| |

ID |

Date |

Author |

Subject |

|

|

463

|

Wed Jan 10 19:27:08 2024 |

CB, JM | Manifold and more bias tests |

Mounted water manifold on CARME with help from GSI plumber. Connected all the hoses with Swagelok self-locking connectors. Tested for water leaks - it leaks from nearly every port. The issue appear to be the connections between the manifold and the plugs, as opposed to the plugs and the hoses which do not leak.

Will try to find a solution tomorrow.

FEEs connected from bottom-left, top-left and top-right detector.

Top right detector showed same behaviour described in previous ELOG entry. Removed all jumpers from PCBs. Beahaviour is gone.

Removed all jumpers from flexi-rigid PCBs for bottom-left detector. Behaviour is improved, but not gone - still 13 uA at 150V. Around 3.5 uA at 120V with no conditioning - that may be the working point.

Missing

- Power cables and ethernet cables for half the fees

- Fix leaks on water manifold

- Fix / change / re-arrange fee holder for bottom-right detector to avoid it fouling on CARME frame. |

|

|

464

|

Thu Jan 11 19:57:20 2024 |

CB, JM | All FEE holders mounted |

After discussions with Davide, changed the holes in the FEE holders for the bottom-right detector to slots in order to slightly change the angle that the FEE inserts into the flexi rigid PCB. This was sufficient, with some difficulties, to insert both FEEs into the flexi rigid.

Attempted to finally mount the last two fees, the top two for the bottom-right detector, which should have been very easy. Somehow managed to break one pin on each PCB in similar spots. One is in the third column (not in use), and one is in the fourth column (in use). This latter PCB connector was unfortunately dropped while trying to dismount it, and the ERNI connector cracked. That connector can be used anymore? Cannot find spares in GSI, must be in Edinburgh?

Dismounted all the hoses from the manifold, and starting to remove teflon from the plugs. Will use instead gaskets + anti-sieze compound. Quite a number of plug thread are damaged, likely in welding. Unclear if this was the reason behind the leaks. Should be done with the manifolds tomorrow. |

|

|

465

|

Sat Jan 13 14:25:05 2024 |

CB, JM | Bias tests with all FEEs connected |

Connected all FEEs.

The two top fees corresponding to the bottom right detector are connected to damaged flexi rigid PCBs. The top one is missing an pin that should not be connected to anything, while the bottom one has a slightly cracked connector and is missing the top left pin. Spares should be in Edinburgh.

Found that the flexi rigid PCB connected to the bottom most FEE of the bottom-left detector has a damaged ground lemo connector. Possibly pulled during mounting? The bias cables were off most of the time. Seems to bias fine using the other bias lemo, but not ideal.

Attached, a V-I plot of the four detectors being biased. Note bottom-left was only biased to 120V vs. 150 since it shows relatively high leakage current. Time is wrong - bias was given over ~2 minutes. Unclear why the x-axis is incorrect.

Leakage currents for all detectors, and especially bottom-left and bottom-right drop significantly waiting a sufficently long amount of time, e.g. down to ~5.5 uA after 15 minutes.

To create this plots in case it is needed.

ssh to CARMEbakingpi

cd Programs/caenlogger

python3 caenlogger.py

This will capture the data and pass it to the server (carme-gsi) in ~/caen_current.dat where they will be APPENDED. Delete / save / move the file from the CARME server if required. Backups are in Programs/caenlogger/bias_logs

THEN Bias on

THEN

ssh carme-gsi

cd Programs/caenlogger

gnuplot plot_current.gp

|

| Attachment 1: Screenshot_2024-01-13_15-24-40.png

|

|

| Attachment 2: 20240113_150158.jpg

|

|

|

|

466

|

Sat Jan 13 14:32:21 2024 |

CB, JM | Leaky manifold and cable management |

Found two leaks in the welding of the manifolds, marked them in tape. Manifold to be repaired on Monday. Remember to re-install missing hoses, which are in a bucket in the cave.

See attached how it is supposed to look like.

Left hand hose (inlet) was too short and was cut to dismount the manifold. Davide will obtain a new tube of the same type and mount it for us. NOTE THAT THE INLET connector (BLUE manifold) was leaking. Unclear if this was the hose or poor plumbing.

Installed cable management system that was never used during the last beamtime. Started to thread cables through it. There should be sufficient space to re-install the manifolds with the cable tray in place. If this is difficult, the tray is installed with zip ties only so altering position should be relativly straightforward. The mounting points of the outlet manifold on the CARME chamber can also be rotated around to give a bit more space.

Cleaned up some boxes and moved heaters and some empty boxes to the CRYRING roof. |

| Attachment 1: 20240112_111838.jpg

|

|

| Attachment 2: 20240112_105936.jpg

|

|

| Attachment 3: 20240113_183019.jpg

|

|

|

|

496

|

Wed Feb 7 10:09:14 2024 |

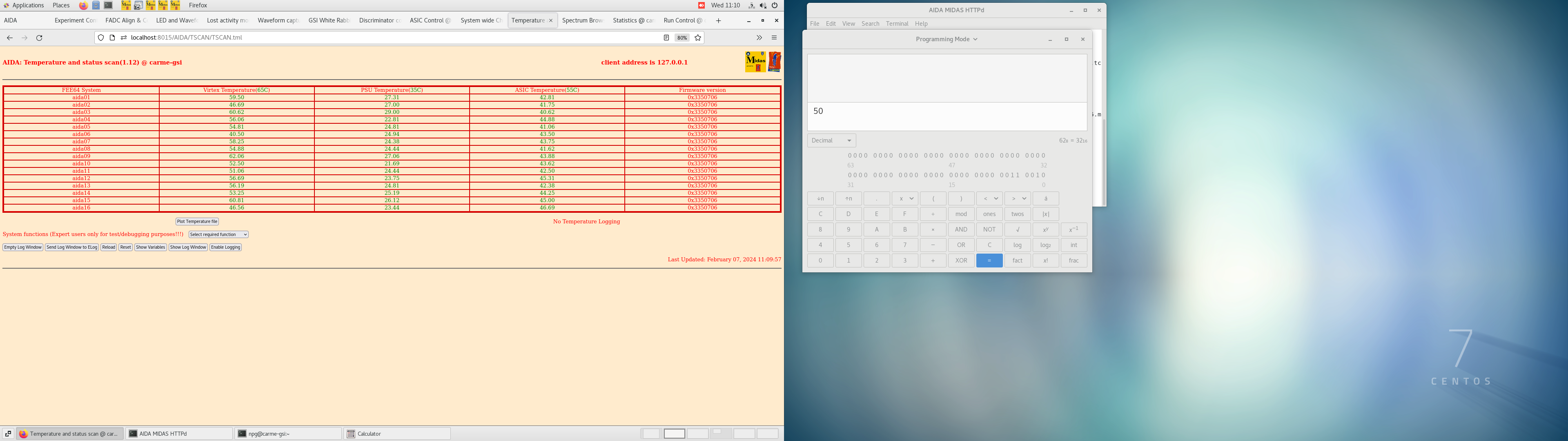

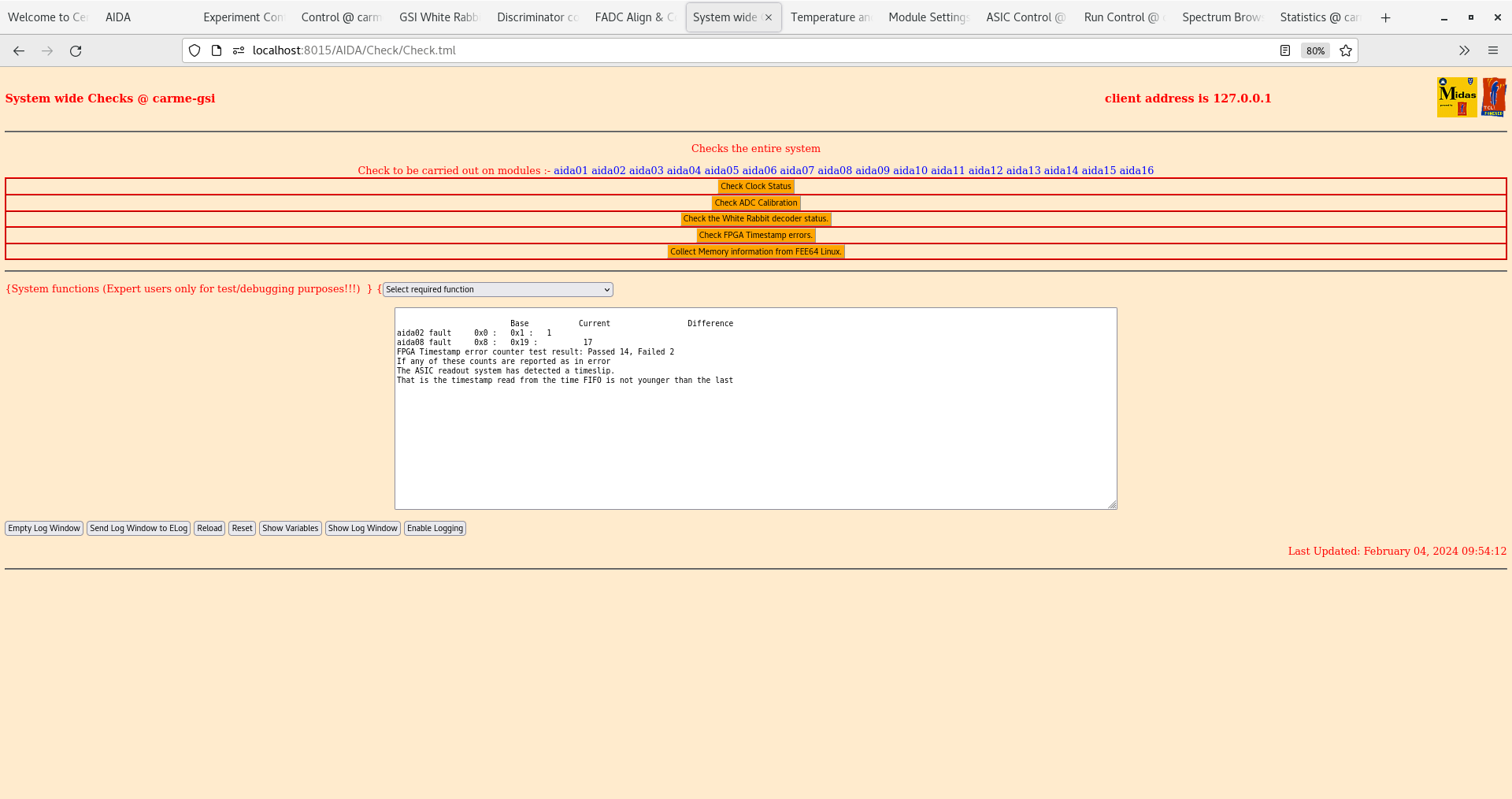

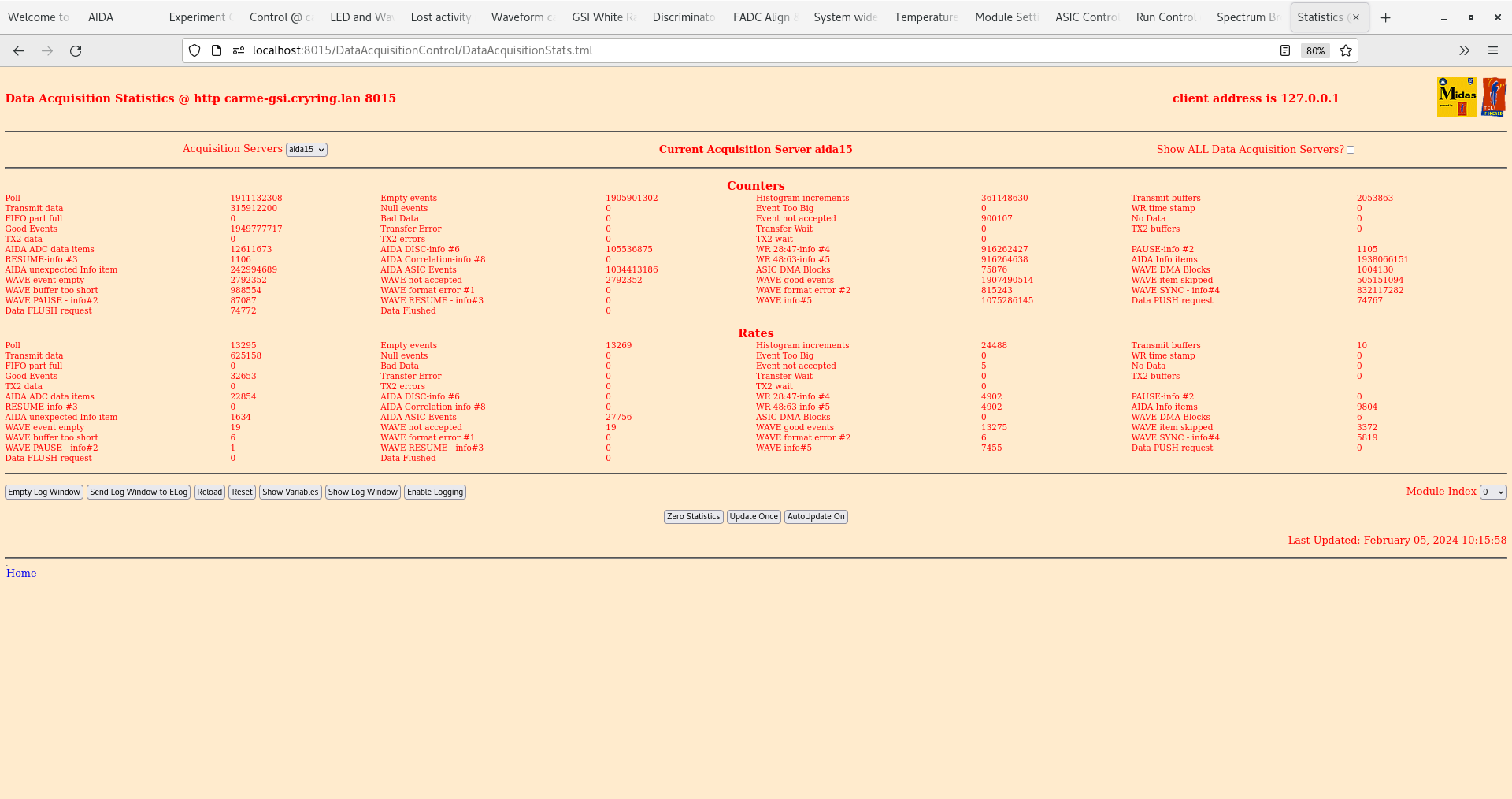

CB, JG, EM | Morning Shift |

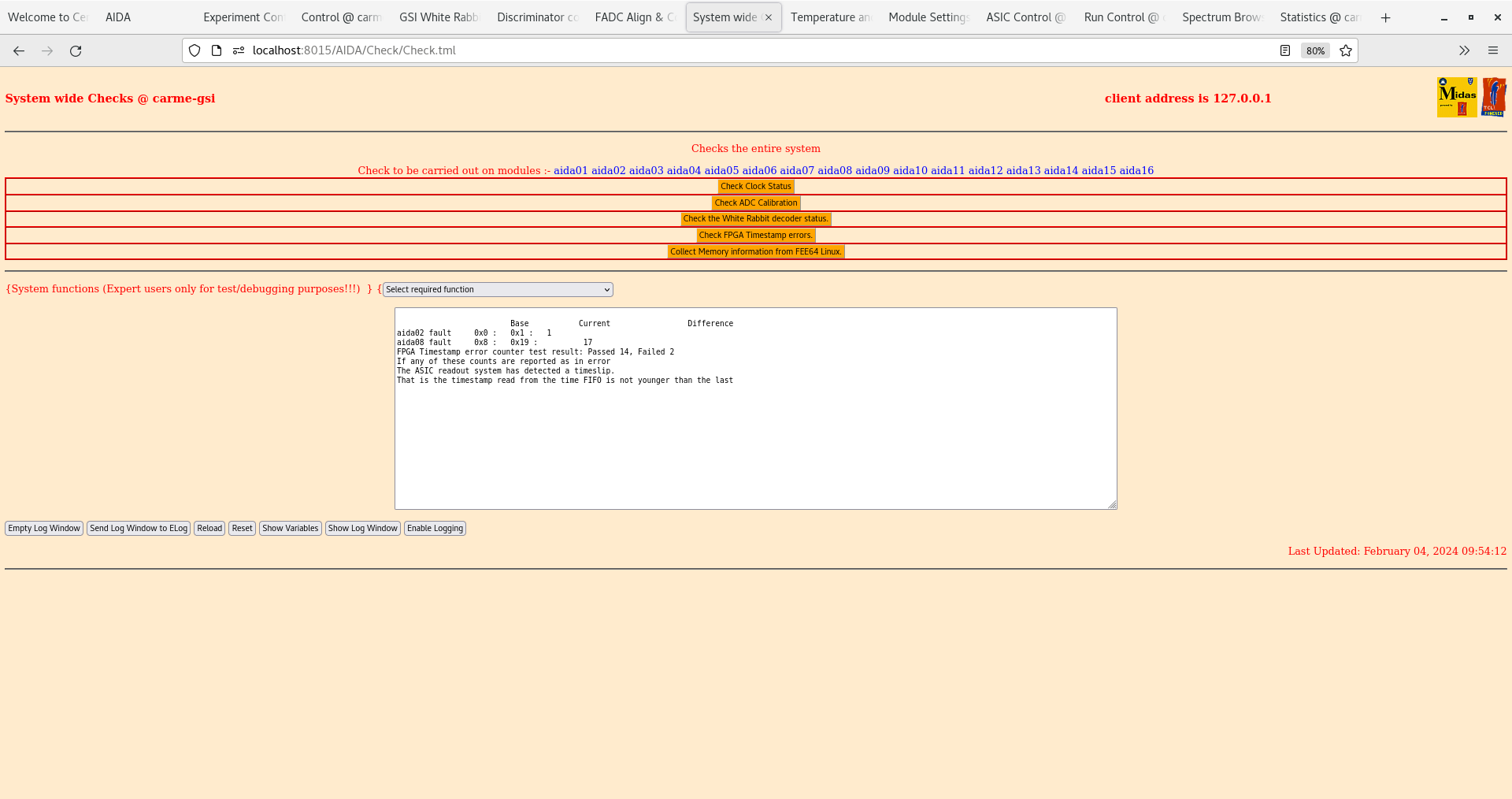

11:00

Changed slow comp threshold to 0x32 (500 keV). Checkloaded.

Temperature, Statistics fine (see screenshots).

System wide checks fine (see below).

All FEEs pass clock check.

All FEEs pass White Rabbit check.

ADC Calibration check:

FEE64 module aida02 failed

FEE64 module aida16 failed

Calibration test result: Passed 14, Failed 2

If any modules fail calibration , check the clock status and open the FADC Align and Control browser page to rerun calibration for that module

FPGA timestamp error check:

Base Current Difference

aida09 fault 0x1 : 0xa : 9

FPGA Timestamp error counter test result: Passed 15, Failed 1

If any of these counts are reported as in error

The ASIC readout system has detected a timeslip.

That is the timestamp read from the time FIFO is not younger than the last

|

| Attachment 1: Screenshot_from_2024-02-07_11-10-08.png

|

|

| Attachment 2: Screenshot_from_2024-02-07_11-10-59.png

|

|

| Attachment 3: Screenshot_from_2024-02-07_11-15-53.png

|

|

| Attachment 4: Screenshot_from_2024-02-07_11-20-38.png

|

|

|

|

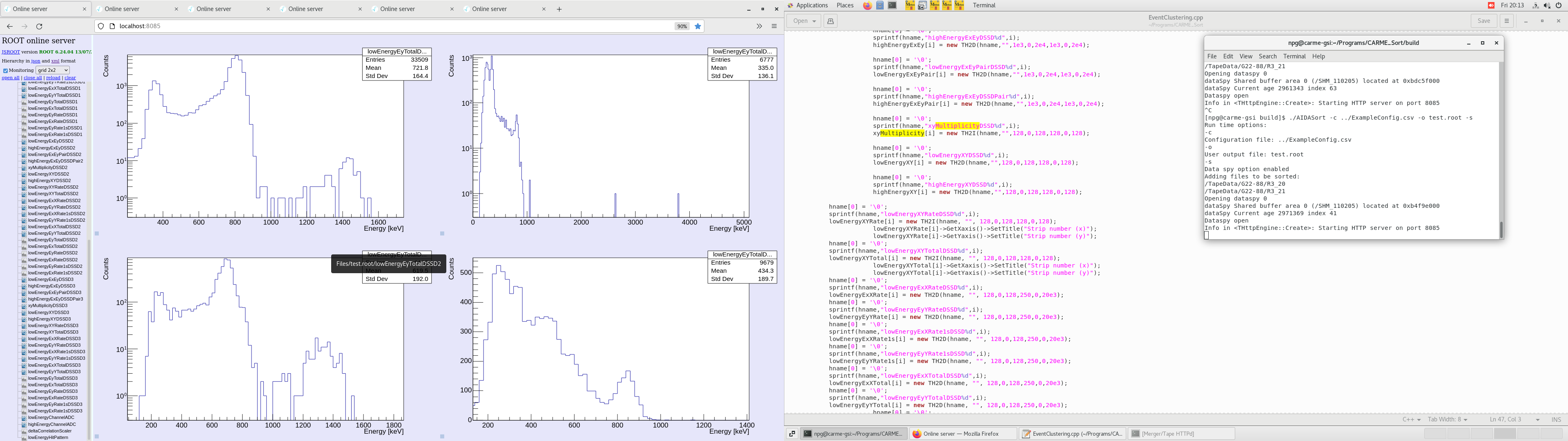

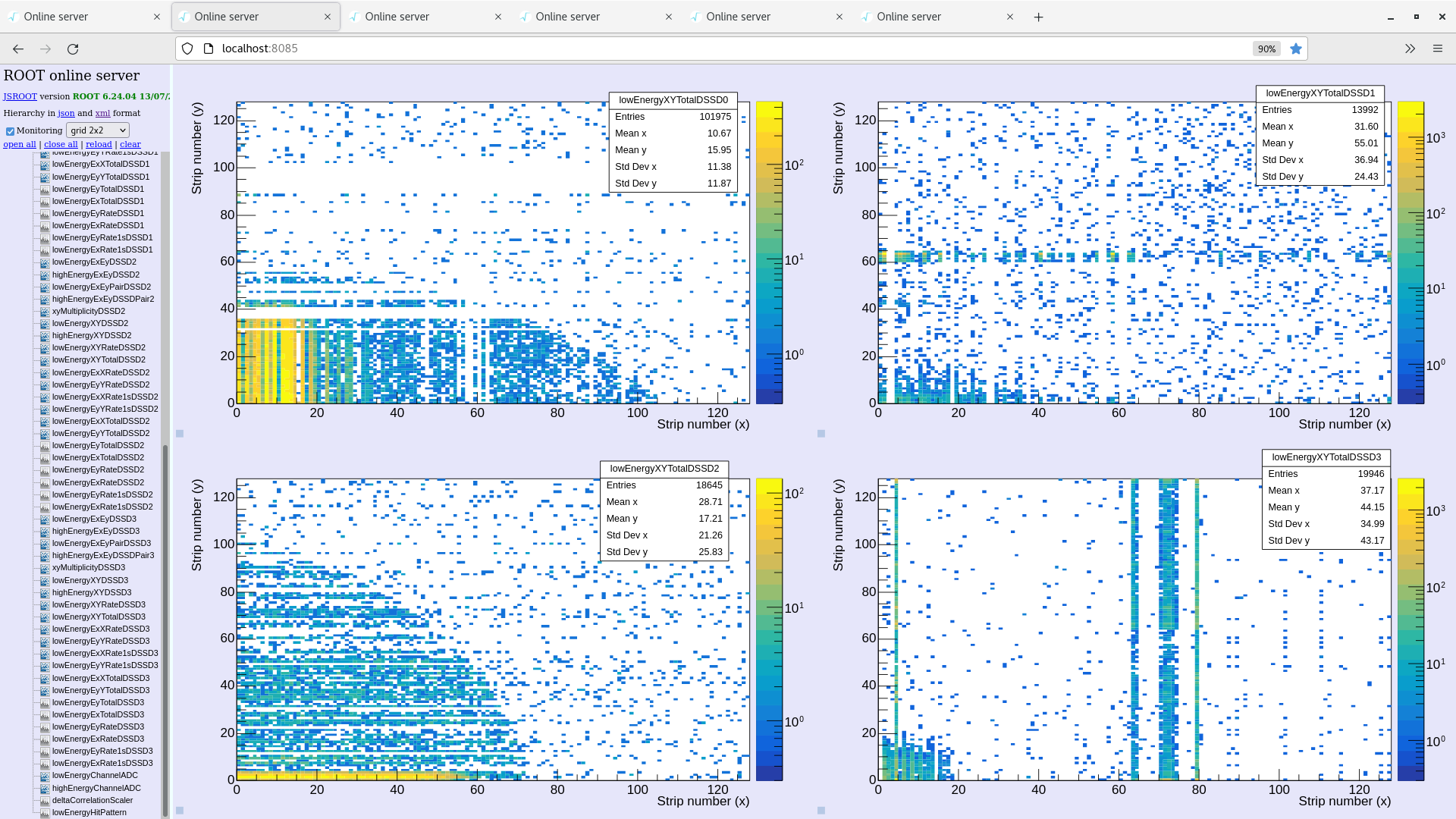

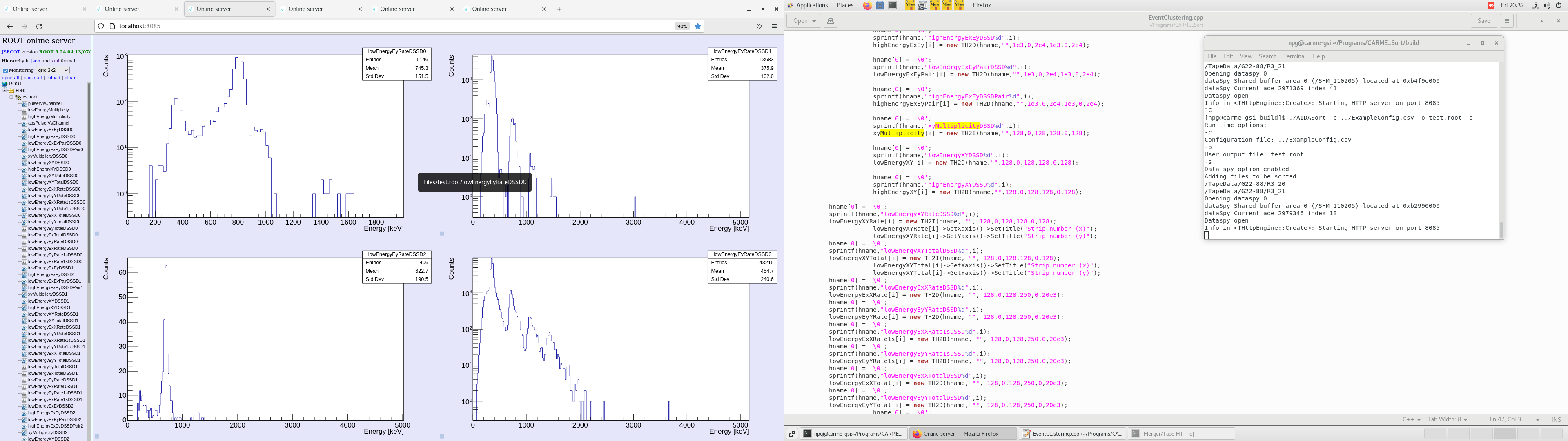

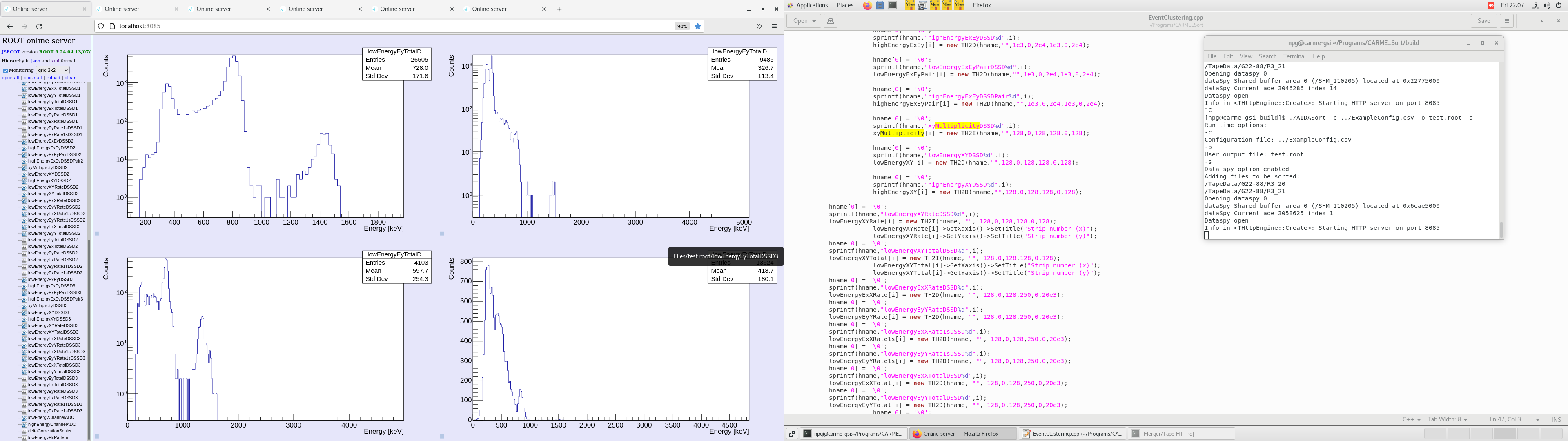

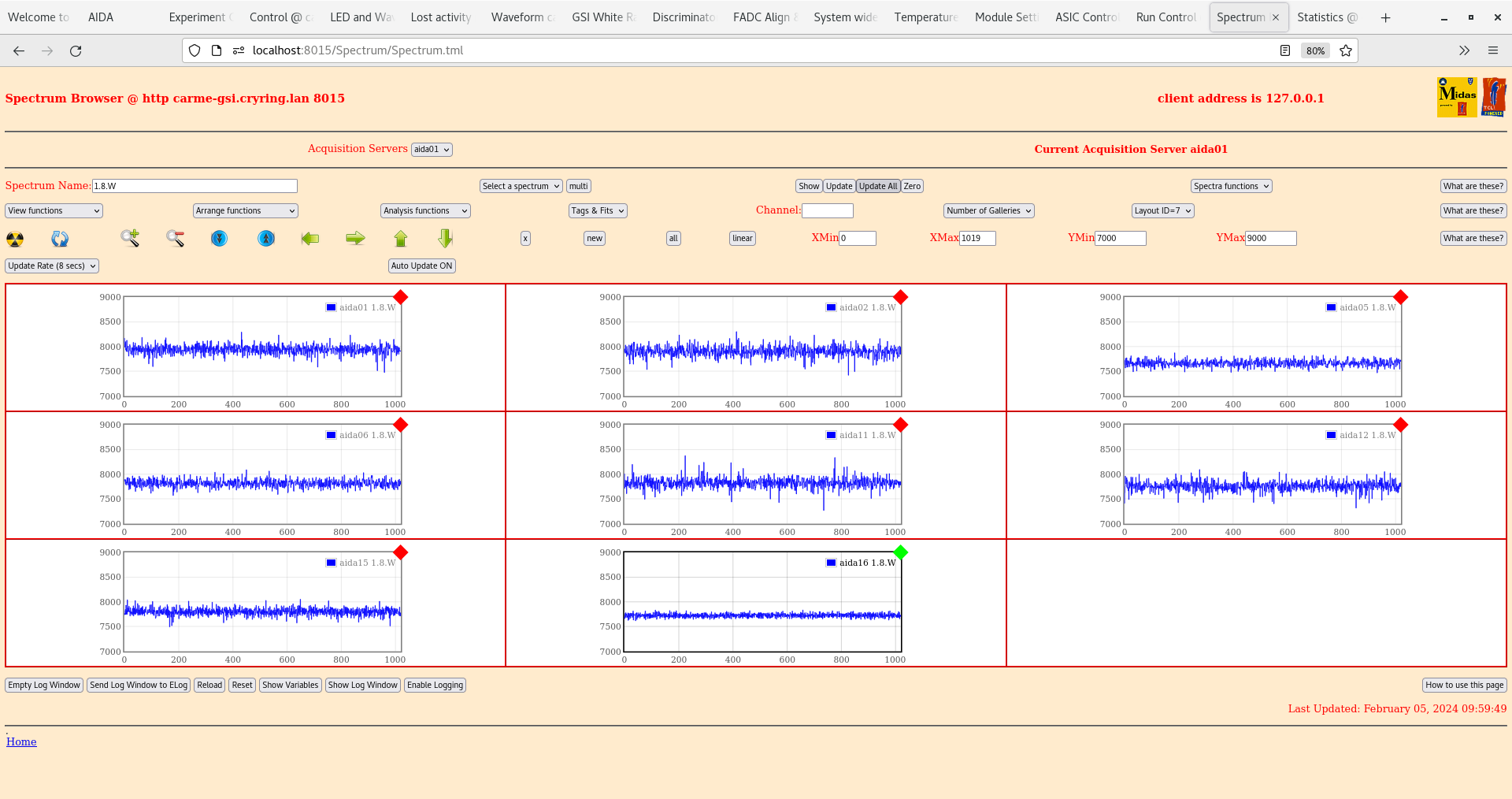

566

|

Fri May 31 19:12:01 2024 |

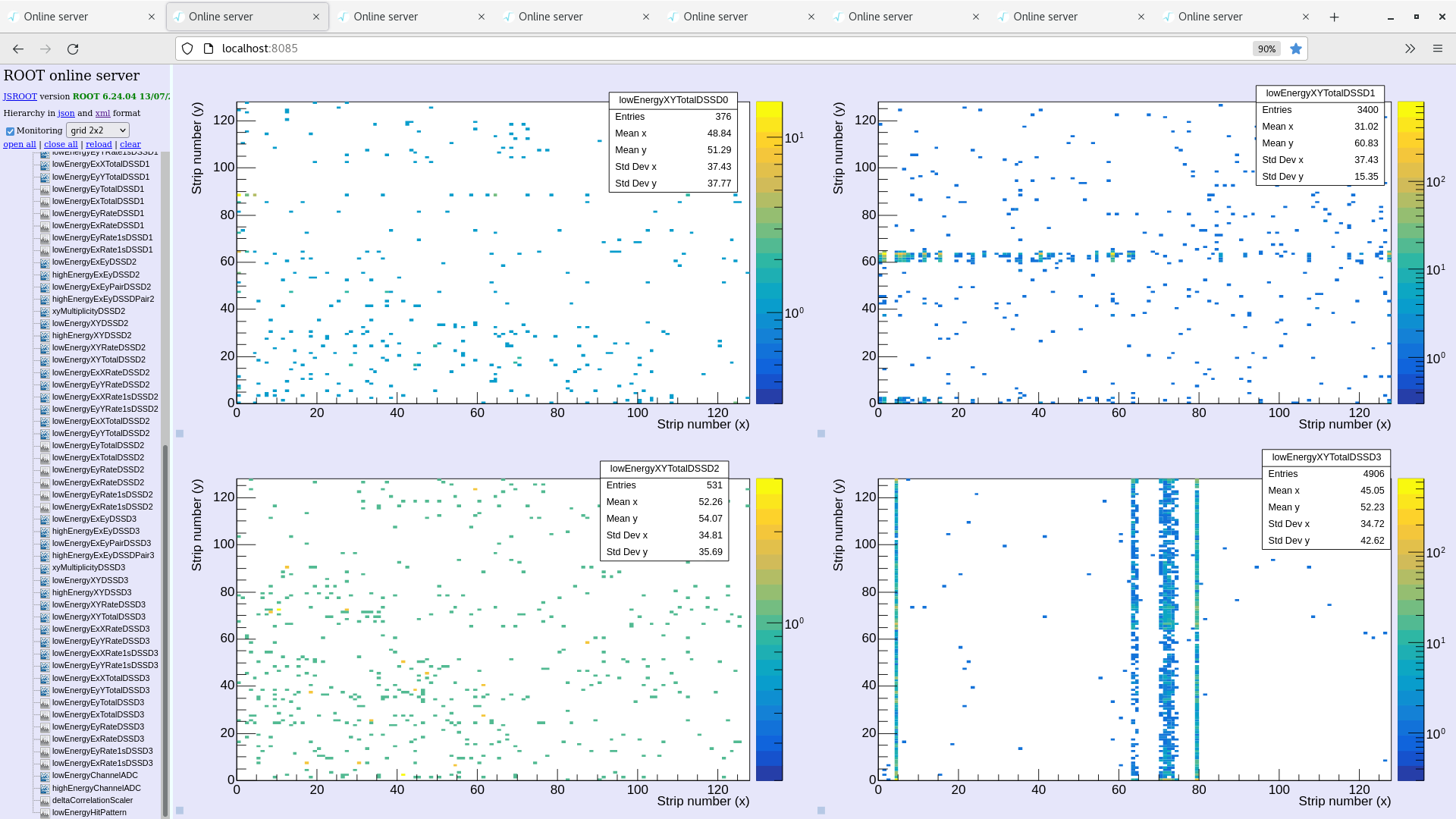

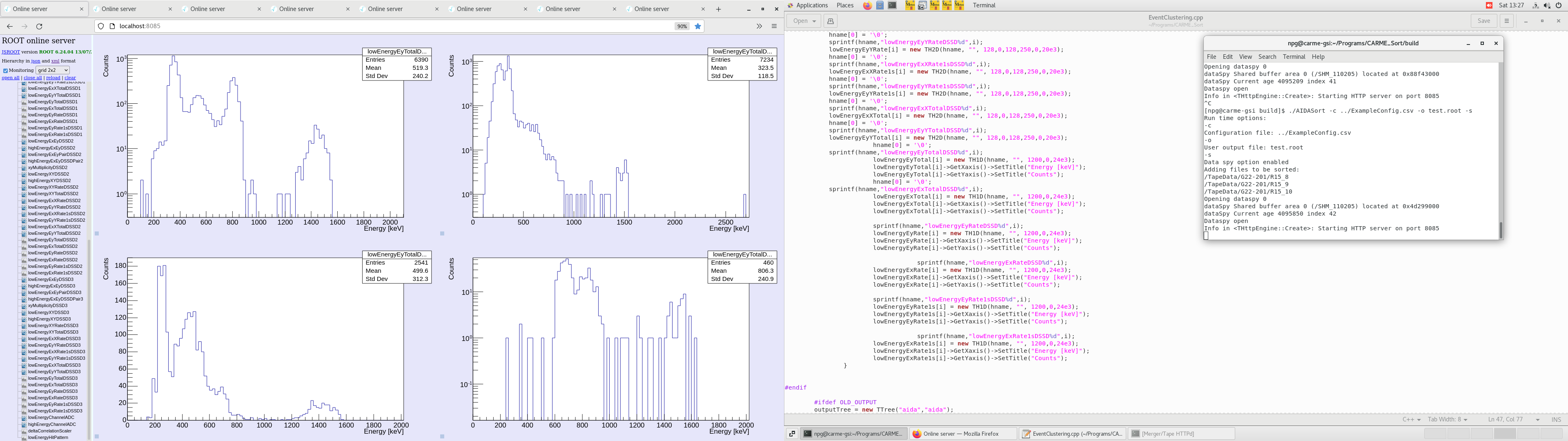

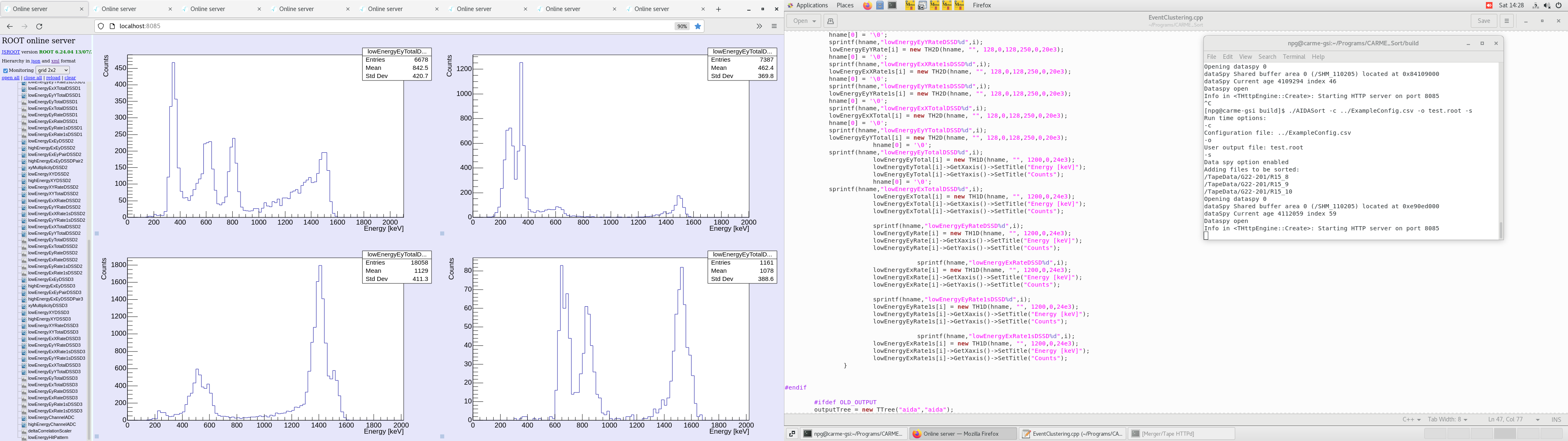

CB, EM | Run 13 - test with beam |

20:00

The beam is set at the correct energy, operators cross-checked it again. What we see at 750 is due to the molecular beam. The operotors are trying to optimize and get rid of this in the next 30min.

Temps and system checks OK

Leakage current OK

Merger and tape server OK

Potentiometer at 28.06 mm and 29.23 mm

20:30

Keep going with the beam tests. A new peak appears around 950 keV( See attached). Still try to understand what it is. The operators keep going |

| Attachment 1: Screenshot_from_2024-05-31_20-13-46.png

|

|

| Attachment 2: Screenshot_from_2024-05-31_20-27-58.png

|

|

| Attachment 3: Screenshot_from_2024-05-31_20-32-59.png

|

|

|

|

567

|

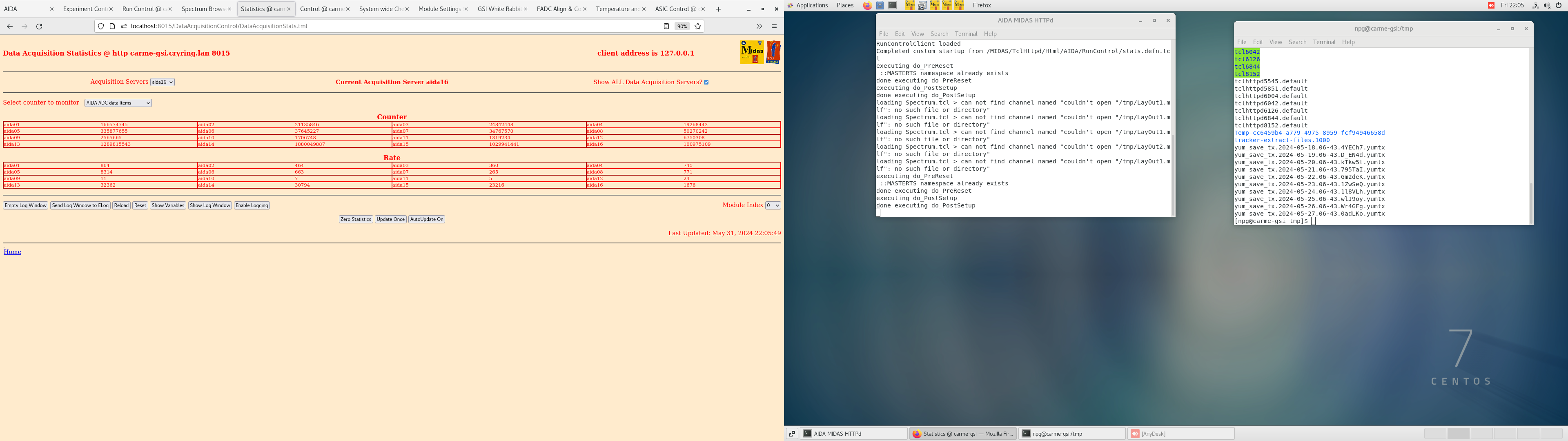

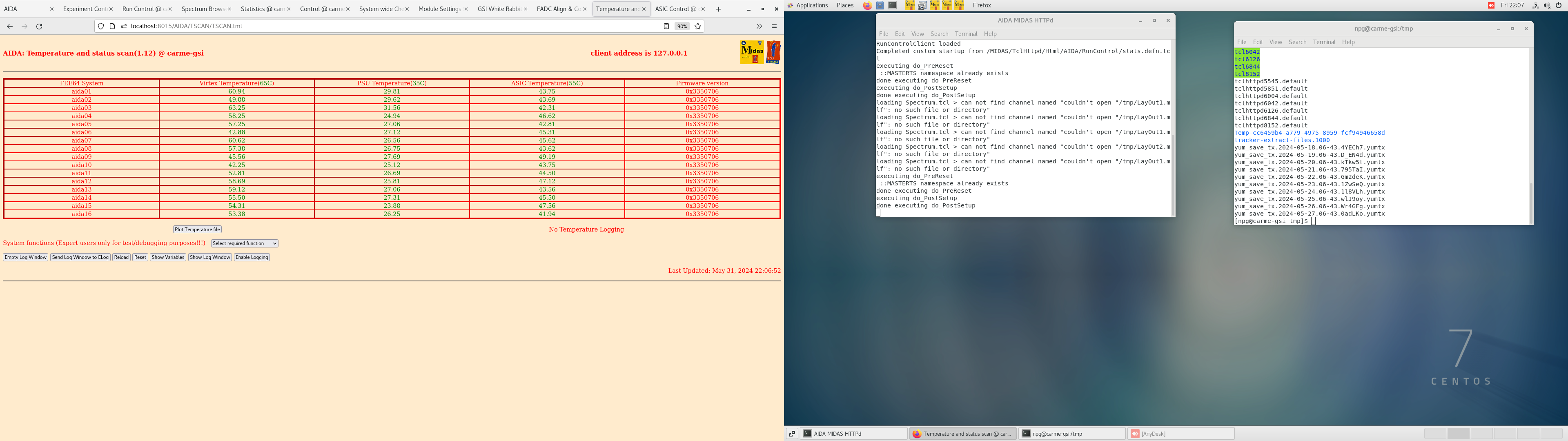

Fri May 31 21:03:21 2024 |

CB, EM | Run14 |

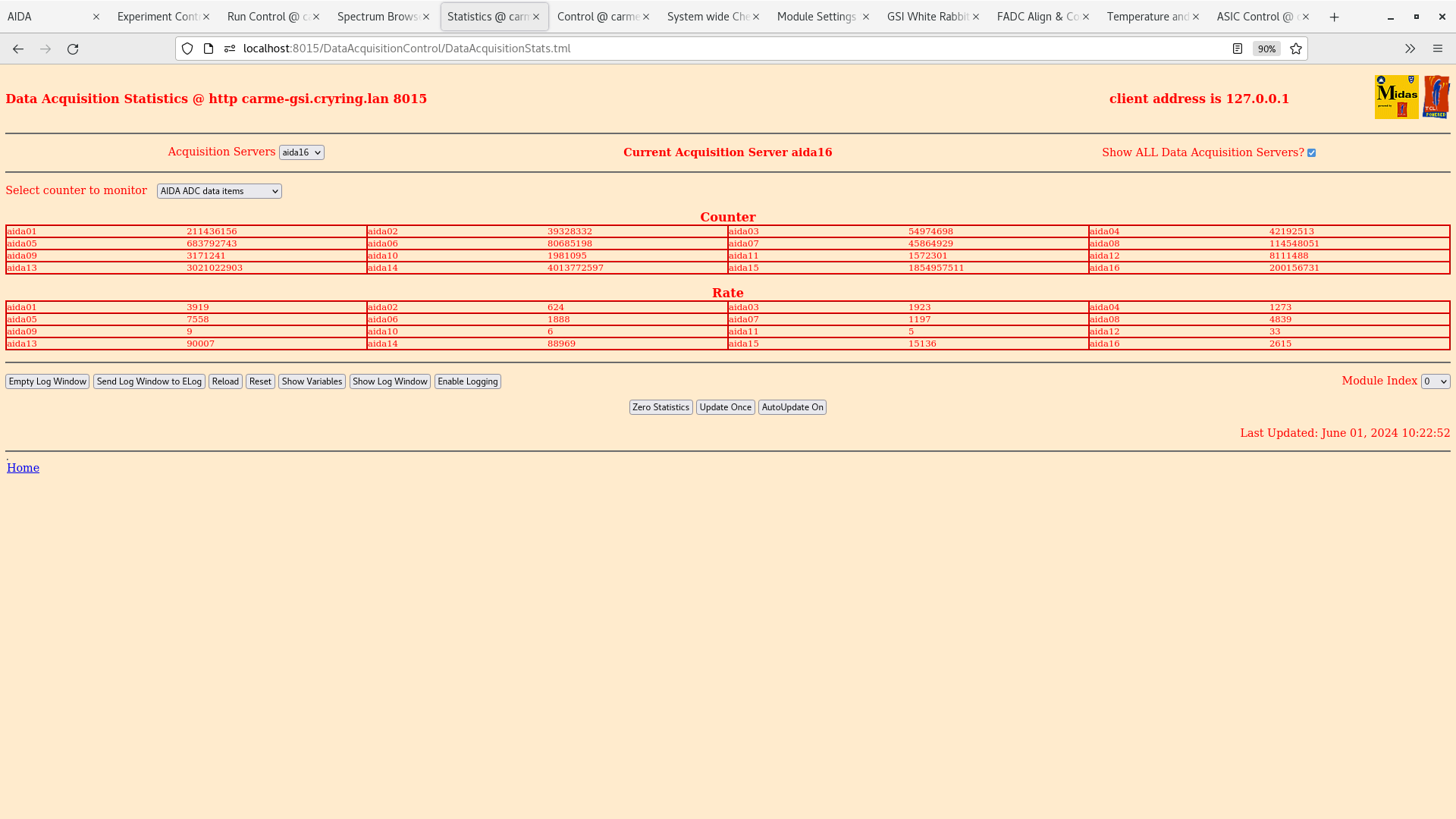

22:03

Before this run we checked quickly beam with the target on but it does not make sense with the current status of the beam.

We removed target and starte Run14

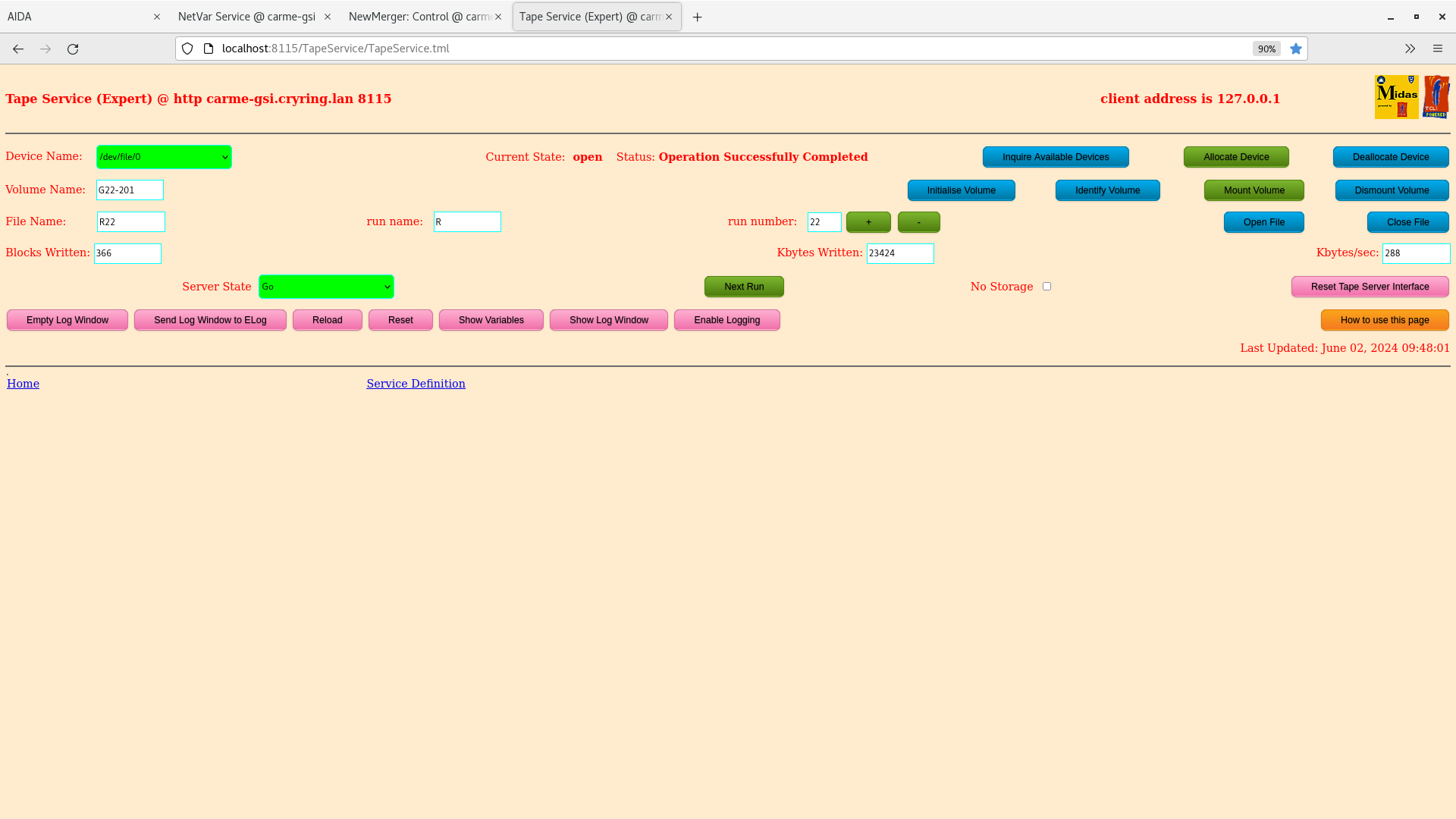

Merger OK, Tape server OK

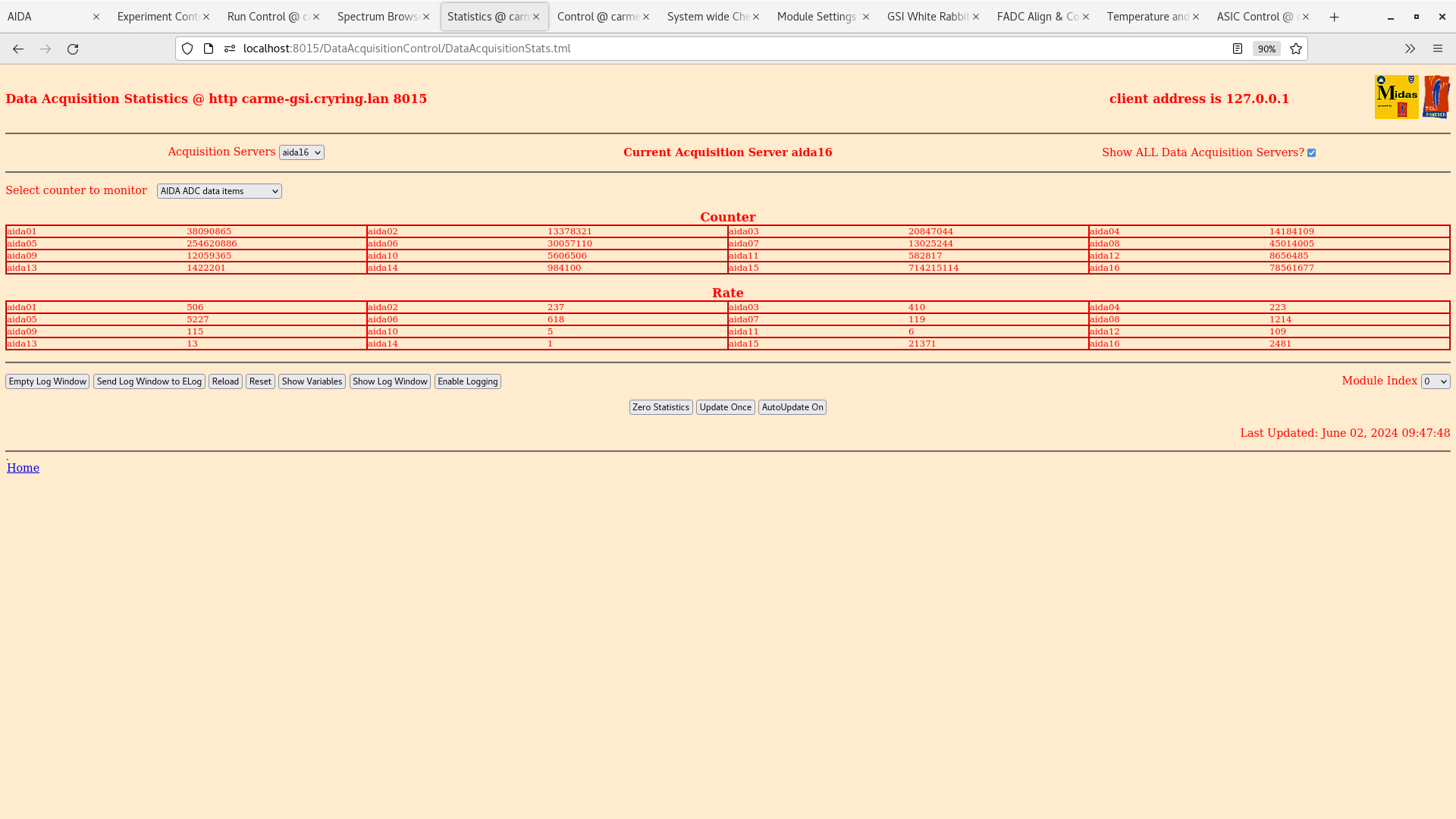

ADC data item statistics looks as before. OK

FEE temperatures look OK

System checks OK

Leakage current stable |

| Attachment 1: Screenshot_from_2024-05-31_22-05-57.png

|

|

| Attachment 2: Screenshot_from_2024-05-31_22-07-01.png

|

|

| Attachment 3: Screenshot_from_2024-05-31_22-07-49.png

|

|

|

|

500

|

Thu Feb 8 17:11:50 2024 |

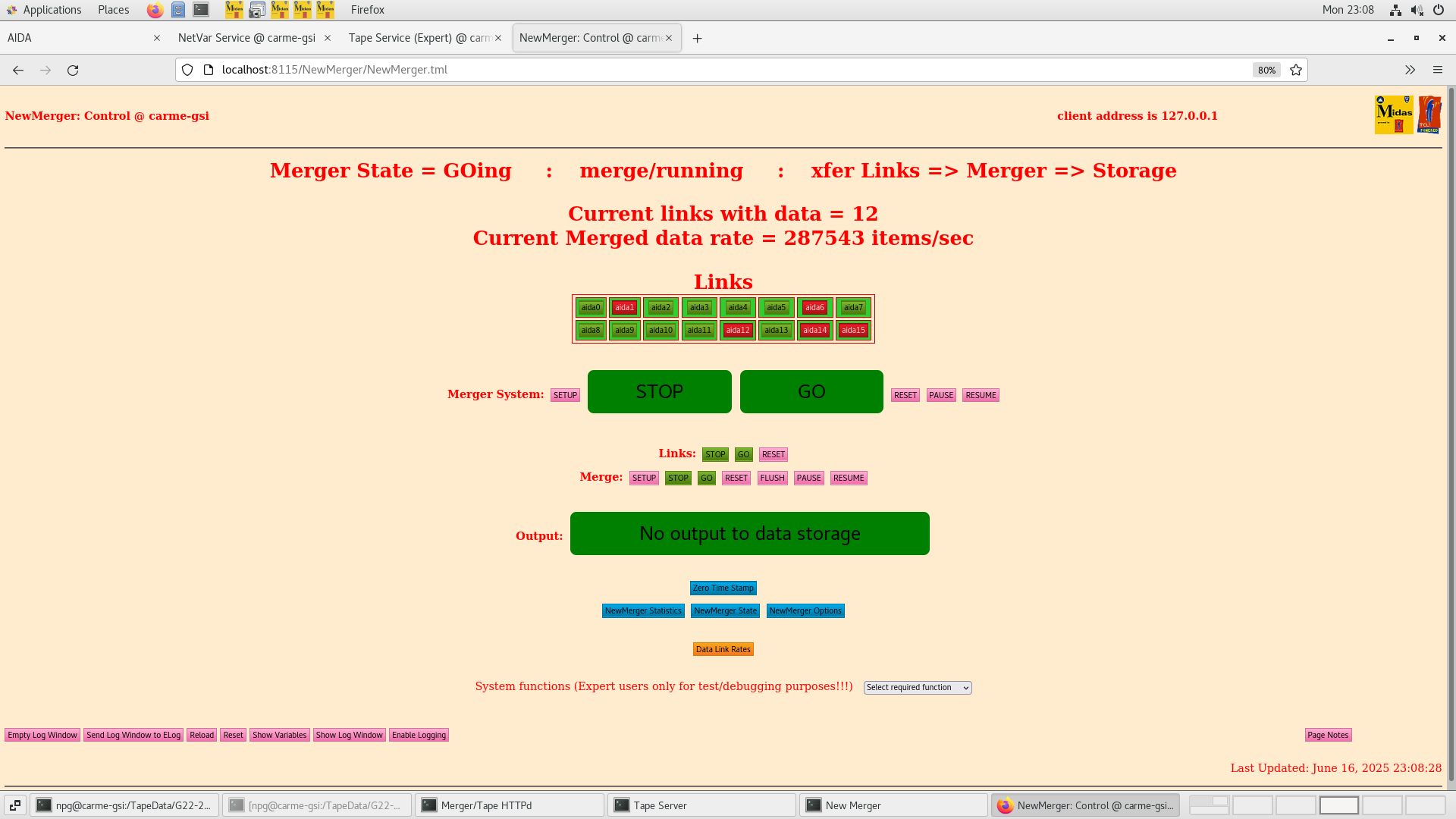

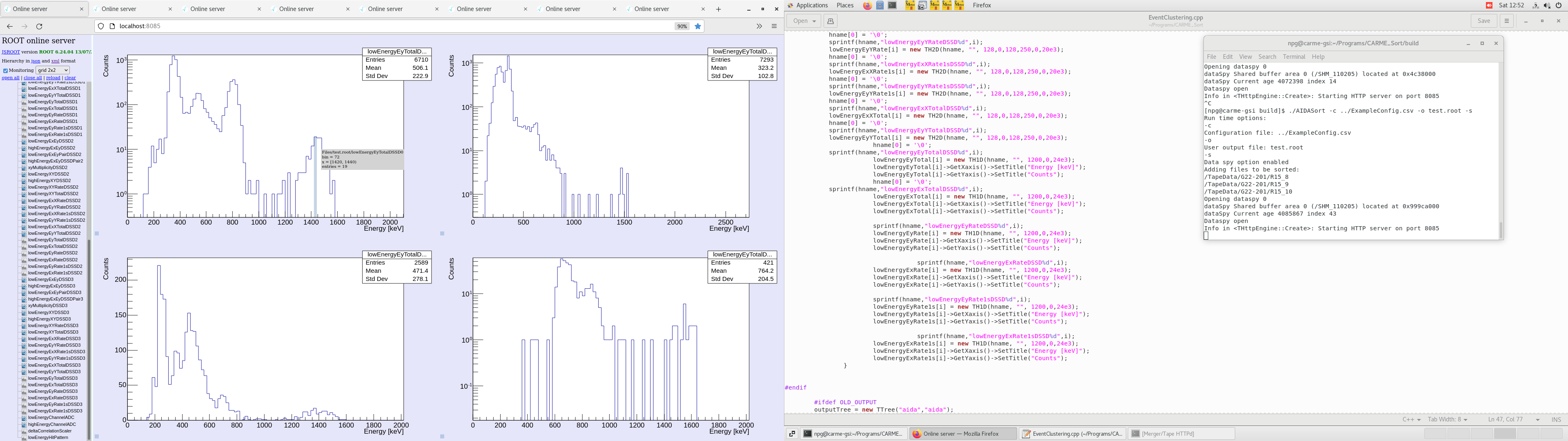

CB, EH | Pulser walkthrough |

17:30 File G22-88/R8

Pulser walkthrough

EGG Ortec 448 Pulser

Amplitide 90,000-10,000 @ 10,000 step

Normalise 5.0

Attenuators x5 IN

t_r 100ns

Tau_d 50us

Frequency Int Osc 50Hz

Polarity + ( - polarity via Cooknell SA1 Sum & Invert Amp )

18:10 Moved to new run R9

Pulser off. Overnight background. |

| Attachment 1: 4.png

|

|

| Attachment 2: 3.png

|

|

|

|

257

|

Wed Feb 23 16:57:35 2022 |

CB, CN | Optimising motor motion |

Optimised motor motion during run R58

Moved 2 mm in (20.3 potentiometer)

29.47 potentiometer

36.5 potentiometer

(started moving pneumatic)

64.36 potentiometer

74.03 potentiomater (servo in by 10 mm)

Moved in, collected counts for 5 minutes, moved out, waited for re-injection.

20.3 - 400 counts on the Rutherford peak, bins 125-131 on lowEnergyExTotalDSSD0

20.47 - 646

36.5 - 827

64.36 - 3900

74.03 - 10040

Based on Rutherford rate ratio, estimated we are 40-50 mm away from interaction point, i.e. beam roughly 1-2 cm on outer half of ring which may be consistent with BPM measurement in YR08

Decided to use 74.03 mm for data collection.

Started data acquisition on R59 at 17:27

Beam 3E7 at injection, 600 second storage, 3 second between cycles

Target pressure 1.3E12 based on 8.21E18 x S1=1.6E-8 |

|

|

722

|

Fri Jun 6 16:49:59 2025 |

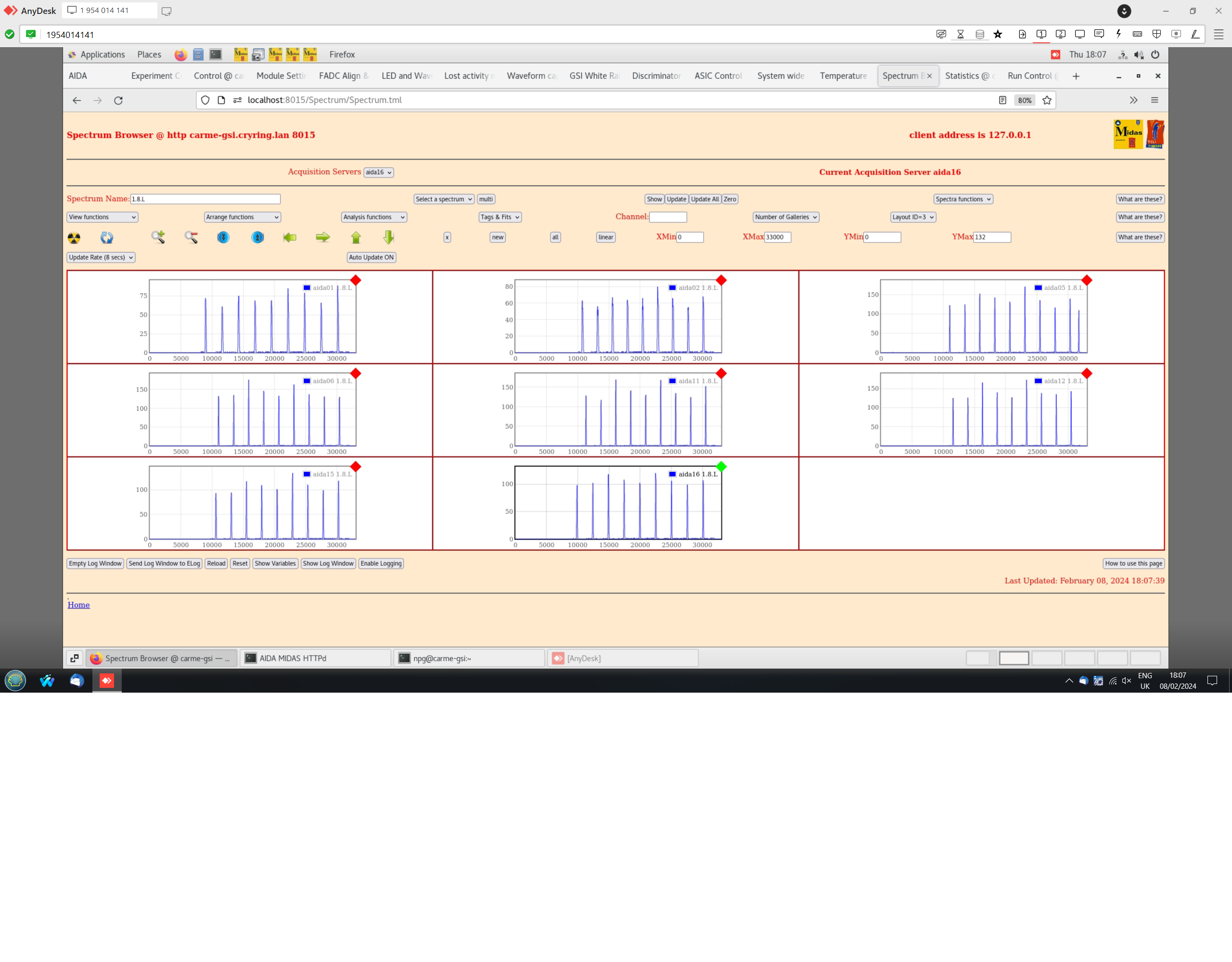

CB, AY, ST | Beam overlap results for 200keV and 250keV |

For 200keV the optimal horizontal position is -5mm.

For 250keV the optimal horizontal position is -2mm.

Both values are already given to the operators, so tomorrow we can just switch to 200keV and go on :)

Nonetheless, we now went to 250keV and start measuring. |

| Attachment 1: 2025_06_06_17_46_56_Greenshot.png

|

|

|

|

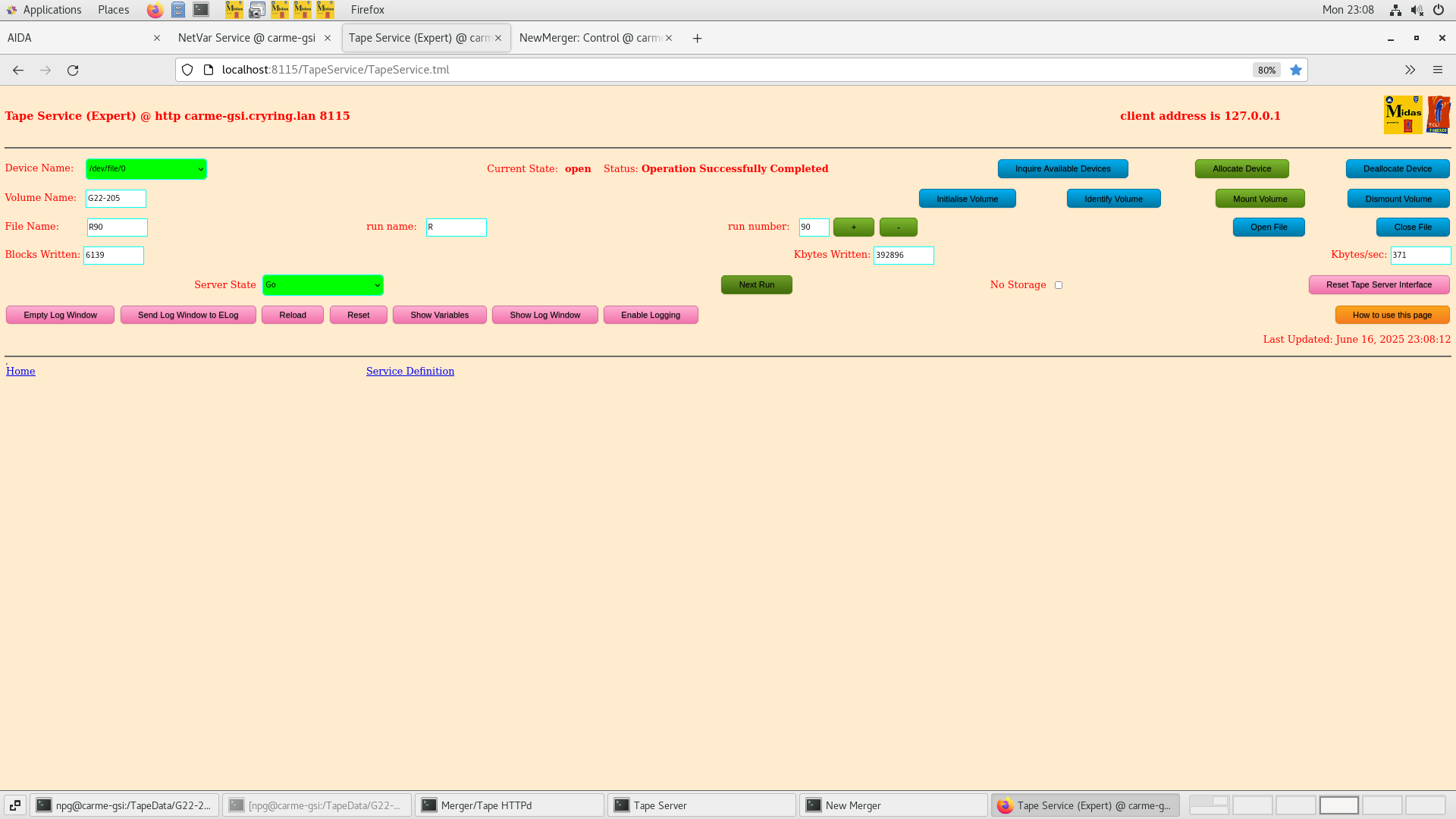

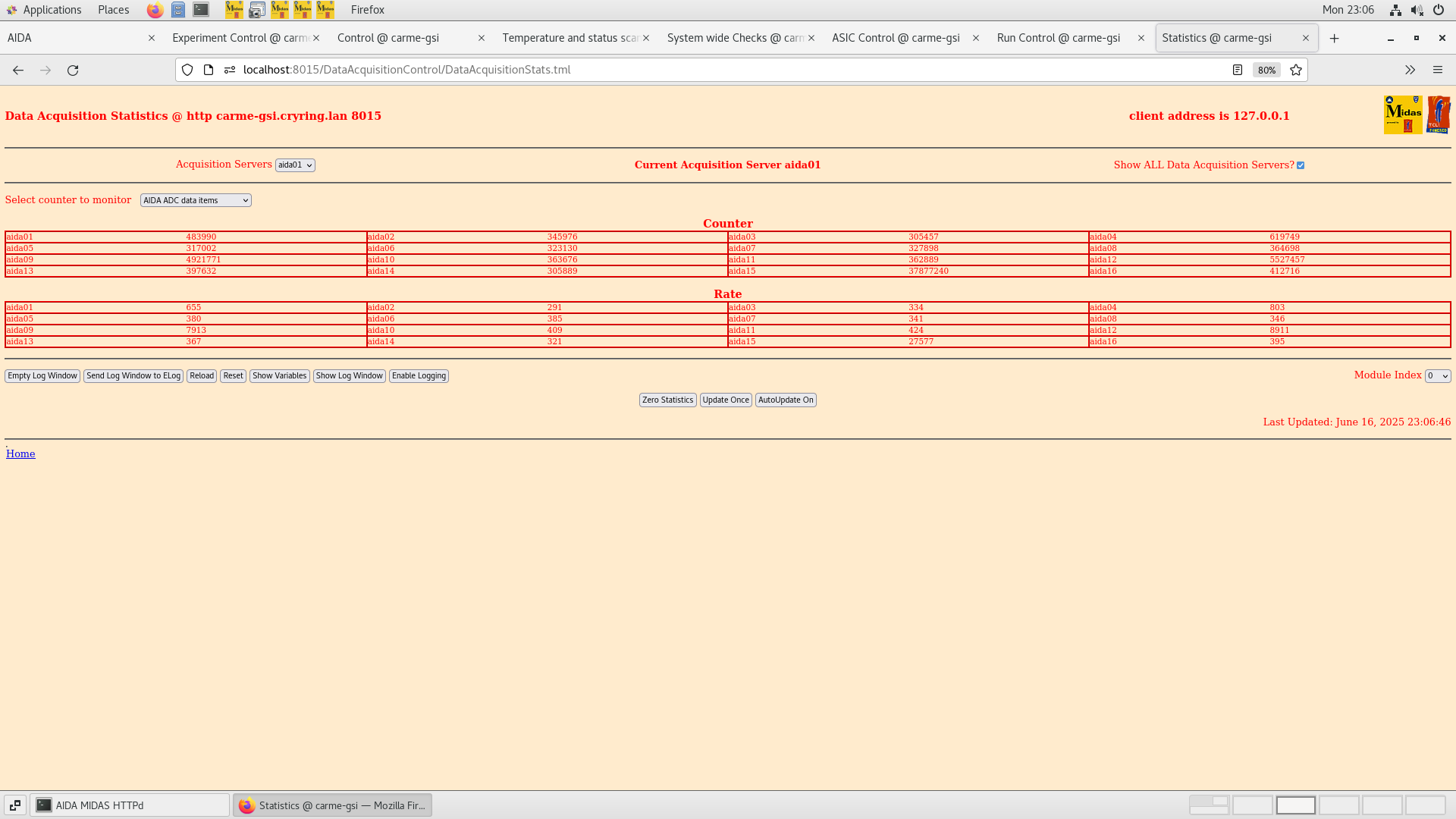

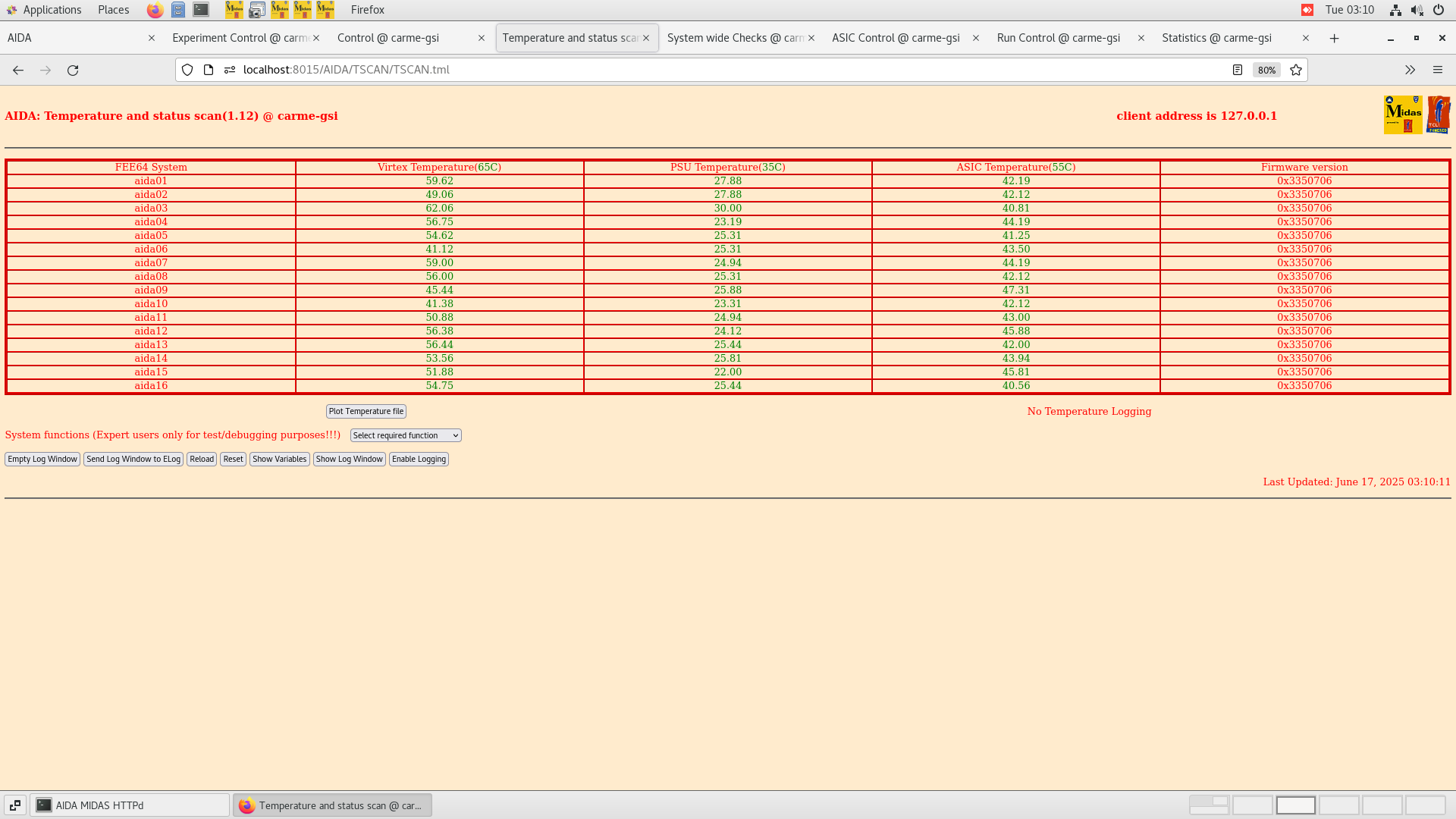

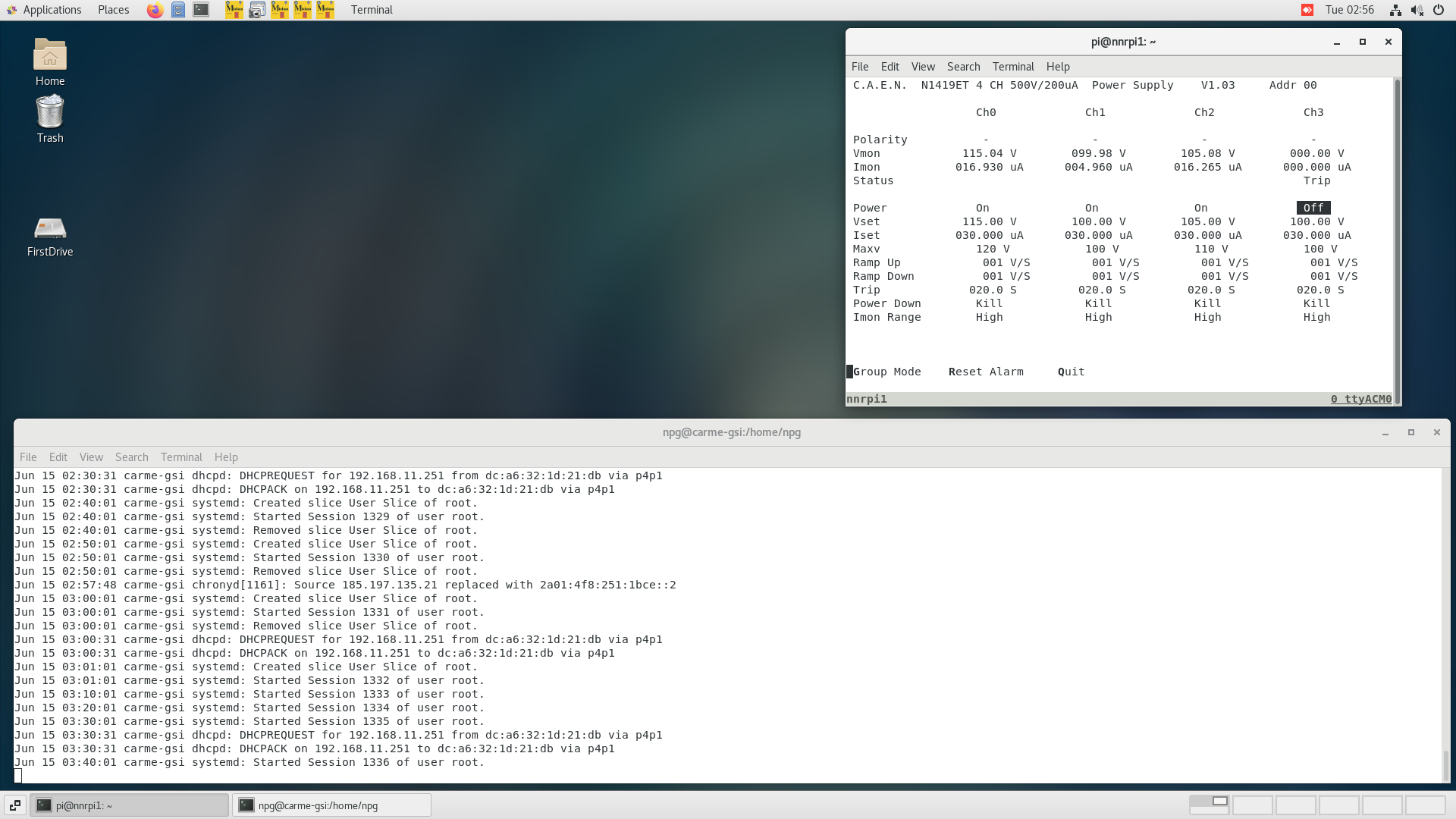

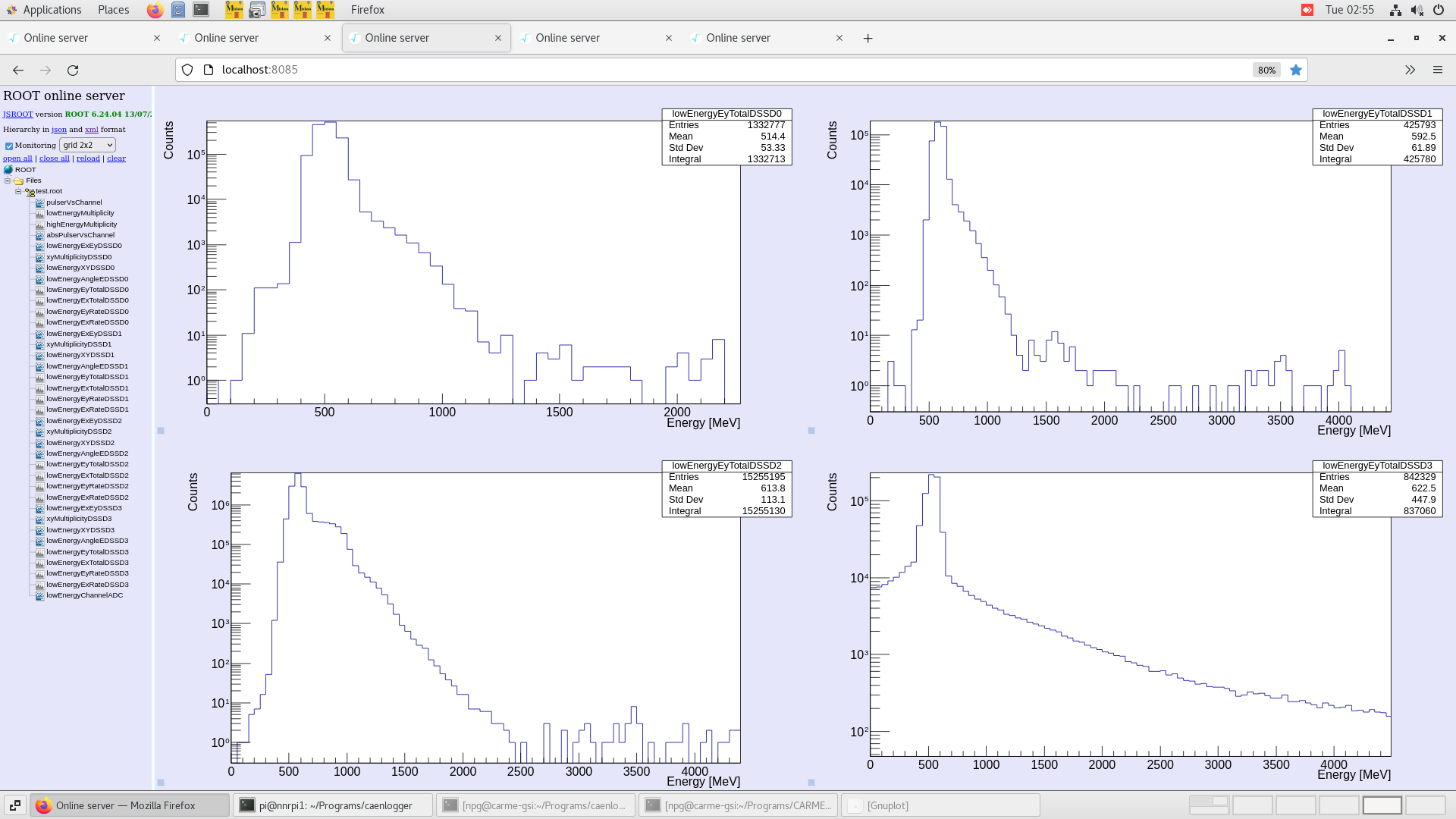

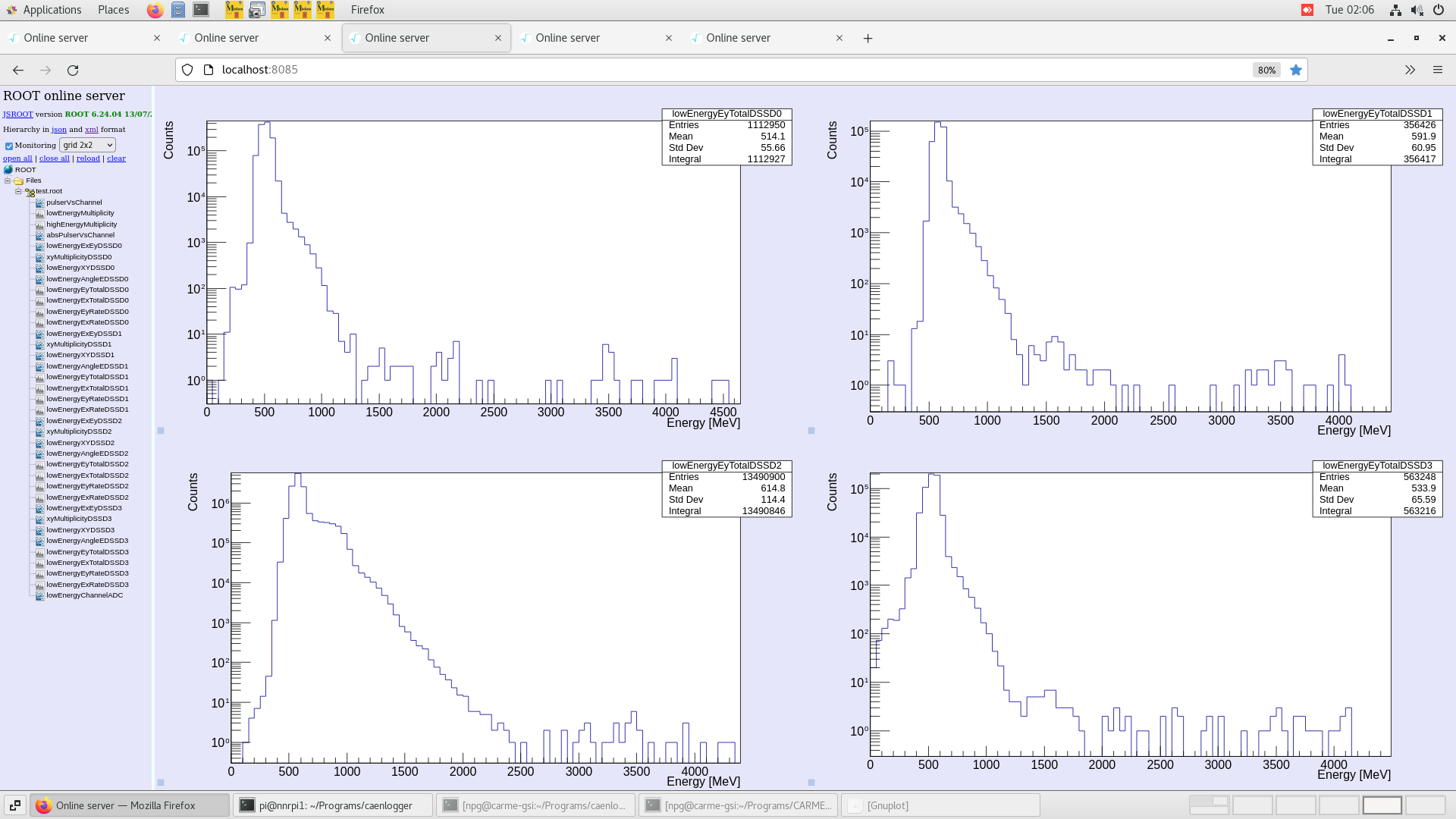

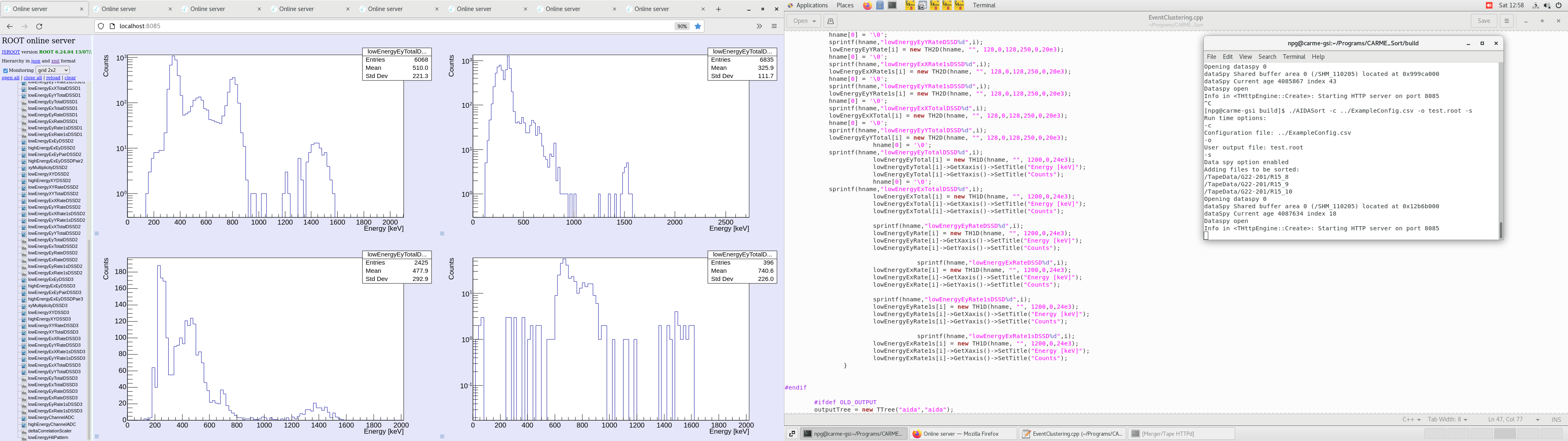

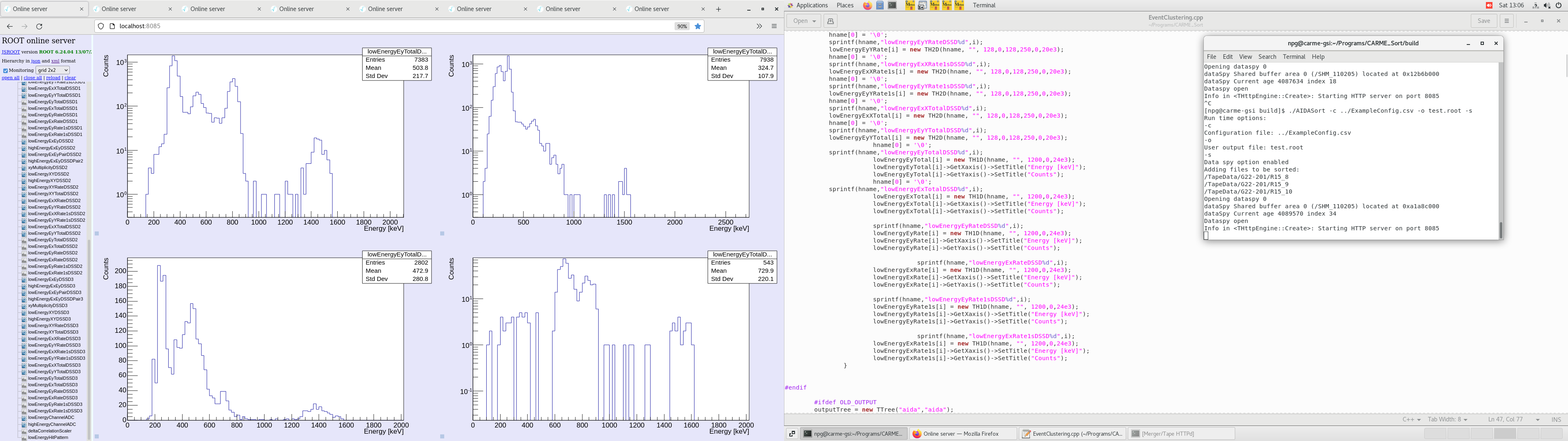

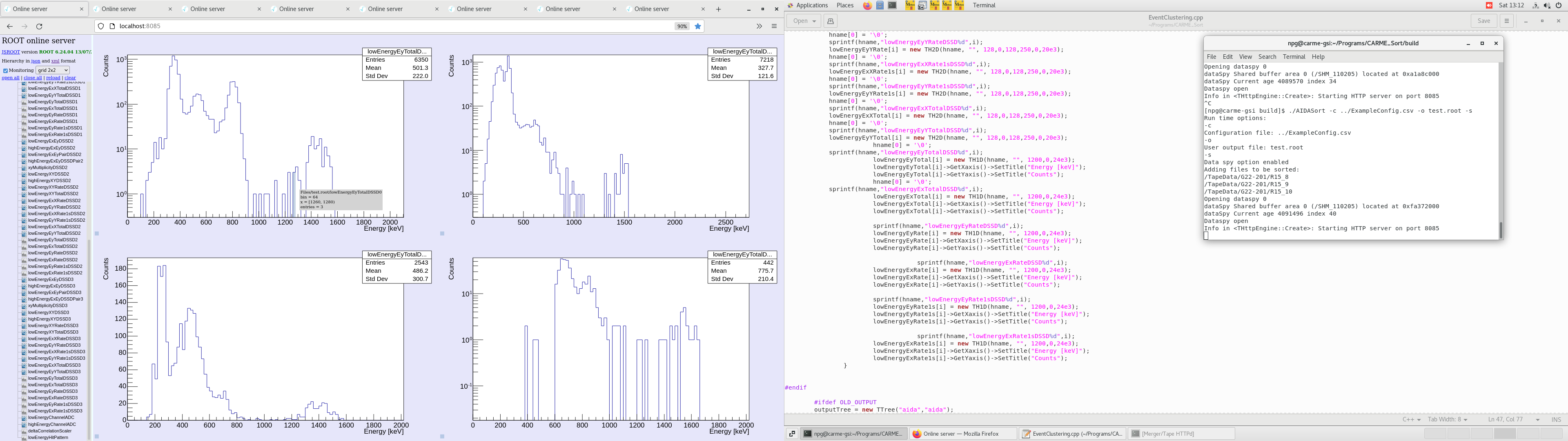

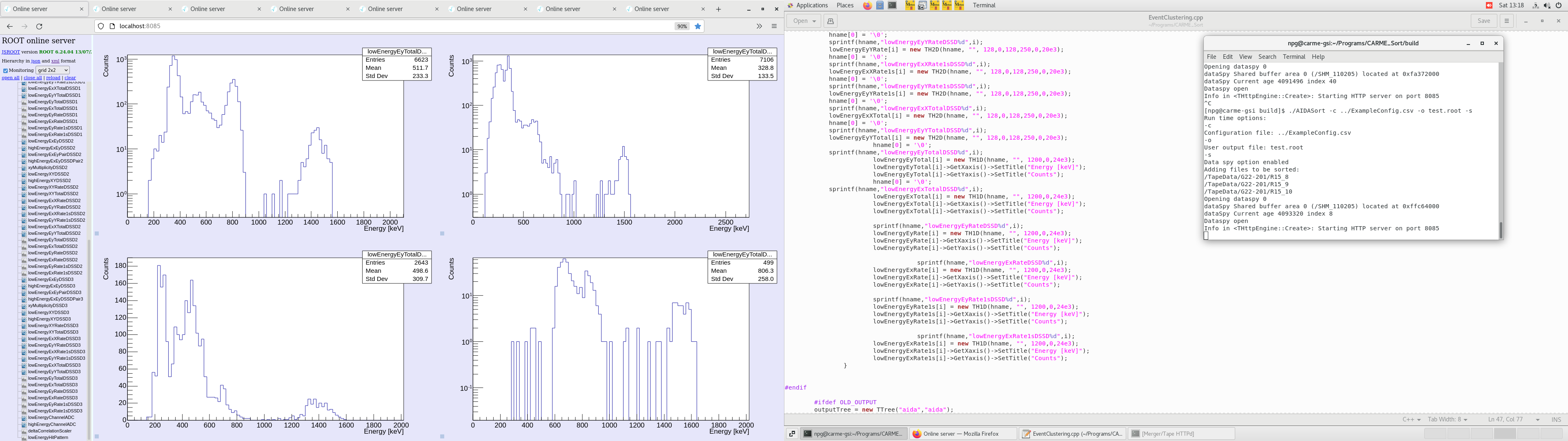

752

|

Mon Jun 16 22:06:00 2025 |

CB, AR, EW | RUN 90-91 |

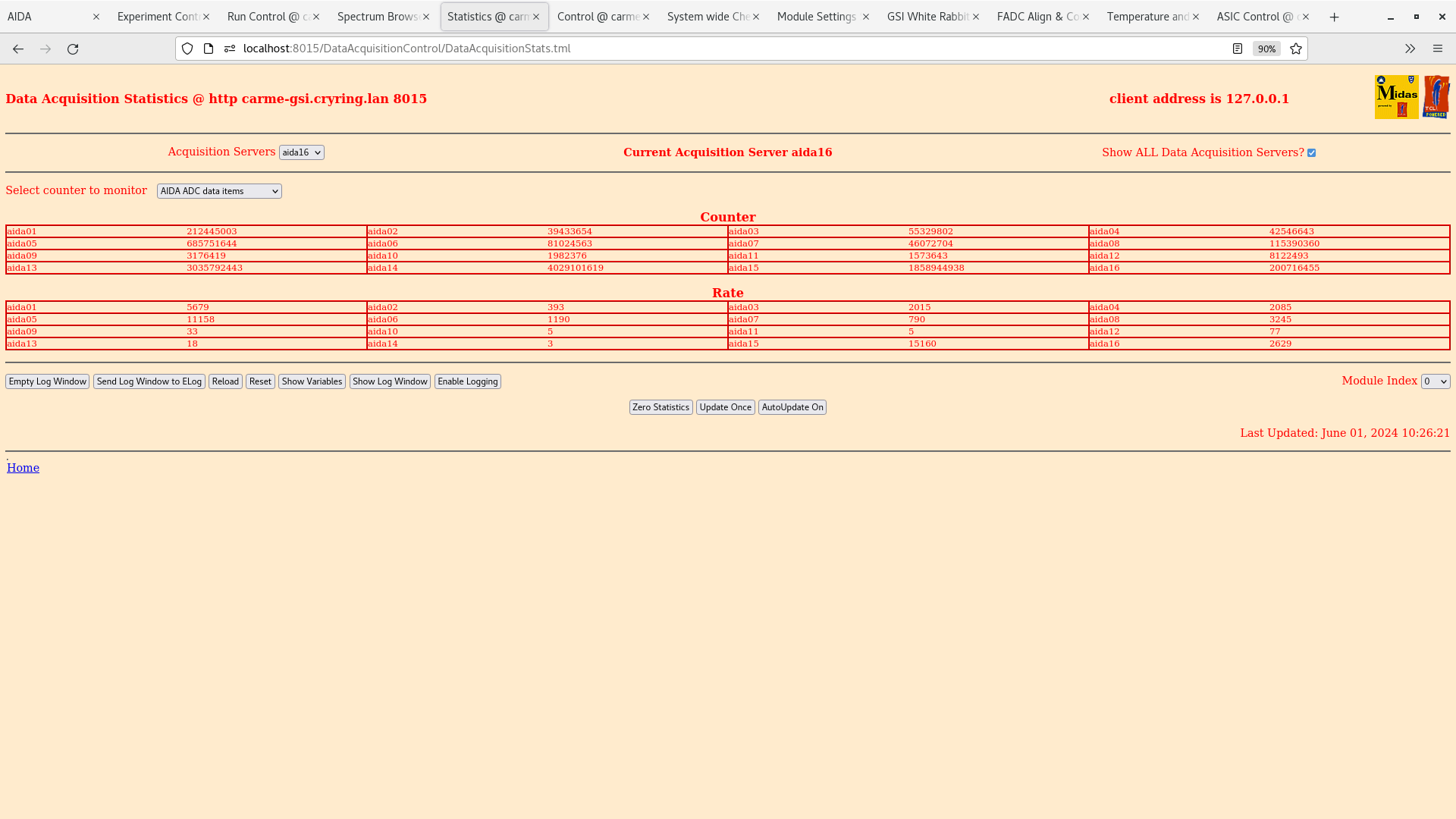

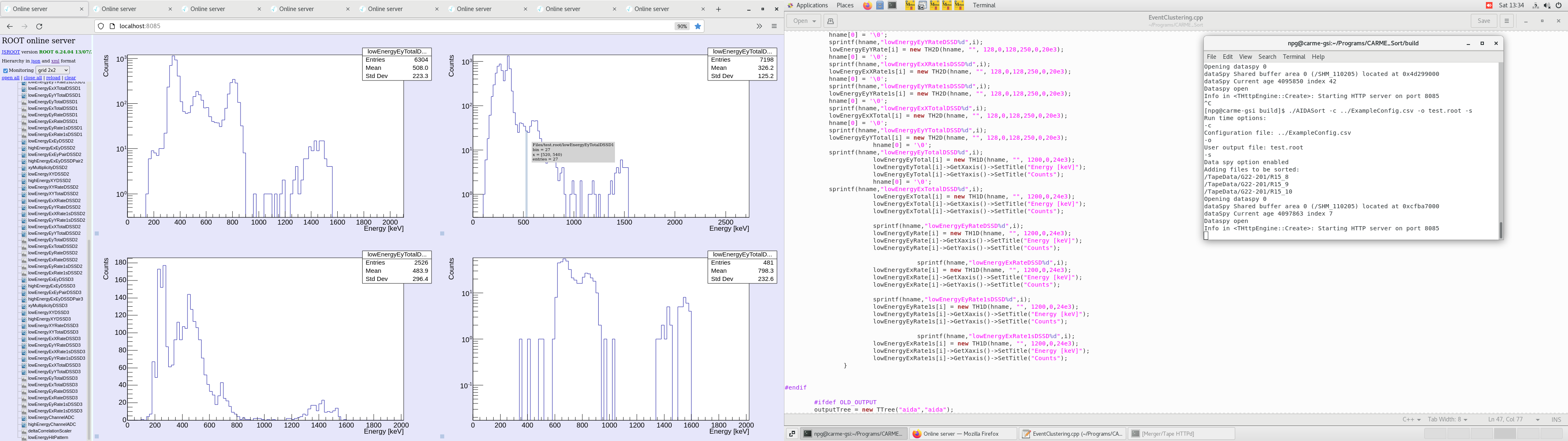

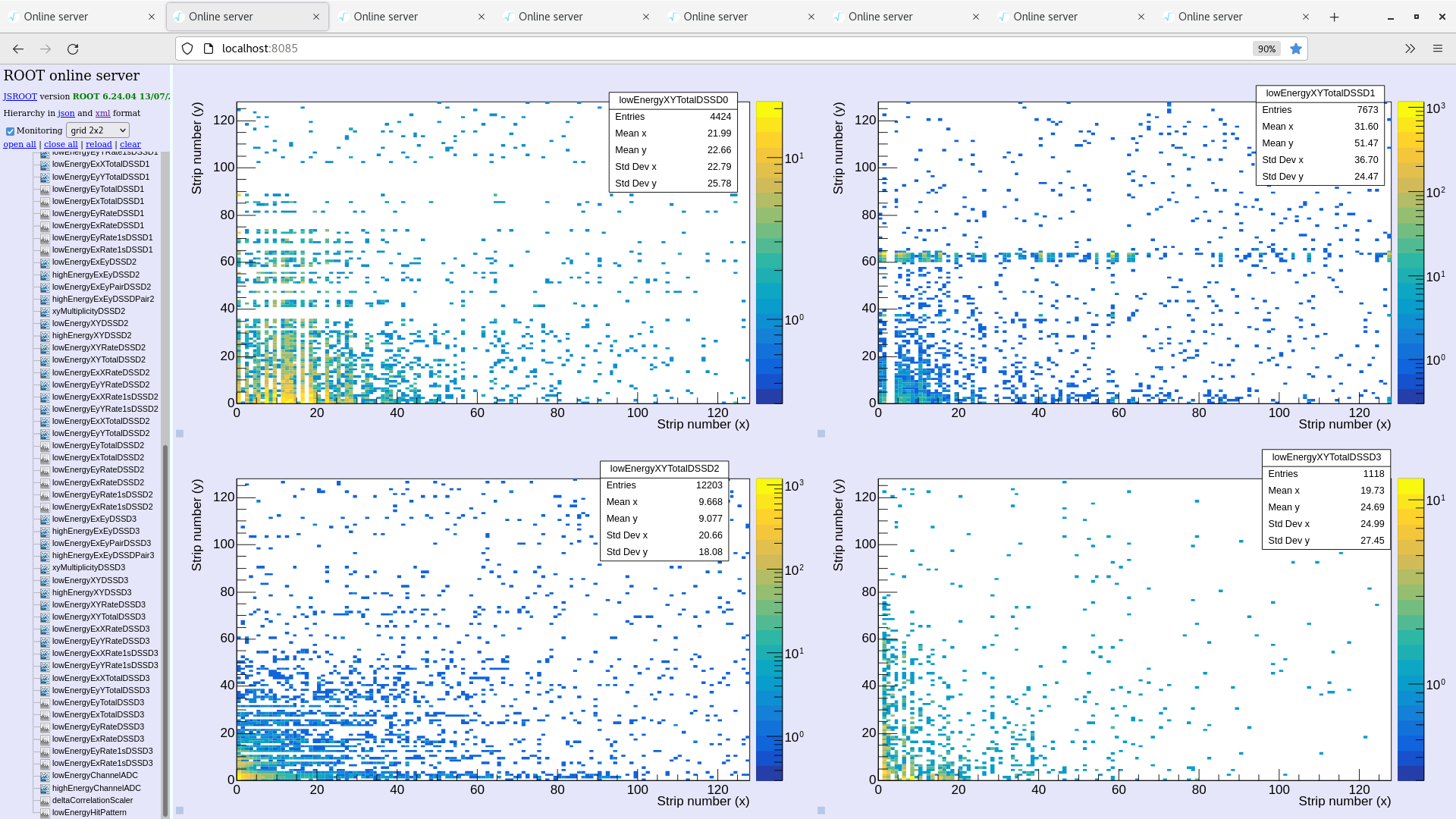

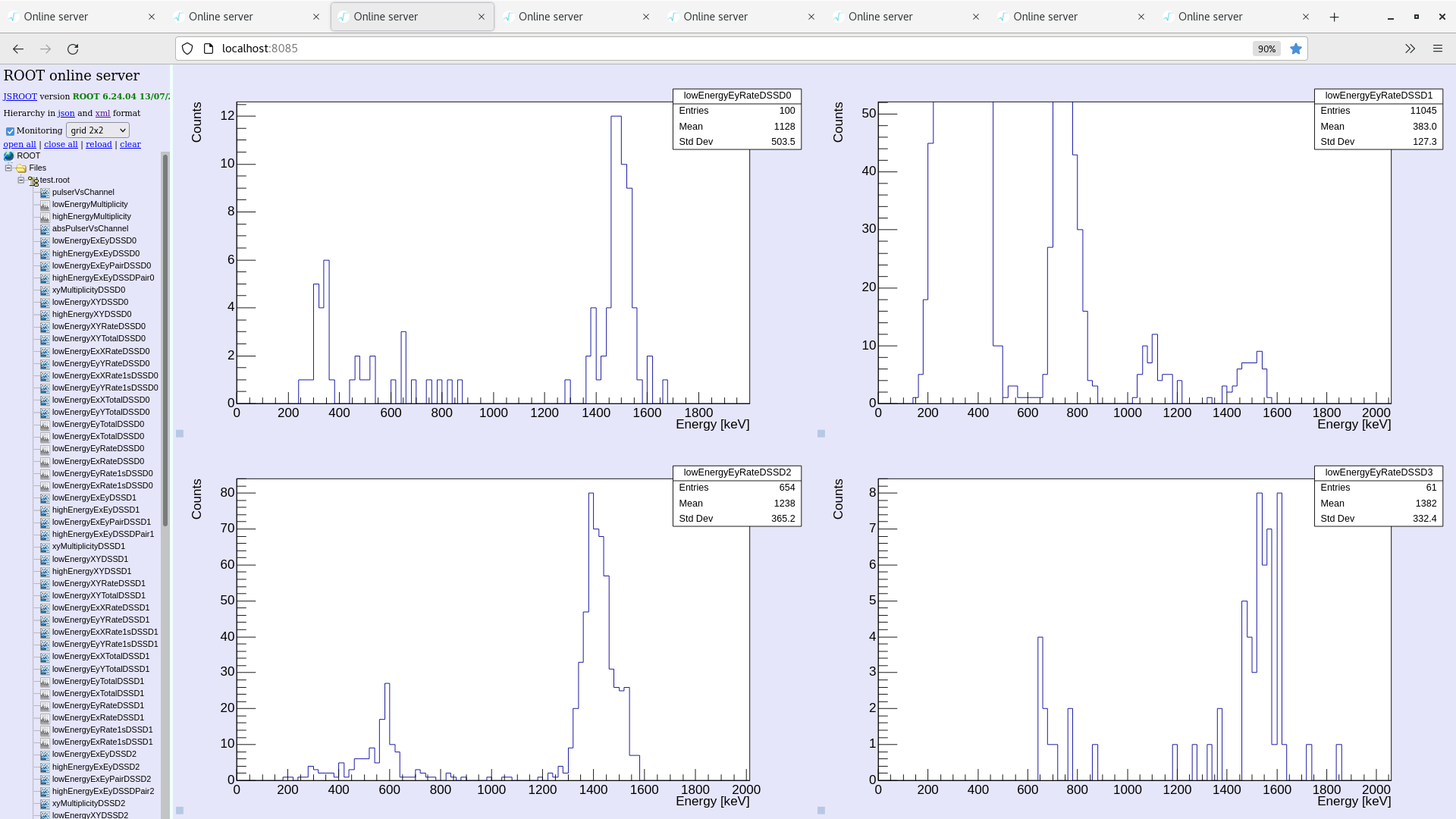

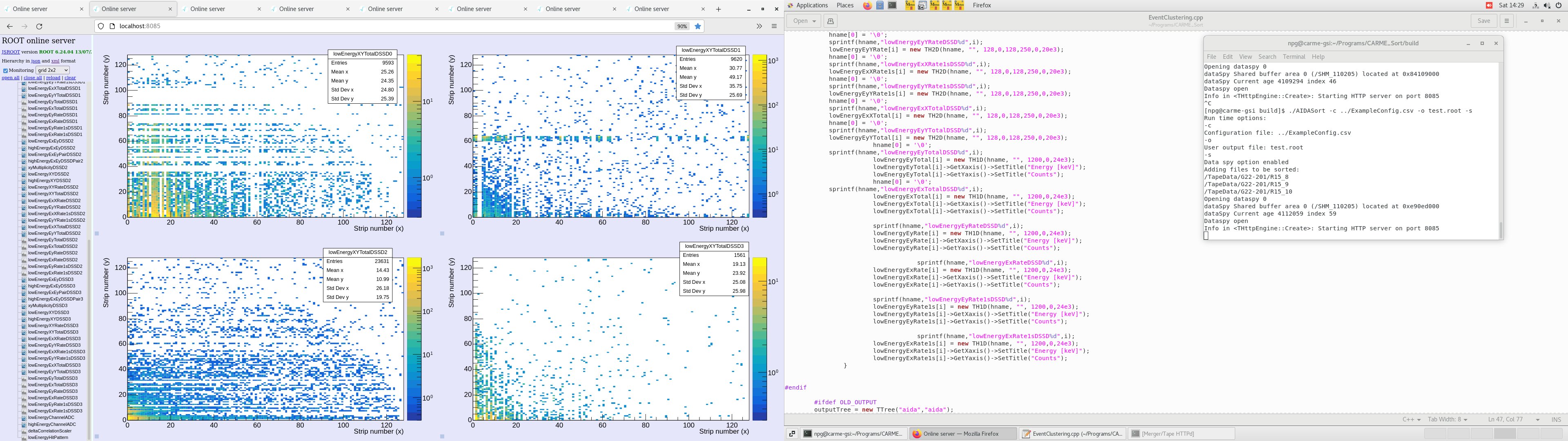

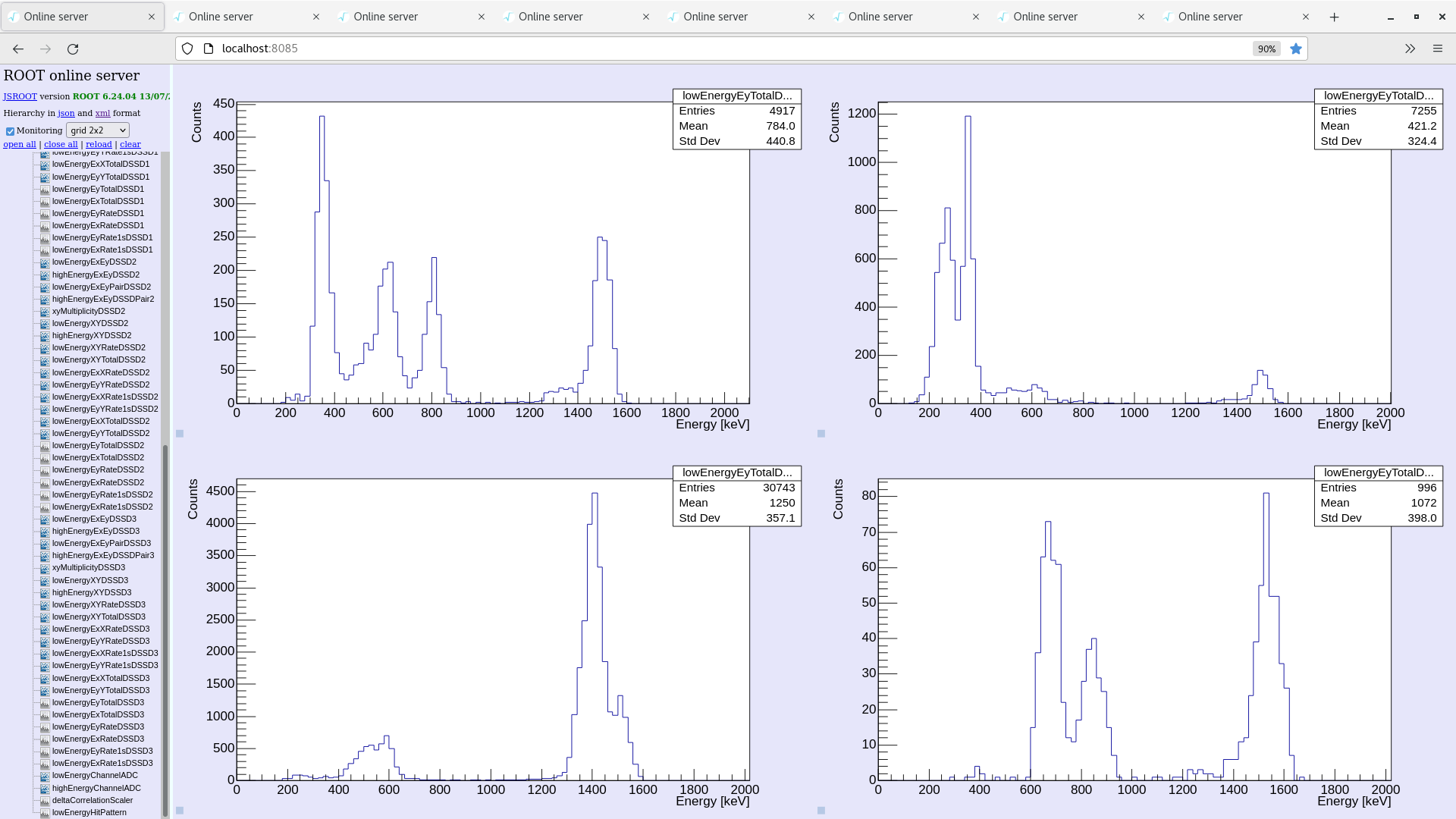

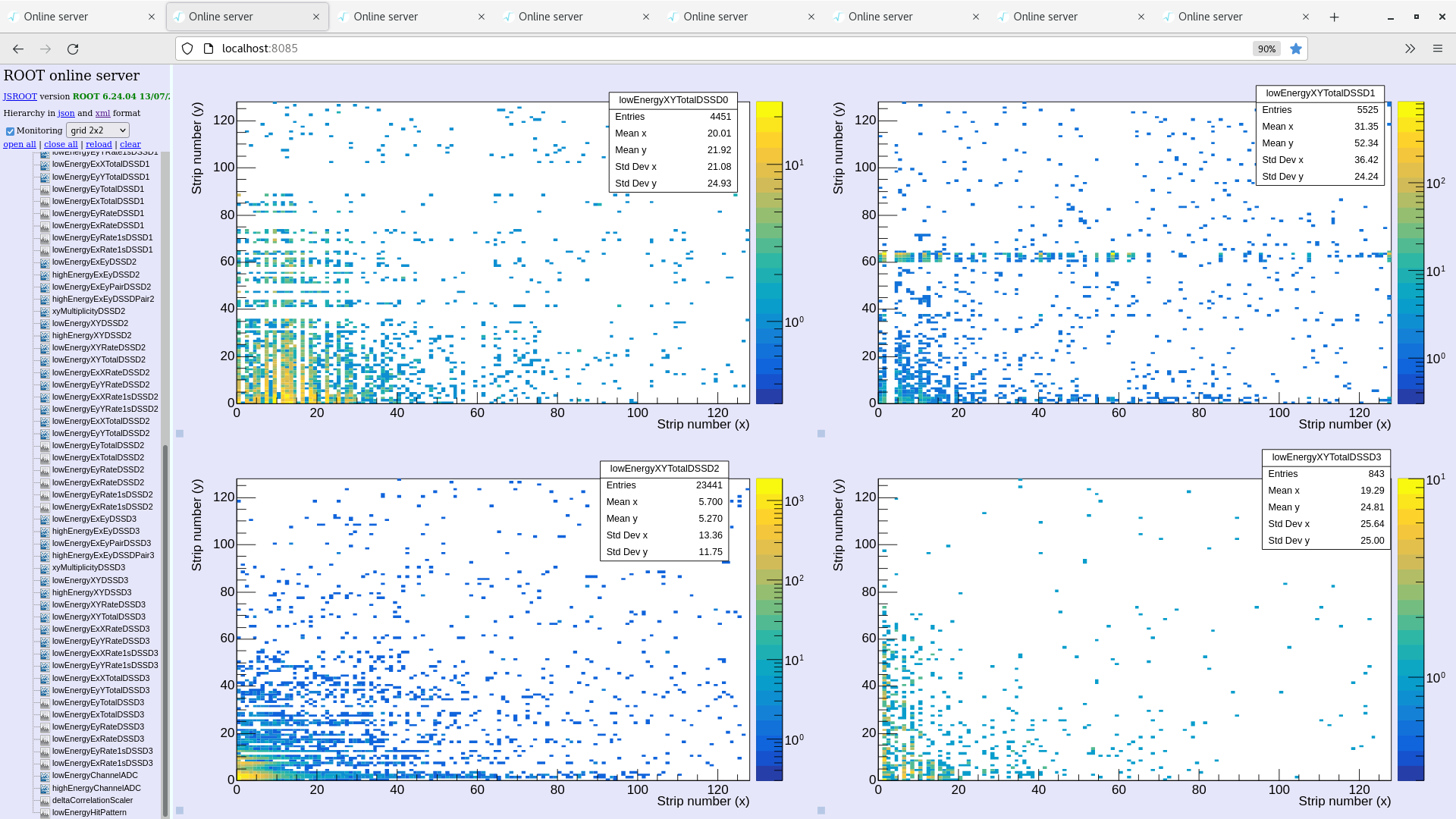

23:00 DAQ restored and data now being written okay. Checks all okay, see screenshots below. Histograms reset. 40 bars in bottle @ 23:45 - should last 30 hours.

12:00 Checks all ok. No problems with aidas or writing to disk.

01:10 Checks all ok.

02:05 Checks all ok. See attatchment 6 for peak update after reset histograms 3 hours prior. Target okay, dropped a little to 6e12 but seems to be going up itself. Will monitor and then move position if needed.

03:10 During checks, noticed detector 4 had tripped so turned it off. Writing to disk increased alot, statistics increased to alost 250000. Put aida13-16 in low/medium energy. Started new run. (see attatchment 7-14 for before and afters)

RUN 91

03:15 Checks all ok after turning off detector 4. Moved target around and got abit more density but x is very sensitive and y did not seem to do much. Density 5.5e12.

04:30 Checks all ok. Target decreasing in density - monitoring it.

04:35 Target density back up to 1e13 after moving in y.

05:30 Checks all ok. Target density decreased slightly to 8e12

06:30 Checks all ok, target density stable for past hour

07:30 Checks all ok

08:30 Checks all ok, target density at 1e13 for past two hours

09:00 Run stopped

|

| Attachment 1: Screenshot_from_2025-06-16_23-08-33.png

|

|

| Attachment 2: Screenshot_from_2025-06-16_23-08-17.png

|

|

| Attachment 3: Screenshot_from_2025-06-16_23-07-42.png

|

|

| Attachment 4: Screenshot_from_2025-06-16_23-06-56.png

|

|

| Attachment 5: Screenshot_from_2025-06-16_23-06-36.png

|

|

| Attachment 6: Screenshot_from_2025-06-17_02-06-51.png

|

|

| Attachment 7: Screenshot_from_2025-06-17_03-10-21.png

|

|

| Attachment 8: Screenshot_from_2025-06-17_03-09-43.png

|

|

| Attachment 9: Screenshot_from_2025-06-17_02-57-31.png

|

|

| Attachment 10: Screenshot_from_2025-06-17_02-56-20.png

|

|

| Attachment 11: Screenshot_from_2025-06-17_02-55-51.png

|

|

| Attachment 12: Screenshot_from_2025-06-17_02-55-38.png

|

|

| Attachment 13: Screenshot_from_2025-06-17_02-55-25.png

|

|

| Attachment 14: Screenshot_from_2025-06-17_02-06-51.png

|

|

|

|

573

|

Sun Jun 2 06:41:00 2024 |

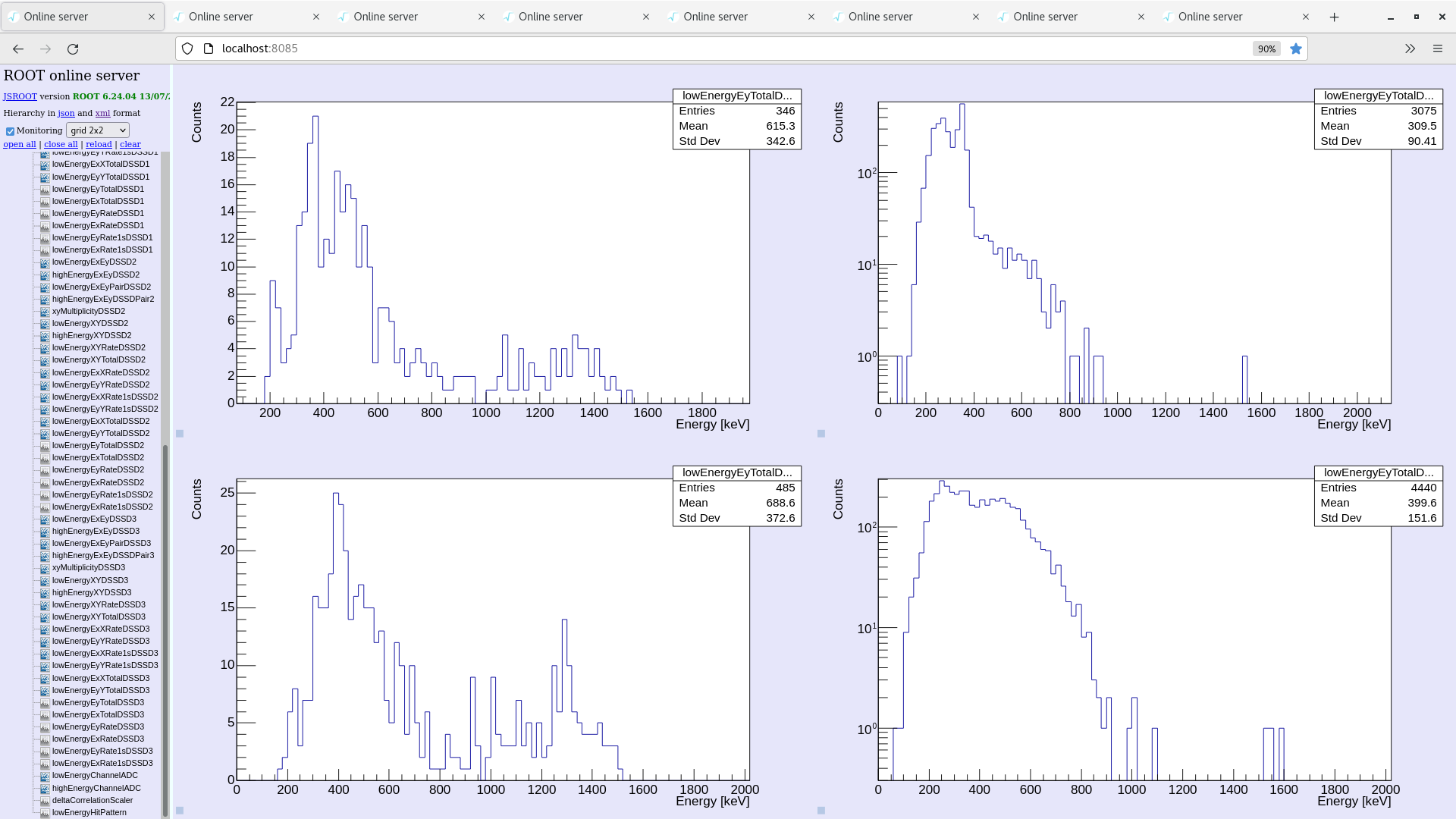

CB, AG | Run 21 - tests |

07:41

Switching to bunched beam to check D vs H content.

8:24

Attach 1&2

ONE spill

Detectors fully out

Switched to bunched beam

12 seconds pre-acceleration

100x cycles (600 seconds) -

Loss over 600 seconds 3.97E7 ions to 3.40E7 ions, i.e. negligible.

Attach 3&4

Coasting beam

12 seconds pre-acc

100x cycles

Attch 5&6

Coasting beam

12 seconds pre-acc

100x cycles

Detectors pneumatics IN

Attach 7& 8

Coasting beam

6 seconds pre-acc

100x cycles

Detector pneumatics IN

Attach 8&9

Coasting beam

12 seconds pre acc

200x cycles

Detector pneumatics IN

Running in this configuration for the rest of the shift

Target is barely 1E11 atoms/cm2 and keeps decreasing |

| Attachment 1: Screenshot_from_2024-06-02_08-23-21.png

|

|

| Attachment 2: Screenshot_from_2024-06-02_08-23-36.png

|

|

| Attachment 3: Screenshot_from_2024-06-02_08-44-38.png

|

|

| Attachment 4: Screenshot_from_2024-06-02_08-44-54.png

|

|

| Attachment 5: Screenshot_from_2024-06-02_08-58-17.png

|

|

| Attachment 6: Screenshot_from_2024-06-02_08-58-25.png

|

|

| Attachment 7: Screenshot_from_2024-06-02_09-18-02.png

|

|

| Attachment 8: Screenshot_from_2024-06-02_09-18-10.png

|

|

| Attachment 9: Screenshot_from_2024-06-02_09-44-16.png

|

|

| Attachment 10: Screenshot_from_2024-06-02_09-44-24.png

|

|

|

|

574

|

Sun Jun 2 08:47:01 2024 |

CB, AG | Run 22 - longer rung with 20 min storage |

09:47

12 seconds pre acc

200x cycles

Detector pneumatics IN, not moving

Running in this configuration for the rest of the shift

Target is barely 1E11 atoms/cm2 and keeps decreasing

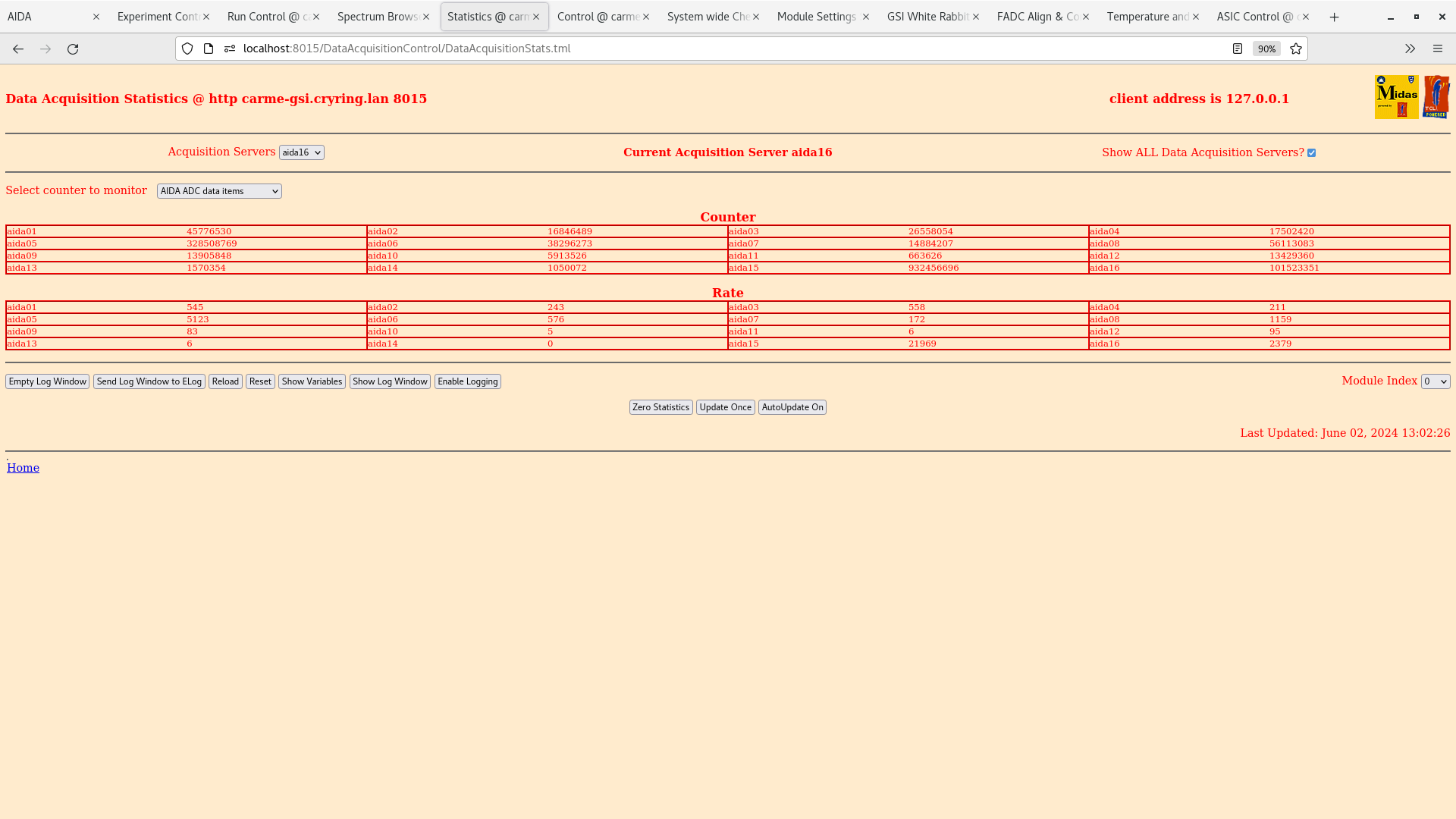

Temps OK, checks OK, Stats OK

Writing to disk rate OK

11:22

Targets gets thinner and thinner <1E11 atoms/cm2

Temps OK System wide checks OK Merger OK

Rates OK

13:02

Temps OK. Target around 1E11 atoms/cm2

Merger OK

Rates OK |

| Attachment 1: Screenshot_from_2024-06-02_09-47-53.png

|

|

| Attachment 2: Screenshot_from_2024-06-02_09-48-06.png

|

|

| Attachment 3: Screenshot_from_2024-06-02_11-21-59.png

|

|

| Attachment 4: Screenshot_from_2024-06-02_11-22-27.png

|

|

| Attachment 5: Screenshot_from_2024-06-02_13-02-31.png

|

|

|

|

569

|

Sat Jun 1 07:16:15 2024 |

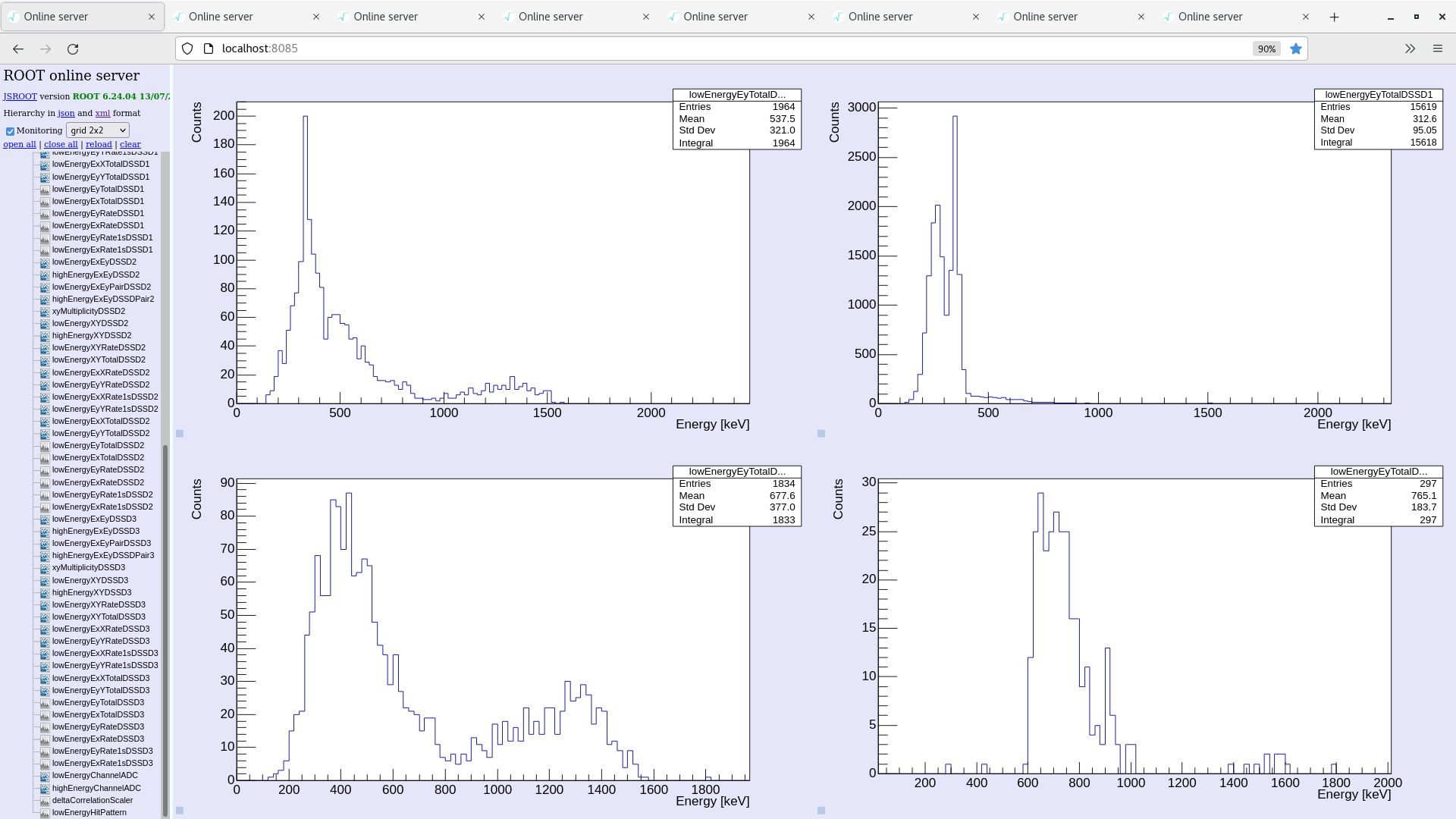

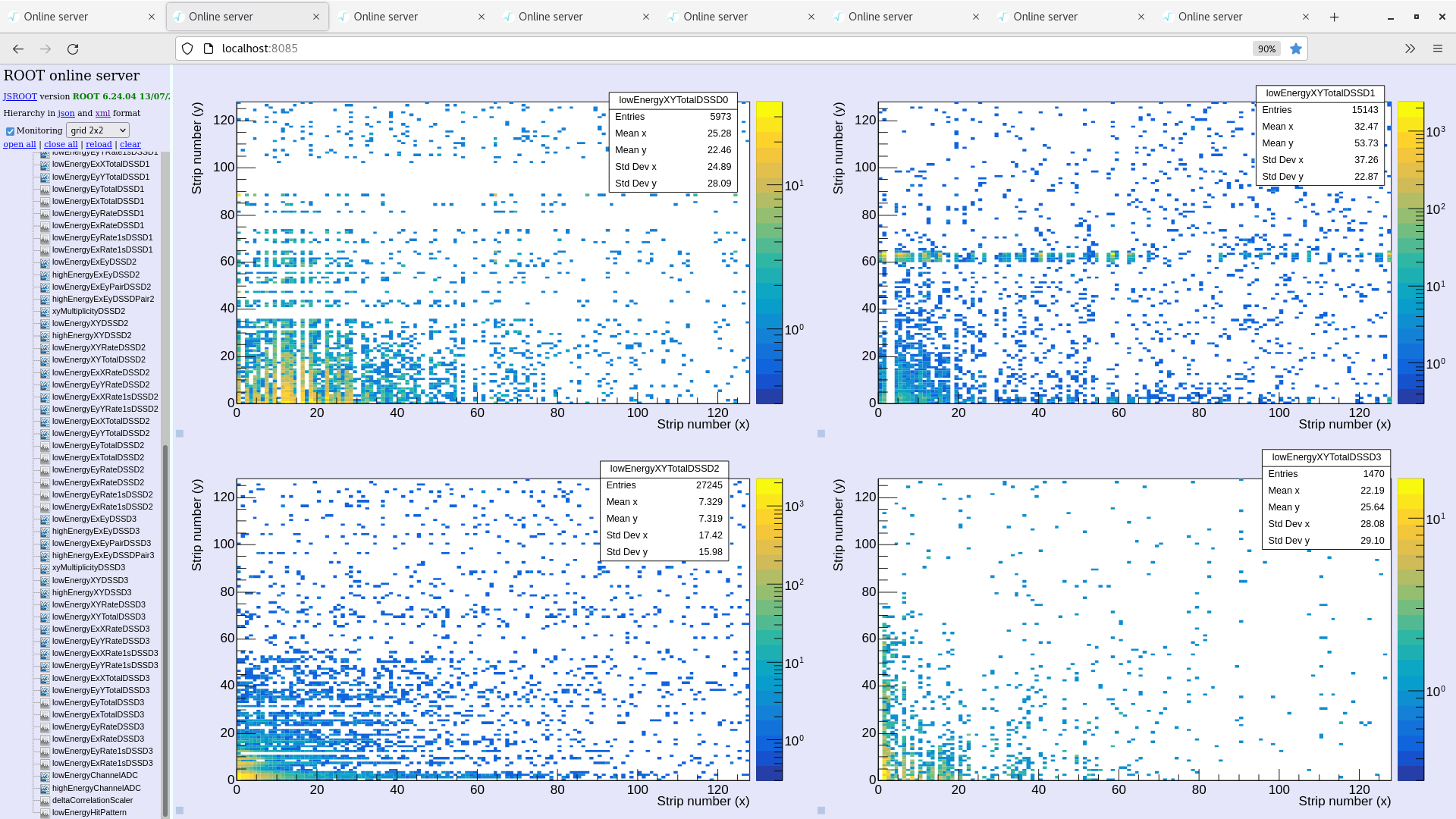

CB, AB, EM, JM | Run 19 - beam target overlap |

Morning shift

08:16 - as run 18, target off

9:00 Increased storage time to 5 minutes. Aquired data after initial beam loss. Attach 1 &2. Far less H2+ vs D.

Temps OK

Rates as before

10:00 beam being optimised to reduce 2H+ content

Rates in aida 13, 14 suddenly spike as during overnight. Checkloaded repeatedly. No effect. Increased thresholds in 13, 14 to 0x32 bringing them in line with 15,16.

12:50

We started test with beam

Test1 ( Attached 12-52-55)

Horiz. offset: 8mm

Max vuel on 1.5MeV =1480 counst

Test2

Horiz. offset: 7mm

Test3

Horiz. offset: 6mm

target density=2.4E11

Test4

Horiz. offset: 5mm

target density=from 1.7E11 to 2.5E11

Test5

Horiz. offset: 4mm

target density=from 5.6E11 to 1.1E11 several fluctuations

Test6

Horiz. offset: 3mm

target density=1.1E11 several fluctuations. Until now we do not see a clear signel from the reaction!

Test7

Horiz. offset: 2mm

target density=1.1E11 several fluctuations.

Test8

Beam back again. Coasting beam. Detectors IN

Horiz. offset: 8mm

xy and energy histograms - attachment 12 and 13.

Test9

Bunched beam Detectors IN

Horiz. offset: 8mm

xy and energy histograms - attachment 14 and 15.

Test10

Horiz. offset: 6mm

xy and energy histograms - attachment

target:1.6E11

xy and energy histograms - attachment 16 and 17.

Afternoon shift

From previous overlap tests we can see that moving the beam position does cause a change in the number of events observed in the detectors.

But the change in events appears to be due to beam halo hitting the detectors rather than elastic scattering. New approach required.

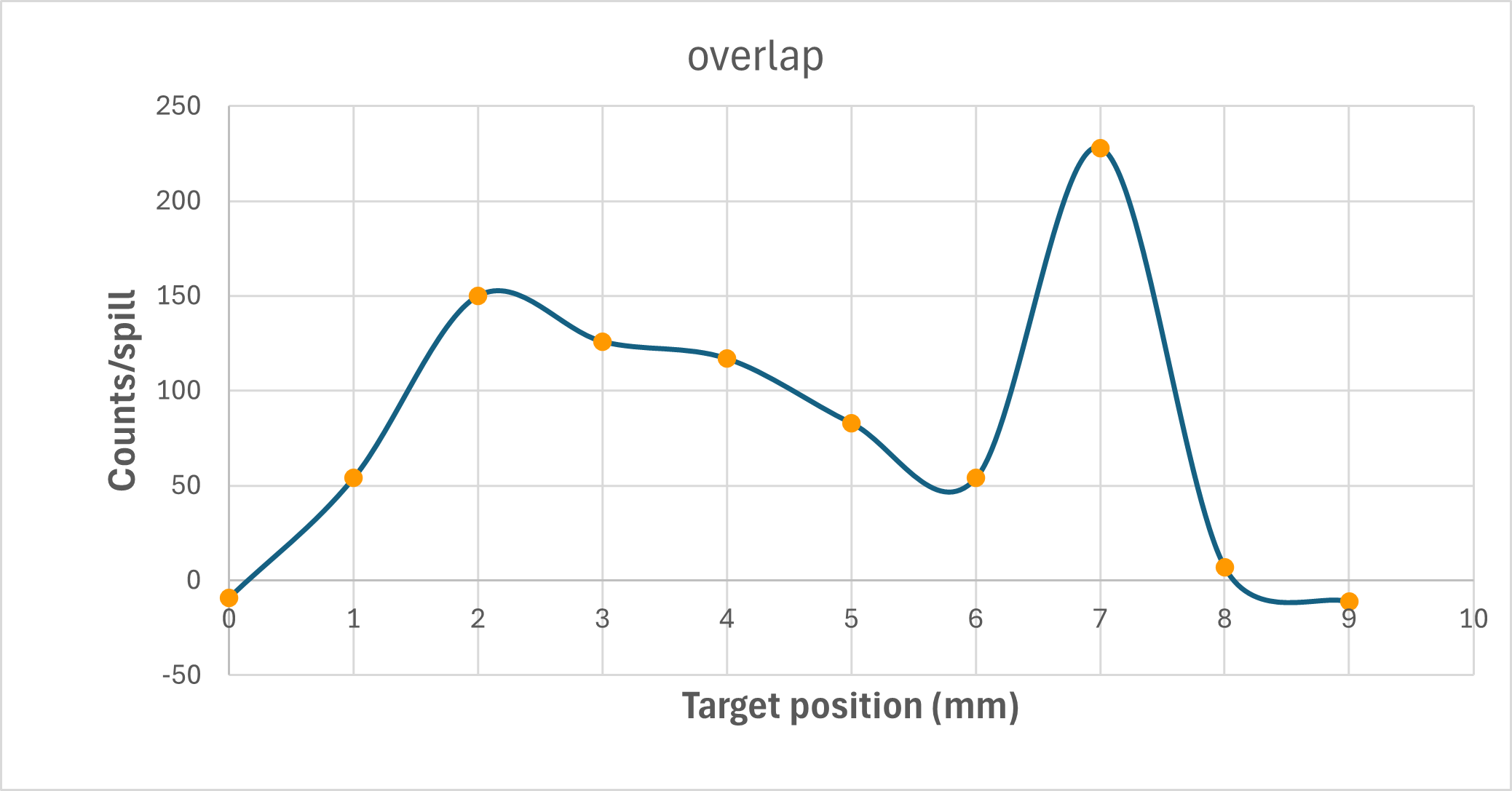

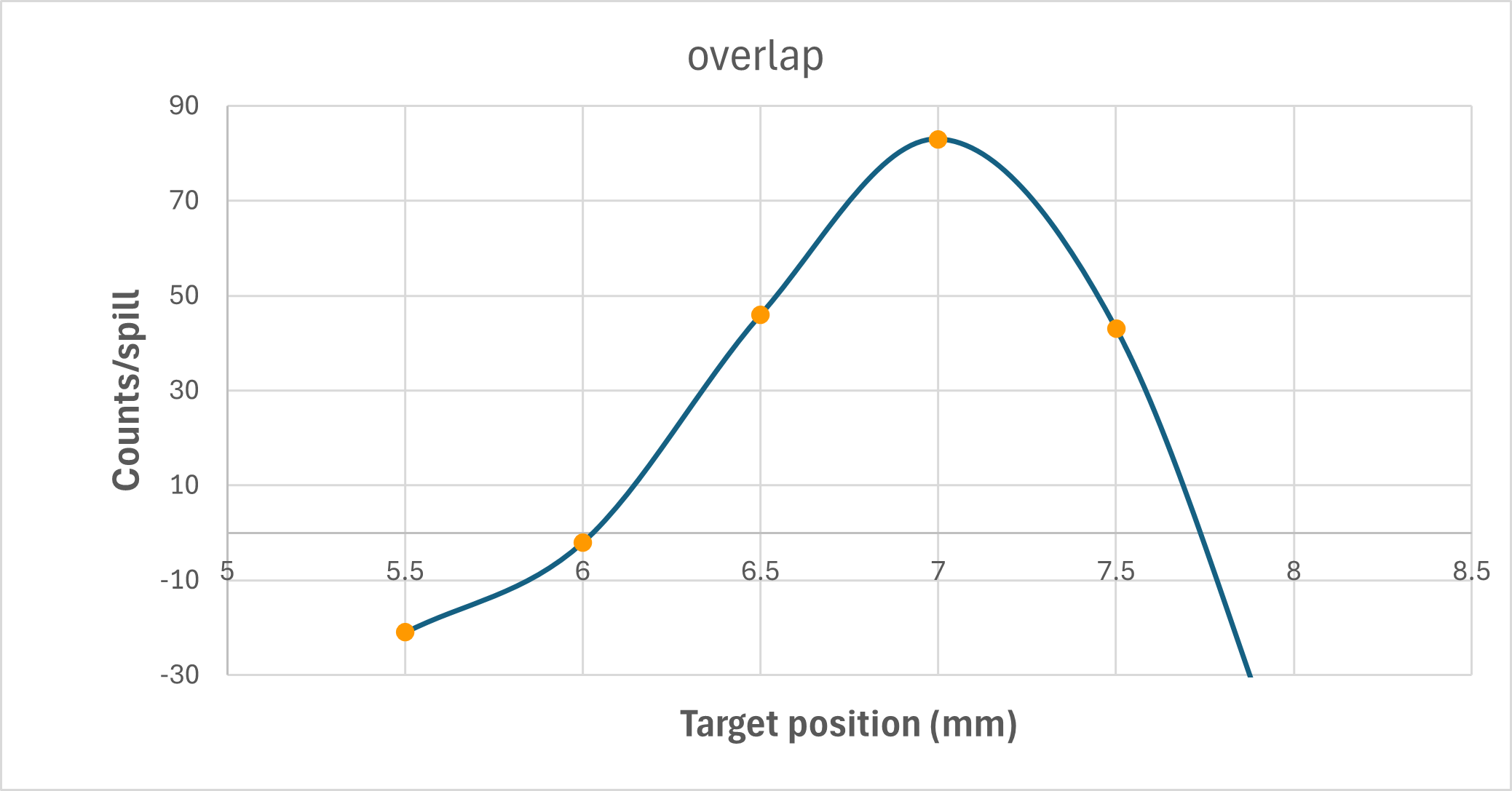

We have varied the beam position (horizontal) in 1mm steps from 0mm to 9mm (the maximum allowed). We do this with the target ON and then with the target OFF.

Integral of events ~1.5 MeV taken . Difference between the target and no target plotted to gauge overlap position.

Note we have moved left arm fully out as we were worried about beam hitting dssds on injection. Will check overlap with right dssds only as left dssds have very low rate at this position.

We have determined the overlap position is about 7.0mm horizontal

Attachment 18 shows initial scan.

Attachment 19 shows a second scan in the region we highlighted as possible overlap. |

| Attachment 1: Screenshot_from_2024-06-01_09-15-54.png

|

|

| Attachment 2: Screenshot_from_2024-06-01_09-16-11.png

|

|

| Attachment 3: Screenshot_from_2024-06-01_10-23-17.png

|

|

| Attachment 4: Screenshot_from_2024-06-01_10-29-48.png

|

|

| Attachment 5: Screenshot_from_2024-06-01_12-52-55.png

|

|

| Attachment 6: Screenshot_from_2024-06-01_12-58-44.png

|

|

| Attachment 7: Screenshot_from_2024-06-01_13-06-01.png

|

|

| Attachment 8: Screenshot_from_2024-06-01_13-12-10.png

|

|

| Attachment 9: Screenshot_from_2024-06-01_13-18-32.png

|

|

| Attachment 10: Screenshot_from_2024-06-01_13-27-12.png

|

|

| Attachment 11: Screenshot_from_2024-06-01_13-34-07.png

|

|

| Attachment 12: Screenshot_from_2024-06-01_14-18-55.png

|

|

| Attachment 13: Screenshot_from_2024-06-01_14-19-10.png

|

|

| Attachment 14: Screenshot_from_2024-06-01_14-28-08.png

|

|

| Attachment 15: Screenshot_from_2024-06-01_14-29-26.png

|

|

| Attachment 16: Screenshot_from_2024-06-01_14-39-31.png

|

|

| Attachment 17: Screenshot_from_2024-06-01_14-39-43.png

|

|

| Attachment 18: Overlap1.png

|

|

| Attachment 19: Overlap2.png

|

|

|

|

488

|

Sat Feb 3 00:13:03 2024 |

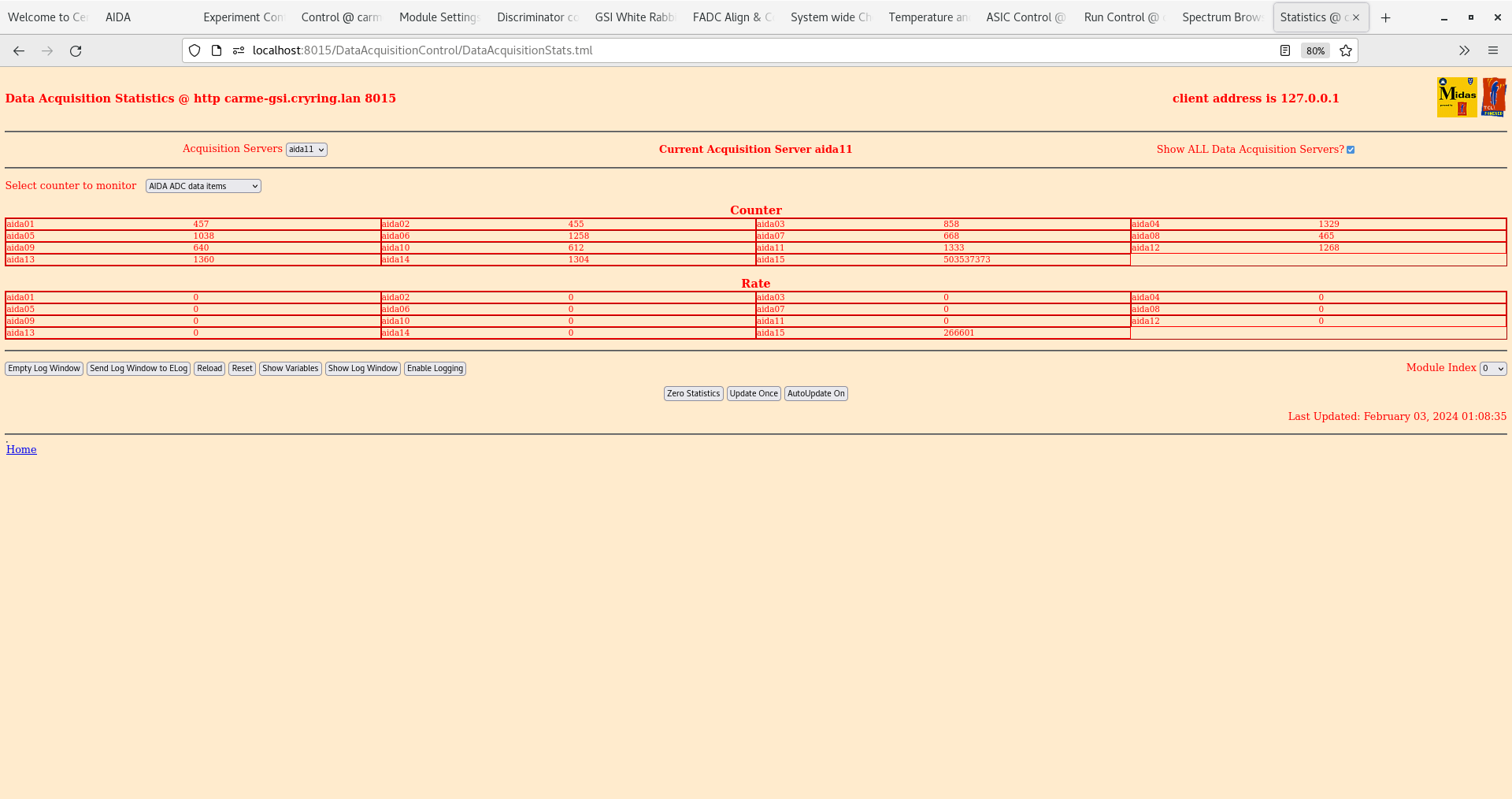

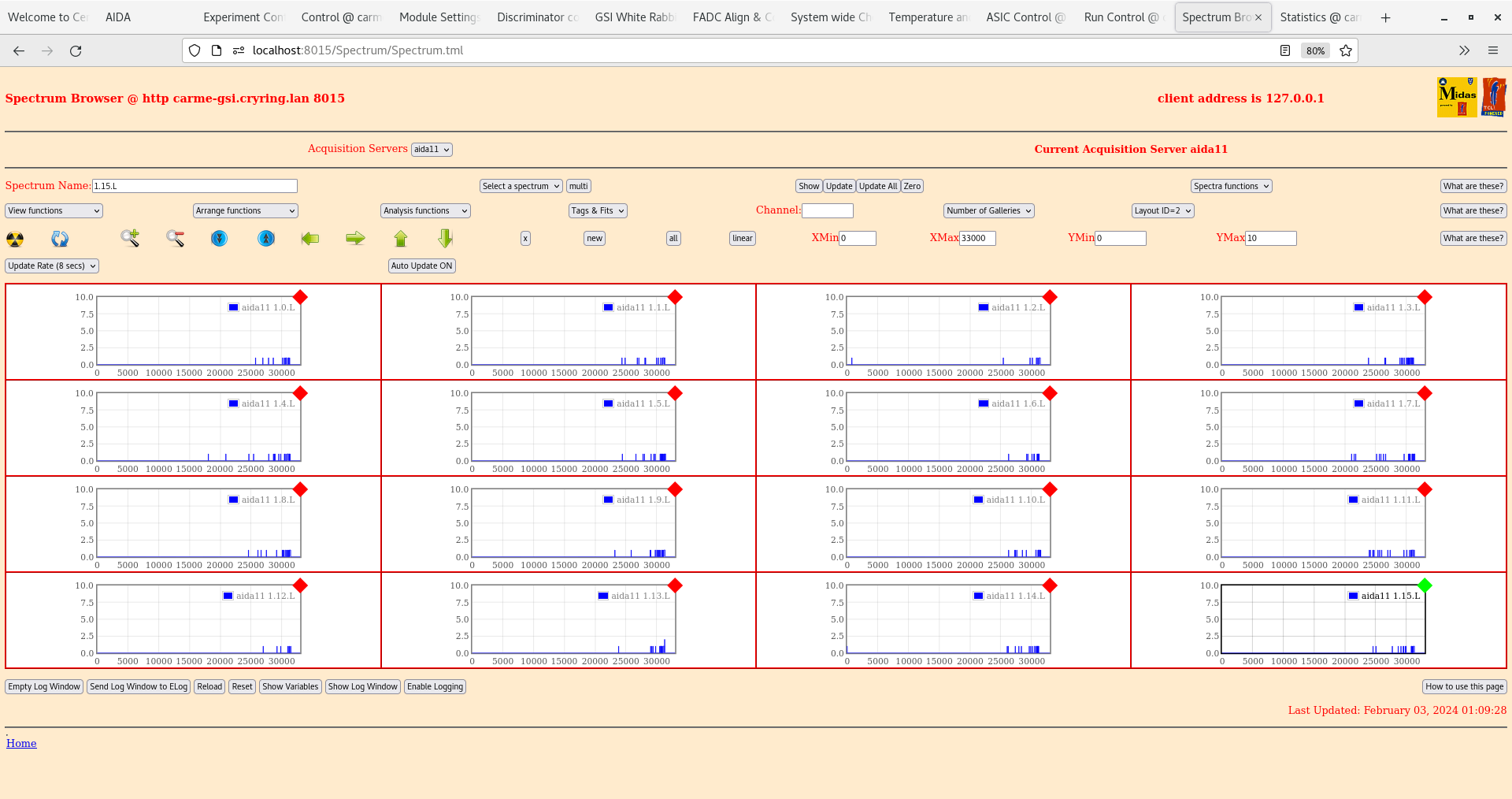

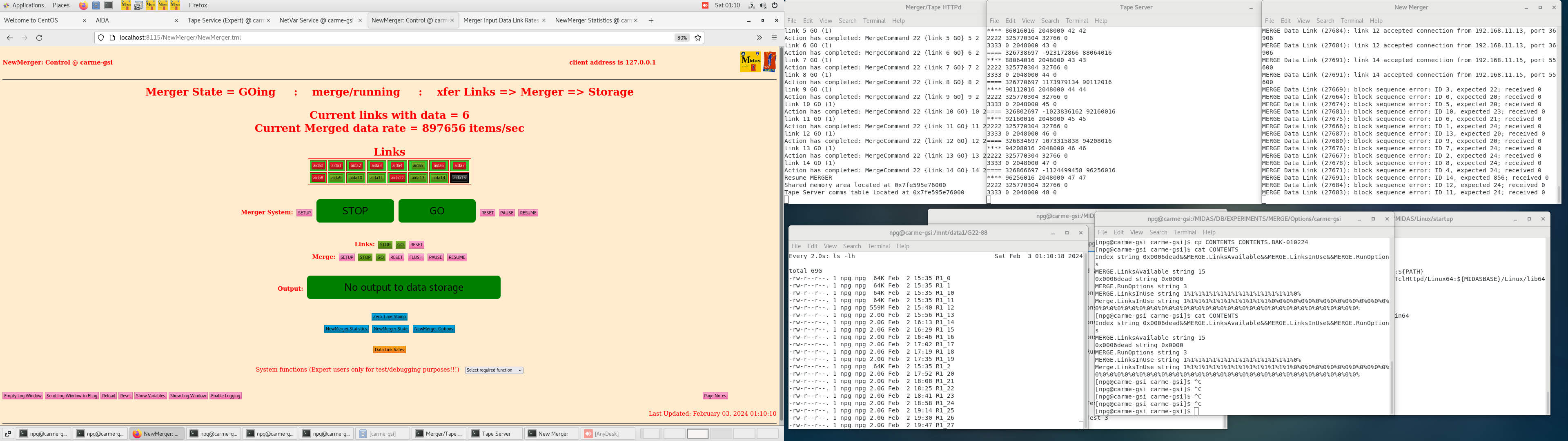

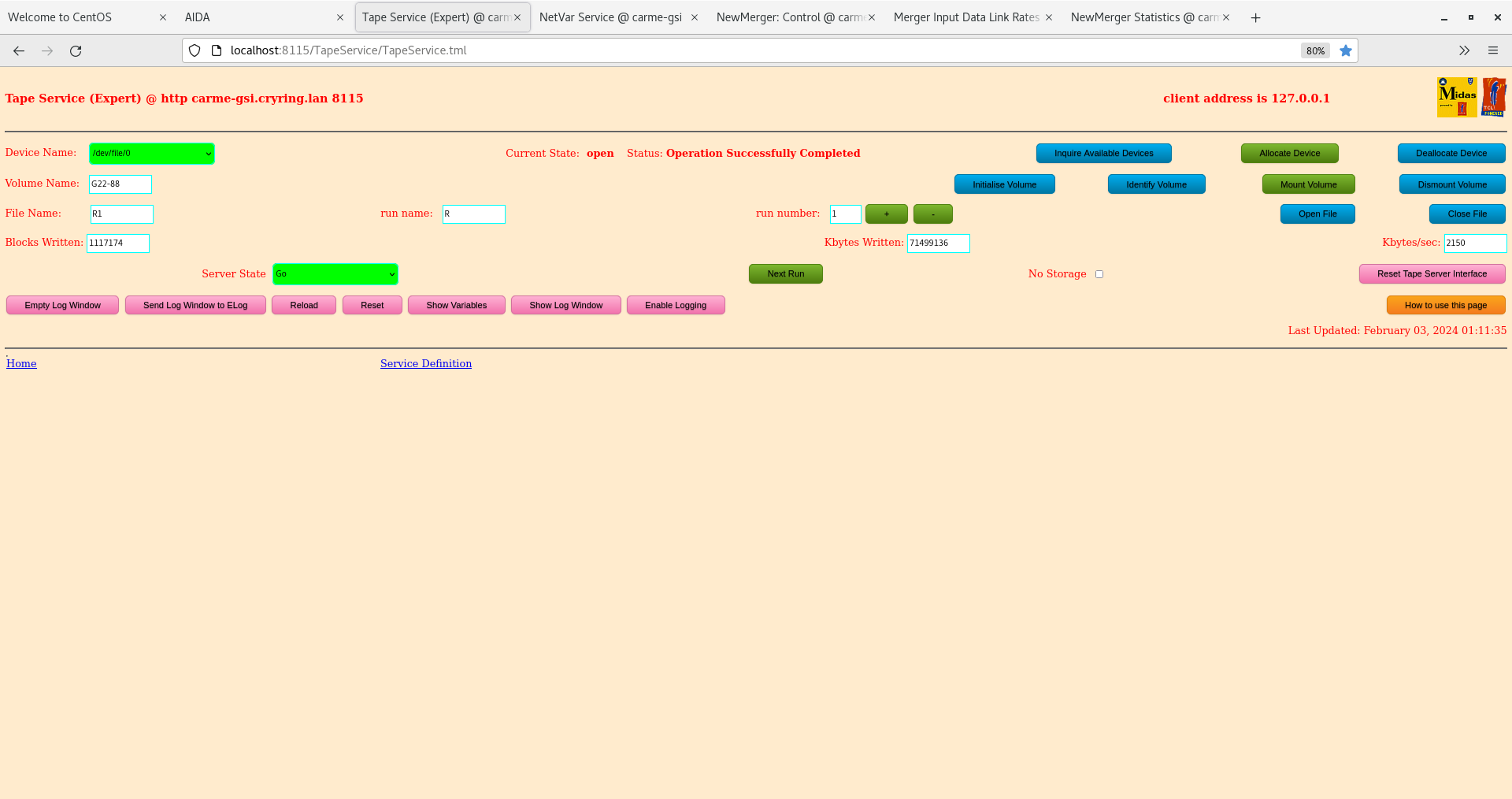

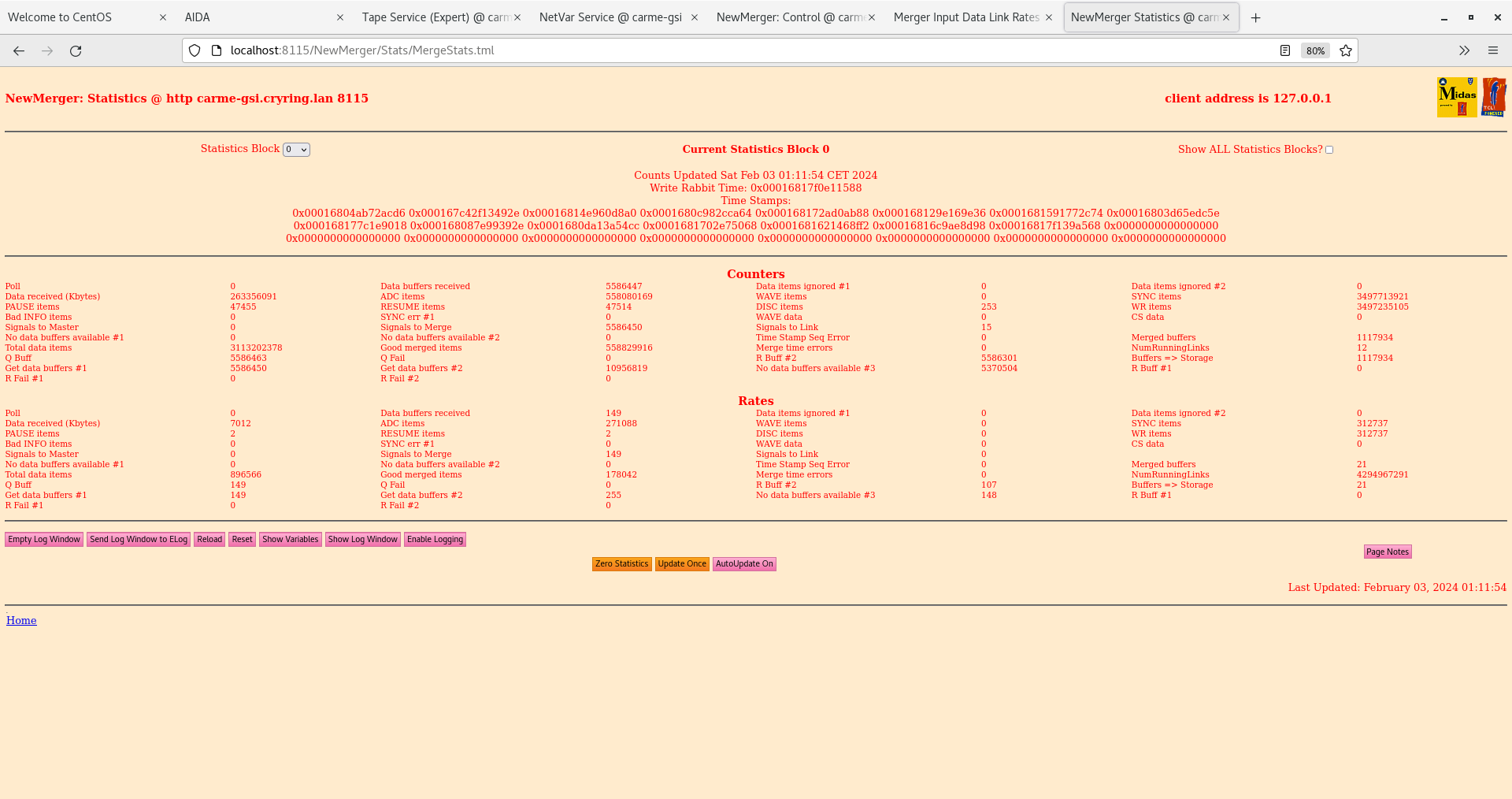

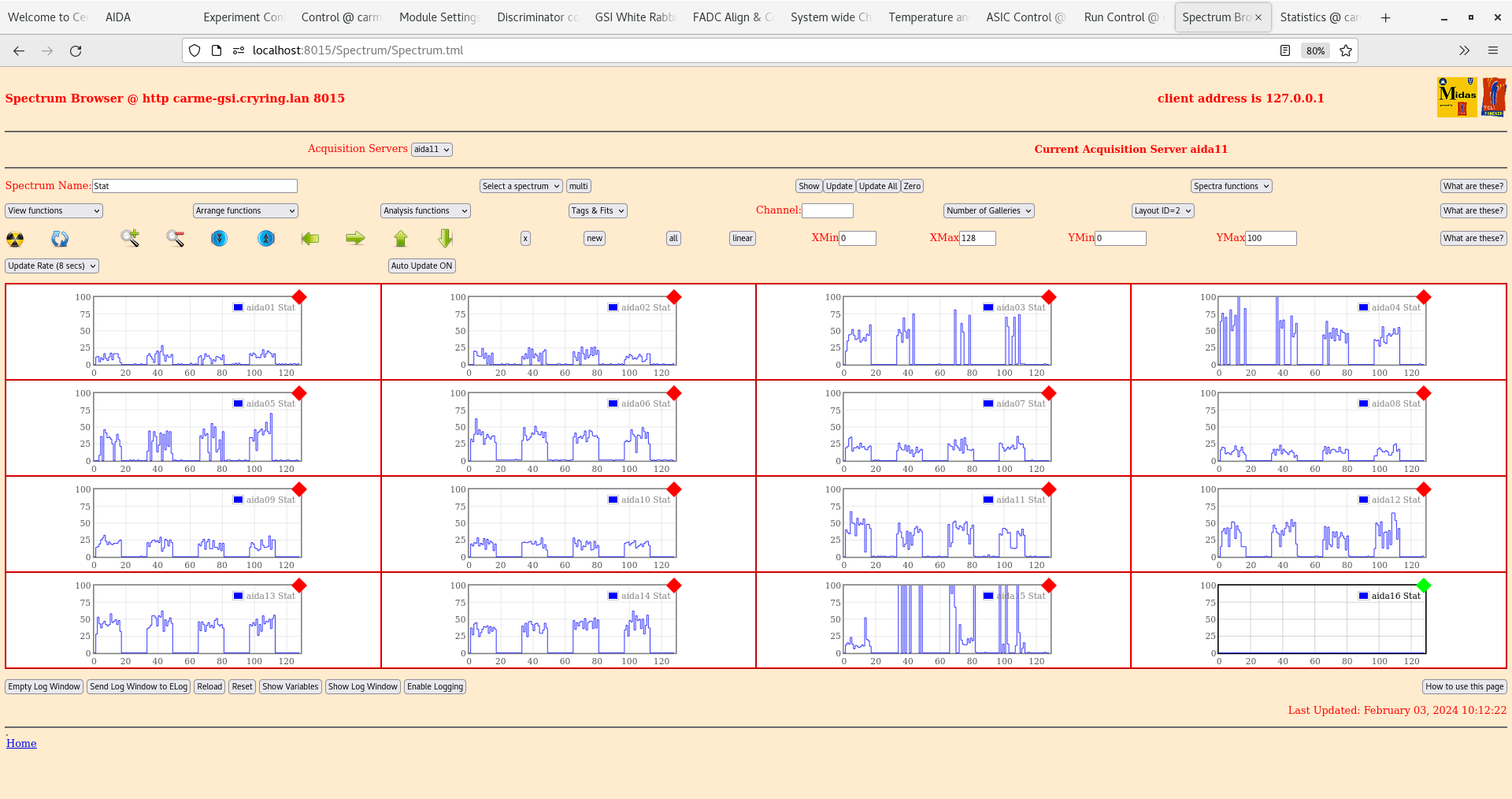

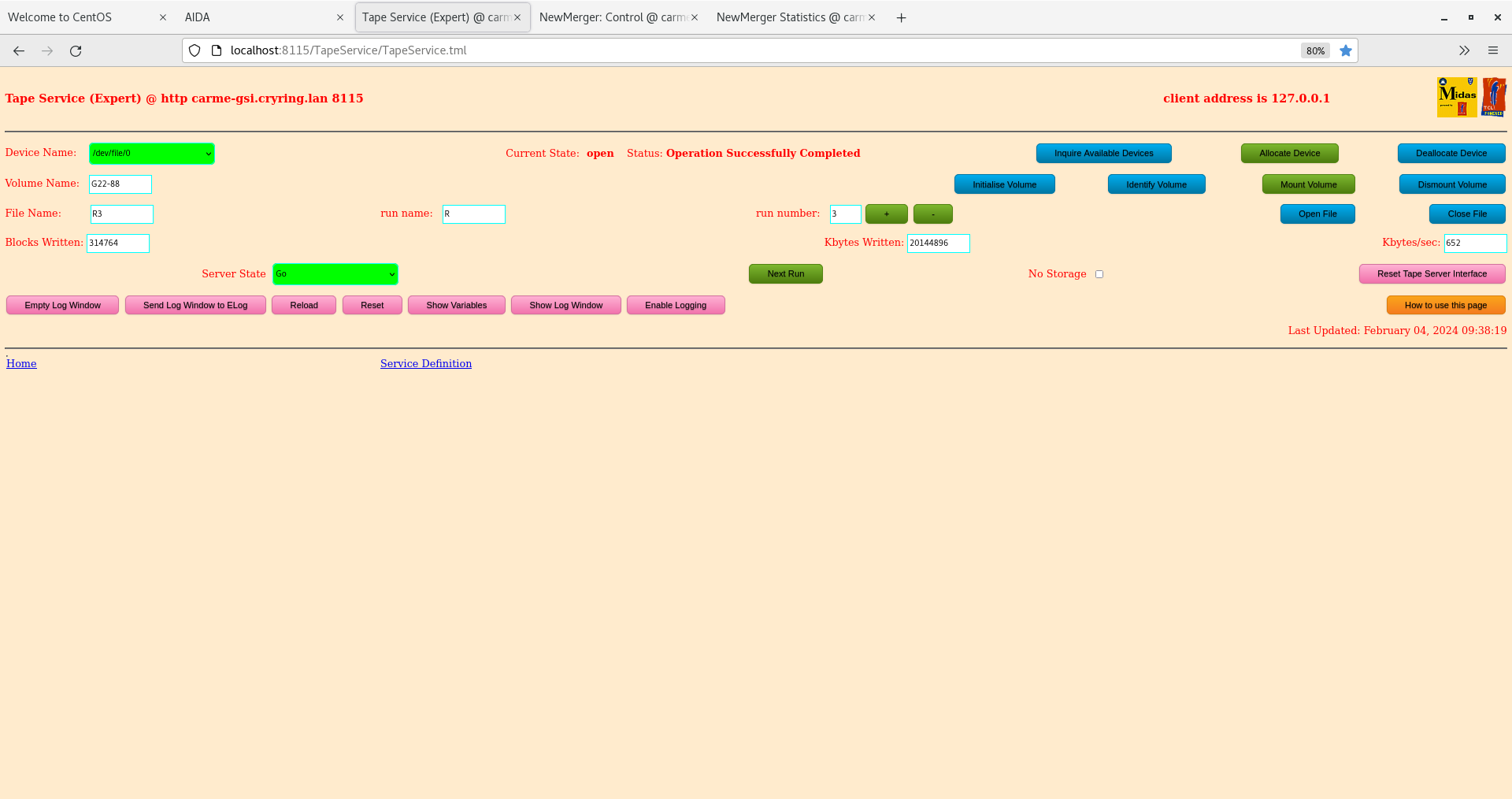

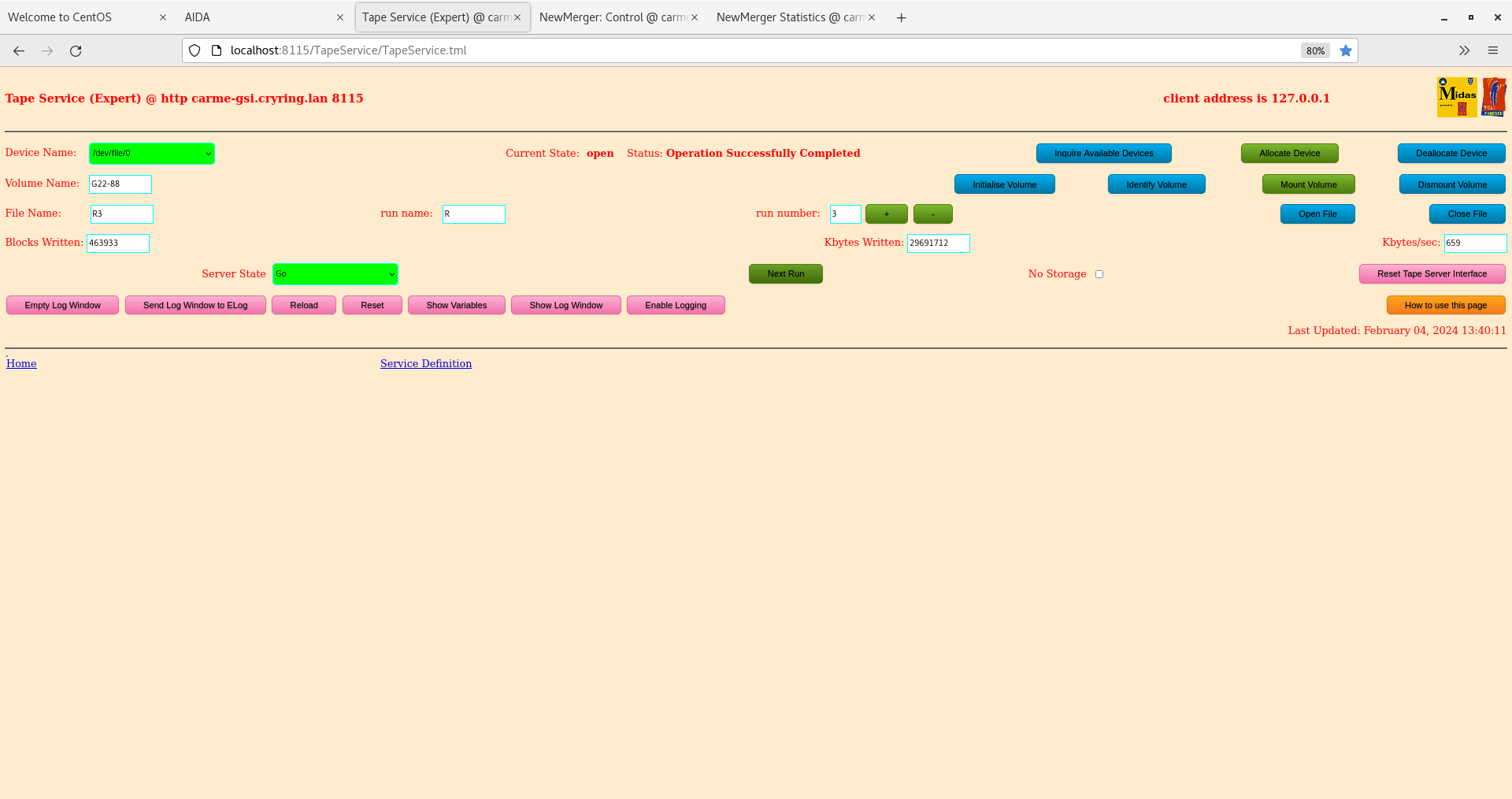

CB TD | Run1 end - R3 start |

01.07 DAQ continues file G22-88/R1_46

background alpha

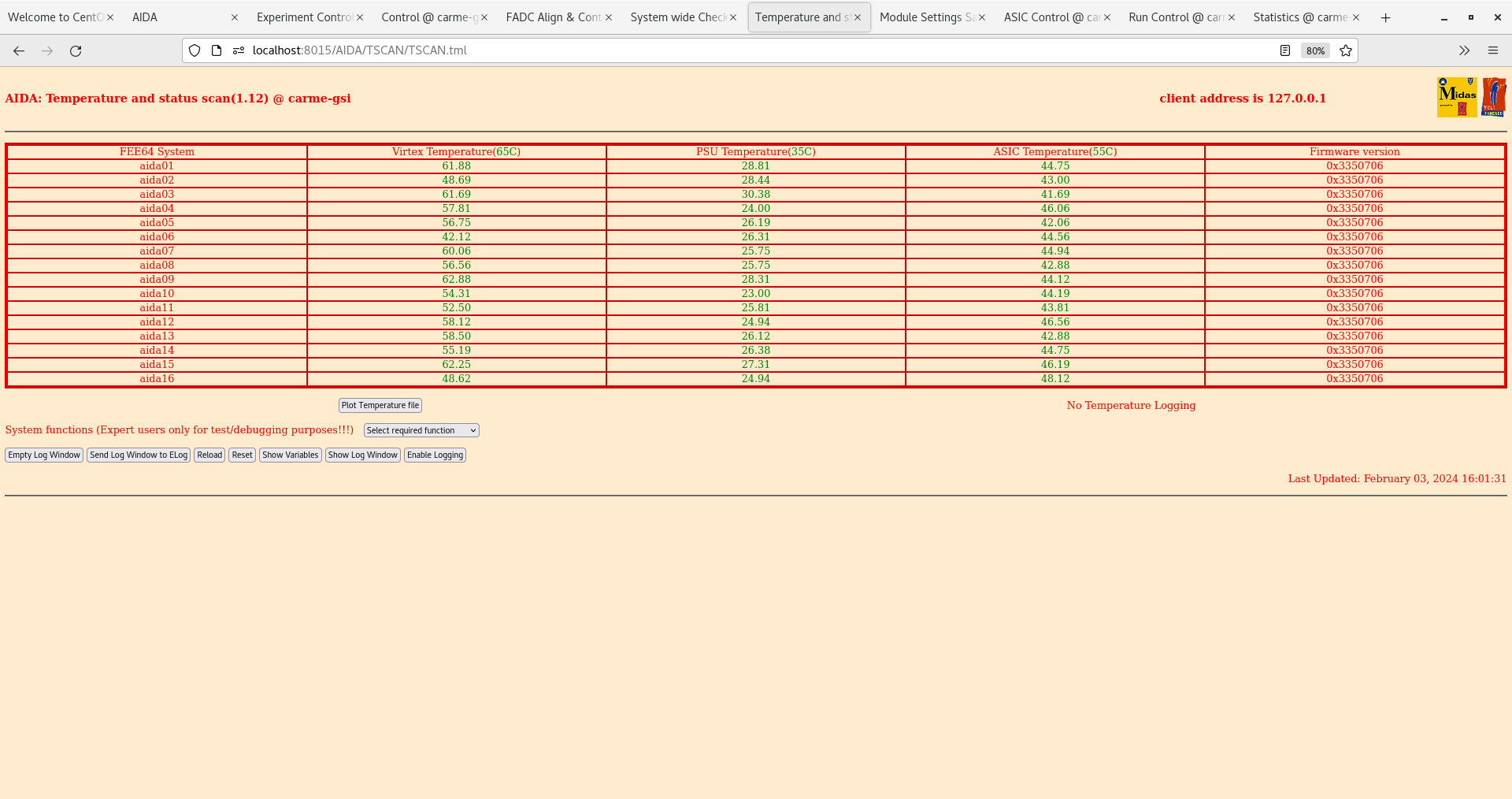

DSSSD bias OK - attachment 1

FEE64 temps OK - attachment 2

ADC data item stats - attachment 3

aida15 asic #2 u/s - rate c. 266k

aida11 1*L spectra - attachment 4

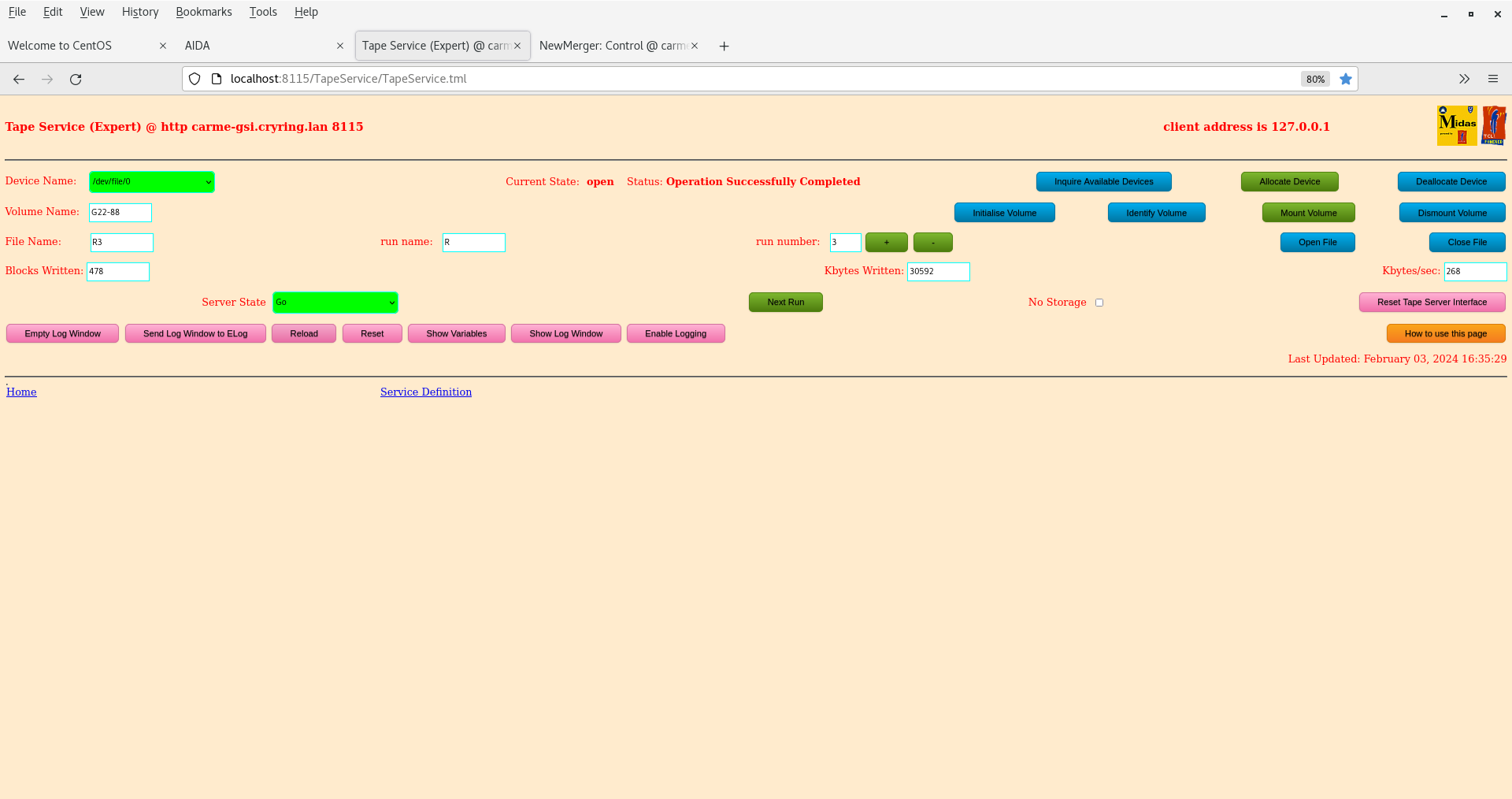

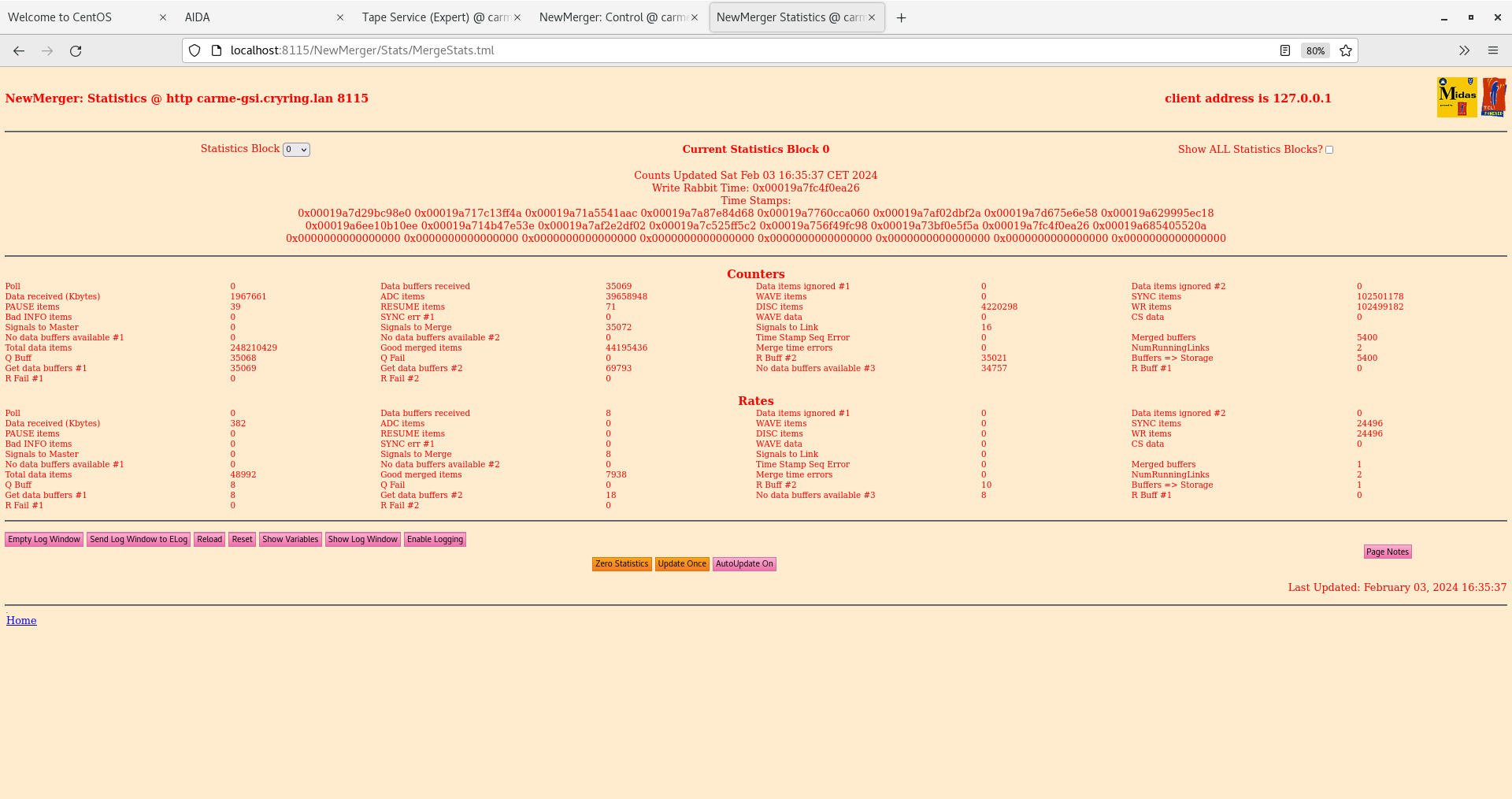

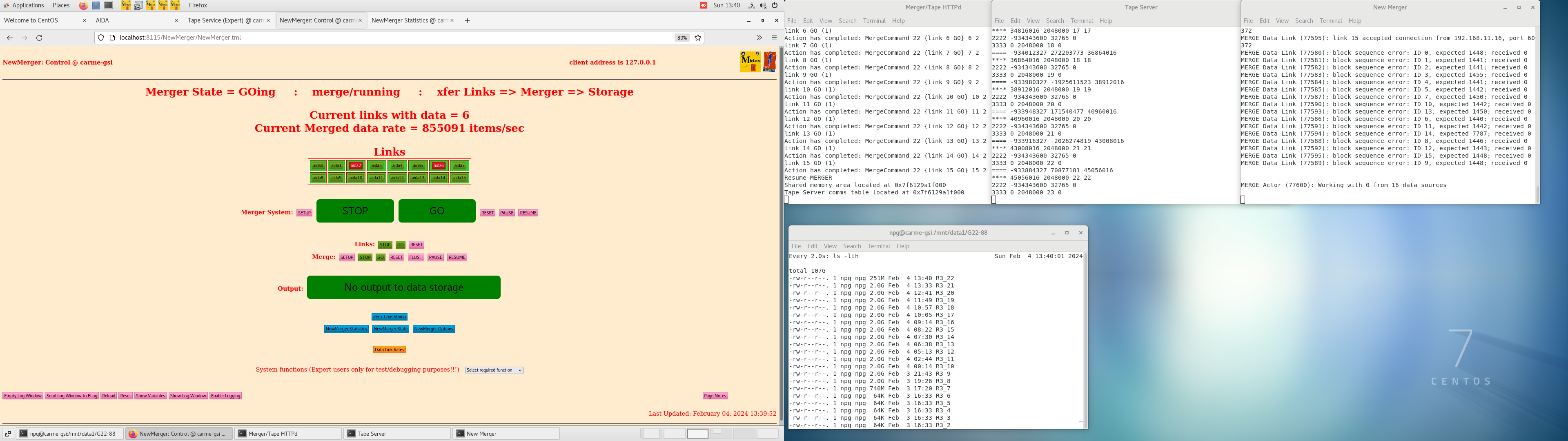

ADC data items/s Merger, Tape Server & Merger stats - attachments 5-7

data rate to disk c. 2Mb/s dominated by aida15 asic 2

10.05 DAQ continues file G22-88/R1_79

background alpha

DSSSD bias OK - attachment 8

ambient temperature 16.8 deg C

FEE64 temps OK - attachment 9

ADC data item stats - attachment 10

aida15 asic #2 u/s - rate c. 266k

aida11 1*L spectra - attachment 11

ADC data items/s Merger, Tape Server & Merger stats - attachments 12-14

data rate to disk c. 2Mb/s dominated by aida15 asic 2

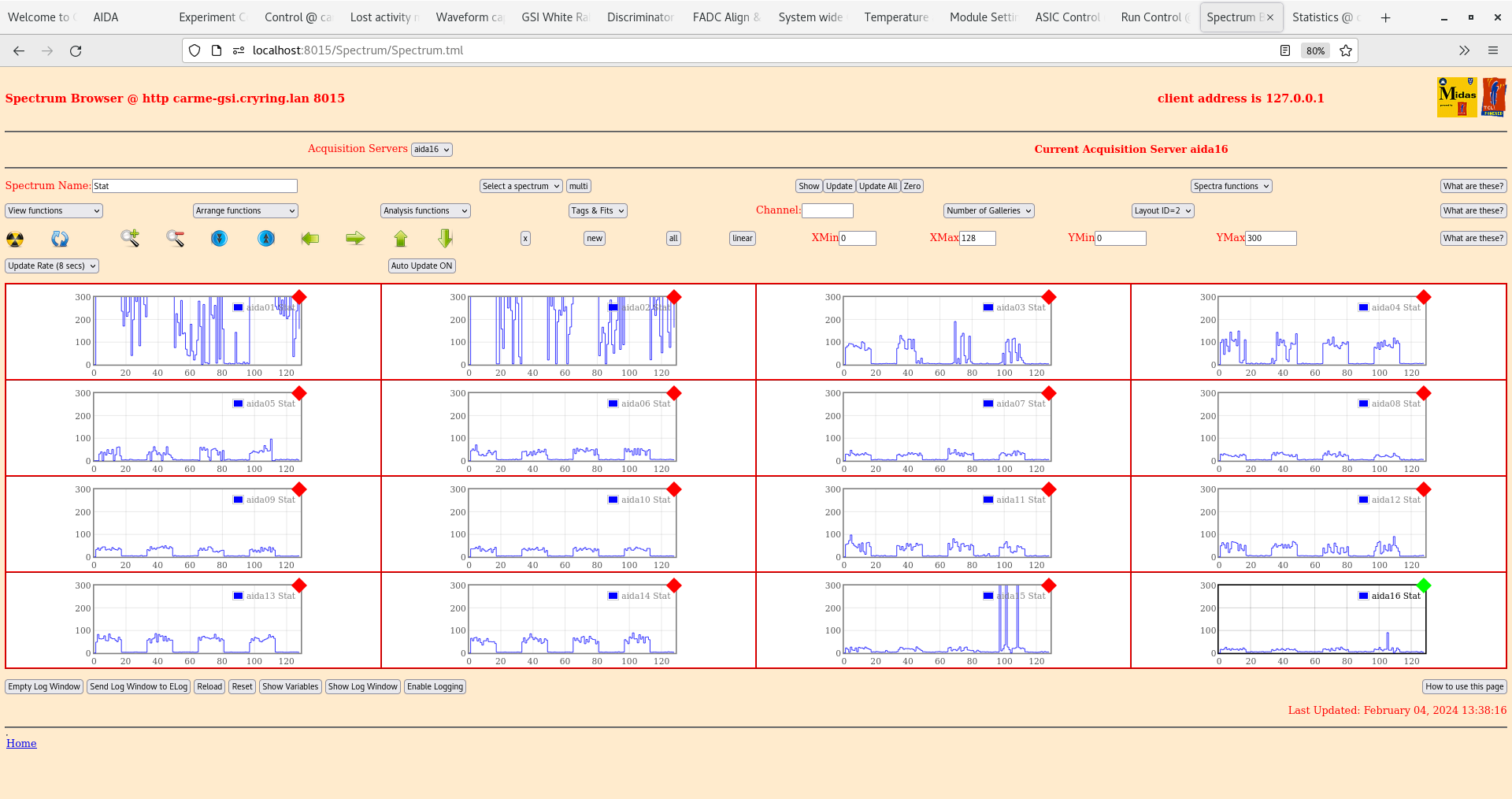

10.12 per FEE64 Stat spectra - attachment 15

missing channels aida03, aida04, aida05 & aida15

Check ASIC load aida03, aida04, aida05 & aida15

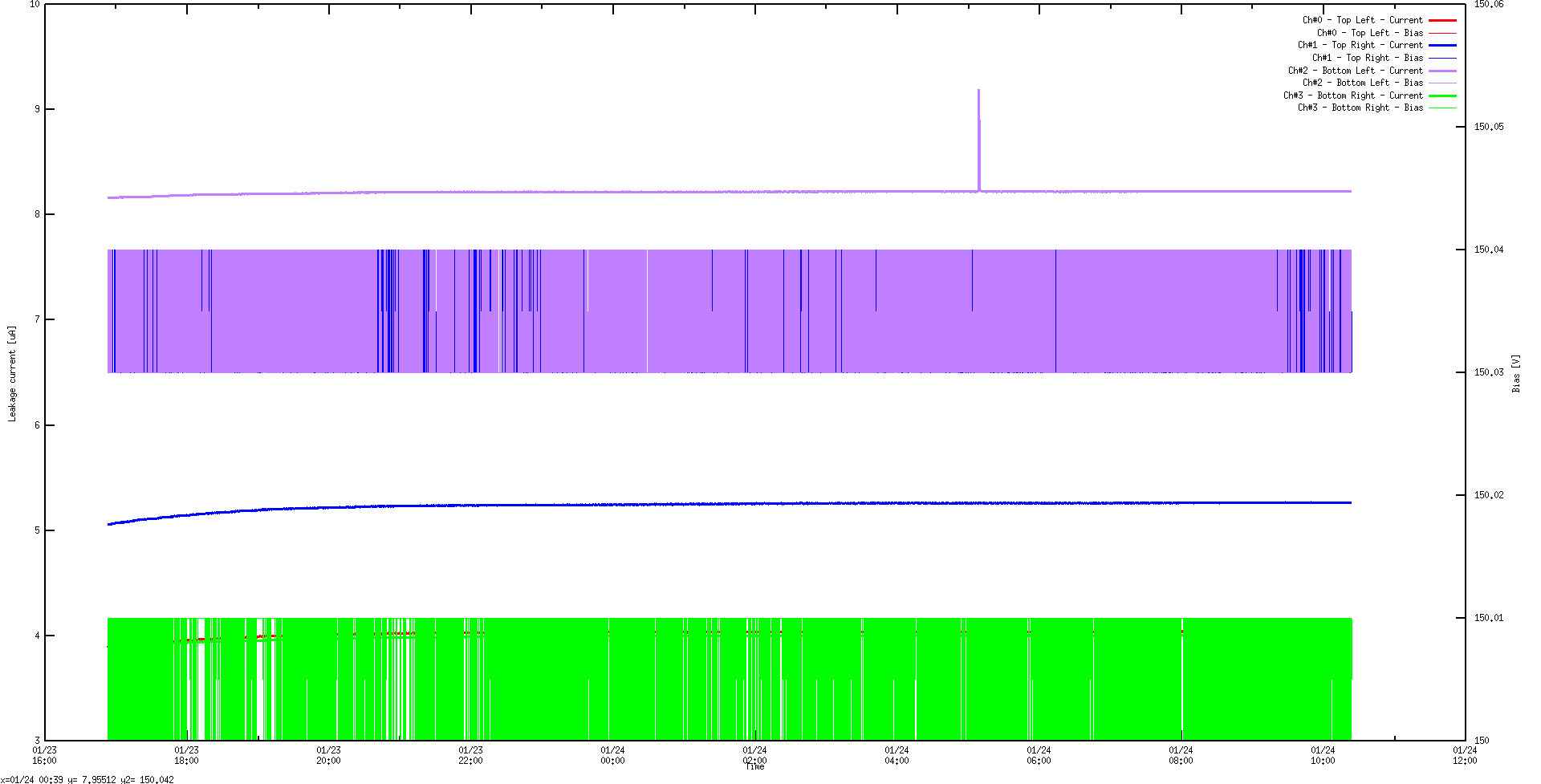

13:25 Overnight leakage current plot - att 16

13.38 DAQ continues file G22-88/R1_92

background alpha

DSSSD bias OK - attachment 17

ambient temperature 16.8 deg C

FEE64 temps OK - attachment 18

ADC data item stats - attachment 19

aida15 asic #2 u/s - rate c. 266k

aida11 1*L spectra - attachment 20

ASIC check load at 10.12 should result in 1-2 hits per channel in the Stat spectra aida03, aida04, aida05 and aida15

Channels which continue to show zero counts likely indicate a FEE64-adaptor PCB connection issue

Channels which now show 1, or more, counts cf. attachment 15 likely correspond to channels now working following the check ASIC load

ADC data items/s Merger, Tape Server & Merger stats - attachments 21-23

data rate to disk c. 2Mb/s dominated by aida15 asic 2

13.48 Stopped DAQ file G22-88/R1_93

DSSSD bias OFF

FEE64 power OFF

16.00 Installed FEE64 power cable to aida16

Replaced aida15 with new FEE64 MAC 41:f6:5a

Update dhcpd.conf

Update MIDAS config to include aida16

FEE64 power ON

All system wide checks OK

DSSSD bias OK - attachment 24

FEE64 temperatures OK - attachment 25

ADC data item stats - attachment 26

aida15 rate changes from c. 260k to c. 25k ( 2x 'hot' channels, 1x channel missing, all other channels OK )

per FEE64 Rate spectra - attachment 27

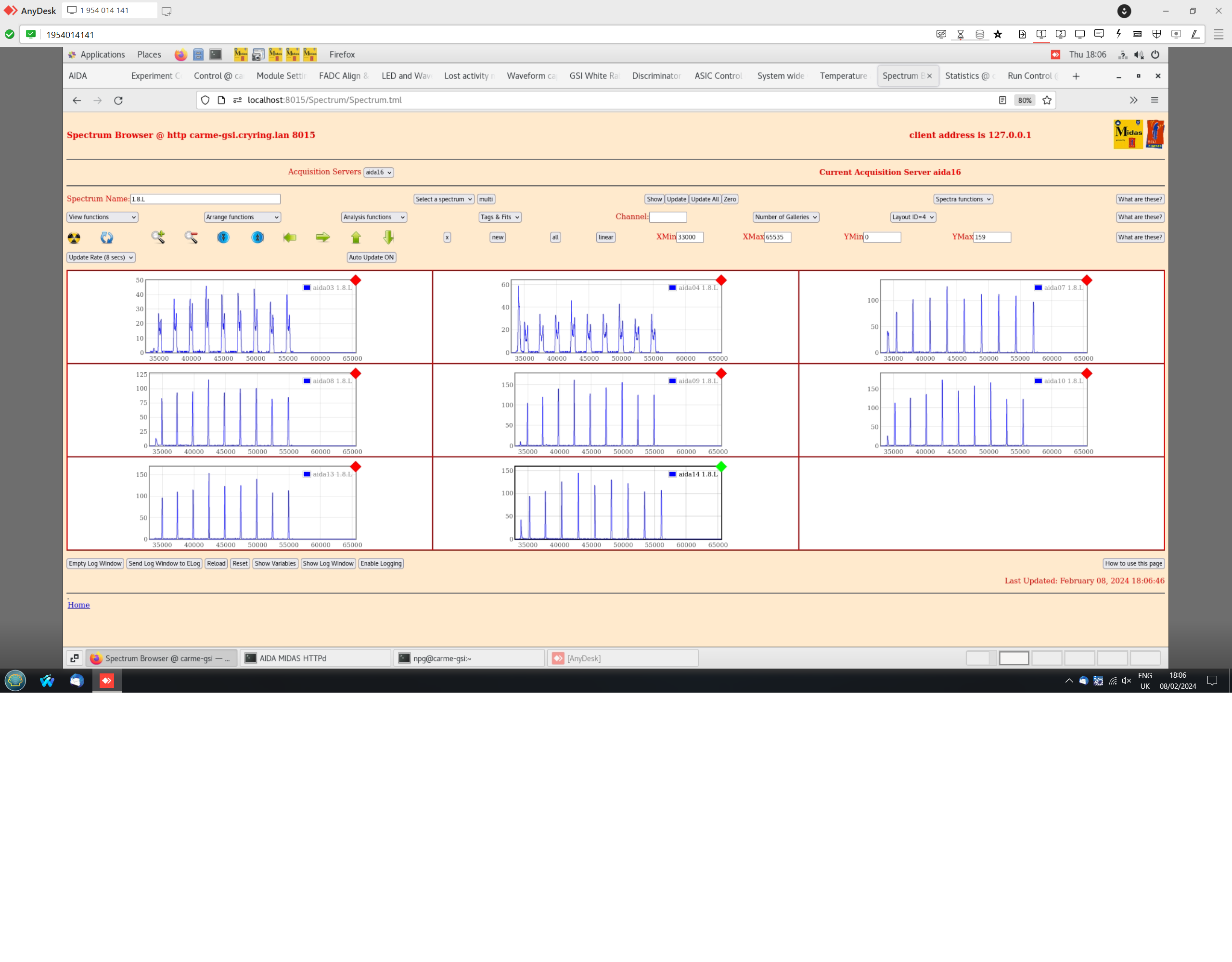

per FEE64 1.8.L spectra - attachments 28-29

pulser peak width aida11 44 ch FWHM, aida14 57 ch FWHM

per FEE64 1.8.W spectra - 20us FSR - attachments 30-31

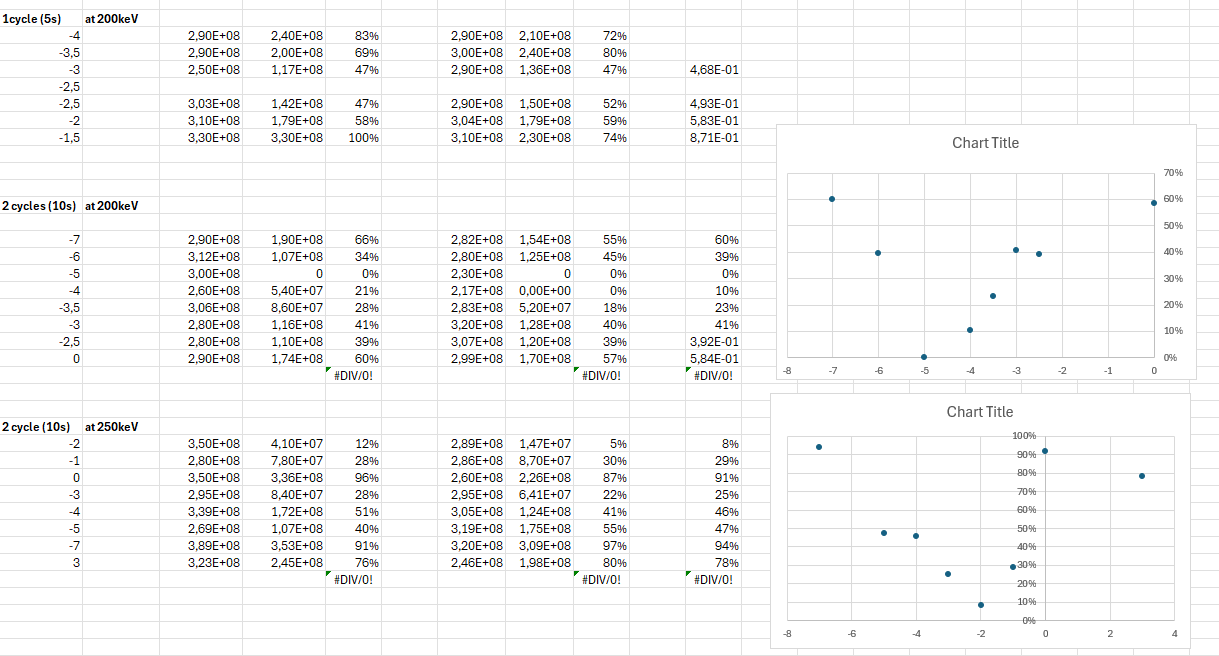

Update NewMerger startup script and Options for 16x FEE64s - see attachments 32-33

16.20 file G22-88/R2

Pulser 50Hz

16.28 DAQ stop

Pulser OFF

All histograms zero'd

16.33 DAQ starts file G22-88/R3

alpha background

ADC data item stats OK - attachment 34

NewMerger, TapeServer and Merger stats - attachments 35-38

16.50 Pulser peak width spreadsheet for file R2 - attachment 39

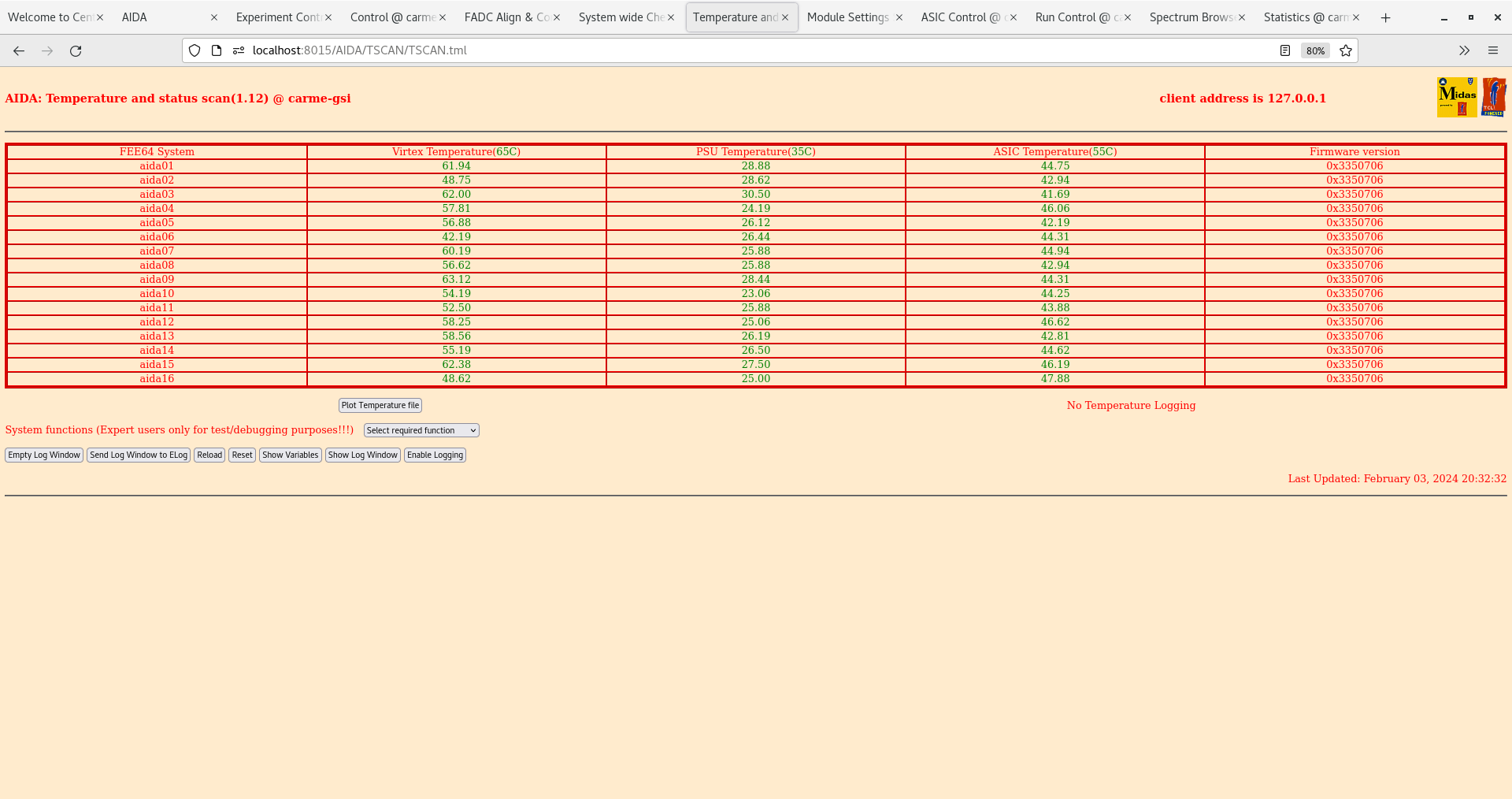

20.32 DAQ continues file G22-88/R3_9

DSSSD bias OK - attachment 40

FEE64 temperatures OK - attachment 41

ADC data item stats - attachment 42

aida15 rate c. 25k ( 2x 'hot' channels, 1x channel missing, all other channels OK )

per FEE64 Stat spectra - attachment 43

Merger, Merger stats and TapServer - attachments 44-46

Disc data items - attachment 47

aida15 disc rate c. 8k

Disable aida15 disc ( fast comparator ) outputs for asic#3 - attachment 48

Disc data items- attachment 49

all FEE64s rate << 1Hz

Update NewMerger startup script and Options for 16x FEE64s - see attachments 32-33 |

| Attachment 1: Screenshot_from_2024-02-03_01-07-28.png

|

|

| Attachment 2: Screenshot_from_2024-02-03_01-08-15.png

|

|

| Attachment 3: Screenshot_from_2024-02-03_01-09-00.png

|

|

| Attachment 4: Screenshot_from_2024-02-03_01-09-39.png

|

|

| Attachment 5: Screenshot_from_2024-02-03_01-10-20.png

|

|

| Attachment 6: Screenshot_from_2024-02-03_01-11-45.png

|

|

| Attachment 7: Screenshot_from_2024-02-03_01-12-23.png

|

|

| Attachment 8: Screenshot_from_2024-02-03_10-02-22.png

|

|

| Attachment 9: Screenshot_from_2024-02-03_10-02-50.png

|

|

| Attachment 10: Screenshot_from_2024-02-03_10-03-29.png

|

|

| Attachment 11: Screenshot_from_2024-02-03_10-04-15.png

|

|

| Attachment 12: Screenshot_from_2024-02-03_10-04-46.png

|

|

| Attachment 13: Screenshot_from_2024-02-03_10-05-09.png

|

|

| Attachment 14: Screenshot_from_2024-02-03_10-05-48.png

|

|

| Attachment 15: Screenshot_from_2024-02-03_10-12-32.png

|

|

| Attachment 16: Screenshot_from_2024-02-03_13-24-46.png

|

|

| Attachment 17: Screenshot_from_2024-02-03_13-38-40.png

|

|

| Attachment 18: Screenshot_from_2024-02-03_13-38-47.png

|

|

| Attachment 19: Screenshot_from_2024-02-03_13-39-04.png

|

|

| Attachment 20: Screenshot_from_2024-02-03_13-40-06.png

|

|

| Attachment 21: Screenshot_from_2024-02-03_13-40-43.png

|

|

| Attachment 22: Screenshot_from_2024-02-03_13-41-00.png

|

|

| Attachment 23: Screenshot_from_2024-02-03_13-41-06.png

|

|

| Attachment 24: Screenshot_from_2024-02-03_16-01-18.png

|

|

| Attachment 25: Screenshot_from_2024-02-03_16-01-33.png

|

|

| Attachment 26: Screenshot_from_2024-02-03_16-01-42.png

|

|

| Attachment 27: Screenshot_from_2024-02-03_16-02-27.png

|

|

| Attachment 28: Screenshot_from_2024-02-03_16-03-16.png

|

|

| Attachment 29: Screenshot_from_2024-02-03_16-06-11.png

|

|

| Attachment 30: Screenshot_from_2024-02-03_16-07-05.png

|

|

| Attachment 31: Screenshot_from_2024-02-03_16-07-35.png

|

|

| Attachment 32: CONTENTS

|

0x0006dead string 0x0000

MERGE.LinksAvailable string 16

Index string MERGE.LinksAvailable&&0x0006dead&&MERGE.RunOptions&&MERGE.LinksInUse

Merge.LinksInUse string 1%1%1%1%1%1%1%1%1%1%1%1%1%1%1%1%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%0%

MERGE.LinksInUse string 1%1%1%1%1%1%1%1%1%1%1%1%1%1%1%1%

MERGE.RunOptions string 3

|

| Attachment 33: NewMerger

|

#!/bin/csh -f

echo "Tidy up"

killall -s9 MERGE

killall -s9 merge64.AD

killall -s9 master64

killall -s9 link64

killall -s9 merge64

killall -s9 statrate64

echo "Starting New Merger"

/bin/echo -e "\033];New Merger\007"

if (! $?MIDASBASE) setenv MIDASBASE /MIDAS

#

#

setenv PATH ${MIDASBASE}/Linux/bin64:${PATH}

setenv LD_LIBRARY_PATH ${MIDASBASE}/TclHttpd/Linux64:${MIDASBASE}/Linux/lib64:${MIDASBASE}/lib_Linux64

netint MERGE_SyncStep 0x0000000

cd ${MIDASBASE}/NewMerger/MergeServer/bin64

./master64 -i 16 -l 16 -p 11001 &

sleep 100000000000

#

echo startup complete

#

|

| Attachment 34: Screenshot_from_2024-02-03_16-35-07.png

|

|

| Attachment 35: Screenshot_from_2024-02-03_16-35-20.png

|

|

| Attachment 36: Screenshot_from_2024-02-03_16-35-24.png

|

|

| Attachment 37: Screenshot_from_2024-02-03_16-35-31.png

|

|

| Attachment 38: Screenshot_from_2024-02-03_16-35-40.png

|

|

| Attachment 39: Pulser-widths-carme-2024.xlsx

|

| Attachment 40: Screenshot_from_2024-02-03_20-32-07.png

|

|

| Attachment 41: Screenshot_from_2024-02-03_20-32-40.png

|

|

| Attachment 42: Screenshot_from_2024-02-03_20-33-01.png

|

|

| Attachment 43: Screenshot_from_2024-02-03_20-33-24.png

|

|

| Attachment 44: Screenshot_from_2024-02-03_20-34-17.png

|

|

| Attachment 45: Screenshot_from_2024-02-03_20-34-40.png

|

|

| Attachment 46: Screenshot_from_2024-02-03_20-35-02.png

|

|

| Attachment 47: Screenshot_from_2024-02-03_20-35-52.png

|

|

| Attachment 48: Screenshot_from_2024-02-03_20-36-55.png

|

|

| Attachment 49: Screenshot_from_2024-02-03_20-37-14.png

|

|

| Attachment 50: Screenshot_from_2024-02-04_09-55-02.png

|

|

|

|

490

|

Sun Feb 4 08:40:04 2024 |

CB TD | Run3 - contd |

09.30 DAQ continues file G22-88/R3_17

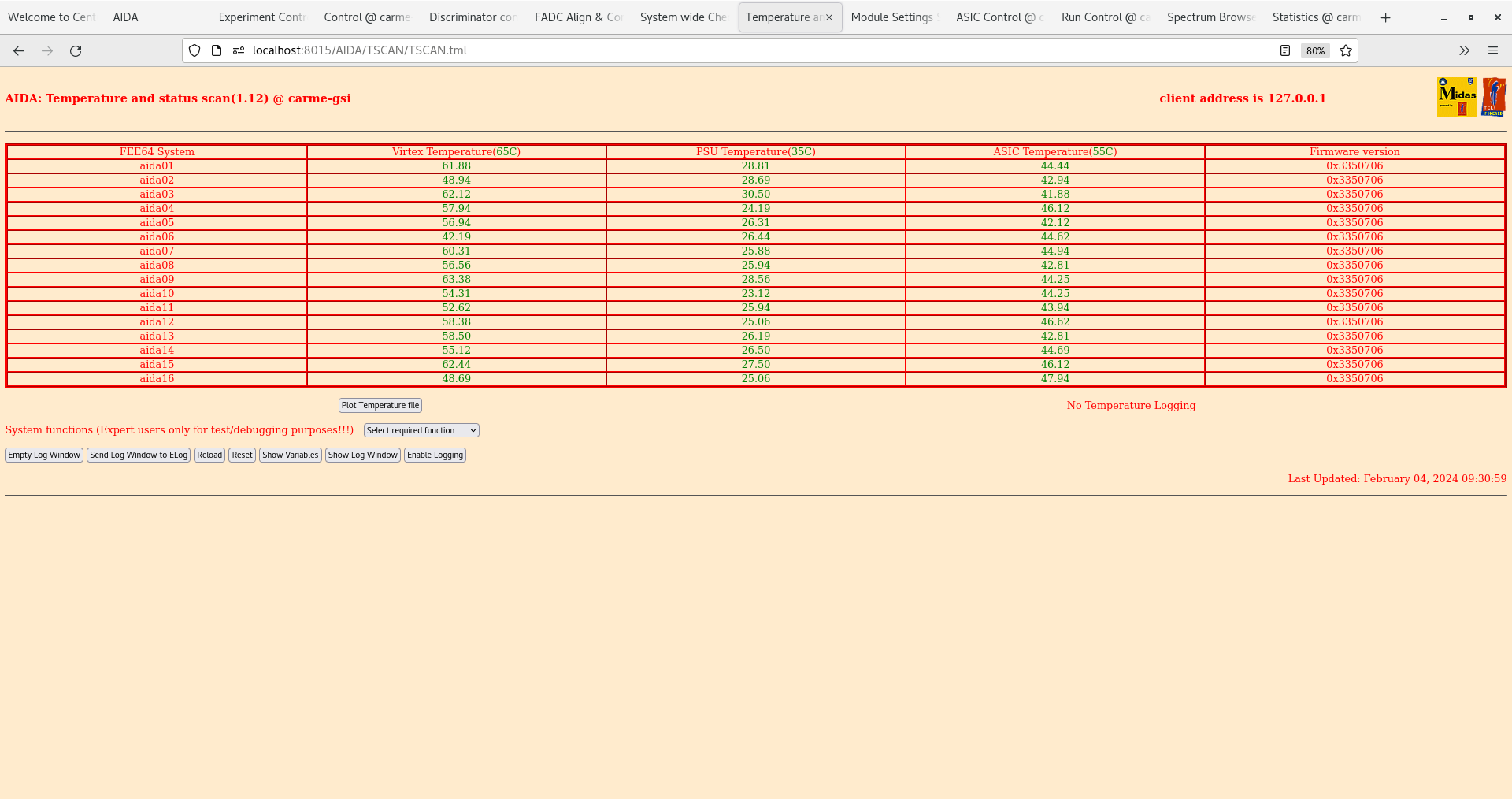

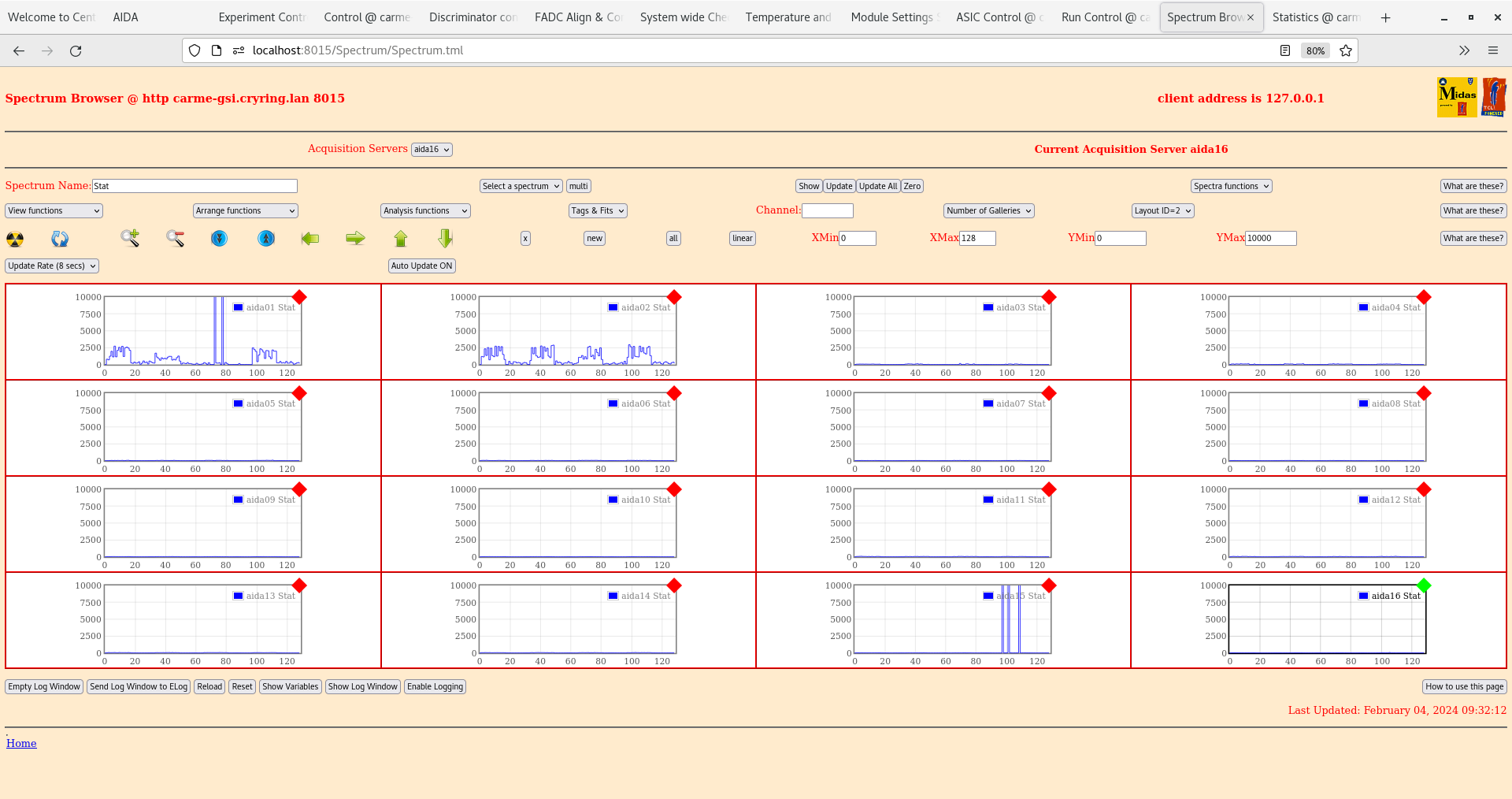

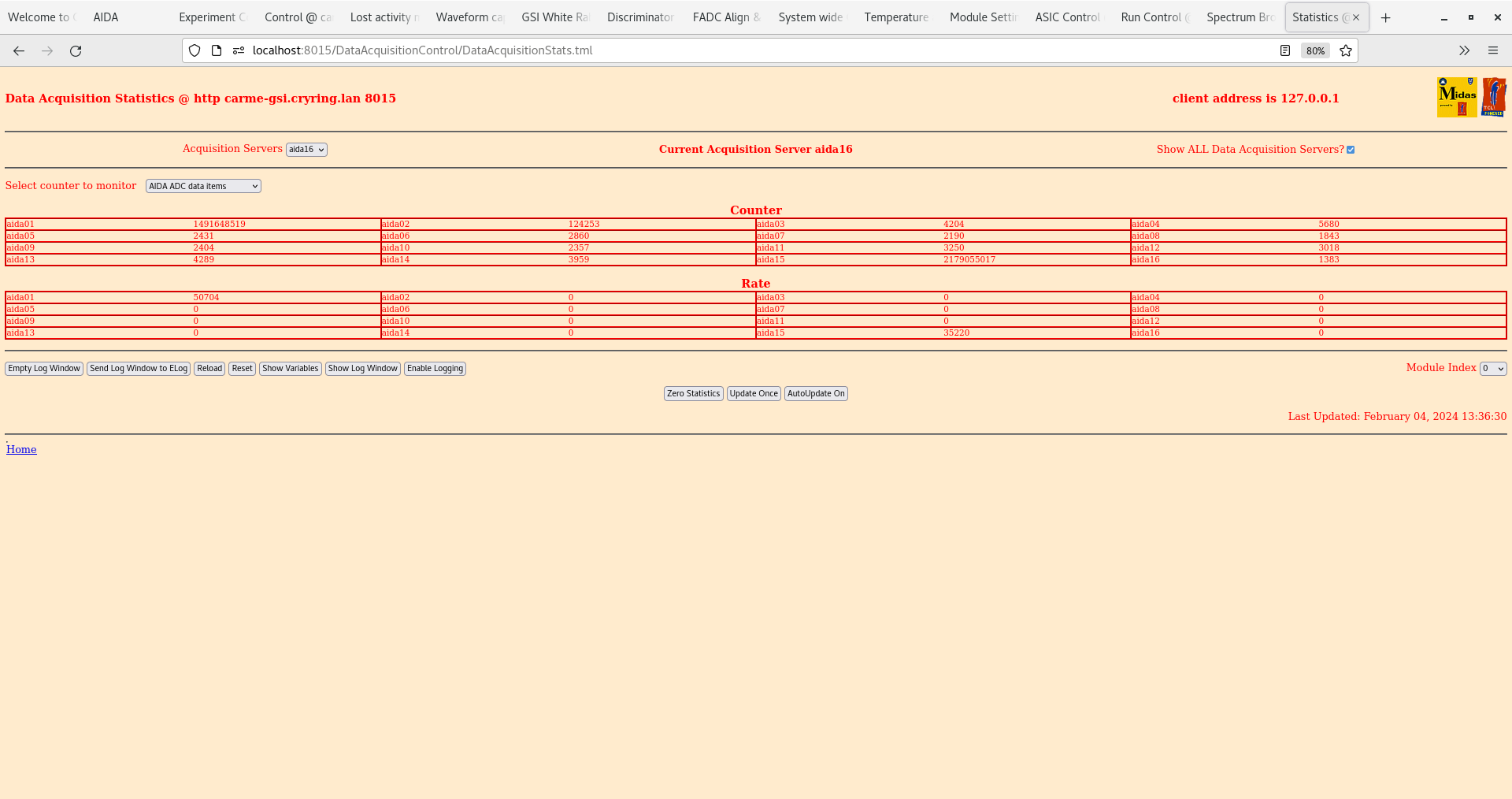

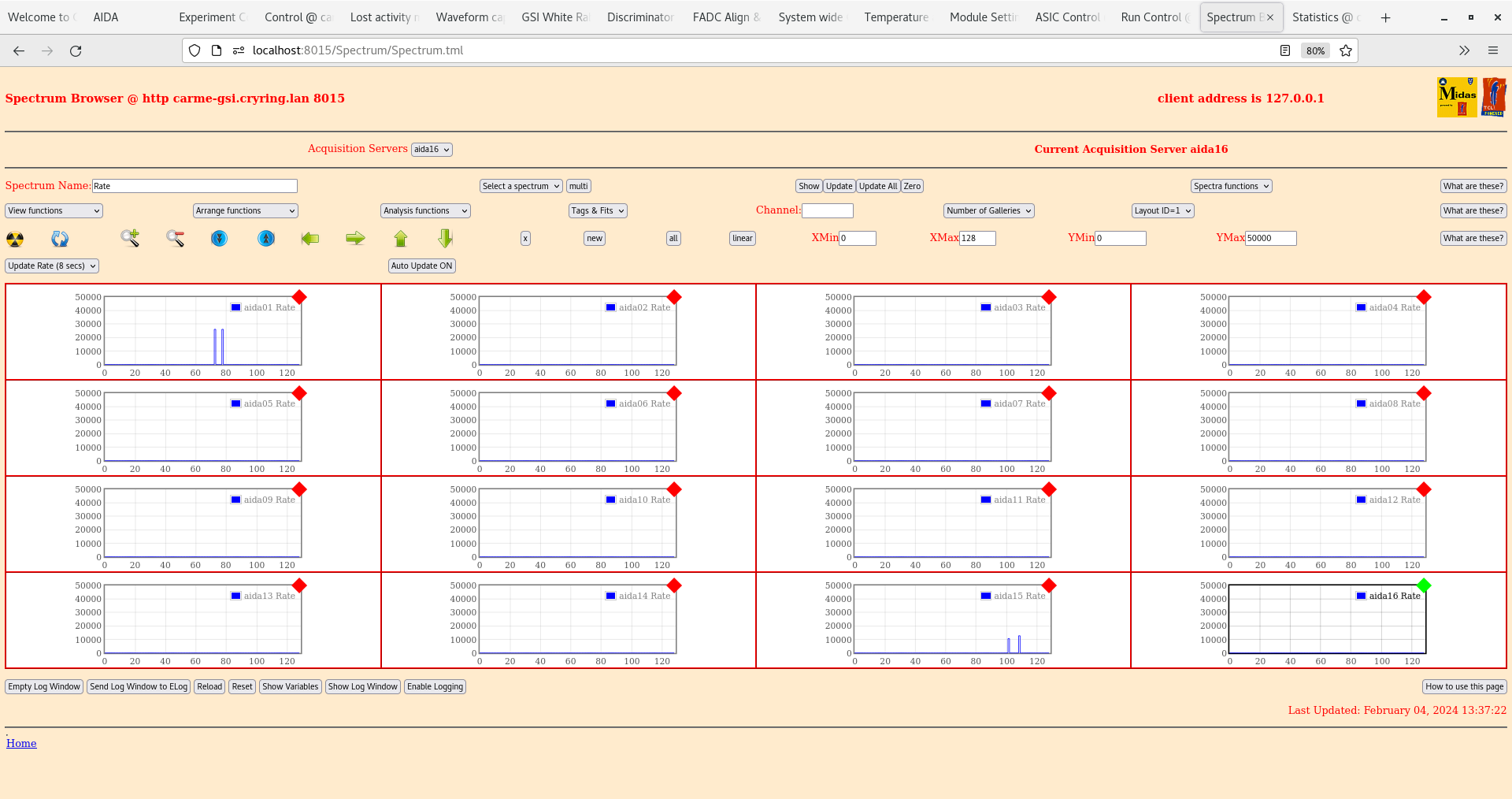

DSSSD bias OK - attachment 1

ambient temperature 16.8 deg C

FEE64 temperatures OK - attachment 2

ADC data item stats - attachment 3

aida15 rate c. 25k ( 2x 'hot' channels, 1x channel missing, all other channels OK )

aida01 rate c. 45k ( 2x 'hot' channels )

per FEE64 Stat spectra - attachments 4-5

per FEE64 1.8.L spectra - attachments 6-7

per FEE64 1.8.W spectra - 20us FSR - attachments 8-9

Merger and TapeServer - attachments 10-11

09.36 Check ASIC load

No change to aida01 ADC data item rate

Last access times of data files indicate that data rate changed c. 05.00 - 06.00 this am.

No obvious vacuum/temperature transients in last six hours.

09.55 All system wide checks OK except

FPGA timestamp errors - attachment 12

WR timestamps OK - attachment 13

10:06 V-I plot overnight - attach 14.

13.35 DAQ continues file G22-88/R3_22

DSSSD bias OK - attachment 15

ambient temperature 16.8 deg C

FEE64 temperatures OK - attachment 16

ADC data item stats - attachment 17

aida15 rate c. 35k ( 2x 'hot' channels, 1x channel missing, all other channels OK )

aida01 rate c. 51k ( 2x 'hot' channels )

per FEE64 Rate spectra - attachments 18

per FEE64 Stat spectra - attachments 19-20

Merger and TapeServer - attachments 21-22 |

| Attachment 1: Screenshot_from_2024-02-04_09-30-41.png

|

|

| Attachment 2: Screenshot_from_2024-02-04_09-31-07.png

|

|

| Attachment 3: Screenshot_from_2024-02-04_09-31-40.png

|

|

| Attachment 4: Screenshot_from_2024-02-04_09-32-26.png

|

|

| Attachment 5: Screenshot_from_2024-02-04_09-32-42.png

|

|

| Attachment 6: Screenshot_from_2024-02-04_09-33-23.png

|

|

| Attachment 7: Screenshot_from_2024-02-04_09-34-00.png

|

|

| Attachment 8: Screenshot_from_2024-02-04_09-34-37.png

|

|

| Attachment 9: Screenshot_from_2024-02-04_09-35-21.png

|

|

| Attachment 10: Screenshot_from_2024-02-04_09-37-23.png

|

|

| Attachment 11: Screenshot_from_2024-02-04_09-38-28.png

|

|

| Attachment 12: Screenshot_from_2024-02-04_09-55-02.png

|

|

| Attachment 13: Screenshot_from_2024-02-04_09-55-18.png

|

|

| Attachment 14: Screenshot_from_2024-02-04_10-05-07.png

|

|

| Attachment 15: Screenshot_from_2024-02-04_13-35-51.png

|

|

| Attachment 16: Screenshot_from_2024-02-04_13-36-21.png

|

|

| Attachment 17: Screenshot_from_2024-02-04_13-36-41.png

|

|

| Attachment 18: Screenshot_from_2024-02-04_13-37-35.png

|

|

| Attachment 19: Screenshot_from_2024-02-04_13-38-27.png

|

|

| Attachment 20: Screenshot_from_2024-02-04_13-38-52.png

|

|

| Attachment 21: Screenshot_from_2024-02-04_13-40-02.png

|

|

| Attachment 22: Screenshot_from_2024-02-04_13-40-20.png

|

|

|

|

491

|

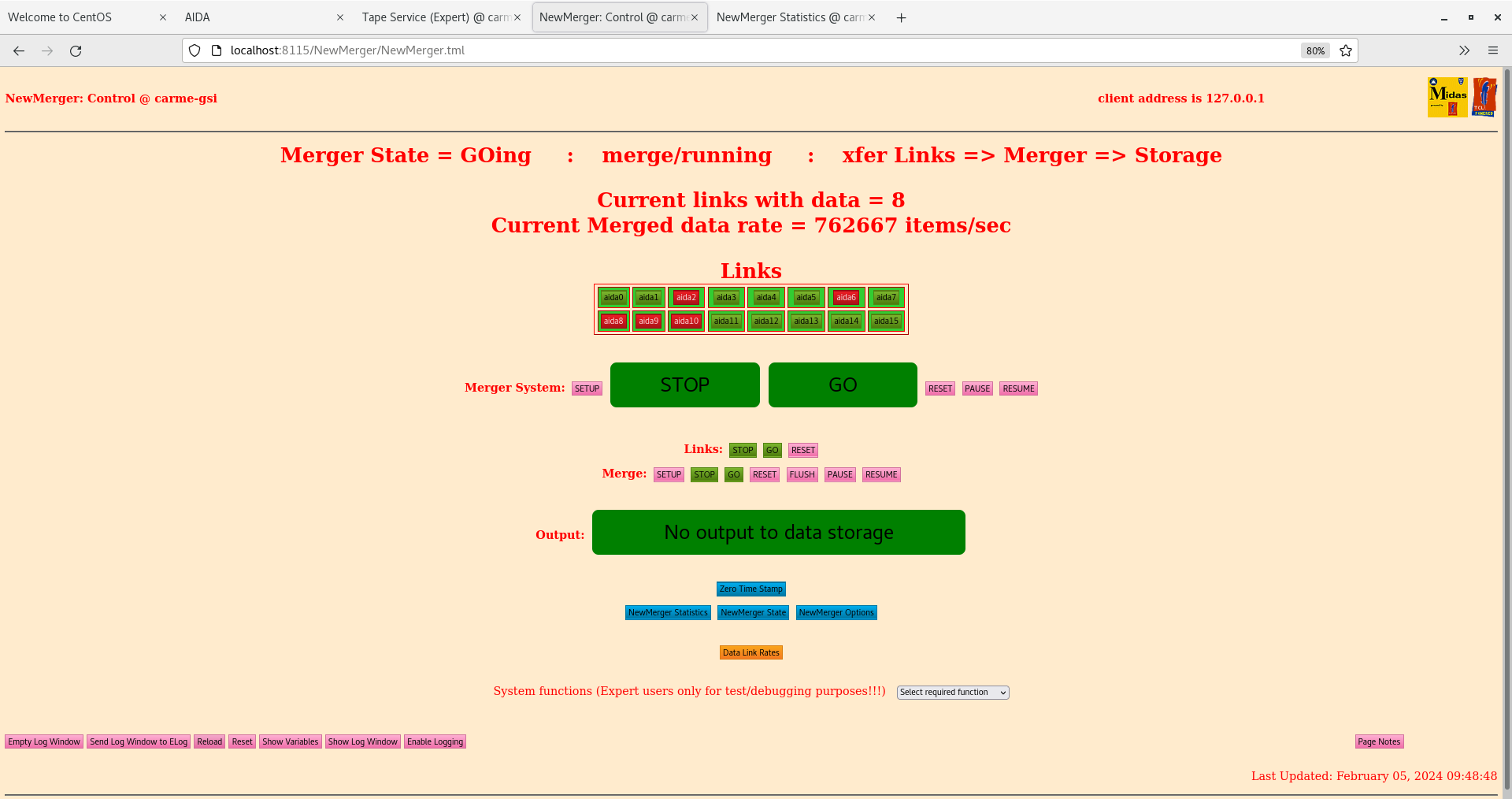

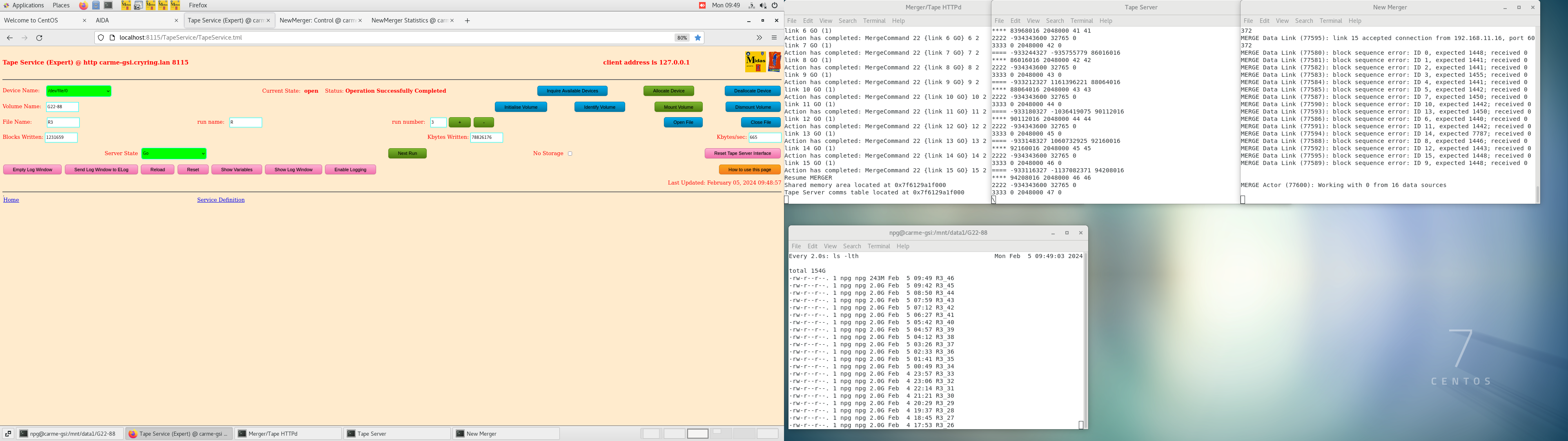

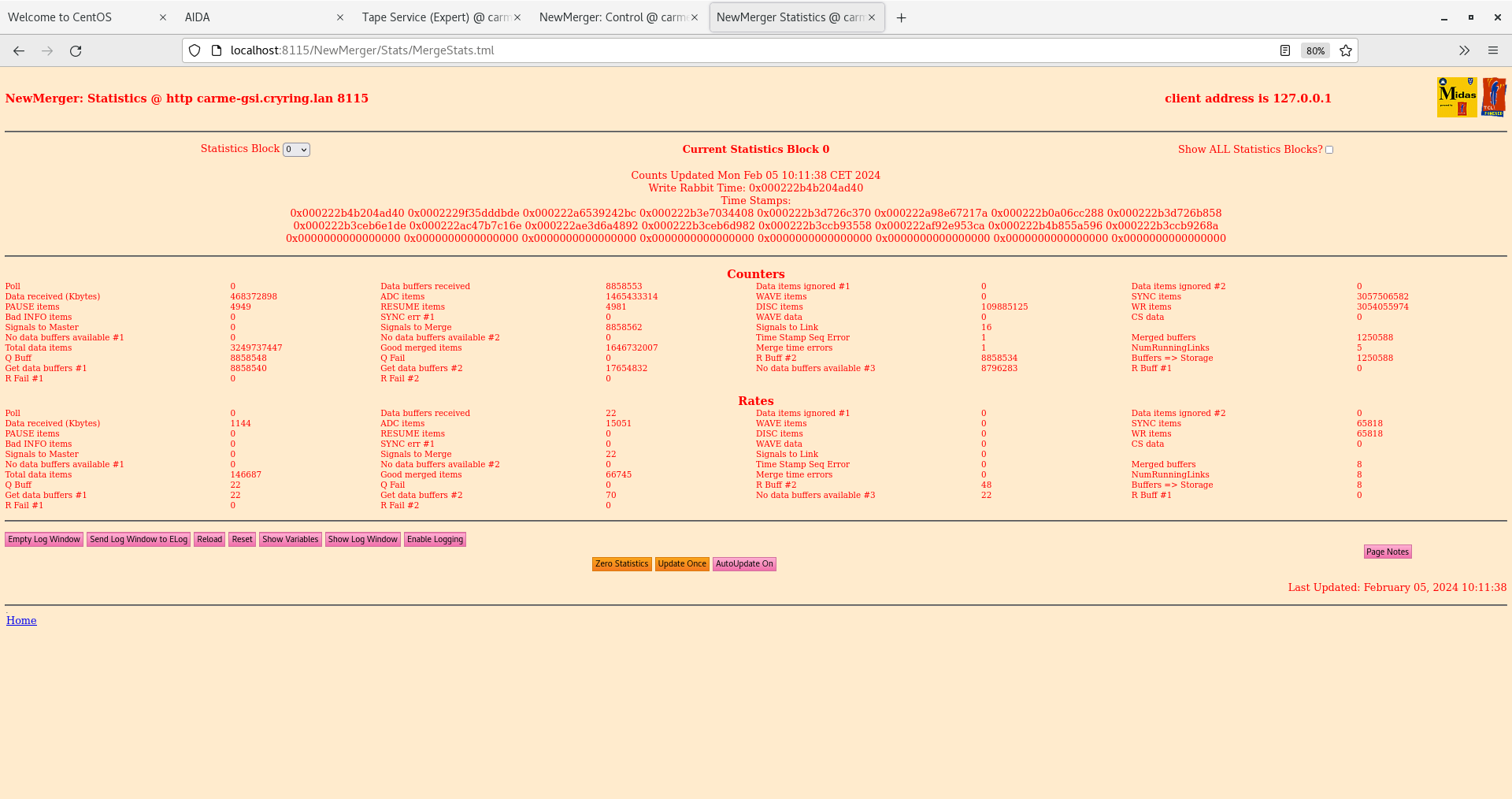

Mon Feb 5 05:45:26 2024 |

CB TD | Run3 - end |

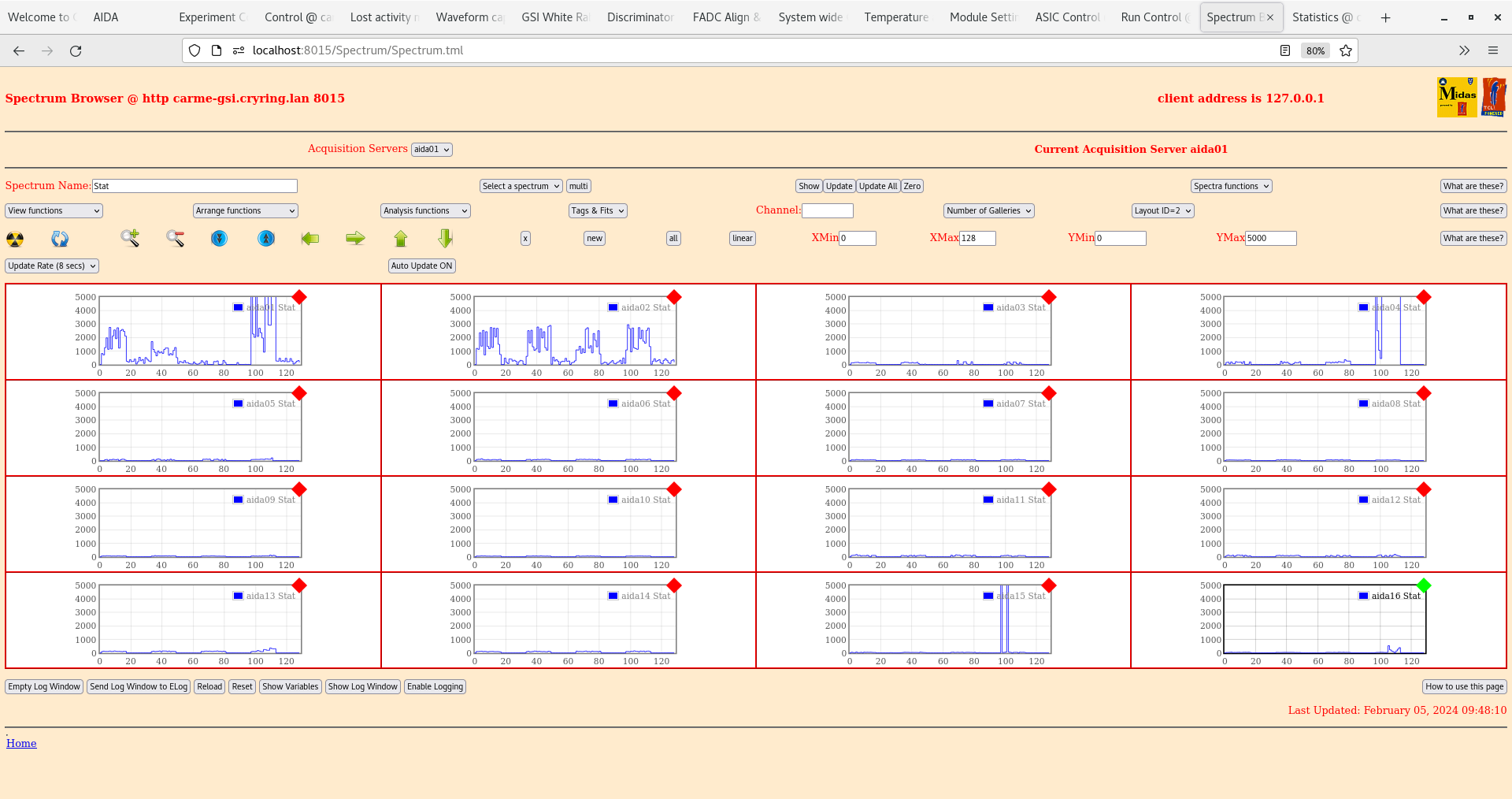

06.40 DAQ continues file G22-88/R3_42

DSSSD bias OK - attachment 1

ambient temperature 16.8 deg C

FEE64 temperatures OK - attachment 2

ADC data item stats - attachments 3

aida15 rate c. 34k ( 2x 'hot' channels, 1x channel missing, all other channels OK )

aida01 rate c. 75k ( 2x 'hot' channels )

per FEE64 Stat spectra - attachments 4-5

Merger and TapeServer - attachments 6-7

All system wide checks OK except

aida02 & aida08 FPGA timestamp error - attachment 8

WR timestamps OK - attachment 9

09.47 DAQ continues file G22-88/R3_46

DSSSD bias OK - attachment 10

ambient temperature 16.8 deg C

FEE64 temperatures OK - attachment 11

ADC data item stats - attachments 12

aida15 rate c. 34k ( 2x 'hot' channels, 1x channel missing, all other channels OK )

aida01 rate c. 75k ( 2x 'hot' channels )

per FEE64 Stat spectra - attachments 13-14

Merger and TapeServer - attachments 15-16

09.52 per FEE64 Rate spectra - attachments 17-18

per FEE64 1.8.L spectra - attachments 19-20

per FEE64 1.8.H spectra - attachments 21-22

per p+n FEE64 1.8.W spectra - 20us, 200us, 2ms & 20ms FSR - attachments 23-26

per n+n FEE64 1.8.W spectra - 20us, 200us, 2ms & 20ms FSR - attachments 27-30

10.11 Merger stats blocks 0-4, 14-16 - attachments 31-38

10.14 aida01-aida04, aida14-aida16 stats- attachments 39-45

10.21 Overnight V-I attach 46

10.23 Save current ASIC settings 2024Feb05-10.22.28

changes to disc mask and LED waveform threshold for some FEE64s

10.32 Analysis of data file G22-88/R3_45 - attachments 47

deadtime aida01 c. 0.5%, all other FEE64s deadtime c. 0%

13.07 DAQ stop file G22-88/R3_50

Stop merger

Stop tapeserver

Afternoon: Tested detector motion. Channels on p+n strips drop out with high threshold (1 MeV), but not with low threshold (100 keV). No issues on n+n strips. Reasons unclear. |

| Attachment 1: Screenshot_from_2024-02-05_06-40-57.png

|

|

| Attachment 2: Screenshot_from_2024-02-05_06-41-22.png

|

|

| Attachment 3: Screenshot_from_2024-02-05_06-41-47.png

|

|

| Attachment 4: Screenshot_from_2024-02-05_06-42-04.png

|

|

| Attachment 5: Screenshot_from_2024-02-05_06-42-29.png

|

|

| Attachment 6: Screenshot_from_2024-02-05_06-42-55.png

|

|

| Attachment 7: Screenshot_from_2024-02-05_06-43-16.png

|

|

| Attachment 8: Screenshot_from_2024-02-05_06-44-10.png

|

|

| Attachment 9: Screenshot_from_2024-02-05_06-44-55.png

|

|

| Attachment 10: Screenshot_from_2024-02-05_09-46-59.png

|

|

| Attachment 11: Screenshot_from_2024-02-05_09-47-39.png

|

|

| Attachment 12: Screenshot_from_2024-02-05_09-47-52.png

|

|

| Attachment 13: Screenshot_from_2024-02-05_09-48-22.png

|

|

| Attachment 14: Screenshot_from_2024-02-05_09-48-29.png

|

|

| Attachment 15: Screenshot_from_2024-02-05_09-48-51.png

|

|

| Attachment 16: Screenshot_from_2024-02-05_09-49-05.png

|

|

| Attachment 17: Screenshot_from_2024-02-05_09-52-04.png

|

|

| Attachment 18: Screenshot_from_2024-02-05_09-52-14.png

|

|

| Attachment 19: Screenshot_from_2024-02-05_09-52-57.png

|

|

| Attachment 20: Screenshot_from_2024-02-05_09-53-33.png

|

|

| Attachment 21: Screenshot_from_2024-02-05_09-55-33.png

|

|

| Attachment 22: Screenshot_from_2024-02-05_09-56-09.png

|

|

| Attachment 23: Screenshot_from_2024-02-05_09-57-05.png

|

|

| Attachment 24: Screenshot_from_2024-02-05_09-58-51.png

|

|

| Attachment 25: Screenshot_from_2024-02-05_09-59-23.png

|

|

| Attachment 26: Screenshot_from_2024-02-05_09-59-56.png

|

|

| Attachment 27: Screenshot_from_2024-02-05_10-03-26.png

|

|

| Attachment 28: Screenshot_from_2024-02-05_10-02-25.png

|

|

| Attachment 29: Screenshot_from_2024-02-05_10-01-57.png

|

|

| Attachment 30: Screenshot_from_2024-02-05_10-01-25.png

|

|

| Attachment 31: Screenshot_from_2024-02-05_10-11-41.png

|

|

| Attachment 32: Screenshot_from_2024-02-05_10-11-46.png

|

|

| Attachment 33: Screenshot_from_2024-02-05_10-11-51.png

|

|

| Attachment 34: Screenshot_from_2024-02-05_10-11-57.png

|

|

| Attachment 35: Screenshot_from_2024-02-05_10-12-04.png

|

|

| Attachment 36: Screenshot_from_2024-02-05_10-12-39.png

|

|

| Attachment 37: Screenshot_from_2024-02-05_10-12-44.png

|

|

| Attachment 38: Screenshot_from_2024-02-05_10-13-11.png

|

|

| Attachment 39: Screenshot_from_2024-02-05_10-14-43.png

|

|

| Attachment 40: Screenshot_from_2024-02-05_10-14-50.png

|

|

| Attachment 41: Screenshot_from_2024-02-05_10-15-43.png

|

|

| Attachment 42: Screenshot_from_2024-02-05_10-15-48.png

|

|

| Attachment 43: Screenshot_from_2024-02-05_10-15-54.png

|

|

| Attachment 44: Screenshot_from_2024-02-05_10-16-00.png

|

|

| Attachment 45: Screenshot_from_2024-02-05_10-16-06.png

|

|

| Attachment 46: Screenshot_from_2024-02-05_10-21-03.png

|

|

| Attachment 47: R3_45

|

*** TDR format 3.3.0 analyser - TD - May 2021

*** ERROR: READ I/O error: 5002

blocks: 32000

ADC data format: 261748120 ( 83699.2 Hz)

Other data format: 171882 ( 55.0 Hz)

Sample trace data format: 0 ( 0.0 Hz)

Undefined format: 0 ( 0.0 Hz)

Other data format type: PAUSE: 194 ( 0.1 Hz)

RESUME: 194 ( 0.1 Hz)

SYNC100: 43648 ( 14.0 Hz)

WR48-63: 43648 ( 14.0 Hz)

FEE64 disc: 84198 ( 26.9 Hz)

MBS info: 0 ( 0.0 Hz)

Other info: 0 ( 0.0 Hz)

ADC data range bit set: 3 ( 0.0 Hz)

Timewarps: ADC: 0 ( 0.0 Hz)

PAUSE: 0 ( 0.0 Hz)

RESUME: 0 ( 0.0 Hz)

SYNC100: 0 ( 0.0 Hz)

WR48-63: 0 ( 0.0 Hz)

FEE64 disc: 0 ( 0.0 Hz)

MBS info: 0 ( 0.0 Hz)

Undefined: 0 ( 0.0 Hz)

Sample trace: 0 ( 0.0 Hz)

*** Timestamp elapsed time: 3127.246 s

FEE elapsed dead time(s) elapsed idle time(s)

0 17.539 0.000

1 0.000 0.000

2 0.000 0.000

3 0.000 991.338

4 0.000 0.000

5 0.000 0.000

6 0.000 0.000

7 0.000 0.000

8 0.000 0.000

9 0.000 0.000

10 0.000 0.000

11 0.000 0.000

12 0.000 0.000

13 0.000 0.000

14 0.500 0.000

15 0.000 0.000

16 0.000 0.000

17 0.000 0.000

18 0.000 0.000

19 0.000 0.000

20 0.000 0.000

21 0.000 0.000

22 0.000 0.000

23 0.000 0.000

24 0.000 0.000

25 0.000 0.000

26 0.000 0.000

27 0.000 0.000

28 0.000 0.000

29 0.000 0.000

30 0.000 0.000

31 0.000 0.000

32 0.000 0.000

*** Statistics

FEE ADC Data Other Data Sample Undefined Pause Resume SYNC100 WR48-63 Disc MBS Other HEC Data

0 172462915 139302 0 0 170 170 27567 27567 83828 0 0 0

1 45 2 0 0 0 0 0 0 2 0 0 1

2 58 0 0 0 0 0 0 0 0 0 0 0

3 167035 79 0 0 0 0 24 24 31 0 0 0

4 332 0 0 0 0 0 0 0 0 0 0 0

5 257 0 0 0 0 0 0 0 0 0 0 0

6 254 0 0 0 0 0 0 0 0 0 0 0

7 370 0 0 0 0 0 0 0 0 0 0 0

8 336 0 0 0 0 0 0 0 0 0 0 0

9 75 0 0 0 0 0 0 0 0 0 0 0

10 99 0 0 0 0 0 0 0 0 0 0 0

11 240 164 0 0 0 0 0 0 164 0 0 0

12 1266 0 0 0 0 0 0 0 0 0 0 0

13 218 0 0 0 0 0 0 0 0 0 0 0

14 89113402 32165 0 0 24 24 16057 16057 3 0 0 2

15 1218 170 0 0 0 0 0 0 170 0 0 0

16 0 0 0 0 0 0 0 0 0 0 0 0

17 0 0 0 0 0 0 0 0 0 0 0 0

18 0 0 0 0 0 0 0 0 0 0 0 0

19 0 0 0 0 0 0 0 0 0 0 0 0

20 0 0 0 0 0 0 0 0 0 0 0 0

21 0 0 0 0 0 0 0 0 0 0 0 0

22 0 0 0 0 0 0 0 0 0 0 0 0

23 0 0 0 0 0 0 0 0 0 0 0 0

24 0 0 0 0 0 0 0 0 0 0 0 0

25 0 0 0 0 0 0 0 0 0 0 0 0

26 0 0 0 0 0 0 0 0 0 0 0 0

27 0 0 0 0 0 0 0 0 0 0 0 0

28 0 0 0 0 0 0 0 0 0 0 0 0

29 0 0 0 0 0 0 0 0 0 0 0 0

30 0 0 0 0 0 0 0 0 0 0 0 0

31 0 0 0 0 0 0 0 0 0 0 0 0

32 0 0 0 0 0 0 0 0 0 0 0 0

*** Timewarps

FEE ADC Pause Resume SYNC100 WR48-63 Disc MBS Undefined Samples

0 0 0 0 0 0 0 0 0 0

1 0 0 0 0 0 0 0 0 0

2 0 0 0 0 0 0 0 0 0

3 0 0 0 0 0 0 0 0 0

4 0 0 0 0 0 0 0 0 0

5 0 0 0 0 0 0 0 0 0

6 0 0 0 0 0 0 0 0 0

7 0 0 0 0 0 0 0 0 0

8 0 0 0 0 0 0 0 0 0

9 0 0 0 0 0 0 0 0 0

10 0 0 0 0 0 0 0 0 0

11 0 0 0 0 0 0 0 0 0

12 0 0 0 0 0 0 0 0 0

13 0 0 0 0 0 0 0 0 0

14 0 0 0 0 0 0 0 0 0

15 0 0 0 0 0 0 0 0 0

16 0 0 0 0 0 0 0 0 0

17 0 0 0 0 0 0 0 0 0

18 0 0 0 0 0 0 0 0 0

19 0 0 0 0 0 0 0 0 0

20 0 0 0 0 0 0 0 0 0

21 0 0 0 0 0 0 0 0 0

22 0 0 0 0 0 0 0 0 0

23 0 0 0 0 0 0 0 0 0

24 0 0 0 0 0 0 0 0 0

25 0 0 0 0 0 0 0 0 0

26 0 0 0 0 0 0 0 0 0

27 0 0 0 0 0 0 0 0 0

28 0 0 0 0 0 0 0 0 0

29 0 0 0 0 0 0 0 0 0

30 0 0 0 0 0 0 0 0 0

31 0 0 0 0 0 0 0 0 0

32 0 0 0 0 0 0 0 0 0

*** Program elapsed time: 24.477s ( 1307.373 blocks/s, 81.711 Mb/s)

|

|

|

492

|

Mon Feb 5 12:48:50 2024 |

CB TD | Pulser walkthough - Run4 |

13.41 DAQ start - file G22-88/R4

Pulser walkthrough

EGG Ortec 448 Pulser

Amplitide 90,000-10,000 @ 10,000 step

Normalise 5.0

Attenuators x5 IN

t_r 100ns

Tau_d 50us

Frequency Int Osc 50Hz

Polarity + ( - polarity via Cooknell SA1 Sum & Invert Amp )

File G22-88/R4

14.08 DAQ stop file G22-88/R4_8 |

| Attachment 1: Screenshot_from_2024-02-05_14-04-33.png

|

|

| Attachment 2: Screenshot_from_2024-02-05_14-05-16.png

|

|

|

|

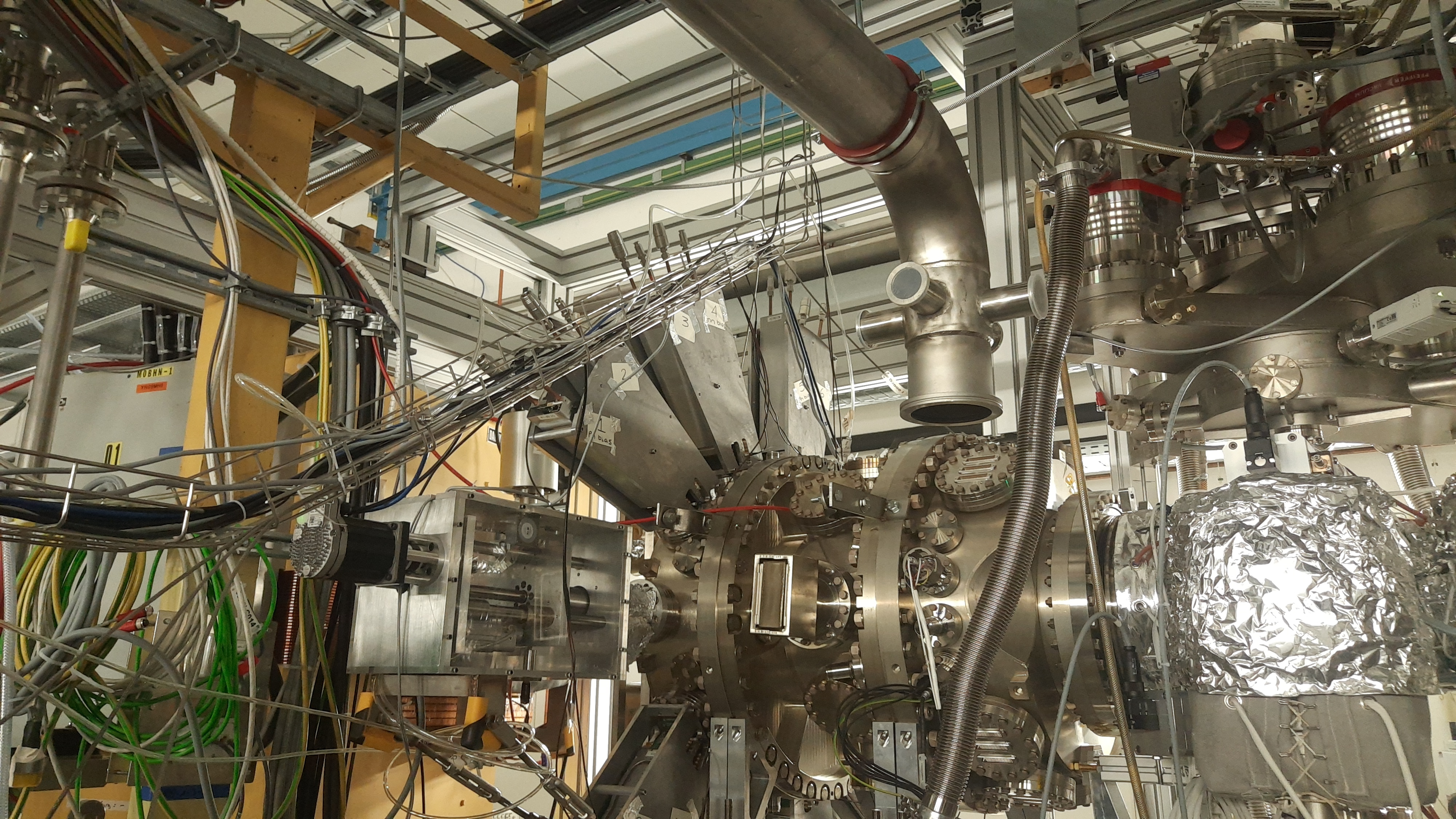

53

|

Thu Sep 2 21:04:26 2021 |

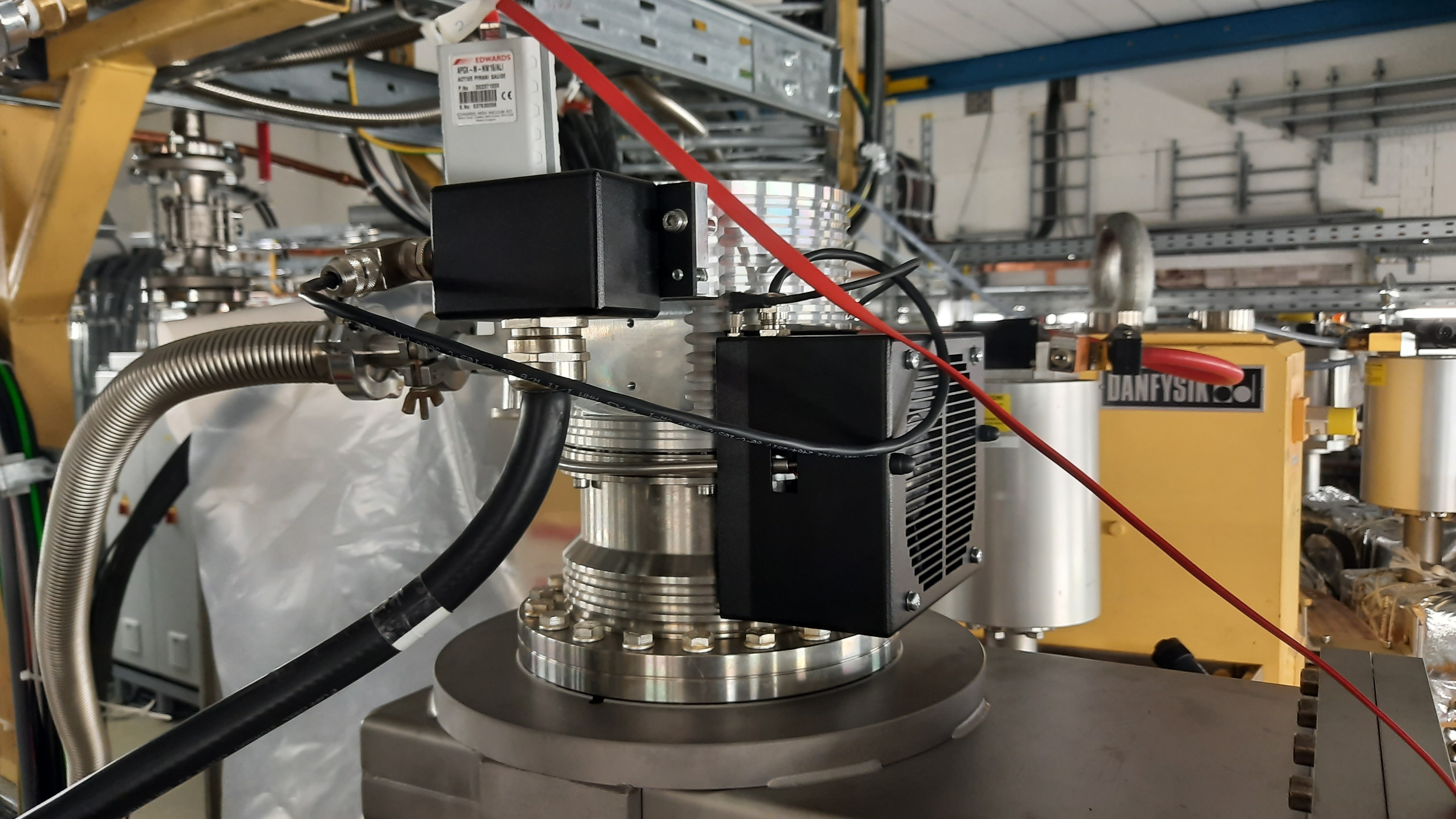

CB RSS ML + DR OG | Gate valves mounted + pump down |

Mounted both gate valves and support. Gate

valves could not be installed one bolt

rotated from 90 degrees as per drawings

due to mechanical conflict with back foot.

Using rotating flanges some small rotation

from 90 was achieved. This may be

sufficient given the reason for the

rotation was to avoid mechanical conflicts

with ring parts that are no longer there.

Valve struts had to be modified as gate

valve is much lower and close to Al frame

than in Daresbury.

ML suggested that the reason for the

change in height mentioned in previous

entry is that the ring gate valve to YR10

is not centered. Solutions will be

considered when the other two setups in

YR09 are mounted and the alignment

situation is more clear

Noted a few blind flanges are bluish,

which indicates SS 304 instead of 316. Did

we get the wrong ones from ITL? Did we

swap them in Daresbury by mistake? Is it

just an odd colour?

Installed turbo pump on top gate valve,

Pirani gauge provided by ABD (where is

ours?) and pumped down.

Reached 10-1 mbar in 10 minutes. Turbo on.

Reached 10-5 mbar on IE514 in 17 more

minutes (where is its manual?)

Will leave pumping overnight. |

| Attachment 1: 20210902_152536.jpg

|

|

| Attachment 2: 20210902_153213.jpg

|

|

| Attachment 3: 20210902_170002.jpg

|

|

| Attachment 4: 20210902_192104.jpg

|

|

| Attachment 5: 20210902_192751.jpg

|

|

| Attachment 6: 20210902_193944.jpg

|

|

|

|

66

|

Fri Sep 10 10:50:55 2021 |

CB RSS ML | Pressure after overnight pump down |

Pressure found in 10-7 mbar range.

Decided to leak test anyway for safety.

Closed top valve. Vented turbo and backing

line. Installed additional valve and T

piece.

Pumping down again. Will begin leak

testing soon. |

| Attachment 1: 20210910_101131.jpg

|

|