| |

ID |

Date |

Author |

Subject |

|

|

223

|

Tue Feb 22 00:32:35 2022 |

JM, CB, LV, PM, AK | Beam ON, Target ON Run 54 |

01:30

Beam ON ~6E6 pps

Target ON and open to the ring

Target E4 inlet pressure 8.12E-9 mbar

Dump S3 ~ 7E-10 mbar

Nozzle temperature 150 K

1:40

Run 54 started, monitoring code restarted. |

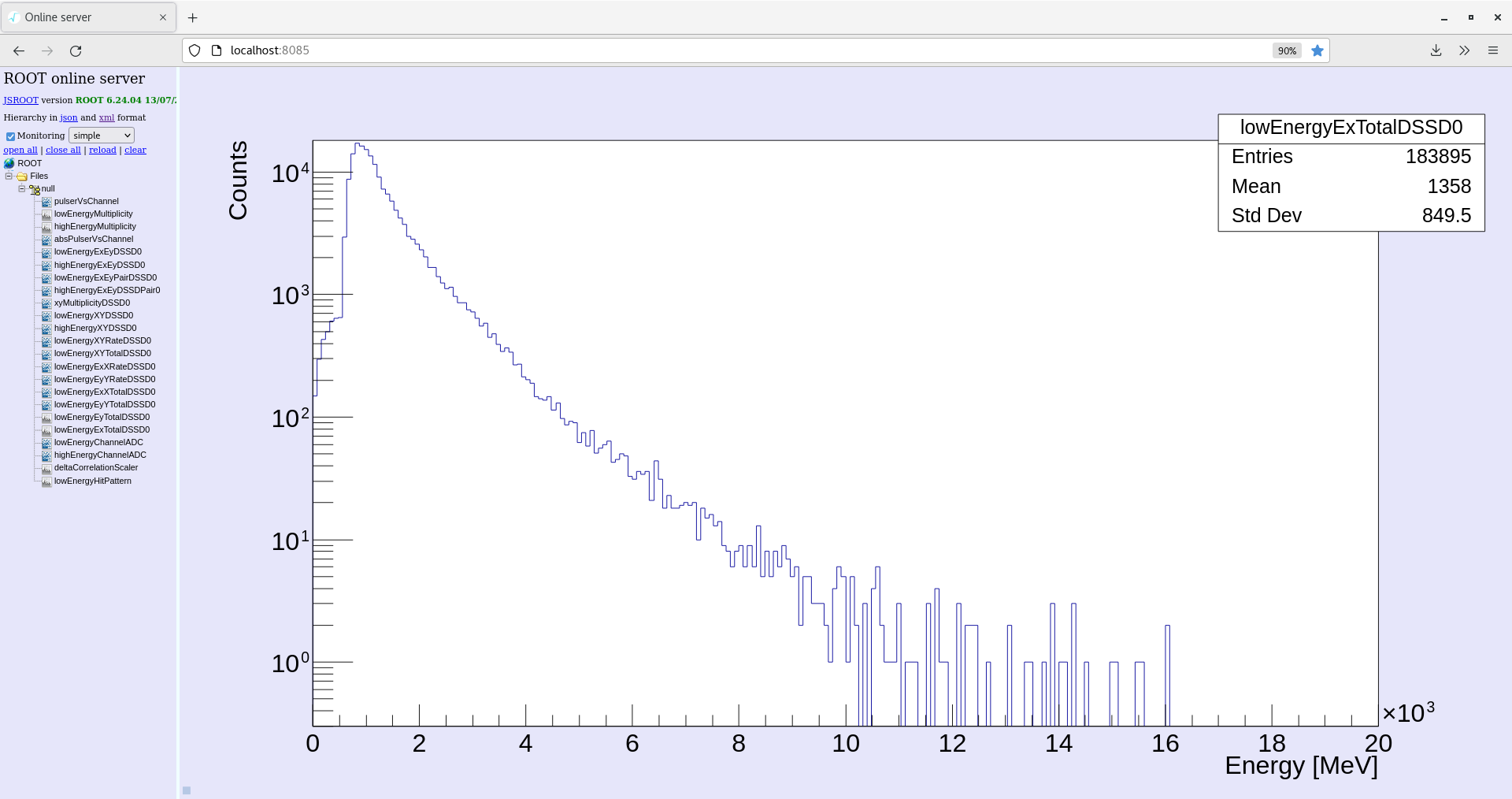

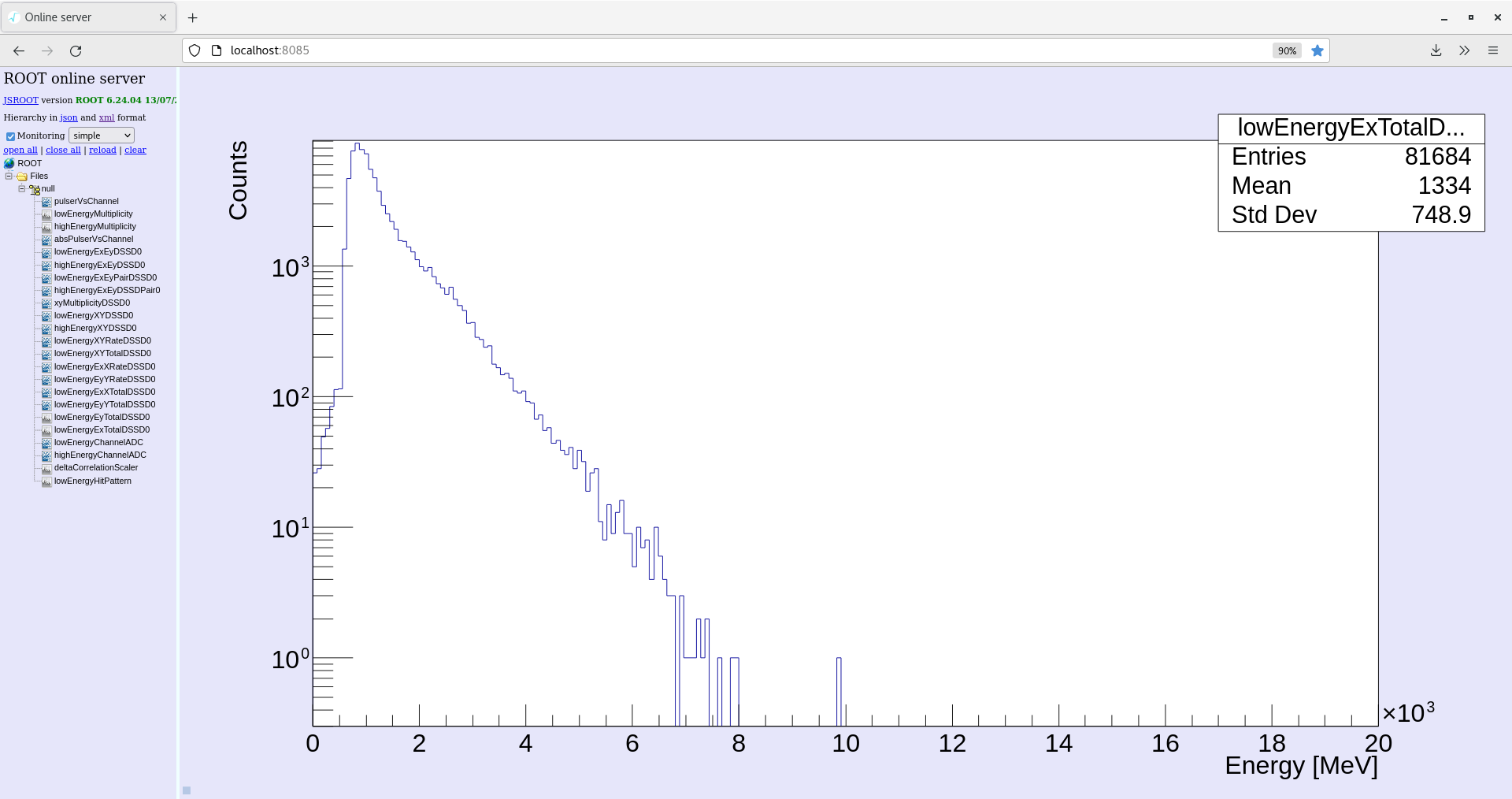

| Attachment 1: 2022-02-22_01-38-53-Ex-histogram.png

|

|

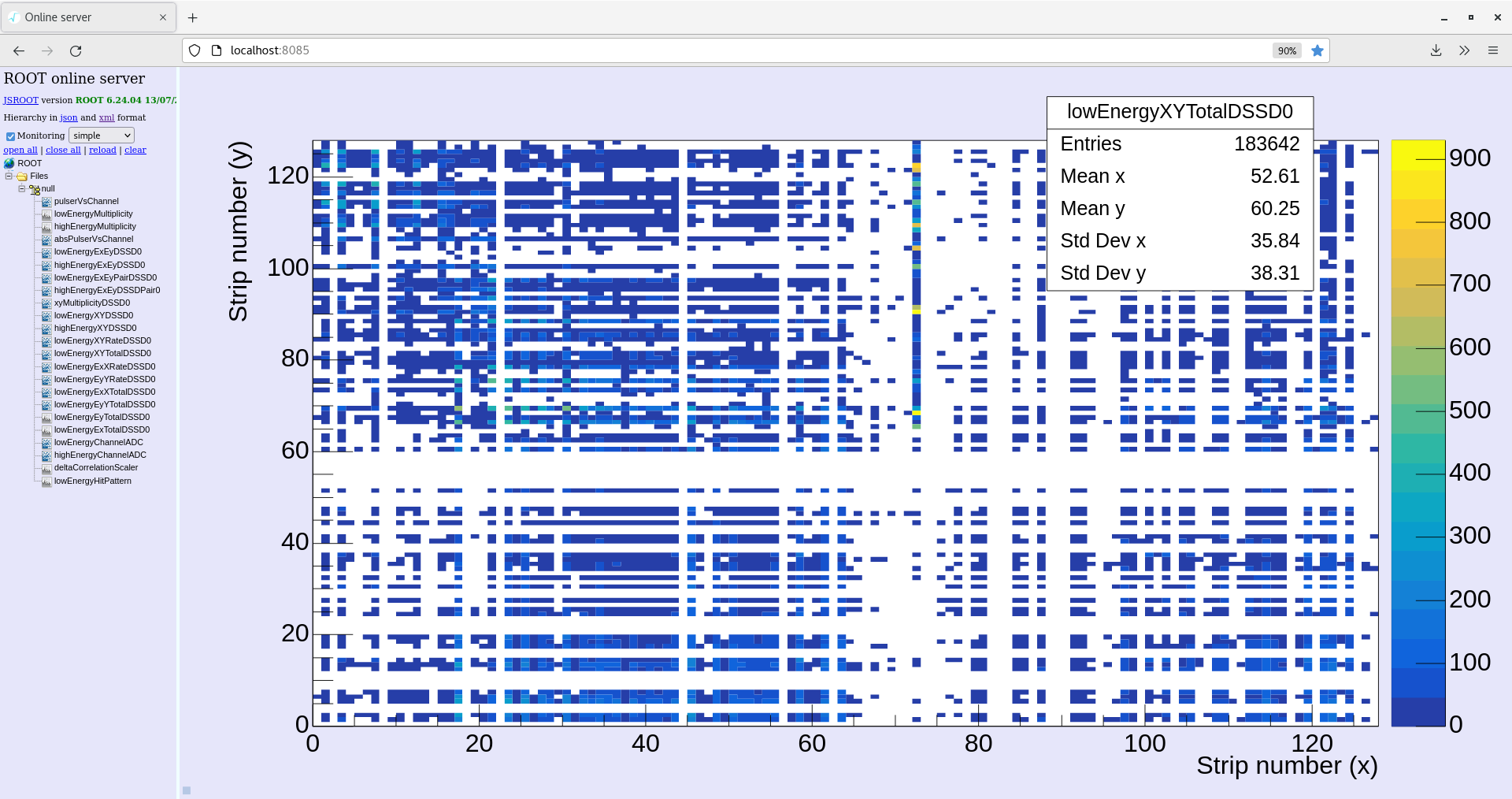

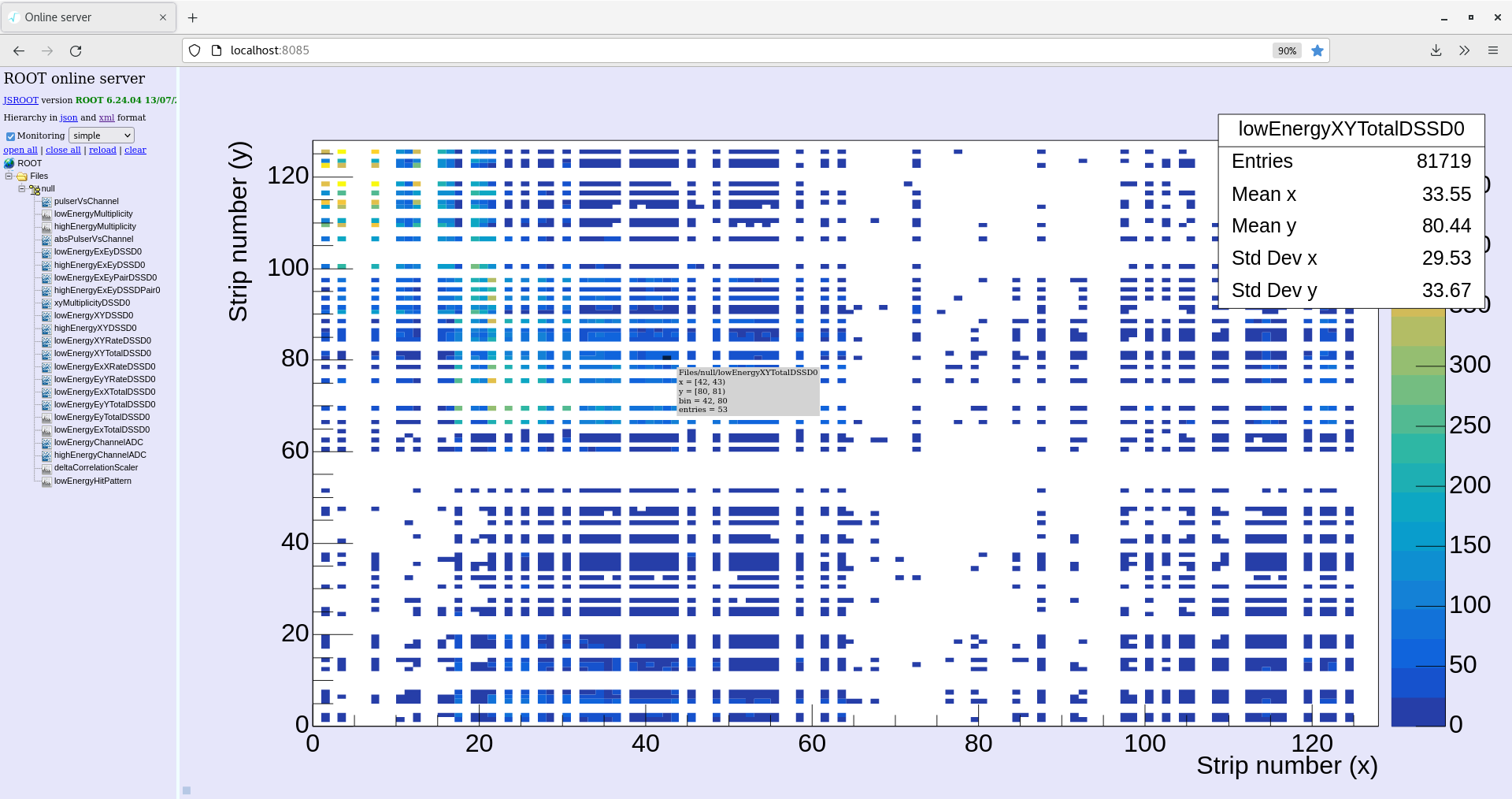

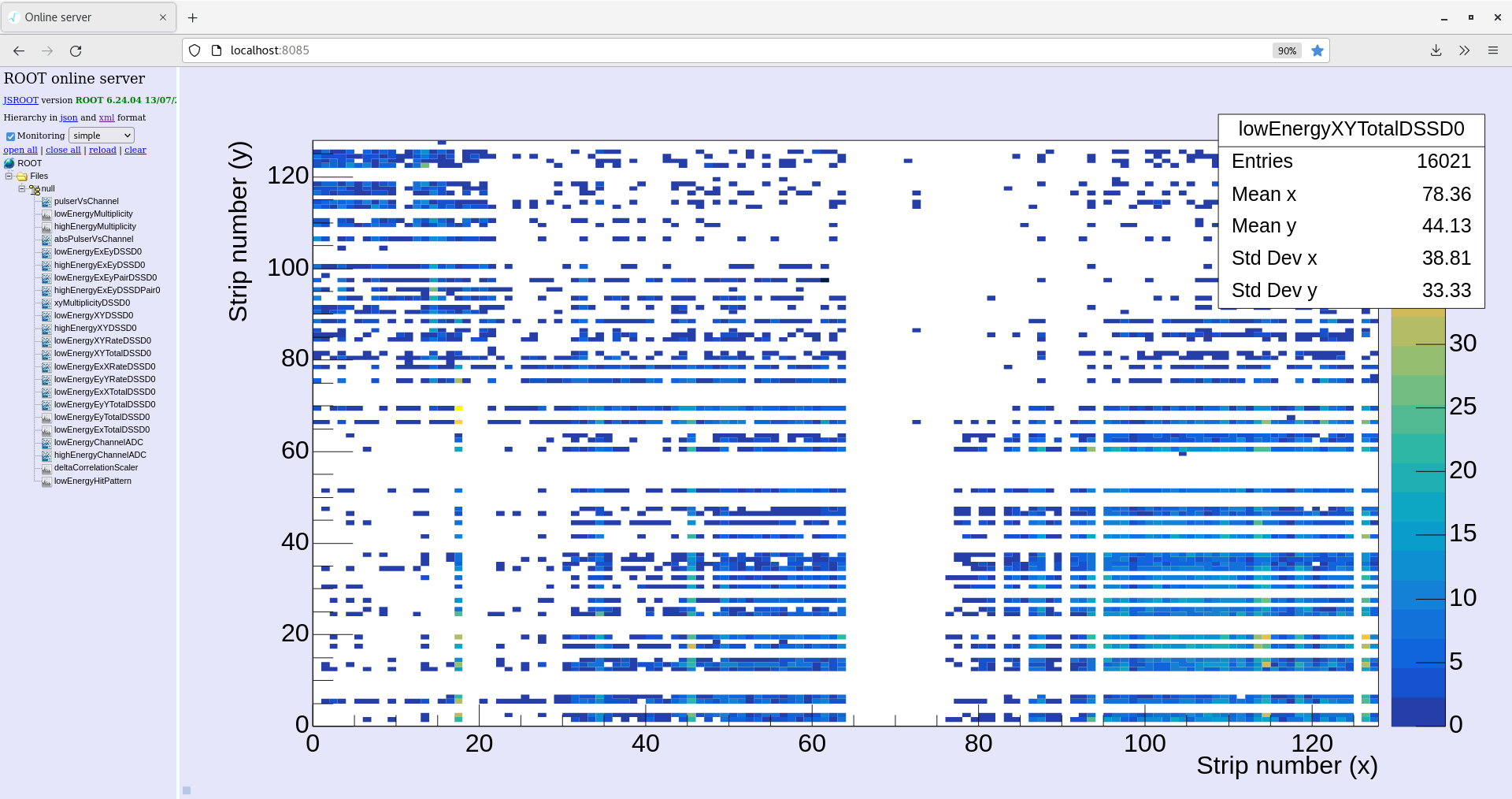

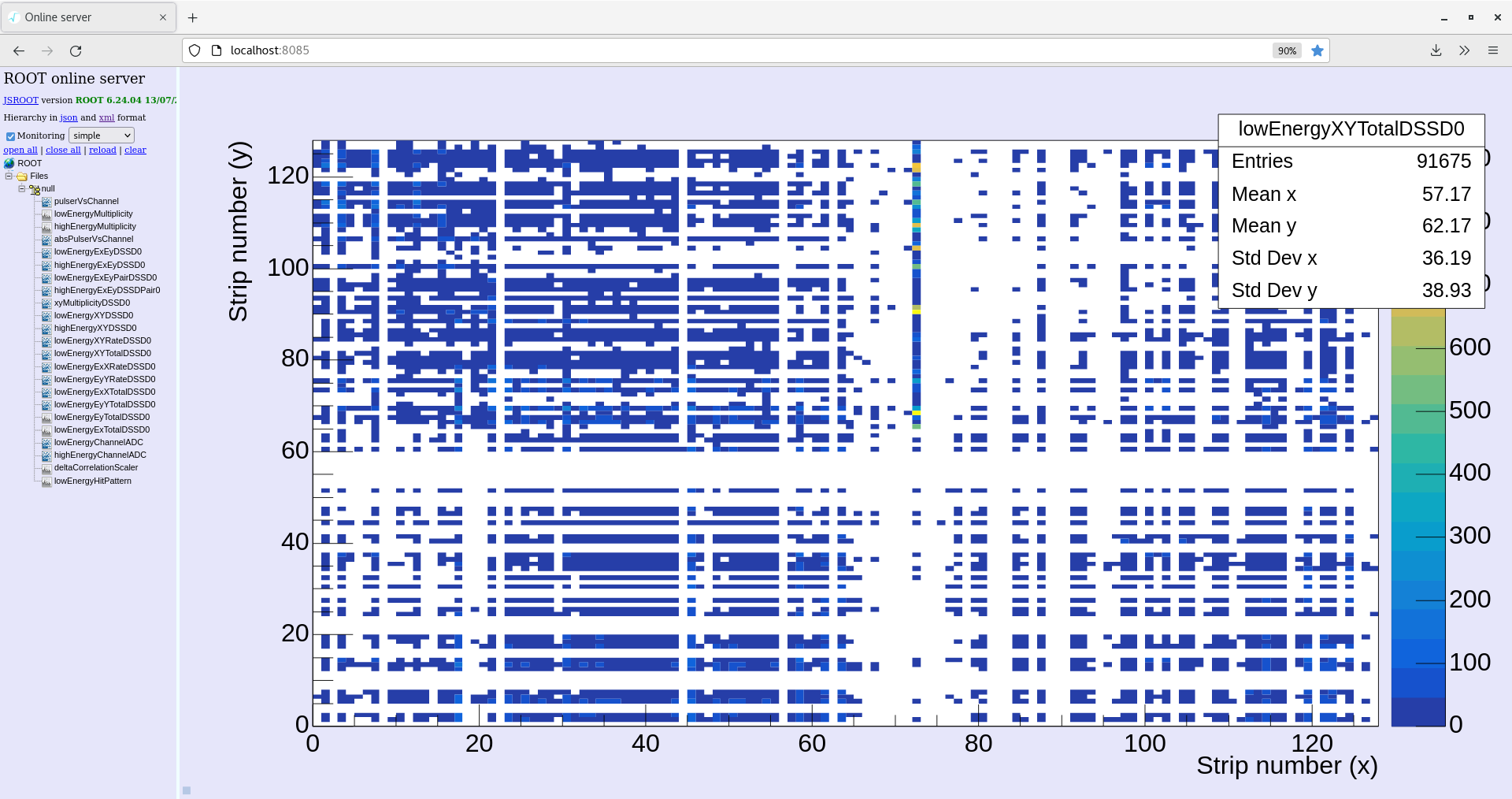

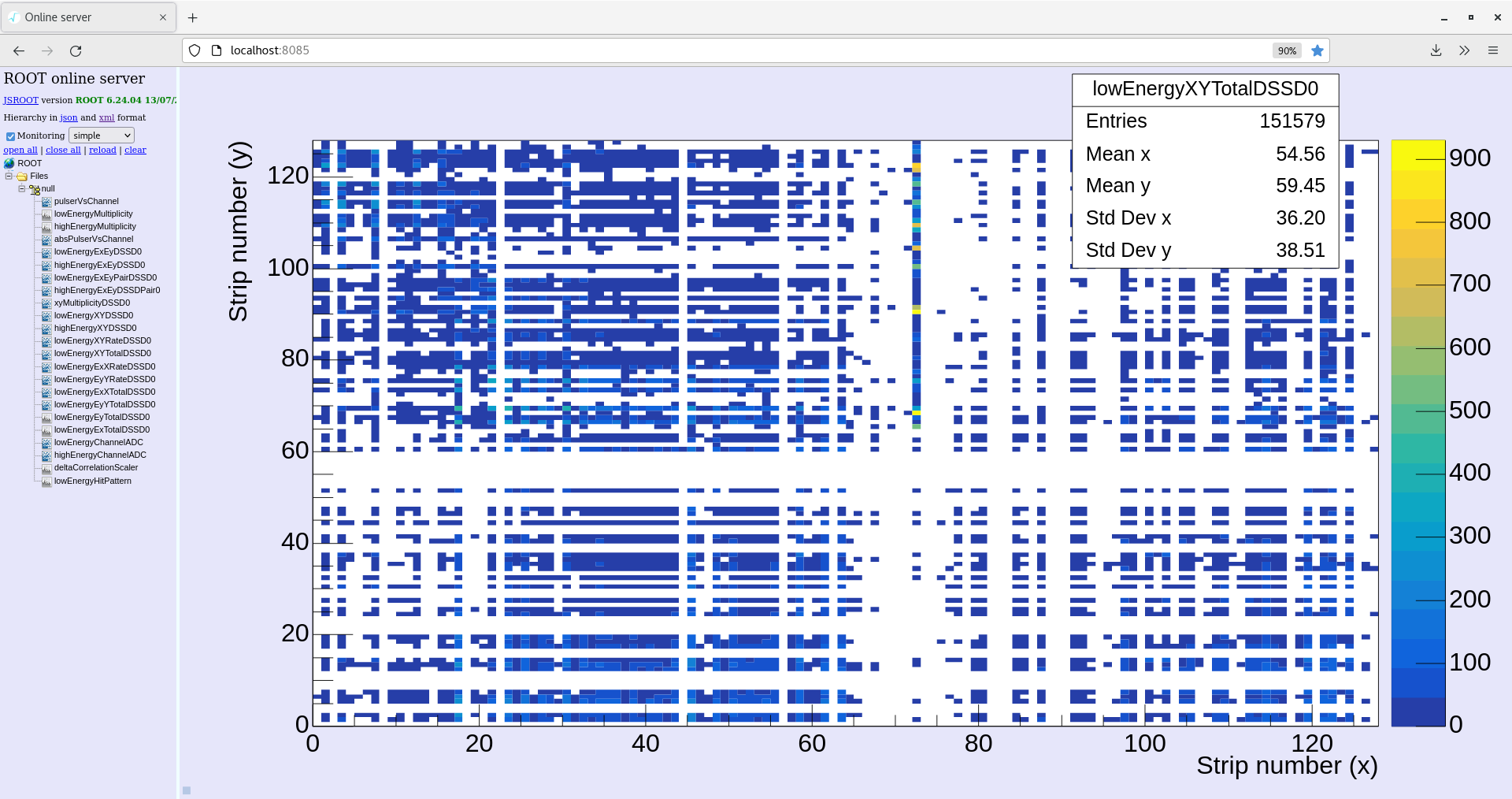

| Attachment 2: 2022-02-22_01-38-17-XYtotal.png

|

|

|

|

224

|

Tue Feb 22 02:02:11 2022 |

JM, CB, LV, PM, AK | Beam ON, Target ON Run 54 |

03:00

Beam ON ~7E6 pps

Target ON and open to the ring

Target E4 inlet pressure 8.5E-9 mbar

Dump S3 ~ 7.3E-10 mbar

Nozzle temperature 150 K

Run 54 started, monitoring code restarted. |

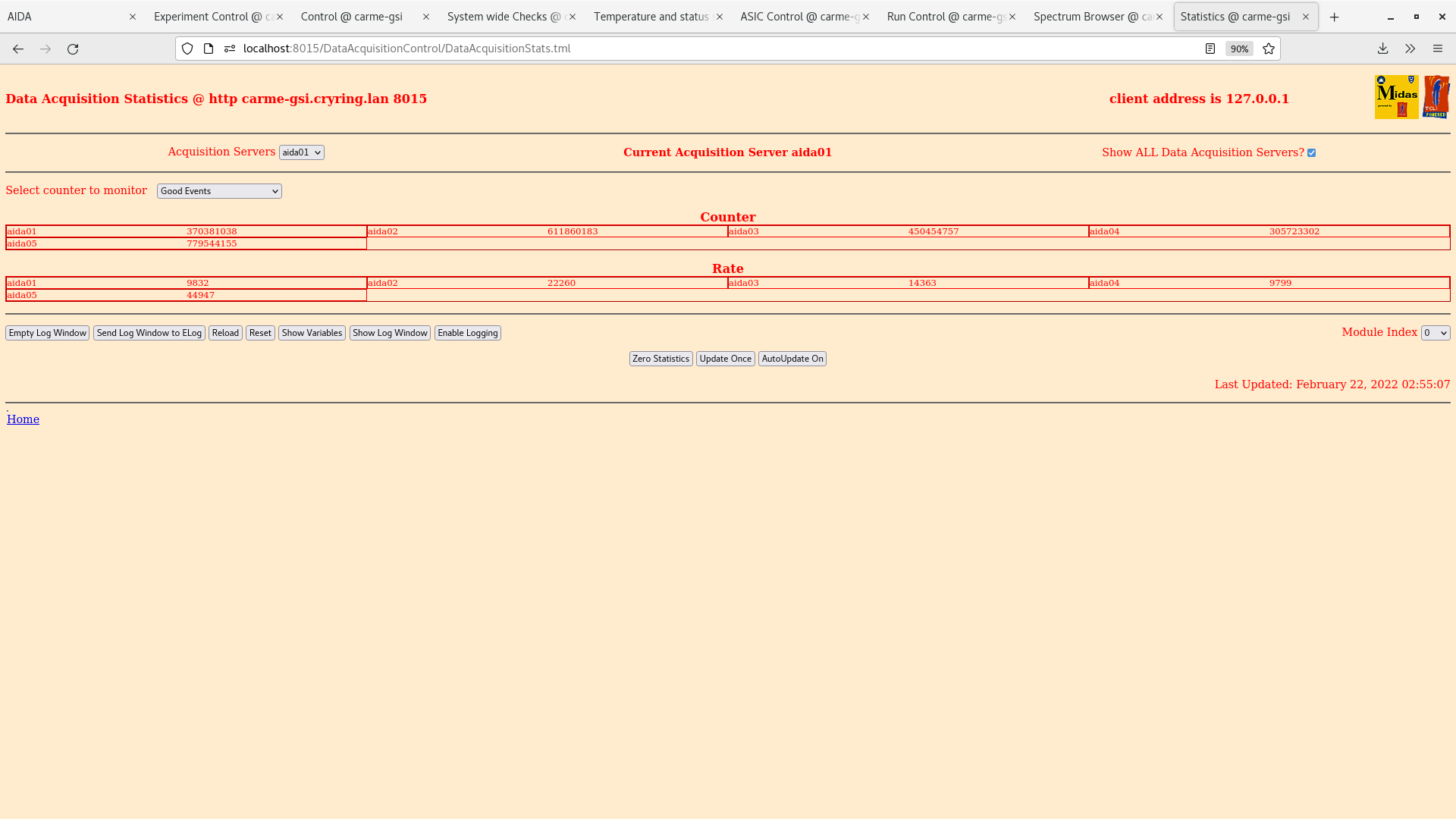

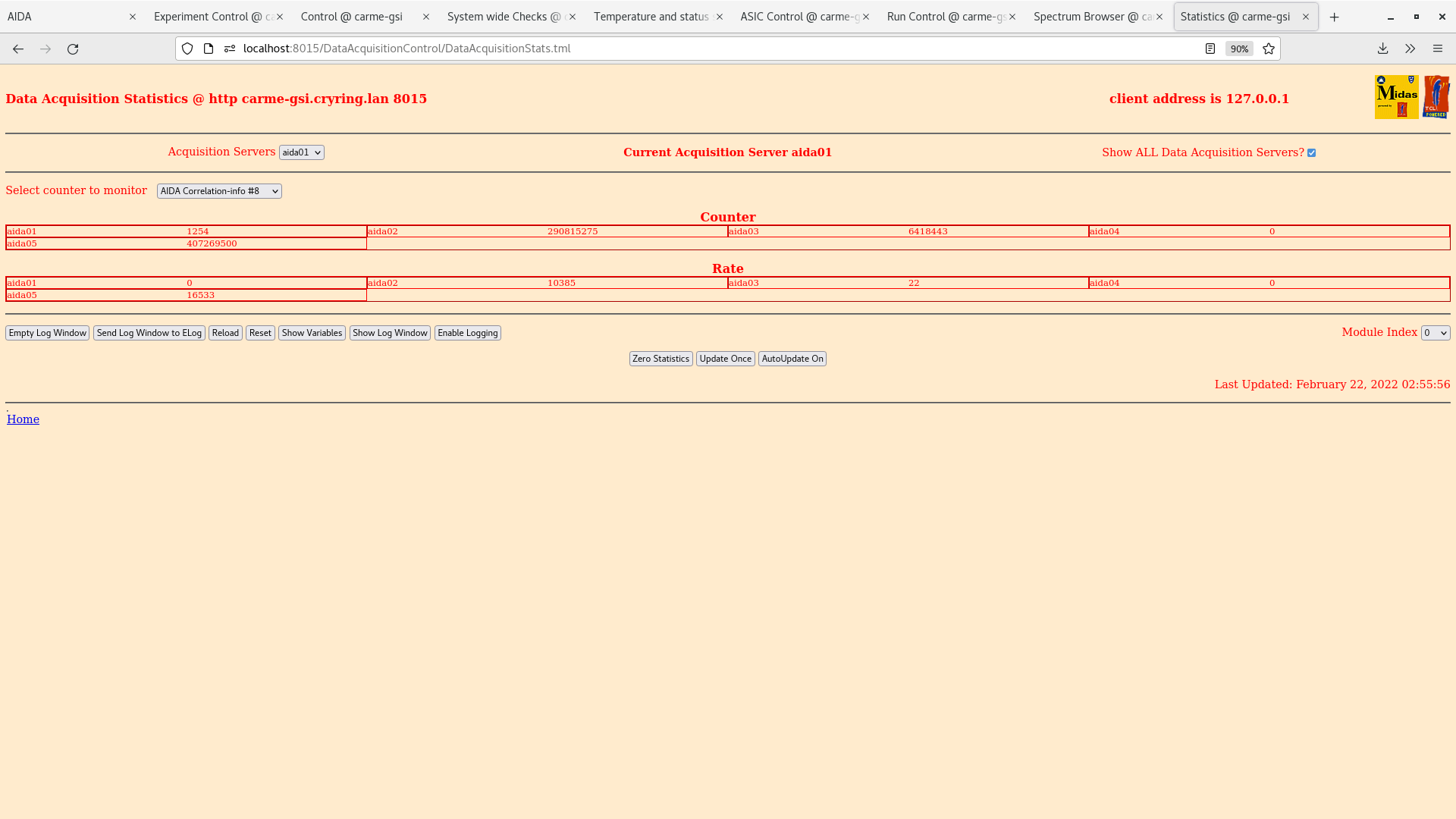

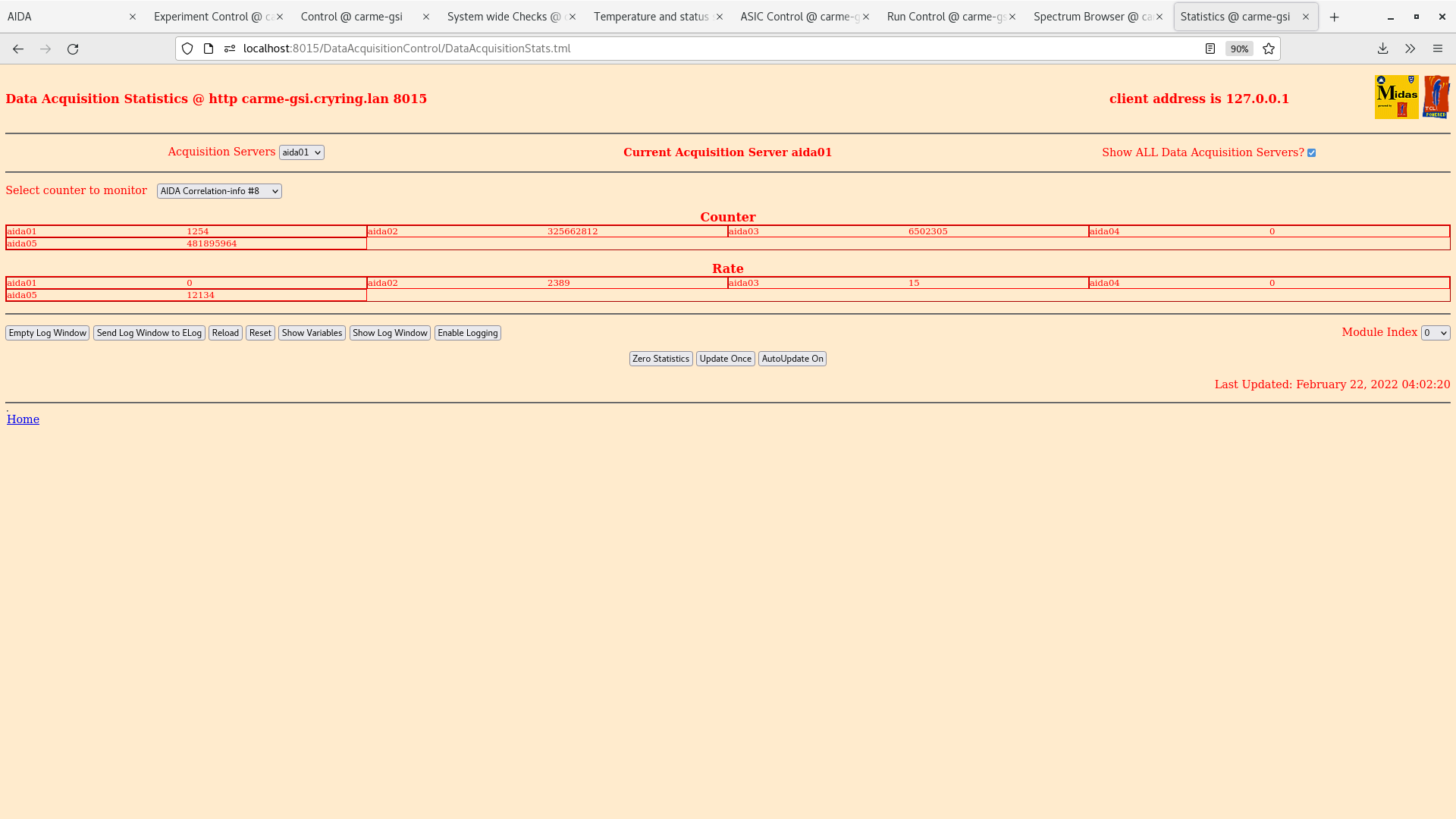

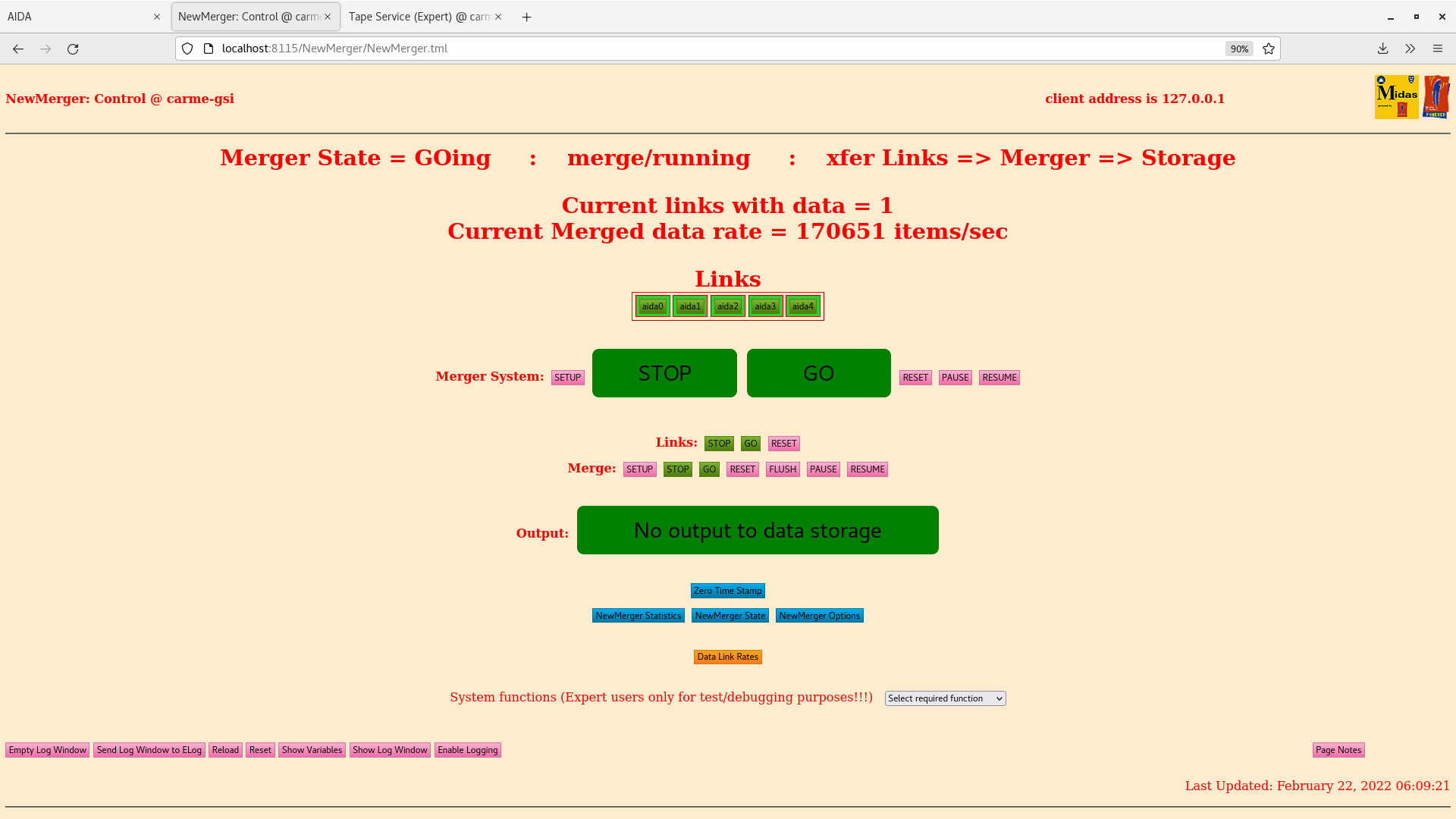

| Attachment 1: TapeServer2022-02-22_02-49-29.png

|

|

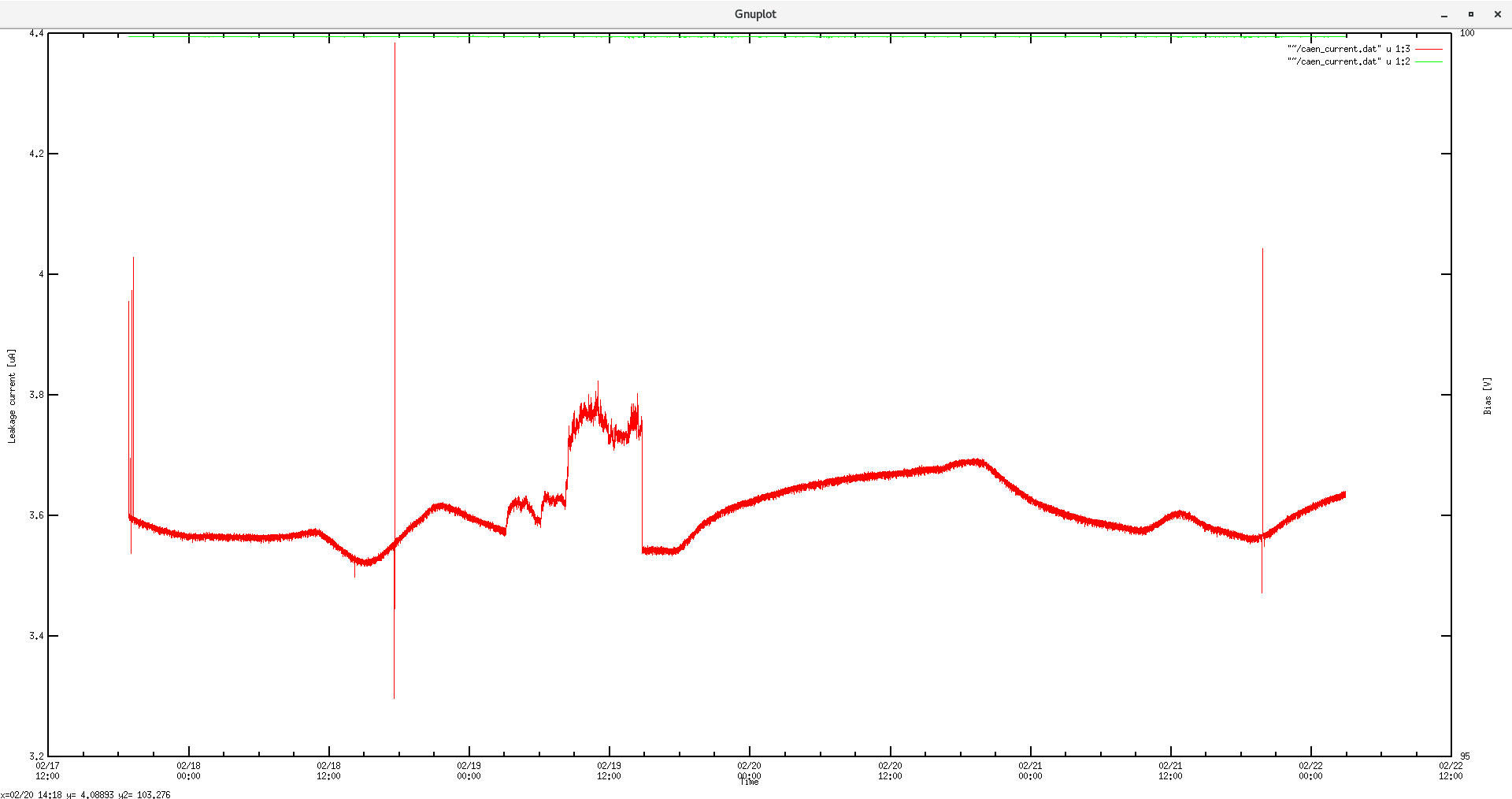

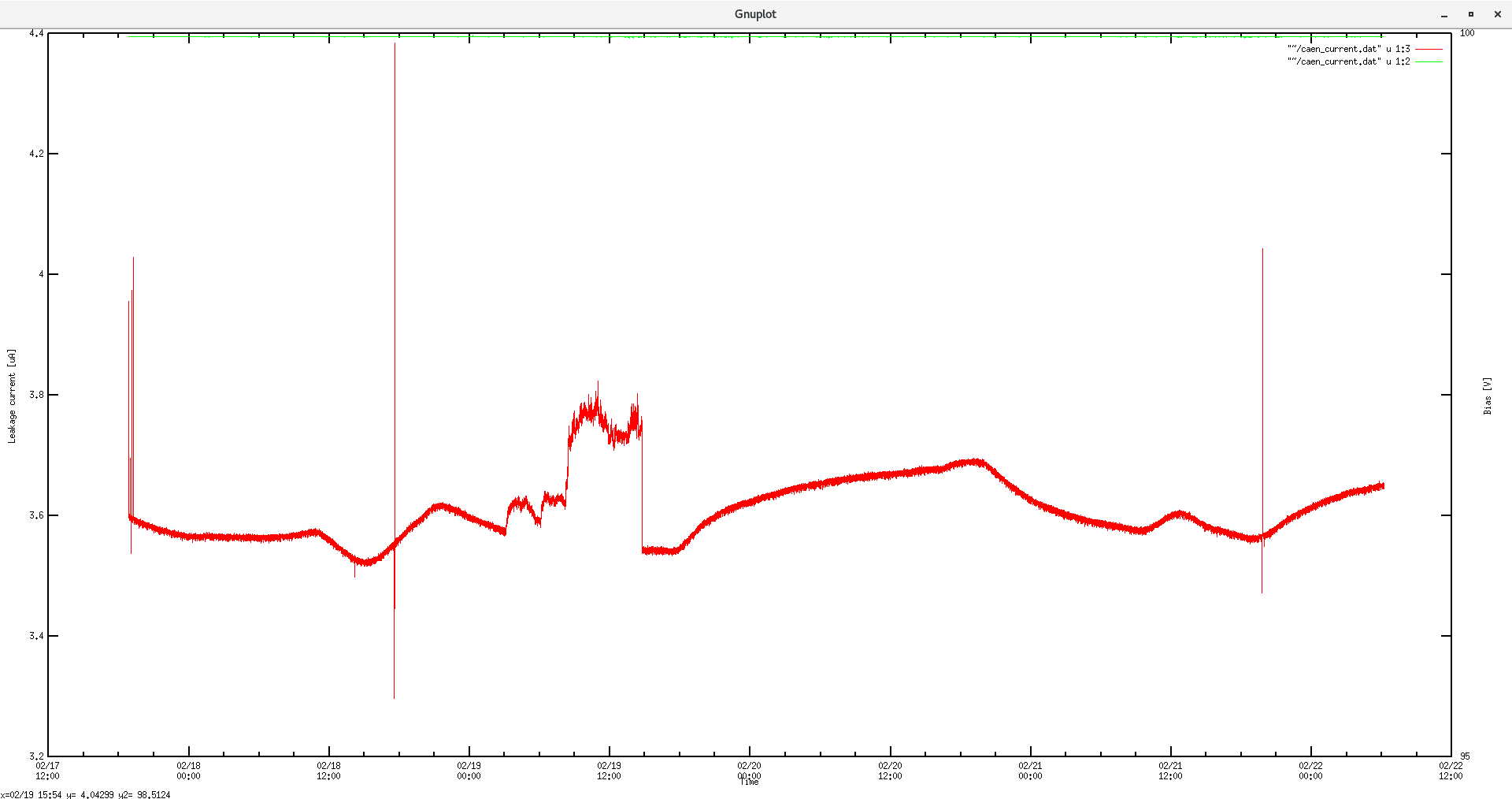

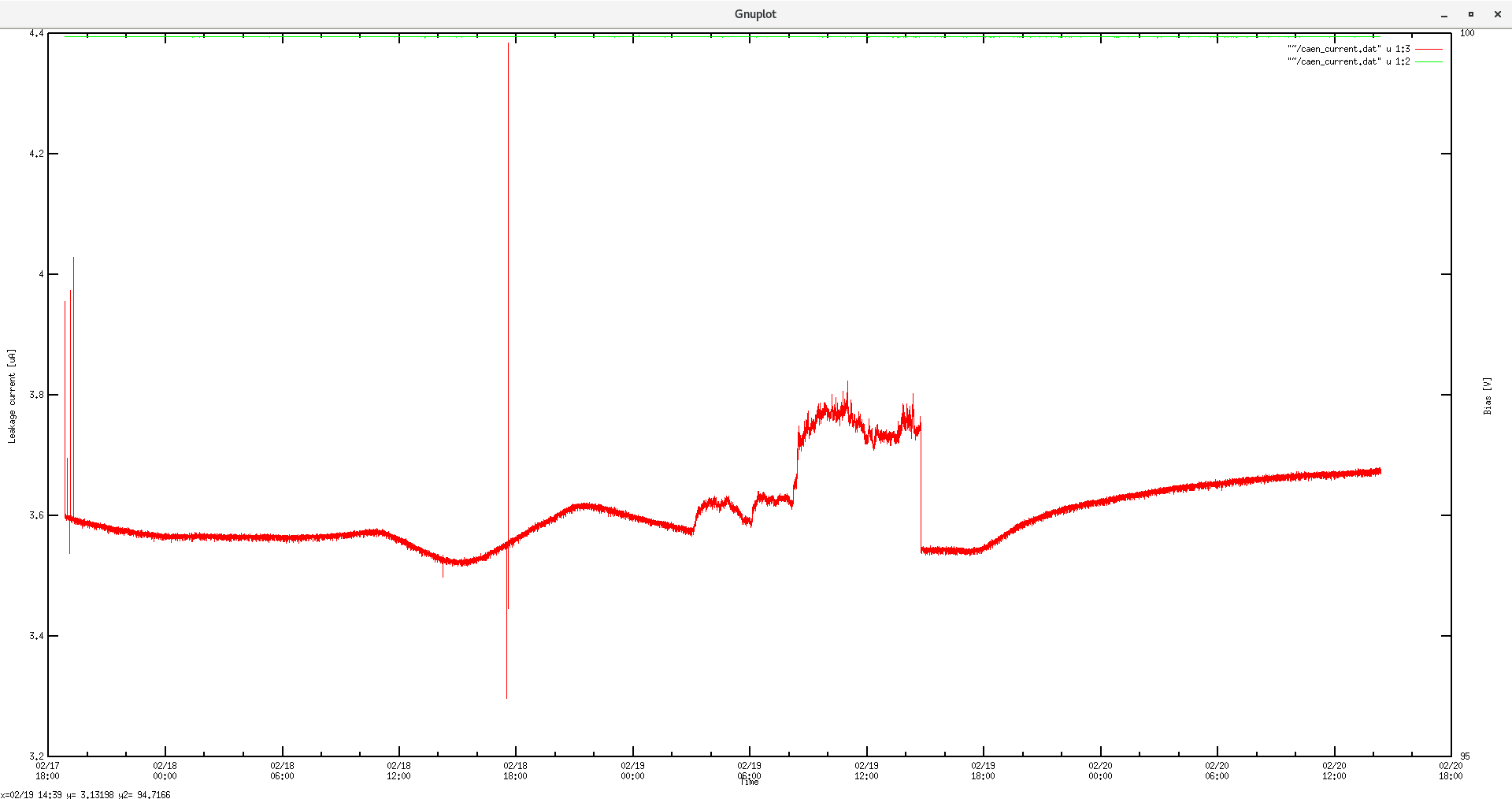

| Attachment 2: Leakage_current2022-02-22_02-50-39.png

|

|

| Attachment 3: Temperature2022-02-22_02-52-02.png

|

|

| Attachment 4: Screenshot_from_2022-02-22_02-54-34.png

|

|

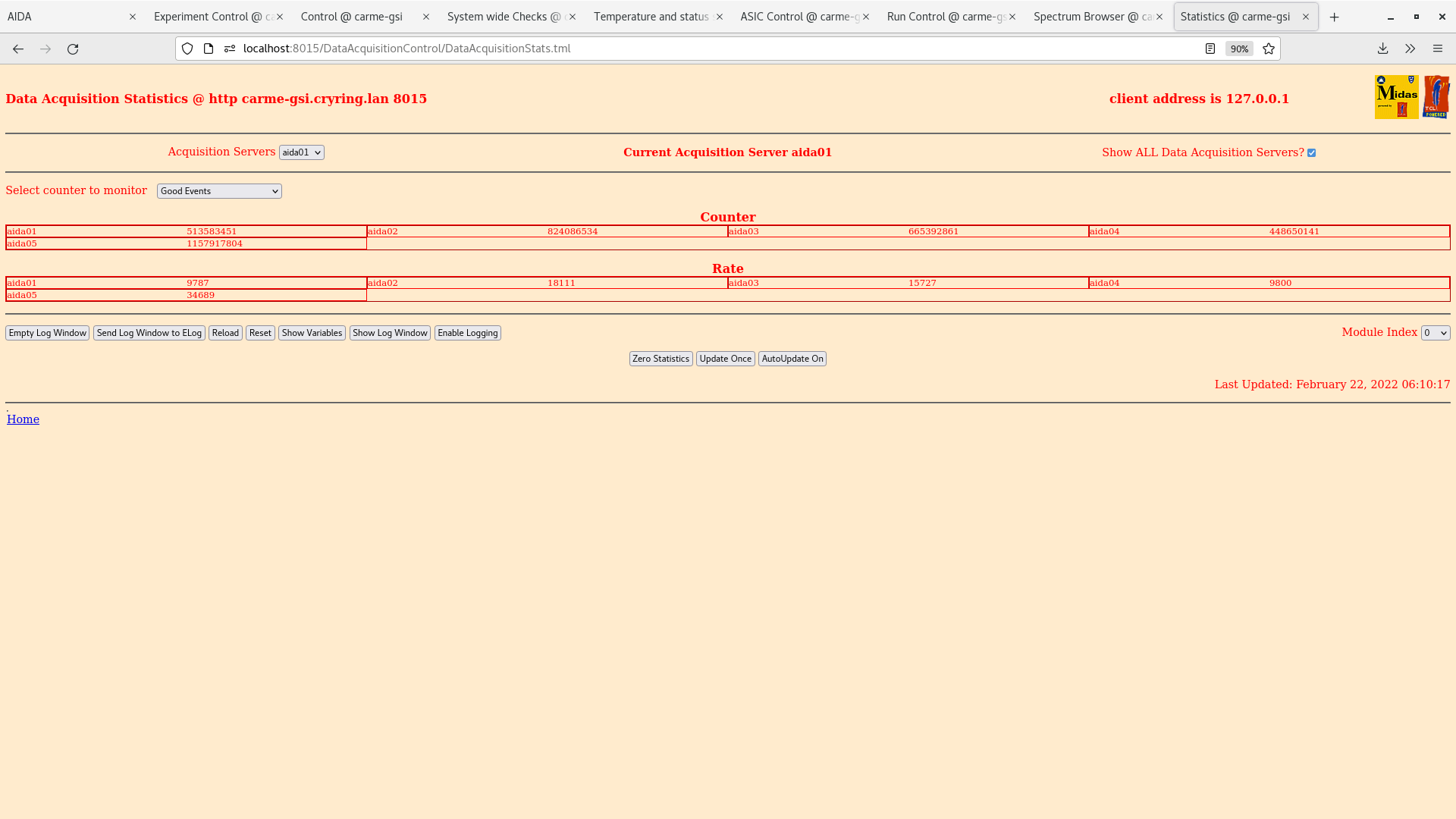

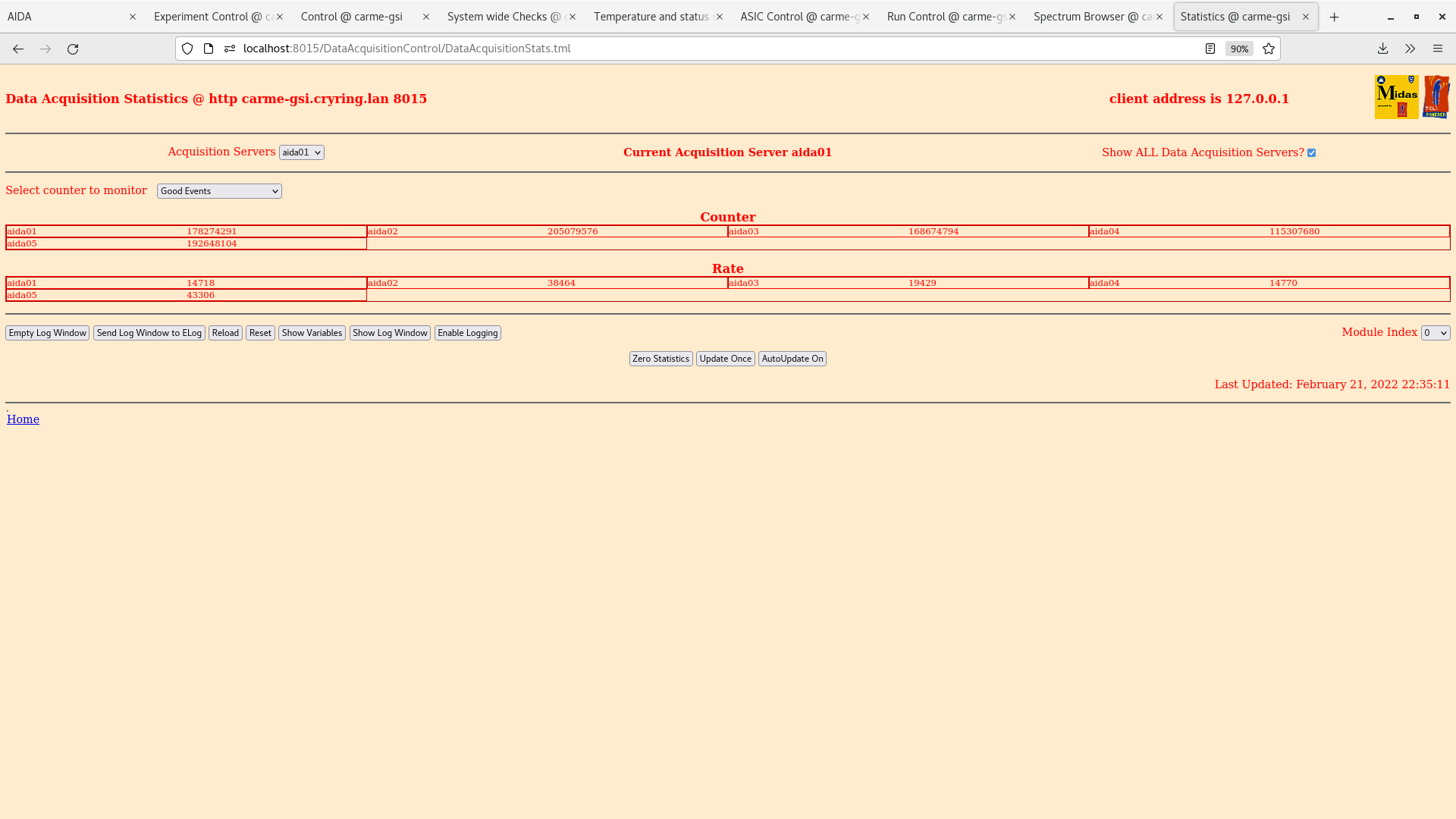

| Attachment 5: Good_events2022-02-22_02-55-14.png

|

|

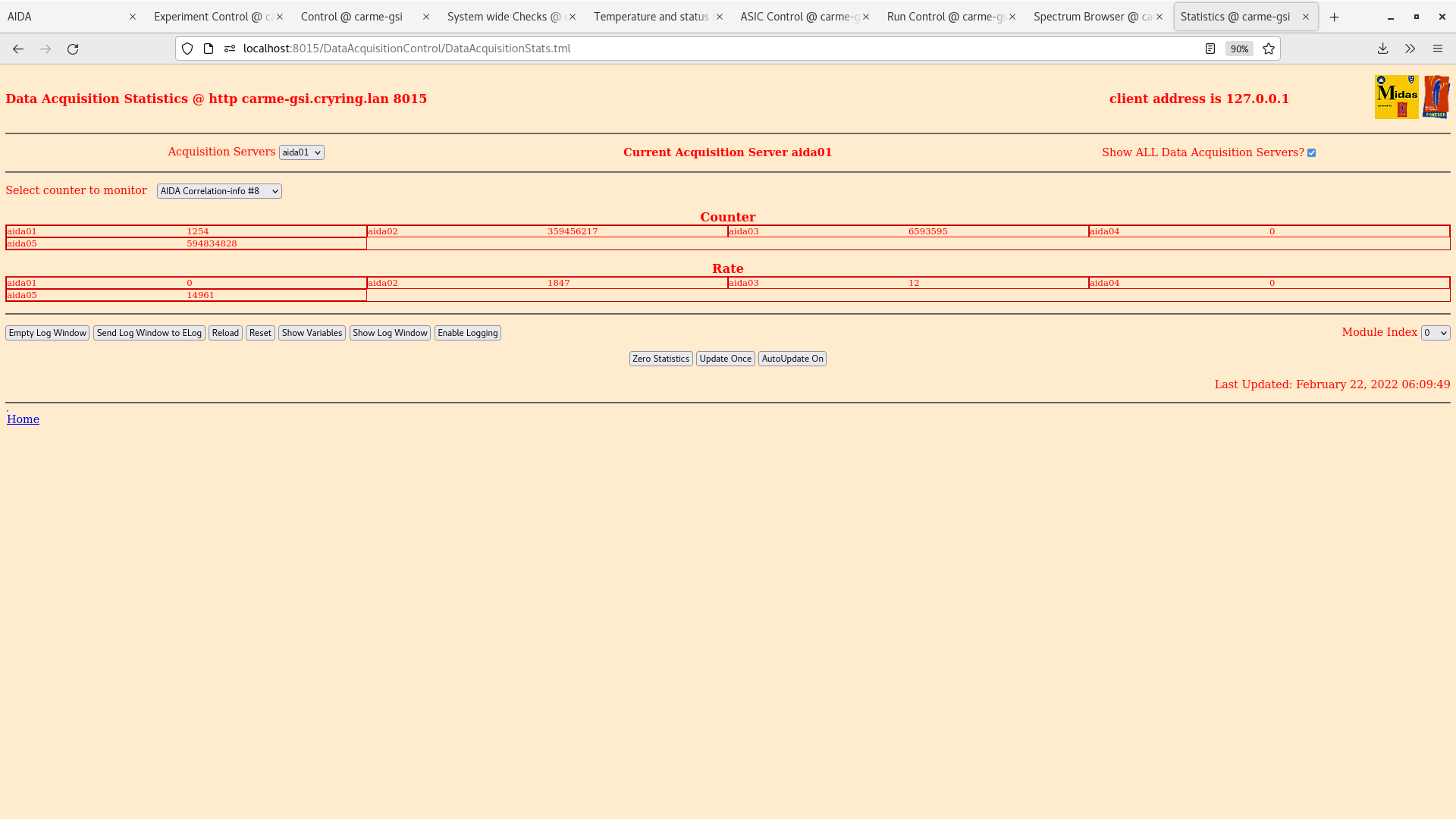

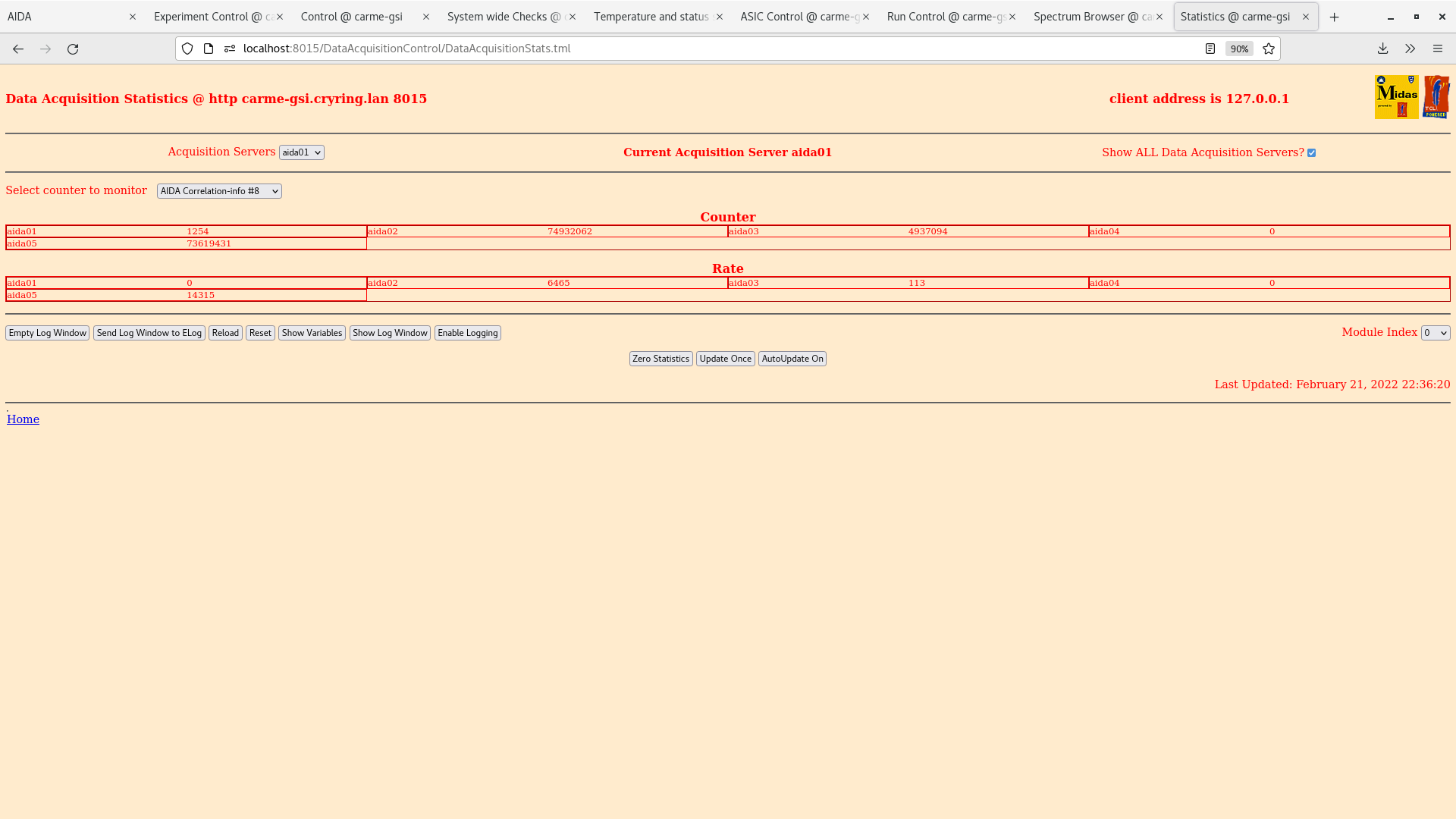

| Attachment 6: AIDA_CorrelationScreenshot_from_2022-02-22_02-56-04.png

|

|

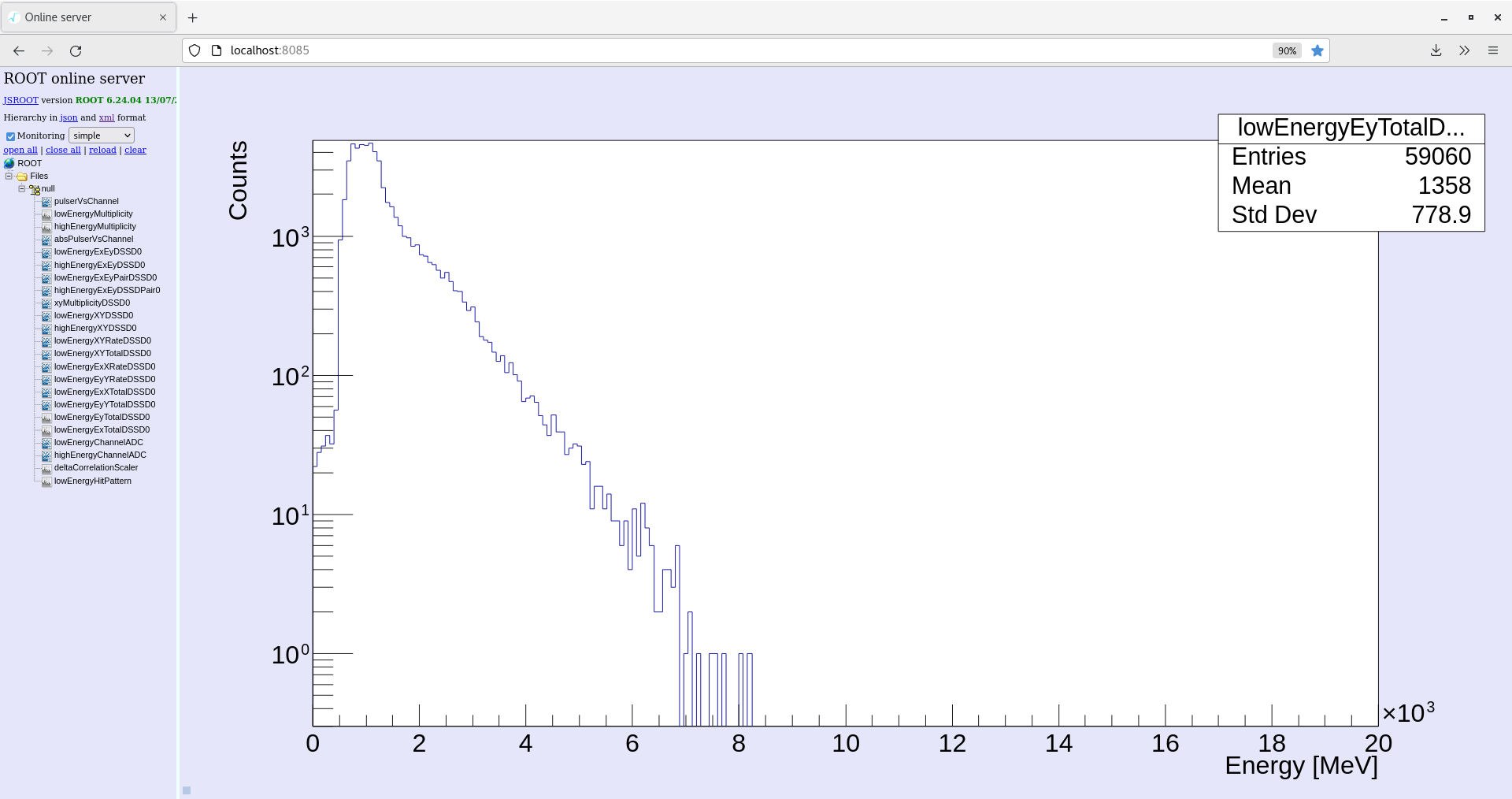

| Attachment 7: Spectrum_Browser2022-02-22_02-59-28.png

|

|

| Attachment 8: LowEx2022-02-22_03-00-02.png

|

|

| Attachment 9: LowEy2022-02-22_03-00-28.png

|

|

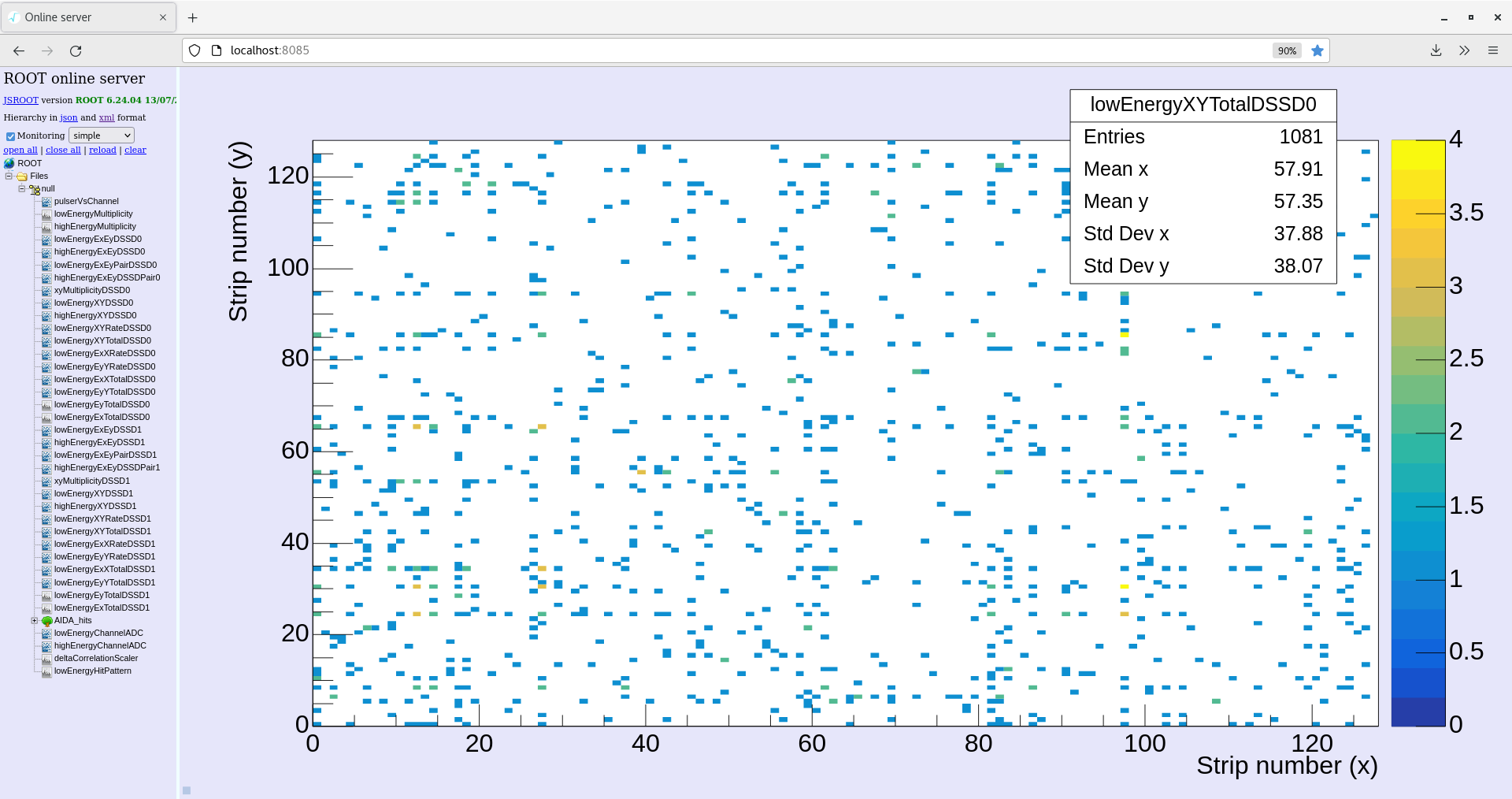

| Attachment 10: LowEXYTotal2022-02-22_03-01-16.png

|

|

|

|

225

|

Tue Feb 22 03:05:06 2022 |

JM, CB, LV, PM, AK | Beam ON, Target ON Run 54 |

04:00

Beam ON ~5.5E6 pps, but it fluctates between 2e6 and 6e6 (like a step function) in about each 5-10min

Target ON and open to the ring

YR09xxx ETarget ~1.8e-10

Target E4 inlet pressure 8.4E-9 mbar

Dump S3 ~ 7.0E-10 mbar

Nozzle temperature 150 K

Run 54 started, monitoring code restarted. |

| Attachment 1: Screenshot_from_2022-02-22_04-02-25.png

|

|

| Attachment 2: Screenshot_from_2022-02-22_04-03-08.png

|

|

| Attachment 3: Screenshot_from_2022-02-22_04-03-44.png

|

|

| Attachment 4: Screenshot_from_2022-02-22_04-03-24.png

|

|

| Attachment 5: Screenshot_from_2022-02-22_04-04-28.png

|

|

| Attachment 6: Screenshot_from_2022-02-22_04-04-10.png

|

|

| Attachment 7: Screenshot_from_2022-02-22_04-03-55.png

|

|

| Attachment 8: Screenshot_from_2022-02-22_04-10-57.png

|

|

| Attachment 9: Screenshot_from_2022-02-22_04-10-37.png

|

|

|

|

227

|

Tue Feb 22 05:12:38 2022 |

JM, CB, LV, PM, AK | Beam ON, Target ON Run 54 |

06:00

Beam ON ~1.5E6 pps, still fluctates between 1e6 and 6e6 (like a step function)

Target ON and open to the ring

YR09xxx ETarget ~1.8e-10

Target E4 inlet pressure 8.2E-9 mbar

Dump S3 ~ 6.5E-10 mbar

Nozzle temperature 150 K

Run 54 started, monitoring code restarted. |

| Attachment 1: Screenshot_from_2022-02-22_06-11-18.png

|

|

| Attachment 2: Screenshot_from_2022-02-22_06-10-59.png

|

|

| Attachment 3: Screenshot_from_2022-02-22_06-10-22.png

|

|

| Attachment 4: Screenshot_from_2022-02-22_06-10-09.png

|

|

| Attachment 5: Screenshot_from_2022-02-22_06-09-54.png

|

|

| Attachment 6: Screenshot_from_2022-02-22_06-09-31.png

|

|

| Attachment 7: Screenshot_from_2022-02-22_06-09-12.png

|

|

| Attachment 8: Screenshot_from_2022-02-22_06-08-58.png

|

|

| Attachment 9: Screenshot_from_2022-02-22_06-08-22.png

|

|

| Attachment 10: Screenshot_from_2022-02-22_06-07-57.png

|

|

| Attachment 11: Screenshot_from_2022-02-22_06-07-46.png

|

|

|

|

219

|

Mon Feb 21 17:26:19 2022 |

JM, CB, SHB, OH (remotely) | Beam ON run 53 |

21/2/22 16:00

Call from main control room, beam is ON, probably has been for several hours judging by rate on xy total plot.

Changes made to online monitoring code by OH, include setting to only 1 DSSD, correct offsets from the pulser walkthrough, offline analysis capabilities and X/Y position correction.

Monitoring code restarted in CARME_SORT/build_no_output

17:31 Run 50 ended, run 51 started now beam is definitely in the ring. Tried to insert span zero schottky into aida2 correlation scalar, however rate was far too high.

18:03 Removed span zero schottky signal, started new run 52.

With beam ON we noticed some missing channels in the xy total plot. Aida 1 and 2 stat totals on spectrum browser show missing channels. Asic check on both to no effect. Fees power cycled.

19:57 Started run 53. Currently waiting for beam

21:20 Beam ON

1*L plots checked for aida 1, several channels showed no data (noise)

Slow comparator LEC threshold lowered to 0x32 to aida 1, checked 1*L plots and channels are now showing lots of noise. So those channels appear to be quiet using 0x64 threshold. (attachment 3)

Threshold increased back to 0x64

22:33

System checks OK -white rabbit fails on all. ~30 seperation

Temperatures OK

Statistics within range - new scalars added for aida02 and aida05

Data being written ~300 kb/sec

Leakage current ~3.6 uA

00:39

System checks checks OK -white rabbit fails on all. ~42 seperation

Temperatures OK

Statistics within range with new scalars

Data being written 256 kb/sec

Leakage current ~3.615 uA

XY counts dominated by hot channels - most blue pixels are ~10 counts

|

| Attachment 1: 2022-02-21_18-50-06-xyTotal.png

|

|

| Attachment 2: 2022-02-21_19-05-27-aida1-4-rate.png

|

|

| Attachment 3: 2022-02-21_22-17-54-aida1-1*L-lowerThreshold.png

|

|

| Attachment 4: 2022-02-21_22-35-19-goodEvents.png

|

|

| Attachment 5: 2022-02-21_22-35-53-ADC-dataitems.png

|

|

| Attachment 6: 2022-02-21_22-36-28-aida-correlation.png

|

|

| Attachment 7: 2022-02-21_22-58-18-Ex-histogram.png

|

|

| Attachment 8: 2022-02-21_22-59-22-XY-total.png

|

|

| Attachment 9: 2022-02-22_00-42-14-XY-total.png

|

|

|

|

213

|

Sat Feb 19 20:08:43 2022 |

JM, CB | Beam ON run 49 |

Run started 19/2/22 21:05. Beam ON

Temperatures OK

System wide checks OK - white rabbit fails on all.

Statistics are within normal range (10-20K goodevents)

Leakage current 3.6 uA

potentiometer = 20.28 mm

20/2/22

Leakage current ~3.675 uA. Looks stable now motors can not move (attachment 1)

potentiometer = 20.28 mm

Temperatures OK

System wide checks OK - white rabbit fails all

Statistic within normal range (see attachment 2 - ADC data items) Counter for aida 1 and aida 2 much higher due to noise bursts (elog 212)

XY total plot (attachment 3)

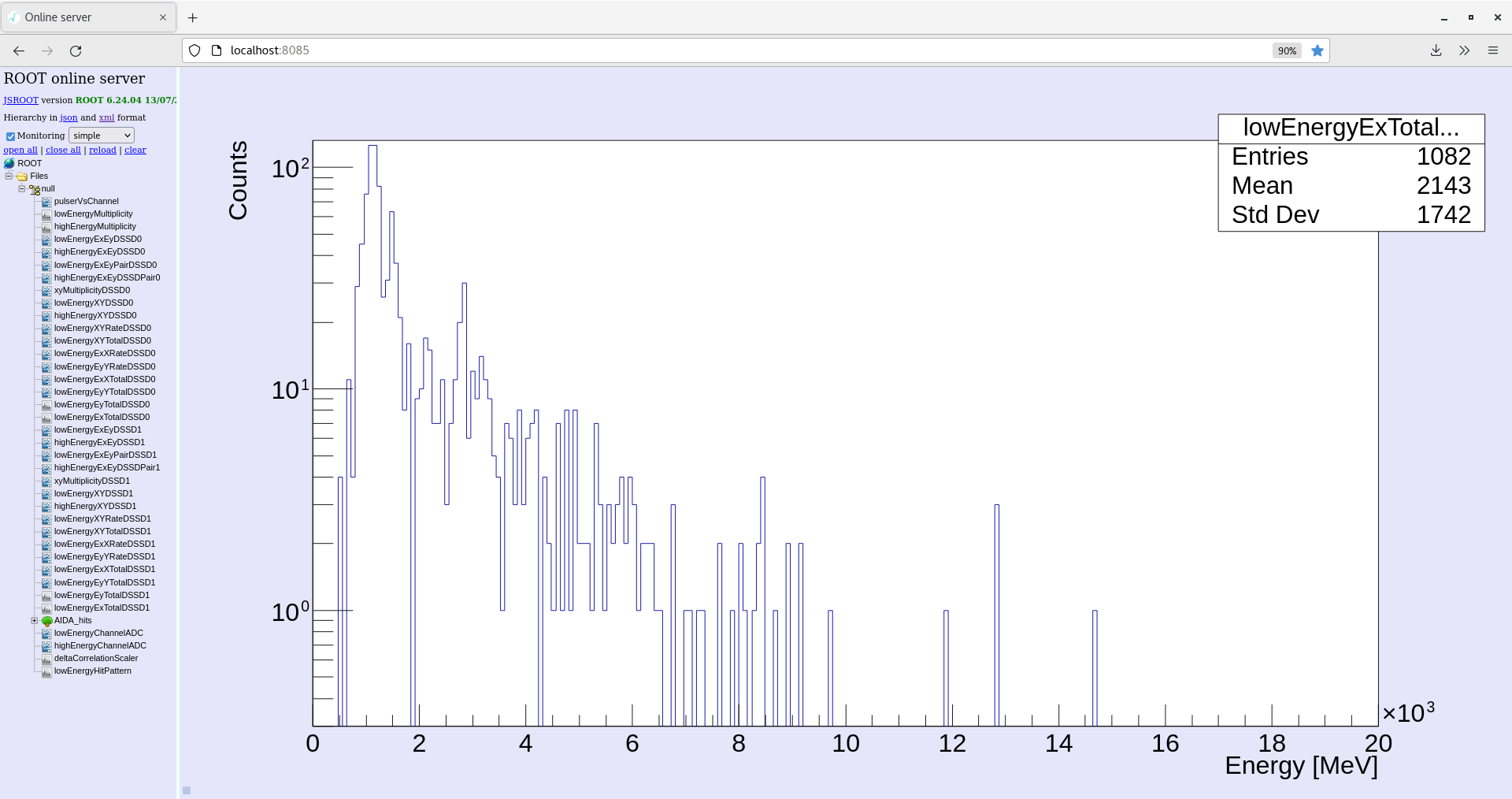

Low energy Ex histogram (attachment 4)

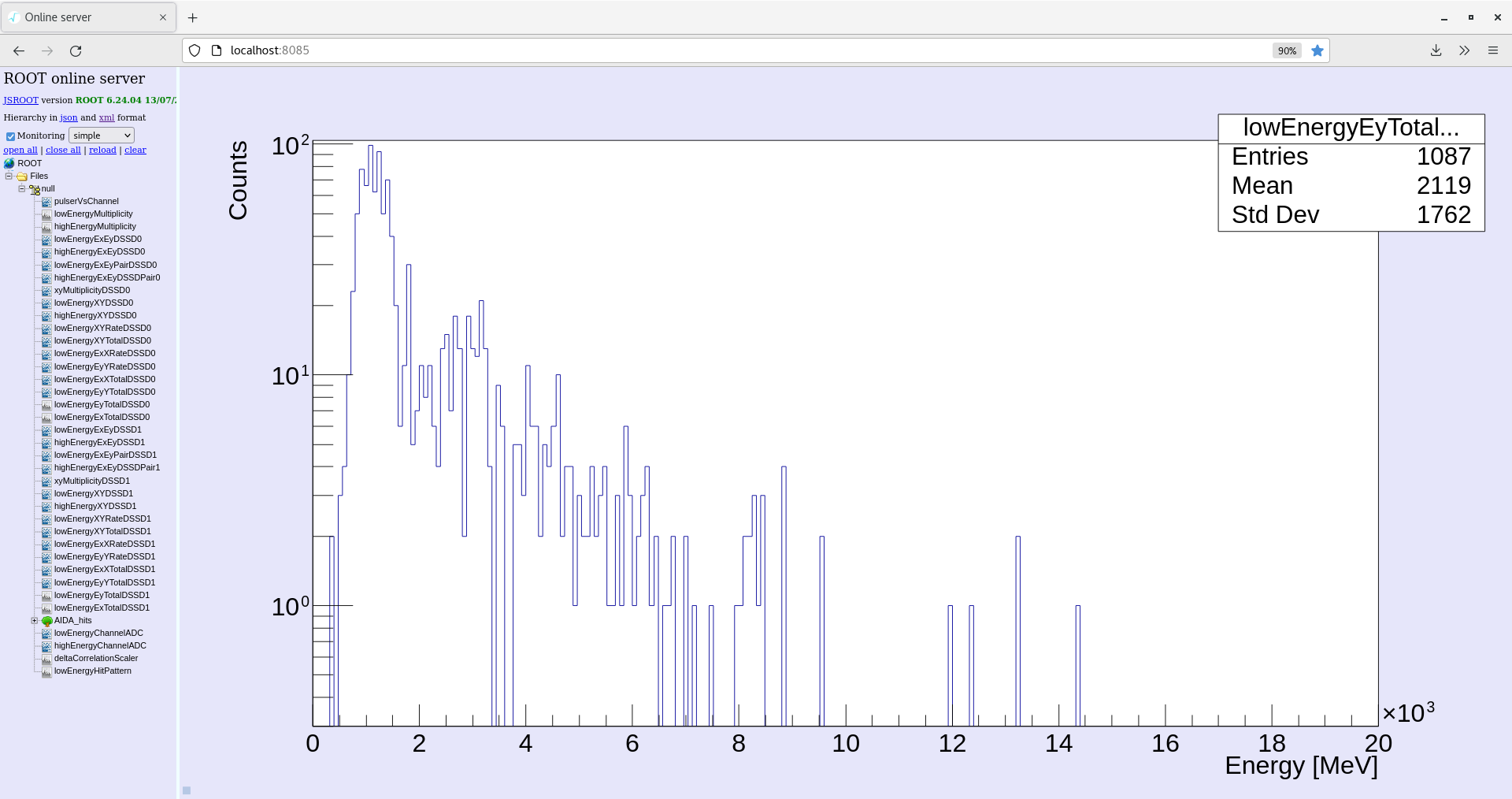

Low energy Ey histogram (attachment 5)

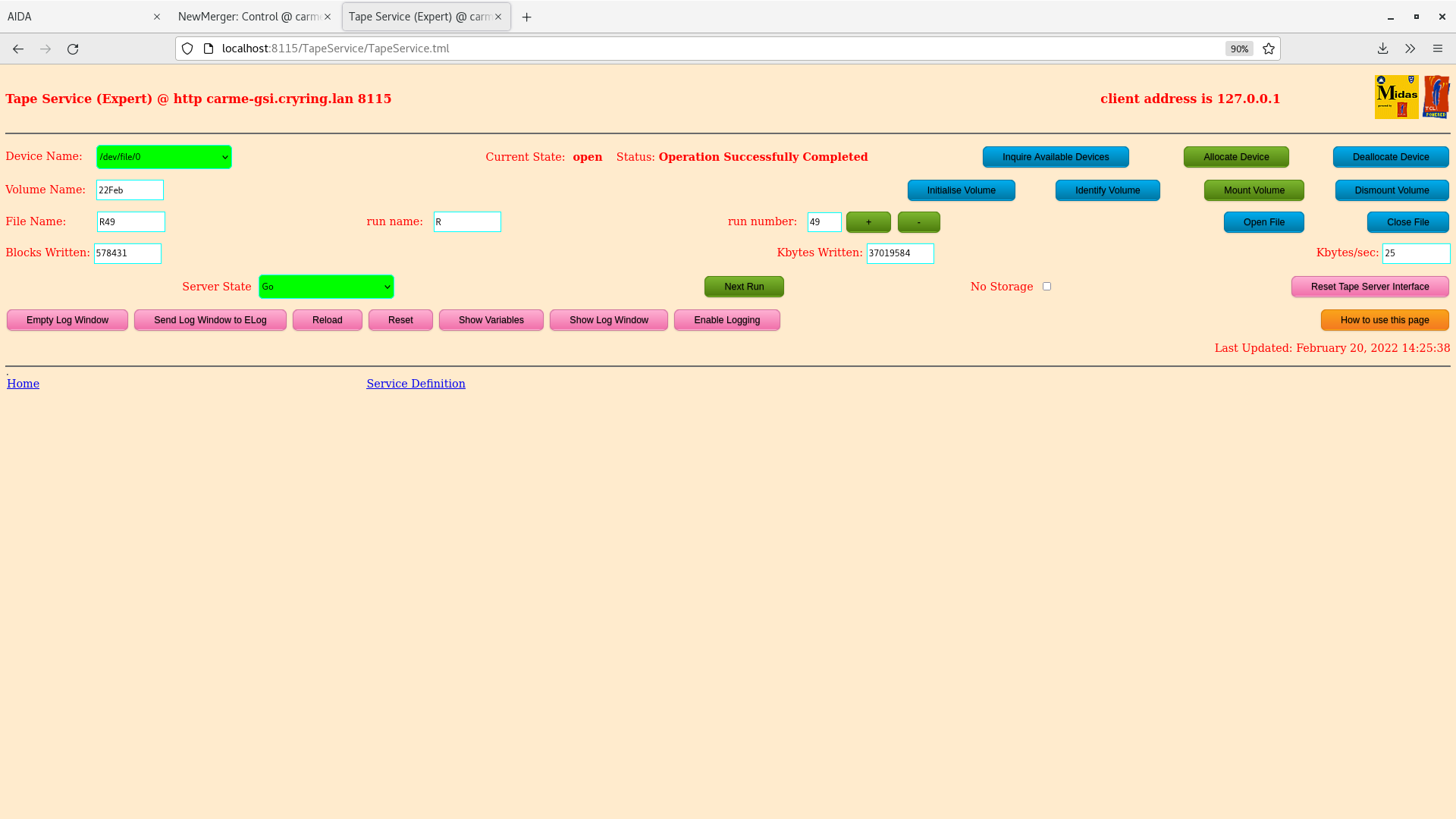

Tape Server data written (attachment 6)

Run end 20/2/22 15:08 |

| Attachment 1: 2022-02-20_14-16-16-leakage-current.png

|

|

| Attachment 2: 2022-02-20_14-18-07-statistic-ADCdata.png

|

|

| Attachment 3: 2022-02-20_14-20-43-xyTotal.png

|

|

| Attachment 4: 2022-02-20_14-24-19-LowEnergy-ExTotal.png

|

|

| Attachment 5: 2022-02-20_14-28-02-LowEnergy-EyTotal.png

|

|

| Attachment 6: 2022-02-20_14-25-45-Tape-server-data-written.png

|

|

|

|

359

|

Tue Mar 1 23:43:15 2022 |

David, George | Beam Intensity Drop |

00:38

Intensity in the ring dropped by 2 orders of magnitude to 5e5 on injection

Lost rutherford rate (as seen in last e-log post)

All pressures seem fine

00:48

Called main control room, said they will take a look

00:59

Servo motor control restarted and homed

01:11

Ion source is confirmed to be off

Zoran will try and fix it, should take 1hr or so and not guaranteed to work.

|

|

|

610

|

Mon Jun 10 07:40:47 2024 |

RSS, DB | Beam |

08:26: There is no beam and Gleb is informed.

08:46: Beam is back. |

|

|

167

|

Mon Jan 10 20:52:53 2022 |

JM, TD, OH | Baking tent removed, VI tests |

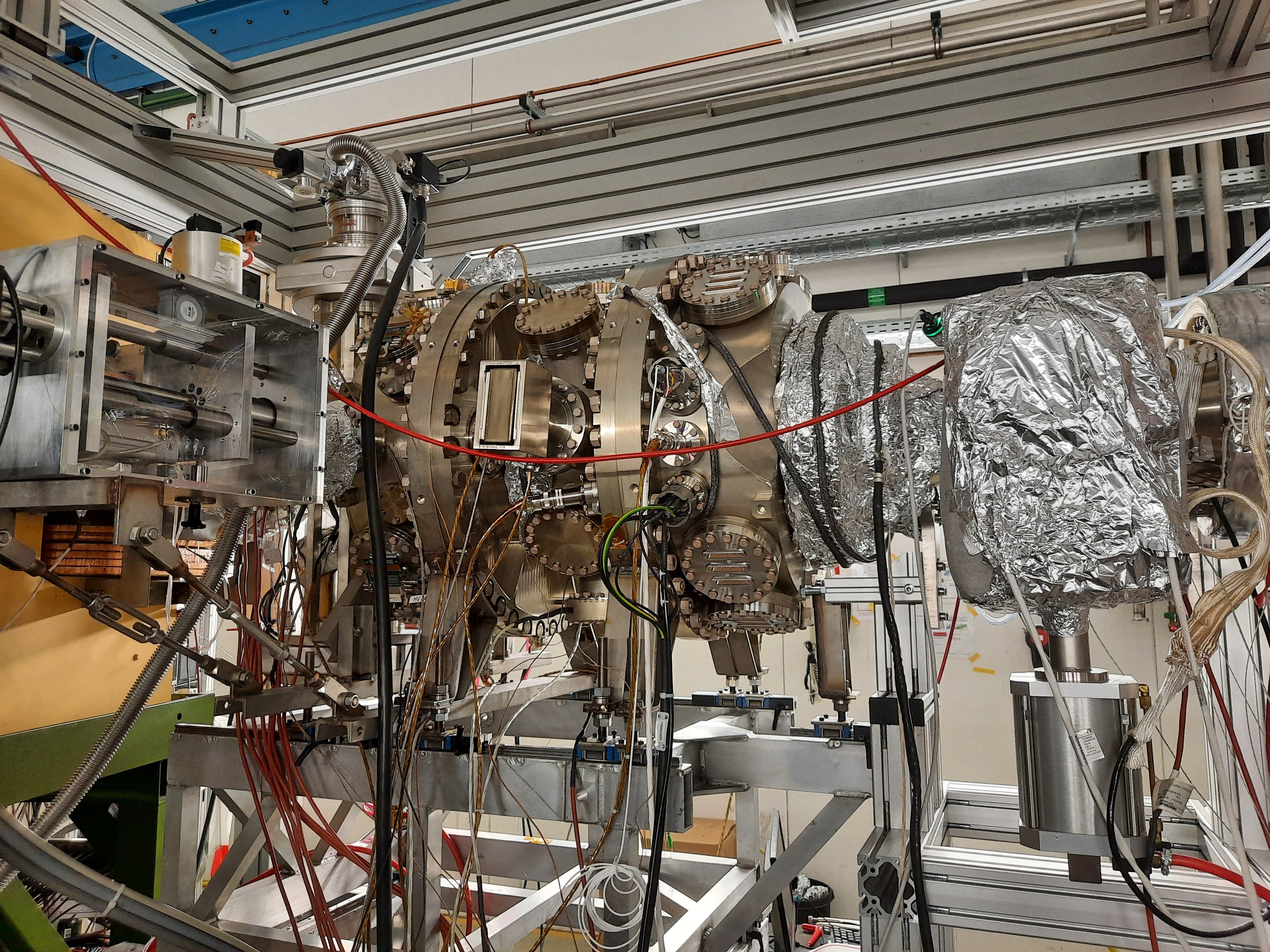

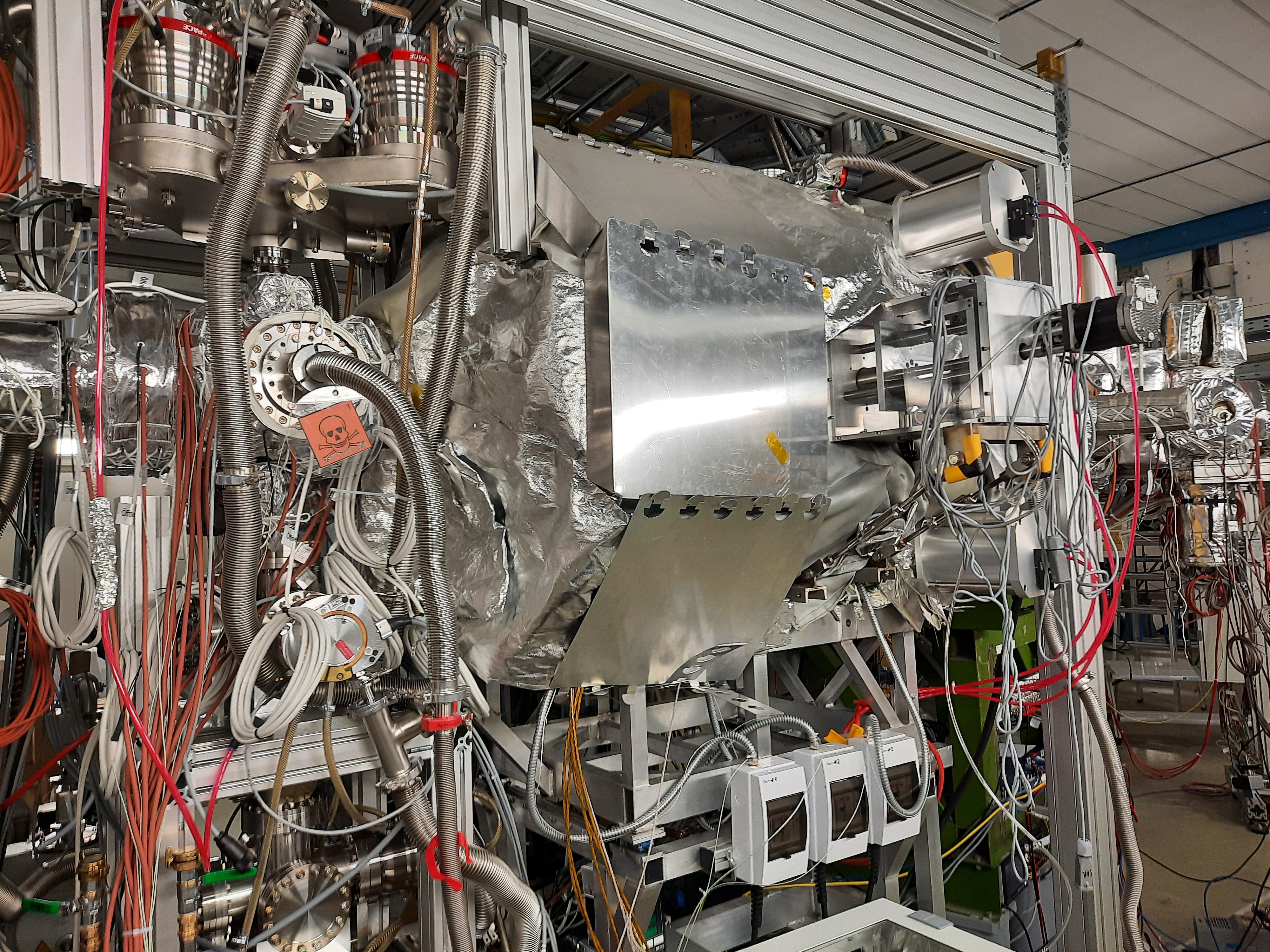

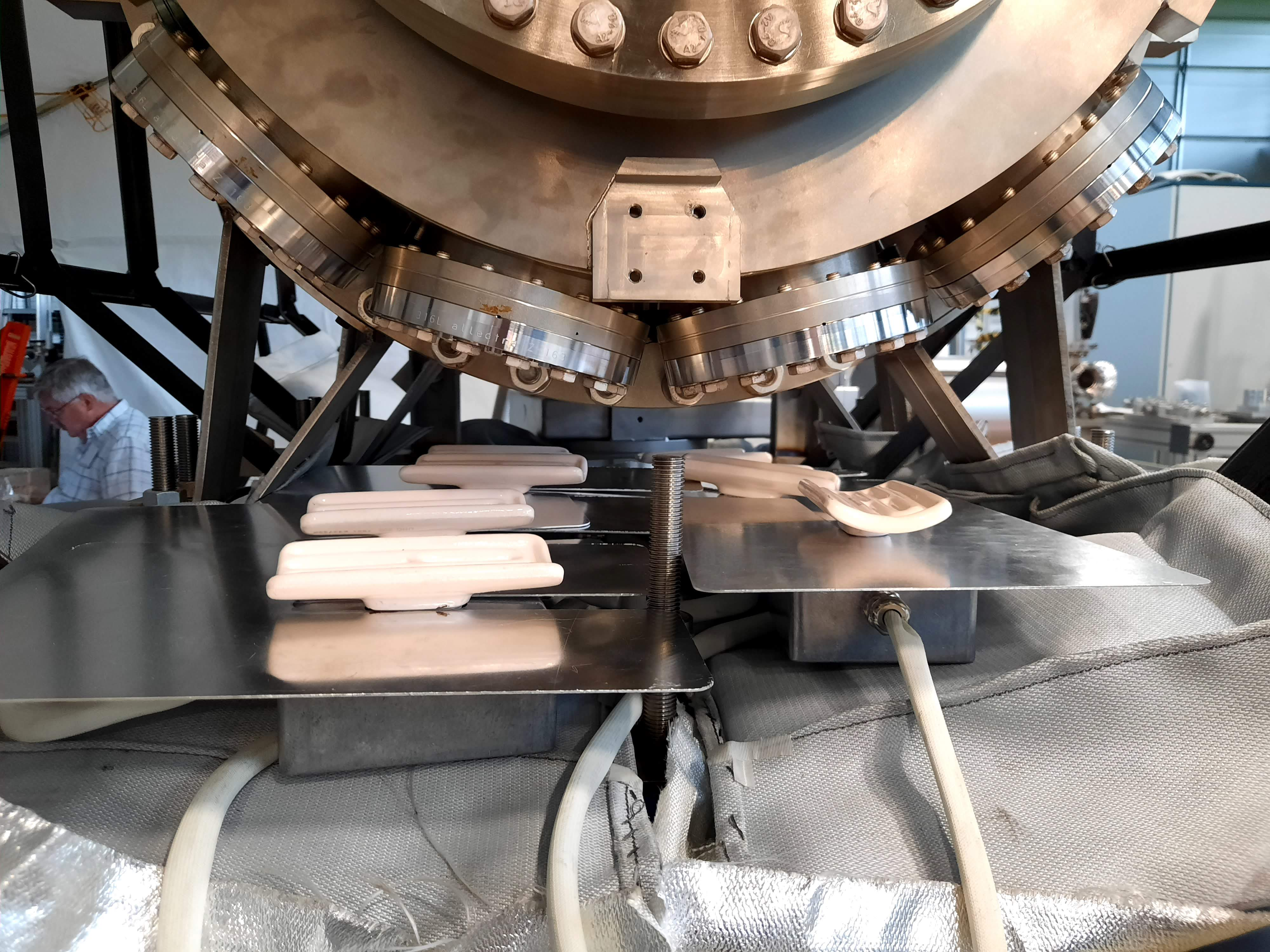

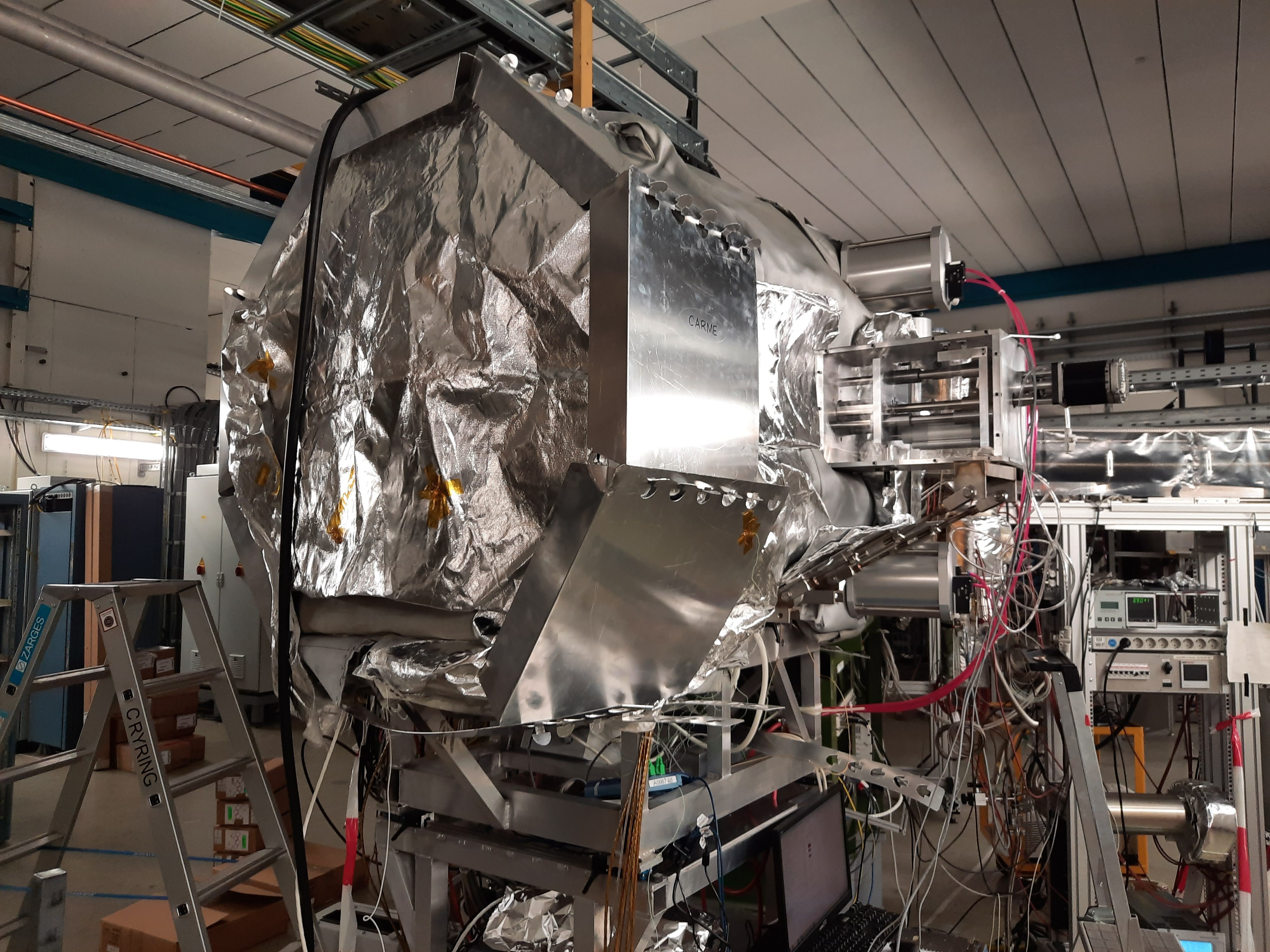

Baking tent, frame and trays fully removed from CARME chamber. Removal of baking frame required removing air lines from upper gate valve and repositioning of vacuum hose connecting turbo pump to backing line and turbo power cable. Some difficulty encountered removing upper baking frame now the target support frame is assembled. Small modification seperating section in two would aid future installation and disammebly.

Baking trays removed with difficulty. Main baking tray bent to extract from the frame -> updated design required for future bakeout cycle.

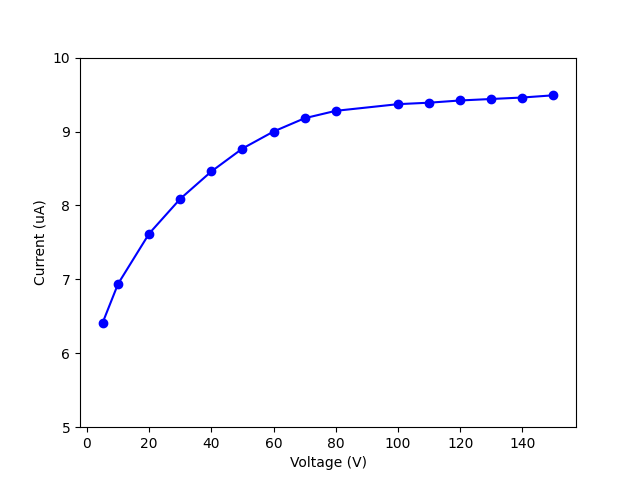

VI tests performed on the upper and lower detectors. Upper detector shows characteristic curve (attached plot), lower detector shows no response to increased voltage. Multimeter used on adapter boards with resistance of ~18.5 kΩ observed between bias pins for the upper detector. Open line seen between bias pins on the lower detector, some connections observed for other pins on the board -> requires further investigation.

NOTE - Channel 0 on bias supply is unstable, should not be used.

Most equipment for installation of FEE's and coolant manifolds found, assembley of FEE holders started. Full list of current swagelock inventory as follows:

| SS-QTM2-D-8M0 MALE QUICK DISCONNECT |

15 |

| SS-8M0-1-6RS MNIFOLD ADAPTOR |

40 |

| NY-8M4-1 ferrule fronts (nylon) |

120 |

| NY-8M3-1 ferrule rears (nylon) |

120 |

| SS-QTM2A-B-8M0 FEMALE QUICK DISCONNECT |

15 |

|

| Attachment 1: 20220110_175547.jpg

|

|

| Attachment 2: 20220110_175811.jpg

|

|

| Attachment 3: vi-curve.png

|

|

|

|

424

|

Fri Jul 21 08:21:54 2023 |

TD, RSS | Baking tent manual |

09.20 Pirani 1.00e-3 mbar IE514 3.90e-8 mbar

Today - install TCs, connect to Pico controller and test

10.00 Bakeout tent setup guide (draft) - attachment 1

14:30 Tested all TCs and are fine

05.25 Pirani 1.00e-3 mbar IE514 3.71e-8 mbar |

| Attachment 1: CARME-baking-guide_(1).pdf

|

-0.png)

-1.png)

-2.png)

-3.png)

-4.png)

-5.png)

|

|

|

431

|

Thu Aug 10 07:51:43 2023 |

JM | Baking tent and heater testing |

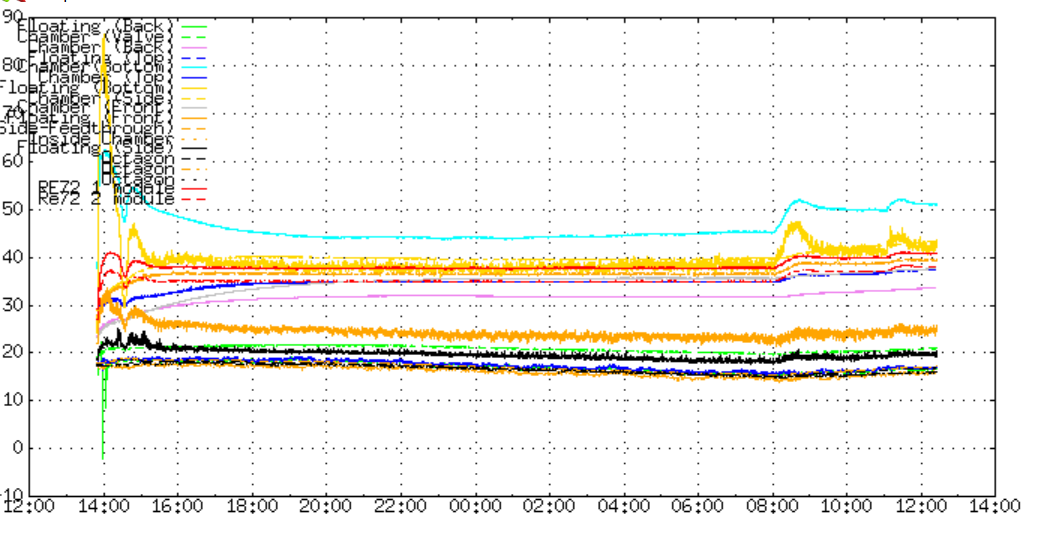

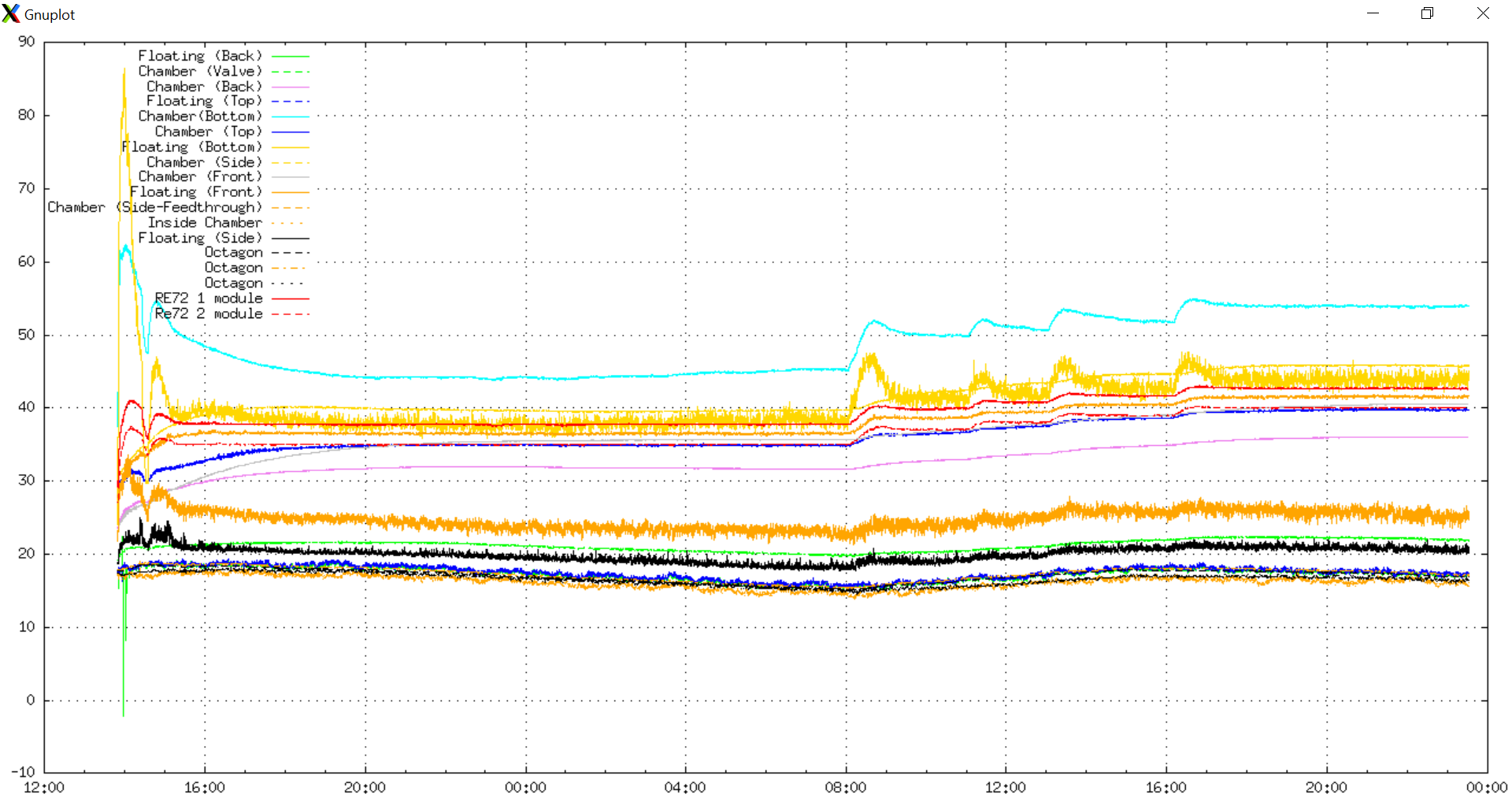

09/08/23

Attached is the current pumpdown plot taken from grafana.

I have started to re-work the baking tent in order to close gaps from its initial installation. The heaters work and were tested to a temperature of 50C. Testing is required to gauge the heater temperature required to heat the baking volume, we suspect the heaters will be several hundred degrees.

11/08/23

Baking tent has been fully constructed again, see photos attached. Some thermocouples have been re-positioned, new thermocouples positions are given in elog 433. GSI ion pump cable has been connected. Roughing pump on the outside of the berylium window has been connected and berylium window is at < 10 mbar. |

| Attachment 1: current-pump-down.png

|

|

| Attachment 2: 20230812_120951.jpg

|

|

| Attachment 3: 20230812_120925.jpg

|

|

| Attachment 4: 20230811_152942.jpg

|

|

| Attachment 5: 20230811_152926.jpg

|

|

| Attachment 6: 20230811_152923.jpg

|

|

| Attachment 7: 20230811_152918.jpg

|

|

| Attachment 8: 20230811_152913.jpg

|

|

|

|

13

|

Wed Sep 16 08:52:03 2020 |

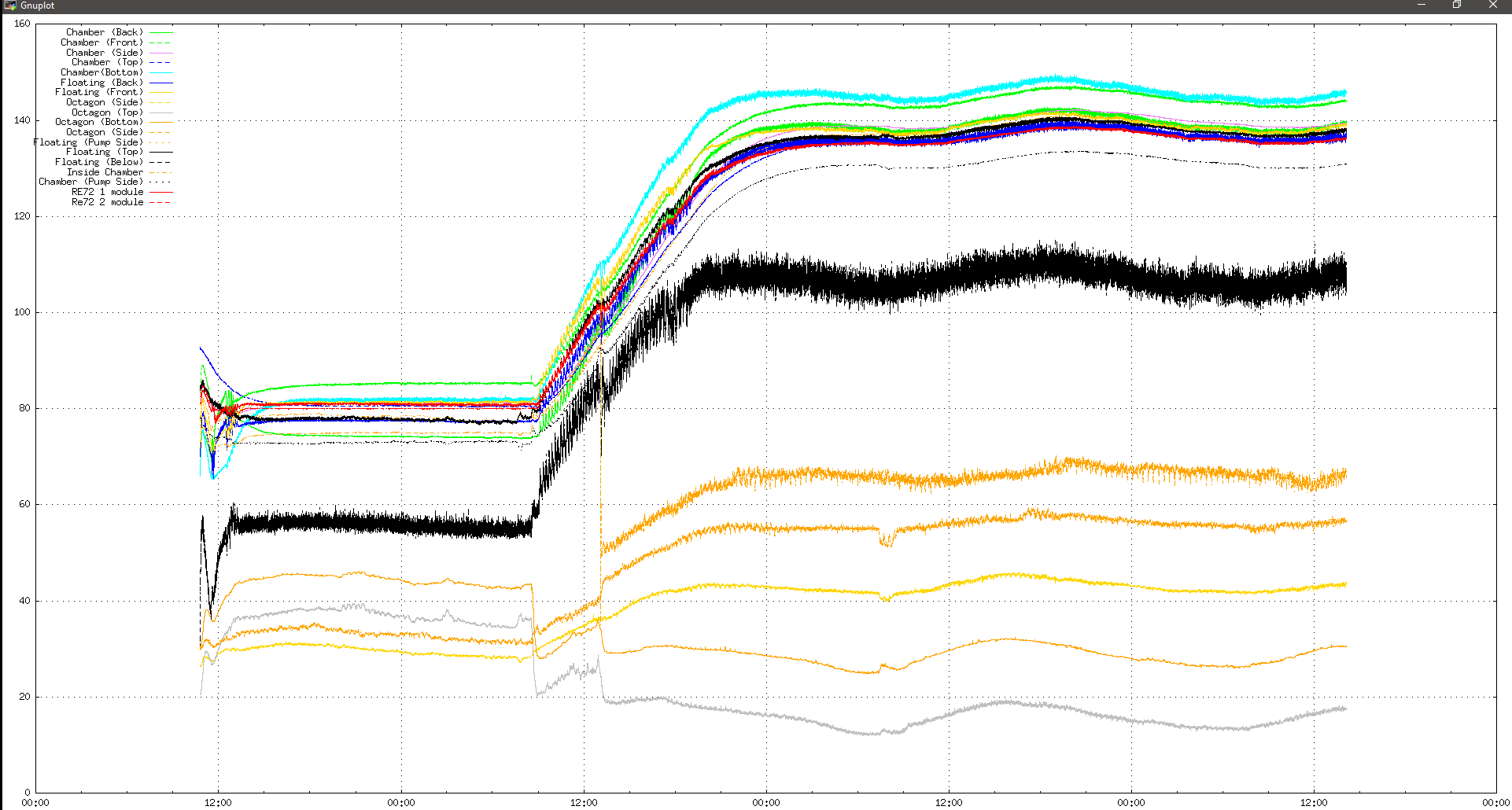

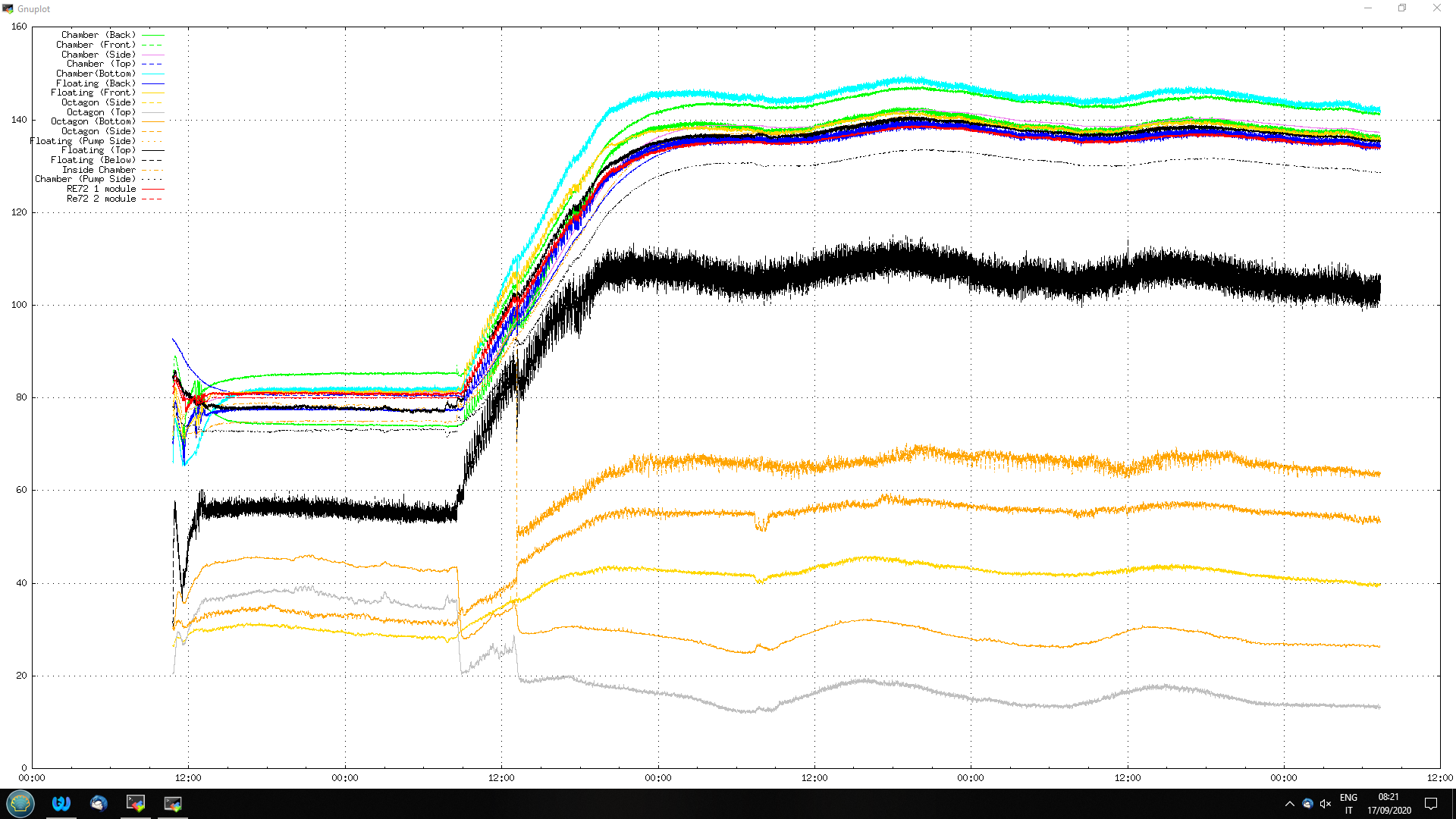

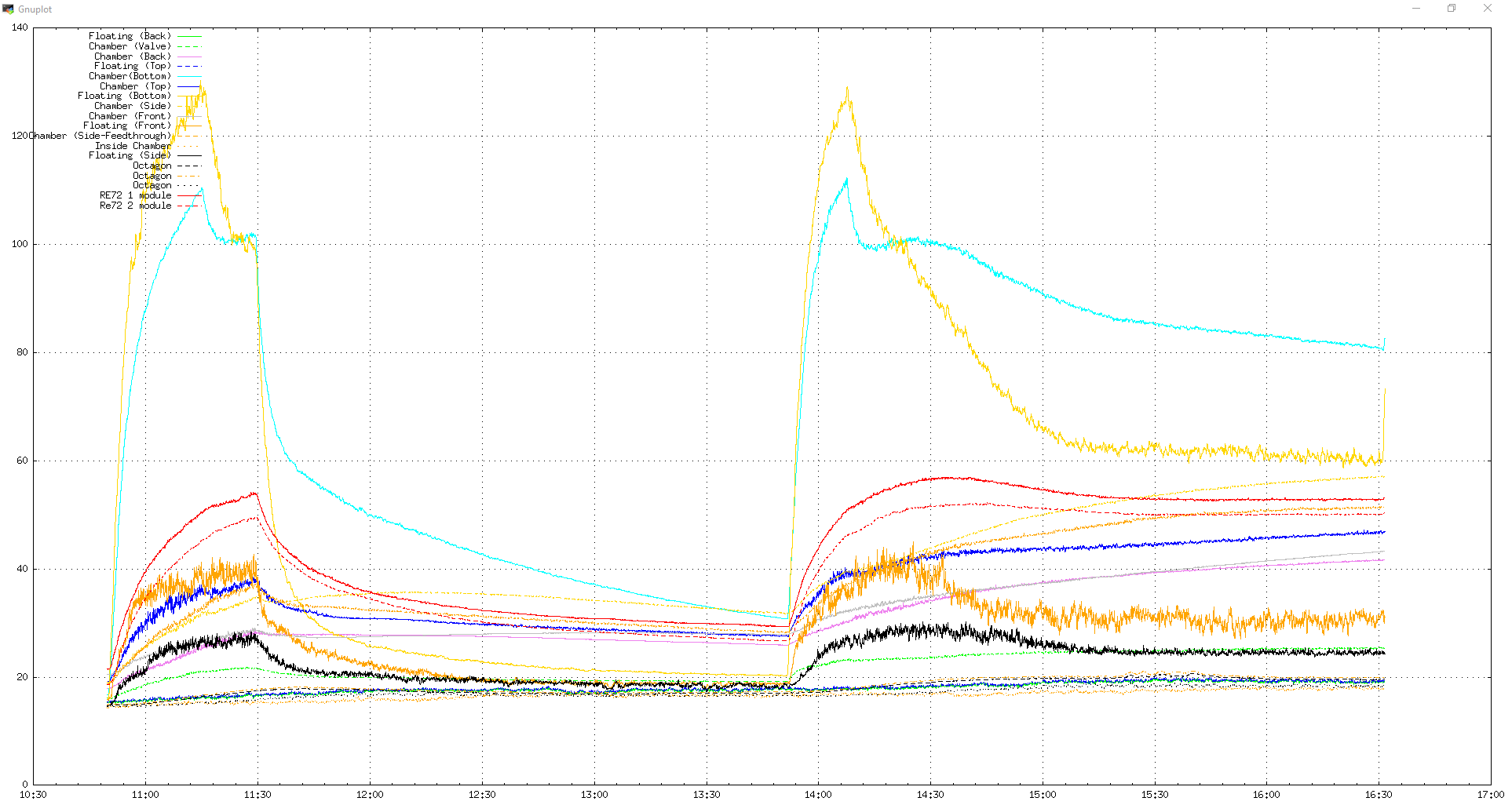

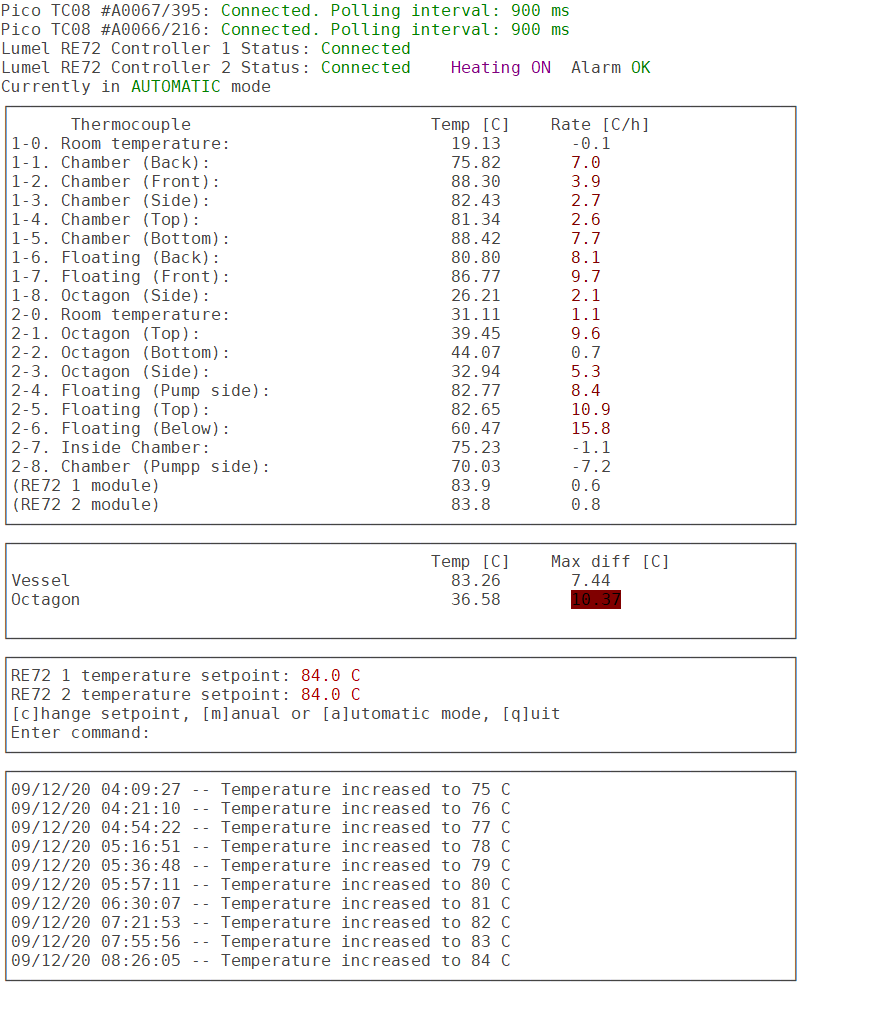

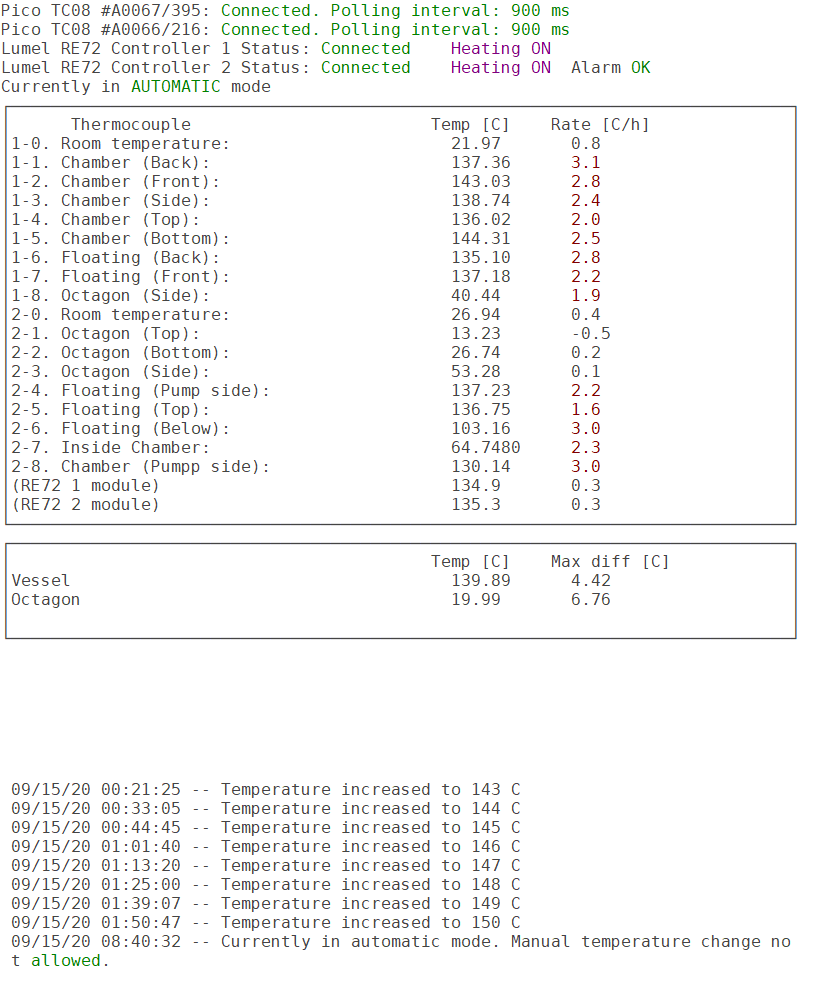

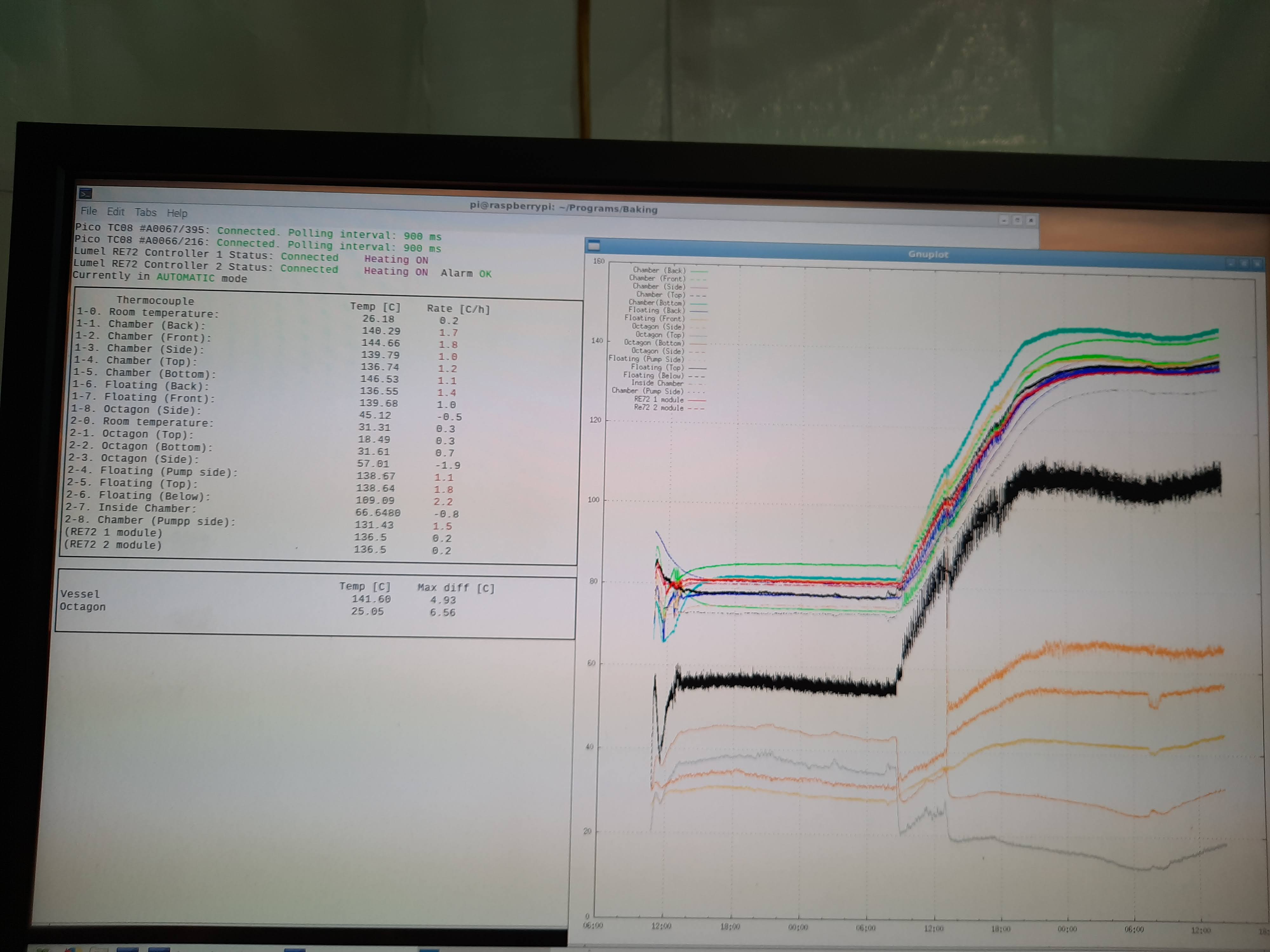

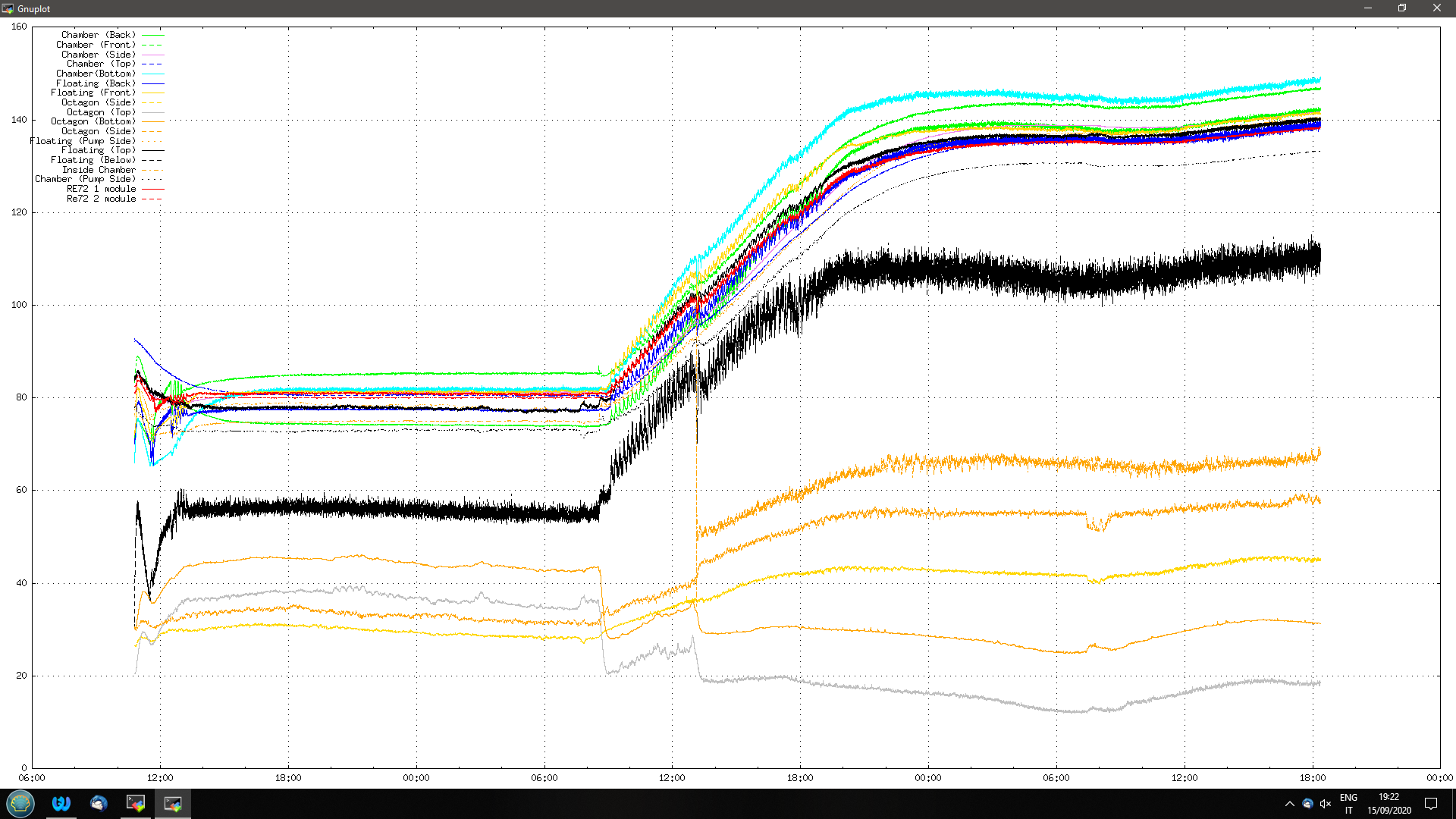

CB (remotely) | Baking status 16-17 September |

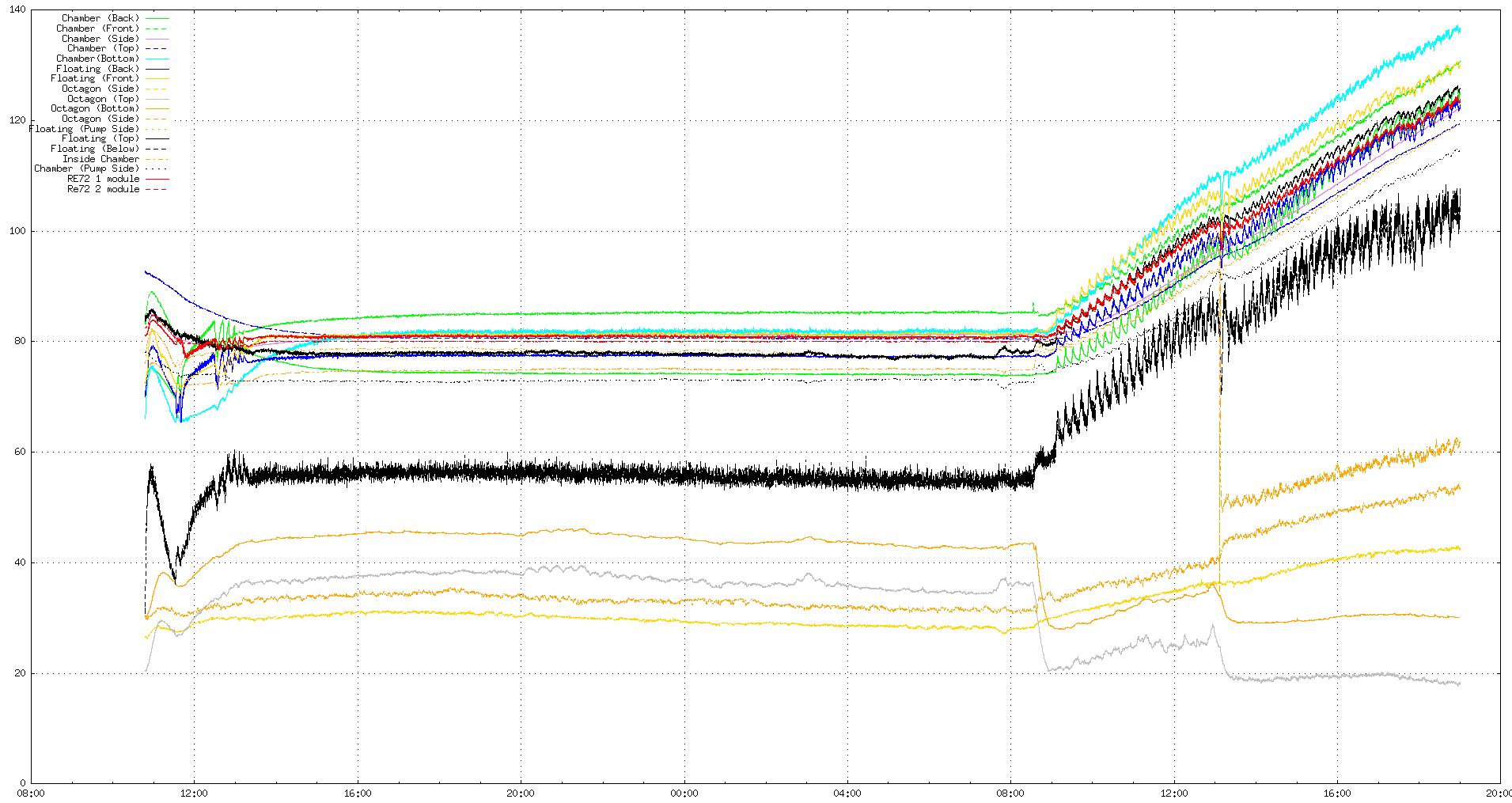

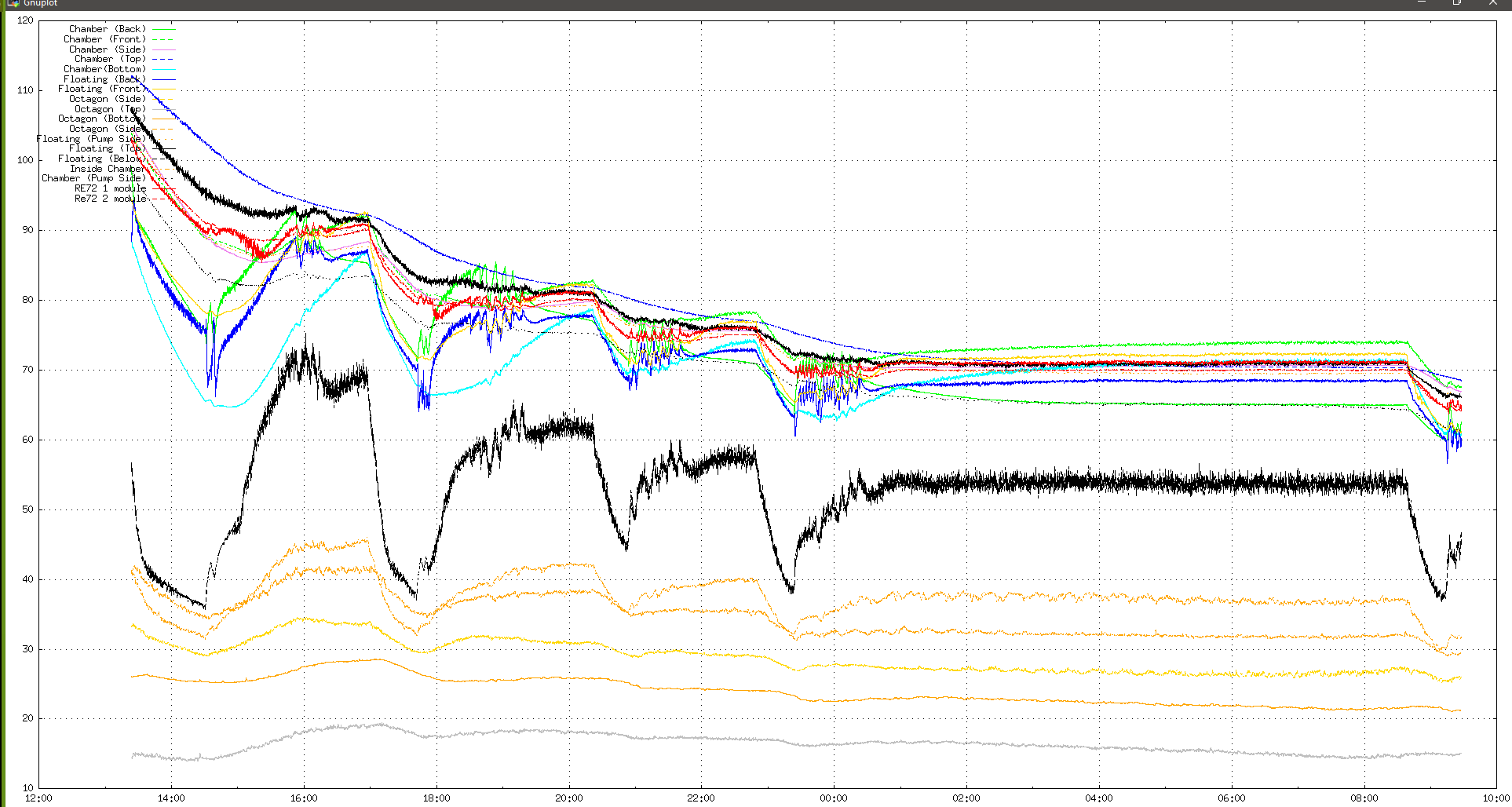

16 September

08:50

Baking continues OK. Temperatures stable, did not increase with respect to yesterday evening.

See attached.

15:00

Baking continues OK.

See attached.

20:22

Baking continues OK.

See attached.

17 September

08:20

Baking continues OK. Temperatures slightly decreasing?

See attached. |

| Attachment 1: 20200916_0850_temps.png

|

|

| Attachment 2: 20200916_0850_ctrl.png

|

|

| Attachment 3: 20200916_1500_temps.png

|

|

| Attachment 4: 20200916_2022_temps.png

|

|

| Attachment 5: 20200917_0820_temps.png

|

|

|

|

11

|

Mon Sep 14 12:07:40 2020 |

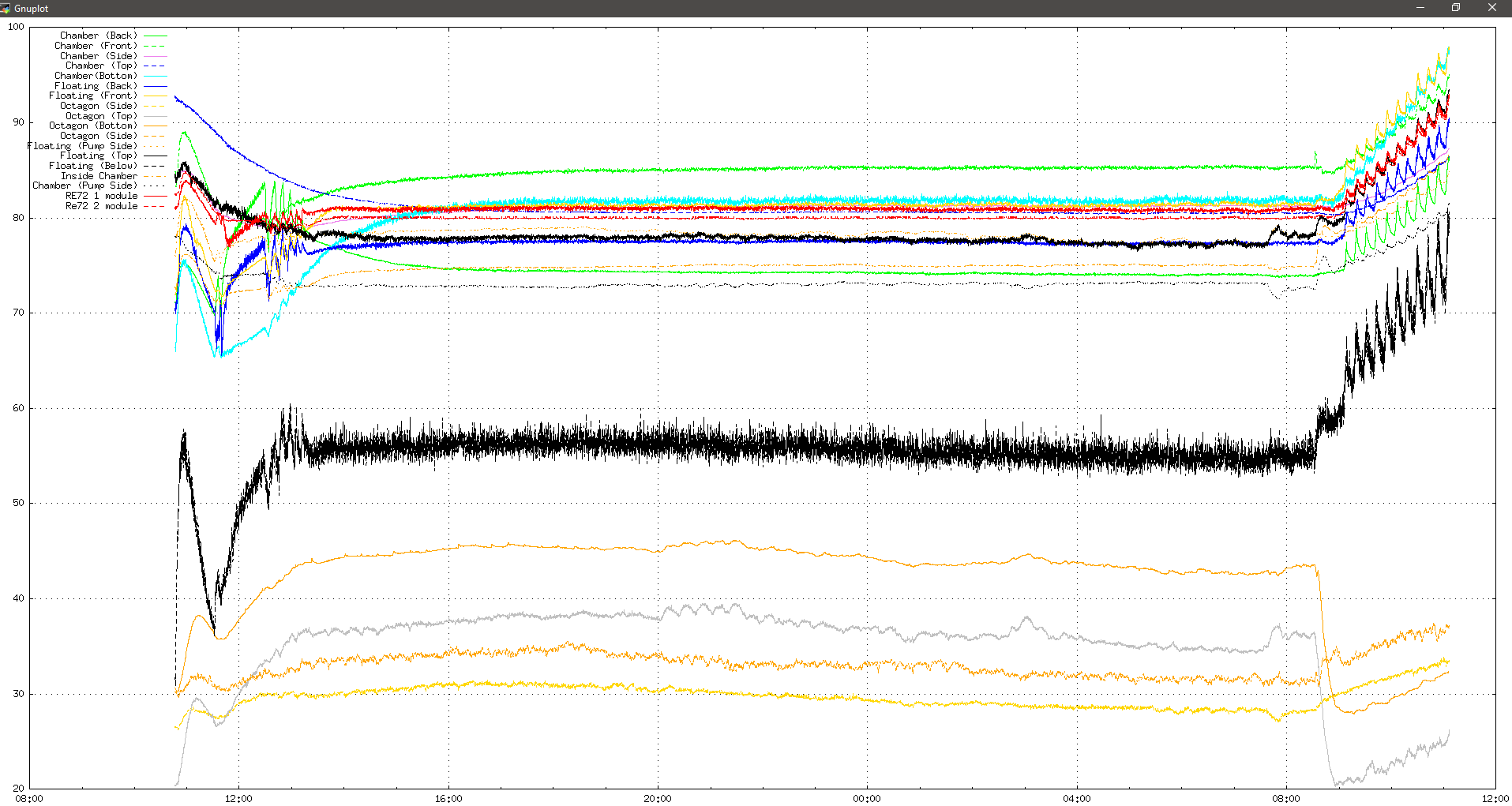

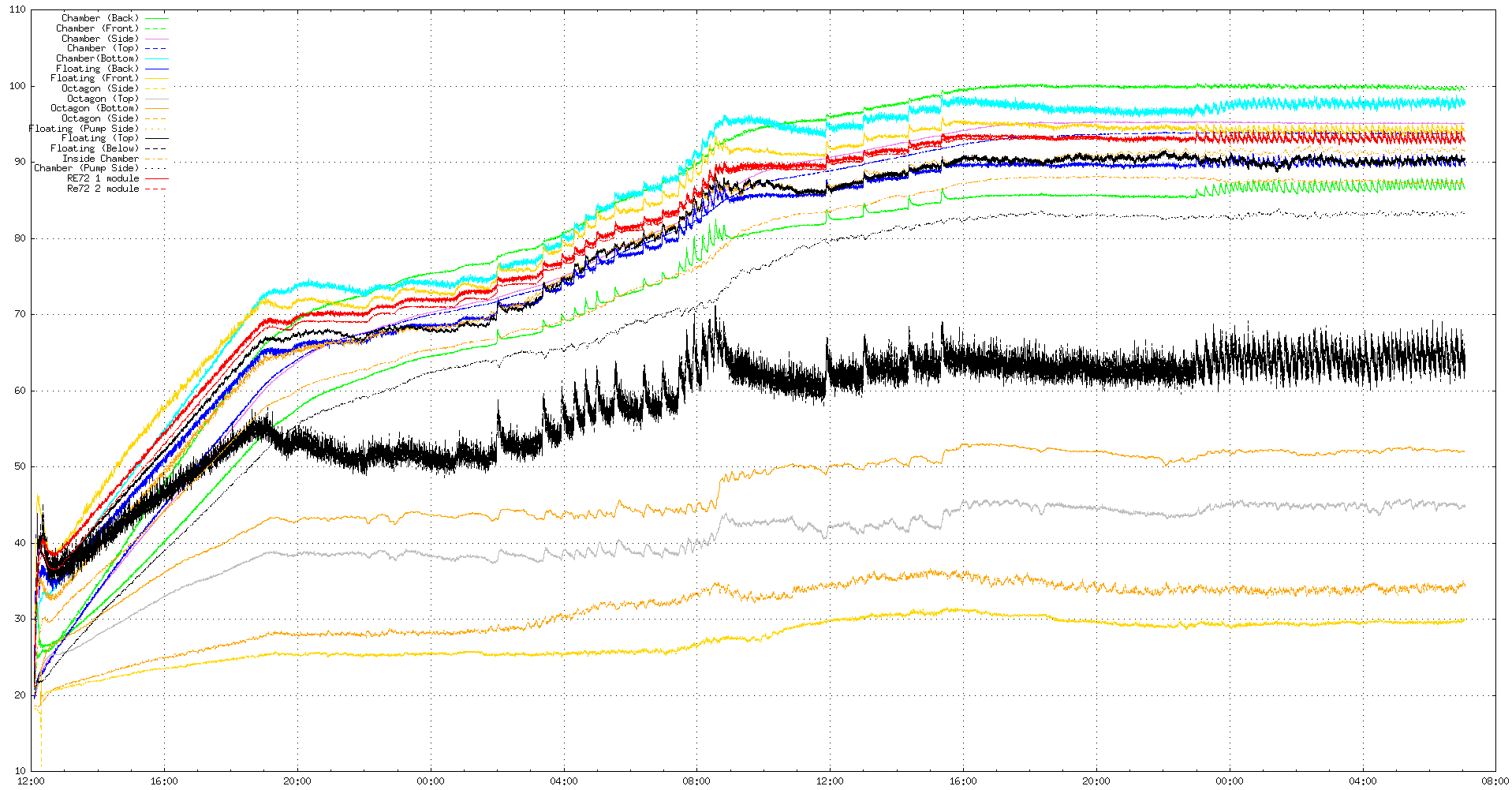

JM, CB (remotely) | Baking status |

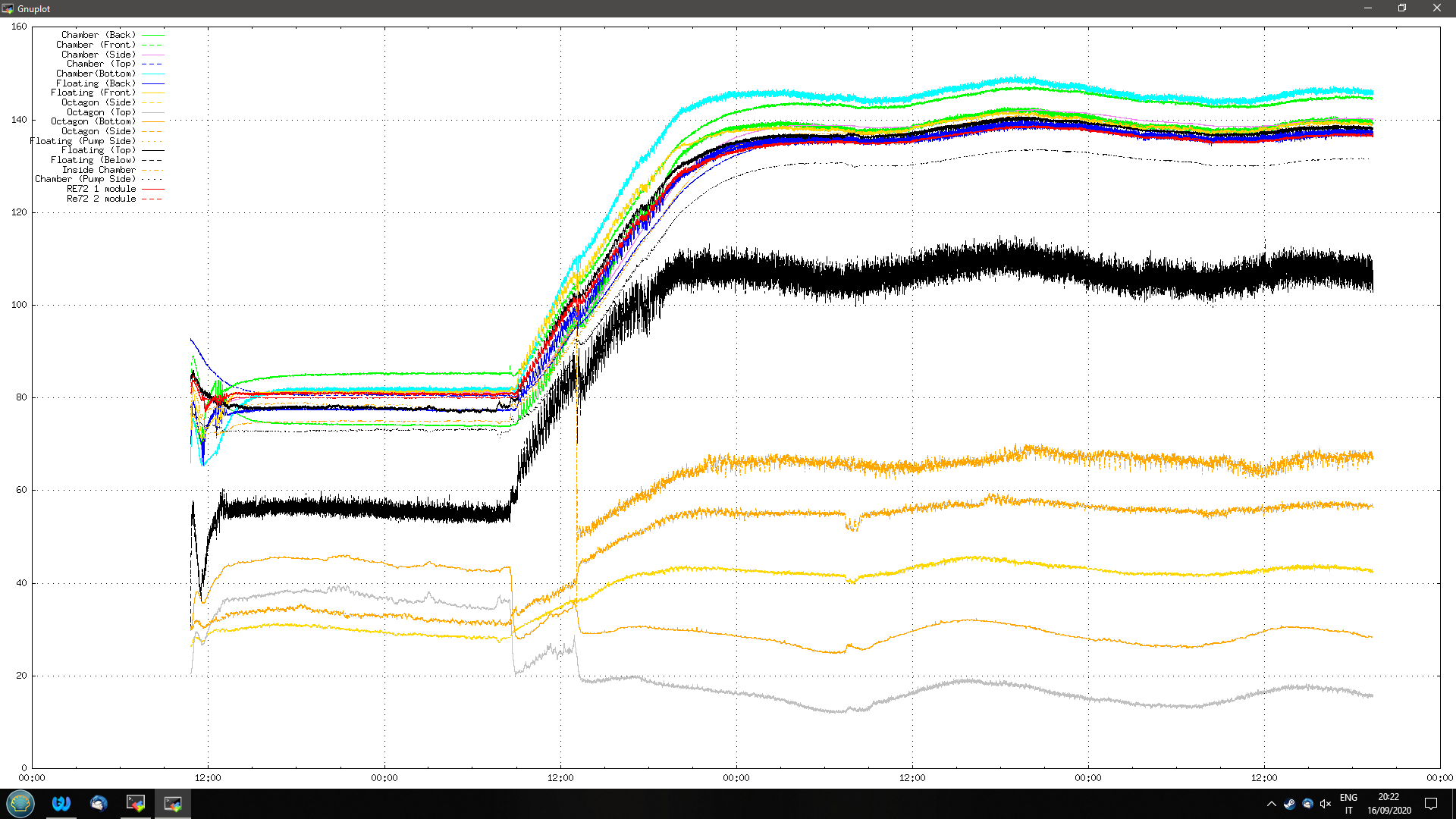

Mon 14 Sep 09:50

Jordan moved the TC08 picolog 2 away from the chamber and built a makeshit heatshield.

Picolog 2 was facing a slit in the cloth thorugh which the scroll pump flexible hose is connected.

Baking restarted in automatic mode from 80 C

12:09

Baking progressed OK - see attached.

~13:00

CJC 2 getting too high again. Baking went off. Jordan caught it and temporarily set in manual mode.

Moved picolog 2 further away. Increased amount of heatshield. Restarted in auto

17:30

Baking continues OK - see attached.

Will leave overnight.

19:30

Baking continues OK, T=124C , see attached.

However rates shown on Baking.x program appear nonsensical. Too high, too low, sometimes they all go to zero.

Clearly a bug in the code. Should not affect baking for now.

Will try to debug. |

| Attachment 1: 20200914_1207_temps.png

|

|

| Attachment 2: 20200914_1207_ctrl.png

|

|

| Attachment 3: 20200914_1727_temps.png

|

|

| Attachment 4: 20200914_2000_temps.png

|

|

|

|

16

|

Fri Sep 18 10:28:57 2020 |

JM, CB(remotely) | Baking status |

10:28

Reducing temperature in steps. System cooling down. See attached.

Pressure on the leak cart: 1.6e-6 mbar |

| Attachment 1: 20200918_1029_temps.png

|

|

|

|

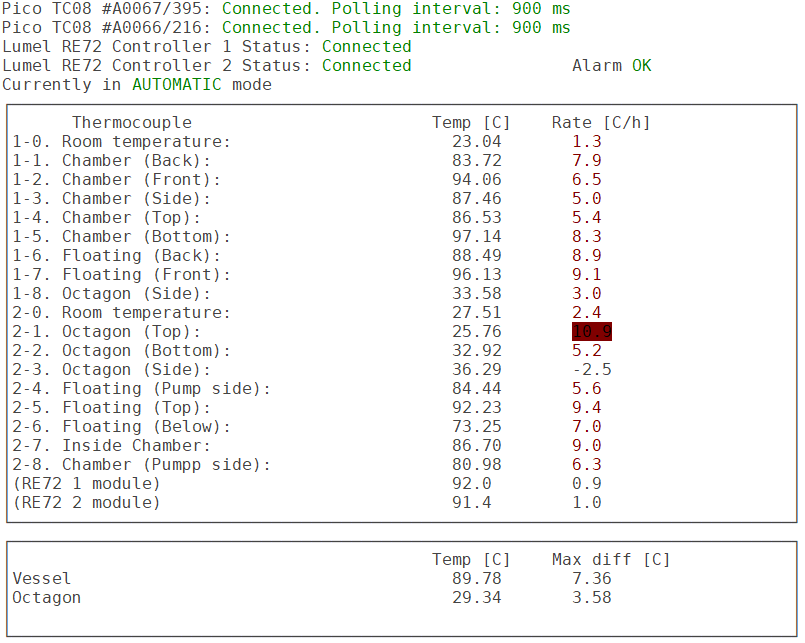

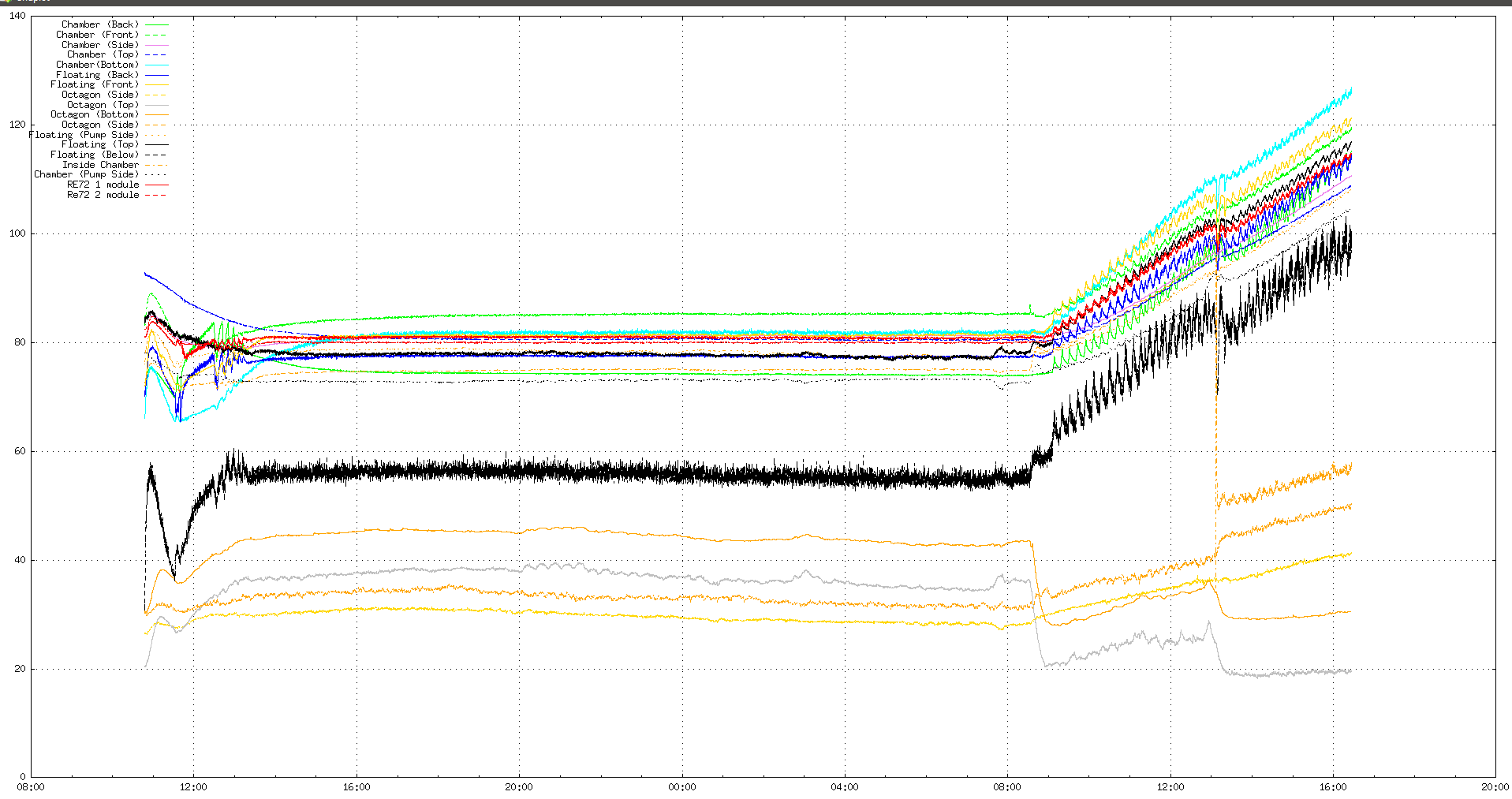

22

|

Sat Sep 26 09:31:46 2020 |

JM, CB (both remotely) | Baking over weekend |

Sat 26 Sep

09:15 Baking started automatic mode

13:30 Baking continues, heating is slower than expected due to high chamber bottom temperatures

00:00 Baking stopped. Temperatures won't increase due to high temperature of the bottom of the chamber producing thermal gradients that are too high. I believe this is due to heaters being closer to the chamber as tray sits higher up than in previous test (see heaters.png). A shield above the heaters, similar to those we utilised in early tests in Edinburgh, may help to disperse the heat more evenly around the baking volume and not directly at the bottom of the chamber. I can improvise a shield similar to those using pieces of the aluminium outer layer of the baking setup I have spare on Monday and restart baking. This will also allow me to replace the two damaged thermocouples

Sun 27 Sep

11:50 Baking restarted. Manually set temperature to 50 C. Started automatic mode for additional safety checks. Will check again / increase temperature manually in a few hours

13:45 Found baking had stopped due to automatic mode detecting negative temperature gradient in TC7 Floating (bottom). See plot attached. Restarted baking at 50 C in manual mode

17:30 Found temperatures had stabilised. Increased temperature to 60 C. Issues seems to be that bottom thermocouples run hotter than the reference thermocouples of the RE72. The temperature the RE72 are set to maintain is not the temperature of the chamber. This is the cause of the strong gradients. Swapping the position of the thermocouples may be sufficient. Thermocouples presumed faulty on Friday may be working OK - could just be positioned in hot spot immediately above heaters.

18:00 Baking off to allow cooling down overnight. |

| Attachment 1: temps.png

|

|

| Attachment 2: temps2.png

|

|

| Attachment 3: Heaters.jpg

|

|

| Attachment 4: 20200927_1732_temps.png

|

|

|

|

10

|

Sun Sep 13 08:06:25 2020 |

CB (remotely) | Baking over the weekend -2 |

Sun 13 Sep 08:06

Baking reached 93 C yesterday afternoon at 16:18 and paused as a result of a percieved temperature gradient in

the octagon.

See attached.

Left system overnight to check whether octagon gradient was going to equilibrate via convection.

No changes this morning.

Thermocouple 1-8 labeled "Octagon (side)" likely is not in thermal contact with the octagon.

It appears to have a temperature lower than room temperature. Possibly sits outside the tent? Gradient will not

decrease with time.

Temporarily overrode automatic mode, set temperature to 100 C, restarted automatic mode. Will keep monitoring.

Sun 13 Sep 10:00

Vessel reached 100 C, no gradients. All OK, except octagon gradient (ignoring).

Manually increased temperature to 110 C. Restored automatic mode.

Sun 13 Sep 12:00

Baking stopped automatically at 10:30 due to CJC temperature (aka room temperature 2) in TC-08 Picolog 2

exceeding 40 C.

Max operating temperature of picolog TC08 is 50 C, and accuracy is lost above 30 C.

https://www.picotech.com/data-logger/tc-08/usb-tc-08-specifications

Stopped baking. Removed thermocouple 1-8 "Octagon (side)" from Octagon gradient calculation and recompiled.

Restarted manually at T = 80 C

Please move picolog away from the tent tomorrow, and we can then increase temperature. Tent does not need to be

opened.

Sun 13 Sep 19:00

Vessel temperature at 80 C stable.

Other temperatures stable.

Leaving at 80 C overnight. |

| Attachment 1: 20201309_0806_ctrl.png

|

|

| Attachment 2: 20201309_0806_plot.png

|

|

|

|

9

|

Sat Sep 12 08:38:52 2020 |

CB (remotely) | Baking over the weekend |

Saturday 12 Sep 08:43

Remotely checked status of baking. See attached.

Baking appears to be proceeding OK. No thermocouples disconnected.

Speed is slower than previously observed, limited by thermal gradients observed across both octagon and CARME

vessel as a result of new thermocouple placement.

Octagon gradient may not be real, and could be a result of placement of Octagon side thermocouple?

Main concern is temperature recorded by CJC in Picolog2 (aka Room temperature 2) at 31 C, increasing.

The second picolog may be too close to the tent. If the temperature keeps increasing it may stop working. Will

keep monitoring. |

| Attachment 1: 20200912_0839_ctrl.png

|

|

| Attachment 2: 20200912_0839_plot.png

|

|

|

|

12

|

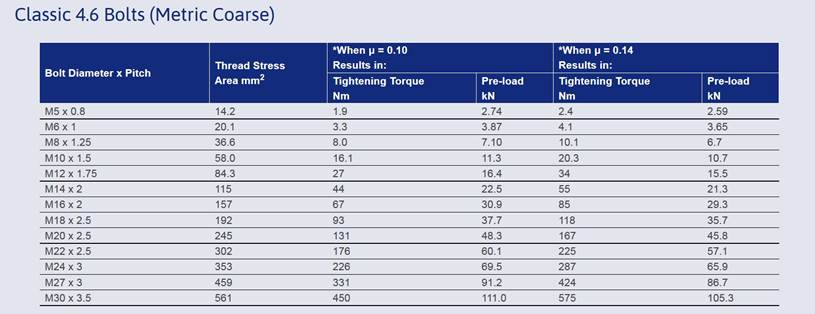

Tue Sep 15 08:39:26 2020 |

CB (remotely), JM | Baking and Chamber status |

Tuesday 15 September

08:40

Rates started working again. Unclear what yesterday evening's bug was caused by. Will investigate eventually.

Temperature setpoint reach T=150 , however even at full power (heating constantly on) the RE72 appear unable to

reach past T = 135

See attached.

Perhaps better insulation would be required.

However, this temperature is sufficient to bake CARME with the detectors inserted.

Day shift

Baking continues and will be left overnight to gather more data. Vessel temperatures are increasing by roughly 1.5 deg/hour with the vessel average temperature now 141.5

deg.

Wire seals fully closed and tightened. Bolts were tightened first finger tight, then to 50 N.m and finally to 80 N.m in a pattern so that seal is closed evenly. Leak and

pump cart are ready to be connected to the turbo for leak testing tomorrow.

19:20

Baking continues OK. Temperatures seem to increase slowly. See attached. |

| Attachment 1: 20200915_0842_ctrl.png

|

|

| Attachment 2: 20200915_0842_temp.png

|

|

| Attachment 3: 20200915_152708.jpg

|

|

| Attachment 4: image007.jpg

|

|

| Attachment 5: 20200915_1920_temps.png

|

|

|

|

71

|

Sun Sep 19 09:11:34 2021 |

CB (remotely) | Baking RasPi status |

Accessed Pi remotely

( 1. Without the Internet, the Pi has no way of knowing what time is it.

In case of power loss make sure to set correct date via

sudo date -s 'YYYY-MM-DD HH:MM:SS'

Or all log files will have wrong timestamp )

EDIT: Pi now connected to GSI time server.

2. Temperature logging OK

3. Commands/events logging enabled. Logging to file Log.dat, automatically moved to Logs/$(timestamp)_log.dat on

gracefuly quit.

Cannot test due to TC08 / RE72 not being connected. Please test when possible.

4. Plot_temps.gp gnuplot script currently optimised for 1080p monitor. Monitor in use is 1024x768.

Please optimise first line of script (size, position) to make it fit while we search for a better monitor.

5. Hostname changed to CARMEbakingpi |

|

|

88

|

Mon Sep 27 17:53:35 2021 |

JM RSS | Baking Jacket upgrade + NEG controllers connected |

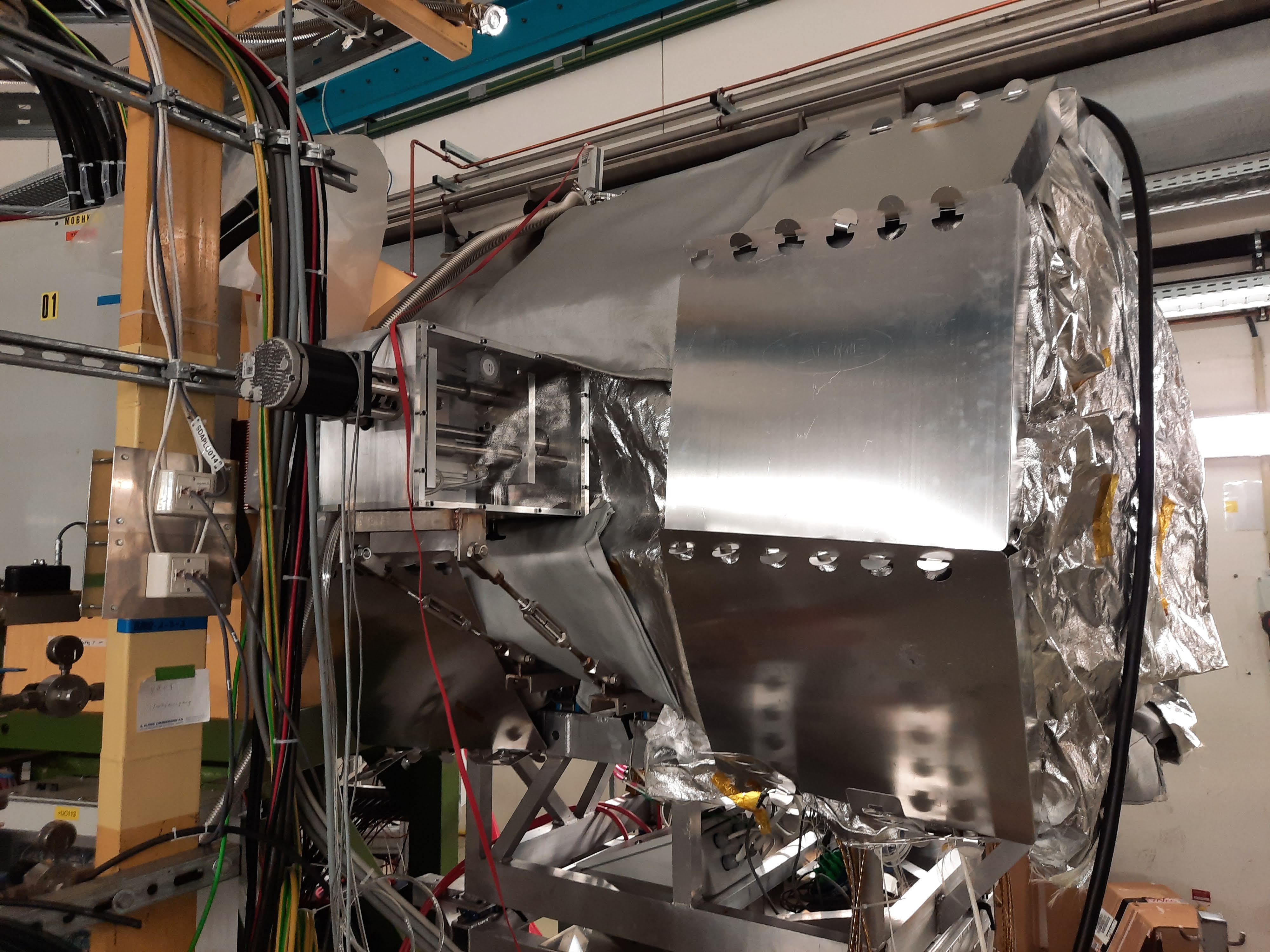

Additional baking jacket sections for the turbo section arrived today. Baking was halted at ~11:00 to allow for the chamber to cool to install new sections. New sections installed and baking restarted at 15:25. Jacket fits much better with gaps near the turbos and the motors now covered much better. Attached are some photos.

While heaters were off, the pressure fell to ~3E-9 mbar and was continuing to fall before baking was restarted.

Current baking temperature is ~75C and code is in automatic mode.

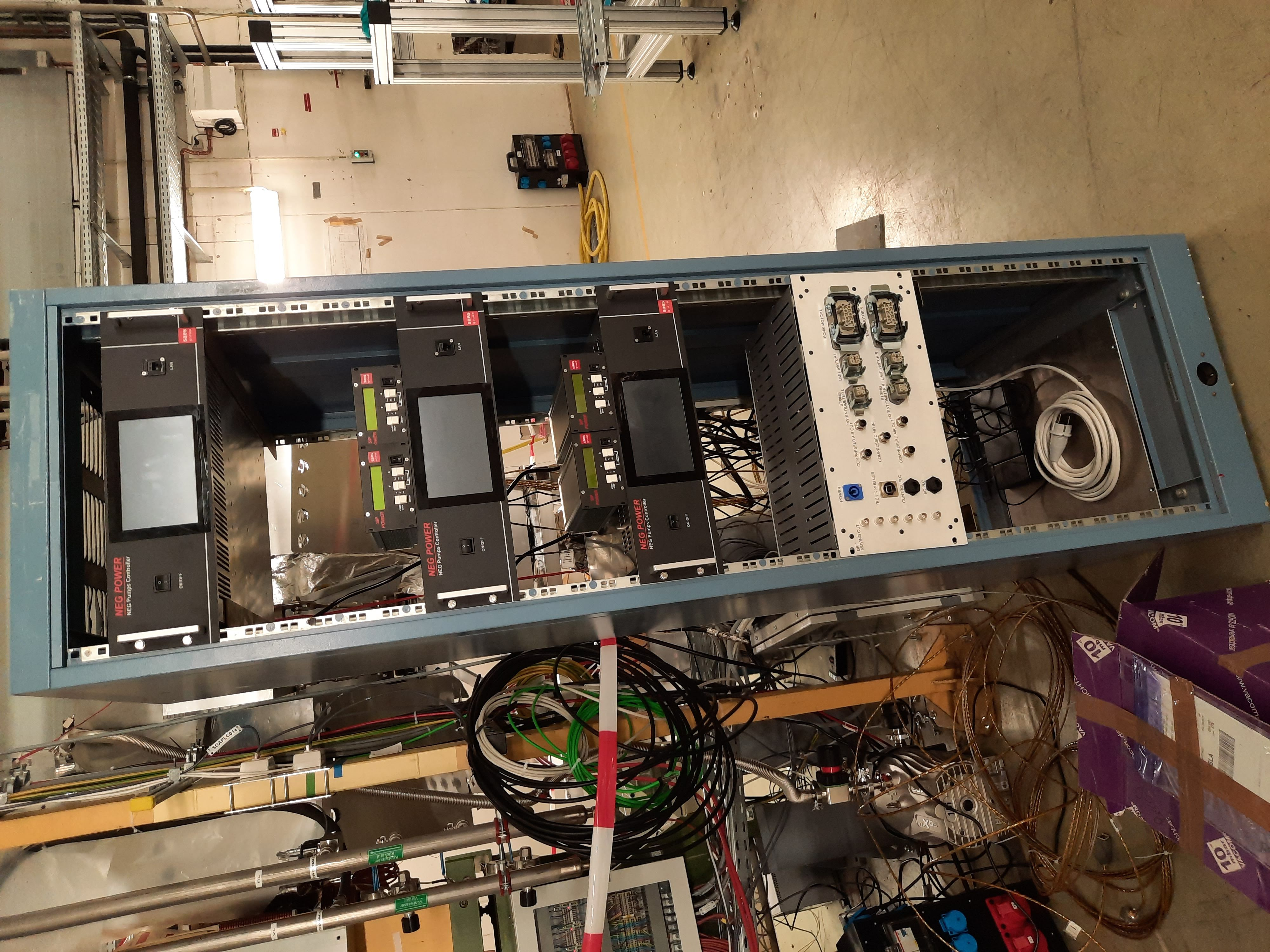

The NEG and motor controllers have been installed on the rack next to the chamber. See attached. The bottom NEG controller is connected to the 4 D-2000 NEG-ion pumps. The cables for the D-2000s have kapton tape attached. The middle NEG controller is connected to the NEG pumps whose feedthroughs are on the chamber on the inside of the ring. One of the connections on the middle controller is for the 3 NEGs connected together oppose to the usual 2. This connection is marked by white tape. The top controller is connected to the feedthrough who are on the side of the chamber on the outside of the ring. |

| Attachment 1: 20210927_151650.jpg

|

|

| Attachment 2: 20210927_151706.jpg

|

|

| Attachment 3: 20210927_151721.jpg

|

|

| Attachment 4: 20210927_170139.jpg

|

|