| |

ID |

Date |

Author |

Subject |

|

|

67

|

Fri Sep 10 18:09:14 2021 |

CB RSS ML | Leak test + baking system test |

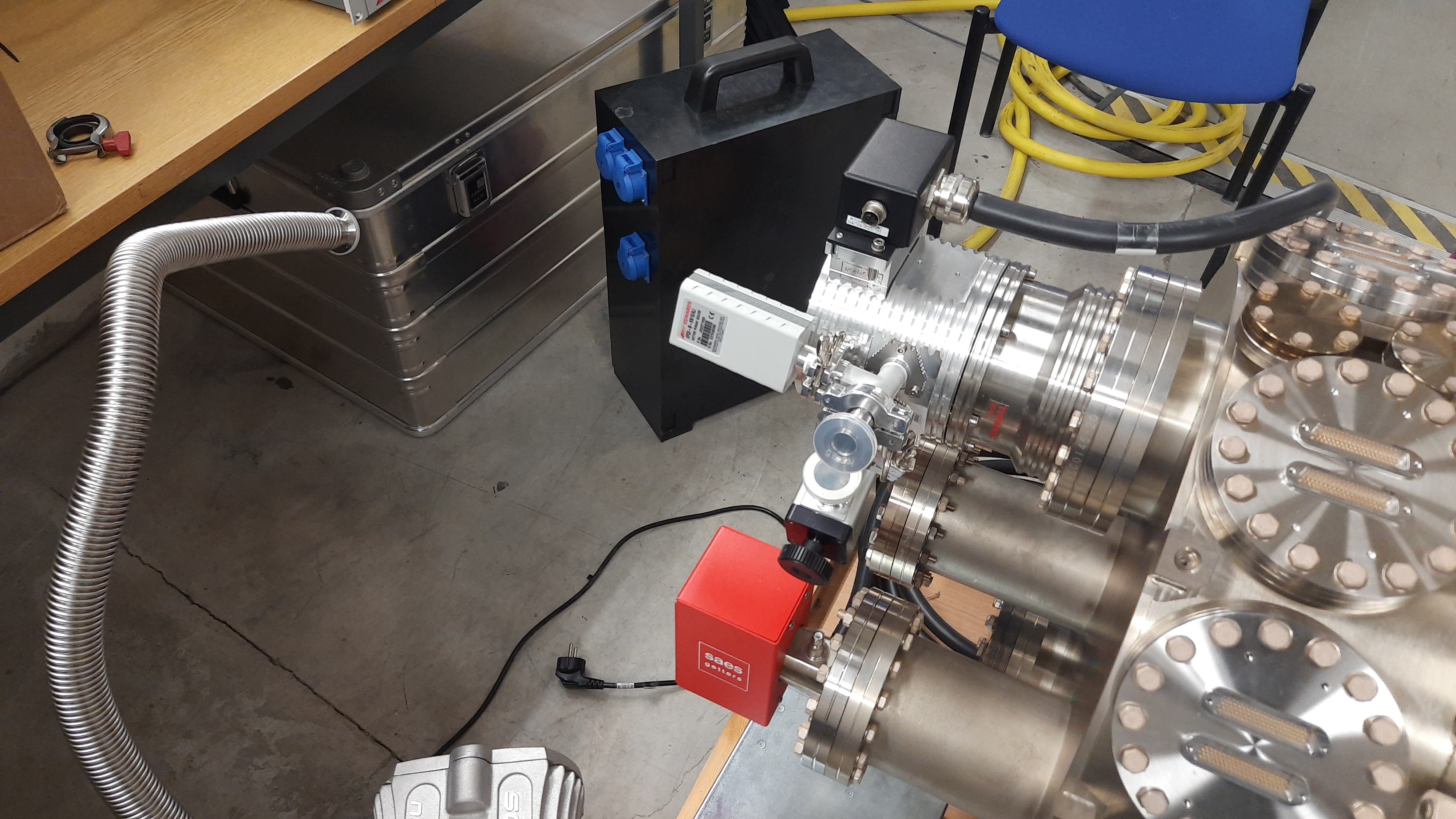

Leak tested CARME via He leak tester + He

bottle. No leaks could be found. Some

indication of potential leak close to

blind flange on bottom valve - disappeared

after closer checks.

Outgassing from cables? If so second turbo

may be required for baking.

Removed leak tester. Scroll on, turbo on.

Pumping down overnight.

Tested baking system. Missing:

- Monitor (not shipped from DL??)

- Monitor power cable

- Power cable for USB hub (not shipped??)

Could find the first two, but monitor is

of poor quality.

USB to RS232 cable damaged in shipping

(poorly secured). Still works, may be

worth repairing but not trivial. Only

works plugged in to top USB 3 port on Pi.

System tested and still working aside from

these issues.

Connected webcam to pi facing IE514

display. Will take pictures every hour on

the hour as in DL.

Will stop pumping tomorrow pm due to

imminent shutdown.

Pressure at 5E-6 mbar decreasing. |

|

|

64

|

Wed Sep 8 17:03:07 2021 |

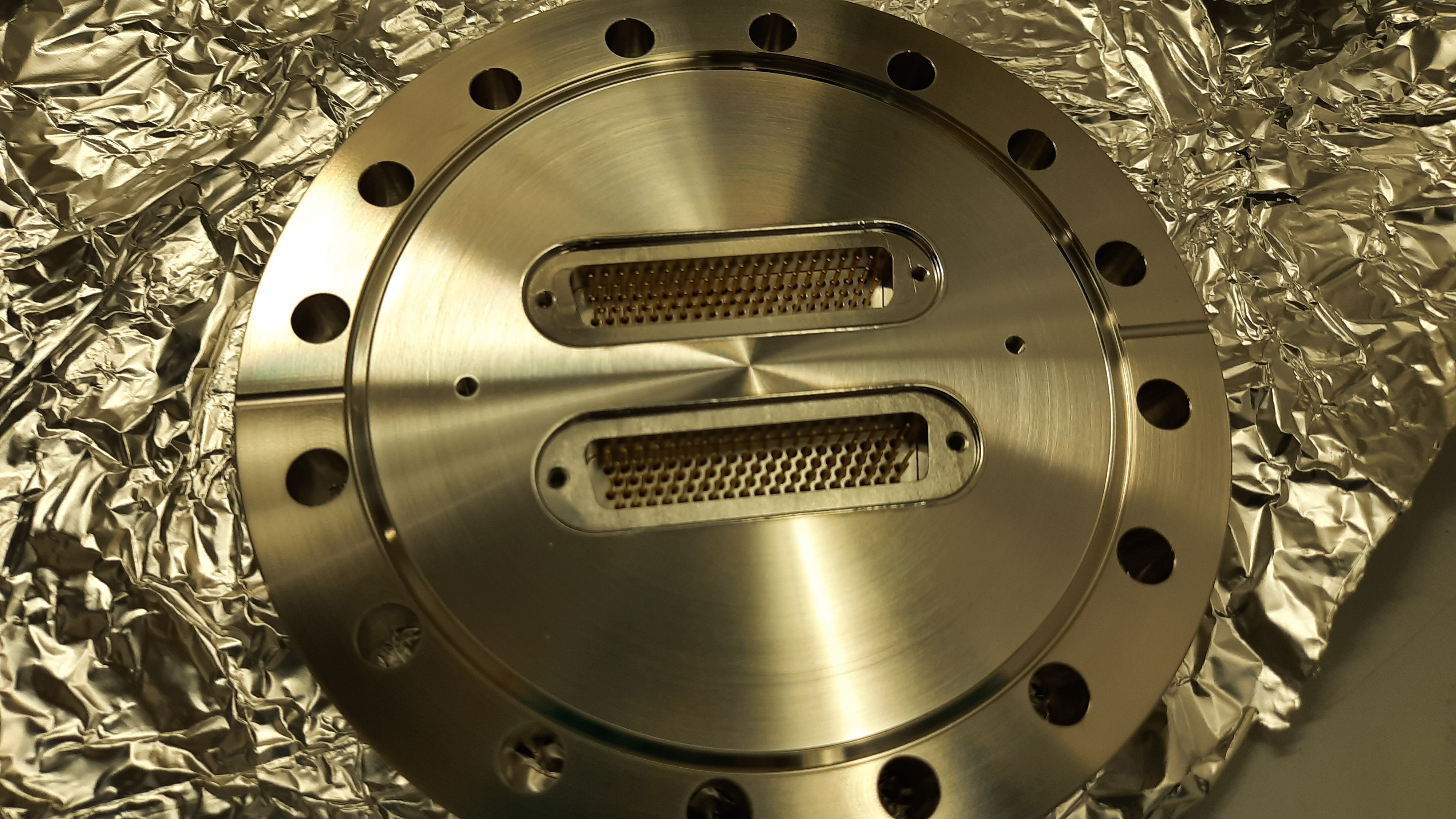

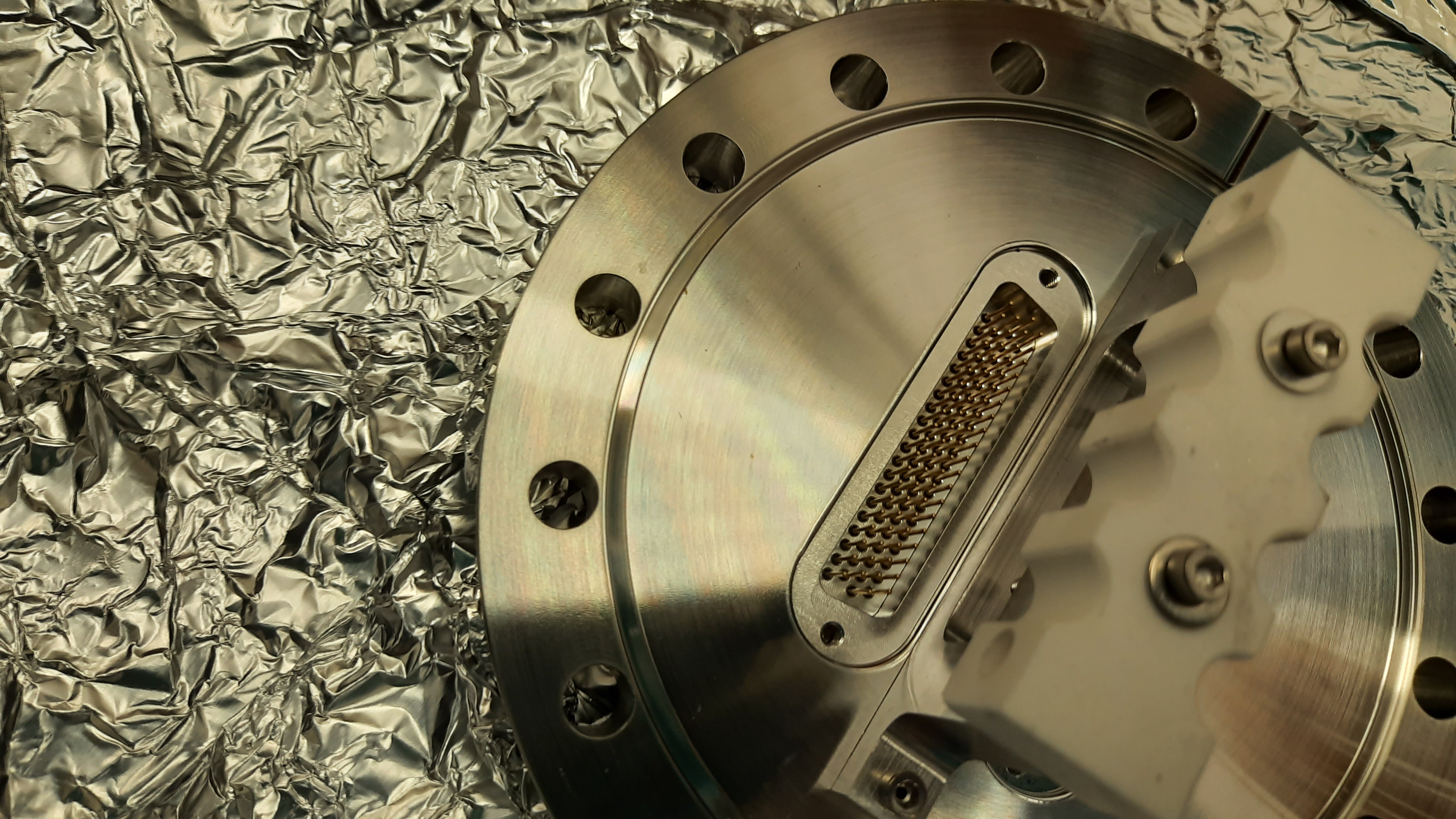

CB RSS + OG NB | Six feedthrough flanges mounted |

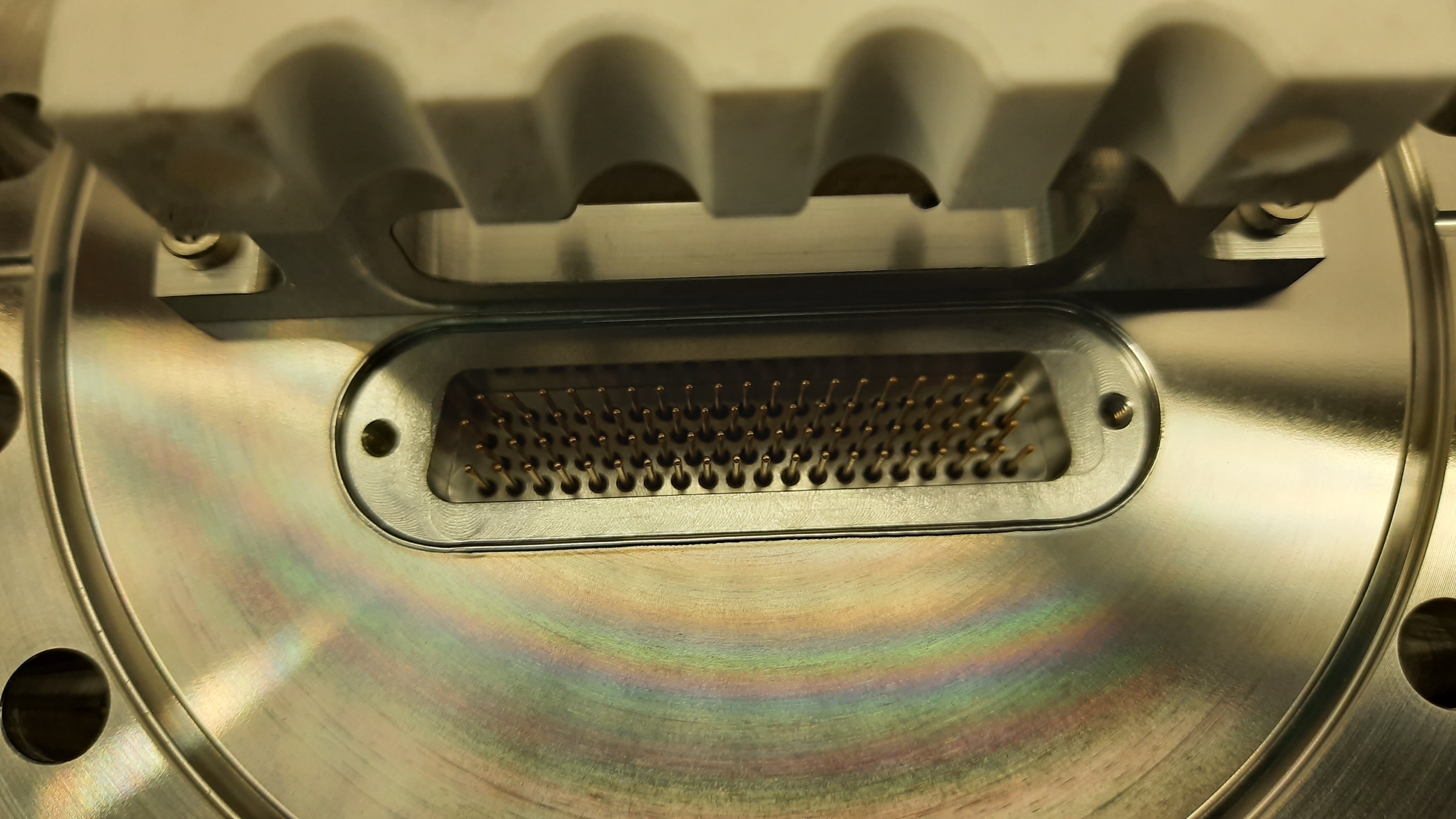

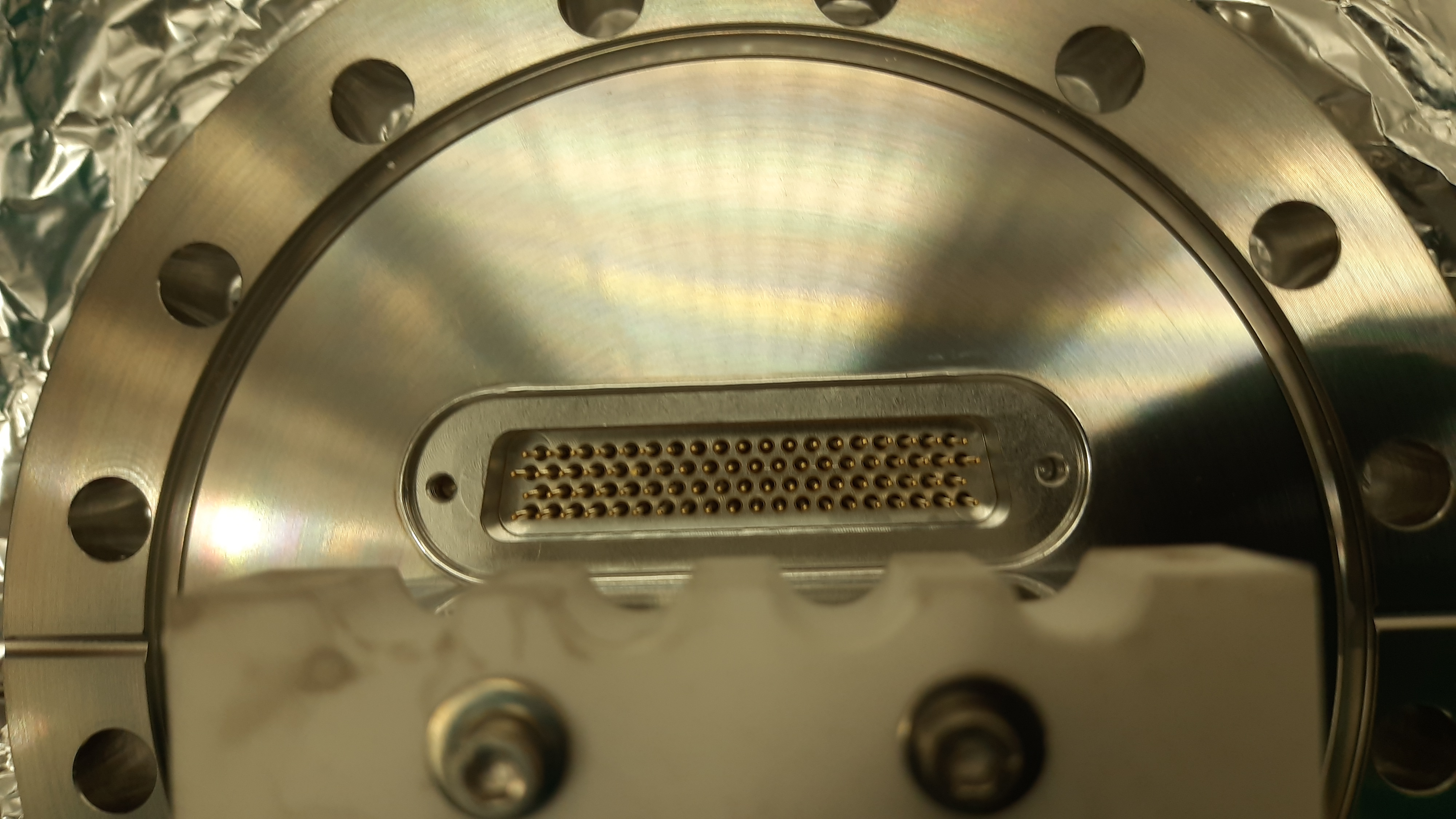

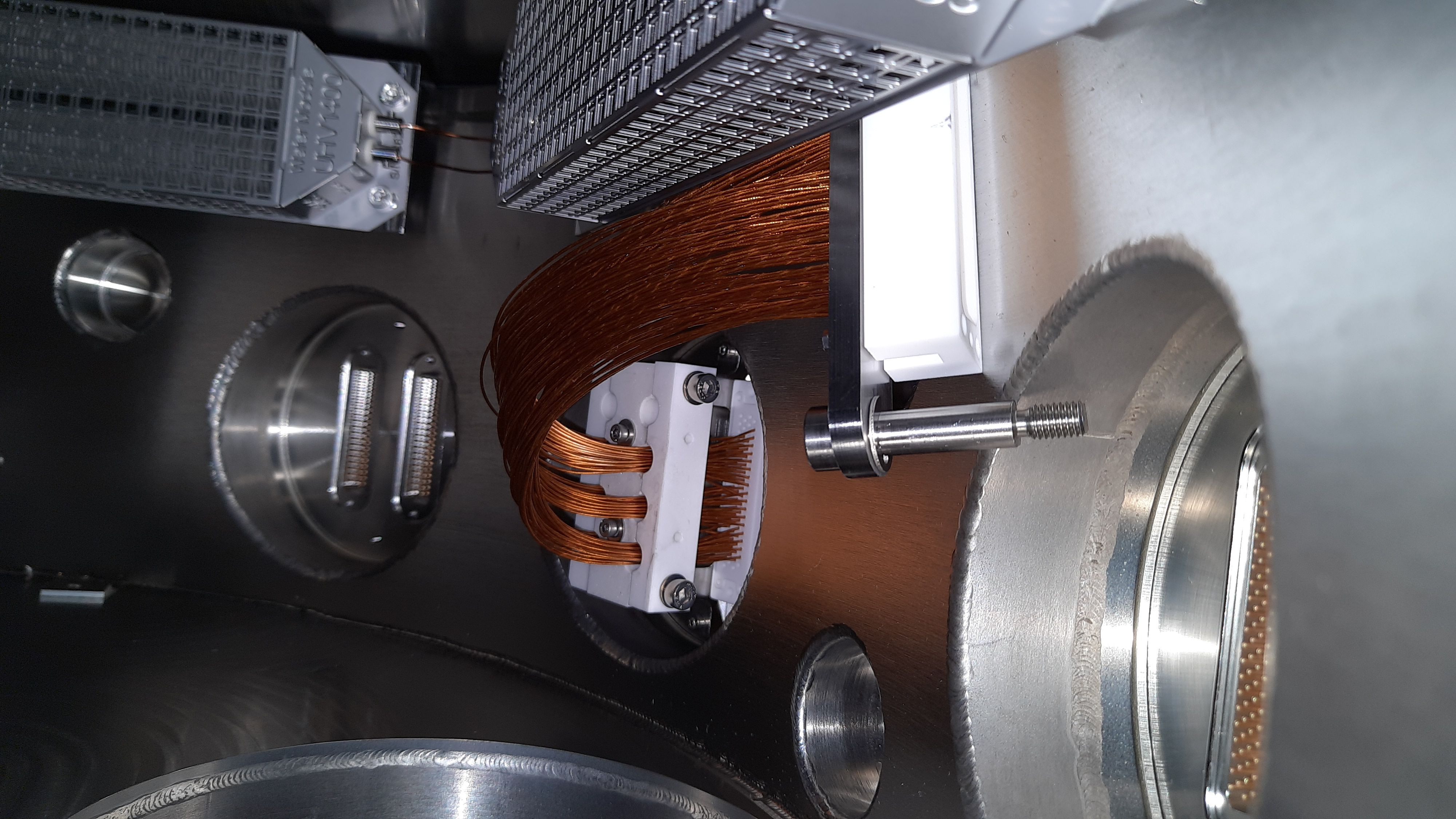

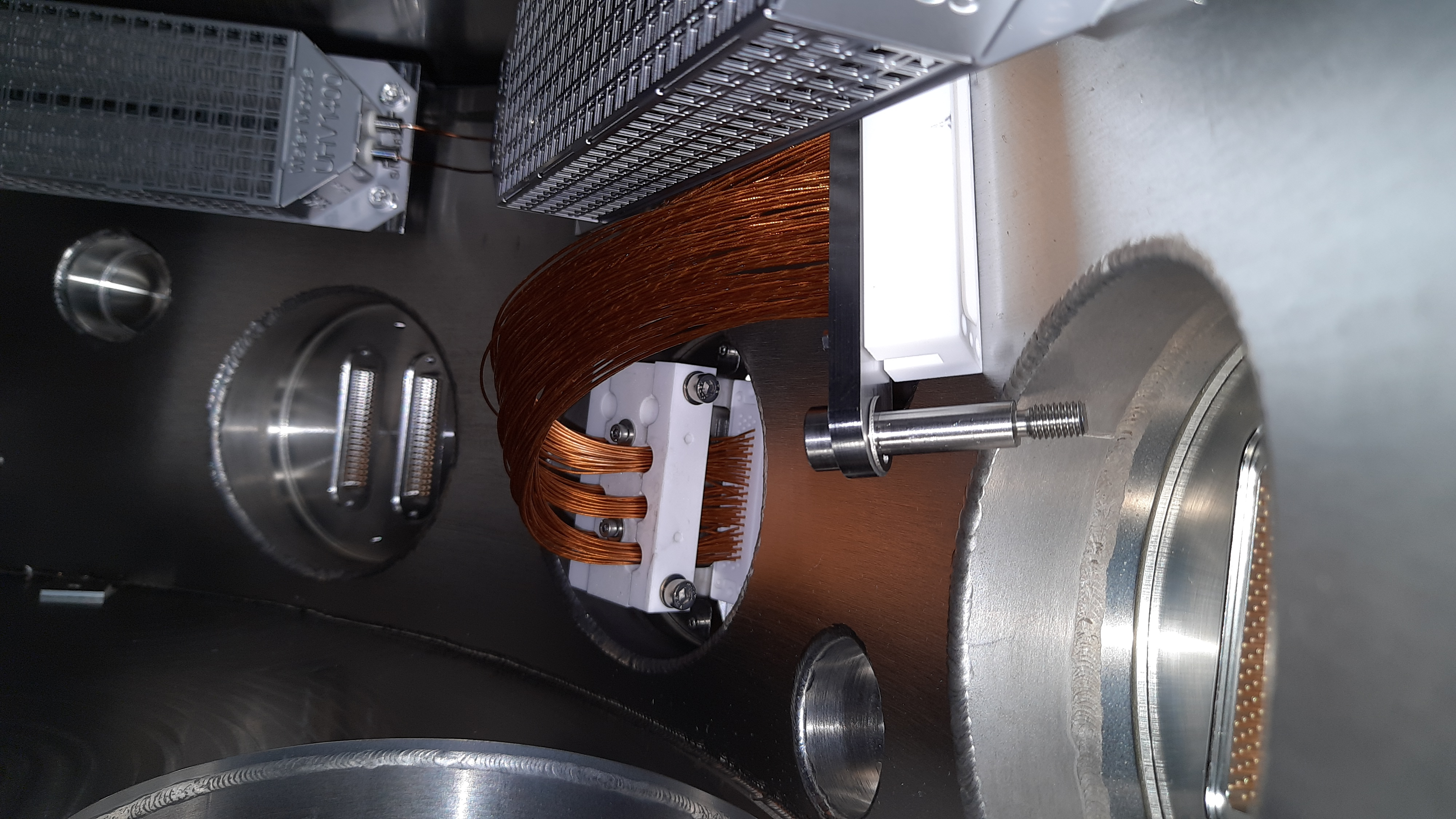

Continued to mount flanges as per previous ELOG entry.

Peter also remarked that the wires look a bit loose inside the holes, although this is how they were during

dirty tests in Edinburgh.

Attempted to pack the wires in two holes rather than 4 - too tight. Cannot close.

Packed the wires in 3 holes instead. Better, but still a bit loose. Wire harness feels quite robust and no

obvious strain is placed on the connectors.

#1 flange left with four strands for now.

Connectors were tested in this way in Edinburgh for motion tests. No broken cables after several thousand

repetitions.

Had troubles with second flange being mounted. Glove was caught under MACOR connector. Managed to free it

somehow with a cleaned screwdriver. Other half of the flange refused to go in due to bent pins, until NB was

able to repair it.

Mounted as #5.

Most other connector pins OK. Had to adjust a very small number. Cause of damage unclear - transportation? See

photos.

Took some pictures inside the chamber. Most connectors look OK, but

- One harness is touching the NEG wires (#2). This could be an issue. Will try to move it tomorrow

- Wires hanging from the top may be putting a lot of weight on the connectors. See pictures. Given number of

wires this may be acceptable.

- One harness is touching the NEG cage. Definitely an issue. Will fix tomorrow

Top/bottom flanges mounted with short harnesses. Side flanges mounted with long harnesses.

Two flanges left to mount.

Only #1 has been tightened. Other flanges left finger tight for Grossmontage to tighten properly tomorrow.

Outside motor to be fixed tomorrow. |

| Attachment 1: 20210908_132331.jpg

|

|

| Attachment 2: 20210908_132410.jpg

|

|

| Attachment 3: 20210908_132430.jpg

|

|

| Attachment 4: 20210908_133340.jpg

|

|

| Attachment 5: 20210908_141933.jpg

|

|

| Attachment 6: 20210908_141938.jpg

|

|

| Attachment 7: 20210908_144225.jpg

|

|

| Attachment 8: 20210908_144229.jpg

|

|

| Attachment 9: 20210908_144234.jpg

|

|

| Attachment 10: 20210908_144857.jpg

|

|

| Attachment 11: 20210908_144916.jpg

|

|

| Attachment 12: 20210908_145931.jpg

|

|

| Attachment 13: 20210908_151808.jpg

|

|

| Attachment 14: 20210908_152422.jpg

|

|

| Attachment 15: 20210908_152440.jpg

|

|

| Attachment 16: 20210908_152653.jpg

|

|

| Attachment 17: 20210908_153333.jpg

|

|

| Attachment 18: 20210908_153336.jpg

|

|

| Attachment 19: 20210908_155714.jpg

|

|

| Attachment 20: 20210908_163205.jpg

|

|

| Attachment 21: 20210908_155714.jpg

|

|

| Attachment 22: 20210908_164845.jpg

|

|

| Attachment 23: 20210908_164853.jpg

|

|

|

|

60

|

Tue Sep 7 11:37:05 2021 |

CB RSS + OG | Update on strain relief screw issues |

Tested every strain relief. M3 screws get stuck at different points in each hole. Only one good hole out of 16

(2x8).

They were tested in Edinburgh - unclear if this is a result of baking at high temperatures, or bad screws, or

something else.

Easiest solution may be to re-machine holes and clean the connectors here in GSI.

Now investigating options. |

|

|

62

|

Tue Sep 7 14:10:02 2021 |

CB RSS + OG | Strain relief SS support re-drilled |

Re-drilled SS supports in order to fit M3 screws.

Used hand tool cleaned with alchool for 6 of the 8.

Had to use machine for another two with thread damaged.

All 8 will be sent for cleaning. Should be able to start mounting at least the 6 ones tomorrow.

Reason for lack of fit still not clear. They were tested in Edinburgh. Possibly result of high-temperature baking? |

|

|

63

|

Wed Sep 8 10:52:54 2021 |

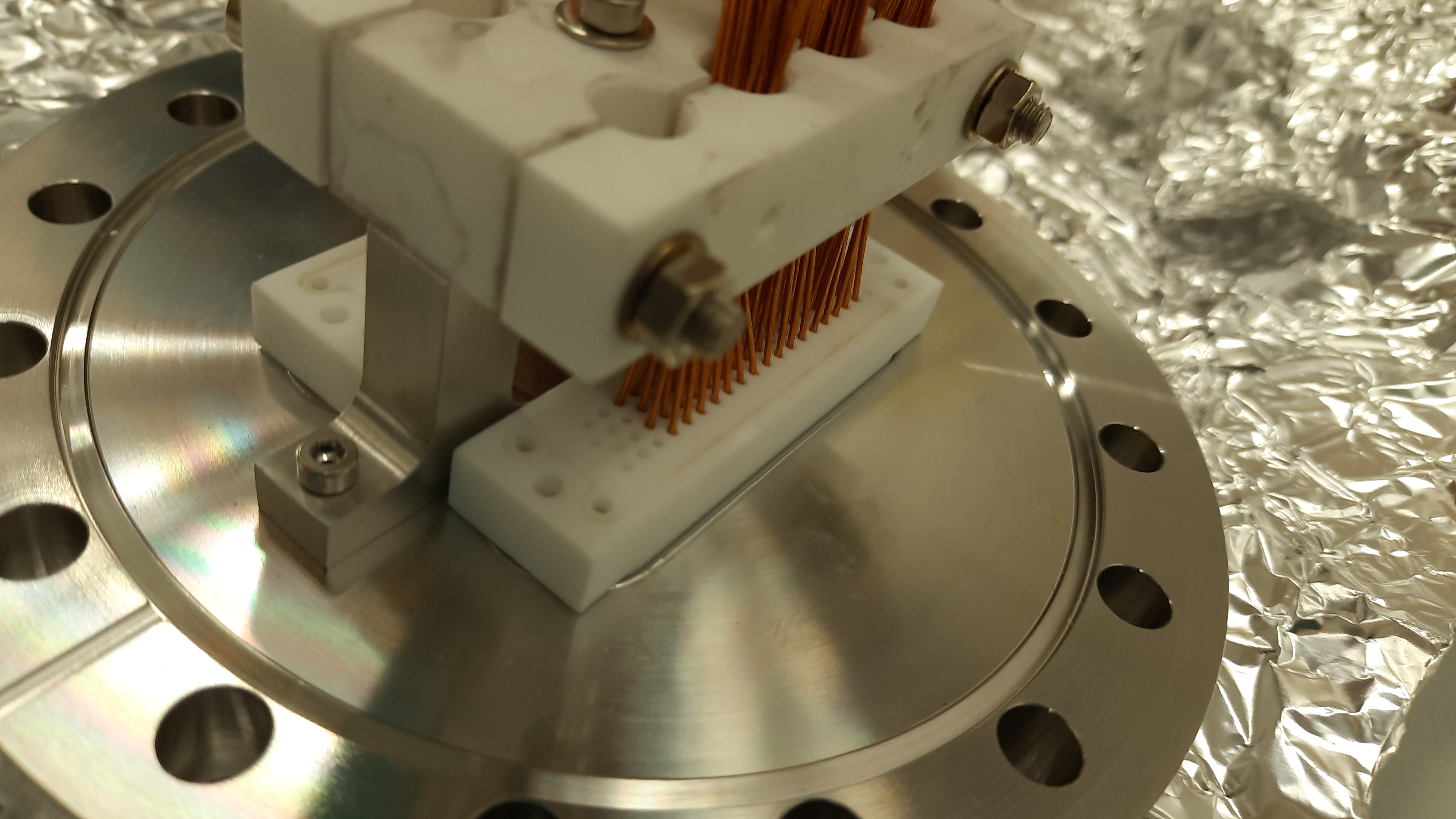

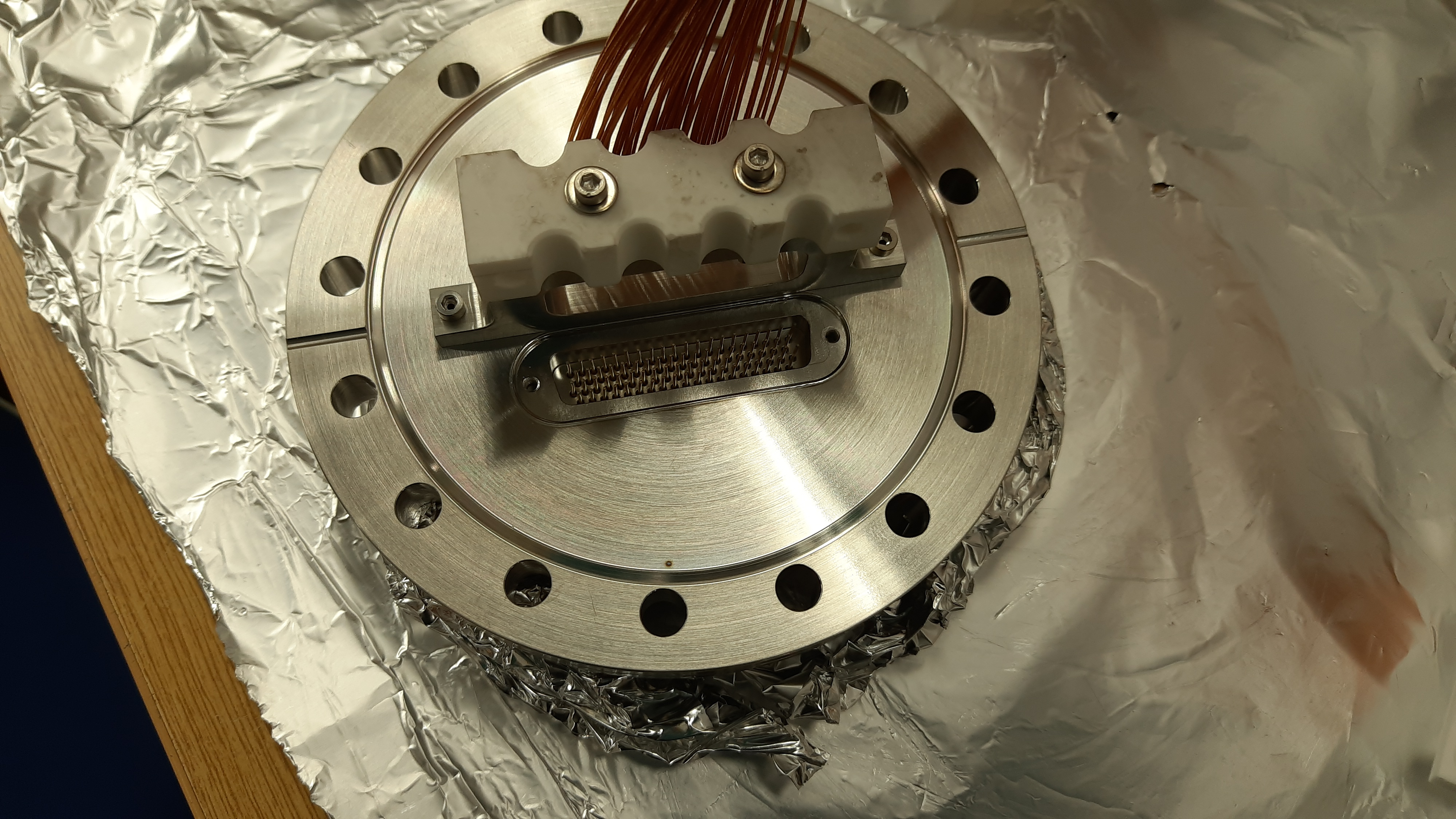

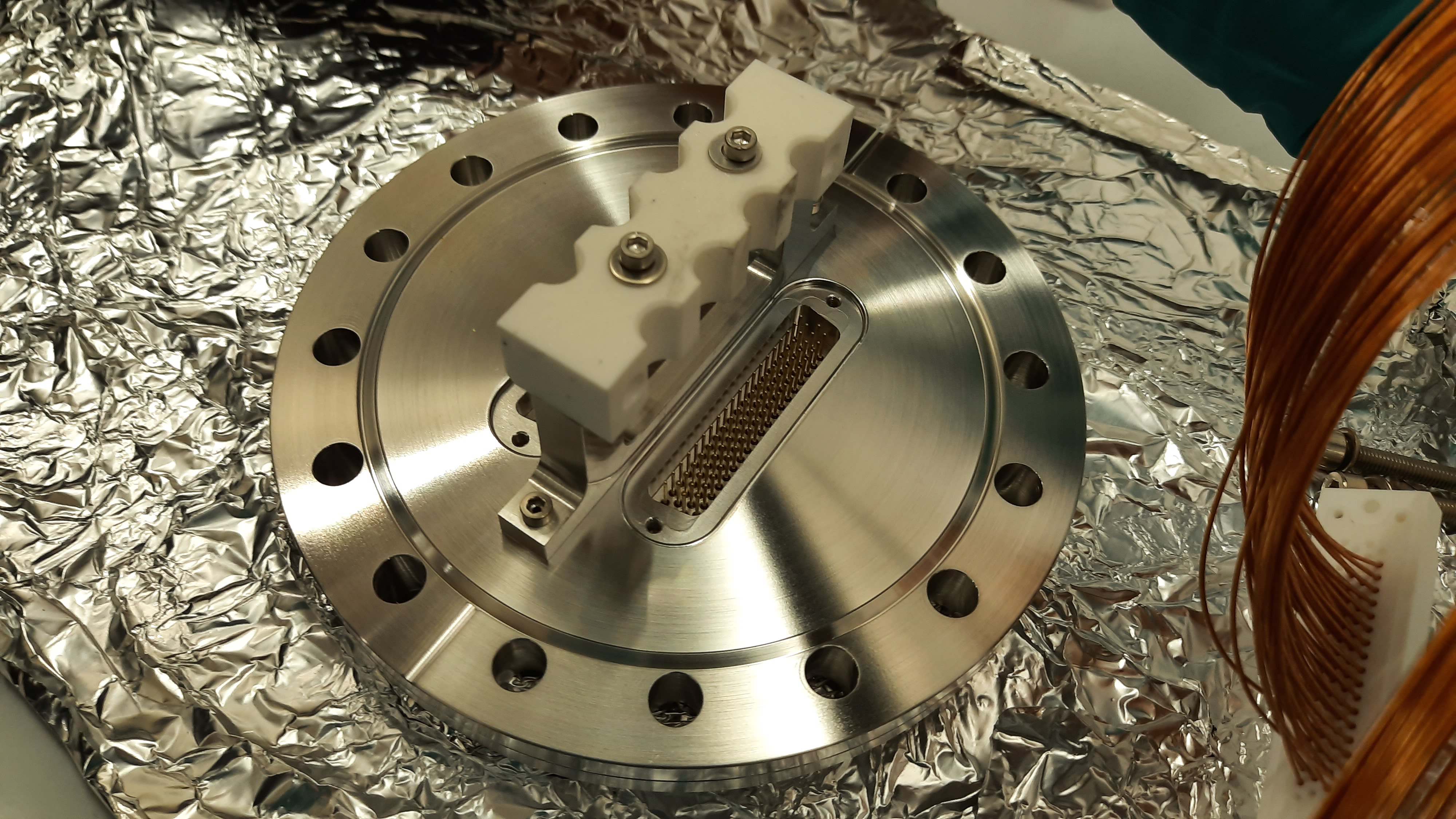

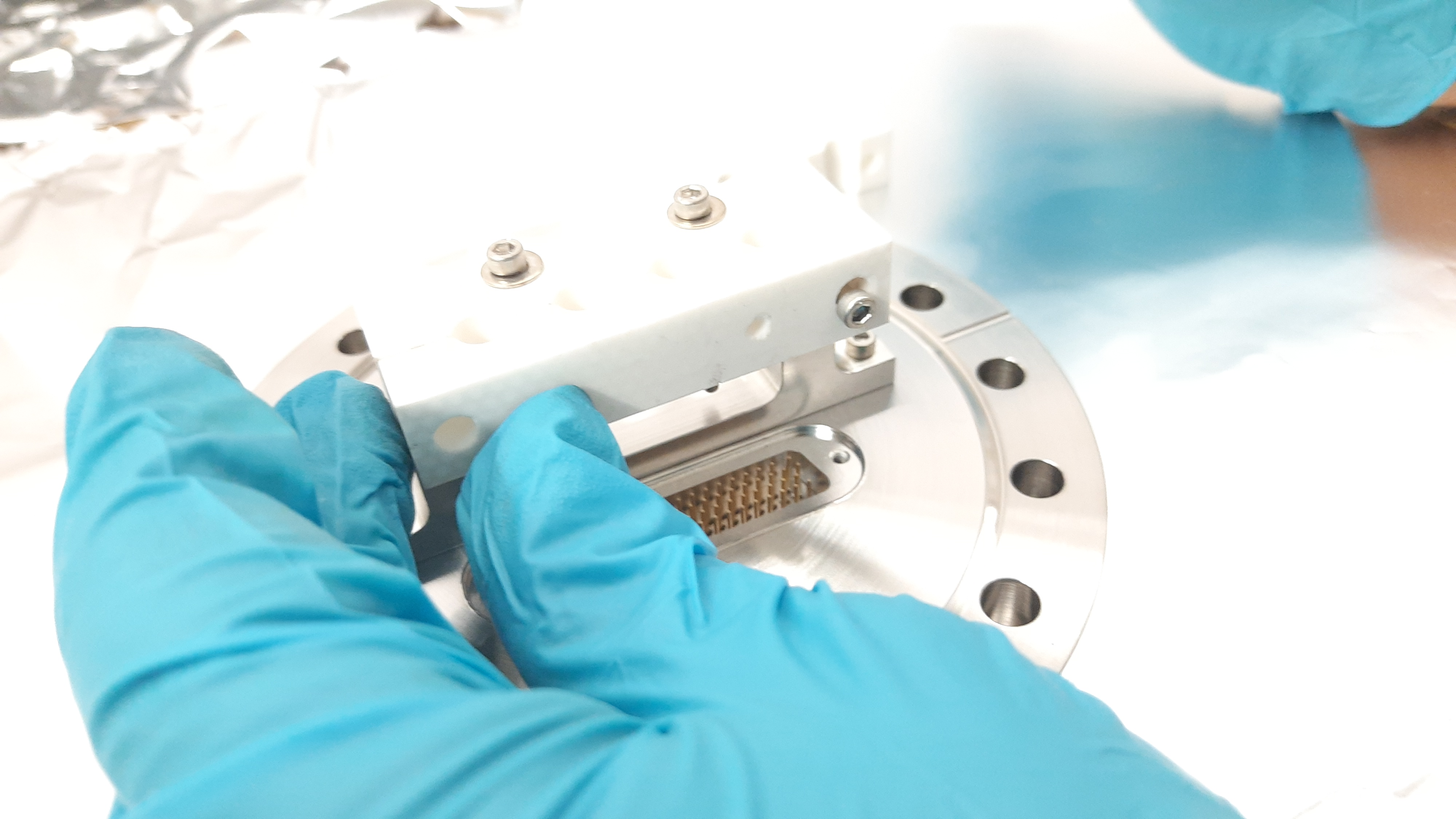

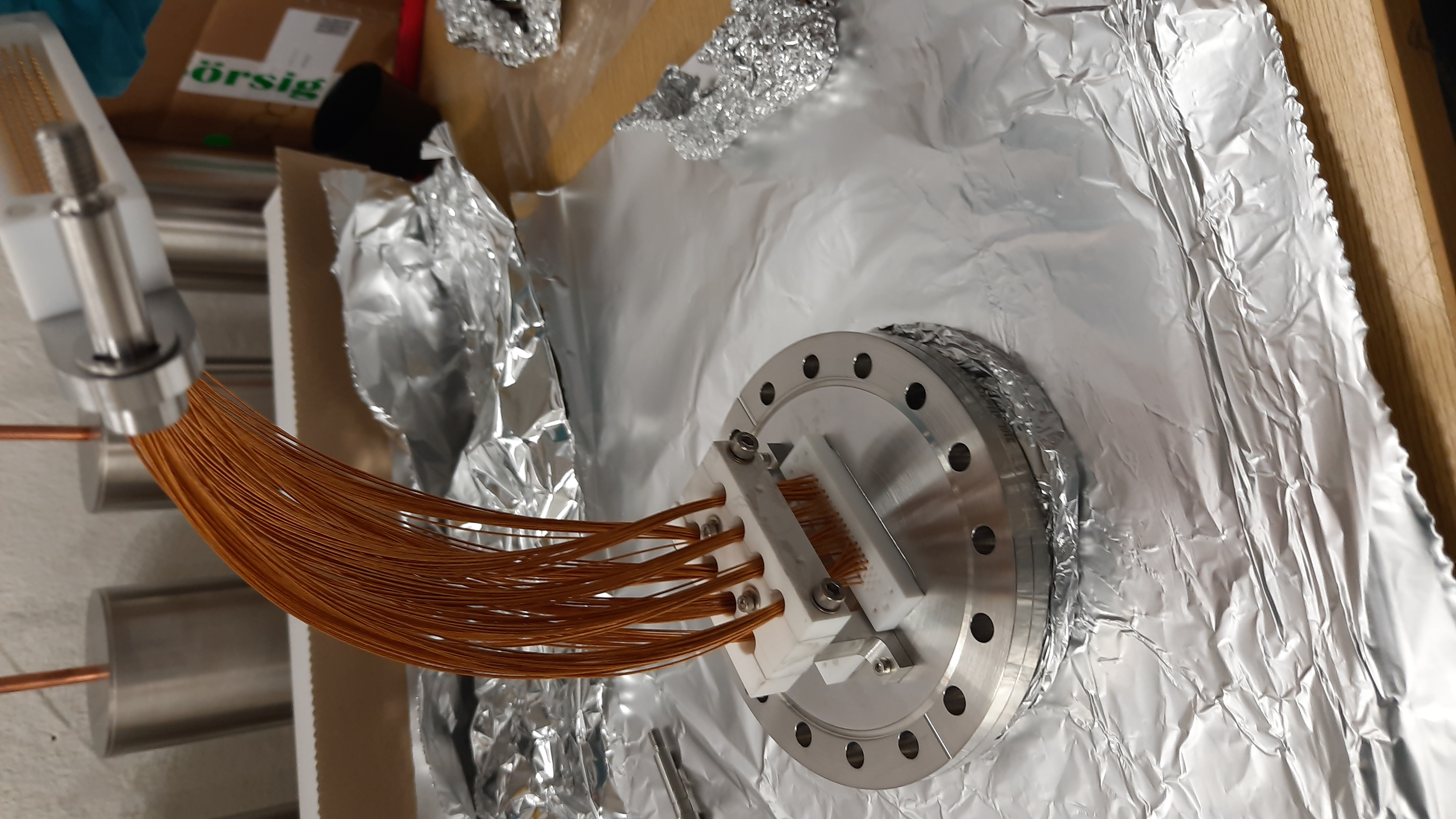

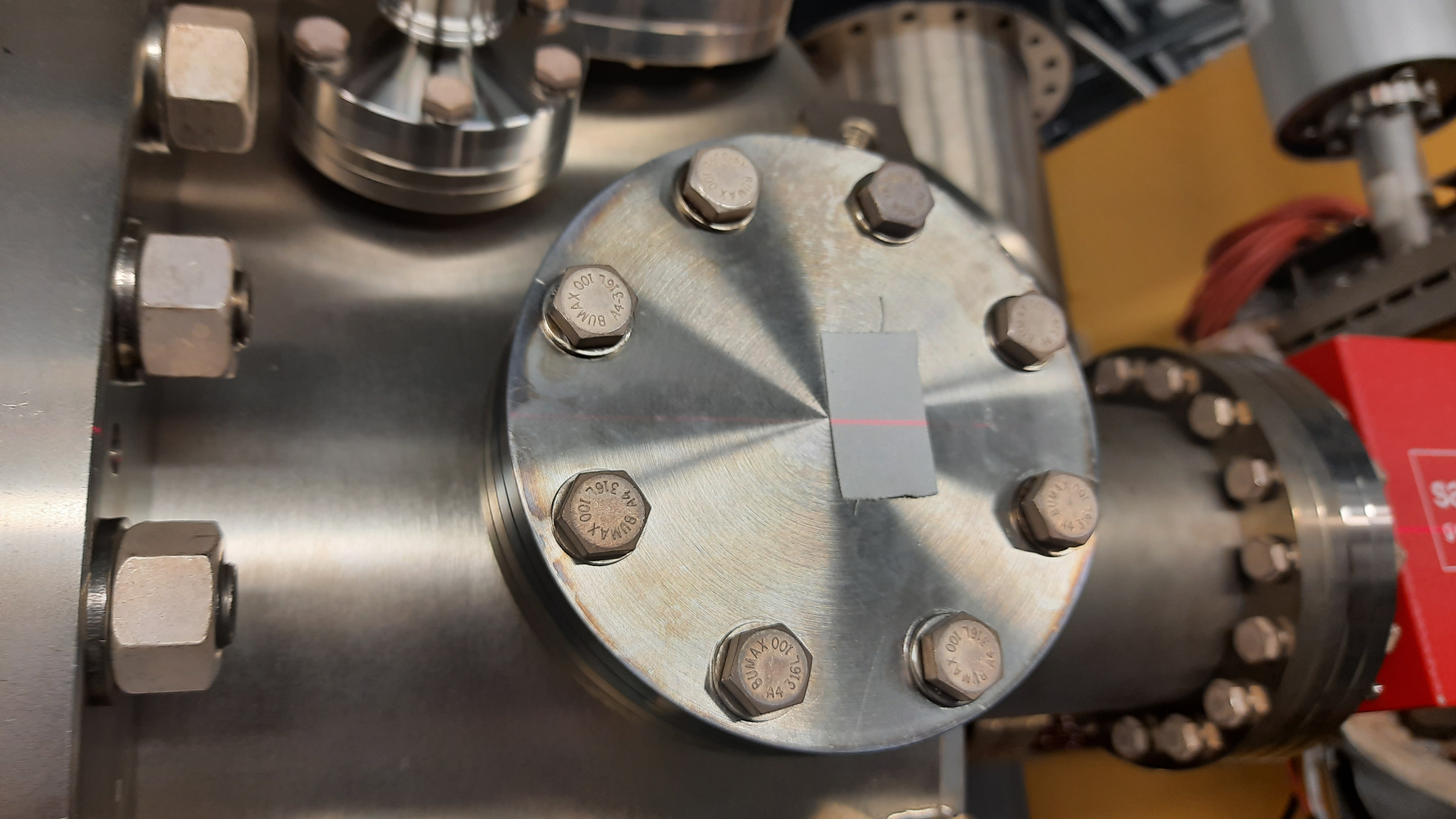

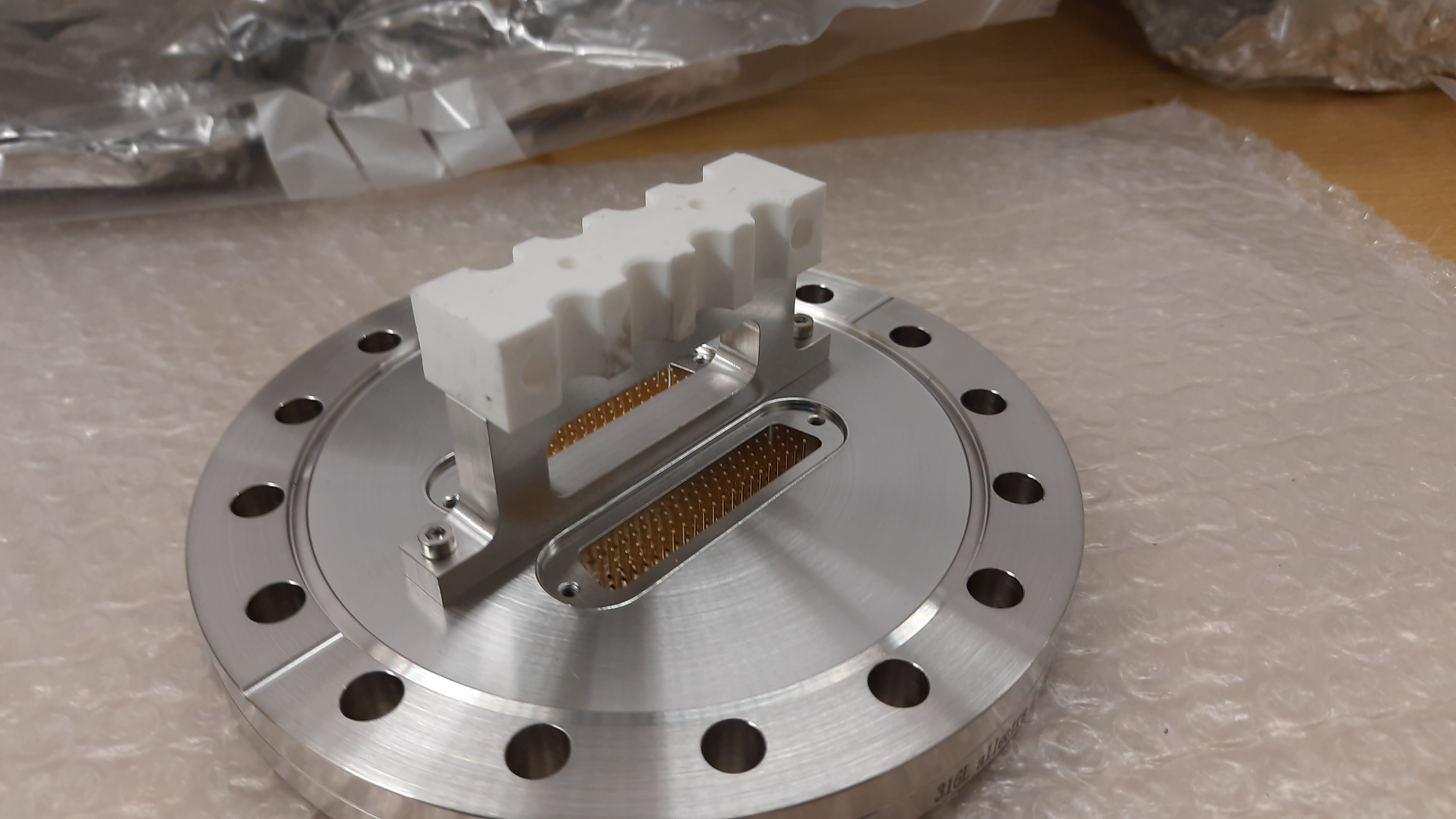

CB RSS + OG | First feedthrough flange mounted |

Assembled feedthrough flange with re-cut

SS support bracket. M3 vented on the

sides, M3x30 partly threaded on top. Top

screws don't touch the

Macor (by design? See first attachment).

Macor affixed but has

some play - good for thermal dilation.

Mounted long wire harness (side flange) on

top. Unable to get one of the two

connectors fully in. Unable to get it out

as well. See last attach, it's a small gap.

Tested few pins with multimeter - all ok.

Decided to mount.

No issues mounting. Slowly and carefully

threaded wires harness in CARME taking

care not to hit negs.

Slightly concerned about weight of Macor

connector on wires, but no obvious

alternative.

Please have a look at attachments and

comment. Will keep mounting in the

afternoon. |

| Attachment 1: 20210908_101743.jpg

|

|

| Attachment 2: 20210908_111958.jpg

|

|

| Attachment 3: 20210908_112002.jpg

|

|

| Attachment 4: 20210908_112006.jpg

|

|

| Attachment 5: 20210908_112010.jpg

|

|

|

|

65

|

Thu Sep 9 13:01:07 2021 |

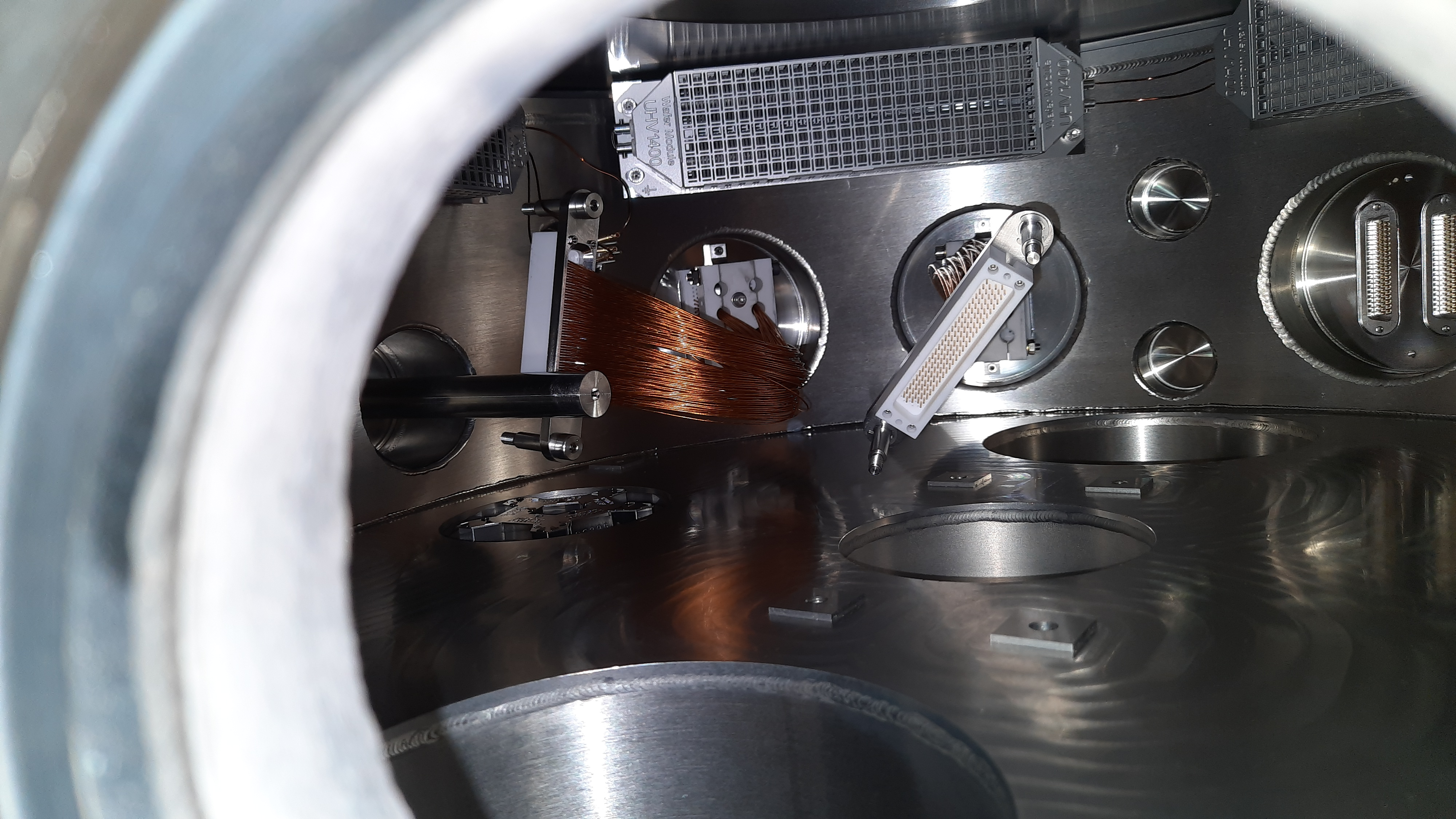

CB RSS + OG | All feedthrough flanges mounted and motor rotated |

Moved cables that touched neg pumps. See

photos. Please bear in mind perspective.

Note avoiding touching chamber

bottom is not possible.

Re-installed motor to fix alignment

issues. All good. See attached.

Started pumping down. Reached 3E-1 mbar in

20 minutes (ok). Turbo on. After one hour

turbo stable at 0.85 A, pressure on Pirani

at 1.1E-2 (not reliable).

IE514 doesn't report pressure, i.e. > 1E-4

mbar.

Leak likely. Will try to pinpoint

tomorrow. We only changed 10 flangese. |

| Attachment 1: 20210909_111933.jpg

|

|

| Attachment 2: 20210909_112120.jpg

|

|

| Attachment 3: 20210909_112125.jpg

|

|

| Attachment 4: 20210909_133027.jpg

|

|

|

|

142

|

Wed Nov 3 16:39:01 2021 |

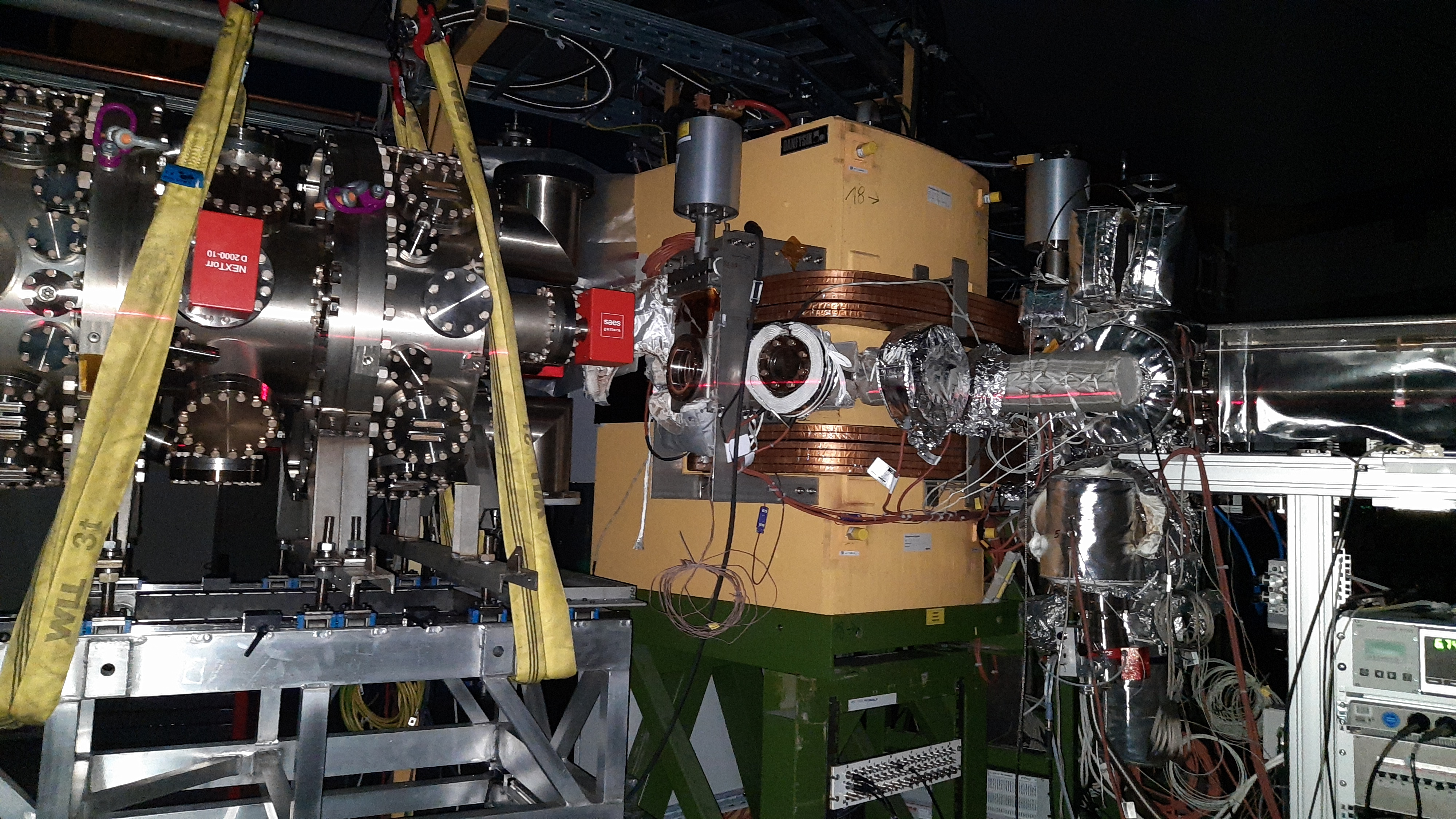

CB RSS + NP DR NK ML | Interaction chamber lifted in place |

Prepared to move interaction chamber in place. Ok CARME side, flange has M10 bolts. On interaction chamber side i.e. bellows it has M8 bolts.

DS designed this to have loose fit under assumption of M10 side actually being 3/8 holes i.e. 9.9 mm. However holes are 10.2 mm. Furthermore Grossmontage suggest loose fit will be damaged in baking in the long term.

Dismounted bellow ring from spare bellows. Re-drilled to M10 and cleaned. Remounted. Old bellow outer ring moved with spare bellows.

Lifted interaction chamber in place. Alignment started. Will finish tomorrow morning, followed by pump down and leak test. Last step before beginning final pump down should be mounting Be window on Friday. Need US for that. |

| Attachment 1: 20211103_161553.jpg

|

|

| Attachment 2: 20211103_161813.jpg

|

|

| Attachment 3: 20211103_175457.jpg

|

|

|

|

48

|

Tue Aug 31 18:34:41 2021 |

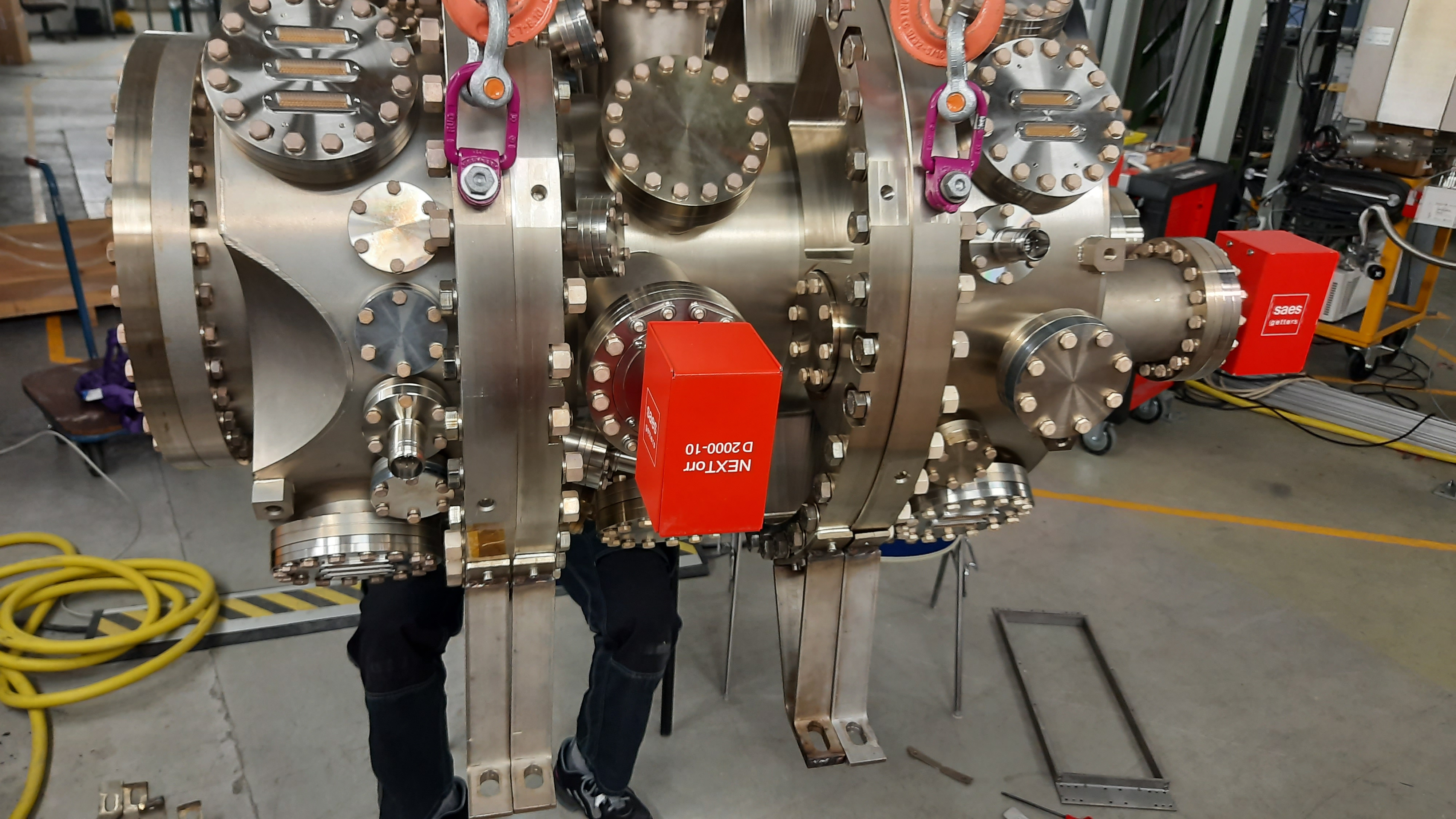

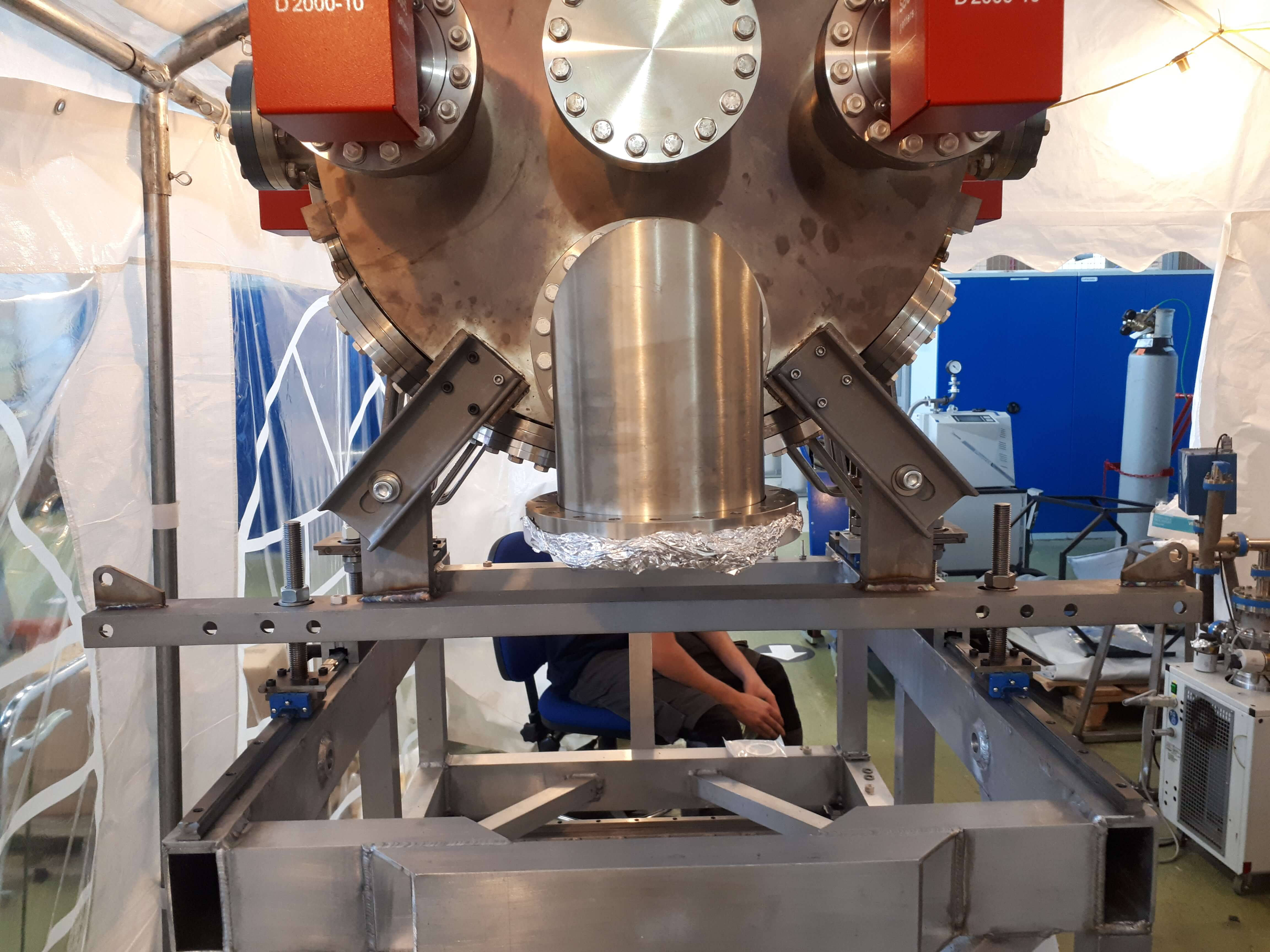

CB RSS + DR OG | CARME on Al stand |

Lifted CARME off the floor and mounted feet on sides. It was found impossible to put four bolts for each foot

due to alignment conflict. Three bolts were mounted per foot instead.

One of the mounting holes in CARME has been damaged and the thread has been ruined. Simple rethreading attempts

failed. Three good holes left - not an issue for now.

One of the shims between the feet and the chamber had to be modified in the workshop. Some feet were rather

difficult to mount, but in the end we succedeed.

CARME was then lifted on the Al frame and gently dropped. The crane remains in place overnight to prevent it

falling over given it is not anchored to the floor.

Front foot and back foot were also mounted.

Elbows at the back were mounted.

Currently considering whether to mount gate valves before or after lifting in place on YR09. Lift experts will

decide tomorrow what is the easiest procedure given constraints on the ring.

See other attachment and next entry for current status.

YR09 downstream will be cleared tomorrow morning. Lift will proceed tomorrow afternoon. |

| Attachment 1: 20210831_144545.jpg

|

|

| Attachment 2: 20210831_171442.jpg

|

|

| Attachment 3: 20210831_171447.jpg

|

|

| Attachment 4: 20210831_171449.jpg

|

|

| Attachment 5: 20210831_171453.jpg

|

|

|

|

52

|

Thu Sep 2 10:41:16 2021 |

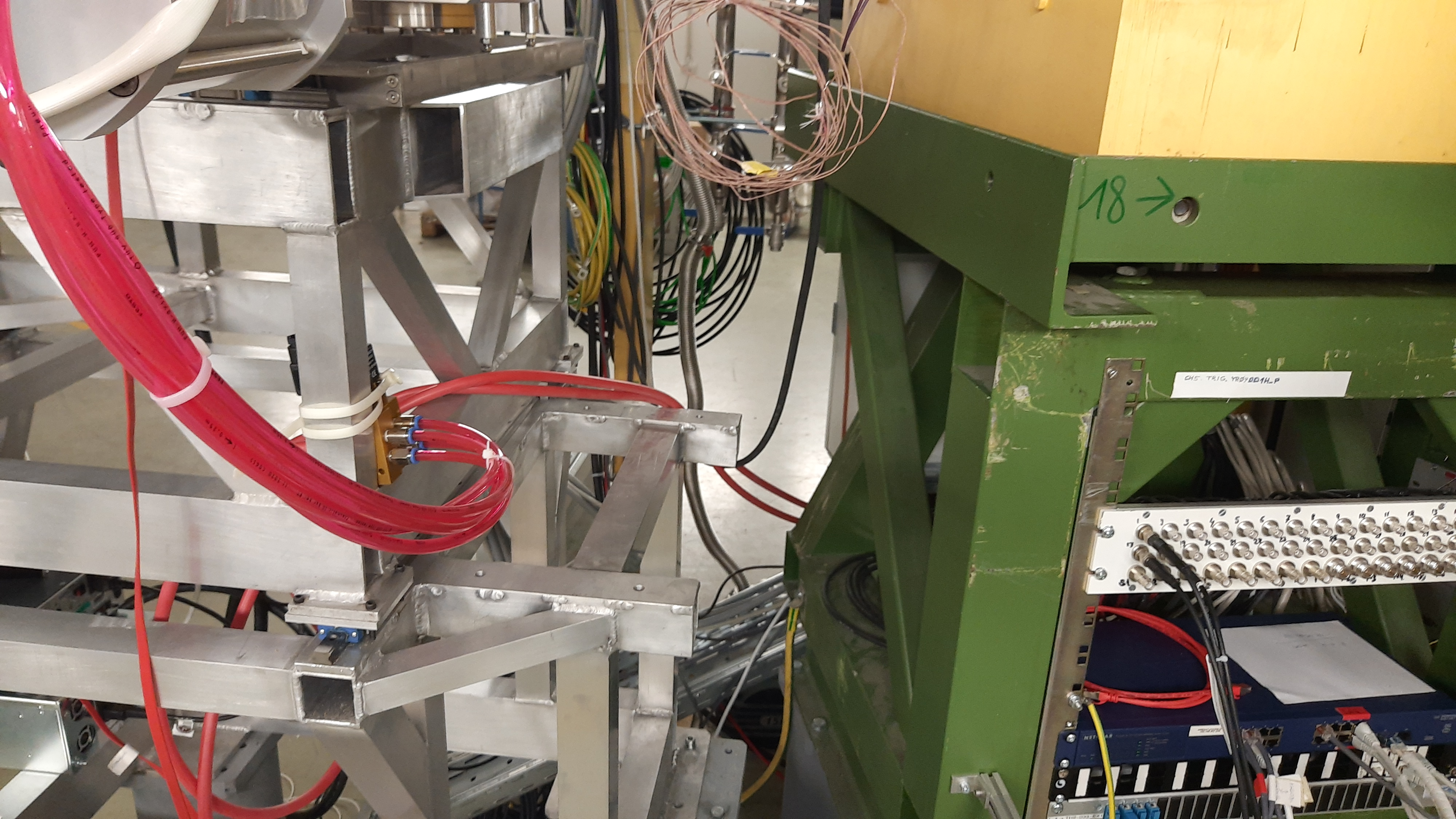

CB RSS + DR OG | CARME connected to the CRYRING |

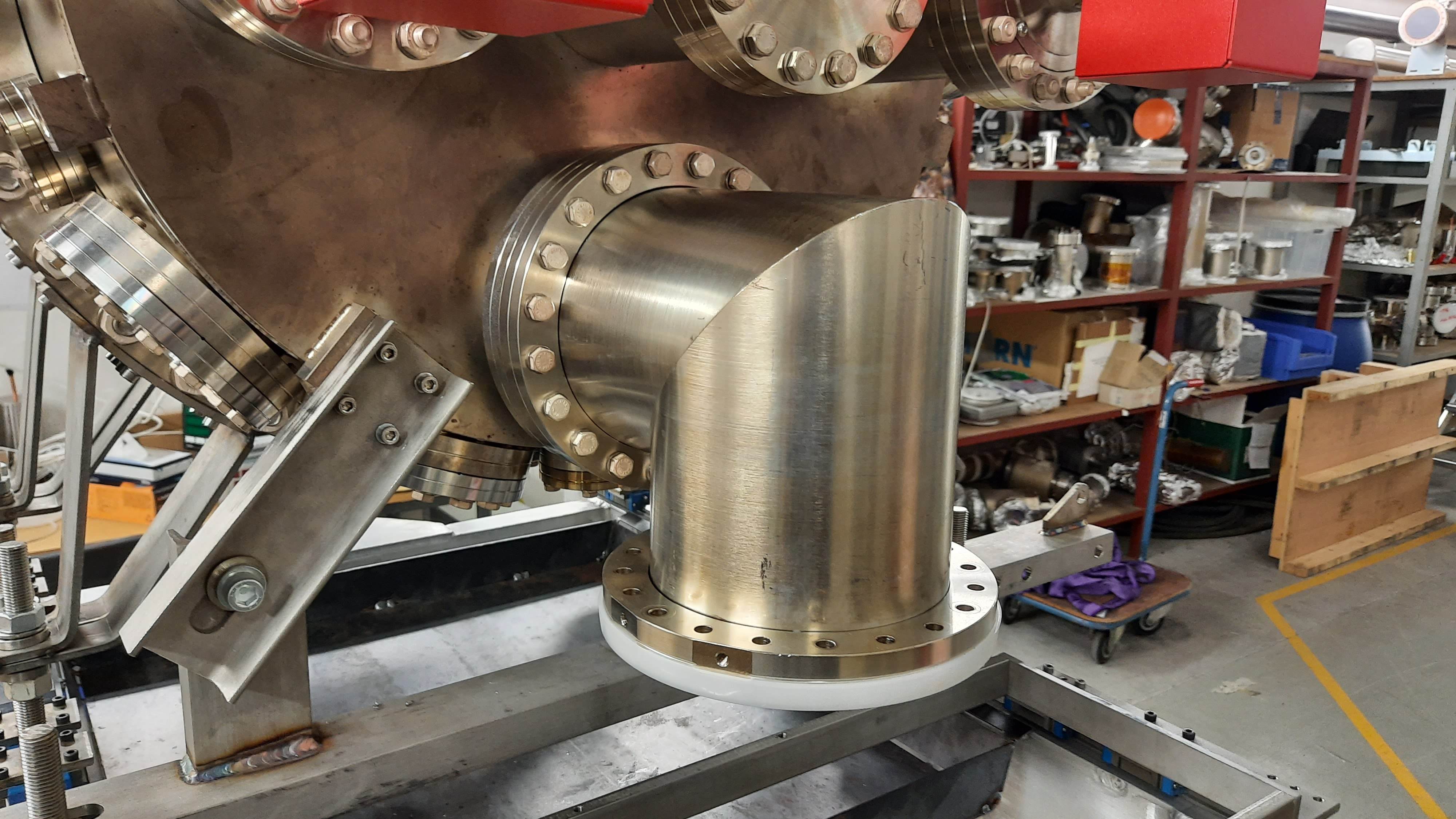

Connected CARME to the CRYRING via tube

plus bellows. See attach.

Had to lift CARME slightly wrt yesterday

beam alignment to get a straight tube. |

| Attachment 1: 20210902_114031.jpg

|

|

|

|

143

|

Fri Nov 5 12:27:11 2021 |

CB RSS + DR NP ML US | First pump down of YR09 |

Tightened all flanges.

Added Pirani gauge and third IE514 to interaction chamber.

Stated pump down. Around 100 mbar on Interaction chamber Pirani gauge very loud metallic noise is heard. Found bellows between CARME and interaction chamber completely pressed flat. CARME and interaction chamber now much closer. Vented immediately. No pictures. Bellows return to normal state.

Repeated slowly and carefully using theodolite laser on reference point on CARME. Found CARME does not move appreciably forward, thus motion must come from interaction chamber frame.

Mounted two feet between CARME and interaction chamber. Pumped down again. Interaction chamber now moves by few mm. No issues with bellows. Left pumping overnight (Thu 4 November)

Found at 1E-6 mbar this morning. Leak tested. Found four minor leaks. Fixed by tightening.

US + Kosmos installed Be window. Pumping down extremely slowly. 1 mbar per 2 second. Started turbo at 1 mbar. Pumping down overnight. No damage to window.

See attached new plastic free struts and motion of interaction chamber before after pumping. See skull nose. |

| Attachment 1: 20211105_131748.jpg

|

|

| Attachment 2: 20211105_135918.jpg

|

|

| Attachment 3: 20211105_135929.jpg

|

|

| Attachment 4: 20211105_140451.jpg

|

|

| Attachment 5: 20211105_150616.jpg

|

|

|

|

141

|

Wed Nov 3 11:18:11 2021 |

CB RSS + DR NK ML | Leak closed |

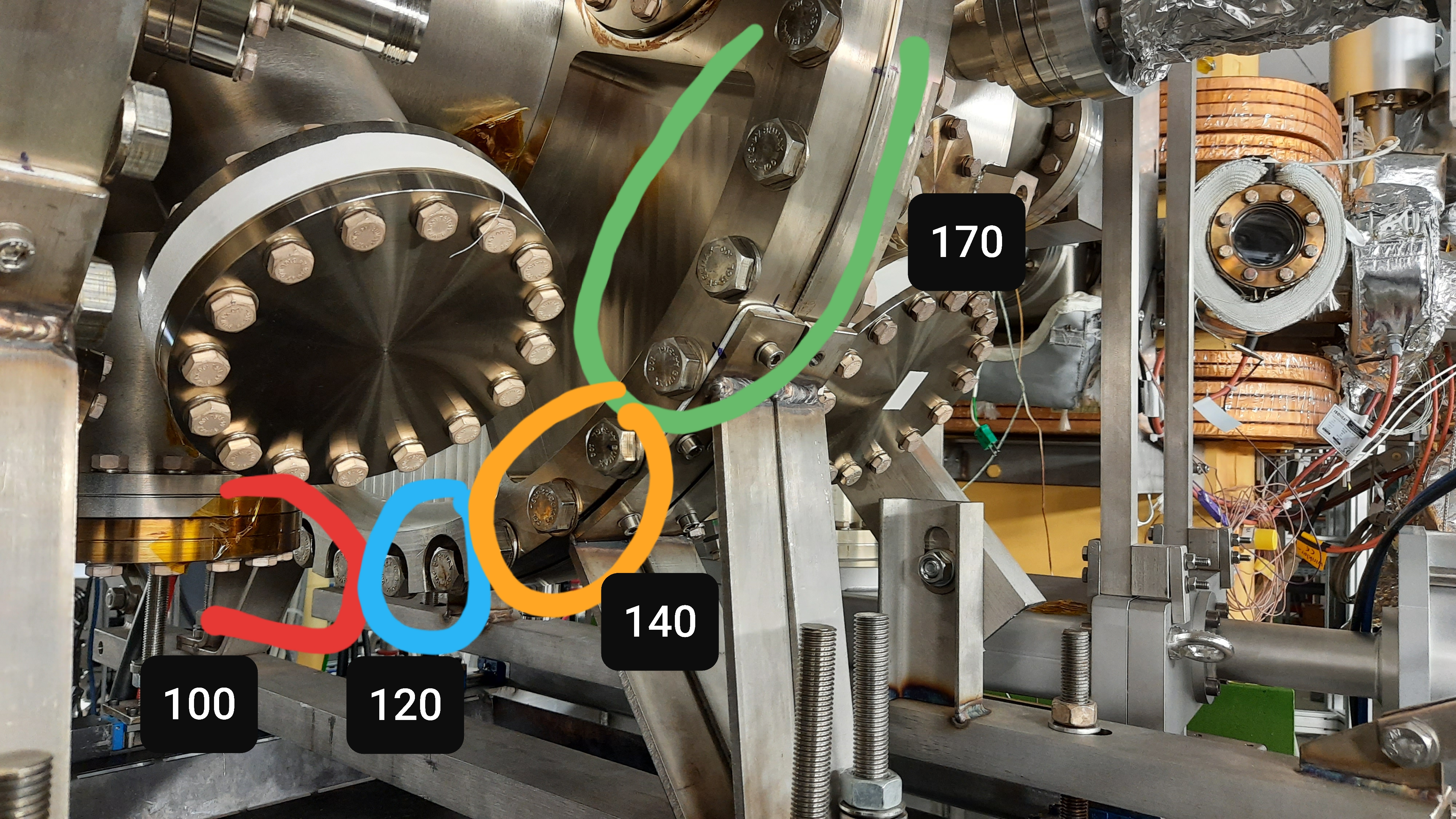

Found CARME at 1.0E-6 mbar. Beginning leak test.

Found leaks in the same location as before. Roughly 1~3E-8 mbar l second vs. base leak of 1E-12

Tightened right hand half of bolts to 120 Nm. No changes but leak goes up to 1E-10 mbar l second when tightening bolts closer to leak location, without He being sprayed.

Tightened bolts closer to leak to 140. Leak goes down to 1E-9 mbar l second

Tightened four bolts closest to leak to 170 Nm. Leak disappeared (<1E-11 mbar). Tested repeatedly all around CARME including left hand side of 600 COF flange. No leaks.

Vented. Installing jet target in the afternoon.

|

| Attachment 1: 20211103_110244.jpg

|

|

| Attachment 2: 20211103_110414.jpg

|

|

|

|

51

|

Wed Sep 1 17:14:16 2021 |

CB RSS + DR ML | CARME mounted on the CRYRING |

Lifted CARME with Al support on the

CRYRING. No issues during transportation.

Drilled new holes in the Al feet to fit

elephant feet. Unclear if the issue is

with the model, the frame or the feet

themselves. In any case this issue is

sorted.

CARME was designed to interface with the

CRYRING via the cross section with pumps

and sensors that we decided dismount. To

replace this section a length of xhv

tubing and a bellow will be employed.

Prepared today, to be mounted tomorrow.

Aligned CARME height with beam height.

This posed issues due to difficulty to

adjust bolts under the cross members used

to support the motors. See previous log

entry.

Bolts under those cross members are now

only finger tight. Unclear whether the

CARME section will drop slightly if

disconnected from main body. It's the

section housing the moving Dssds. May be

an issue for tightening it back. Will

investigate.

Gate valves and supports to be installed

tomorrow morning. |

| Attachment 1: 20210901_162435.jpg

|

|

| Attachment 2: 20210901_173059.jpg

|

|

| Attachment 3: 20210901_174157.jpg

|

|

| Attachment 4: 20210901_134635.jpg

|

|

| Attachment 5: 20210901_173059.jpg

|

|

|

|

46

|

Tue Aug 31 07:09:54 2021 |

CB RSS (rem) JM | Preparation for mounting |

(30 August 2021)

The current state of YR09 is as per attach 1. CCC has been removed, but additional pumps and gauges remain. Some

will have to be mounted on CARME. Dismounting is scheduled for this Wed.

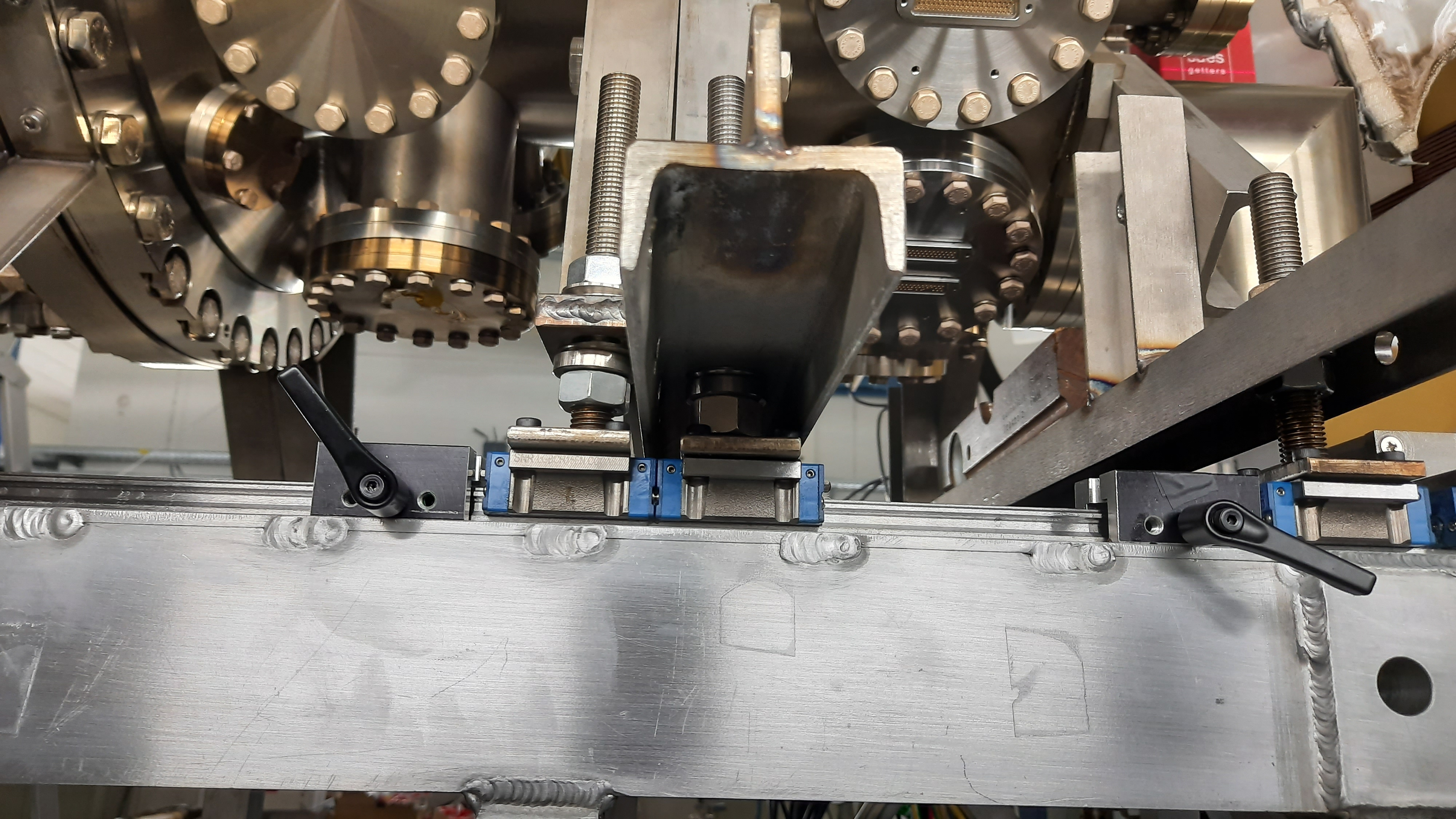

CB and RSS have been preparing for CARME to be mounted. JM supplied pictures of mounting process in DL. Attach 2-5.

2: Studs on carriages

3: CARME feet

4: Back foot

5: Elbows support

All components required have been located in the boxes except

- Cap hex bolts (M4 x 12?) to mount studs on carriages

- Plastic rails to remove cariages (a solution with bubble-wrap was found. Extra carriages are now in a box. Do

not turn it around.)

- Baking tray does not fit with carriages. Unclear how it did before. Will try to file down edges today.

- Bolts for CARME feet are of rather poor quality, and a host of different sizes. We may have to buy some, but

unclear what length.

- Studs are of different heights. That was not clear from previous pictures (attach 6)

- New and improved valve/elbow support (attach 7) is aligned worse than old one. Will keep using old one. Should

still work somehow. |

| Attachment 1: 20210830_110920.jpg

|

|

| Attachment 2: Al_frame.jpg

|

|

| Attachment 3: 20200814_142437.jpg

|

|

| Attachment 4: 20200902_153219.jpg

|

|

| Attachment 5: 20210830_160613.jpg

|

|

| Attachment 6: 20210830_115903.jpg

|

|

|

|

47

|

Tue Aug 31 11:55:11 2021 |

CB RSS | Last preparations for CARME lift |

Found strut bolts in the bag with

spherical washers. Mounted the struts and

the washers. See attach 1.

Vented CARME in preparation for lift.

Turbo off

Pressure starts increasing without

introducing leaks. Up to 10-4 mbar. IE 514

off.

Removed plastic cap from leak valve.

Pressure rate increases. Leaky valve?

Turbo motor speed reaches 0 Hz in 1h

Opened leak valve. Scroll off. Pressure to

10 mbar. Not increasing anymore. Turbo

leak aperture likely to small to vent

CARME volume.

Disconnected scroll. Carefully let air in

by tweaking flexible hose connection. Not

recommended again, but should be safe

given turbo fully stop and chamber nearly

vented.

Reached atmosphere in 10 minutes.

Now waiting for lifting support to mount

feet. |

| Attachment 1: 16304077162843806956479048661374.jpg

|

|

| Attachment 2: 16304077904321905824276870110392.jpg

|

|

|

|

50

|

Wed Sep 1 12:05:28 2021 |

CB RSS | Preparation for CARME on CRYRING YR09 |

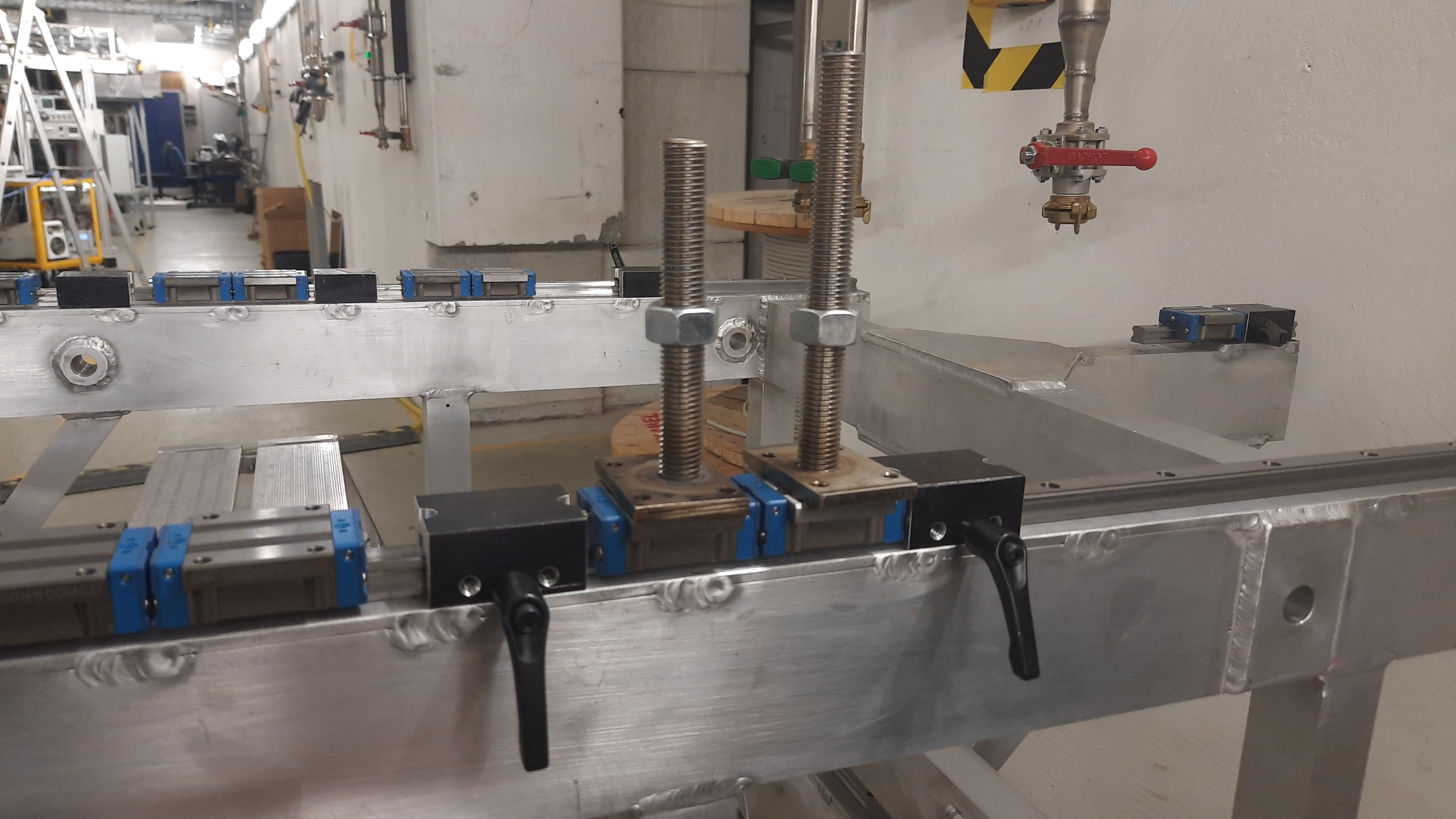

Mounted additional cross member for motor

support. See attach 1

Washer required to make it fit on foot on

one side.

Holes in Al support are not matching elephant feet...! Will have to re-

drill them now.

Yr09 fully dismounted downstream |

| Attachment 1: 20210901_125504.jpg

|

|

| Attachment 2: 20210901_125517.jpg

|

|

|

|

54

|

Fri Sep 3 08:12:39 2021 |

CB RSS | Pressure after overnight pump down |

03.09.2021 09:00 5.27E-7 mbar

03.09.2021 13:00 4.08E-7 mbar

09;00 Will keep pumping down this morning. |

| Attachment 1: 20210903_085646.jpg

|

|

| Attachment 2: IMG_4487.JPG

|

|

|

|

55

|

Fri Sep 3 08:14:51 2021 |

CB RSS | Issues foreseeable splitting CARME |

In order to install the detector supports

and eventually install the detectors

themselves CARME must be split and

separated via rails.

However it does not look like we have

sufficient clearance on either side. See

pictures attached.

I suggest we mount the strain relievers

wires and motors, not split CARME, and

pump down + bake to give us time to figure

out what is different from the models and

how to fix it. Outgassing from detector

supports should be negligible wrt wires.

One possibility would be to install rail

extension on the back side of the Al frame

where the cross was meant to be supported,

temporarily remove the tube connecting

CARME to the YR09 valve and slide CARME

back. Will need to discuss with Peter. |

| Attachment 1: 20210903_085801.jpg

|

|

| Attachment 2: 20210903_085805.jpg

|

|

| Attachment 3: 20210903_085811.jpg

|

|

| Attachment 4: 20210903_085822.jpg

|

|

| Attachment 5: 20210903_085958.jpg

|

|

| Attachment 6: 20210903_090003.jpg

|

|

| Attachment 7: 20210903_090024.jpg

|

|

|

|

57

|

Fri Sep 3 15:55:00 2021 |

CB RSS | Issues with cable clamps |

Attempted to mount cable clamps for strain

relief on inner part of Allectra

feedthroughs.

SS support mounted with M3 vented screws

OK

Cannot figure out which bolt type to use

to fix Macor on SS support.

M2 falls through

M3 screws in partly and gets stuck...

Will need to figure out how to get unstuck

No M2.5 bolts available.

In contact with Peter. Not clear what the

solution was

Will try again tomorrow or move to motors

first. |

| Attachment 1: 20210903_154614.jpg

|

|

| Attachment 2: 20210903_162519.jpg

|

|

|

|

58

|

Sat Sep 4 15:54:50 2021 |

CB RSS | Motor mounting preparation |

Prepared the motors to be mounted and

found all components required. No issues.

May have to partly dismount again to fix

bellows depending on ease of mounting.

Note extremely long screws mentioned in

previous Elog inventory are to be used for

the motors.

Attempted to swap Pirani gauge with ours

but realised it's CF and needs appropriate

port without risk of baking. That port

would be on the interaction chamber which

is not going to be mounted. Will probably

keep using ABD gauge for now.

Peter spotted mistake in mounting front

foot of CARME which is back to front.

Correct mount will gain us 2-3 cm but will

conflict with current CARME position fixed

by tube on the back. Will discuss options

with ML.

Motor mounting to take place on Mon with

local technical support. No activities

tomorrow unless a solution for the clamps

mentioned in previous entry is found (i.e.

what size bolts go on top). Peter will

check step file and we will consult with

local engineers on Mon pm. |

| Attachment 1: 20210904_162517.jpg

|

|

| Attachment 2: 20210904_162520.jpg

|

|

|

|

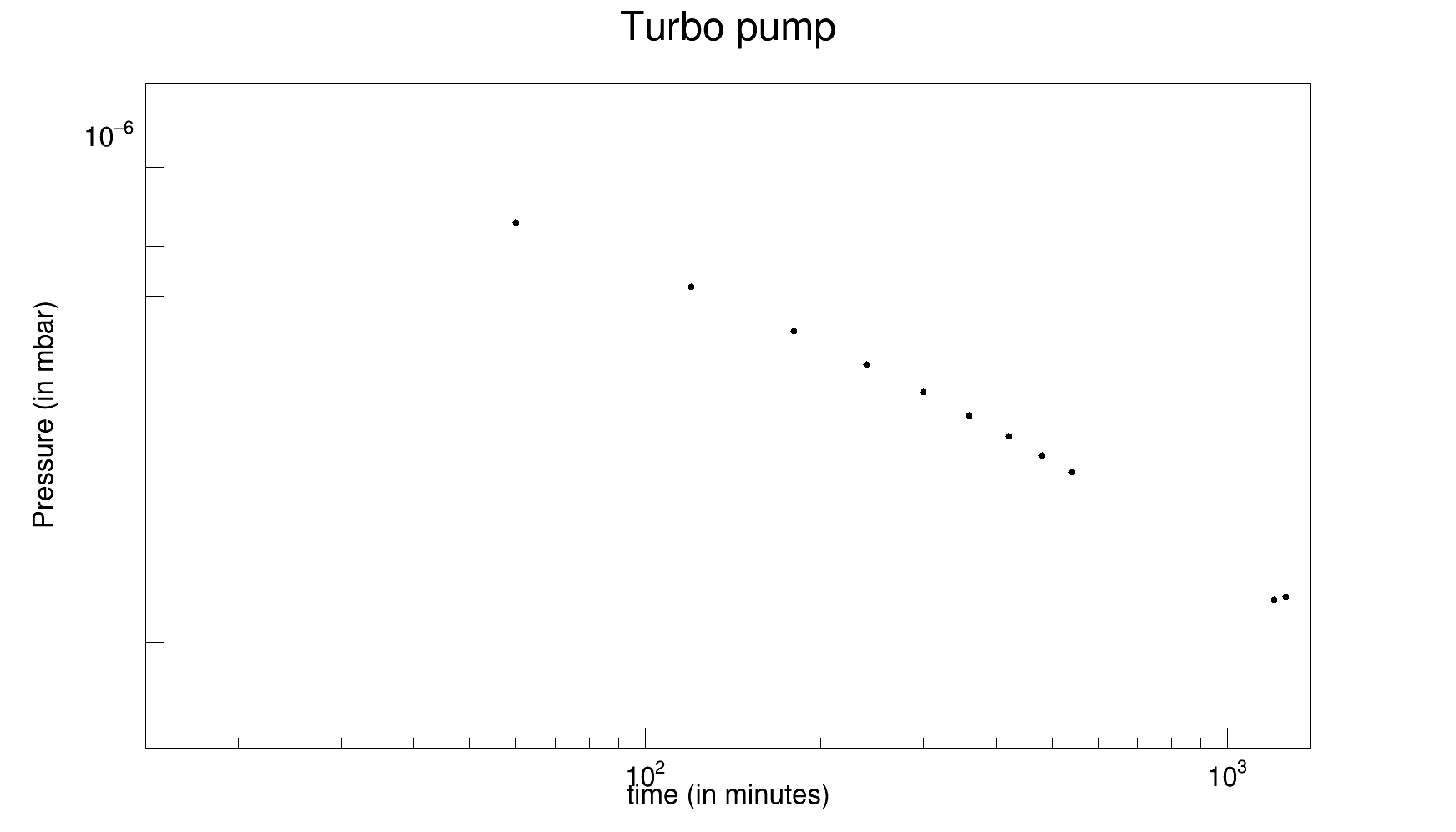

68

|

Sat Sep 11 16:01:44 2021 |

CB RSS | Preparations for shutdown |

Found CARME pressure at 2E-7 mbar

Raspberry pi took pictures until 4 am and

then lost contact with camera. Reasons

unclear. Plugging camera in / out solved

the issue. Will have to be investigated

if it happens again.

Left list of things to do with RSS. In

particular:

- Install xhv feedthrough and

thermocouples. Prepared on desk

- Install blocking pin in right hand motor

after pressure returns to atmosphere

- Cover bellows with aluminium to protect

from fibreglass when mounting tent

eventually

- Check all parts available for detector

supports with mounting sketch Peter sent (

RSS to recover sketch)

- Investigate baking program logging.

Unclear if logging is working - did we

disable it for some reason?

Valve on scroll closed. Scroll off. Turbo

off. Pressure sensors off. Raspberry pi

off.

Activities to resume on 16 September.

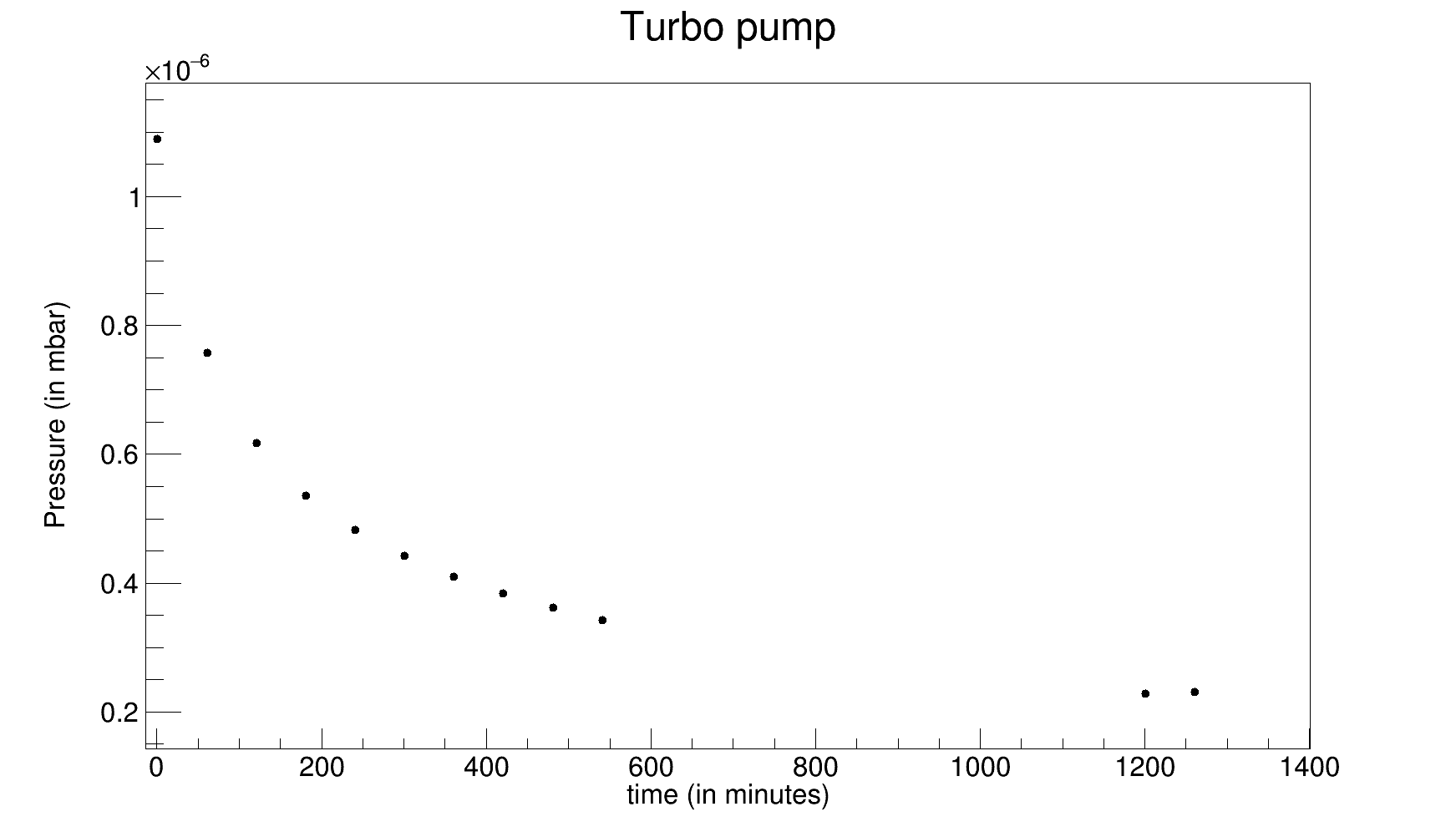

Attached are the pumping down plots

start point: 10.09.2021 19:00

end point: 11.09.2021 16:00

10.09.2021 19:00 1.09e-6

10.09.2021 20:00 7.57e-7

10.09.2021 21:00 6.17e-7

10.09.2021 22:00 5.36e-7

10.09.2021 23:00 4.82e-7

11.09.2021 00:00 4.42e-7

11.09.2021 01:00 4.10e-7

11.09.2021 02:00 3.84e-7

11.09.2021 03:00 3.62e-7

11.09.2021 04:00 3.43e-7

11.09.2021 15:00 2.29e-7

11.09.2021 16:00 2.31e-7 |

| Attachment 1: turbo_pump.png

|

|

| Attachment 2: log_scale.png

|

|