| ID |

Date |

Author |

Subject |

|

336

|

Mon Feb 28 23:54:02 2022 |

JM, EM | Current Status, Temperature cycle |

00:51

Temperature setpoint = 116 K

Detector position IN potentionmeter = 34.89mm

Rutherford rate fluctuates, consistently above 100 counts peak height

Merger OK

Data rate = 1600 kb/sec

Leakage current = 3.235 uA

Temperatures OK

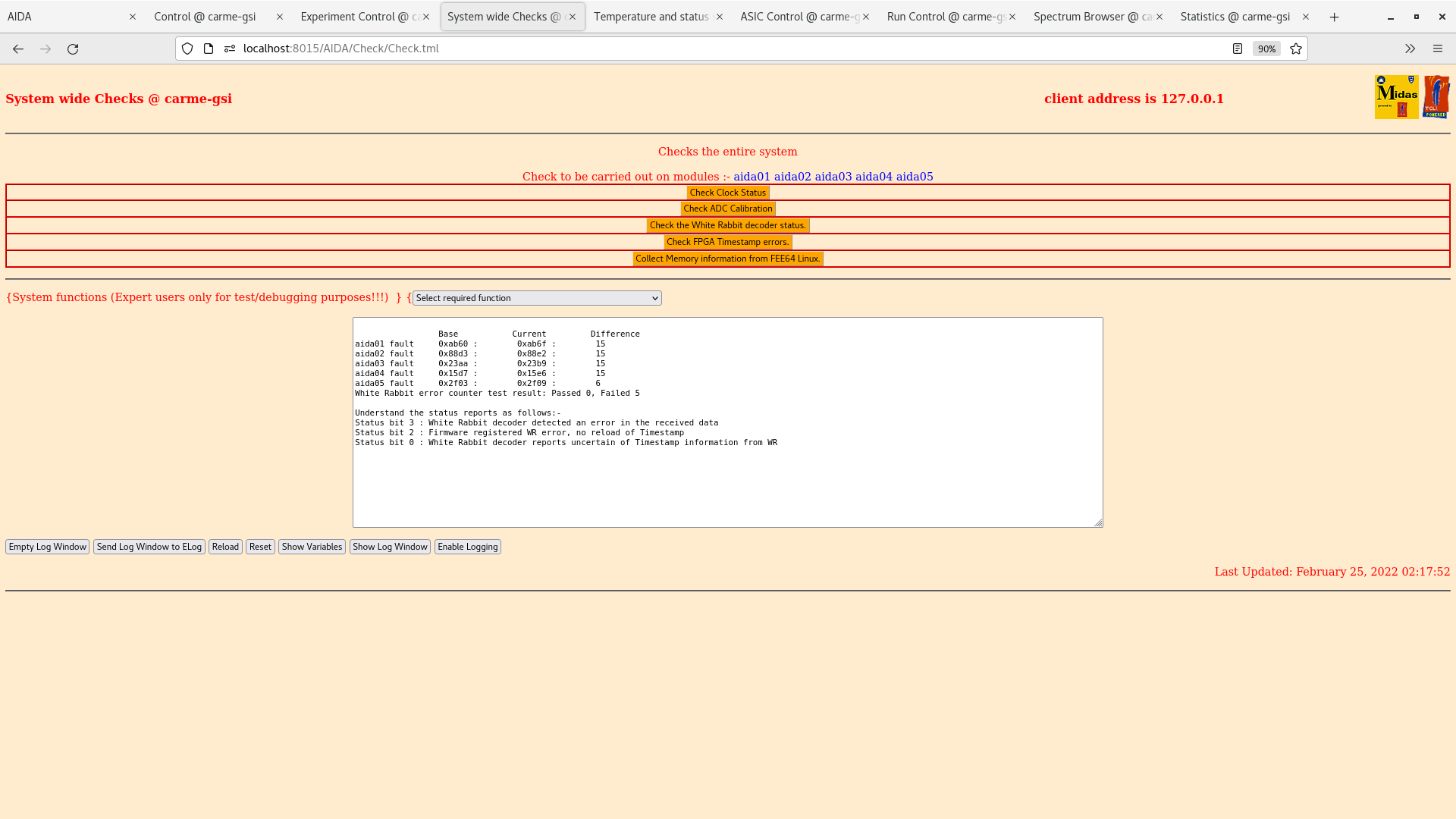

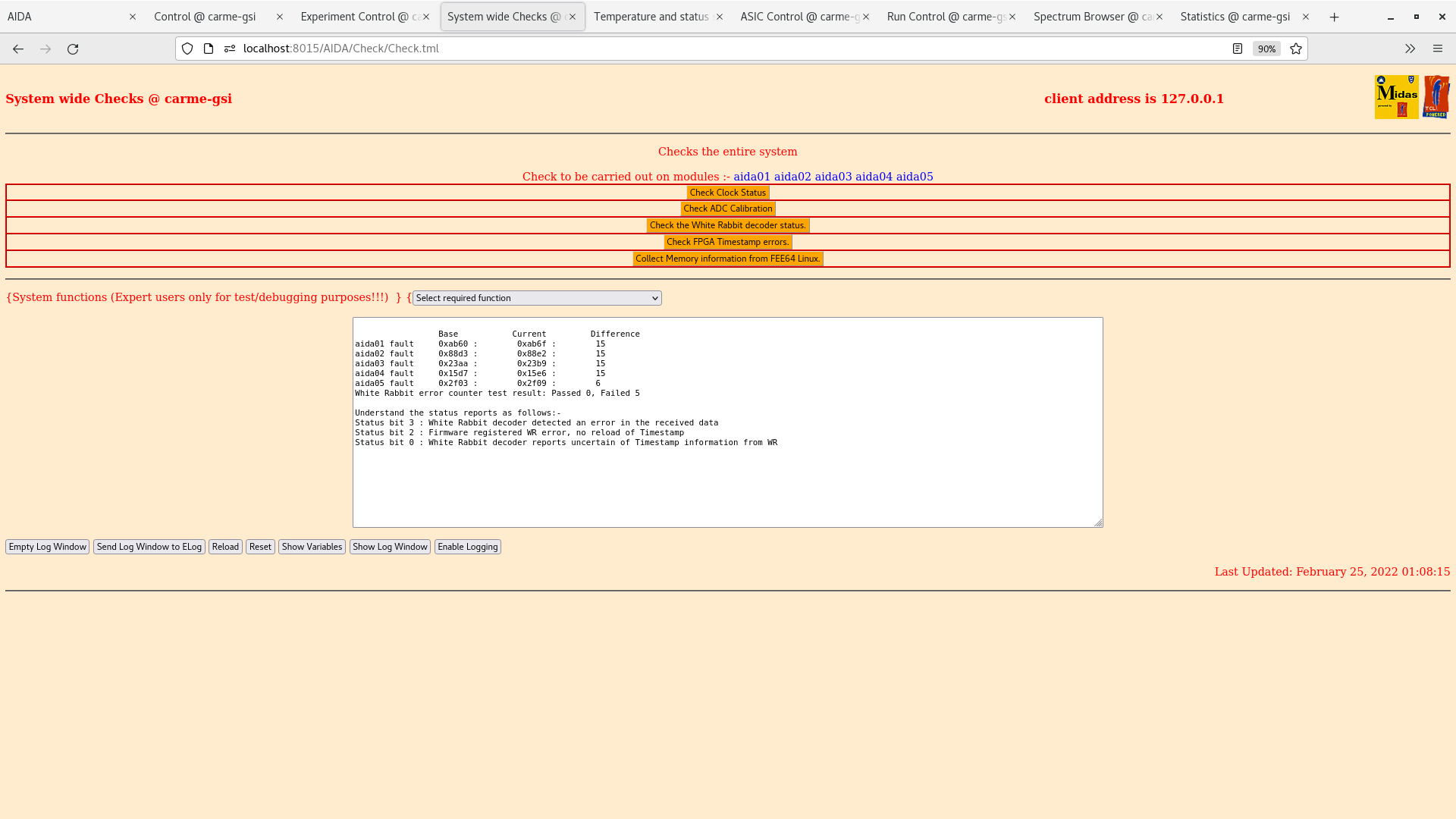

System checks OK - wr fails

Base Current Difference

aida01 fault 0xab60 : 0xab8c : 44

aida02 fault 0x88d3 : 0x88fe : 43

aida03 fault 0x23aa : 0x23d6 : 44

aida04 fault 0x15d7 : 0x1603 : 44

aida05 fault 0x2f03 : 0x2f0f : 12

White Rabbit error counter test result: Passed 0, Failed 5

Understand the status reports as follows:-

Status bit 3 : White Rabbit decoder detected an error in the received data

Status bit 2 : Firmware registered WR error, no reload of Timestamp

Status bit 0 : White Rabbit decoder reports uncertain of Timestamp information from WR

Avg ring pressure = 4.4 E-10 mbar

01:18

Rutherford rate showed sustained drop to below 10 counts peak level. E4 was also consistently down, fluctuating in the low -9 mbar range compared to -8 mbar range previously.

Temperature increased to 125 K

01:39

Completed increase to 125k, drop to 95k and back to 116k. Rate has improved somewhat, however is still lower than before. Will monitor and see if any further change in temperature helps.

01:48

E4 pressures and rutherford rate remain low ~40 counts peak height. Decreasing temperature in 1k steps to see if any improvement.

02:05

Rates still low at decreased temperature. Setting to 140 K for 15-20 mins and then bringing back down.

02:36

Temperature brought back down, optimum temperature appears to be 118 K. E4 ~ 3E-9 mbar and rutherford rate is back around 100 counts peak heught. |

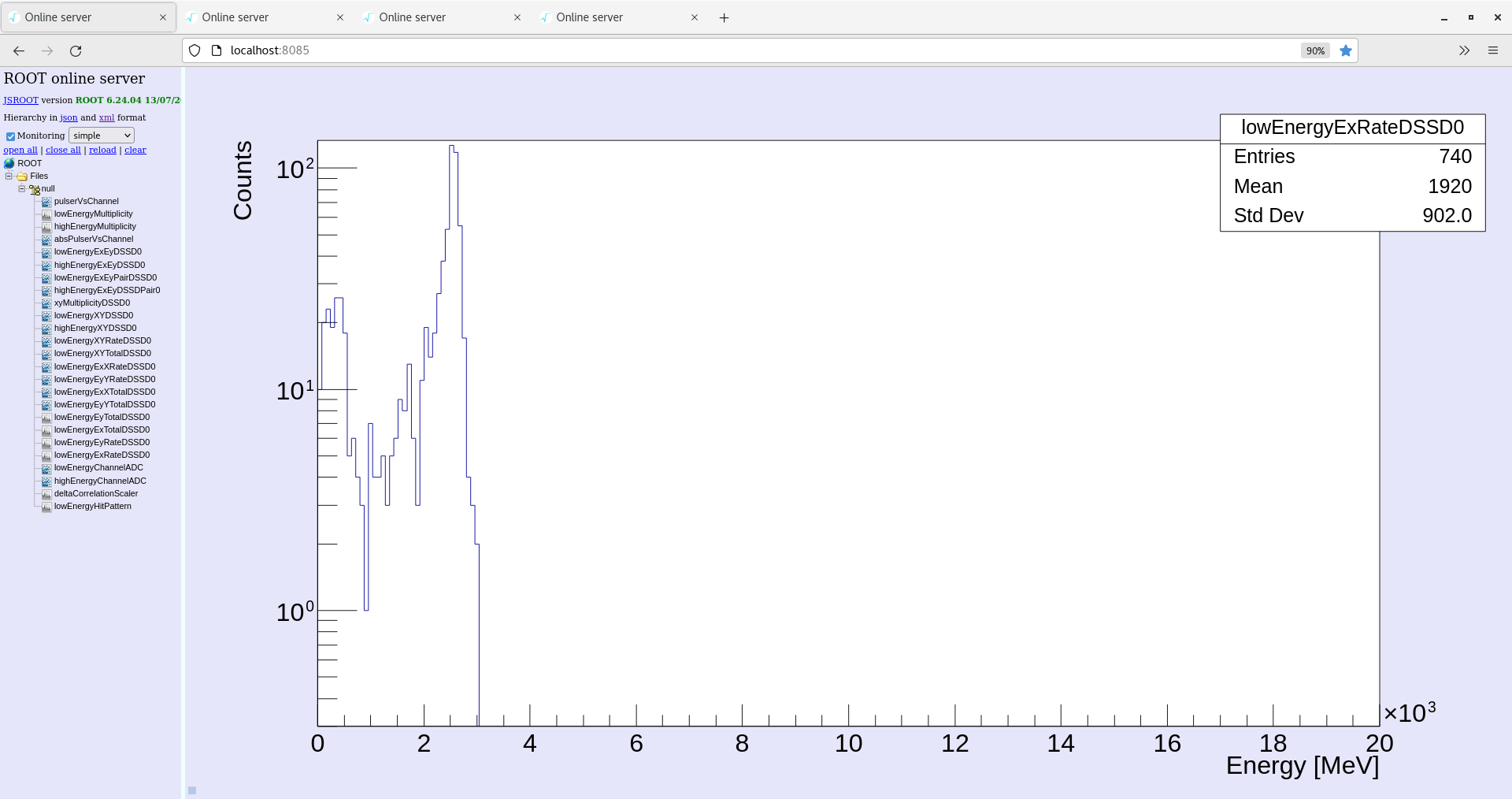

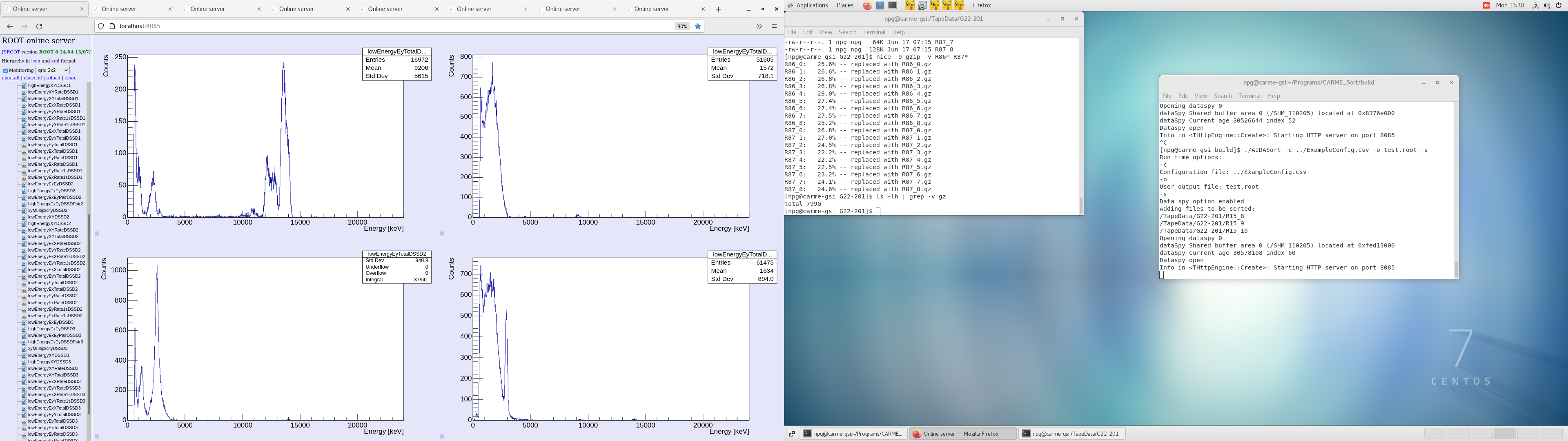

| Attachment 1: 2022-03-01_00-57-44-Exrate.png

|

|

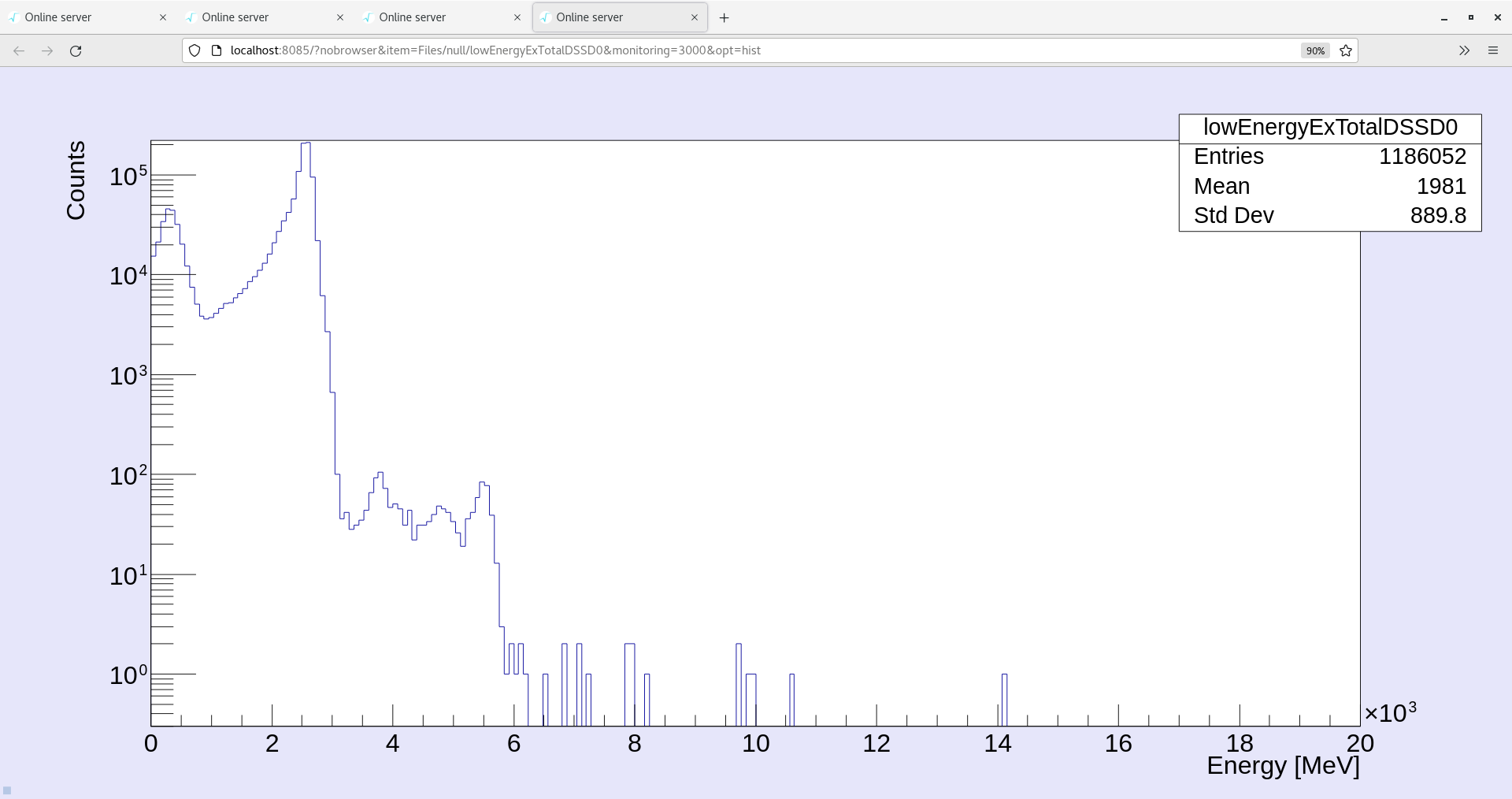

| Attachment 2: 2022-03-01_00-58-41-ExTotal.png

|

|

| Attachment 3: 2022-03-01_00-58-14-EyTotal.png

|

|

|

278

|

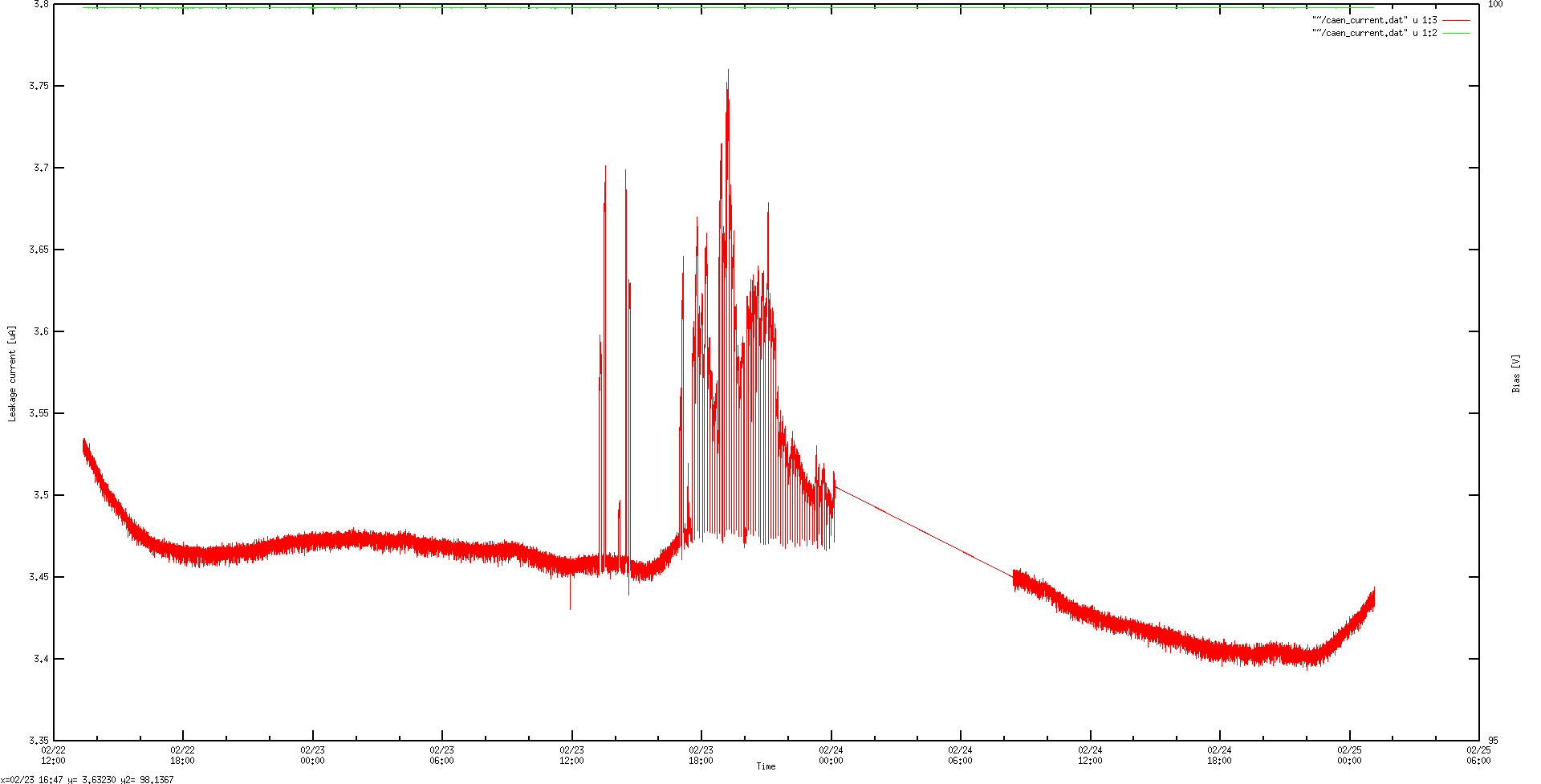

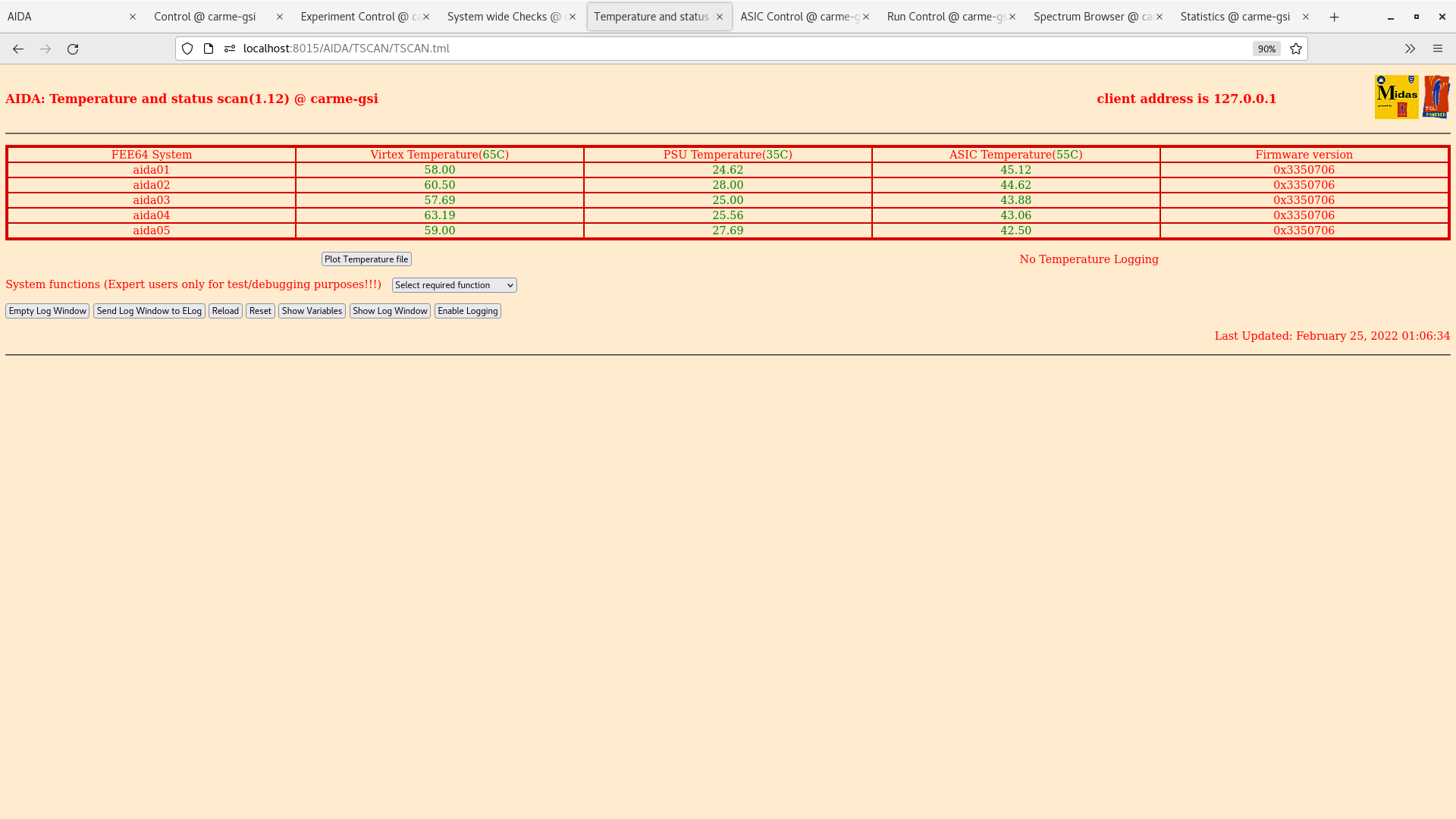

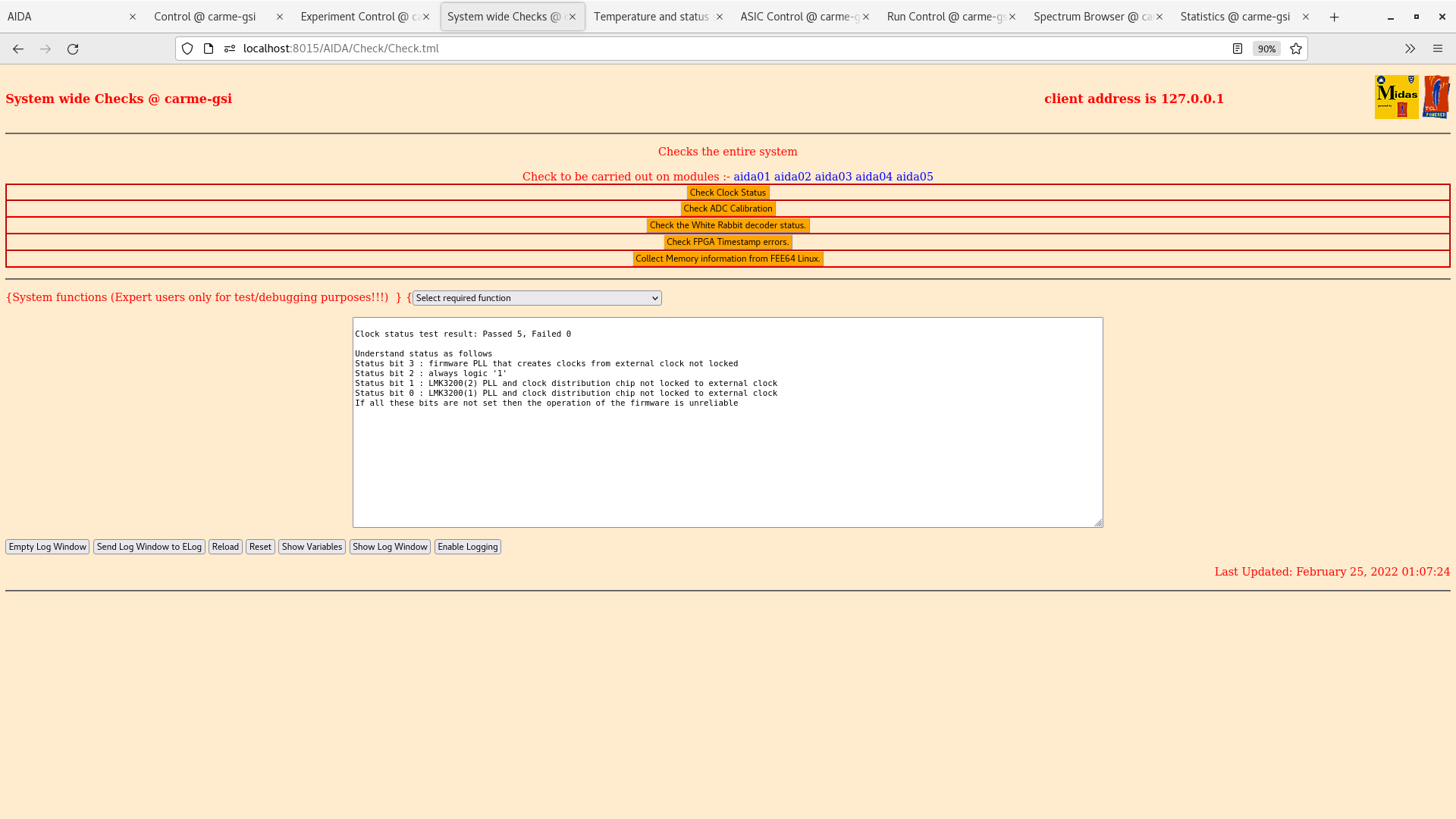

Fri Feb 25 06:28:12 2022 |

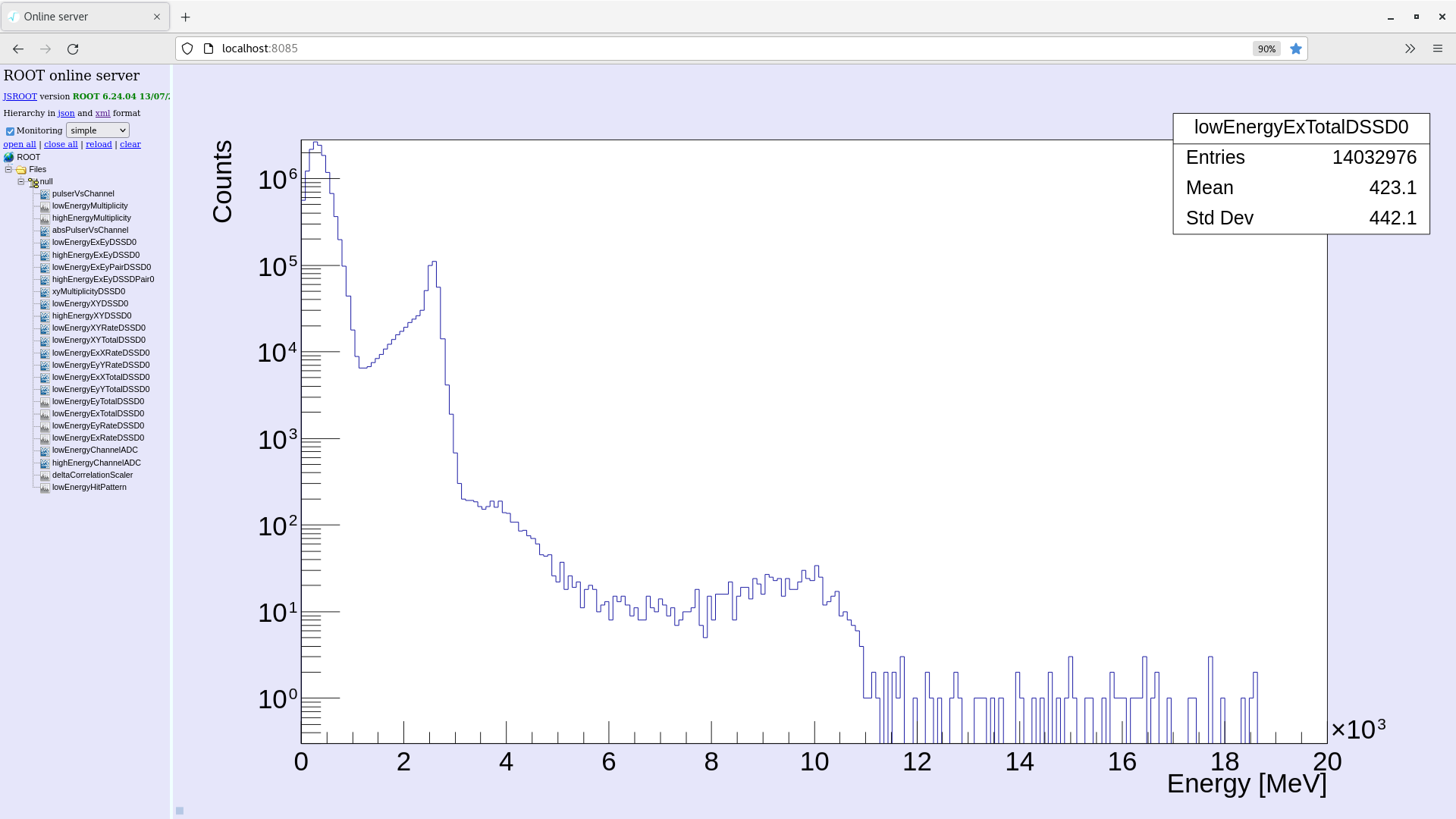

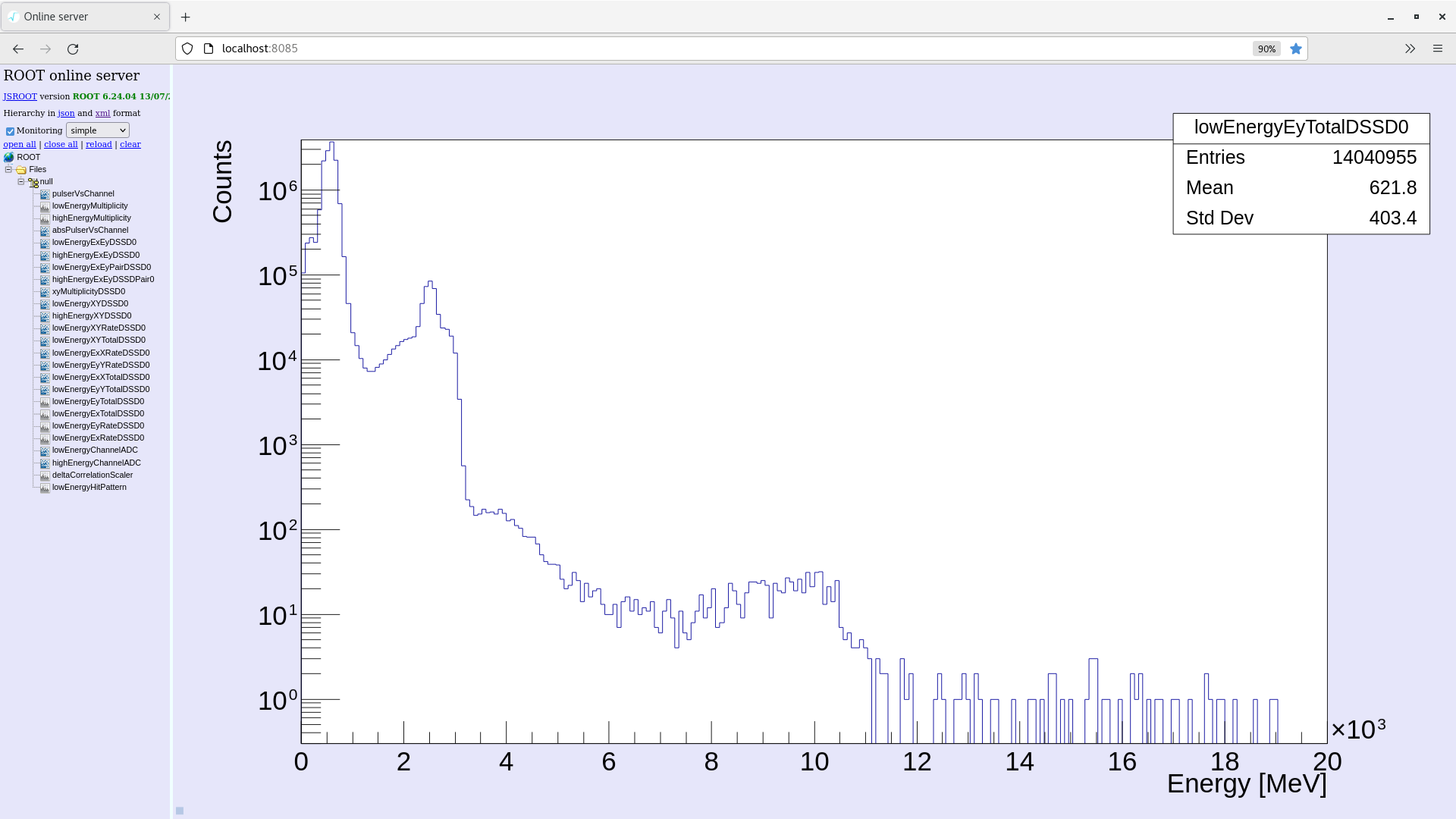

George, Esther | Current Status |

07:30

Some signals on the beam monitor, seems they are optimising it.

System Check OK

Temps OK

White Rabbit fail diff: 24

Leakage Current: 3.48uA

Pressures OK

Data rate ~1Mb/s |

| Attachment 1: 2022-02-25_07-33-44exRate.png

|

|

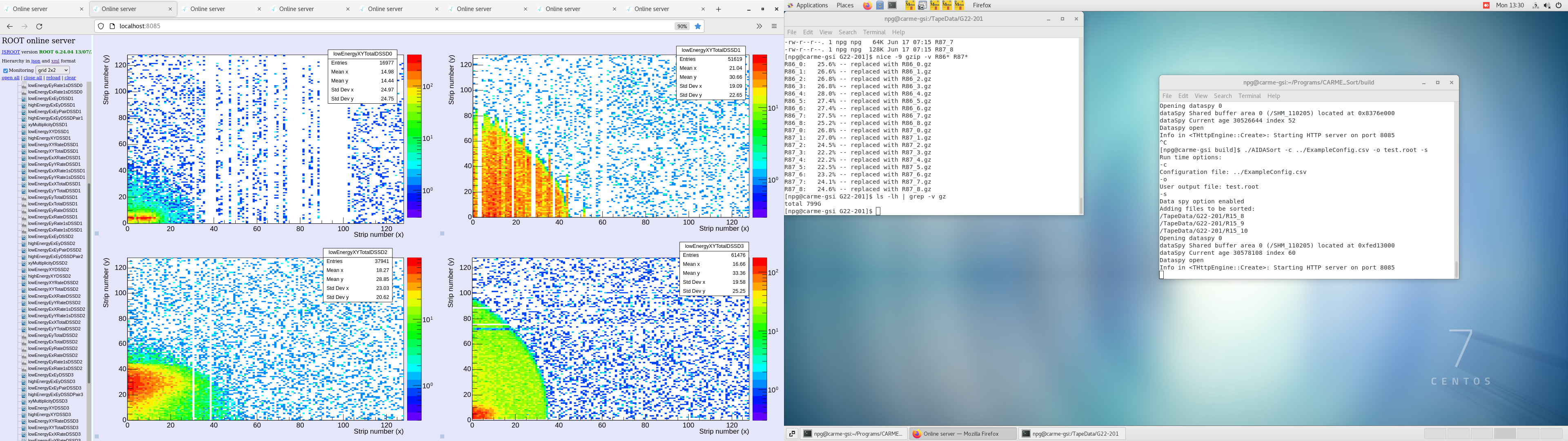

| Attachment 2: 2022-02-25_07-35-11xyTotal.png

|

|

|

315

|

Sun Feb 27 22:03:51 2022 |

JM, OF | Current Status |

23:00

Target Temperature setpoint 95 K

Current in the ring ~ 5e7 pps

Rutherford rate appears to fluctuate by 2 ordera of magnitude depending on target density. Rate currently ~10^2 counts per 20s. (attachmet 1) can vary to nothing (attachment 6). When consistently low will increase temperature

Effect of target density can be observed in beam current plots. (attachment 7). When rutherford rate is high, beam current tends to decrease over the shot. When the rate is low the current maintains a level throughout.

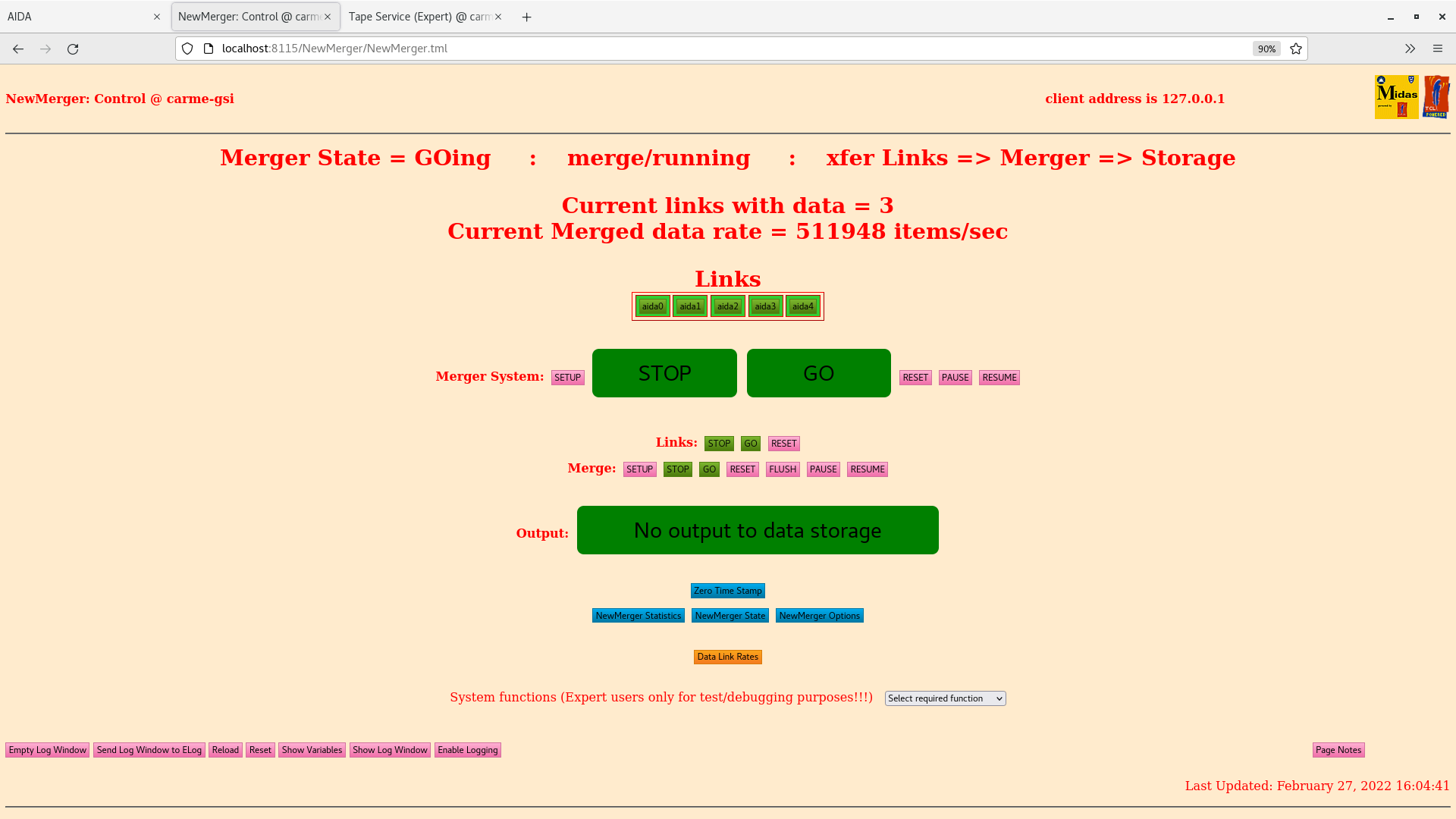

Merger OK

Data rate ~ 800 kb/sec. Current run 78

Leakage current ~3.24 uA

Temperatures OK

System Checks OK - white rabbit fail attached

23:36

Rutherford rate consistently low. Maximum rate was just below 10^2 counts, only lasted for one beam shot then low count rates < 10^1 counts.

Setpoint increase to 125 K.

Increase in pressure across the board in gasjet after increasing temperature which reduces fairly rapidly after 5 minutes. Current in E1 pump reduced from 2.7 A to 2.3 A at 125k.

Rate at 125K attachment 8. Appears stable.

23:49

Setpoint decrease to 115 K,

23:56

Temperature now stable at 115K. Rate has increased to ~10^2 counts per 20 secs and appears stable (no large fluctuations). Will keep at this level to see if it can be maintained for significant time period. |

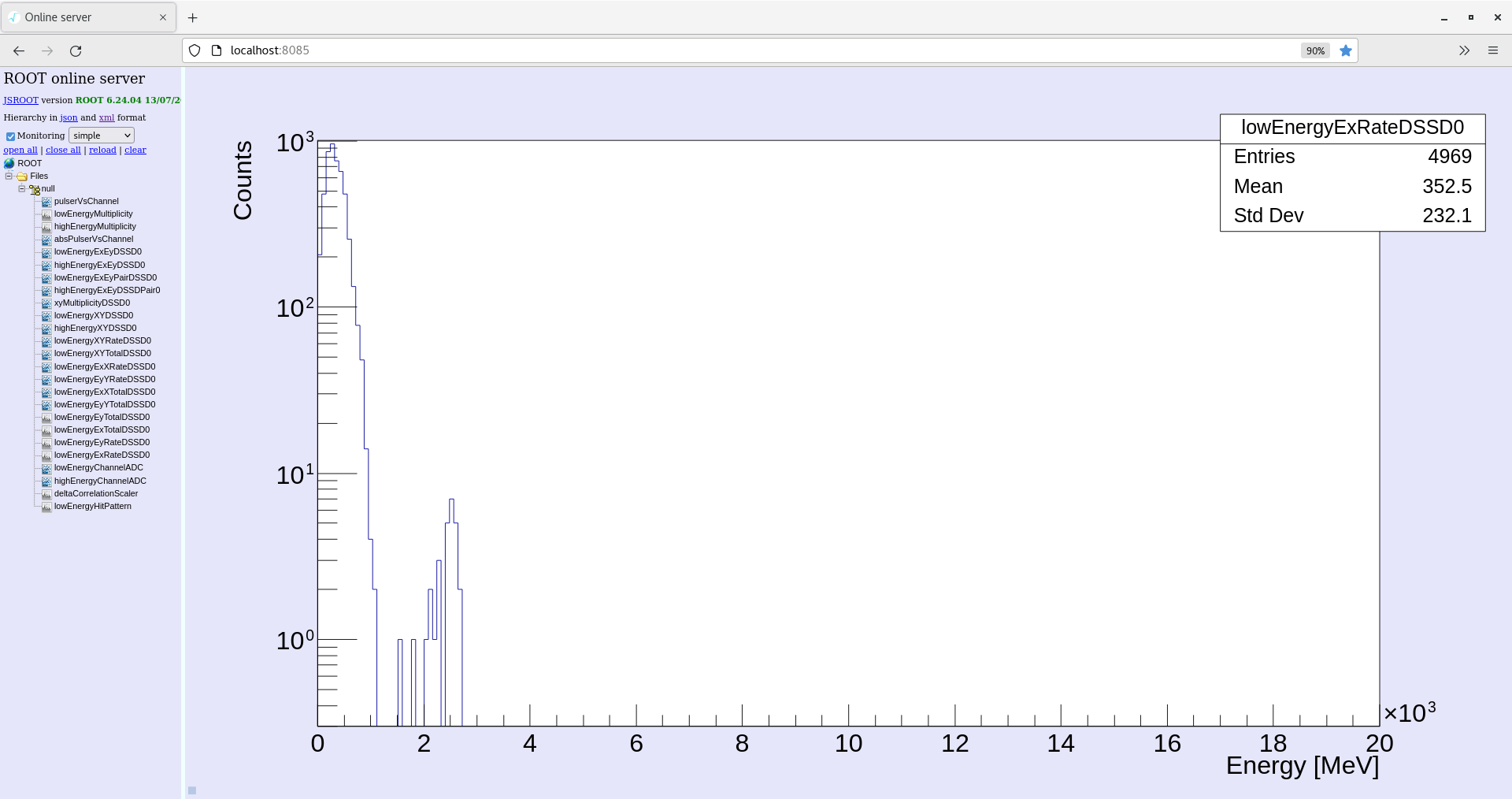

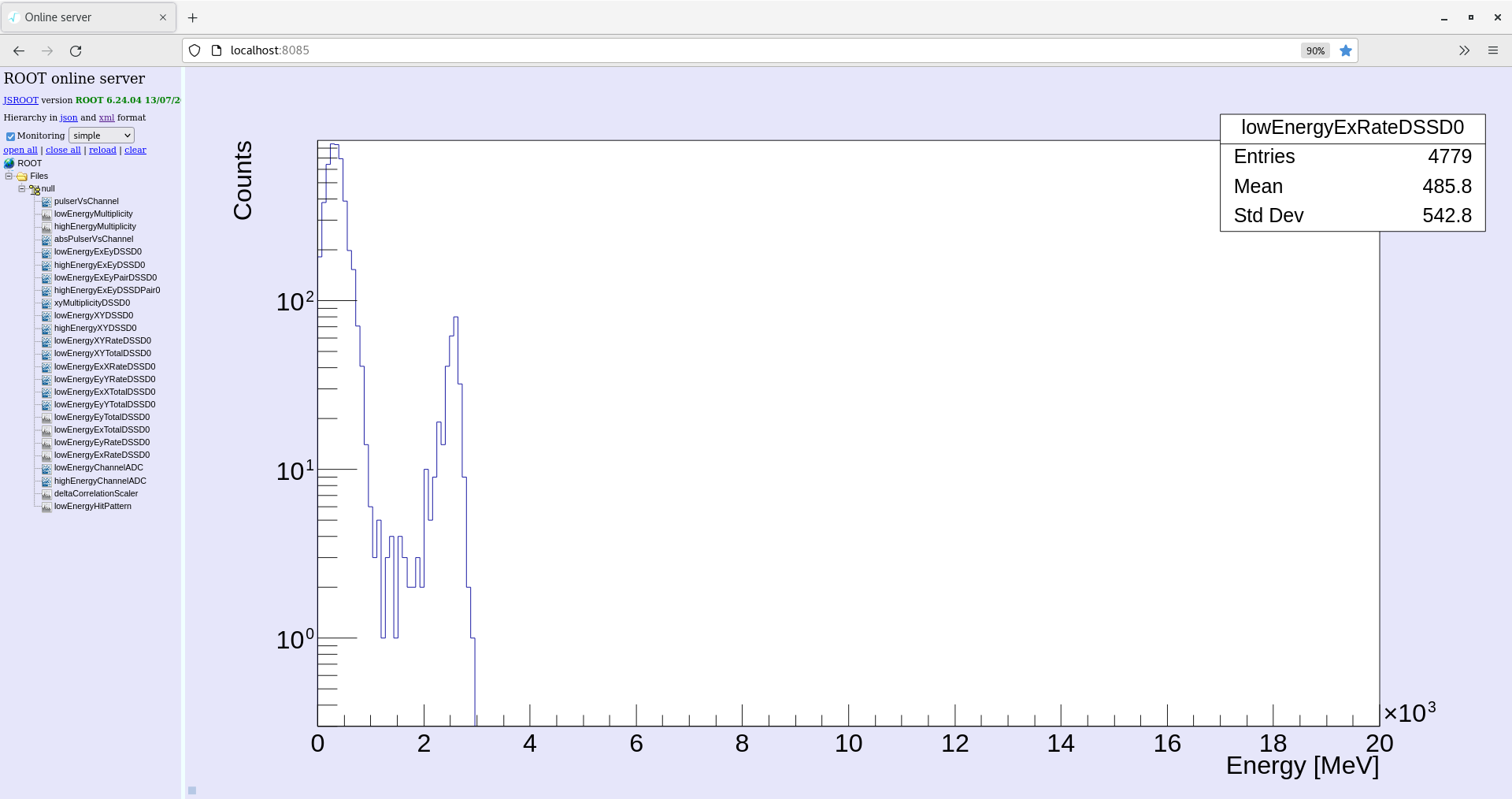

| Attachment 1: 2022-02-27_23-04-21-ExRate.png

|

|

| Attachment 2: 2022-02-27_23-09-55-white-rabbit.png

|

|

| Attachment 3: 2022-02-27_23-10-52-correlation8.png

|

|

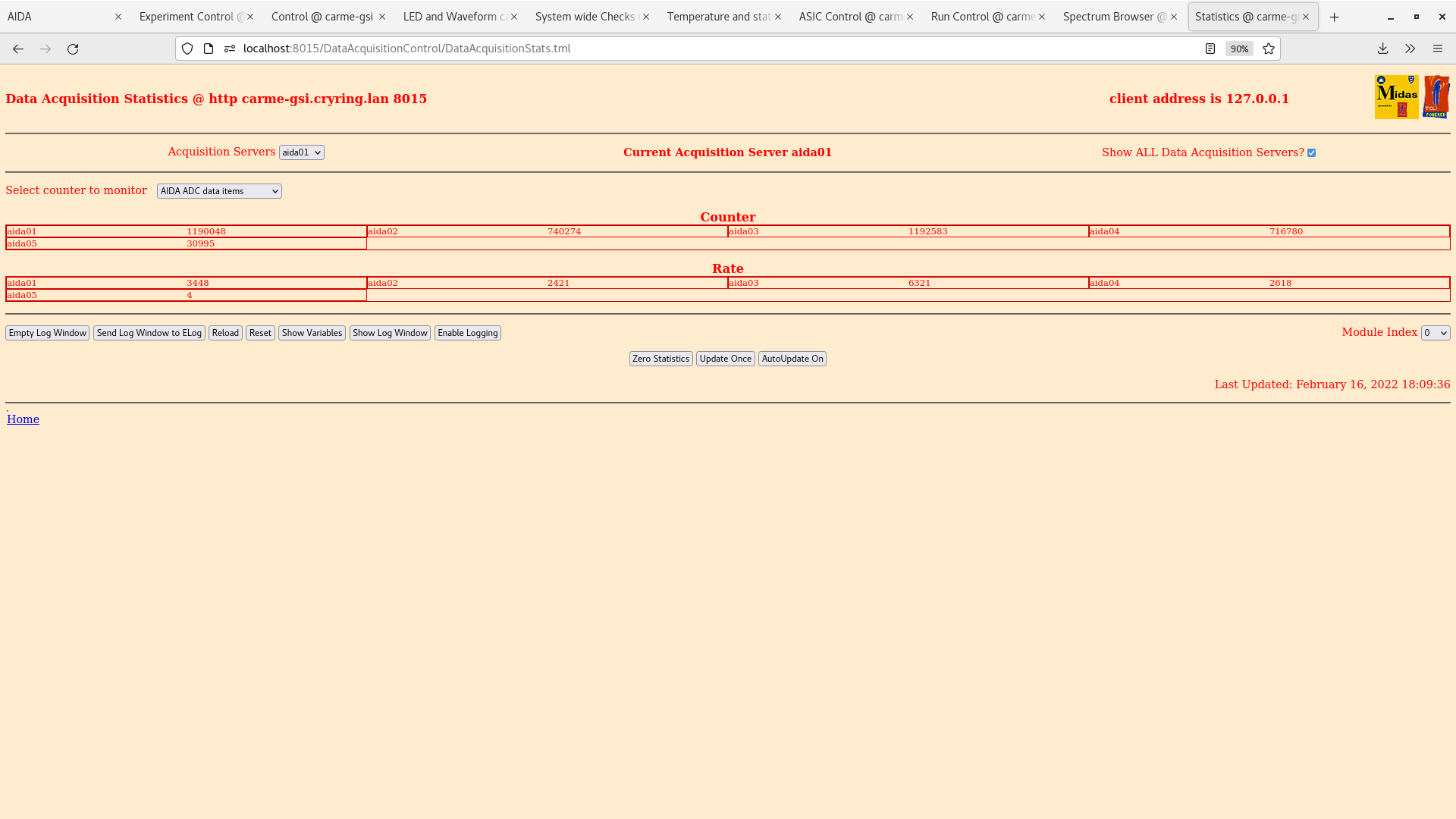

| Attachment 4: 2022-02-27_23-12-11-ADCitems.png

|

|

| Attachment 5: 2022-02-27_23-12-41-goodEvents.png

|

|

| Attachment 6: 2022-02-27_23-13-47-Rate.png

|

|

| Attachment 7: 20220227_231653.jpg

|

|

| Attachment 8: 2022-02-27_23-46-13-Rate125K_1.png

|

|

| Attachment 9: 2022-02-27_23-56-51-Rate115K.png

|

|

|

201

|

Wed Feb 16 21:27:31 2022 |

JM | Cryring signals, Pulser tests, Waveforms |

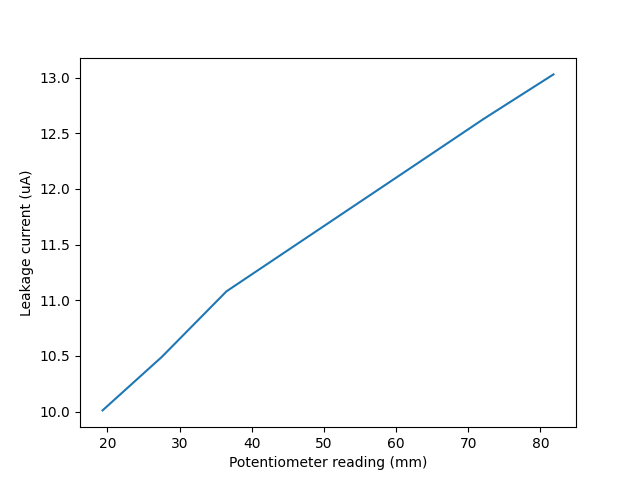

On 15/2/22 it was noted that the leakage current increases when the motors are moved IN. This is contary to tests conducted on 12/2/22 (elog 192) where no increase was observed.

16/2/22: Servo motor and pneumatic used to move in by different differences with leakage current observed to increase linearly with distance moved in, measured using the potentiometer. (attachment 10)

After each movement the pulser width was measured for each of aida1,2,3,4. No change observed for aida3,4 with pulser width ~220 channels. Pulser width decreased for aida1,2 when moved IN. (attachment 11)

Noise on aida 2,3,4 appeared low throughout tests. Aida1 has a large noise peak when in fully out position. When moved fully in, the noise peak disappears (attachments 1,2)

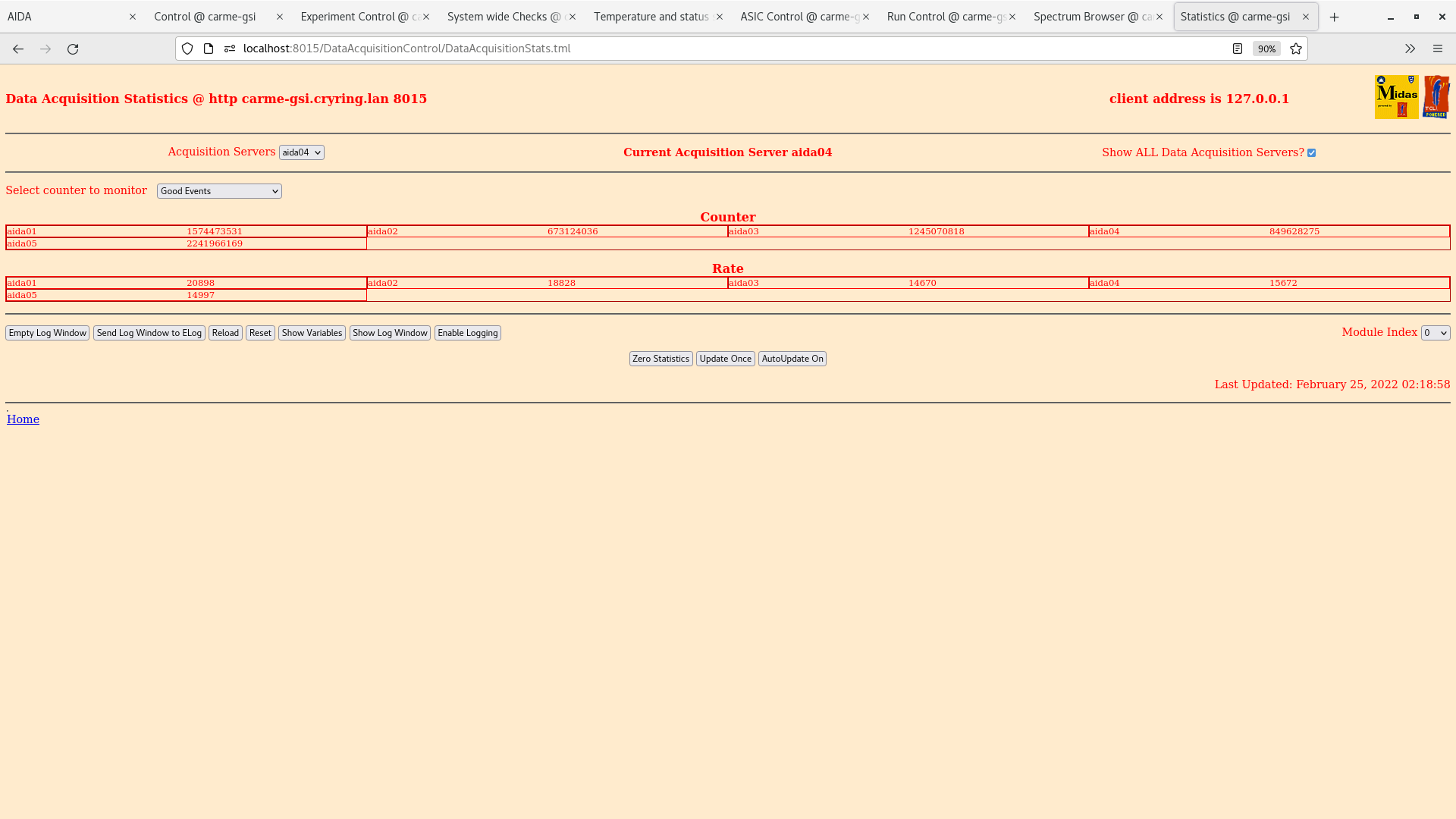

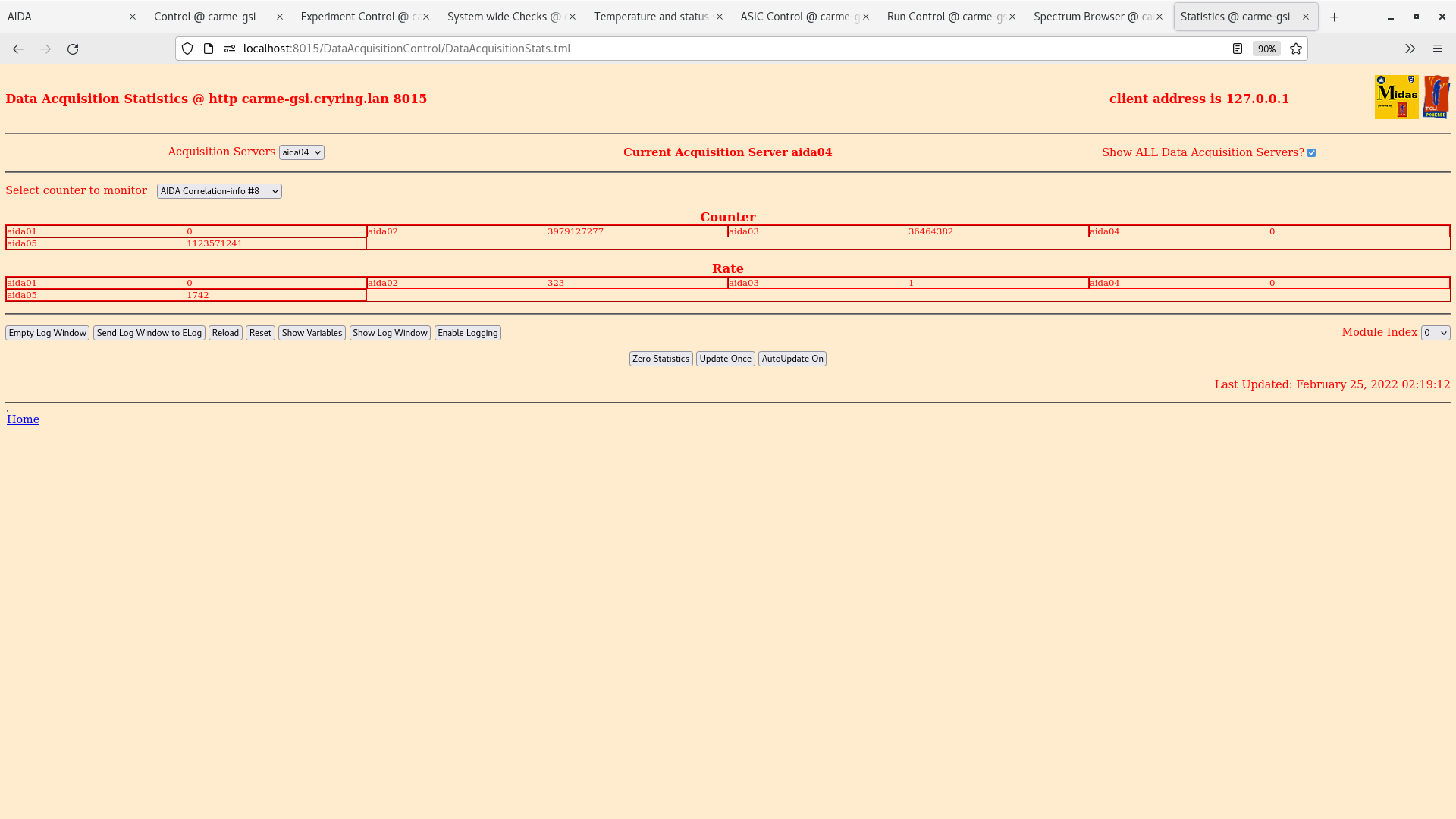

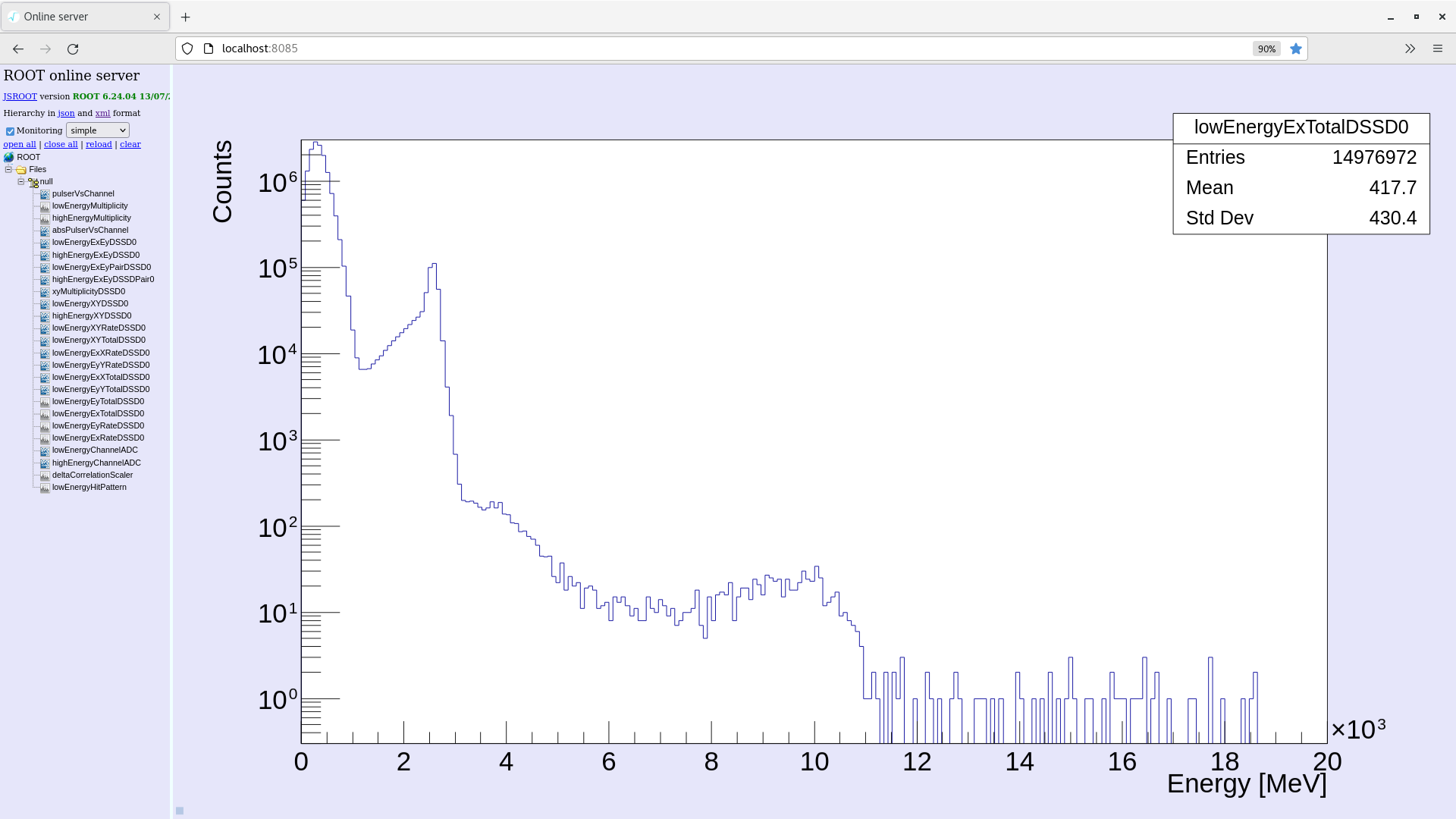

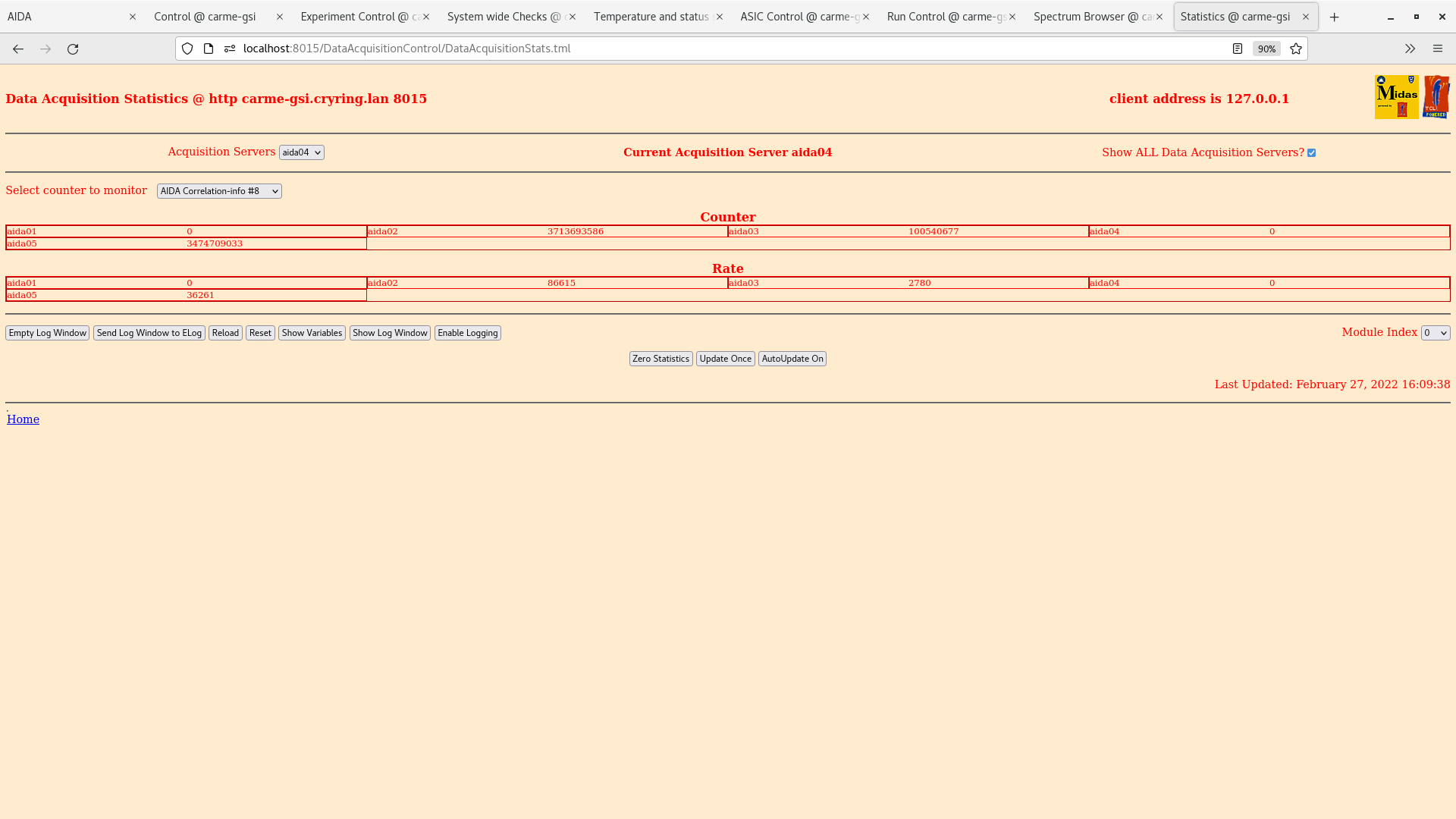

Cryring signals for ring RF, electron cooler voltage and schottky added to the motors signal and fed into mac b to be read in daq as aida correlation info #8 signal.

cryring bnc 13 - ring rf - aida5 ~ 500,000 rate

cryring bnc 14 - e cooler voltage - aida3 ~ 80 rate

cryring bnc 15 - shottky -aida2 ~2000 rate

cryring bnc 16 motors - aida1 ~3 rate

correlation info #8 appears to be added to the good events rate (attachments 4,5) ADC items (attachment 3)

Waveforms 1.8*W attached for 20us, 200us, 2ms, 20ms |

| Attachment 1: 2022-02-16_16-01-32aida1-2-1.8*L-fullyout.png

|

|

| Attachment 2: 2022-02-16_15-58-02aida1-2-1.8*L-fullyin.png

|

|

| Attachment 3: 2022-02-16_18-10-14-ADCdataItems.png

|

|

| Attachment 4: 2022-02-16_18-13-03-aidaCorrelation.png

|

|

| Attachment 5: 2022-02-16_18-10-53-goodEvents.png

|

|

| Attachment 6: 2022-02-16_18-28-35aida125-1.8*W-20us.png

|

|

| Attachment 7: 2022-02-16_18-27-30aida125-1.8*W-200us.png

|

|

| Attachment 8: 2022-02-16_18-25-11aida125-1.8*W-2ms.png

|

|

| Attachment 9: 2022-02-16_18-23-50aida125-1.8*W-20ms.png

|

|

| Attachment 10: leakage-potentiometer.png

|

|

| Attachment 11: pulserWidth_potentiometer.png

|

|

|

333

|

Mon Feb 28 14:42:48 2022 |

CB, TD | Cryostat set to 115K |

Cryostat set to 115K |

|

29

|

Thu Oct 22 22:15:00 2020 |

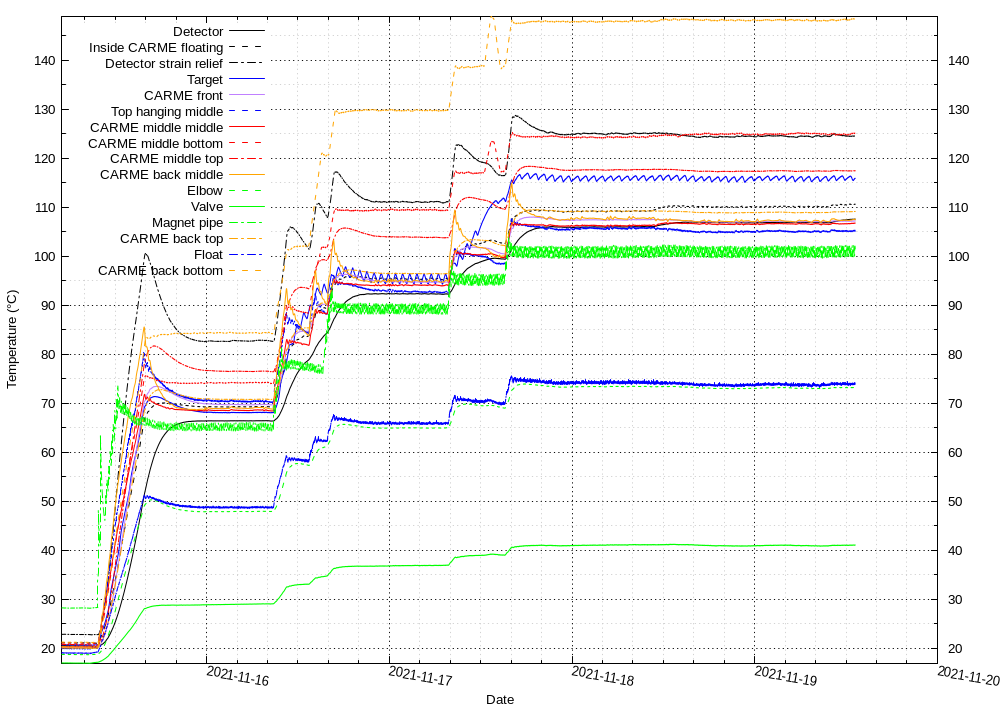

CB (remotely) | Cooling down after first NEG activation |

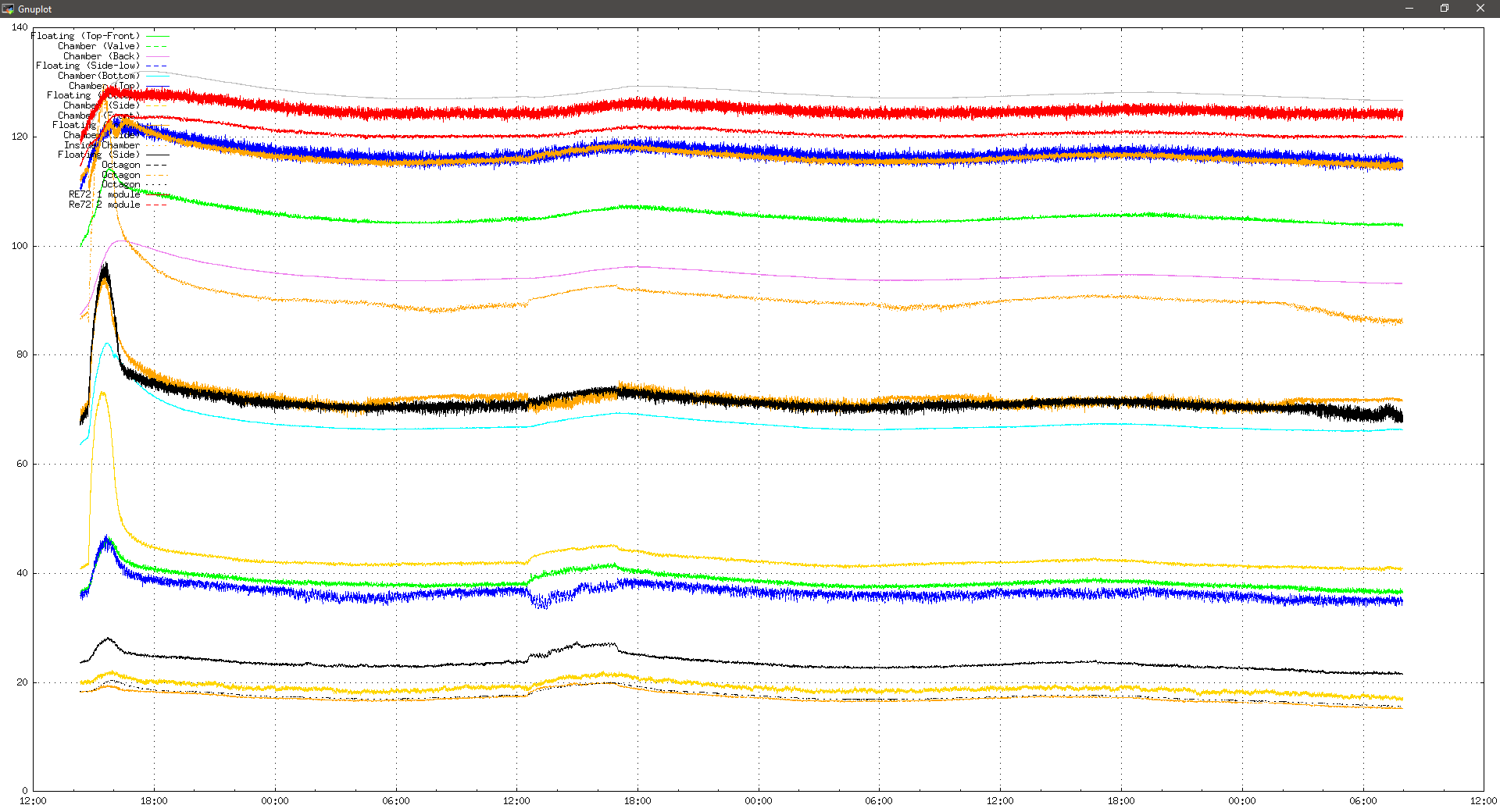

Thu 22 October

22:15 Temperatures stables, slowly decreasing.

Bump - rising front corresponds to heaters turned on. Falling front to D2000 turned off?

See attached.

Fri 23 October

09:57 Temperatures stable. See attached.

13:09 Temperatures remain stable. No significant changes.

Sat 24 October

21:27 Temperatures stable. See attached.

Sun 25 October

*Daylight saving is in effect. Time on the Raspberry Pi is no longer incorrect*

07:57 Temperatures stable. See attached.

19:05 Temperatues mostly stable. See attached. Will leave overnight and move setpoint to 80 C early tomorrow morning

Mon 26 October

07:37 Temperatures mostly stable. See attached. Setpoint to 80 C. |

| Attachment 1: 20201022_2214.png

|

|

| Attachment 2: 20201023_0957.png

|

|

| Attachment 3: 20201024_2117.png

|

|

| Attachment 4: 20201025_0757.png

|

|

| Attachment 5: 20201025_1905.png

|

|

| Attachment 6: 20201026_70736_temps.png

|

|

| Attachment 7: 20201026_0736_ctrl.png

|

|

|

30

|

Mon Oct 26 10:35:05 2020 |

JM, CB(remotely) | Cooling |

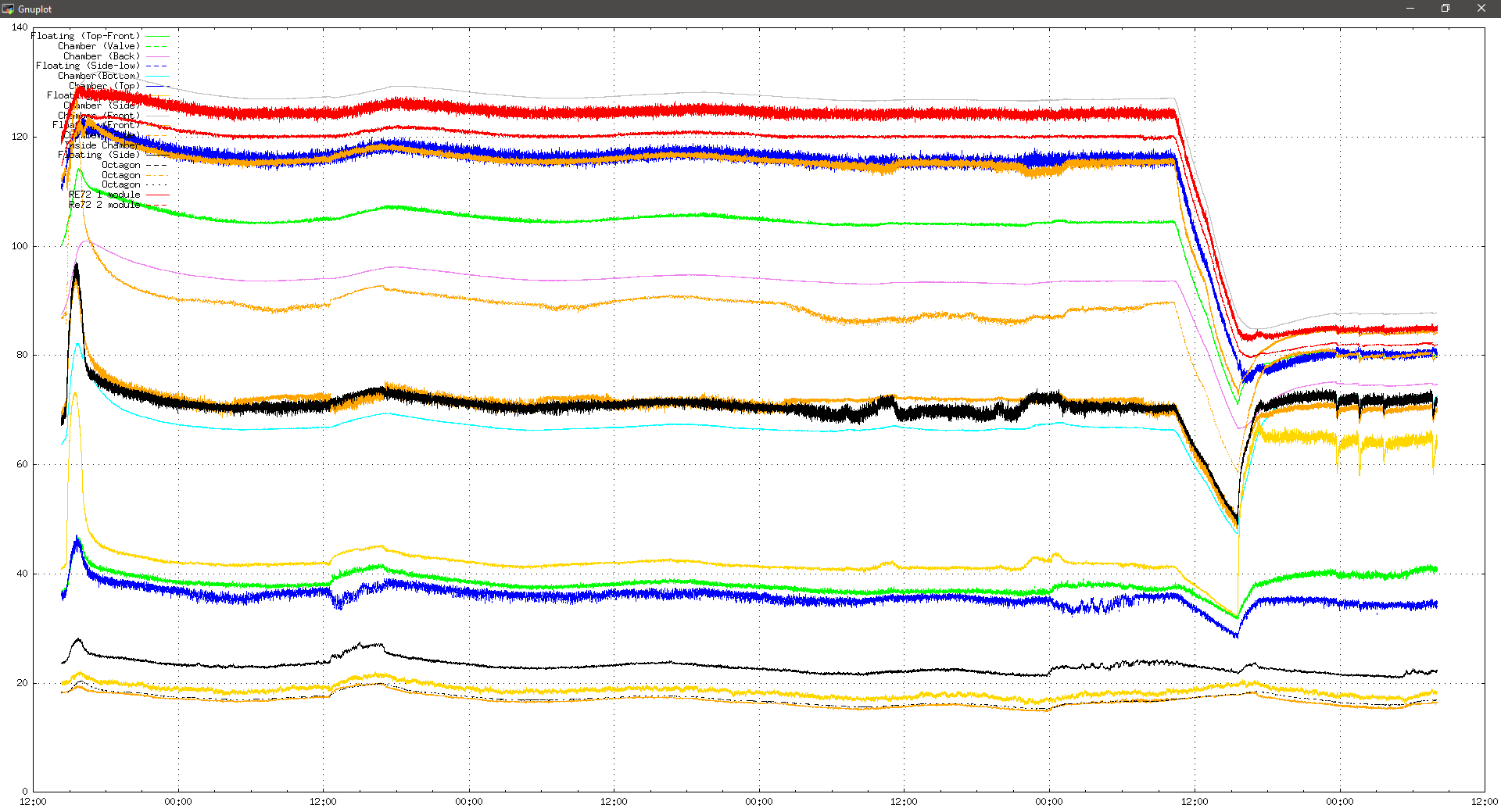

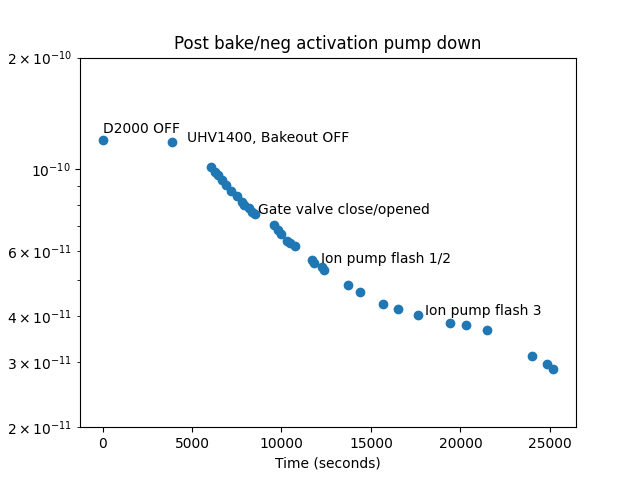

10:10 Pressure on the chamber = 3.1e-8mbar. RE-72 temperatures are ~120-125C with set limits at 80C. D2000 temperatures are ~370C. D2000's reduced from 60W to 30W and all UHV 1400s reduced to 50W each to cool both the chamber and the D2000s so that ion pumps can be activated.

10:38 Pressure on the chamber = 1.7e-9mbar. Re-72 temperatures begining to fall and are currently ~117-122C. D2000 temperatures are ~290C.

11:05 Pressure on chamber = 1.1e-9mbar. RE-72 temperatures are ~114-118C. D2000 temperatures ~275C.

11:42 Pressure on chamber = 9e-10mbar. RE-72 temperatures are ~109-113C. D2000 temperatures ~230C. Power in the D2000s reduced to 10W each to speed up cooling.

13:02 Pressure on chamber = 3e-10mbar. RE-72 temperatures are 100-103C. D2000 temperatures ~200C. Power in the UHV 1400s reduced to 25W to speed up cooling. Total heating power is now 325W from the UHV1400s and 40W from the D2000s.

14:11 Temperature plot attached.

15:40 Pressure on chamber = 1.2e-10mbar. RE-72 temperatures are ~80-84C with the heaters starting to control temperature of the bakeout. D2000s temperatures are ~150C. I will leave things as they are to let temperatures reach equillibrium overnight.

27 October

08:00 Temperature stable. See attached.

08:30 Pressure on chamber = 1.2e-10mbar. D2000s temperatures are 150C, have turned them off to cool to below 80C

09:35 Pressure on chamber 1.18e-10mbar. D2000s temperatures are 110C. Bakeout set point reduced to 0C and neg elements switched off. Ion pumps set up and will be activated when D2000 temperatures are below 80C.

Settings on the ion pump have been left to default, except for the ramp rate which has been reduced to 1s from 10s as we are only flashing pumps for a short period of time, and the conversion factor which is set to 150A/torr for D2000 pumps.

10:50 Pressure on the chamber = 7.53e-11mbar. D2000 temperatures at 80C. Gate valve was closed leading to an increase in pressure up to the high -9 / low -8 mbar range. Conclusion at the time was that the UHV1400s were still too hot and thus outgassing at such a rate that caused the large pressure increase. Once the valve was opened again, the pressure dropped to the mid -11 range again. Gate valve has been found to have been installed upside down, this may also contribute to the pressure increase. Due to low pressure on the backing line and neg pumps cooling which will increase pumping power we may not have to close the valve to reach the -12 mbar range however.

After speaking with Keith, valve being installed upside down shouldn't pose any significant difference to obtainable pressure, however would be good to install properly at next chance.

11:45 Pressure on the chamber = 5.55e-11mbar. D2000s temparatures are 75C. Ion pumps activated for first flash of 30s pumping.

11:55 Pressure on the chamber =5.44e-11mbar. Ion pumps flashed for the second time. Pressure given inside 3 ion pumps reached the minimum of 8.9e-12mbar, 4th pump registered 1.3e-10mbar.

13:24 Pressure on the chamber = 4.02e-11mbar. Ion pumps flashed for the third time. Pressure inside ion pumps was the same as last flash.

15:40 Pressure on chamber = 2.88e-11mbar

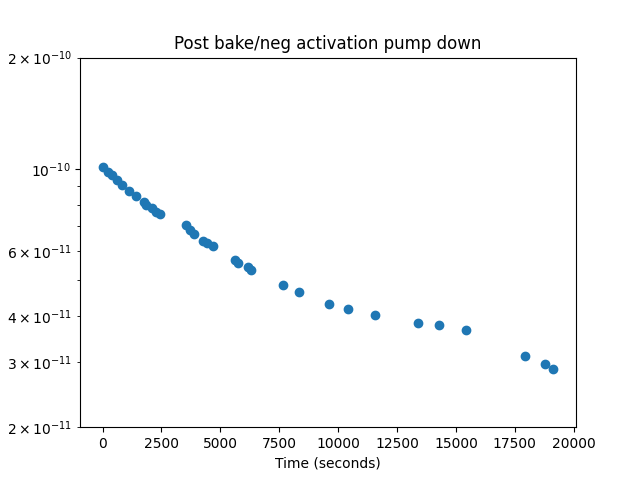

Find attached plot of pressure (mbar) against time for the pump down from 10:11 on 27/10/20. It looks like negs may have cooled enough to begin pumping nearer the end of the day where the rate of pumping speed appears to increase.

|

| Attachment 1: Screenshot_from_2020-10-26_14-10-08.png

|

|

| Attachment 2: 20201027_0803_temps.png

|

|

| Attachment 3: 27102020_pump_down.png

|

|

| Attachment 4: 27102020_pump_down.png

|

|

|

168

|

Tue Jan 11 12:45:15 2022 |

TD, JM, OH | Coolant manifold installation + detector pin tests |

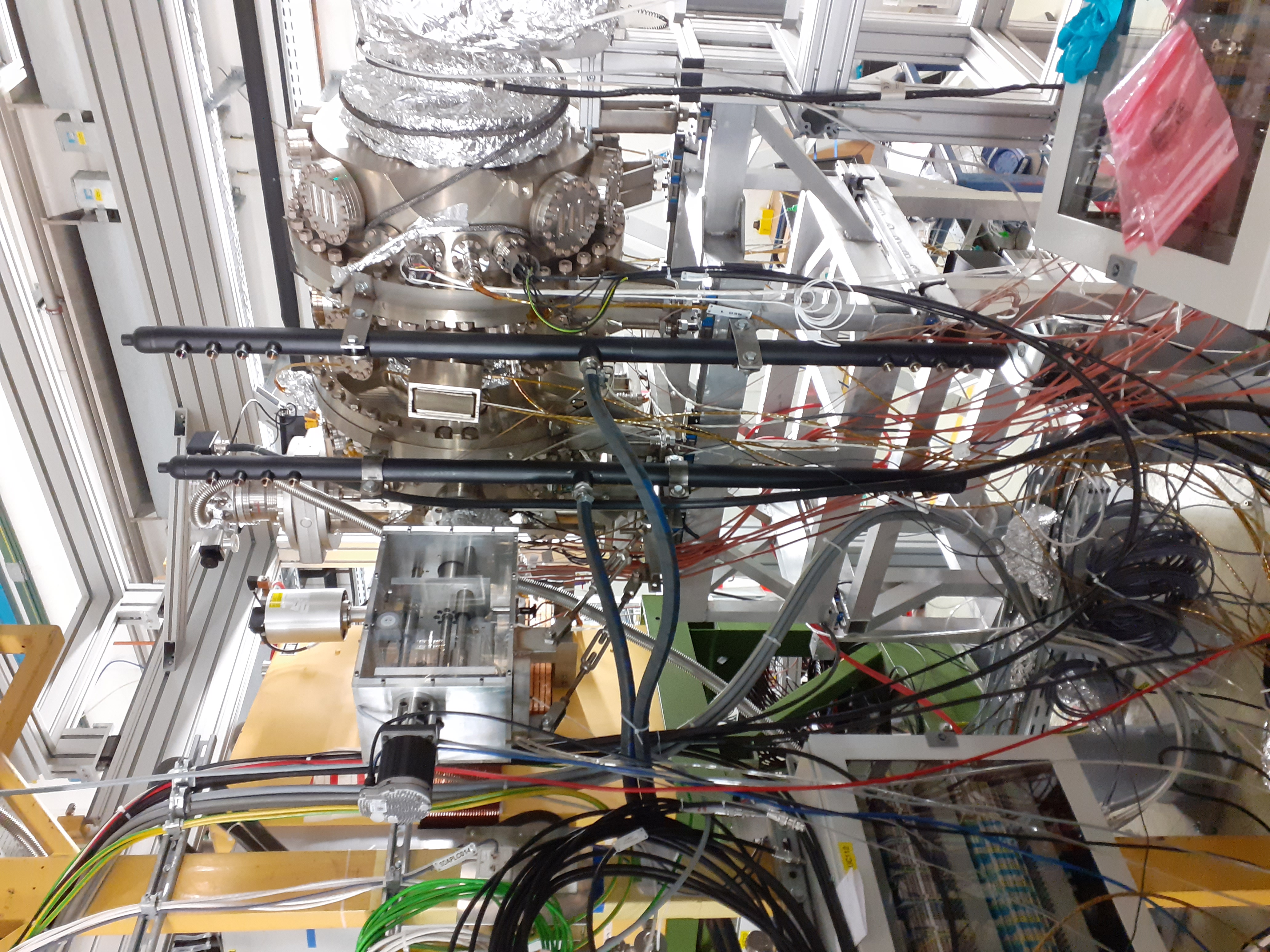

2x cooling water manifolds with 2x 8 ports have been installed - see attachments 1 & 2

'drain' ports at top of manifold to permit release of trapped air volumes. Local technicians will install a standard blank in one manifold and a small nipple valve on the

other so that we can bleed air in a controlled way.

#Multimeter detector pin tests.

Pins on feedthrough flanges investigated using multimeter for the top and bottom detector due to no response from bottom detector when bias was applied. Bias pins on

correct D connectors are number 78.

#Top detector

>Observe -18.5 kohm; between nn bias pin and pn bias pin (multimeter 200kohm setting)

>observe open line between nn bias pin and pins 'near' pn bias pin (multimeter 200kohm setting)

>Between random pins on same D connector (nn bias pin connector) ~0.02Mohm (multimeter 2Mohm setting)

>Between random pins and unconnected on same D connector (nn bias pin connector) - open line (multimeter 2Mohm setting)

>Between random pins and bias pin on same D connector (nn bias pin connector) ~0.01-0.02 Mohm (multimeter 2Mohm setting)

>Between nn bias pin and random pin on another D connector ~-0.4Mohm (multimeter 2Mohm setting)

#Bottom detector

>Observe open line between nn bias pin and pn bias pin (multimeter 200kohm+2Mohm; setting)

>Observe open line between nn bias pin and pins 'near' bias bias pin (multimeter 200kohm+2Mohm; setting)

>Between random pins on same D connector (nn bias pin connector) ~0.02Mohm (multimeter 2Mohm setting)

>Between random pins and unconnected on same D connector (nn bias pin connector) - open line (multimeter 2Mohm setting)

>Between random pins and bias pin on same D connector (nn bias pin connector) ~0.01-0.02 Mohm (multimeter 2Mohm setting)

>Between random pins on same D connector (pn bias pin connector) ~0.02Mohm (multimeter 2Mohm setting)

>Between random pins and unconnected on same D connector (pn bias pin connector) - open line (multimeter 2Mohm setting)

>Between random pins and bias pin on same D connector (pn bias pin connector) ~open line (multimeter 2Mohm setting)

>Between nn bias pin and random pin on another D connector ~-0.4Mohm (multimeter 2Mohm setting)

We see a similar response for both detectors except that the pn bias pin gives no response.

We have looked to find the bias pin on nearby pins to pin 78 and on the other side of the D connector (in case of cabling error-mirror or swapped cables) but cannot find.

4 FEE holders constructed and ready to install |

| Attachment 1: 20220111_113628.jpg

|

|

| Attachment 2: 20220111_113613.jpg

|

|

| Attachment 3: 20220111_111428.jpg

|

|

|

159

|

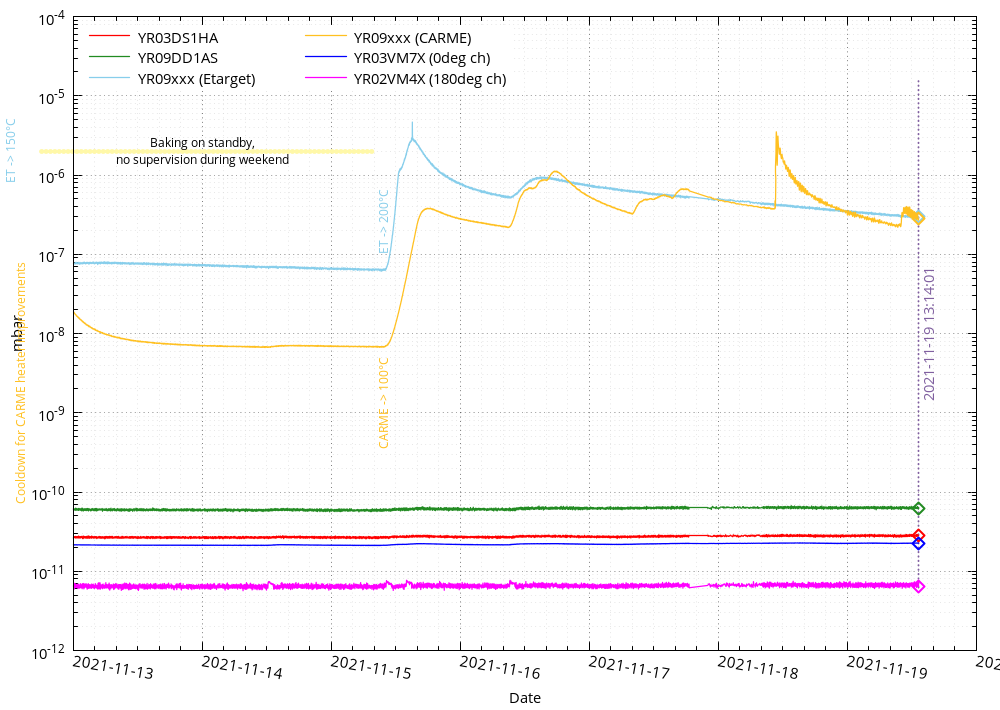

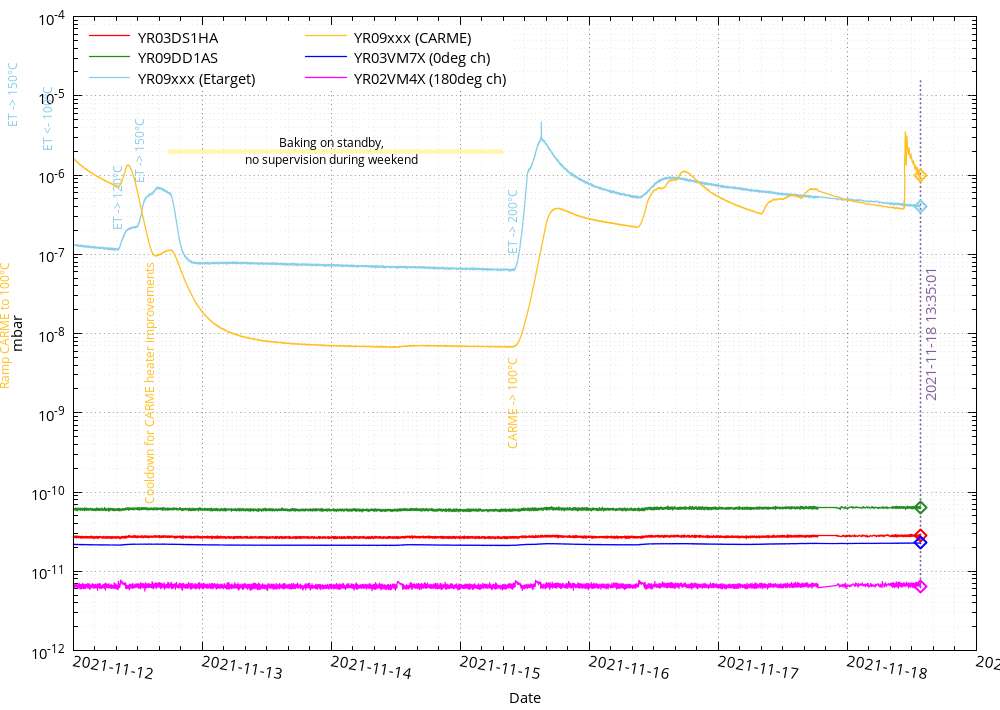

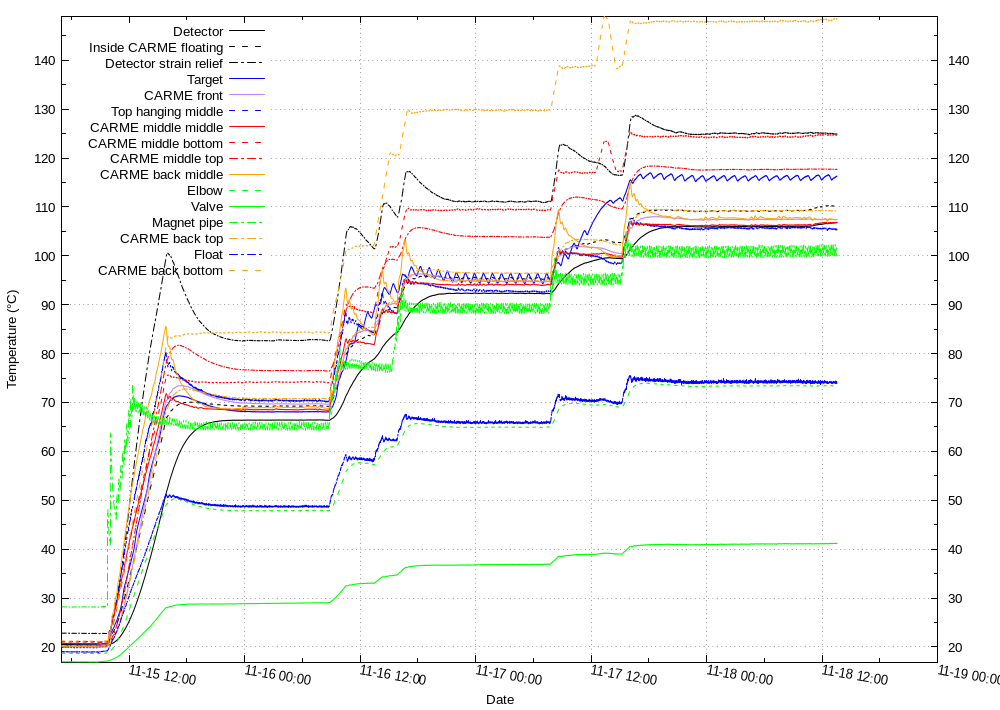

Fri Nov 19 12:03:51 2021 |

CB RSS | Conditionings NEGs |

Increased conditioning temperature in D2000 #3 and 4 (behind detectors) to 150C from 130/140C. No appreciable change in temperature. Minor effects in pressure.

Pressure has completely recovered from yesterday and did not settle on higher/lower plateau value which may suggest conditioning the D2000 NEG elements has helped outgassing the chamber as a result of the low baking temperature.

Will now try to condition the UHV1400 furthest from the detectors at very low power according to SAES conditioning instructions.

The advantages are unclear at present, but more temperature during baking should not hurt final vacuum level. Will re-activate all NEGs anyway.

14:00 - Set power for all UHV1400 except those in the moving DSSD chamber to 20W. Some effects on both pressure and temperature. Will leave over weekend, start activation on Monday. |

| Attachment 1: CARMEtemps.png

|

|

| Attachment 2: vacplot.png

|

|

|

157

|

Thu Nov 18 12:29:50 2021 |

CB RSS | Conditioning D2000 NEGs |

D2000 thermocouples report temperatures around 100C (D2000 #1,2) and 120C (3,4). 1,2 are in the intermediate chamber, 3,4 are behind the moving arms. 3 is directly being the detectors.

Wanted to flash ion elements in D2000, but SAES recommend >100C to flash.

Followed SAES procedure / pre-sets to condition D2000 NEG elements while baking, but reduced temperature from 250 to 150 C (1,2) 140 C (4) and 130 C (3).

No appreciable changes in temperature. Change in pressure quite apparent. Left elements at temperatures above. May consider increasing everything to 150 tomorrow assuming detector temperatures do not change.

May also consider conditioning NEG elements in intermediate and DSSD wall chambers with 15W power (150C?) during baking as per SAES procedure. We never did this before, but we never baked as such low temperatures either. Will have to activate NEG elements after conditioning either way. |

| Attachment 1: vacplot.png

|

|

| Attachment 2: CARMEtemps.png

|

|

|

420

|

Mon Jul 17 08:45:11 2023 |

TD | Closing CARME again |

Grosmantage are scheduled to arrive 10.00 to inspect COF600 seals and their fit to the COF600 flange. They may decide to adjust the seals so that they fit the flange

under

tension.

Once Grosmontage are satisfied with the seal and its fit we can close the CARME chamber and start pumping down.

Attachment 1 - photo of bakeout tent parts including those adapted/modified by Davide.

18.40 Grosmontage were re-tasked this morning.

Davide, Omer, Cosmas checked alignment of COF600 male and female flanges.

4x COF600 seals were checked - for some seals we observed wave over a ~ 10cm section of the circumference and/or surface scratches/roughness.

Also observed that COF600 seals appeared to be too large - consequently the wire seal would be seated well ( i.e. in contact with the flange surface )

for the majority of the circumference but would lift from flange surface for part(s) of the circumference.

The fourth COF600 seal seated well over all of the circumference and we decided to proceed with closing the chamber.

COF600 flange bolts tightened sequentially 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160Nm.

ML roughed CARME chamber slowly ( < 1mbar/s ) to protect Be window. Turbo started at 1.3mbar. Pirani gauge indicated e-3 mbar range when turbo at speed.

18.53 IE514 gauge ON pressure 4.05e-5mbar.

19.10 Pirani 1.42e-3 mbar IE514 3.02e-5 mbar |

| Attachment 1: 20230717_093106.jpg

|

|

|

406

|

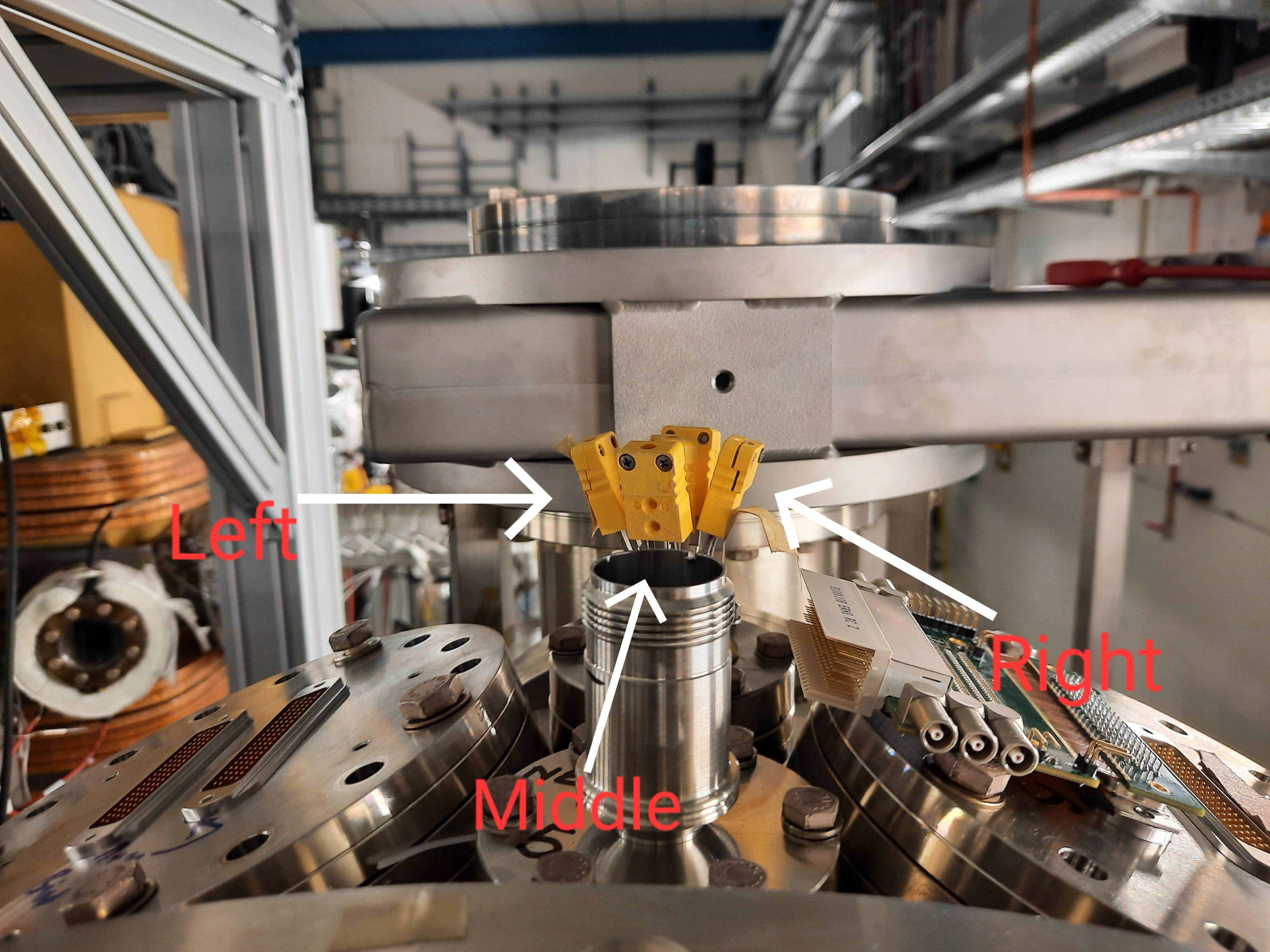

Wed Jun 21 18:47:36 2023 |

JM, TD | Closing CARME |

Internal CARME installations complete.

- New strain reliefs (flange side) installed on each cable harness.

- 2x sets of SAES UHV1400 NEG pumps installed and connected to 2x power feed-through flanges -> continuity checked OK -> 3x UHV1400 modules gives a resistance of 7.4 Ohms, 2x UHV1400 modules gives resistance of 4.8 Ohms.

- Pins B & D open circuit wrt ground ( DMM OL > 20M ? )

- Pin C connection to ground OK

- Internal thermocouples connected. Middle thermocouple connected to strain reliefs, right thermocouple connected to a standoff on the detector, left thermocouple floating (see attached images). Resistance on thermocouples checked for middle and right thermocouples ~ 4 Ohms per thermocouple.

V-I tests performed prior to closing CARME. All detectors show expected curve, but light leaks are present. Pressing my hand against the aluminium shield yielded 0.5-1.5 uA drop in leakage current. Could not turn off lights for the test due to other people working in the cave. Will repeat test when closed. Temperature in the cave ~ 21.5 C.

Both chamber sections have now been closed. Wire seal appeared correctly positioned immediately prior to final close. Bolts closing the wire seal have been tightend to 100 Nm, plan to increase to 140 Nm tomorrow. DN100 feed-through flanges have been tightend with a torque of 24 Nm.

Plan is to move chamber back onto the ring tomorrow and get ready for leak testing. |

| Attachment 1: 20230621_104911.jpg

|

|

| Attachment 2: 20230621_104918.jpg

|

|

| Attachment 3: 20230621_110010.jpg

|

|

| Attachment 4: 21-06-23-VI.png

|

|

|

77

|

Thu Sep 23 14:19:27 2021 |

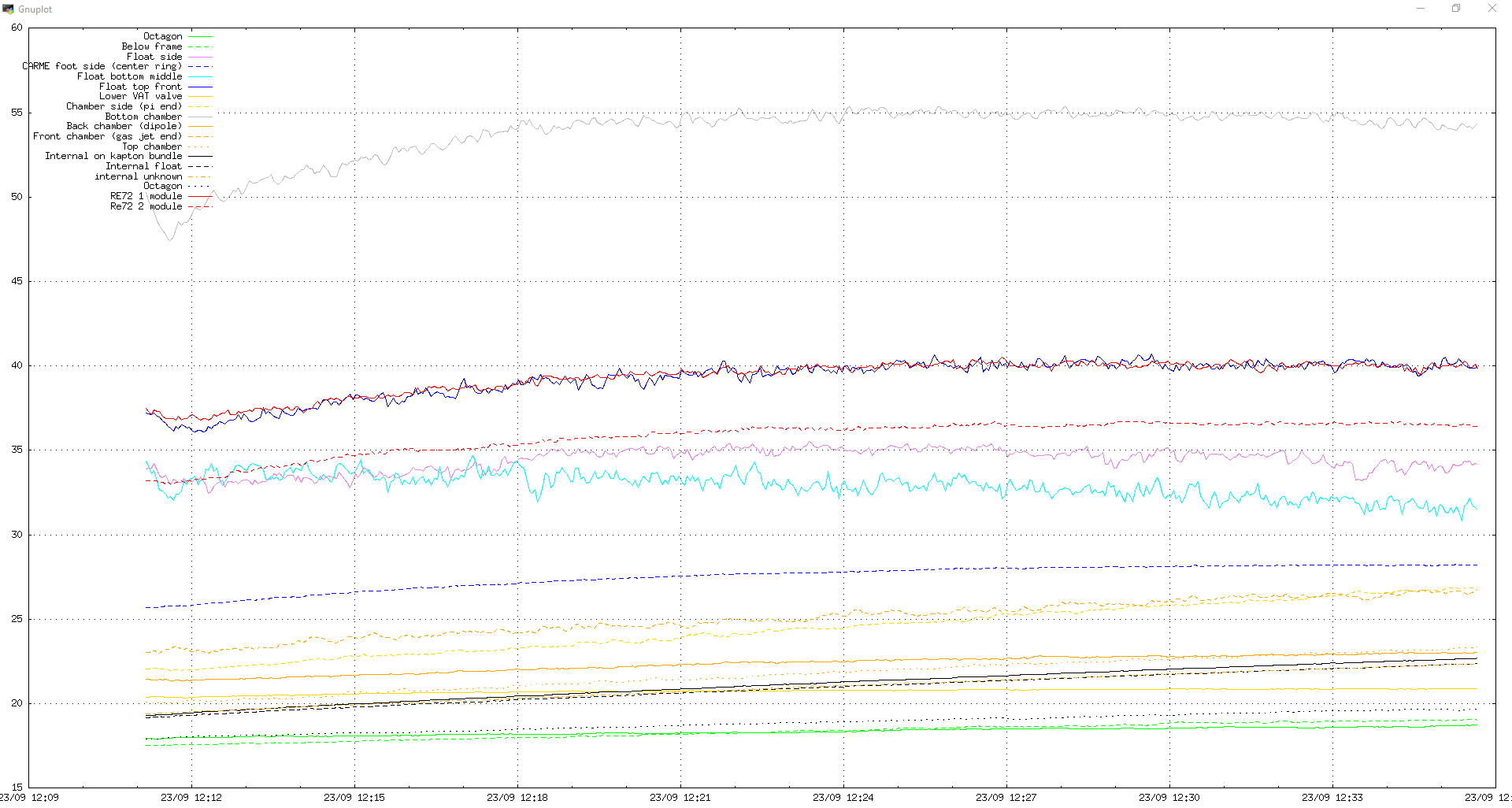

CB (remotely) | Checking baking remotely - instructions |

1. Connect to pi on CRYRING local network

ssh pi@192.168.207.127

Password available on request

2. To check state of baking code

screen -x

please do not press any keyboard button if unsure how the code works.

Pressing q instantly stops baking in case of emergencies

when done, to disconnect

CTRL+A

d

3. To check log of commands / previous status of baking code

cd Programs/Baking

cat Log.dat

4. To check temperature plot

cd Programs/Baking

gnuplot Plot_temps.gp

CTRL+C on terminal to quit

Please remember the Pi has limited computing power and the gnuplot window will consume some of that when open

One remote user is no problem, but multiple may give issues to the Pi

5. Check current pressure

Currently:

https://uoe-my.sharepoint.com/:x:/g/personal/cbruno2_ed_ac_uk/EVbsVOubNHRLj0PKiFIvd00BClMJ6WSJ1UDAyLA2F3R4jA?e=hEoZt7

(Pictures from webcam are in ~/Webcam on the pi

CM52 data also to be available online in real time soon) |

| Attachment 1: Temp.png

|

|

|

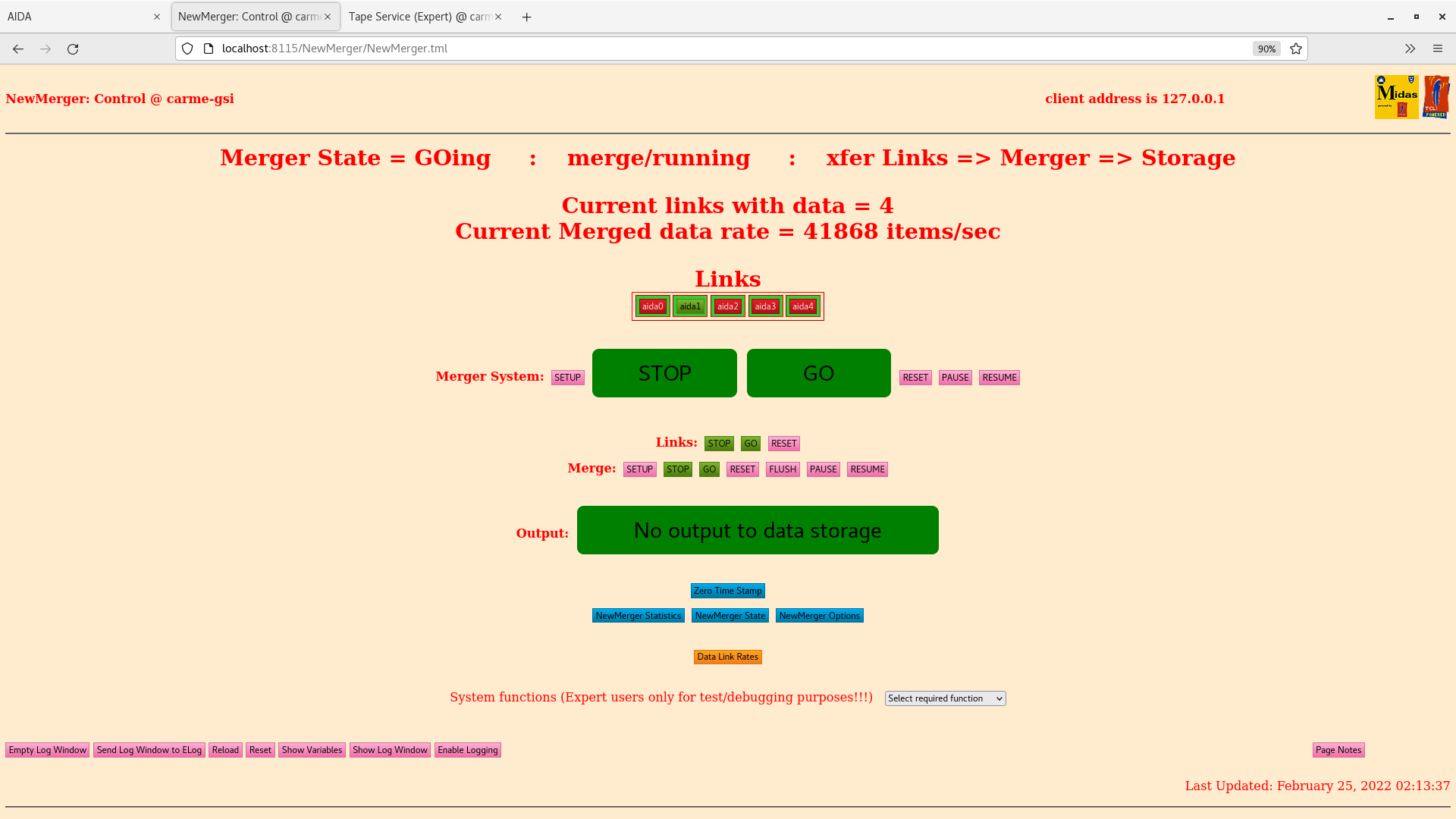

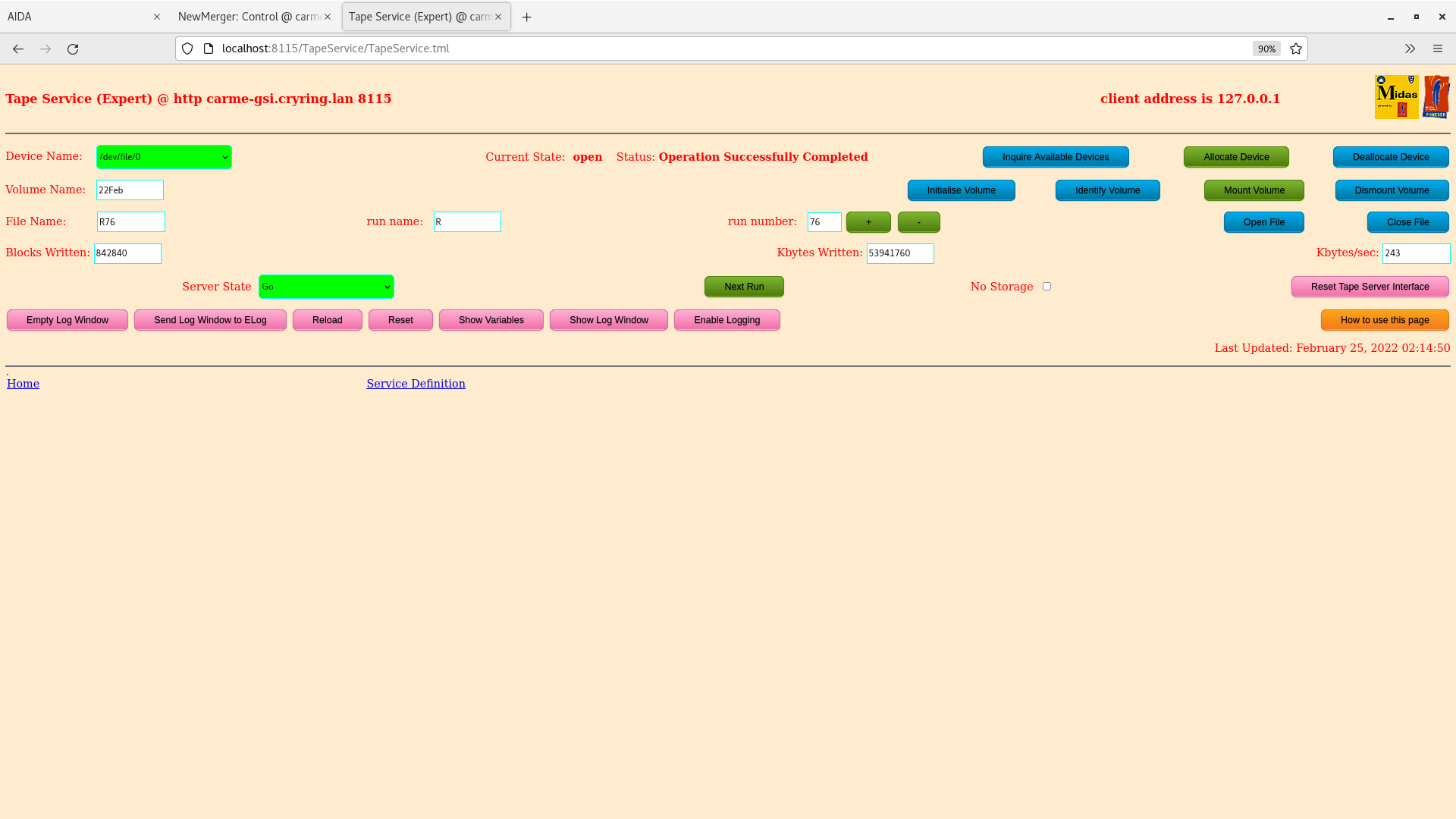

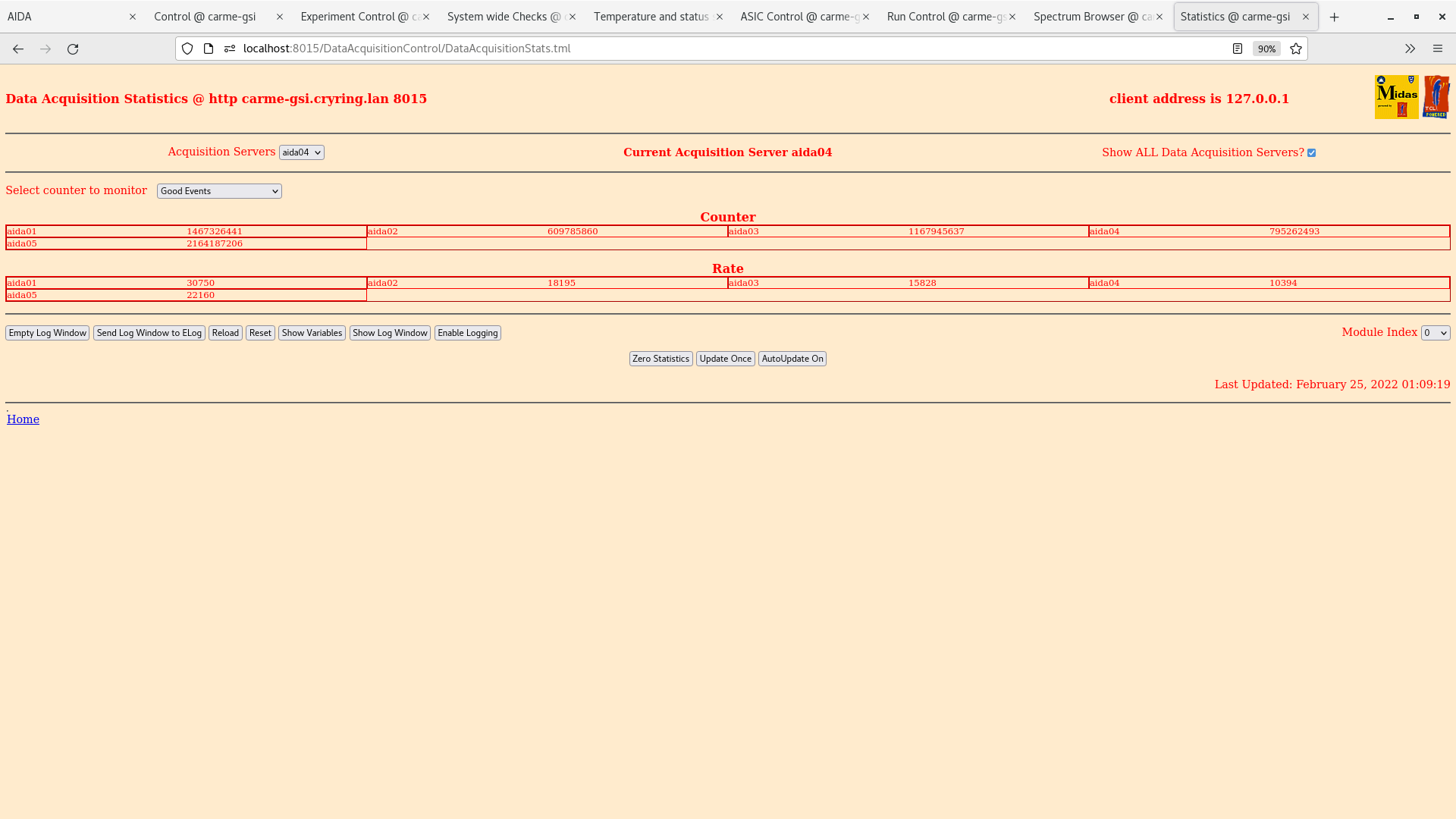

274

|

Fri Feb 25 01:12:49 2022 |

Rui-Jiu Chen, Alex | Check |

Still no beam in CRING.

Motor fully out position.

SW3

- Merger OK

- Screenshot uploaded

- Data rate : 243 kbytes/s

SW4

- current plot uploaded

SW2

- T OK

- system wide checks OK

- Check statistics tab ok

- Spectra ok

SW5

4 plots uploaded |

| Attachment 1: Screenshot_from_2022-02-25_02-13-46.png

|

|

| Attachment 2: Screenshot_from_2022-02-25_02-14-56.png

|

|

| Attachment 3: Screenshot_from_2022-02-25_02-16-05.png

|

|

| Attachment 4: Screenshot_from_2022-02-25_02-16-54.png

|

|

| Attachment 5: Screenshot_from_2022-02-25_02-17-29.png

|

|

| Attachment 6: Screenshot_from_2022-02-25_02-17-39.png

|

|

| Attachment 7: Screenshot_from_2022-02-25_02-17-57.png

|

|

| Attachment 8: Screenshot_from_2022-02-25_02-19-05.png

|

|

| Attachment 9: Screenshot_from_2022-02-25_02-19-17.png

|

|

| Attachment 10: Screenshot_from_2022-02-25_02-20-01.png

|

|

| Attachment 11: Screenshot_from_2022-02-25_02-21-36.png

|

|

| Attachment 12: Screenshot_from_2022-02-25_02-22-17.png

|

|

| Attachment 13: Screenshot_from_2022-02-25_02-23-40.png

|

|

|

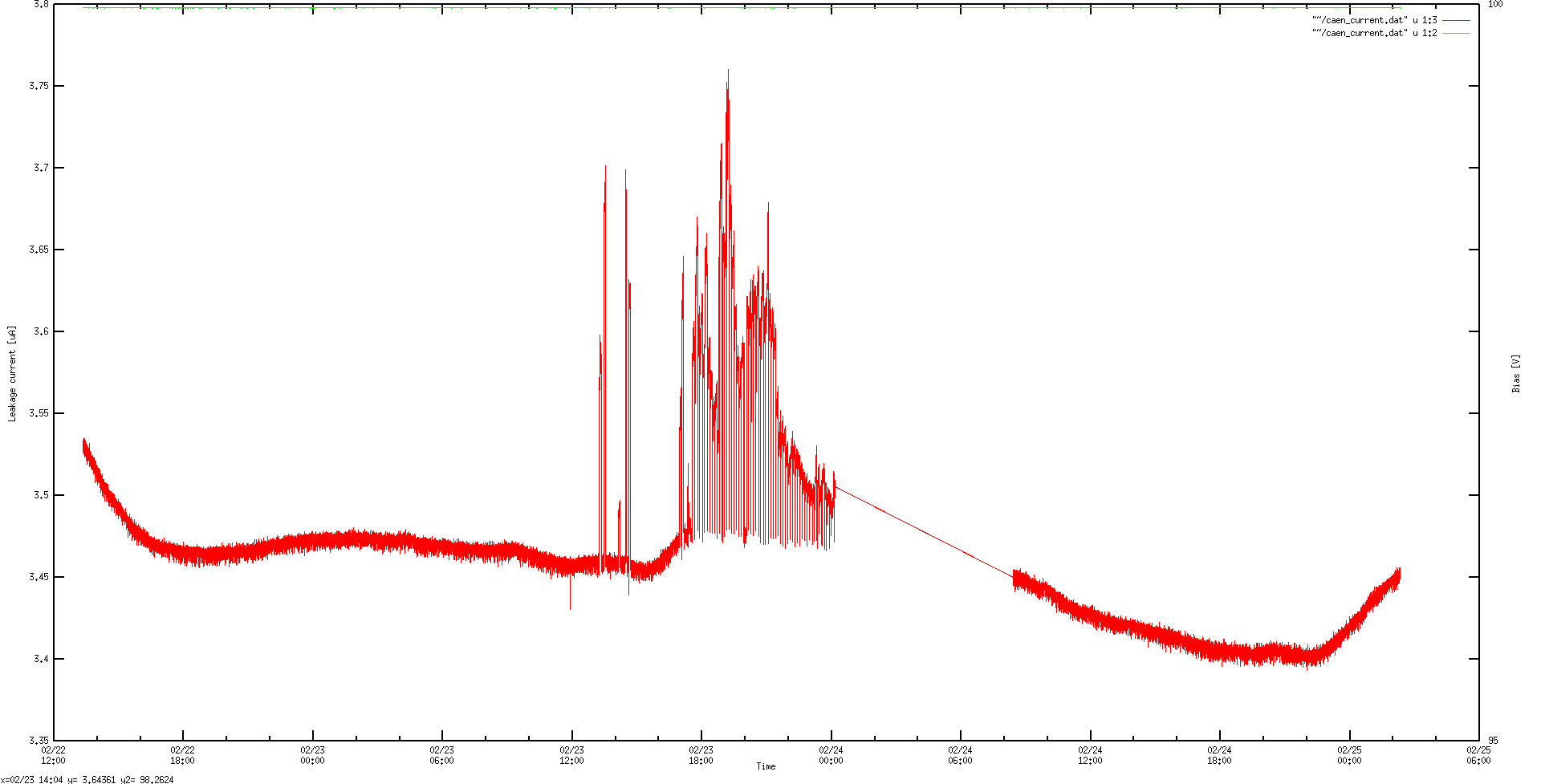

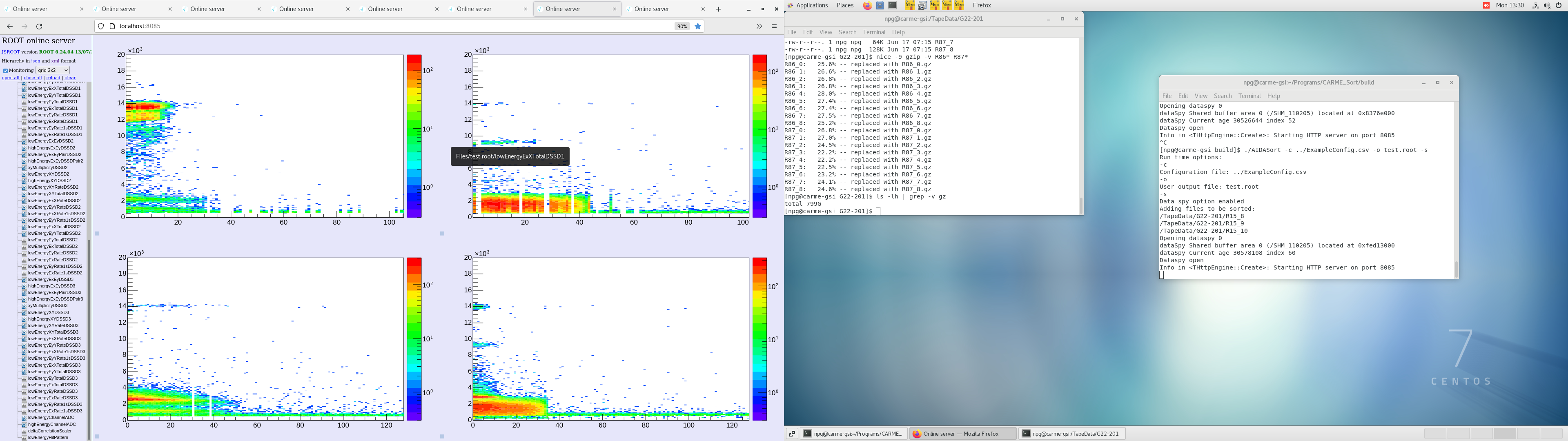

273

|

Fri Feb 25 00:00:40 2022 |

Rui-Jiu Chen, Alex | Check |

There are some problems with ion source. No beam in CRYING.

Motor fully out position.

SW3

- Merger OK

- Screenshot uploaded

- Data rate : 230 kbytes/s

SW4

- current plot uploaded

SW2

- T OK

- system wide checks OK

- Check statistics tab ok

- Spectra ok

SW5

4 plots uploaded |

| Attachment 1: Screenshot_from_2022-02-25_01-02-48.png

|

|

| Attachment 2: Screenshot_from_2022-02-25_01-02-58.png

|

|

| Attachment 3: Screenshot_from_2022-02-25_01-04-09.png

|

|

| Attachment 4: Screenshot_from_2022-02-25_01-06-45.png

|

|

| Attachment 5: Screenshot_from_2022-02-25_01-07-30.png

|

|

| Attachment 6: Screenshot_from_2022-02-25_01-07-55.png

|

|

| Attachment 7: Screenshot_from_2022-02-25_01-08-22.png

|

|

| Attachment 8: Screenshot_from_2022-02-25_01-09-24.png

|

|

| Attachment 9: Screenshot_from_2022-02-25_01-10-03.png

|

|

| Attachment 10: Screenshot_from_2022-02-25_01-12-00.png

|

|

| Attachment 11: Screenshot_from_2022-02-25_01-15-34.png

|

|

| Attachment 12: Screenshot_from_2022-02-25_01-16-22.png

|

|

| Attachment 13: Screenshot_from_2022-02-25_01-17-24.png

|

|

| Attachment 14: Screenshot_from_2022-02-25_01-17-58.png

|

|

|

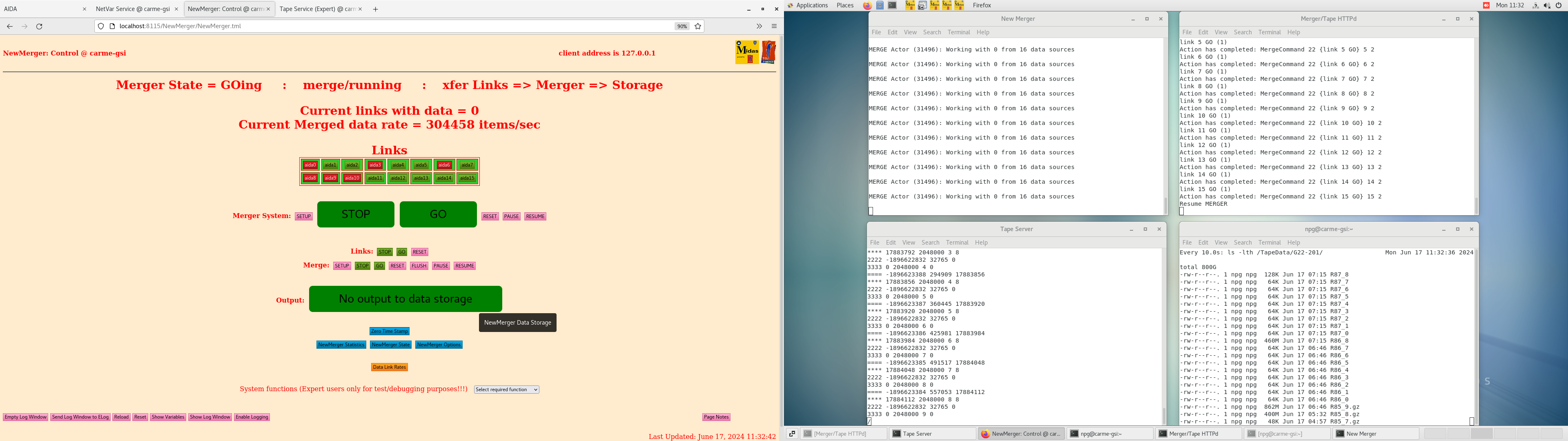

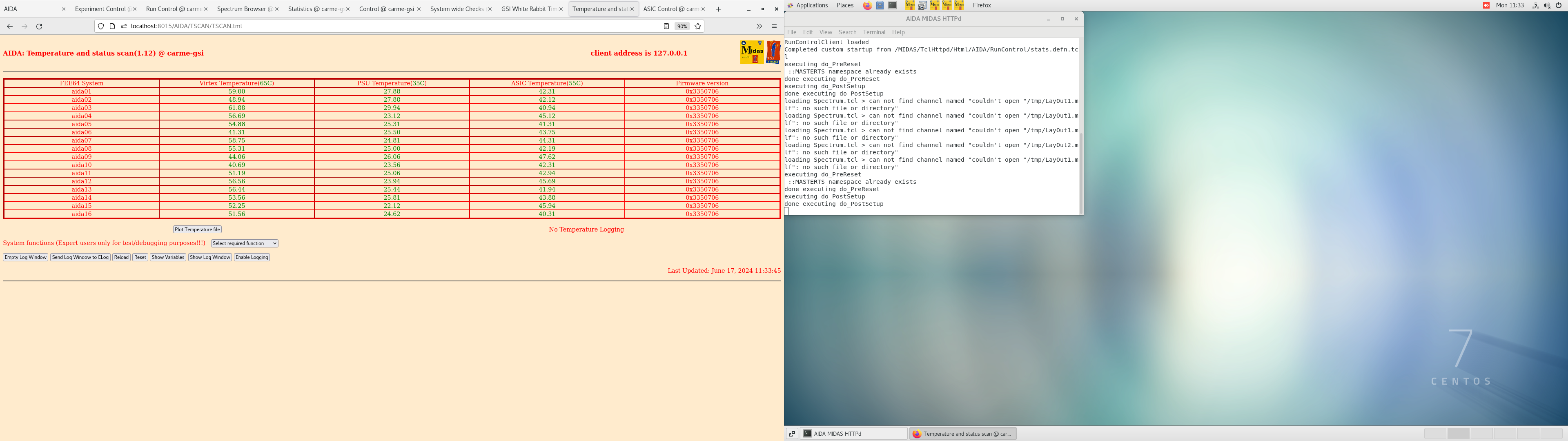

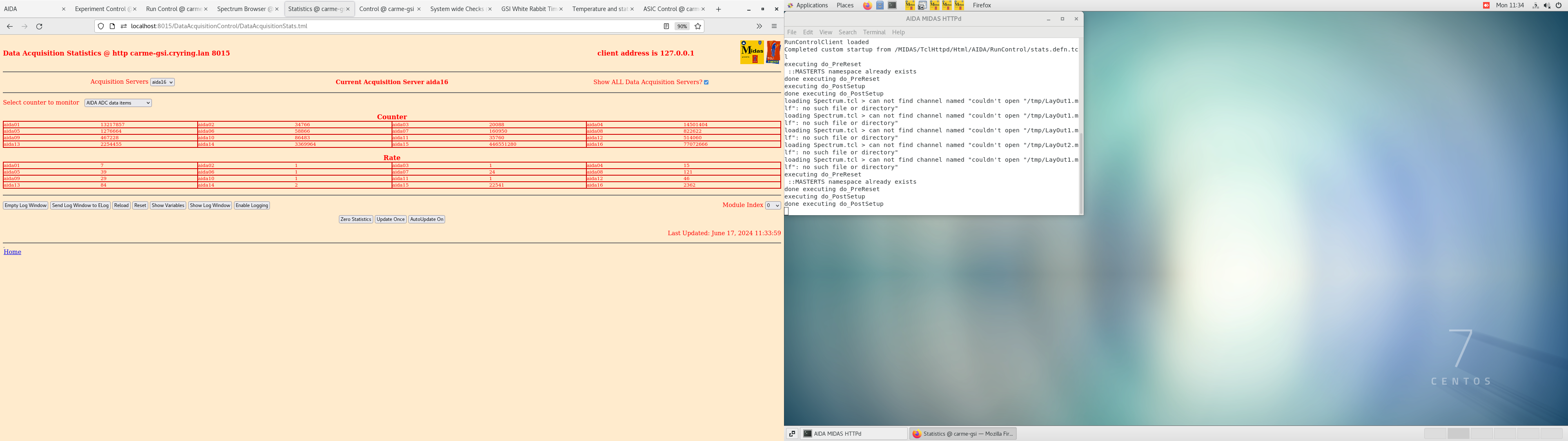

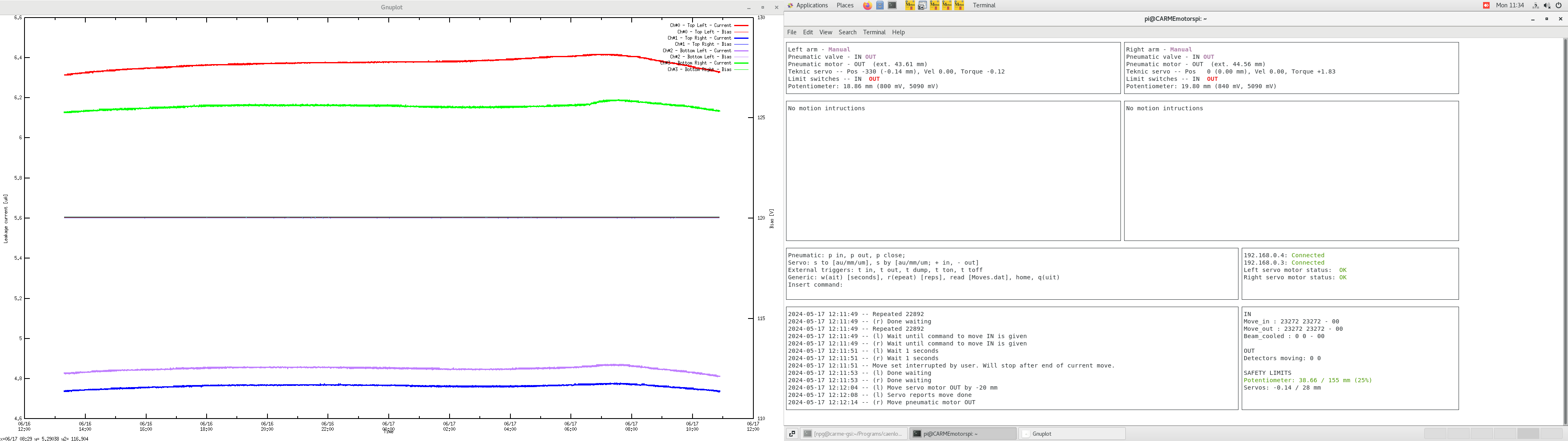

649

|

Mon Jun 17 06:26:45 2024 |

JM, OF, AK, CB | Change to 5+ beam |

07:00

We are changing to 5+ beam so that we can access higher energies and possibly observe a higher lying, wider resonance.

Beam energy change to 1.06 MeV/u.

Detectors out

Target nozzle out

Pressure in E1 had reached 2e-1 mbar and turbo was spinning down to 810 Hz. Pressure reduced and E1 has reduced to 8.2e-2 mbar. We may require a pressure increase when we want the target back?

Run changed and out into no storage mode so we do not write rubbish to disk.

11:34

Beam tuning in the ring in progress

Merger OK. Not writing to disk.

Temps OK. Rates OK.

Leakage current OK.

Motors out. Target out.

13:31

Checks OK. Beam tuning near completion.

Some data acquired during beam tuning attached. |

| Attachment 1: Screenshot_from_2024-06-17_11-32-46.png

|

|

| Attachment 2: Screenshot_from_2024-06-17_11-33-47.png

|

|

| Attachment 3: Screenshot_from_2024-06-17_11-34-01.png

|

|

| Attachment 4: Screenshot_from_2024-06-17_11-34-11.png

|

|

| Attachment 5: Screenshot_from_2024-06-17_13-30-41.png

|

|

| Attachment 6: Screenshot_from_2024-06-17_13-30-52.png

|

|

| Attachment 7: Screenshot_from_2024-06-17_13-30-56.png

|

|

|

309

|

Sun Feb 27 16:30:35 2022 |

Rui-Jiu Chen, Yuri | Change target temperature again |

1. change T from 95 k to 140 k.

2. keep T at 140k for 15 minutes.

3. change T from 140 k to 95 k. |

|

307

|

Sun Feb 27 15:02:16 2022 |

Rui-Jiu Chen, Yuri | Change target temperature |

16:00 change temperature from 95 k to 120k.

16:07 change temperature from 120 k to 95k.

Ring current ~4.97e7 particles/s

SW3

- Merger OK

- Screenshot uploaded

- Data rate : 1036 kbytes/s

SW4

- current plot uploaded. 3.25 uA.

SW2

- T OK

- system wide checks OK

- Check statistics tab ok

- Spectra ok

SW5

4 plots uploaded |

| Attachment 1: Screenshot_from_2022-02-27_16-04-47.png

|

|

| Attachment 2: Screenshot_from_2022-02-27_16-04-58.png

|

|

| Attachment 3: Screenshot_from_2022-02-27_16-05-55.png

|

|

| Attachment 4: Screenshot_from_2022-02-27_16-06-35.png

|

|

| Attachment 5: Screenshot_from_2022-02-27_16-07-06.png

|

|

| Attachment 6: Screenshot_from_2022-02-27_16-07-15.png

|

|

| Attachment 7: Screenshot_from_2022-02-27_16-07-27.png

|

|

| Attachment 8: Screenshot_from_2022-02-27_16-09-29.png

|

|

| Attachment 9: Screenshot_from_2022-02-27_16-09-43.png

|

|

| Attachment 10: Screenshot_from_2022-02-27_16-10-20.png

|

|

| Attachment 11: Screenshot_from_2022-02-27_16-12-44.png

|

|

| Attachment 12: Screenshot_from_2022-02-27_16-13-41.png

|

|

| Attachment 13: Screenshot_from_2022-02-27_16-14-13.png

|

|

| Attachment 14: Screenshot_from_2022-02-27_16-14-48.png

|

|

|

311

|

Sun Feb 27 18:46:42 2022 |

Rui-Jiu Chen, Yuri | Change target temperature |

time Temperature E1 current(A) E1 frequency(Hz)

19:06 170 1.2 820

19:11 200 1.53 820

19:37 230 1.56 820

19:37 275 1.35 820

19:48 300 1.2 820

keep this temperature for 15 minues.

20:07 change the temperature from 300 k to 95 k.

21:11 95 2.65 820

|

|

499

|

Thu Feb 8 14:59:59 2024 |

JM, TD | Change p+n FEE64 settings |

ASIC settings for the pn FEEs has been reset to the default aida settings. This was done to combat the observed dropping of several channels in pn only FEE modules

following motors movement. This effect was also observed in 2022 in several pulser walkthroughs conducted pre and post detector movement. No dropped channels were

observed in nn FEEs.

ASIC seetings changed;

IBias LF feedback from 0xf to 0x8

diode link threshold from 0xbf to 0xca

We also set the slow comparatort for all FEE modules back to 0x64 (1 MeV)

Settings tested using only 2 pn FEE modules (aida05 and aida16). Movement left and right. Dropped channels observed in all pn FEEs except aida05 and aida16. All pn ASIC

settings then changed. Movement for 10 repeptitions. No dropped channels observed in pn FEEs.

New settings saved in 2024Feb08-15.59.09 |