| ID |

Date |

Author |

Subject |

|

182

|

Mon Jan 31 08:58:38 2022 |

OH, TD, JM | centos server configuration | Steps taken:

- MIDAS_Releases, Embedded and Exports files brought across from the previously working SL6 aida-gsi install. Brought as tar balls to preserve ownership

- dhcpd.conf set up with same IP addresses as used on the SL6 install from aida-gsi

- nfs-utils package installed on centos7

- Paths to directories listed in /etc/exports checked that they point to the correct locations on the centos system

- Firewall disabled to confirm that it is not interfering

- setenforce 0 to confirm selinux is not interfering.

- Attachment 1 Screenshot of FEE console for aida04 as it stops booting.

- Attachment 2 text dump of /var/log/messages during the FEE boot sequence

- Attachment 3 text dump from tcpdump filtered to aida04

- Attachment 4 /var/lib/dhcp/dhcp.leases file as mentioned in the /var/log/messages dump

- Attachment 5 A copy of dhcpd.conf

- Attachment 6 A copy of /etc/hosts

- Attachment 7 A copy of /etc/exports

- Attachment 8 Text dump of ifconfig -a (Note the FEEs are conencted to p4p1)

From the messages dump it seems there is an issue being encountered with dhcp leases for the static IP addresses of the FEEs. They are then getting assigned new IP addresses which are getting put in the leases file. |

| Attachment 1: 220131_0950_FEE_CONSOLE.png

|

|

| Attachment 2: 220131_0951_logmessages.txt

|

an 31 09:48:40 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d0:05 via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d0:05 via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPOFFER on 192.168.11.3 to d8:80:39:41:d0:05 via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.3 (192.168.11.99) from d8:80:39:41:d0:05 via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.3 (192.168.11.99) from d8:80:39:41:d0:05 via p4p1: unknown lease 192.168.11.3.

Jan 31 09:48:40 carme-gsi dhcpd: DHCPACK on 192.168.11.3 to d8:80:39:41:d0:05 via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:b4:0b via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPOFFER on 192.168.11.5 to d8:80:39:41:b4:0b via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:b4:0b via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d7:cd via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d7:cd via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPOFFER on 192.168.11.8 to d8:80:39:41:d7:cd via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.5 (192.168.11.99) from d8:80:39:41:b4:0b via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPACK on 192.168.11.5 to d8:80:39:41:b4:0b via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.5 (192.168.11.99) from d8:80:39:41:b4:0b via p4p1: unknown lease 192.168.11.5.

Jan 31 09:48:40 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.8 (192.168.11.99) from d8:80:39:41:d7:cd via p4p1: unknown lease 192.168.11.8.

Jan 31 09:48:40 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.8 (192.168.11.99) from d8:80:39:41:d7:cd via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPACK on 192.168.11.8 to d8:80:39:41:d7:cd via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d8:20 via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPOFFER on 192.168.11.6 to d8:80:39:41:d8:20 via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d8:20 via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.6 (192.168.11.99) from d8:80:39:41:d8:20 via p4p1

Jan 31 09:48:40 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.6 (192.168.11.99) from d8:80:39:41:d8:20 via p4p1: unknown lease 192.168.11.6.

Jan 31 09:48:40 carme-gsi dhcpd: DHCPACK on 192.168.11.6 to d8:80:39:41:d8:20 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d7:c2 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPOFFER on 192.168.11.4 to d8:80:39:41:d7:c2 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d7:c2 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.4 (192.168.11.99) from d8:80:39:41:d7:c2 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.4 (192.168.11.99) from d8:80:39:41:d7:c2 via p4p1: unknown lease 192.168.11.4.

Jan 31 09:48:41 carme-gsi dhcpd: DHCPACK on 192.168.11.4 to d8:80:39:41:d7:c2 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:42:0d:0c via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:42:0d:0c via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:b4:16 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:b4:16 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPOFFER on 192.168.11.7 to d8:80:39:41:b4:16 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.7 (192.168.11.99) from d8:80:39:41:b4:16 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.7 (192.168.11.99) from d8:80:39:41:b4:16 via p4p1: unknown lease 192.168.11.7.

Jan 31 09:48:41 carme-gsi dhcpd: DHCPACK on 192.168.11.7 to d8:80:39:41:b4:16 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d8:2b via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPDISCOVER from d8:80:39:41:d8:2b via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPOFFER on 192.168.11.2 to d8:80:39:41:d8:2b via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.2 (192.168.11.99) from d8:80:39:41:d8:2b via p4p1: unknown lease 192.168.11.2.

Jan 31 09:48:41 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.2 (192.168.11.99) from d8:80:39:41:d8:2b via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPACK on 192.168.11.2 to d8:80:39:41:d8:2b via p4p1

Jan 31 09:48:41 carme-gsi rpc.mountd[79344]: authenticated mount request from 192.168.11.3:956 for /home/Embedded/XilinxLinux/ppc_4xx/rfs/aida03 (/home/Embedded/XilinxLinux/ppc_4xx/rfs)

Jan 31 09:48:41 carme-gsi rpc.mountd[79344]: authenticated mount request from 192.168.11.8:675 for /home/Embedded/XilinxLinux/ppc_4xx/rfs/aida08 (/home/Embedded/XilinxLinux/ppc_4xx/rfs)

Jan 31 09:48:41 carme-gsi rpc.mountd[79344]: authenticated mount request from 192.168.11.5:907 for /home/Embedded/XilinxLinux/ppc_4xx/rfs/aida05 (/home/Embedded/XilinxLinux/ppc_4xx/rfs)

Jan 31 09:48:41 carme-gsi rpc.mountd[79344]: authenticated mount request from 192.168.11.6:883 for /home/Embedded/XilinxLinux/ppc_4xx/rfs/aida06 (/home/Embedded/XilinxLinux/ppc_4xx/rfs)

Jan 31 09:48:41 carme-gsi rpc.mountd[79344]: authenticated mount request from 192.168.11.4:985 for /home/Embedded/XilinxLinux/ppc_4xx/rfs/aida04 (/home/Embedded/XilinxLinux/ppc_4xx/rfs)

Jan 31 09:48:41 carme-gsi rpc.mountd[79344]: authenticated mount request from 192.168.11.7:682 for /home/Embedded/XilinxLinux/ppc_4xx/rfs/aida07 (/home/Embedded/XilinxLinux/ppc_4xx/rfs)

Jan 31 09:48:41 carme-gsi rpc.mountd[79344]: authenticated mount request from 192.168.11.2:707 for /home/Embedded/XilinxLinux/ppc_4xx/rfs/aida02 (/home/Embedded/XilinxLinux/ppc_4xx/rfs)

Jan 31 09:48:41 carme-gsi dhcpd: DHCPOFFER on 192.168.11.121 to d8:80:39:41:d0:05 via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPOFFER on 192.168.11.122 to d8:80:39:41:b4:0b via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPOFFER on 192.168.11.120 to d8:80:39:41:d7:cd via p4p1

Jan 31 09:48:41 carme-gsi dhcpd: DHCPOFFER on 192.168.11.118 to d8:80:39:41:d8:20 via p4p1

Jan 31 09:48:42 carme-gsi dhcpd: DHCPOFFER on 192.168.11.119 to d8:80:39:41:d7:c2 via p4p1

Jan 31 09:48:42 carme-gsi dhcpd: DHCPOFFER on 192.168.11.123 to d8:80:39:42:0d:0c via p4p1

Jan 31 09:48:42 carme-gsi dhcpd: DHCPOFFER on 192.168.11.123 to d8:80:39:42:0d:0c via p4p1

Jan 31 09:48:42 carme-gsi dhcpd: Can't create new lease file: Permission denied

Jan 31 09:48:42 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.123 (192.168.11.99) from d8:80:39:42:0d:0c via p4p1

Jan 31 09:48:42 carme-gsi dhcpd: DHCPACK on 192.168.11.123 to d8:80:39:42:0d:0c via p4p1

Jan 31 09:48:42 carme-gsi dhcpd: Wrote 0 deleted host decls to leases file.

Jan 31 09:48:42 carme-gsi dhcpd: Wrote 0 new dynamic host decls to leases file.

Jan 31 09:48:42 carme-gsi dhcpd: Wrote 8 leases to leases file.

Jan 31 09:48:42 carme-gsi dhcpd: DHCPREQUEST for 192.168.11.123 (192.168.11.99) from d8:80:39:42:0d:0c via p4p1

Jan 31 09:48:42 carme-gsi dhcpd: DHCPACK on 192.168.11.123 to d8:80:39:42:0d:0c via p4p1

Jan 31 09:48:42 carme-gsi dhcpd: DHCPOFFER on 192.168.11.124 to d8:80:39:41:b4:16 via p4p1

Jan 31 09:48:42 carme-gsi dhcpd: DHCPOFFER on 192.168.11.125 to d8:80:39:41:d8:2b via p4p1

|

| Attachment 3: 220131_0952_tcpdump.txt

|

[root@carme-gsi MIDAS]# tcpdump host aida04 -vvv -s 192 -i p4p1

tcpdump: listening on p4p1, link-type EN10MB (Ethernet), capture size 192 bytes

09:48:41.015348 IP (tos 0x10, ttl 128, id 0, offset 0, flags [none], proto UDP (17), length 382)

carme-gsi.bootps > aida04.bootpc: BOOTP/DHCP, Reply, length 354, xid 0x37935d60, Flags [none] (0x0000)

Your-IP aida04

Server-IP carme-gsi

Client-Ethernet-Address d8:80:39:41:d7:c2 (oui Unknown)

sname "192.168.11.99"[|bootp]

09:48:41.020188 IP (tos 0x10, ttl 128, id 0, offset 0, flags [none], proto UDP (17), length 382)

carme-gsi.bootps > aida04.bootpc: BOOTP/DHCP, Reply, length 354, xid 0x37935d60, Flags [none] (0x0000)

Your-IP aida04

Server-IP carme-gsi

Client-Ethernet-Address d8:80:39:41:d7:c2 (oui Unknown)

sname "192.168.11.99"[|bootp]

09:48:41.447747 ARP, Ethernet (len 6), IPv4 (len 4), Request who-has carme-gsi tell aida04, length 46

09:48:41.447758 ARP, Ethernet (len 6), IPv4 (len 4), Reply carme-gsi is-at 00:e0:4c:a1:16:af (oui Unknown), length 28

09:48:41.450602 IP (tos 0x0, ttl 64, id 0, offset 0, flags [DF], proto UDP (17), length 112)

aida04.38162 > carme-gsi.sunrpc: [udp sum ok] UDP, length 84

09:48:41.450809 IP (tos 0x0, ttl 64, id 1841, offset 0, flags [DF], proto UDP (17), length 56)

carme-gsi.sunrpc > aida04.38162: [udp sum ok] UDP, length 28

09:48:41.505482 IP (tos 0x0, ttl 64, id 0, offset 0, flags [DF], proto UDP (17), length 112)

aida04.59139 > carme-gsi.sunrpc: [udp sum ok] UDP, length 84

09:48:41.505648 IP (tos 0x0, ttl 64, id 1895, offset 0, flags [DF], proto UDP (17), length 56)

carme-gsi.sunrpc > aida04.59139: [udp sum ok] UDP, length 28

09:48:41.508775 IP (tos 0x0, ttl 64, id 0, offset 0, flags [DF], proto UDP (17), length 68)

aida04.985 > carme-gsi.mountd: [udp sum ok] UDP, length 40

09:48:41.508921 IP (tos 0x0, ttl 64, id 1896, offset 0, flags [DF], proto UDP (17), length 52)

carme-gsi.mountd > aida04.985: [udp sum ok] UDP, length 24

09:48:41.511947 IP (tos 0x0, ttl 64, id 0, offset 0, flags [DF], proto UDP (17), length 148)

aida04.985 > carme-gsi.mountd: [udp sum ok] UDP, length 120

09:48:41.512632 IP (tos 0x0, ttl 64, id 1898, offset 0, flags [DF], proto UDP (17), length 88)

carme-gsi.mountd > aida04.985: [udp sum ok] UDP, length 60

09:48:41.516436 IP (tos 0x0, ttl 64, id 0, offset 0, flags [DF], proto UDP (17), length 68)

aida04.1004 > carme-gsi.nfs: NFS request xid 1193702076 40 null

09:48:41.516487 IP (tos 0x0, ttl 64, id 1902, offset 0, flags [DF], proto UDP (17), length 60)

carme-gsi.nfs > aida04.1004: NFS reply xid 1193702076 reply ok 32 null

09:48:46.461884 ARP, Ethernet (len 6), IPv4 (len 4), Request who-has aida04 tell carme-gsi, length 28

09:48:46.464693 ARP, Ethernet (len 6), IPv4 (len 4), Reply aida04 is-at d8:80:39:41:d7:c2 (oui Unknown), length 46

|

| Attachment 4: 220131_0953_dhcpdleases.txt

|

# The format of this file is documented in the dhcpd.leases(5) manual page.

# This lease file was written by isc-dhcp-4.2.5

lease 192.168.11.118 {

starts 1 2022/01/31 08:48:40;

ends 1 2022/01/31 08:50:40;

cltt 1 2022/01/31 08:48:40;

binding state free;

hardware ethernet d8:80:39:41:d8:20;

}

lease 192.168.11.120 {

starts 1 2022/01/31 08:48:40;

ends 1 2022/01/31 08:50:40;

cltt 1 2022/01/31 08:48:40;

binding state free;

hardware ethernet d8:80:39:41:d7:cd;

}

lease 192.168.11.122 {

starts 1 2022/01/31 08:48:40;

ends 1 2022/01/31 08:50:40;

cltt 1 2022/01/31 08:48:40;

binding state free;

hardware ethernet d8:80:39:41:b4:0b;

}

lease 192.168.11.121 {

starts 1 2022/01/31 08:48:40;

ends 1 2022/01/31 08:50:40;

cltt 1 2022/01/31 08:48:40;

binding state free;

hardware ethernet d8:80:39:41:d0:05;

}

lease 192.168.11.125 {

starts 1 2022/01/31 08:48:41;

ends 1 2022/01/31 08:50:41;

cltt 1 2022/01/31 08:48:41;

binding state free;

hardware ethernet d8:80:39:41:d8:2b;

}

lease 192.168.11.124 {

starts 1 2022/01/31 08:48:41;

ends 1 2022/01/31 08:50:41;

cltt 1 2022/01/31 08:48:41;

binding state free;

hardware ethernet d8:80:39:41:b4:16;

}

lease 192.168.11.119 {

starts 1 2022/01/31 08:48:41;

ends 1 2022/01/31 08:50:41;

cltt 1 2022/01/31 08:48:41;

binding state free;

hardware ethernet d8:80:39:41:d7:c2;

}

lease 192.168.11.123 {

starts 1 2022/01/31 08:48:42;

ends 1 2022/01/31 20:48:42;

cltt 1 2022/01/31 08:48:42;

binding state active;

next binding state free;

rewind binding state free;

hardware ethernet d8:80:39:42:0d:0c;

}

server-duid "\000\001\000\001)\211c\037\000\340L\241\026\257";

|

| Attachment 5: dhcpd.conf

|

#

# DHCP Server Configuration file.

# see /usr/share/doc/dhcp*/dhcpd.conf.example

# see dhcpd.conf(5) man page

#

# 2 days

#default-lease-time 172800;

# 4 days

default-lease-time 345600;

# 8 days

max-lease-time 691200;

option domain-search code 119 = string;

option domain-name "dl.ac.uk";

option domain-name-servers 193.62.115.16, 148.79.80.78;

option netbios-name-servers 148.79.160.89;

option netbios-node-type 8;

option nis-domain "nuclear.physics";

option nis-servers 193.62.115.77;

subnet 192.168.11.0 netmask 255.255.255.0 {

option subnet-mask 255.255.255.0;

option broadcast-address 192.168.11.255;

pool {

range 192.168.11.118 192.168.11.199;

}

}

group {

use-host-decl-names true;

default-lease-time 3600;

max-lease-time 14400;

server-name "192.168.11.99";

next-server 192.168.11.99;

host nnrpi1 {

hardware ethernet dc:a6:32:1d:21:db;

fixed-address 192.168.11.251;

}

host nnrpi2 {

hardware ethernet b8:27:eb:40:53:e8;

fixed-address 192.168.11.117;

}

host aida01 {

hardware ethernet d8:80:39:42:02:0c;

fixed-address 192.168.11.1;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida01";

}

host aida02 {

hardware ethernet d8:80:39:41:d8:2b;

fixed-address 192.168.11.2;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida02";

}

host aida03 {

hardware ethernet d8:80:39:41:d0:05;

fixed-address 192.168.11.3;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida03";

}

host aida04 {

hardware ethernet d8:80:39:41:d7:c2;

fixed-address 192.168.11.4;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida04";

}

host aida05 {

hardware ethernet d8:80:39:41:b4:0b;

fixed-address 192.168.11.5;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida05";

}

host aida06 {

hardware ethernet d8:80:39:41:d8:20;

fixed-address 192.168.11.6;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida06";

}

host aida07 {

hardware ethernet d8:80:39:41:b4:16;

fixed-address 192.168.11.7;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida07";

}

host aida08 {

hardware ethernet d8:80:39:41:d7:cd;

fixed-address 192.168.11.8;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida08";

}

host aida09 {

hardware ethernet d8:80:39:41:f6:ee;

fixed-address 192.168.11.9;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida09";

}

host aida10 {

hardware ethernet d8:80:39:41:ba:89;

fixed-address 192.168.11.10;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida10";

}

host aida11 {

hardware ethernet d8:80:39:41:f6:5a;

fixed-address 192.168.11.11;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida11";

}

host aida12 {

hardware ethernet d8:80:39:41:cf:ac;

fixed-address 192.168.11.12;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida12";

}

host aida13 {

hardware ethernet d8:80:39:42:d:15;

fixed-address 192.168.11.13;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida13";

}

host aida14 {

hardware ethernet d8:80:39:42:d:b;

fixed-address 192.168.11.14;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida14";

}

host aida15 {

hardware ethernet d8:80:39:41:ee:10;

fixed-address 192.168.11.15;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida15";

}

host aida16 {

hardware ethernet d8:80:39:41:f6:ed;

fixed-address 192.168.11.16;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida16";

}

}

subnet 192.168.12.0 netmask 255.255.255.0 {

option subnet-mask 255.255.255.0;

option broadcast-address 192.168.12.255;

pool {

range 192.168.12.100 192.168.12.199;

}

}

group {

use-host-decl-names true;

default-lease-time 3600;

max-lease-time 14400;

server-name "192.168.12.99";

next-server 192.168.12.99;

host aida21 {

hardware ethernet d8:80:39:41:d8:2a;

fixed-address 192.168.12.1;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida21";

}

host aida22 {

hardware ethernet 00:04:a3:2a:d0:26;

fixed-address 192.168.12.2;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida22";

}

host aida23 {

hardware ethernet 00:04:a3:2b:09:ce;

fixed-address 192.168.12.3;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida23";

}

host aida24 {

hardware ethernet 00:04:a3:2b:09:e8;

fixed-address 192.168.12.4;

option root-path "/home/Embedded/XilinxLinux/ppc_4xx/rfs/aida24";

}

}

|

| Attachment 6: hosts.txt

|

127.0.0.1 localhost localhost.localdomain localhost4 localhost4.localdomain4

::1 localhost localhost.localdomain localhost6 localhost6.localdomain6

192.168.11.251 nnrpi1

192.168.11.1 aida01

192.168.11.2 aida02

192.168.11.3 aida03

192.168.11.4 aida04

192.168.11.5 aida05

192.168.11.6 aida06

192.168.11.7 aida07

192.168.11.8 aida08

|

| Attachment 7: exports.txt

|

/home/Embedded/XilinxLinux/ppc_4xx/rfs 192.168.0.0/255.255.0.0(rw,sync,nohide,no_root_squash)

/home/npg/MIDAS_Releases/23Jan19/MIDAS_200119 192.168.0.0/255.255.0.0(rw,sync,nohide)

/MIDAS_130718 192.168.0.0/255.255.0.0(rw,sync,nohide)

|

| Attachment 8: ifconfig.txt

|

enp0s31f6: flags=4099<UP,BROADCAST,MULTICAST> mtu 1500

ether a4:bb:6d:d1:81:9a txqueuelen 1000 (Ethernet)

RX packets 0 bytes 0 (0.0 B)

RX errors 0 dropped 0 overruns 0 frame 0

TX packets 0 bytes 0 (0.0 B)

TX errors 0 dropped 0 overruns 0 carrier 0 collisions 0

device interrupt 16 memory 0x90300000-90320000

enp2s0: flags=4163<UP,BROADCAST,RUNNING,MULTICAST> mtu 1500

inet 192.168.207.142 netmask 255.255.255.0 broadcast 192.168.207.255

inet6 fd43:525a:5249:4e47:d923:1a54:9ea8:e9b1 prefixlen 64 scopeid 0x0<global>

inet6 fe80::4194:b06d:5173:1c42 prefixlen 64 scopeid 0x20<link>

ether a4:bb:6d:d1:7f:ca txqueuelen 1000 (Ethernet)

RX packets 15104702 bytes 22030764707 (20.5 GiB)

RX errors 0 dropped 29 overruns 0 frame 0

TX packets 2199234 bytes 424845717 (405.1 MiB)

TX errors 0 dropped 0 overruns 0 carrier 0 collisions 0

device memory 0x90100000-9017ffff

lo: flags=73<UP,LOOPBACK,RUNNING> mtu 65536

inet 127.0.0.1 netmask 255.0.0.0

inet6 ::1 prefixlen 128 scopeid 0x10<host>

loop txqueuelen 1000 (Local Loopback)

RX packets 1157441 bytes 870407343 (830.0 MiB)

RX errors 0 dropped 0 overruns 0 frame 0

TX packets 1157441 bytes 870407343 (830.0 MiB)

TX errors 0 dropped 0 overruns 0 carrier 0 collisions 0

p4p1: flags=4163<UP,BROADCAST,RUNNING,MULTICAST> mtu 1500

inet 192.168.11.99 netmask 255.255.255.0 broadcast 192.168.11.255

inet6 fe80::74a5:671:a523:2bc5 prefixlen 64 scopeid 0x20<link>

ether 00:e0:4c:a1:16:af txqueuelen 1000 (Ethernet)

RX packets 2283907 bytes 3266470097 (3.0 GiB)

RX errors 0 dropped 0 overruns 0 frame 0

TX packets 256271 bytes 19134505 (18.2 MiB)

TX errors 0 dropped 0 overruns 0 carrier 0 collisions 0

p4p2: flags=4099<UP,BROADCAST,MULTICAST> mtu 1500

ether 00:e0:4c:a1:16:b0 txqueuelen 1000 (Ethernet)

RX packets 0 bytes 0 (0.0 B)

RX errors 0 dropped 0 overruns 0 frame 0

TX packets 0 bytes 0 (0.0 B)

TX errors 0 dropped 0 overruns 0 carrier 0 collisions 0

p4p3: flags=4099<UP,BROADCAST,MULTICAST> mtu 1500

ether 00:e0:4c:a1:16:b1 txqueuelen 1000 (Ethernet)

RX packets 0 bytes 0 (0.0 B)

RX errors 0 dropped 0 overruns 0 frame 0

TX packets 0 bytes 0 (0.0 B)

TX errors 0 dropped 0 overruns 0 carrier 0 collisions 0

p4p4: flags=4099<UP,BROADCAST,MULTICAST> mtu 1500

ether 00:e0:4c:a1:16:b2 txqueuelen 1000 (Ethernet)

RX packets 0 bytes 0 (0.0 B)

RX errors 0 dropped 0 overruns 0 frame 0

TX packets 0 bytes 0 (0.0 B)

TX errors 0 dropped 0 overruns 0 carrier 0 collisions 0

virbr0: flags=4099<UP,BROADCAST,MULTICAST> mtu 1500

inet 192.168.122.1 netmask 255.255.255.0 broadcast 192.168.122.255

ether 52:54:00:9c:18:b1 txqueuelen 1000 (Ethernet)

RX packets 0 bytes 0 (0.0 B)

RX errors 0 dropped 0 overruns 0 frame 0

TX packets 0 bytes 0 (0.0 B)

TX errors 0 dropped 0 overruns 0 carrier 0 collisions 0

virbr0-nic: flags=4098<BROADCAST,MULTICAST> mtu 1500

ether 52:54:00:9c:18:b1 txqueuelen 1000 (Ethernet)

RX packets 0 bytes 0 (0.0 B)

RX errors 0 dropped 0 overruns 0 frame 0

TX packets 0 bytes 0 (0.0 B)

TX errors 0 dropped 0 overruns 0 carrier 0 collisions 0

|

|

181

|

Sat Jan 29 11:04:07 2022 |

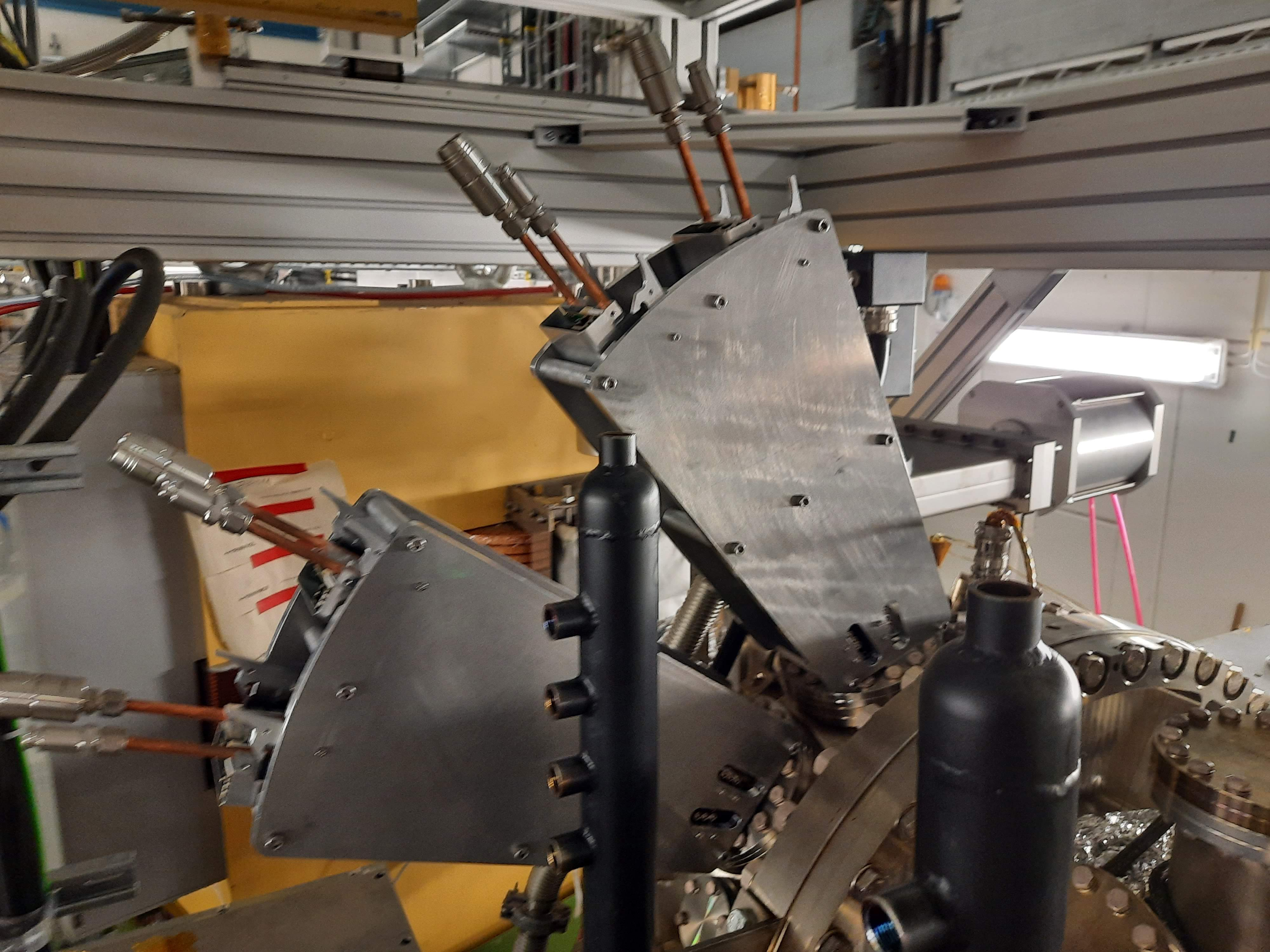

JM, OH | Grounding and Pulser | Grounding

Ground cables have been daisy chained together from FEE to FEE. Ground cables are screwed into a feee bolt hole on the FEE body using an M3 bolt.

LEMO cables have been connected in a similar way between the grounds on the adaptor boards for each FEE. Short LEMO cables go between J6 on pairs of adaptor boards in the same FEE holder and long LEMO cables go between J7 on adaptor boards in different FEE holders.

The LEMO grounds from the adaptor boards and the ground cables attached to the FEE bodies are then connected together and then connected to the CRYRING grounding cable.

Pulser

Jan has kindly lent us a pulser. We send the pulser to an inverter giving us a +ve and -ve signal.

The +ve signal goes into the pn FEEs (1,2,5,6)

The -ve signal goes into the nn FEEs (3,4,78)

LEMO cable connecting FEEs in the same holder using J3 on adaptor board. J4 is used for recieving the pulse signal, connecting FEEs in different holders or terminating the signal. |

| Attachment 1: Silkscreen_Top.pdf

|

|

|

180

|

Thu Jan 27 21:33:40 2022 |

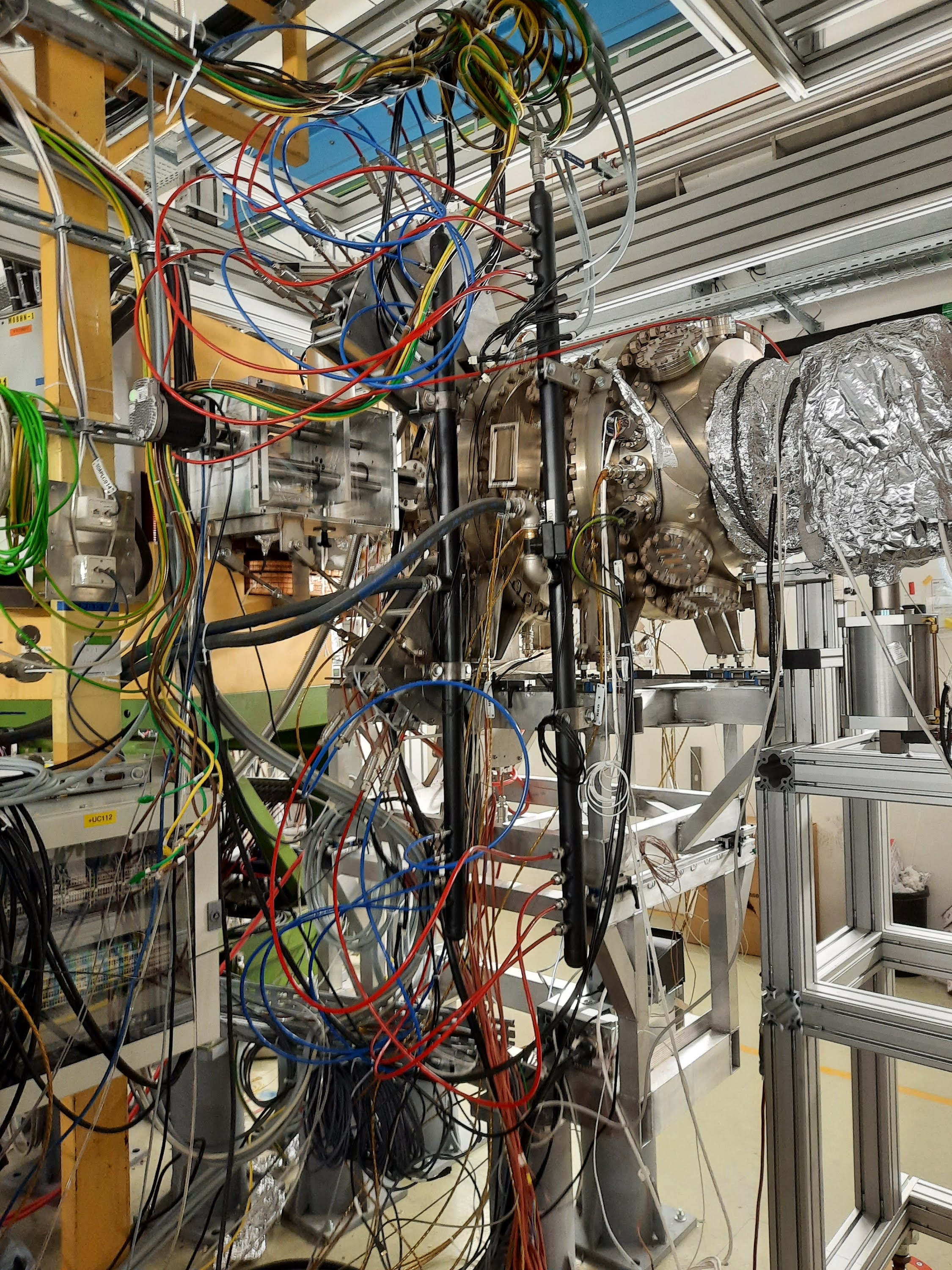

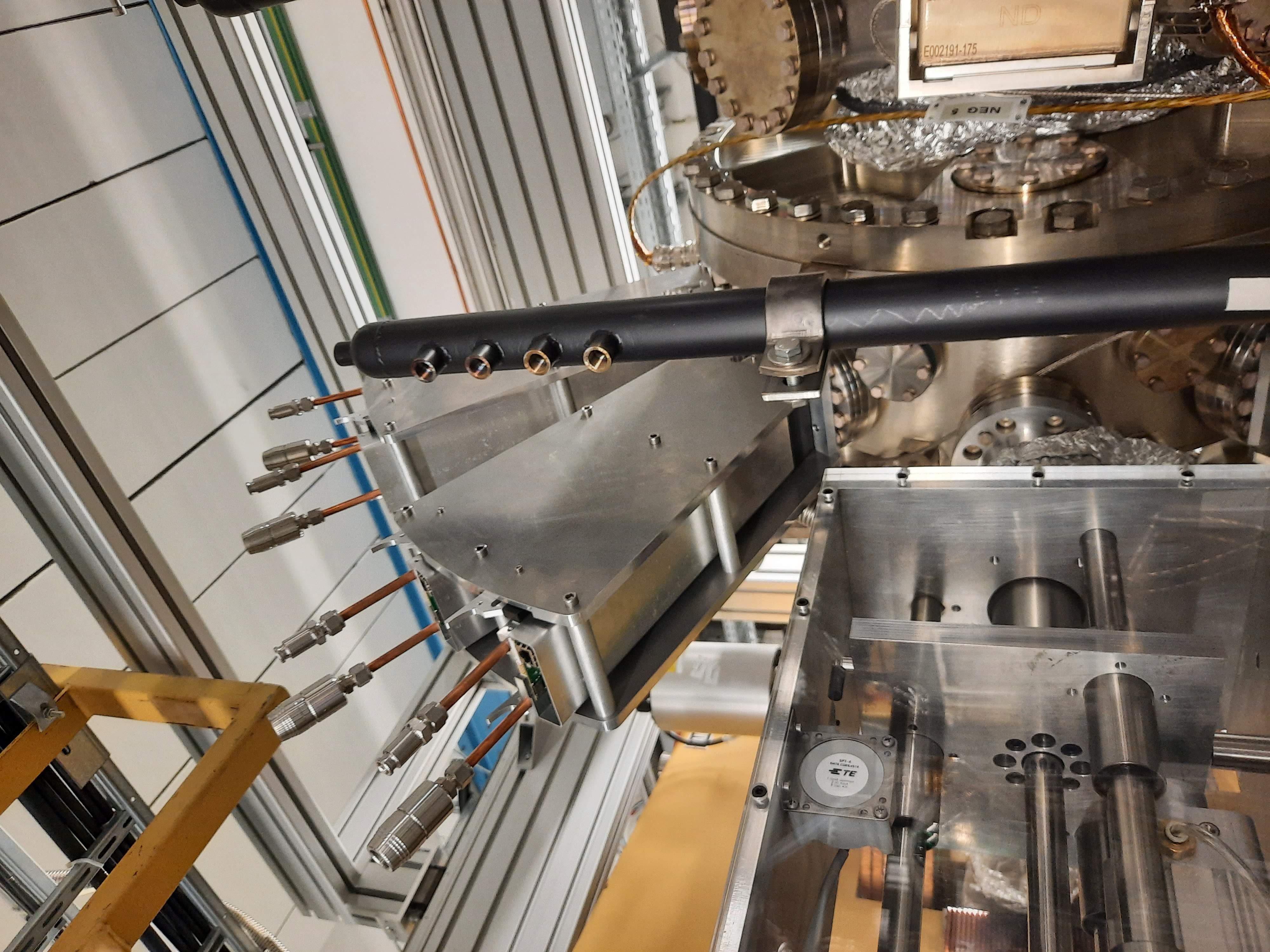

JM, OH | AIDA config files, remote access, motor test | Power, Ethernet and HDMI cables connected to FEEs. To prevent cables coming out of connectors, power and HDMI cables are zip tied to FEE cooling pipe (see attached image).

Correct FEE MAC addresses have been updated in /etc/dhcp/dhcpd.conf

Remote access to carme sever has been setup. Remote access instructions in elogs 176-179.

New ASIC settings which reflect polarity of FEES produced 2022Jan27-16-43-00

New Options file updated to point to new ASIC settings.

/MIDAS/config/TclHttpd/carme-gsi@8015/startup.tcl updated for 8 FEEs

/MIDAS/Linux/startup/NewMerger Updated line from "./master64 -i 16 -l 16 -p 11001 &" to "./master64 -i 8 -l 16 -p 11001 &"

Quick motors test performed. Motors accesible remotely (elog 179). Motors moving output (BNC 1 on motors box) connected to motors module (BNC 1). When not moving +12V is observed at BNC 2 on motors module. When moving 0V is observed on BNC 2. |

| Attachment 1: 20220127_101513.jpg

|

|

|

179

|

Thu Jan 27 15:24:02 2022 |

OH, JM | Access to Motors PI | 1. ssh <user>@lxpool.gsi.de

2. ssh <user or carme>@atppc022.gsi.de

3. ssh pi@CARMEmotorspi (Standard npg password) |

|

177

|

Thu Jan 27 15:19:18 2022 |

OH, JM | Enabling internet access on the carme-gsi server | To use both anydesk and firefox on the carme server require an internet connection.

As the server is on the cryring local network an ssh tunnel needs to be opened to the GSI proxy server.

To do this: ssh -L 8080:proxy.gsi.de:8080 carme@atppc025` and leave terminal open and running.

Both anydesk and firefox have been configured to use the proxy localhost:8080

For the carme password ask J. Marsh or C. Bruno |

|

176

|

Thu Jan 27 14:04:34 2022 |

OH, JM | Remote access to CARME server | 1. ssh into lxpool network: ssh <user>@lxpool.gsi.de

2. ssh into atppc022.gsi.de: ssh carme@atppc022.gsi.de (This is an rpi access server. Don't run code)

3. ssh into carme server: ssh npg@carme-gsi

For the password to the carme user account on the cryring network please contact O. Hall or J. Marsh. |

|

175

|

Wed Jan 26 19:16:18 2022 |

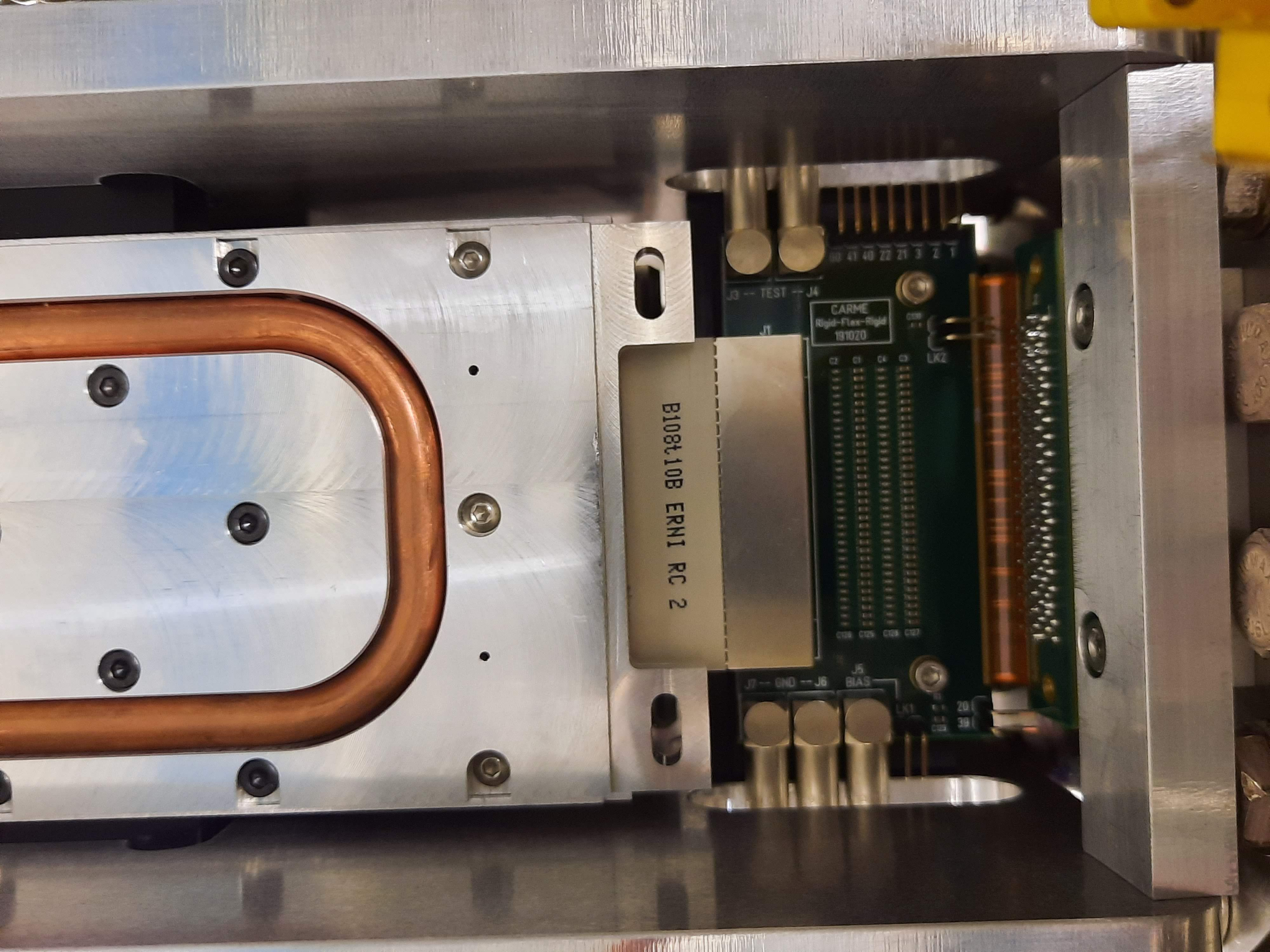

JM, OH | Water cooling, FEE MAC address | Water cooling has been connected to the FEE's. Flow meter installed to outlet manifold by way of two right angled pieces. No leaks observed rom any points in the coolant loop, loop will be bled using taps tomorrow. Water turned OFF overnight.

FEE's powered up with the MAC addresses of each read. 1 is the very bottom FEE and 8 the very top. FEE's have also labelled with the MAC addresses.

1. 0xd8 0x80 0x39 0x42 0x0d 0x0c

2. d8:80:39:41:d8:2b

3. d8:80:39:41:d0:05

4. 0xd8 0x80 0x39 0x41 0xd7 0xc2 (Now AIDA 5 see elog 185)

5. 0xd8 0x80 0x39 0x41 0xb4 0x0b (Now AIDA 4 see elog 185)

6. d8:80:39:41:d8:20

7. 0xd8 0x80 0x39 0x41 0xb4 0x16

8 .0xd8 0x80 0x39 0x41 0xd7 0xcd

MACB firmware has been updated by Nic

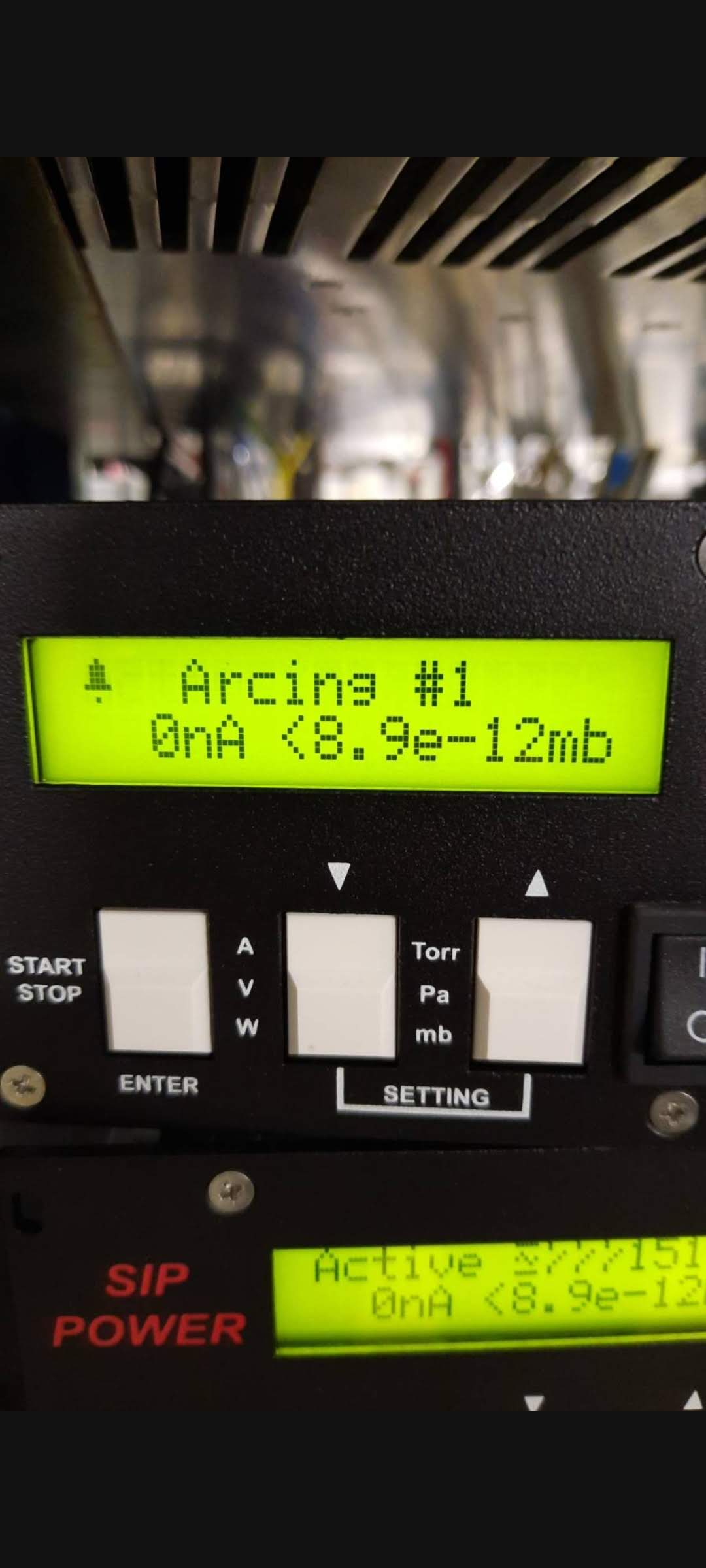

One ion pump showed the warning 'arcing' (see attached photo) and was subsequently turned OFF. Most likely cause is the cable was moved during installlation of the flow meter as the pump showed no error this morning. The pump was turned back ON, no error observed -> cable not damaged but sensitive to movement. |

| Attachment 1: 20220126_162435.jpg

|

|

| Attachment 2: 20220126_162448.jpg

|

|

| Attachment 3: 20220126-142809.jpg

|

|

|

174

|

Sat Jan 15 15:38:25 2022 |

JM, OH, TD | FEE installation, cable management | All 8 FEEs have been installed in their holders.

The damaged feedthrough does not have the D-connector on the adaptor board inserted into the falnge but the FEE is connected to the adaptor board.

FEE's were carefully installed, with one person inserting FEE and another making sure FEE was straight and on the correct pin positions. The spring lock on the bottom FEE's have been tightend and zip ties have been placed to make sure they are secured.

Rack has been populated with cables from the rack to chamber laid out. Cables mostly go above the rack and hang off the large frame. This frame or the CARME frame takes most of the weight of the cables before they are plugged into the FEEs.

Cables are numbered 1-8. Brown ethernet cables are numbered 1-4, green 5,6 and yellow 7,8. Numbers correspnd to Bottom FEE (1,2), Side bottom FEE (3,4), Side top FEE (5,6), Top FEE (7,8)

|

| Attachment 1: 20220114_104819.jpg

|

|

| Attachment 2: 20220114_105152.jpg

|

|

| Attachment 3: 20220114_105213.jpg

|

|

| Attachment 4: 20220115_133808.jpg

|

|

| Attachment 5: 20220115_133820.jpg

|

|

|

173

|

Sat Jan 15 11:28:10 2022 |

JM | Inventory |

Vaccum

DN250CF 1x gaskets

DN200CF 5x gaskets

DN160CF 1x gaskets, 2x blank flanges

DN100CF 69x gaskets, 19x blank flanges, 14 double feedthroughs (1 damaged)

DN63CF 3x gaskets, 2x blank flanges

DN300CF 5x gaskets

DN350CF 0x gaskets

1X WIRE SEAL

DN35CF 3x gaskets, 13 blank flanges

DN16CF 22x silver gaskets, 27x copper gaskets

Swagelock

SS-QTM2-D-8M0 Male quick disconnect X18

SS-QTM2A-B-8M0 Female quick disconnect X21

SS-8M0-1-6RS Manifold adaptor X39

NY-8M3-1 Front ferrule X118

NY-8M4-1 Back ferrule X120

Stainless ferrules XMANY

FEE/FEE HOLDER PARTS

FEES x1

Fully assembled FEE holder (MINUS ADAPTOR BOARDS) x1

Cylindrical supports x32

Feedthrough mounts x12

Black adaptor board mounts x11

Spring loaded FEE lock x26

FEE holder side panels x5 pairs

Adaptor boards x2 (1 slightly bent pins)

FEE rail bolts x4

M3X16 281-013 x91

M3 locknuts 260-5815 x34

Springs 821-273 x40

M4x25 (2mm too long) 281-057 x32

M6x20 281-120 x69

M3x6 280-981 x34

Assembled Hose 1.5M (Red) x8

Assembled Hose 1.5M (Blue) x8

Blue Hose ~16M

Red Hose ~10M

We require additional gaskets for those we are low on (<5) DN35,63,160,250,350 and more wire seals

We should have enough swagelock and FEE holder parts to construct another 4 FEE holders for the remaining required for mounting all moving detector FEEs.

We also need fuses for the USB mains relay and power supply -> 2x 250v 10A, 16x 250v 1.6A. Dimensions for both are the same, length=20mm, Diameter=5mm (images attached)

Additional fittings provided by GSI for the manifold are in the swagelock box. |

| Attachment 1: 20220115_162649.jpg

|

|

| Attachment 2: 20220115_162712.jpg

|

|

|

172

|

Fri Jan 14 10:00:18 2022 |

TD, OH, JM | Friday 14 January |

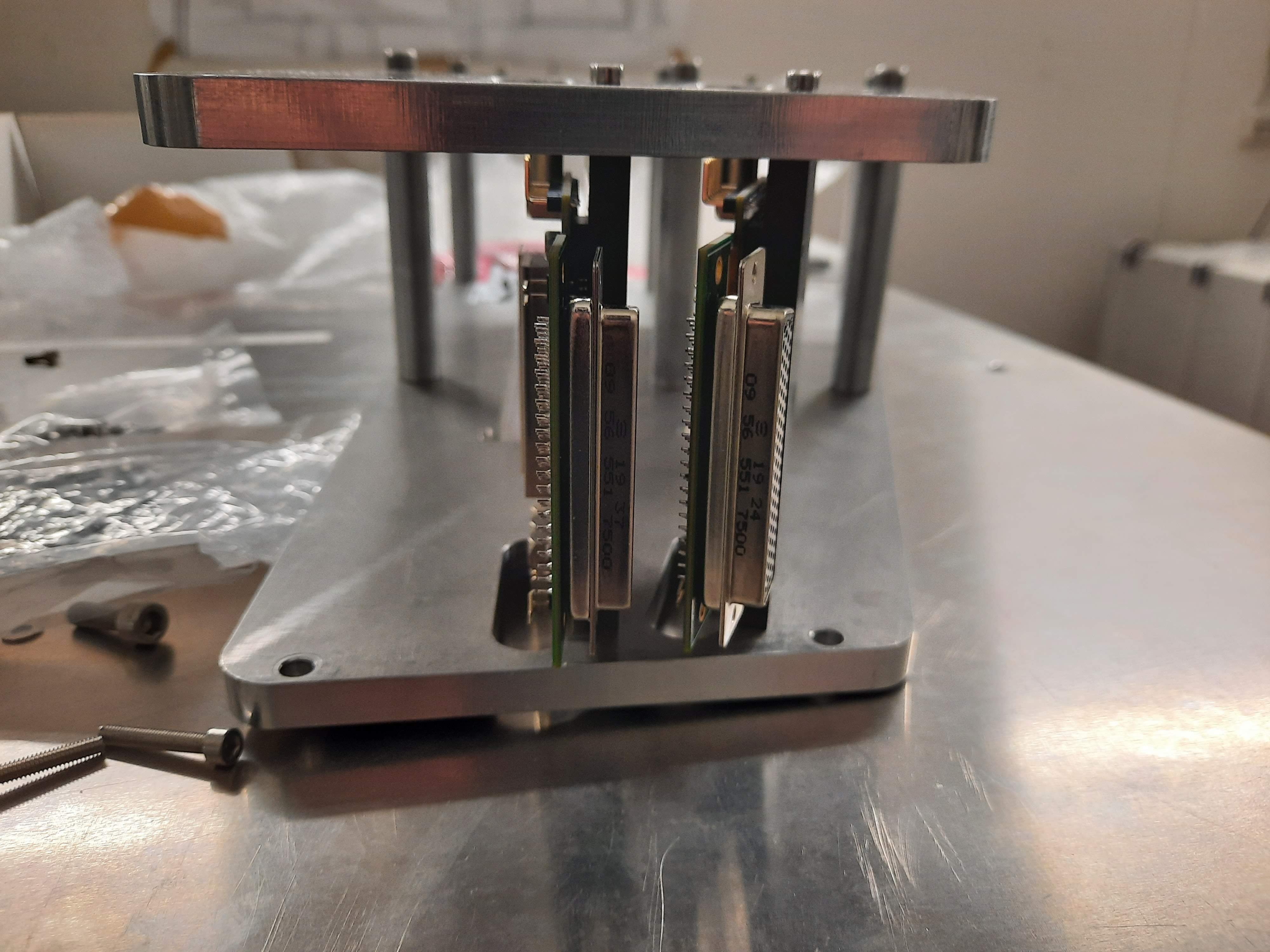

11.00 Per https://elog.ph.ed.ac.uk/CARME/170 and https://elog.ph.ed.ac.uk/CARME/171 issues have been identified with the FEE64 carriers and adaptor PCBs

Some additional comments

1) Per https://elog.ph.ed.ac.uk/CARME/170 attachments 6-9 we can see that there are no cable strain reliefs to which we can attach the FEE64 power, RJ45 network and

timestamp HDMI cabling. It would probably be straightforward to design something which could be attached to the FEE64 carrier side panels. For the time being we will use

the copper piping of each FEE64 as the nearest, mechanically stable point to which we secure the cabling.

2) Before the skimming of 1x Delron rail yesterday there was a small amount (<1mm say?) of transverse movement of the FEE64 during insertion into the carrier and it is

not clear why. Small sample of measurements of FEE64 carriers, spacers etc.

Delron adaptor PCB support widths 92.85, 92.87, 92.90

Al DN100CF flange attachment width 92.97, 92.99, 93.01

Al FEE64 carrier spacing rod 93.03, 93.04, 93.03

FEE64 width (w/ 1x c. 2mm skimmed Delron rail) 100.2, 100.2, 100.3 (3 measurements along the length of the 1x FEE64)

FEE64 carrier width 102.8, 103.0 (2 measurements of 1x FEE64 carrier)

probably indicates that the spacing between the FEE64 plates is consistent. There is some variability (~0.1mm) in the Delron adaptor PCB which could affect the relative

position of the ERNI pins and sockets. Is there some variability in the width of the FEE64s (w/ rails)? |

|

171

|

Thu Jan 13 10:33:24 2022 |

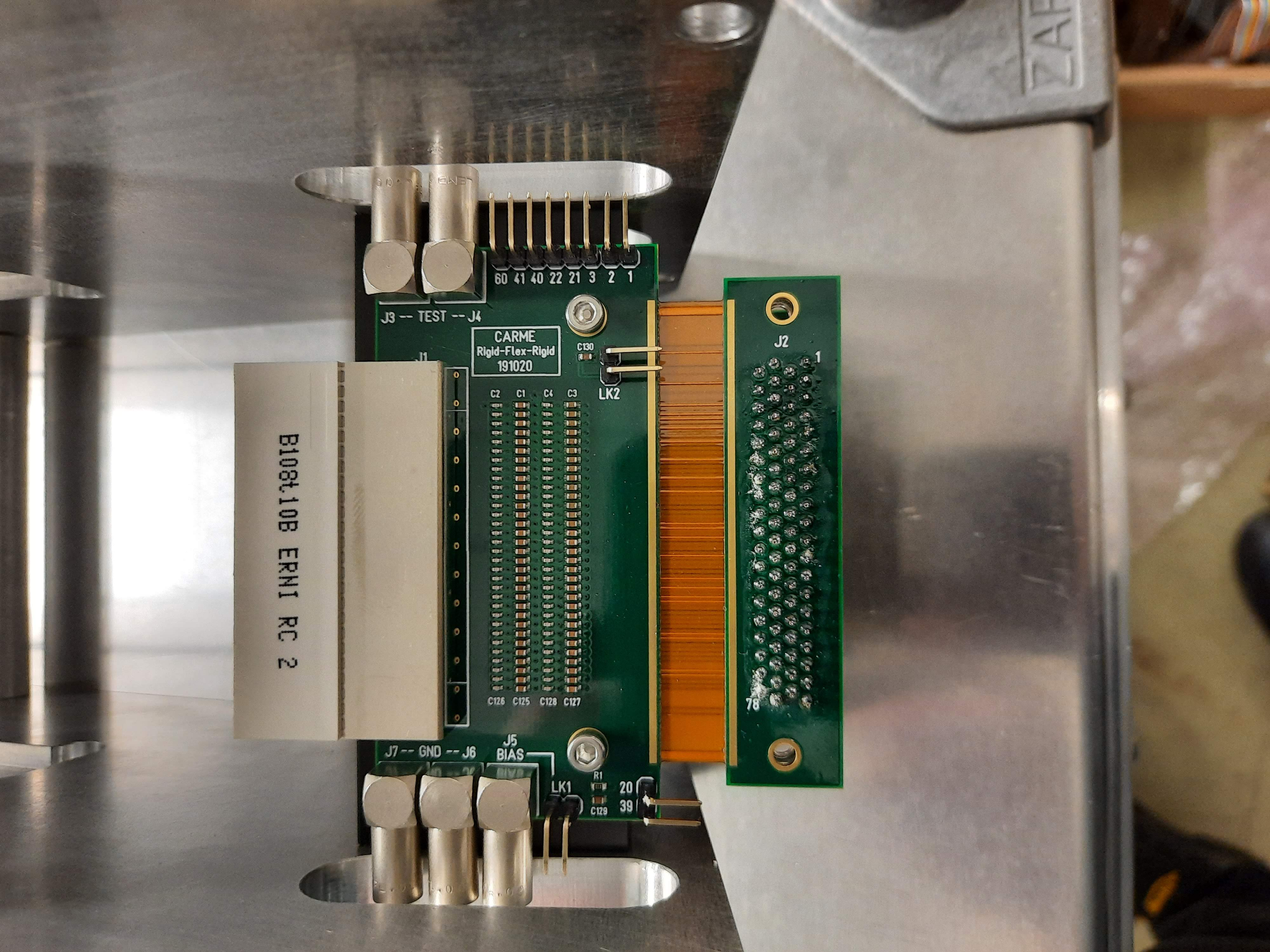

JM, OH, TD | Adaptor Board misallignment | The ERNI connector is not central on the adaptor boards causing misallignment with the FEE.

The adaptor board is 80mm long. The ERNI connector is 50mm long. The connector is 13mm from the 2x Lemo side and 17mm from the 3x Lemo side. This results in misallignment between the FEE and adaptor board.

To correct for misallignment, 2mm will be skimmed from one of the rails on the FEE.

Skimming the rail allows the FEE to now be inserted straight into the adaptor board connector. Attached image shows test FEE holder on the bench. FEE needs to be carefully inserted to make sure it is straight as it can now move around within the FEE holder with the 2mm skimmed off the rails. For CARME, where sight lines and space are limited, one person is required to hold and push in the FEE whilst another checks the positioning of the connectors is straight. |

| Attachment 1: 20220112_160951.jpg

|

|

| Attachment 2: 20220113_145105.jpg

|

|

| Attachment 3: 20220113_145147.jpg

|

|

|

170

|

Wed Jan 12 20:07:20 2022 |

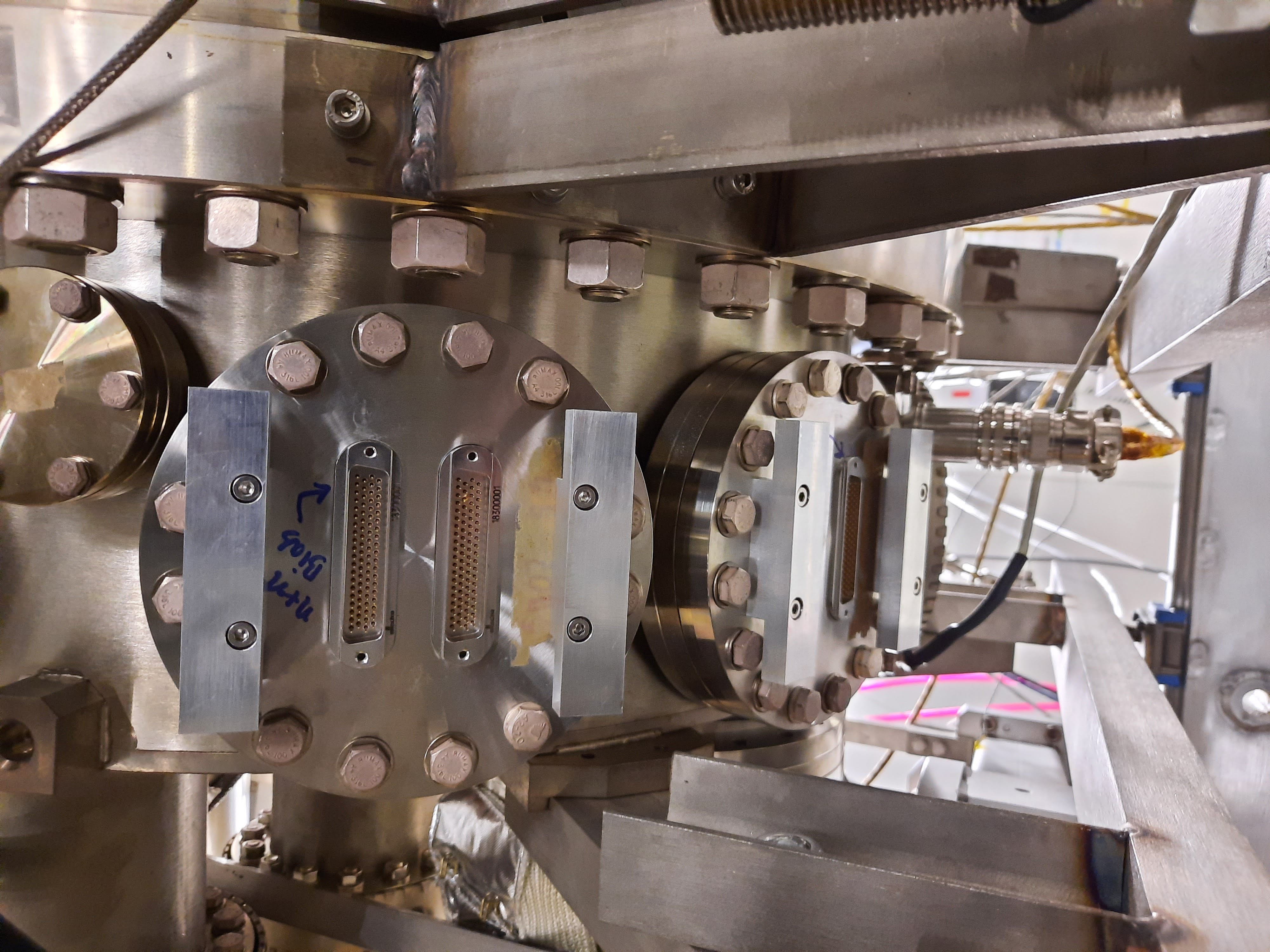

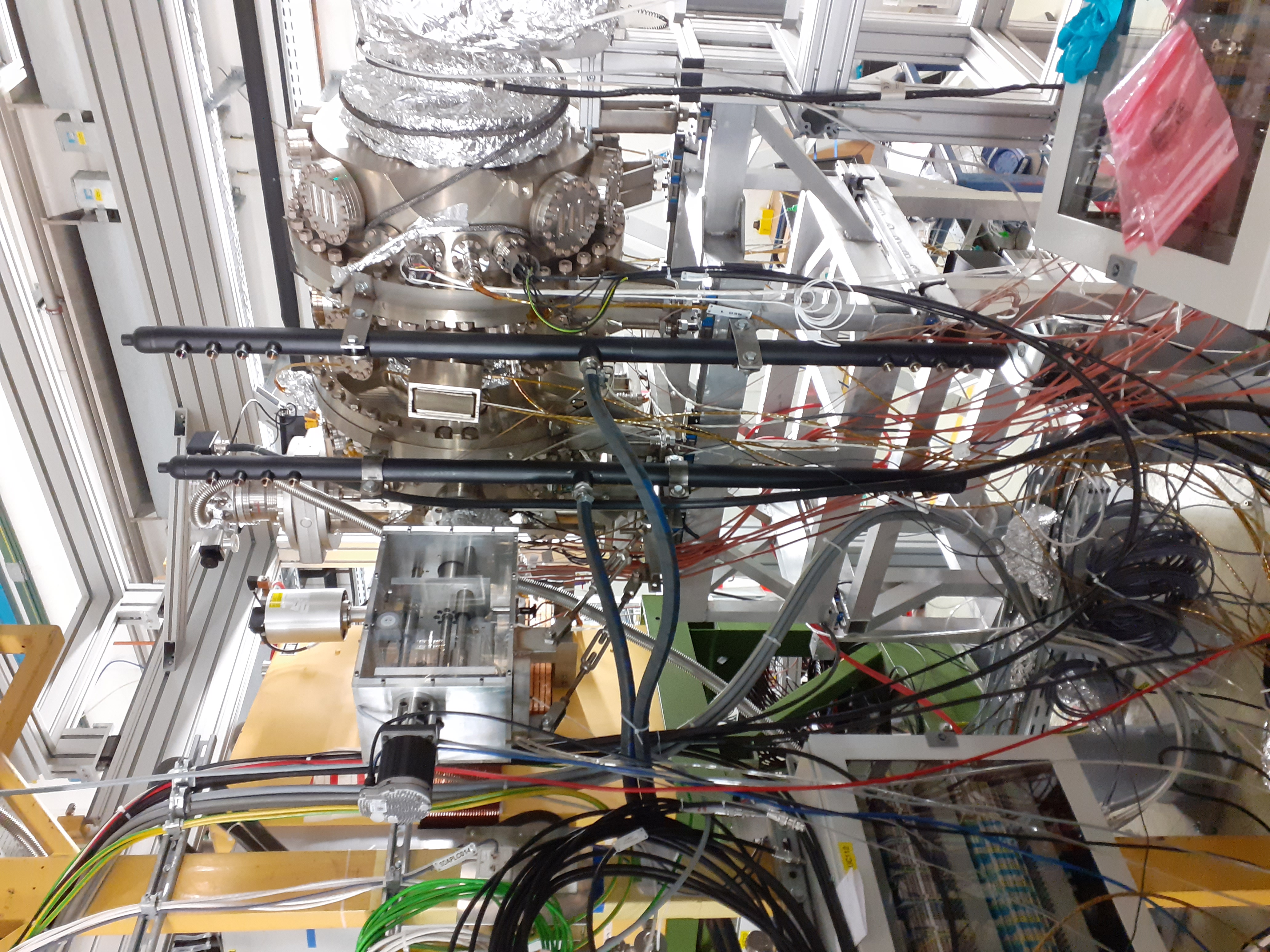

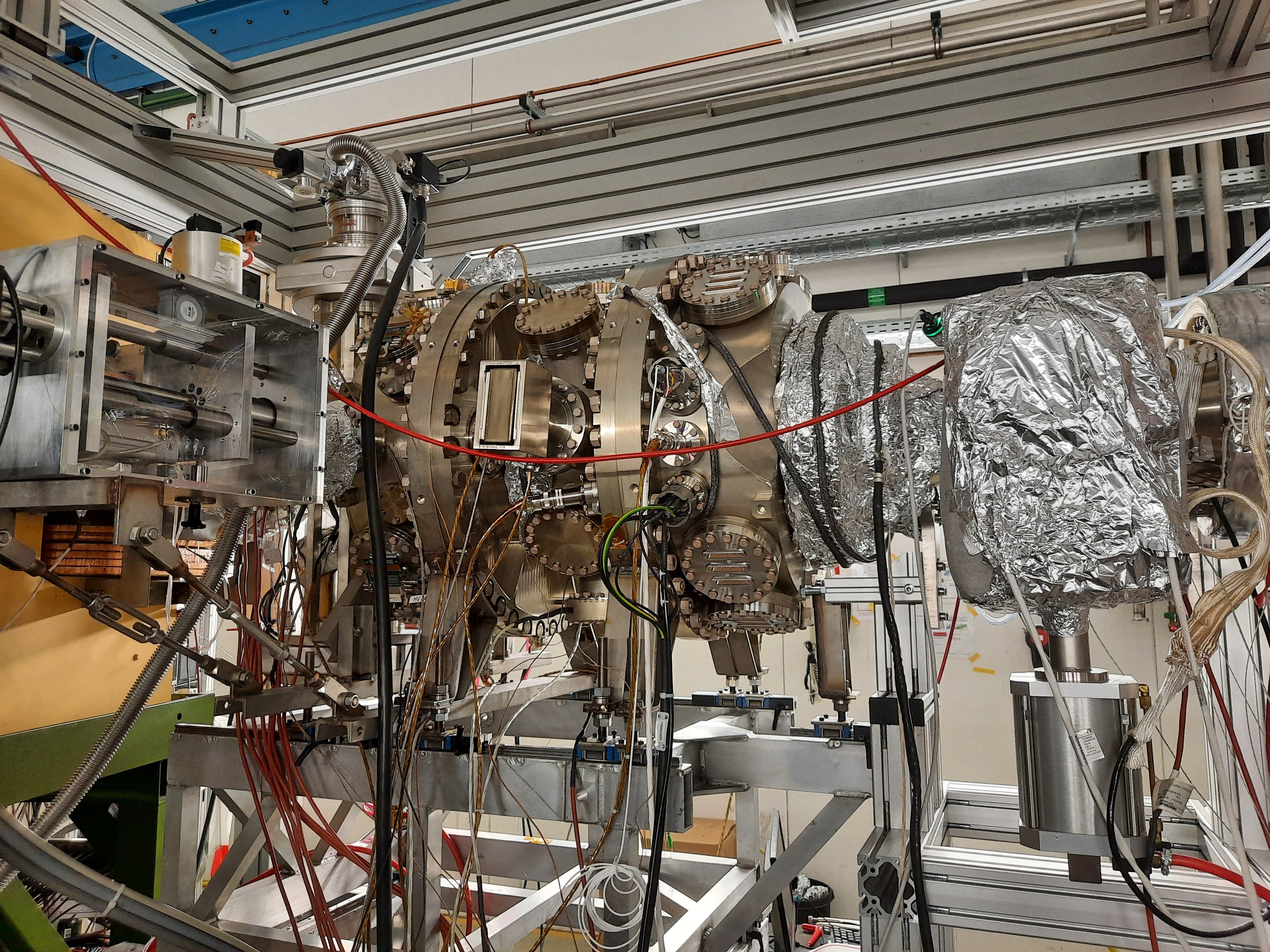

JM, OH, TD | FEE holder installation | 4 FEE holders installed on CARME. Mounting procedure devised due to limited working space to install.

Mounting procedure:

>Install FEE holder mounts (image 1) onto feedthrough flange

>Partially make up FEE holders on workbench. Only 3 cylindrical support rods, spring latches and one of the black adaptor card mounts should be attached to aid install. Bolts should be loose to aid install on CARME.

>Mount FEE holder to flange

>Connect first adaptor card into D connector on feedthrough, then screw adaptor card to black mount.

>Screw in second black adaptor card mount but do not tighten bolts. Connect second adaptor card to D connector and screw to black mount.

>Attach remaining cylindrical supports and tighten all bolts.

Bolts to install FEE holder mount onto flange (M4x25) are 2mm too long for the hole on the flange. Washer were initially used however this prevents adaptor cards being able to be secured onto thier black mounts. Bolts were shortend 2mm by davide to install. 5 shortend bolts remain in addition to thebag of unshortend M4x25 bolts.

On the nn flange of the bottom detector (non bias pin D-connector) the feedthrough is damaged. Damage may be repairable, to prevent further damage an adaptor card was not plugged into this D-connector. (image 1)

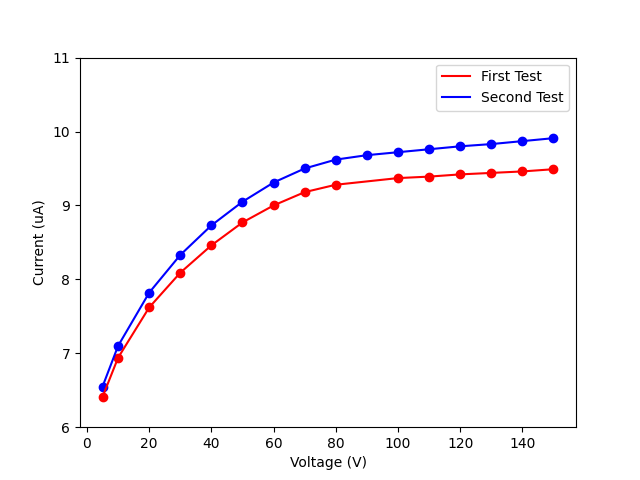

A bias test was performed for the top detector once adaptor cards are installed. First test is the bias test performed prior to adaptor cards being installed, second test was performed after installation of adaptor cards.

Installing FEEs on the outer side of the ring in the future may have some mechanical conflict with the gas target frame, see attached images. |

| Attachment 1: 20220112_134113.jpg

|

|

| Attachment 2: 20220112_155052.jpg

|

|

| Attachment 3: 20220112_160956.jpg

|

|

| Attachment 4: 20220112_161020.jpg

|

|

| Attachment 5: 20220112_161034.jpg

|

|

| Attachment 6: 20220112_170144.jpg

|

|

| Attachment 7: 20220112_170435.jpg

|

|

| Attachment 8: 20220112_165918.jpg

|

|

| Attachment 9: 20220112_170048.jpg

|

|

| Attachment 10: Bias2.png

|

|

|

168

|

Tue Jan 11 12:45:15 2022 |

TD, JM, OH | Coolant manifold installation + detector pin tests | 2x cooling water manifolds with 2x 8 ports have been installed - see attachments 1 & 2

'drain' ports at top of manifold to permit release of trapped air volumes. Local technicians will install a standard blank in one manifold and a small nipple valve on the

other so that we can bleed air in a controlled way.

#Multimeter detector pin tests.

Pins on feedthrough flanges investigated using multimeter for the top and bottom detector due to no response from bottom detector when bias was applied. Bias pins on

correct D connectors are number 78.

#Top detector

>Observe -18.5 kohm; between nn bias pin and pn bias pin (multimeter 200kohm setting)

>observe open line between nn bias pin and pins 'near' pn bias pin (multimeter 200kohm setting)

>Between random pins on same D connector (nn bias pin connector) ~0.02Mohm (multimeter 2Mohm setting)

>Between random pins and unconnected on same D connector (nn bias pin connector) - open line (multimeter 2Mohm setting)

>Between random pins and bias pin on same D connector (nn bias pin connector) ~0.01-0.02 Mohm (multimeter 2Mohm setting)

>Between nn bias pin and random pin on another D connector ~-0.4Mohm (multimeter 2Mohm setting)

#Bottom detector

>Observe open line between nn bias pin and pn bias pin (multimeter 200kohm+2Mohm; setting)

>Observe open line between nn bias pin and pins 'near' bias bias pin (multimeter 200kohm+2Mohm; setting)

>Between random pins on same D connector (nn bias pin connector) ~0.02Mohm (multimeter 2Mohm setting)

>Between random pins and unconnected on same D connector (nn bias pin connector) - open line (multimeter 2Mohm setting)

>Between random pins and bias pin on same D connector (nn bias pin connector) ~0.01-0.02 Mohm (multimeter 2Mohm setting)

>Between random pins on same D connector (pn bias pin connector) ~0.02Mohm (multimeter 2Mohm setting)

>Between random pins and unconnected on same D connector (pn bias pin connector) - open line (multimeter 2Mohm setting)

>Between random pins and bias pin on same D connector (pn bias pin connector) ~open line (multimeter 2Mohm setting)

>Between nn bias pin and random pin on another D connector ~-0.4Mohm (multimeter 2Mohm setting)

We see a similar response for both detectors except that the pn bias pin gives no response.

We have looked to find the bias pin on nearby pins to pin 78 and on the other side of the D connector (in case of cabling error-mirror or swapped cables) but cannot find.

4 FEE holders constructed and ready to install |

| Attachment 1: 20220111_113628.jpg

|

|

| Attachment 2: 20220111_113613.jpg

|

|

| Attachment 3: 20220111_111428.jpg

|

|

|

167

|

Mon Jan 10 20:52:53 2022 |

JM, TD, OH | Baking tent removed, VI tests | Baking tent, frame and trays fully removed from CARME chamber. Removal of baking frame required removing air lines from upper gate valve and repositioning of vacuum hose connecting turbo pump to backing line and turbo power cable. Some difficulty encountered removing upper baking frame now the target support frame is assembled. Small modification seperating section in two would aid future installation and disammebly.

Baking trays removed with difficulty. Main baking tray bent to extract from the frame -> updated design required for future bakeout cycle.

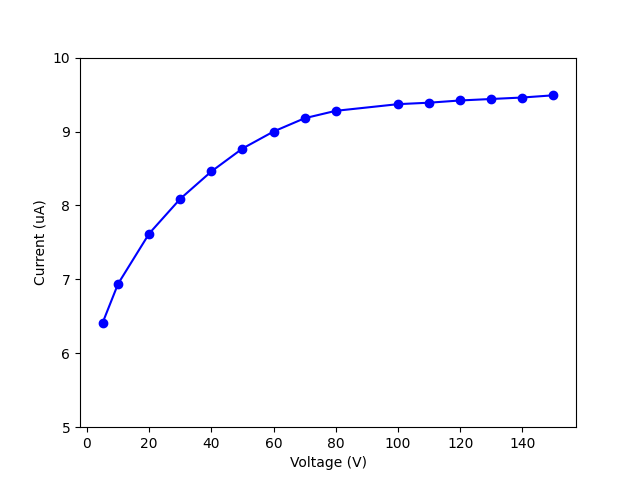

VI tests performed on the upper and lower detectors. Upper detector shows characteristic curve (attached plot), lower detector shows no response to increased voltage. Multimeter used on adapter boards with resistance of ~18.5 kΩ observed between bias pins for the upper detector. Open line seen between bias pins on the lower detector, some connections observed for other pins on the board -> requires further investigation.

NOTE - Channel 0 on bias supply is unstable, should not be used.

Most equipment for installation of FEE's and coolant manifolds found, assembley of FEE holders started. Full list of current swagelock inventory as follows:

| SS-QTM2-D-8M0 MALE QUICK DISCONNECT |

15 |

| SS-8M0-1-6RS MNIFOLD ADAPTOR |

40 |

| NY-8M4-1 ferrule fronts (nylon) |

120 |

| NY-8M3-1 ferrule rears (nylon) |

120 |

| SS-QTM2A-B-8M0 FEMALE QUICK DISCONNECT |

15 |

|

| Attachment 1: 20220110_175547.jpg

|

|

| Attachment 2: 20220110_175811.jpg

|

|

| Attachment 3: vi-curve.png

|

|

|

166

|

Tue Dec 7 09:39:59 2021 |

CB (remotely) | Gate valves closed | Dry run complete.

YR09 section valves closed. Section isolated. Manual valve between electron target and CARME remain open. |

|

165

|

Tue Nov 30 10:49:43 2021 |

CB (remotely) GV | Gate valve opened | GSI vacuum division IE514 gauge connected.

Gleb reports gate downstream opened. Vacuum goes up and recovers as expected. |

| Attachment 1: vacplot24.png

|

|

|

164

|

Sun Nov 28 15:57:45 2021 |

CB (remotely) | Nov 2021 temperatures | Attached |

| Attachment 1: 211128164424_temperatures.zip

|

|

163

|

Fri Nov 26 10:01:45 2021 |

CB (remotely) ML | Power cut in the CRYRING cave | ML reports power cut in CRYRING cave. Reasons unknown. No effect on vacuum, but top valve closed for safety reason. Ramping down temperature. |

|

162

|

Wed Nov 24 12:08:08 2021 |

CB + ML OG | Ion pumps on | Found SIP power unit for D2000 #4 not functioning correctly. Max current regardless of ion element connected to.

ML kindly loaned a spare. All D2000 work Ok now. Will have to send faulty unit for repairs back to SAES.

Opened up front part of tent just enough to allow GSI vacuum division to connect IE 514 and GSI ion pump. Tent to remain until January.

Left to do this year:

- Turn on GSI ion pump

- Turn on GSI IE514

- Close top gate valve

- Turn off maglev turbo (very close to magnet) |

| Attachment 1: vacplot24.png

|

|

| Attachment 2: vacplot.png

|

|

| Attachment 3: CARMEtemps.png

|

|

|

161

|

Tue Nov 23 08:49:33 2021 |

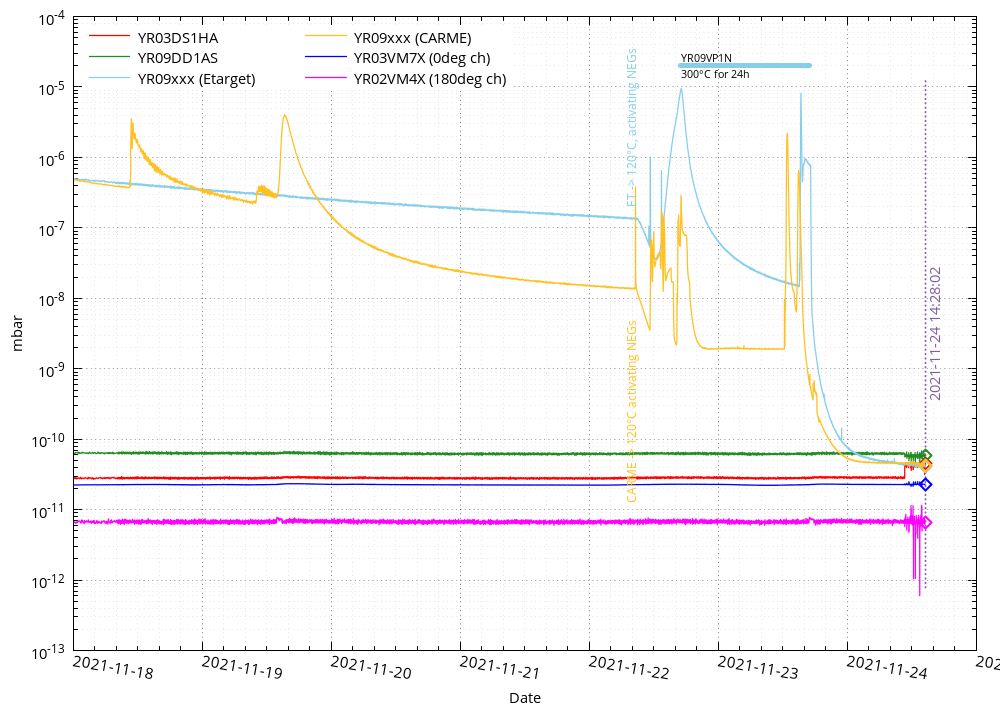

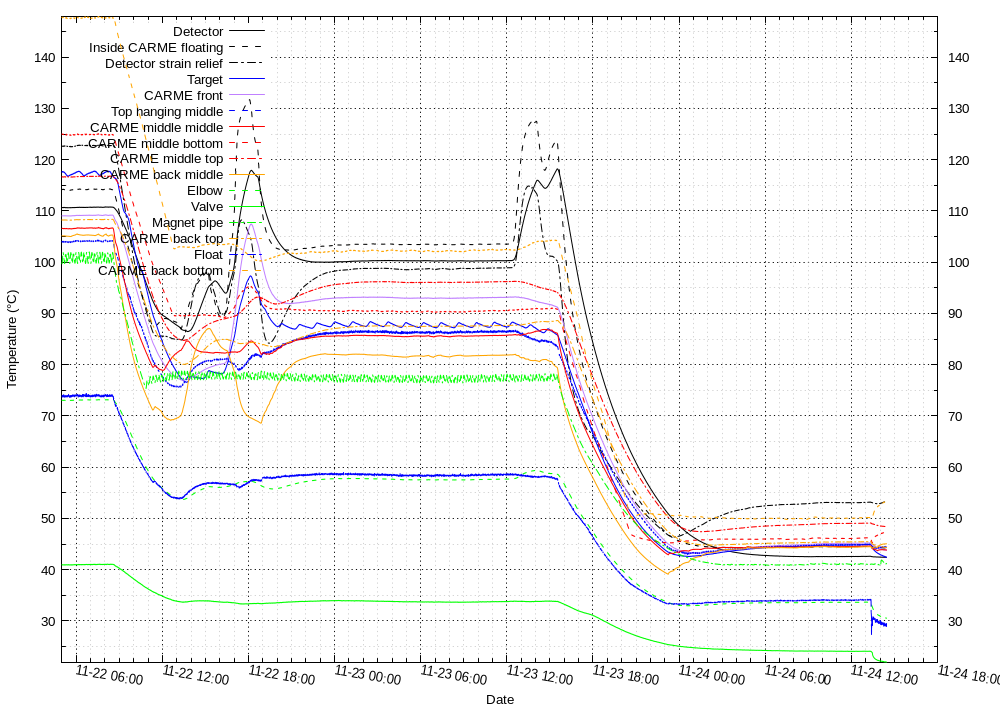

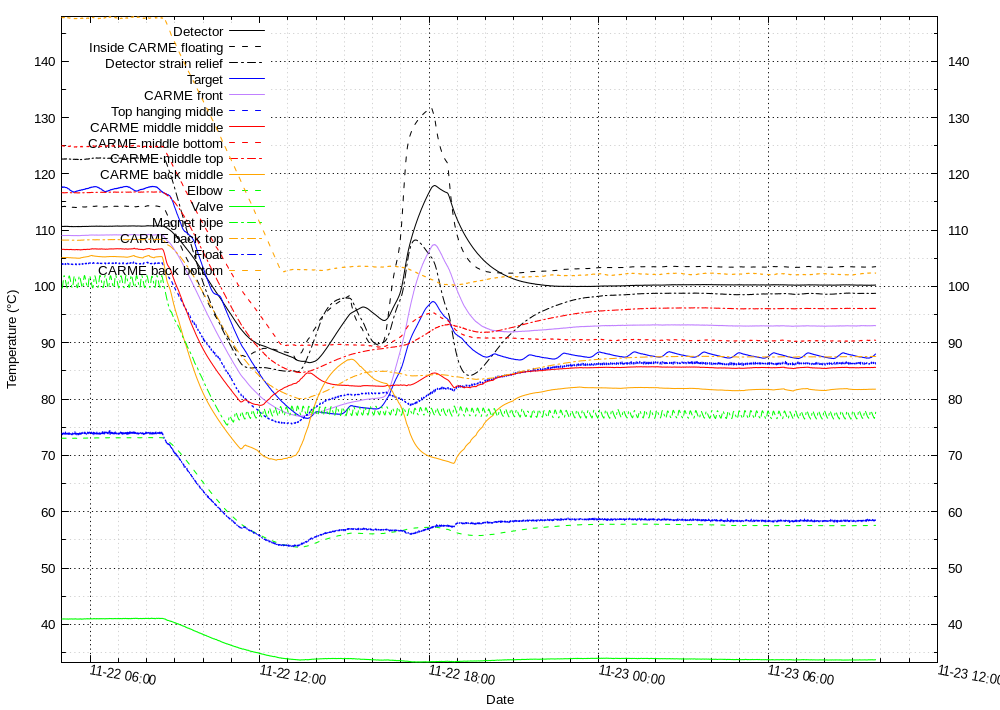

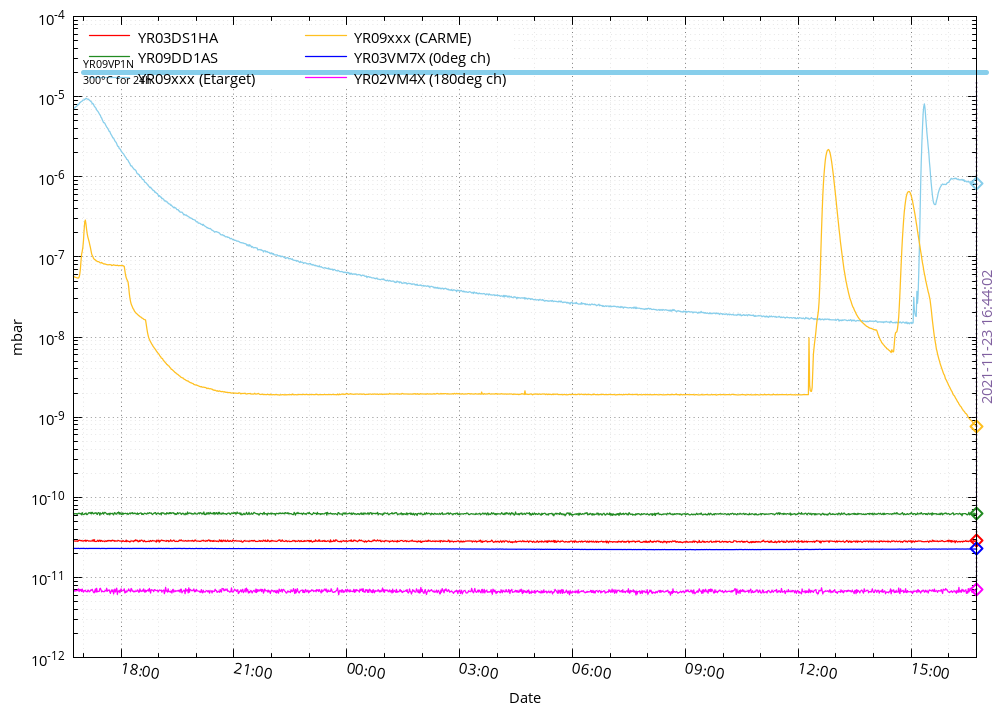

CB + ML | NEG activation completed | Found temperatures and pressure stabilised overnight. See attached.

12:00 Began activation of 3x UHV1400 in channel 2, top module. Started using 90 W as per procedure. No effect on temperature. Increased to 120 W. OK

14:30 Began activation of 2x UHV1400 in channel 1, in front of the detectors. Considered moving detectors but decided against it since bellows are rated to move at 20C at most. Activated at 60 W (vs. 75 W in procedure). OK

All NEG elements off. CARME heaters ramping down to 60 C overnight.

Ion pumps activated < 100 C. Valve closed. #4 doesn't come online properly. Sone issues with #2 as well but it recovered on its own. Left cooling down. No changes. Ion pumps off and valve open. Will try tomorrow. Could be faulty cable?

Vacuum division may want to activate their pump as well - times unclear. |

| Attachment 1: vacplot24.png

|

|

| Attachment 2: CARMEtemps.png

|

|

| Attachment 3: vacplot24-1.png

|

|

| Attachment 4: CARMEtemps-1.png

|

|

|