| ID |

Date |

Author |

Subject |

|

14

|

Thu Feb 22 07:58:48 2018 |

Thomas Chillery, Tom Davinson, Raffaele Buompane, David Rapagnani, Lucio Gialanella | Setup - Beam Tuning and Prepare Chamber for Measurement at 3.0MeV 7Li | On 21/02/2018 we reattempted the beam tuning. We expected this to be easier now the rogue mylar is removed from the beamline.

At 8:30 we started the roughing pumps. At 8:37 the turbos were switched on. By 8:55 the preassures read: Up = 1.6e-5, and Down = 4.3e-5 mBar.

The preamp box was mounted on top of the chamber ready, the box lid was still left off.

The S2 was biased to -130.3V, leak current = 1.03 uA.

On FAIR DAQ with no beam: Trigger Rate ~ 8000/s, Event Mult = 5.0

The 10mm blank frame was in the beam axis. We began beam tuning. By 11:30 we had beam on the downstream faraday cup FC-E1 = 40pA, so now we can pass beam through the chamber - good!

We moved the target ladder to 95.010mm, swapping from the blank 10mm frame to the blank 3mm frame to assist in beam tuning. Now FC-E1 ~ 8pA.

We decided to move back to the 10mm frame to optimise tuning. The target ladder was moved back to position 80.024mm for this purpose.

We moved the slits located upstream from the bending magnet (close to FC-4) to 1.5X1.5mm.

We moved the GSI slits located before the quadrupole to optimise current on FC-0, the upstream faraday cup. We find the following slit positions:

Up = 0mm, Right = 1.5mm, Down = 5.5mm, Left = 5.5mm.

We also performed further tuning by adjusting the quadrupoles located at the immediate end of the tandem accelerator - note the beam tuning is very sensitive here.

After beam tuning we had the following currents:

For 10mm blank frame in beam axis: FC0 = 42pA, FCE1 = 30pA, transmission ~ 71%

For 3mm blank frame in beam axis: FC0 = 41pA, FCE1 = 13pA, transmission ~ 32%

We decided this was acceptable for testing

At 13:30 we switched off the S2 and vented the chamber.

After venting we did the following:

- Removed 12um mylar from the front of the S2

- Visually inspected the ribbon cable connections on the S2 connector and the vacuum feedthrough connector. I saw no loose connection and left the cable alone.

- Set the Si diode angle to 62 degrees relative to the beam axis (28 degrees relative to the normal of the beam axis) - in future we need a fixed angle mount to ensure this angle is reproducible

- Mounted targets on the ladder at the following positions:

| Position |

Target |

| 1 |

Blank 3mm |

| 2 |

Blank 10mm |

| 3 |

CH2 I |

| 4 |

CH2 II |

| 5 |

CH2 III |

| 6 |

CH2 VI |

| 7 |

natC I

|

The target ladder was set to position 3, looking from above I confirmed it was in the center of the beam axis.

The alpha source was removed as someone pointed out the ladder may be moved in such a way that beam hits the source. However later on (morning of 22/02/2018) I was informed this is being over cautious and we can leave the source at the far position 7 of the ladder during beam.

The ladder, downstream, and upstream lids were remounted on the chamber. The S2 (no mylar) was still on the downstream lid. The diode was still on the central lid.

The roughing pumps were switched on. However the following mistake was made: when both Ecodry 1 and Ecodry 2 were switched on, the automatic gate valve for Ecodry 1 was still open. This meant the chamber was evacuated at a fast rate, likely > 10mBar/s. When I noticed this after a few seconds of pumping the pressures read 10^-1mBar at the chamber upstream and downstream positions.

Speaking to David I learned Ecodry 1 may be switched on ready as long as the gate valve "T1600 Backing" is closed

Learning point: Ensure the automatic gate valve "T1600 Backing" is closed before pumping. This way we can control the roughing speed using the manual gate valve on Ecodry 2.

I wanted to inspect if anything was damaged in the chamber by this fast pump speed. The pumps were stopped and the chamber vented.

Upon visual inspection the S2 and 0.9um mylar in front of the diode were undamaged.

Target CH2 I on the ladder was loose at one side, the target ladder was removed and CH2 I at position 3 was replaced with CH2 VII.

Now the target ladder is in the following configuration: See attached IMG_2738.jpg

| Position |

Target |

| 1 |

Blank 3mm |

| 2 |

Blank 10mm |

| 3 |

CH2 VII |

| 4 |

CH2 II |

| 5 |

CH2 III |

| 6 |

CH2 V |

| 7 |

natC I |

At 16:45 the roughing pumps were switched on, this time with the "T1600 Backing" gate valve closed. The manual valve was cracked open.

By 17:01 the pressures read Up = 4.2e-1 mBar, Down = 4.1e-1 mBar.

At 17:08 the turbos were switched on.

At 18:07 the pressures read Up = 1.2e-5mBar, Down = 3.2e-5mBar.

We are ready to connect the preamp box for the S2, and also connect the preamp for the pin diode. |

| Attachment 1: IMG_2738.JPG

|

|

|

10

|

Tue Feb 20 09:19:19 2018 |

Thomas Chillery, Tom Davinson, Raffaele Buompane, David Rapagnani | Setup - Testing Chamber Vacuum and Mounting Detectors and Alpha Source | (Note: Tom Davinson is now in CIRCE until the 21st)

On 19/02/2018 we performed the following:

This morning we gave CIRCE technician Antonio slanted spacer boxes (for mounting preamps) and also the Al box (used for target ladder) for minor modifications

I needed to unmount the Al box from the target chamber. As I did so some air rushed in as I unmounted the box, indicating the chamber was not back at atmosphere from pumping on Friday.

I also removed the central lid with the iris attached. I discovered the iris was broken beyond repair. We will need to order a new one and some spares.

Learning note: To avoid damage always have irises fully opened when pumping down the chamber.

In the meantime Tom D has been wiring up the rest of the electronics setup. He discovered the CAMAC crate was not supplying any voltage. We removed the crate and double checked the connection between the rear power box and the crate – it was not fully screwed in on the bottom. After fixing this we remounted the CAMAC and found all voltages read out correctly, including a current readout of -10A at the -6V voltage.

Next we set out to vacuum test the chamber. In total today we performed four vacuum tests.

In each test the diode mount, lemo feedthrough, 64-way vacuum feedthrough, and an iris mounts were installed in the central section (the iris mount in the central chamber had no iris due to damage mentioned above). The iris mount with an iris (fully opened) and 64-way vacuum feedthrough were installed in the downstream section. The Al spacer box for the target ladder was also installed, however the target ladder was not because Antonio was not finished with modifications. Instead of the target ladder a blank flange was installed. The two actuators for opening and closing the irises were also installed in the central and downstream chamber sections.

The first two vacuum tests showed a high leak rate, high 10^-4 mBar even without helium injected close to the chamber.

In the first test we found the two 64-way vacuum feedthroughs were causing a leak, after venting the chamber these were removed and mounted flat to the lid using four bolts, one at each feedthrough corner. We then started the second test.

In the second test we discovered a leak was caused by the lemo vacuum feedthrough on the central lid. After the test we put additional grease on the o-ring and around the flange section of the feedthrough (atmosphere side) to help it seal.

On the third vacuum test after ~ 20 minutes of running the up and downstream turbos the pressures levelled to:

Up = 3.6e-4 mBar, down = 3.4e-4 mBar

We then switched off the turbos and continued monitoring the vacuum. After ~30 minutes from turning off power to the turbos, they had completely stopped spinning, the pressures read:

Up = 6.5e-1 mBar, down = 6.5e-1 mBar

We found during this test the lemo feedthrough was still not sealing, and in addition neither was the Al spacer box for the target ladder.

After venting we found a hair on the lemo feedthroughs o-ring. The hair was removed and additional grease was applied to the o-ring and lid. We also confirmed the nut was tight. For the spacer box we found the bolts used were slightly too long, and so removed ~ 2mm from the threads. The box was then remounted and looked flush with the side of the chamber.

After this test at ~16:00 Antonio had finished and delivered both the modified spacer boxes for the preamps and the target ladder mounting box, now it correctly uses a 16mm centering ring.

We then started the fourth vacuum test, now with the target ladder actuator mounted too (as well as all the other parts from tests 1-3):

At 16:43 the roughing pump in the leak test was started. At ~16:50 the turbos were started, both up and downstream from the chamber.

At 17:04 (~15 minutes later) the pressures in the chamber read: Up = 3.1e-4 mBar, Down = 2.8e-4 mBar.

We declared victory for the vacuum and decided to mount the detectors and an alpha source.

On the central lid we mounted the Si diode with 0.9um mylar and a 1mm collimator at ~28 degrees rotation (relative to the central lid) -> currently this is performed using an angle measuring app on my android phone and one screw, so this angle selection needs to be better reproducible for the future.

We discovered there was no way to mount the S2 detector on the central lid -> either the legs of its connectors collide with the lid, or when the iris mount is rotated 180 degrees (moves detector slightly upstream) the iris then collides with the target ladder. The way we mount the detector on the central lad needs redesign -> I will take the central lid with irises and diode mount back to Edinburgh to address and fix this problem. I can also use this opprtunity ot find a better mounting procedure for the Si diode.

We did mount the S2 2323-18 (496um) detector to the downstream iris mount. 12um mylar was placed in front with a central hole of max width <20mm to allow the beam to pass trough.

On the target ladder we mounted an alpha source at position 5mm. The alpha source specifications are:

Type: EAX

Prod No: 111109-1242002

Radionuclide: 241Am + 239Pu

Activity: 8.153 kBq

Reference Date: 25/3/2010

At 20:49 with the single S2 detector, diode detector and the alpha source mounted in the chamber we started the roughing pumps.

At 20:54 we started the turbos, including not only the up and downstream turbos but also the large turbo located below the chamber. The pressures read: Up = 1.3e-4 mBar, Down = 1.5e-4 mBar.

We went to dinner. Raffaele had fish.

22:19 The pressures read: Up = 1.4e-5 mBar, Down = 3.7e-5 mBar

We mounted the preamp box on top of the chamber with preamp 2 inside. The cables for the detector bias, +15 and -15V preamp power, +ve pulser, and ribbon signal cables were connected.

Biasing the S2 to -130V we read a leakage current = 1.16 uA. Powering the preamp we read currents: V=+15V -> I = 0.9A, and V=-15V -> I = 0.4A, as expected. The pressures read: Up = 1.4e-5 mBar, Down = 3.2e-5 mBar

Using DSO we observe

- RAL 1 CH 0->7 pulser OK, no alpha

- RAL 2 CH 0 no pulser or alpha

- RAL 6 CH 1->7 pulser OK, no alpha

- RAL 8 CH 6 no alpha, pulser not connected to n+n ohmic strips

We declared today a good day and left the lab. |

|

12

|

Tue Feb 20 17:03:08 2018 |

Thomas Chillery, Tom Davinson, Raffaele Buompane, David Rapagnani | Setup - Beam Tuning | The pumps were left on overnight, in the morning at 8:25 the pressure reads:

Up = 1.5e-5 mBar and Down = 4.0e-5 mBar.

We made a first attempt at collecting an alpha spectrum for the far S2 detector using ADC 2 and ADC 3. However ADC 3 appeared to be acting as a TDC for no obvious reason.

During this attempt we noticed ADC 2 channels 0, 1, and 5 had a high rate, and ADC 2 channel 8 had a low rate.

We moved the ribbon inputs on ADC 3 to ADC 4, the spectra on ADC 4 looked better. ADC 4 Channel 30 had a low rate.

We noticed ADC 3 was still active -> removing the ribbon inputs had no effect on the module writing to the DAQ. We raised the lower threshold of ADC 3 to 2046 (total 2047 channels), effectively stopping it from writing.

The thresholds for ADC 2 and ADC 4 were set to channel 40 for both. The thresholds on the RAL shaping amplifiers are set to 15mV.

At 9:09 we started collecting an alpha spectrum for a preset time of 900 seconds, finishing at 9:24. The dead time was 24% and the event multiplicity 3.2 (event mult. was 40 before removing ADC 3). The trigger rate was ~9kHz. The data were saved in /RemoteObjs/RData_1/180220091352/

To try and lower the trigger rate I removed the 6th breaker in the top IDC convertor box, which corresponds to the 5th channel of RAL I, which in turn corresponds to the 5th channel of ADC 2.

The trigger rate had risen (strangely) to ~12kHz, we saw ADC2 CH 0 had a high rate.So I removed the 1st breaker in the top convertor box, which corresponds to the 0th channel of RAL I, which in turn corresponds to the 0th channel of ADC 2.

Now the trigger rate was ~9kHz, with a good event rate ~ 40 Hz. We agreed that since the preamp box does not have its cover on there will be noise, particularly from the turbo located immediately downstream from the preamp box.

At 11:30 we started trying to tune the beam. Before sending beam I moved the target ladder to position 95.010mm, achieved by first moving the actuator to position 96mm and then back in position to account for backlash.

Note: All the target ladder calibration points were obtained by moving the ladder towards the actuator.

By 12:44 we were still tuning. We obtained a beam current of 200pA in FC-0, the faraday cup located ~1m upstream from the chamber, however we were unable to find the beam downstream from the chamber.

We were using the 3mm diameter blank frame for beam tuning, and decided to now attempt tuning with the 10mm blank frame.

We were using the only blank 10mm target frame available to support the alpha source, so we decided to vent the chamber and move this to an accesible part of the target ladder for beam. This would also allow us to inspect the beamline and check it is clear of obstruction with the telescope.

We switched off the detector and vented the chamber. I then removed the target ladder and switched the 10mm blank frame holding the alpha source with a 3mm blank frame. The 10mmblank frame was attached at position 2 of the ladder.

See attached (IMG_2709.jpg) for the first target ladder setup. See attached (IMG_2712.jpg) for the new target ladder setup.

We set the target ladder to 80.024mm for the 10mm blank frame, and then using the telescope confirmed it was in the beam axis. This involved removing the upstream lid and putting a piece of white paper in.

We then sealed the chamber and at 14:40 started the roughing pumps. The gate valve was cracked open -> we want a pumping speed <10mBar/s to avoid damaging the detectors and/or mylar foils.

At 15:04 the gate valve was fully opened and the turbos started. By 15:12 the pressures read: Up = 9.2e-5mBar, and Down = 1.0e-4mBar. The detector was biased at -130.3V with a leakage current 1.19uA.

With no beam the DAQ trigger rate ~ 6kHz.

At 15:29 we started the beam tuning with the 10mm blank frame in the beam axis.

During tuning the power supply on the 1st analysing magnet, located between the cathode source and accelerator, showed problems and was replaced.

At 17:50 I checked the S2 leakage current = 1.28 uA. The slight rise from 1.19 uA could be due to temperature fluctuations (8 degrees temp increase causes factor 2 difference)

At 18:20 we decided to vent the chamber and shine a light upstrean from the faraday cup FC-0. After switching off the detector and venting the chamber we discovered the piece of paper used to check the 10mm aperture alignment was left inside the upstream section of the chamber since the last time we vented. No beamspot was seen on the paper.

At 19:00 we restarted the roughing pump and cracked open the gate valve. At 19:03 the turbos were started. At 19:06 the pressures read Up = 7.0e-5, Down = 1.3e-4 mBar. The S2 was biased back to -130.3V, leak current = 1.20 uA.

We went back to tuning (third time today). With no beam we had a DAQ trigger rate ~ 2.6kHz, event multiplicity = 10.

We were able to see beam on FC-0, but unable to see beam on either of two faraday cups located downstream of the chamber. We decided to check the beamline again.

At 20:40 the detector was switched off. The turbos were then switched off. At 21:00 a tiny amount of air was allowed into the chamber to help slow the turbos, by 21:05 they were <12Hz. We vented the chamber.

After inspection of the beamline we discovered a new cause of the tuning problem. A small piece of mylar was in the bellow located downstream from FC-0. See attached IMG_2724.jpg.

We inspected the 12um mylar in front of the S2, it was not damaged, suggesting the rogue piece of mylar from the bellow is from a previous experiment.

We removed the rogue mylar and remounted the bellow to the beamline, we confirmed it was aligned using the telescope. We had a clear line of sight through the beamline, suggesting the problem is solved.

We declared victory.

At 22:30 we started the roughing pump for the section of beamline upstream from FC-0.

|

| Attachment 1: IMG_2712.JPG

|

|

| Attachment 2: IMG_2709.JPG

|

|

| Attachment 3: IMG_2724.JPG

|

|

|

13

|

Wed Feb 21 10:46:22 2018 |

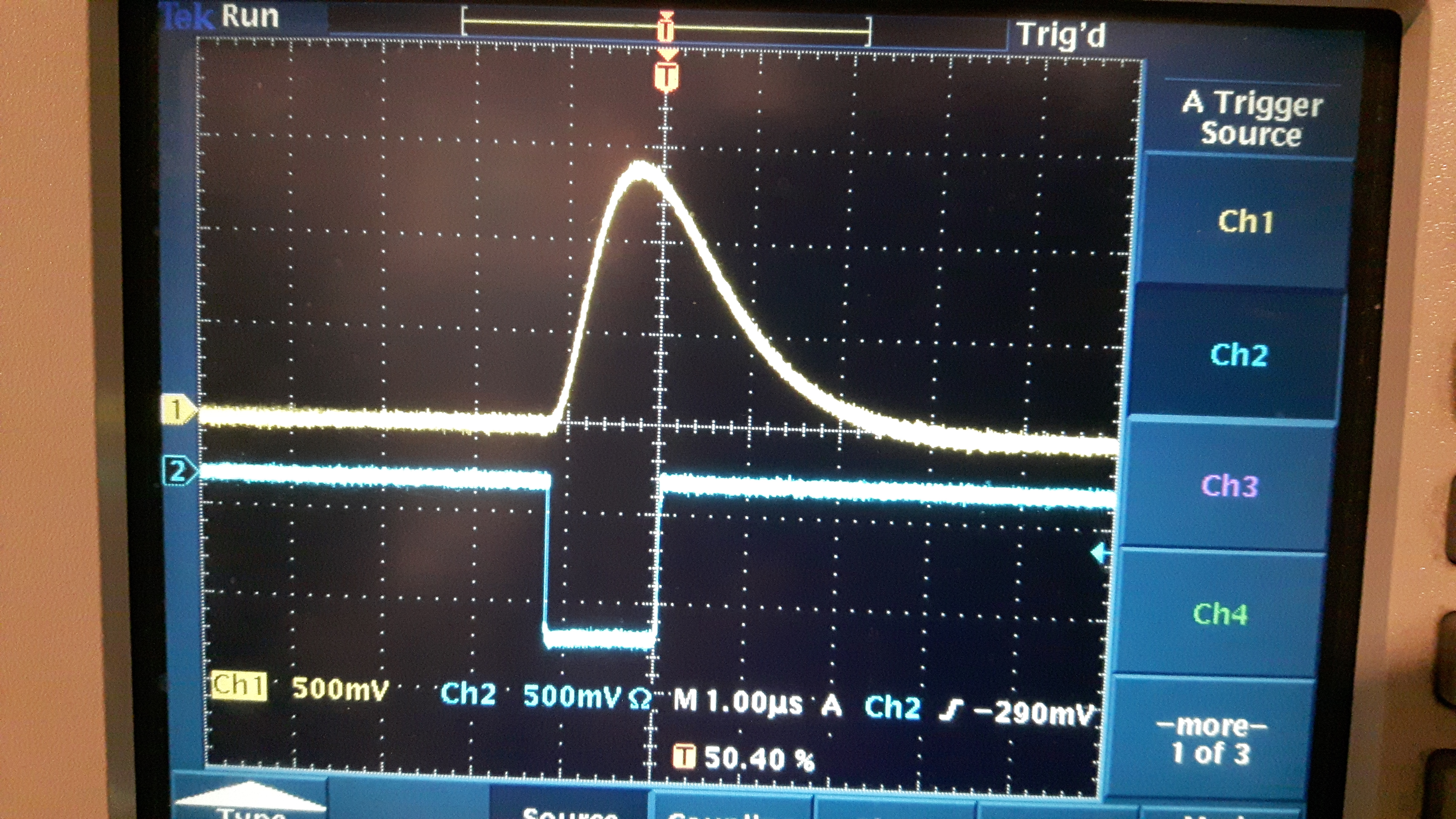

Thomas Chillery, Tom Davinson, Raffaele Buompane, David Rapagnani | Setup - Pulser Settings and 20/02/2018 Pulser Walkthrough | The PB-5 Pulse Generator settings are as follows:

Fall Time = 100us

Rate = 2.00Hz

Delay = 250ns

Ampl = 0.50000V

Pol = POS

Pulse Top = Tail

Atten = 1X

PB-5 Pulse = ON

CLAMP = OFF

During the second beam tuning on 20/02/2018 we performed two pulser walkthroughs to determine the ADC offset.

For the walkthrough the rate was increased to 10Hz.

The first pulser walkthough was saved as: Remote_Objs/RData_1/180220170900

The pulser amplitudes used were: 0.1, 0.2, 0.3, 0.4, and 0.5 V

After this walkthrough I remembered channels 24 -> 31 of ADC 2 were unplugged from the RAL shaping amplifier, and so plugged these back in. I then repeated the walkthrough.

The second pulser walkthrough was saved as: Remote_Objs/RData_1/180220172838

Like the first walkthrough, the pulser ampltudes were 0.1, 0.2, 0.3, 0.4, and 0.5 V.

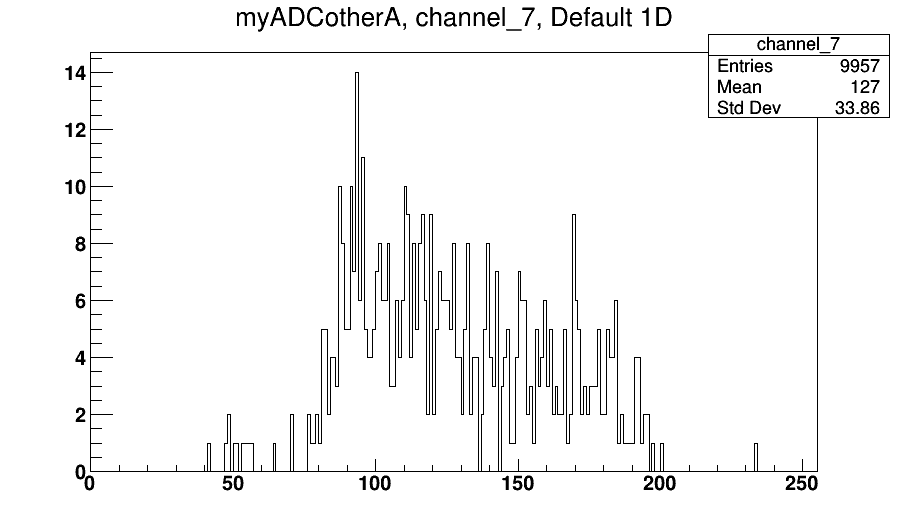

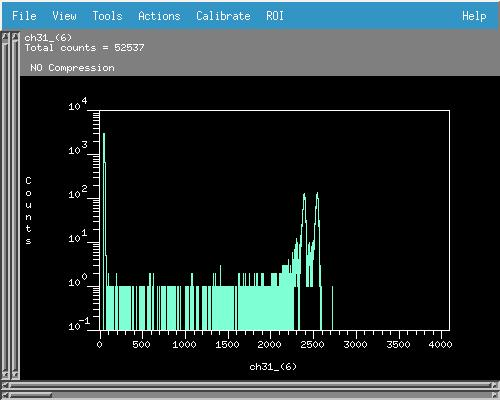

A sample pulser walkthough spectrum is attached. |

| Attachment 1: BKG_zoombeam1.jpg

|

|

|

28

|

Fri Apr 6 12:07:52 2018 |

Thomas Chillery, Raffaele Buomparte, David Rapagni, Jeremias Duartes | Tests - Attempting to solve noise issues, 15 min alpha calibration | On 05/04/18:

At 9:00 the pressures read ~10mBar inside the chamber (static vacuum). We began venting the chamber.

During venting the cable daisy chain on top of the preamp boxes was removed, the downstream preamp box was removed. It was decided to also removed the central preamp box and its respective spacer box to avoid any collisions when removed the downstream lid.

By 9:20 the chamber was vented. The downstream aperture was removed. The downstream lid was removed, the S2-> vacuum feedthrough cable was changed.

The downstream S2 was remounted into the chamber, and the downstream aperture was remounted onto the chamber collar.

During this process the 4mm diameter collimator for the diode was ready, we decided to also mount this in front of the diode since the chamber was already vented.

The central aperture was removed and the central lid was then removed. The 4mm collimator with 0.9um mylar was installed in from of the diode. The 0.9um mylar was held in place on the collimator using an epoxy.

The central lid was reinstalled, followed by the central aperture on the collar.

The downstream aperture was set to 1.5mm, and the central aperture was set to 14.0mm, opening the irises ready for pumping.

At 10:45 Ecodry 1 and 2 were switched on, the gate valve was cracked open. During roughing the downstream preamp box was mounted followed by the central preamp box.

At 11:03 the T1600 Backing valve was opened and chamber pressures read ~1.0e-1mBar. The 7 turbos were started. (Turbos Up 1 and 2, Turbos Down 1 and 2, Turbo Entrance 3, Turbo CSSM, and T1600)

The +15V, -15V, +ve test, and HV bias cables were reconnected to the central and downstream S2 preamp boxes, and also the diode preamp.

Preamp power was applied, +15V draws 1.5A and -15V draws ~0.6A as expected.

At 11:15 CHUP = 2.6e-5mBar, CHDW = 6.8e-5mBar. Central S2 bias ramped to -130.0V, leak I = 3.51 uA. With the preamp lid off a 0.1V pulser on RAL X CH 1 produced a 1.5V amplified signal with ~200mV noise.

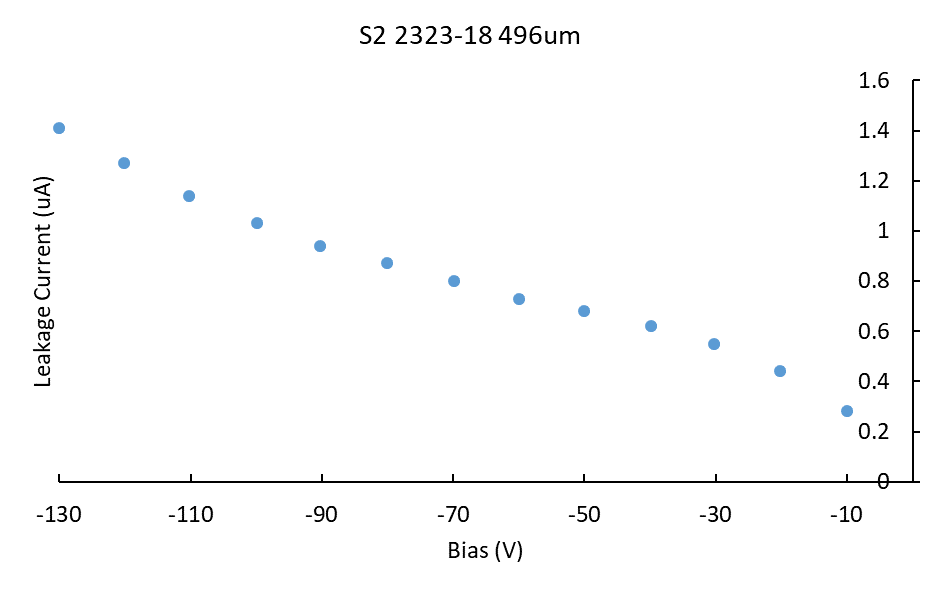

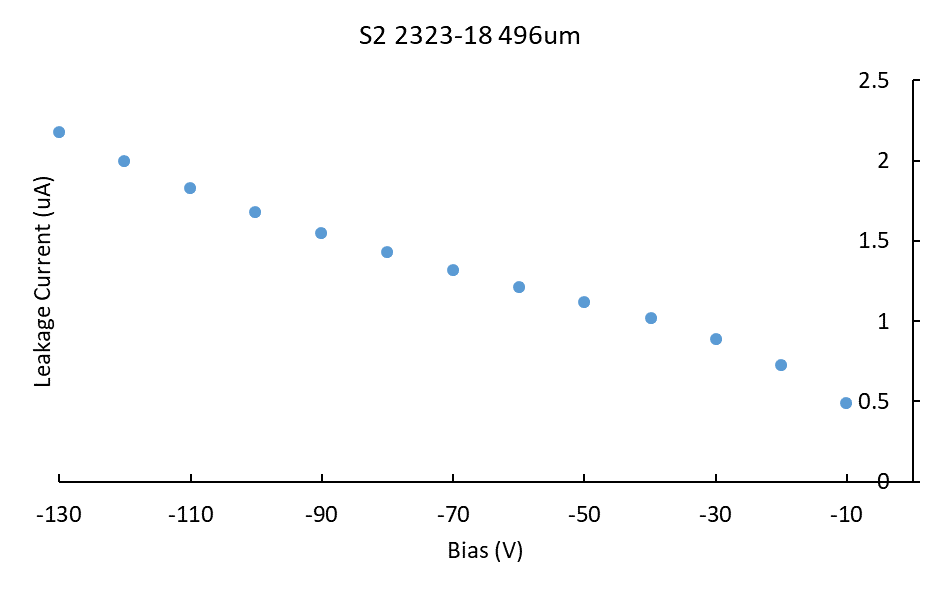

I recollected the bias vs leak I curve for the downstream S2. See S2_2323-18_496um_Bias_Vs_Leakage_Current_050418.png

RAL 1 CH1 looked clearer than yesterday, 0,6V pulser setting produces 3V signal. However there was a strange reflection on the end tail of the pulser peak. I mounted both preamp lids but still saw the reflection. This effect dissapeared after disconnecting the diode preamp test input from the daisy chain with the S2 preamp boxes. I replaced this with a 50 ohm terminator.

We adjusted the downstream S2 RAL thresholds (they were 15mV to begin with except RAL I (100mV) which was adjusted yesterday)

Now the thresholds are:

| RAL Ident |

Threshold (mV) |

| I |

90.0 |

| II |

75.0 |

| XI |

115.0 |

| IV |

90.0 |

| V |

75.0 |

| VI |

76.0 |

| VII |

76.0 |

| VIII |

73.0 |

We tried starting the DAQ using an OR trigger from the downstream S2, however we were presented with an error: Too Many Bad Events

We tried disconnecting all of the RAL ECL outputs except RAL I's, we still recieved the error.

We tried increasing the pulser amplitude setting from 0.2 -> 0.6V, still recieved the error.

We tried restarting the FAIR DAQ, after restarting we got good events. We can see a pulser peak and two alpha peaks.

We reconnected the ECL outputs for RAL II -> RAL VIII to the DAQ OR trigger

Note: ADC 2 (module 3) still shows strange "TDC-Like" behaviour, so we avoid this module.

The first 8 channels of RAL I still show alot of noise, we increased RAL I threshold from 90 to 100 mV

Triggering DAQ only on downstream S2, we see a dead time ~ 9% and trigger rate ~3700Hz

I tried removing the downstream preamp box lid and checked both the preamp -> feedthrough and also the preamp -> IDC convertor box connections on the preamp PCB. I resealed the preamp box lid.

Check on RAL I CH1 (downstream S2) noise: for pulser setting 0.5V amplified peak has height 2.8V noise 100mV

Check on RAL X CH 1 (central S2) noise, for same pulser setting amplified peak has height 2.8V noise 100mV, signal to noise ratio ~ 3.57% for both channels

We then connected the central detector ECL signals to the 3rd and 4th MALU 4532 Logic modules in the CAMAC crate. RAL X -> "R" sent to ADC 4, RAL "S" and "Q" sent to first 16 channels of ADC 5. Channel 31 of ADC 5 is diode. Currently the diode CFD threshold = 200mV. RAL X -> "Q" thresholds were all kept at 15mV.

We set the DAQ trigger to an OR of all 129 channels (64 from each S2 and 1 from diode)

Started DAQ, dead time 9%, trigger rate 3500 Hz, event mult = 52.5.

We decided to run an alpha spectrum.

Pulser Settings:

- Fall Time = 100us

- Rate = 10Hz

- Delay = 250ns

- Ampl = 0.5V

- Pol = POS

- Pulse Top = Tail

- Atten = 1X

- Clamp = OFF

14:55 started DAQ for 15 min alpha spectrum, save name: /Remote_Objs/RData_1/180405140038

Dead time = 71%, trigger rate ~ 1600Hz, event mult = 57.6 |

| Attachment 1: S2_2323-18_496um_Bias_Vs_Leakage_Current_050418.png

|

|

|

29

|

Fri Apr 6 13:33:27 2018 |

Thomas Chillery, Raffaele Buomparte, David Rapagni, Jeremias Duartes | Tests - Attempting to solve noise issues | On 05/04/18, after eLog #28

After the alpha calibrationrun Raffaele arrived and started beam tuning for 7Li 2+ at 5.0MeV using a LiO molecular source

We set the target ladder to position II (80.024 mm) - no target frame or target

Set downstream sperture to 82.5mm and central aperture to 85.5mm (iris diameter ~ 18mm)

Raffaele was struggling with tuning on accelerator end of beamline - decided to perform a pulser walkthrough

16:02 started DAQ for pulser walthrough, save name: 180405150720

Voltages covered: (Pulser amplitude setting)

- 1.4V

- 1.2V

- 1.0V

- 0.8V

- 0.6V

- 0.4V

- 0.2V

Note: pulser is daisy chained between both S2 preamp boxes (NOT diode preamp)

16:56 DAQ stopped, RT = 00:54:05, DT = 67%, Trigger Rate ~ 2kHz, Event mult = 53.1

At 16:57 the pressures read:

- TPU1 = 6.2e-6 mBar

- TPU2 = 9.1e-7 mBar

- TPD1 = 1.7e-6 mBar

- TPD2 = 1.7e-6 mBar

- CHUP = 9.4e-6 mBar

- CHDW = 2.5e-5 mBar

Checked detectors:

- Central S2 bias = -130.0V, leak I = 8.23 uA

- Diode bias = -70.1V, leak I = 0.00uA

- Downstream S2 bias = -130.1V, leak I = 2.44 uA

We opened the line valve, with no beam DAQ reads: DT = 8%, Trigger rate ~ 3400 Hz, event mult = 52.9

Beam tuning was performed with no target frame in the beam axis, beam voltage = 2.1358 MV

We had 1.2nA in FC 4, we supplied -400V to FC-E0 (FC immediately before chamber) for electron suppression

FC - 0 = 1.8nA (unsuppressed immediately after chamber)

We moved the target ladder to position I (3mm collimator)

FC-0 = 600pA

We need to use the ERNA magnet to bend the bean into FC-45 located after the chamber, this faraday cup is suppressed

CSSM magnet ON = 906.13mT, we noticed this section of the beamline needed pumping, switched on pump at 17:45

Received email from Tom D regarding noise, he suggested a few checks:

- Try changing preamp - feedthrough cable (currently have one spare which is wrapped in Al foil instead of copper tape - not ideal)

- Feedthrough - preamp cable drain wire should be connected to PCB at one end and the other left floating (both are attached to PCB at this time)

- Try isolating feedthrough - preamp cable from preamp lid - it may be touching

At 18:00 Raffaele needed to leave the lab, Jeremias could stay until 20:00, we decided to try and address the noise issue further

I switched off the detectors and preamp power, I removed the downstream preamp box lid and disconnected one end of the feedthrough - preamp drain wire (the end where the first 32 channels are connected on the PCB - connector P1)

I remounted the downstream preamp box lid.

The DAQ shows DT = 8% with 3kHz trigger rate.

To check the effect from the central S2, I tried setting the DAQ OR to only come from the central S2 and diode - I realised I could no longer see the pulser peak in the central S2 -> suggested central S2 trigger not working

I changed the cable between the 3rd and 4th MALU 4532 modules and the respective ECL-NIM converter -> now see triggers -> DAQ gives DT = 51% and trigger rate ~ 5.6kHz, but see pulser peaks in ADC modules 5 and 6

I considered only the downstream S2, setting pulser to 1.0V, RAL 1 CH1 amplifies this to ~5.5V with ~20mV noise.

Setting the DAQ OR to only come from this detector, the DAQ DT = 10% and trigger rate = 10Hz, event mult = 133.2. So it seems making one of the drain wires loose had a big effect on the noise.I decided to make the same change for the central preamp.

After switching off the detectors and preamp, I opened up the central preamp box and left one end of the drain wire on the preamp - feedthrough cable hangng loose. This is the same end as the one chosen for the downstream preamp.

Leaving the central preamp lid off, I reapplied preamp power and rebiased the detectors

- central S2 bias = -130.0V, leak I = 8.10uA

- diode bias = -70.0V, leak I = 0.01uA

- downstream S2 bias = -130.1V, leak I = 2.27uA

Checking RAL X CH1 (central S2) amplifiedoutput: 1.0V pulser output is amplified to ~5.5V with 50mV noise. Note the preamp box lid is off, so this looks promising.

I set the DAQ OR trigger to come only from the central S2, DT = 91%, trigger rate ~ 7kHz. High rate seen in ADC 6 channels 1->7 and channel 31

Changed DAQ OR to come from all 3 detectors, DAQ DT = 93% with trigger rate = 6700Hz, still see high rate in ADC6 channels 1-> 7 and channel 31

The time was 20:00 so we stopped for the day, it looks like the downstream S2 electronics is working fine, will check effect of mounting central preamp lid back tomorrow

All detector biases ramped down to 0V, preamp power off |

|

30

|

Fri Apr 6 14:54:12 2018 |

Thomas Chillery, Raffaele Buomparte | Tests - Attempting to solve noise issues | Today we started by mounting the central and downstream preamp box lids.

The pumps were left running overnight, at 9:06 CHUP = 2.1e-5mBar and CHDW = 5.8e-5mBar.

We biased the detectors

- central S2 bias = -129.9V, leak I = 8.09uA

- diode bias = -70.0V, leak I = 0.01uA

- downstream S2 bias = -130.0V, leak I = 1.66uA

The DAQ OR is all 3 detectors, DAQ DT = 82% and trigger rate ~ 6kHz. So the preamp lids made little difference. We saw particularly high rate in ADC 2 channels 1->4, 6 and 7, ADC 4 channels 6 and 31 (both of these are the downstream S2, ADC 5 channels 4 and 5 (central S2), and ADC 6 channels 1->7 (central S2) and 31 (diode)

Decided to ensure copper taped cable is isolated from preamp lid. I cut two sheets of plastic ~ 31 X 19cm and (after powering down the detectors and preamps) placed these between the copper taped preamp - feedthrough cable and the preamp box lid, for both preamp boxes.

Now when the DAQ is triggered from all 3 detectors DAQ DT = 7%, trigger rate ~ 2600Hz, event mult = 49.7

I saw ADC 3 (the "TDC-like" module) was not disabled, i set its ADC threshold to 2046 (out of 2047 channels).

I opened the irises in front of both S2s and moved the target ladder to position VII - alpha source facing downstream.

Now DAQ DT = 7%, trigger rate ~4100Hz, event mult = 18.6

I reset all of the RAL thresholds back to 15mV, I also disconnected the 2nd ECL-NIM converter channel 13 from the Lecroy quad coincidence module because the last 16 channels werent being used for the DAQ trigger anyway.

DAQ DT rose to 85% and trigger rate 32kHz, event mult = 11.8.

ADC 2 channels 1->4, 6, and 7, and ADC 4 channels 30 and 31 still show high rates. Disconnected RAL I and RAL VIII analogue and ECL outputs to remove these.

Now DAQ DT = 22% and trigger rate 8.5kHz, still see a high rate for the diode in ADC 6 CH 31

I tried plugging in the pulser to the diode preamp, pulser setting 0.3V. Ultimately after checking DAQ rate and signals on oscilloscope I raised the diode CFD threshold from 200 to 226mV and settled on this new value.

I decided to keep the diodes analogue delay set to 1us (same used in Feb 2018)

I realised I do need the 2nd ECL-NIM convertor channel 13 in the DAQ OR, because otherwise i could not trigger ADC 6 channels 0->31. This was now remedied

So, the DAQ trigger OR was from RAL II -> VII (downstream S2), RAL X -> "Q" (central S2) and the diode

At 12:03 we started data collection for a 15 minute alpha spectrum, save name = 180406110805

DT = 78%, trigger rate = 10kHz, event mult = 12.5. DT had dropped to ~ 50Hz during this run. Still saw high rate in ADC 6 channels 1->7 and 31

I was unable to see alpha peaks with good statistics for the downstream S2

At 12:35 I started a 30 minute alpha spectru, save name: 180406114011. DT ~ 73%, trigger rate ~ 9.6kHz

I noticed the central detector leakage current had risen to 10.01uA (bias -129.9V). The diode leak I was still 0.00uA and the downstream S2 leak I was still 2.21uA

When the downstream S2 was connected to the DAQ OR and ADCs a high dead time is seen. Because of this we decided to try and collect some beam data with the central S2. |

|

15

|

Thu Feb 22 10:40:49 2018 |

Thomas Chillery, Raffaele Buompane, David Rapagnani, Lucio Gialanella | Measurement / Test - 3.0MeV 7Li on CH2 Target VII | On 21/02/2018 after beam tuning and pumping down at 18:07 the pressures read Up = 1.2e-5mBar, Down = 3.2e-5mBar. We were happy to power the detectors and try to observe spectra from beam in both the S2 and pin diode.

Whilst waiting for the turbos to spin up the Pin diode was daisy chained with the +ve pulser, +15V, and -15V preamp power cables used with EDI Preamp 2 for the S2.

Channel 3 of the Silena Quad Power Supply was set to -70V ready for the diode.

The S2 bias was ramped to -130.3V, leak current = 1.19uA. The Pin diode bias was ramped to -70V, leak current = 0.01uA.

The preamp power was switched on, +15V read current 0.8A, -15V read current 0.4A, as expected.

The pin diode output was split between an Ortec 571 Amplifier and channel 2 of a Quad TFA.

The unipolar output of the Ortec 571 Amplifier was sent to a Delay Amp 1457. The Delay Amp output was sent to ADC 6 Channel 31.

The Quad TFA output was sent to channel 4 of a Quad CFD. The CFD output was sent to the Lecroy 622 module and setup as an OR with the S2 strips. This OR is sent to the DAQ trigger.

We mounted the preamp box cover. The grounding cable for the ribbon signal cables was attached to the box. We confirmed the grounding of these ribbon cables with a voltmeter.

Now with no beam the DAQ trigger rate ~ 60Hz. This suggests the ~6kHz rate seen before is noise from the previously exposed preamp, note the downstream turbo is very close (a couple centimeters) to this preamp.

To double check the tuning was still ok we sent the 7Li beam to FC-0 = 48pA.

We decided to close the GSI slits located before the quadrupole and slowly open these to their values in eLog entry #14. We closing the left and right slits had no effect on reducing beam current, so we kept these positioned at 5.5mm and 1.5mm respectively. The up slit was already 0.0mm.

Slowly opening the down slit we saw the following:

| GSI Down Slit Position (mm) |

DAQ Trigger Rate (Hz) |

| 0.0 |

60 |

| 0.1 |

110 |

| 0.2 |

180 |

| 0.3 |

250 |

| 0.4 |

250 |

| 0.5 |

380 |

| 0.6 |

450 |

| 0.7 |

550 |

| 0.8 |

675 |

| 0.9 |

750 |

| 1.0 |

850 |

| 1.1 |

925 |

| 1.2 |

850 |

| 1.3 |

1000 |

| 1.4 |

1100 |

| 1.5 |

1100 |

| 1.6 |

1050 |

| 1.7 |

1100 |

| 2.0 |

1300 |

| 2.2 |

1350 |

| 2.5 |

1300 |

| 3.0 |

1300 |

| 3.5 |

1400 |

| 4.0 |

1600 |

| 5.0 |

1600 |

| 5.5 |

1600 |

We saw on the backscattered diode counts at channels 50 -> 400, even when increasing the Ortec 571 Amplifier gain to 1K and the fine gain to maximum.

We checked the faraday cup upstream from the bending magnet, FC-4 = 100pA.

We also checked the faraday cup just upstream from the chamber, FC-0 = 53 pA.

The Ortec 571 Amplifier settings (for pin diode) were:

Fine gain = Max

Course gain = 1K

Shaping time = 0.5us

Input = Neg

BLR AUTO ON

Uni Output taken with Out setting

The Ortec 935 Quad CFD CH4 threshold was = 175mV

At 20:50 we sent 3.0 MeV of 7Li beam onto CH2 930ug/cm2 Target VII. We started the DAQ whilst writing to disk.

The DAQ dead time ~ 3%, Trigger rate ~ 1500 Hz, Event Mult. = 6.2.

The save path and name: /Remote_Objs/RData_1/180221205456

It became apparent within the first 1/2 hour that the trigger rate (1500 Hz) is almost entirely from the pin diode.

At 22:10 we stopped the DAQ data collection, run time = 01:19:46, dead time = 4%, # of Good Events = 7180956.

We checked the current on FC-0 = 53 pA.

The beam voltage ~1.2730 MV.

Checking the detectors: The pin diode voltage = -70V, leak I = 0.00uA. The S2 bias = -130.3V, leak I = 1.46uA. Both detectors were switched off for the night.

At 22:18 the pressures in the chamber are:

TPU1 = 3.4e-6mBar

TPU2 = 7.5e-7mBar

TPD1 = 1.5e-6mBar

TPD2 = 1.8e-6mBar

CHUP = 6.1e-6mBar (also referred to as Up)

CHDW = 1.6e-5mBar (also referred to as Down)

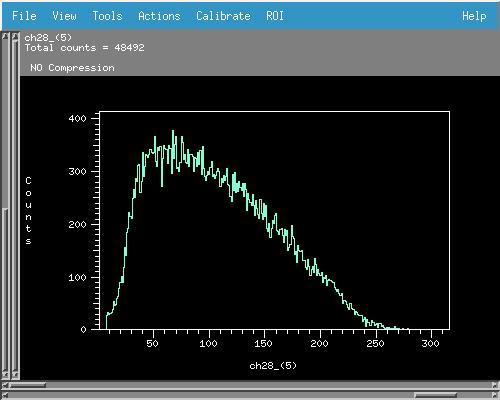

See attached "180221_PinDiode.png" for the pin diode spectrum after the run. In the morning of 22/02/2018 we realised this was just amplified noise.

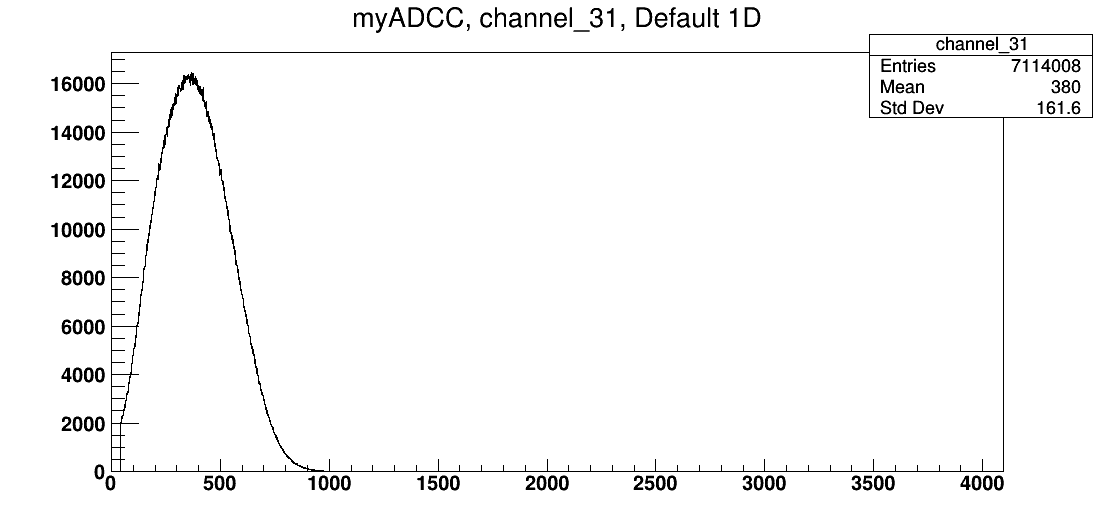

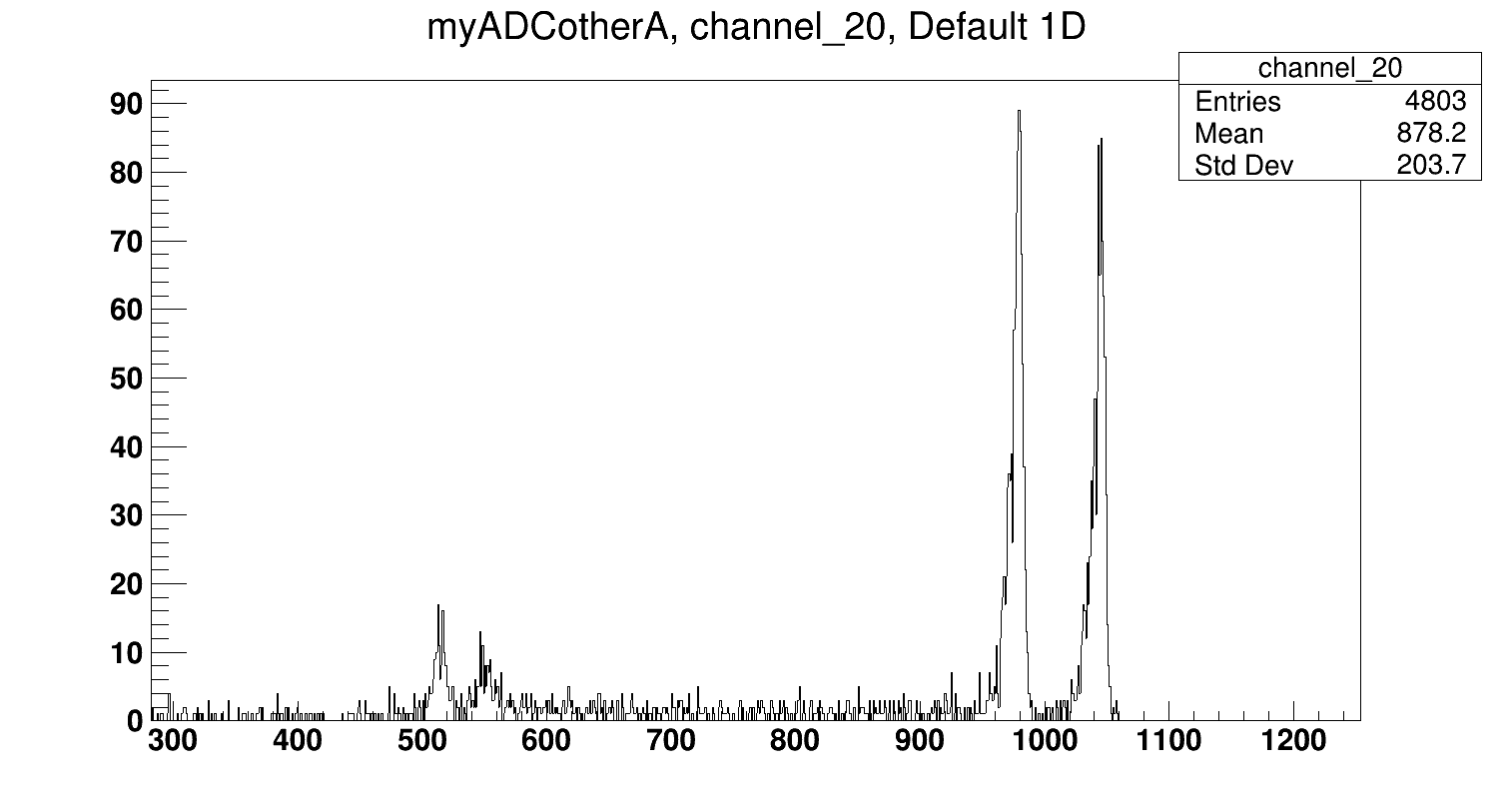

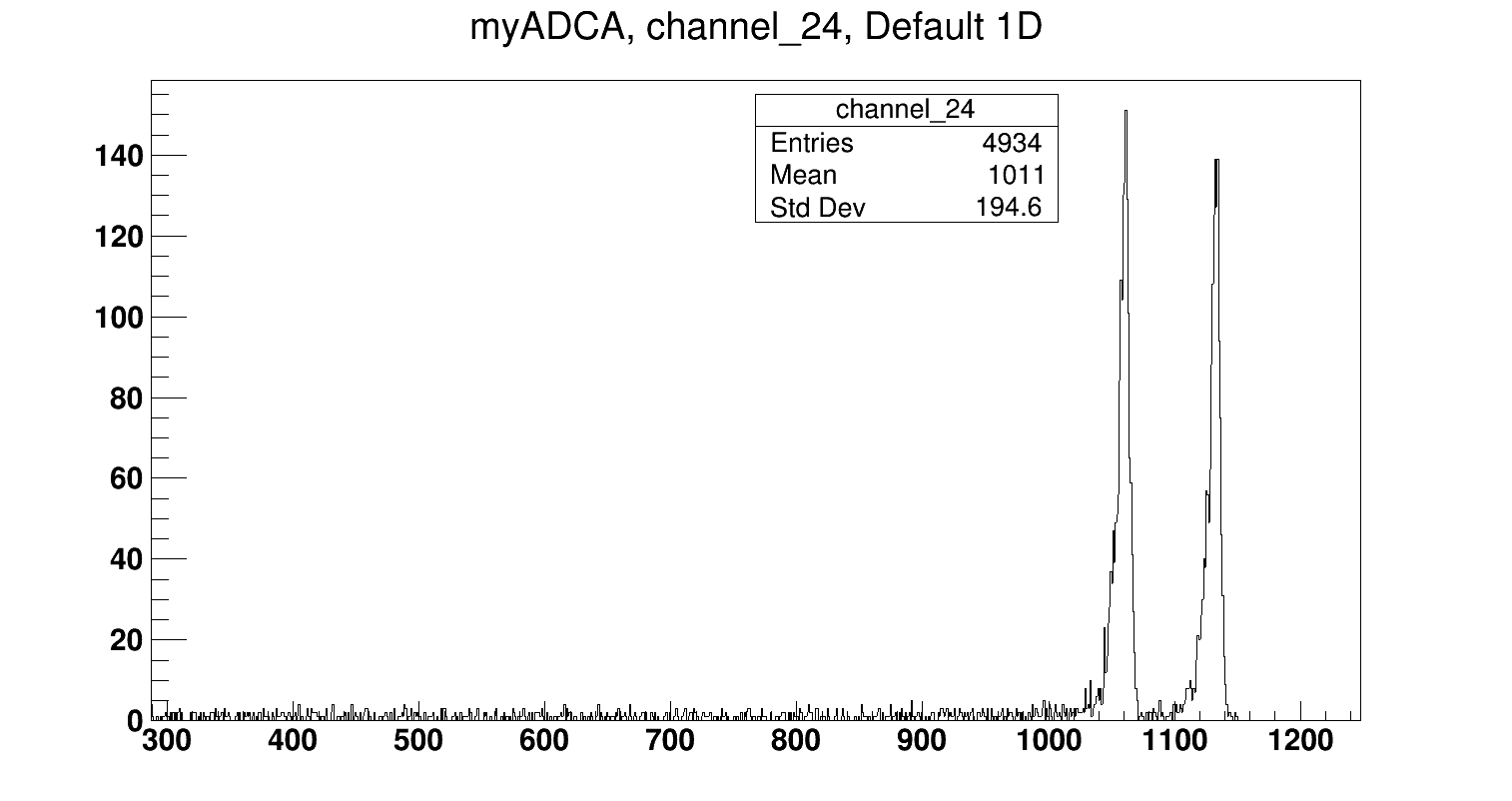

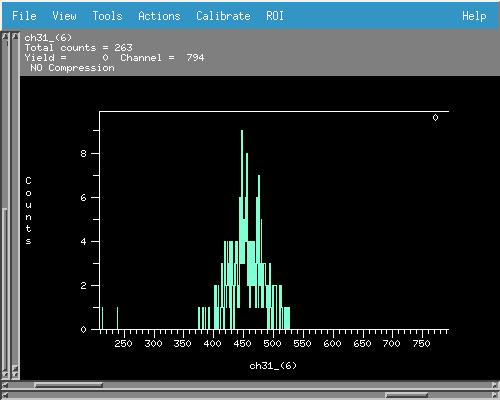

See attached "180221_S2BackStrip_ADC4CH24.png" for a sample spectrum of one of the S2 back strips

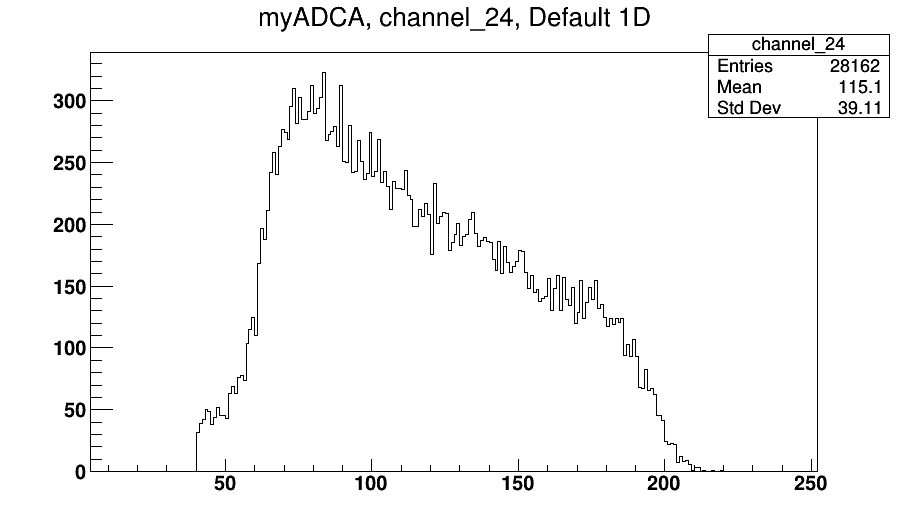

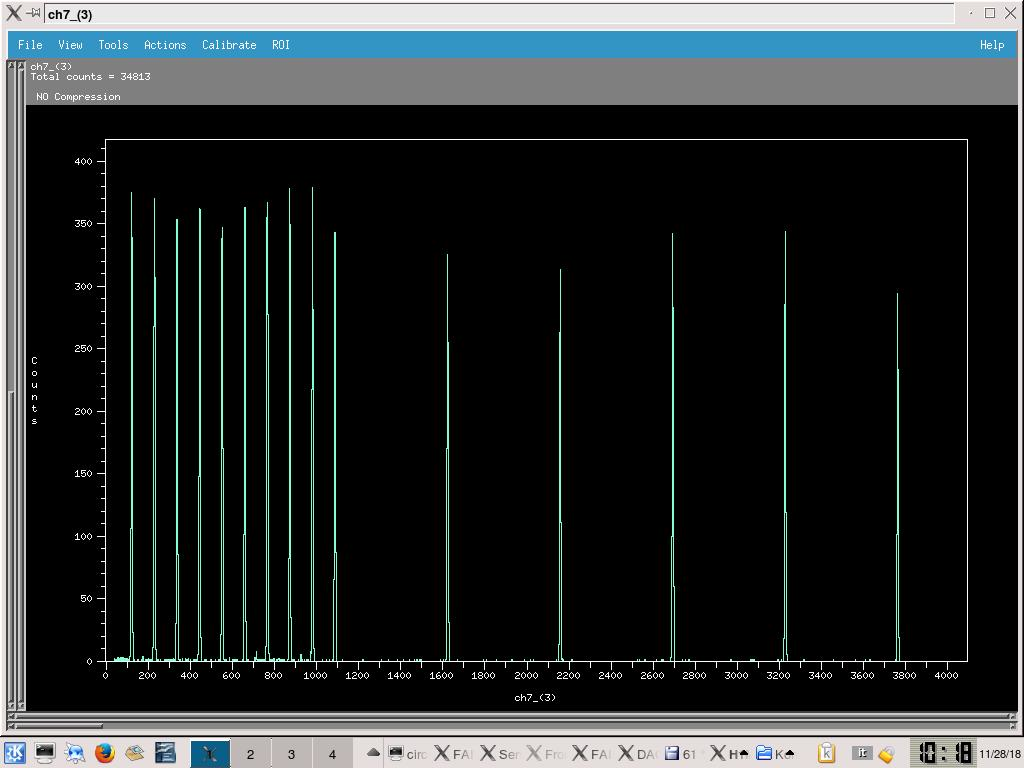

See attached "180221_S2BackStrip_ADC2CH7.png" for a sample spectrum of one of the S2 front strips |

| Attachment 1: 180221_PinDiode.png

|

|

| Attachment 2: 180221_S2BackStrip_ADC4CH24.png

|

|

| Attachment 3: 180221_S2FrontStrip_ADC2CH7.png

|

|

|

17

|

Thu Feb 22 18:04:12 2018 |

Thomas Chillery, Raffaele Buompane, David Rapagnani, Lucio Gialanella | Measurement - 3.0MeV 7Li on CH2 Target VII | Yesterday (21st) night we saw this low channel, high rate (1500Hz) noise on the diode spectrum - see eLog entry #15.

This morning the S2 bias was ramped to -130.3V, leak I = 1.43uA. Diode bias ramped to -70.0V, leak I = 0.01uA.

Starting the DAQ with no beam, the trigger rate is ~250 Hz, with most triggers coming from the diode. Inspecting with the oscilloscope we find a very high noise of ~300mV. The amplifier course gain = 1K.

Lowering the course gain to 200 we decided to try sending beam on target VII and check the diode output on the oscilloscope. I was able to see some signals at ~3V, with very low rate ~0.1Hz

I checked the rutherford scattering rate using the Nuclear_Reaction-master.xlsx excel file, sheet "Rutherford Scattering" columns BH and BP. See attached.

With the current collimator radius = 0.5mm, at our scattering angle 152 degrees, we find an expected rate 2.72e-3 particles per second.

We decided to remove the diode collimator, for the 10X10mm diode this would give an expected rate 0.272 particles per second. This is still not ideal, and before the next shifts we should optimise the position of the diode to improve the rates. This is for a beam current ~40pA, so we would benefit from higher beam current too. A rate of 5 - 10 particles per second would be nice. For now we stuck with the current situation.

At 10:52 the S2 and diode biases were switched off. The preamp power was also switched off. The turbos were also switched off. By 11:48 I saw the turbos had stopped spinning and started venting the chamber.

Once the chamber was vented we managed to remove the central lid without needing to remove the S2 preamp box on the downstream lid.

The 1mm diameter collimator was removed from the diode, this completely destroyed the 0.9um mylar in the process. Next shifts we will use a metal plate to glue the mylar in place, avoiding this issue. For now we left no mylar in front of the diode, because this will not be useful until running 7Be beam.

We also decided to remount the alpha source, allowing us to check the diode is functioning as expected. The target ladder configuration is as follows:

| Position |

Target |

| 1 |

Blank 3mm |

| 2 |

No Target |

| 3 |

CH2 VII |

| 4 |

CH2 III |

| 5 |

CH2 VI |

| 6 |

No Target |

| 7 |

Alpha source facing upstream |

After removing the diode collimator the central lid was remounted and at 12:50 the roughing pumps started. At 13:12 the turbos were started.

By 13:53 the pressures read CHUP = 1.2e-5mBar and CHDW = 3.3e-5mBar.

We switched on the preamp power. The S2 bias was ramped to V = -130.3V, leak I = 1.25uA. The diode bias was ramped to -70.0V, leak I = 0.01uA.

The target ladder was moved to position 7 (5.019mm), centering the alpha source in the beam axis and pointing upstream.

We were able to see the two highest intensity alpha peaks in the pin diode spectrum (ADC6 CH31) - so the diode is certainly working

At 14:06 we started an alpha calibration run for the pin diode.We collected data for a preset time 900 seconds. The trigger rate ~80Hz, Event Mult. = 3.0, dead time = 0%.

The save name is: /Remote_Objs/RData_1/180222141134

See attachment PinDiode_AlphaSpectra.jpg for a sample spectrum

The Ortec 871 Amplifier Settings were:

Fine gain = Max

Course gain = 50

Shaping time = 0.5us

BLR Auto On

The Delay Amp 1457 settings were:

Delay: 1us

Range: 10V

Polarity: Pos

At 14:21 the DAQ stopped, # good events = 61406.

Now we were ready to proceed with a beam measurement.

The target ladder was moved to position 3, 65.000mm, target: CH2 930ug/cm2 VII

We still see some alphas from the source, these are 5.1->5.5MeV, and from the kinematics we expect the beam scatters to be ~2.9MeV so there should be no overlap in energy.

I disconnected the pulser from the pin diode (it was set to too high an amplitude to appear on the alpha spectrum) and switched it ON for the S2 front strips. The pulser rate was changed from 10Hz to 2Hz. (Set to 10Hz when diagnosing pin diode)

With no beam trigger rate ~85Hz, event mult. ~ 8.0

We checked the beam at FC-E0, just upstream from chamber, = 45pA

We bombarded CH2 VII with 3.0MeV 7Li beam, trigger rate ~700Hz.

The pin diode rate for backscattered beam was very low, but we do see some counts at channel ~1300, which is expected.

We decided to run for 1 hour and see the rates.

15:00 DAQ started for 3.0MeV 7Li on CH2 930 ug/cm2 target VII

Save file: Remote_Objs/RData_1/180222150540

Trigger rate ~ 550Hz, Event Mult. ~ 6.2, dead time ~4%

Note: from previous tuning and running yesterday (21st) I estimate beam has already bombarded target VII for ~3 hours before starting this run.

At run time = 01:01:09 we have the following areas:

ADC 6 CH31 (pin diode) area between channels 1159->1268 = 285

ADC 4 CH24 (S2 back strip) total area = 7353

ADC 2 CH 3 (front S2 strip) total area = 21647 (2Hz pulser connected)

Ratio of back strip to diode = 76.0

We decided to collect data until 20:00 giving us ~5 hours of data at 3.0MeV.

At DAQ runtime = 03:03:09 we have the following areas:

ADC 6 CH31 (pin diode) area between channels 1159->1268 = 911

ADC 4 CH24 (S2 back strip) total area = 66704

ADC 2 CH 3 (front S2 strip) total area = 22335 (2Hz pulser connected)

ADC 2 CH 7 (front S2 strip) total area = 22734 (2Hz pulser connected) - more statistics than ADC2 channel 3, continued monitoring this channel instead of channel 3

Ratio of back strip to diode = 73.2

Ratio of last ~2 hours runtime = 71.0, so target is degrading

At 19:25 we decided to go to dinner and leave the setup to collect data.

At this time CHUP = 5.4e-6mBar, CHDW = 1.4e-5mBar. S2 bias = -130.3V, leak I = 1.71uA. Diode bias = -70.1V, leak I = 0.00uA.

At 20:50 we returned from dinner. The DAQ was manually stopped.

DAQ monitor:

Run time = 05:49:09

Event mult. = 6.2

Dead time =7%

# good events = 34296773

At the end of data collection the areas are:

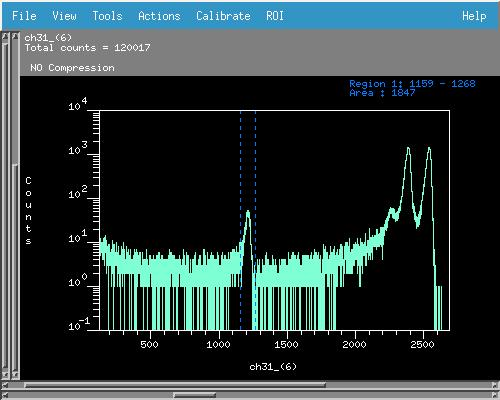

ADC 6 CH31 (pin diode) area between channels 1159->1268 = 1847

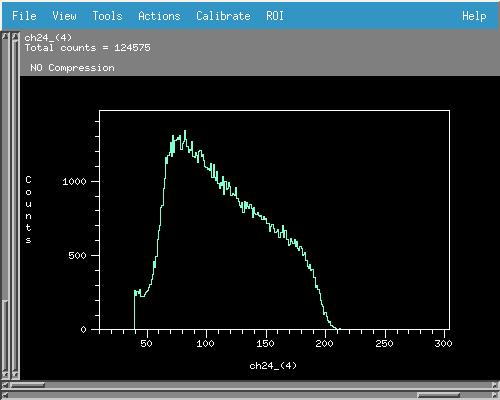

ADC 4 CH24 (S2 back strip) total area = 124876

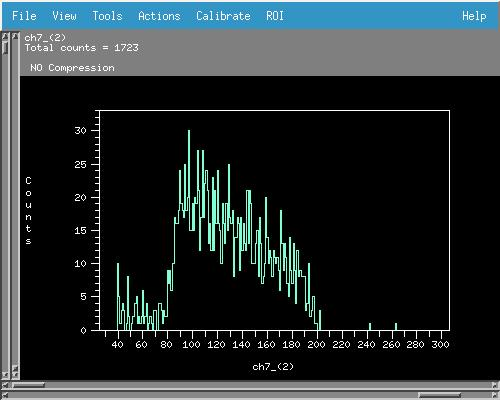

ADC 2 CH 7 (front S2 strip) total area = 43334 (2Hz pulser connected)

Ratio of back strip to diode = 67.6

Ratio of last ~ 3hours = 62.1 - so target is still degrading

The S2 bias = -130.3V, leak I = 1.75uA. S2 Bias ramped OFF

The diode bias = -70.1V, leak I = 0.00uA. Diode bias ramped OFF

Preamp power OFF

At 20:53 the pressures read:

TPU1 = 2.5e-6mBar

TPU2 = 6.4e-7mBar

TPD1 = 1.6e-6mBar

TPD2 = 1.6e-6mBar

CHUP = 5.2e-6mBar

CHDW = 1.3e-5mBar

See attached 180222_diode.jpg for the final diode spectrum.

See attached 180222_ADC4CH24.jpg for the final S2 back strip spectrum

See attached 180222_ADC2CH7.jpg for the final S2 front strip spectrum |

| Attachment 1: Nuclear_Reaction-master.xlsx

|

| Attachment 2: 180222_diode.jpg

|

|

| Attachment 3: 180222_ADC4CH24.jpg

|

|

| Attachment 4: 180222_ADC2CH7.jpg

|

|

| Attachment 5: PinDiode_AlphaSpectra.jpg

|

|

|

27

|

Fri Apr 6 11:39:10 2018 |

Thomas Chillery, Raffaele Buompane, David Rapagnani, Lucio Gialanella | Tests - Pumping down chamber and starting electronics tests | On 04/04/18:

We mounted S2 2323-18 (496um) in the downstream position with 12um mylar

We mount the central and downstream iris arms, we set the central arm position to 14.0mm and the downstream arm position toe 1.5mm - opening both irises.

We started Ecodry 1 and 2, we checked T1600 Backing valves was closed. At 10:11 cracked open the gate valve. After several minutes of pumping Ecodry 1 cutoff, suggesting a big leak.

The downstream chamber lid was sitting at a slight angle, we vented the chamber and reset the downstream aperture to 82.5mm. We removed the downstream aperture. Lifting off the downstream lid we found the O-ring between the lid and collar was not correctly in its groove, this was corrected.

We closed the downstream lid and remounted the downstream aperture. We set the aperture back to 1.5mm (iris open). We closed the turbo vent valves ready for a second venting attempt.

There was a problem with the Labview DAQ, Guiseppe and Raffaele fixed this.

Ecodry 1 and 2 were switched back on, at 11:20 the gate valve was opened. At 11:28 the gate valve was fully opened and pressures read < 1mBar on all 6 gauges. T1600 Backing valves was opened allowing Ecodry 2 to pump on chamber. At 11:31 all 7 turbos were switched on.

During pumping we began mounting the preamp boxes onto the chamber. We discovered the preamp box to be mounted on the central lid needed its holes enlarging to accomodate the bolts for mounting the preamp box to the spacer box.

We mounted the downstream preamp box first, currently holding preamp 2 with the now copper taped preamp - feedthrough signal cable. We then mounted the central preamp box, holding preamp 1 with a copper taped preamp - feedthrough signal cable.

We daisy chained the preamp -15V and +15V cables for the two S2 preamp boxes and the diode preamp, we also daisy chained the +ve test input for the two S2 preamp boxes.

Originally, the central S2 HV was connected to the Silena module CH1, the downstream S2 HV was connected to Silena CH 2, and the diode HV was connected to Silena module CH3.

Powering the diode to -70V, leak I = 0.00uA.

However when powering the S2s to -130V, no leakage current was observed. It turned out the silena CH2 did not work, moving the downstream S2 HV to silena CH4 and powering to -130V reads 1.69uA leakage current.

For the central S2 the problem was found on the respective preamp box. It turned out the SMA connection of the BNC->SMA feedthrough was loose, tightening this and powering the central S2 to -130V reads a leakage current of 2.47uA.

The target ladder was set to position VII - alpha source facing downstream.

Checking RAL signals for central detector, RAL X, XII, XIII, R, S, Q all looked good, RAL U CH 6 was dead, RAL W channel 0 and 1 were dead.

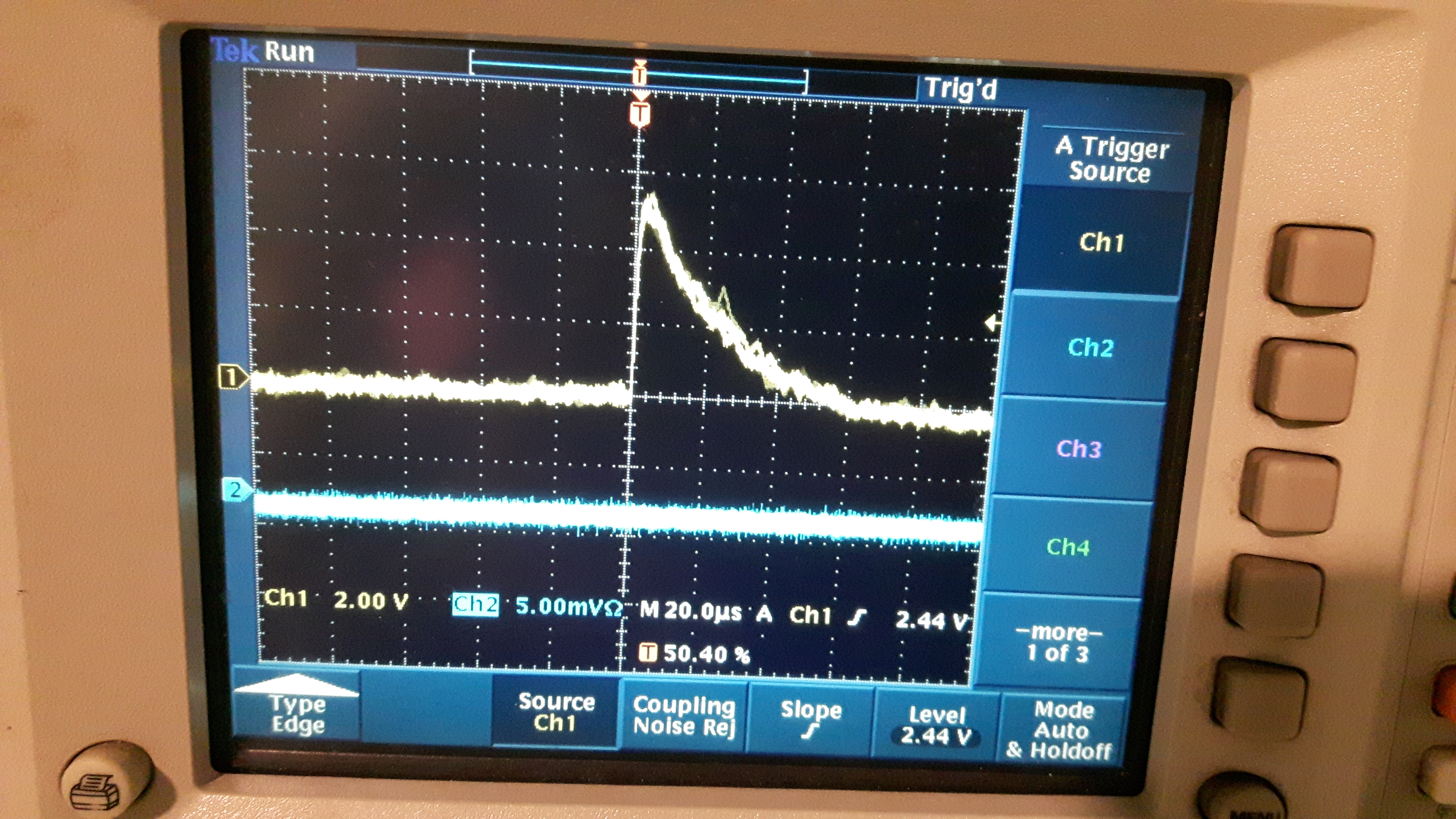

We discovered RAL I (dowsntream S2) showed poor noise, for a 0.2V pulser setting, the amplified signal on RAL I CH 2 was ~5V with noise ~400mV. See 20180404_Pulser_PreampLid_ON.jpg

I emailed Tom Davinson for ideas, he suggested checking what happens when the preamp is disconnected from the vacuum feedthrough.

When the preamp was disconnected from the vacuum feedthrough the amplified signal on RAL I CH 2 was ~1.5V with noise ~40mV. 20180404_Pulser_DisconnectedFromFeedthrough.jpg

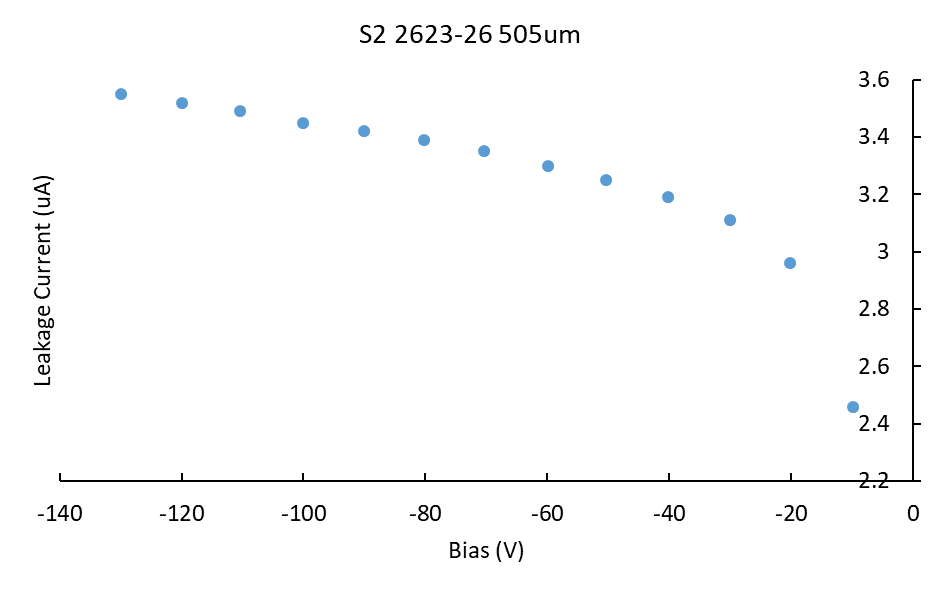

We collected vias vs leakage current curves for the two detectors. See attached S2_2323-18_496um_Bias_Vs_Leakage_Current.png for the downstream S2 and S2_2623-26_505um_Bias_Vs_Leakage_Current.png for the upstream S2.

I suspected the new cable between the downstream S2 and vacuum feedthrough is damaged - perhaps it has a short.

I also checked the central S2, again for a pulser setting of 0.2V RAL X CH 1 showed a 1.2V signal with ~50mV noise, which seemed a better case than for the downstream S2.

The time was 20:20, we decided to stop for the day. The turbos, Ecodry 1 and 2, both S2s, the diode, and the preamp power were switched off ready for dismounting the downstream S2 for a cable change the next day.

|

| Attachment 1: S2_2323-18_496um_Bias_Vs_Leakage_Current.png

|

|

| Attachment 2: S2_2623-26_505um_Bias_Vs_Leakage_Current.png

|

|

| Attachment 3: 20180404_Pulser_PreampLid_ON.jpg

|

|

| Attachment 4: 20180404_Pulser_DisconnectedFromFeedthrough.jpg

|

|

|

18

|

Fri Feb 23 13:15:05 2018 |

Thomas Chillery, Raffaele Buompane, David Rapagnani | Setup - Beam Tuning and Prepare Chamber for Measurement at 3.45MeV 7Li - Night of 22nd | Checking SRIM 3.5 MeV 7Li is stopped in 9.06um mylar or 10.09 um CH2.

After the long run at 3.0MeV on 22/02/2018 we decided to put the 12um mylar back in front of the S2 and start tuning the beam for 3.45MeV 7Li. We also decided to tune the beam to a higher current of ~ 100pA to try and improve the detection rates.

At 20:54 The turbos were switched off. The manual gate valve for Ecodry 2, automatic gate valve for Ecodry 1, and line valves were closed.

Whilst the turbos spun down we removed the S2 preamp box from the top of the chamber.

At 21:31 the vent valve at FC-O was opened. At 21:49 we noticed the chamber was vented.

The S2 was removed from the chamber and 12um mylar mounted in front of it. The S2 was remounted in the downstream section of the chamber.

At 22:03 the manual gate valve was cracked open -> we began roughing the chamber with Ecodry 2. At 22:18 the manual gate valve was fully opened and we then opened the T1600 Backing valve allowing Ecodry 1 to pump the chamber. We then started the turbos.

During pump down the S2 preamp box was remounted on top of the downstream chamber lid. The lid to the preamp box was also mounted. The following pin diode preamp cables were reconnected: -15V, +15V, +ve test, input from lemo feedthrough, and HV.

By 22:34 the pressures in the chamber were CHUP = 1.3e-5mBar, and CHDW = 3.2e-5mBar. The S2 was biased to -130.3V, leak I = 1.54uA. The diode was biased to -70.1V, leak I = 0.00uA. The preamp power was switched on, correct currents were being drawn.

The target ladder was set to position 2, 80.024mm, no target or frame.

After tuning with no target, the GSSI slits were fully open at:

Up = 0mm

Down = 5.5mm

Right = 1.5mm

Left = 5.5mm

We found the following currents:

FC-4 = 740pA (upstream from bending magnet)

FC-0 = 430 pA (upstream from chamber)

FC-E1 = 70pA (downstream from chamber and GSSI magnet)

The target ladder was moved to position I, 95.010mm, blank 3mm frame.

After further beam tuning we obtain currents:

FC-E0 = 330pA

FCE1 ~ 200pA

Transmission: ~63%

At 23:33 CHUP = 6.5e-6mBar, and CHDW = 1.7e-5mBar. S2 bias = -130.3V and leak I = 1.66uA. Diode bias = -70.1V and leak I = 0.00uA.

We decided to call it a day. Both the S2 and diode was switched off for the night. The accelerator beam voltage ~ 1.4730MV.

Raffaele let a note for Liz to improve the transmission to 70% the next morning (23rd).

See next eLog entry #19 to continue the beam tuning adventure. |

|

2

|

Thu Feb 15 17:34:28 2018 |

Thomas Chillery, Raffaele Buompane | Setup - Mounting Target Chamber Sections | This morning both myself and Raffaele mounted the beamline section of the target chamber.

We also mounted the turbo located immediately downstream from the target chamber, see attached IMG_2621.jpg image - the beam will enter from the right of the image

We then mounted the collar section of the target chamber.

We mounted the two linear actuators onto the collar section, which are used to open and close the iris apertures.

These apertures will be essential to stop the beam during beam focussing |

| Attachment 1: IMG_2621.JPG

|

|

|

3

|

Thu Feb 15 17:45:07 2018 |

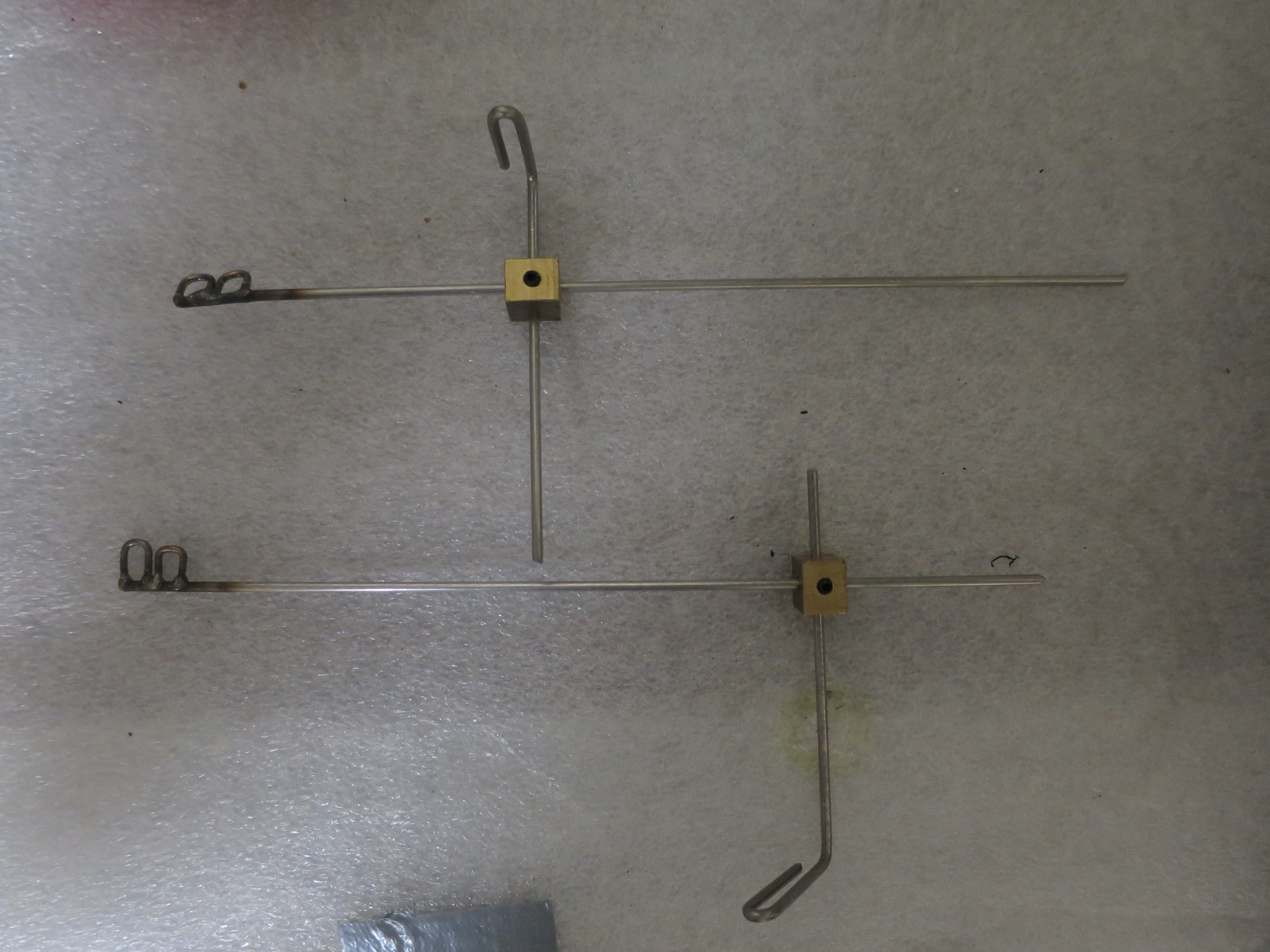

Thomas Chillery, Raffaele Buompane | Setup - Problem: Connecting the actuator arm to the iris aperture arm | After lunch we attempted to connect the actuator arms to the iris arm used to change the iris diameter. We need two iris diameters: fully open for experiment measurements and a 5mm diameter for beam focusing

To do this the original design uses a cuboid with two rods, one rod is connected to the actuator arm, and the other rod is connected to the iris arm with a hook - see attached. The rods were first cut down to fit into the chamber. This would allow us to change the iris diameter whilst under vacuum.

We decided to first check we could connect the hook to the iris in the central section of the target chamber, because this has the most amount of access space. We mounted the iris onto the bottom of the central lid using it's two legs.

After several attempts we could not find a suitable position for the hook and box combination, for several reasons:

1. The cuboid used to hold the metal hook will hit the iris legs at the limits of the actuator arms movement. This means the iris cannot be completely opened or closed. We could close the iris until a diameter of 13mm is left, however the active region of the S2 detectors starts at ~11.5mm diameter so this will not work when focusing the beam.

2. Also if we mount the hook facing upwards (above the cuboid) it is too high to reach the iris arm

3. If we rotate the hook such that it faces downwards (below the cuboid) it now reaches the iris arm. However, the hooks height needs to be adjustable because the iris arm moves vertically as the iris is opened and closed. This is currently not possible as the hook cannot be loosed without falling into the chamber

Note: when the iris is fully opened or closed its arm is at its furthest vertical distance from the chamber lid. When the iris is halfway between open (or closed) its arm is at its closest vertical distance from the chamber lid.

We noticed the cuboid used to hold the two rods is assymetrical and so attempted switching around the two rods, this did not solve the problem.

We then attempted a simpler solution: We replaced the cuboid and two rods with two long screws placed directly in the actuator arms threaded holes, see second attached photo.

The idea being that we can simply move the iris arm with these two screws - there will be some backlash to this technique because the distance between the two screws is larger than the diameter of the iris arm. This should not be a problem because we will only need two positions.

However we found the screws still collide with the iris legs close to the limits of the iris arm movement.

Most importantly: We realised that either the hook or screw technique will both hit the ribbon cable connecting the detector to the vacuum feedthrough, see attached sketch

The central collar of the chamber does have a second position for the actuator arm, however this will hit the Si diode we intend to use to measure the backscattered beam. So this will not work.

At 18:30 we decided to leave the lab and sleep on this problem.

The only solution seen so far is to focus the beam with no detectors mounted. Then after focusing is complete: vent the chamber, mount the detectors, repump the chamber down to vacuum, and remount the preamplifiers on top of the chamber. This would not be optimal but it may be a temporary fix until a better solution is found. |

| Attachment 1: ApertureAdjustmentHooks.JPG

|

|

| Attachment 2: ApertureArm_TwoScrews.JPG

|

|

| Attachment 3: IrisArmProblemSketch.JPG

|

|

|

21

|

Tue Mar 6 15:29:55 2018 |

Thomas Chillery, Raffaele Buompane | Collecting S2 Alpha Calibration Spectra at End of February Test Shifts | On 23/02/2018:

We moved the target ladder to position 7, 5.019mm, with the alpha source facing downsteam.

At 17:17 we started the DAQ for a 15 minute alpha spectrum on the downstream S2. Save name: /Remote_Objs/RData_1/180223172135

The trigger rate ~ 160 Hz, Event Mult. = 5.8, Dead time = 0%

Note: For both this alpha spectrum and the beam measurement at 3.45 MeV 7Li (See entry #20) the pulser test input was also plugged into the diode preamp, hence the pulser peak appears at a lower channel in the S2 spectra. It still does not overlap the alpha peaks.

See attached "180223_Alpha_S2FrontStrip_ADC2CH20.png" for sample alpha spectrum of front S2 strip

See attached "180223_Alpha_S2BackStrip_ADC4CH24.png" for sample alpha spectrum of back S2 strip

In the S2 front strips we observed some additional peaks at lower channels ,~500, to the alpha peaks, but were unsure what they were. We decided to run a background to confirm whether this was caused by the source.

We moved the target ladder to position 1, 95.010mm, to position the alpha source as far from the central beam axis as possible. We then collected a background run for 5 minutes 16 seconds. Save name: /Remote_Objs/RData_1/180223174450.

We did not observe these low channel peaks in the background run, suggesting they are the result of the alpha source - perhaps a geometry effect. |

| Attachment 1: 180223_Alpha_S2FrontStrip_ADC2CH20.png

|

|

| Attachment 2: 180223_Alpha_S2BackStrip_ADC4CH24.png

|

|

|

22

|

Tue Mar 6 15:41:53 2018 |

Thomas Chillery, Raffaele Buompane | Pin Diode Pulser Walkthrough at End of February Shifts | On 23/02/2018:

After the alpha source calibration of the S2 (See eLog entry #21) we decided to perform a pulser walkthrough for the pin diode on ADC 6 CH 31.

The pulser was only connected to the pin diode preamp to ensure it wasnt being split.

Note: Since the pulser is still being 50 ohm terminated the amplitude setting is divided by 2 regardless of any signal splitting. Example: Setting a pulse height of 1.0V on the PB-5 corresponds to an output pulse height of 0.5V.

The pulser settings for this walkthrough were:

Fall Time = 100us

Rate = 10.00Hz

Delay = 250ns

Ampl = varied 1.0V -> 0.25V

Pol = POS

Pulse Top = Tail

Atten = 1X

PB-5 Pulse = ON

CLAMP = OFF

For this test we also needed to change the Delay Amp 1457 delay setting from 1us to 3us to ensure pulses were occuring after the DAQ OR trigger

I collected a DAQ run for the following pulse amplitude settings:

0.1V, 0.15V, 0.2V, 0.25V, and 0.3V

We also attempted 0.05V and 0.07V but were unable to see a clearly defined peak in the spectrum - likely caused by the high level of noise from the CFD we see at the low ADC channels. This should be better optimised at the start of the next shifts.

The save name for this pulser walkthrough is: Remote_Objs/RData_1/180223180747

See attached "180323_PulserWalk_PinDiode_ADC6CH31.png" for the pulser walkthrough spectrum. |

| Attachment 1: 180223_PulserWalk_PinDiode_ADC6CH31.png

|

|

|

23

|

Tue Mar 6 15:55:04 2018 |

Thomas Chillery, Raffaele Buompane | End of February 2018 Shifts | On 23/02/2018:

At the end of the February 2018 shifts the detectors bias settings were:

S2 bias = -130.3V, leak I = 2.42uA

Pin diode bias = -70.1V, leak I = 0.00uA.

Both detectors were switched off, the preamp power was also switched off.

At 18:22 the chamber pressures read:

TPU1 = 2.3e-6 mBar

TPU2 = 6.9e-7 mBar

TPD1 = 1.6e-6 mBar

TPD2 = 1.7e-6 mBar

CHUP = 5.7e-6 mBar

CHDW = 1.5e-5 mBar

We closed the manual gate valve and T1600 Backing Valves. We switched off the turbos and roughing pumps Ecodry 1 and 2.

The nim bin for the quad bias and other nim modules was switched off. The Lecroy 1434A CAMAC Crate was switched off. The RAL shaping amp crate was switched off.

We put away the S2 and pin diode detectors.

The alpha source was removed from the target ladder.

The target ladder was remounted in the following configuration:

| Position |

Target |

| 1 |

Blank 3mm |

| 2 |

No Target

|

| 3 |

CH2 VII |

| 4 |

CH2 III |

| 5 |

CH2 IV |

| 6 |

No Target |

| 7 |

No Target |

We performed a general tidy-up around the chamber and workspaces we used during the past 9 days.

I took the PB-5 Pulse Generator and three 64 Way - 2X32 Way ribbon cables (for minor modification) back to Edinburgh.

I also took the mylar we discovered in the beamline on Tuesday 20th as a keepsake/ reminder anything can happen

At ~20:00 we declared victory for the week. |

|

31

|

Thu Apr 12 12:47:04 2018 |

Thomas Chillery, Raffaele Buompane | Central S2 Alpha Calibration | Date: 06/04/2018

We connected the analogue signals of RAL X, XII, XIII, and "R" to the 3rd ADC (Module 4)

We connected the analogue signals of RAL "S", "Q", "u", and "w" to the 4th ADC (Module 5)

We set the DAQ or to come from the central S2 and the diode monitor. The downstream S2 was not connected to the DAQ

At 15:14 we started the DAQ, a message appeared: Performing Automatic Clear. After a few seconds this message disappeared

At 15:15 we restarted the DAQ for a 15 minute alpha calibration, 241Am + 239Pu alpha source facing downstream, save name: RData_1/180406142007

The dead time = 3%, trigger rate ~ 1100Hz, Even mult = 5.5

At 15:31 the DAQ stopped, # good events = 1278692

The pressures in the chamber were:

- TPU1 = 3.0e-6 mBar

- TPU2 = 8.2e-7 mBar

- TPD1 = 1.6e-6 mBar

- TPD2 = 1.7e-6 mBar

- CHUP = 1.0e-5 mBar

- CHDW = 2.8e-5 mBar

The detector bias and leak I were:

- Downstream S2 bias = -130.1V, leak I = 2.53 uA

- Central S2 bias = -129.9V, leak I = 16.53 uA

- diode bias = -70.1V, leak I = 0.00 uA

Jeremias needed the alpha source, so after this run we vented the chamber. The detectors and preamps were switched off before starting the venting procedure.

At 16:15 Raffaele and Jeremias removed the target ladder and dismounted the alpha source from position VII. No other changes were made to the ladder.

The ladder was remounted and at 16:19 we started roughing down the chamber. At 16:29 the turbos were started.

At 16:40 the pressures read:

- TPU1 = 1.8e-5 mBar

- TPU2 = 3.8e-6 mBar

- TPD1 = 4.0e-6 mBar

- TPD2 = 5.6e-6 mBar

- CHUP = 1.9e-5 mBar

- CHDW = 5.1e-5 mBar

We were ready to repower the detectors and attempt to run beam on target.

|

|

32

|

Thu Apr 12 13:12:00 2018 |

Thomas Chillery, Raffaele Buompane | 7Li 5.0MeV Beam tests with Central S2 | Date: 06/04/2018 (after 16:40)

We powered the preamps for the two S2 detectors and the diode.

We biased the detectors:

- Downstream S2 bias = -130.1V, leak I = 2.18uA

- Central S2 bias = -129.9V, leak I =16.71 uA

- diode bias = -70.1V, leak I = 0.01uA

The target ladder was set to position II (No target/frame).The downstream iris was closed to 18mm diameter (actuator setting = 82.5mm). The central iris was closed to 18mm diameter (actuator setting = 85.5mm)

We were ready to begin beam tuning with 7Li.

With no beam, DAQ DT = 2%, trigger rate ~ 800Hz, event mult = 3.6. The DAQ OR is from the central S2 and diode.

During the tuning we had a problem with the CSSM valve -> this is needed to operate the CSSM ERNA magnet for bending the beam into the electron suppressed Faraday cup FC-E1, located downstream from the chamber.

Raffaele fixed this by using an older version of the CSSM magnet labview software.

During tuning we cut the beam using the High Energy slits, the final slit positions were 1mm for the Up, Down, Right, and Left

After tuning with no target frame in the beam axis, we had: FC-4 = 138 pA and FC-E1 = 120 pA, Total transmission = 87%

We set the target ladder to position IV, target CH2 III. The central iris was opened (central actuator = 14.0mm).

At 17:50 we started the DAQ for 5.0MeV 7Li 2+ on target CH2 III. The beam current on FC-0 (immediately before chamber) was 118 pA.

- DT = 18%

- Save name: 180406165546

We saw no signal on the diode monitor, however we saw signals on the central S2, during this run we were adjusting the diode monitor CFD threshold to try and see coincidences with the diodes delayed analogue output on an oscilloscope. So this run is invalid for the diode spectrum,

At 18:40 the DAQ was stopped, run time = 00:47:16

We decided to try adjusting the diode analogue gain on the Ortec 571 amplifier

At 18:40 we restarted the DAQ, again for 5.0MeV 7Li on target CH2 III

- Save name: RData_1/180406174522

- In February 2018 the diode course gain = 50, which corresponded to channel 1000 when no mylar was placed in front of the diode. Now we have 0.9um thick (nominal) mylar in front of the diode.

- During this run we increased the course gain of Ortec 571 to 200

- The delay amplifier was adjusted from 1us to 1.5us, however we saw no difference in the diode spectrum, so this was set back to its original value of 1us

We decided to change over to 7Be beam |

|

33

|

Thu Apr 12 14:14:09 2018 |

Thomas Chillery, Raffaele Buompane | 7Be 5.0MeV Beam test with central S2 | Date: 06/04/2018

Before starting this beam test we lowered the channel thresholds on ADC 3 and 4 (modules 4 and 5) from 40 to 8

The diode Ortec 571 settings are:

- Fine gain = MAX

- Course gain = 200

- Shaping Time = 0.5us

The diode Delay Amp 1457 settings are:

- Delay = 1us

- Polarity = POS

- Range = 10V

The diode quad CFD (channel 4) threshold = 196 mV

The PB-5 Pulse Generator settings are:

- Fall Time = 100us

- Rate = 10Hz

- Delay = 250 ns

- Ampl = 1V

- Pol = POS

- Pulse Top = Tail

- Atten = 1X

- Clamp = OFF

(Make sure PB-5 = ON to output pulses)

At 19:14 we started the DAQ for 5.0 MeV 7Be at charge state 2+ on target CH2 III

- Dead time = 5%

- Trigger rate ~ 1.8kHz

- Event mult ~ 22.1

- Save name = RData_1/180406181929

At 19:30 we stopped the DAQ, Real time = 00:15:53, dead time = 5%, # good events = 1936195

See attached images for an example back strip and front strip of the central S2, and also for the diode spectrum

Before finishing for the day we decided to once again try to incorporate the downstream S2 into the DAQ setup, because this should have better angular resolution than the central S2

We opened the downstream iris (actuator setting = 1.5mm)

We plugged in RAL I, II, XI, and IV into ADC 1 (module 2) channels 0 ->31, these are the first 32 channels of the downstream S2 preamp output

Even with no beam the DAQ DT = 92% with event mult = 52.0 --> still have a noise problem with the downstream S2

At 19:41 the pressures read:

- TPU1 = 3.3e-6 mBar

- TPU2 = 9.6e-7 mBar

- TPD1 = 1.5e-6 mBar

- TPD2 = 1.7e-6 mBar

- CHUP = 1.0e-5 mBar

- CHDW = 2.7e-5 mBar

The detector biases were:

- Central S2 bias = -129.9V, leak I = 18.39 uA

- diode bias = -70.1V, leak I = 0.00uA

- Downstream S2 bias = -130.1V, leak I = 2.78uA

We called it a day and at 19:45 the detectors were switched off and the line valve closed for the night |

| Attachment 1: 180406_7Be_5MeV_CentralS2_BackStrip.jpg

|

|

| Attachment 2: 180406_7Be_5MeV_Diode.jpg

|

|

| Attachment 3: 180406_7Be_5MeV_CentralS2_FrontStrip.jpg

|

|

|

67

|

Mon Dec 3 17:51:46 2018 |

Thomas Chillery, Raffaele Buompane | Pulser Walkthrough | On 28/11/2018:

Performed pulser walkthrough, Run # 181128090835

- Run time: 1986s

- Pulser ON, amplitude changed

- Target: None

- Beam: None

- DT ~ 11%

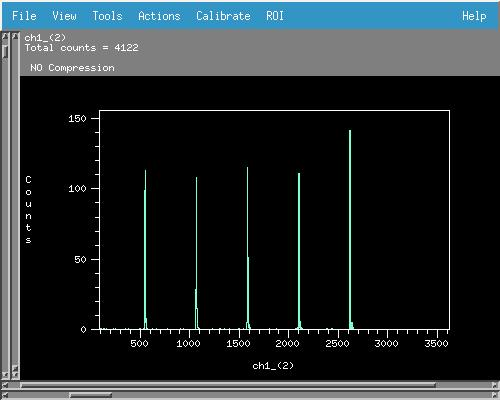

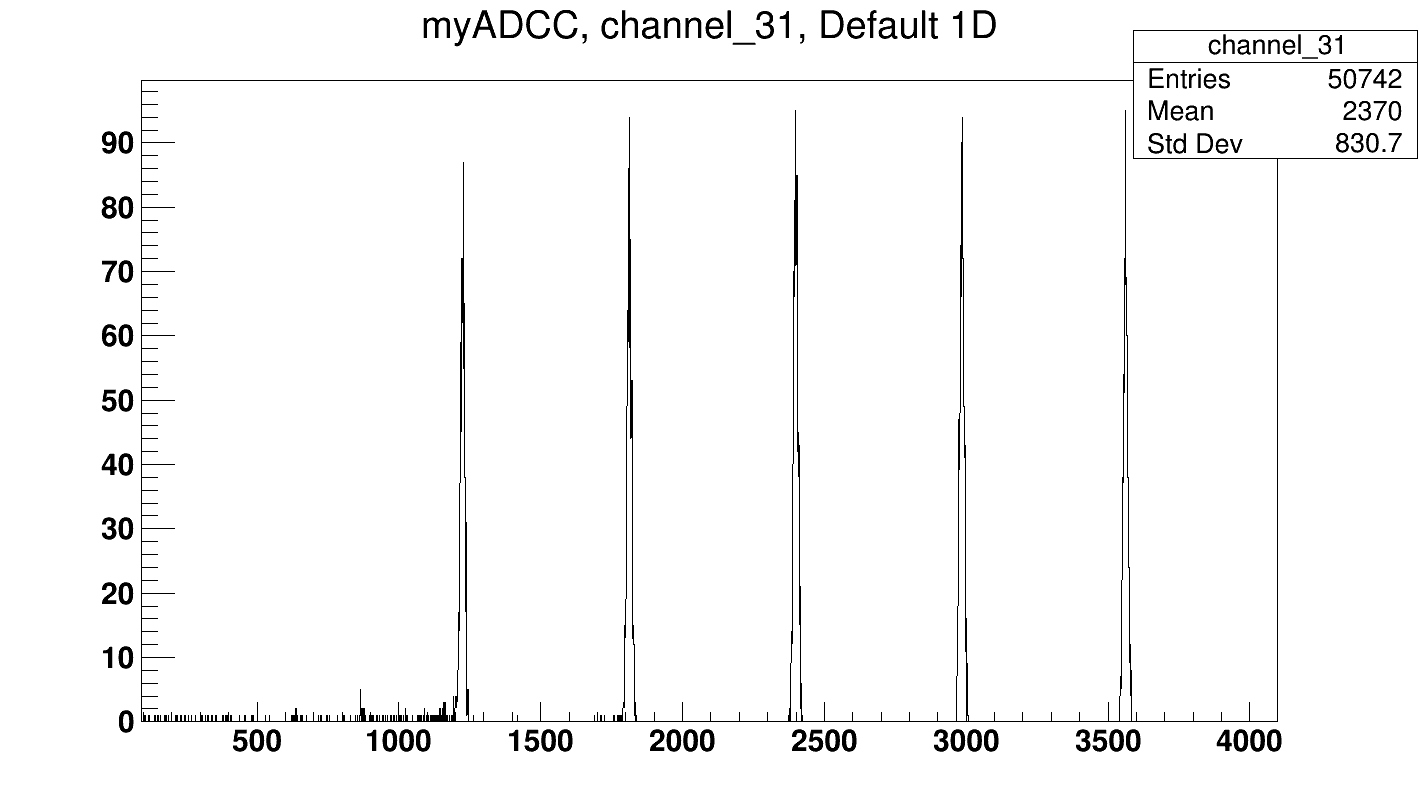

- See attached picture 1 for sample pulser walkthrough spectrum, ADC 2 channel 3 (ADC 3 in DAQ file browser)

Pulser amplitudes swept through (measured amplitude checked after collecting pulser walkthrough to ensure no additional load was placed on pulser):

| Pulser Amplitude Setting |

Pulser Measured Amplitude (mV) |

| 70000 |

366 |

| 60000 |

318 |

| 50000 |

268 |

| 40000 |

206 |

| 30000 |

155 |

| 20000 |

102 |

| 18000 |

92.4 |

| 16000 |

82.8 |

| 14000 |

72.8 |

| 12000 |

62.4 |

| 10000 |

51.8 |

| 8000 |

42.0 |

| 6000 |

32.0 |

| 4000 |

22.0 |

| 2000 |

11.4 |

After walkthough pulser amplitude setting set back to 70000, all other settings left unchanged

Far S2 and diode biases switched off. Preamp power off. Line valve and FCC valve closed. Turbos off. Manual and T1600 backing valves closed. Ecodry 1 and 2 off. Waited for turbos to spin down.

By 10:20 turbos had finished spinning, vented chamber ready to mount alpha source. |

| Attachment 1: 182811_PulserWalkthrough.jpg

|

|

|