| |

ID |

Date |

Author |

Subject |

|

|

160

|

Mon Nov 22 08:06:01 2021 |

RSS CB + ML | NEG activation starts |

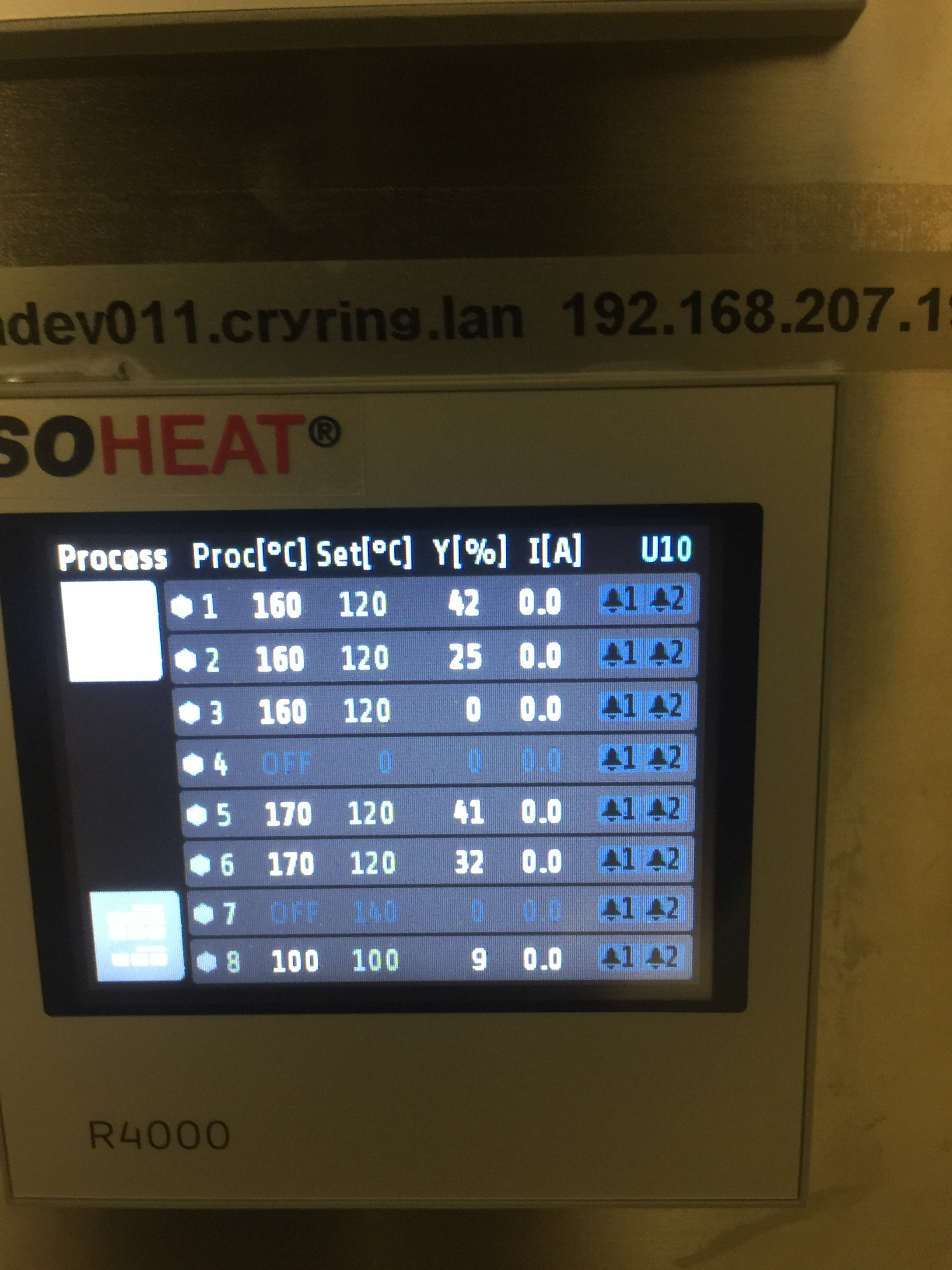

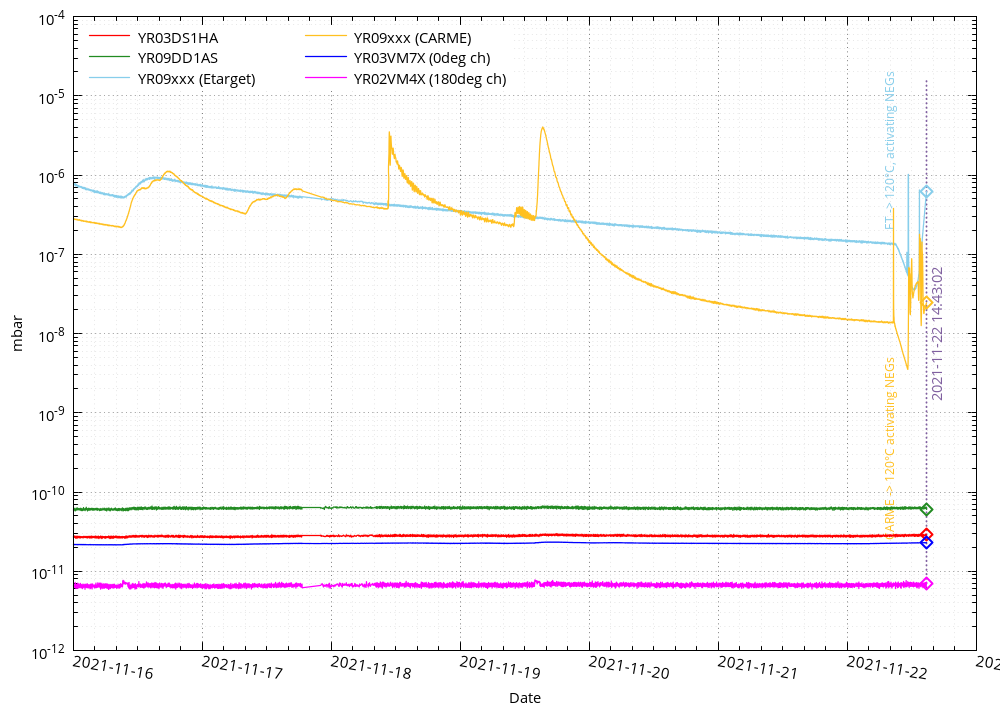

08:20 Temperature of channels 1-3 and 5-6 were reduced to 120 degrees. Immediately after, the conditioning of the NEGs was stopped and D2000s ion pumps were flashed 5 times. The temperature of the gas jet target and the electron target channels was reduced to 120 degrees.

11:00 Started activation of D2000 following procedure in ... at T=400 C for trise 30 min + thold 90 minute. After activation, NEG elements are left at 200 C to maintain cleanliness. Temperatures increasing, but still well below safety margins.

16:00 Started activation of NEGs from channel 1 at 200 W. No effects on temperatures. Activated channel 2 as well. No significant effects. Increased activation power to 250 W. No issues

16:30 Given temperatures are still low decided to activate 3 and 4 with 230 W (Vs. 150 W last time). Ok for 30 minutes then temperature starts increasing a bit too quickly. Decreased to 200 W. Ok.

18:45 Activation all NEGs on middle module complete. Left overnight to stabilise / cool.

21:00 Channel 6 of the heater stops responding properly. ML asked HKR to disable. No effects on temperatures.

|

| Attachment 1: IMG_5674.JPG

|

|

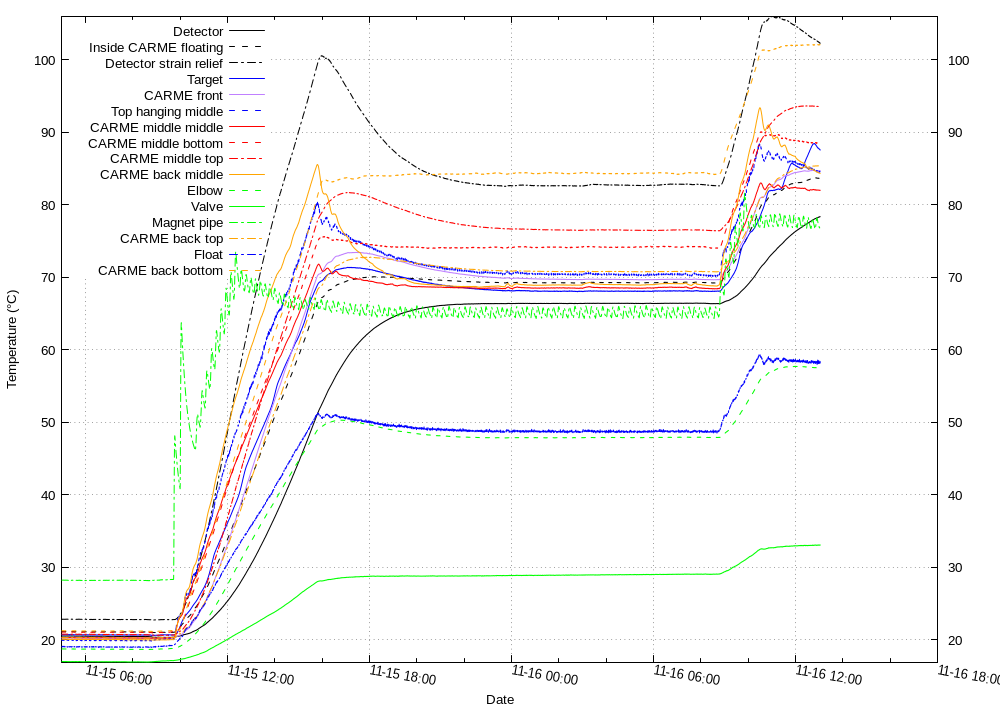

| Attachment 2: CARMEtemps.png

|

|

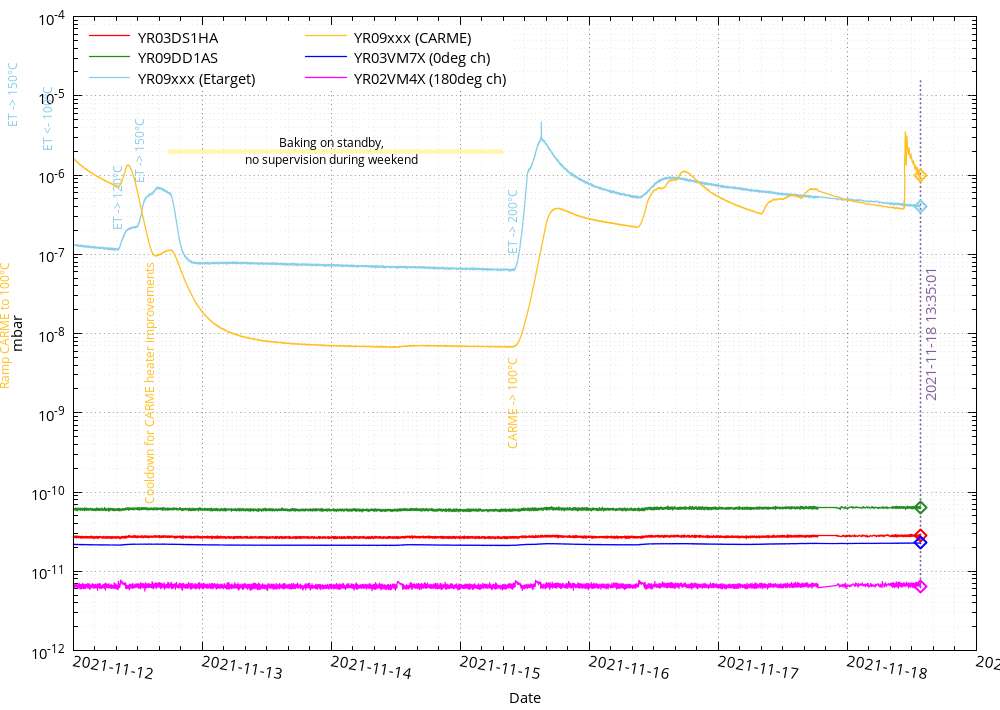

| Attachment 3: vacplot.png

|

|

|

|

159

|

Fri Nov 19 12:03:51 2021 |

CB RSS | Conditionings NEGs |

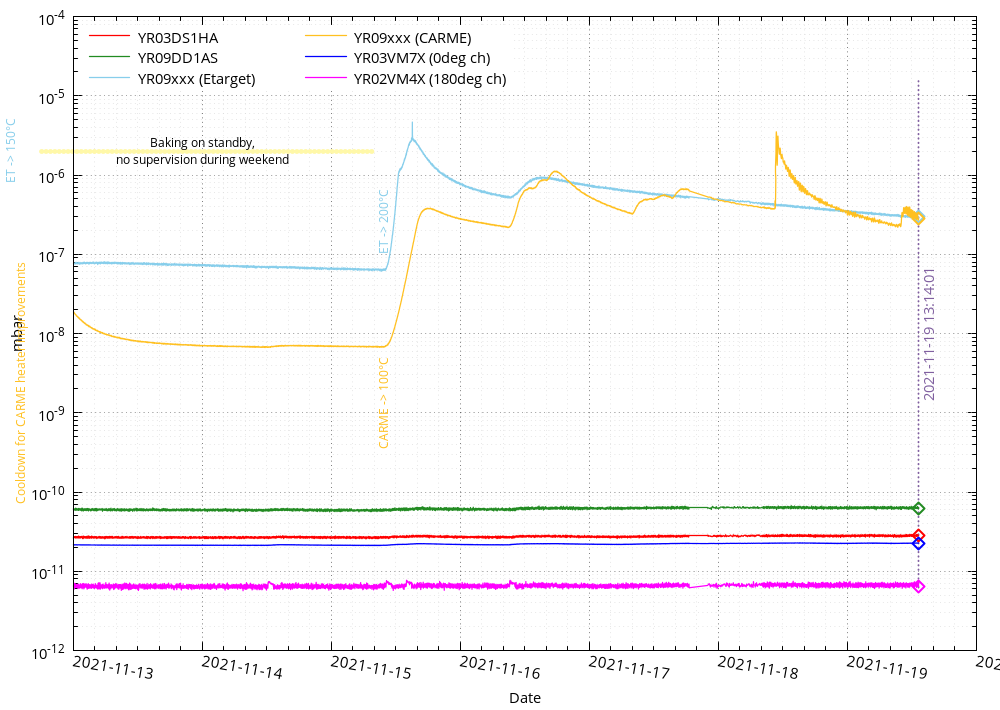

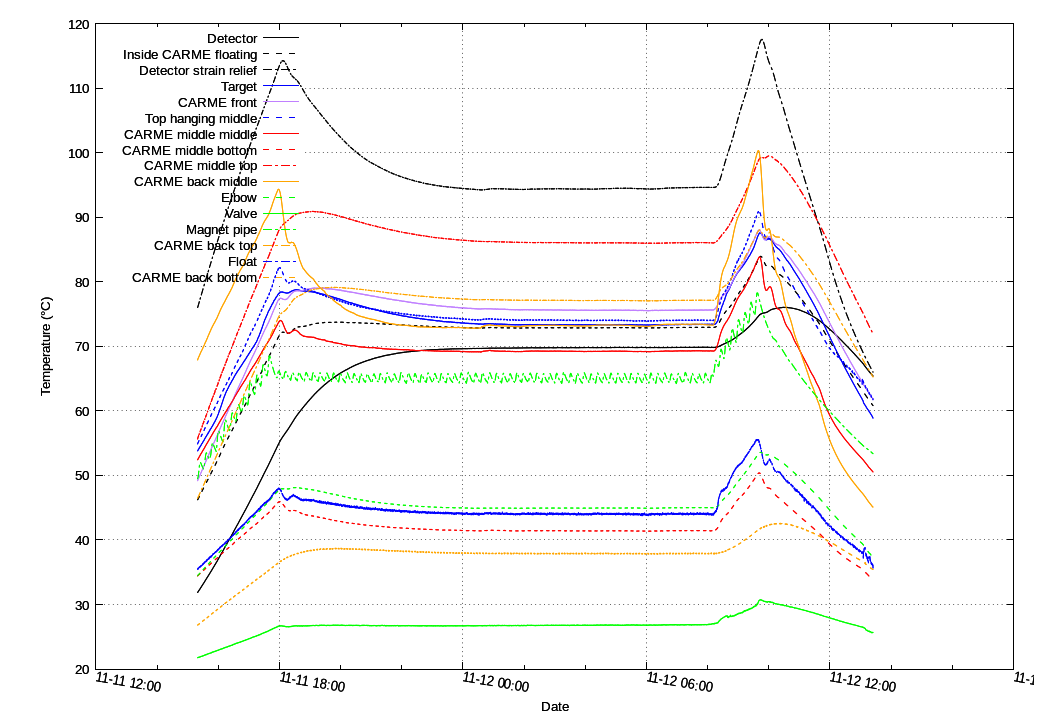

Increased conditioning temperature in D2000 #3 and 4 (behind detectors) to 150C from 130/140C. No appreciable change in temperature. Minor effects in pressure.

Pressure has completely recovered from yesterday and did not settle on higher/lower plateau value which may suggest conditioning the D2000 NEG elements has helped outgassing the chamber as a result of the low baking temperature.

Will now try to condition the UHV1400 furthest from the detectors at very low power according to SAES conditioning instructions.

The advantages are unclear at present, but more temperature during baking should not hurt final vacuum level. Will re-activate all NEGs anyway.

14:00 - Set power for all UHV1400 except those in the moving DSSD chamber to 20W. Some effects on both pressure and temperature. Will leave over weekend, start activation on Monday. |

| Attachment 1: CARMEtemps.png

|

|

| Attachment 2: vacplot.png

|

|

|

|

158

|

Thu Nov 18 13:50:51 2021 |

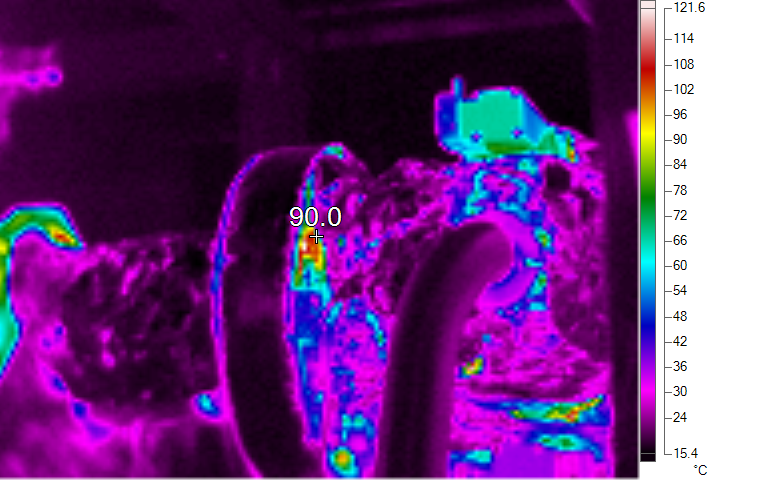

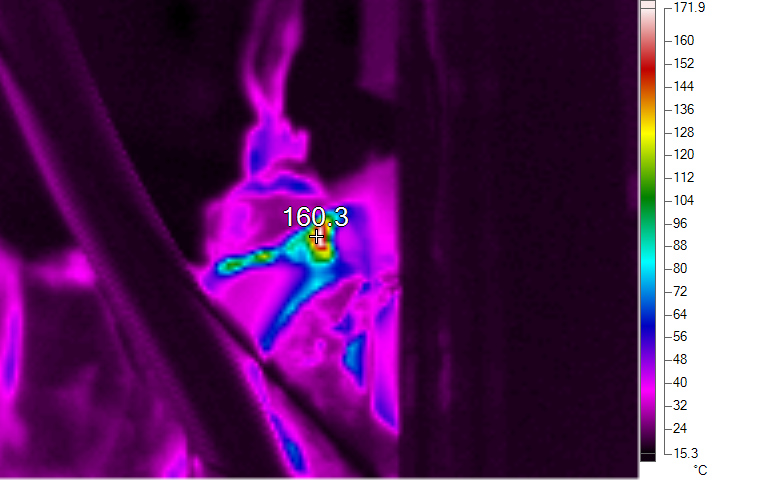

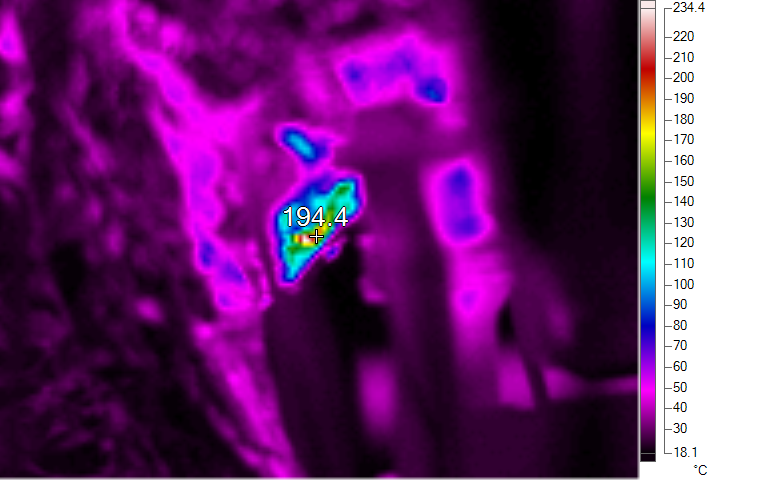

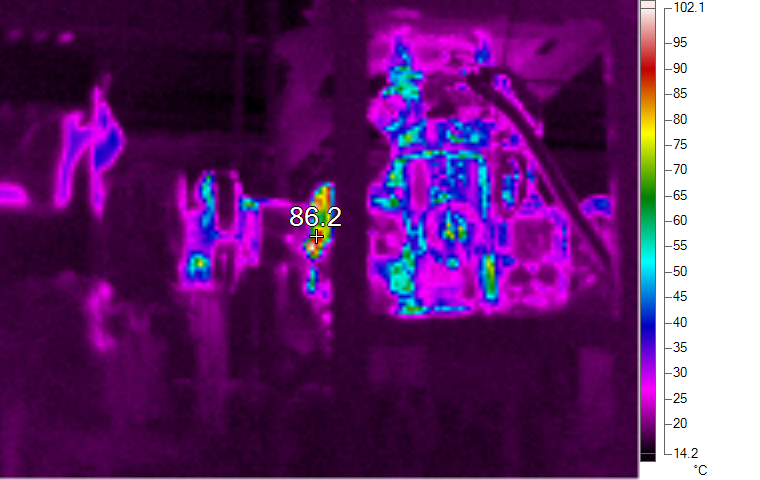

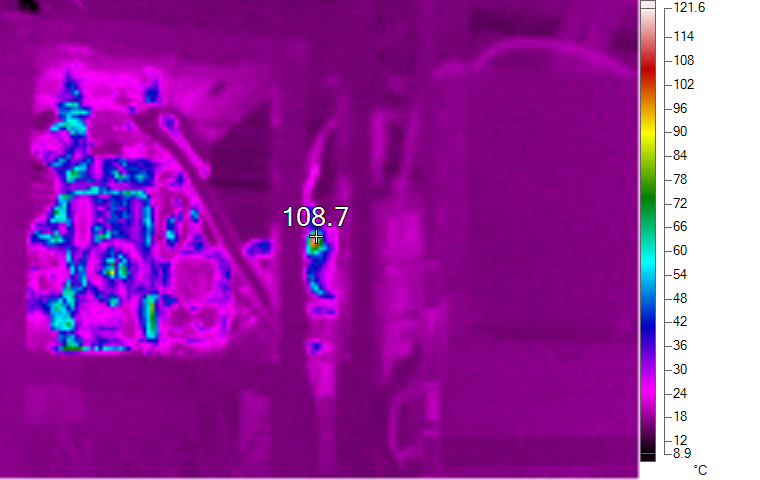

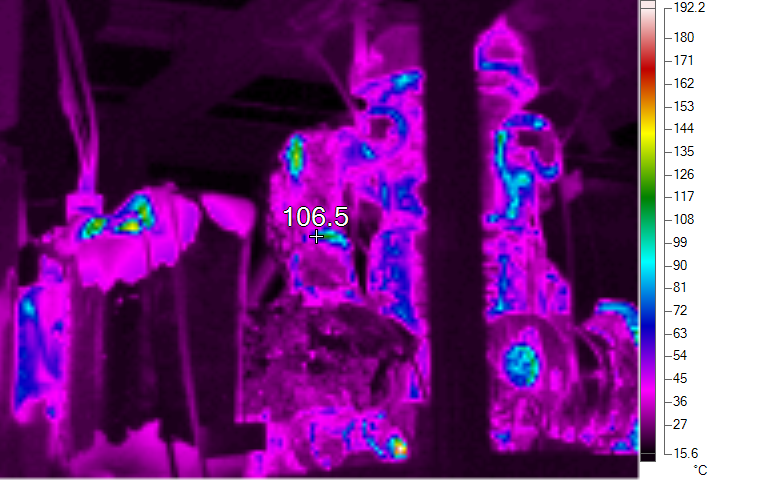

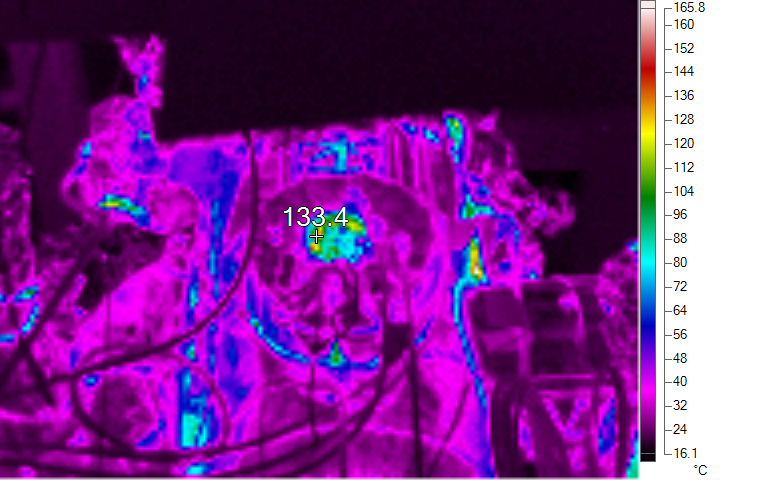

CB RSS | Thermocamera images |

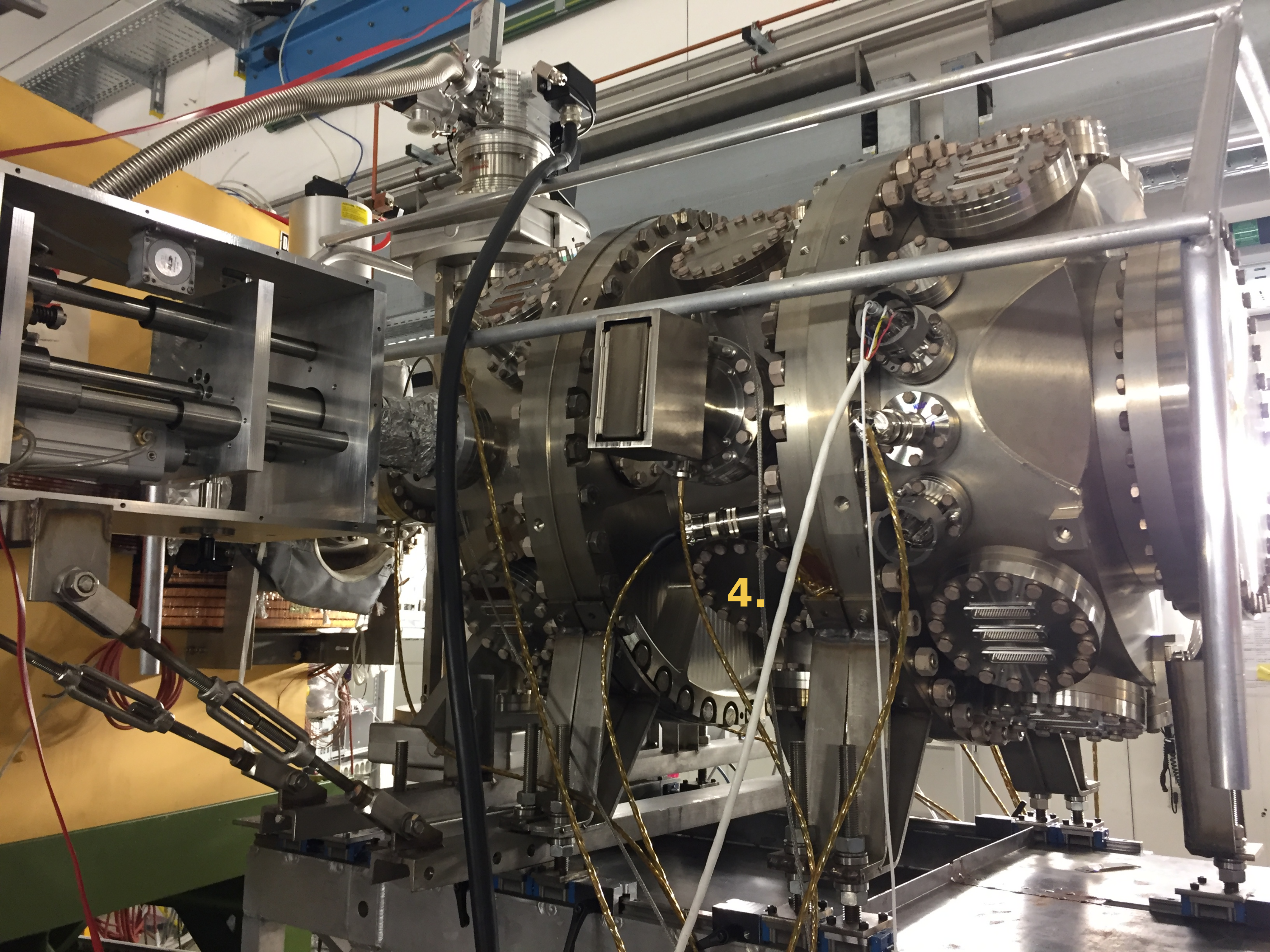

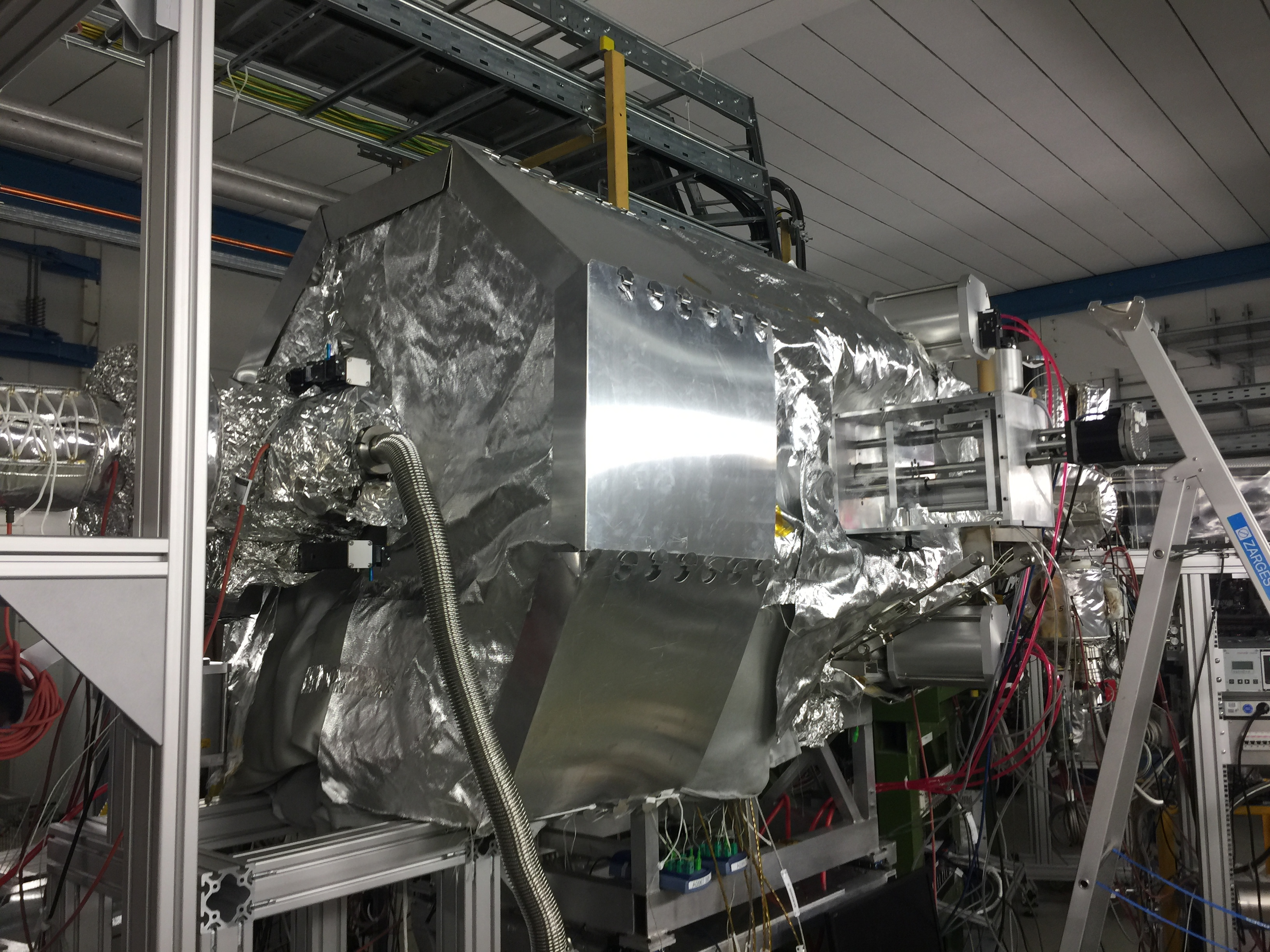

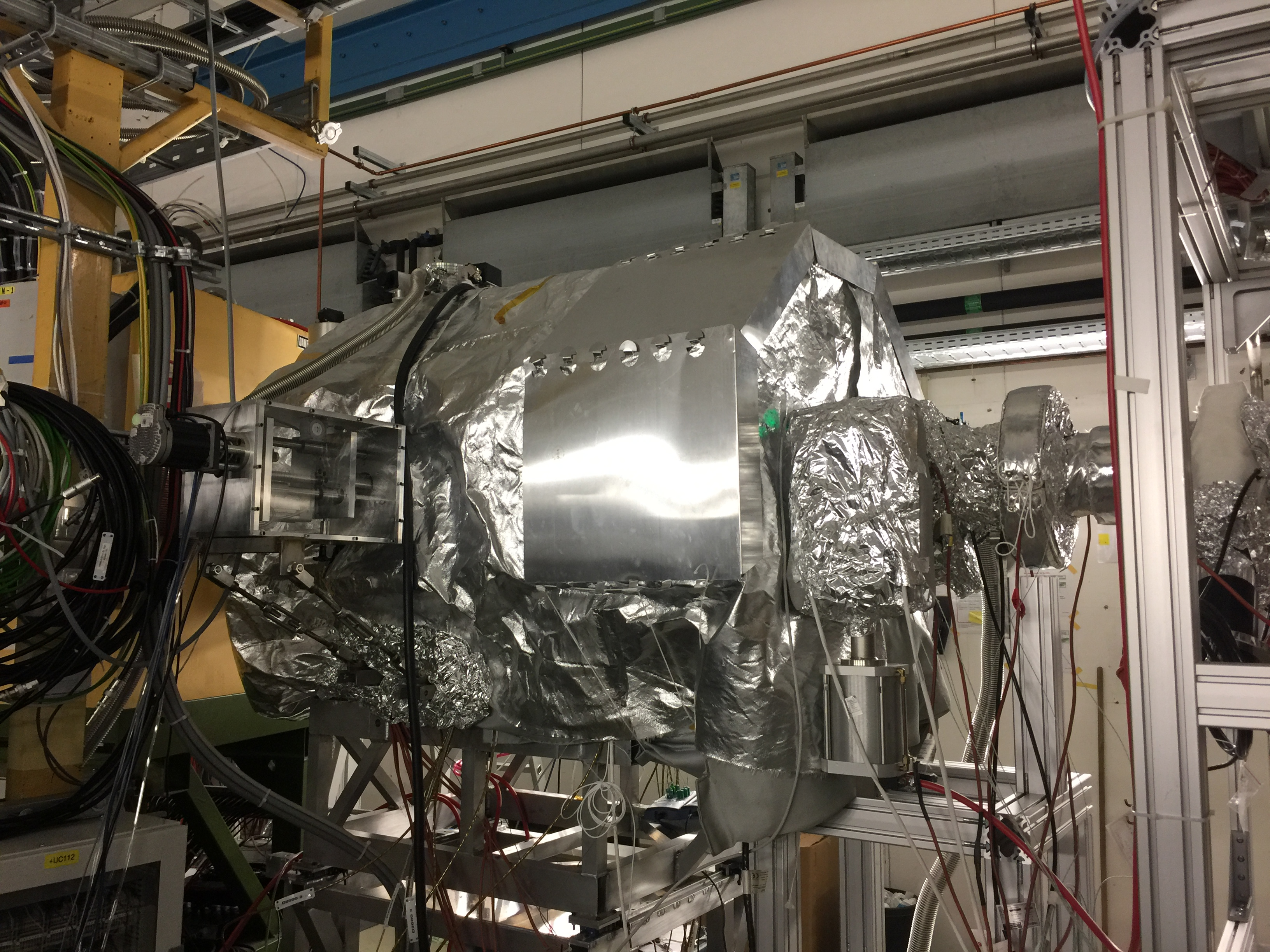

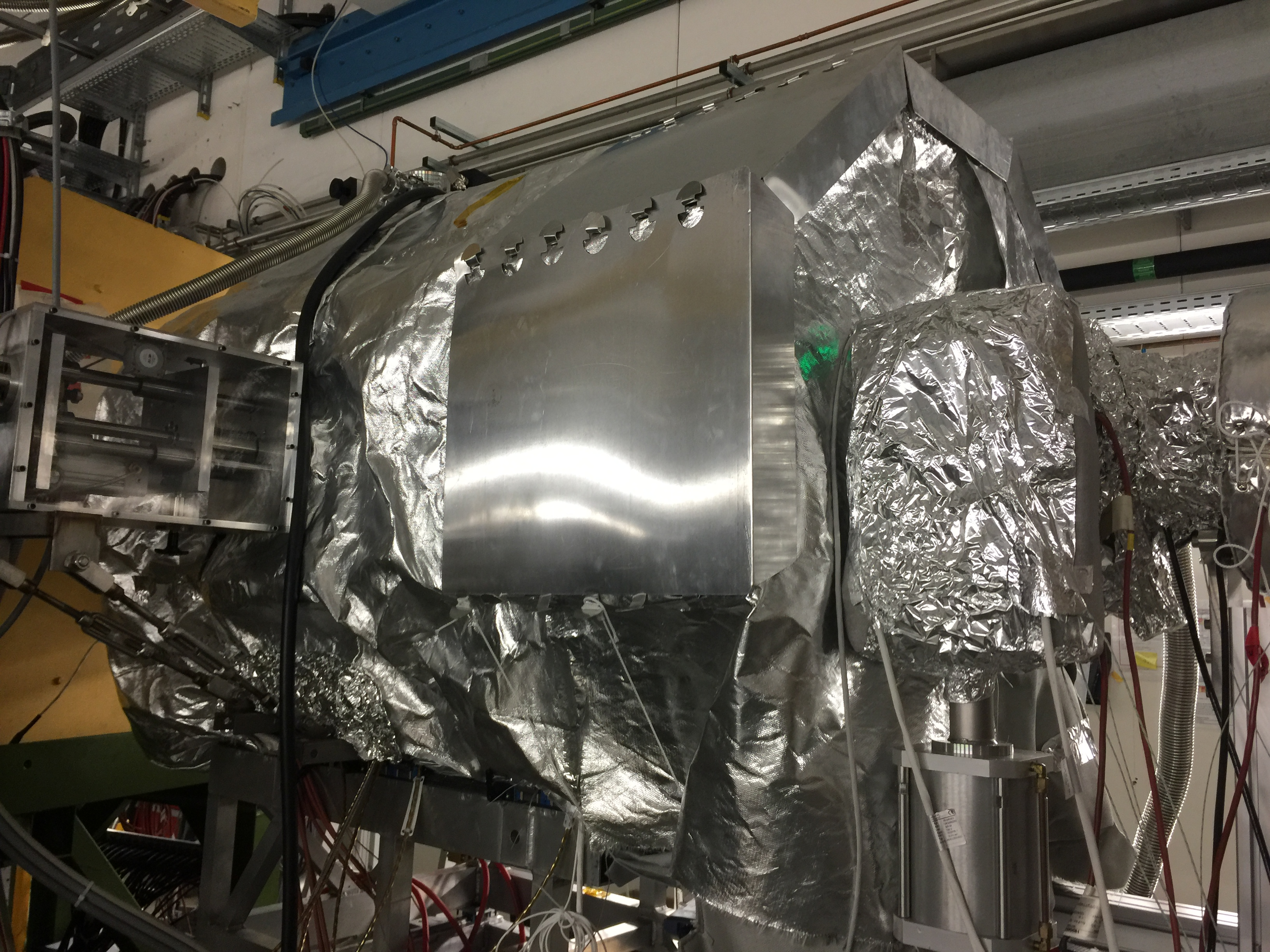

Used thermocamera provided by GSI beam diagnostic division to take some pictures of YR09. See attached.

Due to aluminium outer wrapping some reflections are inevitable, but tried to only take pictures of heat spots that did not disapper from different angles.

Temperature calibration may be not perfectly reliable as well.

1. Gap close to CARME outside motors

2. CARME top valve

3. CARME top valve

4. CARME turbo

5. Interaction chamber looking downstream from outside of ring. Note flexible hose pumping Be window.

6. As 5, from inside the ring.

7. Interaction chamber detail (see top left in picture above)

8. IE514 sensor on interaction chamber bottom

9. YR09 from inside the ring. Note electron target

10. As above, looking further upstream

11. YR09 from inside the ring, looking downstream towards CARME

12. Electron target from inside the ring

13. Electron target from outside the ring. Biggest flange.

14. Interaction chamber from inside the ring |

| Attachment 1: IR000087.png

|

|

| Attachment 2: IR000088.png

|

|

| Attachment 3: IR000089.png

|

|

| Attachment 4: IR000090.png

|

|

| Attachment 5: IR000091.png

|

|

| Attachment 6: IR000092.png

|

|

| Attachment 7: IR000093.png

|

|

| Attachment 8: IR000094.png

|

|

| Attachment 9: IR000096.png

|

|

| Attachment 10: IR000098.png

|

|

| Attachment 11: IR000099.png

|

|

| Attachment 12: IR000101.png

|

|

| Attachment 13: IR000102.png

|

|

| Attachment 14: IR000103.png

|

|

|

|

157

|

Thu Nov 18 12:29:50 2021 |

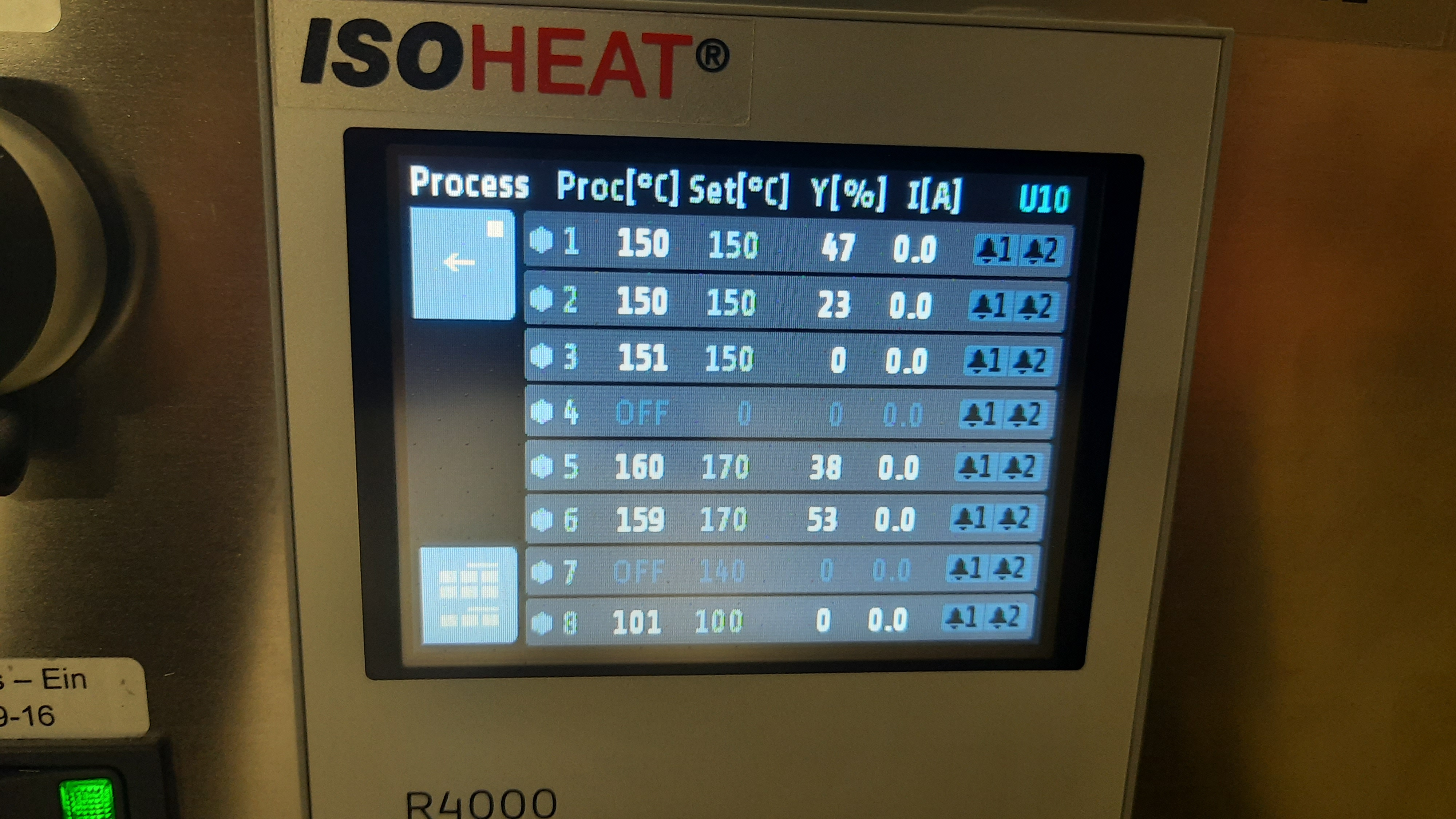

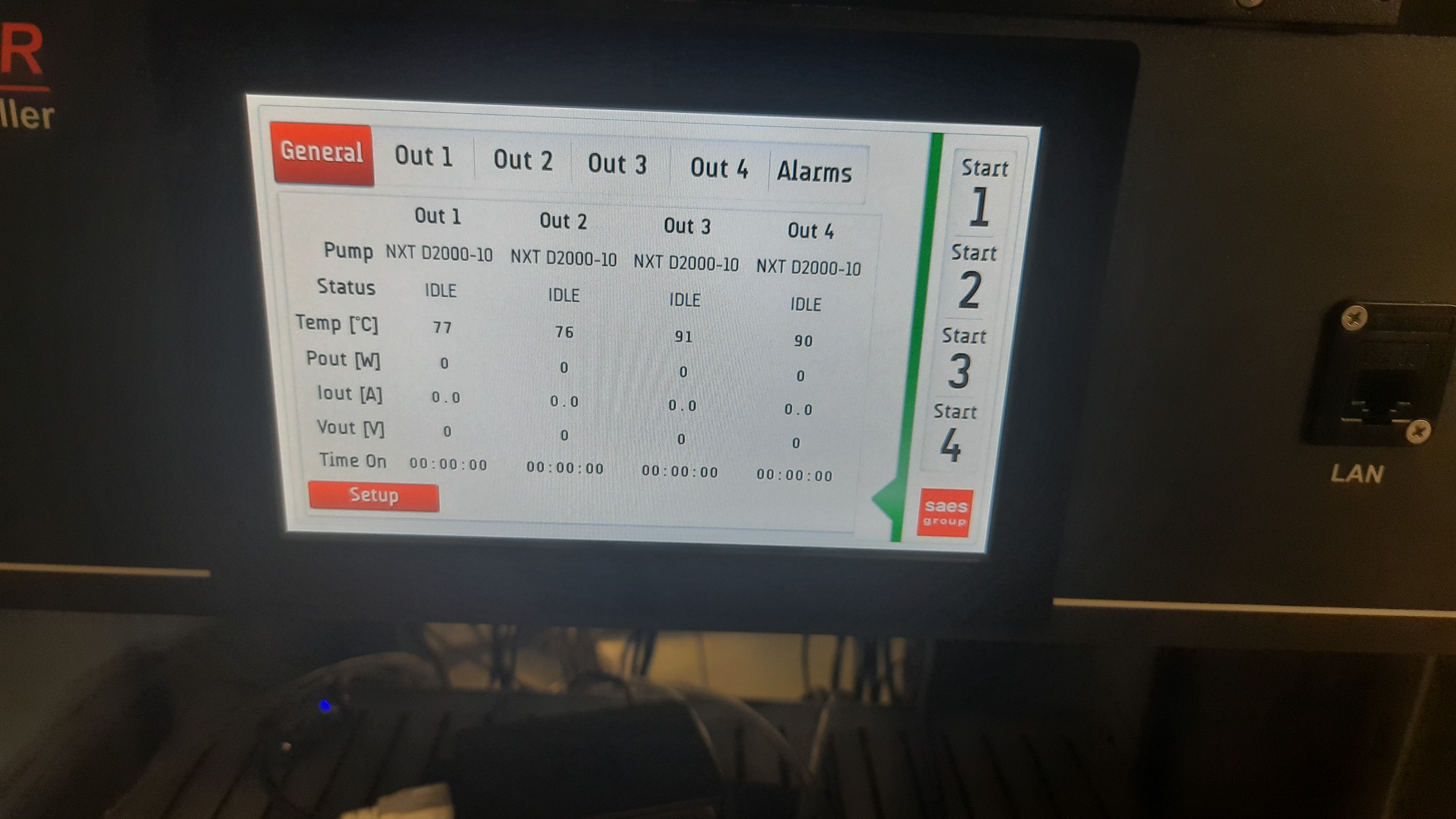

CB RSS | Conditioning D2000 NEGs |

D2000 thermocouples report temperatures around 100C (D2000 #1,2) and 120C (3,4). 1,2 are in the intermediate chamber, 3,4 are behind the moving arms. 3 is directly being the detectors.

Wanted to flash ion elements in D2000, but SAES recommend >100C to flash.

Followed SAES procedure / pre-sets to condition D2000 NEG elements while baking, but reduced temperature from 250 to 150 C (1,2) 140 C (4) and 130 C (3).

No appreciable changes in temperature. Change in pressure quite apparent. Left elements at temperatures above. May consider increasing everything to 150 tomorrow assuming detector temperatures do not change.

May also consider conditioning NEG elements in intermediate and DSSD wall chambers with 15W power (150C?) during baking as per SAES procedure. We never did this before, but we never baked as such low temperatures either. Will have to activate NEG elements after conditioning either way. |

| Attachment 1: vacplot.png

|

|

| Attachment 2: CARMEtemps.png

|

|

|

|

156

|

Wed Nov 17 07:12:22 2021 |

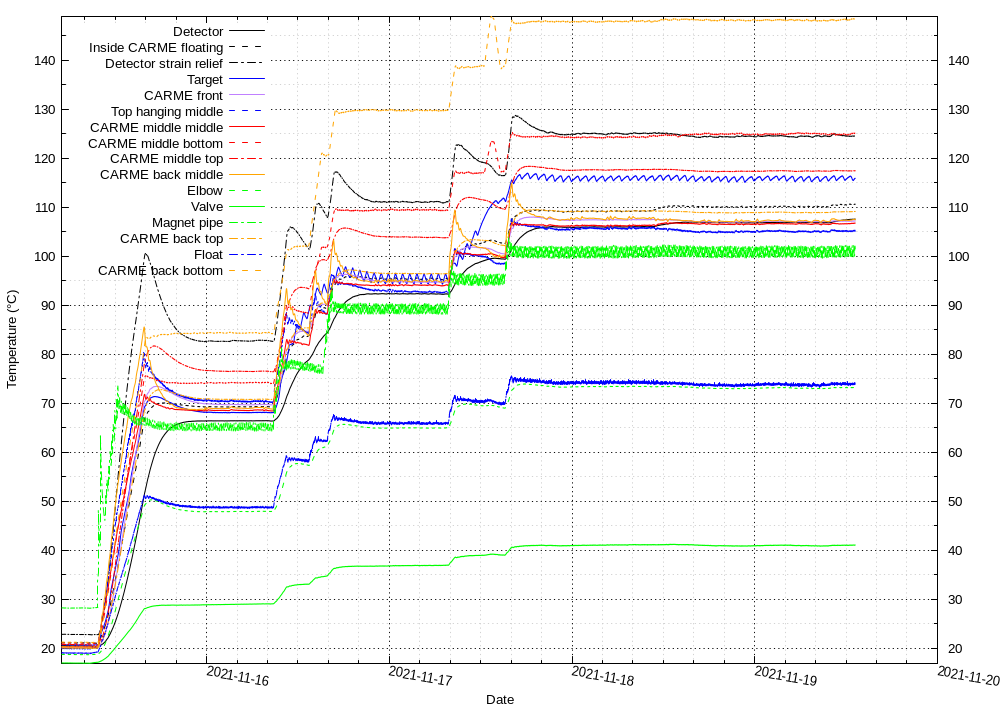

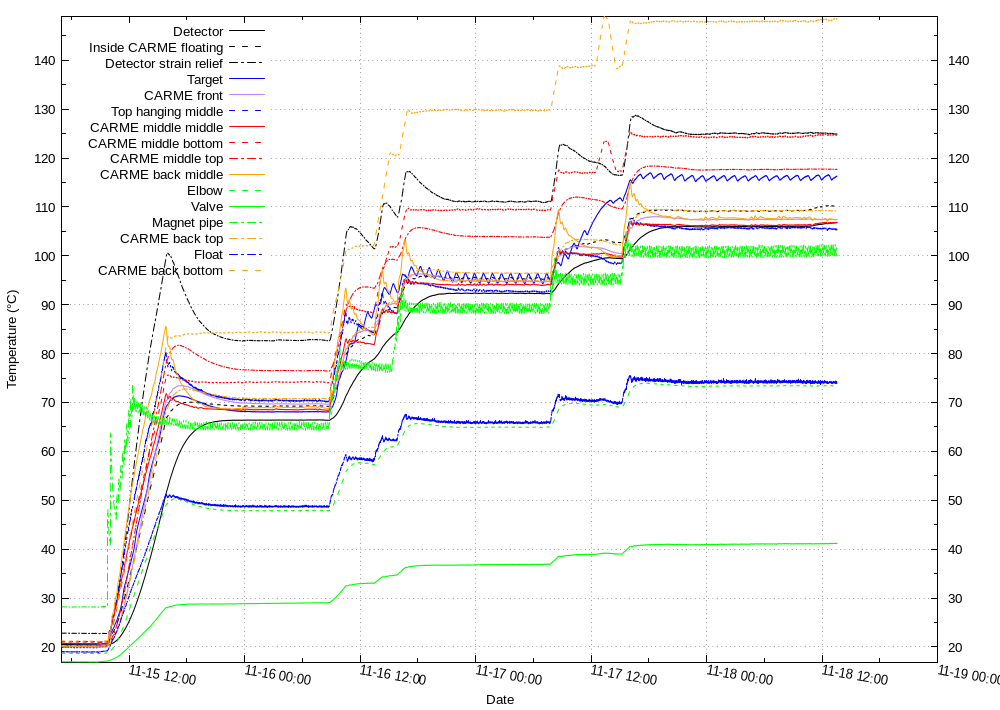

RSS CB + ML (remotely) | CARME baking with tape continues 17 Nov |

CARME baking with heating tape continues

Left overnight at -

Ch1-3: 140 degrees

Ch5-6: 150 degrees

Ch8: 100 degrees

07:50 - Increased channels 1-3 to 150, channels 5 and 6 to 160, and channel 8 remain at 100. For the gas jet target, channel 2 increased to 150.

12:39 - Increased channels 5 and 6 to 170 C. All of CARME is >100 C except "Magnet Pipe" that is at 95 (probably OK given proximity to gate valve).

13:40 - Decreased channel 5 to 160 C. Bottom back of CARME was going up, but rest of chamber was not following along. Thermal gradients were getting excessive.

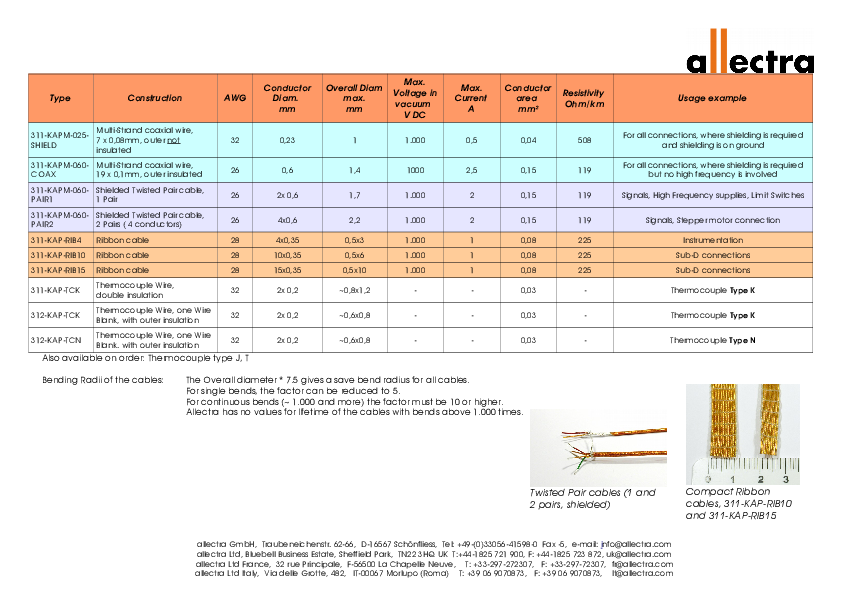

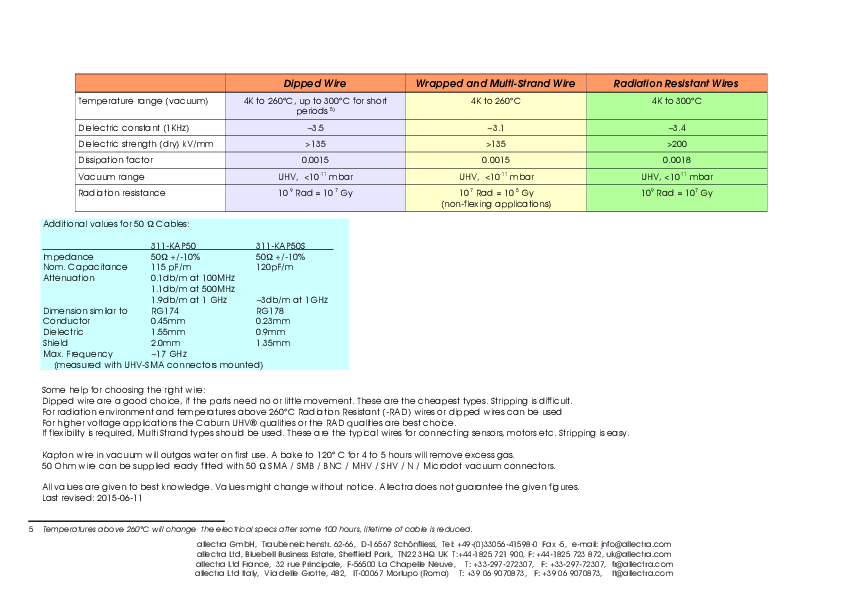

15:10 - Checked Kapton wire specs from Allectra. Max temperature of 311-KAPM-060 is 260 C in a vacuum not 160 C as erroneously remembered. Increased Ch 1 2 3 to 160 and channel 5 to 170. Planning on leaving until weekend.

Progress can be followed on

http://web-docs.gsi.de/~lestinsk/baking.php

http://web-docs.gsi.de/~lestinsk/vacplot.php |

| Attachment 1: IMG_5600.JPG

|

|

| Attachment 2: IMG_5602.JPG

|

|

| Attachment 3: 20211117_122601.jpg

|

|

| Attachment 4: 20211117_151041.jpg

|

|

| Attachment 5: 20211117_151500.jpg

|

|

| Attachment 6: Kaptonwires-overview.pdf

|

|

| Attachment 7: CARMEtemps.png

|

|

|

|

155

|

Tue Nov 16 12:05:13 2021 |

CB RSS | CARME baking with tape continues |

CARME baking with heating tape continues

Left overnight at 100C. Turned up this morning at 9:00 to 120C.

All good except detector strain relief seems to be going much higher than detector (no obvious reason) and then cool down. Proximity to flange / heating tape likely. One potential solution would be to push the motor in, putting some distance between detector / strain relief and outside flange.

13:30 - Increased channel 1 to 130 (long tape) and channels 5 and 6 to 140 (bottom flange heaters). Left rest as was.

15:20 - Increased channel 2 and 3 to 130. No obvious effects except Magnet pipe goes up

16:00 - Increased channel 1, 2, 3 to 140. Increased channels 5 and 6 to 150 C.

Progress can be followed on

http://web-docs.gsi.de/~lestinsk/baking.php

http://web-docs.gsi.de/~lestinsk/vacplot.php |

| Attachment 1: CARMEtemps.png

|

|

| Attachment 2: 20211116_132048.jpg

|

|

| Attachment 3: 20211116_155138.jpg

|

|

| Attachment 4: 20211116_155857.jpg

|

|

|

|

154

|

Fri Nov 12 08:54:11 2021 |

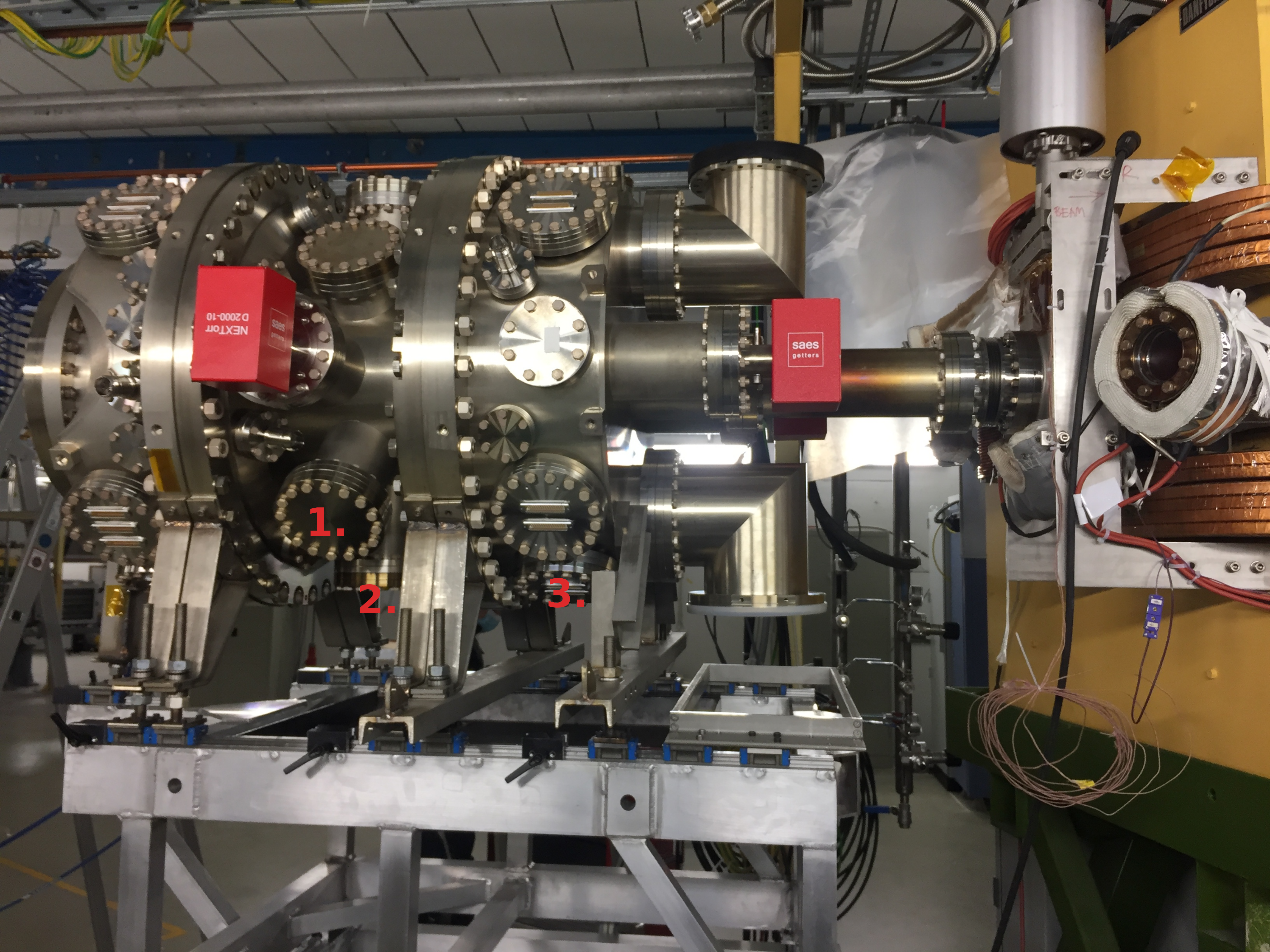

RSS ML + CB (remotely) NK AK NP | First CARME baking attempt |

07:50 Small leaks (near the motors and upper valve) were detected in the tent which were covered with Al foil.

08:10 ML changed the baking temperature to 120 degrees.

09:40 Since the bottom of CARME is cold, due to uneven distribution of heat, baking is stopped.

13:00 Tent was slightly opened from the sides so that the heat can escape.

13:15 NK mounted three 200 W (see red labels in the picture below) and one 40 W (see the yellow label in the picture below) heating jacket on four CF100 flanges. Power cables and thermocouples were taken care of by AK.

14:00 Tent was closed.

14:00-17:00 ML started baking at temperature 80 degrees to check the heat distribution in the tent. Baking was then stopped and will start from Monday.

Attached - thermocouple temperatures (now correct) |

| Attachment 1: Capture.PNG

|

|

| Attachment 2: 200W_heaters.svg

|

|

| Attachment 3: 40W_heater.svg

|

|

|

|

153

|

Thu Nov 11 14:01:00 2021 |

AK, ML | Heater channel layouts |

Schematic layout of heaters and channel assignment attached. Table kindly provided by AK. I hope the conversion from excel to pdf didn't swallow any important information. |

| Attachment 1: 2020.11.05_Cryring-YR09-baking-layout.pdf

|

|

|

|

151

|

Thu Nov 11 11:44:58 2021 |

RSS + ML OG + CB (remotely) | CARME baking started |

With the help of OG, the baking tent was built. MG started baking around 11:30 am with a rate of 0.2 K/minute.

Heating update can be found on: https://web-docs.gsi.de/~lestinsk/baking.php (CARME temperature plot now visible as well - thanks Michael!)

where, device - 192.168.207.192 is for CARME.

Ch1: CARME chamber long tape (2 kW)

Ch2: CF100 flanges exit side

Ch3: CF100 bellows exit side

Ch5: 200 W (x3) CF 100 flanges

Ch6: 40 W CF 100 flange

Ch8: VAT 100 gate valve to ring

example: in 39:50, 39 is the temperature and 50 is the set temperature. |

| Attachment 1: IMG_5535.JPG

|

|

| Attachment 2: IMG_5537.JPG

|

|

| Attachment 3: IMG_5531.JPG

|

|

| Attachment 4: IMG_5534.JPG

|

|

| Attachment 5: IMG_5539.JPG

|

|

|

|

150

|

Wed Nov 10 18:38:16 2021 |

RSS TD + ML OG AK NK | CARME wrapped in heating tape |

Heating and electronic experts were in CRYRING and were unhappy with the damaged wire. Heaters were opened by OG, but no damage was found. It is suggested to replace the entire wire and then get it approved by the concerned authority.

To avoid further delays, ML and TD agreed on heating tapes/wires covering the chamber. OG helped in wrapping the heating wire around. Tent is to be built by tomorrow.

MG and RSS tried the magnetic power back off thing which eventually did not work.

AK and NK helped with the power and thermocouple of the heating wire. NK has also covered the pipe and bellows near the magnet with heating jackets.

|

| Attachment 1: IMG_5514(1).JPG

|

.JPG.png)

|

| Attachment 2: IMG_5517(1).JPG

|

.JPG.png)

|

| Attachment 3: IMG_5518.JPG

|

|

| Attachment 4: IMG_5520.JPG

|

|

| Attachment 5: IMG_5521(1).JPG

|

.JPG.png)

|

|

|

149

|

Wed Nov 10 18:24:12 2021 |

RSS | Thermocouple labelling |

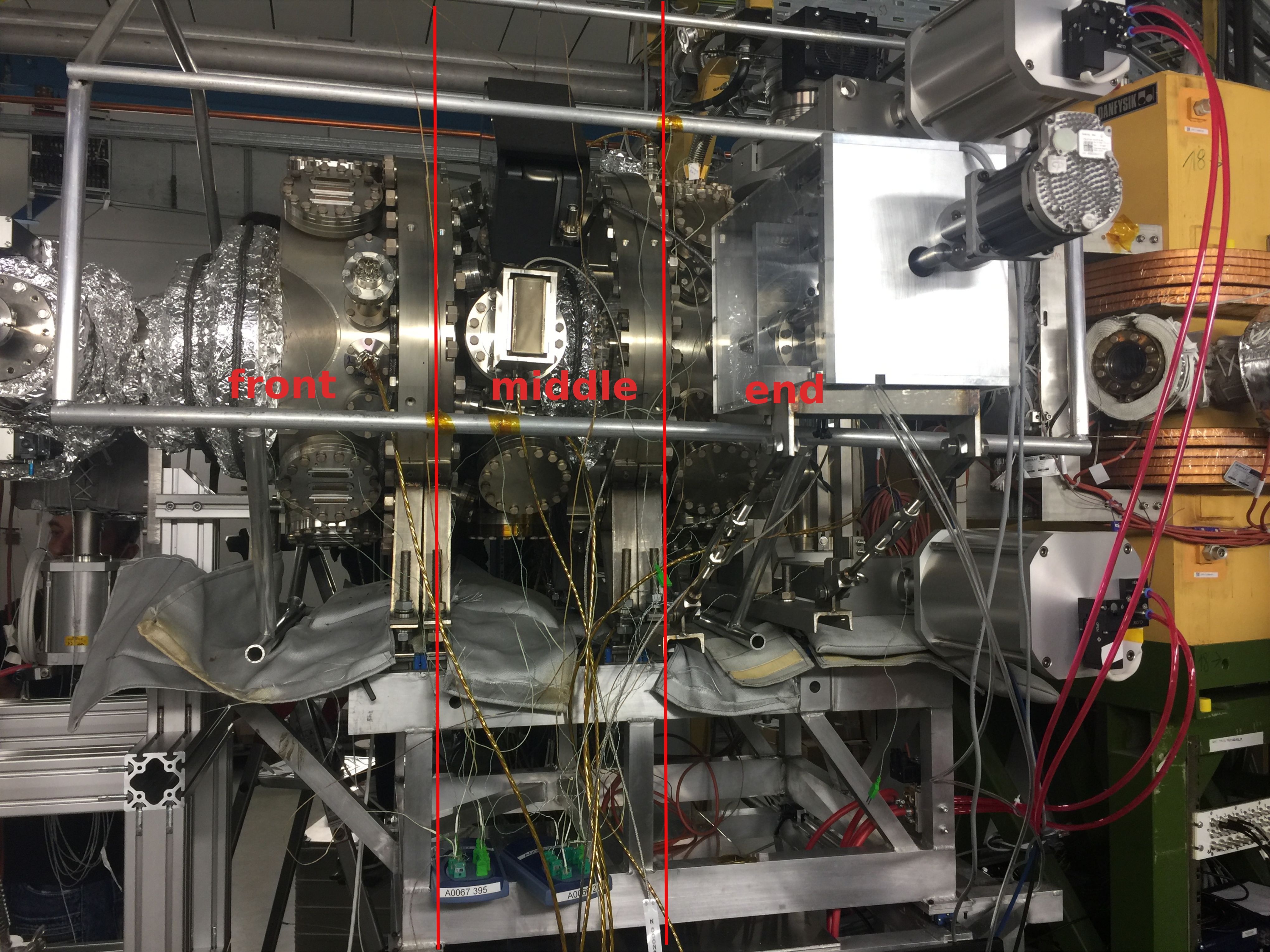

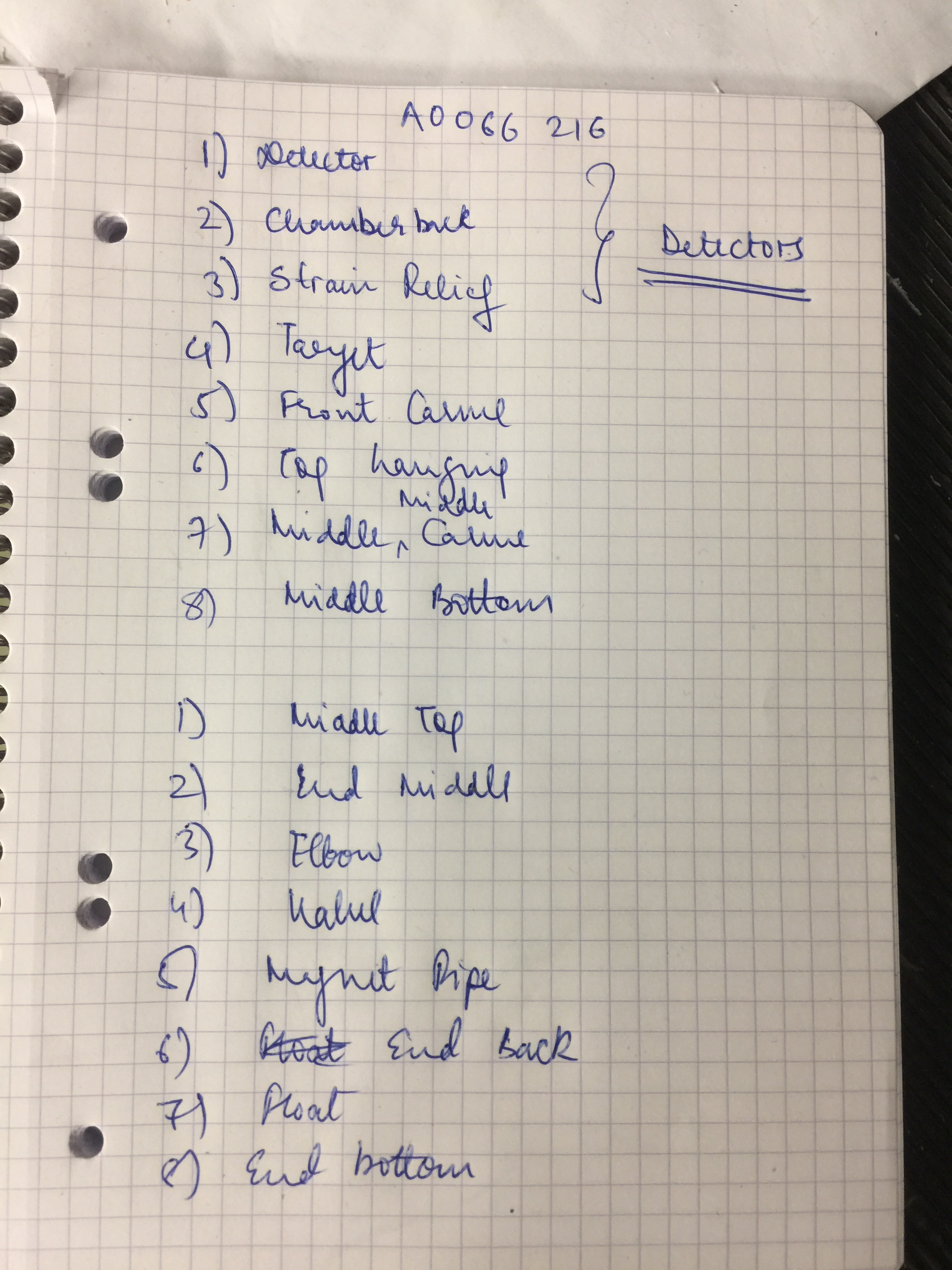

1. Detector

2. Chamber back

3. Strain relief

4. Target

5. Front CARME

6. Top hanging

7. Middle middle CARME

8. Middle bottom

1. Middle top

2. End middle

3. Elbow

4. Valve

5. Magnet pipe

6. End back

7. Float

8. End bottom |

| Attachment 1: labeling.JPG.svg

|

|

| Attachment 2: Labelling.svg

|

|

| Attachment 3: IMG_5512.JPG

|

|

|

|

147

|

Wed Nov 10 14:41:12 2021 |

TD RSS + CB (remotely) | Wrapping CARME in heating tape |

ML reports that baking of the upstream section (gas jet interaction chamber plus e-target) has commenced - initially to 50 deg C to check thermocouples. If OK baking

temperature will be ramped slowly (which I think means c. 10 deg C per h) to limits established for specific components by the e-target.

Ragan and Oemer are currently threading a 10m heating tape helically around the CARME chamber.

16.20 ML reports baking of upstream section is proceeding OK - currently ramping to 100 deg C at 10 deg C / h.

16.25 RSS reports that he completed the install of the thermocouples this morning and will update the Elog with specific locations of each thermocuple and TC08 channel

later today.

16:30 All CARME thermocouples <20 C. No temperature changes. Monitor.x left under screen. Please summon with screen -x and dismiss with CTRL+a d

17:40 One CARME thermocouple at 40C (CARME front) |

|

|

146

|

Tue Nov 9 15:03:29 2021 |

RSS + OG | Burnt cables issues |

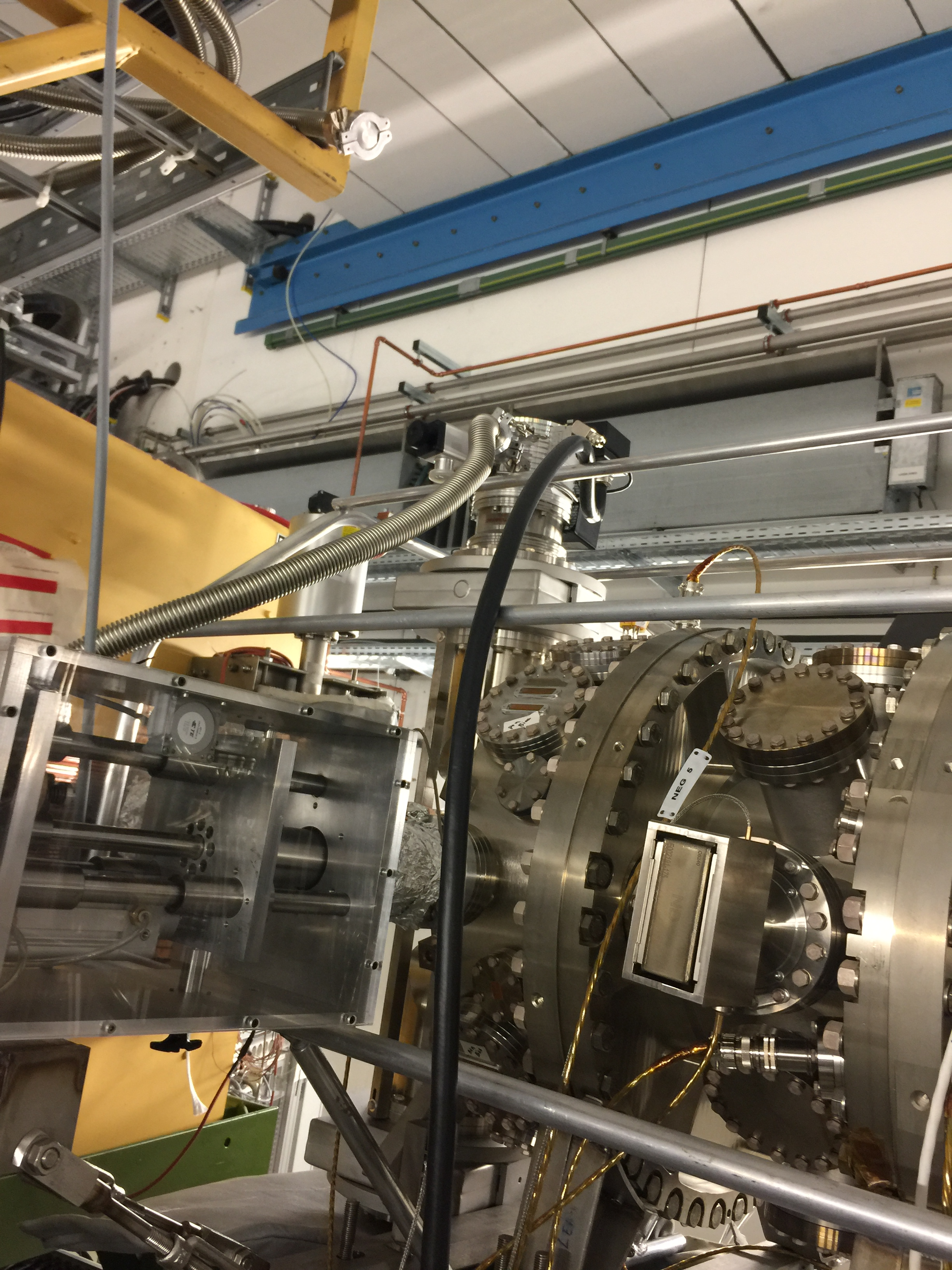

Upper part of the frame was mounted. In order to do so, the valve was closed, turbo wire and hose were disconnected and then connected. Valve was opened again. See pictures 1-2.

Bottom part of the tent was constructed with 3 heaters (from one of the controllers) at the front, 4 in the middle, and 4 at the back (4+4 from the other controller). See pictures 3.

Thermocouples were tested and connected to TC08 modules.

Wire connecting to four heaters was damaged which caused a spark and sound when the upper tent was being constructed. This caused a power failure two times, turning off all three pumps. The upper valve was immediately closed. Power supplies of heaters were disconnected and pumps were turned on again. Valve was opened again as well.

Construction of tent is paused. Waiting for the wire to be repaired by tomorrow and start again. |

| Attachment 1: IMG_5493.JPG

|

|

| Attachment 2: IMG_5496.JPG

|

|

| Attachment 3: IMG_5497.JPG

|

|

| Attachment 4: IMG_5500.JPG

|

|

| Attachment 5: IMG_5502.JPG

|

|

| Attachment 6: IMG_5503.JPG

|

|

| Attachment 7: IMG_5507.JPG

|

|

|

|

145

|

Mon Nov 8 17:19:02 2021 |

RSS + OG | Neg and ion cables connected |

Neg and ion pump cables were labeled and connected.

Kapton tape wrapped around the neg cable connectors for the strain support.

Lower frame mounted. |

| Attachment 1: IMG_5480.JPG

|

|

| Attachment 2: IMG_5483.JPG

|

|

| Attachment 3: IMG_5488.JPG

|

|

|

|

144

|

Sat Nov 6 14:21:10 2021 |

CB RSS | Preparation for bakeout tent mounting + to do for next week |

Connected pneumatic hoses prepared by Gleb. Opened flow to pressure reducer set at 2 bar. Ok. Attempted to operate pneumatic motors. Somehow left / right pneumatic motors controls swapped around! Works fine otherwise. Most likely hardware issue, i.e. hoses are inverted inside motor box. Software fix possible in principle. Probably easiest to swap hoses going out from motor box (top to bottom and vice versa). Could not pull out hoses after installing. To do for next week.

Started connecting NEG and ion pumps. Realised wires are only labeled on one side. Had to separate all wires in one harness to make absolutely sure to know which wire is which. Second harness to be done next week. Please connect D2000 elements to bottom C4 power module, NEG getters wires 1-4 to middle power module and 5-6 to top power module. This means activation can proceed bottom to top of rack with minimal risk of mix ups. Please install top C4 module back in rack - missing appropriate rack shelf.

Installed Jan's Nim bin in rack. Jan thought that it was dead but seems to work just fine. Maybe test again?

To do next week

Place thermocouples as per suggestion on file in baking Pi Baking directory.

Remove valves support. Install bottom of tent.

Install aluminium frame and heaters. This may require stopping the turbo pump and closing top gate valve.

Install rest of tent. Be careful not to pull or stretch the fabric. It's fragile to tension and fibreglass will pour out.

Install aluminised fibreglass and aluminium shell.

Start baking. Target temperature 120C. |

|

|

143

|

Fri Nov 5 12:27:11 2021 |

CB RSS + DR NP ML US | First pump down of YR09 |

Tightened all flanges.

Added Pirani gauge and third IE514 to interaction chamber.

Stated pump down. Around 100 mbar on Interaction chamber Pirani gauge very loud metallic noise is heard. Found bellows between CARME and interaction chamber completely pressed flat. CARME and interaction chamber now much closer. Vented immediately. No pictures. Bellows return to normal state.

Repeated slowly and carefully using theodolite laser on reference point on CARME. Found CARME does not move appreciably forward, thus motion must come from interaction chamber frame.

Mounted two feet between CARME and interaction chamber. Pumped down again. Interaction chamber now moves by few mm. No issues with bellows. Left pumping overnight (Thu 4 November)

Found at 1E-6 mbar this morning. Leak tested. Found four minor leaks. Fixed by tightening.

US + Kosmos installed Be window. Pumping down extremely slowly. 1 mbar per 2 second. Started turbo at 1 mbar. Pumping down overnight. No damage to window.

See attached new plastic free struts and motion of interaction chamber before after pumping. See skull nose. |

| Attachment 1: 20211105_131748.jpg

|

|

| Attachment 2: 20211105_135918.jpg

|

|

| Attachment 3: 20211105_135929.jpg

|

|

| Attachment 4: 20211105_140451.jpg

|

|

| Attachment 5: 20211105_150616.jpg

|

|

|

|

142

|

Wed Nov 3 16:39:01 2021 |

CB RSS + NP DR NK ML | Interaction chamber lifted in place |

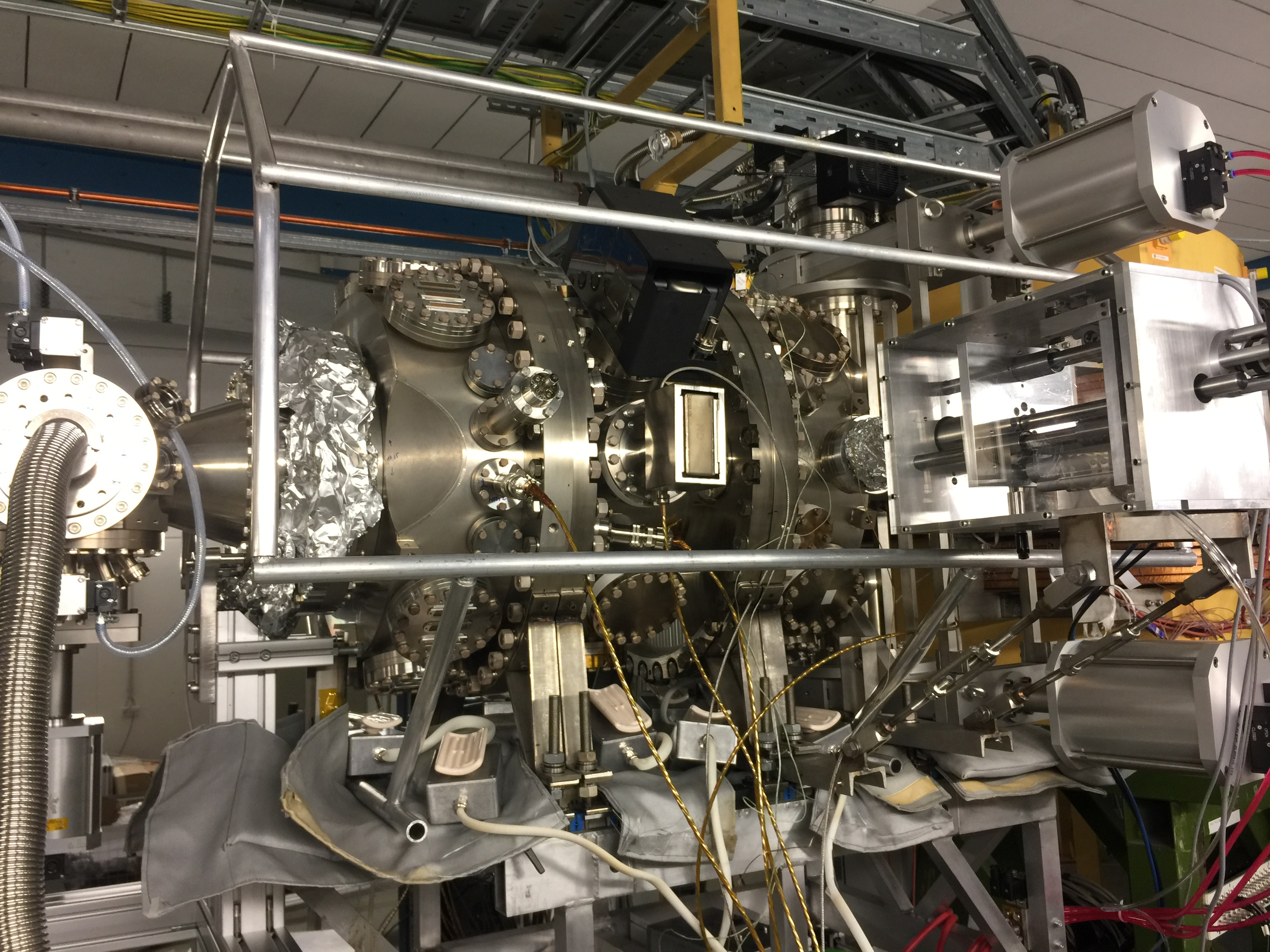

Prepared to move interaction chamber in place. Ok CARME side, flange has M10 bolts. On interaction chamber side i.e. bellows it has M8 bolts.

DS designed this to have loose fit under assumption of M10 side actually being 3/8 holes i.e. 9.9 mm. However holes are 10.2 mm. Furthermore Grossmontage suggest loose fit will be damaged in baking in the long term.

Dismounted bellow ring from spare bellows. Re-drilled to M10 and cleaned. Remounted. Old bellow outer ring moved with spare bellows.

Lifted interaction chamber in place. Alignment started. Will finish tomorrow morning, followed by pump down and leak test. Last step before beginning final pump down should be mounting Be window on Friday. Need US for that. |

| Attachment 1: 20211103_161553.jpg

|

|

| Attachment 2: 20211103_161813.jpg

|

|

| Attachment 3: 20211103_175457.jpg

|

|

|

|

141

|

Wed Nov 3 11:18:11 2021 |

CB RSS + DR NK ML | Leak closed |

Found CARME at 1.0E-6 mbar. Beginning leak test.

Found leaks in the same location as before. Roughly 1~3E-8 mbar l second vs. base leak of 1E-12

Tightened right hand half of bolts to 120 Nm. No changes but leak goes up to 1E-10 mbar l second when tightening bolts closer to leak location, without He being sprayed.

Tightened bolts closer to leak to 140. Leak goes down to 1E-9 mbar l second

Tightened four bolts closest to leak to 170 Nm. Leak disappeared (<1E-11 mbar). Tested repeatedly all around CARME including left hand side of 600 COF flange. No leaks.

Vented. Installing jet target in the afternoon.

|

| Attachment 1: 20211103_110244.jpg

|

|

| Attachment 2: 20211103_110414.jpg

|

|

|

|

140

|

Tue Nov 2 12:45:36 2021 |

CB + DR NK | Issues with CARME feet |

Attempted to close CARME as carefully as possible.

Swapped out one foot for another one and temporarily removed a second to allow CARME to rotate slightly and get a better alignment of the two surfaces of the COF600 flange.

Closed CARME but realised carriages with struts are such that carriages touch before flanges do. Worse on side with leak than side without. See attached. As a result we would not be able to close properly.

DR to modify the holes in the feet closest to flange on CARME front to allow surfaces to touch before carriages come in contact. Hopefully close later today.

Issue was not encountered earlier because CARME was fully mounted before being dropped on feet. Struts were forcefully brought close to allow CARME to descend. Unclear how this was done in DL but may be baking had altered some sizes enough for the issue to appear. Spare feet do not help significantly.

Closed CARME . 1. Bolts finger tight. 2. Bolts tightened with tools stopping as soon as resistance is felt. Tightening done from the top descending towards the right (clockwise) and from the bottom counterclockwise. 3. 20 Nm applied in the same way 3. 40 4. 60 5. 80 6 80 again but single operator going round 6. 100 single operator

Pumping down overnight

|

| Attachment 1: 20211102_134446.jpg

|

|

|

|

139

|

Mon Nov 1 14:48:16 2021 |

CB + ML DR | CARME opened |

Confirmed leak as per previous Elog.

Tightened to 100 Nm - no effects.

Tightened to 130 Nm - bottom leak disappeared. Top leak still at 1.3E-8 mbar l second.

Decided to open. Lifted front part of CARME down.

No obvious damage to wire seal.

Inspected wire seat and seal part. Part corresponding to leak feels rough to the touch. Suggested damage when SS parts come together?

DR sanded down gently the valve seal. Cleaned with compressed air and ethanol.

Gently sanded down seat as well, barely touched it.

Grossmontage experts will be back tomorrow am for final cleaning and re-assembly. |