezier curve to estimate wire length. Bezier curve calculated by inputting the endpoints of the wire and control points such that the wire comes out of the connector at the specified angle in the scale diagram. Figure 1 shows the bezier curve (orange), distance between the endpoints (green) and the control point plot. The length of wire required by the bezier curve is approximately that of cutting wire to fit the scale model.

Two groups of harnesses are needed to be built, a short section which correspond to the top and bottom of the detectors, and longer sections needed for the sides of the detectors. Lengths of these wires is;

Short: 225 mm

Long: 285 mm

Wire is cut to length using a circular object with the required circumference. Wire is wrapped round the object and cut to give required length. Wire is then stripped, crimped and inserted into the connectors with the correct pin assignment. Inserting wire into connectors acts as a good quality check, as incorrectly crimped wires will not fit into connectors. Crimp is set to setting 12 for the male crimps and 10 for the female crimps. Wire stripper has to be cleaned of stripped ends often as it is liable to jam and wire must be inserted into stripper straight, else strip will clip some of the conductors in the wire.

As of 9/11/20 two harnesses (1 long, 1 short) have been constructed.

8 harnesses constructed and sent to DAresbury for cleaning 20/11/20 |

| Attachment 1: 20201102_155336.jpg

|

|

| Attachment 2: Figure_1.png

|

|

| Attachment 3: 20201102_154648.jpg

|

|

| Attachment 4: Photos.zip

|

|

635

|

Sat Jun 15 00:46:45 2024 |

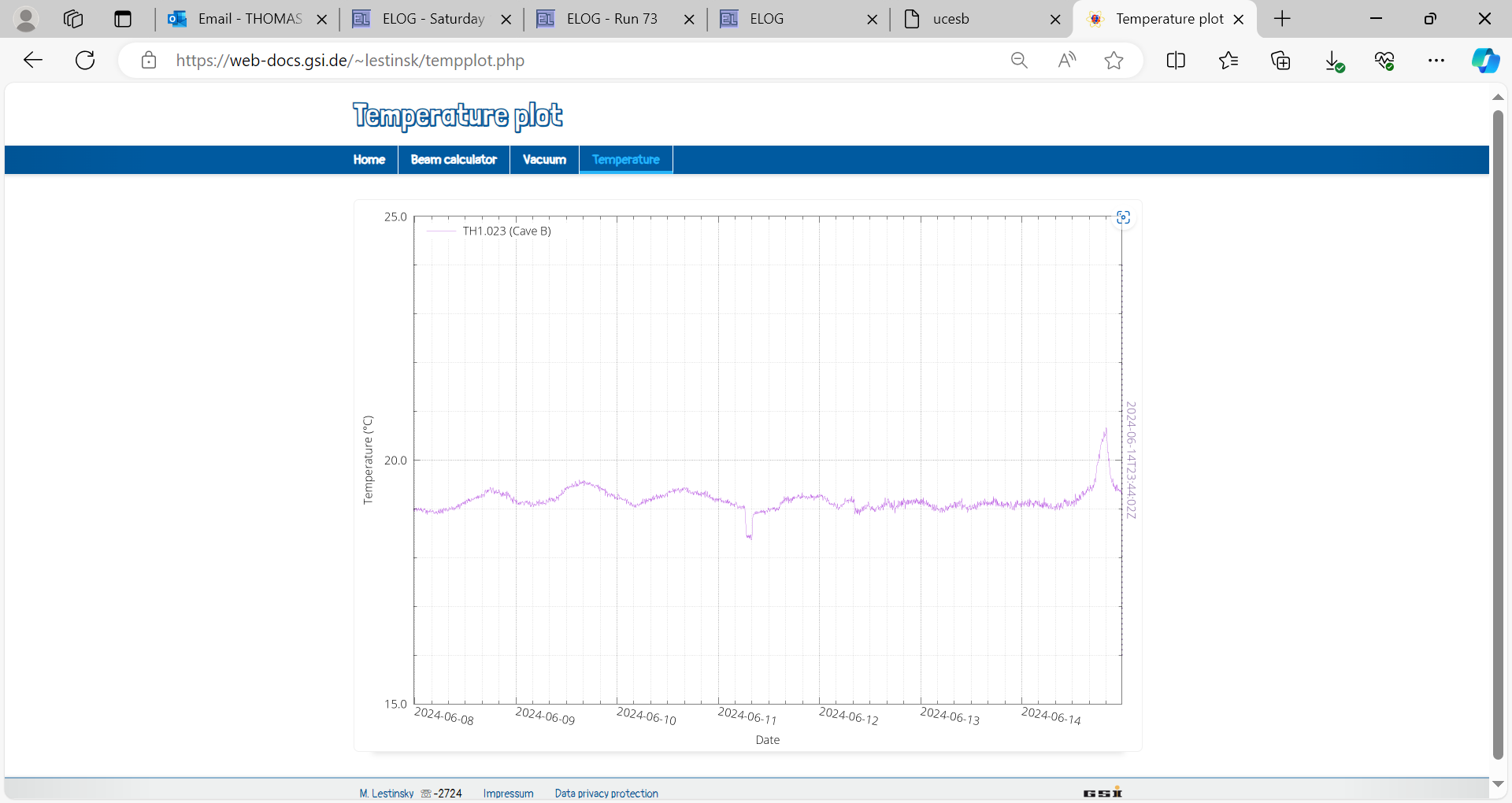

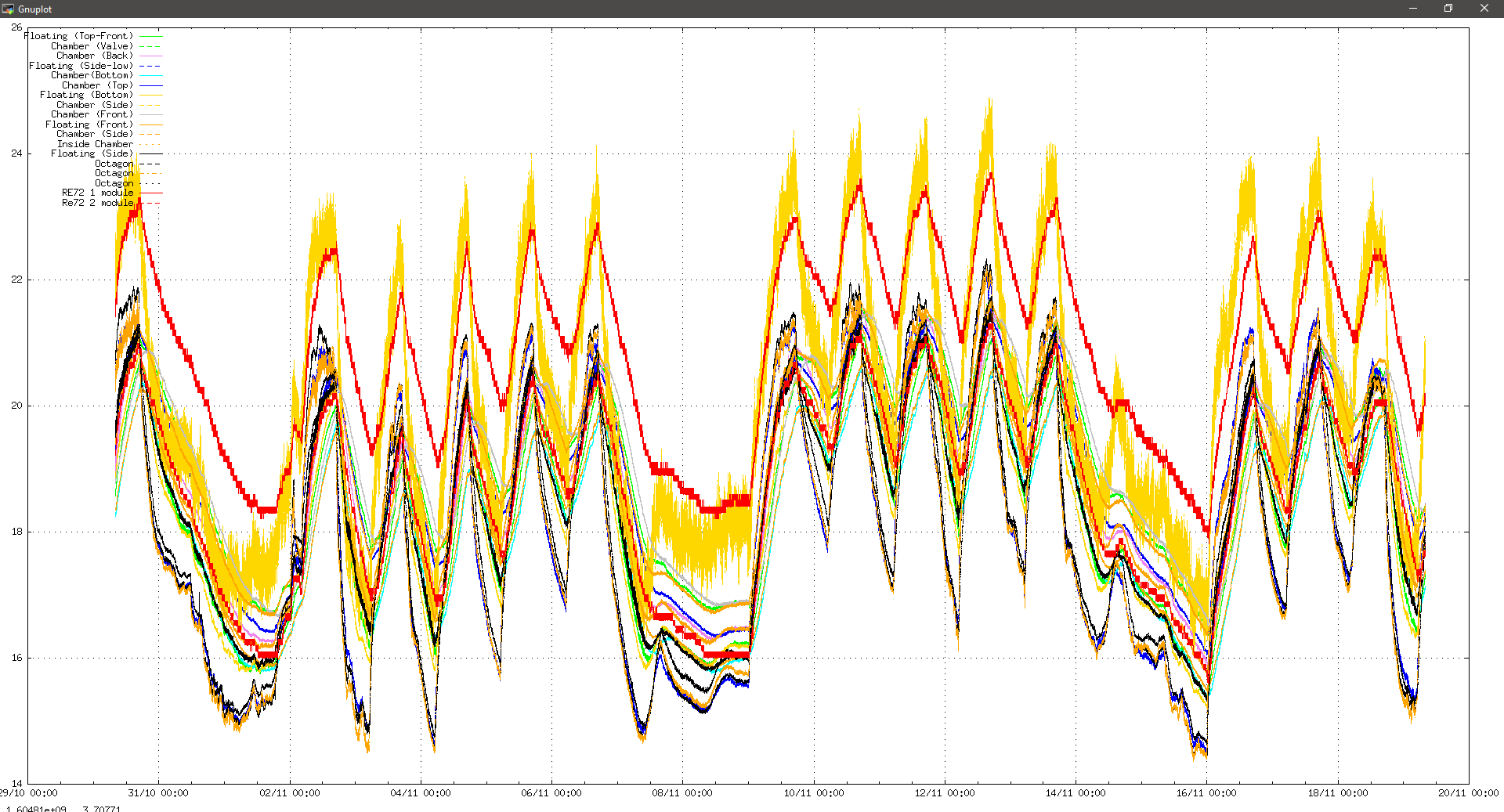

TD | CRYRING hall temperature transient |

CRYRING hall temperature transient - evening of Friday 14 June

Cooling of recirculating water failed on a number of circuits within the GSI experimental hall including S4 and CRYRING

Subsequently repaired bu on-call maintenance engineer |

| Attachment 1: Capture.PNG

|

|

|

150

|

Wed Nov 10 18:38:16 2021 |

RSS TD + ML OG AK NK | CARME wrapped in heating tape |

Heating and electronic experts were in CRYRING and were unhappy with the damaged wire. Heaters were opened by OG, but no damage was found. It is suggested to replace the entire wire and then get it approved by the concerned authority.

To avoid further delays, ML and TD agreed on heating tapes/wires covering the chamber. OG helped in wrapping the heating wire around. Tent is to be built by tomorrow.

MG and RSS tried the magnetic power back off thing which eventually did not work.

AK and NK helped with the power and thermocouple of the heating wire. NK has also covered the pipe and bellows near the magnet with heating jackets.

|

| Attachment 1: IMG_5514(1).JPG

|

.JPG.png)

|

| Attachment 2: IMG_5517(1).JPG

|

.JPG.png)

|

| Attachment 3: IMG_5518.JPG

|

|

| Attachment 4: IMG_5520.JPG

|

|

| Attachment 5: IMG_5521(1).JPG

|

.JPG.png)

|

|

388

|

Tue Apr 25 13:22:19 2023 |

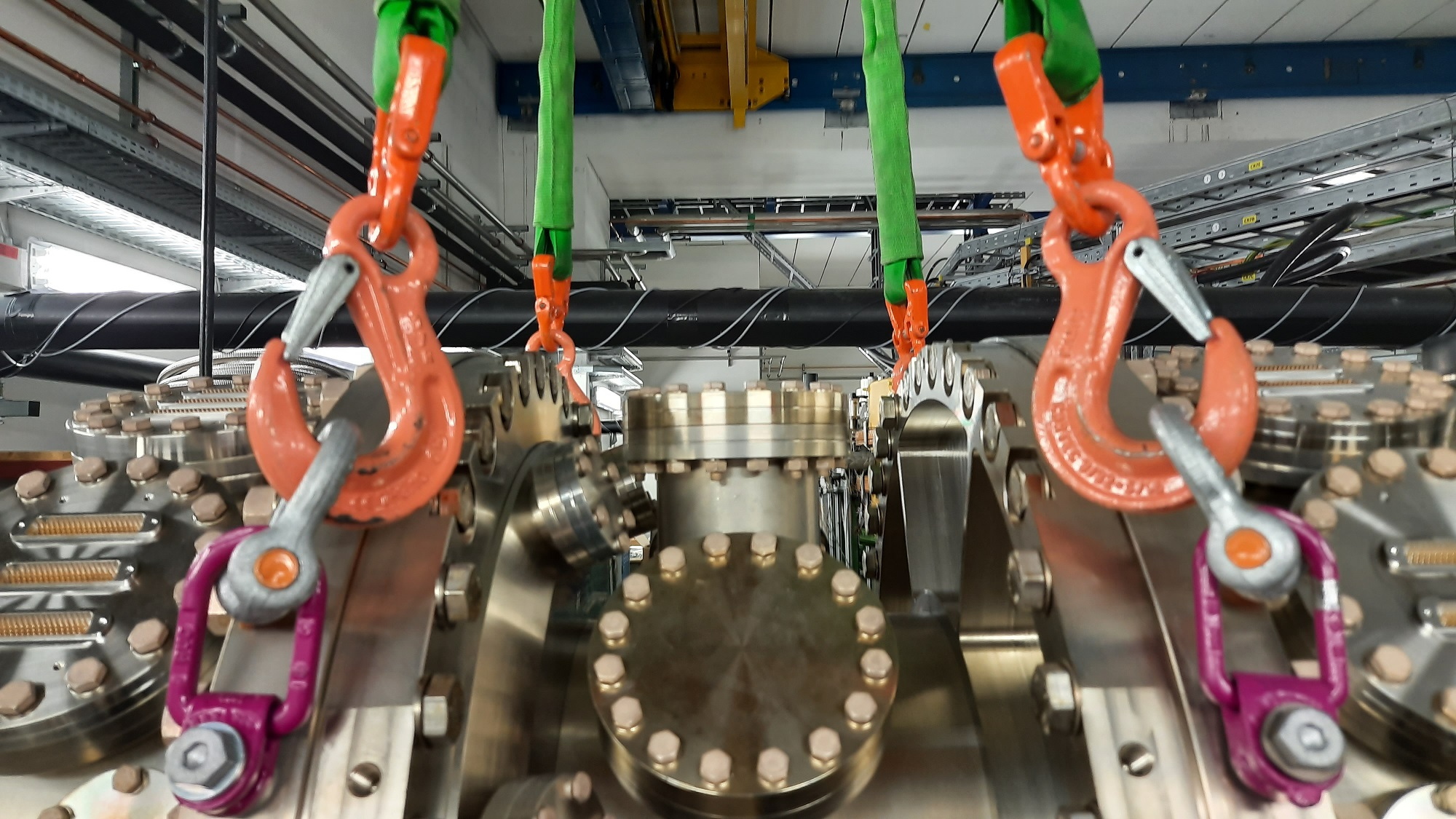

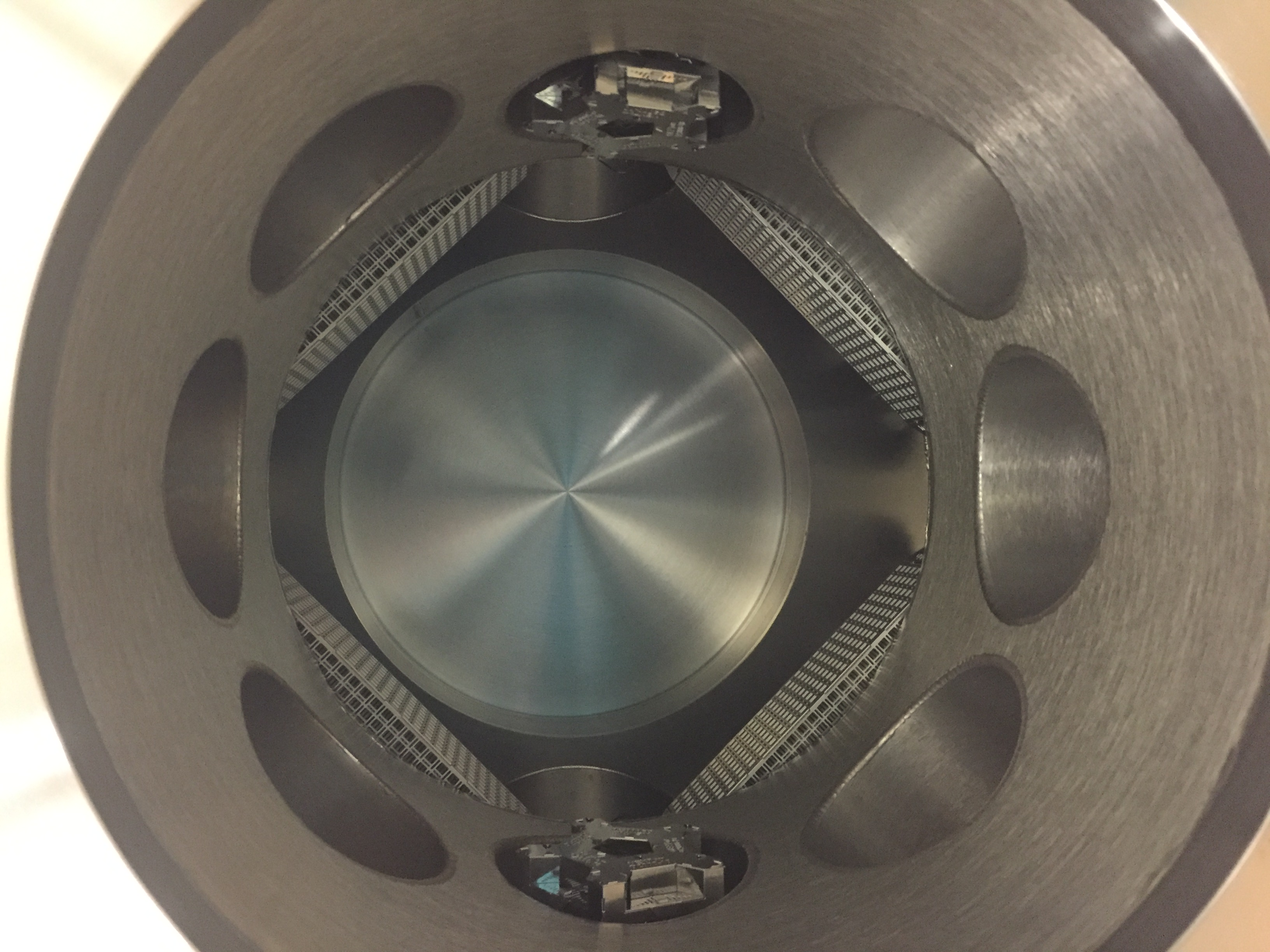

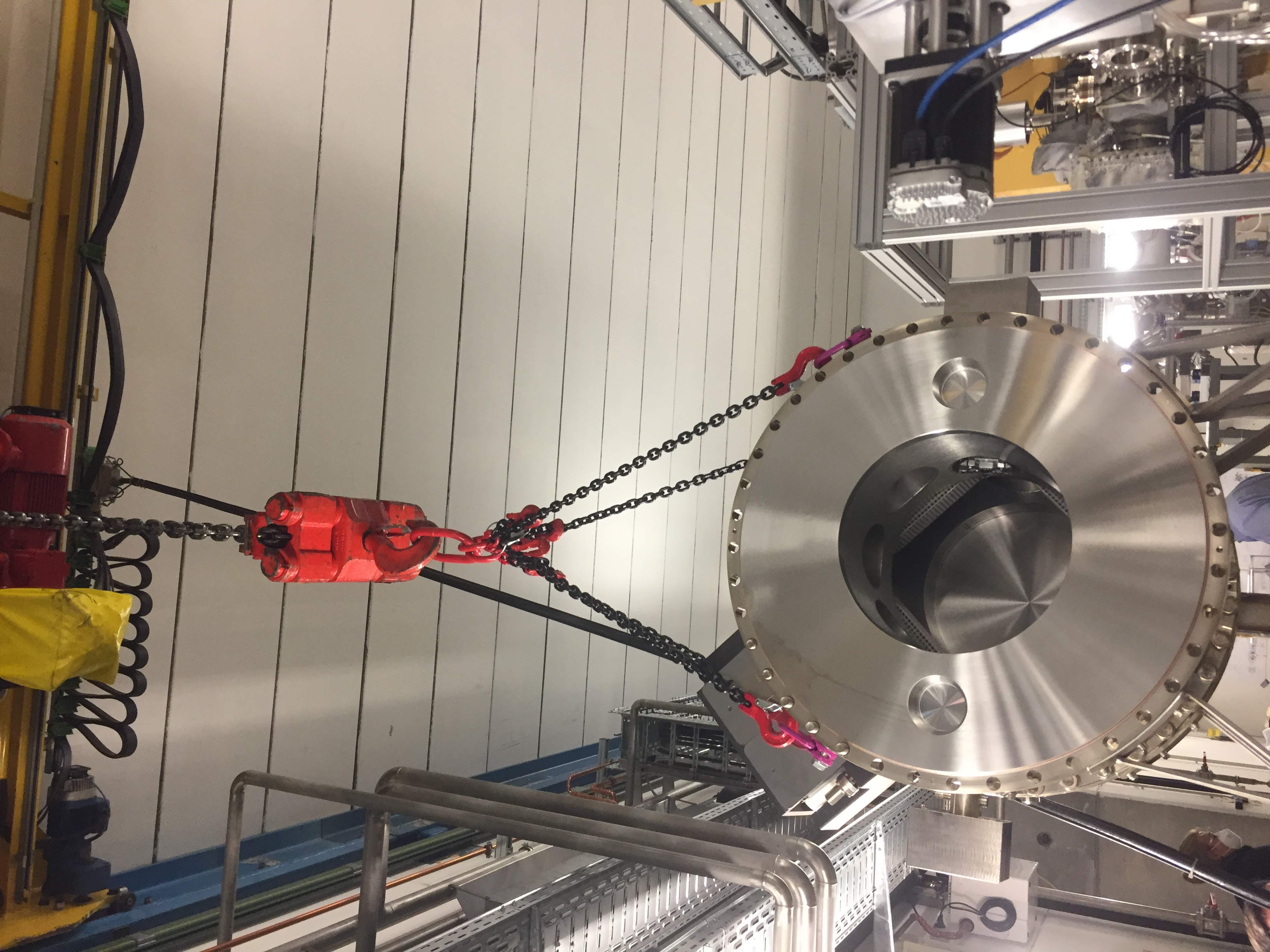

JM | CARME venting |

CARME venting using nitrogen gas bottle.

Coolant pipes dismounted from the chamber

Feed-through flange for n+n bias flange for bottom detector has a bent pin image attached. Clearer image of bent pin for ERNI connector used for aida03 also attached. All other feed-throughs and adaptor cards appear undamaged. |

| Attachment 1: 20230425_134119.jpg

|

|

| Attachment 2: 20230425_132944.jpg

|

|

|

69

|

Thu Sep 16 15:24:29 2021 |

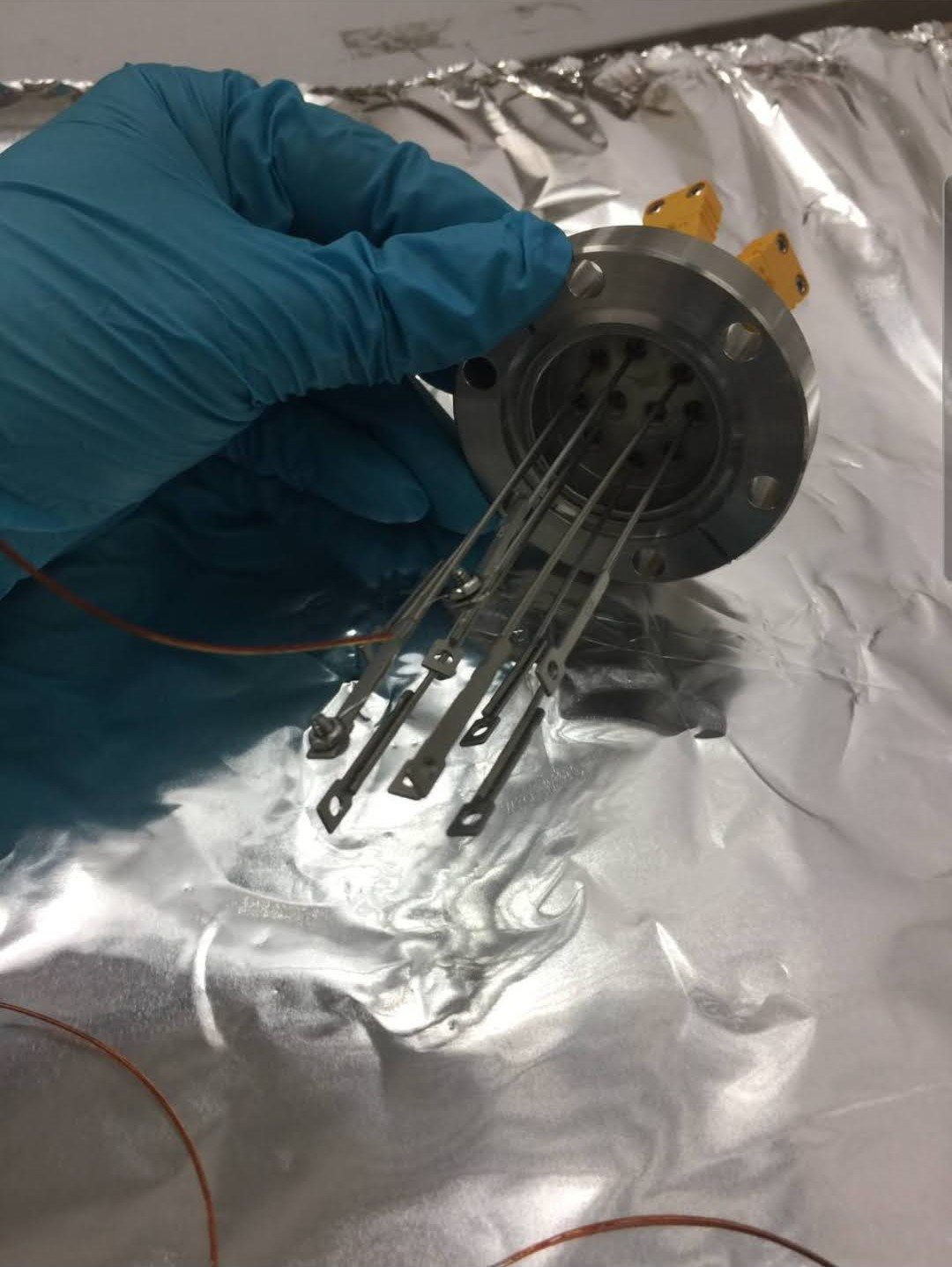

JM RSS | CARME vented + thermocouple feedthrough |

Chamber has been vented back to atmosphere.

Motor was able to be pulled back to insert bloacking pin once at atmosphere.

Thermocouple feedthrough constructed with 4 thermocuples attached. Internal thermocouples each ~200mm in length with external thermocouples each ~1m in length. All were tested by plugging into TC08 and using baking code. Feedthrough will be installed under the motors flange tomorrow.

Survey team come tomorrow morning, afterwhich ion pump and RGA will also be installed. |

| Attachment 1: 1.jpg

|

|

| Attachment 2: 2.jpg

|

|

| Attachment 3: 3.jpg

|

|

|

412

|

Mon Jun 26 14:49:05 2023 |

JM, TD | CARME vented |

26/06/23

This morning the pressure was 4e-7 mbar. The bolts on the windows and the large flange on the bottom of the interaction chamber were tightend. No leak was present on the windows following tightening. However, the leak on the rotatable flange, although decreased in magnitude, was still in the 1e-9 mbar l/s range when helium was sprayed. The torque on these bolts was 36 Nm, which is already past the 33 Nm recommendation for M8 bolts. It was decided to vent the section and examine the flange.

Tomorrow morning the gasket will be replaced and we will begin pumping again in the afternoon.

27/06/23

Flange was removed and examined. Several scratches on the surface of the flange including on the knife edge were visible. These scratches were sanded away by the grossmontage and the flange was remounted. CARME was pumped down in the afternoon. Pressure was in the 1.5E-3 mbar range when the scroll pump stalled causing the pressure to increase and the turbo to increase in current to keep up. Error symbol was observed on the scroll, unknown to why it stalled. VAT gate valve to the chamber was closed and all pumps turned off to be safe, P~ 1mbar.

28/06/23

Jan started the scroll pump on just the backing line using the gas balast to see if too much water was pumped. Scroll running fine so the gate valve to the chamber was opened and the turbo started.

|

|

61

|

Tue Sep 7 12:40:43 2021 |

CB ML + RH | CARME survey preparation |

Rudi and survey group representative came

to CARME.

Elephant feet confirmed to be out of

position with respect to the models. Still

unclear if CARME is where it should be

with respect to the jet target and

electron target. I.e. do they have space

to mount? Do we have to move CARME again

(hopefully not!!)

Valve to downstream confirmed out of

alignment. Solution unclear but may be

needed to ensure beam goes through

detectors correctly.

Survey group will come to confirm CARME

position on Thursday 16 September. We

cannot mount baking tent until then, but

no major issue given delays due to strain

relieves and shutdown on 12-15 September. |

|

49

|

Tue Aug 31 18:56:35 2021 |

CB | CARME status |

(ELOG does not allow more pictures to be added to previous entry) |

| Attachment 1: 20210831_171533.jpg

|

|

| Attachment 2: 20210831_171458.jpg

|

|

| Attachment 3: 20210831_171501.jpg

|

|

| Attachment 4: 20210831_171506.jpg

|

|

| Attachment 5: 20210831_171510.jpg

|

|

| Attachment 6: 20210831_171514.jpg

|

|

| Attachment 7: 20210831_171517.jpg

|

|

| Attachment 8: 20210831_171520.jpg

|

|

| Attachment 9: 20210831_171524.jpg

|

|

|

658

|

Wed Jun 19 12:11:22 2024 |

CB, RSS | CARME status |

DSSD off

FEEs off

Motors out, pin inserted, compressed air closed, power removed from motors box.

Motors and temperature logs are in carme-gsi:logs/G22-200

Next experiment will install new setup attached to gas target. Some baking and vacuum operations required. Everything should stay off for safety until they are done. |

|

761

|

Wed Jul 9 11:21:14 2025 |

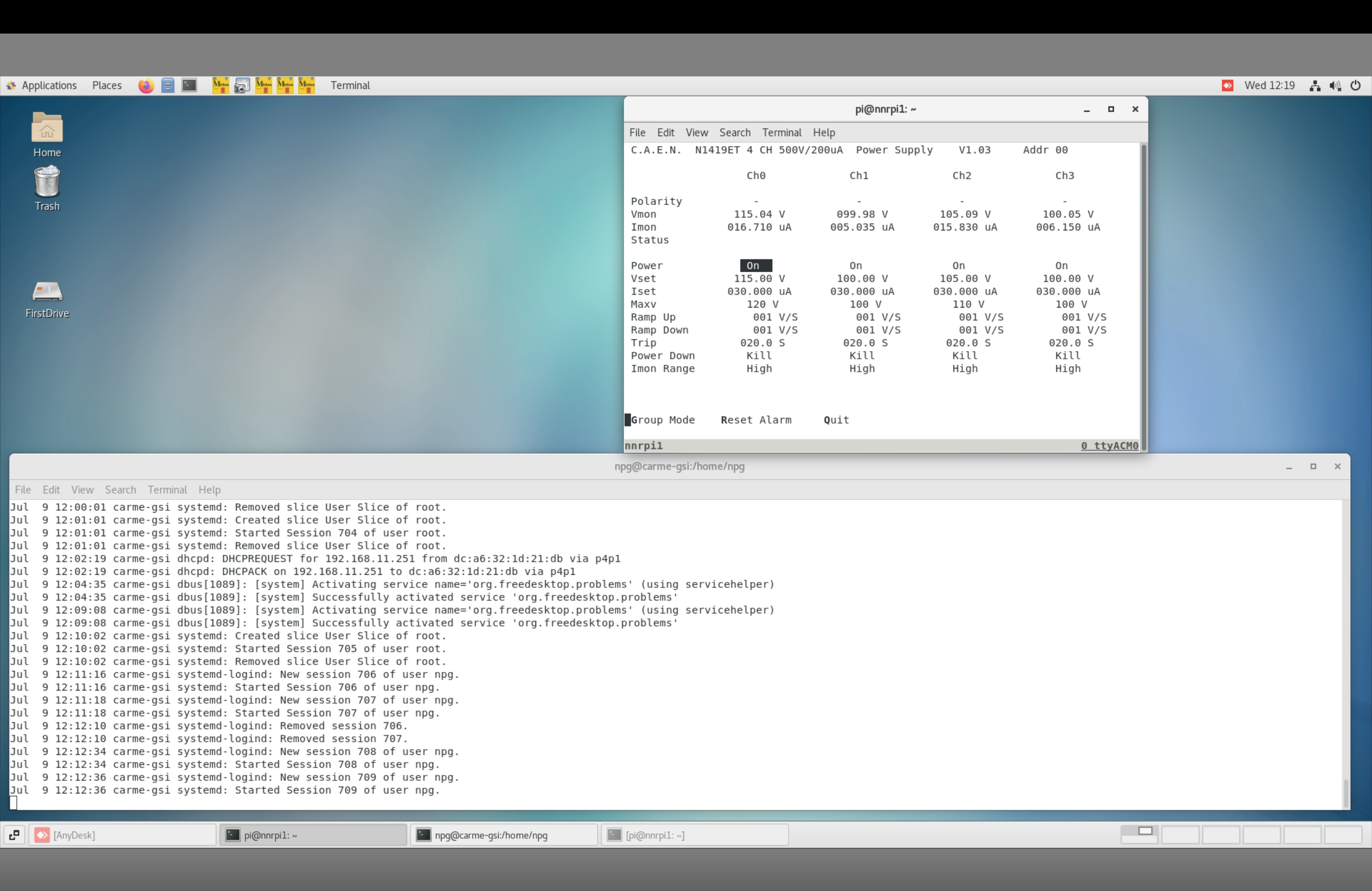

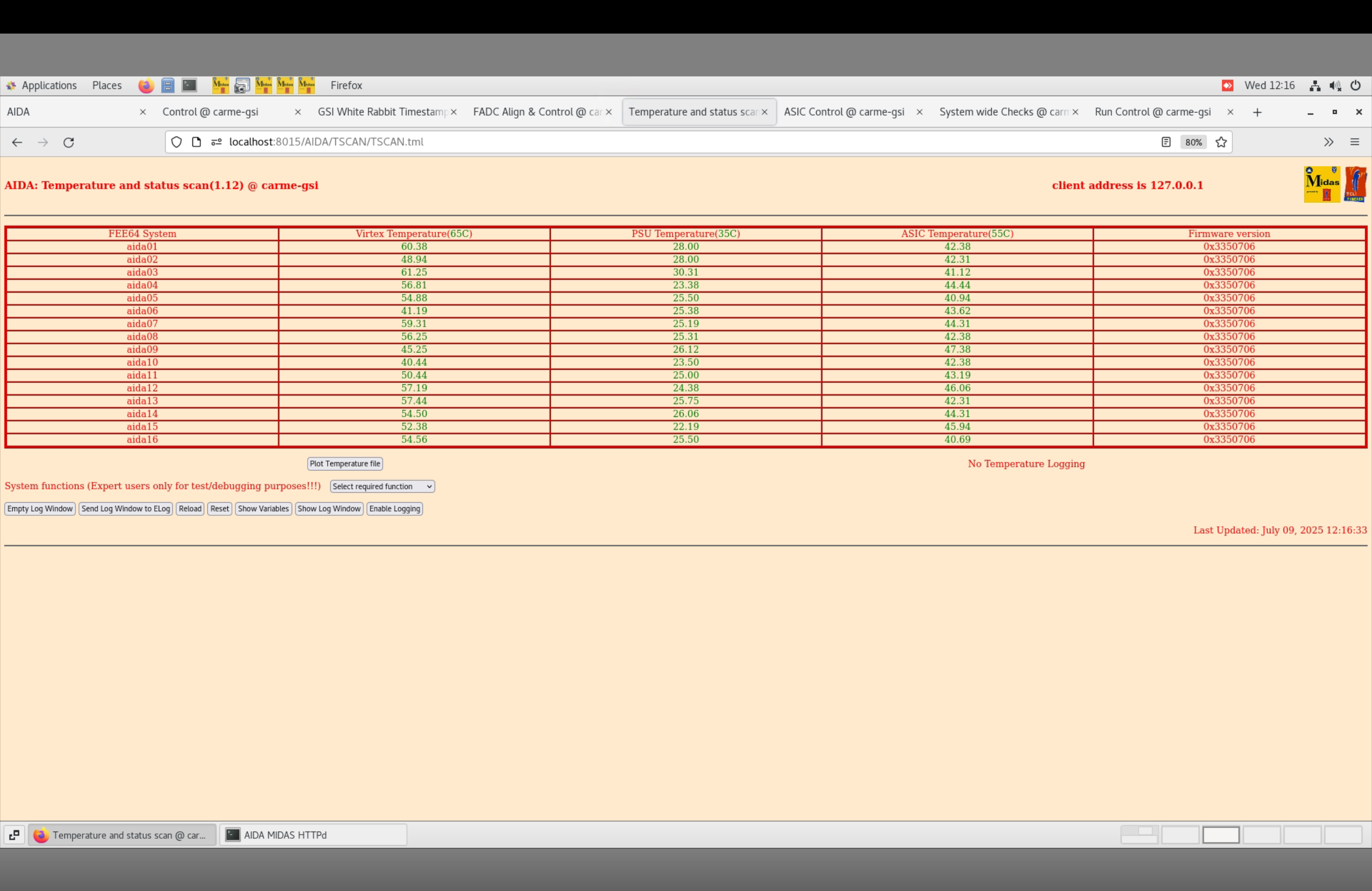

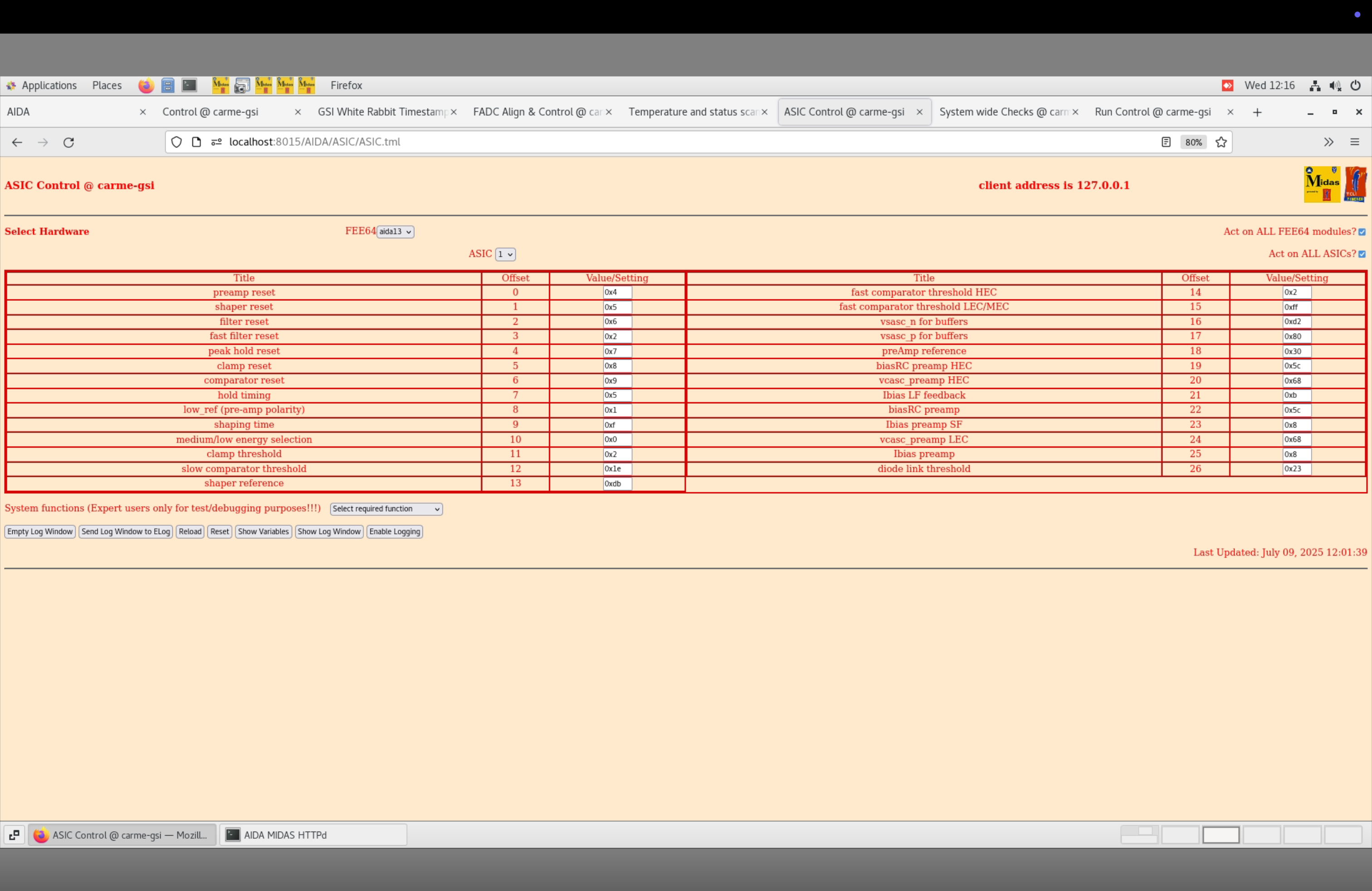

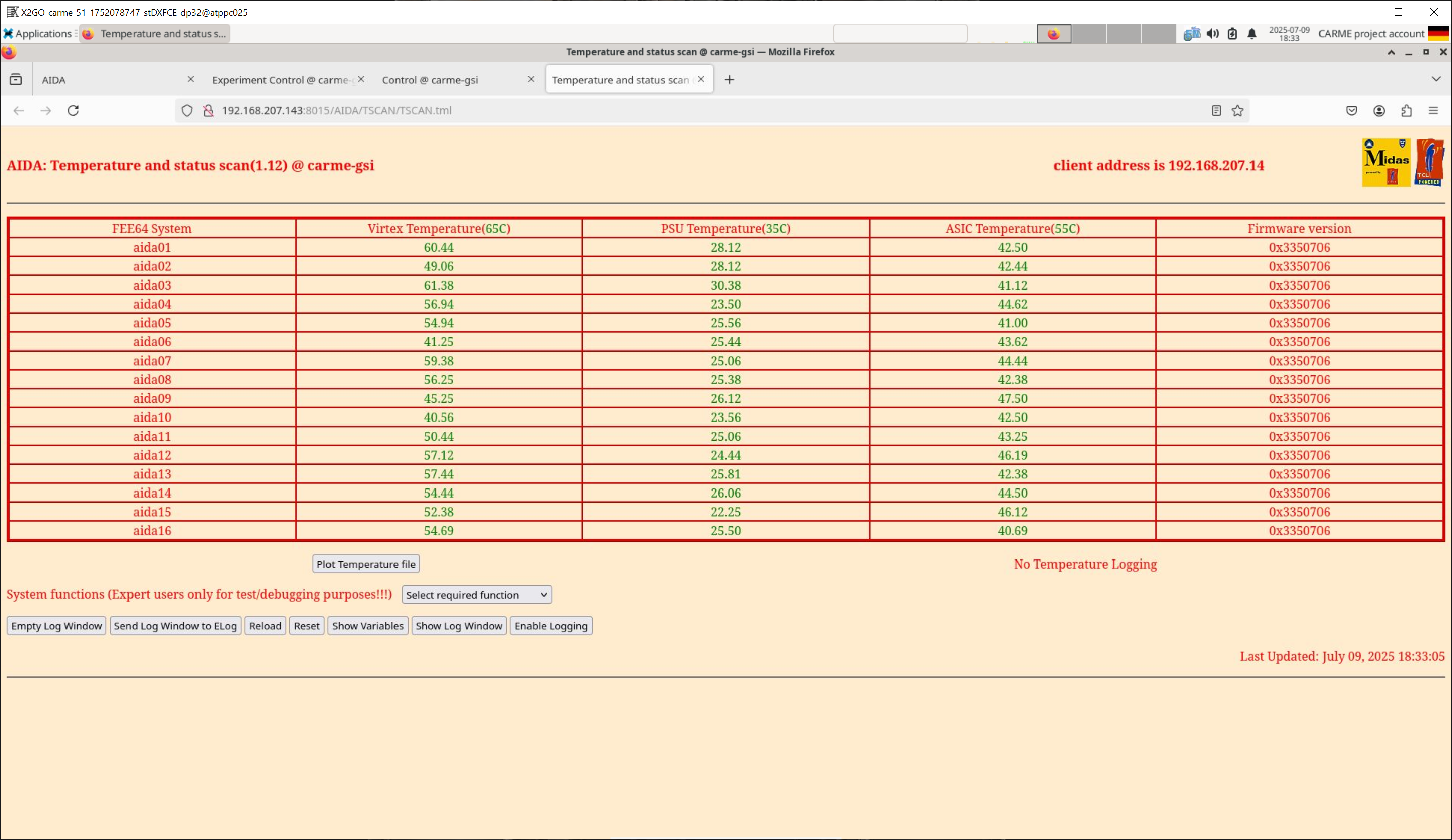

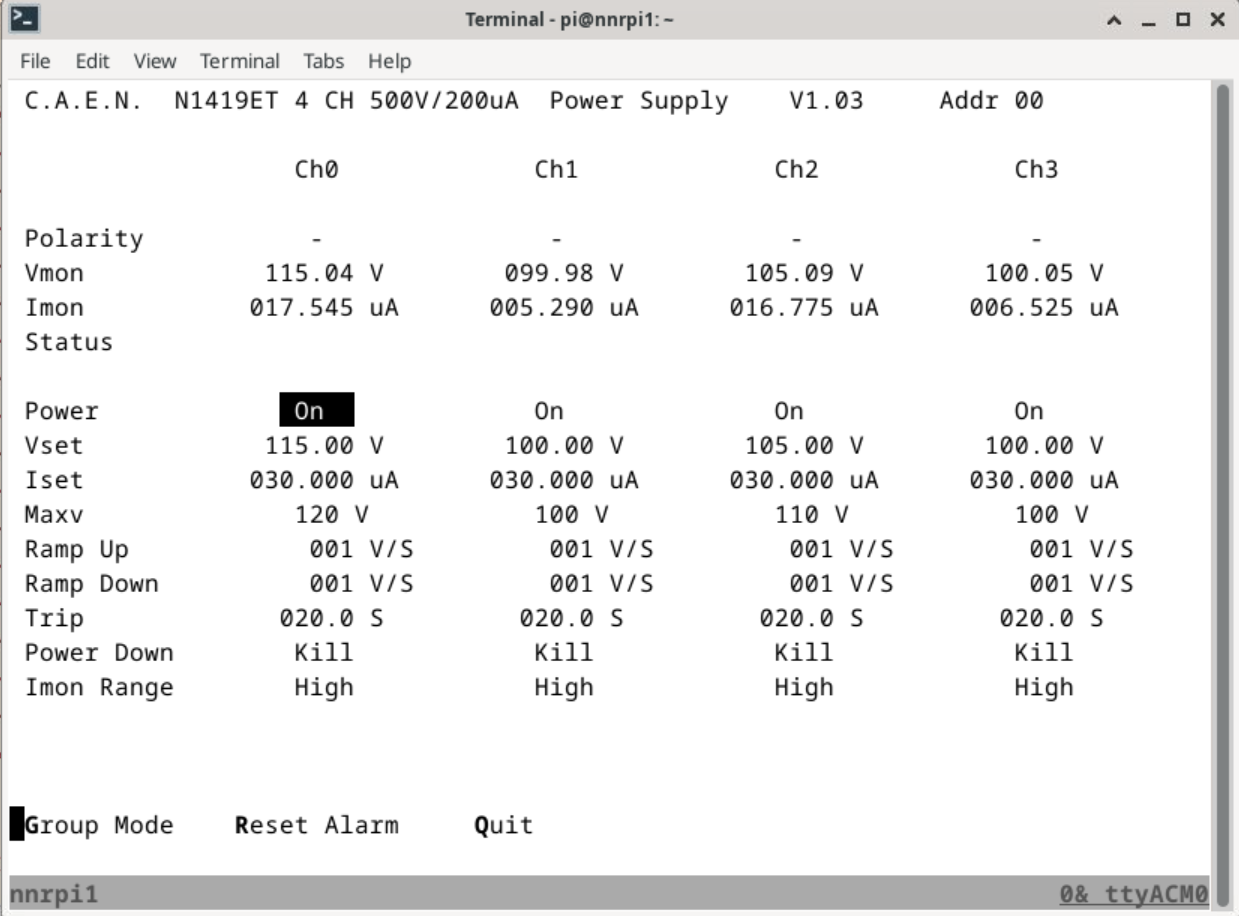

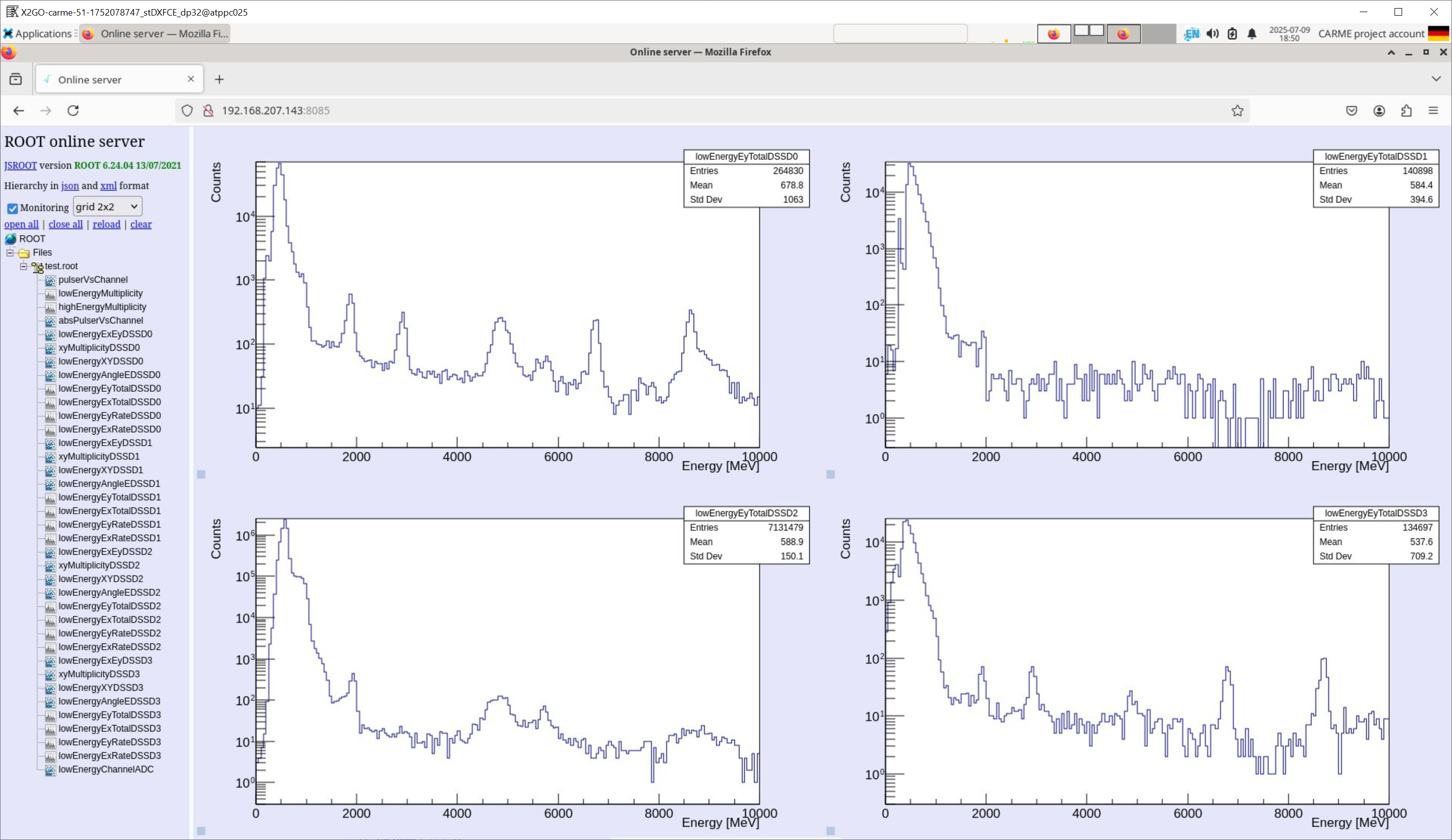

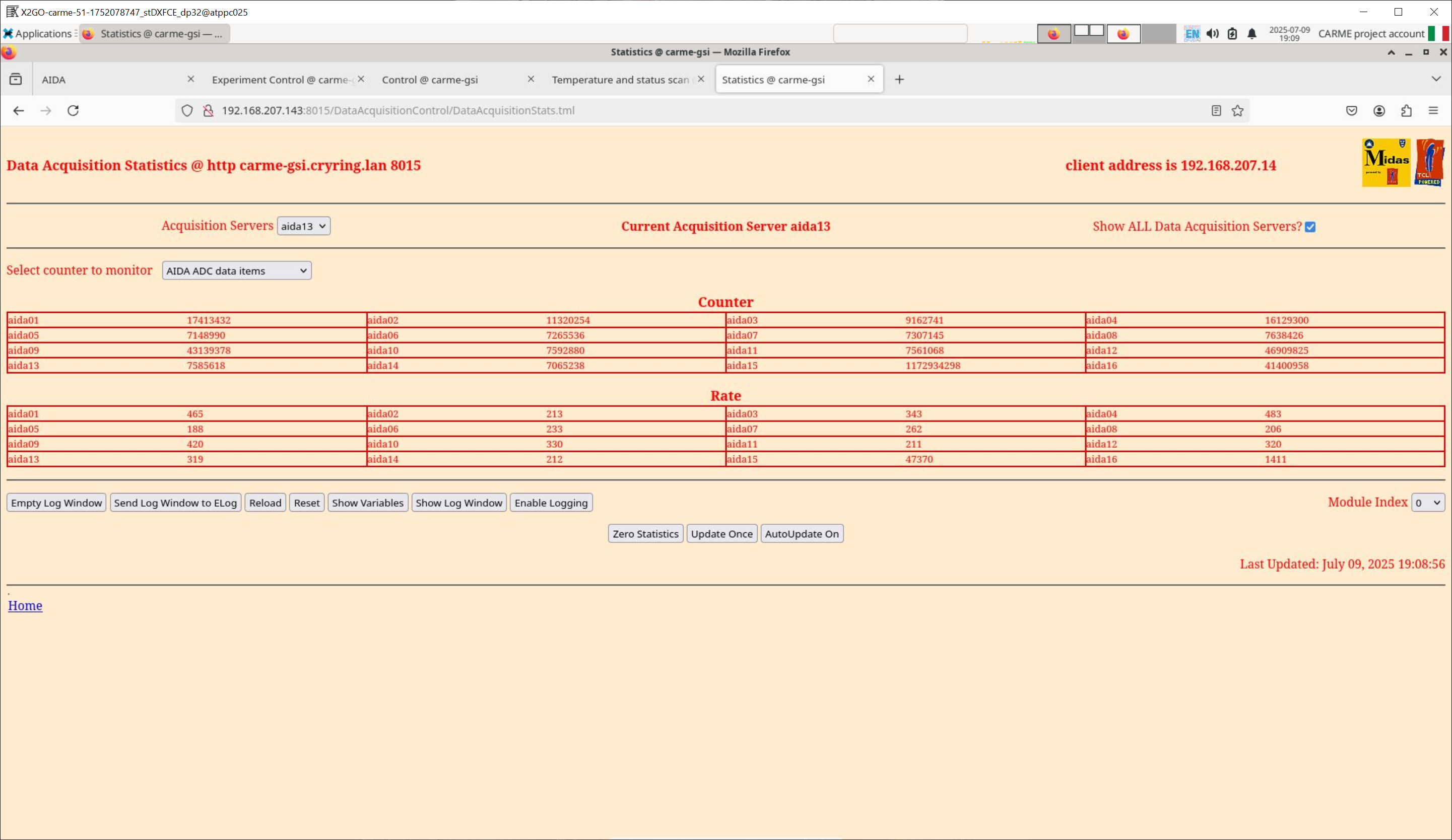

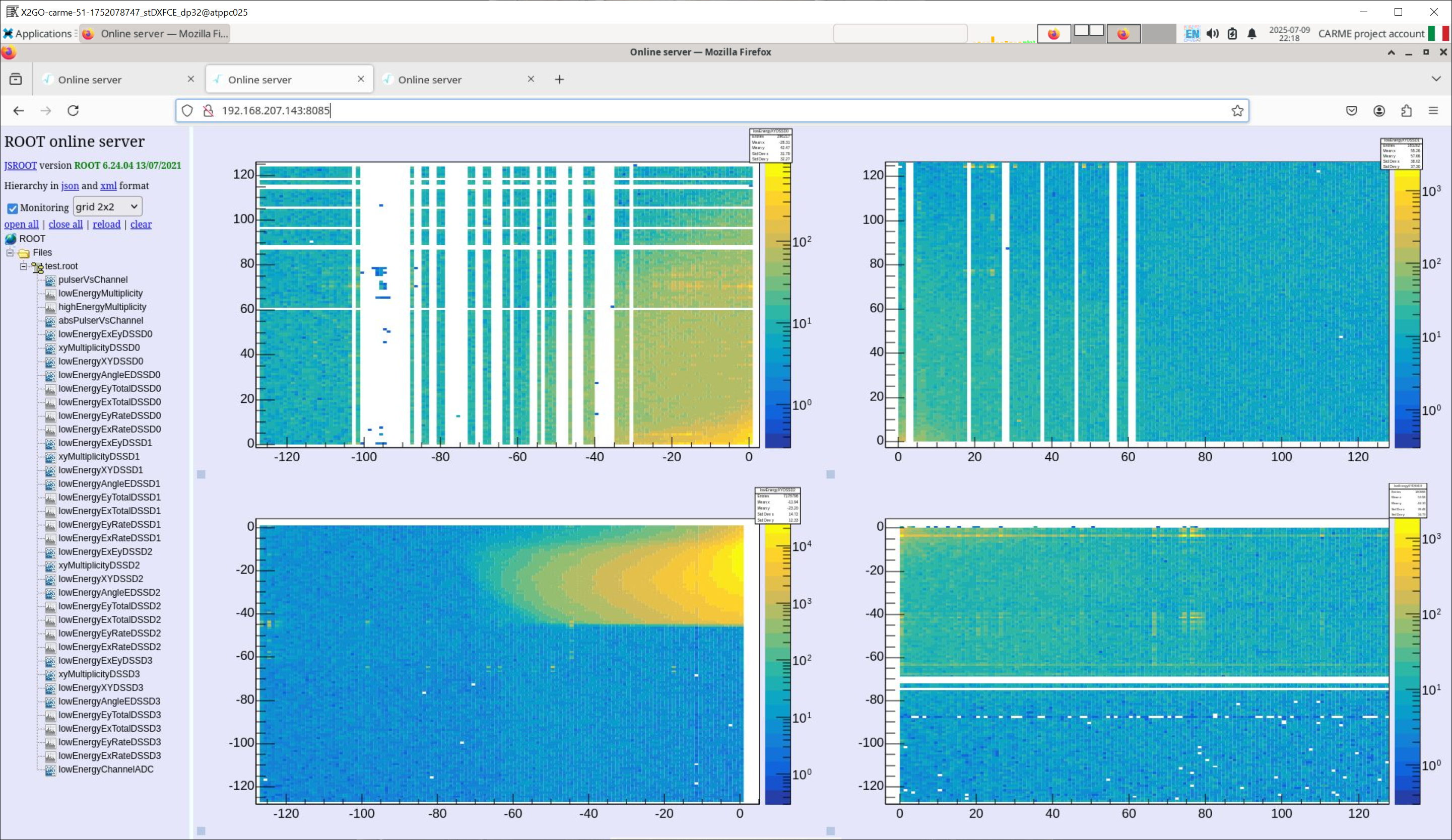

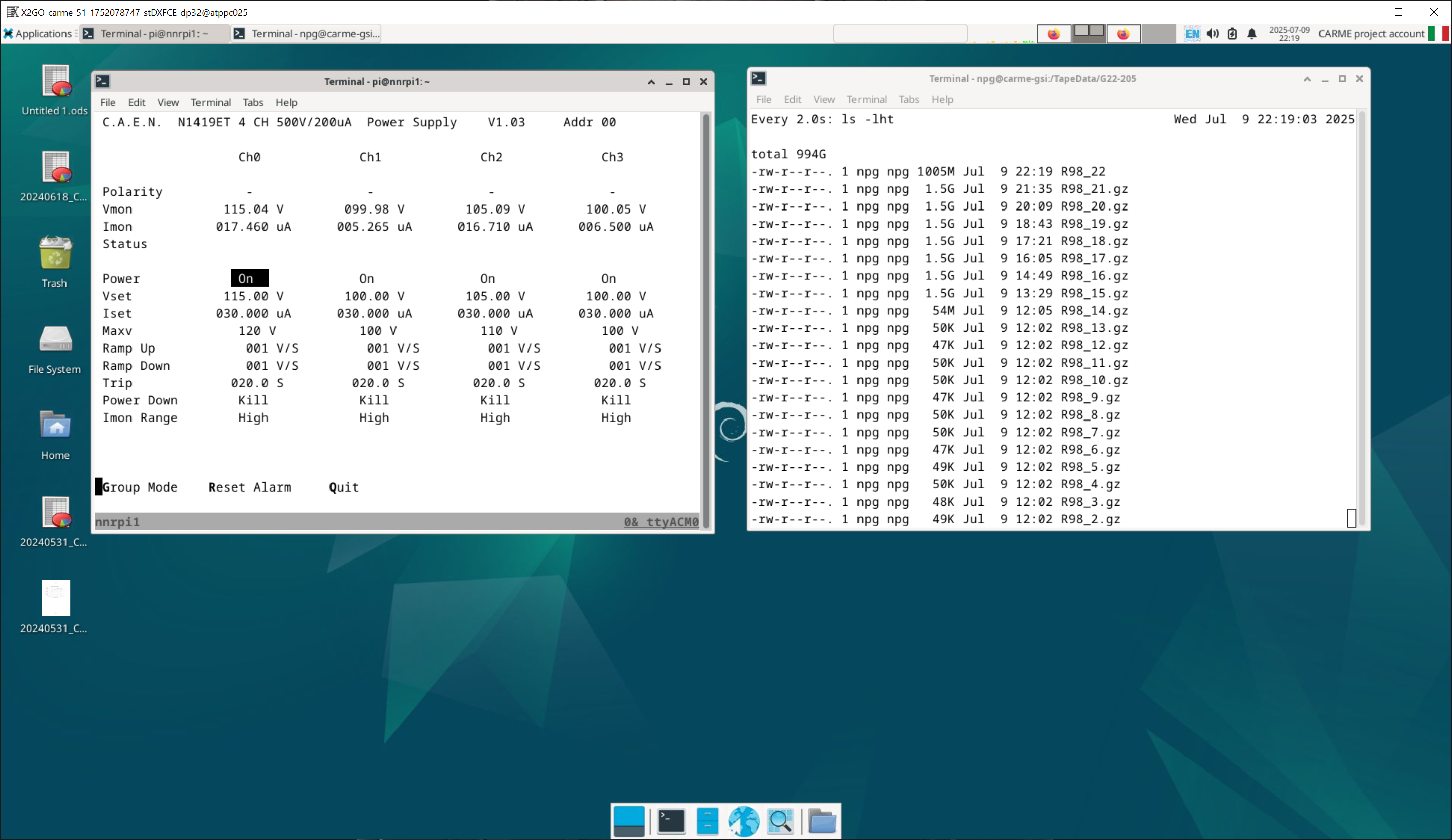

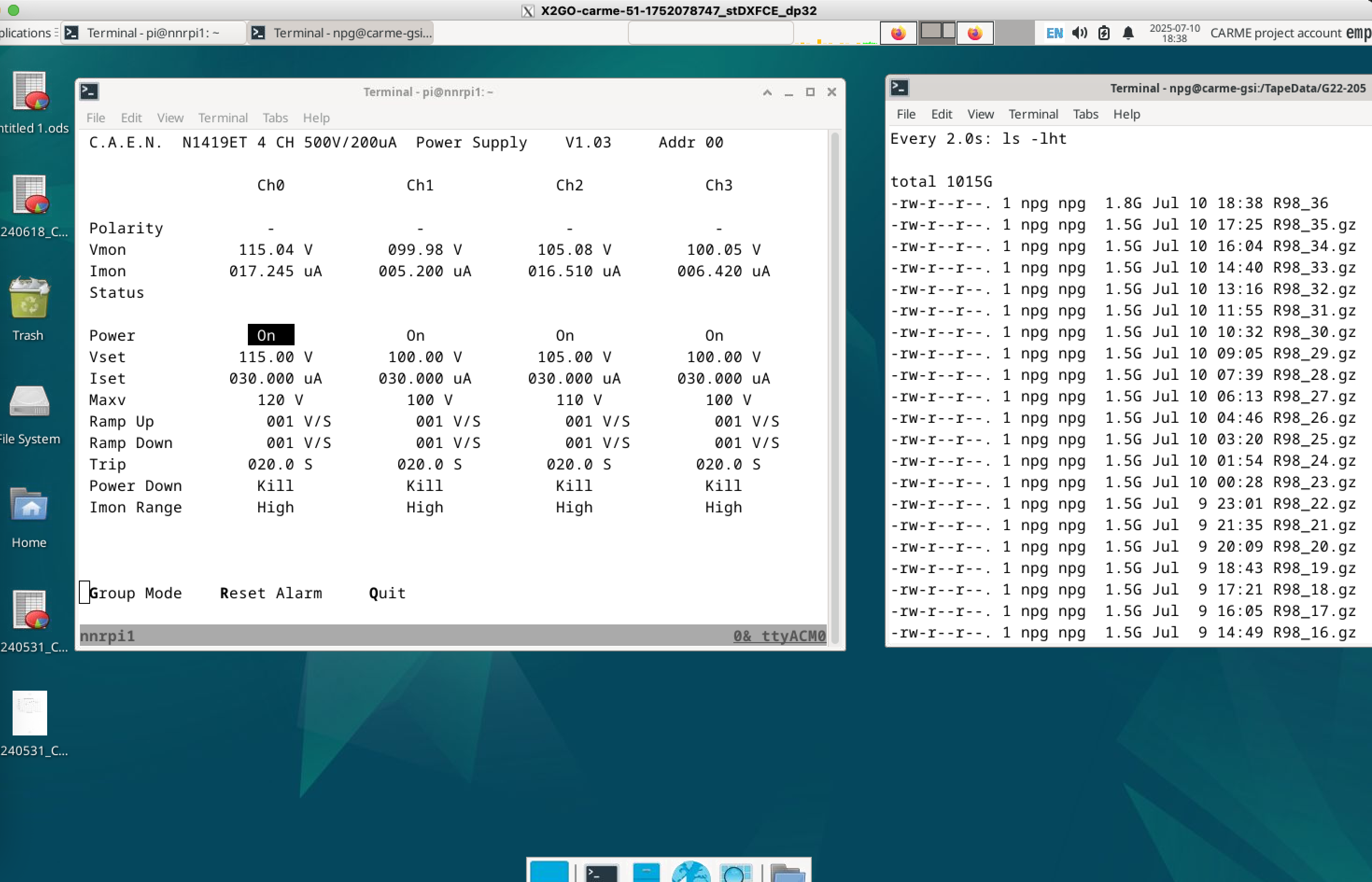

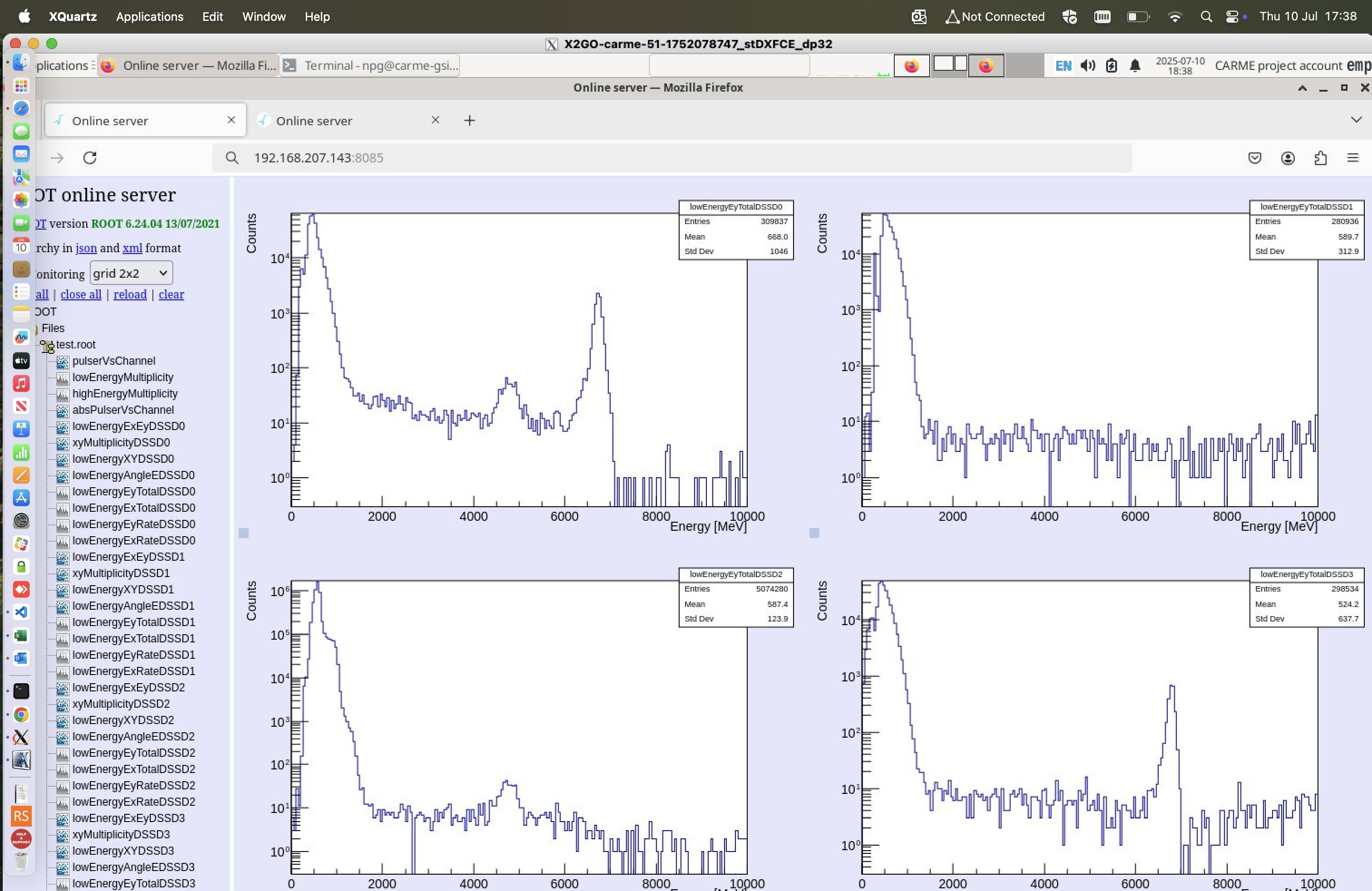

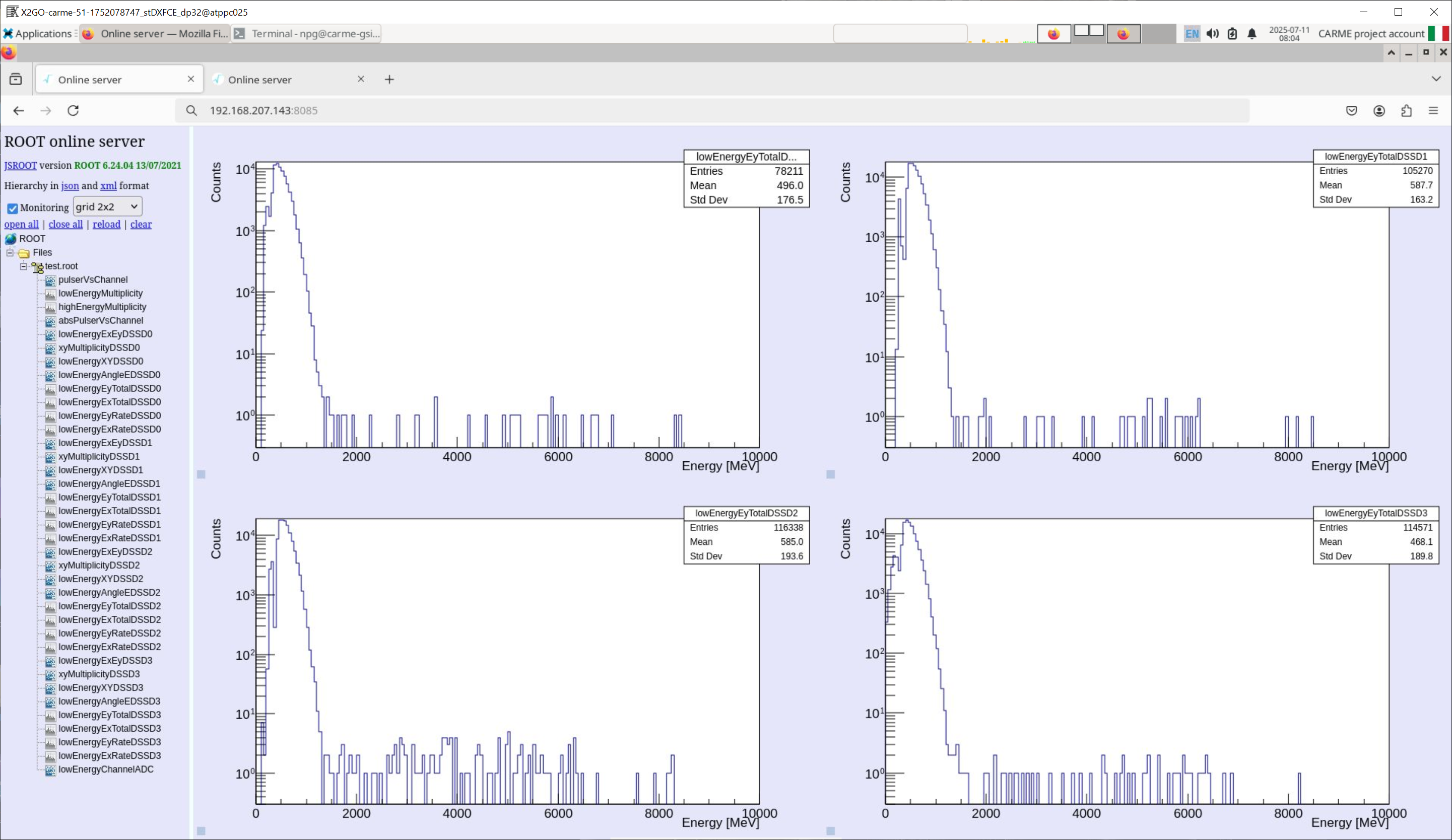

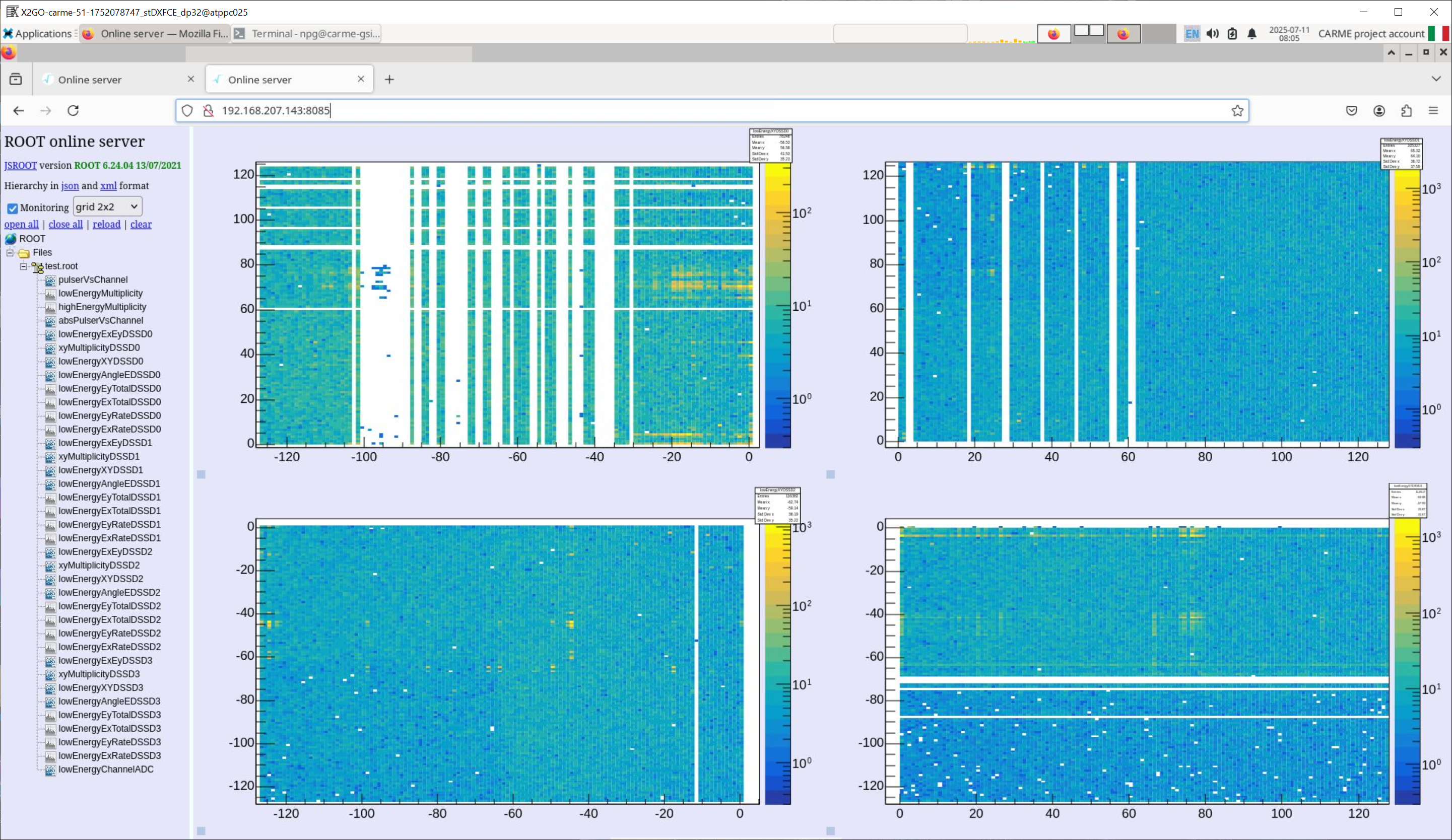

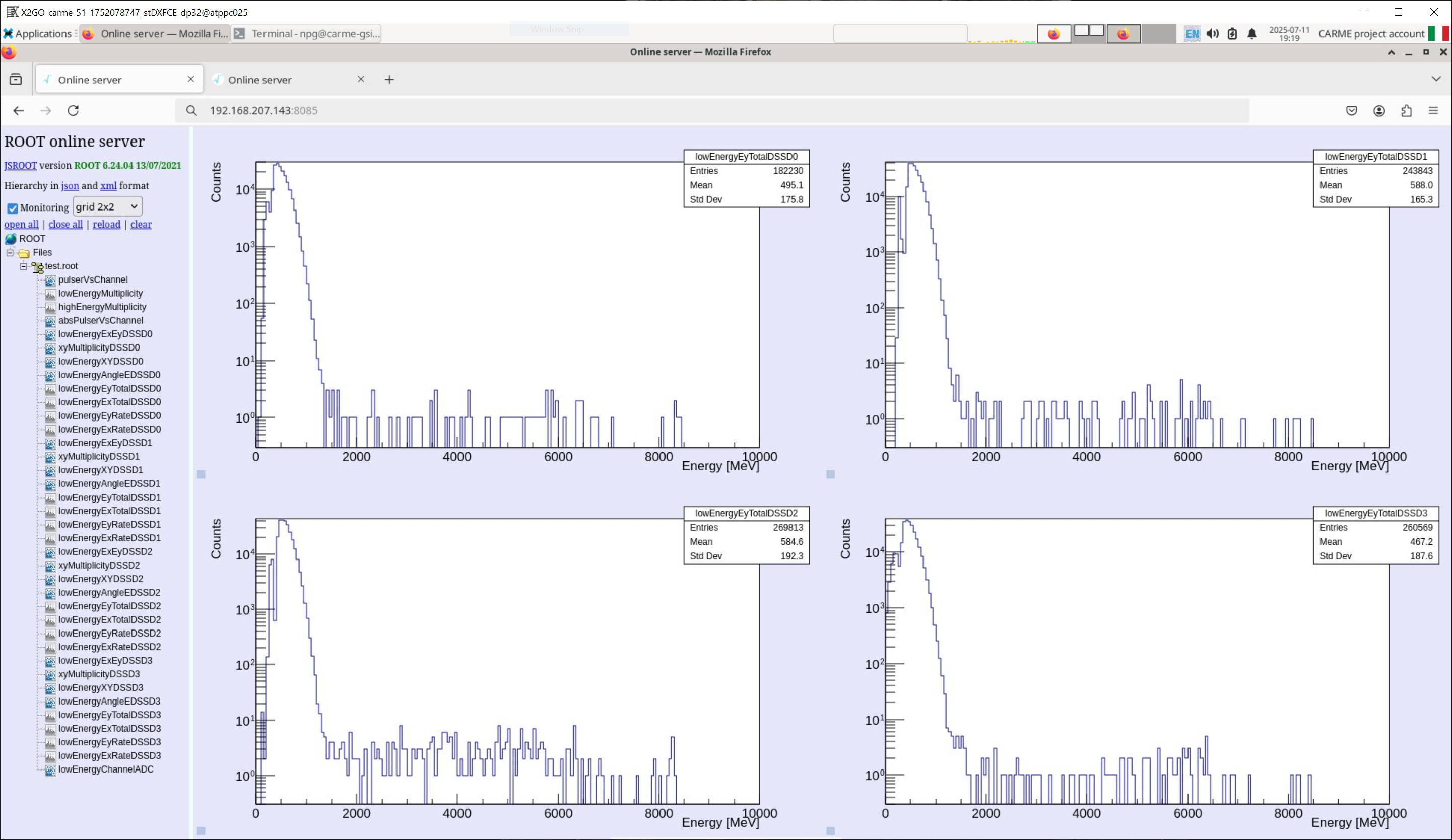

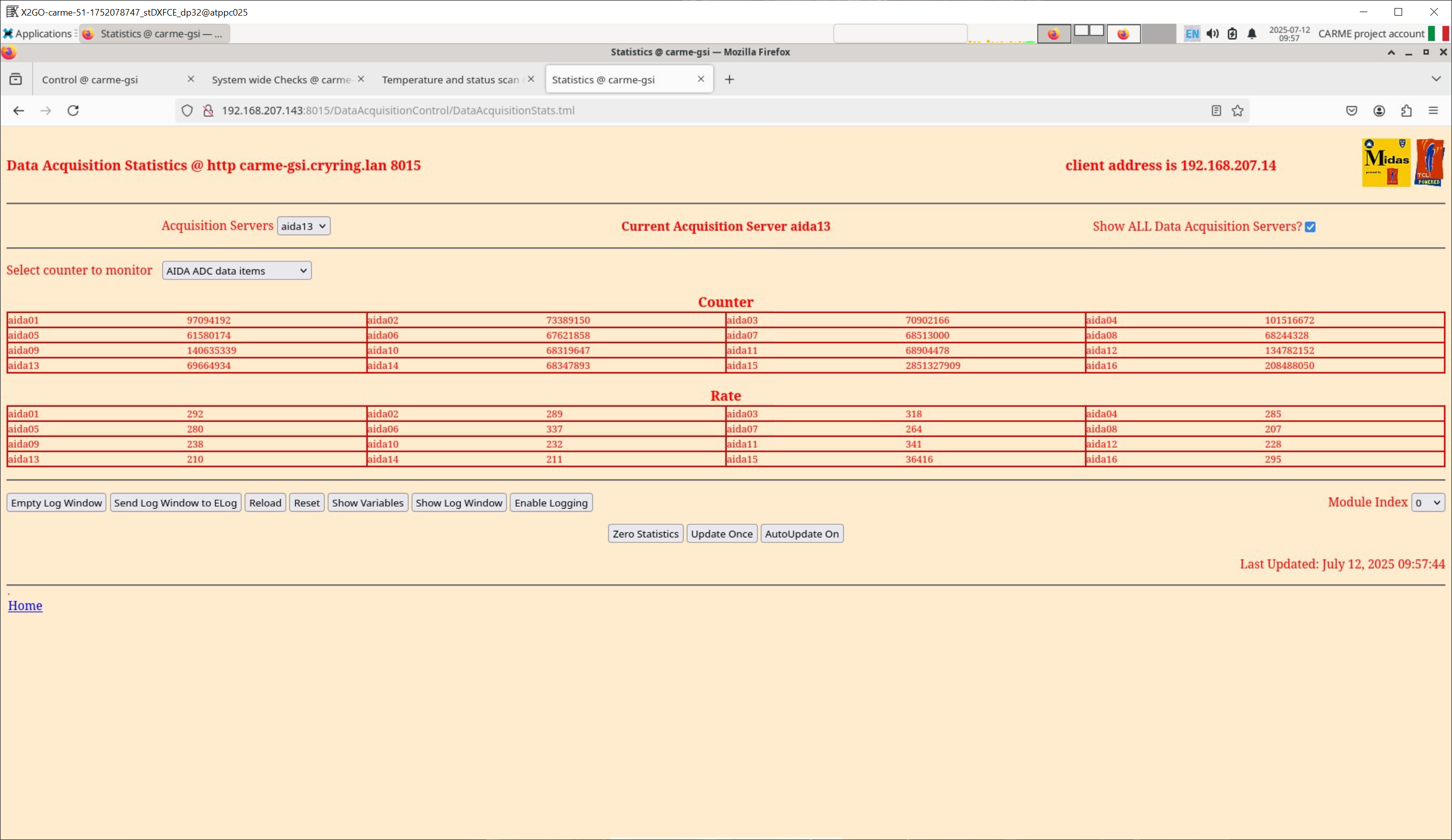

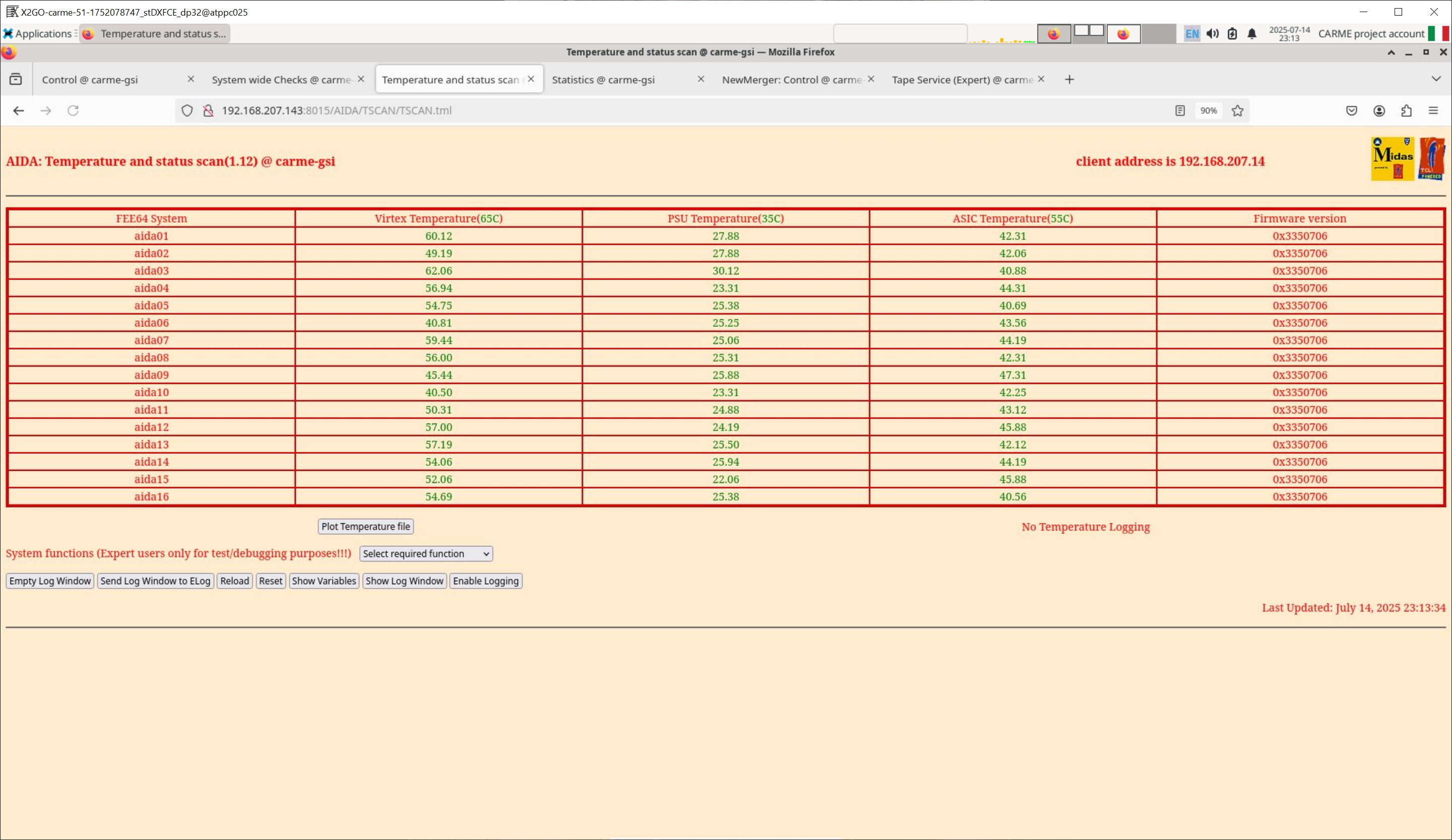

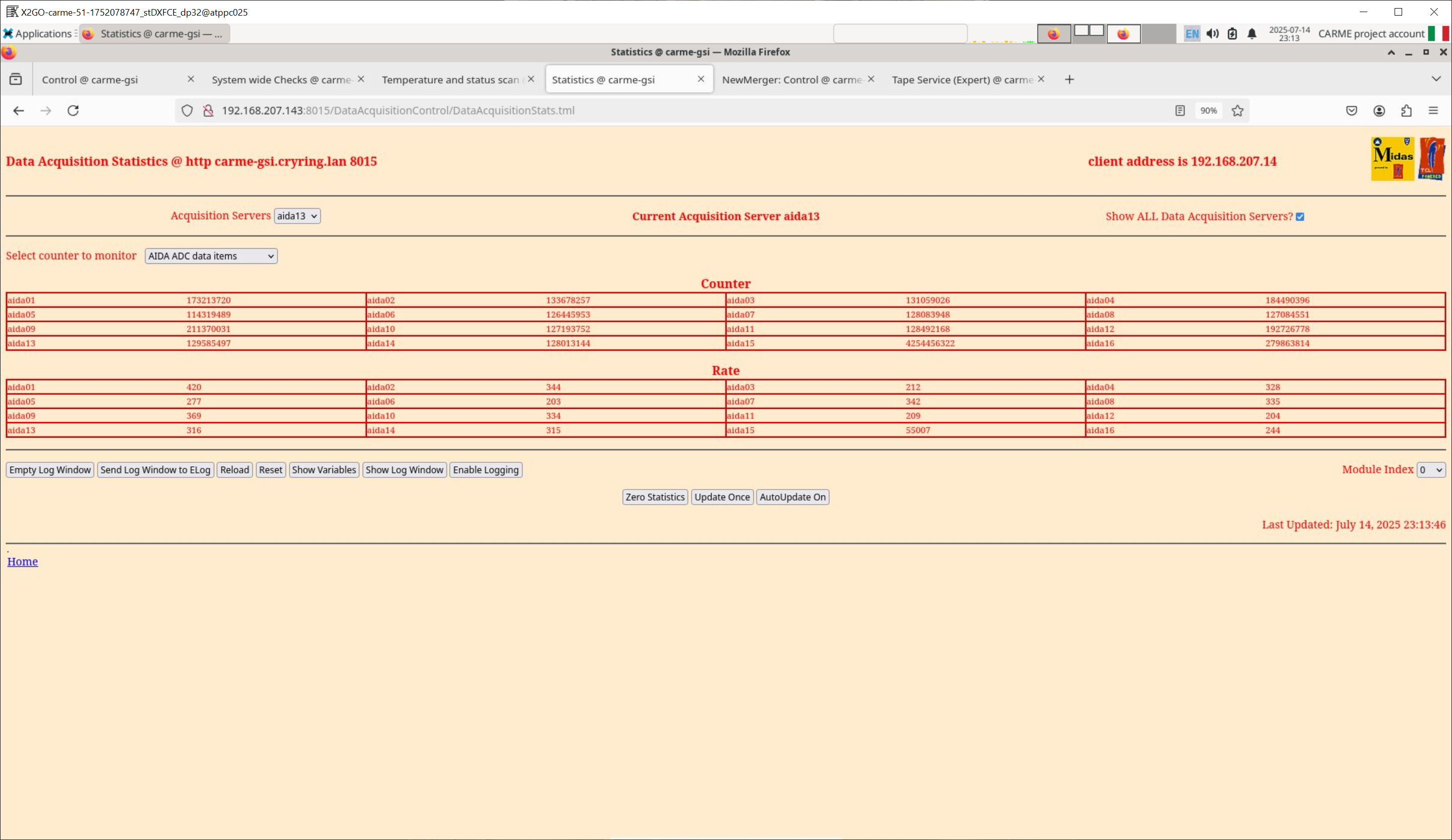

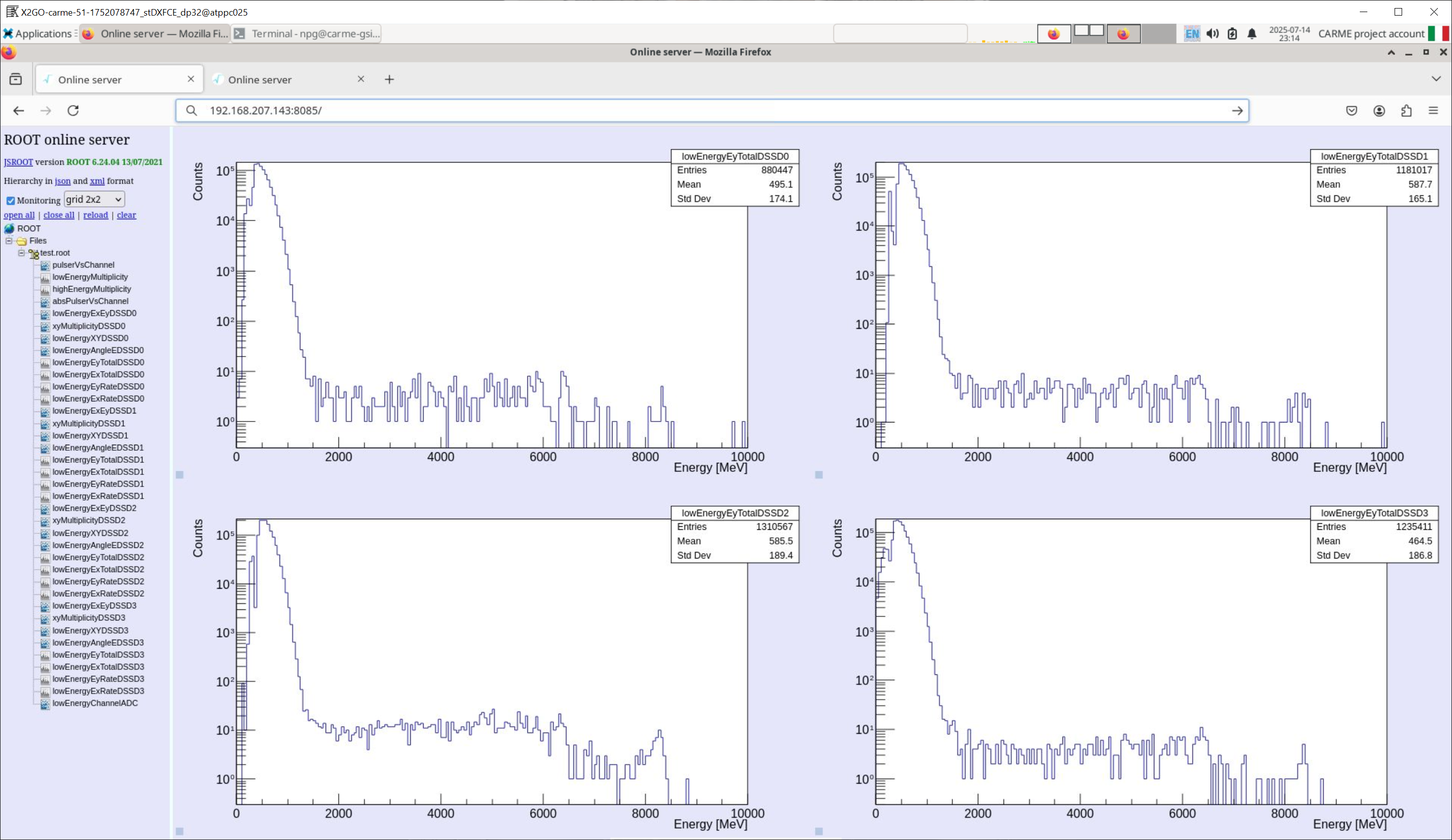

EW, CB | CARME restarted - long background R98 |

---9 July---

11:00

Turned detectors on - all stable see attachment 1

AIDA started - all okay. See attachment 2 for FEE temps.

All FEEs set to LEC (0x0) and slow comparator threshold set to 300keV (0x1e). See attachment 3.

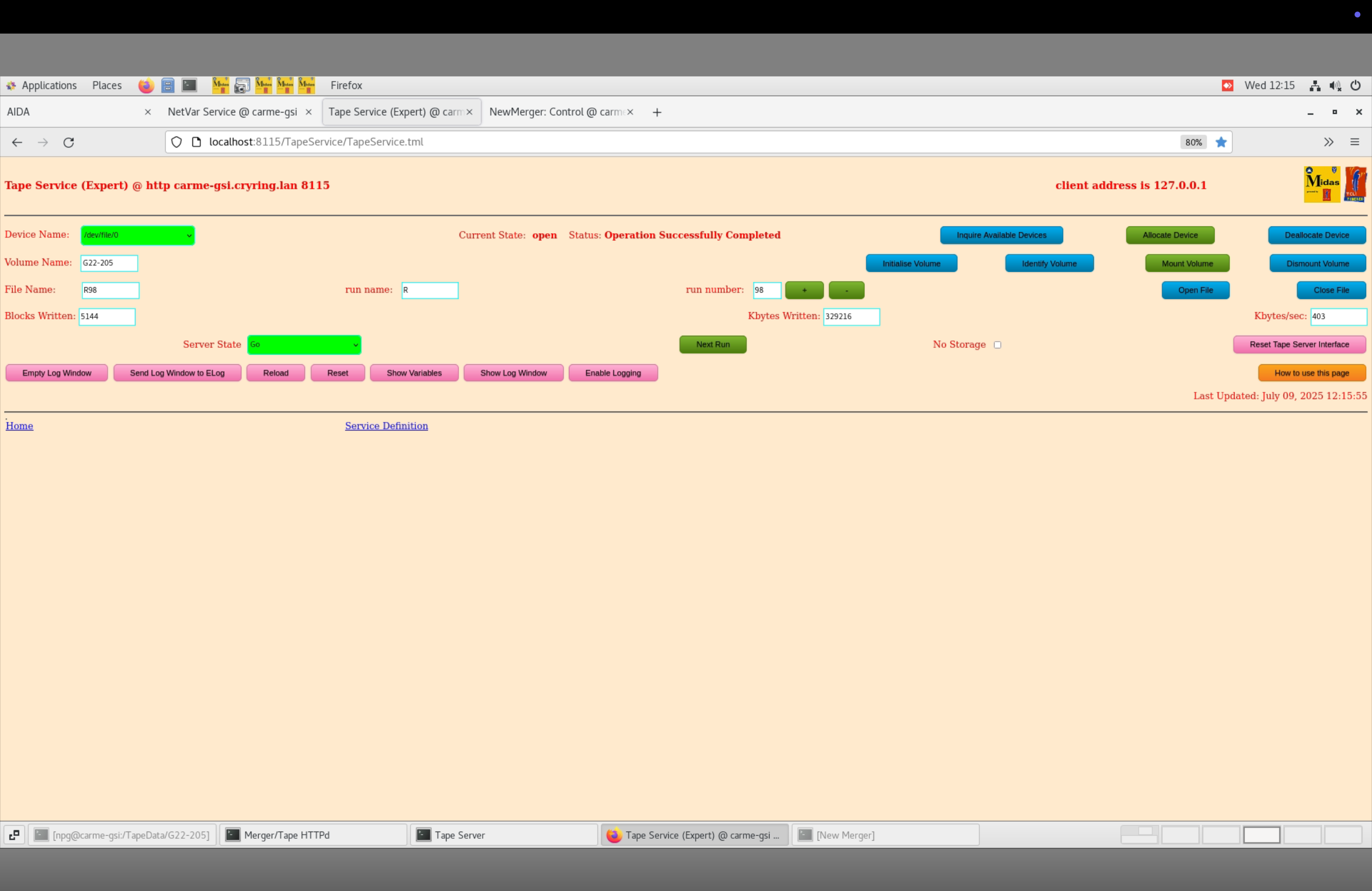

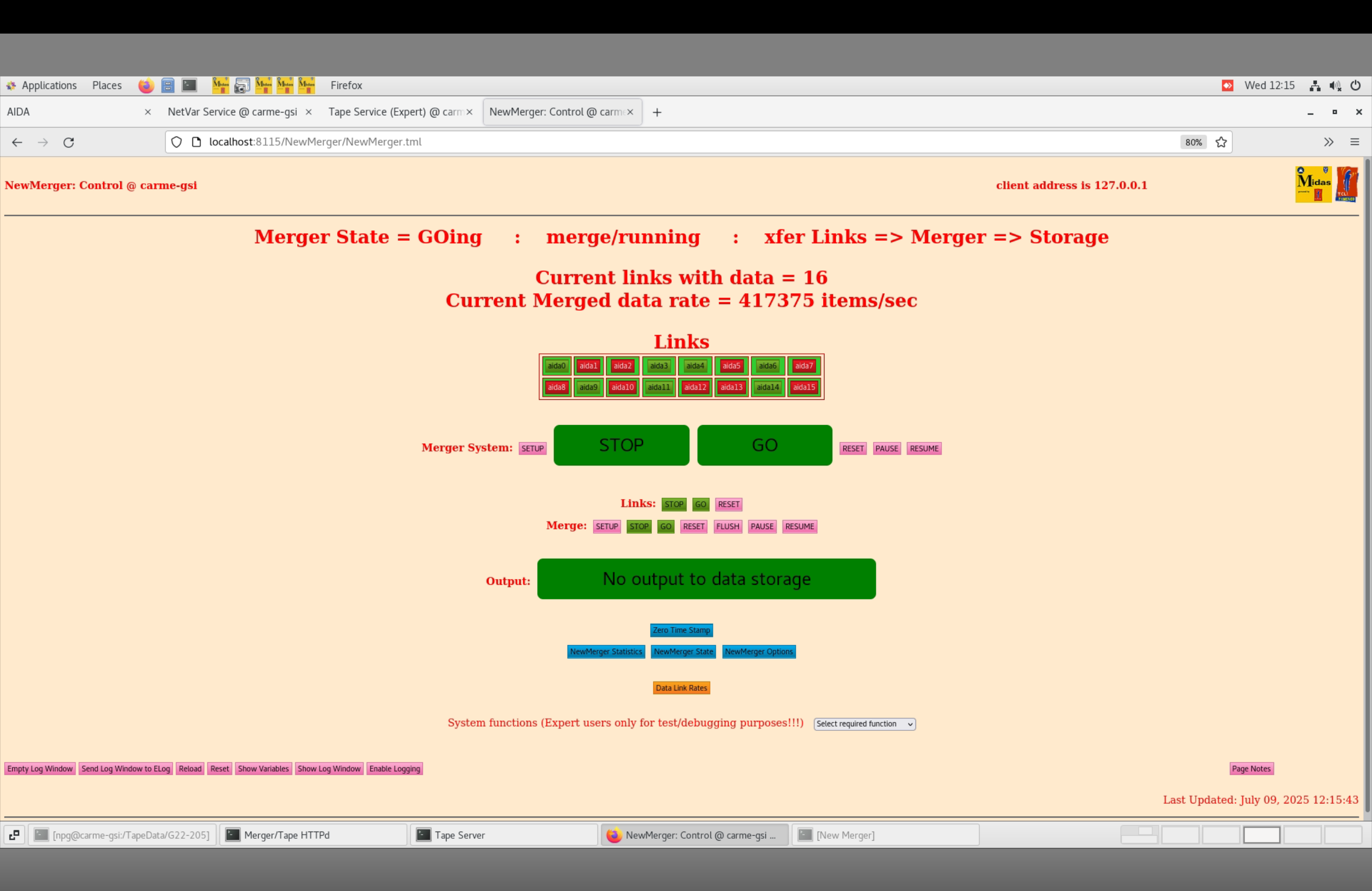

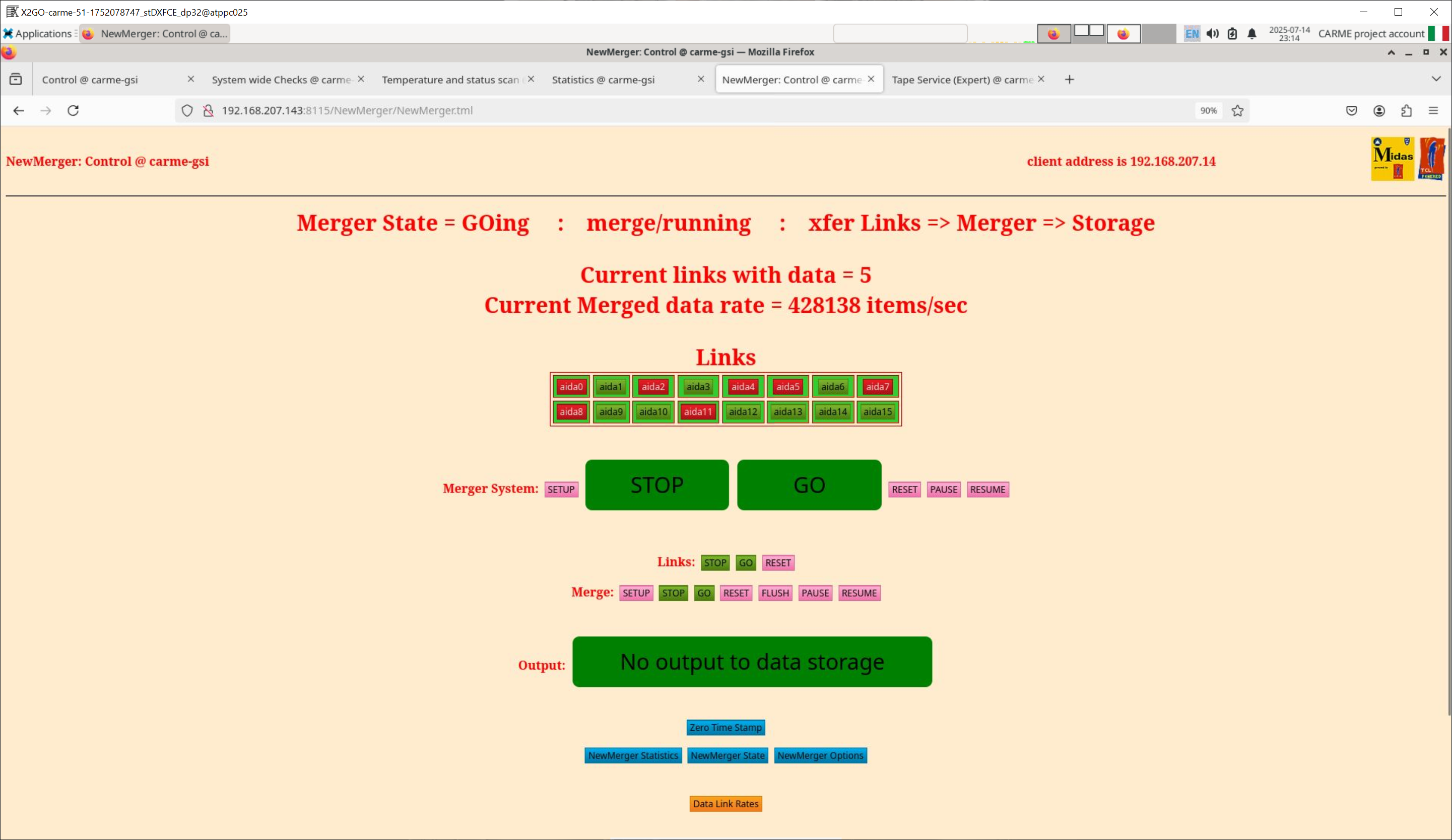

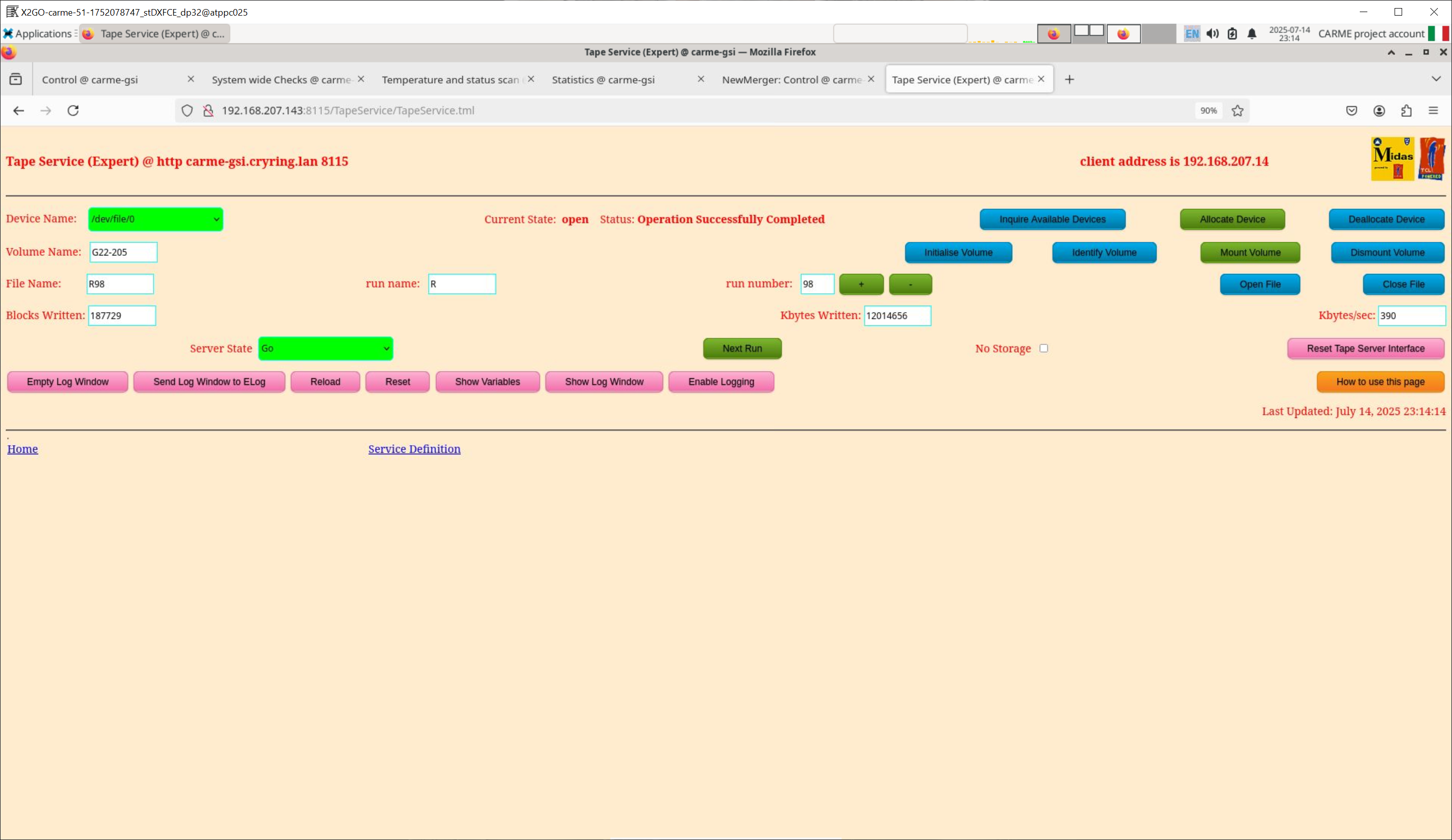

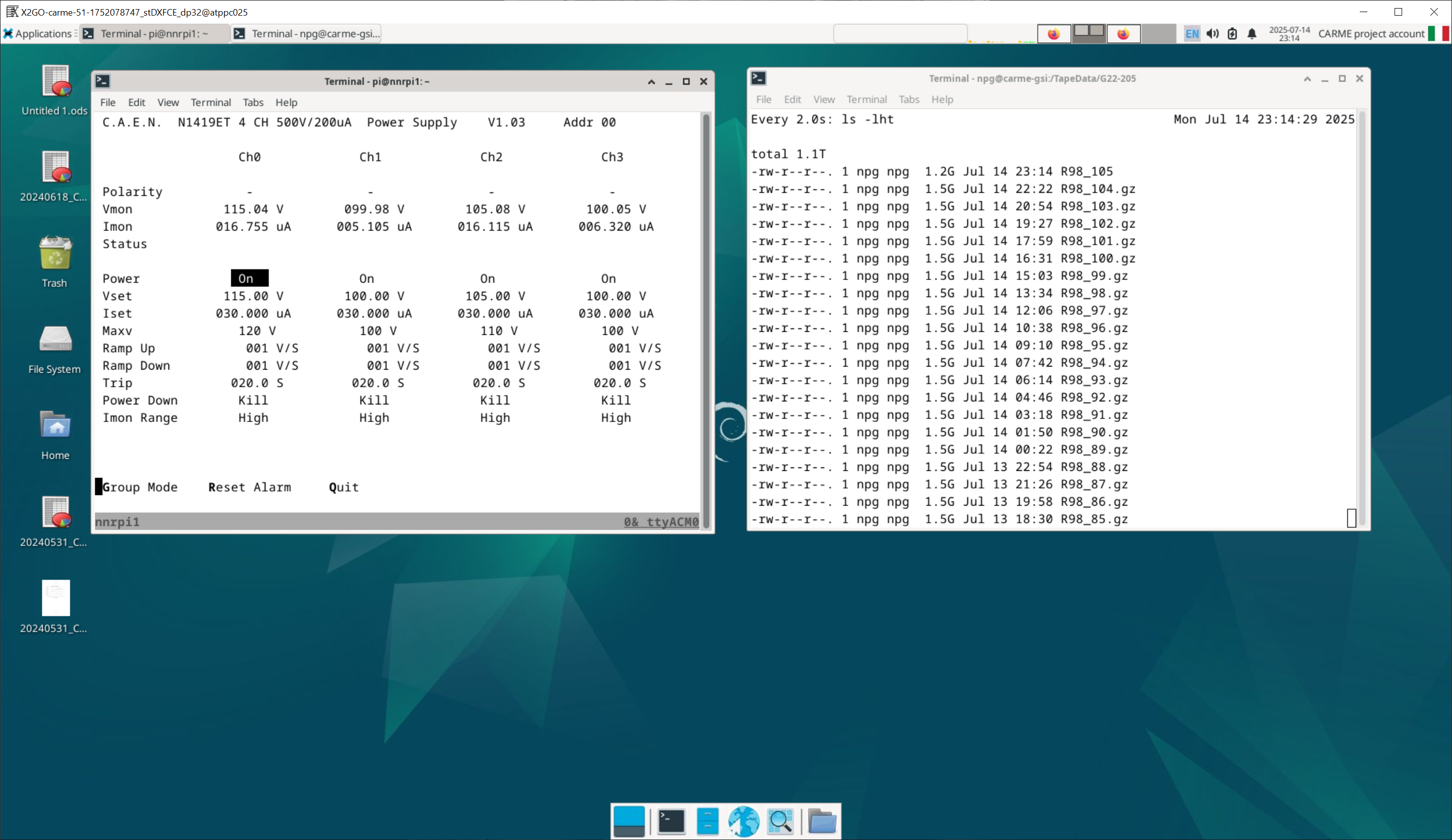

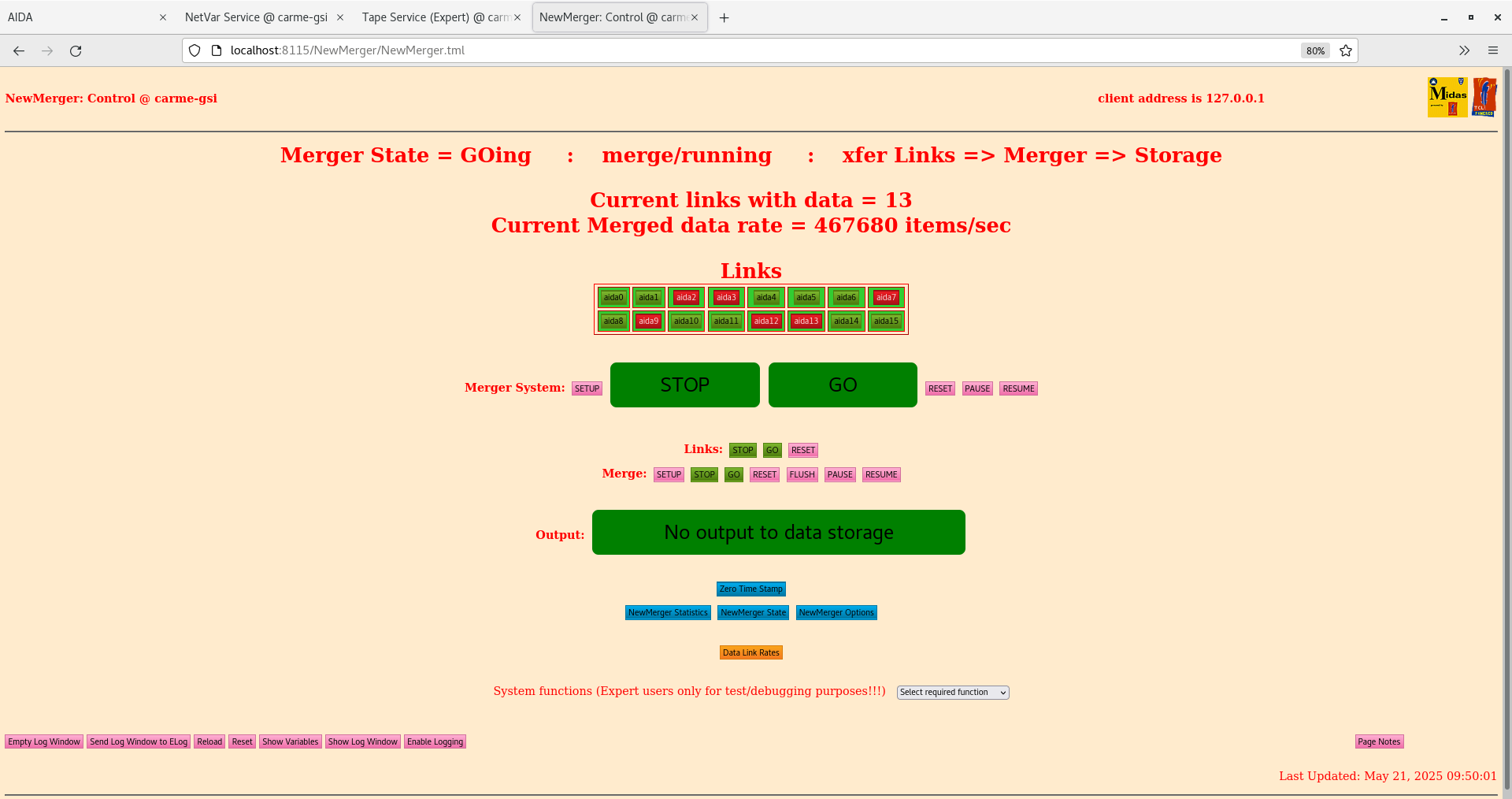

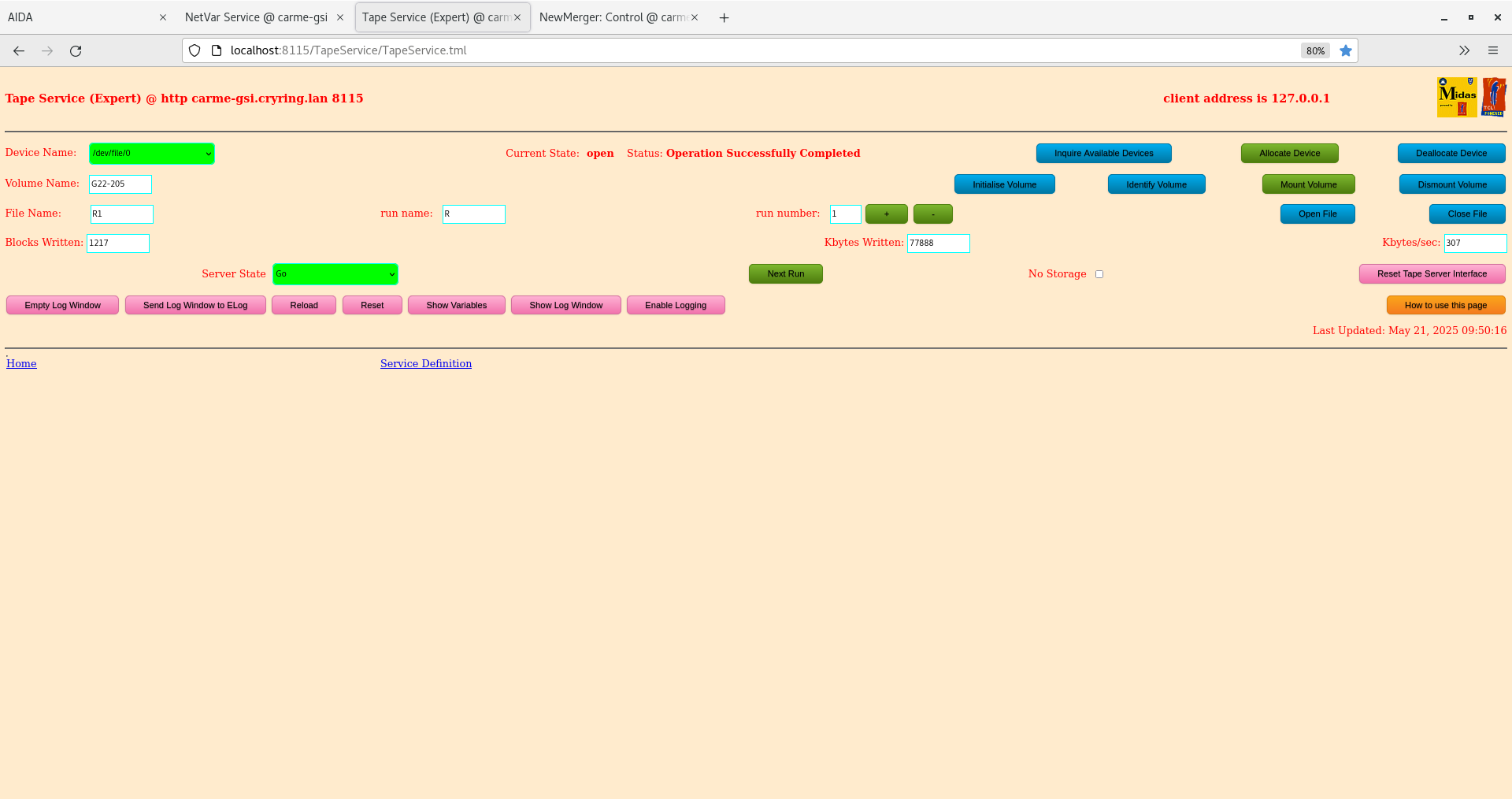

After some issues tape server and merger all set up, NetVar not working??? have tried to reboot things but still getting issues. See attachment 4 for tape service and attachment 5 for merger.

Currently writing to data to G22-205/R98 (R97 empty), doing background run.

13:30

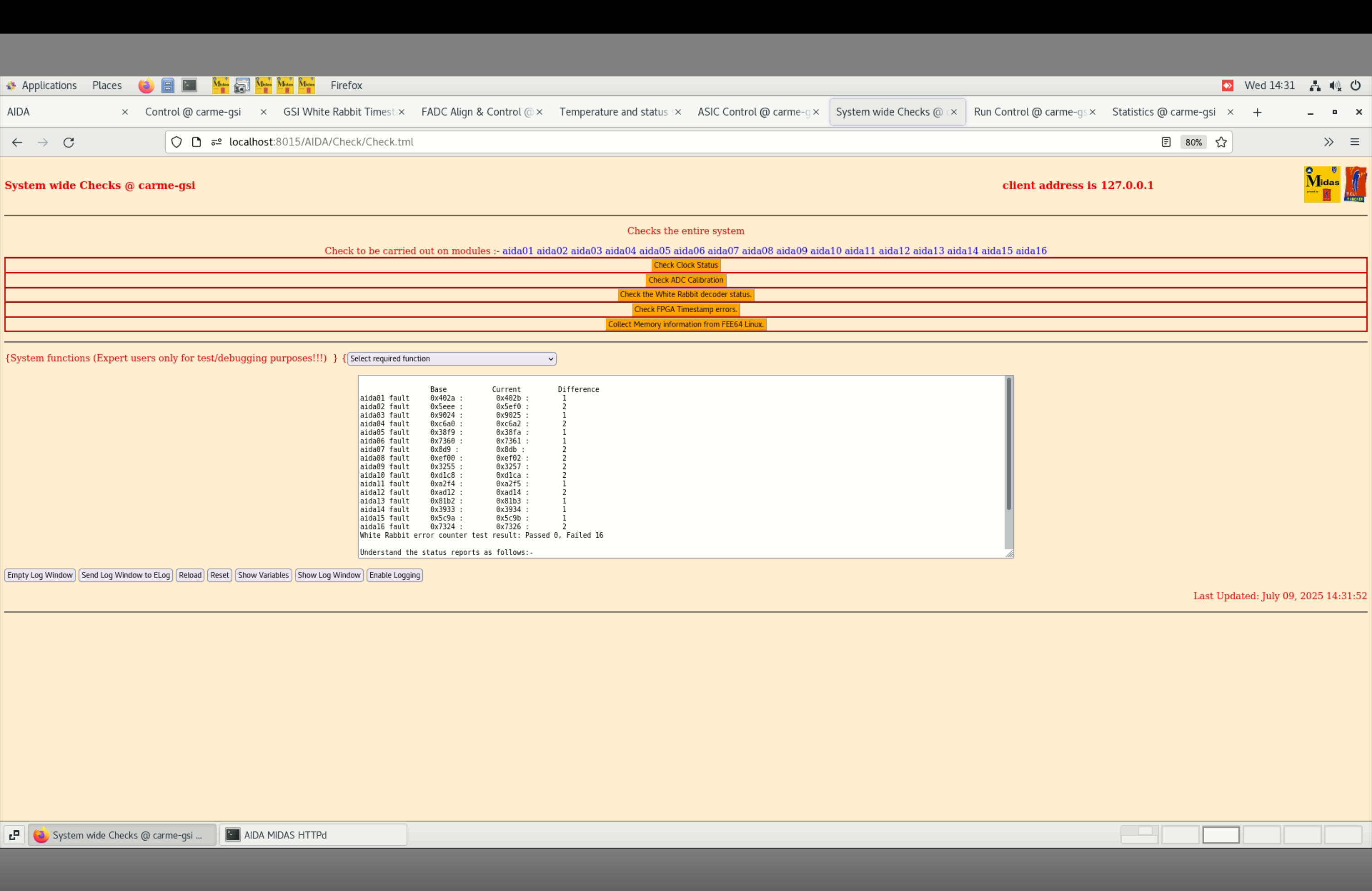

All checks okay apart from white rabbit, see attachment 6.

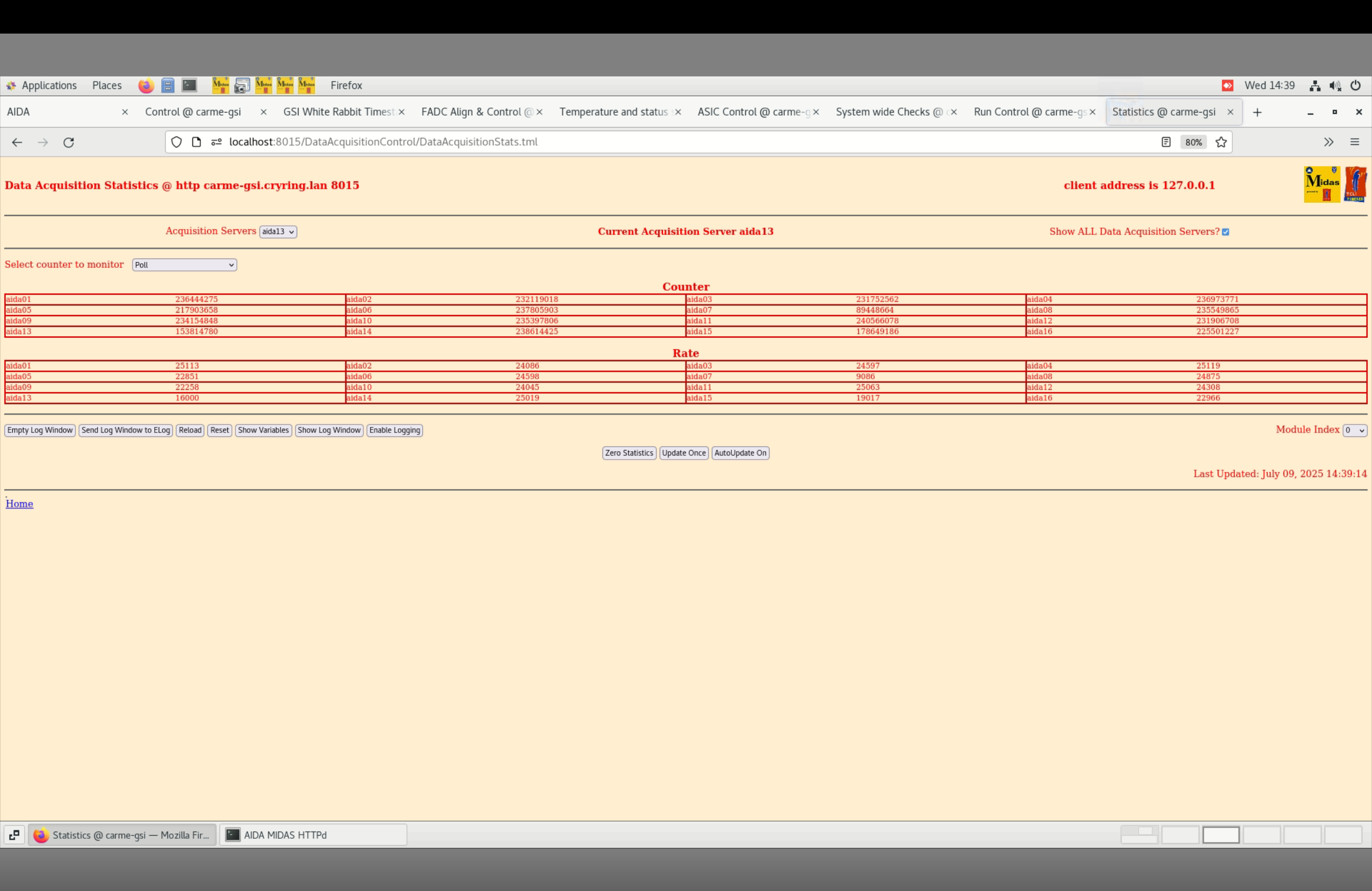

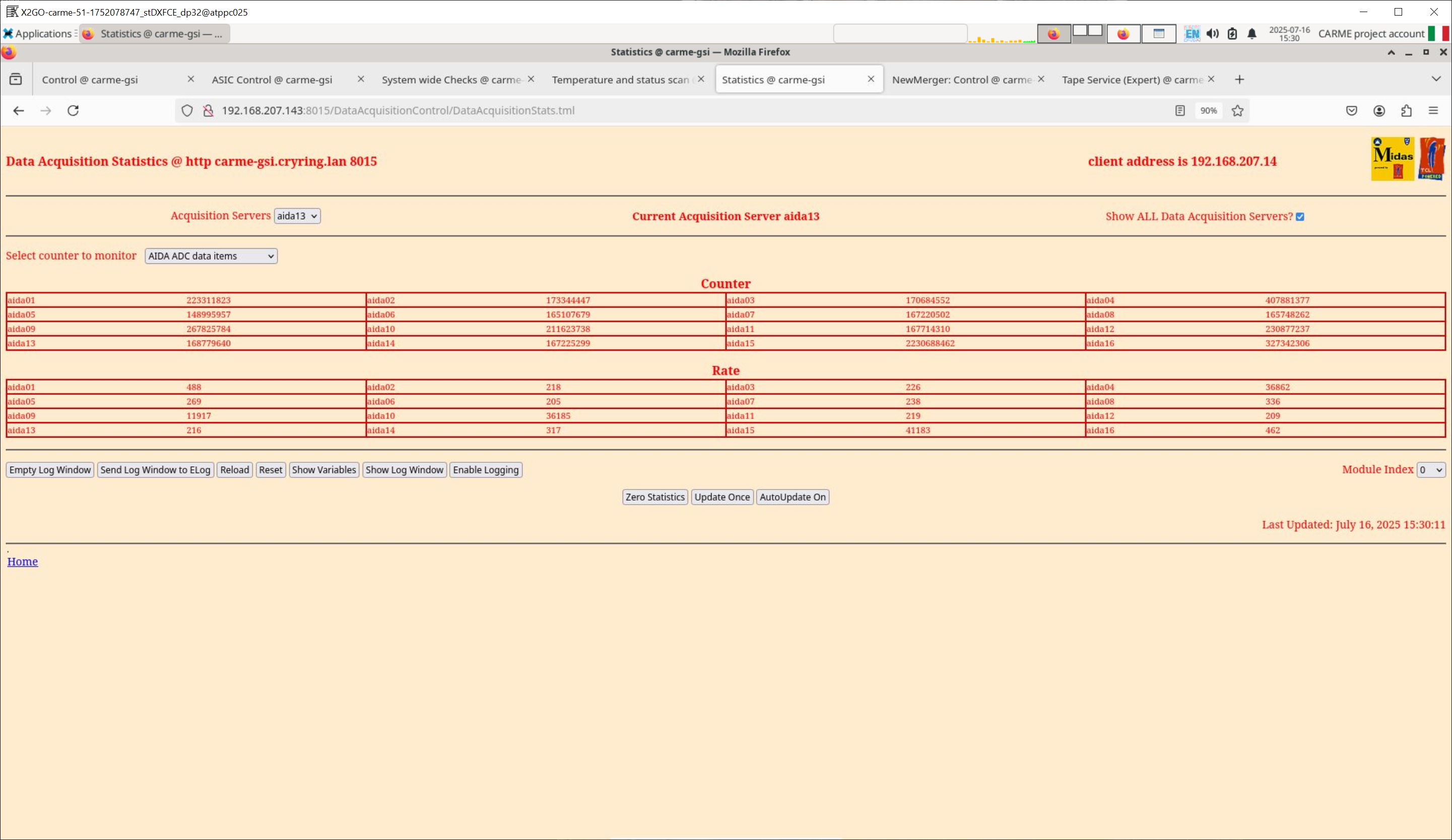

Attachment 7 - stats

18:30 CEST

More issues with anydesk - now refuses to connect with error message desk_rt_ipc

May be as simple as the monitor being turned off. Will have to be checked in person

Connected to atppc025 via x2go and from there checked

- Temperatures are fine (attached)

- Detector bias / leakage current is fine (attached)

- Data rate from file size being written is around 500 kB/s (fine)

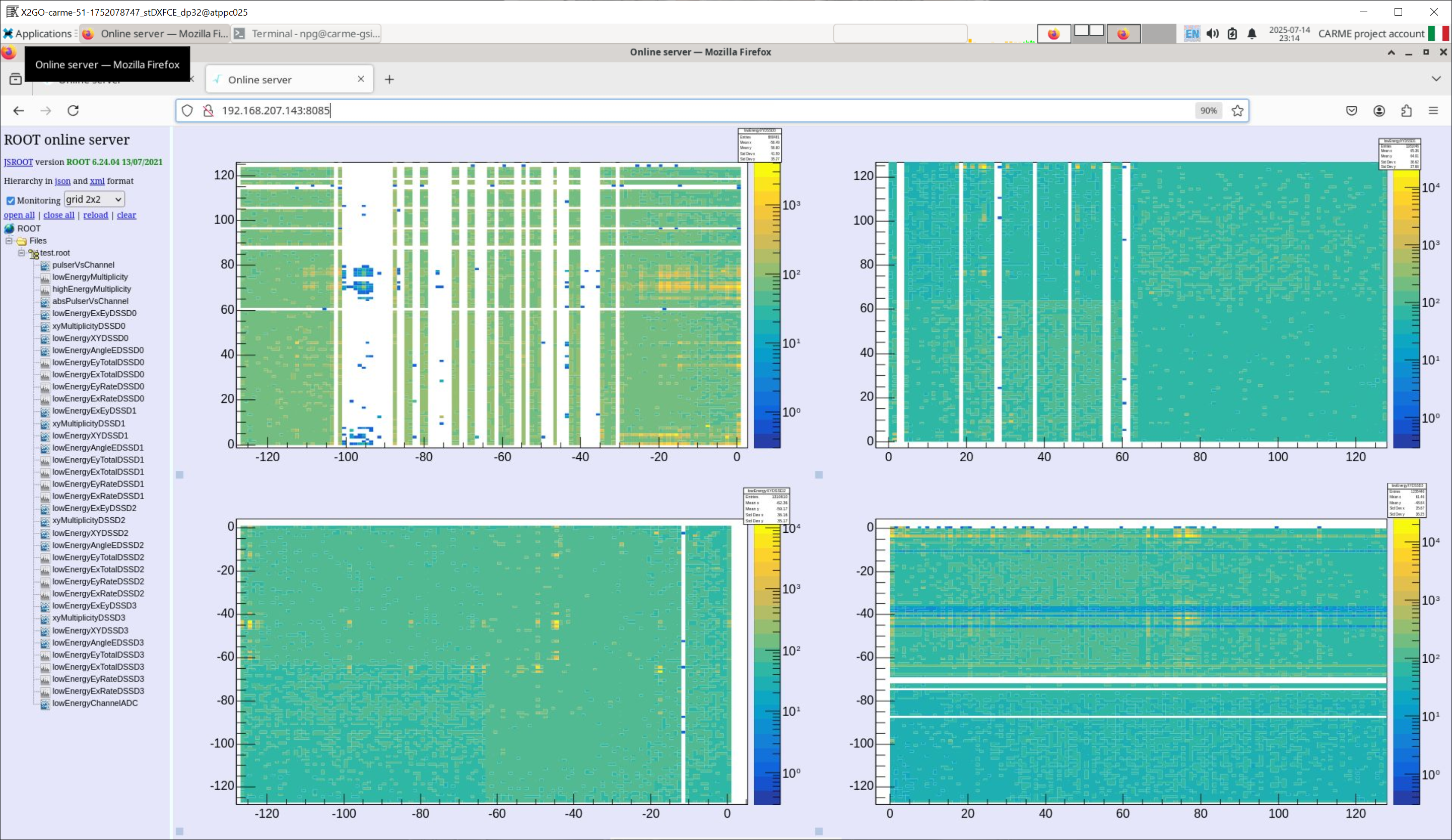

- A number of interesting features in the online background spectrum. Likely all non-physical (attached)

- Stats OK (attached)

20:50 CEST

All checks good.

22:28 CEST

All checks good.

Features in the XY plot rensemble beam hitting the detectors. Attached.

Leakage currents and rates are good - unlikely to be major detector damage. Attached.

Only beam in the ring between now and end of D+D was stable uranium.

Killed CARMEsort via terminal (still no access to anydesk).

Restarted CARMEsort. No obvious structures appear after a few minutes. Was there beam in the ring today?

23:09 CEST

All checks good

Features in the XY plot and Ey plots disappeared.

---10 July---

03:22 CEST

All checks good.

Features gone. Attached.

05:15 CEST

All checks good.

07:34 CEST

All checks good.

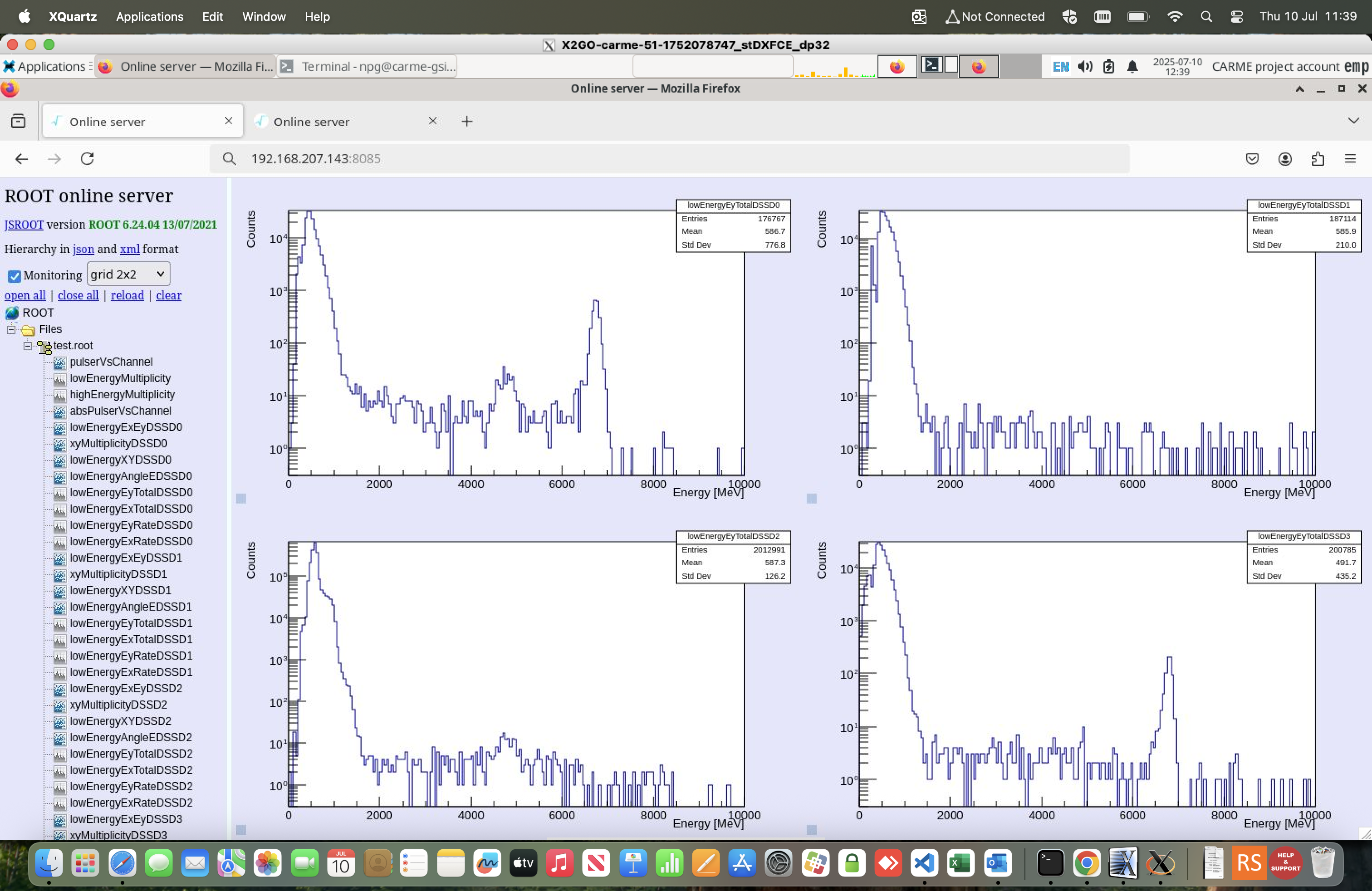

10:40 CEST

All checks good.

12:35 CEST

All checks good. Some features in plots again appeared in last 2 hours, attached Ey plot (attachment 15).

14:40 CEST

All checks okay.

16:40 CEST

All checks okay.

18:40 CEST

All checks okay. Attachment 16 leakage current stable.

Attachment 17 Ey plot.

19:35 CEST

All checks OK.

Reset the Root spectra again - highly unlikely to have beam overnight without experiments running.

23:39 CEST

All checks OK.

Still seeing peak at 6 MeV like attachment 17, after resetting the Root spectra. Detector damage? Still seems implausible.

Events are focussed as in attachment 12.

Reset again. No obvious peak or pattern after a few minutes running.

From Claude K

"CRYRING was running with the Uranium beam from ESR until Tuesday (8 July) night around 22:00.

From Wednesday noon we started to inject D+ from the local source and had the D+ beam stored at various energies from 14:30 until 17:40. During the night from Wednesday (9 July) to Thursday (10 July) there was no beam.

We then continued measurements with stored D+ On Thursday from ca. 11:00 to 21:00. Since then CRYRING is in shutdown."

---11 July---

08:07 CEST

All checks OK.

Peak at 6 MeV did not re-appear overnight. Attached x2.

12:00 CEST

All checks good! All plots look good!

16:00 CEST

All checks okay!

19:20 CEST

All checks OK.

Background peaks almost visible.

22:53 CEST

All checks OK.

---12 July---

07:25 CEST

All checks OK.

10:00 CEST

All checks OK. Temps attached.

11:00 CEST

All checks OK.

19:00 CEST

All checks OK.

23:00 CEST

All checks OK.

---13 July---

07:42 CEST

All checks OK.

11:00 CEST

All checks OK.

ELOG down during the afternoon

--14 July--

11:00 CEST

All checks ok.

14:40 CEST

Tape service and merger now working on atppc025

All checks ok, briefly went no storage at around 14:38 CEST for 1-2 minutes whilst getting tape service and merger up.

17:40 CEST

All checks ok.

21:30 CEST

All checks OK.

23:16 CEST

All checks OK. Several screenshots attached.

Calibration appears to hinders clear alpha peaks.

---15 July---

07:47 CEST

All checks OK.

11:55 CEST

All checks ok.

14:35 CEST

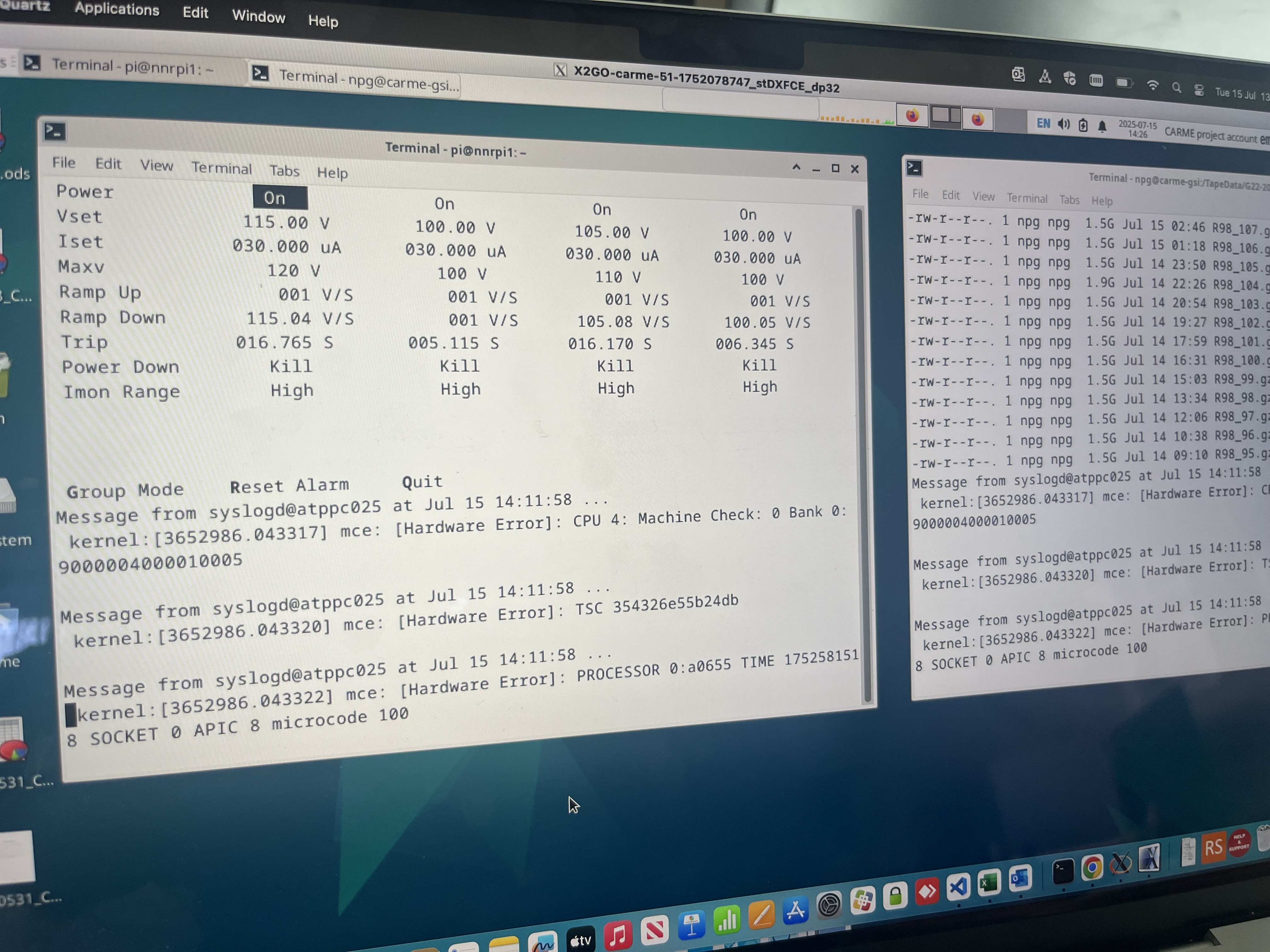

Issue with atppc025, see attachment 29 for error message (desktop 2, detectors etc)

Got error to go, all checks ok.

17:35 CEST

Same issue with atppc025, otherwise all checks ok.

20:30 CEST

All checks OK.

23:07 CEST

All checks OK

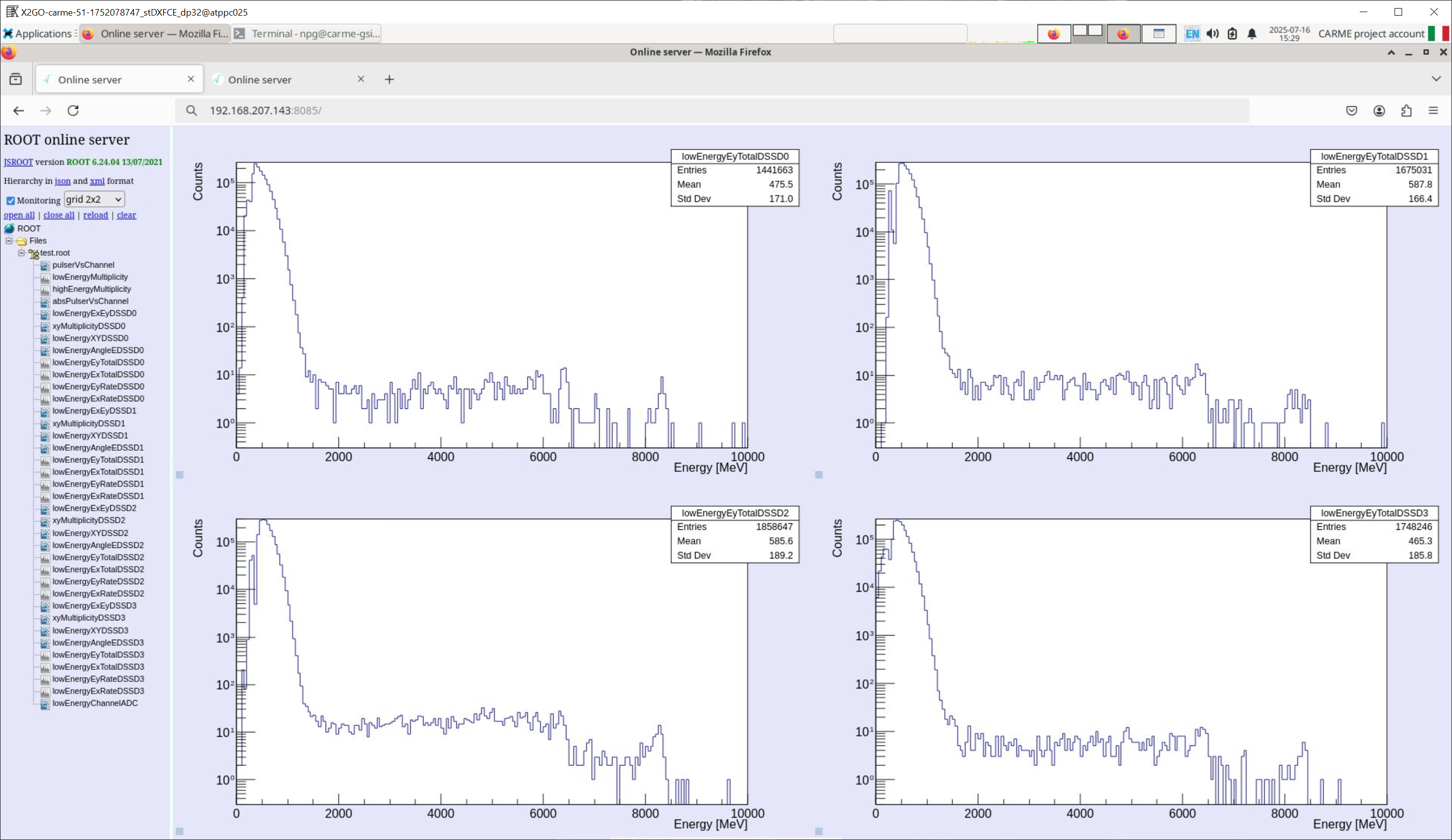

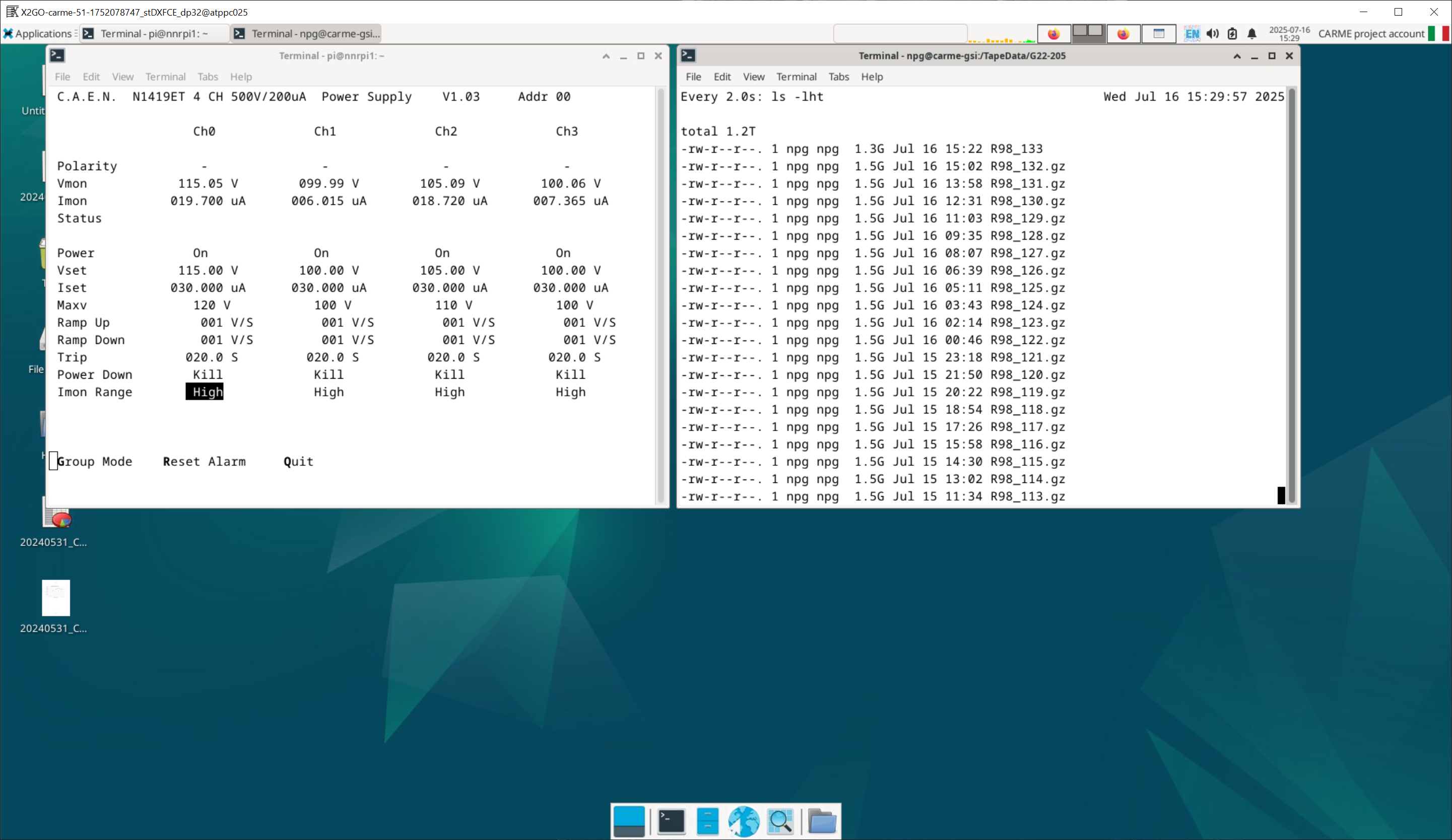

---16 July---

07:41 CEST

All checks OK

12:00 CEST

All check ok.

15:15 CEST

Some fees have high rates, all other checks ok.

15:32 CEST

The above behaviour appears to be correlated with an increase in leakage current across all four detectors. Most likely light?

The background is not reliable -> No storage.

Unfortunately the leakage current logger crashed a few days ago on the server, and without anydesk we did not realise. Restarted it on atppc025.

Informed ML about issue. If it cannot be solved we could increase the thresholds and keep going, but the background may not be representative.

16:35 CEST

Issue persists. ML and ZA are not aware of any changes, except power-saving mode enabled for cave AC. No effect on FEE temperatures - not the issue.

aida04 rates shows 0. Checkloaded. Fine for a few seconds. Back to 0. Data event rate 100,000 may be too high.

Increased thresholds to 1 MeV. Data rates lowered, but e.g. on aida04 still 40,000. Goes back to zero. Checkloaded. OK for a short while, then back to zero.

Tape server stopped. DAQ stopped - all FEEs respond, good! Merger still going.

DSSDs off. Will retry tomorrow morning.

23:44 CEST

Temps OK. |

| Attachment 1: Screenshot_2025-07-09_at_11.19.43.png

|

|

| Attachment 2: Screenshot_2025-07-09_at_11.16.35.png

|

|

| Attachment 3: Screenshot_2025-07-09_at_11.16.07.png

|

|

| Attachment 4: Screenshot_2025-07-09_at_11.15.57.png

|

|

| Attachment 5: Screenshot_2025-07-09_at_11.15.47.png

|

|

| Attachment 6: Screenshot_2025-07-09_at_13.31.55.png

|

|

| Attachment 7: Screenshot_2025-07-09_at_13.39.19.png

|

|

| Attachment 8: 1.png

|

|

| Attachment 9: 2.png

|

|

| Attachment 10: 3.png

|

|

| Attachment 11: 4.png

|

|

| Attachment 12: Capture.PNG

|

|

| Attachment 13: Capture2.PNG

|

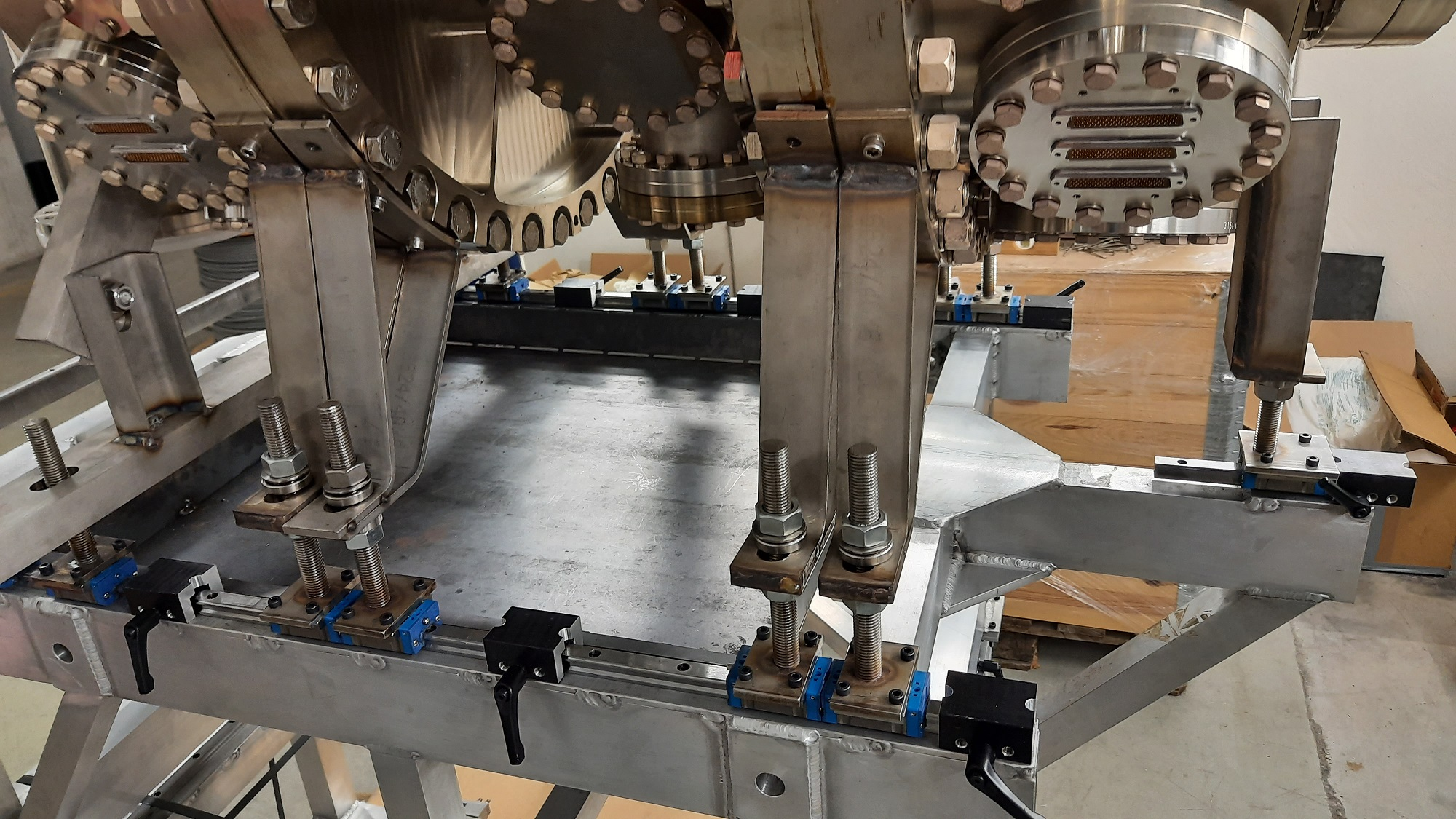

|

| Attachment 14: Capture.PNG

|

|

| Attachment 15: Screenshot_2025-07-10_at_11.39.51.png

|

|

| Attachment 16: Screenshot_2025-07-10_at_17.38.52.png

|

|

| Attachment 17: Screenshot_2025-07-10_at_17.38.39.png

|

|

| Attachment 18: Capture.PNG

|

|

| Attachment 19: Capture2.PNG

|

|

| Attachment 20: Capture.PNG

|

|

| Attachment 21: Capture2.PNG

|

|

| Attachment 22: 1.PNG

|

|

| Attachment 23: 2.PNG

|

|

| Attachment 24: 3.PNG

|

|

| Attachment 25: 4.PNG

|

|

| Attachment 26: 5.PNG

|

|

| Attachment 27: 7.PNG

|

|

| Attachment 28: 6.PNG

|

|

| Attachment 29: IMG_4779.jpeg

|

|

| Attachment 30: 1.PNG

|

|

| Attachment 31: 2.PNG

|

|

| Attachment 32: 3.PNG

|

|

|

685

|

Tue May 20 19:38:36 2025 |

JM | CARME restart |

19:00

Arrived at GSI.

We have 6Li1+ beam in the ring at 2 MeV/u. Injection is about 2.5e7 pps and lifetime with no target is about 40 seconds. We have injection every 25 seconds.

DSSD bias situation remains unchanged from previous elogs. See attachment 1.

AIDA started - all looks OK. All FEE temps OK - coolant pipe must still be fine.

Set aida03 and aida04 to MEC (0x1) and slow comparator thresholds for all FEEs to 0x32 (500 keV).

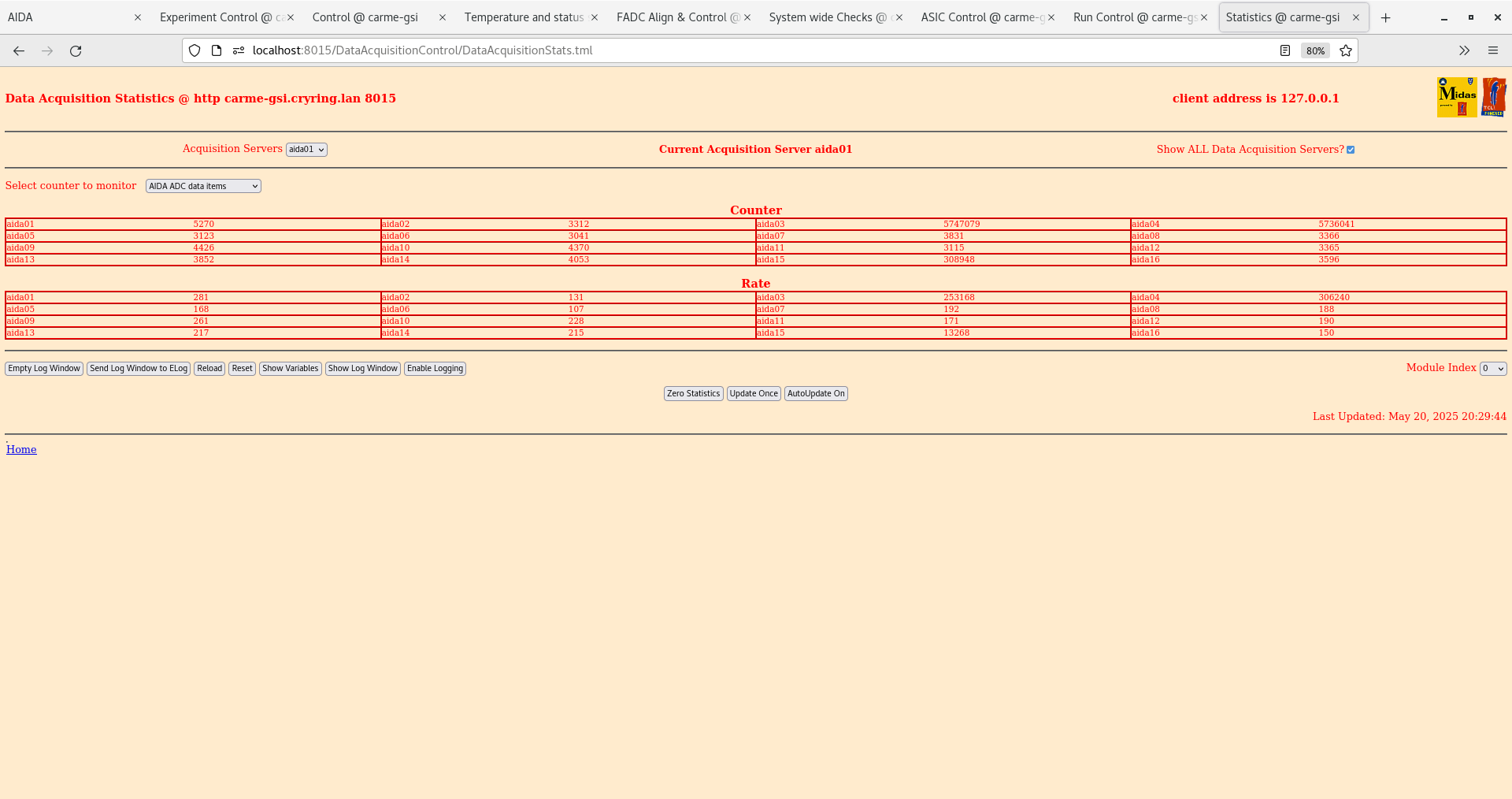

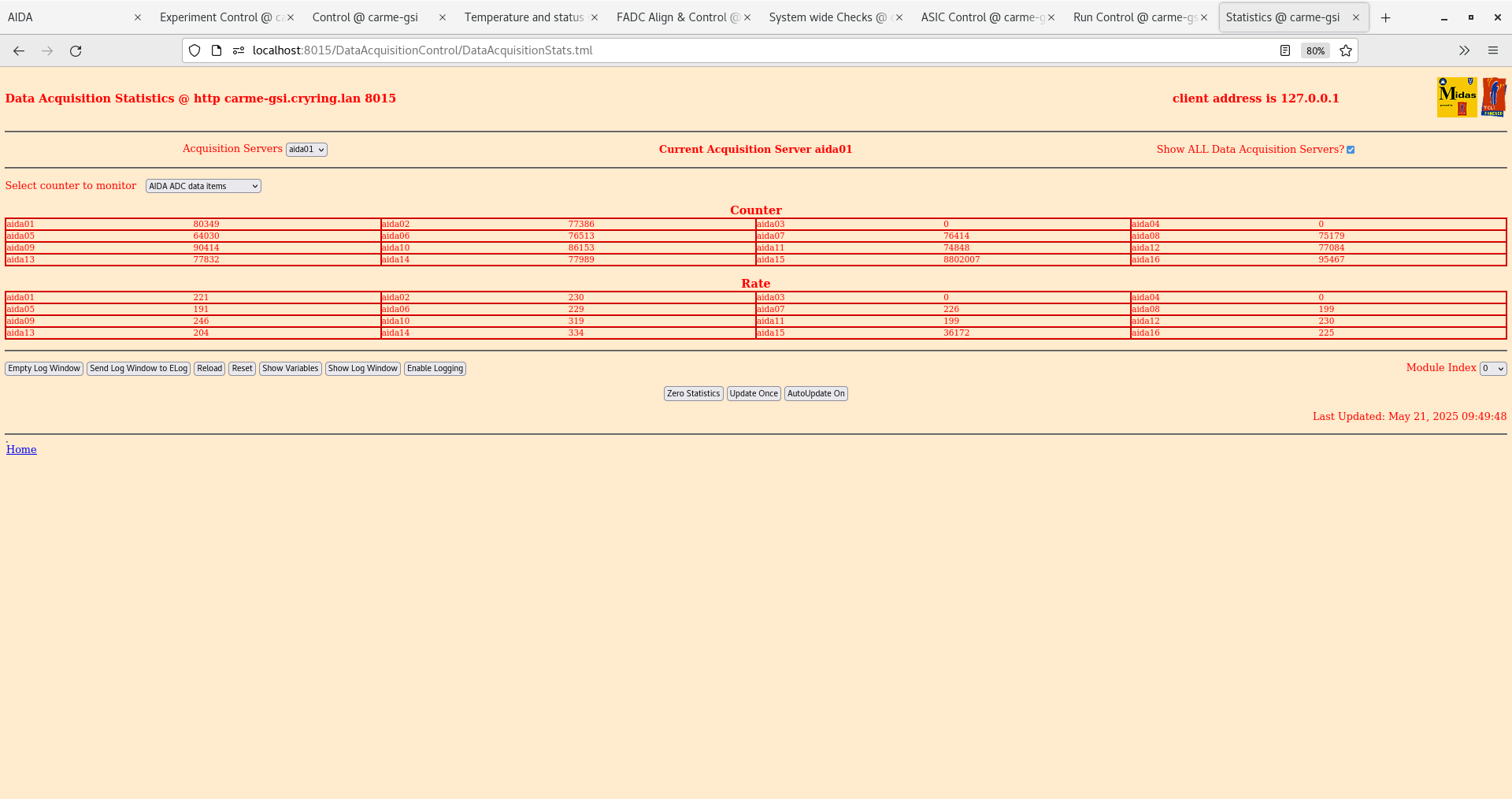

Attachment 2 shows ADC data items rate for 1 MeV threshold. Attachment 3 shows the same but at 500 keV threshold with aida03 and aida04 set to MEC.

DAQ go rates look OK.

Setting up tape server and merger. I notice a strange occurance. NetVar options is set to 3 on loading. I set this equal to 1 so we can write to disk.... but this turns off the enable output to data storage off on the merger. By enabling output to data storage again the neVar options variable returns to 3 and we cannot write data to disk. I have tried reloading the servers for the merger/tape server and rebooting the FEEs -> still have this issue. It is pretty late so have turned FEEs off but left DSSDs biased at 100V.

Note the proxy is back up

09:45

Started up AIDA DAQ.

Started merger and tape server as yesterday. Today I have had no issues (same procedure was used last night?!). We are currently writing data to disk G22-205/R1

All FEEs set to 0x32 thresholds, with aida03 and aida04 set to MEC.

All sytem checks OK - no faults.

Temps OK

Merger running between 100k and 400k. Tape server writing ~300 kb/sec to disk.

Beam is ON. 6Li1+ at 2 MeV/u. Gleb is currently running machine tests.

Motors are not homed yet, waiting until beam is off and access to the cave to double check pins are out, Potentiometers read left=21.45mm and right=19.8mm

Attachment 4 - ADC data rates

Attachment 5 - Merger

Attachment 6 - Tape server

11:00

Safety meeting , beam off and access to the cave

Pins removed from motors and compressed air on. Motors homed.

Started background run (no beam) R3

13:30

We are now waiing for the target before we can begin tests today.

ASIC settings checked. We are using APR2025 settings. Only chnages made are aida03 and aida04 to MEC and slow comparator threshold lowered to 500 keV (0x32)

Fast comparator threshold is 0xff

14:00

Motors movement tested with signals from CRYRING. Dummy test signals sent through number 16 on the control room to CRYRING touch panel. This sent an injection signal followed by a dump signal 5 seconds later. Motors moved according to this pattern.

Command used on CARME motors code for future reference

l t in

l p in

l t out

l p out

l r 20 |

| Attachment 1: Screenshot_from_2025-05-20_20-04-13.png

|

|

| Attachment 2: Screenshot_from_2025-05-20_20-29-54.png

|

|

| Attachment 3: Screenshot_from_2025-05-20_20-38-10.png

|

|

| Attachment 4: Screenshot_from_2025-05-21_09-49-54.png

|

|

| Attachment 5: Screenshot_from_2025-05-21_09-50-08.png

|

|

| Attachment 6: Screenshot_from_2025-05-21_09-50-22.png

|

|

|

74

|

Wed Sep 22 08:30:08 2021 |

CB (remotely) | CARME pressure during first XHV test |

CARME pressure moved to

https://uoe-my.sharepoint.com/:x:/g/personal/cbruno2_ed_ac_uk/EVbsVOubNHRLj0PKiFIvd00BClMJ6WSJ1UDAyLA2F3R4jA?e=hEoZt7

Some photos overnight are over-exposed and pressure cannot be read.

Might be able to fix with image processing if needed, but likely not worth the time.

Baking started: 23/09/2021 14:00

Photo frequency changed to once per 10 minutes. |

|

32

|

Thu Oct 29 08:02:29 2020 |

CB, JM (remotely) | CARME pressure |

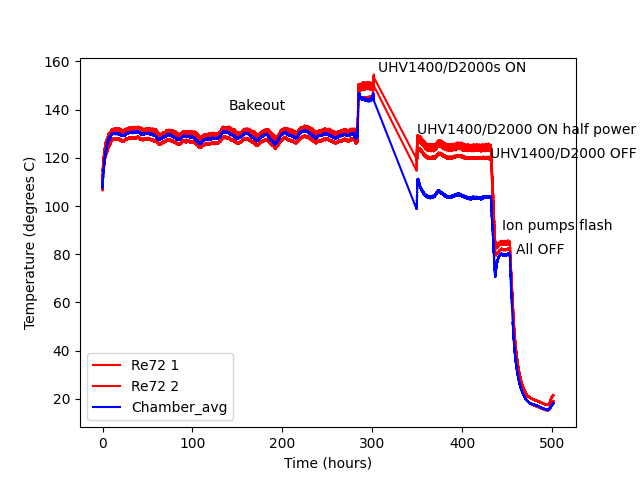

Attached is the temperature plot for bakeout period including tags for NEG activation etc.

28 October -> 27 November

--->See shared Excel document for CARME pressure values<---

https://uoe-my.sharepoint.com/:x:/g/personal/cbruno2_ed_ac_uk/EbaoBvhq8zFFtmuakXKjQWQBTqjjzilT6lk9BmchoxlMNQ?e=XU8DzE

30 October

07:30 Baking code has been shut down, we have no log of the temperatures. Restarted (T=0)

19:40 Pressure back in the E-12 mbar range.

31 October

08:47 Back in the low E-11 mbar range. See temperature plot attached.

15:57 Back in the E-12 mbar range.

1 November

12:30 Pressures updated. Temperature plot updated.

2 November

08:52 Pressure reached E-10 mbar overnight, now back in the E-12 range.

Temperature increasing. See attached.

3 November

08:37 Pressure stable in the E-12 mbar range.

15:36 Pressure mostly stable in the E-12 mbar range

17:30 KM reports re-arranging the mains power connection to borrow an extension reel. No obvious effects on pressure.

18:24 Pressure stable in the E-12 mbar range. Updated temperature plot.

4 November

08:39 Pressure stable in the E-12 mbar range.

Temperature plot updated.

19:31 Pressure mostly stable around 5E-12 mbar

5 November

10:26 Pressure stable in the E-12 mbar range.

6 November

12:26 Pressure stable in the E-12 mbar range.

7 November

11:50 Pressure stable in the E-12 mbar range.

Temperature plot updated.

8 November

20:39 Pressure increasing again. Now in 1E-11 mbar range

9 November

08:50 Pressure returned to E-12 mbar range.

Temperature plot updated

16:51 Pressure fluctuating around 7E-12 mbar range.

10 November

09:04 Pressure oscillating in the 7E-12 mbar range

11 November

08:27 Pressure mostly stable in the 5E-12 mbar range

12 November

08:21 Pressure mostly stable in the 5E-12 mbar range

13 November

08:29 Pressure increased suddenly to 7E-9 mbar yesterday at 14:00, from 6.5E-12 mbar. Was the valve closed? (Confirmed

by KM)

Pressure appears to be slowly recovering. Currently in the low E-10 mbar range.

Temperature plot updated.

15:40 Pressure does not appear to drop. Currently stable around 2E-10 mbar

18:10 KM reports Ion pumps have gone off (tripped by high pressure?)

IE514 gauge still reading 1E-10, but SAES D2000-10 ion pressure gauge reading 1E-12.

Someone will check tomorrow in person.

14 November

08:13 Pressure stable in the 2E-10 mbar range. Does not appear to decrease.

15 November

08:24 Pressure stable in the 2E-10 mbar range

16 November

08:23 Pressure increased to 1E-9 mbar (potentially due to heating being turned on at week start).

17 November

08:18 Pressure back in the E-12 mbar range since yesterday afternoon.

Change was sudden and CM52 control module appears to have been moved in-between.

Unclear what was done locally.

18 November

08:40 Pressure mostly stable in the 5E-12 mbar range.

19 November

07:55 Pressure remains stable in the E-12 mbar range.

Temperature plot updated

20 November

08:00 Pressure remains stable in the E-12 mbar range.

21 November

14:16 Pressure remains stable in the 5E-12 mbar range.

22 November

08:08 Pressure remains stable

23 November

08:24 Pressure remains stable

24 November

08:05 Pressure remains stable

See ELOG entry by JM

25 November

See ELOG entry by TD.

Valve partly closed.

26 November

08:58 Pressure in the E-10 mbar range, very slowly decreasing

27 November

21:07 Pressure stable in the 2E-10 mbar range. Does not appear to be decreasing

28 November

17:49 Pressure stable in the 2E-10 mbar range. |

| Attachment 1: 20201029_080001.jpg

|

|

| Attachment 2: Bakeout_pump_down.png

|

|

| Attachment 3: 20201119_temps.png

|

|

|

37

|

Mon Dec 7 14:29:12 2020 |

JM | CARME packing up |

|

| Attachment 1: 20201207_122353.jpg

|

|

| Attachment 2: 20201207_113905.jpg

|

|

| Attachment 3: 20201207_110714.jpg

|

|

|

369

|

Thu Mar 3 15:14:21 2022 |

JM, OH | CARME packing up |

Pulser walkthrough taken for motor position 23.1mm and motor position 67.43mm.

Points taken at 30,50,70,90,110,130,150,170,190,210,230 for 23.1mm position and 230,210,190,170,150,130,110 for 67.43mm position.

Motors moved to fully OUT position and pin put back in. Current positions before closing program 19.1mm and 19.57mm.

Fee power OFF. Fee power module switched OFF and AC mains cable unplugged.

Bias suppply OFF. NIM crate for bias module switched OFF.

Water supply OFF

CARME ion gauge turned back ON |

|

118

|

Tue Oct 12 13:54:21 2021 |

RSS TD + OD DR | CARME opened |

With the assistance of Oemer and Davide all of the M22 bolts removed from the downstream section of the CARME chamber. To separate the downstream section from the

upstream sections it was necessary to use a lever between M10 bolts screwed into the lift points of adjacent sections of the CARME. The upstream sections were then

lifted from the support frame and placed on the shipment crate base. The open ports of the CARME chamber sections were covered by Al foil.

Attachments 1-3 show downstream section following removal of upstream sections of CARME chamber. Note staining/residue top and bottom right - attachments 2 & 3. |

| Attachment 1: 20211012_143212.jpg

|

|

| Attachment 2: 20211012_143221.jpg

|

|

| Attachment 3: 20211012_143229.jpg

|

|

| Attachment 4: IMG_5002.JPG

|

|

| Attachment 5: IMG_4981.JPG

|

|

| Attachment 6: IMG_4982.JPG

|

|

| Attachment 7: IMG_4987.JPG

|

|

| Attachment 8: IMG_4989.JPG

|

|

| Attachment 9: IMG_4994.JPG

|

|

| Attachment 10: IMG_4999.JPG

|

|

| Attachment 11: IMG_4977.JPG

|

|

| Attachment 12: IMG_4996.JPG

|

|

| Attachment 13: IMG_5001.JPG

|

|

| Attachment 14: IMG_5002.JPG

|

|

| Attachment 15: IMG_5003.JPG

|

|

| Attachment 16: IMG_5004.JPG

|

|

| Attachment 17: IMG_5005.JPG

|

|

| Attachment 18: IMG_5006.JPG

|

|

| Attachment 19: IMG_5007.JPG

|

|

| Attachment 20: IMG_5008.JPG

|

|

|

139

|

Mon Nov 1 14:48:16 2021 |

CB + ML DR | CARME opened |

Confirmed leak as per previous Elog.

Tightened to 100 Nm - no effects.

Tightened to 130 Nm - bottom leak disappeared. Top leak still at 1.3E-8 mbar l second.

Decided to open. Lifted front part of CARME down.

No obvious damage to wire seal.

Inspected wire seat and seal part. Part corresponding to leak feels rough to the touch. Suggested damage when SS parts come together?

DR sanded down gently the valve seal. Cleaned with compressed air and ethanol.

Gently sanded down seat as well, barely touched it.

Grossmontage experts will be back tomorrow am for final cleaning and re-assembly. |

|

391

|

Sat Apr 29 10:12:58 2023 |

CB, JM | CARME opened |

(28 April)

Mounted rails on dolly. The rails don't smoothly connect to those on the Aluminium frame and some thin metal shims were required to get the correct height. A metal support had to be placed above the Delrin pads to support the rails above the gap between frames.

All side feet were mounted but extensive modifications were required to slotted feet due to them not being manufactured to drawing, and to Carme middle section flange width being incorrect (see previous entry).

Removed brakes and started sliding CARME out. The dolly and the aluminium frame came partly separated as the weight of the side feet was shifted on the latter. Strapped them together. No damage.

Kept sliding. Sliding when the carriages passed from one rail to the other was quite hard. The back carriage on the left looking downstream lost a single ball bearing when crossing over. A more sophisticated solution is probably required.

Once Carme was on the dolly, opened it using M8 jacking bolts and lifted away front and middle section.

No obvious damage inside but strain relief did not work as intended. Photos to be uploaded after more detailed inspection on Saturday.

Plan to install right hand side detectors over the weekend. Unclear if bottom left detector is damaged and needs to be replaced. |

| Attachment 1: 20230428_094931.jpg

|

|

| Attachment 2: 20230428_155649.jpg

|

|

| Attachment 3: 20230428_164926.jpg

|

|

| Attachment 4: 20230428_155748.jpg

|

|

| Attachment 5: 20230428_165448.jpg

|

|

| Attachment 6: 20230428_174021.jpg

|

|

| Attachment 7: 20230428_181020.jpg

|

|

| Attachment 8: 20230428_181919.jpg

|

|

|

419

|

Fri Jul 14 08:27:17 2023 |

TD | CARME open - inspecting seal |

09.20 CARME chamber at atmospheric pressure as expected.

Will open CARME chamber and inspect COF600 wire seal for similar (or other) issues to the seal removed yesterday. One possibility is that the COF600 flange

surfaces/structures are misaligned and part of seal is 'escaping' the seal zone. Given the flanges close easily the misalignment would have to be small.

13.30 Observations

The bolts on the upstream feet of the far detector chamber are all loose and have probably been so for some time

Based on measurements with calipers and the insertion of shims into the *radial* gap between COF600 flange surfaces the COF600 flanges may be misaligned and rotated

transversely by a fraction of a millimeter. The challenge is that the chamber is not designed for fine transverse adjustments and it is not easy to measure the changes.

The Pfeiffer recommended procedure for closing COF seals is to start tightening bolts *diametrically* and then to tighten sequentially

https://www.pfeiffer-vacuum.com/en/know-how/mechanical-components-in-vacuum/connections/detachable-flange-connections/cof-flanges/

The plan

Adjust position of far detector chamber and secure upstream feet bolts

Close COF600 flange using Pfeiffer recommended procedure

Today is Friday so it will probably be Monday before we can pump the CARME chamber

13.50 Another view

Grosmontage also inspected the COF600 seal this afternoon. They said that it was important that the seal should be installed under tension to ensure that it remained

in position as the flanges were closed and the bolts begin to be tightened. They think the seals are a little too large in circumference but that they can shorten one on

Monday morning. |