| |

ID |

Date |

Author |

Subject |

|

|

666

|

Sun Apr 6 14:21:53 2025 |

TD | [How To] Startup CARME |

- water flow/interlock checks

check water flow to/from inflow/outflow manifolds

check all coolant lines to all FEE64s are connected

check USB-controlled ac mains relay 'water' LED illuminated water flow and dew point sensor interlocks OK

- carme-gsi network cabling

from patch panel YR10/2

yellow network cable to carme-gsi operating in 19" rack room (2.033)

green network cable to carme-gsi operating in counting room (2.034)

- boot carme-gsi

systemctl start dhcpd start DHCP dynamic network configuration

ssh -L 8080:proxy.gsi.de:8080 carme@atppc025 establish proxy port for AnyDesk access

ssh -X pi@nnrpi1

/MIDAS/TclHttpd/linux-arm/TclHttpd-server & start MIDAS server

ssh -X pi@nnrpi1

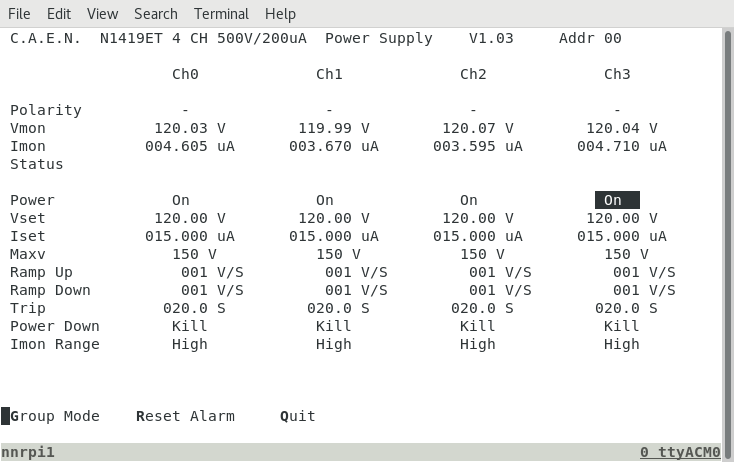

./caen_screen.sh start CAEN N1419ET control interface

- enable current logging

open a new terminal

ssh pi@nnrpi1

cd Programs/caenlogger

caenlogger --config caenlogger_config_gsi.toml

open a new terminal

cd Programs/caenlogger

gnuplot plot_current.gp

- system log

sudo tail -f /var/log/messages monitor system log e.g. filesystem mounts for FEE64 embedded processors

(sudo does not work - use su instead. will have to fix)

- FEE64 power ON

Start browser on nnrpi1:8015

Power On

- Start MIDAS

select server start icon (leftmost) 1x terminal session will appear

Start browser tab localhost:8015

Data Acquisition Control Services

Update (nothing should change)

Act on all Data acquisition server TICKED

RESET

SETUP

Enable histograms and waveforms

Open ASIC control

Act on all FEE64 modules

Act on all ASICS

System functions -> Check ASIC control

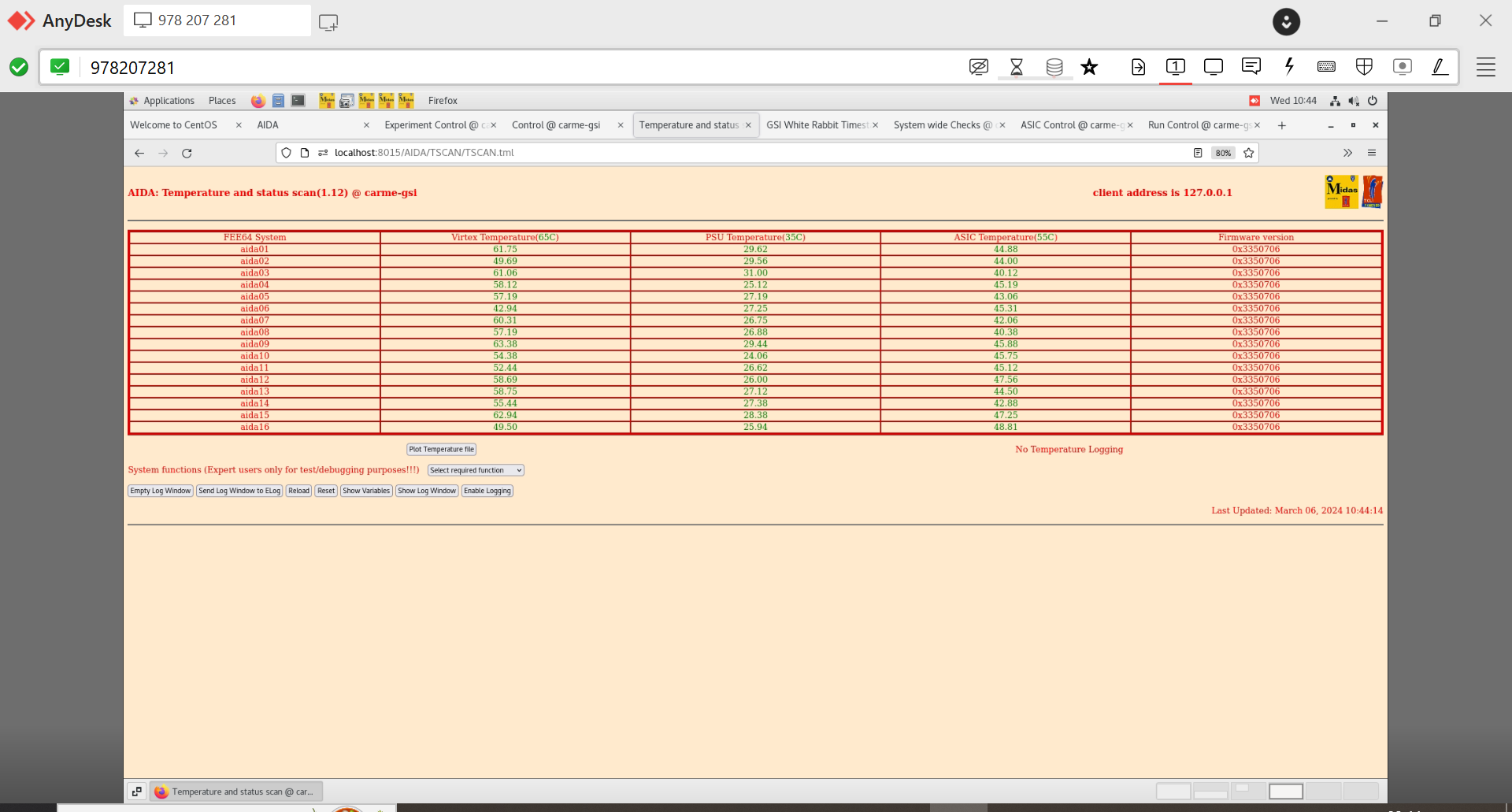

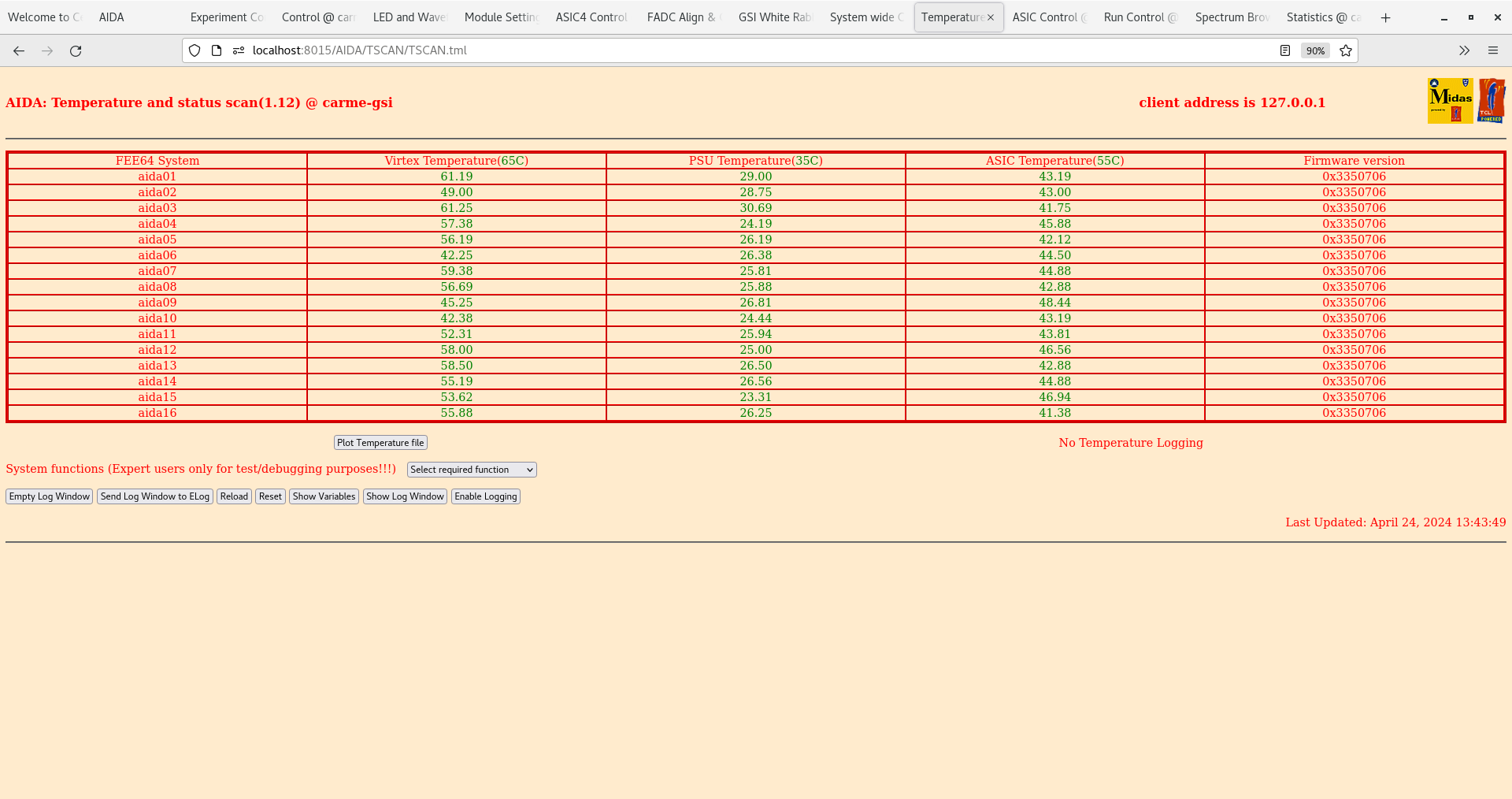

Check FEE64 temperatures (Reload)

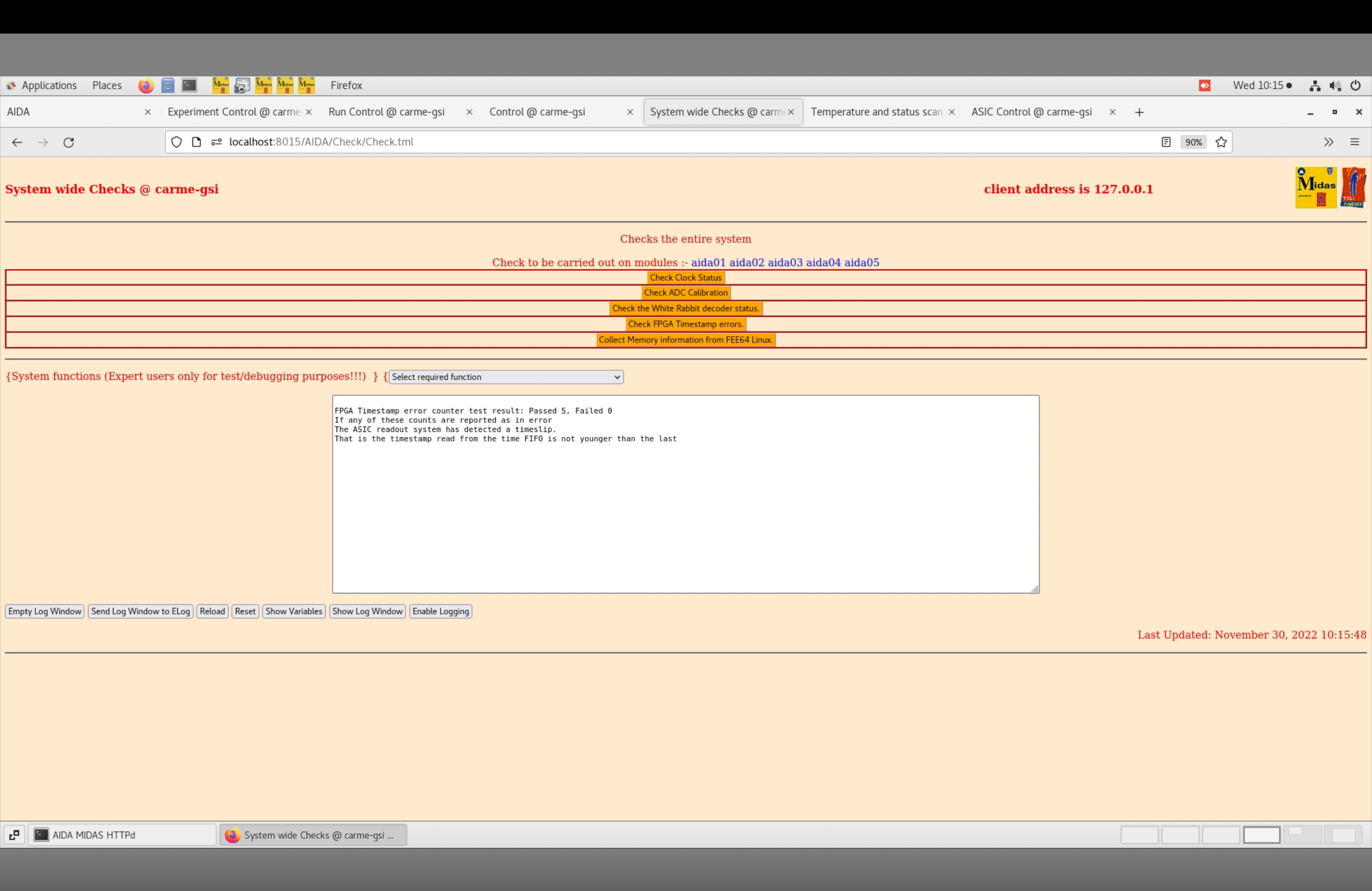

System wide checks

Clock

ADC Calibration

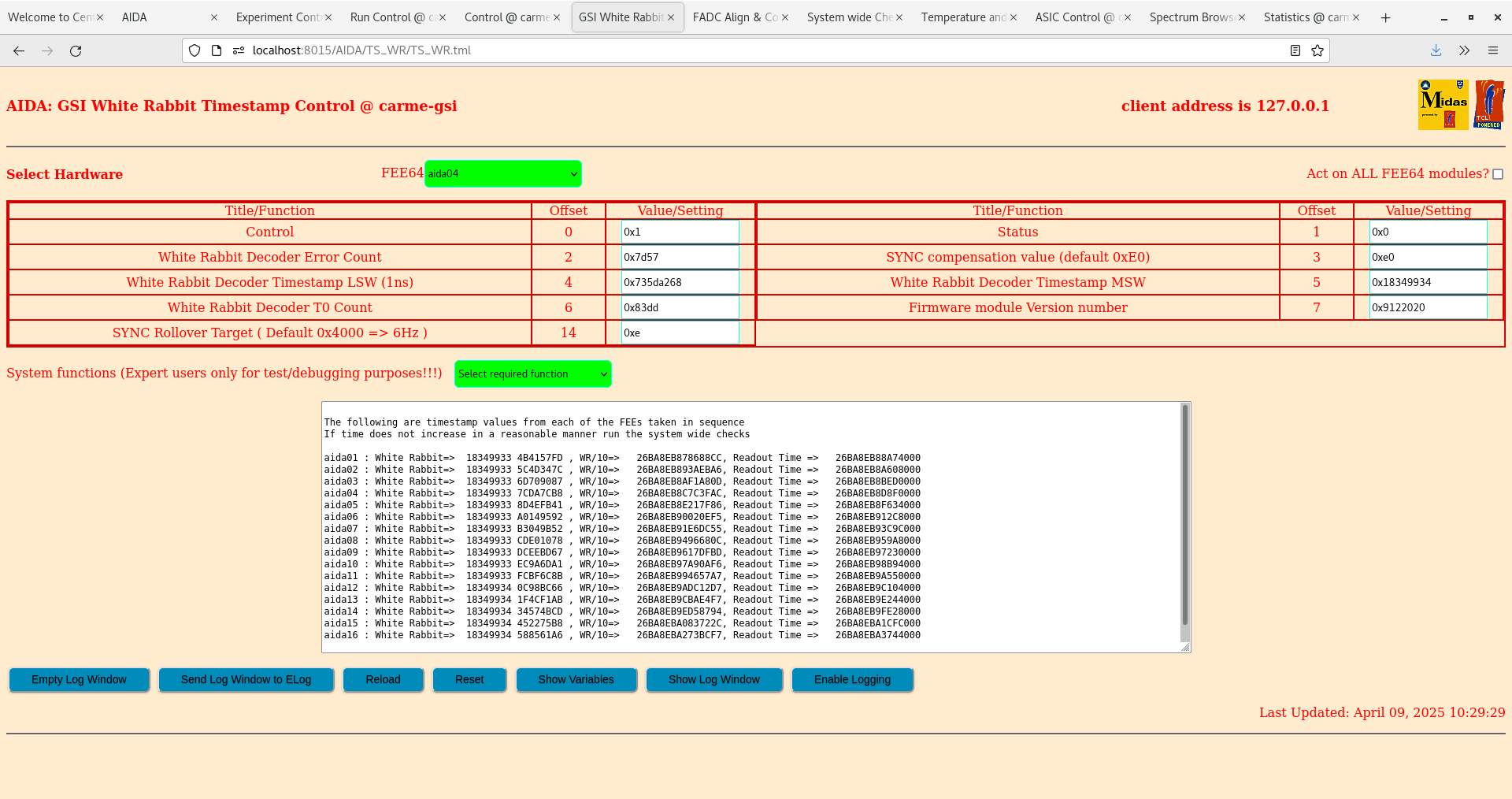

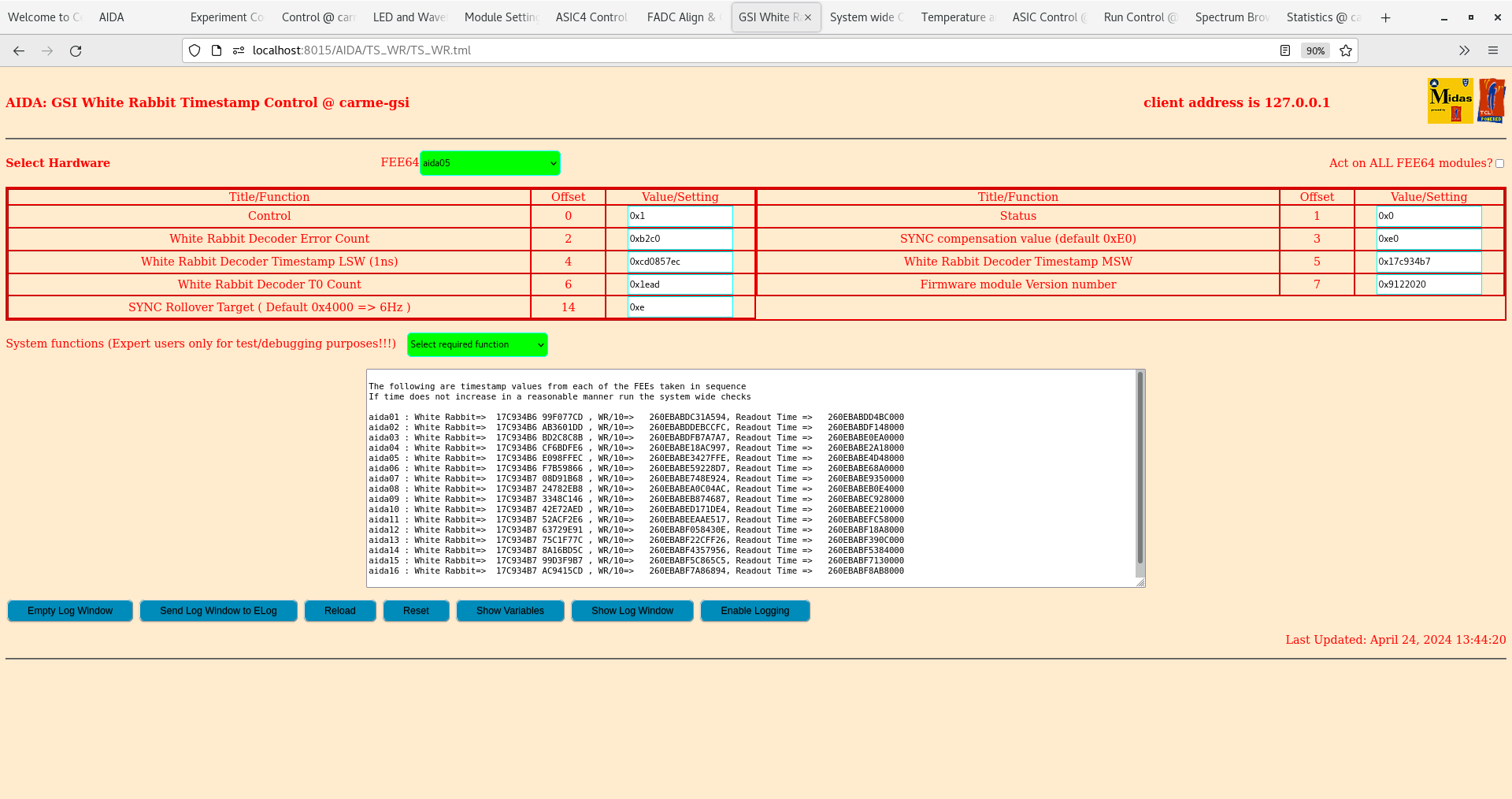

White Rabbit

Drop down -> collect FPGA errors

Check FPGA

Synchronise ASIC clocks

FADC Align & Check - all FEE64s

Drop down -> calibrate ADCs

System wide checks

Clock

ADC calibration

If any FEE fails, FADC calibrate it again

DAQ GO

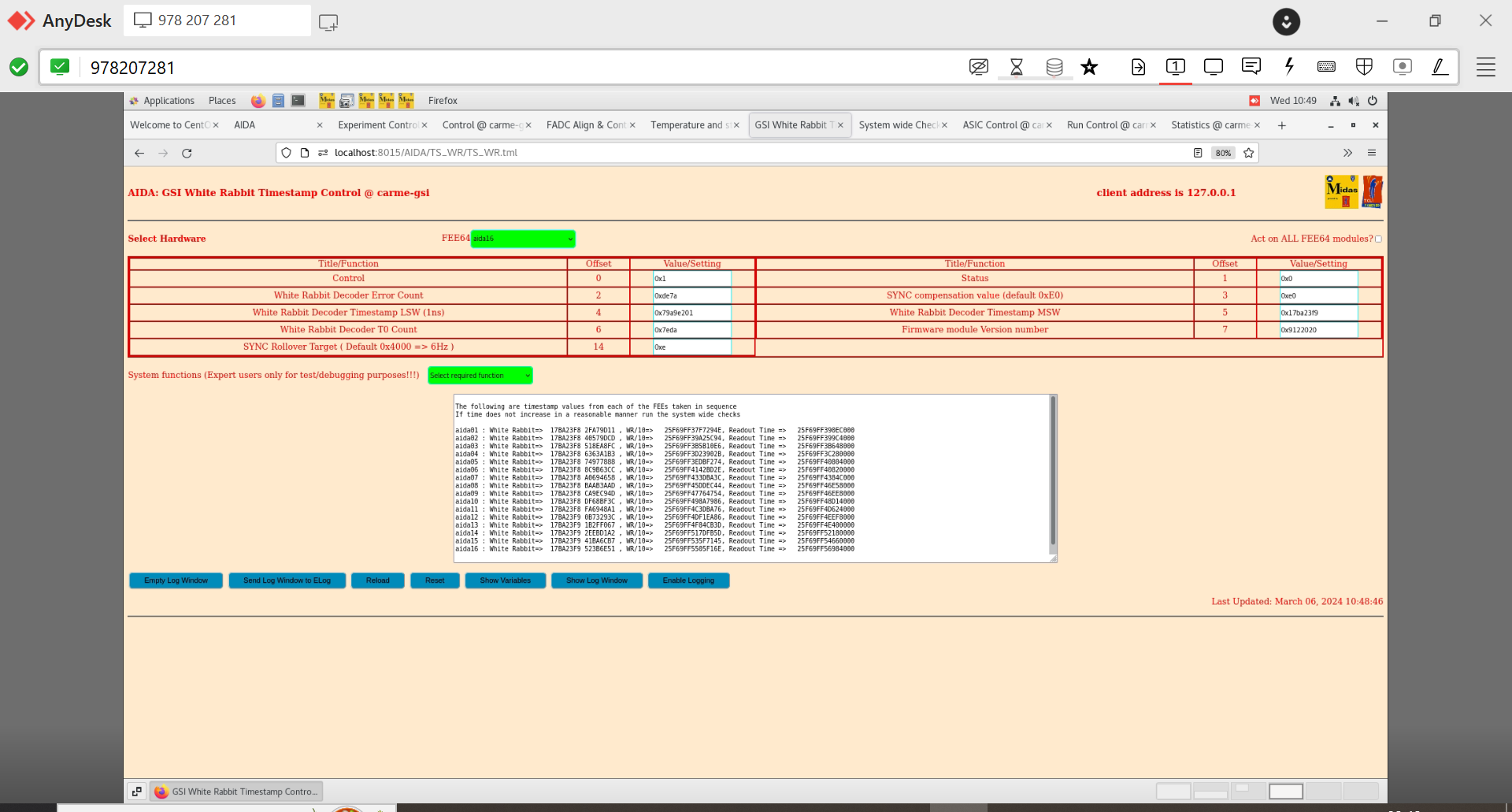

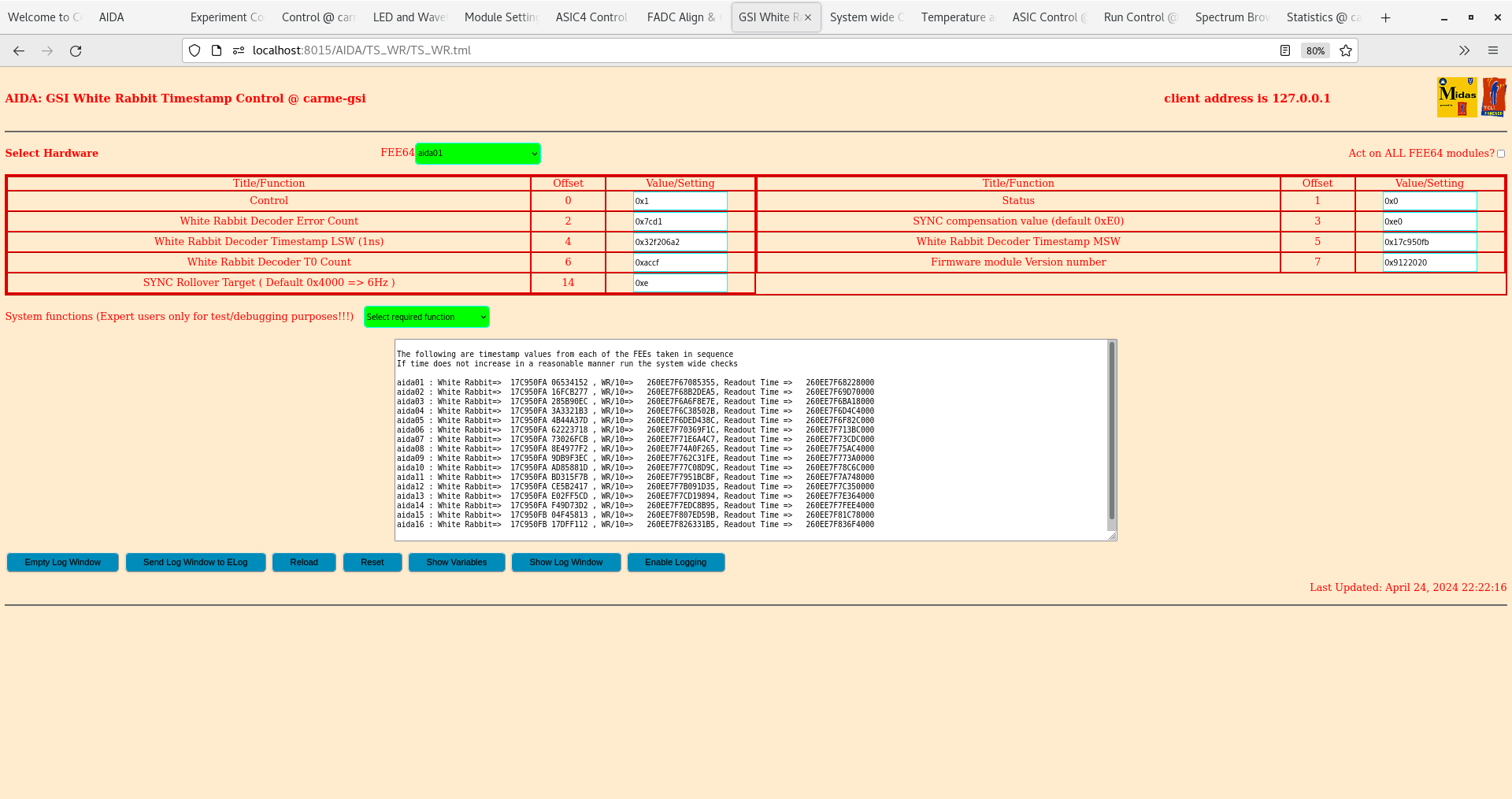

WR timestamp check WR timestamp monotonically increases aida01->aida16

To startup Merger and Tape Server

DAQ STOP

8115 server, tape server, merger -> from buttons on top

3x terminal sessions will appear

Start browser tab localhost:8115

New Merge control

Tape Service

NetVar Service

Merger tab

(top) setup

go (ignore error message)

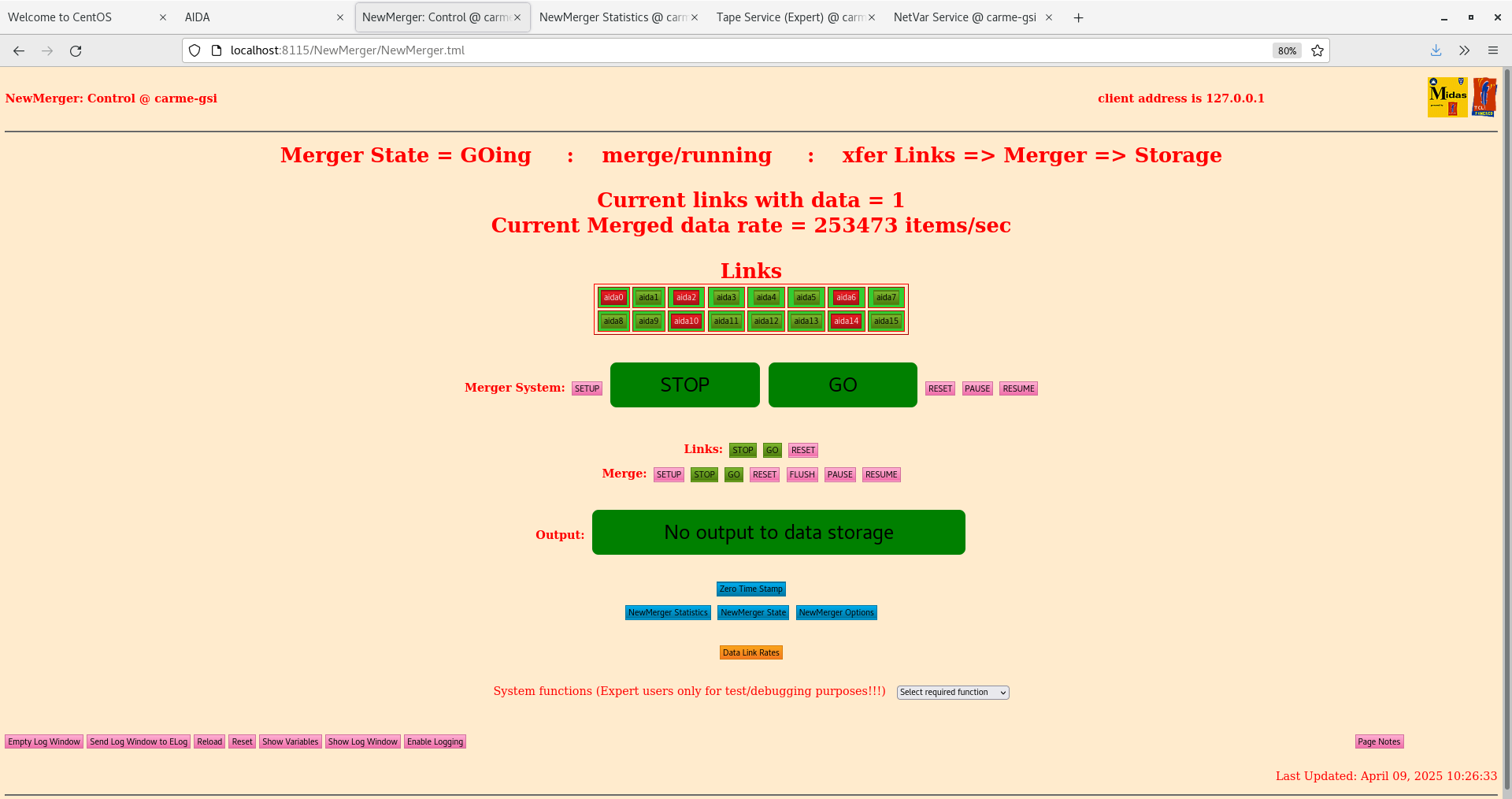

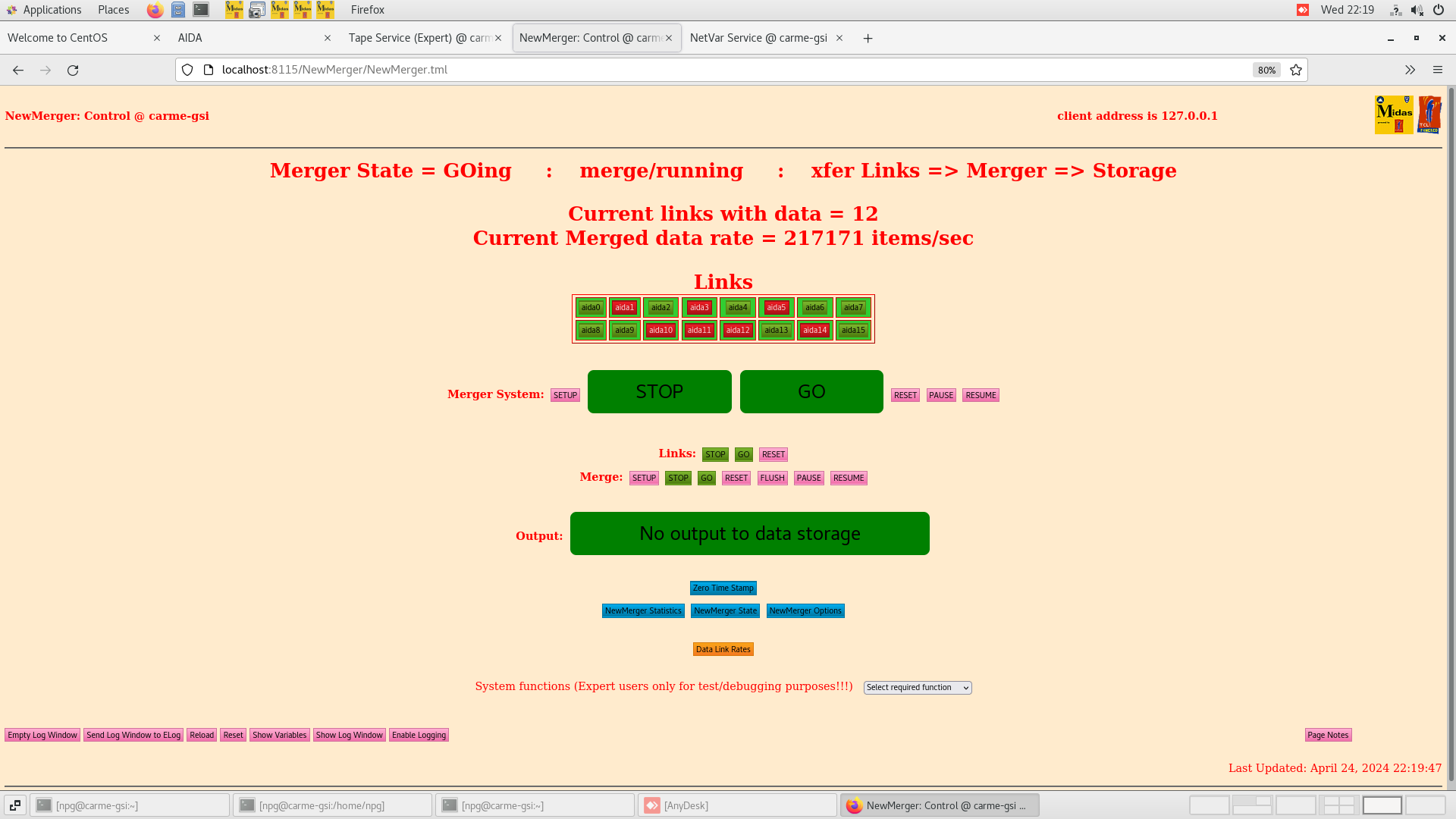

enable output to data storage Merger State = GOing : merge/running : xfer Links => Merger => Storage

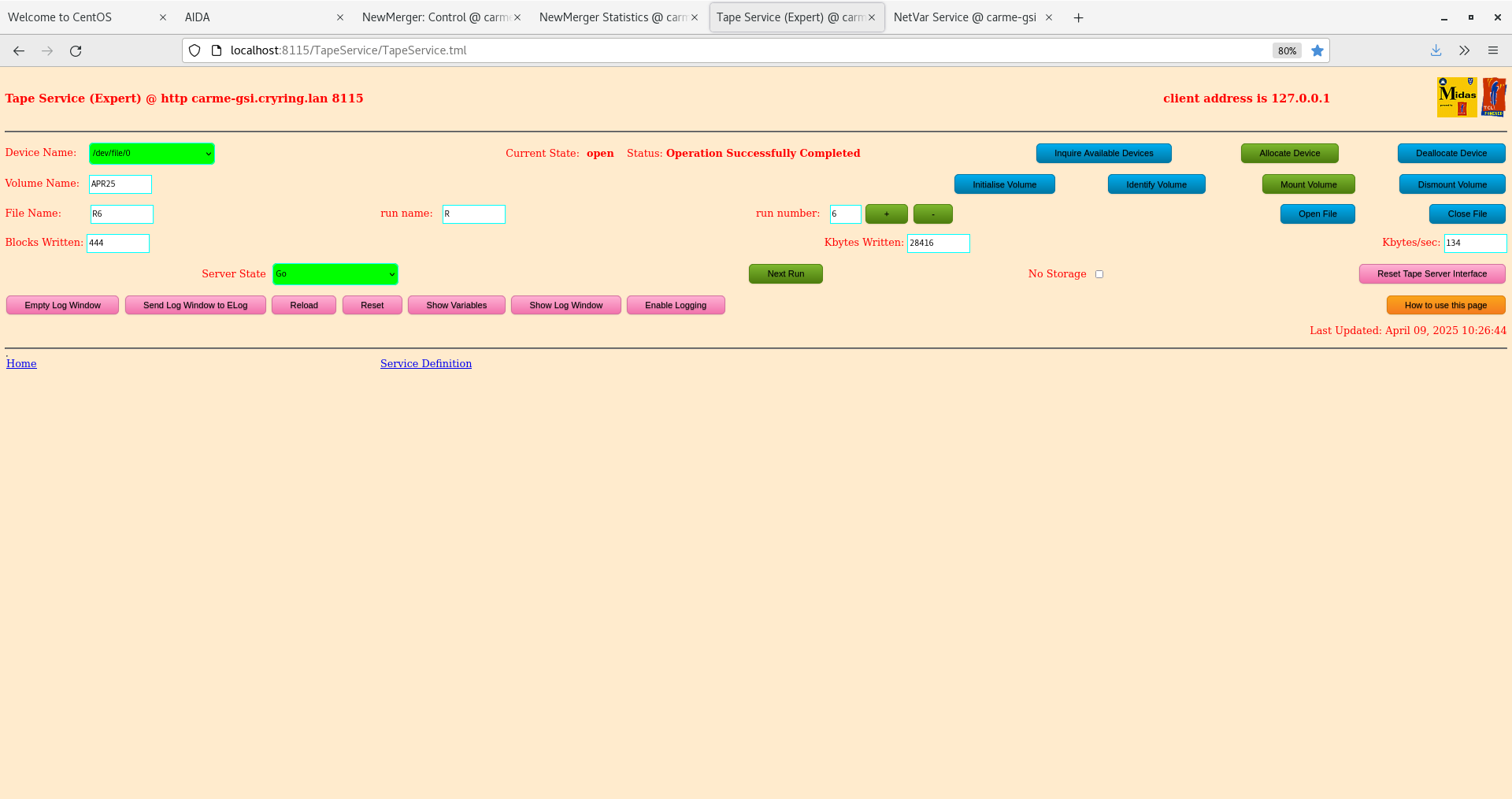

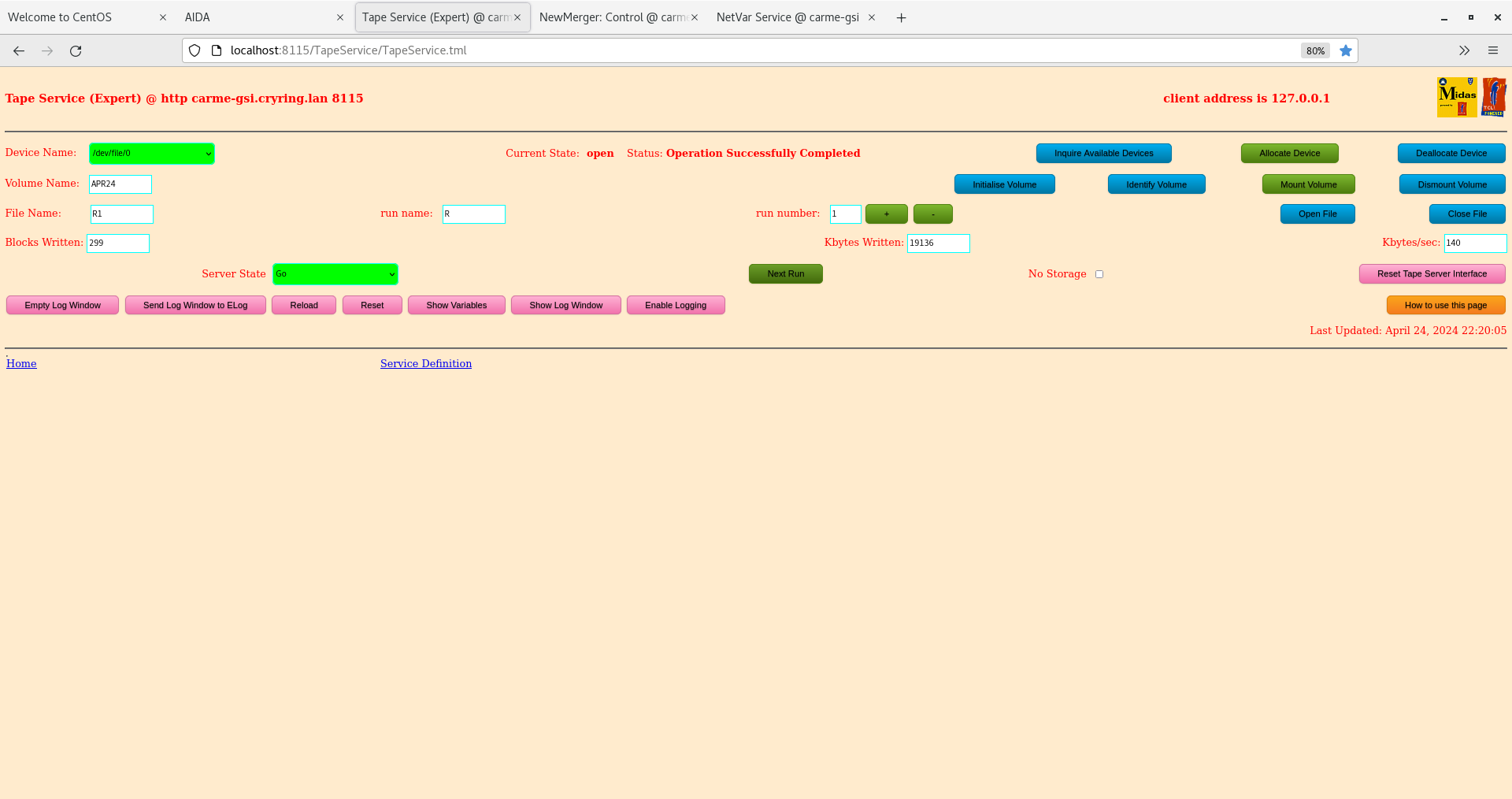

tape server

Inquire Available Devices

Allocate Device

Enter volume name (if already defined)

Mount volume

Reload

Set run number

Open file

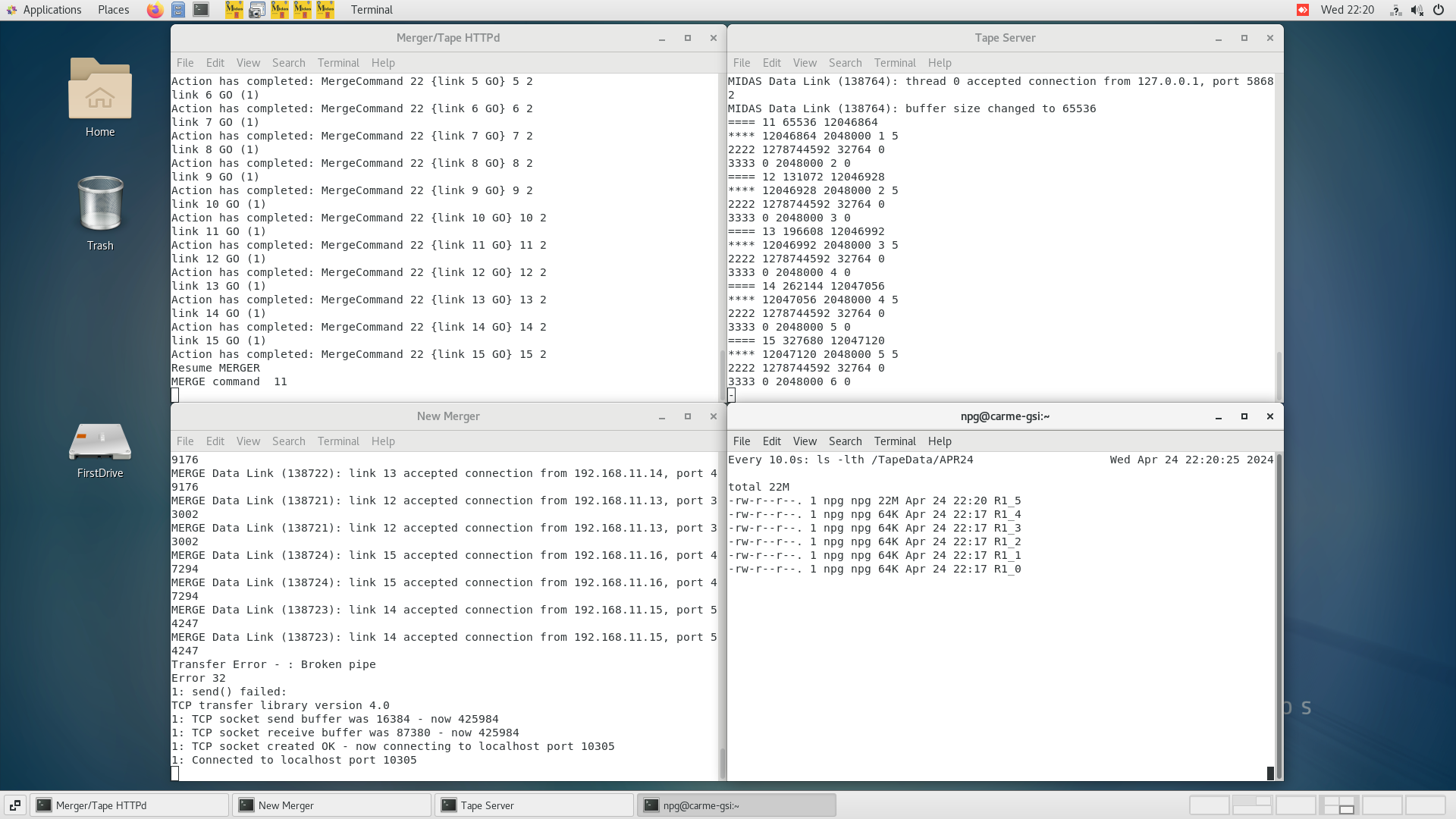

Open a new terminal

Navigate to /TapeData/ and the volume name

watch ls -lht

Enable data transfer #1 (in Run Control)

X should appear next to every FEE

Check netvar variable NetVar.MERGE.RunOptions = 1

DAQ GO

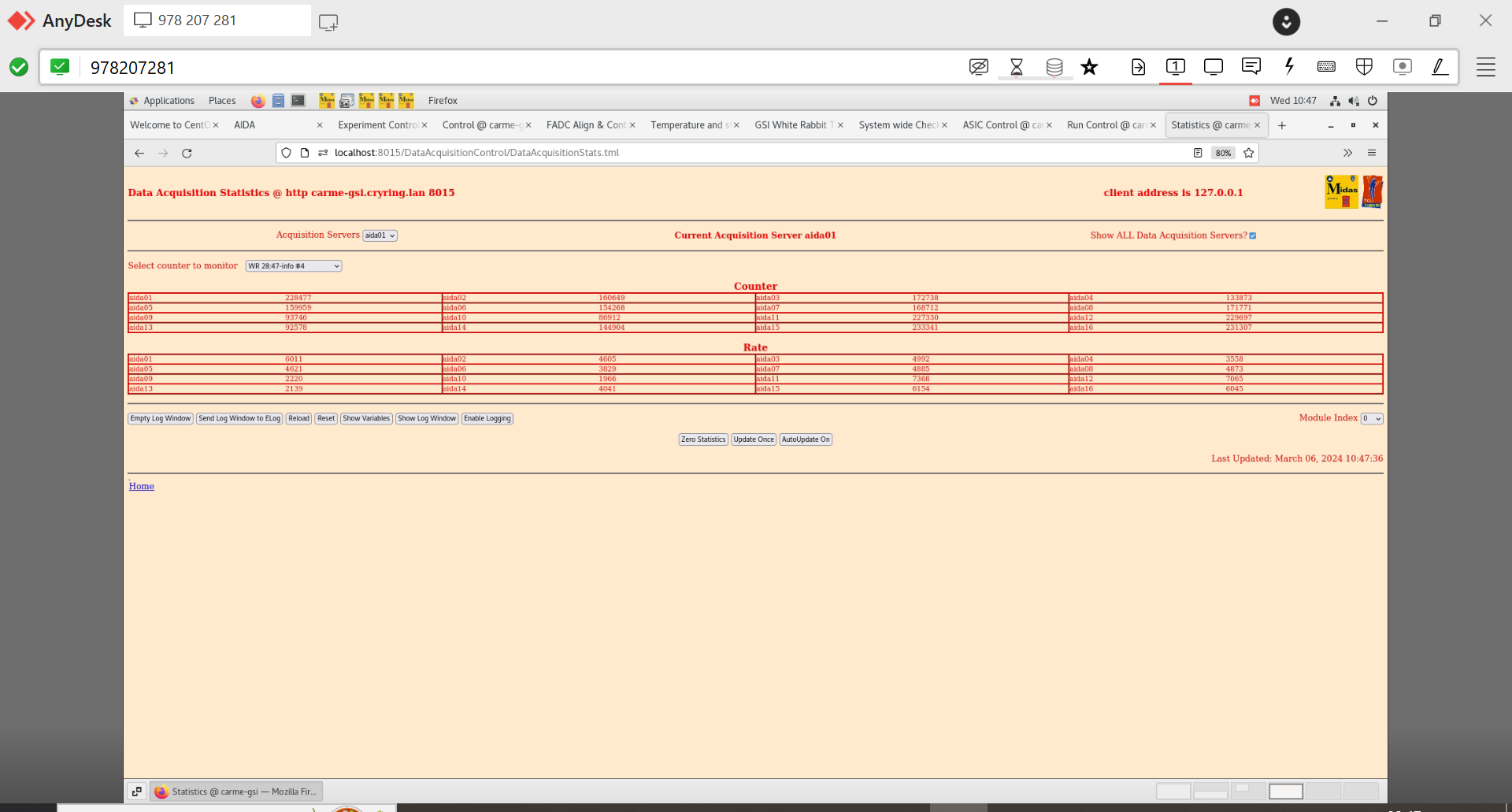

check merger rate and activity of all FEE64s

check tape server blocks written number is increasing

Server state -> Go |

|

|

489

|

Sat Feb 3 15:05:10 2024 |

CB, TD | [How To] Restart Anydesk |

1. Check Proxy server is correct

localhost : 8080

incoming connections 7070

Establish port

ssh -L 8080:proxy.gsi.de:8080 carme@atppc025

2. Check a password for remote access has been set up

3. Close anydesk and check it is *really* closed using

ps -o pid= -C anydesk

kill -9 any process (as root)

4 Restart AnyDesk

systemctl restart anydesk (as npg)

|

|

|

695

|

Tue May 27 08:38:29 2025 |

TD | [How To] Recover DAQ when one FEE64 stops sending data - short(er) version |

1) Select 'No Storage' [workspace 4, display 1, browser tab 'TapeServer']

If already in 'No Storage' mode please ignore this step

2) STOP DAQ [workspace 3, display 1, browser tab 'Run Control']

all FEE64s should change status from 'going' to 'stopped' *except* whichever FEE64(s) have a problem - typically their status is 'going' or 'error'

3) Restart Merger by selecting the Merger icon [workspace 4, display 2]

terminal window showing the startup will popup

4) Setup Merger by selecting 'SETUP' [workspace 4, display 1, browser tab 'NewMerger Control']

5) Start Merger by selecting 'GO' [workspace 4, display 1, browser tab 'NewMerger Control']

all data links will be inactive (red)

6) Start DAQ by selecting 'GO' [workspace 3, display 1, browser tab 'Run Control']

check that DAQ is *actually* going - if not repeat 'GO'

7) Check data is being transferred to Merger and TapeServer

Select 'Reload' [workspace 4, display 1, browser tab 'NewMerger Control']

you should see a non-zero 'current merged data rate' and all links should show as green at least some of the time (requires observation over several reloads)

Select 'Reload' [workspace 4, display 1, browser tab 'TapeServer']

you should see 'Blocks written' and 'kb written' counters increase

8) Unselect 'No Storage' [workspace 3, display 1, browser tab 'TapeServer']

If already in 'No Storage' mode at the start of this procedure please ignore this step

If you continue to have problems, please request expert assistance. |

|

|

589

|

Tue Jun 4 19:19:26 2024 |

TD | [How To] Recover DAQ when one FEE64 stops sending data |

1) STOP DAQ [workspace 2, display 1, browser tab 'Run Control']

all FEE64s should change status from 'going' to 'stopped' *except* whichever FEE64(s) have a problem - typically their status is 'going' or 'error'

2) Restart Merger by selecting the Merger icon [workspace 3, display 2]

terminal window showing the startup will popup

3) Setup Merger by selecting 'SETUP' [workspace 3, display 1, browser tab 'NewMerger Control']

4) Start Merger by selecting 'GO' [workspace 3, display 1, browser tab 'NewMerger Control']

all data links will be inactive (red)

5) Disable data transfer by selecting 'Data transfer Disable #1 all' [workspace 2, display 1, browser tab 'Run Control']

6) Start DAQ

Start DAQ by selecting 'GO' [workspace 2, display 1, browser tab 'Run Control']

check that DAQ is *actually* going - if not repeat 'GO'

7) Check WR timestamps by selecting 'Collect all timestamps' [workspace 2, display 1, browser tab 'GSI White Rabbit Control']

readout times will be displayed for each FEE64

check that the readout times are monotonically increasing as you read down the list of readout times - if not, contact expert support

8) Stop DAQ

Start DAQ by selecting 'STOP' [workspace 2, display 1, browser tab 'Run Control']

check that DAQ has *actually* stopped - if not repeat 'STOP

9) Enable data transfer to Merger and TapeServer and start DAQ

Enable data transfer by selecting 'Enable data transfer Enable #1 All' [workspace 2, display 1, browser tab 'Run Control']

Start DAQ by selecting 'GO' [workspace 2, display 1, browser tab 'Run Control']

check that DAQ is *actually* going - if not repeat 'GO'

10) Check data is being transferred to Merger and TapeServer

Select 'Reload' [workspace 3, display 1, browser tab 'NewMerger Control']

you should see a non-zero 'current merged data rate' and all links should show as green at least some of the time (requires observation over several reloads)

Select 'Reload' [workspace 3, display 1, browser tab 'TapeServer']

you should see 'Blocks written' and 'kb written' counters increase

11) Check AIDA data is being forwarded from the TapeServer to MBS [workspace 3, display 2, command terminal]

12) Restart should now have been successfully completed. Please inform the 'on shift' crew' that AIDA is forwarding data.

If not, please request expert assistance. |

|

|

603

|

Sat Jun 8 17:46:12 2024 |

TD | [How To] Cycle Left DSSSDs |

Interactive Motion Program [workspace 6, display 2]

c stop current command(s)

l s by -20 mm confirm y at prompt

l s by 20 mm confirm y at prompt

read FakeMotion.dat confirm y at prompt |

|

|

631

|

Fri Jun 14 14:48:02 2024 |

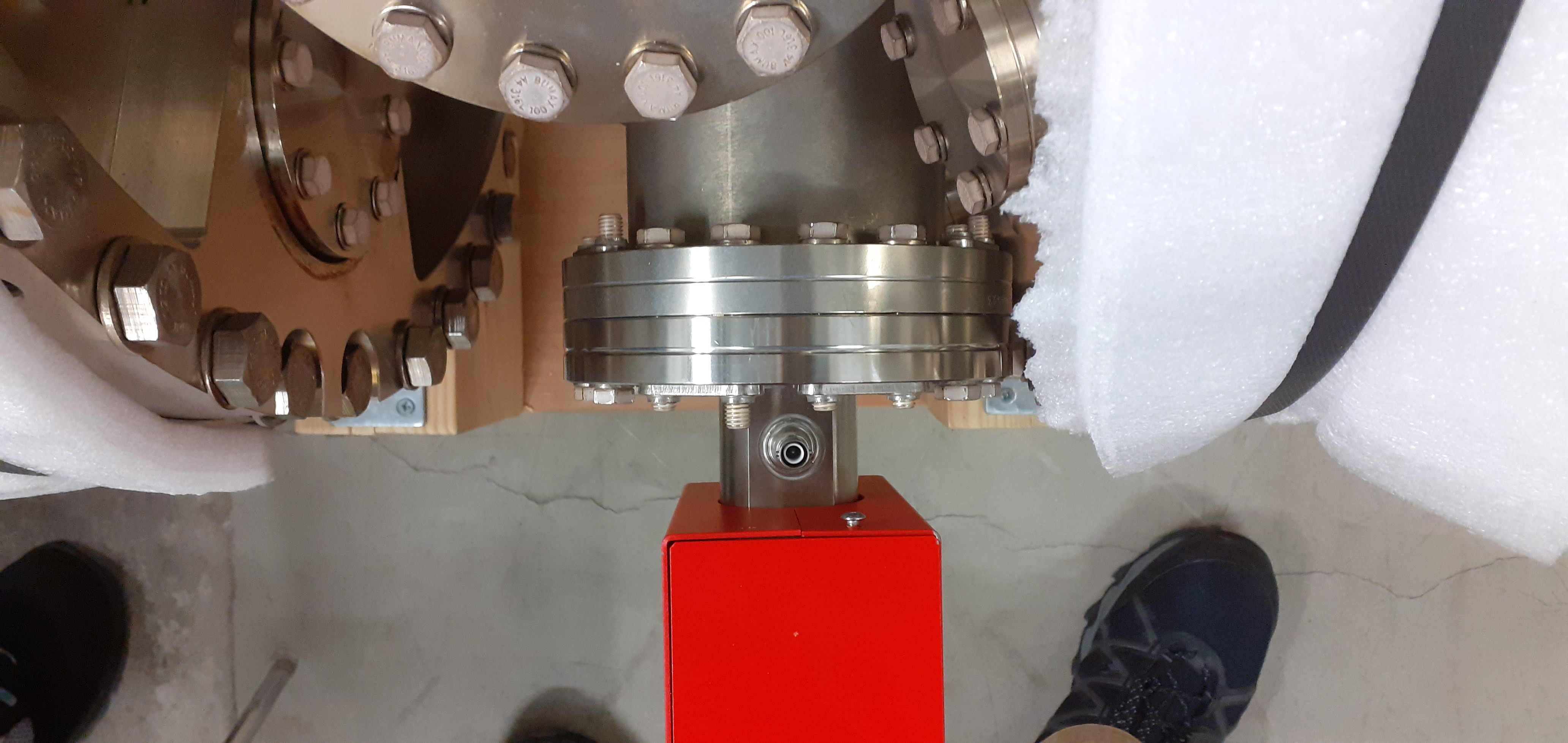

CB NP ML | [How To] Change target pressure. EMERGENCY ONLY! |

ONLY FOLLOW THESE INSTRUCTIONS if E1 turbo is below 820 Hz, pressure in E1 is above 2.5E-1 mbar and experts (Nikos, Andreas) cannot be reached.

Go to the red cabinet under the stairs.

Open rightmost door. See first photo. Do not press the button on the handle or the door will lock!

Turn down pressure regulator indicated in second photo by approximately 1 degree. Read regulator to know which way to turn to decrease. No immediate change should be obvious on the pressure regulator.

Check E1 pressure for 5 minutes. If no effect, turn pressure down again until an effect appears. |

| Attachment 1: 20240614_142435.jpg

|

|

| Attachment 2: 20240614_142440.jpg

|

|

|

|

147

|

Wed Nov 10 14:41:12 2021 |

TD RSS + CB (remotely) | Wrapping CARME in heating tape |

ML reports that baking of the upstream section (gas jet interaction chamber plus e-target) has commenced - initially to 50 deg C to check thermocouples. If OK baking

temperature will be ramped slowly (which I think means c. 10 deg C per h) to limits established for specific components by the e-target.

Ragan and Oemer are currently threading a 10m heating tape helically around the CARME chamber.

16.20 ML reports baking of upstream section is proceeding OK - currently ramping to 100 deg C at 10 deg C / h.

16.25 RSS reports that he completed the install of the thermocouples this morning and will update the Elog with specific locations of each thermocuple and TC08 channel

later today.

16:30 All CARME thermocouples <20 C. No temperature changes. Monitor.x left under screen. Please summon with screen -x and dismiss with CTRL+a d

17:40 One CARME thermocouple at 40C (CARME front) |

|

|

135

|

Sun Oct 31 07:41:20 2021 |

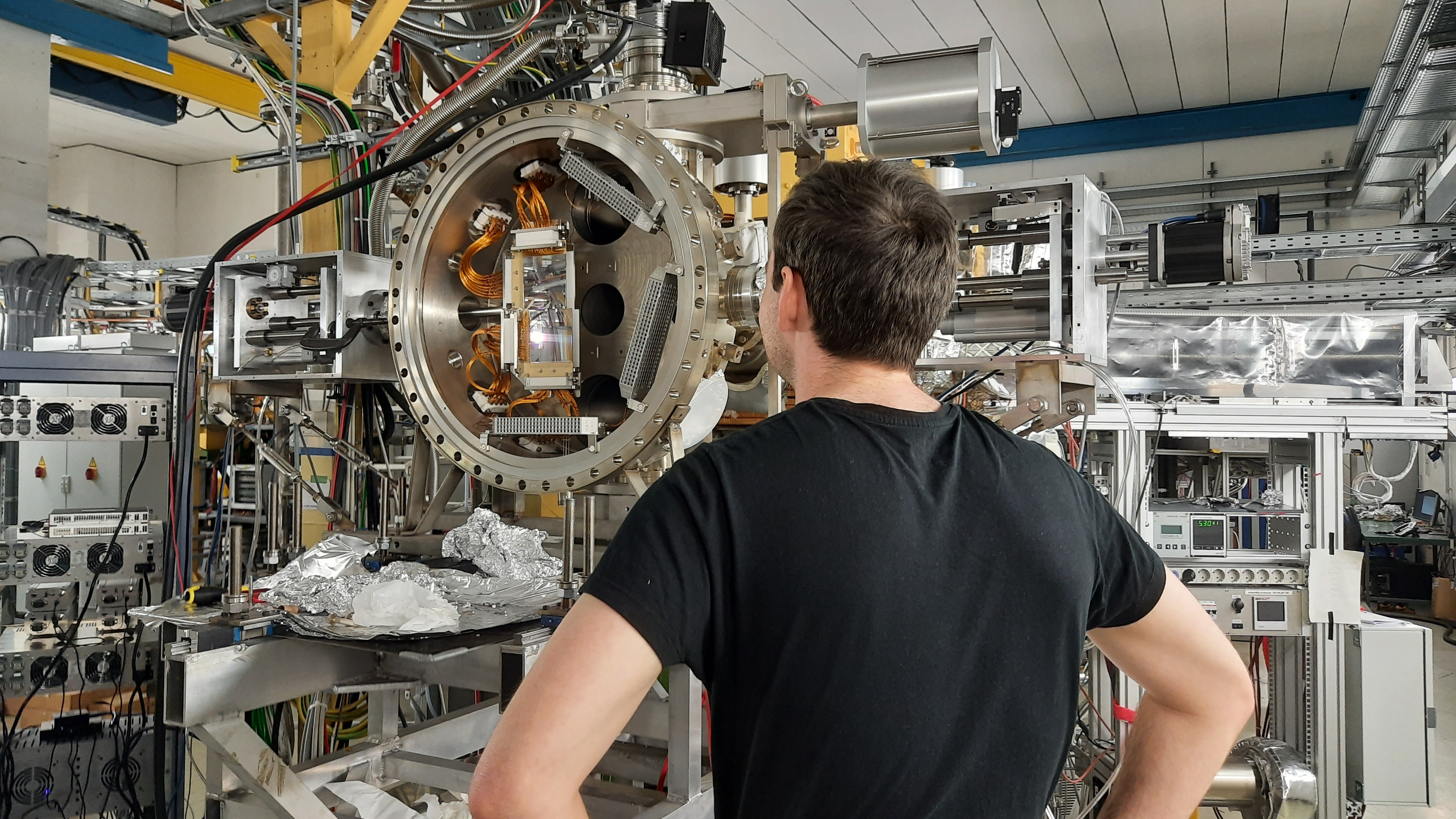

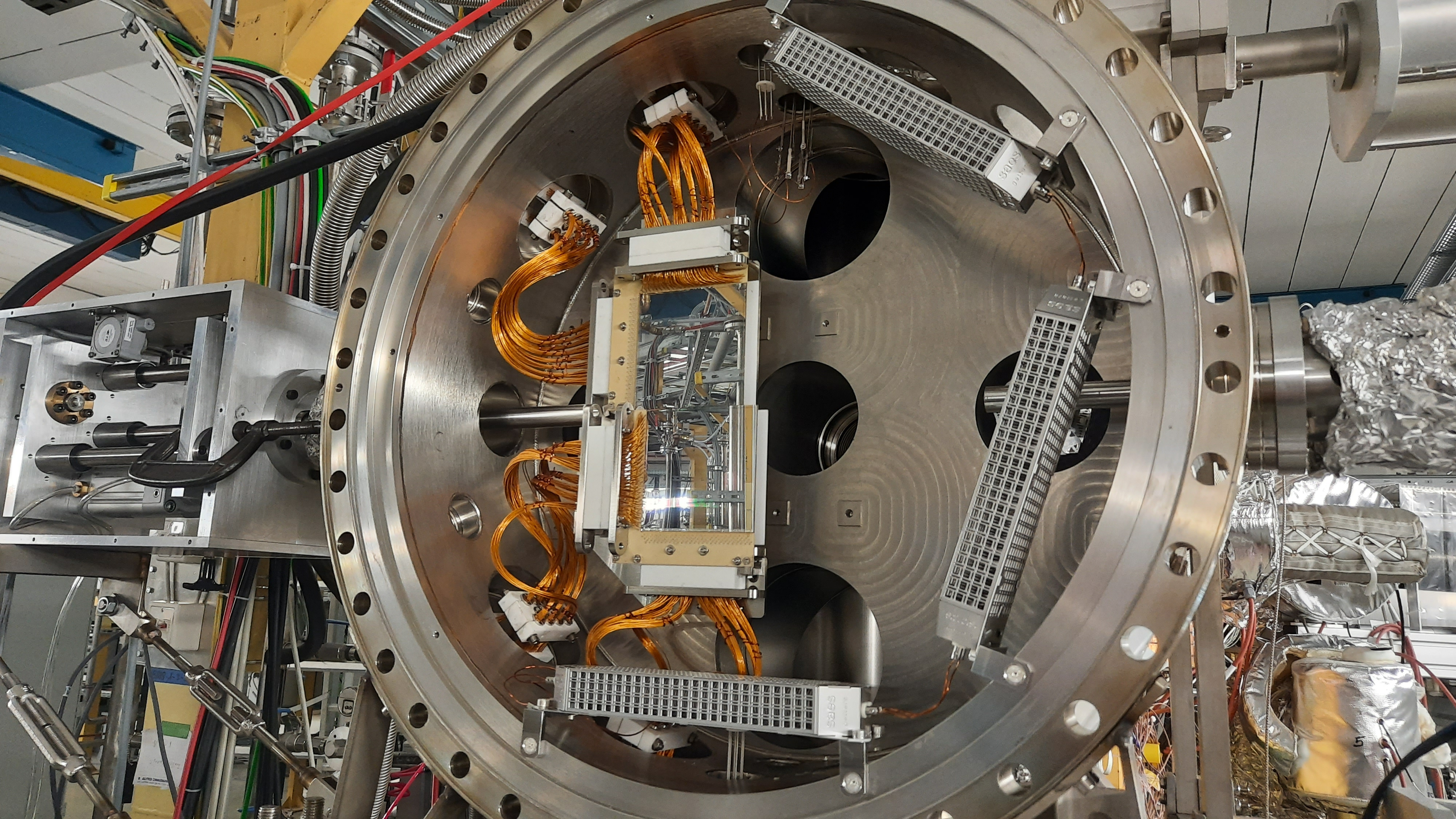

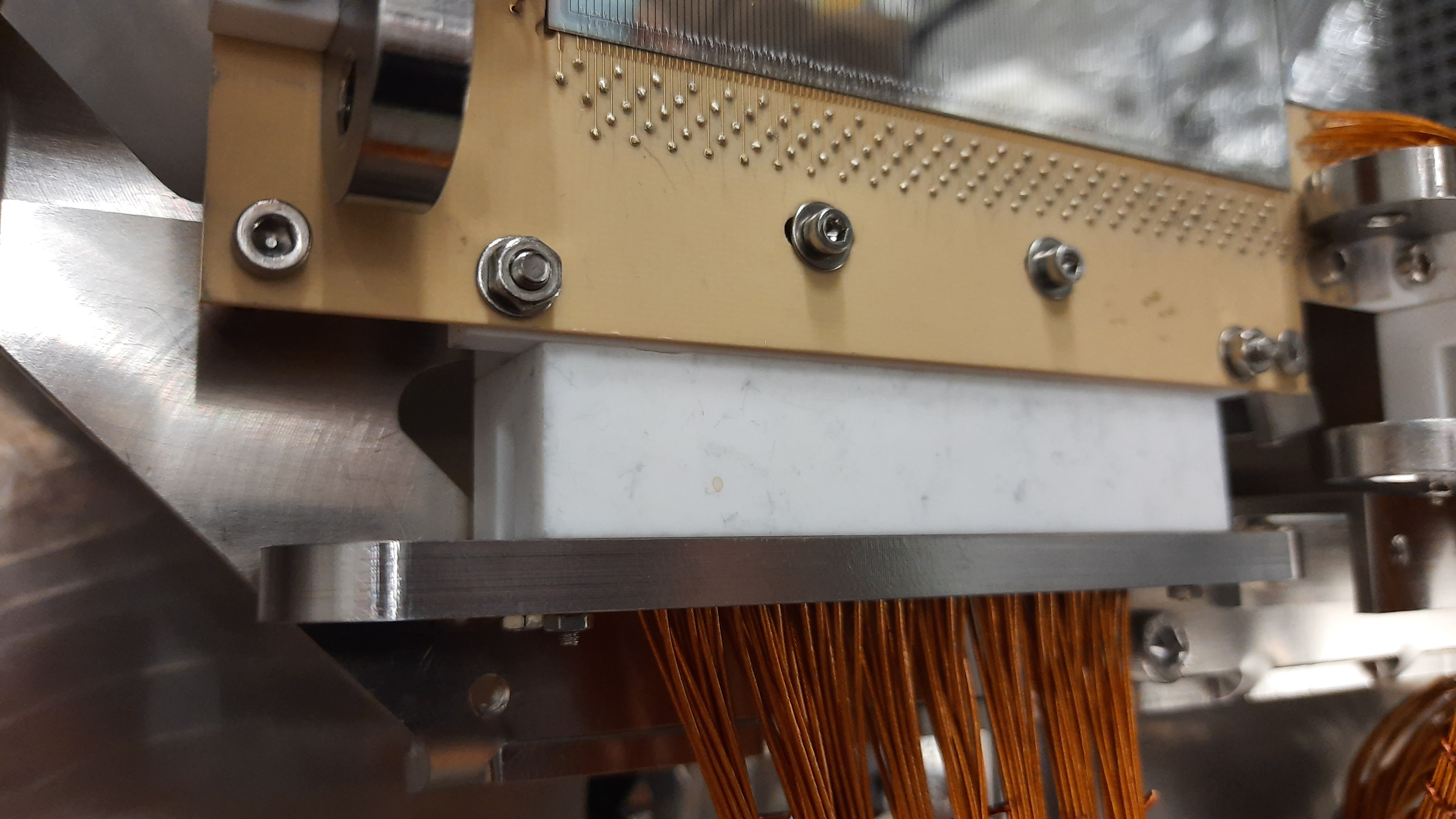

CB JM + RSS | Wires plugged in DSSDs |

(Wed 27 October)

Started with top-most flange. Attemptedto plug in MACOR lead in DSSD plug in preparation for jacking in. Realised that extender plate thickness causes plug to be rasied with respect to nominal position, which results in plug non entering straight. Removed extension plate.

Plugged MACOR lead in. OK. Inserted M6 jacking bolts and gently turned by hand. No resistance until jacking action starts. Jacked plug in with spanner and even 1/4 turns. Removed bolts. All OK.

Attempted same with bottom-most cable harness. Due to strain from top-most wire harness the plate is now rotated on the rod. Rotated back. Jacked in. Removed bolts. No issues.

MACOR plugs show small gap in rear part. Gap seems due to harness strain and disappears depending on plate orientation. Will check but pins are obviously connected.

(Thu 28 October)

Attempted to plug in top-left MACOR lead. Dog leg conflicts with jacking screw! Only solution is to slacken bolt, rotate strut, fasten again with detectors still on plate. Result attached. No clear if design, manufacturing or mounting oversight.

Had to attemping plugging in a few times before jacking bolts went in straight (i.e. no resistance felt). Jacked in both leads. No further issues.

Gap appears less significant in newly plugged leads. probably as a result of lack of rotational freedom.

|

| Attachment 1: 20211027_184502.jpg

|

|

| Attachment 2: 20211027_184527.jpg

|

|

| Attachment 3: 20211027_184535.jpg

|

|

| Attachment 4: 20211028_105802.jpg

|

|

| Attachment 5: 20211028_105919.jpg

|

|

| Attachment 6: 20211028_105711.jpg

|

|

| Attachment 7: 20211028_105728.jpg

|

|

| Attachment 8: 20211028_105734.jpg

|

|

|

|

2

|

Tue Aug 18 11:26:26 2020 |

JM | Week ending Friday 14/08/20 |

Week ending friday 14/08/20

CARME chamber securely mounted upon aluminium frame and support skis. Neg-ion pumps and right angled flanges installed. Neg pumps installed in the wall detector section of the chamber. Neg pumps continuity checked and are electically isolated from the chamber. |

| Attachment 1: Photo.zip

|

|

|

669

|

Wed Apr 9 02:40:04 2025 |

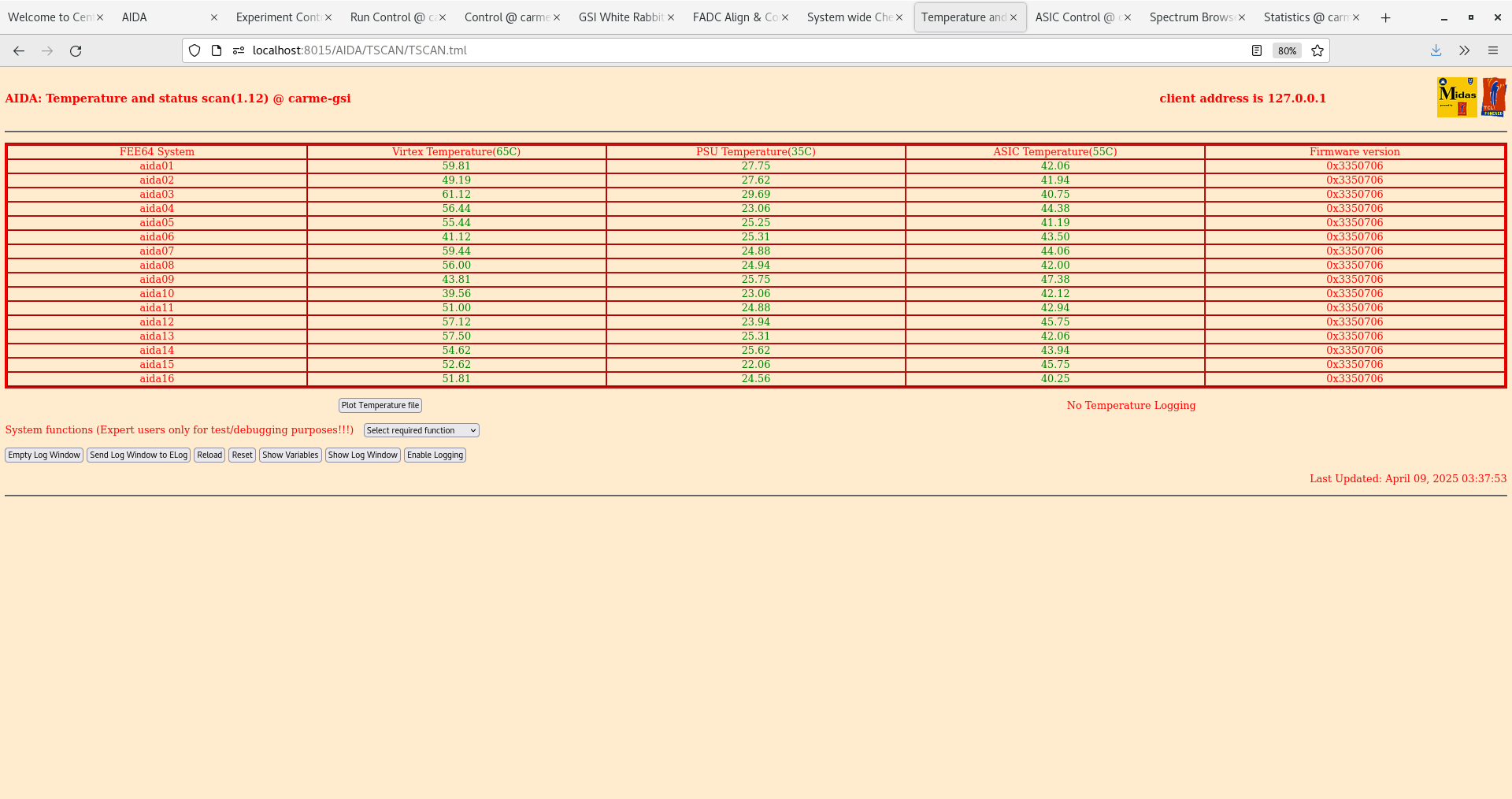

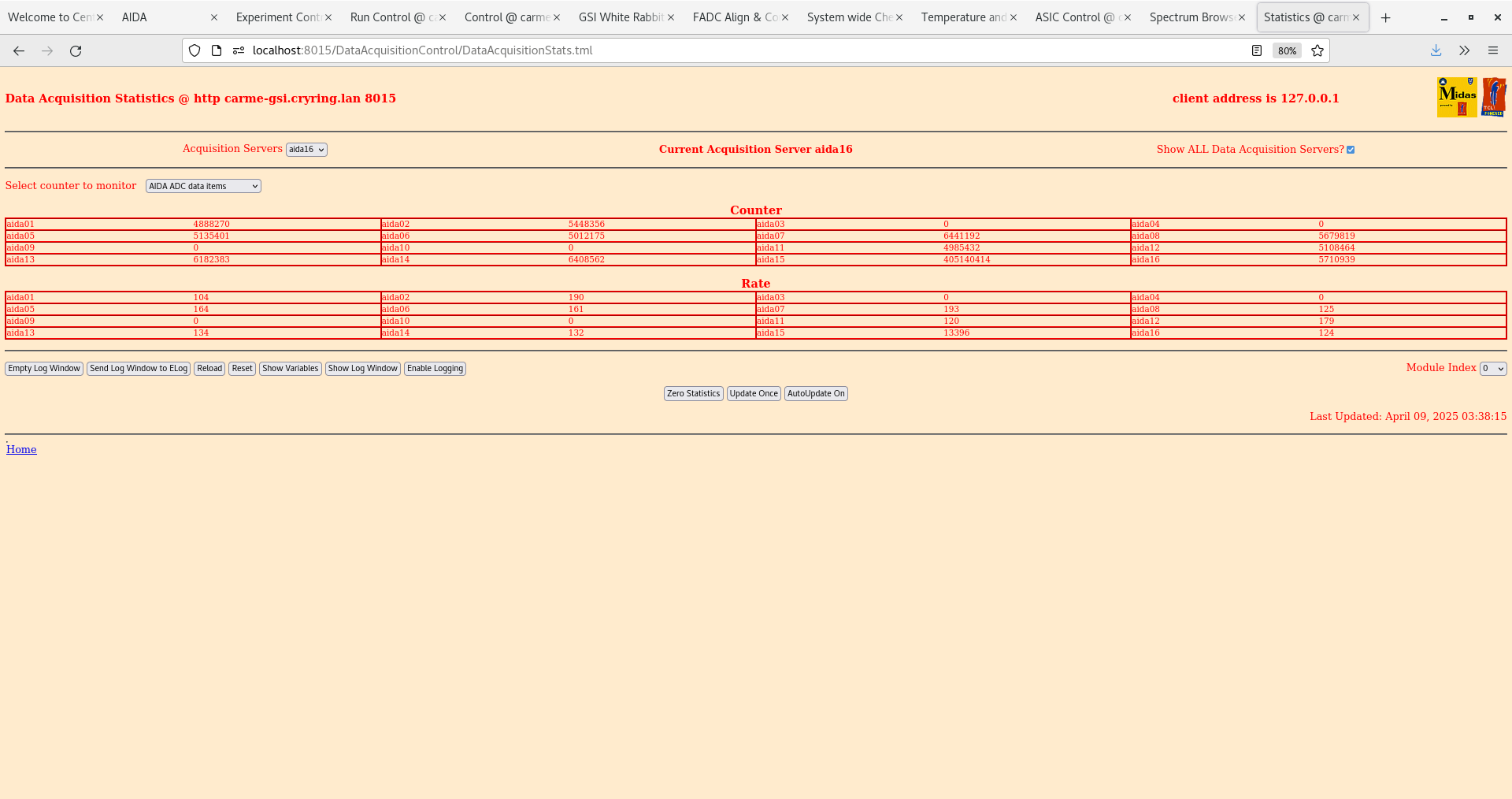

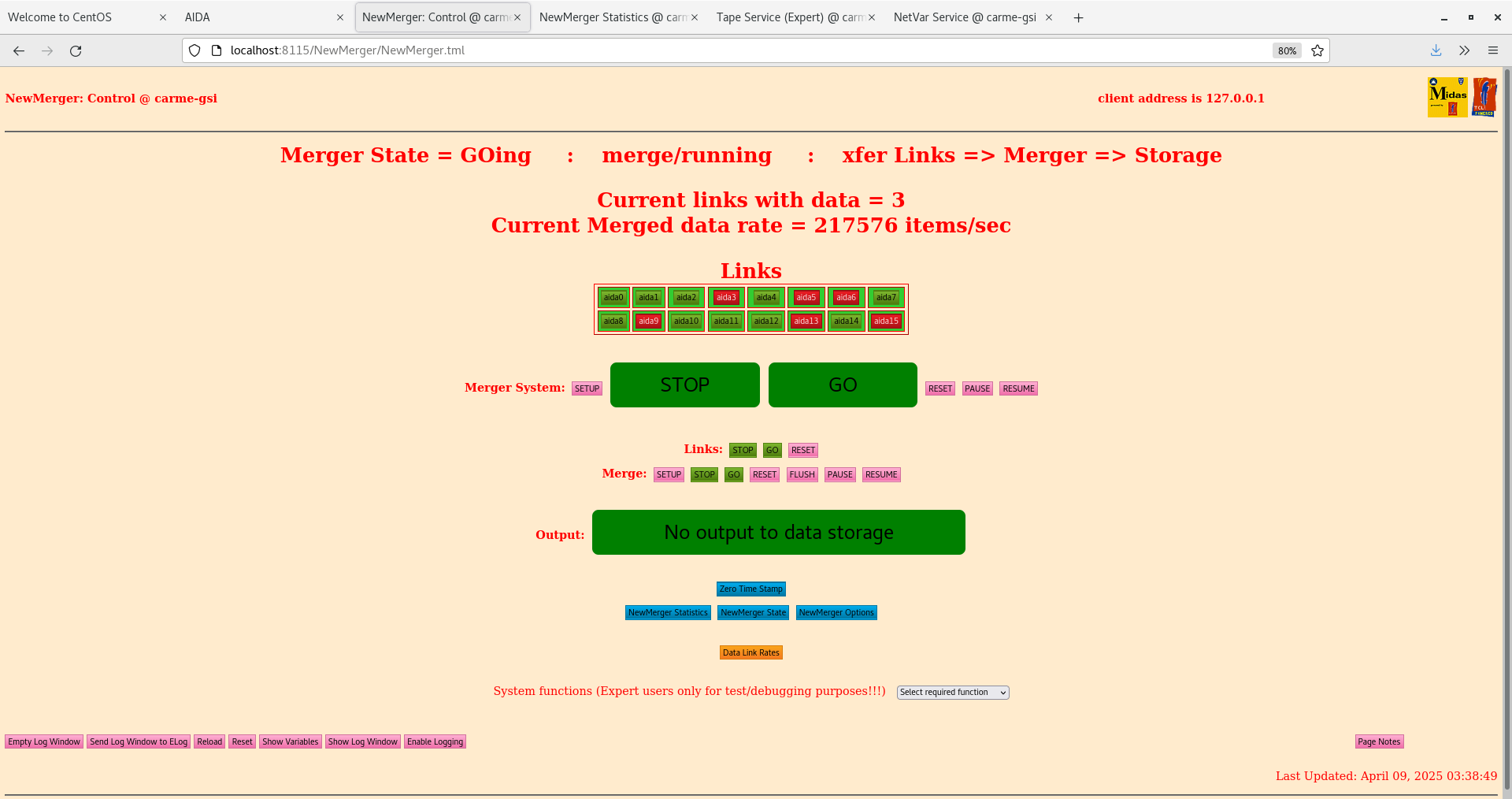

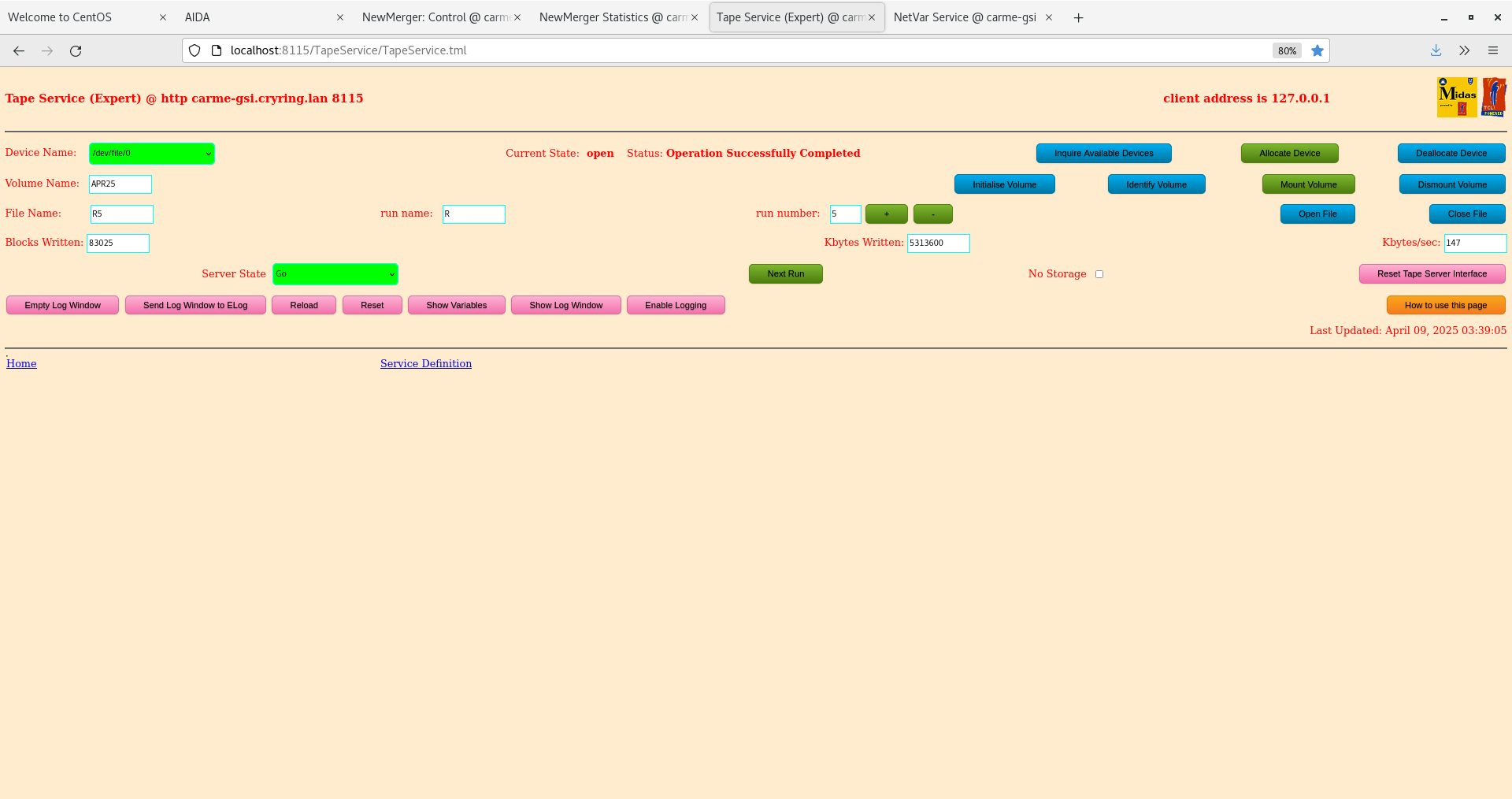

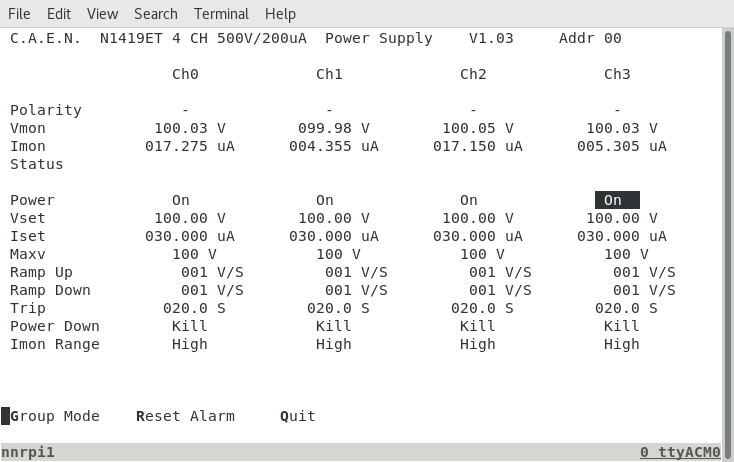

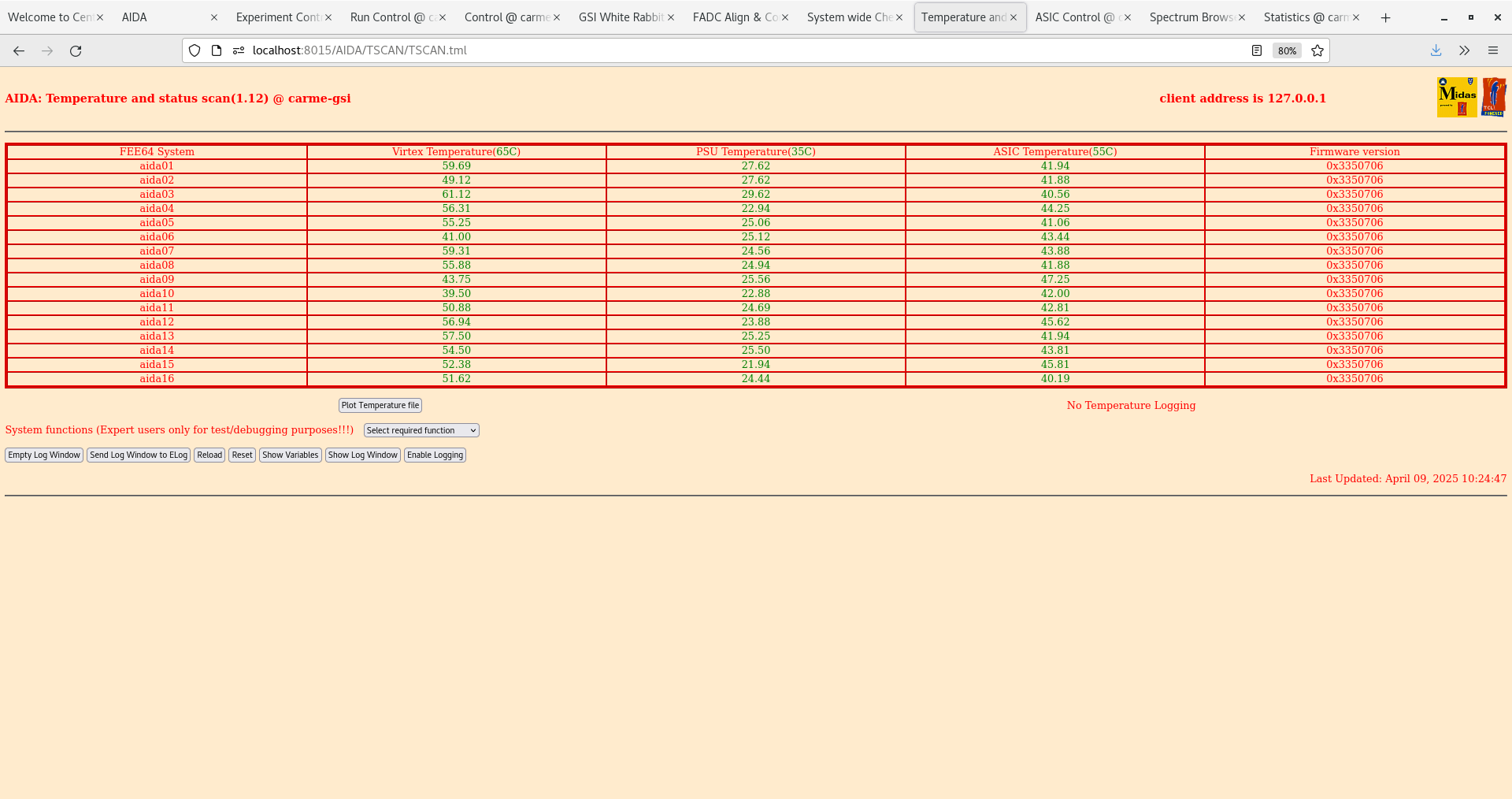

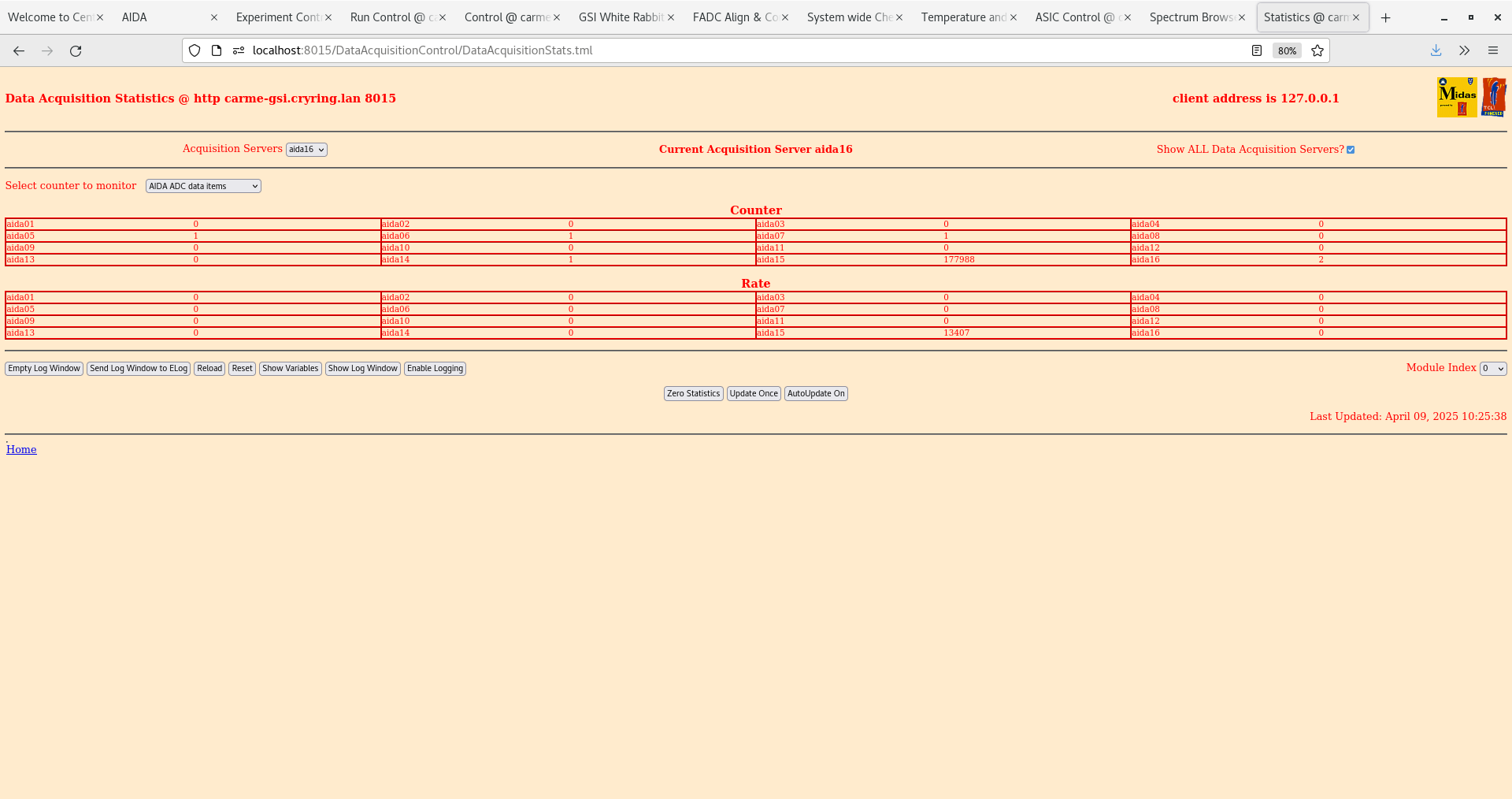

TD | Wednesday 9 April |

03.37 DAQ continues

Data file APR25/R5_8

DSSSD bias & leakage current - attachment 1

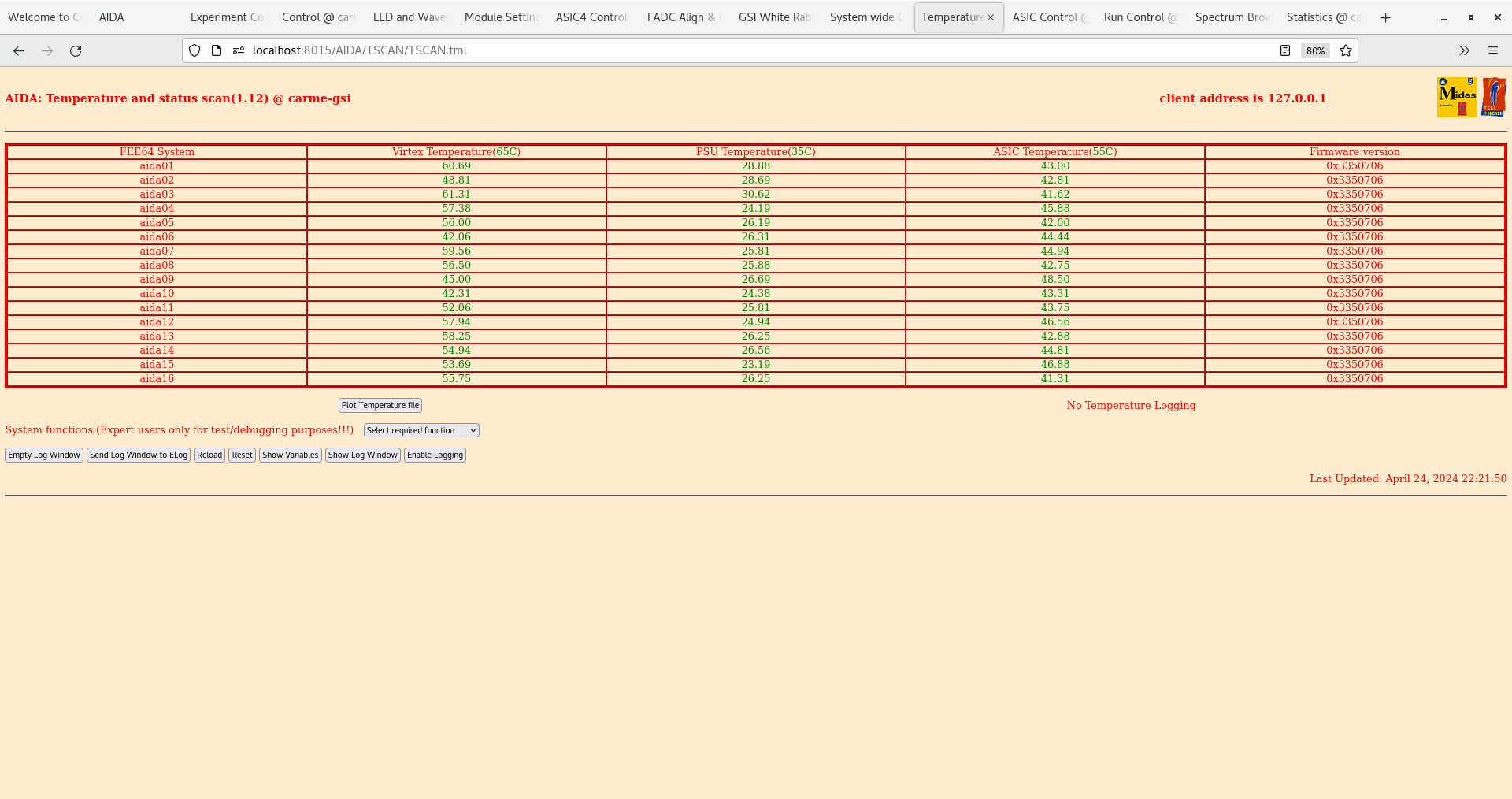

FEE64 temps OK - attachment 2

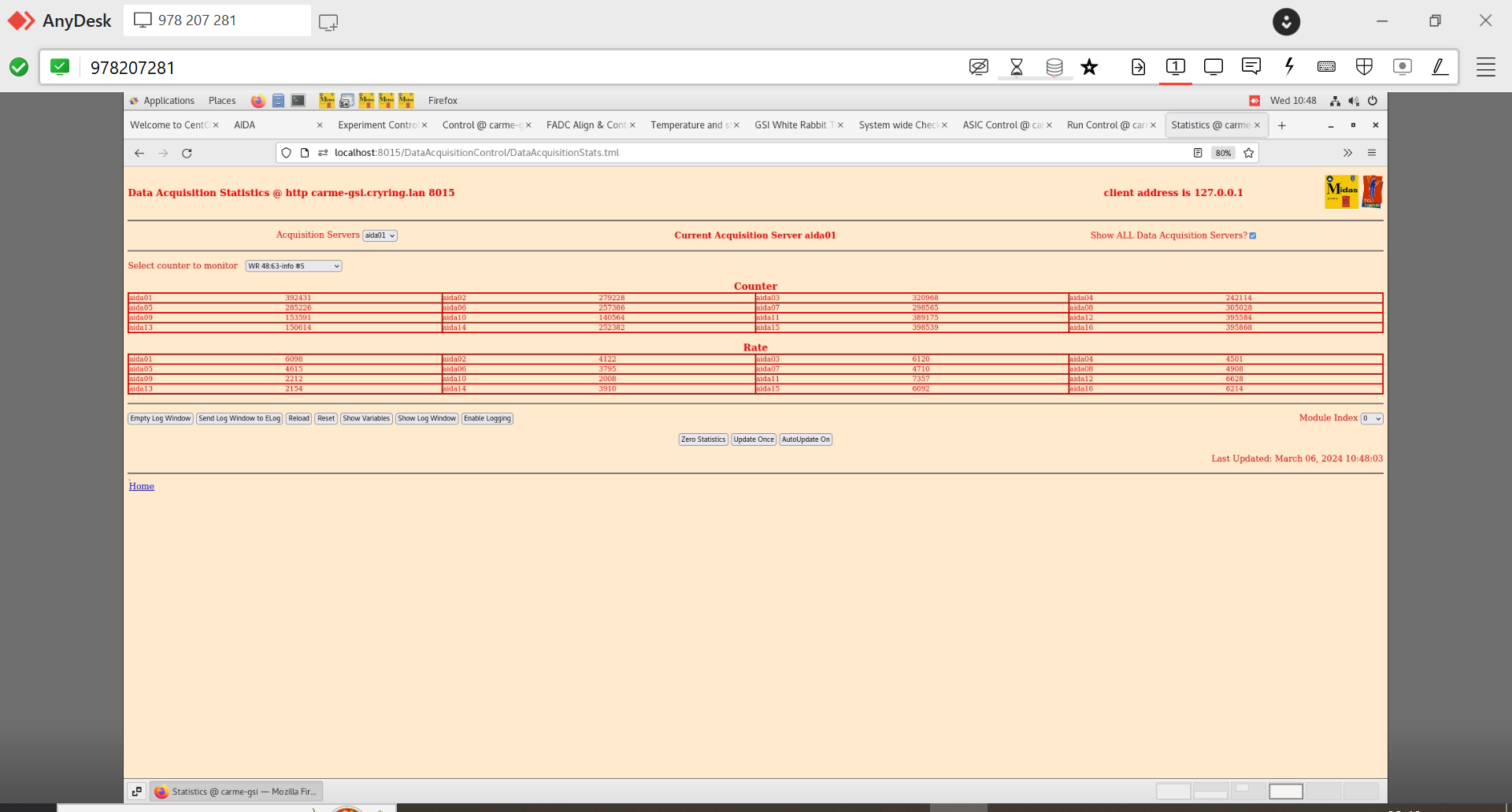

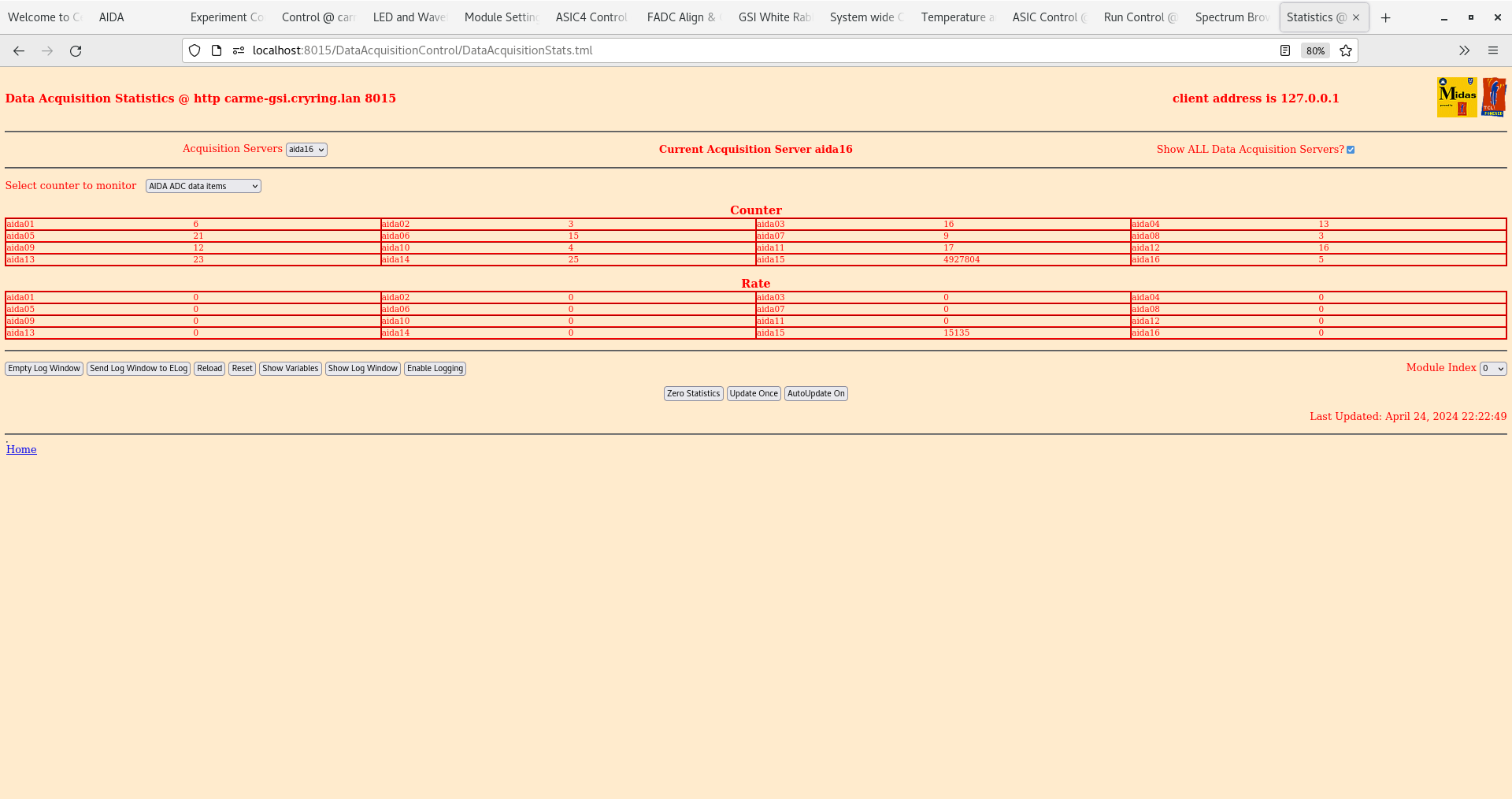

ADC data item stats - attachment 3

Merger & Tape Server - attachment 4-5

10.23 New run

Data file APR25/R6

alpha background - pulser OFF

all histograms & stats zero'd

DSSSD bias & leakage current - attachment 6

FEE64 temps OK - attachment 7

ADC data item stats - attachment 8

Merger & Tape Server - attachment 9-10

WR timestamps OK - attachment 11 |

| Attachment 1: Screenshot_from_2025-04-09_03-37-36.png

|

|

| Attachment 2: Screenshot_from_2025-04-09_03-38-05.png

|

|

| Attachment 3: Screenshot_from_2025-04-09_03-38-36.png

|

|

| Attachment 4: Screenshot_from_2025-04-09_03-38-59.png

|

|

| Attachment 5: Screenshot_from_2025-04-09_03-39-18.png

|

|

| Attachment 6: Screenshot_from_2025-04-09_10-24-34.png

|

|

| Attachment 7: Screenshot_from_2025-04-09_10-24-56.png

|

|

| Attachment 8: Screenshot_from_2025-04-09_10-25-49.png

|

|

| Attachment 9: Screenshot_from_2025-04-09_10-26-39.png

|

|

| Attachment 10: Screenshot_from_2025-04-09_10-26-53.png

|

|

| Attachment 11: Screenshot_from_2025-04-09_10-29-58.png

|

|

|

|

540

|

Wed Mar 6 10:47:11 2024 |

JG, TD | Wednesday 6 March - PEXARIA5 WR test |

Courtesy Nik Kurz, JG has installed a PEXARIA5 PCIe card adjacent to CARME - BuTIS single-mode fibre input

and HDMI output to root MACB input for distribution to the other MACBs and FEE64s.

The PEXARIA5 card provides equivalent functionality to the VETAR2 VME module that we have used to date.

Further information https://www.gsi.de/fileadmin/EE/Module/EXPLODER/pexaria5_14.pdf

Cooling water ON

Via Anydesk startup MIDAS and FEE64s

Power ON

DSSSD HV OFF ( not required for WR test )

FEE64 temperatures OK - attachment 1

All system wide checks OK

Info code 4 & 5 stats OK - attachments 2 & 3

10:48:46 WR timestamps OK - attachment 4

Timestamp (ns) converted to (s) corresponds to 09.49.22 GMT 6.3.24 which appears to be correct

11.00 Power OFF |

| Attachment 1: temps.PNG

|

|

| Attachment 2: stats_1.PNG

|

|

| Attachment 3: stats_2.PNG

|

|

| Attachment 4: wr_0949.PNG

|

|

|

|

382

|

Wed Nov 30 08:52:59 2022 |

AR TD | Wednesday 30 November |

9:40

DSSD bias and leakage current values:

-99.99 V

-13.0960 uA

Pulsar peak widths (ch FWHM)

aida01 ~ 97

aida02 ~ 103

aida03 ~ 134

aida04 ~ 131

aida05 ~ 22

Pretty similar to what was found yesterday

15.30

Per Elog 375

Measured FEE64 voltages are as follows

@ISOL 4 AIDA PSU @FEE64 aida05 nominal

(top-botttom) (right-left)

+6.05V +5.26V +5V

+6.05V +5.26V +5V

+6.05V +5.26V +5V

-6.49V -6.26V -6V

+7.78V +7.46V +7V

Adjusted PowerStax PSU voltage pots of AIDA PSU ISOL 4

@ISOL 4 AIDA PSU @FEE64 aida05 nominal

(top-botttom) (right-left)

+5.79V +4.99V +5V

+5.79V +4.99V +5V

+5.79V +4.99V +5V

-6.23V -6.00V -6V

+7.32V +7.00V +7V

Attatchment 1-12 = BEFORE change

Attatchment 13+ = AFTER change

Pulsar peak widths (ch FWHM) AFTER CHANGE

aida01 ~ 100

aida02 ~ 96

aida03 ~ 130

aida04 ~ 130

aida05 ~ 22 |

| Attachment 1: Screenshot_2022-11-30_at_10.11.36.png

|

|

| Attachment 2: Screenshot_2022-11-30_at_10.11.49.png

|

|

| Attachment 3: Screenshot_2022-11-30_at_10.12.21.png

|

|

| Attachment 4: Screenshot_2022-11-30_at_10.12.30.png

|

|

| Attachment 5: Screenshot_2022-11-30_at_10.12.36.png

|

|

| Attachment 6: Screenshot_2022-11-30_at_10.13.11.png

|

|

| Attachment 7: Screenshot_2022-11-30_at_10.13.18.png

|

|

| Attachment 8: Screenshot_2022-11-30_at_10.14.46.png

|

|

| Attachment 9: Screenshot_2022-11-30_at_10.15.14.png

|

|

| Attachment 10: Screenshot_2022-11-30_at_10.33.38.png

|

|

| Attachment 11: Screenshot_2022-11-30_at_10.34.34.png

|

|

| Attachment 12: Screenshot_2022-11-30_at_10.35.01.png

|

|

| Attachment 13: Screenshot_2022-11-30_at_15.13.50.png

|

|

| Attachment 14: Screenshot_2022-11-30_at_15.14.05.png

|

|

| Attachment 15: Screenshot_2022-11-30_at_15.14.35.png

|

|

| Attachment 16: Screenshot_2022-11-30_at_15.14.41.png

|

|

| Attachment 17: Screenshot_2022-11-30_at_15.14.48.png

|

|

| Attachment 18: Screenshot_2022-11-30_at_15.14.53.png

|

|

| Attachment 19: Screenshot_2022-11-30_at_15.15.00.png

|

|

| Attachment 20: Screenshot_2022-11-30_at_15.16.28.png

|

|

| Attachment 21: Screenshot_2022-11-30_at_15.16.38.png

|

|

| Attachment 22: Screenshot_2022-11-30_at_15.39.31.png

|

|

| Attachment 23: Screenshot_2022-11-30_at_15.40.43.png

|

|

| Attachment 24: Screenshot_2022-11-30_at_15.41.33.png

|

|

| Attachment 25: Screenshot_2022-11-30_at_15.42.01.png

|

|

| Attachment 26: Screenshot_2022-11-30_at_15.46.29.png

|

|

|

|

31

|

Wed Oct 28 10:41:57 2020 |

TD | Wednesday 28 October |

10.32

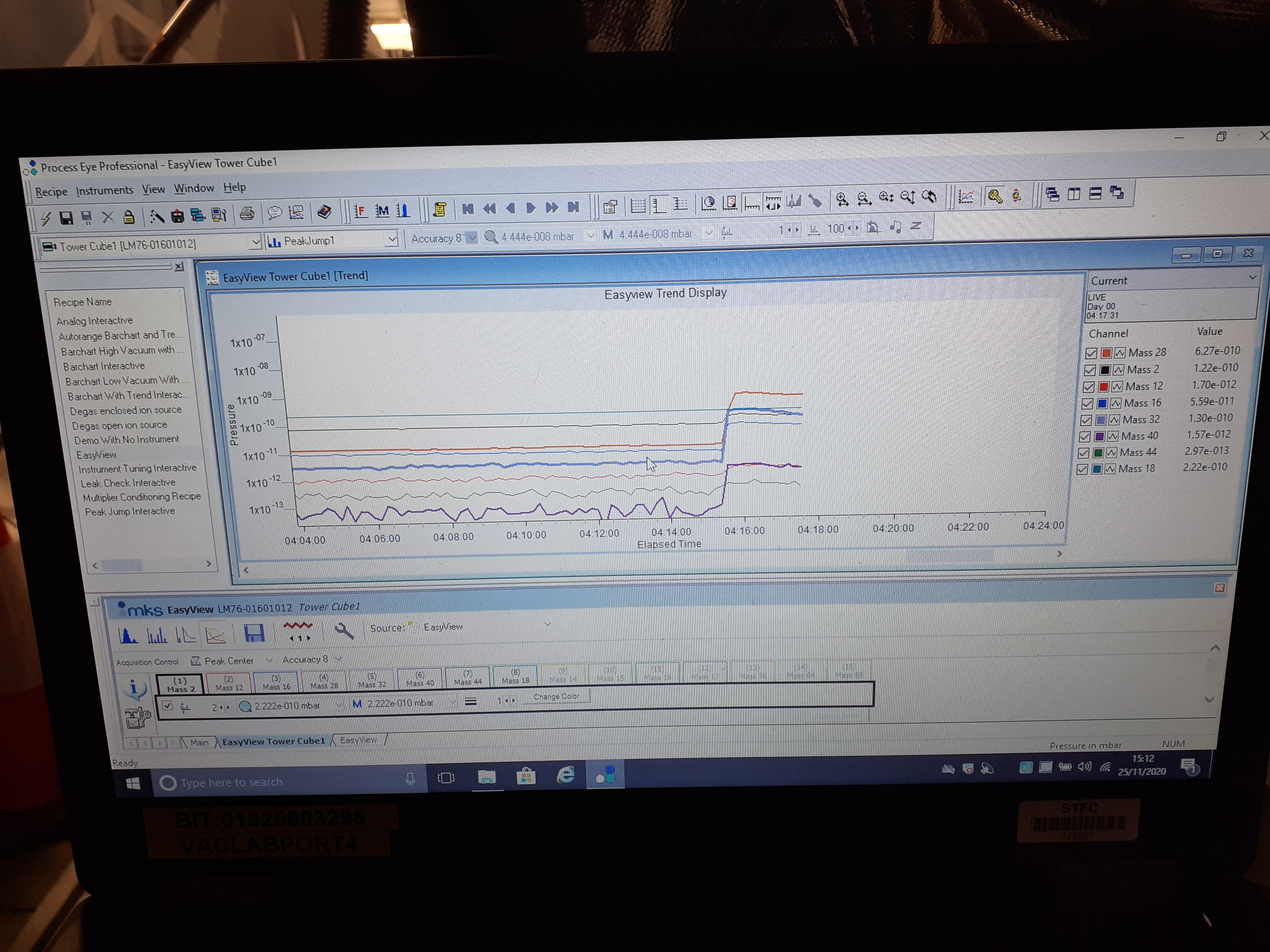

CARME chamber 5.8e-12mbar (see attachment 1)

Backing 1.6e-08mbar (Edwards vacuum cart w/RGA)

CARME temps - see attachment 2

All SAES D2000-10 & UHV1400 NEG power OFF

All SAES D2000-10 ion pump OFF

Gate valve open

11.01

All SAES D2000-10 ion pump ON

# V/V presssure/mbar

1 5012/5019 4-8e-11

2 5012 < 8.9e-12

3 5012 < 8.9e-12

4 5012 < 8.9e-12

11.04

CARME chamber 5.7e-12mbar

Backing 1.7e-08mbar (Edwards vacuum cart w/RGA)

12.12

CARME chamber 5.3e-12mbar

Backing 1.7e-08mbar (Edwards vacuum cart w/RGA)

All SAES D2000-10 & UHV1400 NEG power OFF

Gate valve open

All SAES D2000-10 ion pump ON

# V/V presssure/mbar

1 5012 < 8.9e-12

2 5012 < 8.9e-12

3 5012 < 8.9e-12

4 5012 < 8.9e-12

All ion pumps now stabilising wrt V/I/pressure

log (pressure) versus time - see attachment 3

16.00

CARME chamber 4.9e-12mbar - see attachment 4

Backing 1.7e-08mbar (Edwards vacuum cart w/RGA)

All SAES D2000-10 & UHV1400 NEG power OFF

Gate valve open

All SAES D2000-10 ion pump ON - see attachment 5

# V/V presssure/mbar

1 5012 < 8.9e-12

2 5012 < 8.9e-12

3 5012 < 8.9e-12

4 5012 < 8.9e-12

All ion pumps now stabilising wrt V/I/pressure

CARME temps - see attachment 6

Observing pressure transients from 5e-12mbar to c. 6-7e-12mbar which recover in c. 5-10 minutes

21.00 CARME chamber 4.7e-12mbar |

| Attachment 1: 20201028_103204.jpg

|

|

| Attachment 2: 20201028_103638.jpg

|

|

| Attachment 3: 28102020_pump_down.png

|

|

| Attachment 4: 20201028_161049.jpg

|

|

| Attachment 5: 20201028_155823.jpg

|

|

| Attachment 6: 20201028_155940.jpg

|

|

|

|

446

|

Wed Sep 27 15:56:41 2023 |

TD | Wednesday 27 September |

16.55 CARME IE514 8.2e-11 mbar

Vacuum pressure increased slowly overnight from c. 6e-11 mbar yesterday to c. 8e-11 mbar today following low power startup tests of the bakeout controller heating

the CARME interaction and detector chambers yesterday and today.

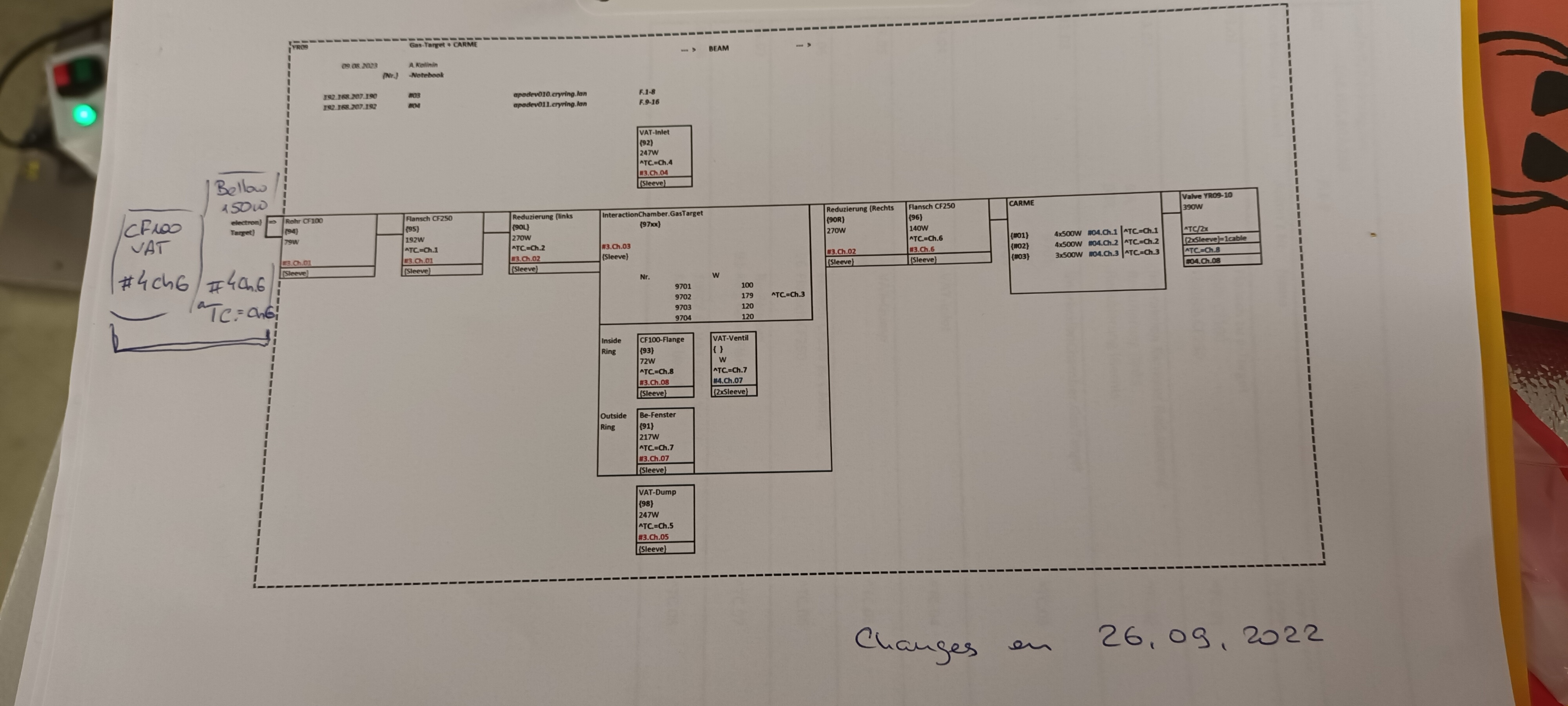

Attachment 1 - bakeout controller config courtesy Anton Kalinin

Attachments 2 & 3 - bakeout controller summary displays and CARME bakeout monitor display c. 17.00 today

The 3x CARME heaters are connected to controller #4 zones # 1-3, i.e. lower right display, zones 1-3, mains fuses F9-F11

17.30 3x ( of 4x ) SAES D-2000 ion pump controllers ( SIP modules ) switched off. Fourth controller was already switched off and SHV cable disconnected from rear panel of

SIP module. |

| Attachment 1: 1000007129.jpg

|

|

| Attachment 2: 1000007127.jpg

|

|

| Attachment 3: 1000007128.jpg

|

|

|

|

35

|

Wed Nov 25 10:39:37 2020 |

TD | Wednesday 25 November |

10.39

CARME XHV chamber pressure 6.0e-12mbar

Backing 2.1e-08mbar (Edwards vacuum cart w/RGA)

CARME temps - heaters OFF - chamber at ambient

temperature

All SAES D2000-10 & UHV1400 NEG power OFF

All SAES D2000-10 ion pump ON

# V/V presssure/mbar

1 5012 < 8.9e-12

2 5012 < 8.9e-12

3 5012 < 8.9e-12

4 5012 < 8.9e-12

Gate valve open

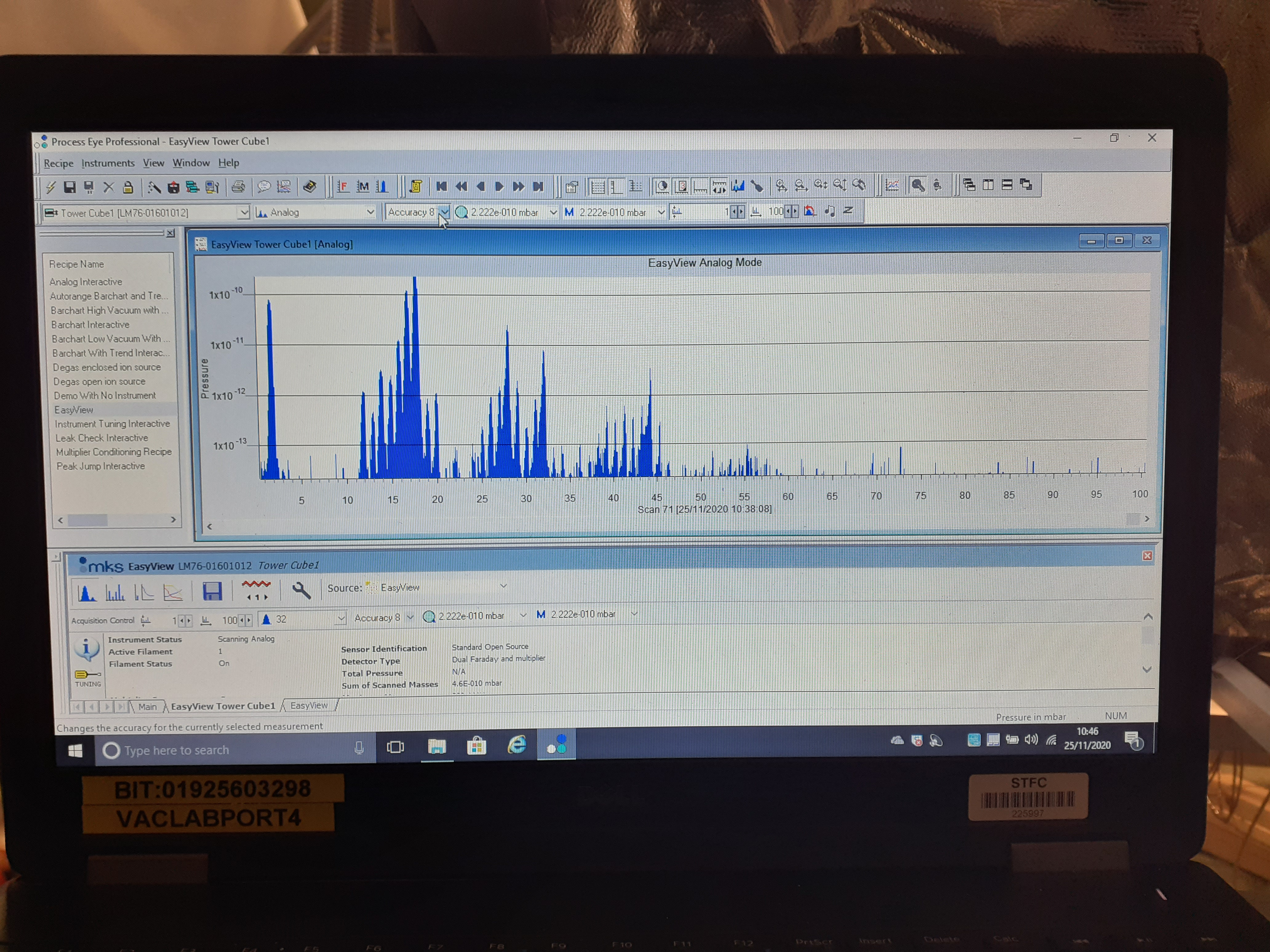

attachment 1 - analog RGA scan (as found this am)

attachment 2 - scan mode

c. 11.15

AH partially closes gate valve using c. 2 bar air pressure

VCARME XHV chamber pressure increases c. 7e-9mbar immediately

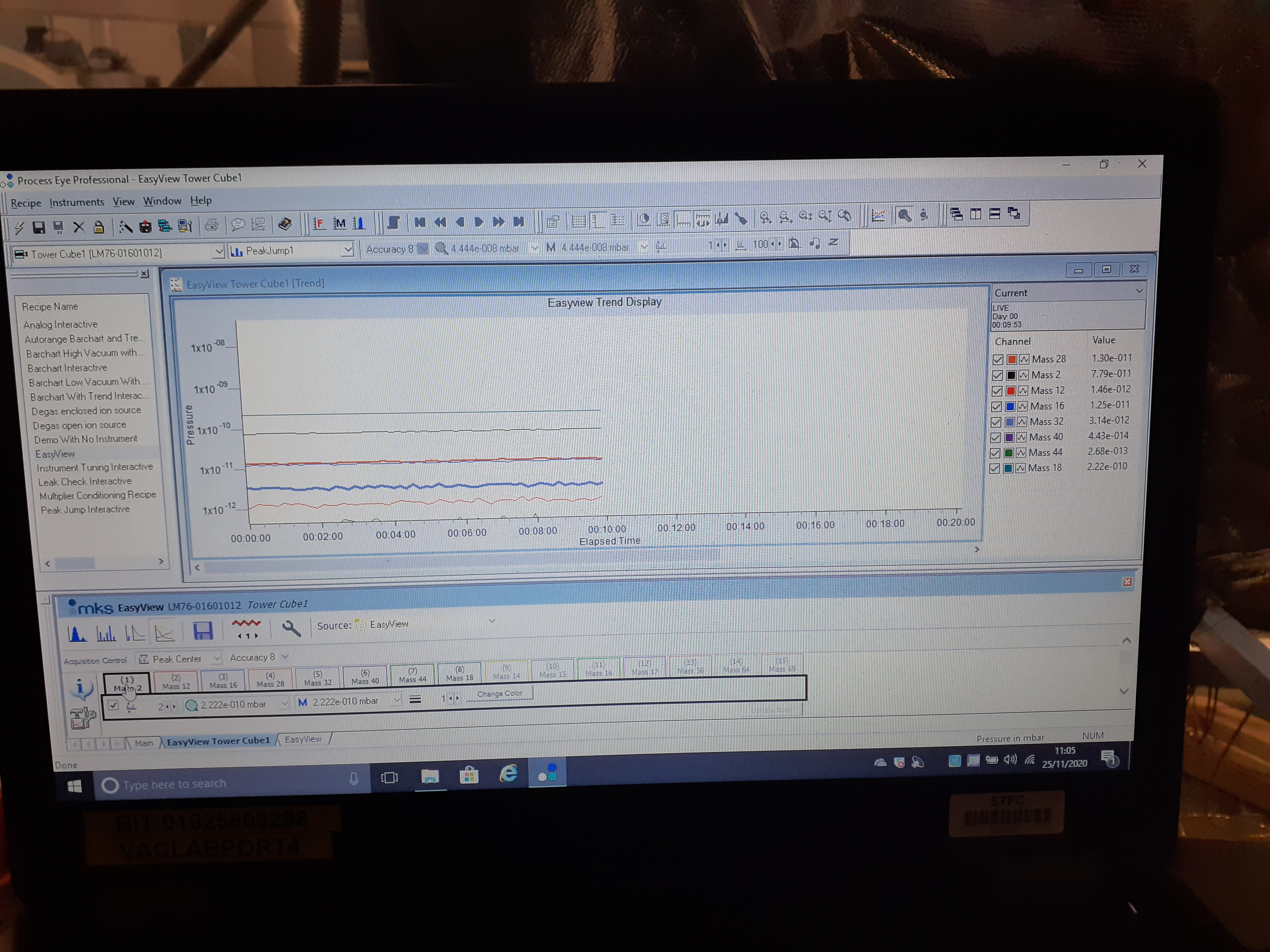

attachment 3 - RGA scan - no obvious change in RGA trends!

attachments 4 & 5 - VAT valve indicators - upper (partially open/closed) and lower (closed)

11.33 CARME XHV chamber pressure 6.6e-9mbar

Backing 2.2e-08mbar (Edwards vacuum cart w/RGA)

All SAES D2000-10 ion pump ON

# V/V presssure/mbar

1 5012 < 8.9e-12

2 5012 < 8.9e-12

3 5012 < 8.9e-12

4 5012 < 8.9e-12

All SAES D2000-10 ion pump OFF

11.40 CARME XHV chamber pressure 5.64e-9mbar

11.46 CARME XHV chamber pressure 5.01e-9mbar

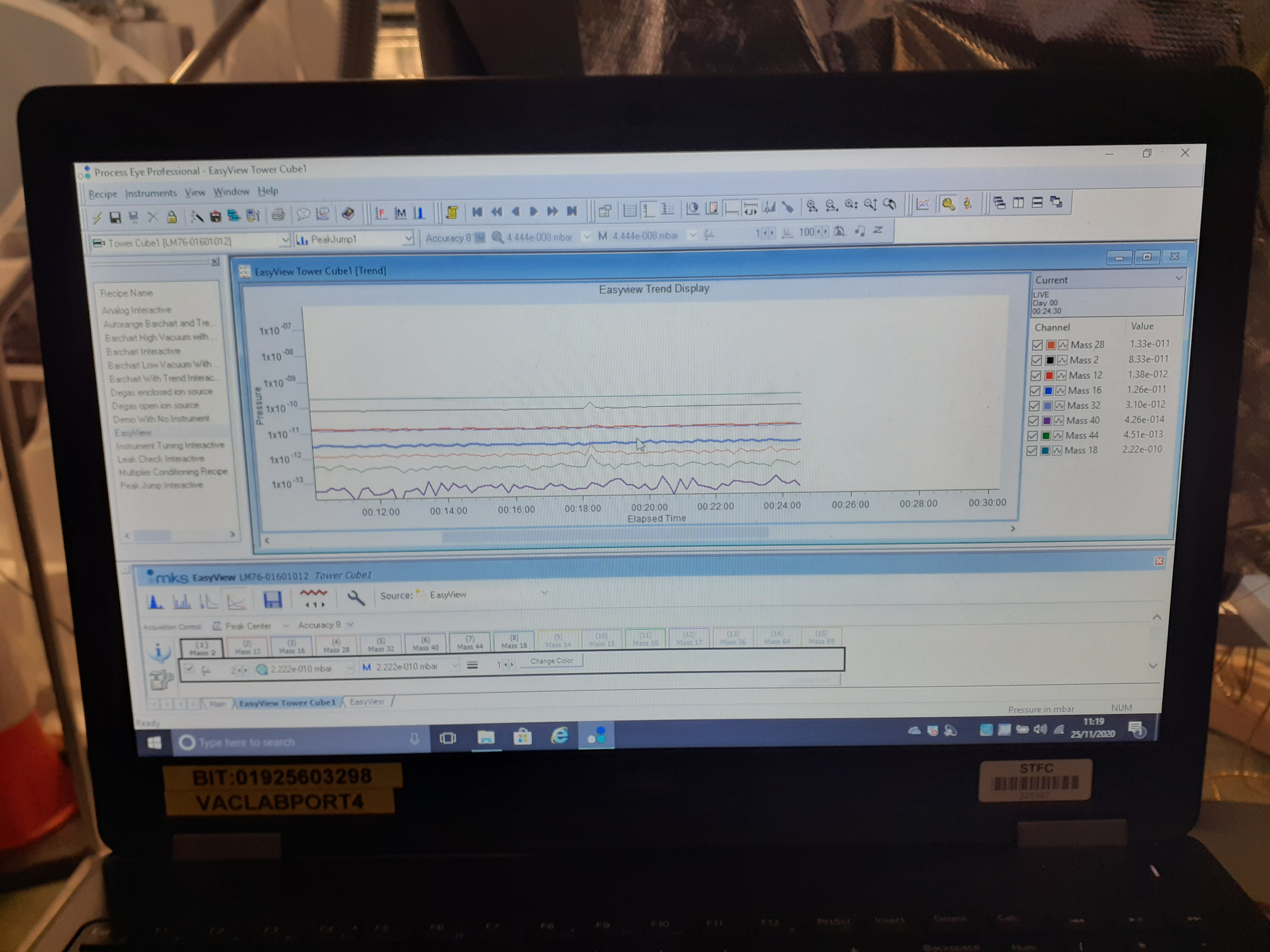

No change in RGA trends!

12.01 CARME XHV chamber pressure 3.78e-9mbar

No change in RGA trends!

12.11 CARME XHV chamber pressure 3.10e-9mbar

12.42 CARME XHV chamber pressure 1.81e-9mbar

Backing 2.4e-08mbar (Edwards vacuum cart w/RGA)

No change in RGA trends!

13.20 CARME XHV chamber pressure 1.06e-9mbar

Backing 2.4e-08mbar (Edwards vacuum cart w/RGA)

No change in RGA trends!

13.36 CARME XHV chamber pressure 8.93e-10mbar

Backing 2.4e-08mbar (Edwards vacuum cart w/RGA)

No change in RGA trends!

13.59 CARME XHV chamber pressure 7.07e-10mbar

Backing 2.5e-08mbar (Edwards vacuum cart w/RGA)

No change in RGA trends!

14.00 Leybold turbo OFF - decelerating

14.30 Leybold turbo OFF - decelerating - 466Hz

CARME XHV chamber pressure 5.62e-10mbar

Backing 2.1e-08mbar (Edwards vacuum cart w/RGA)

No change in RGA trends!

14.40 1x SAES D2000-10 ion pump switched on briefly - settles in c. 10s - pressure < 8.9e-

12mbar

All 4x D2000-10 ion pumps OFF

15.01 Leybold turbo OFF - decelerating - 125Hz

CARME XHV chamber pressure 4.78e-10mbar

Backing 1.4e-08mbar (Edwards vacuum cart w/RGA)

No change in RGA trends!

15.10 Abrupt increase in RGA trends - see attachment 6

Leybold turbo OFF - decelerating - 60Hz

CARME XHV chamber pressure 4.53e-10mbar

Backing 2.6e-08mbar (Edwards vacuum cart w/RGA)

15.19 4x SAES D2000-10 ion pumps ON

RGA record 04.24.00

15.24 see attachment 7 - RGA transient recovering - turbo stopped?

15.10 Leybold turbo OFF - stopped - 0Hz

CARME XHV chamber pressure 4.40e-10mbar

Backing 1.1e-08mbar (Edwards vacuum cart w/RGA)

All SAES D2000-10 ion pump ON

# V/V presssure/mbar

1 5012 < 8.9e-12

2 5012 < 8.9e-12

3 5012 < 8.9e-12

4 5012 < 8.9e-12

16.10 VAT gate valve partially closed

Leybold turbo OFF - stopped - 0Hz

CARME XHV chamber pressure 3.88e-10mbar

Backing 9.8e-09mbar (Edwards vacuum cart w/RGA)

RGA traces recovered to pre-transient levels and stable

All SAES D2000-10 ion pump ON

# V/V presssure/mbar

1 5012 < 8.9e-12

2 5012 < 8.9e-12

3 5012 < 8.9e-12

4 5012 < 8.9e-12 |

| Attachment 1: 20201125_104631.jpg

|

|

| Attachment 2: 20201125_110500.jpg

|

|

| Attachment 3: 20201125_111937.jpg

|

|

| Attachment 4: 20201125_111954.jpg

|

|

| Attachment 5: 20201125_112003.jpg

|

|

| Attachment 6: 20201125_151232.jpg

|

|

| Attachment 7: 20201125_152354.jpg

|

|

|

|

544

|

Wed Apr 24 12:48:35 2024 |

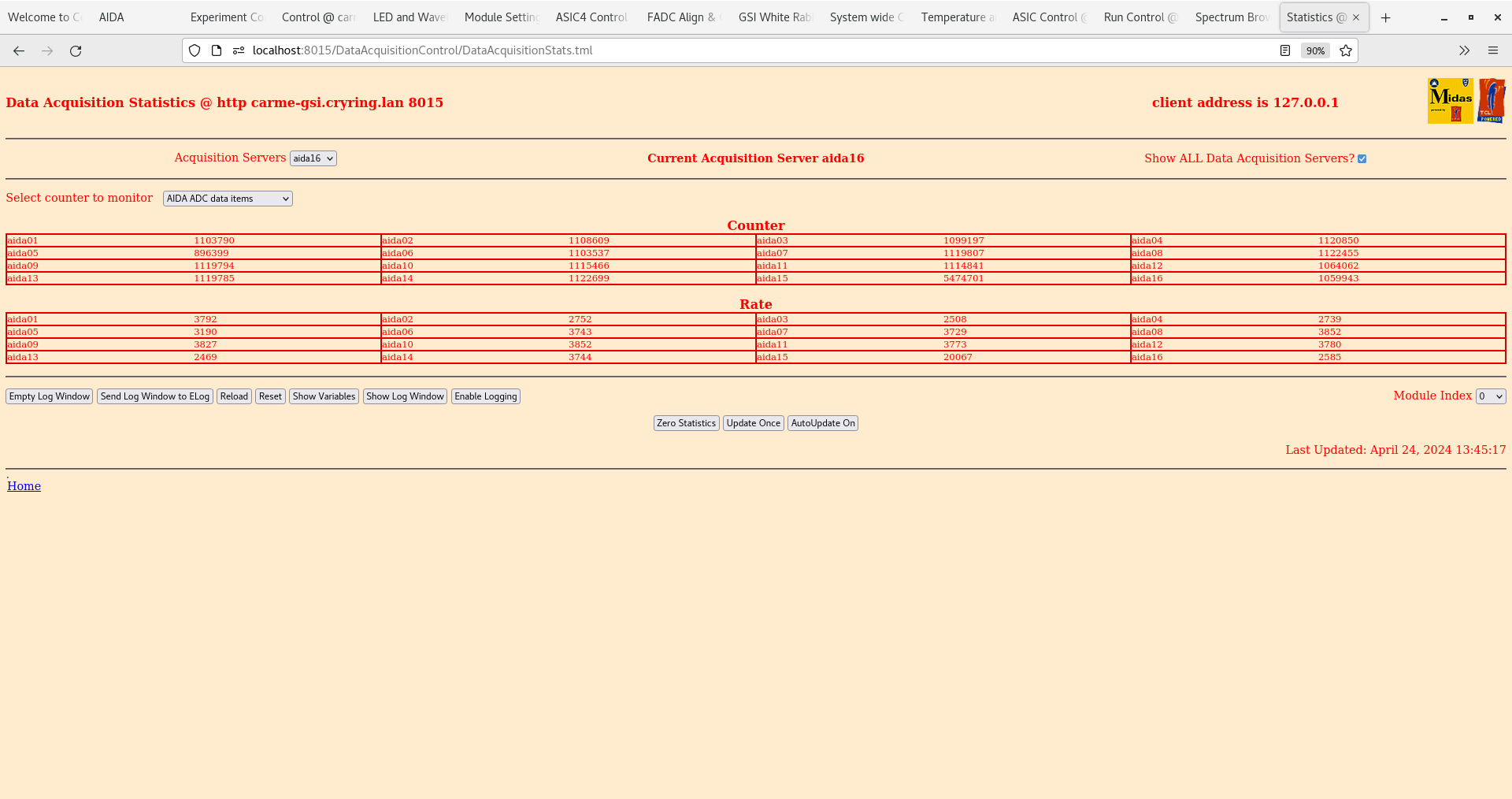

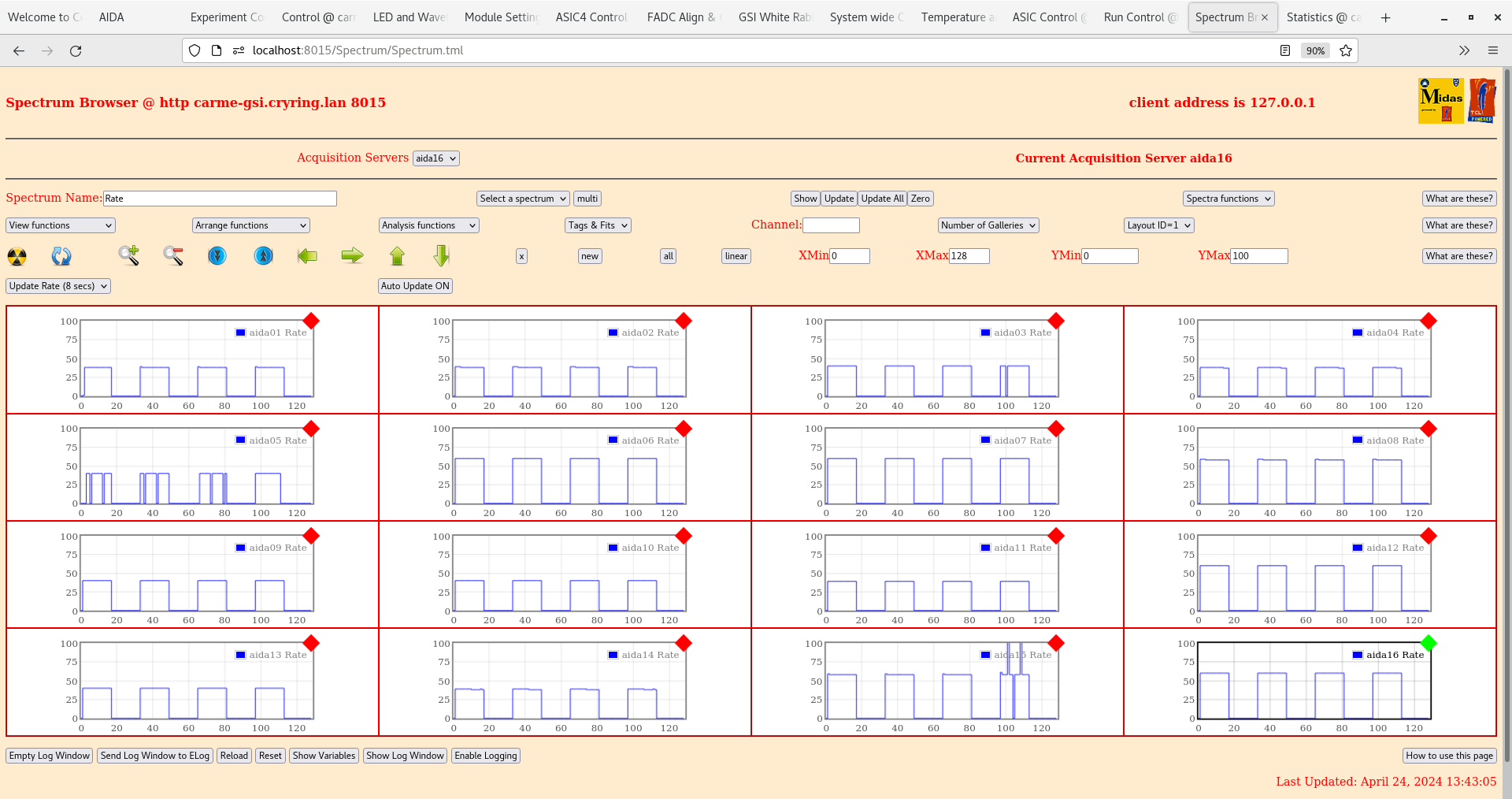

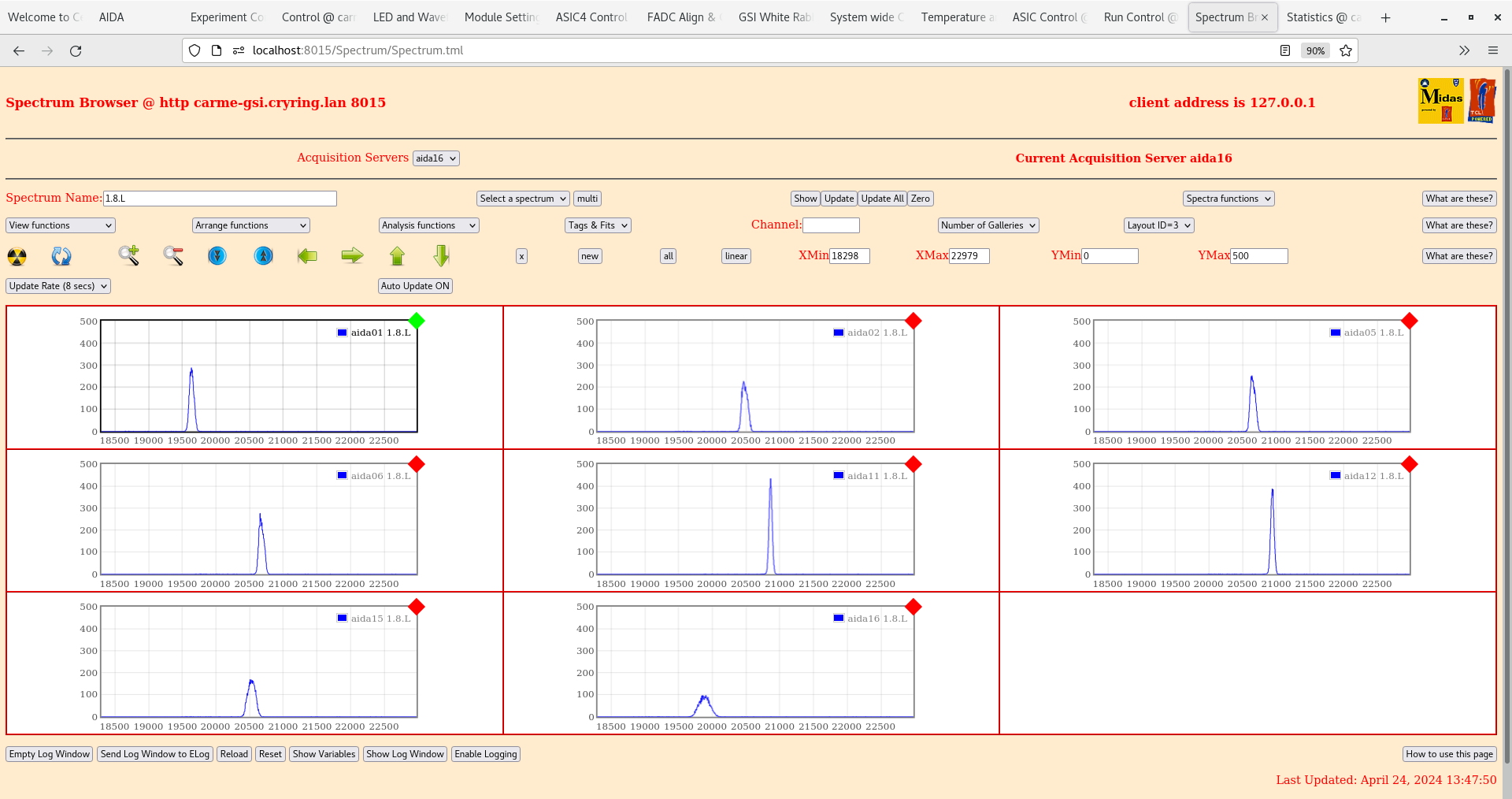

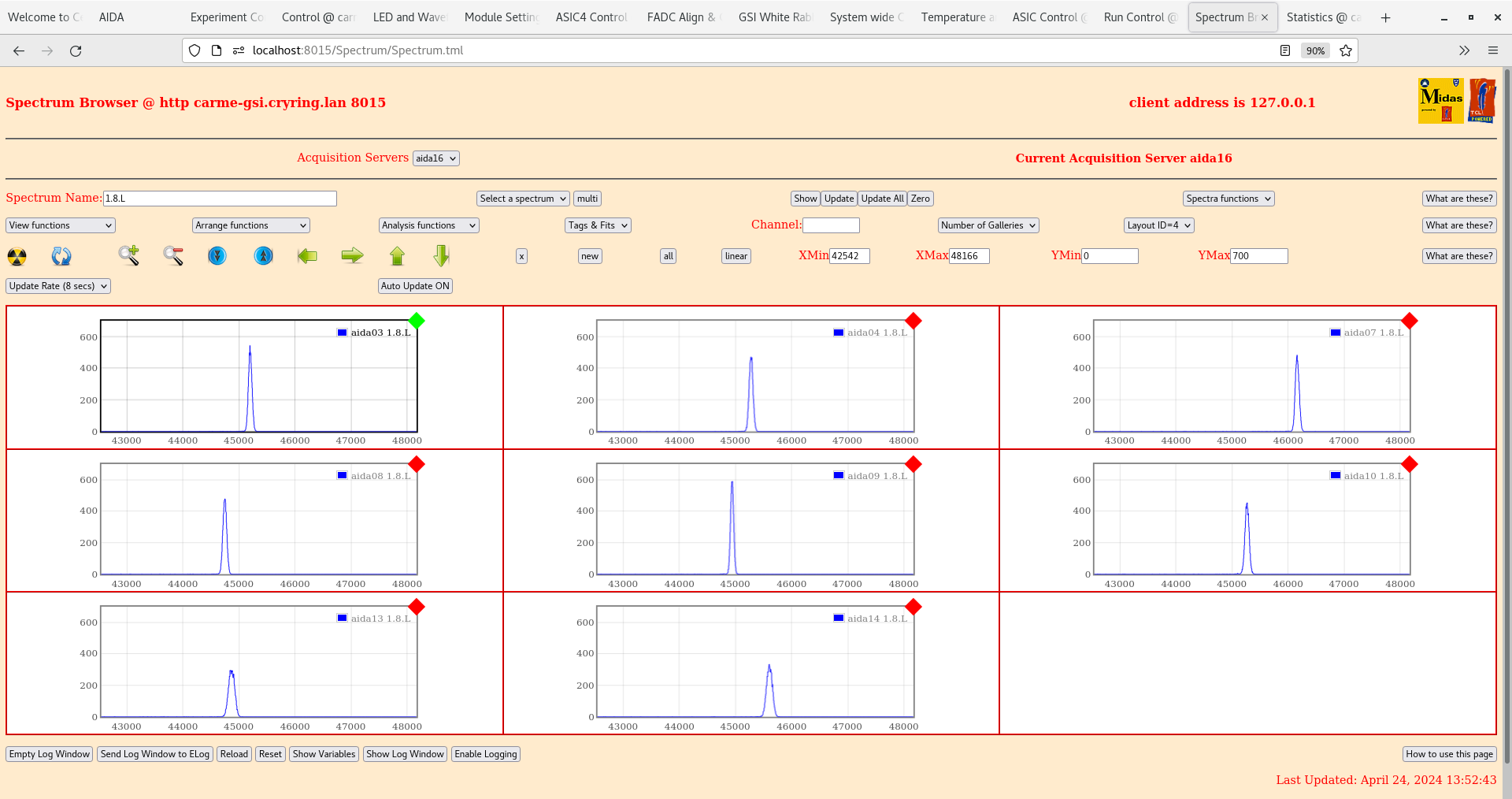

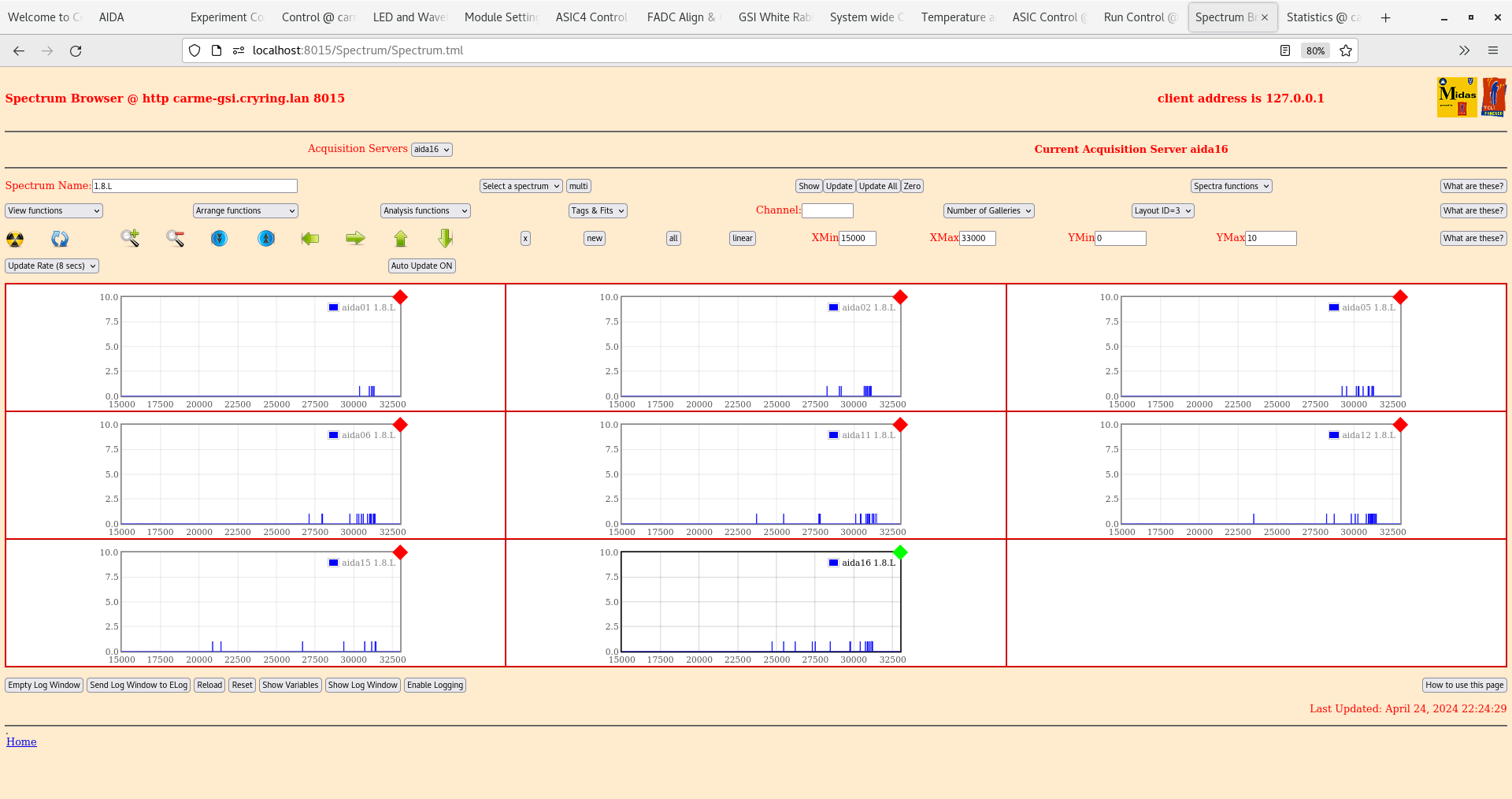

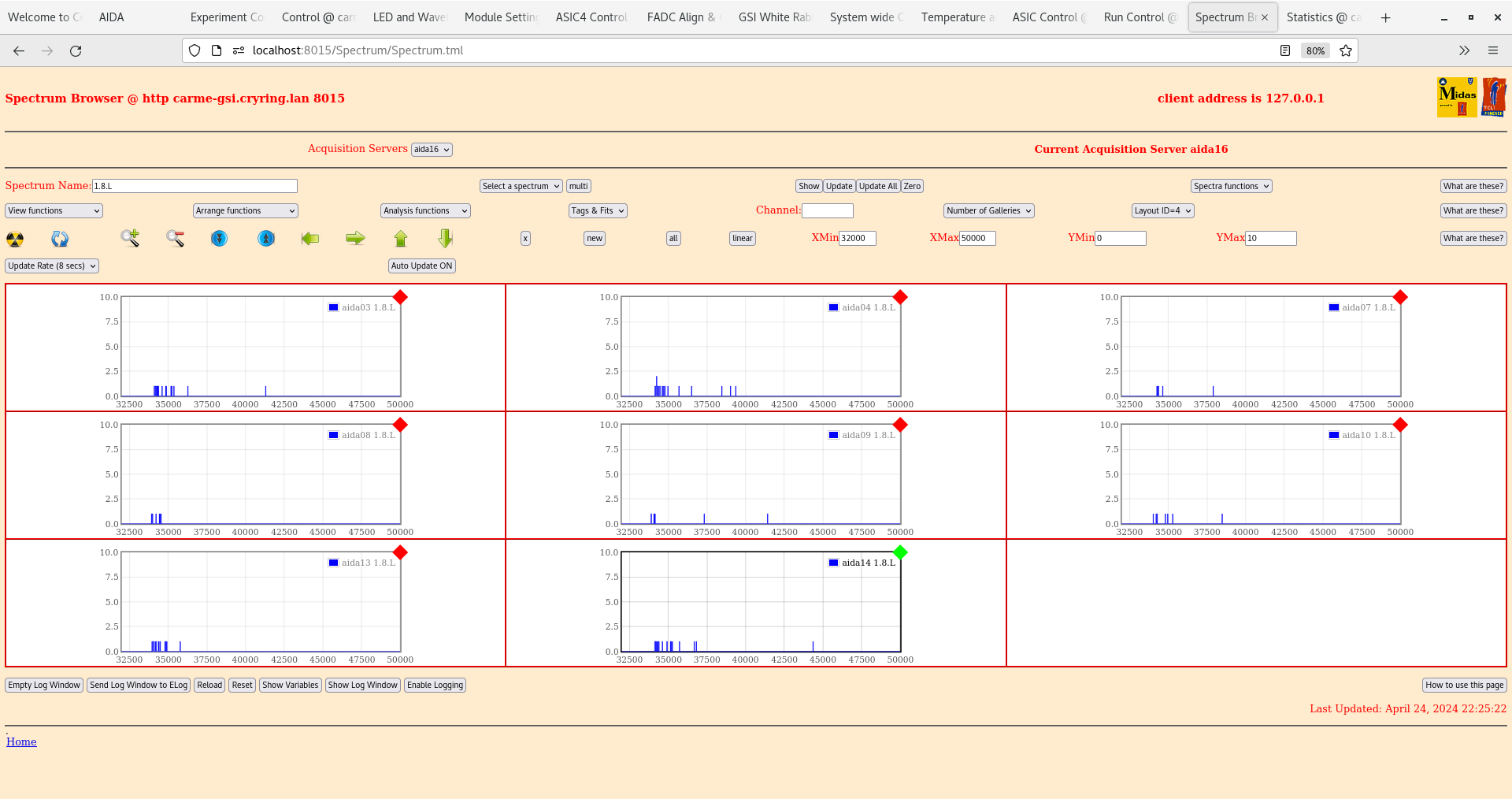

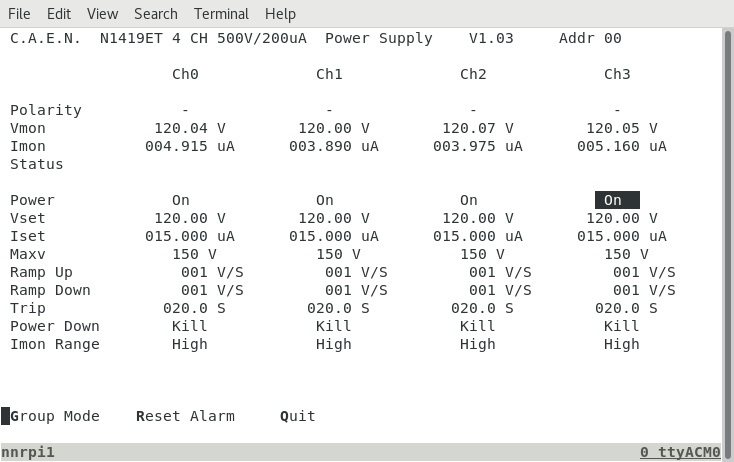

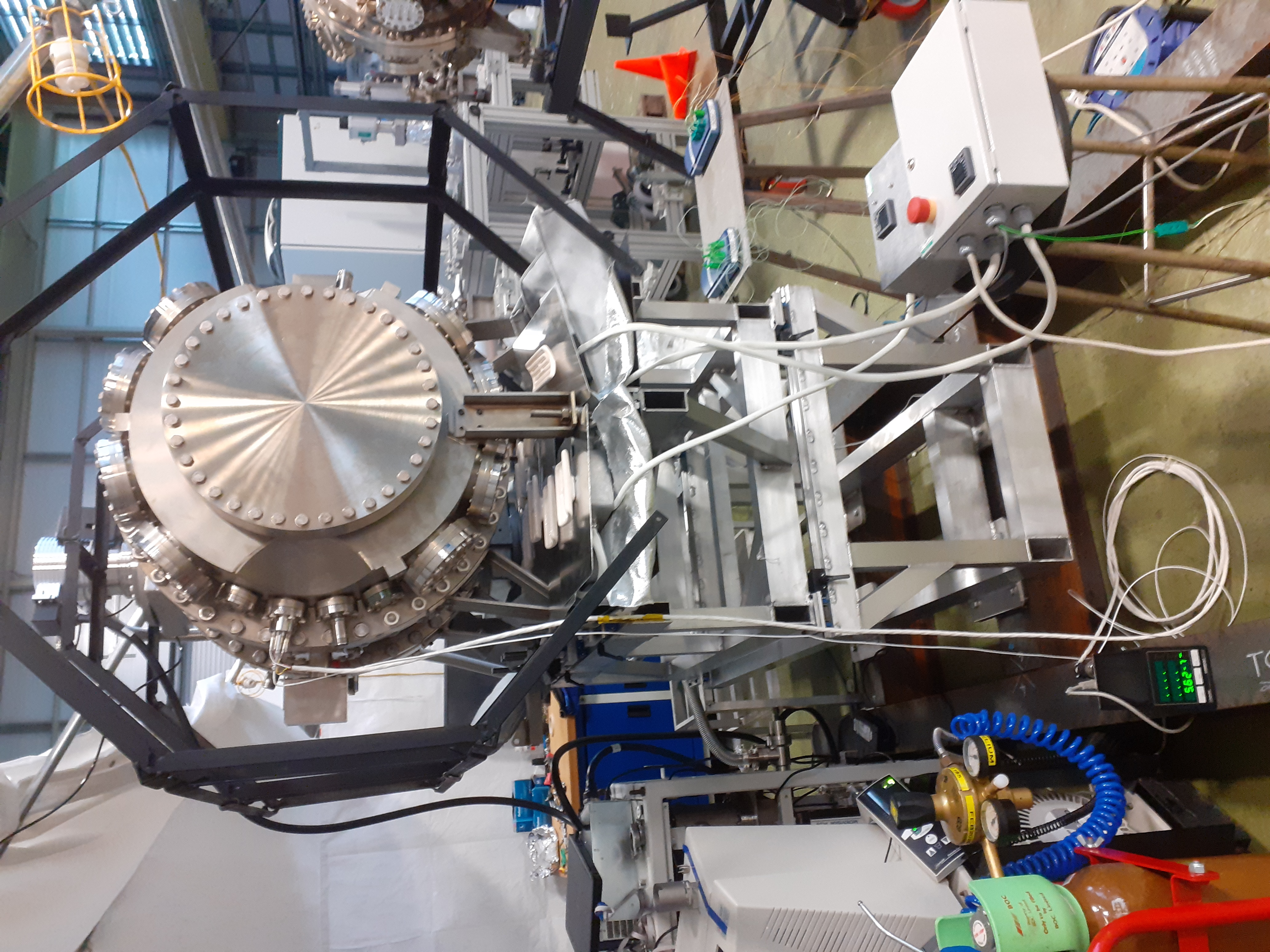

TD | Wednesday 24 April |

Replace AIDA ASIC mezzanine of aida01

13.43 DSSSD bias & leakage current OK - attachment 1

ambient temperature 16.5 deg C

FEE64 temperatures OK - attachment 2

All system wide checks OK

WR timestamps OK - attachment 3

ADC data item stats OK - attachment 4

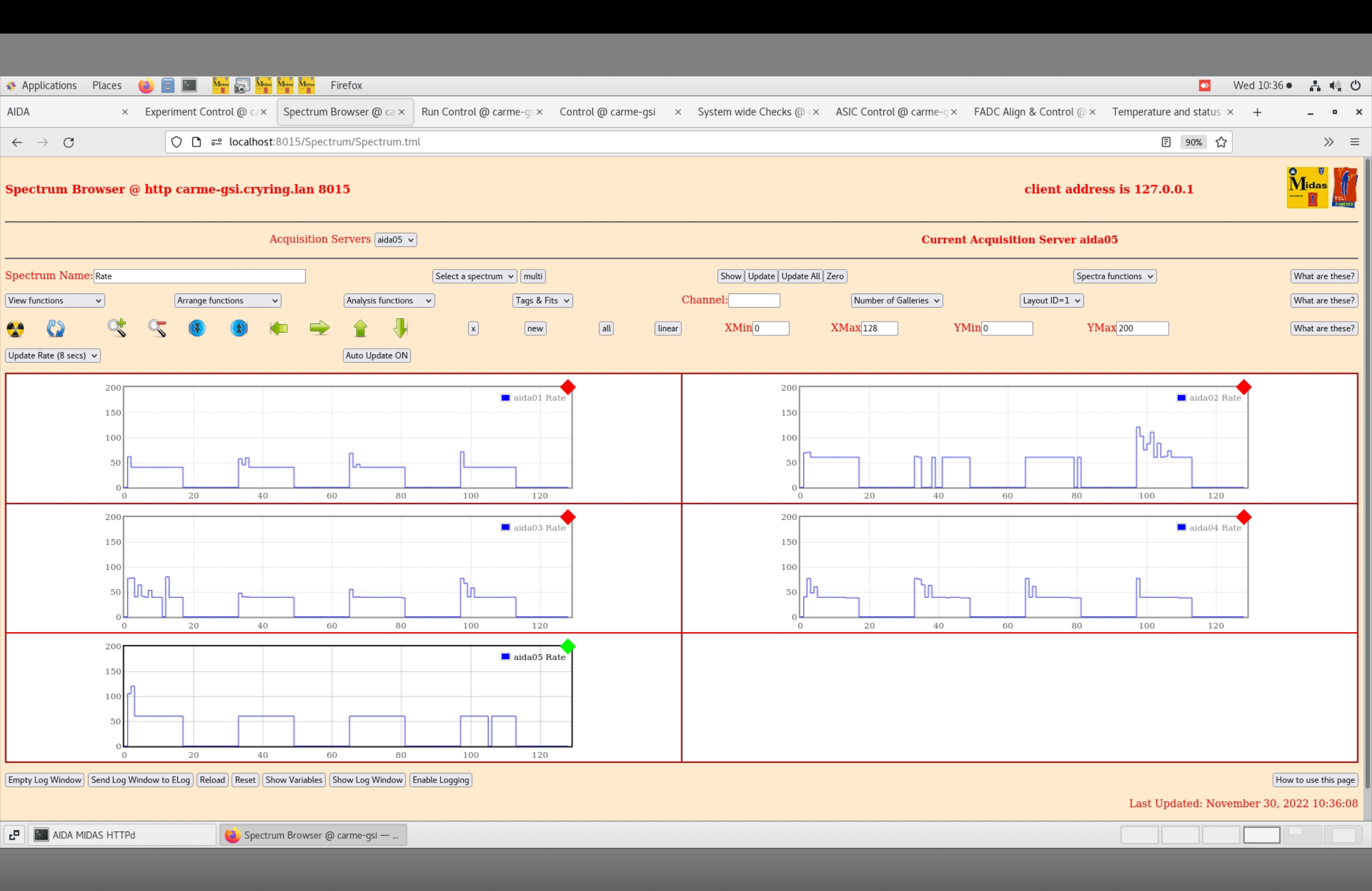

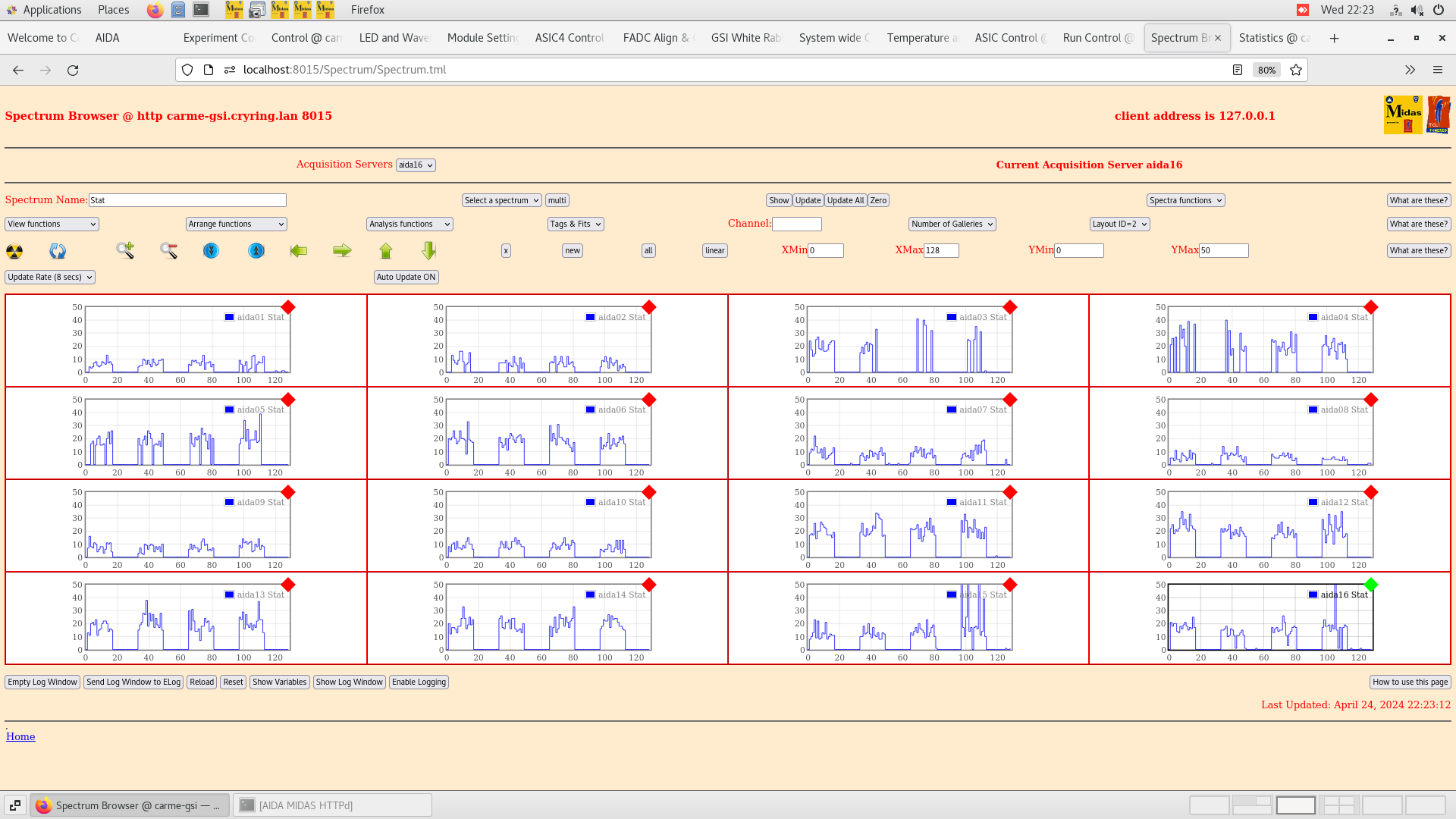

per FEE64 Rate spectra - attachment 5

c. 10 strips (of 1024) not producing data

most missing strips are from aida05 - misaligned or damaged adaptor PCB?

per p+n FEE64 1.8.L spectra - attachment 6

aida01 pulser peak width 75 ch FWHM

common x/y scale => peak height proxy for peak width

per n+n FEE64 1.8.L spectra - attachment 7

aida01 pulser peak width 70 ch FWHM

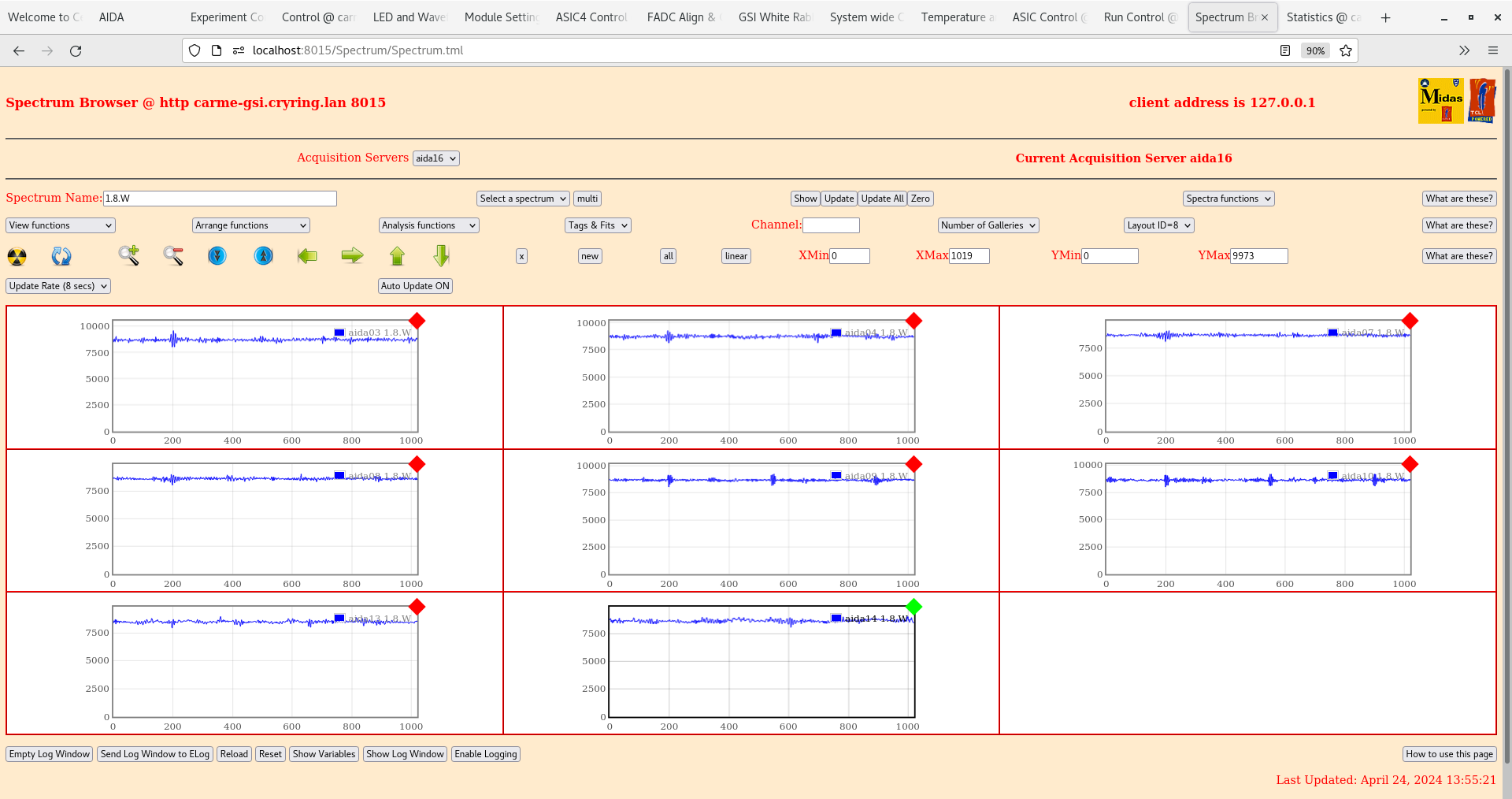

per FEE64 1.8.W spectra - 20us FSR - attachments 8-11

Summary

All FEE64s appear to be working (except aida05 which has c. 8 missing channels) with pulser - which

validates the FEE64, ASICs and adaptor PCB.

Electronic noise c. 50keV FWHM for aida01 & aida03 - other FEE64s better/worse.

Preamplifier noise appears to be similar for all FEE64s which may suggest an issue with the test signal chain

Note

1) e-target is starting up

2) have identified some instances of poor CARME cable management/routing see https://elog.ph.ed.ac.uk/CARME/545

EG&G Ortec 448 Pulser

Amplitude 50,000

Normalise 5.00

x5 attenuator IN

t_r 100ns

tau_d 50us

Polarity +

Frequency relay line (50Hz)

Cooknell SA1 Summing Amplifier

inverted output to test - daisy chain

Current ASIC settings saved to 2024Apr24-14.14.03

14.48 Pulser OFF

All histograms & stats zero'd

LEC slow comparator 0x64 -> 0xff

HEC fast comparator 0x2 -> 0x5

background alpha run to validate signal path from DSSSD to FEE64 adaptor PCB

22.18 Start Merger & TapeServer - attachments 12-14

DSSSD bias & leakage current OK - attachment 21

ambient temperature 16.0 deg C

FEE64 temperatures OK - attachment 15

WR timestamps OK - attachment 16

ADC data item stats OK - attachment 17

per FEE64 Rate spectra - attachment 18

per p+n FEE64 1.8.L spectra - attachments 19-20 |

| Attachment 1: Screenshot_from_2024-04-24_13-43-29.png

|

|

| Attachment 2: Screenshot_from_2024-04-24_13-44-02.png

|

|

| Attachment 3: Screenshot_from_2024-04-24_13-45-01.png

|

|

| Attachment 4: Screenshot_from_2024-04-24_13-45-28.png

|

|

| Attachment 5: Screenshot_from_2024-04-24_13-45-46.png

|

|

| Attachment 6: Screenshot_from_2024-04-24_13-47-59.png

|

|

| Attachment 7: Screenshot_from_2024-04-24_13-52-50.png

|

|

| Attachment 8: Screenshot_from_2024-04-24_13-55-02.png

|

|

| Attachment 9: Screenshot_from_2024-04-24_13-55-32.png

|

|

| Attachment 10: Screenshot_from_2024-04-24_13-56-48.png

|

|

| Attachment 11: Screenshot_from_2024-04-24_13-55-59.png

|

|

| Attachment 12: Screenshot_from_2024-04-24_22-19-55.png

|

|

| Attachment 13: Screenshot_from_2024-04-24_22-20-16.png

|

|

| Attachment 14: Screenshot_from_2024-04-24_22-20-30.png

|

|

| Attachment 15: Screenshot_from_2024-04-24_22-21-58.png

|

|

| Attachment 16: Screenshot_from_2024-04-24_22-22-22.png

|

|

| Attachment 17: Screenshot_from_2024-04-24_22-22-57.png

|

|

| Attachment 18: Screenshot_from_2024-04-24_22-23-27.png

|

|

| Attachment 19: Screenshot_from_2024-04-24_22-24-37.png

|

|

| Attachment 20: Screenshot_from_2024-04-24_22-25-30.png

|

|

| Attachment 21: Screenshot_from_2024-04-24_22-27-58.png

|

|

|

|

19

|

Wed Sep 23 13:34:32 2020 |

JM, TD | Wednesday 23 September |

Connected Leybold Ionivac IE514 to Leybold Combivac CM52 Vacuum Gauge Controller

Rear panel - power ON

POST checks OK

Change parameters by

select PARA

select <-> to display Sen

select PARA to display S-on

select <-> to display HAnd

select PARA and hold for 7s

select CH to select CH3

select -> hold for 2s

With CARME gate valve closed for c. 24h CARME chamber pressure is 6.43e-5mbar @ 13.34, 6.52e-5mbar @ 14.15

15.45 CARME Leybold turbo restarted

16.06 1.58e-6mbar, 3.5e-5mbar (RGA station), leak rate 3.6e-10 mbar.l/s

16.27 9.44e-7mbar, 3.3e-5mbar (RGA station), leak rate 3.6e-10 mbar.l/s

16.39 7.67e-7mbar

17.00 5.85e-7mbar, 2.5e-5mbar (RGA station), leak rate 2.60e-10 mbar.l/s

17.20 4.83-7mbar, 2.3e-5mbar (RGA station), leak rate 2.17e-10 mbar.l/s

Baking octagon moved into position along with the bottom insulation and heaters

|

| Attachment 1: 20200923_170441.jpg

|

|

| Attachment 2: 20200923_170455.jpg

|

|

| Attachment 3: 20200923_170415.jpg

|

|

| Attachment 4: 20200923_161415.jpg

|

|

| Attachment 5: 20200923_161402.jpg

|

|

|

|

258

|

Wed Feb 23 18:58:12 2022 |

TD CN | Wednesday 23 February 15.00-23.00 shift |

Assorted screenshots of the CARME, CRYRING and gas jet target control systems in operation

Attachment 1 - detector motion controls

Attachment 2 - gas jet target pressures (blue proxy for target density, red proxy for gas load to CRYRING)

Attachment 3 - Schottky probe monitor of beam

Attachment 4 - CRYRING controls monitor

Attachment 5 - CRYRING vacuum pressures

Attachment 6 - CRYRING beam position and profile monitor |

| Attachment 1: 20220223_195402.jpg

|

|

| Attachment 2: 20220223_195349.jpg

|

|

| Attachment 3: 20220223_195208.jpg

|

|

| Attachment 4: 20220223_195203.jpg

|

|

| Attachment 5: 20220223_195142.jpg

|

|

| Attachment 6: 20220223_195133.jpg

|

|

|

|

473

|

Wed Jan 17 19:15:47 2024 |

TD | Wednesday 17 January |

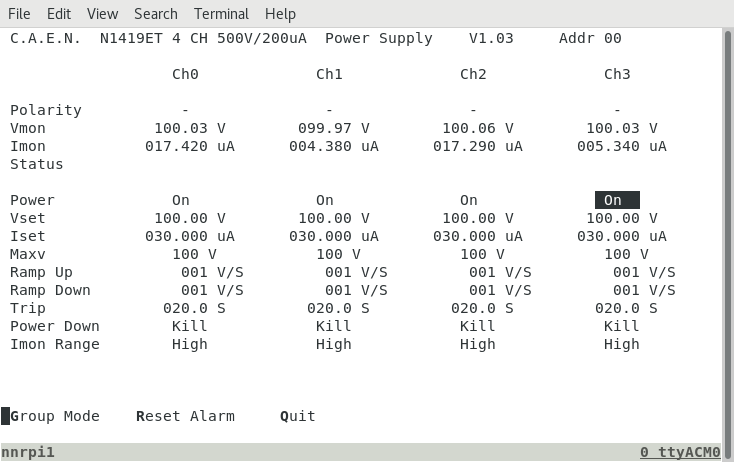

CAEN N1419ET remote control via carme-gsi and nnrpi1 - see https://elog.ph.ed.ac.uk/CARME/472

15x ( of 16x ) AIDA power cables available, labelled #1 - #15, installed

16x ( of 16x ) RJ45 Cat 6 network cables available, 15x labelled #1 - #15

16x ( of 16x ) HDMI cables available, labelled #1 - #16 |

|

|

40

|

Wed Aug 11 12:30:40 2021 |

TD RSS | Wednesday 11 August |

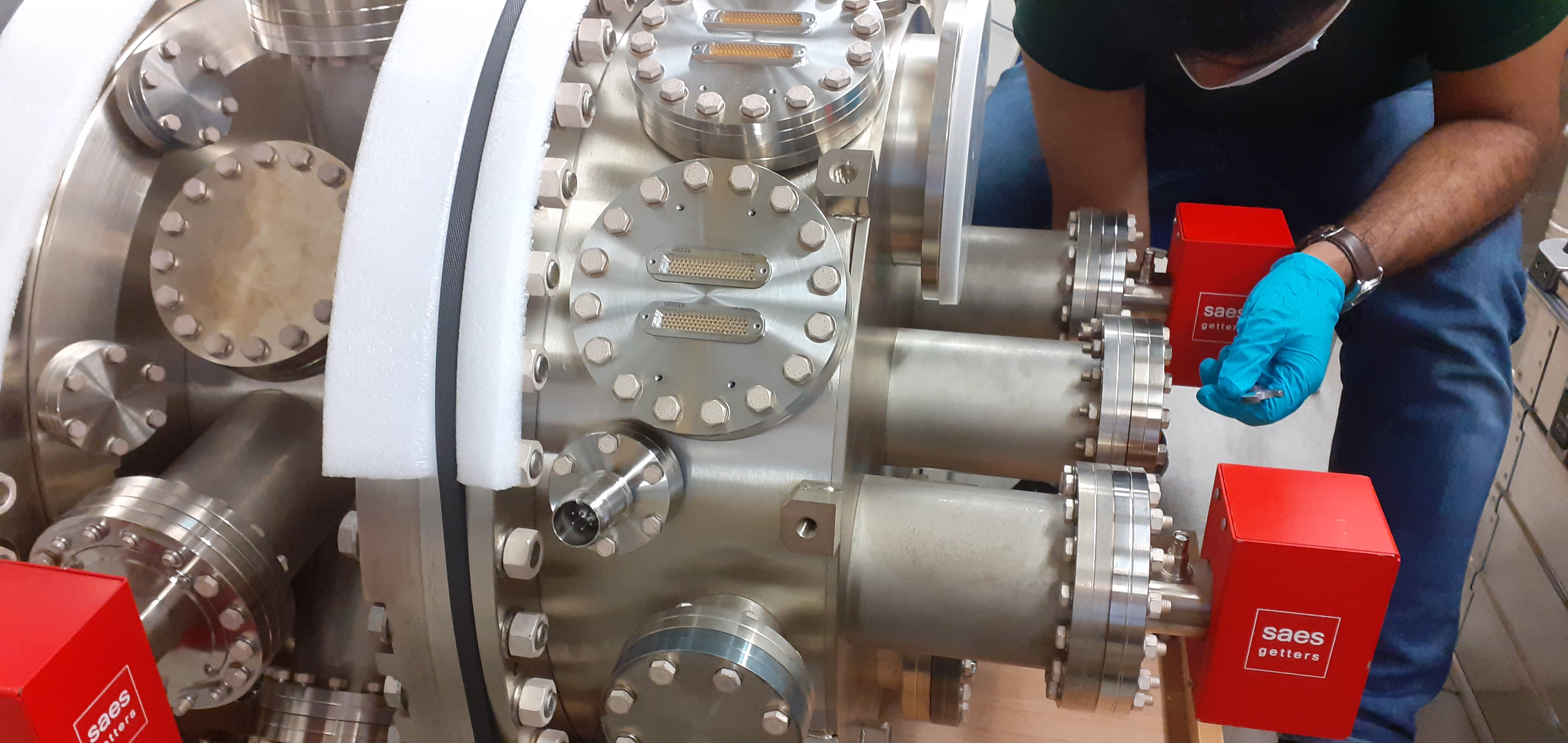

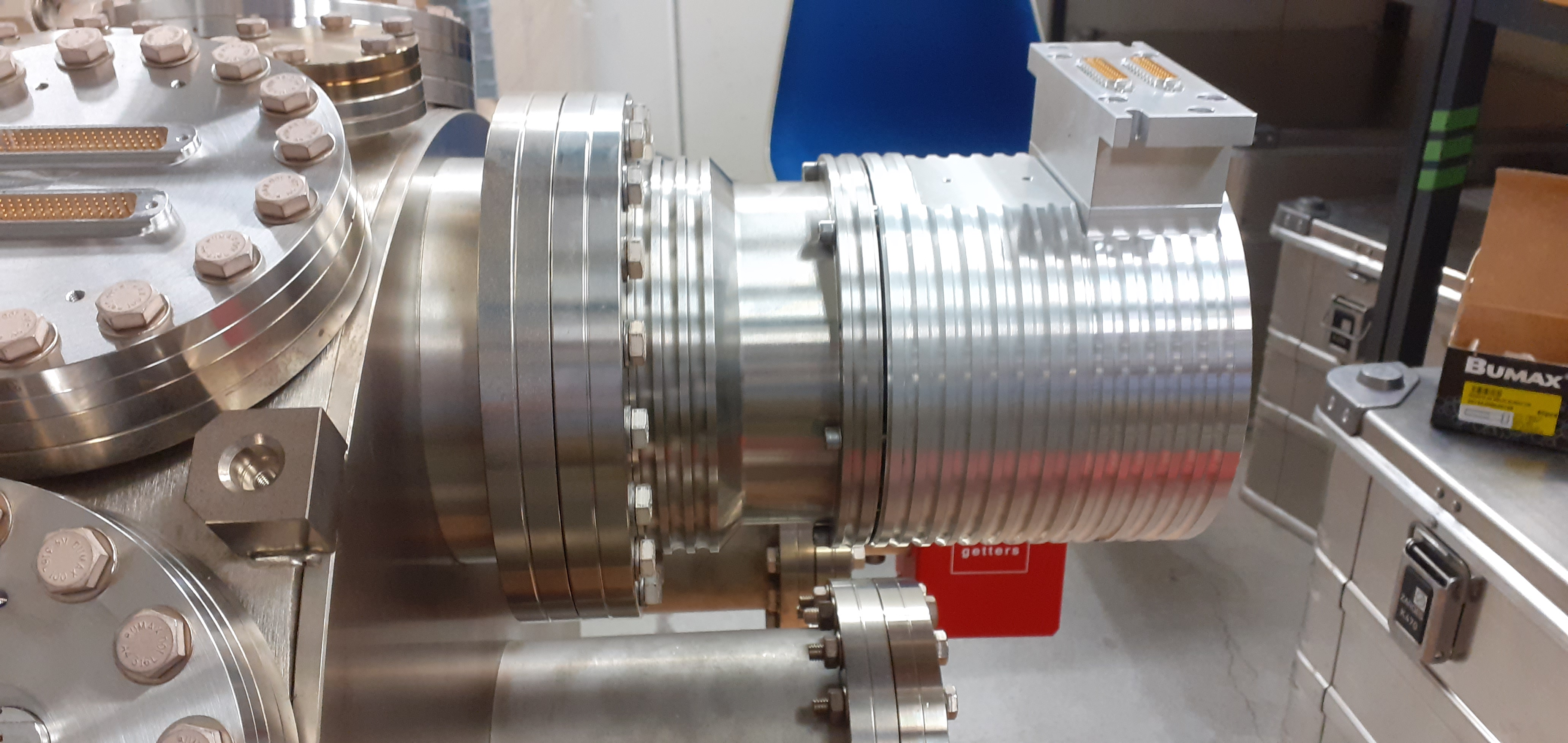

Attachments 1 & 2 - 2x SAES D-2000 re-fitted to side ports

all 4x SAES D-2000 now re-fitted to chamber

Will now fit 1x turbo and blank (currently) unused turbo port.

Attachments 3 & 4 - centre 2x78 pin micro-D feedthrough has some pins slightly bent - can probably be safely bent back into position

ALWAYS check 78-pin feedthroughs for bent/broken pins before fitting connectors/cabling

Attachment 5 - currently unused turbo port

Attachments 6 & 7 - turbo port from above and side

Attachment 8 - turbo + NW16/NW25 adaptor + NW25 s/s hose + scroll pump + turbo controller + CMS52 gauge controller

Note we currently do not have a vent valve or backing line vacuum gauge (both functions provided by leak detector at STFC DL). |

| Attachment 1: 20210811_132906.jpg

|

|

| Attachment 2: 20210811_132918.jpg

|

|

| Attachment 3: 20210811_132932.jpg

|

|

| Attachment 4: 20210811_132943.jpg

|

|

| Attachment 5: 20210811_142615.jpg

|

|

| Attachment 6: 20210811_142629.jpg

|

|

| Attachment 7: 20210811_142638.jpg

|

|

| Attachment 8: 20210811_153236.jpg

|

|