| ID |

Date |

Author |

Subject |

|

749

|

Mon Jun 16 10:46:11 2025 |

CB JM JG AK | Run82 |

Background without beam while source is optimised. |

|

132

|

Fri Oct 29 15:09:27 2021 |

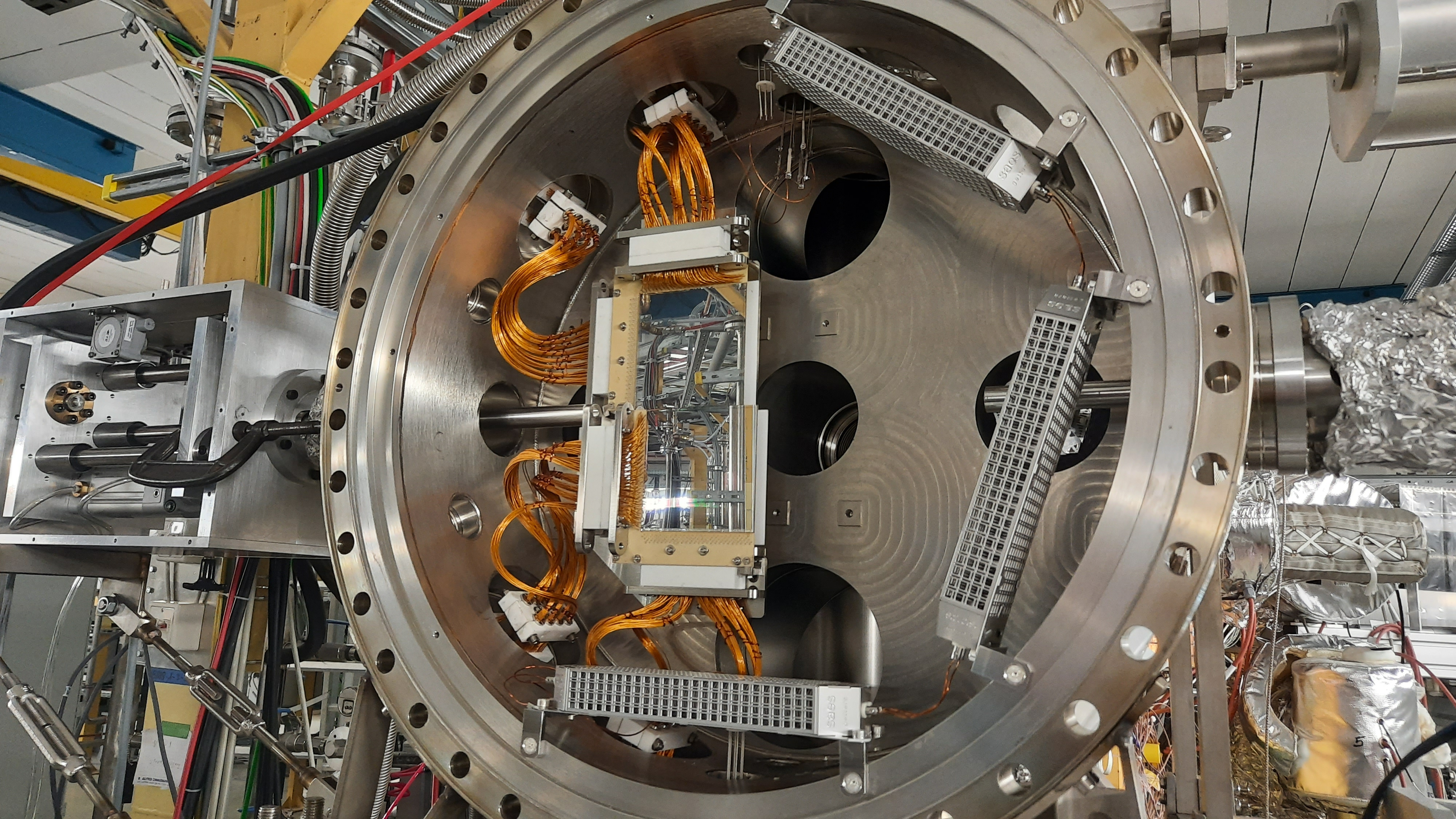

CB JM + RSS OG DR | Preparation to mount new DSSDs |

(Mon 25 October - Tue 26 October)

Considered different strategies to mount DSSDs inside CARME, while waiting for 2x new DSSD to arrive.

Plan A: Mount DSSDs on plate on the bench, slide plate on rod, then attach cables, then attach strain relief

Plan B: Mount DSSDs on plate, attach cables, attach strain relief, slide plate on rod, connect cables to feedthroughs

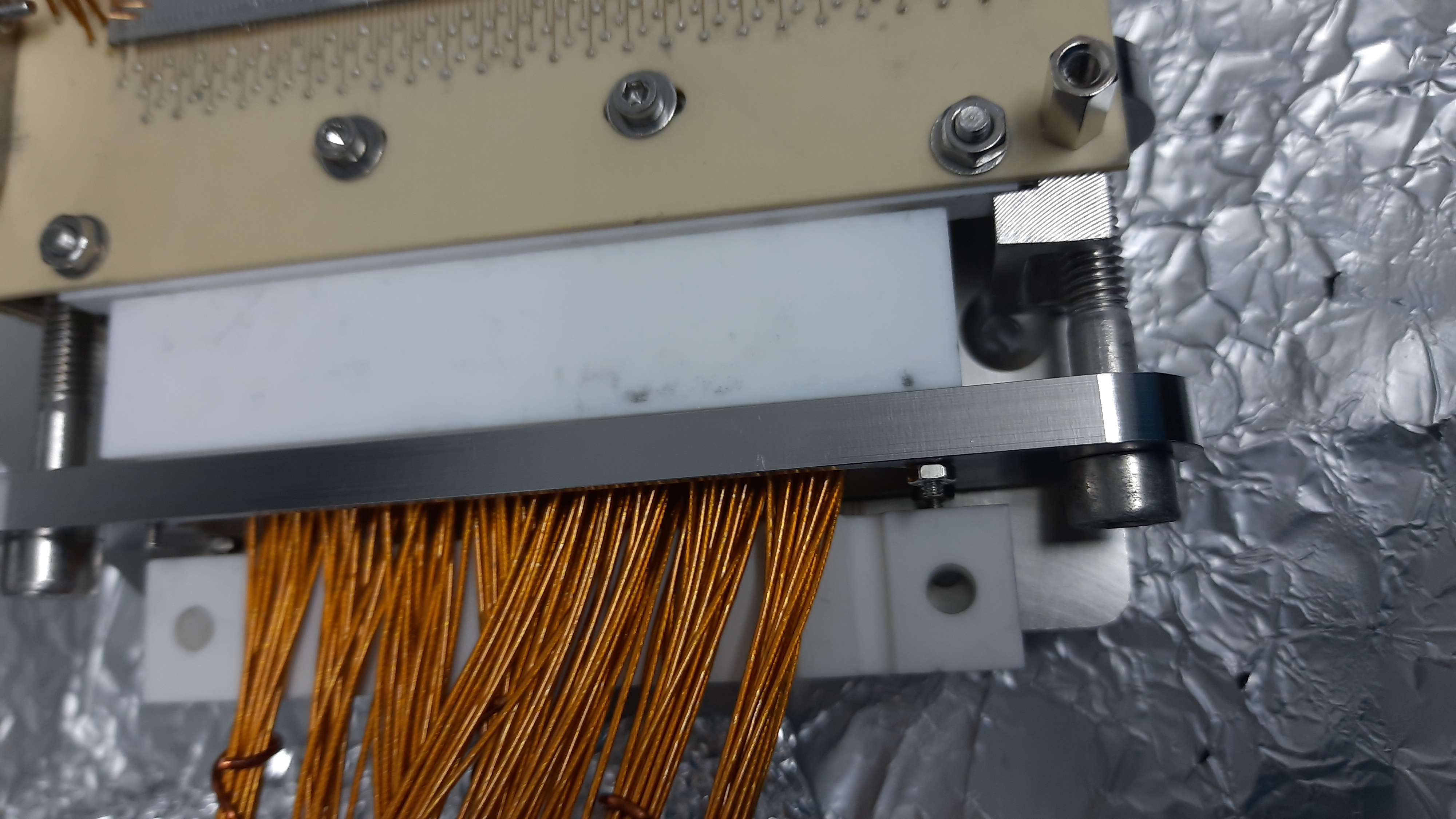

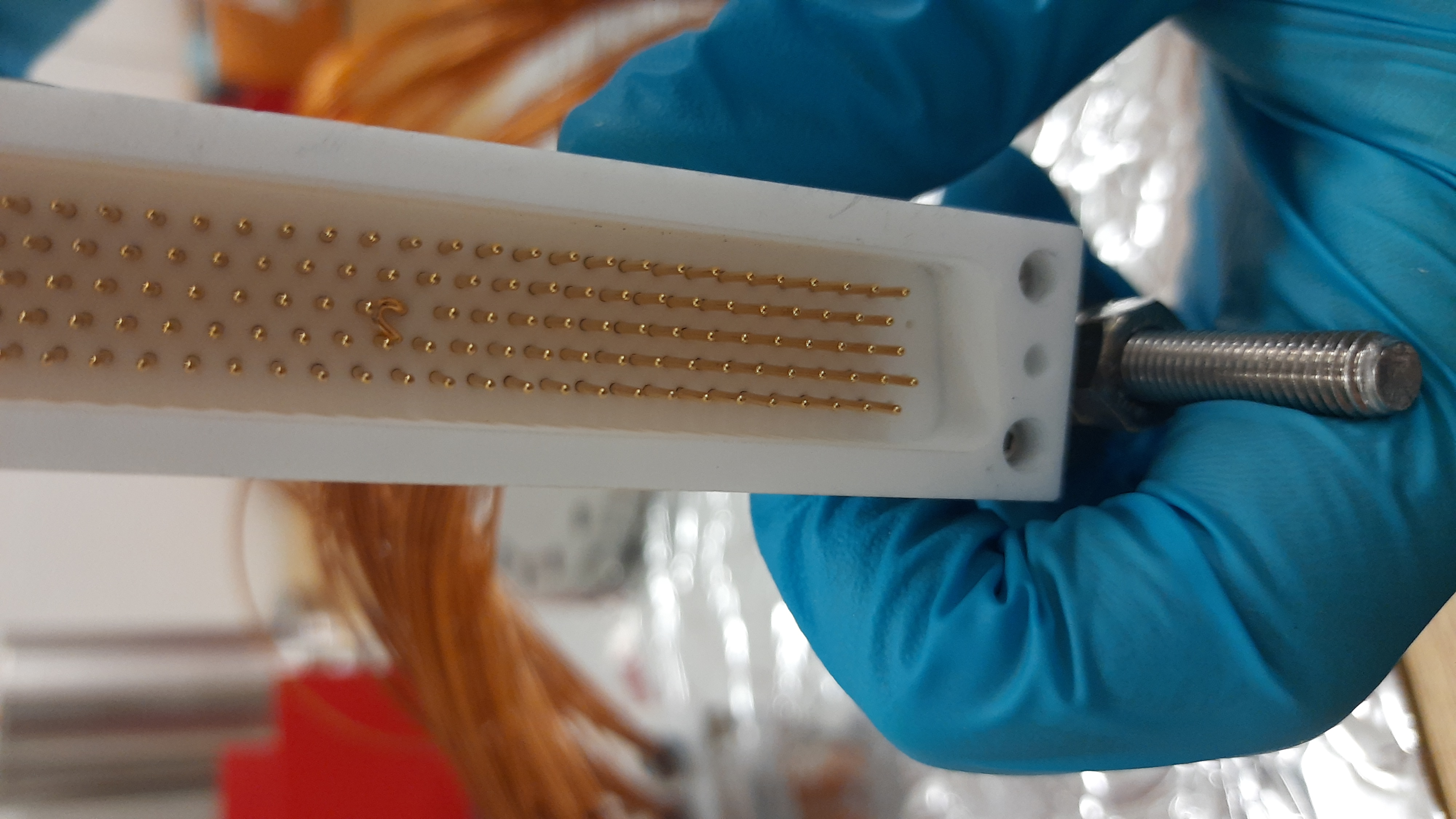

Mounted detectors on plate using new "dog leg" connectors. Threaded and unthreaded holes are flipped! Asked DR to unthread hole in two out of four, and clean.

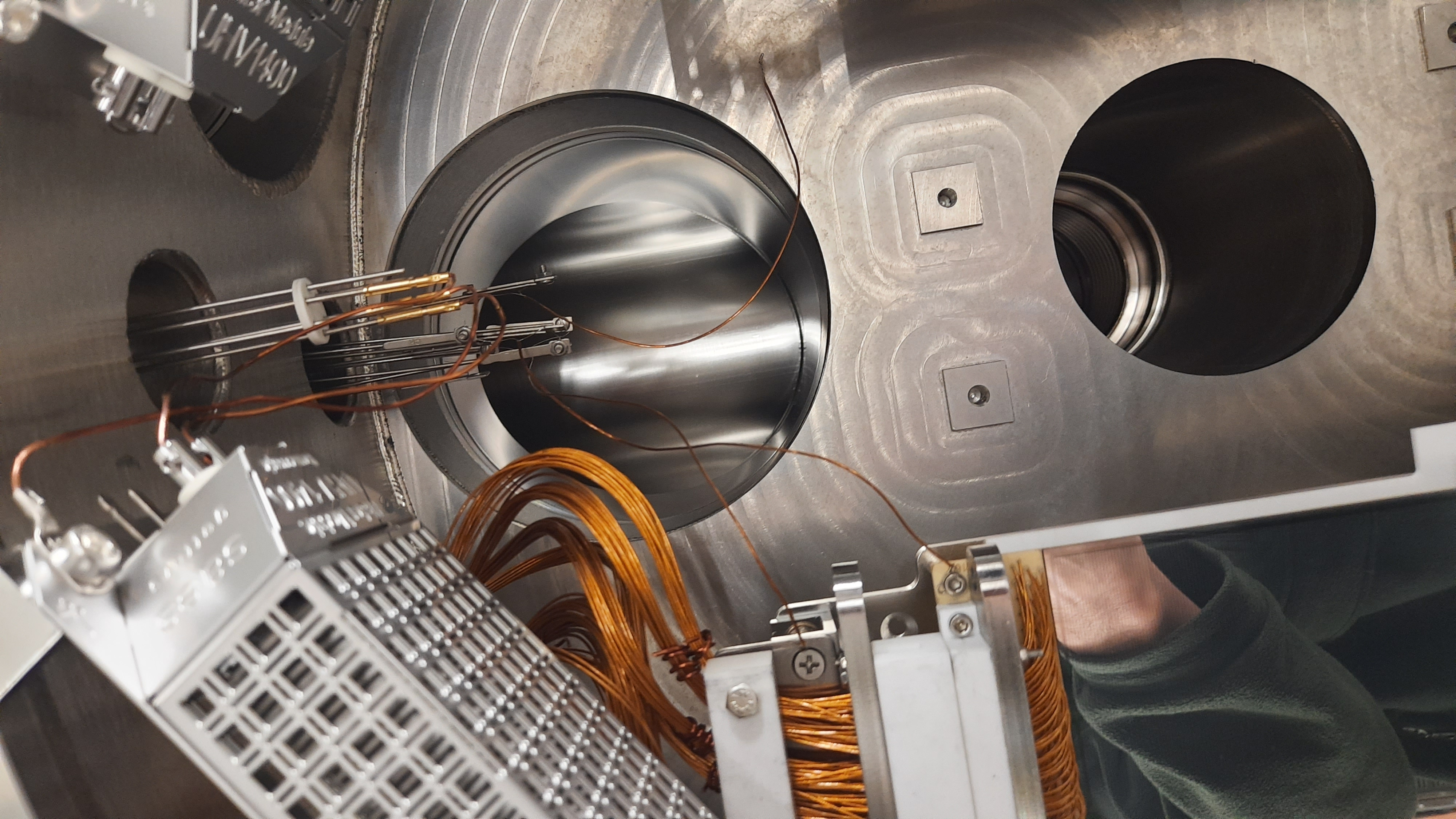

Attempted to proceed with Plan B with stand-in broken detector. Found even a single wire harness attached to the detector was quite hard to insert in the chamber. Temporarily dismounted left-hand 2x UHV1400 to give more space.

Slid plate on rod. New position of rod block makes it easier to mount. Spraying ethanol on the rod to lubricate also helps greatly. Secured plate to rod. Holding flange with cables in left hand, attempted to mount macor plug in feedthrough with right hand. Unable to exert sufficient strength (CB, JM, OG). Pulling on the cable puts strain on the DSSD. Decided to avoid.

Attempted Plan A. Jacked connector in with no issues using M6x40 partly threaded bolts. Unable to unjack due to part threads! Obtained fully threaded rods. Unjacked using washer + two nuts tightened on each other. Jacked and unjacked another connector.

Decided to proceed with A. Having any cable pre-mounted in the chamber is a potential hazard to the detectors while mounting plate. Decided to dismount all flanges, re-organise harnesses and mount one flange+harness at a time after mounting detector on rod.

Used thick Kapton coated Cu from NEG pumps to organise the cables and improve strain relief.

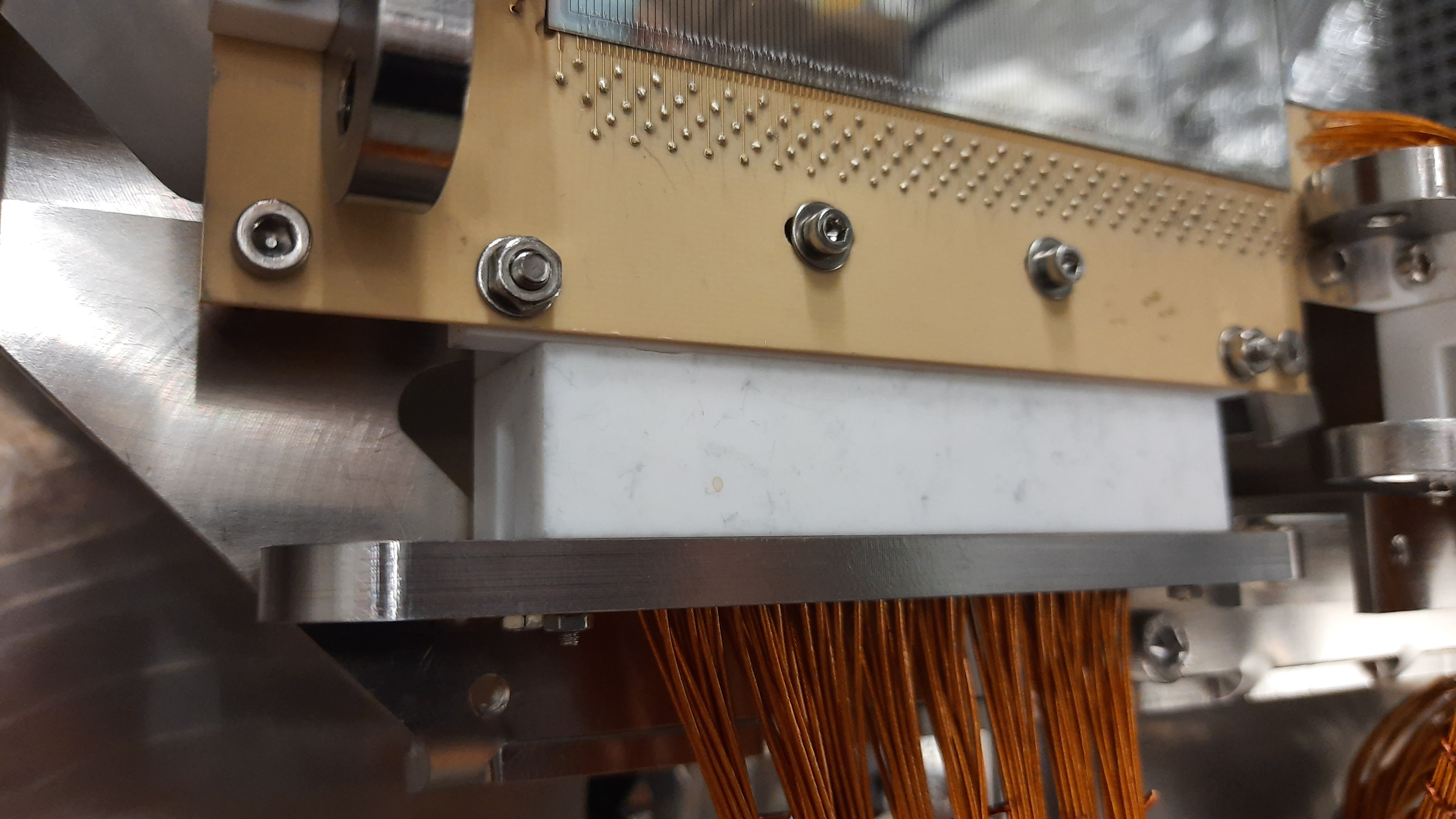

Due to width of MACOR strain relief and nuts on the back of the MACOR plugs, realised strain relief cannot be mounted as intended. Asked DR to produce 90 x 30 x 3 mm extender plates instead. MACOR strain relief are 15 mm wide. Extender plate have 3x M4 unthreaded countersunk to fix to detector plate, 3x M4 threaded holes to hold MACOR strain relief.

Organised cable harnesses.

4 short: all good -> two to be mounted

2 long: all good -> to be mounted

1 long: Broken MACOR backplate and lead. Lead removed. Attempted to mount with backplate in new lead - unable to do so. Removing backplate requires re-crimping. Will have to send back to Edinburgh

1 long: Wires cross in odd way. Will have to re-organise. Probably requires re-crimping. One pin smashed during jacking. Not sure if rescuable. See attached.

|

| Attachment 1: 20211025_104612.jpg

|

|

| Attachment 2: 20211025_161821.jpg

|

|

| Attachment 3: 20211025_161804.jpg

|

|

| Attachment 4: 20211026_161756.jpg

|

|

| Attachment 5: 20211026_163113.jpg

|

|

| Attachment 6: 20211026_163202.jpg

|

|

|

134

|

Sun Oct 31 07:29:17 2021 |

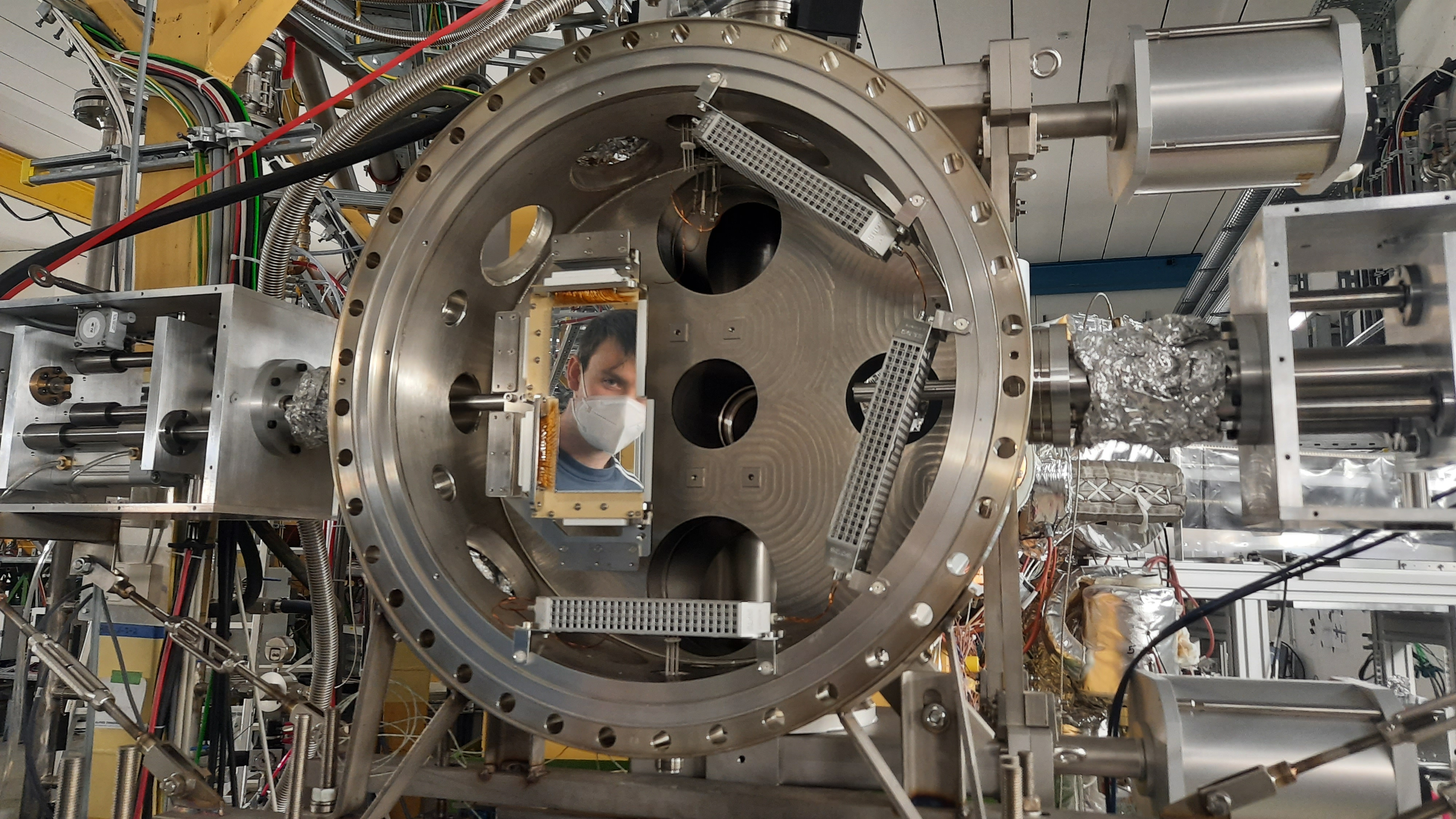

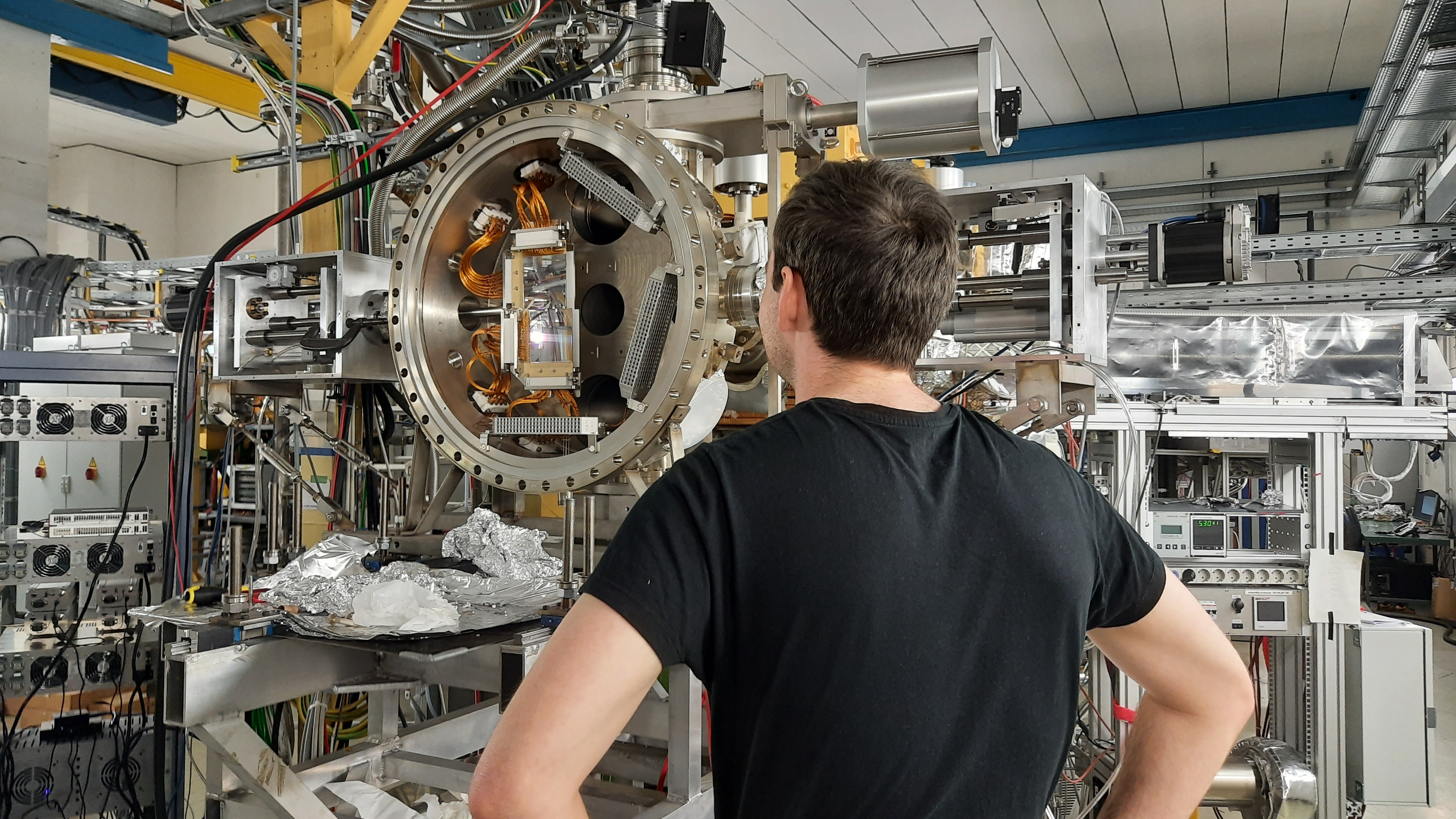

CB JM + RSS OG | Detectors mounted on plate in CARME |

(Wed 27 October)

Dismounted plate from rod. Dismounted broken detectors from plate and placed back in box. Dismounted "dog leg" struts and replaced with fully un-threaded struts.

Mounted 3335-13 in bottom position.

Attempted to mount 3335-2 in top position: dog leg strut conflicts with jacking plate. Attempted to remove - bolt stuck in thread. Removed bolt with great difficulty after dousing the bolt and hole in ethanol. M3 vented bolt is completely bent. Thread in hole appears still good. Bad bolt? Mounted strut upside-down with new M3 vented bolt. No issues. Mounted 3335-2 on plate.

Mounted extension plates for strain relief. Note countersunk bolts.

Removed all flanges with wires from CARME. Lubricated rod with ethanol. Slid rod with 2x detectors on. FIxed with bolt in front and back. Plate securely mounted in CARME, but some degree on rotational freedom is left. |

| Attachment 1: 20211027_172114.jpg

|

|

| Attachment 2: 20211027_172114.jpg

|

|

| Attachment 3: 20211027_172124.jpg

|

|

| Attachment 4: 20211027_172132.jpg

|

|

| Attachment 5: 20211027_172138.jpg

|

|

| Attachment 6: 20211027_175255.jpg

|

|

| Attachment 7: 20211027_175308.jpg

|

|

| Attachment 8: 20211027_174610.jpg

|

|

|

135

|

Sun Oct 31 07:41:20 2021 |

CB JM + RSS | Wires plugged in DSSDs |

(Wed 27 October)

Started with top-most flange. Attemptedto plug in MACOR lead in DSSD plug in preparation for jacking in. Realised that extender plate thickness causes plug to be rasied with respect to nominal position, which results in plug non entering straight. Removed extension plate.

Plugged MACOR lead in. OK. Inserted M6 jacking bolts and gently turned by hand. No resistance until jacking action starts. Jacked plug in with spanner and even 1/4 turns. Removed bolts. All OK.

Attempted same with bottom-most cable harness. Due to strain from top-most wire harness the plate is now rotated on the rod. Rotated back. Jacked in. Removed bolts. No issues.

MACOR plugs show small gap in rear part. Gap seems due to harness strain and disappears depending on plate orientation. Will check but pins are obviously connected.

(Thu 28 October)

Attempted to plug in top-left MACOR lead. Dog leg conflicts with jacking screw! Only solution is to slacken bolt, rotate strut, fasten again with detectors still on plate. Result attached. No clear if design, manufacturing or mounting oversight.

Had to attemping plugging in a few times before jacking bolts went in straight (i.e. no resistance felt). Jacked in both leads. No further issues.

Gap appears less significant in newly plugged leads. probably as a result of lack of rotational freedom.

|

| Attachment 1: 20211027_184502.jpg

|

|

| Attachment 2: 20211027_184527.jpg

|

|

| Attachment 3: 20211027_184535.jpg

|

|

| Attachment 4: 20211028_105802.jpg

|

|

| Attachment 5: 20211028_105919.jpg

|

|

| Attachment 6: 20211028_105711.jpg

|

|

| Attachment 7: 20211028_105728.jpg

|

|

| Attachment 8: 20211028_105734.jpg

|

|

|

136

|

Sun Oct 31 07:55:39 2021 |

CB JM + OH | Strain relief mounted |

(Thu 28 October)

All strain relief extension plates mounted behind the wires, using SS countersunk bolts (not silver plated).

Inserting bottom part of MACOR strain relief causes wires to bend too much with strain placed on DSSD. No reasonable way to proceed like that.

Opted to move hard kapton coated copper wire to line up with holes in top MACOR strain relief, and clamp the wrapped wire bundles between top MACOR strain relief and extension plate on bottom.

Results good. No significant movement when wires are moved or motors actuated. See videos - password abcd1234

https://datasync.ed.ac.uk/index.php/s/5waHTSY9husEgy9

https://datasync.ed.ac.uk/index.php/s/34293z7kQs2Mppd

https://datasync.ed.ac.uk/index.php/s/xmHFVqqIchtixGT

Mounted plate with MACOR shield on other rod. Connected thermocouples. Re-mounted 2x UHV1400 getters.

With help from OH attempted V-I test of detectors. SHV to 2x lemo broken (faulty lemo connector). Had to borrow AID@DESPEC cable.

Diode function OK. VI tests OK but inconclusive. Both DSSDs drain current when voltage is applied, but current not quite stable. Light leak very likely. Will attempt again after closing. |

| Attachment 1: 20211028_190026.jpg

|

|

| Attachment 2: 20211028_192251.jpg

|

|

| Attachment 3: 20211028_192210.jpg

|

|

|

755

|

Tue Jun 17 12:22:50 2025 |

CB EW JG AG SN | Run 94/95/96 |

Run 94

Background with beam at 150 keV and no target.

Note energy is 0.15% off vs. beam and target to have a more realistic orbit.

As prior run but thresholds changed to

DSSD1 - 0xc

DSSD2 - 0x8

DSSD3 - 0x8

DSSD4 - MEC

Run 95

DSSD 4 worked briefly. Tripped again a few minutes into this run. Ignore

Run 96 - as run 94

run stopped at 14:00

Zoran reset to with-target settings for later

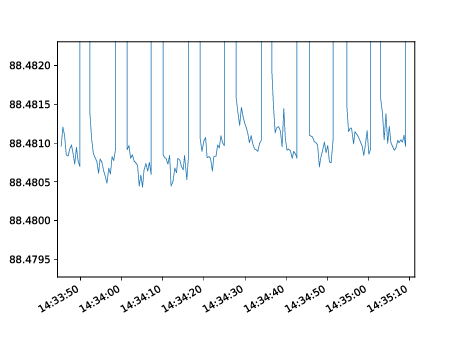

The plotted readout for the G35 voltage divider over several injections for this run is attached. This kind of data can be obtained from Konstantin also after the experiment.

The average is something like 88.4808 V. |

| Attachment 1: G35Voltage.pdf

|

|

|

568

|

Fri May 31 21:53:20 2024 |

CB EM, JM,EM AB | Overnight beam tests |

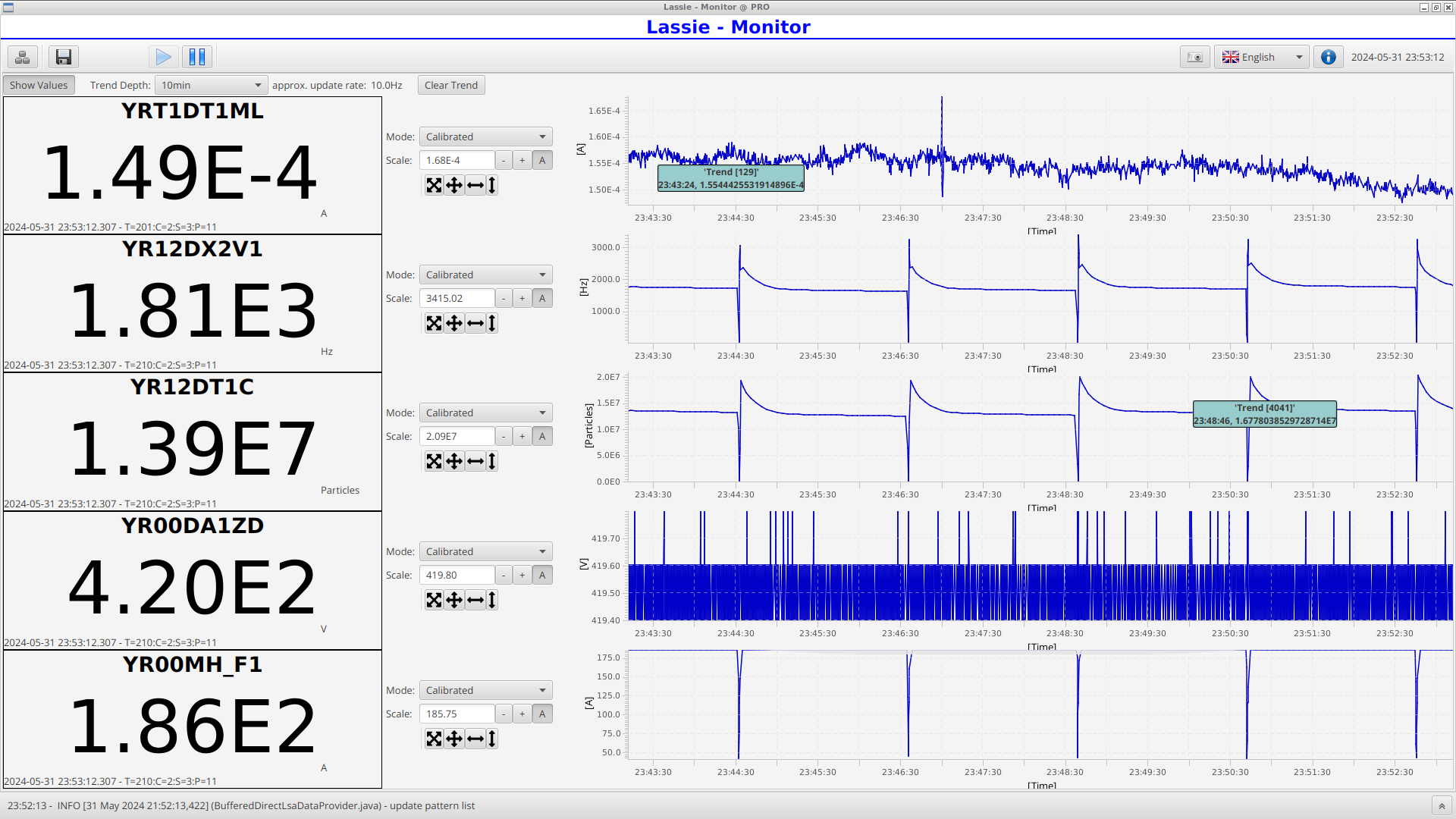

22:53

Run 15 started

Beam tests. We increased the storage time to 2min and switched to bunched beam so that we can see the beam lifetime over the cycle.

D+ Beam energy is set to 1.5 MeV.

Detectors are positioned in with servos only (left arm = 28.06mm, right arm = 29.23 mm)

No target

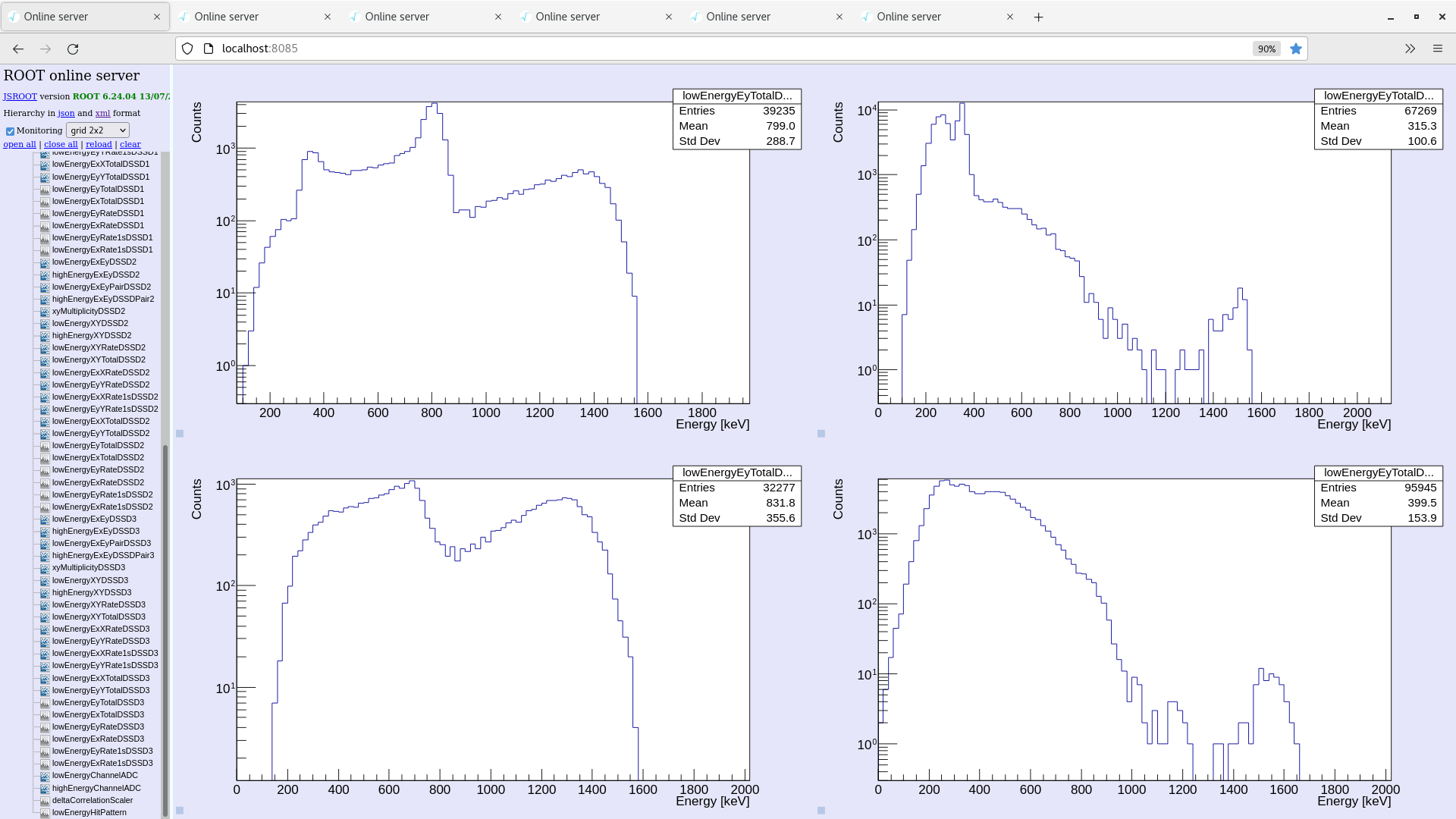

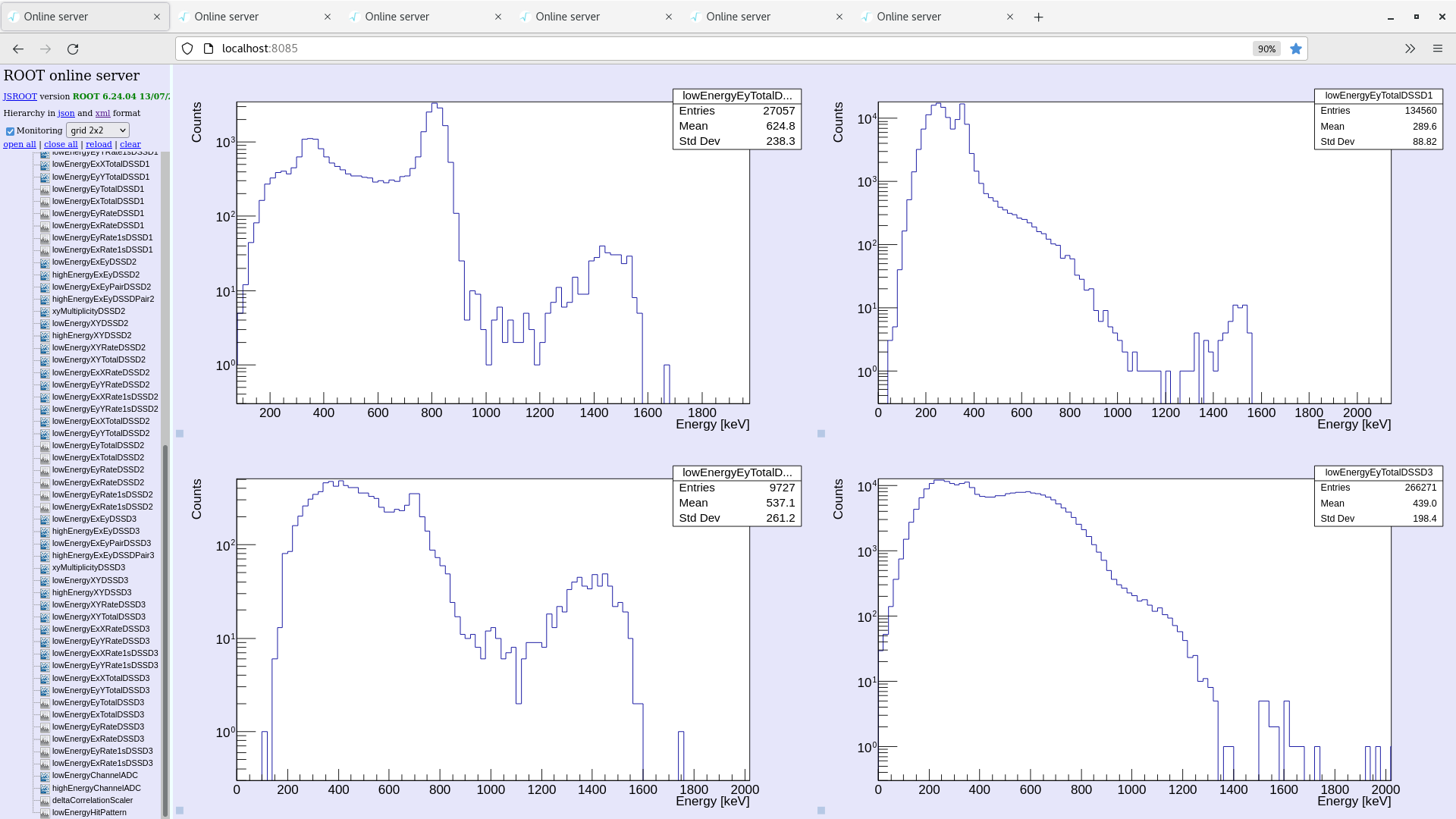

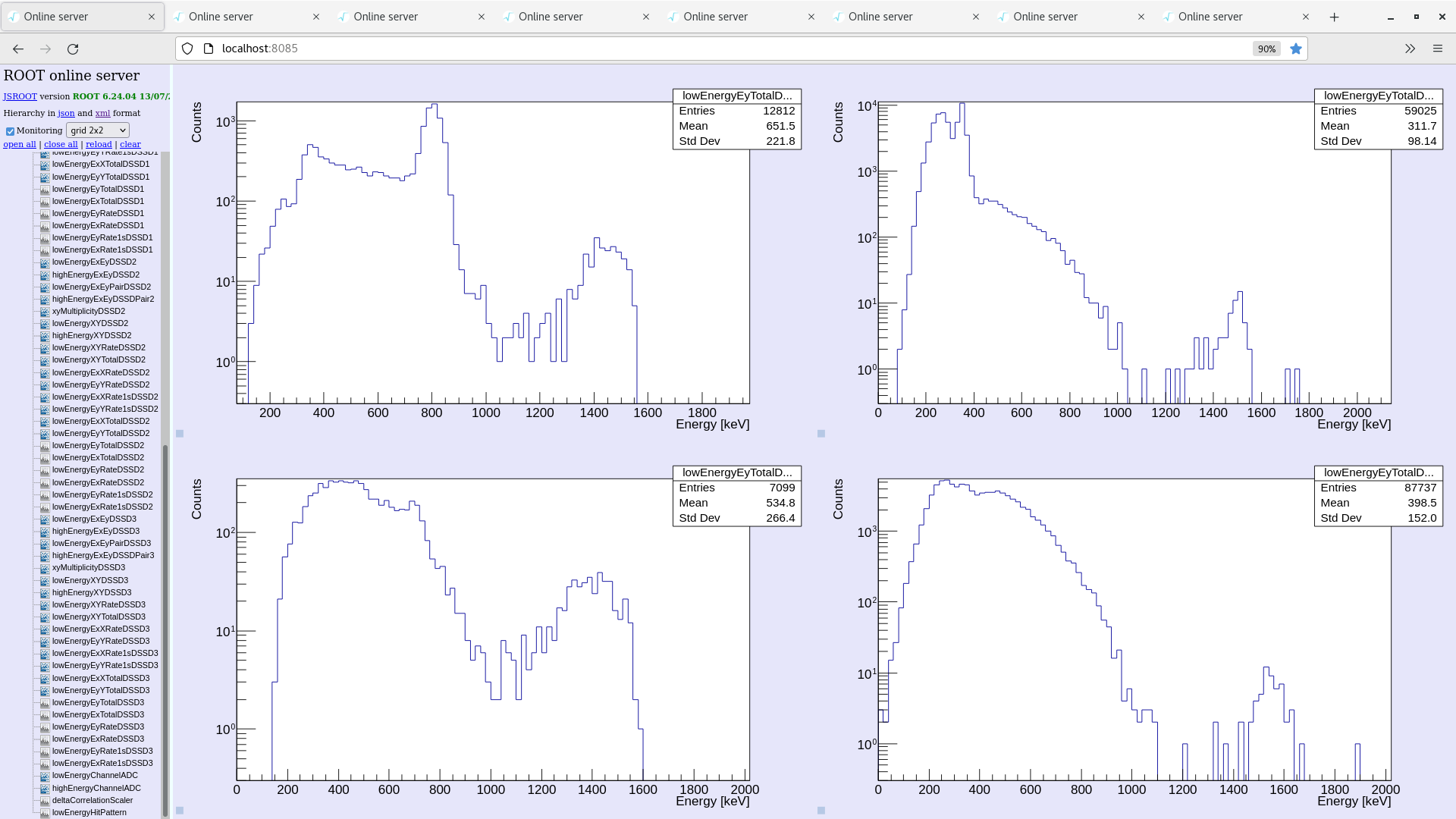

We observe a large peak at the start of the cycle at 750 keV. This seems to be molecular hydrogen circulating in the ring. We also see a much smaller peak at 1.5 MeV (D+)

After a period of time the 750 keV peak decreases significantly and we are left with the 1,5 MeV peak only.

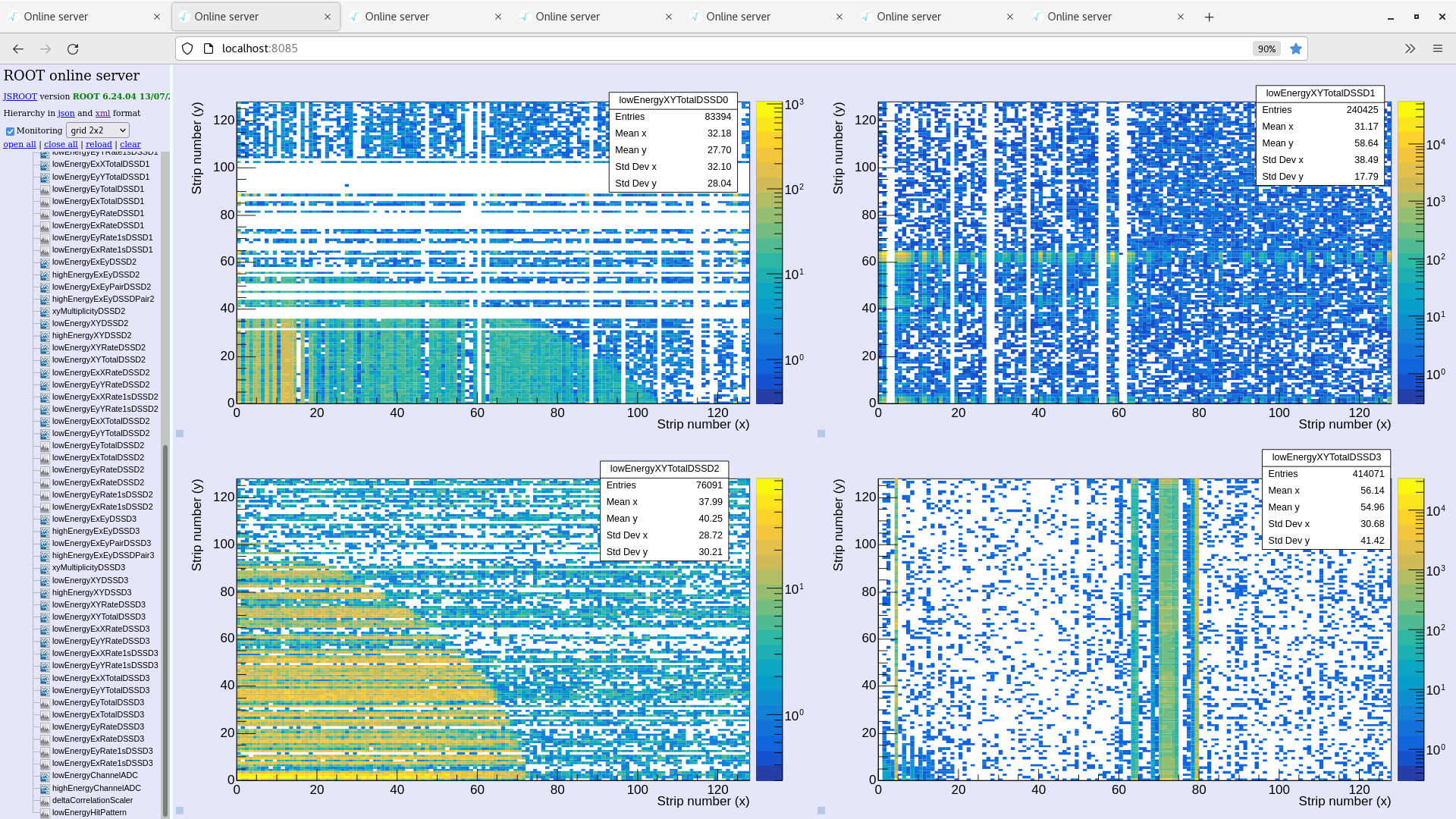

Total energy histogram after running for ~ 1 hour - attachment 1

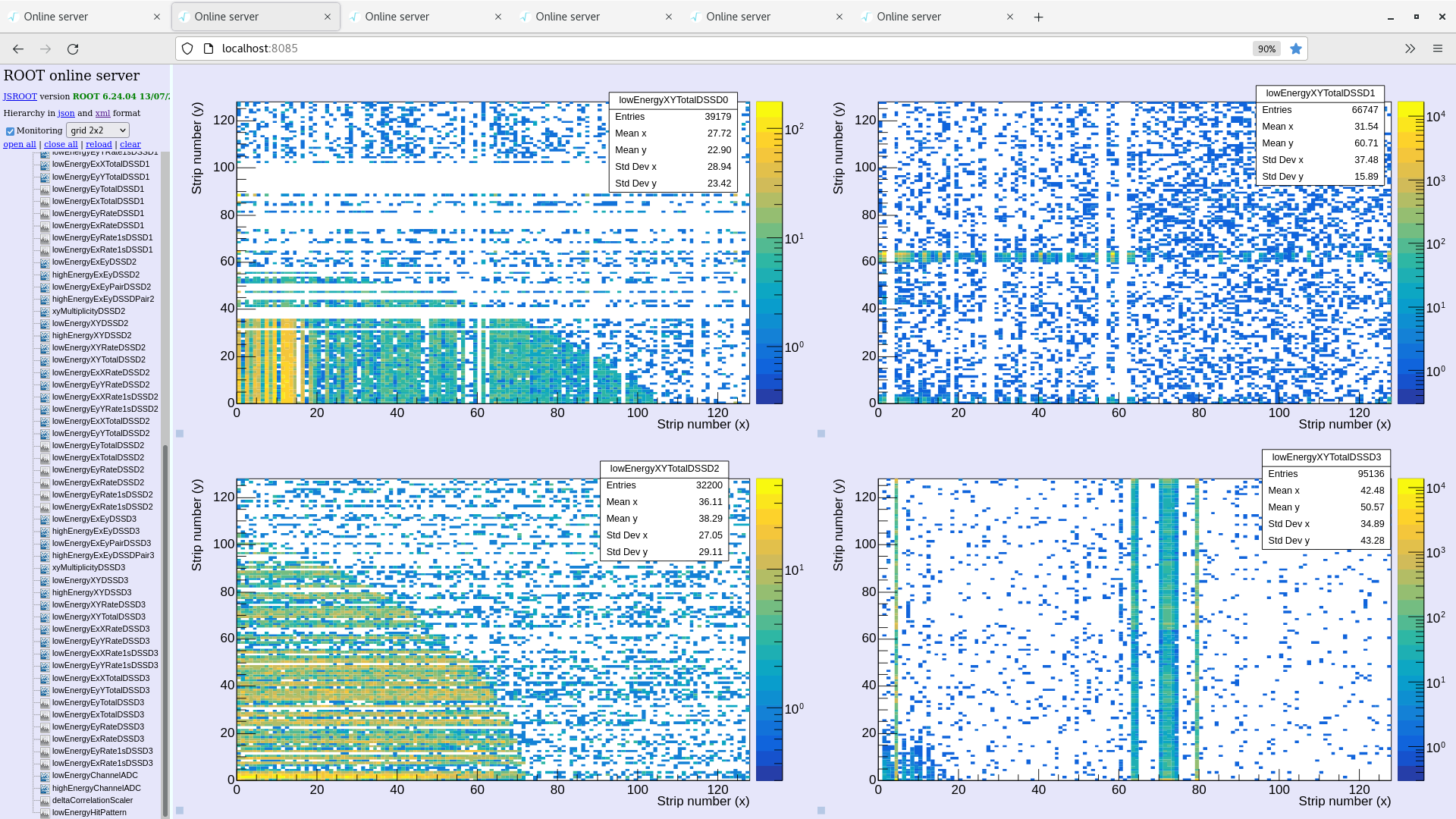

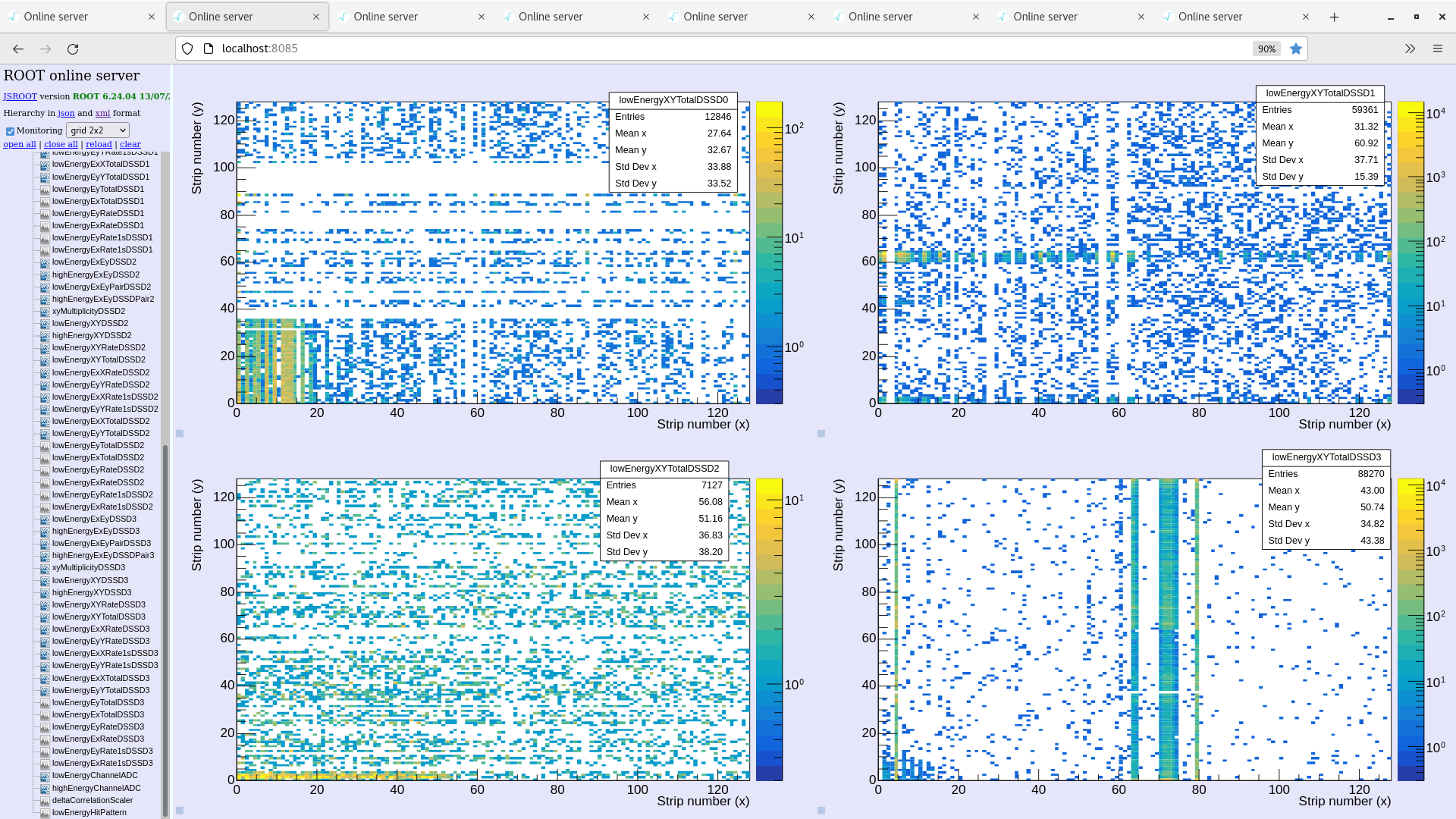

Total xy plot after ~ 1 hour - attachment 2

We observe the large circular structure on the left hand detectors. Is this related to hydrogen or is it the beam type (bunched instead of coasting)?

In the GSI control plots for the number of ions in the ring we observe a large drop in ions circulating at the start of the cycle, and then remains fairly constant throughout the rest of the cycle. - attachment 3

This seems to confirm our hydrogen hypothesis.

23:54

Run 15 stopped, Run 16 started.

All setting the same and still no target, except beam is now coasting. We will compare to Run 15 after one hour of running.

We do not observe the circular distribution on the detector seen in the previous run. It seems this effect comes from the bunched beam. Reason?

We still observe the 750 keV peak at the start of the cycle.

Total energy histogram after running for ~ 1 hour - attachment 4

Total xy plot after ~ 1 hour - attachment 5

00:59

Run16 stopped. Run 17 started.

All settings the same except we have switched back to bunched beam.

Target now on. (X=-13700, Y=0). Target density ~ 1E11 at/cm2.

02:03

Run 17 continues

Target has increased in the average density to ~4e11 at/cm2, no changes made to nozzle position and fluctuates to 1e11 or 1e12 at/cm2.

Energy histograms and the xy plots appear similar to bunched beam with no target. The rates are slightly lower with the target for the left hand dssds, maybe target interactions destroy molecular hydrogen quicker?

Total energy histogram after running for ~ 1 hour - attachment 6

Total xy plot after ~ 1 hour - attachment 7

We will continue to run for another hour or so in this condition

Target density has decreased over the last minutes. We have tried to move the nozzle to maximise density but fluctuations make this difficult.

03:55

Increase in ADC data items statistics for aida 13 and 14 from ~20 kHz to 90 kHz

ASIC checkload has reduced the rates back to ~ 20 kHz

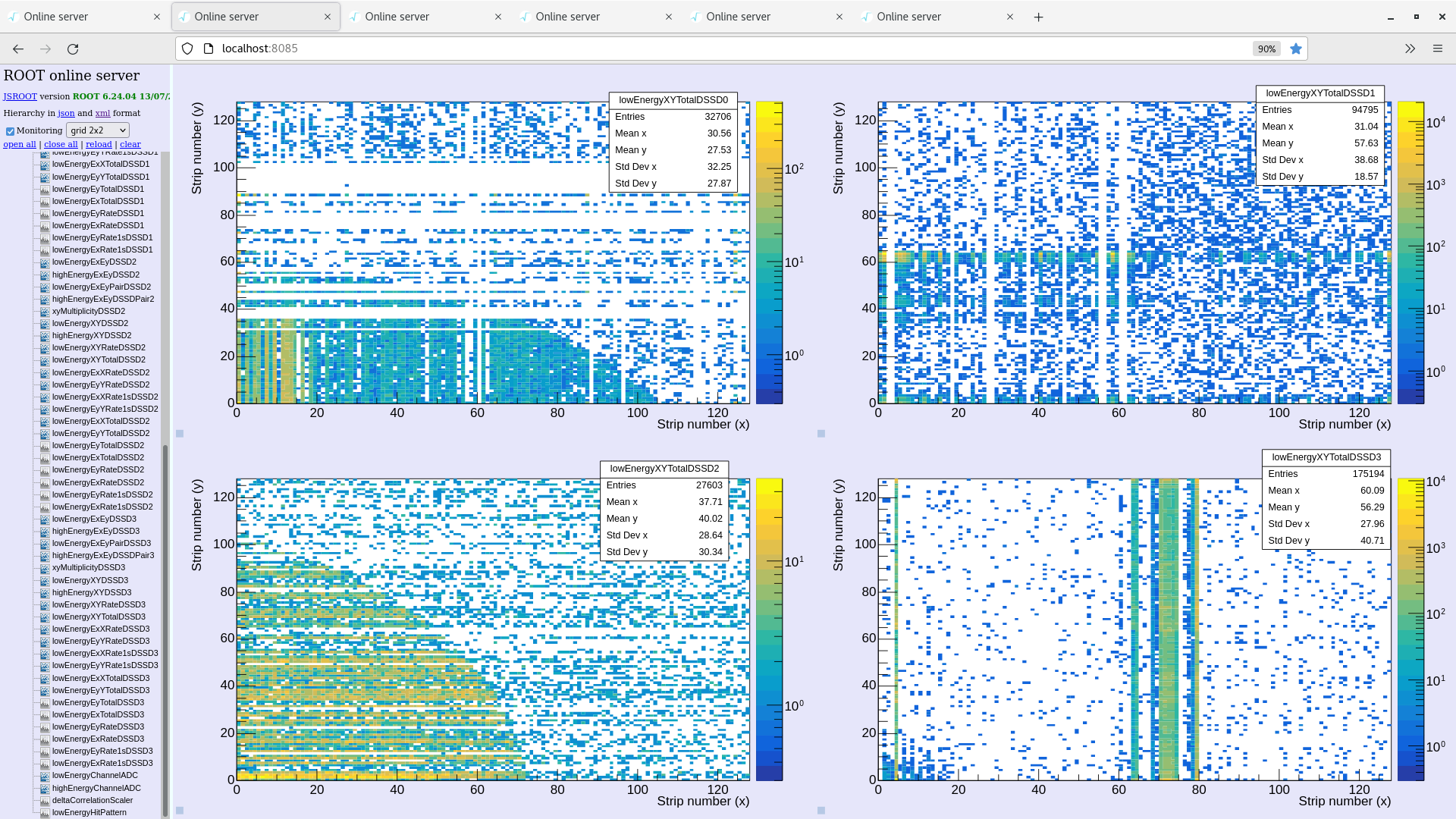

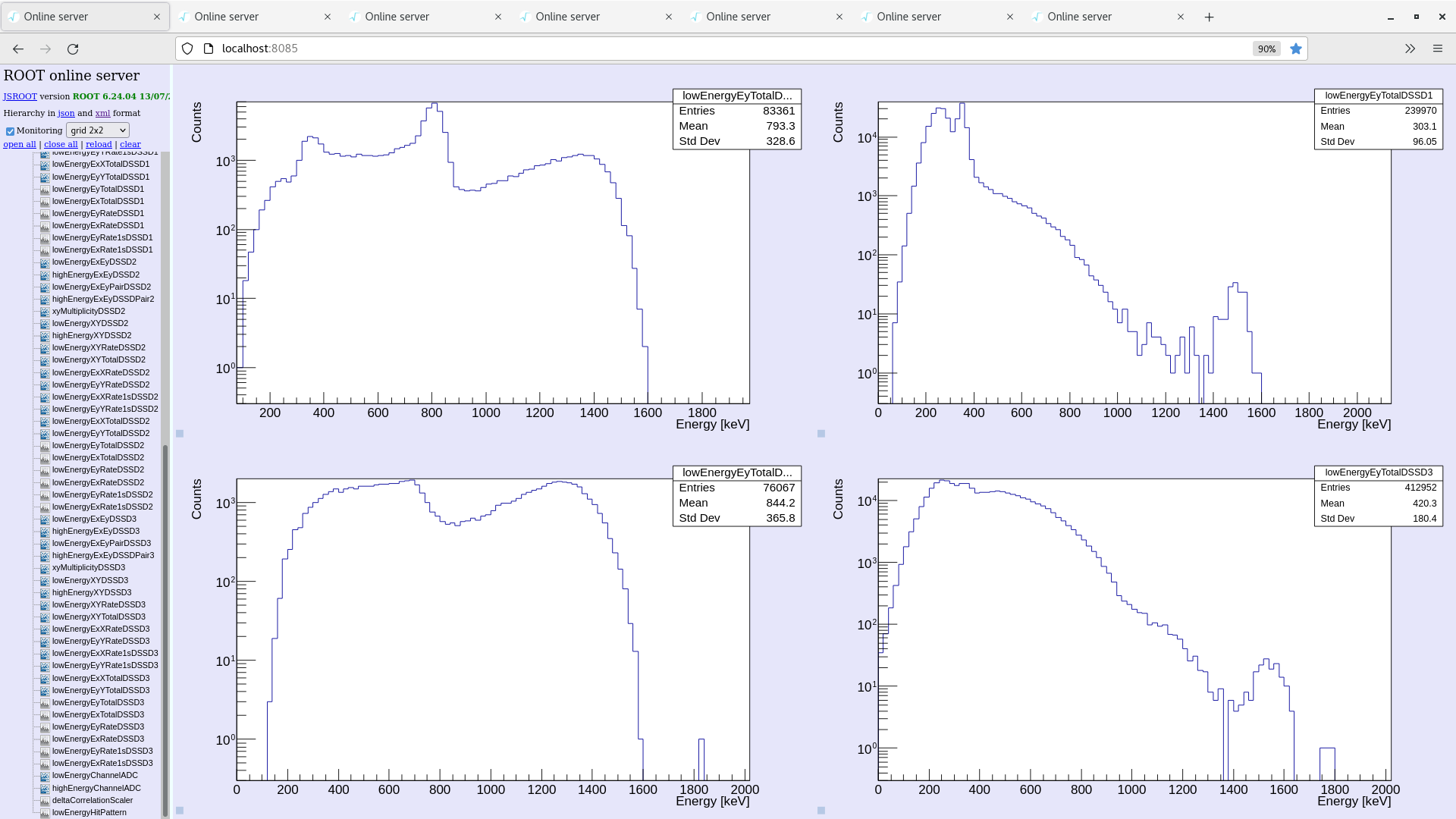

Total energy histogram after running for ~ 3 hour - attachment 8

Total xy plot after ~ 3 hour - attachment 9

Run 17 stopped. Run 18 started

Beam changed back to coasting. All other settings unchanged. Target on.

04:55

Run 18 continues.

Energy histograms and the xy plots appear similar to bunched beam with no target. The rates are lower with the target than without.

Total energy histogram after running for ~ 1 hour - attachment 10

Total xy plot after ~ 1 hour - attachment 11

Note we observed fluctuations in the T2 temperature for the target. T2 is set to 80 K but rapid fluctuations were observed up to 100K. This occurred for only 5 minutes and I am not sure if it is a real effect.

07:20

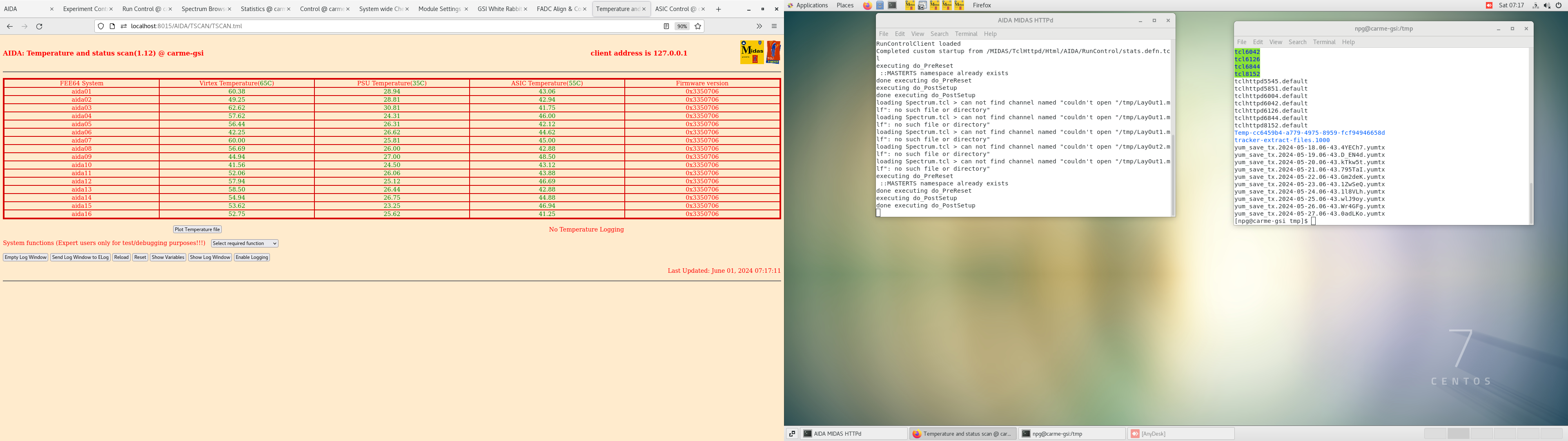

Temperatures OK

System wide checks OK

Rates OK

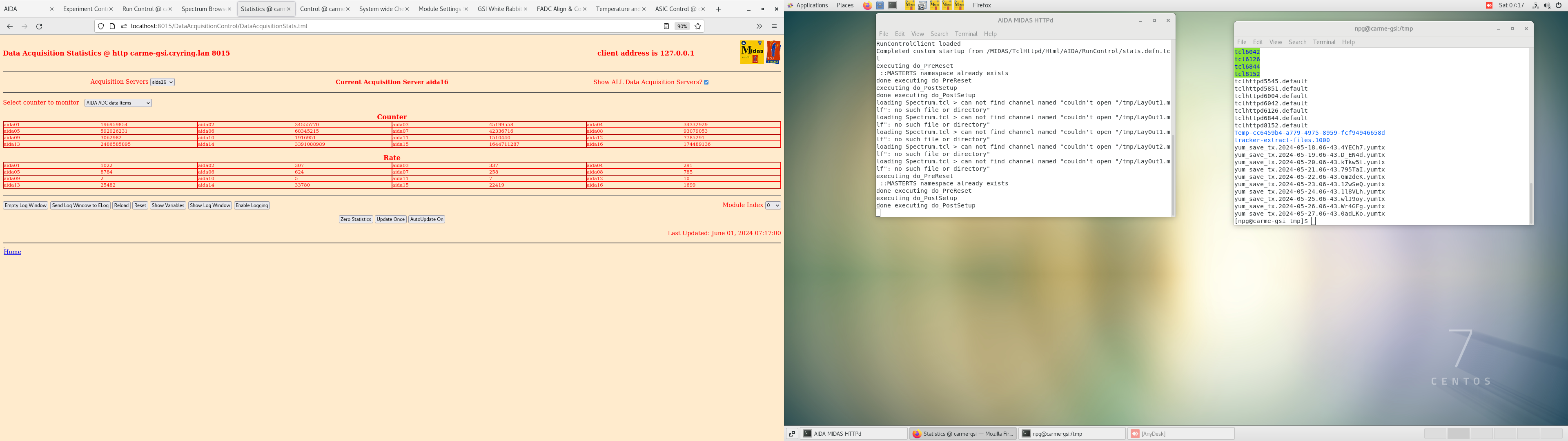

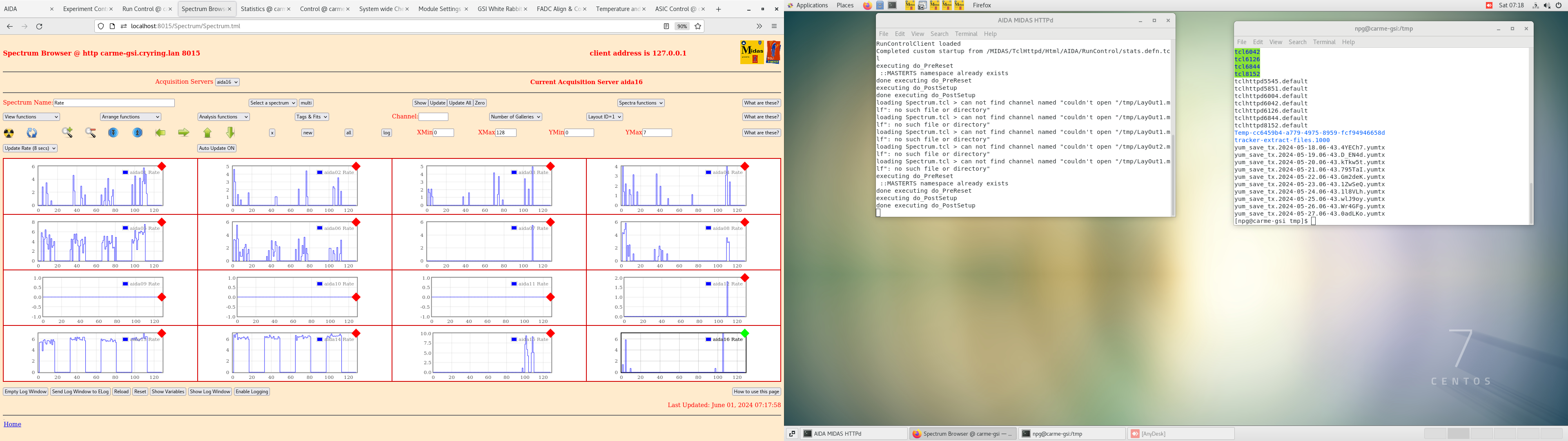

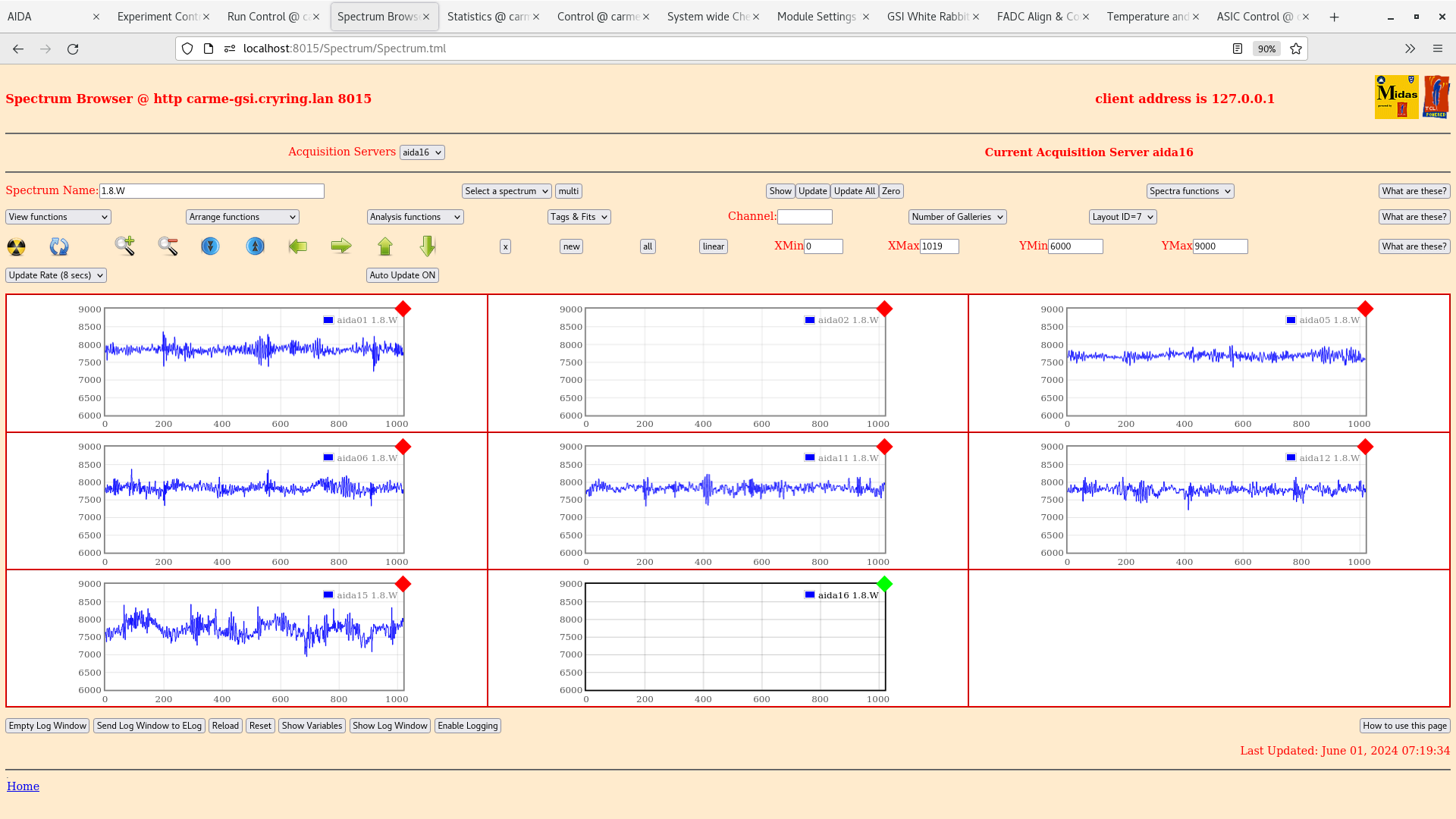

Stats OK

Waveforms attached

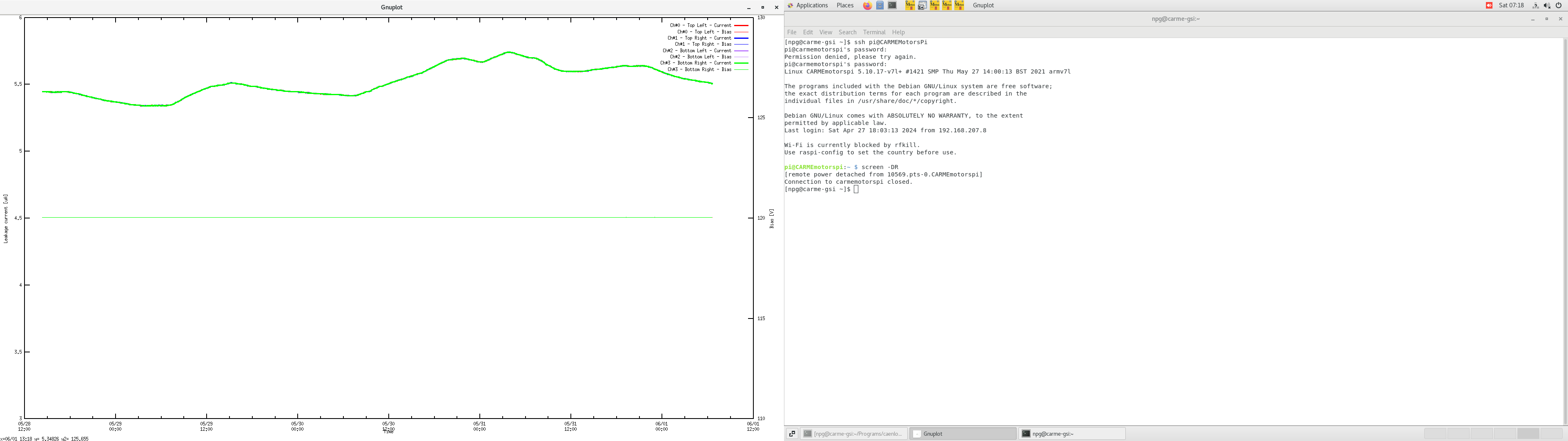

Leakage current decreasing slightly.

No changes to beam or target. |

| Attachment 1: Screenshot_from_2024-05-31_23-52-25.png

|

|

| Attachment 2: Screenshot_from_2024-05-31_23-51-56.png

|

|

| Attachment 3: screenshot-2024-05-31_23-53-125456534733007473468.png

|

|

| Attachment 4: Screenshot_from_2024-06-01_00-59-45.png

|

|

| Attachment 5: Screenshot_from_2024-06-01_00-59-55.png

|

|

| Attachment 6: Screenshot_from_2024-06-01_02-01-33.png

|

|

| Attachment 7: Screenshot_from_2024-06-01_02-02-05.png

|

|

| Attachment 8: Screenshot_from_2024-06-01_03-54-39.png

|

|

| Attachment 9: Screenshot_from_2024-06-01_03-54-52.png

|

|

| Attachment 10: Screenshot_from_2024-06-01_04-54-25.png

|

|

| Attachment 11: Screenshot_from_2024-06-01_04-54-43.png

|

|

| Attachment 12: Screenshot_from_2024-06-01_07-17-28.png

|

|

| Attachment 13: Screenshot_from_2024-06-01_07-17-38.png

|

|

| Attachment 14: Screenshot_from_2024-06-01_07-18-00.png

|

|

| Attachment 15: Screenshot_from_2024-06-01_07-18-12.png

|

|

| Attachment 16: Screenshot_from_2024-06-01_07-19-44.png

|

|

| Attachment 17: Screenshot_from_2024-06-01_07-20-07.png

|

|

|

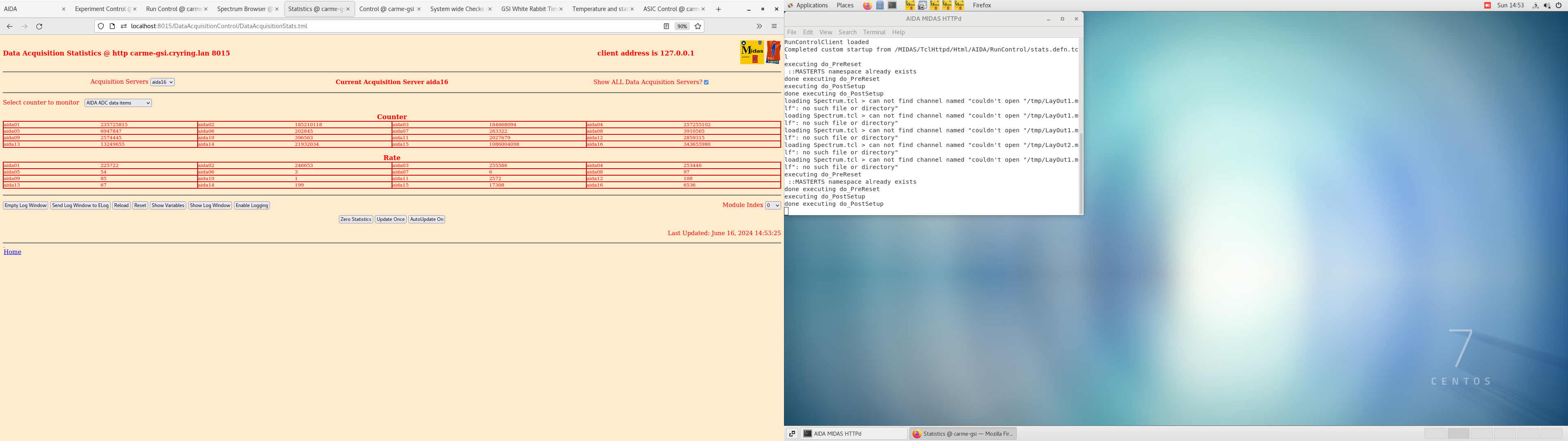

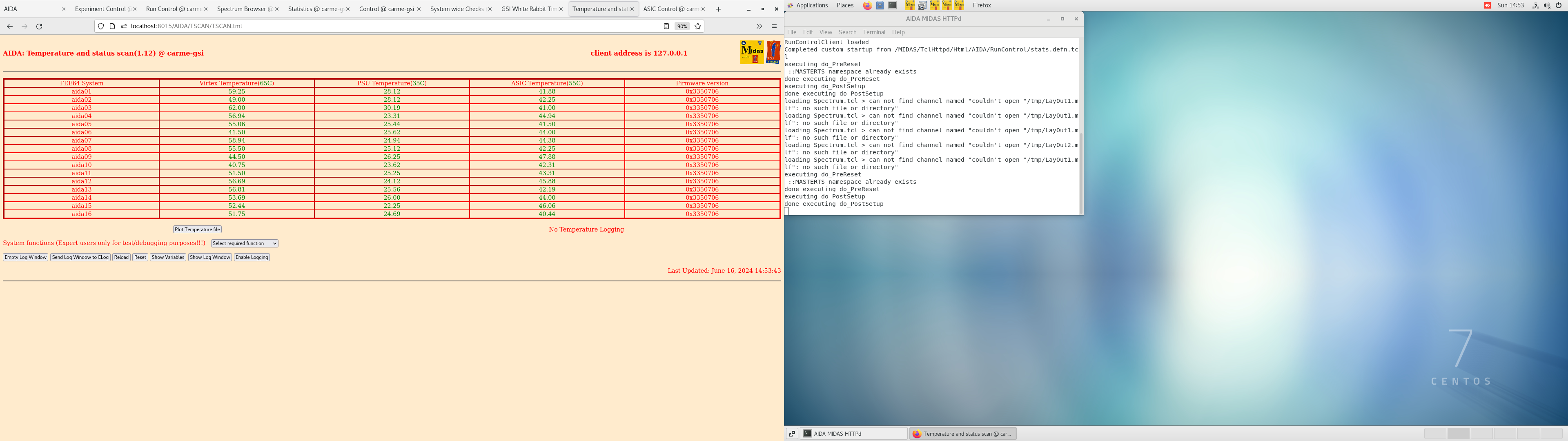

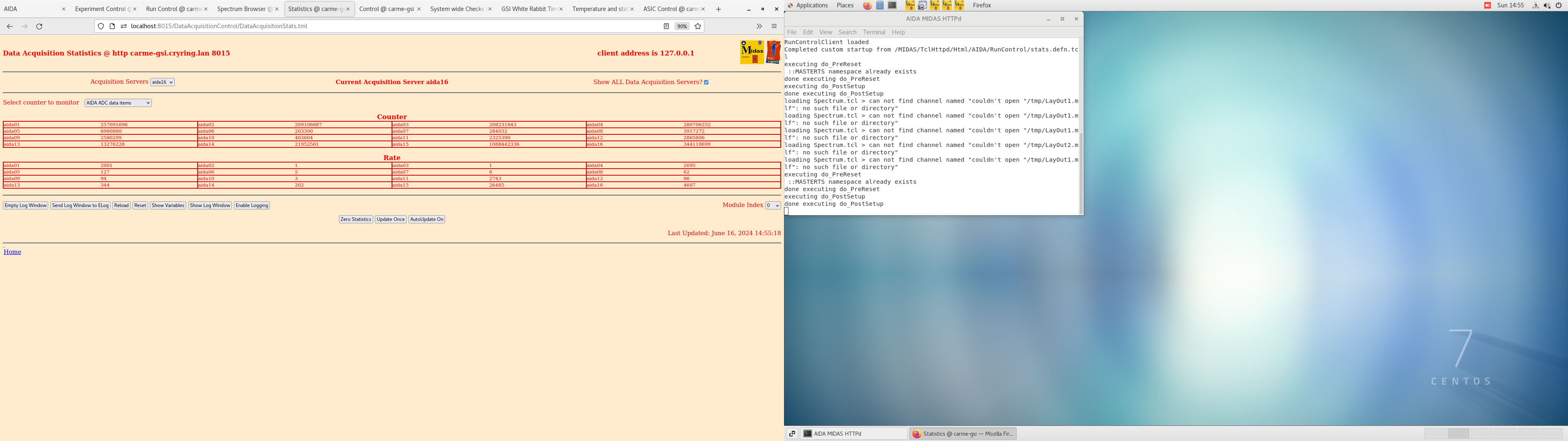

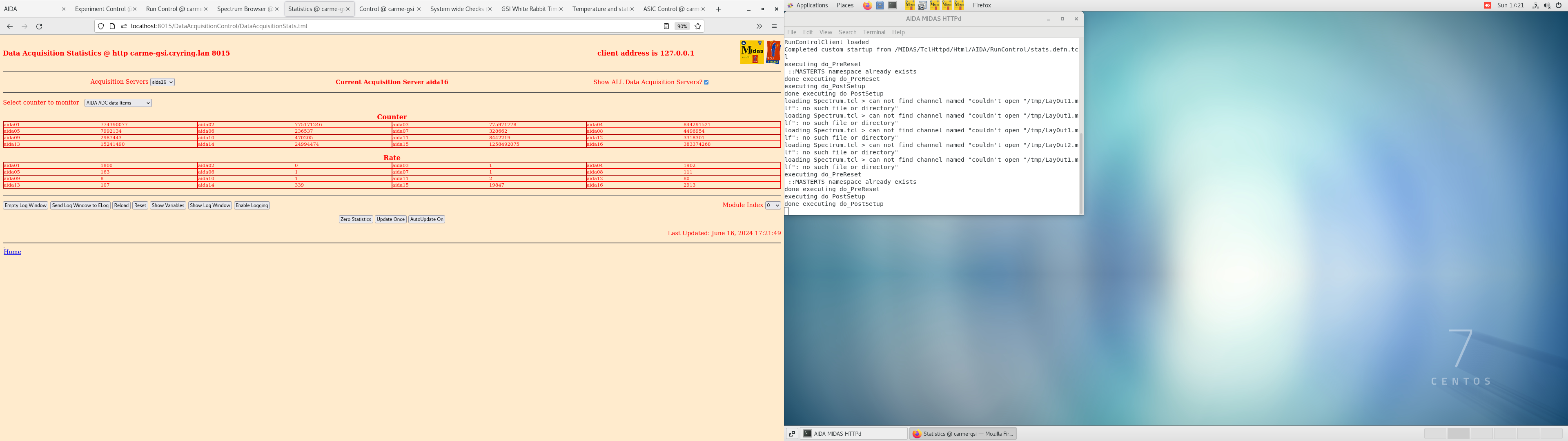

641

|

Sun Jun 16 13:51:11 2024 |

CB EM ML | Run 79 |

14:51

Ecooler setpoint 246.9

Readout 246.35

Collector current 4.3

Target density 4.6E11

Beam intensity 8E7 ions

Shook left arm to fix it.

15:32

Right half on BL detector was not counting. Checkloaded. Fixed.

17:20

Moved left arm out/in to fix it.

Reduced temperature to 38.5 K in steps as the target density was declining.

E1: pressure: 1.57E-1 mbar, turbo frequency: 819 Hz

Target density: 1.5E11 atoms/cm2; Ion beam intensity: 6E7 particles (went down slightly, have not been able to get everything back)

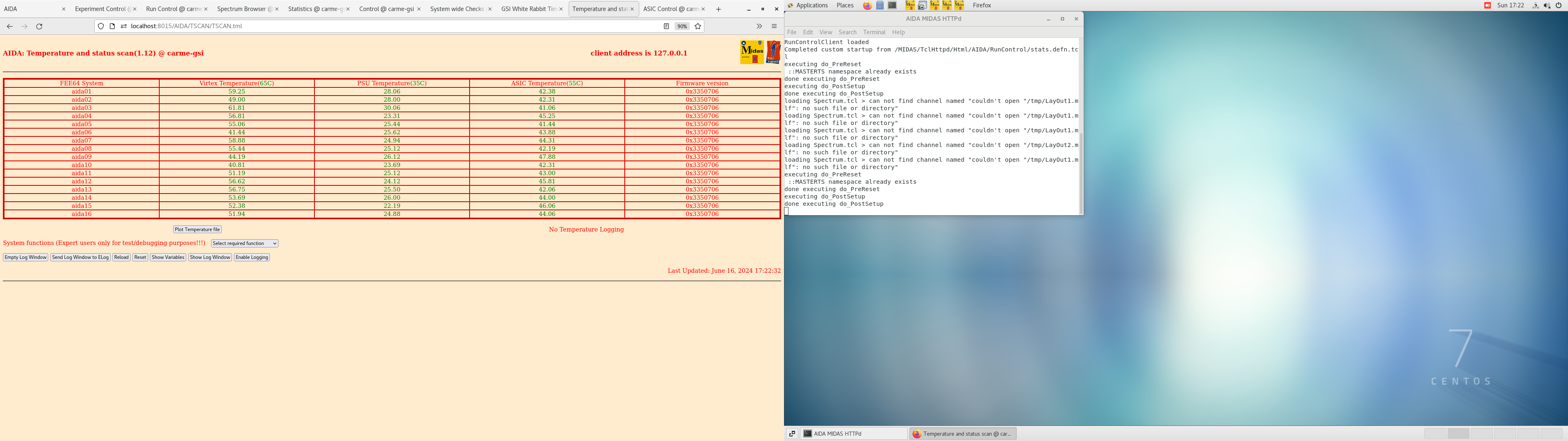

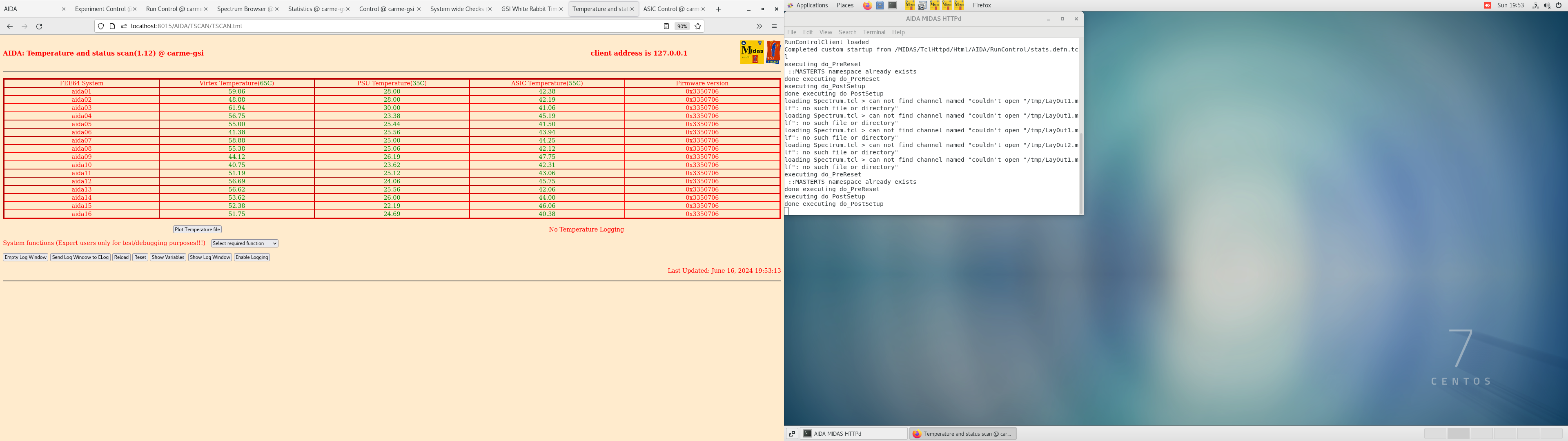

DSSSD bias & leakage current OK

FEE64 temperatures OK

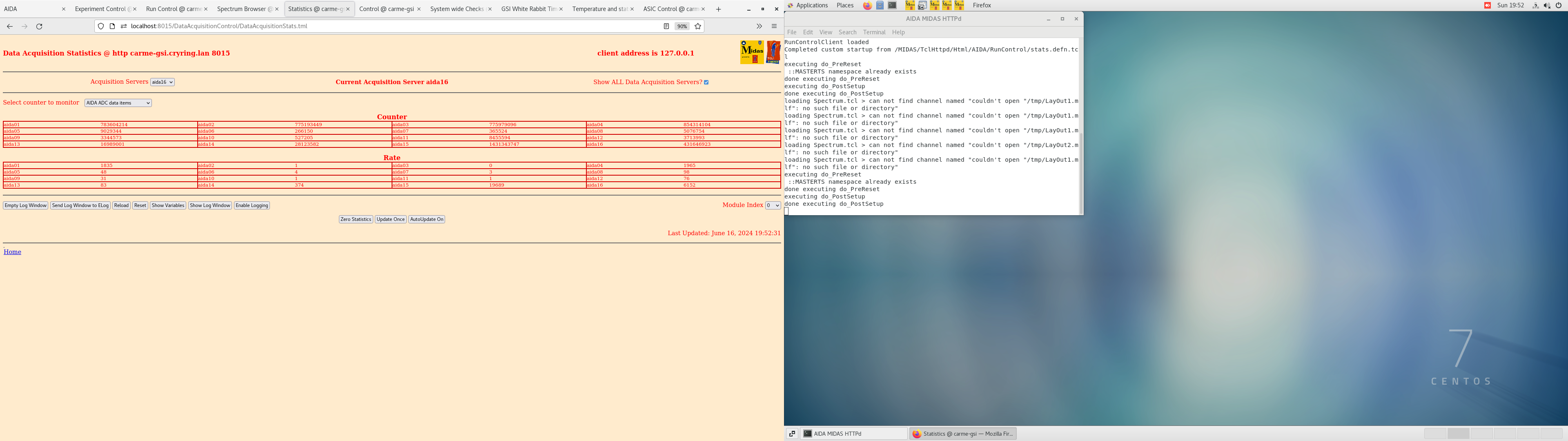

ADC data item stats OK

per FEE64 Rate spectra OK

19:50

E1: pressure: 1.61E-1 mbar, turbo frequency: 819 Hz

Target density: 1.5E11 atoms/cm2; Ion beam intensity: 7E7 particles (recovered slightly)

DSSSD bias & leakage current OK

FEE64 temperatures OK

ADC data item stats OK

per FEE64 Rate spectra OK

|

| Attachment 1: Screenshot_from_2024-06-16_14-53-27.png

|

|

| Attachment 2: Screenshot_from_2024-06-16_14-53-45.png

|

|

| Attachment 3: Screenshot_from_2024-06-16_14-55-19.png

|

|

| Attachment 4: Screenshot_from_2024-06-16_17-21-55.png

|

|

| Attachment 5: Screenshot_from_2024-06-16_17-22-35.png

|

|

| Attachment 6: Screenshot_from_2024-06-16_19-52-34.png

|

|

| Attachment 7: Screenshot_from_2024-06-16_19-53-16.png

|

|

|

511

|

Wed Feb 14 08:44:32 2024 |

CB AR JM | Motors test and turbo ON |

Run number changed 09:44 - Now run 23

Moving motors with the injection

Ring signal very weird, moving in for short time and staying out for 15+ seconds.

R24

Right arm FULLY in (70.49 mm)

Left arm SERVOS ONLY in (36.54)

No appreciable effect on beam (not clipping beam at injection / during circulation)

ML fixed signal cycle. It's now 8 seconds in, 5 seconds out. Motors still not moving. Acquiring more stats in the current conditions.

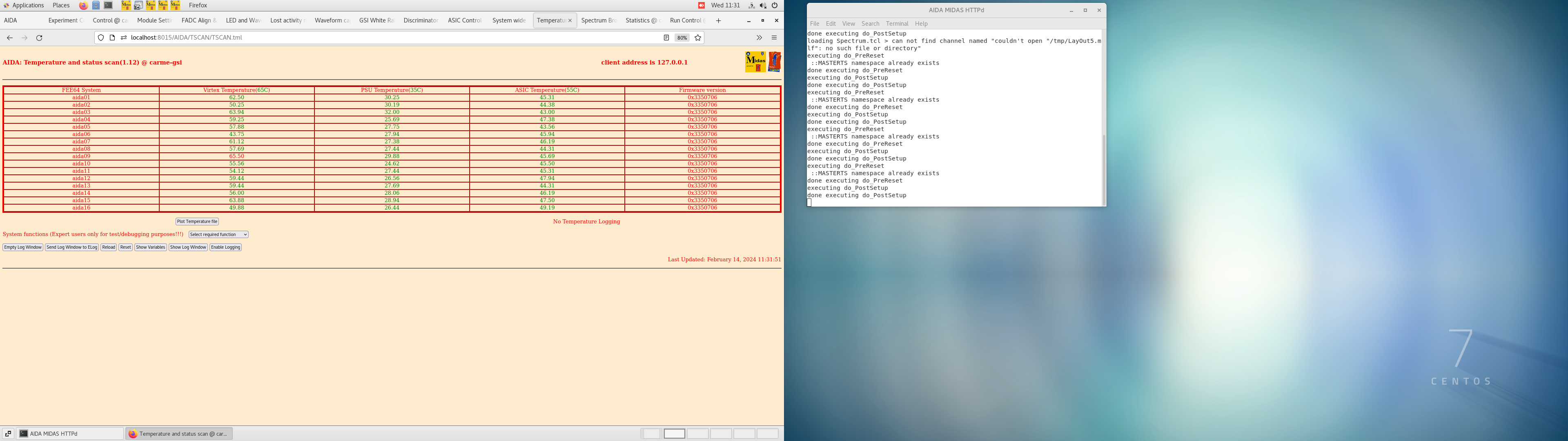

11:07 - Temps & System wide checks good

Stats as before.

Leakage currents & pressure good.

11:44

Leakage current ok. pressure good. Temperatures ok. Merger ok. System wide checks ok.

In with the left 36.5

In with the right 70.5

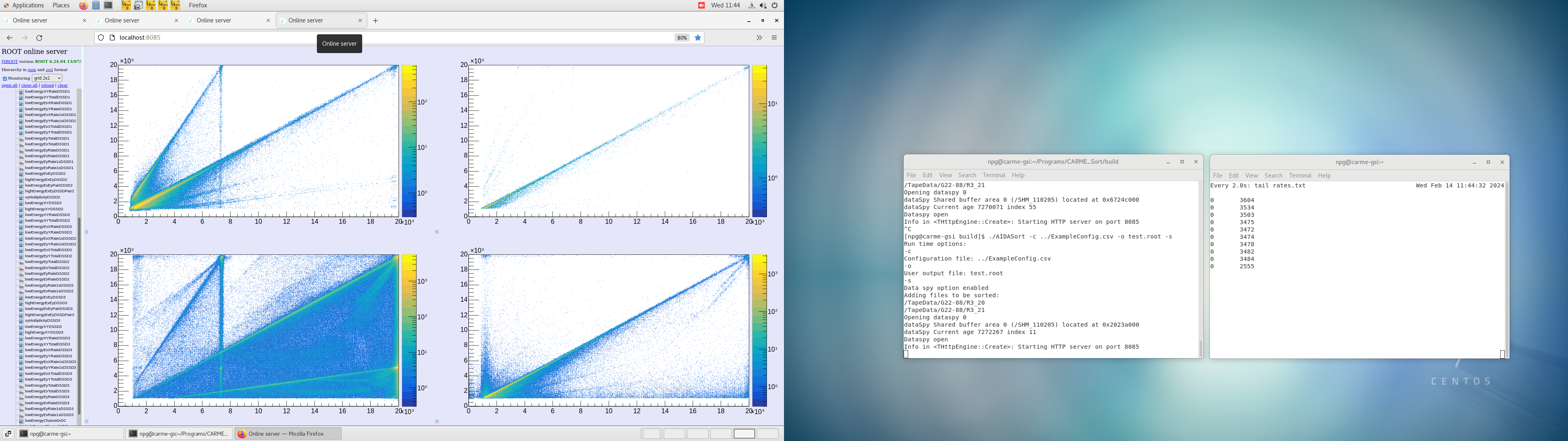

Attatchment 1: Rates

Attatchment 2: Temperatures

Attatchment 3: Waveforms layout 7

Attatchment 4: Waveforms layout 8

Attatchment 5: Waveforms layout 1

Attatchment 6: Waveforms layout 2

Attatchment 7: Leakage current

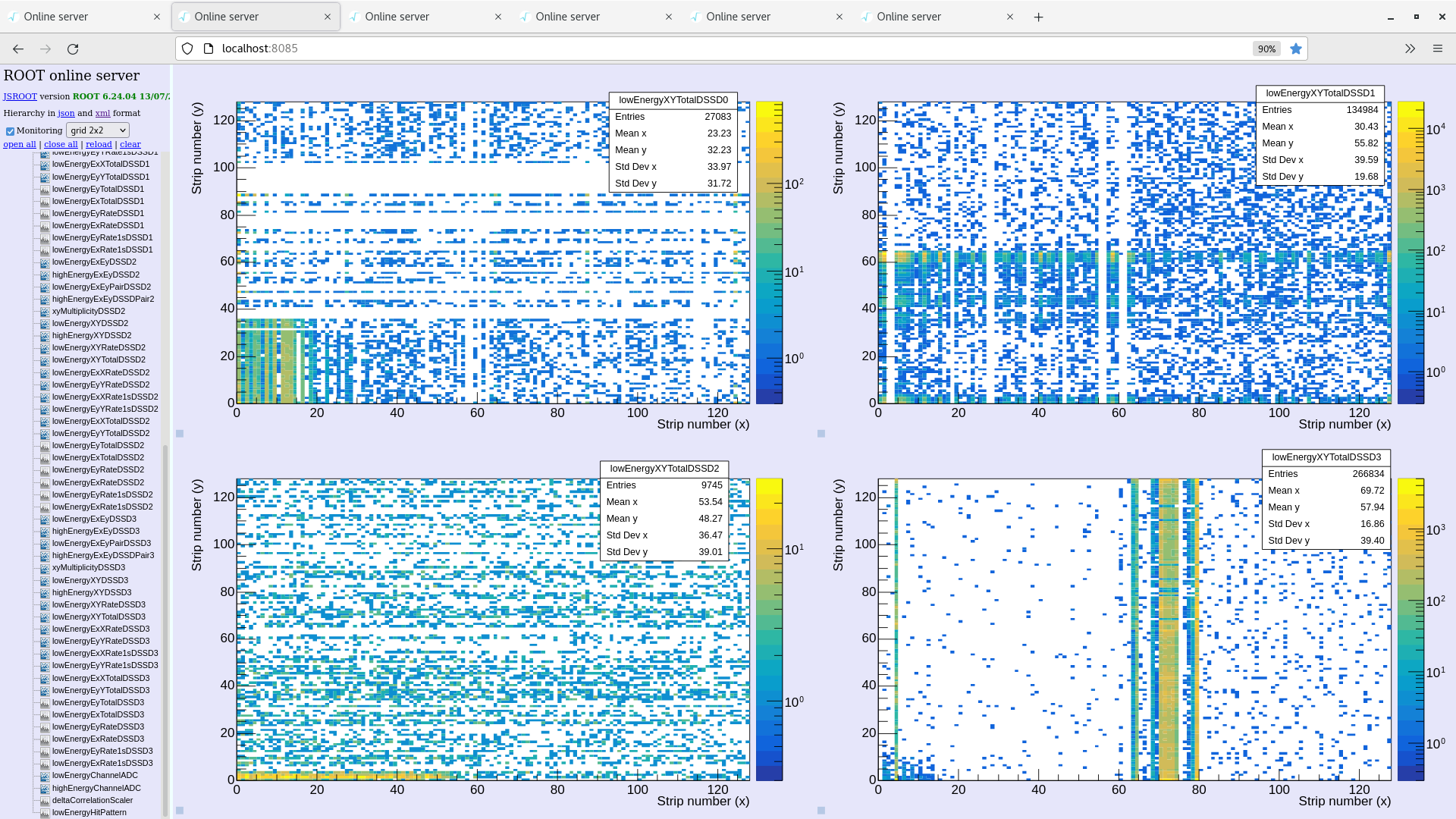

Attatchment 8: lowenergyXYtotal all 4 dets

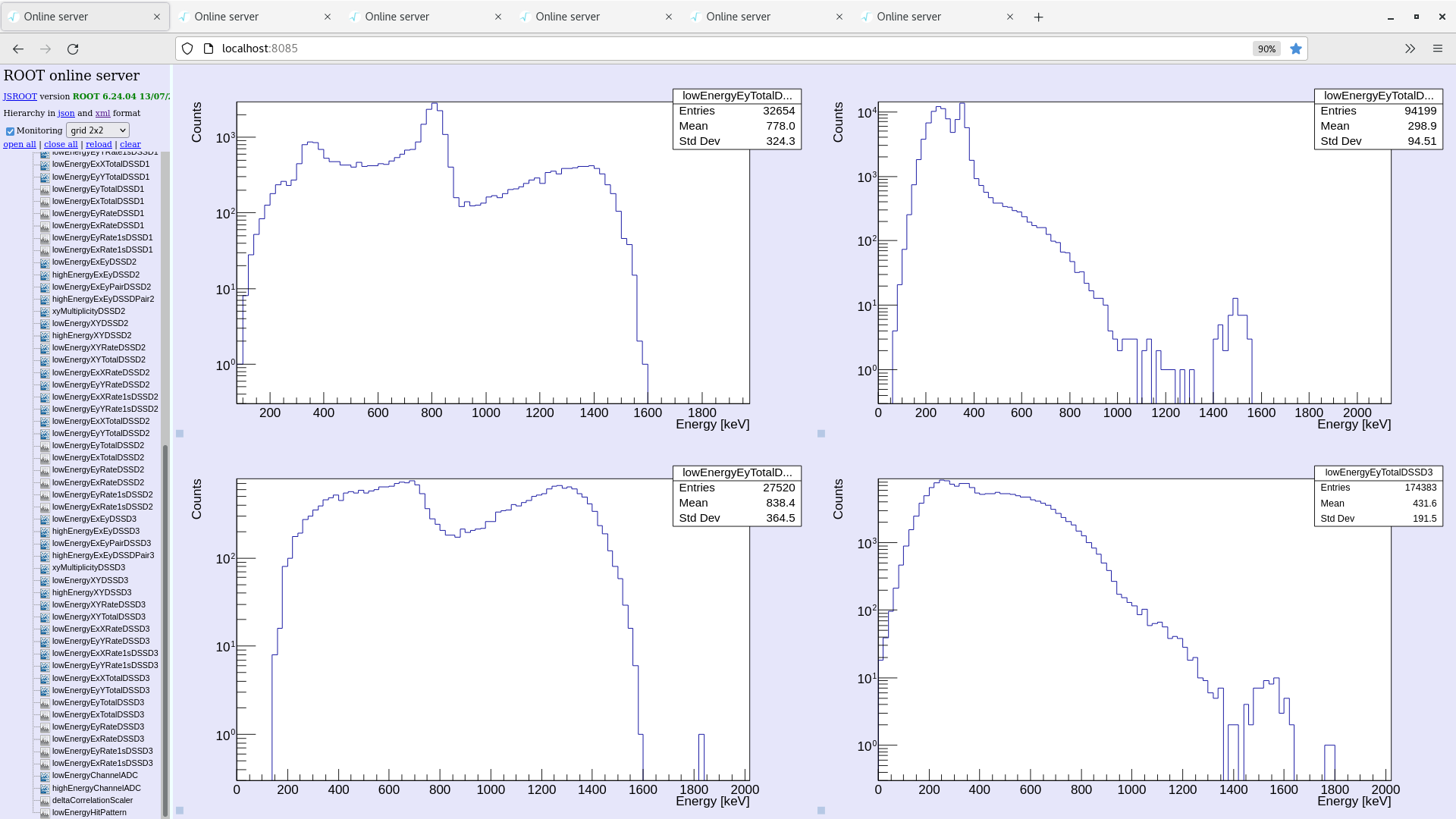

Attatchment 9: lowenergyExEy all dets

Attatchment 10: loveenergyvExEy

Attachment 11: screenshot from the Shottky

14:00 Run 24 stopped to allow access to the cave.

Helium and liquid nitrogen re-filled in the target.

Pulser walkthrough performed R25.

Turned CARME turbo ON, pressure in the ring with target on is reduced by a factor 2.

Tried to find electron cooler voltages to determine the beam energy. We were unable to do this. Hopefully we find out tomorrow.

|

| Attachment 1: Screenshot_from_2024-02-14_11-31-38.png

|

|

| Attachment 2: Screenshot_from_2024-02-14_11-31-52.png

|

|

| Attachment 3: Screenshot_from_2024-02-14_11-32-34.png

|

|

| Attachment 4: Screenshot_from_2024-02-14_11-33-52.png

|

|

| Attachment 5: Screenshot_from_2024-02-14_11-34-51.png

|

|

| Attachment 6: Screenshot_from_2024-02-14_11-35-17.png

|

|

| Attachment 7: Screenshot_from_2024-02-14_11-38-43.png

|

|

| Attachment 8: Screenshot_from_2024-02-14_11-44-19.png

|

|

| Attachment 9: Screenshot_from_2024-02-14_11-44-26.png

|

|

| Attachment 10: Screenshot_from_2024-02-14_11-44-32.png

|

|

| Attachment 11: screenshot-2024-02-14_11-31-236868864019057183143.png

|

|

|

512

|

Wed Feb 14 14:06:28 2024 |

CB AR JM | Pulser Walkthrough |

15:06

Run25

Pulser walkthrough

EGG Ortec 448 Pulser

Amplitide 90,000-10,000 @ 10,000 step

Normalise 5.0

Attenuators x5 IN

t_r 100ns

Tau_d 50us

Frequency Int Osc 50Hz

Polarity + ( - polarity via Cooknell SA1 Sum & Invert Amp )

|

|

751

|

Mon Jun 16 21:58:00 2025 |

CB AR | Runs 84-89 |

Found all Merger Links background black - inactive. Nontheless the tapeservice was working, the data rate to disk was normal, and the file was being written and the histograms were being updated.

Decided to stop DAQ, stop Merger, restart merger. Links rest to green background - but no more writing to disk!

Killed Merger, killed Tape Service. Restarted.

Netvar read out at 3 - set to 1. When the Output of the Merger is enabled Netvar returns to 3. Tapeservice not writing to disk

Killed Merger, killed Tape Service. Restarted x3. Same behaviour.

Not working. No blocks being written.

With Tape Server status Stopped Ticked No storage, Unticked No storage -> Now writing blocks ?!

Tape Server Go. Writing to disk. Merger OK. Histograms updated, observables as normal (see next ELOG).

Lost runs 84-89 in the process. |

|

657

|

Wed Jun 19 12:08:34 2024 |

CB + various | Run 101-105 |

Run 101: no target. See ELOG entry by TD.

Run 102: ??

Run 103: ??

Run 104: After experiment time is over, Gleb tests beam lifetime at "high energies". Some data acquired for 30 minutes.

Run 105: Quick pulser walkthrough. People are working near CARME. Positive polarity 1000-9000 amplitude. |

|

655

|

Wed Jun 19 12:04:02 2024 |

CB + OF, SS | Run 96/97 |

Run 96 - as run 89, while we wait for beam energy change at higher energies

Run stopped around 08:56 June 17

Run 97 - target out, beam optimisation for higher energies.

|

|

162

|

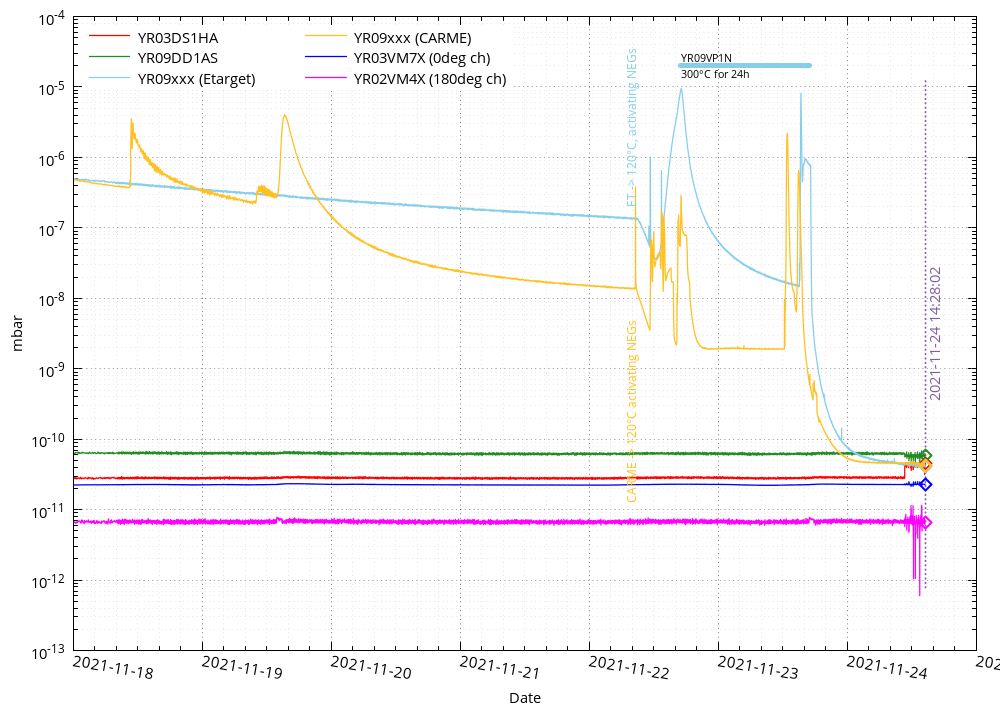

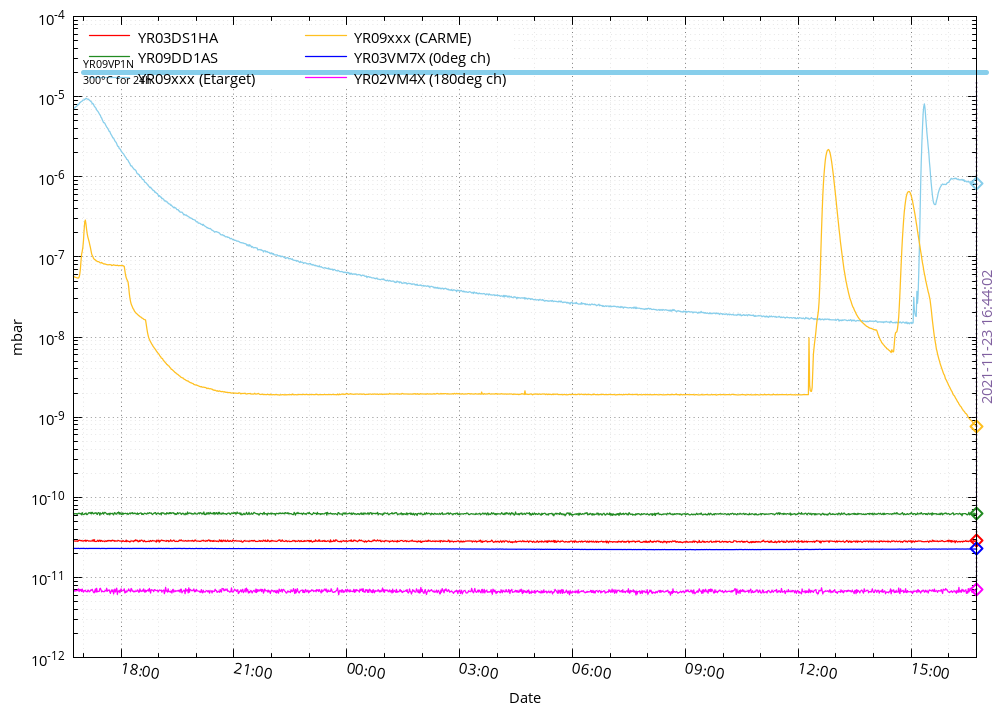

Wed Nov 24 12:08:08 2021 |

CB + ML OG | Ion pumps on |

Found SIP power unit for D2000 #4 not functioning correctly. Max current regardless of ion element connected to.

ML kindly loaned a spare. All D2000 work Ok now. Will have to send faulty unit for repairs back to SAES.

Opened up front part of tent just enough to allow GSI vacuum division to connect IE 514 and GSI ion pump. Tent to remain until January.

Left to do this year:

- Turn on GSI ion pump

- Turn on GSI IE514

- Close top gate valve

- Turn off maglev turbo (very close to magnet) |

| Attachment 1: vacplot24.png

|

|

| Attachment 2: vacplot.png

|

|

| Attachment 3: CARMEtemps.png

|

|

|

139

|

Mon Nov 1 14:48:16 2021 |

CB + ML DR | CARME opened |

Confirmed leak as per previous Elog.

Tightened to 100 Nm - no effects.

Tightened to 130 Nm - bottom leak disappeared. Top leak still at 1.3E-8 mbar l second.

Decided to open. Lifted front part of CARME down.

No obvious damage to wire seal.

Inspected wire seat and seal part. Part corresponding to leak feels rough to the touch. Suggested damage when SS parts come together?

DR sanded down gently the valve seal. Cleaned with compressed air and ethanol.

Gently sanded down seat as well, barely touched it.

Grossmontage experts will be back tomorrow am for final cleaning and re-assembly. |

|

161

|

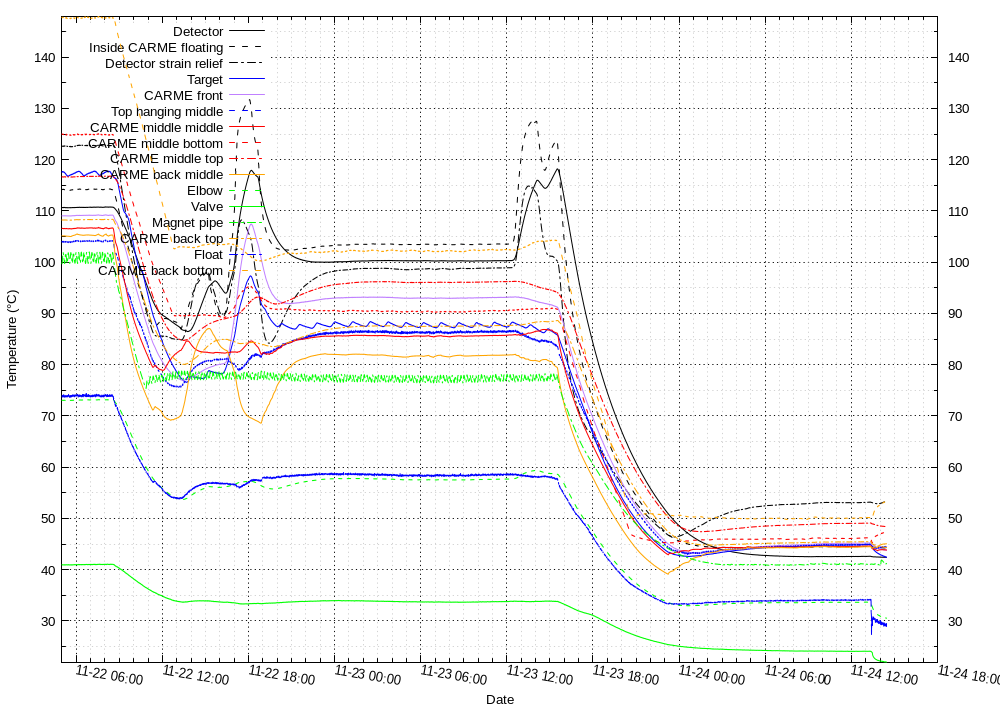

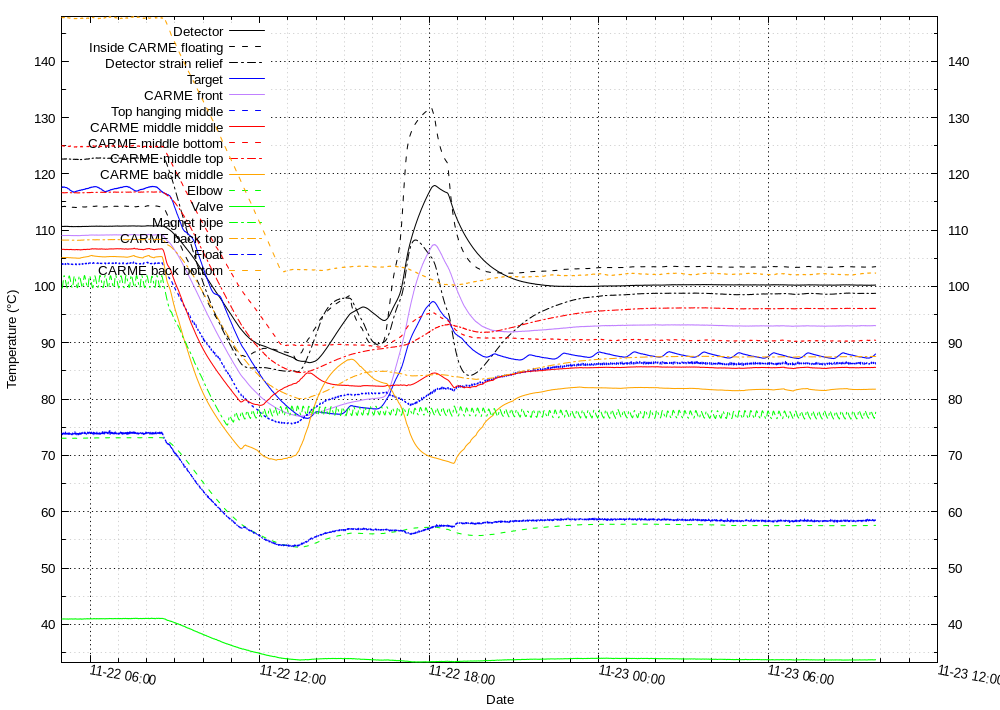

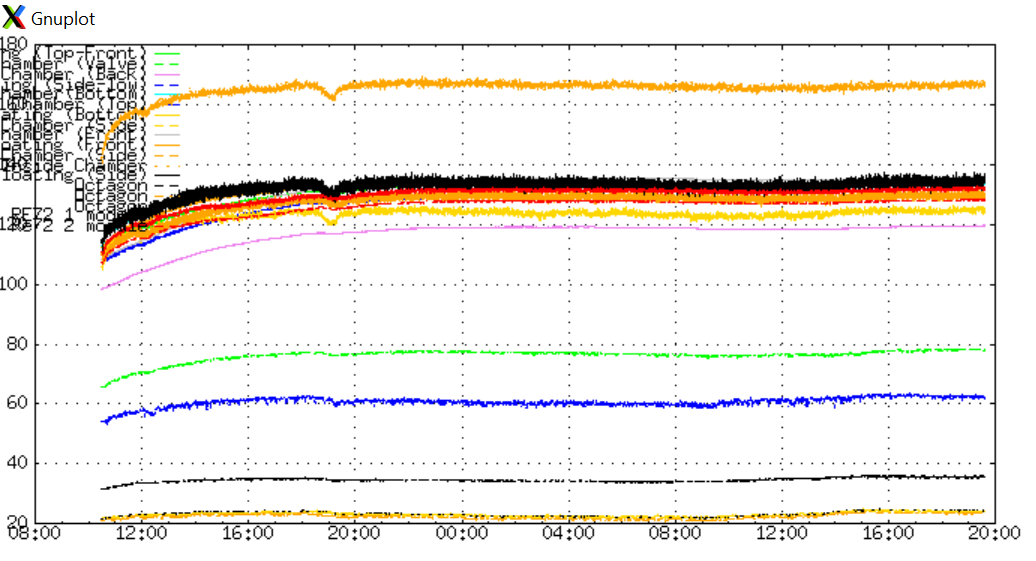

Tue Nov 23 08:49:33 2021 |

CB + ML | NEG activation completed |

Found temperatures and pressure stabilised overnight. See attached.

12:00 Began activation of 3x UHV1400 in channel 2, top module. Started using 90 W as per procedure. No effect on temperature. Increased to 120 W. OK

14:30 Began activation of 2x UHV1400 in channel 1, in front of the detectors. Considered moving detectors but decided against it since bellows are rated to move at 20C at most. Activated at 60 W (vs. 75 W in procedure). OK

All NEG elements off. CARME heaters ramping down to 60 C overnight.

Ion pumps activated < 100 C. Valve closed. #4 doesn't come online properly. Sone issues with #2 as well but it recovered on its own. Left cooling down. No changes. Ion pumps off and valve open. Will try tomorrow. Could be faulty cable?

Vacuum division may want to activate their pump as well - times unclear. |

| Attachment 1: vacplot24.png

|

|

| Attachment 2: CARMEtemps.png

|

|

| Attachment 3: vacplot24-1.png

|

|

| Attachment 4: CARMEtemps-1.png

|

|

|

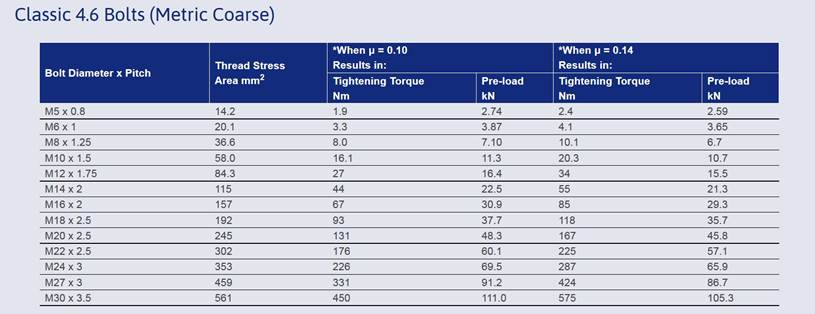

140

|

Tue Nov 2 12:45:36 2021 |

CB + DR NK | Issues with CARME feet |

Attempted to close CARME as carefully as possible.

Swapped out one foot for another one and temporarily removed a second to allow CARME to rotate slightly and get a better alignment of the two surfaces of the COF600 flange.

Closed CARME but realised carriages with struts are such that carriages touch before flanges do. Worse on side with leak than side without. See attached. As a result we would not be able to close properly.

DR to modify the holes in the feet closest to flange on CARME front to allow surfaces to touch before carriages come in contact. Hopefully close later today.

Issue was not encountered earlier because CARME was fully mounted before being dropped on feet. Struts were forcefully brought close to allow CARME to descend. Unclear how this was done in DL but may be baking had altered some sizes enough for the issue to appear. Spare feet do not help significantly.

Closed CARME . 1. Bolts finger tight. 2. Bolts tightened with tools stopping as soon as resistance is felt. Tightening done from the top descending towards the right (clockwise) and from the bottom counterclockwise. 3. 20 Nm applied in the same way 3. 40 4. 60 5. 80 6 80 again but single operator going round 6. 100 single operator

Pumping down overnight

|

| Attachment 1: 20211102_134446.jpg

|

|

|

94

|

Wed Sep 29 09:27:38 2021 |

CB (remotely), RSS JM ML | Power cut |

Sudden and unexpected power cut at 10:02 German time, affecting all the target hall.

It has been caused by the emergency alarm being triggered. Reasons unclear. Electricians were informed.

CARME top gate valve closed.

10:33 power is back

Set point 120C

Scroll on, turbo on (980 Hz normal operation), valve open

Pressure at 1.34E-6 mbar

No obvious issues.

13:00

Power appears back for the whole ring.

Set point 128C

Turbo normal operation - no apparent adverse effects of shutdown

Pressure at ~3E-7 mbar

Pi can again be accessed by ssh. Vacuum plot is updating again. |

|

12

|

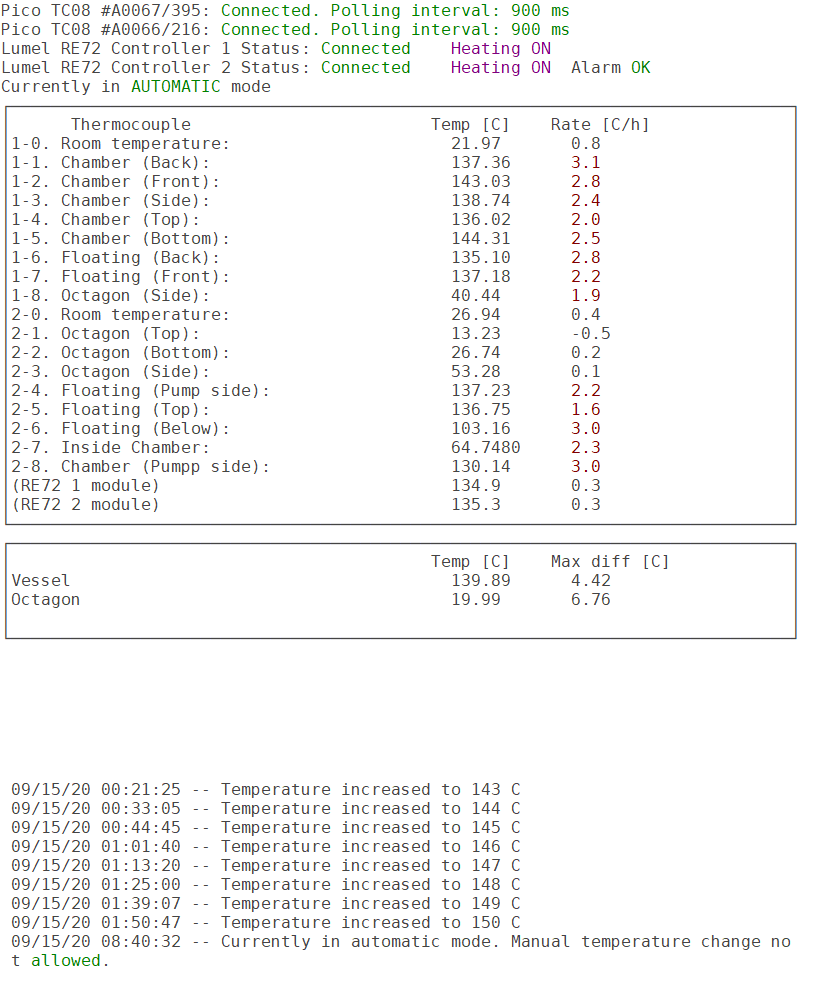

Tue Sep 15 08:39:26 2020 |

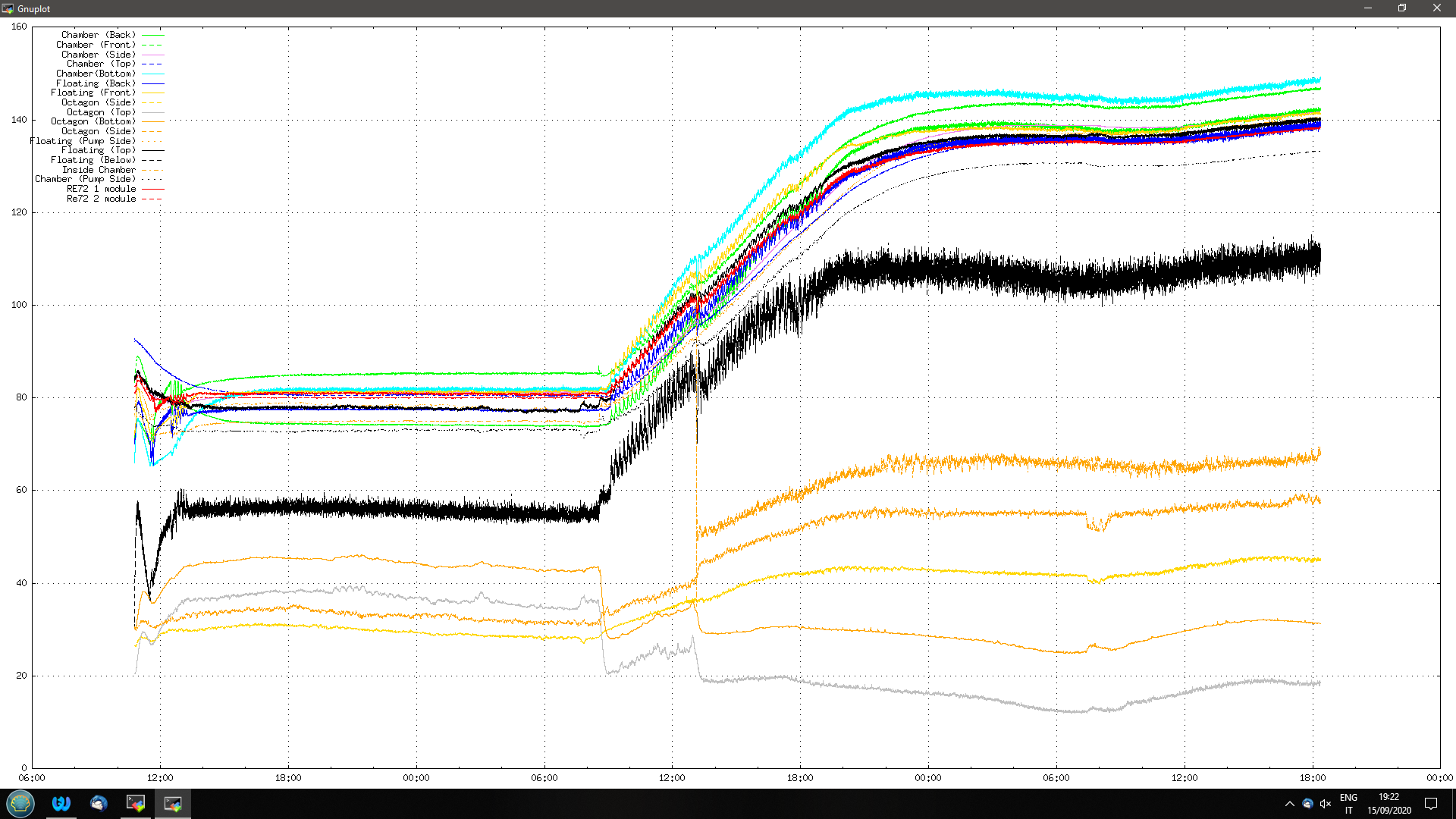

CB (remotely), JM | Baking and Chamber status |

Tuesday 15 September

08:40

Rates started working again. Unclear what yesterday evening's bug was caused by. Will investigate eventually.

Temperature setpoint reach T=150 , however even at full power (heating constantly on) the RE72 appear unable to

reach past T = 135

See attached.

Perhaps better insulation would be required.

However, this temperature is sufficient to bake CARME with the detectors inserted.

Day shift

Baking continues and will be left overnight to gather more data. Vessel temperatures are increasing by roughly 1.5 deg/hour with the vessel average temperature now 141.5

deg.

Wire seals fully closed and tightened. Bolts were tightened first finger tight, then to 50 N.m and finally to 80 N.m in a pattern so that seal is closed evenly. Leak and

pump cart are ready to be connected to the turbo for leak testing tomorrow.

19:20

Baking continues OK. Temperatures seem to increase slowly. See attached. |

| Attachment 1: 20200915_0842_ctrl.png

|

|

| Attachment 2: 20200915_0842_temp.png

|

|

| Attachment 3: 20200915_152708.jpg

|

|

| Attachment 4: image007.jpg

|

|

| Attachment 5: 20200915_1920_temps.png

|

|

|

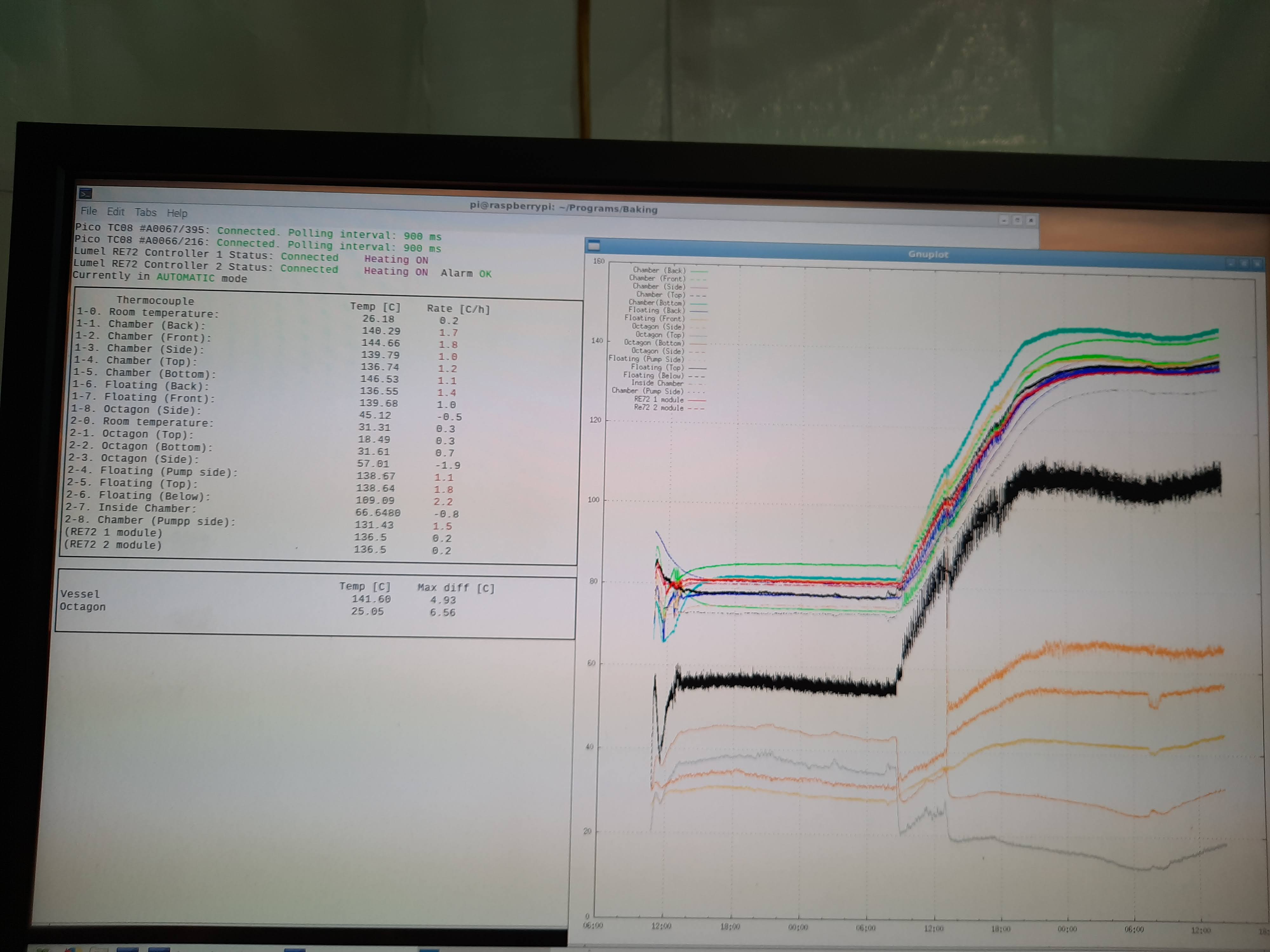

25

|

Mon Oct 5 08:21:40 2020 |

CB (remotely), JM | First bake of CARME with pumps (cont.) |

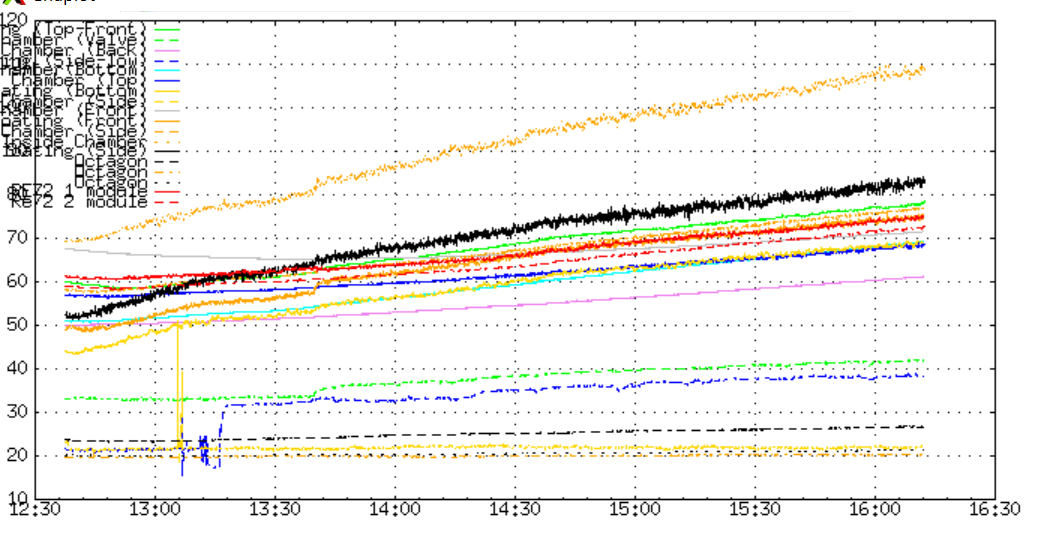

5 OCTOBER

08:21 Temperatures stable overnight. See attached. Baking continues.

Remember to visually inspect the tent for potential new drafts the next time in Daresbury.

Also remember to check on thermocouple 1-4 status / position.

10:15 Draft caused by section of top blanket collapsing slightly producing a hole at the top-back end of the volume. Only way to remove draft is to power down and shift

some of the larger blanket sections over to support the collapsed bit. Keith requires temperatures >120C for the vessel average to proceed so heat was powered down and

jacket reconstructed. See attached photos of the top of the baking volume (Sorry for quality).

Pressure on vessel when baking concluded: 2e-7mbar

13:00 Baking jacket all sorted, temperature set to 60C to equilibrate. New session had to be started as cooling then heating confuses the rates on the baking program. All

looks good at the moment, will continue to monitor and increase temperature when needed. Automatic mode may be able to be utilised again as rectifying the insulation on

the

back has reduced the thermal gradients somewhat.

Pressure on vessel when baking restarted: 1e-8 mbar

Bumax order has also been delivered

16:00 Monitoring remotely, bakeout has been on automatic for an hour and is currently at 67C. Vessel gradient ~7.5C

17:15 All looks okay, will leave for a few hours now. Temp is 73C, gradient ~8.2C

22:00 Automatic baking to 90C gradient >10C. Ramped to 105C for RE72-1 and 100C for RE72-2. Will leave overnight to stabilise

6 October

9:50 Temperatures stable, increasing to 115C, 105C

11:20 Temperatures stable, Increasing to 120C, 115C

13:15 Temperatures stable, increasing to 125C, 120C. Vessel average ~115C.

14:45 Temperatures stable (see attached). Increasing to 130C, 125C. Vessel average~120C

20:16 Temperatures stable, may be getting to edge of how hot we can get. Increasing to 135C, 130C overnight. Vessel average~128C should be sufficient.

7 October

07:30 Temperatures stable, have reached max temperature we can achieve 132C, 128C on RE-72 thermocouples. Vessel average~131C should be sufficient. Temperatures will be

maintained until Monday when negs can be activated.

20:30 Temperatures stable (see attached)

8 October

10:30 Temperatures stable

9 October

8:30 Temoeratures remain stable |

| Attachment 1: 20201005_0821_temps.png

|

|

| Attachment 2: 20201005_110422.jpg

|

|

| Attachment 3: 20201005_134003.jpg

|

|

| Attachment 4: temps3.png

|

|

| Attachment 5: temp4.png

|

|

| Attachment 6: temp5.png

|

|