| ID |

Date |

Author |

Subject |

|

532

|

Mon Feb 19 21:46:32 2024 |

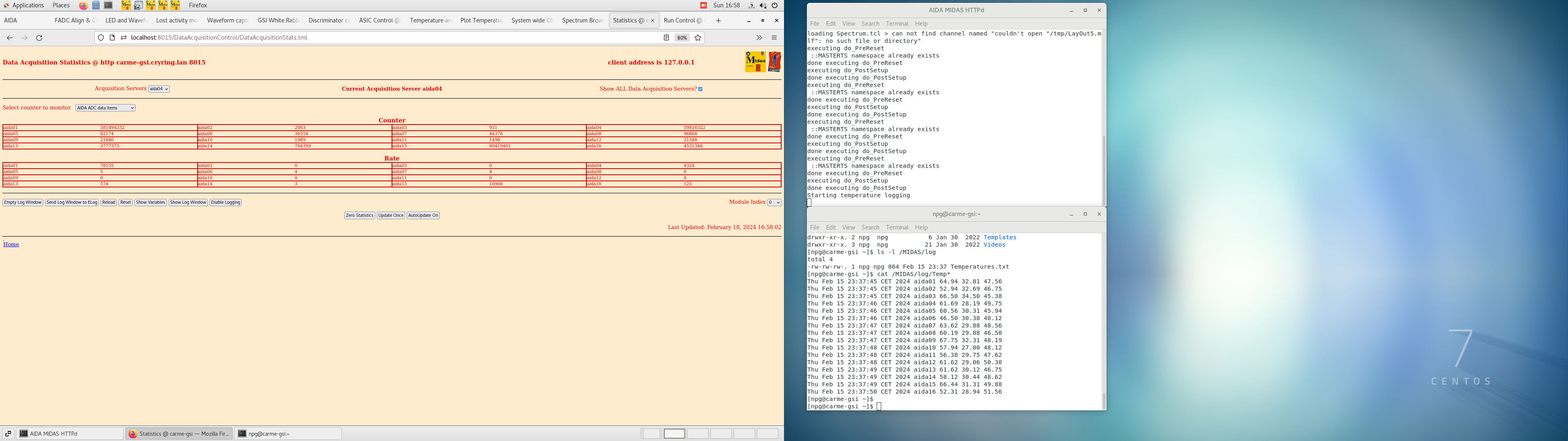

EH, EM, CB | Run 45 + end of late shift |

22:54

We have moved the gas jet target out (y=4000), the density has dropped to zero.

Started a new run (Run45) for background measurement.

Informed HKR that the experiment will be monitored remotely without on-site personnel. They will check on the beam intensity.

02:08

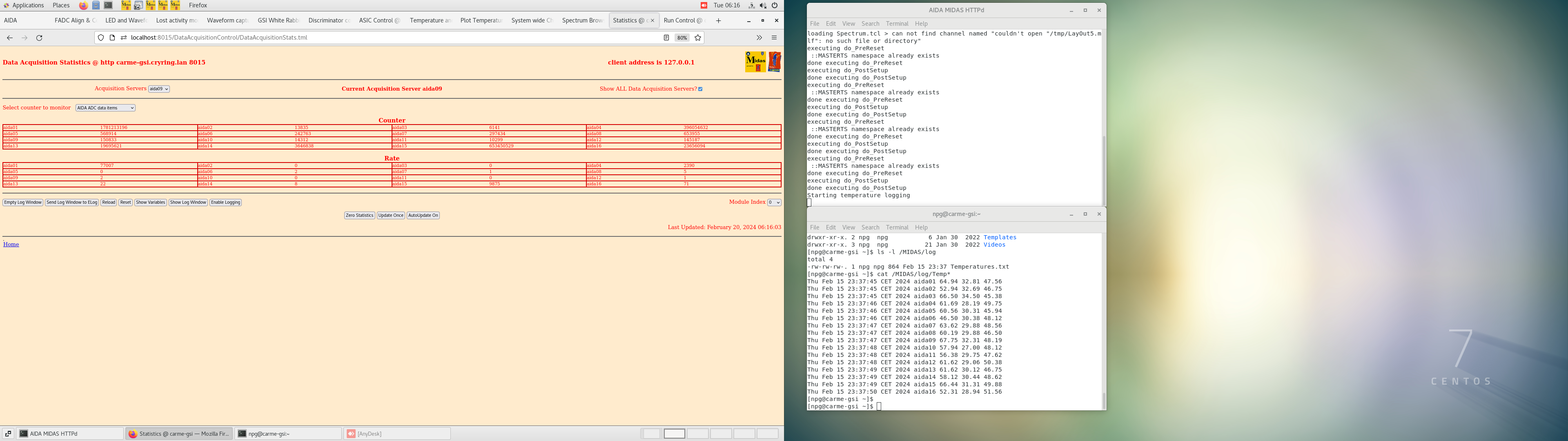

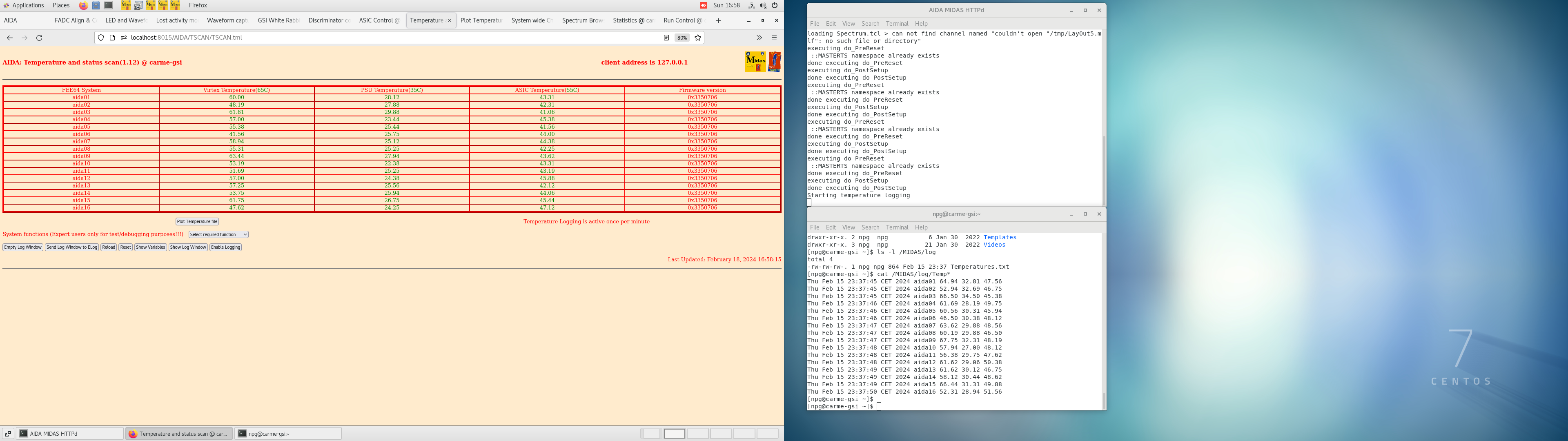

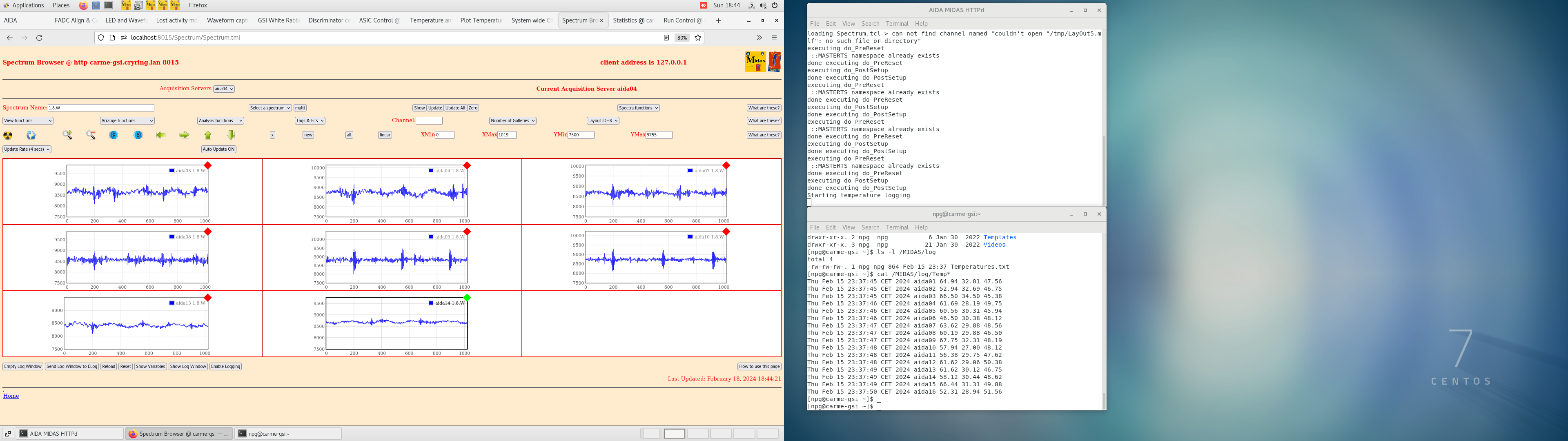

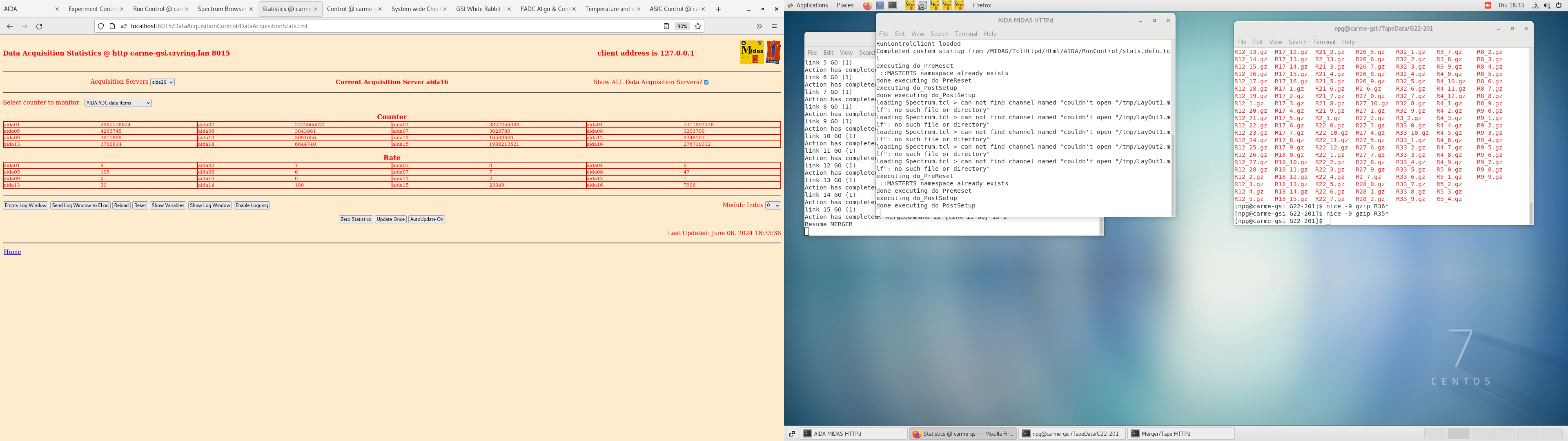

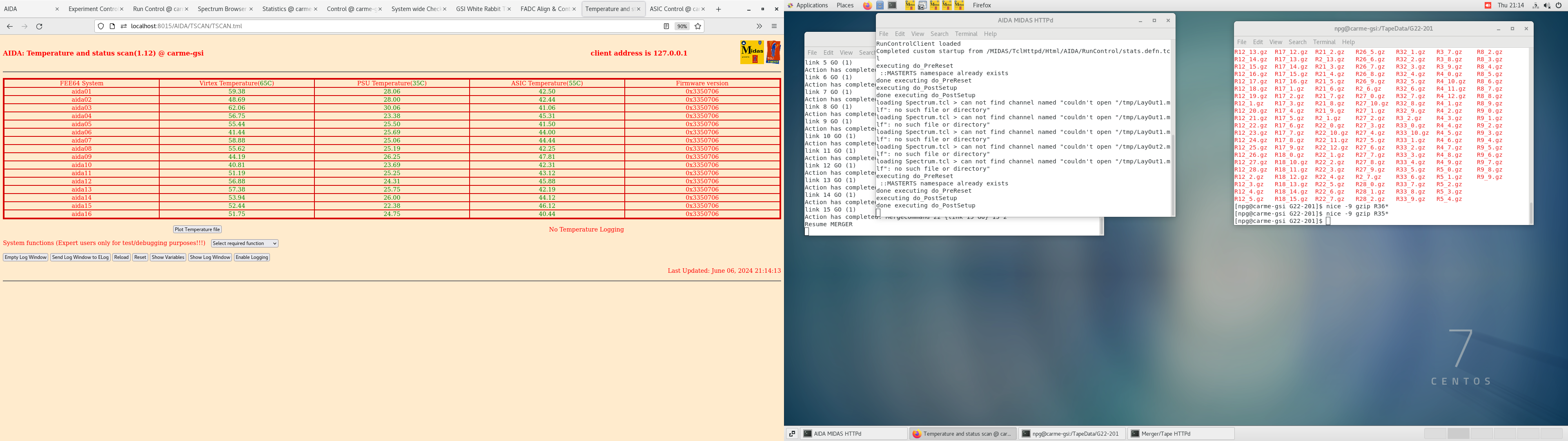

System wide checks OK

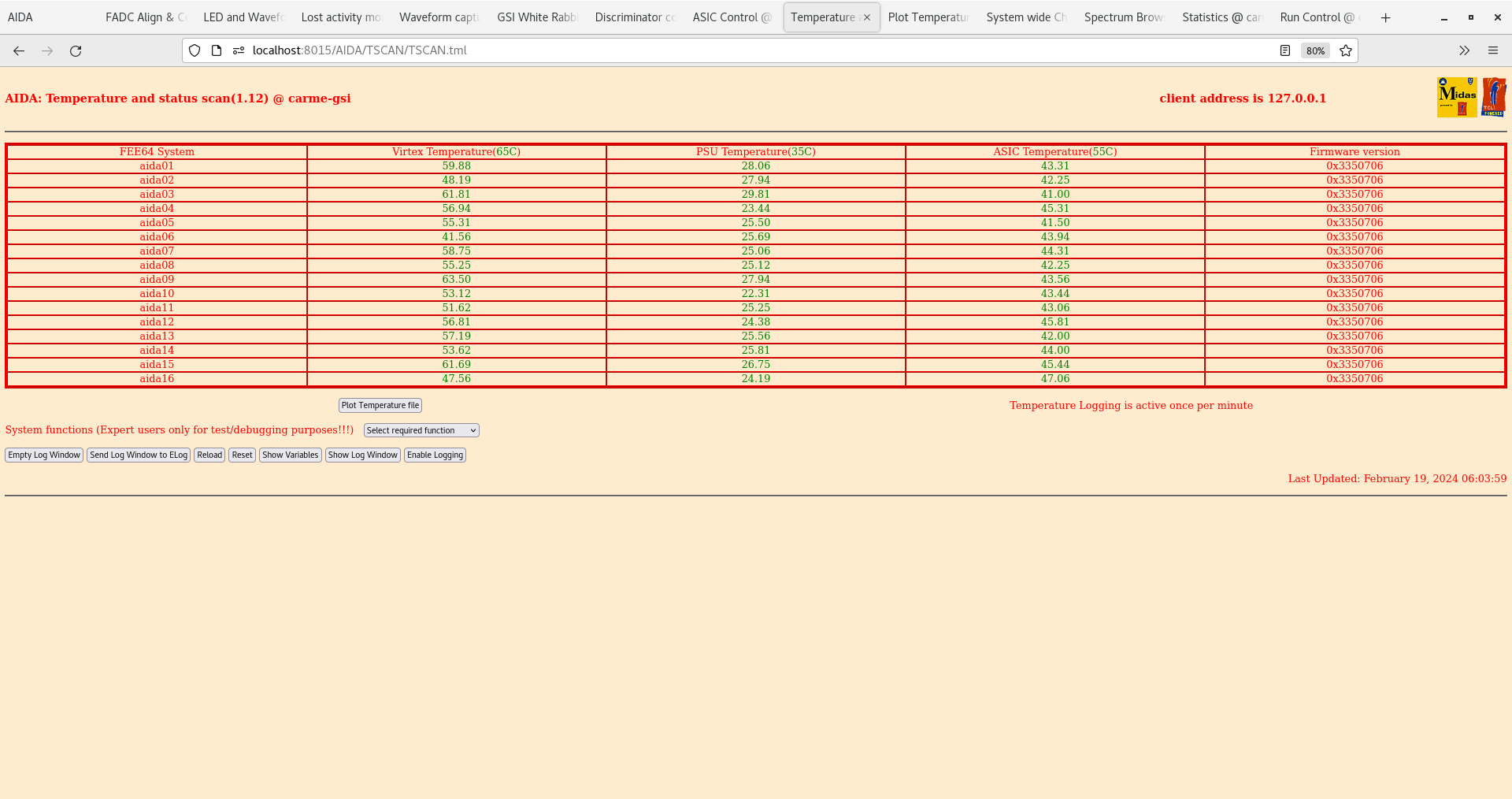

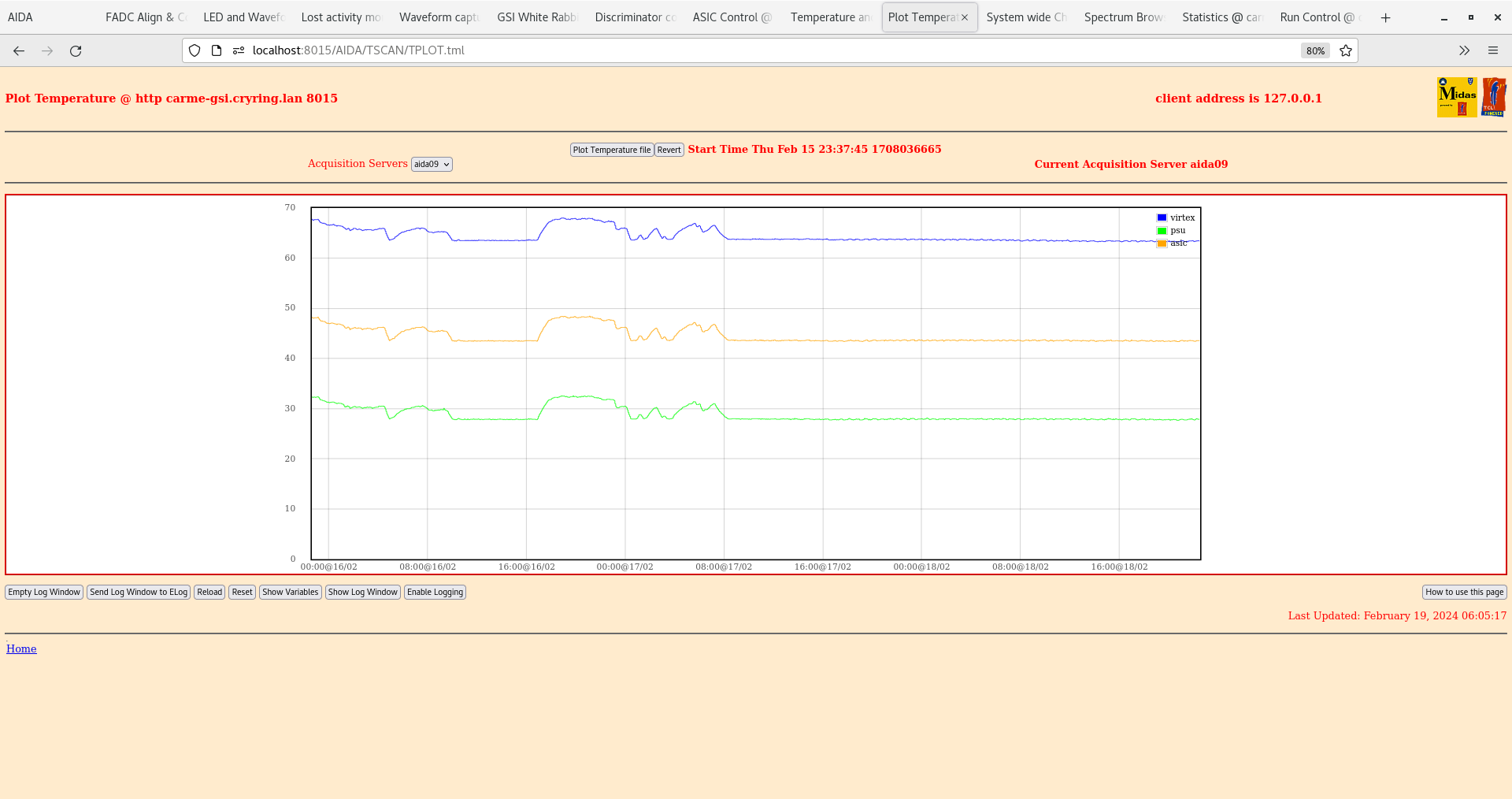

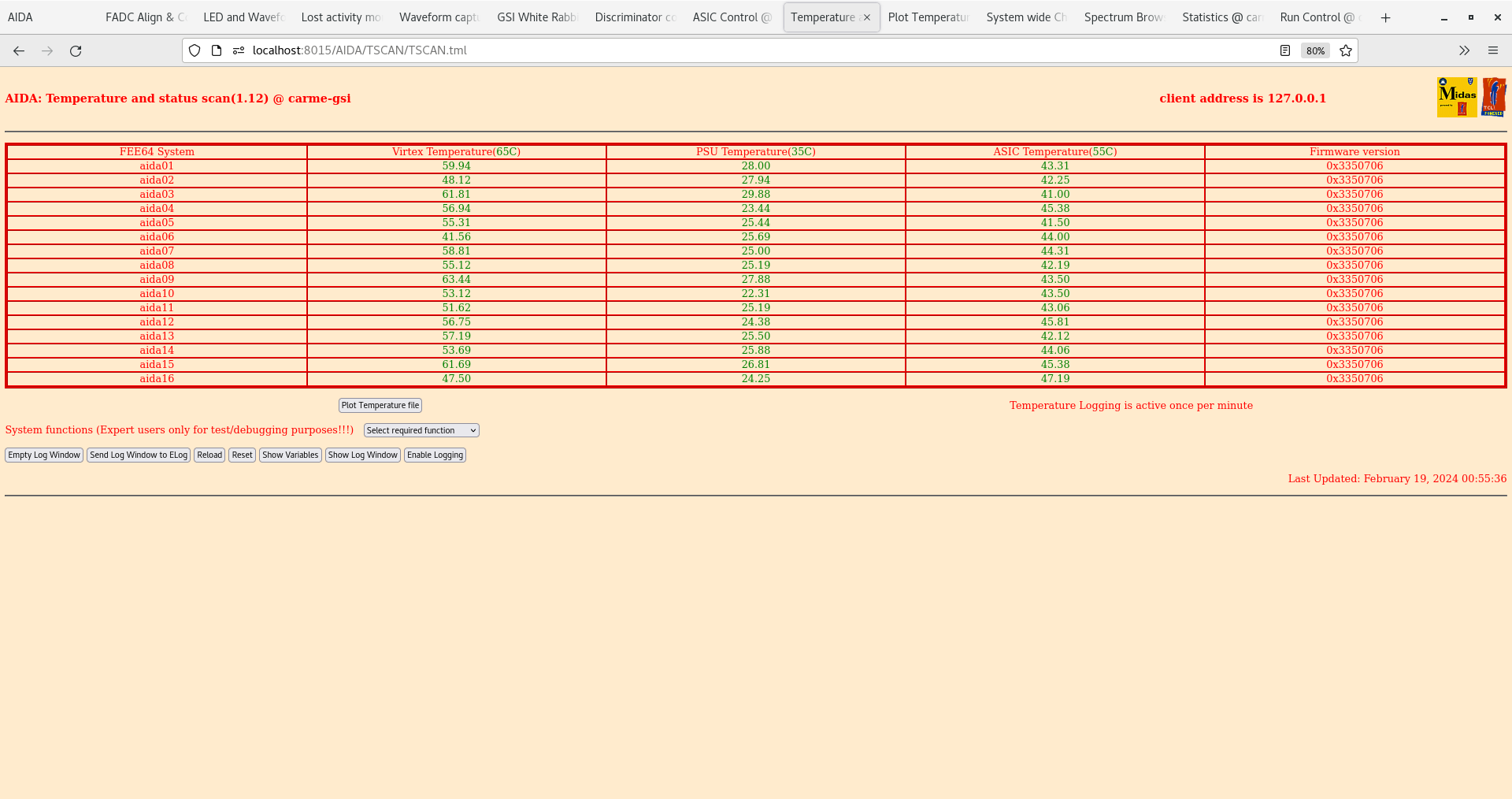

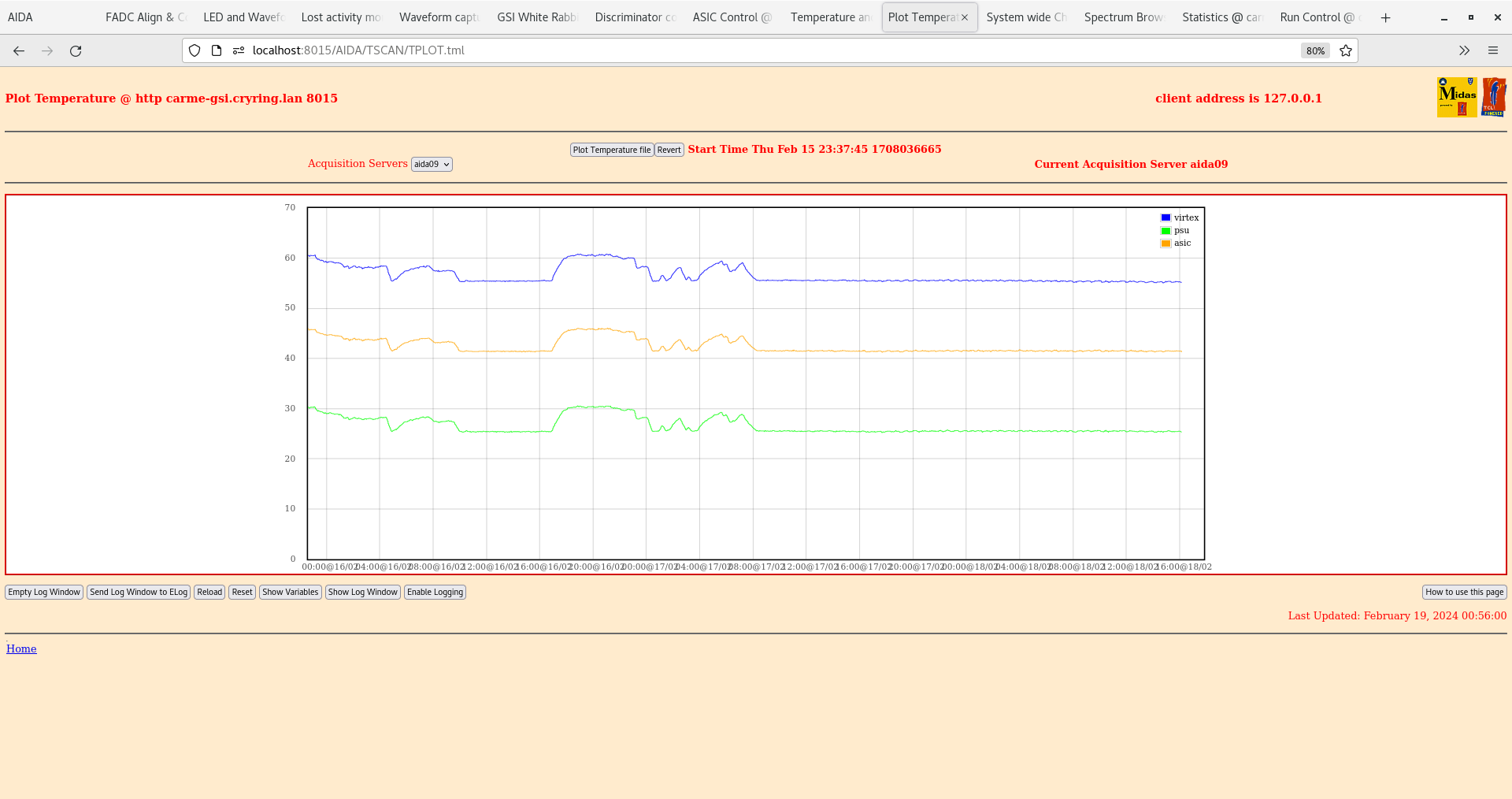

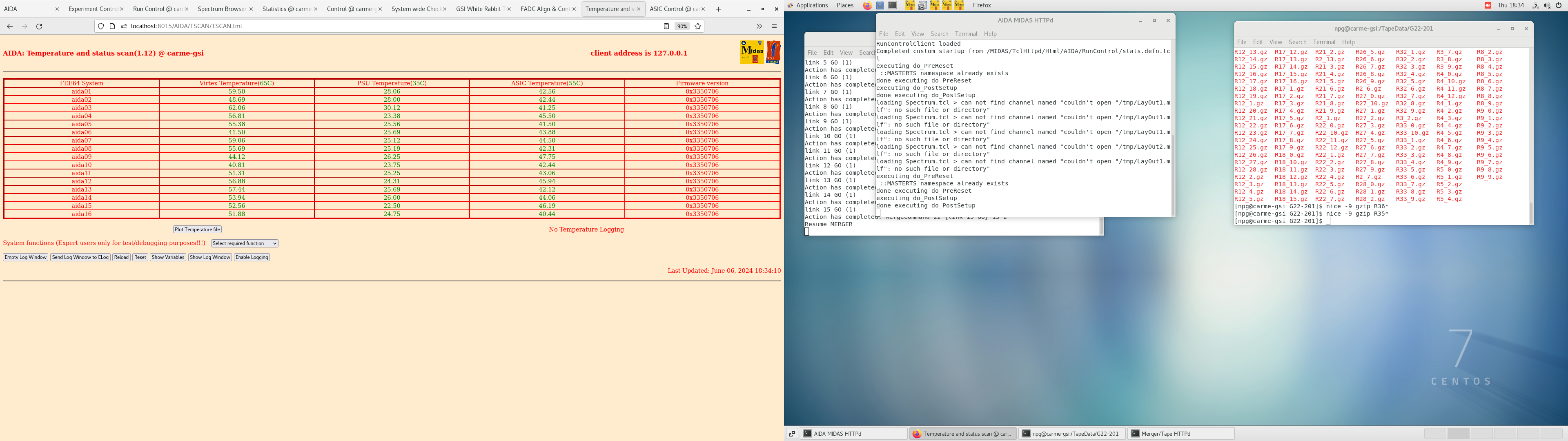

Temperatures OK

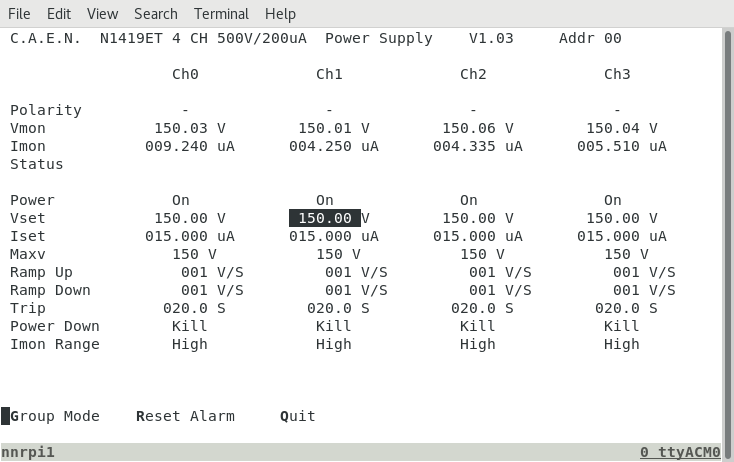

Leakage current going up - OK

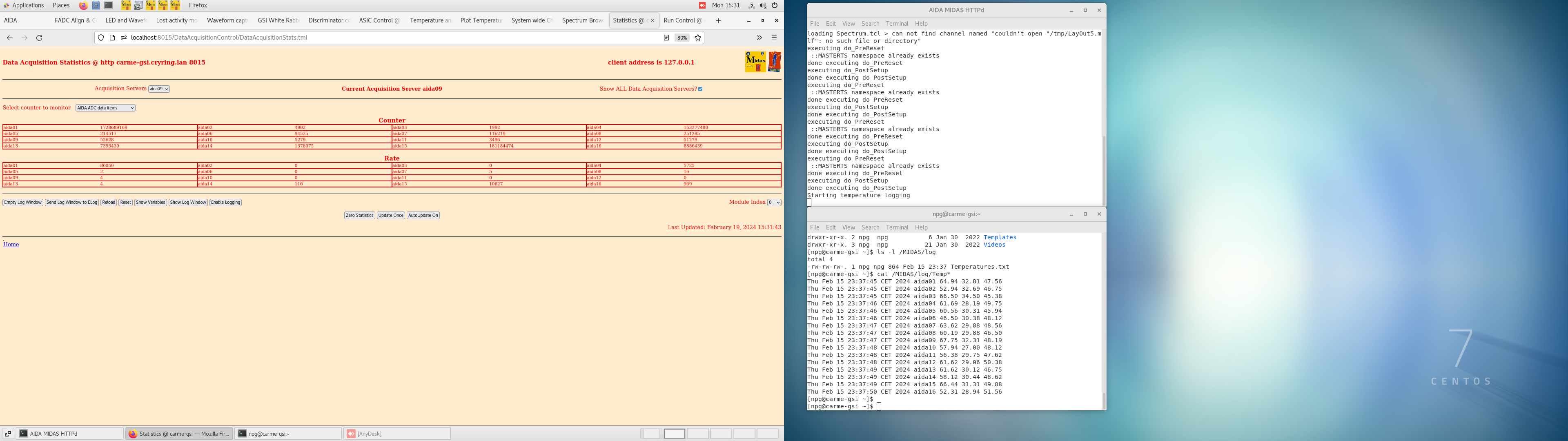

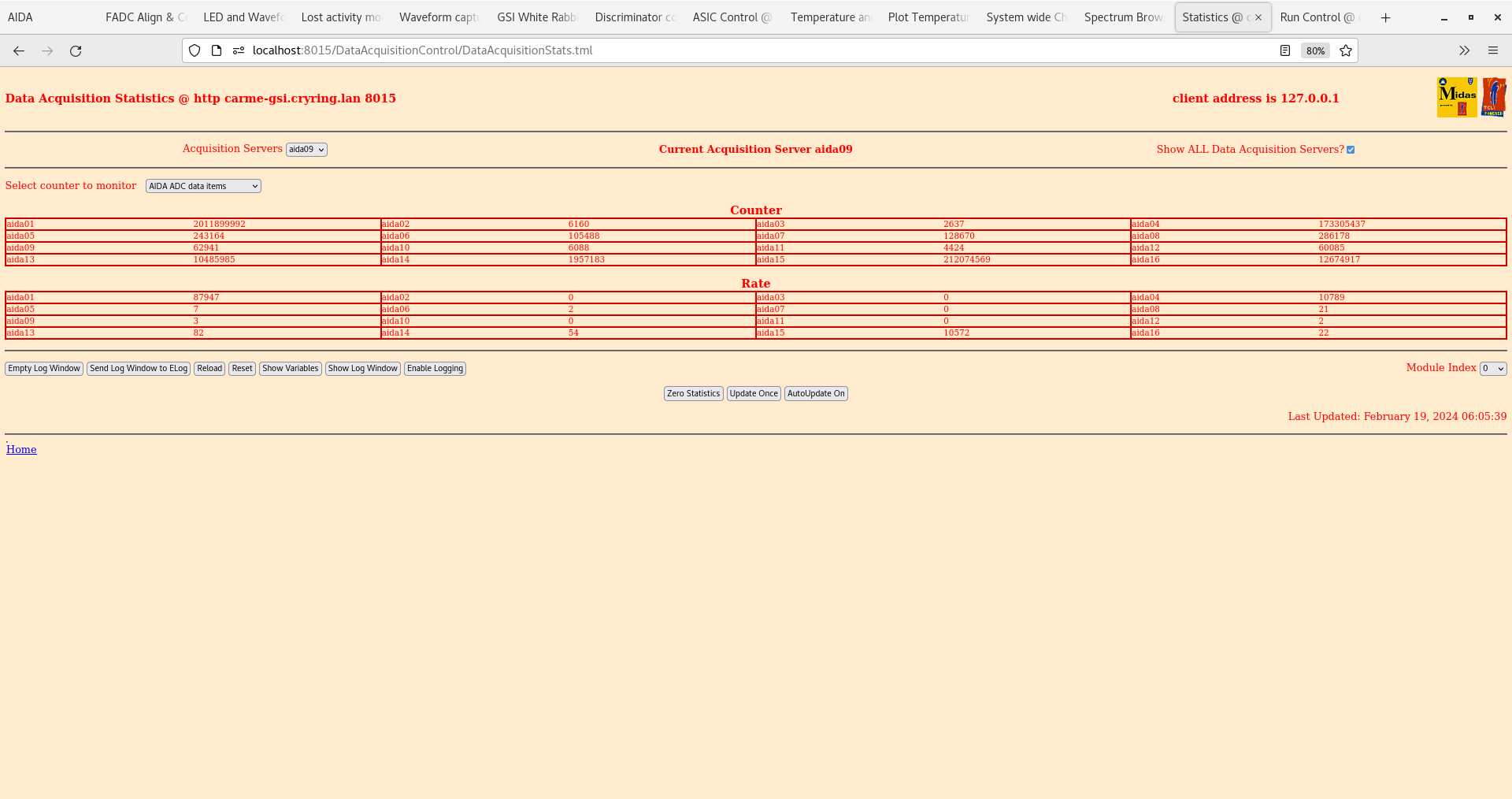

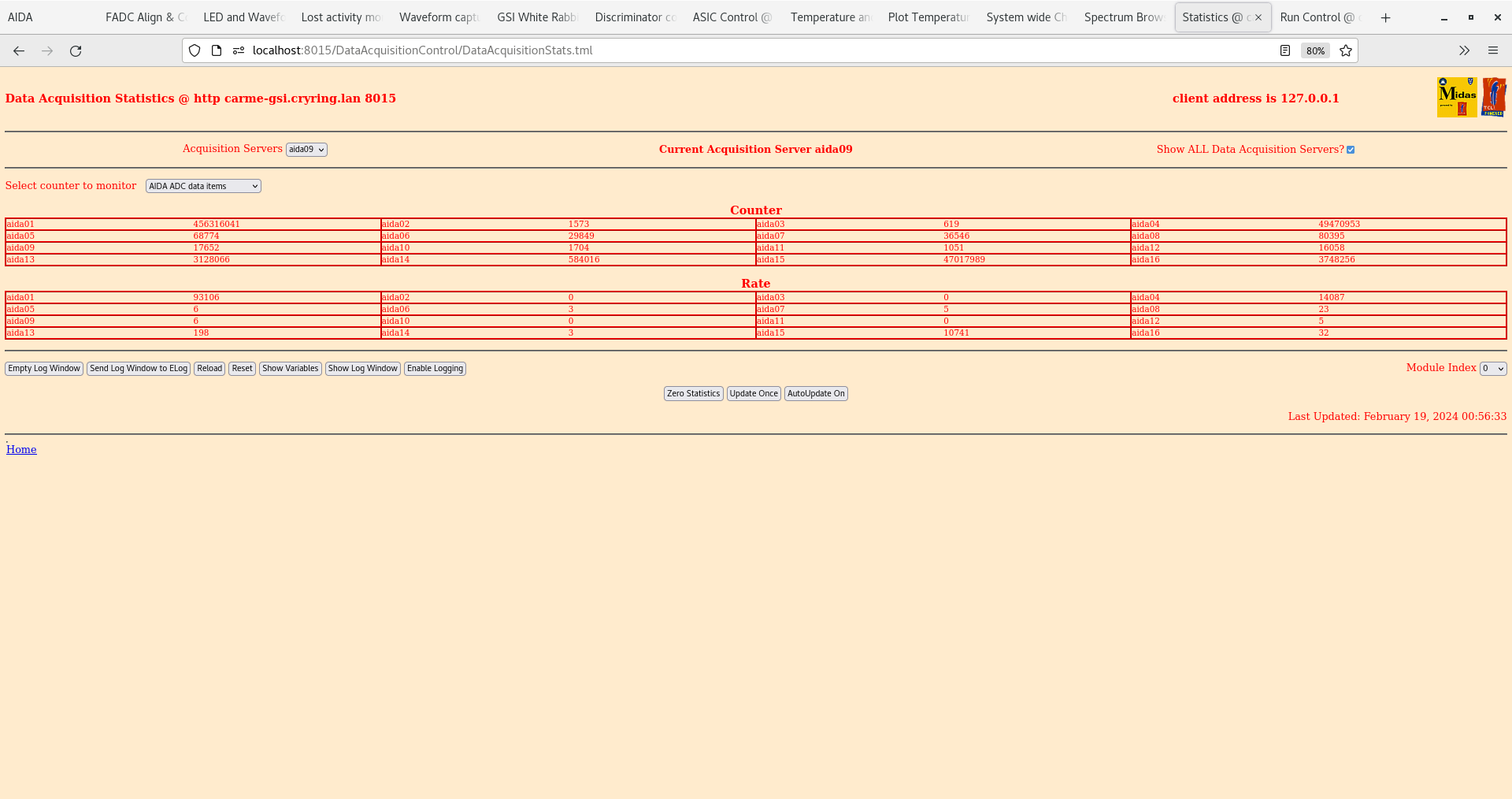

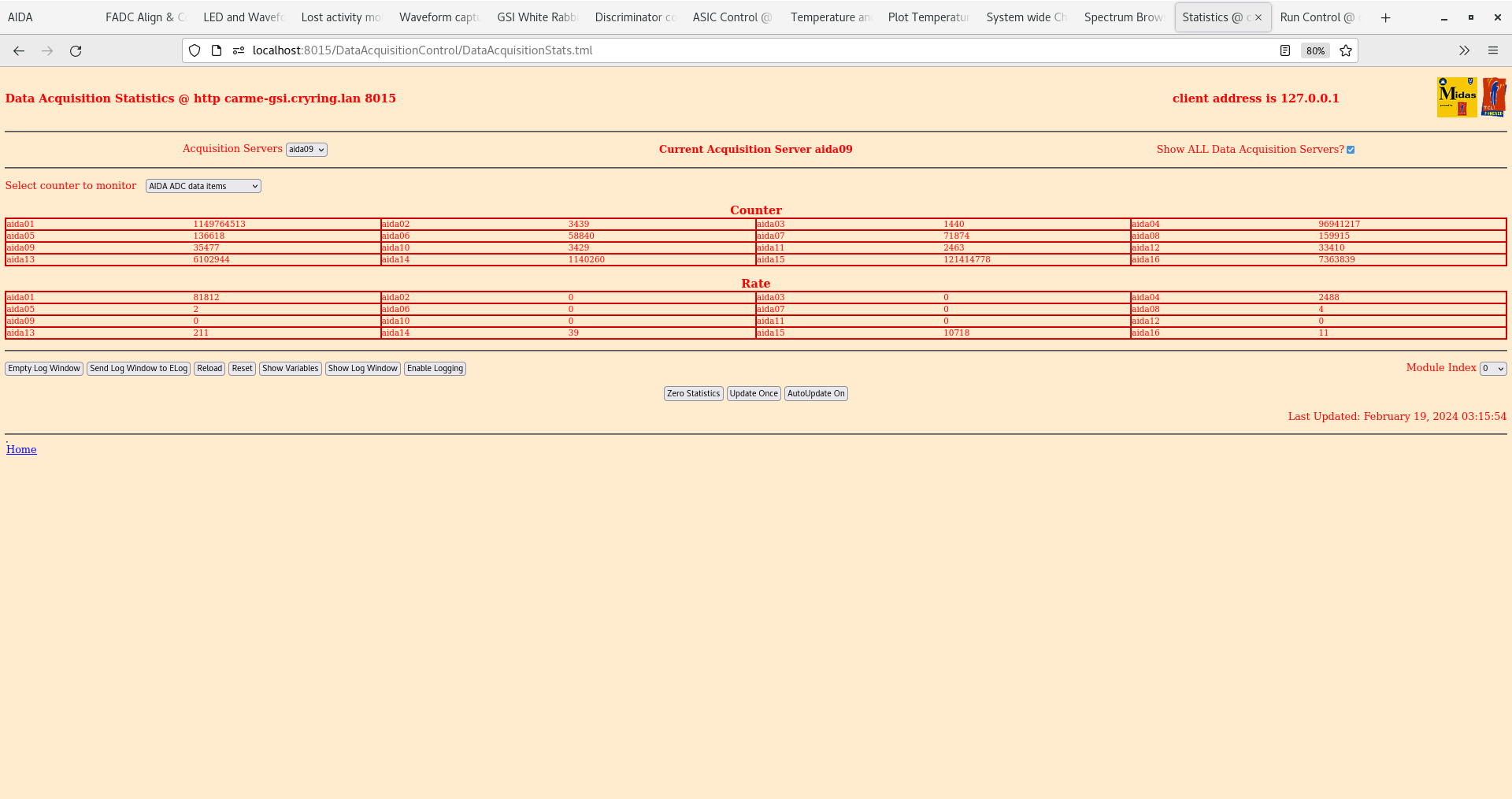

Stats OK

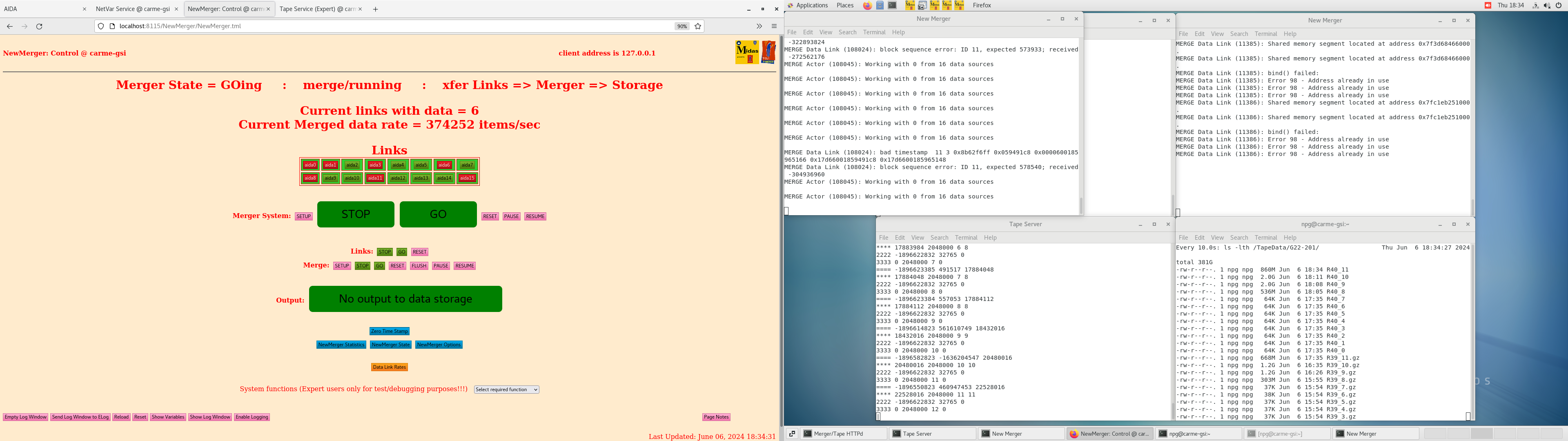

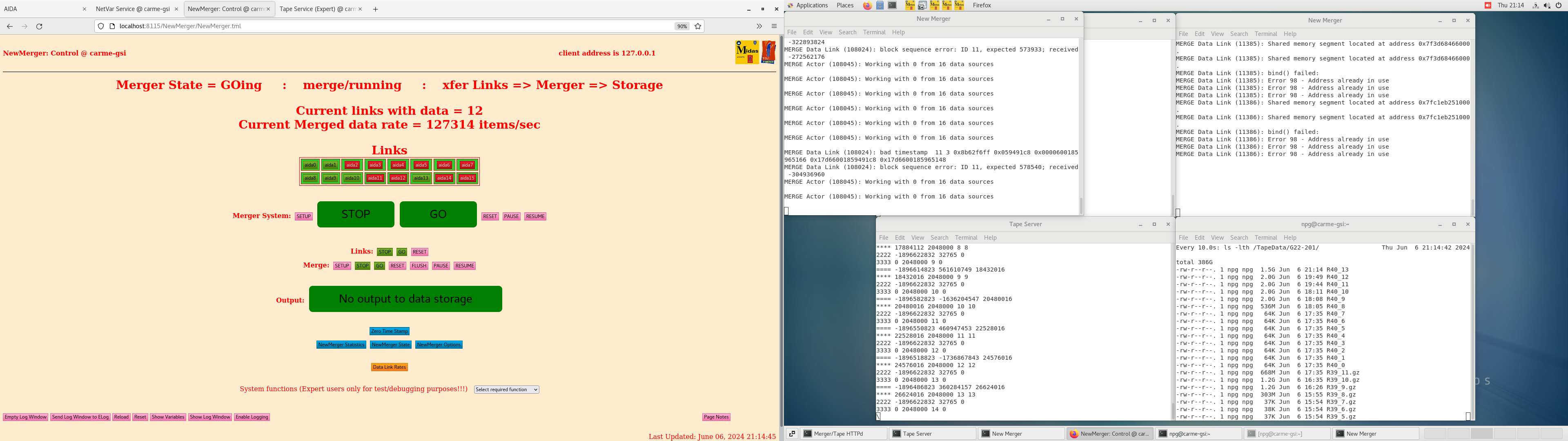

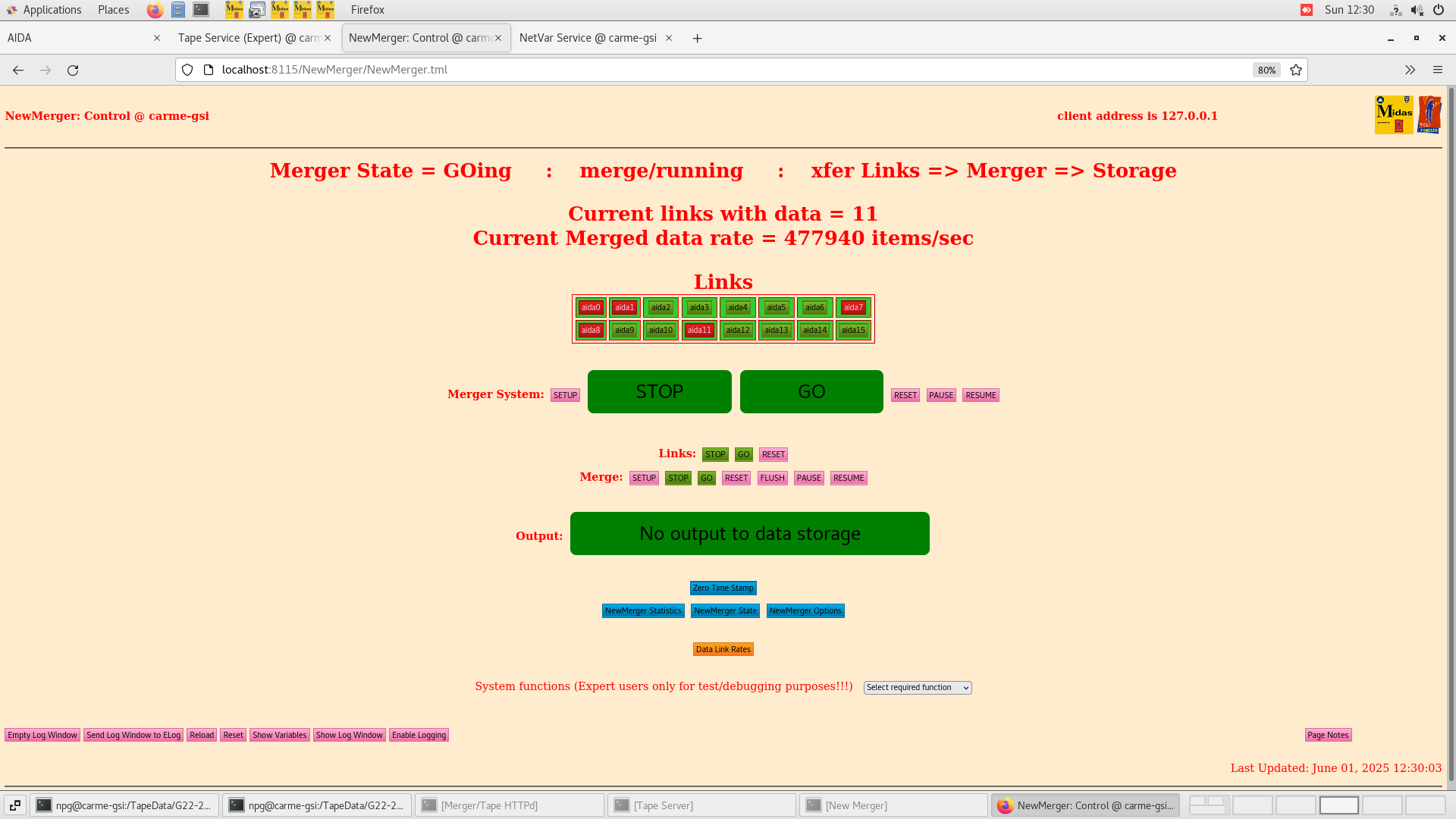

Merger continues OK

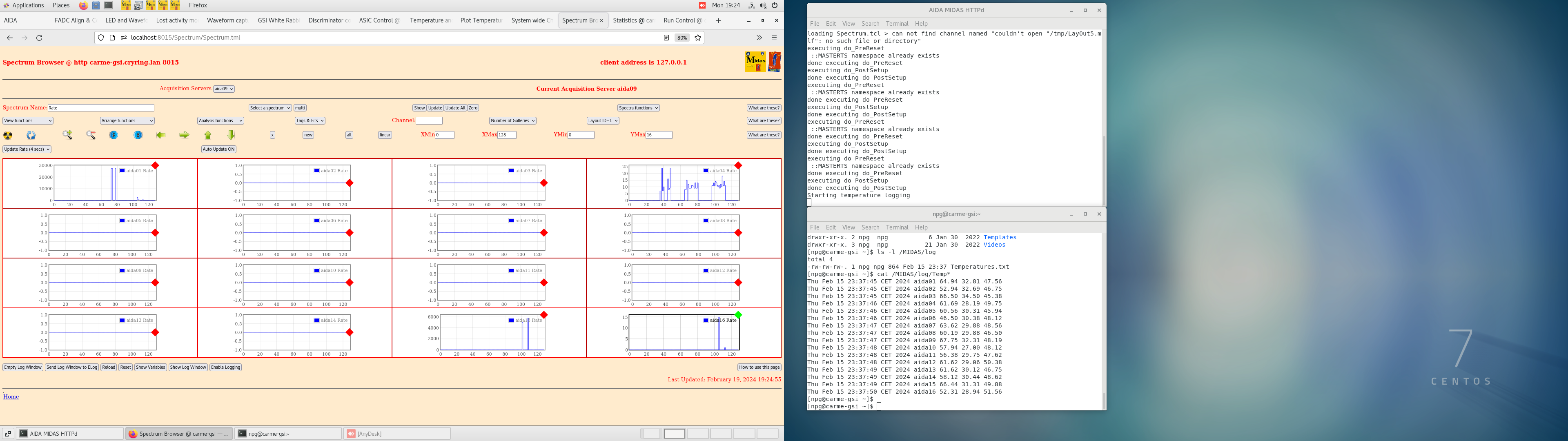

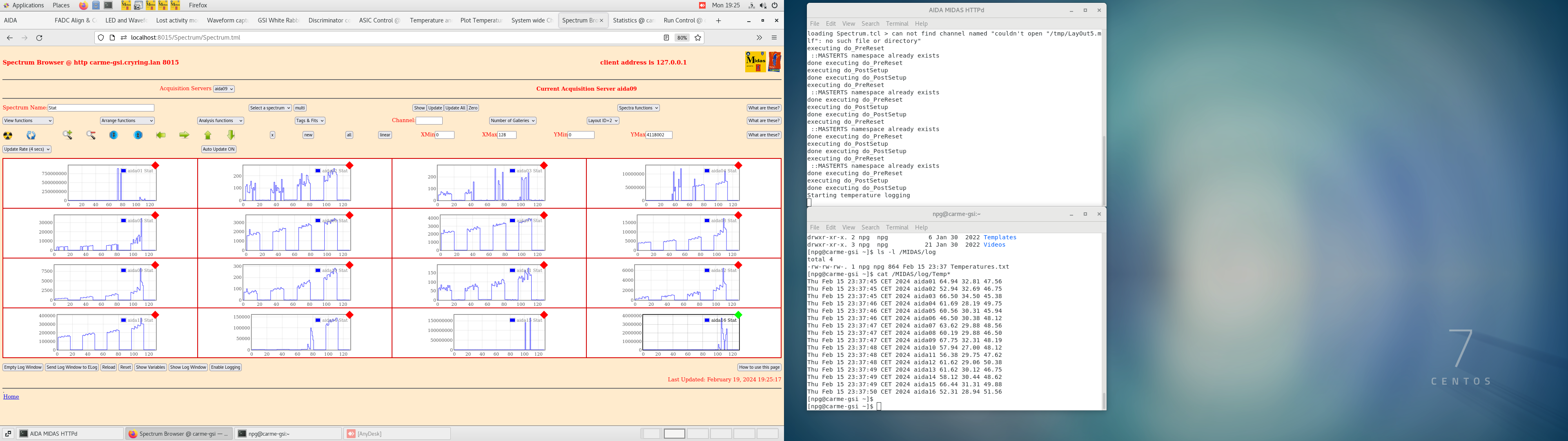

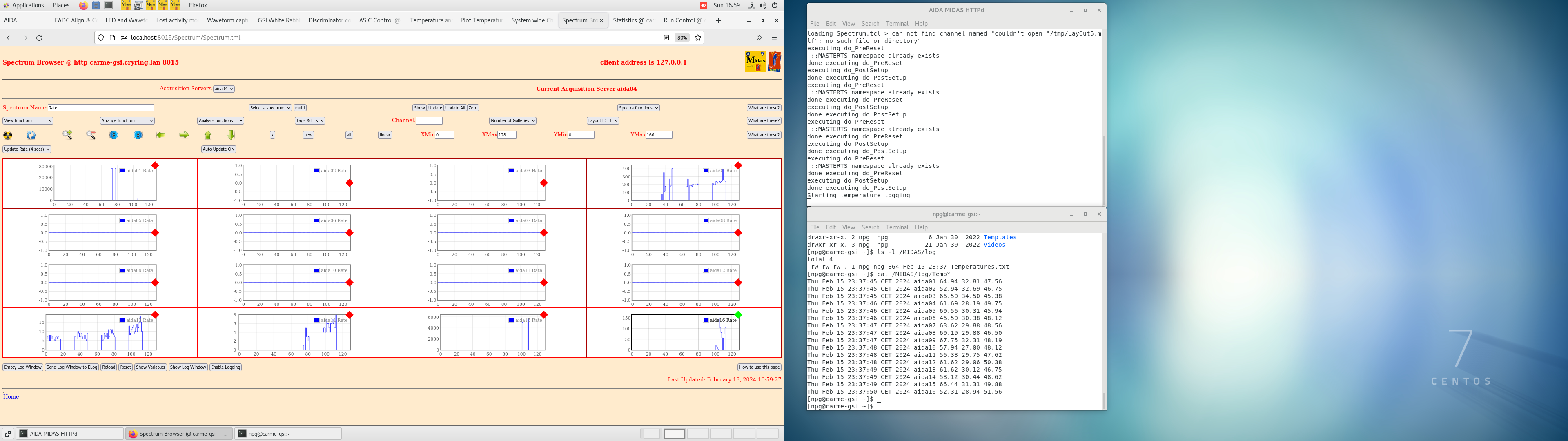

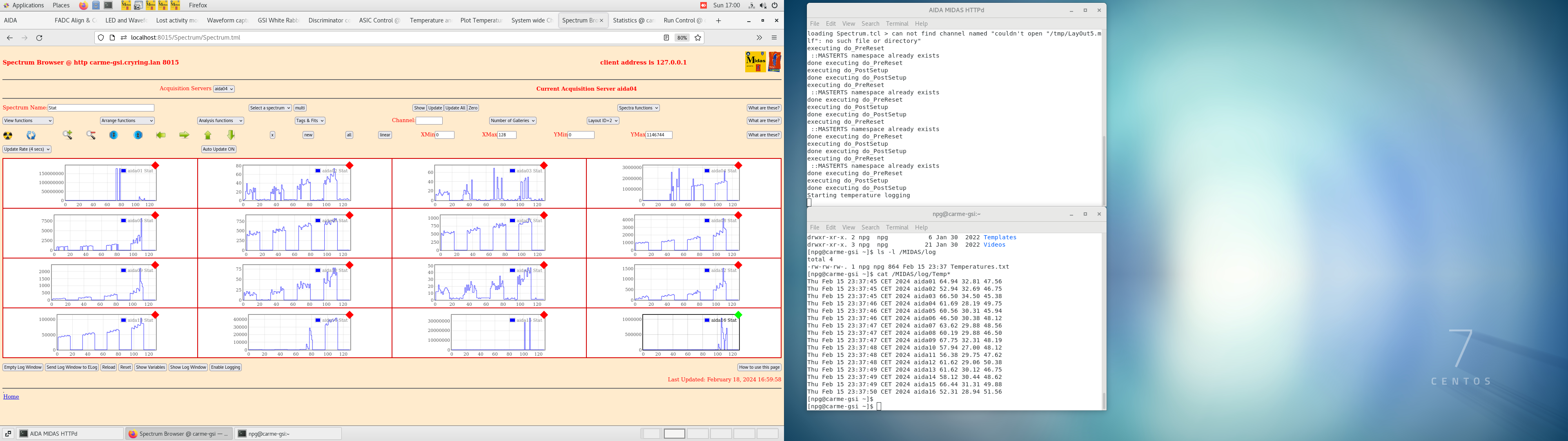

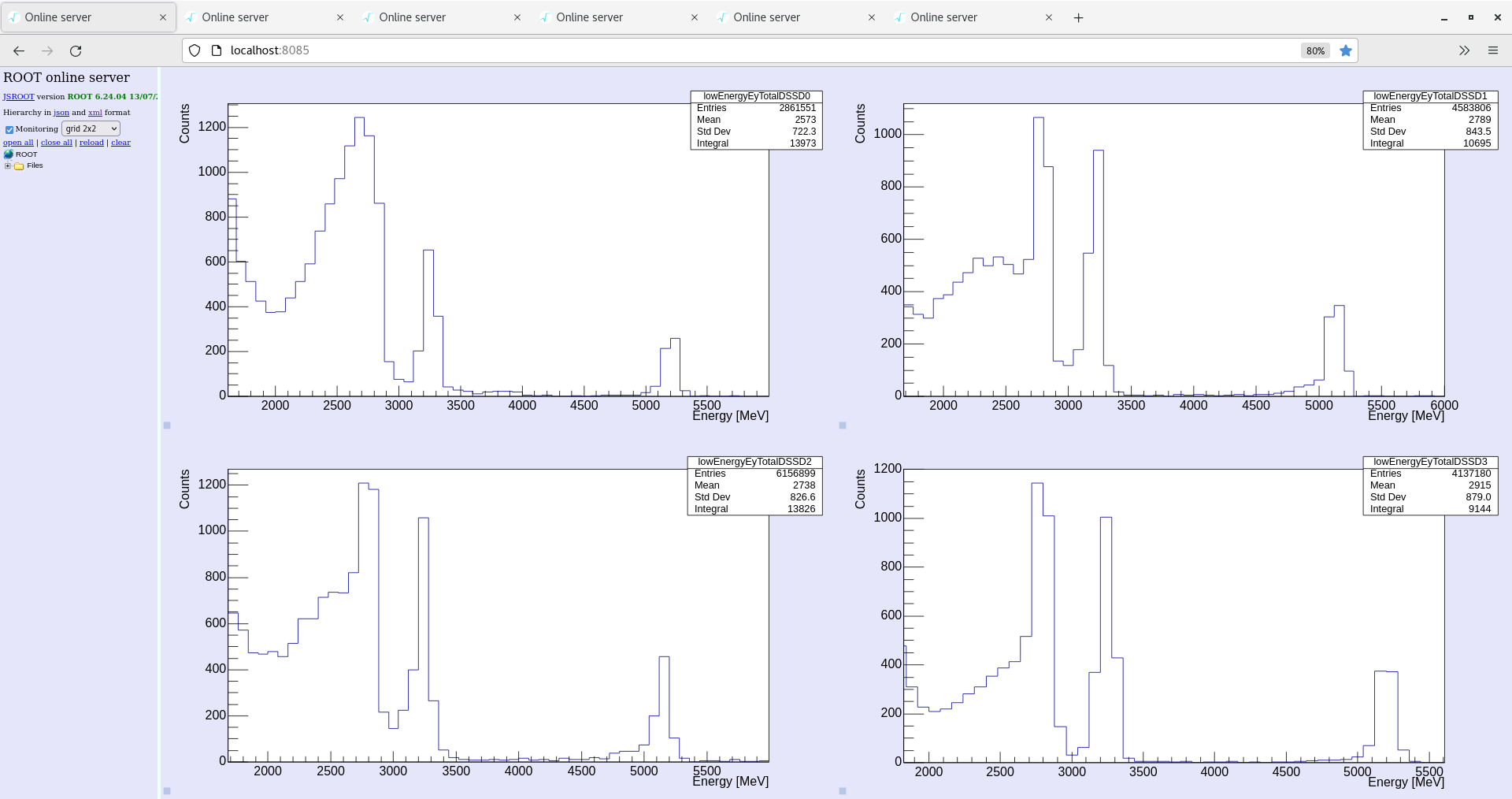

Reset the online spectra (had not been done yet for this run).

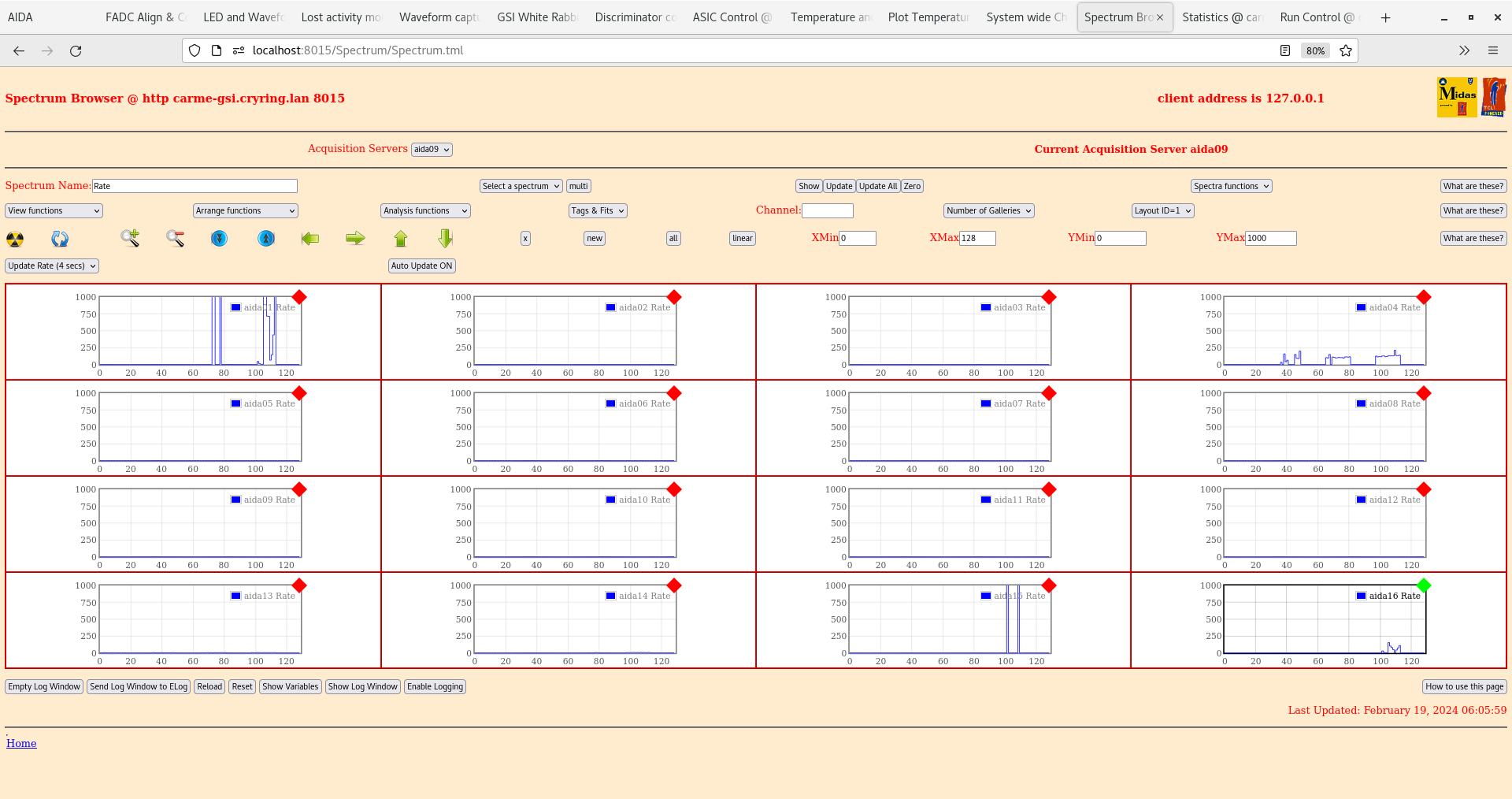

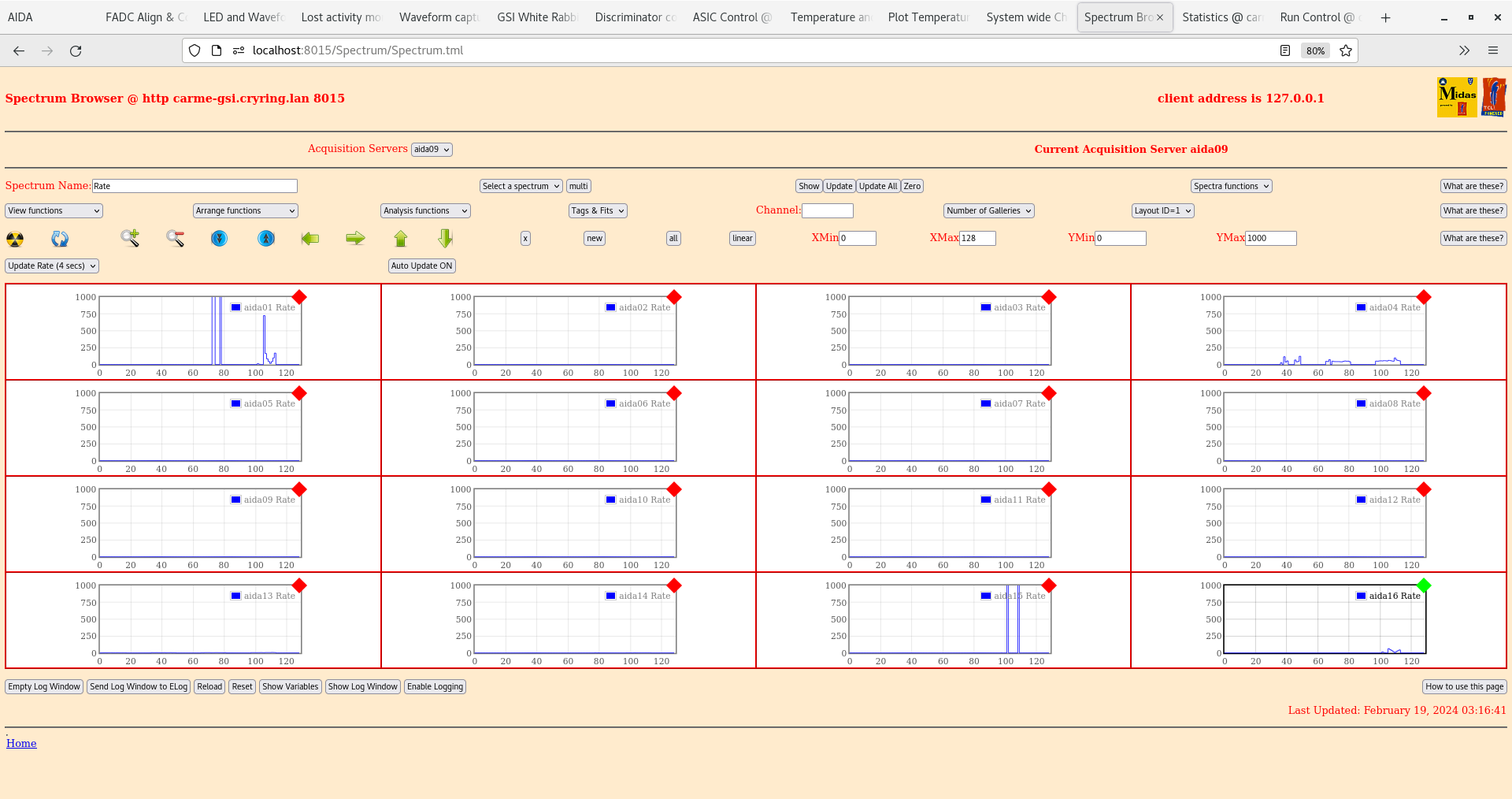

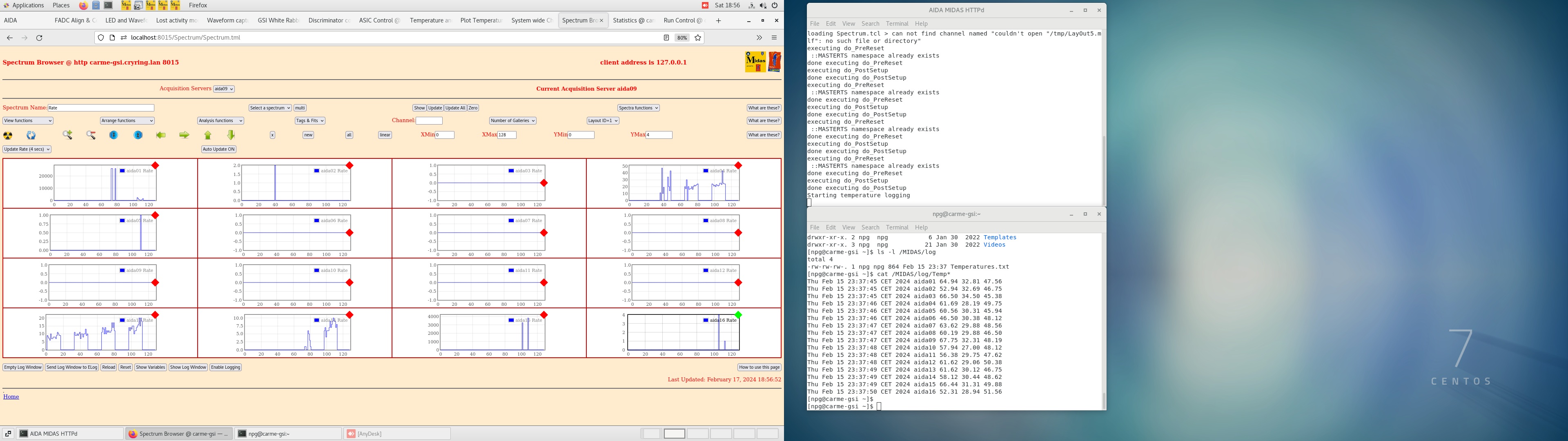

20s rate looks fine, around 1000 counts/s on top left detector. Maybe we are hitting it with beam? But then we should be see a reduction in beam intensity, we do not.

04:00

System wide checks OK

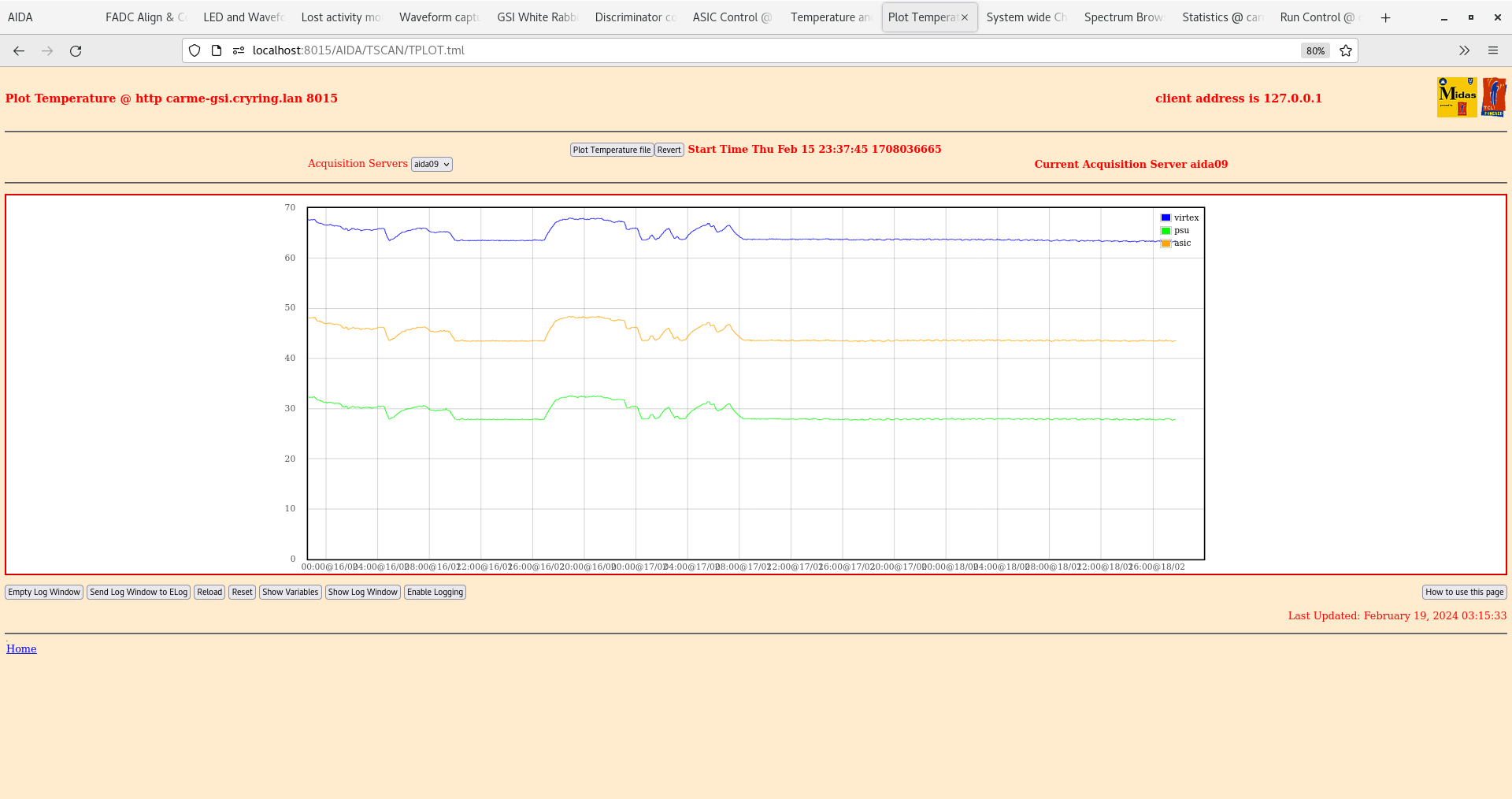

Temps OK

Stats OK

Merger OK

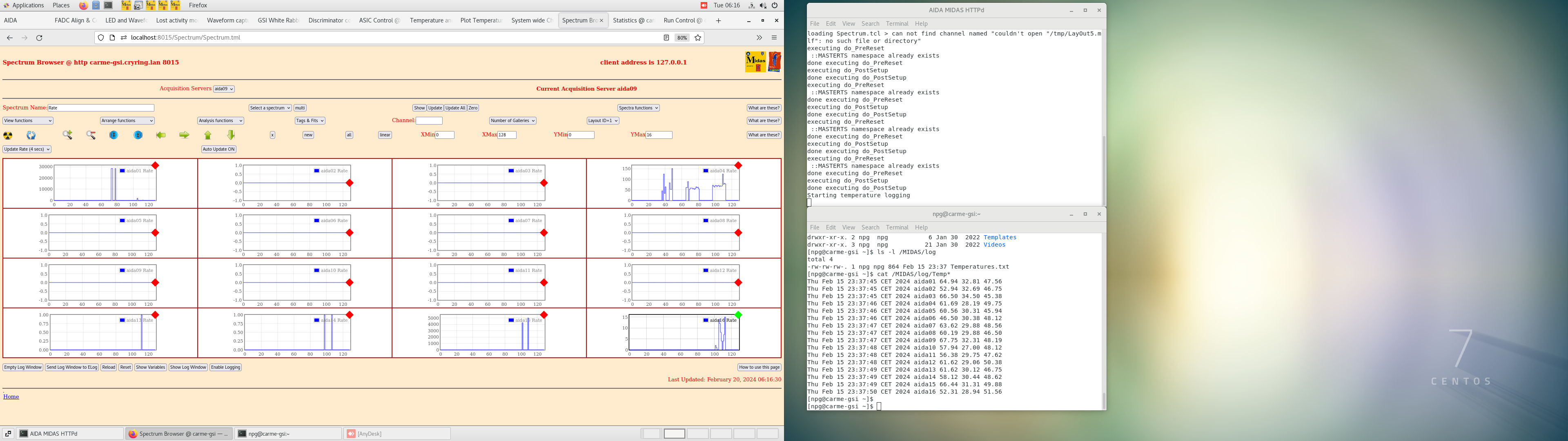

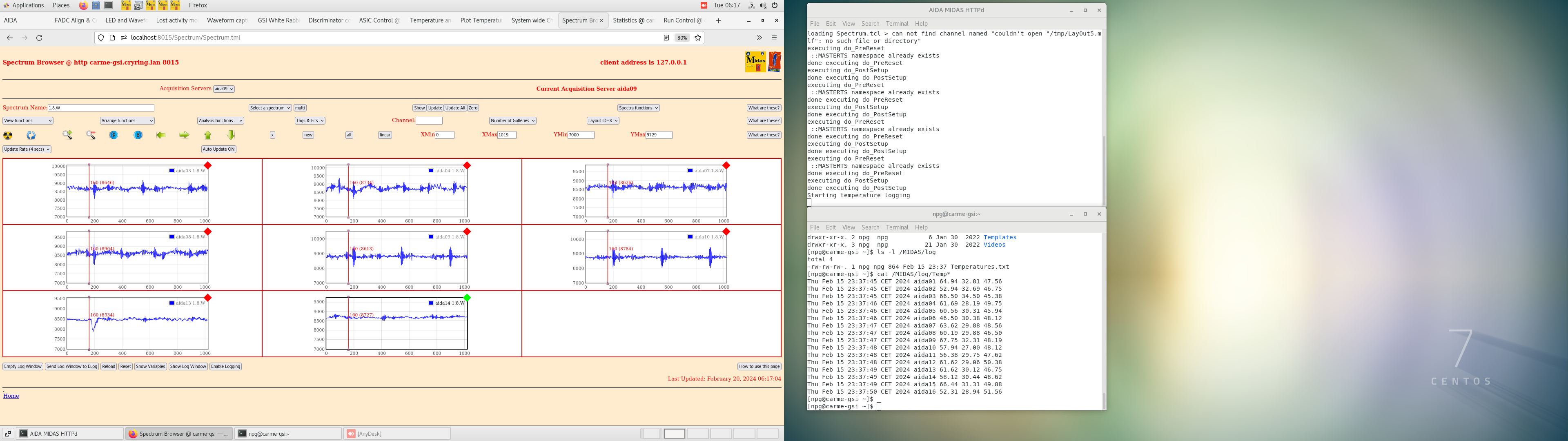

06:20

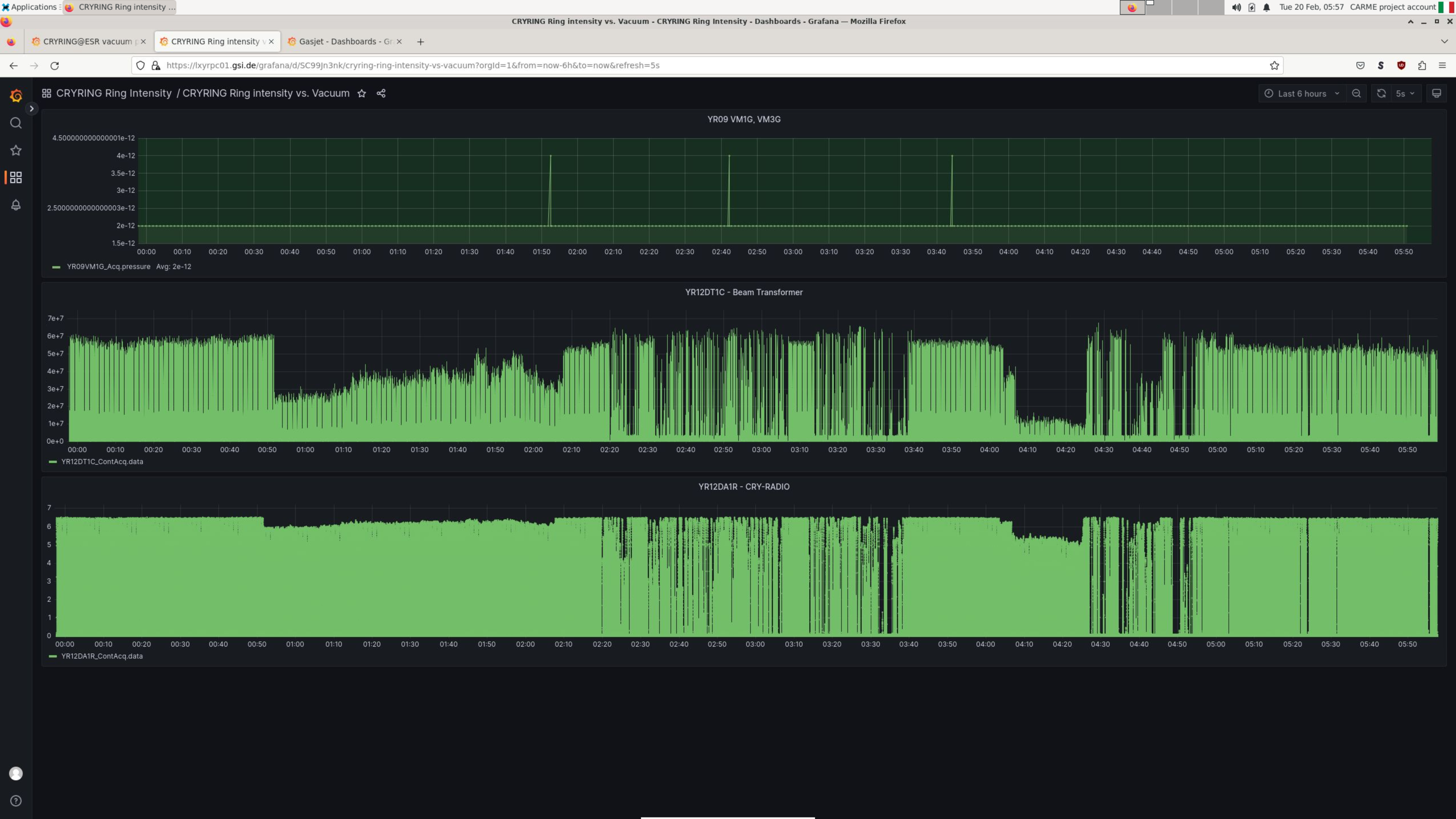

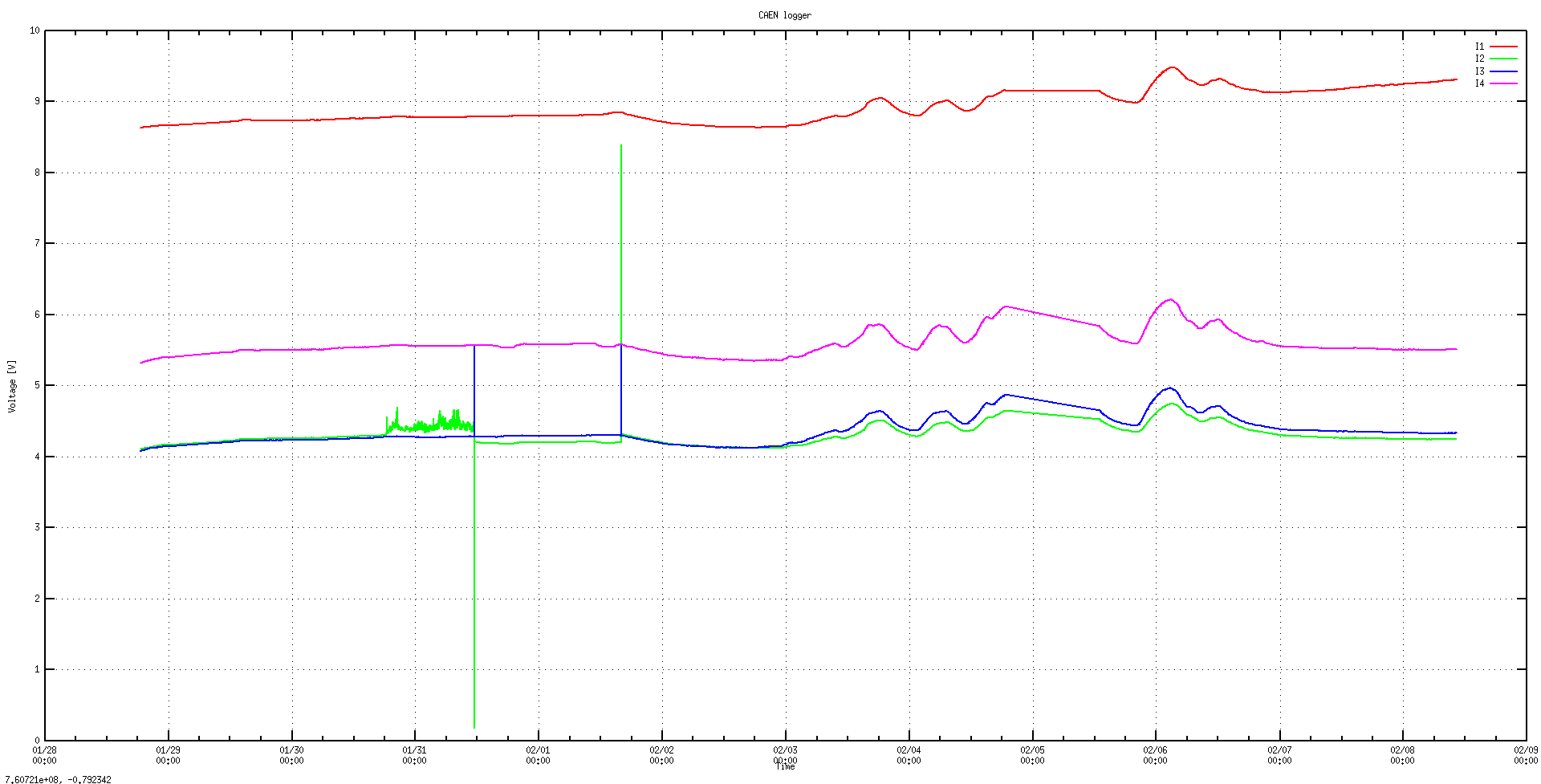

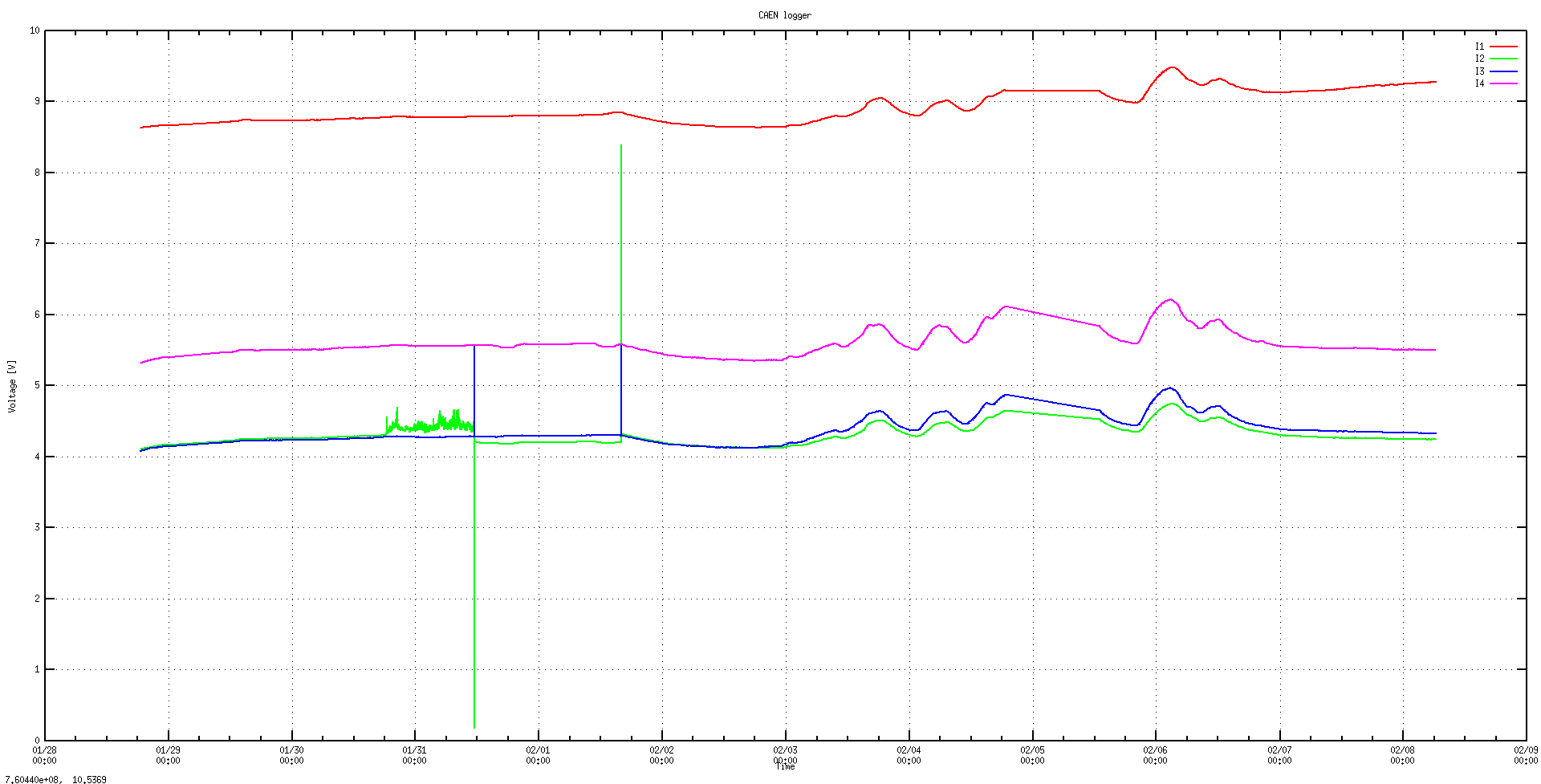

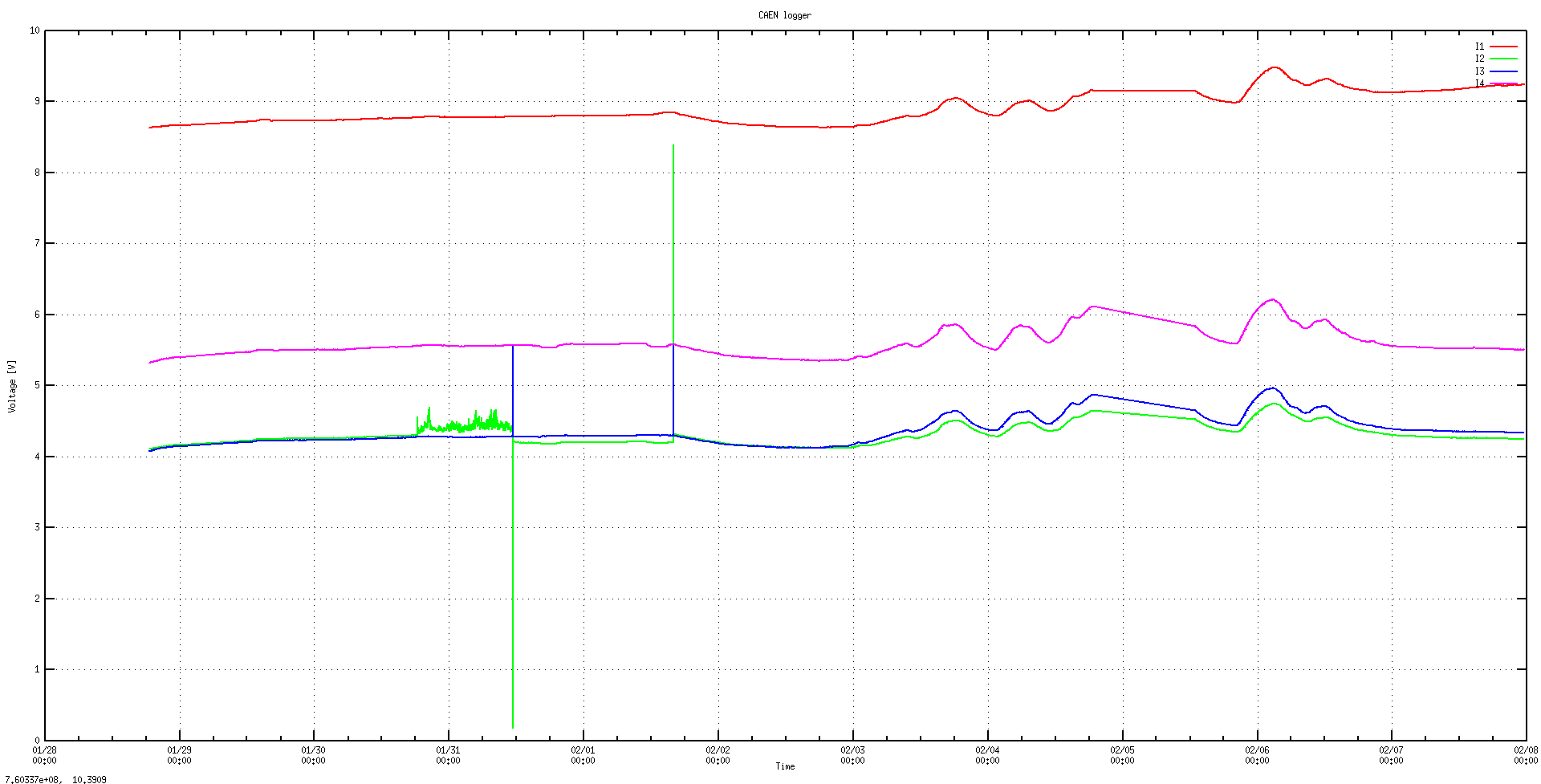

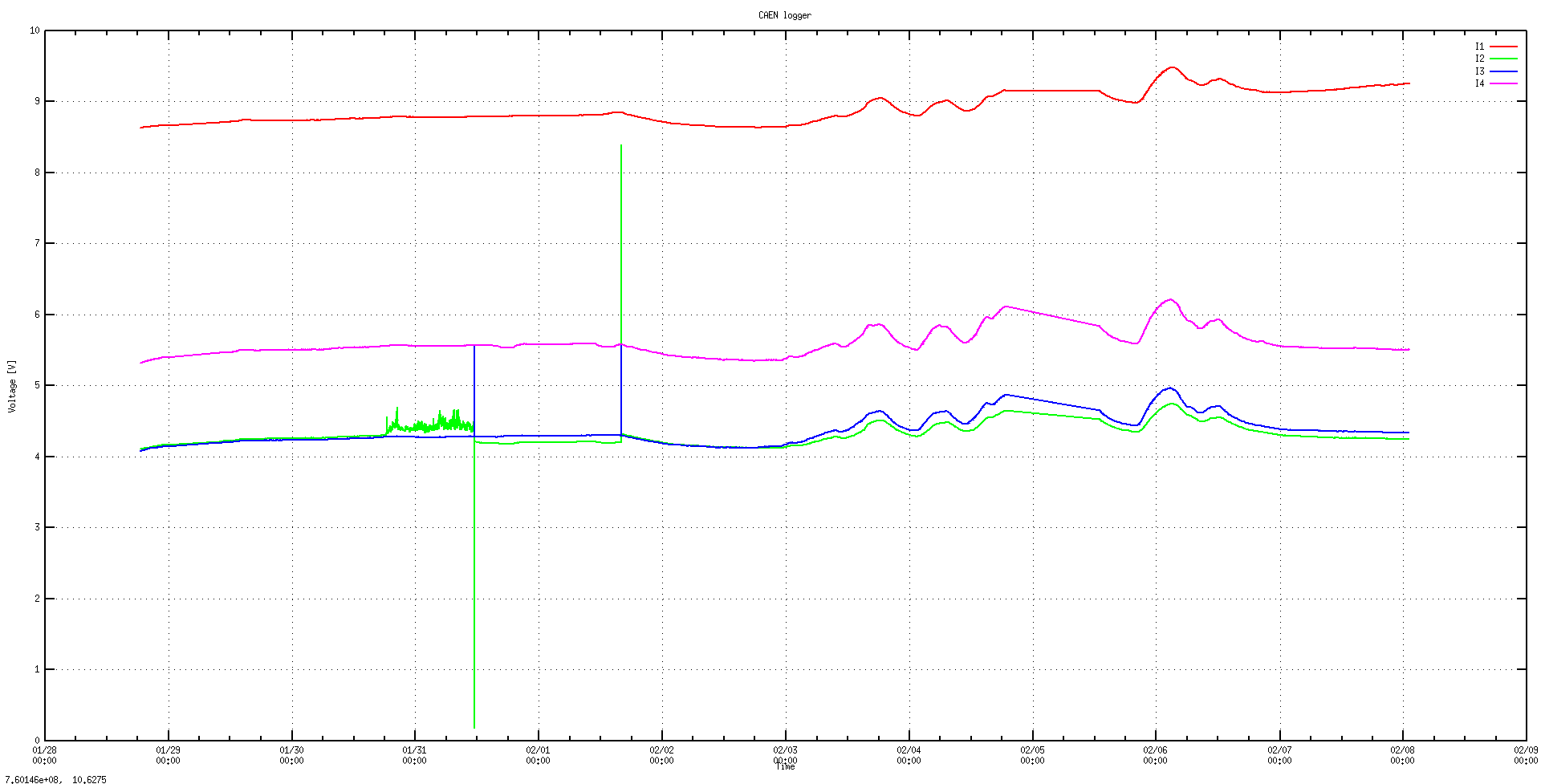

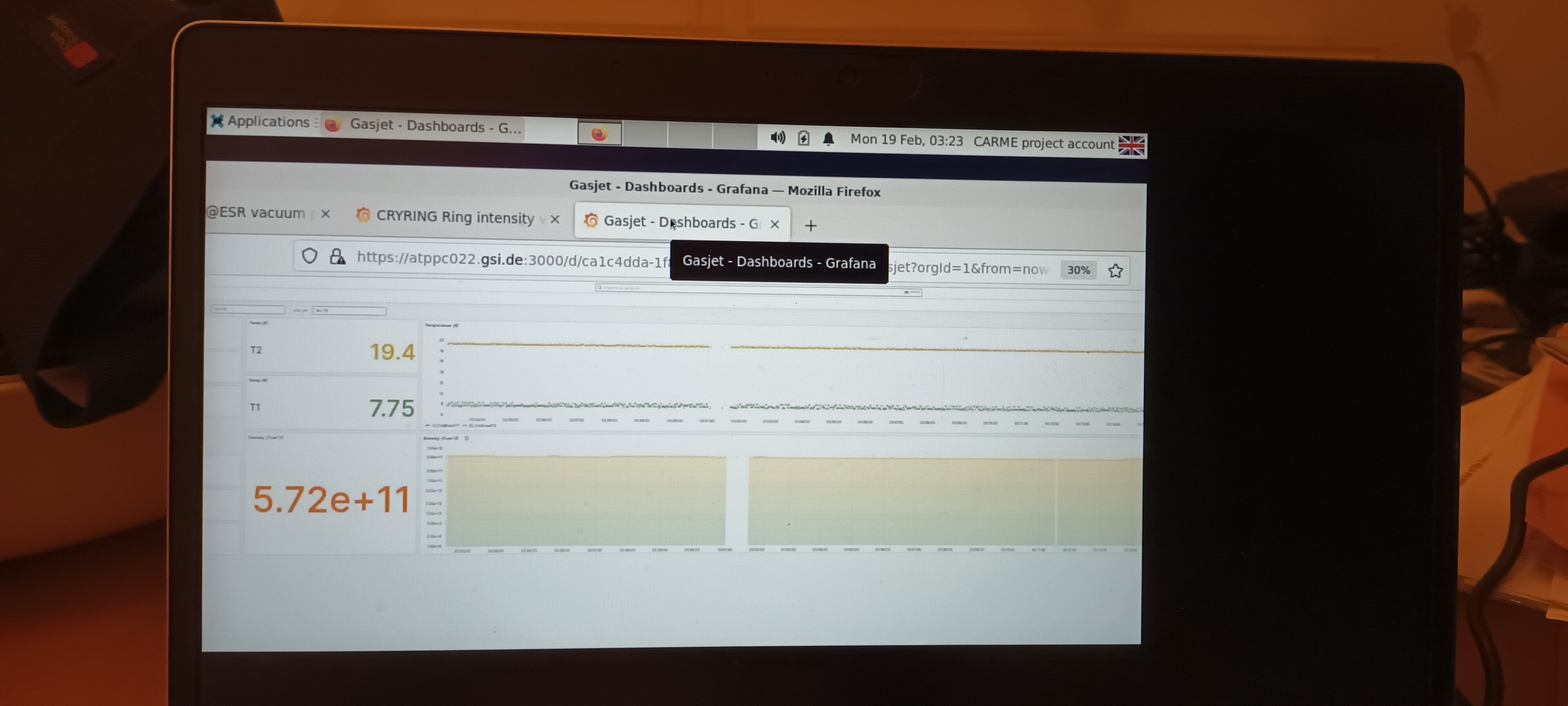

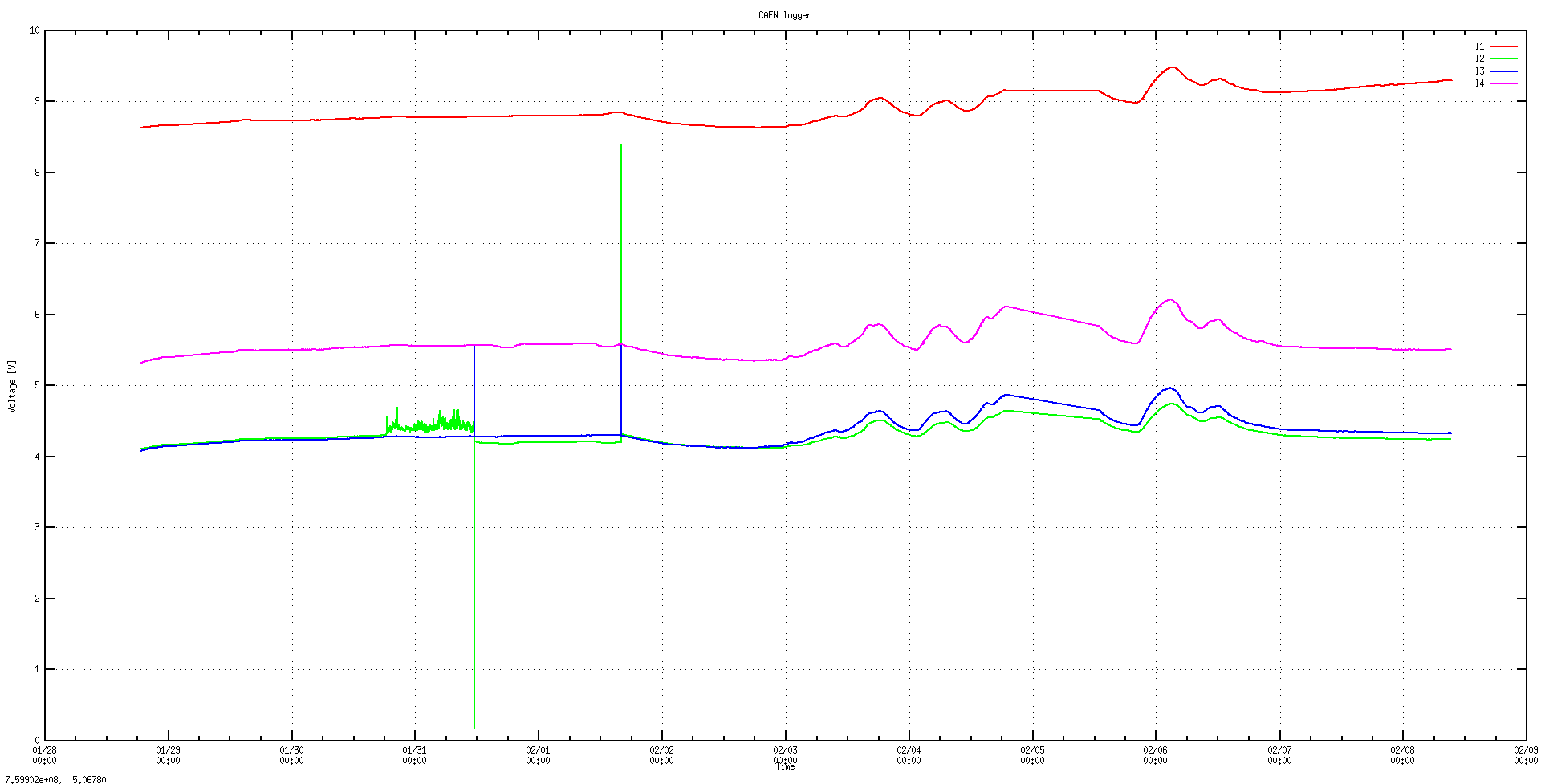

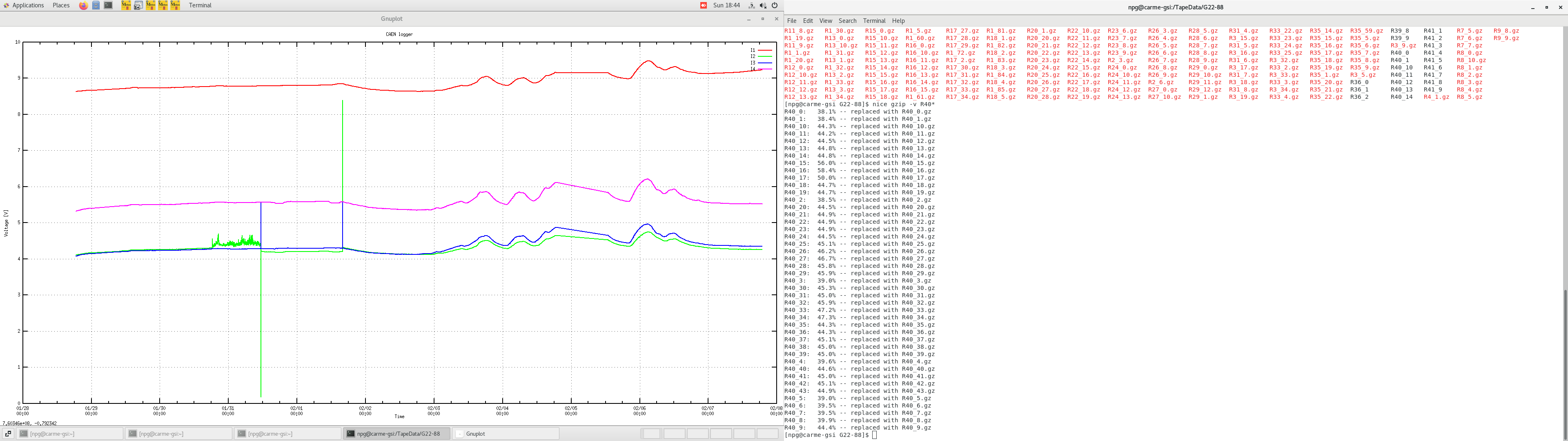

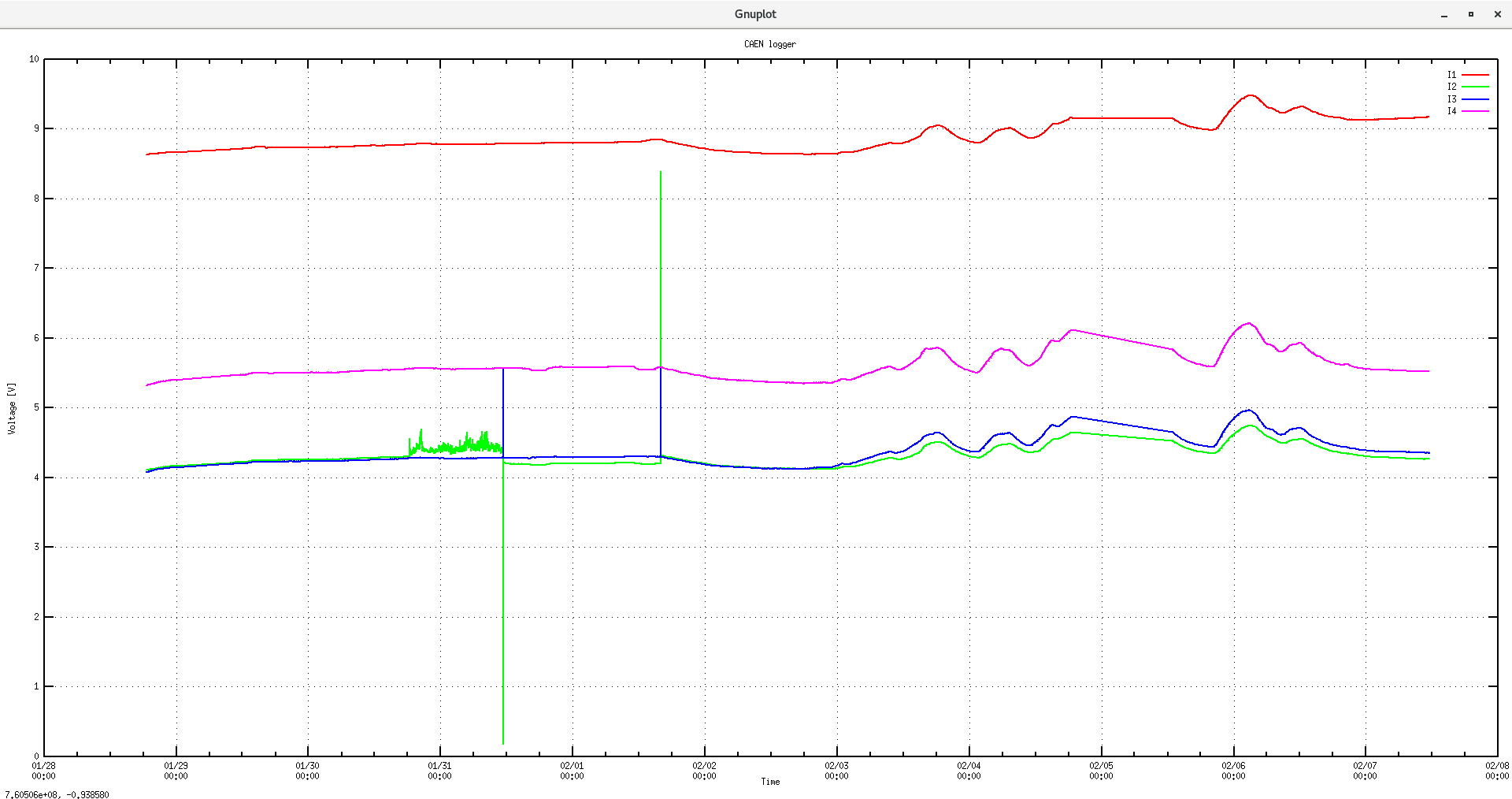

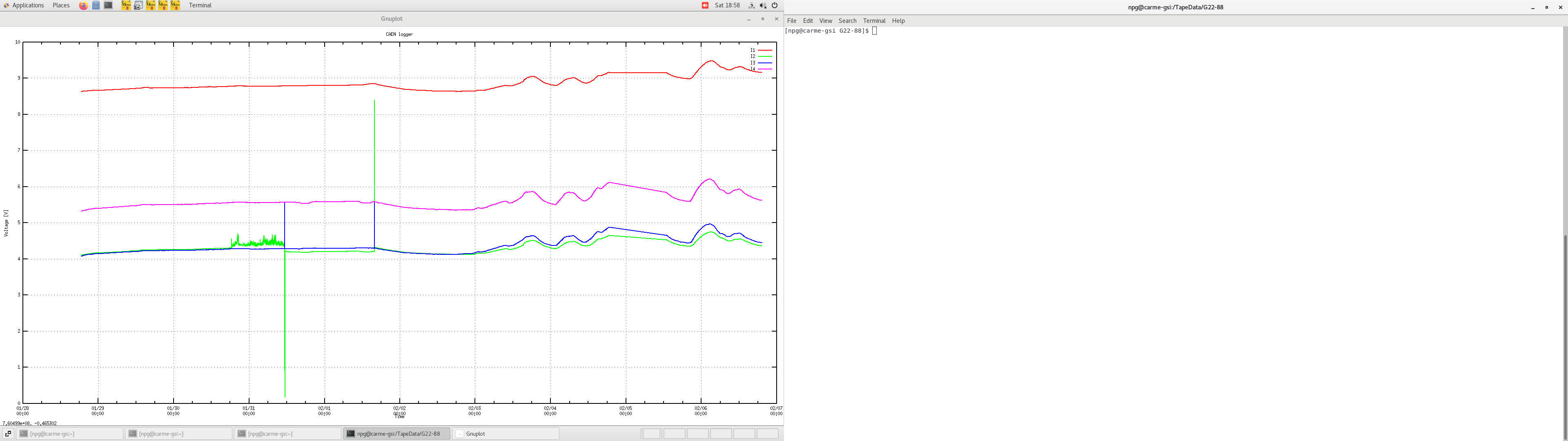

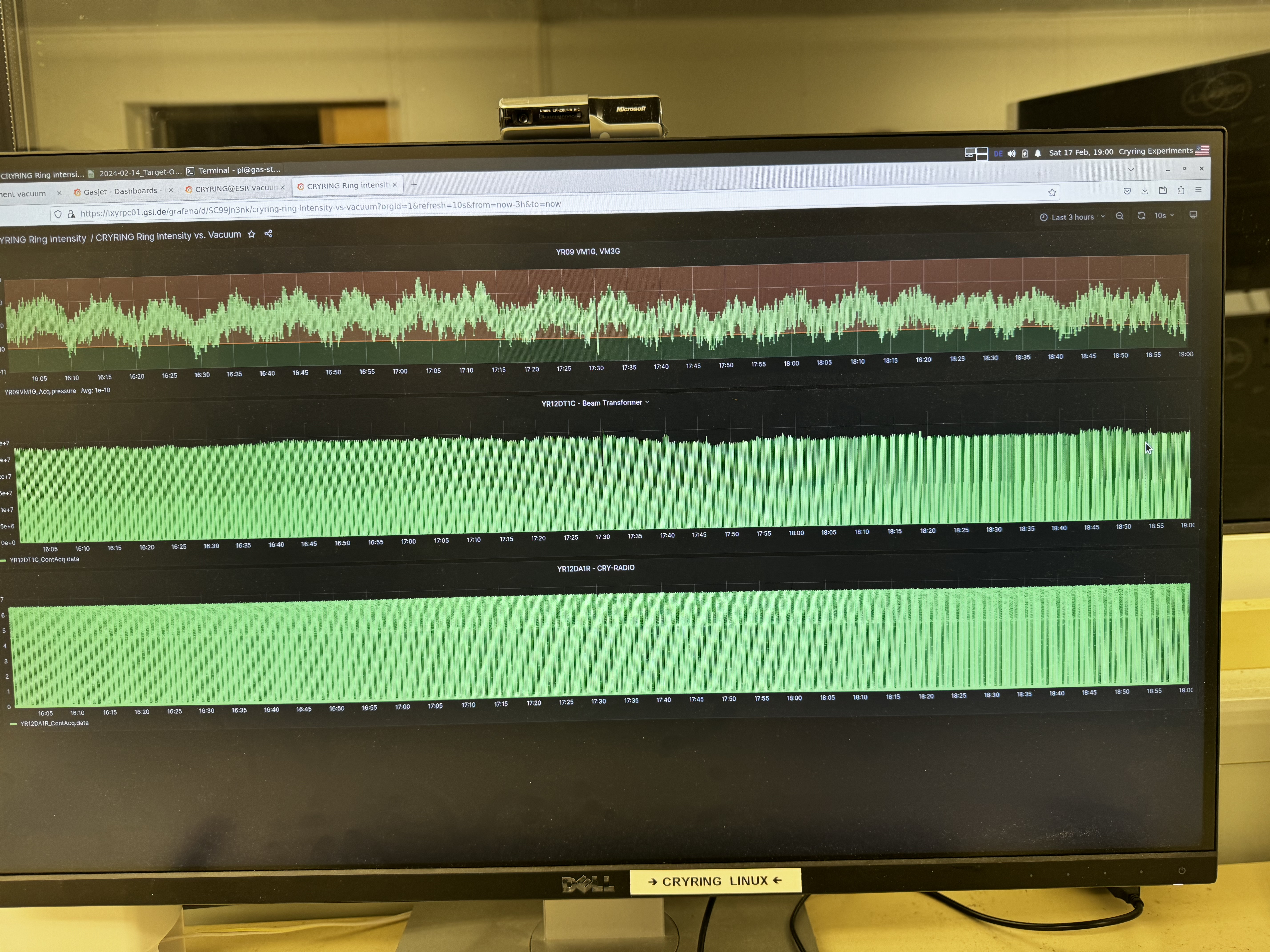

Beam intensity quite unstable, but HKR is correcting - attach 7

Systems wide checks OK

Temps OK

Merger OK

Stats OK

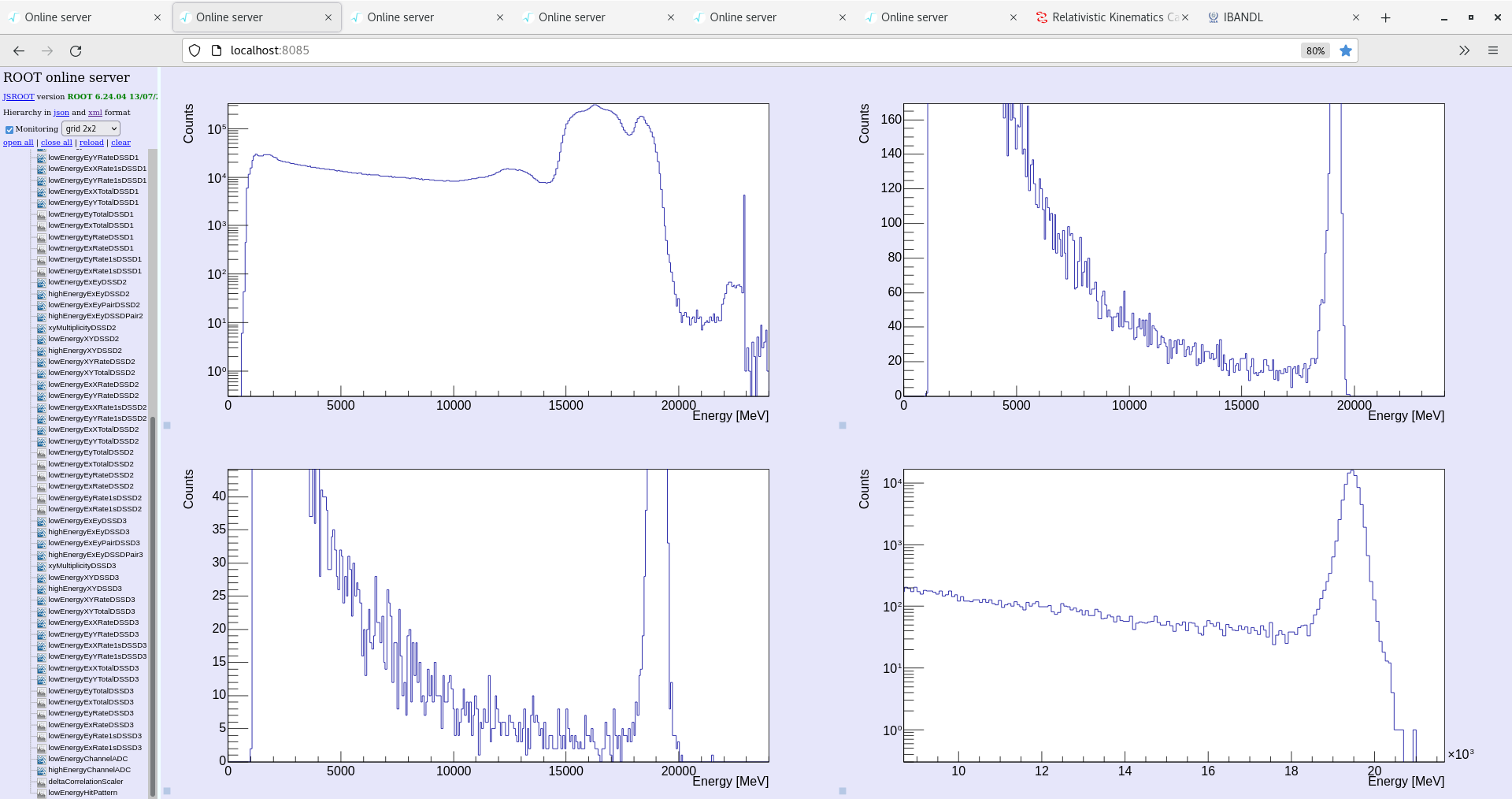

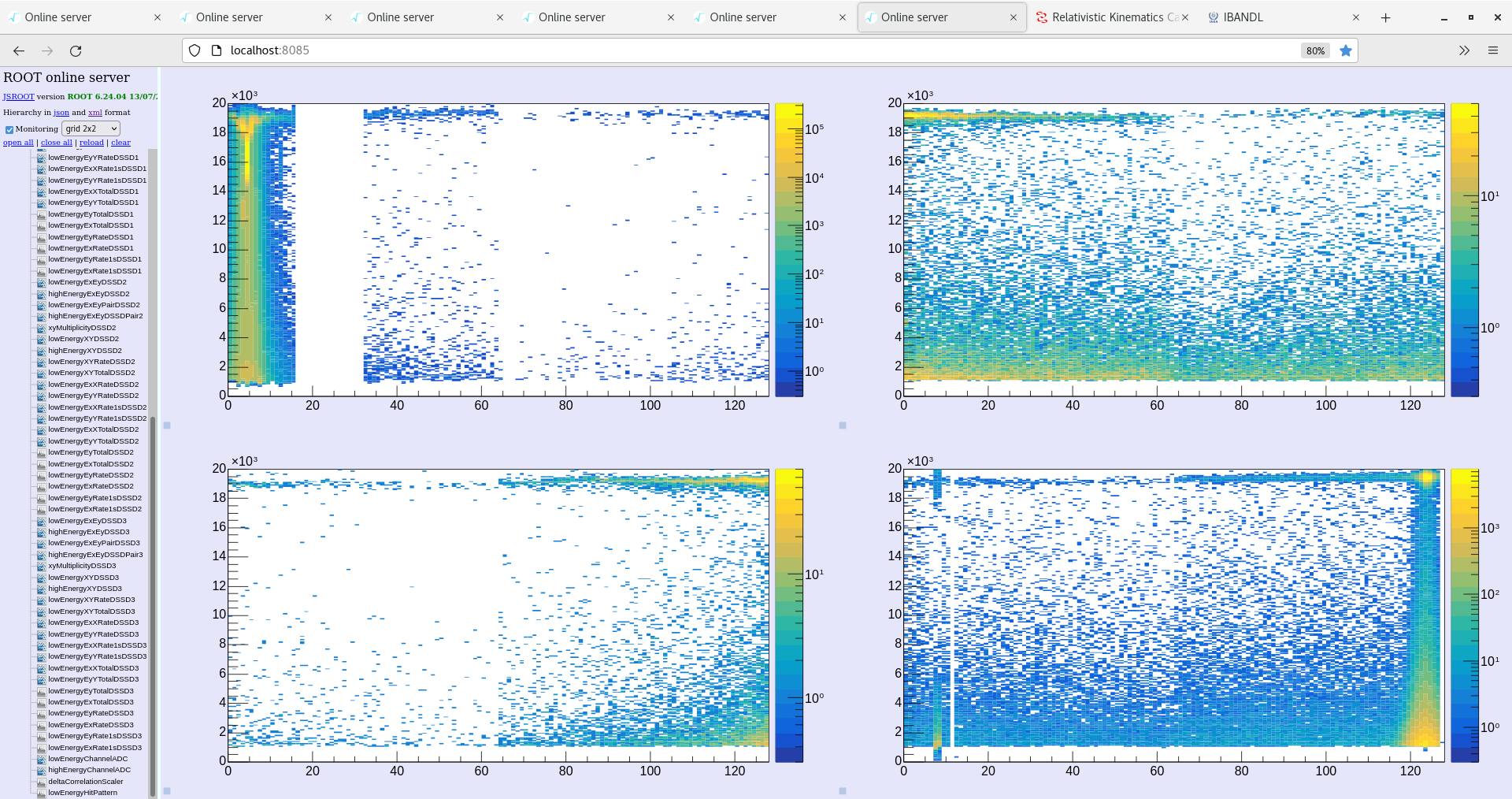

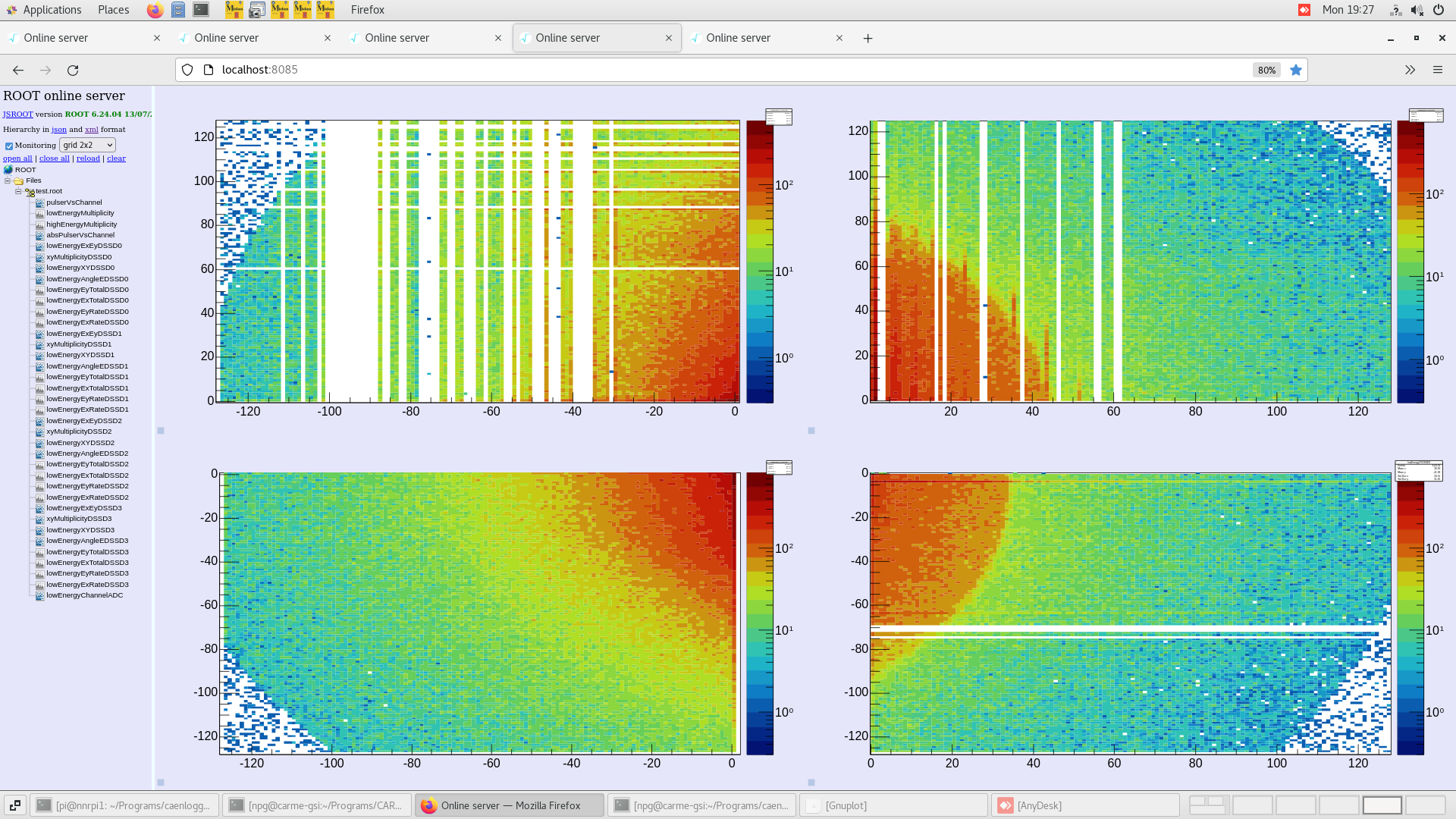

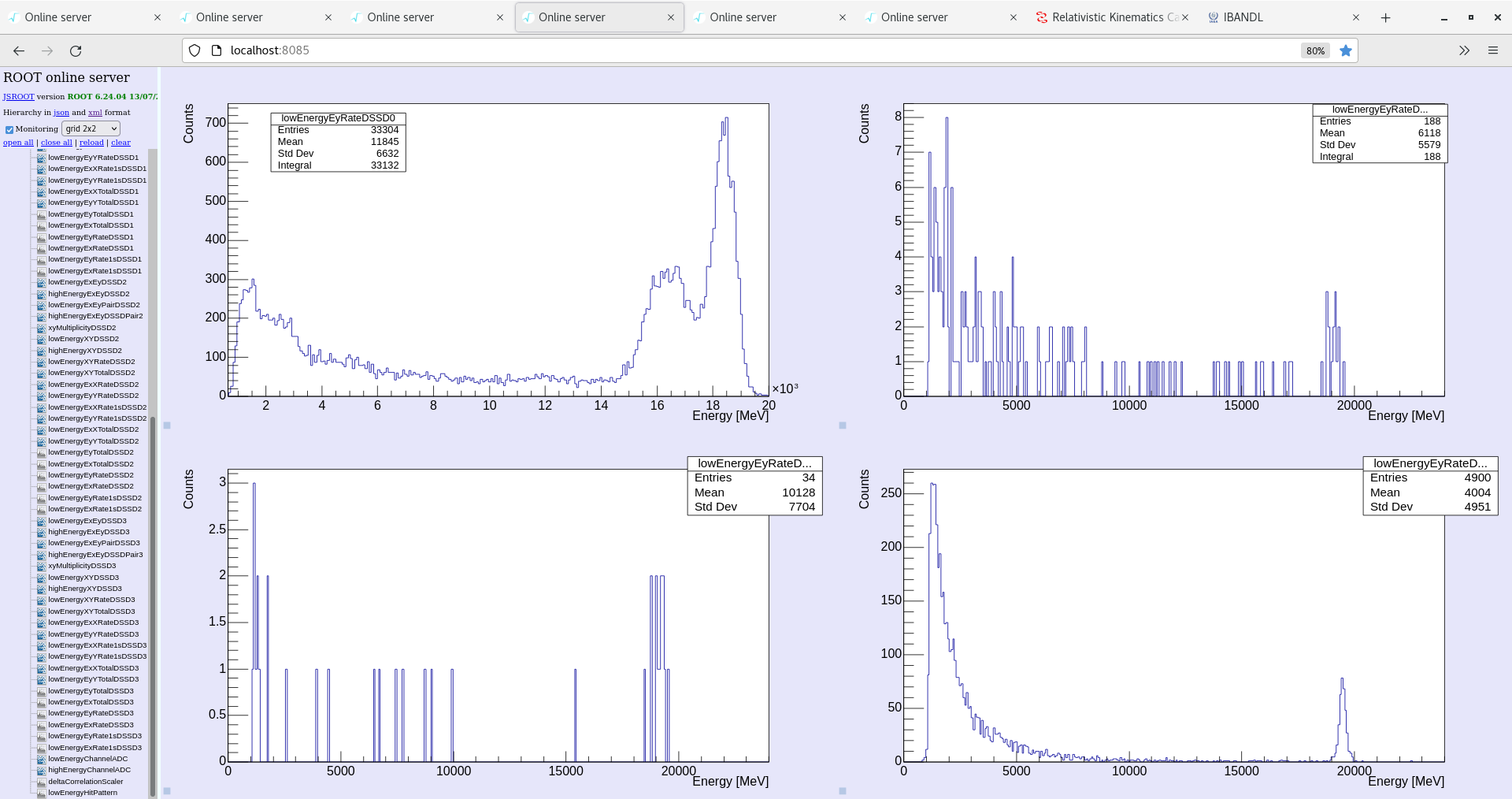

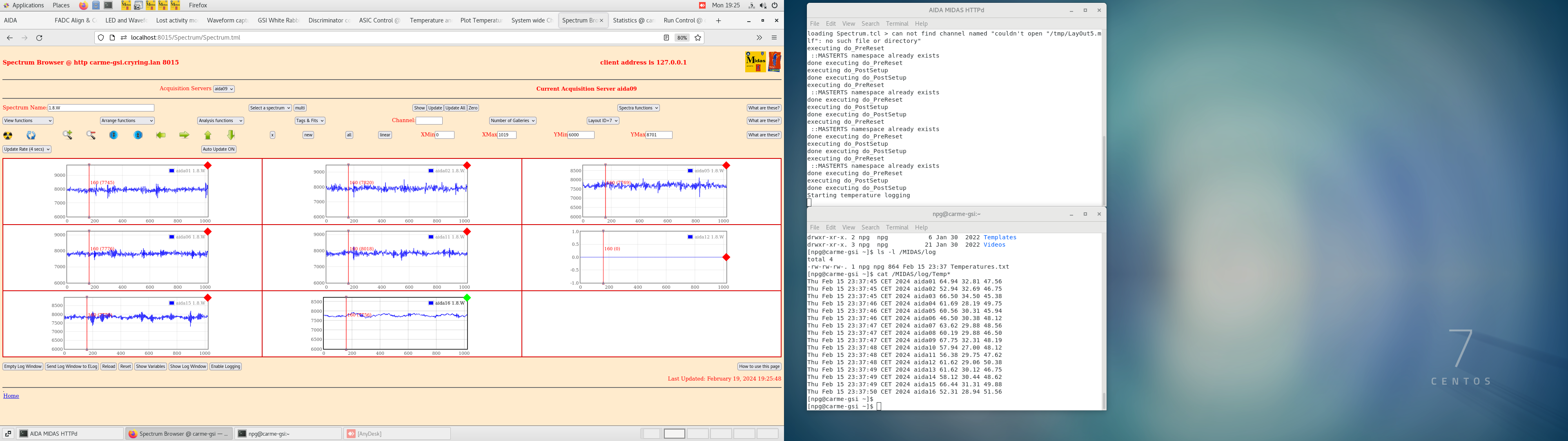

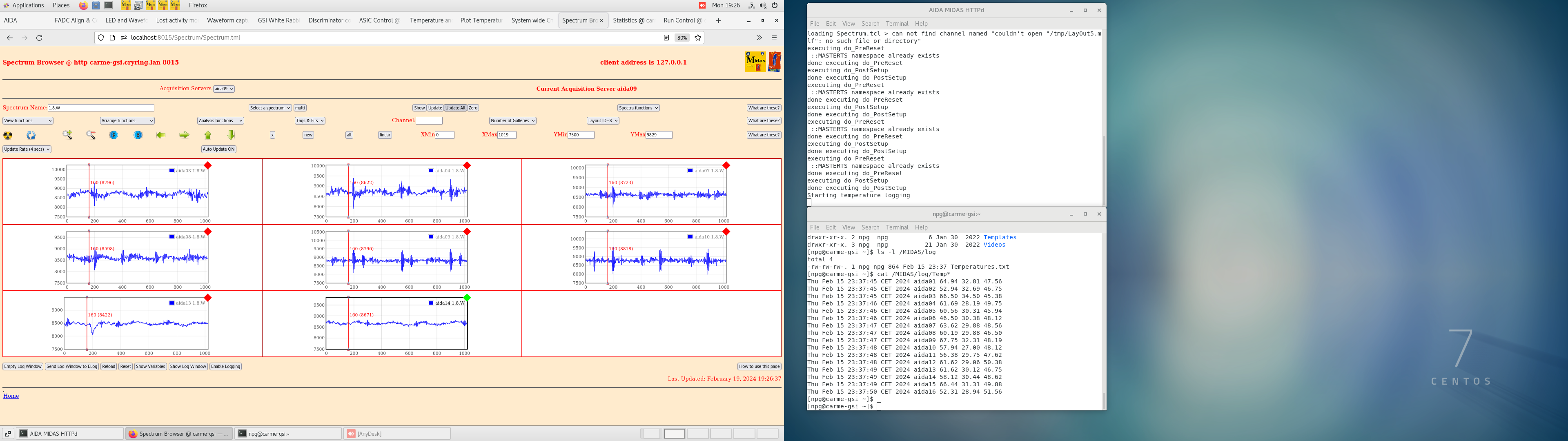

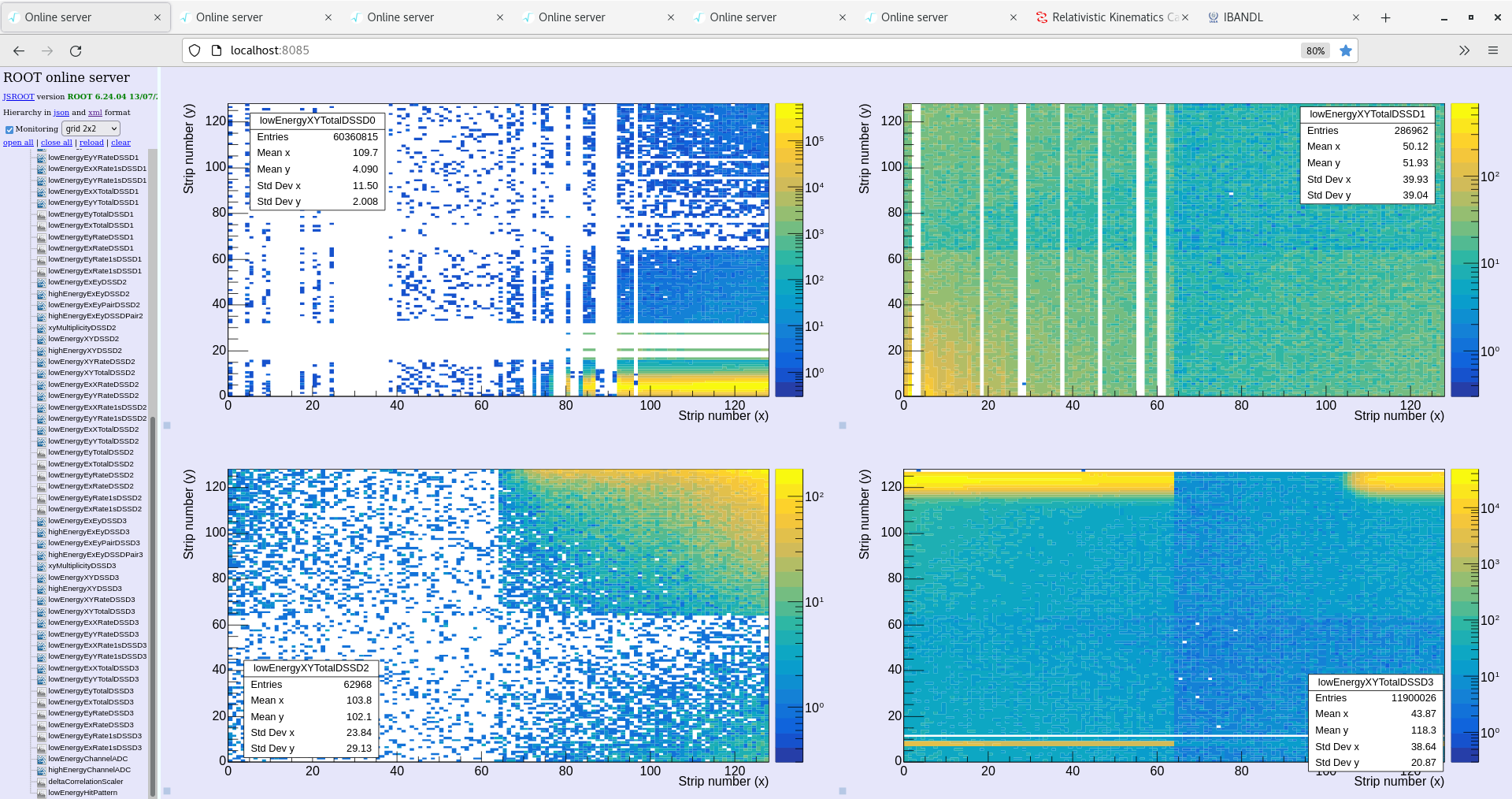

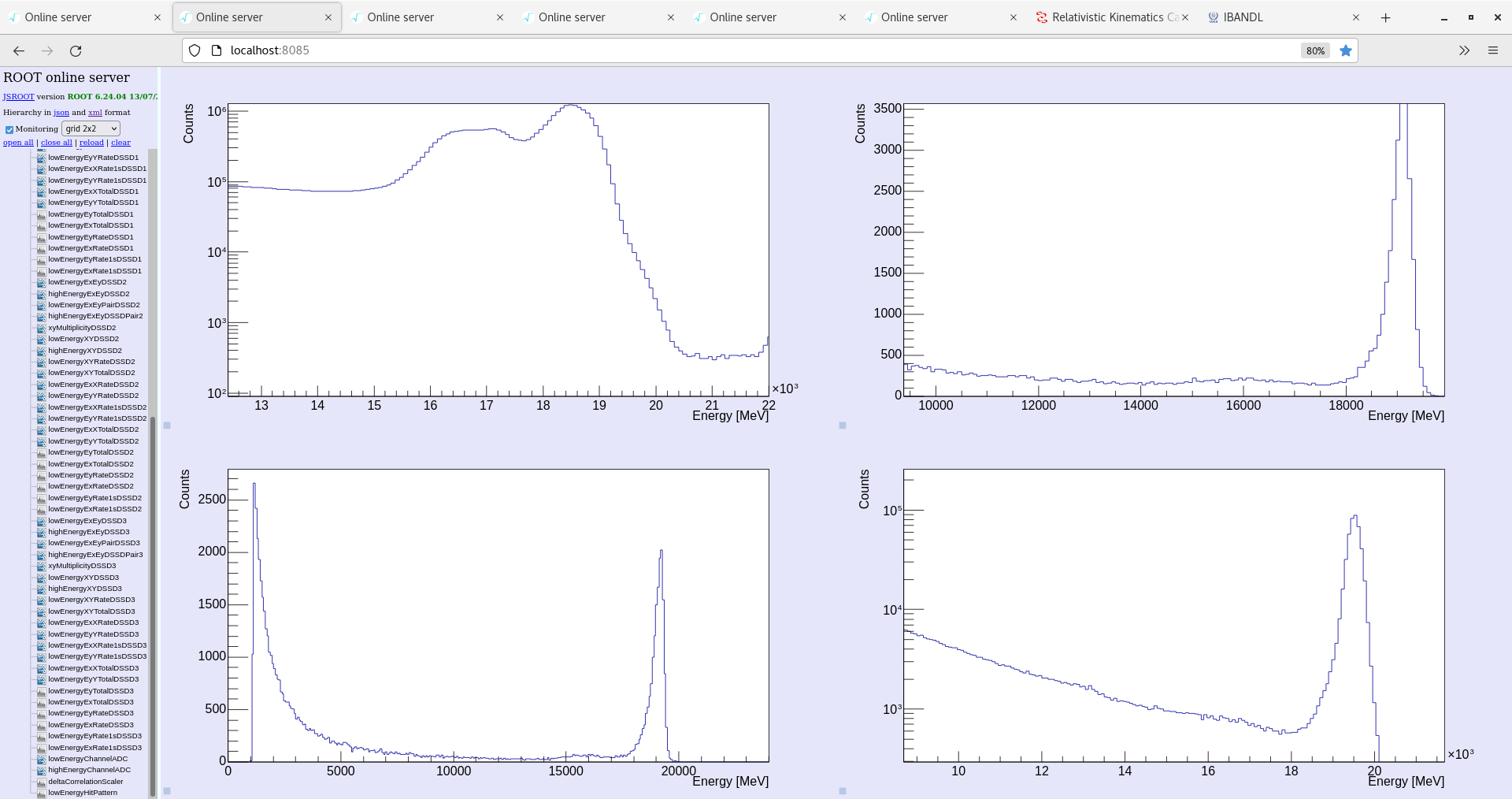

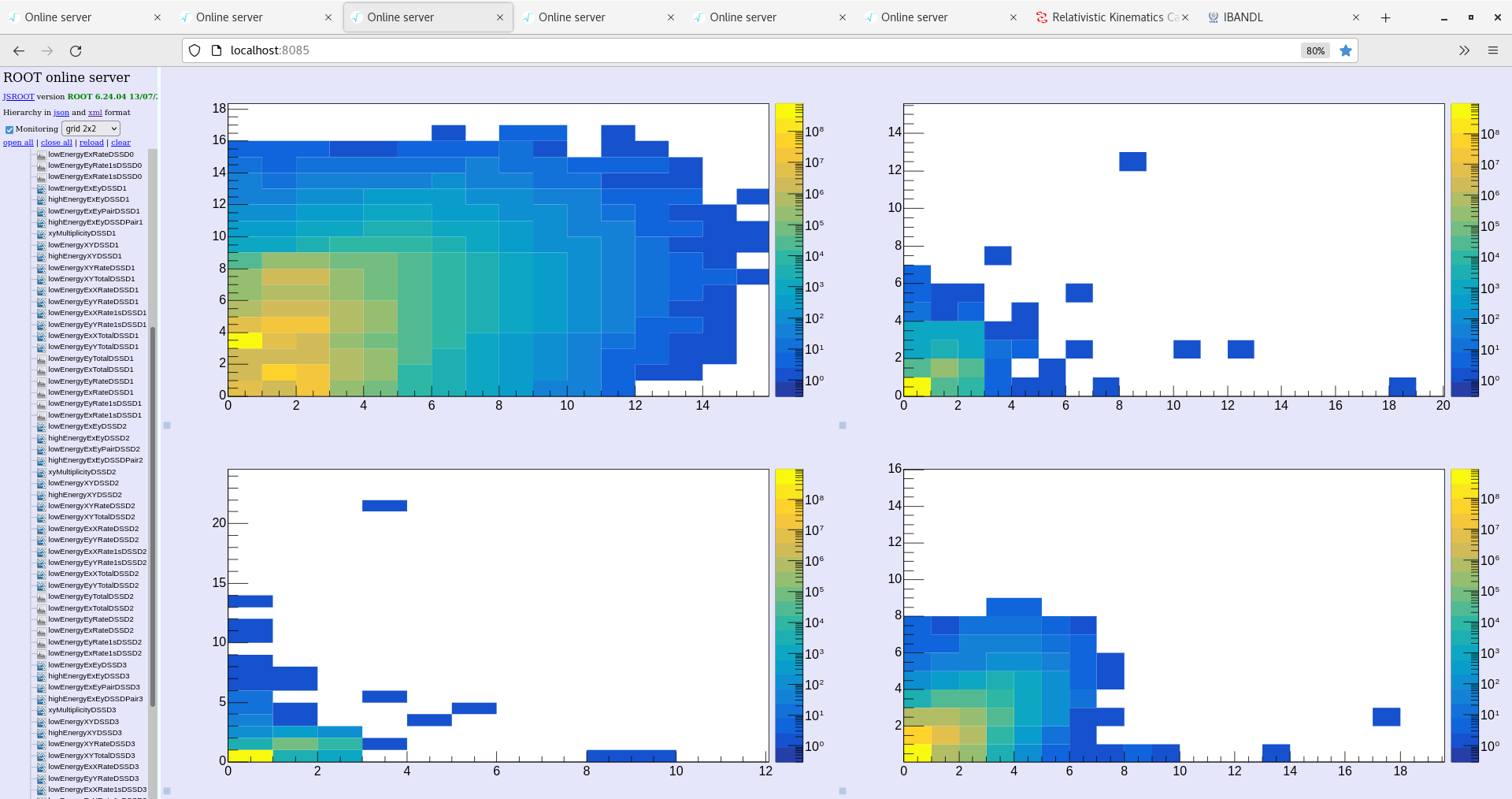

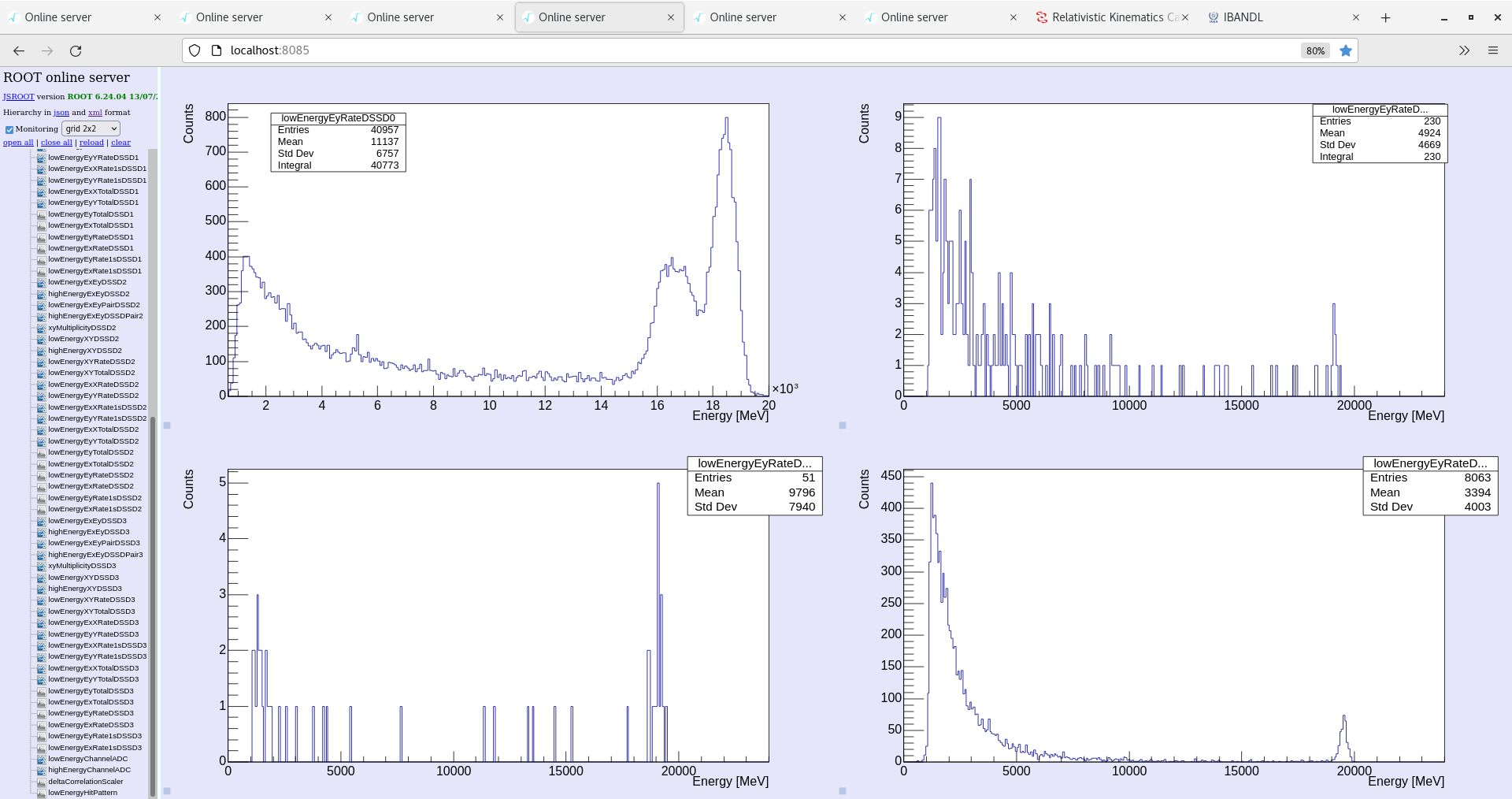

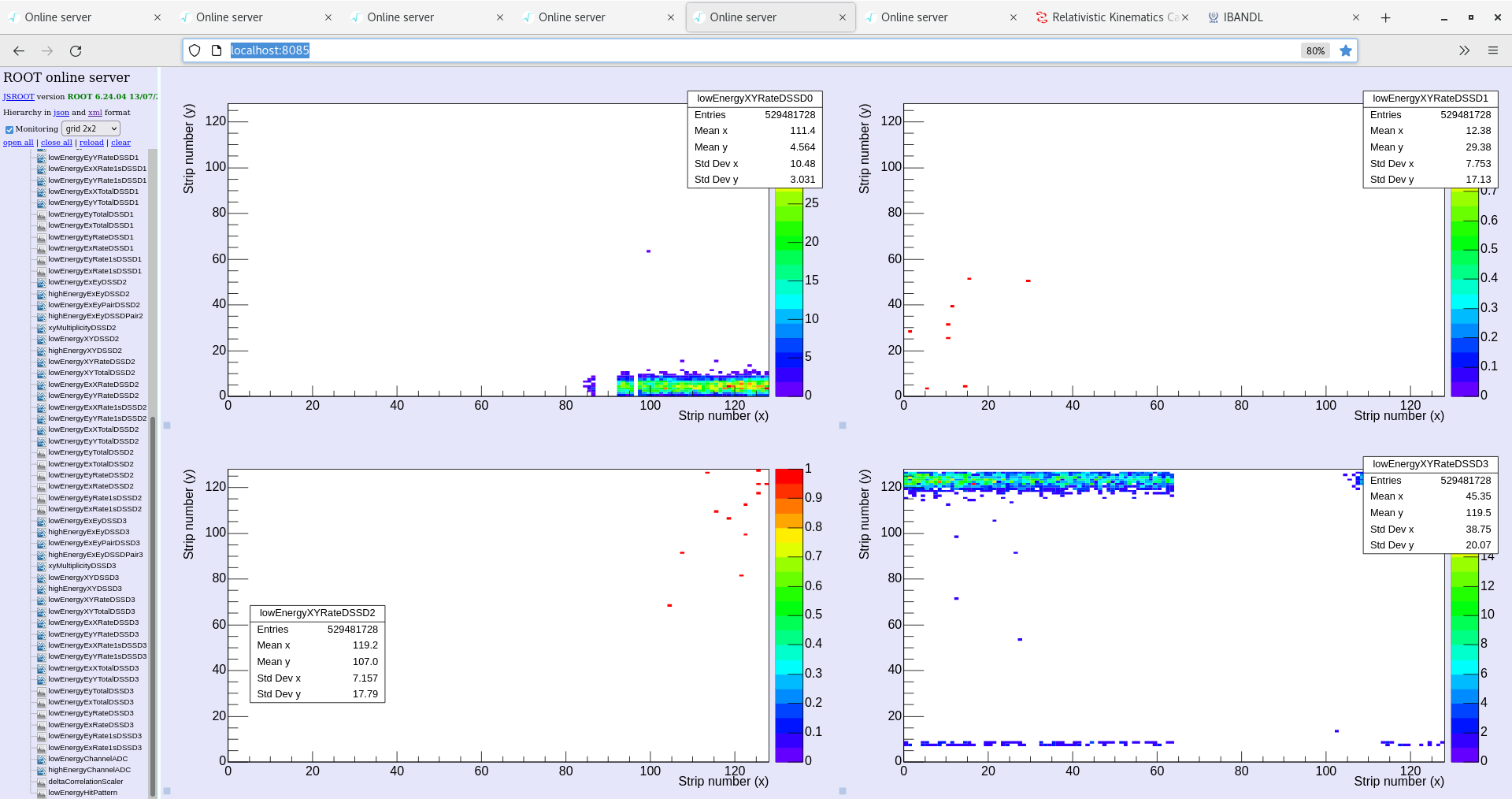

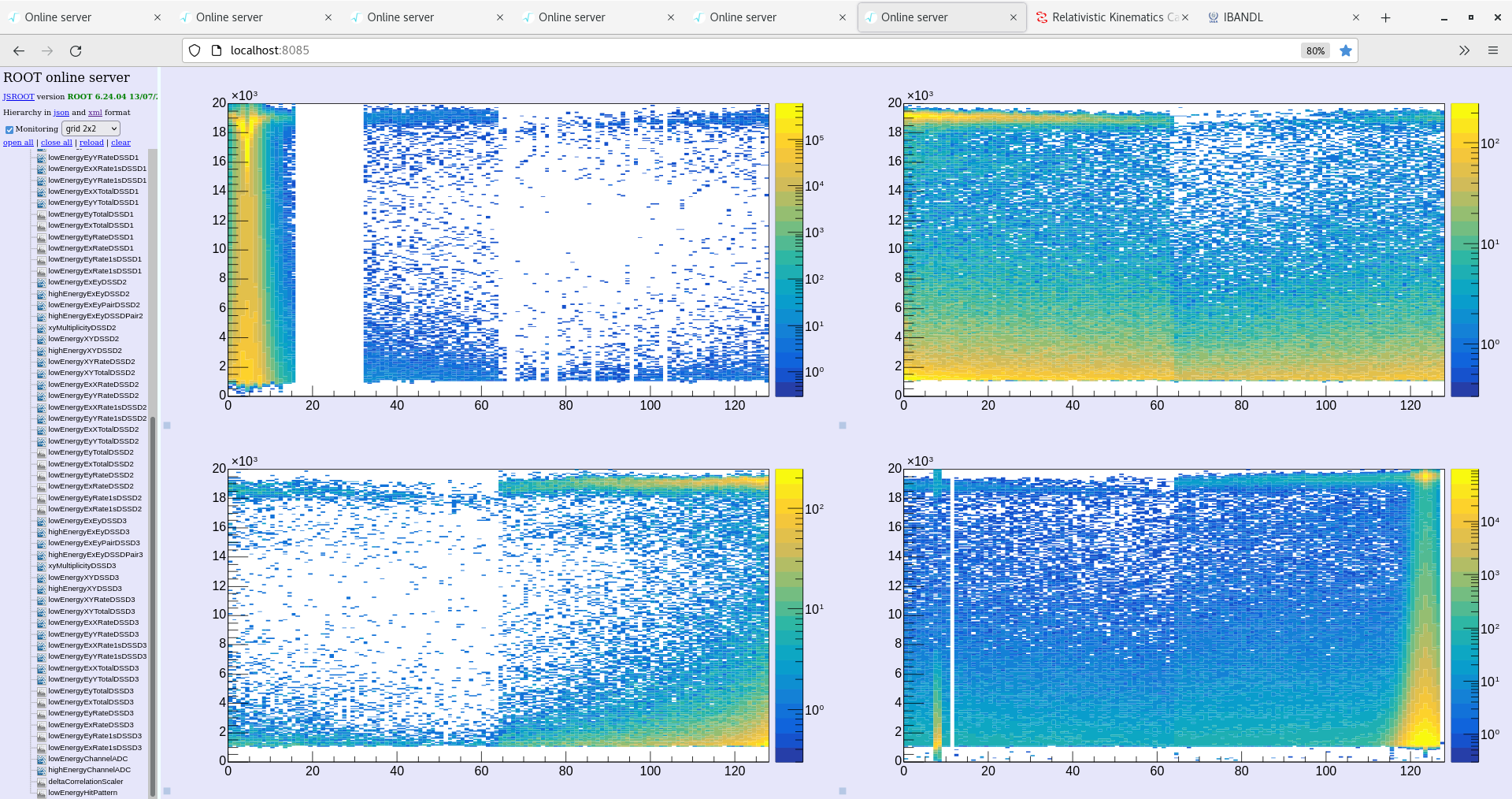

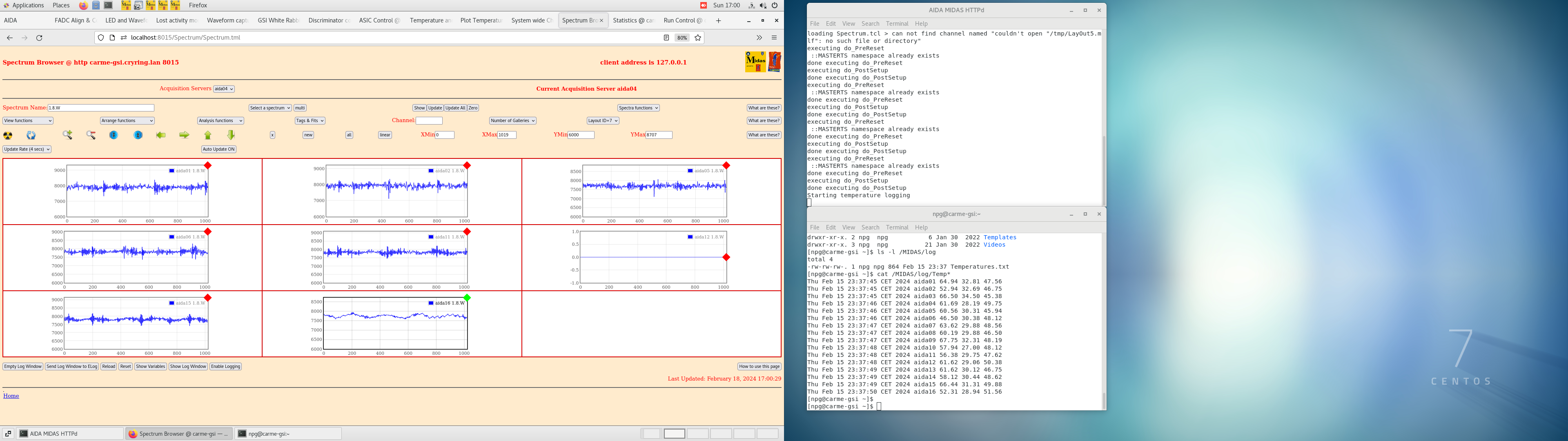

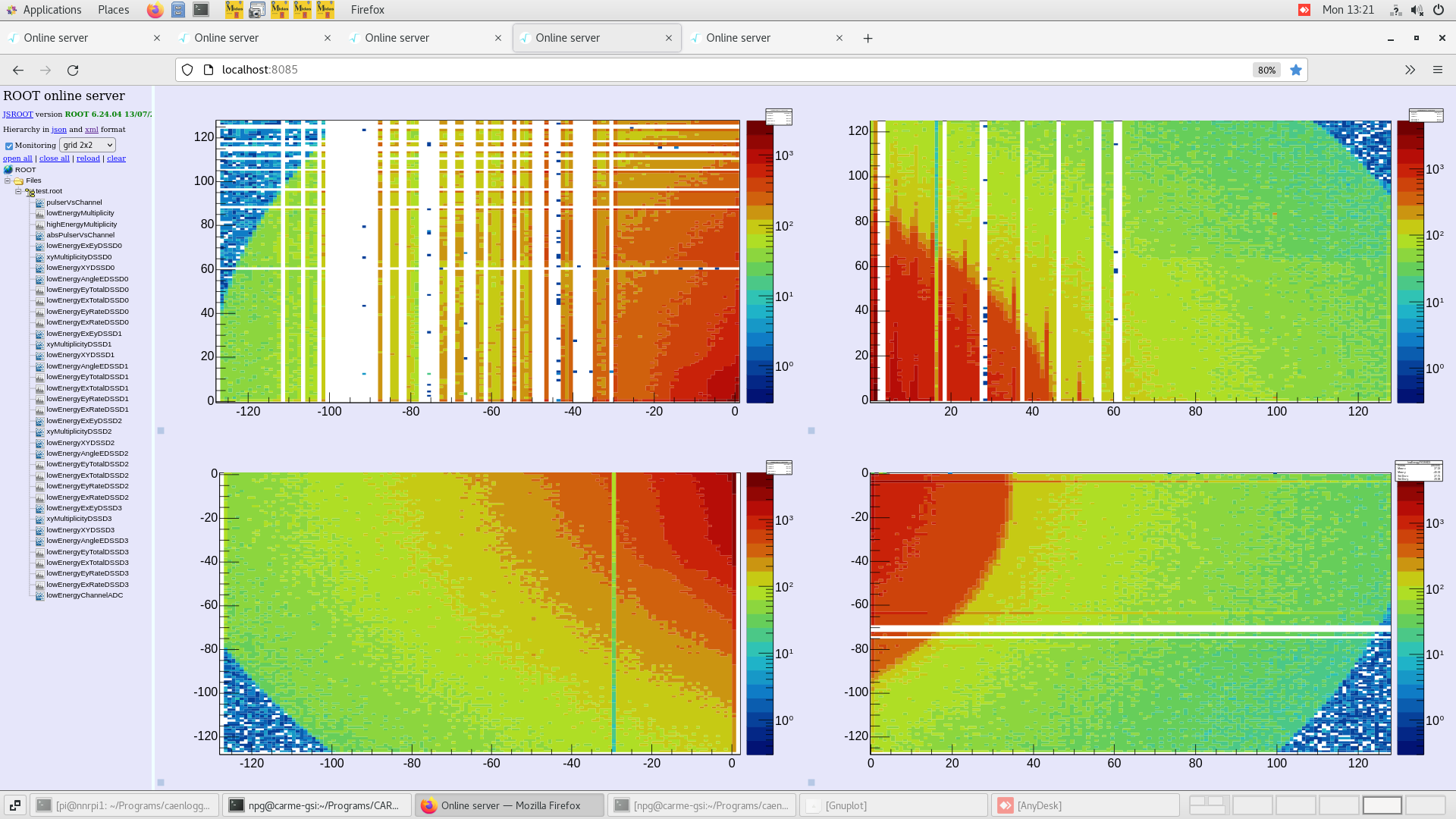

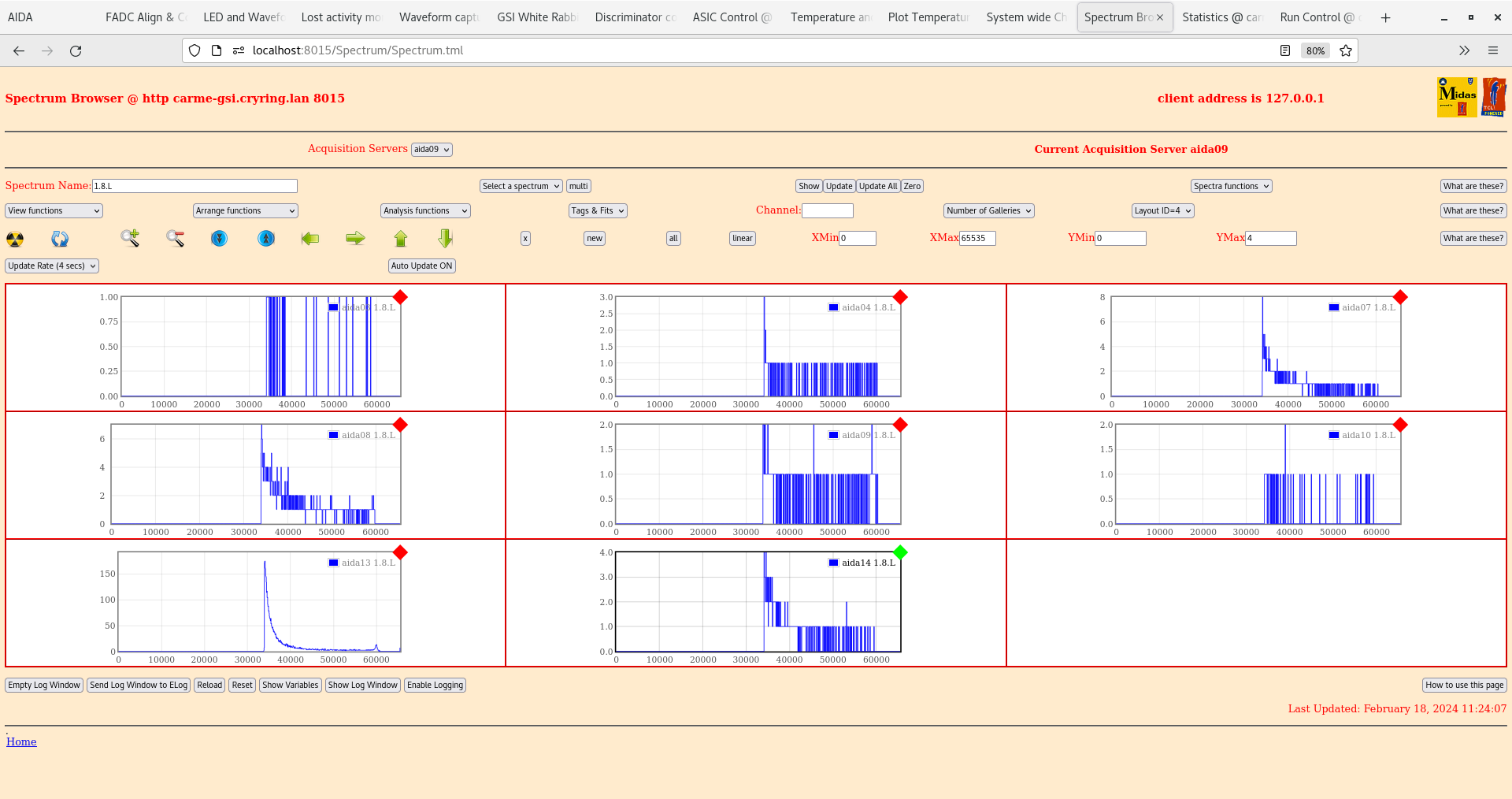

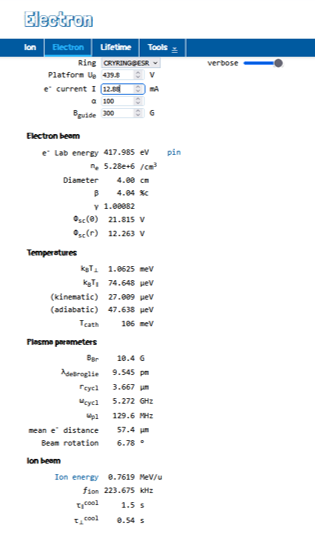

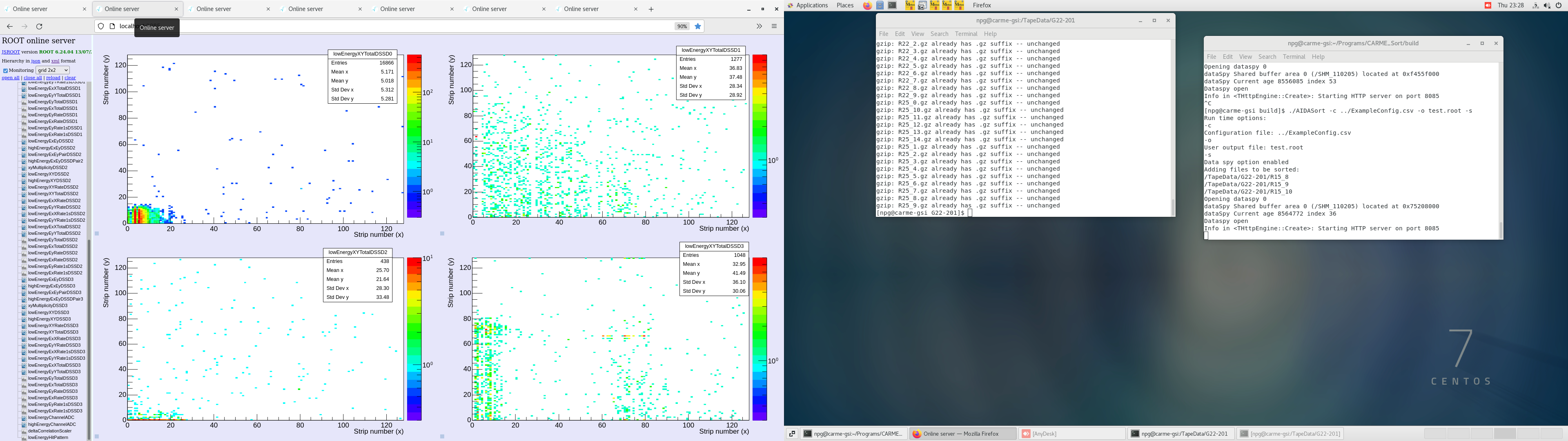

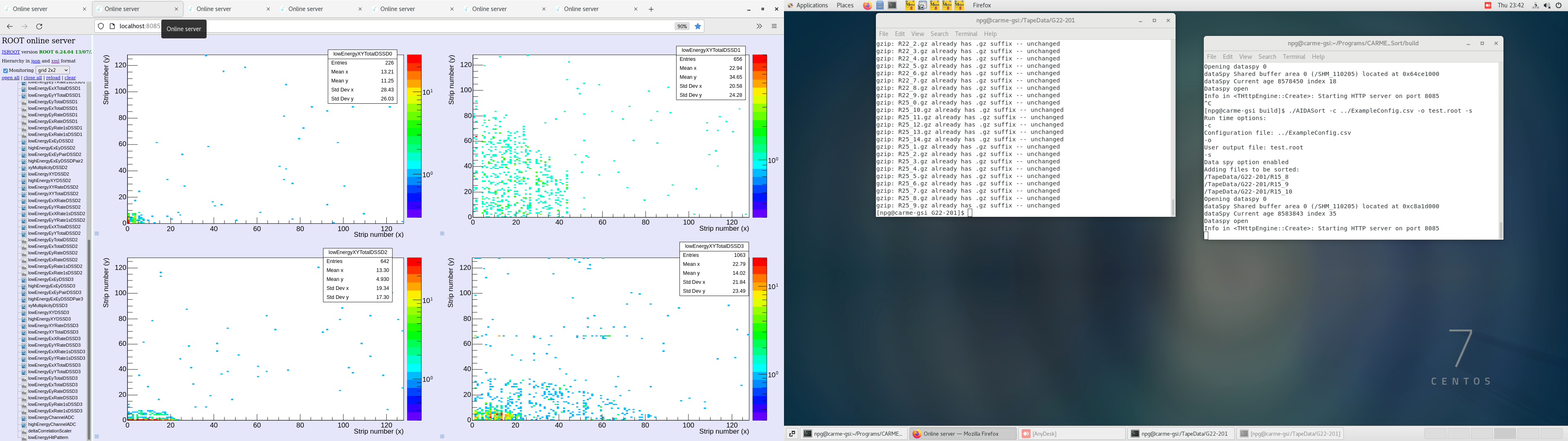

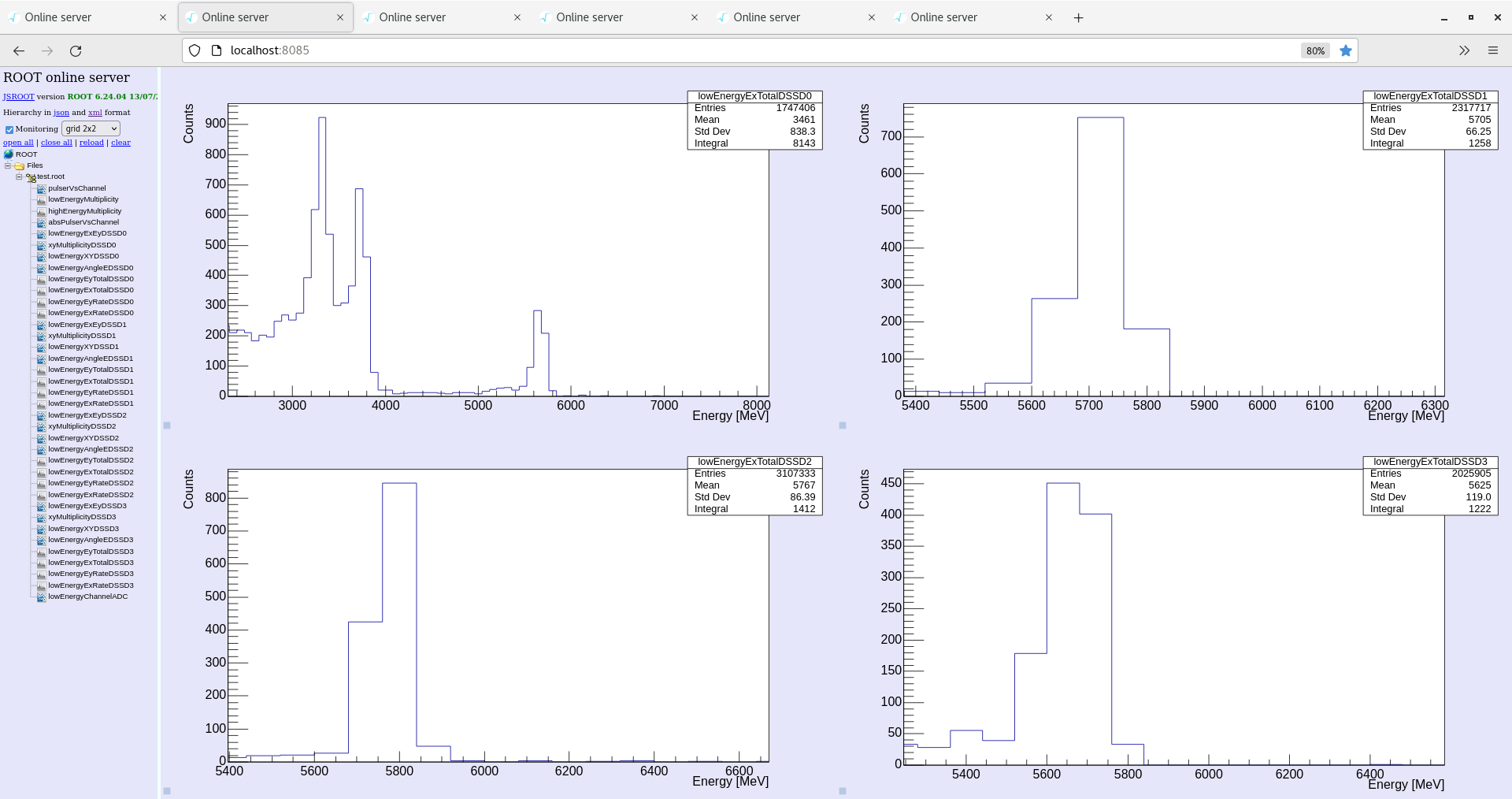

Some interesting features can be seen in the online histograms, e.g. no peak at 16 MeV and a clear straight line in the Ex vs x plot.

07:20

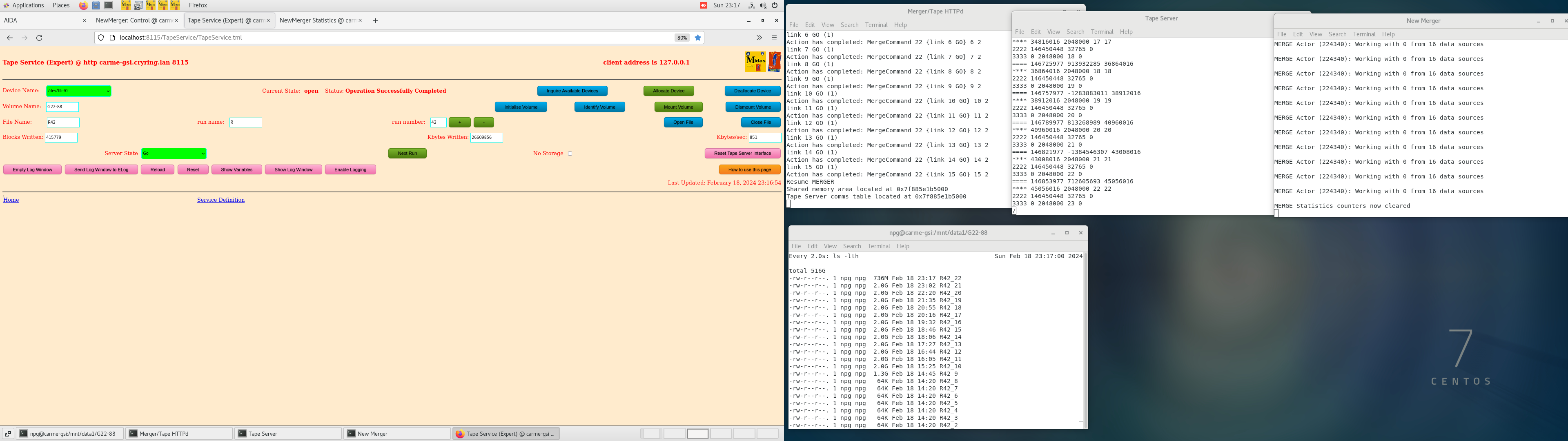

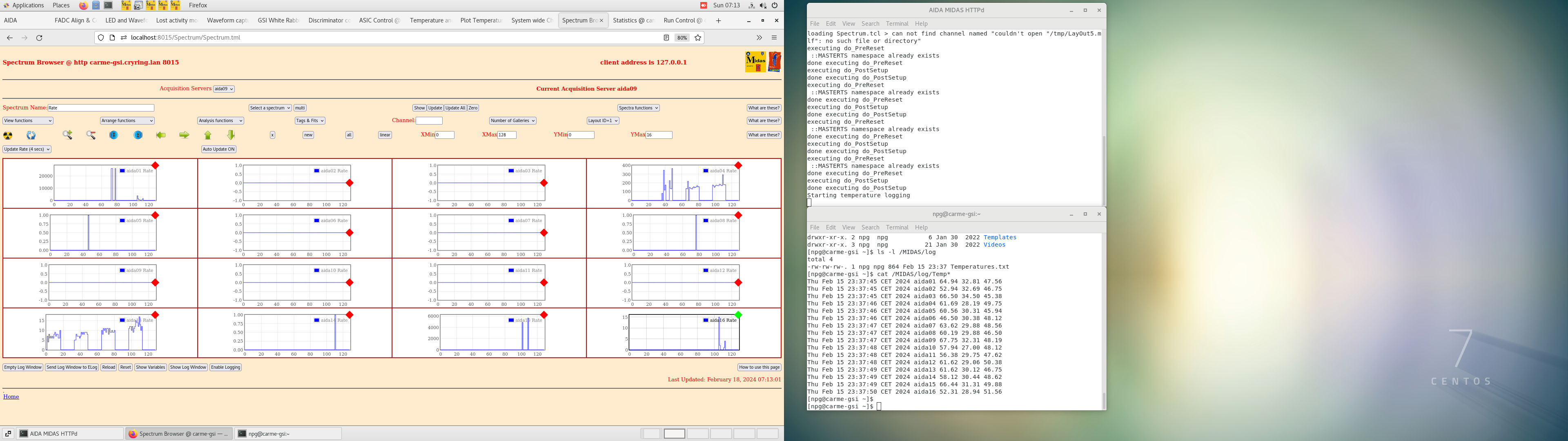

DAQ crashed due to multiple merger / tape server / HTTPD server instances being opened on workspace 5

Cannot soft reboot. FEEs off. |

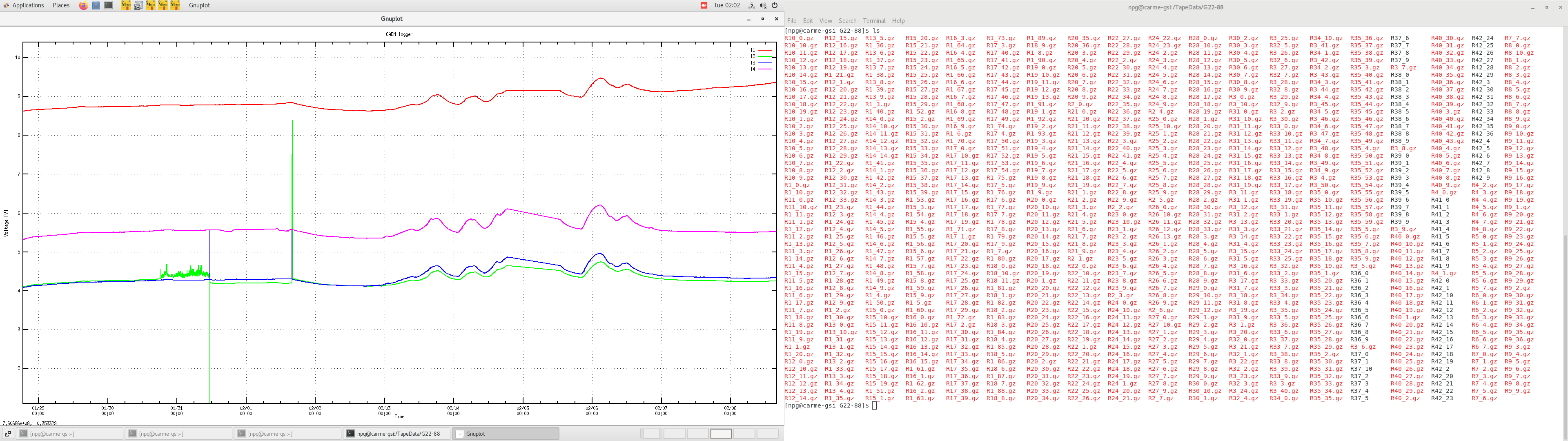

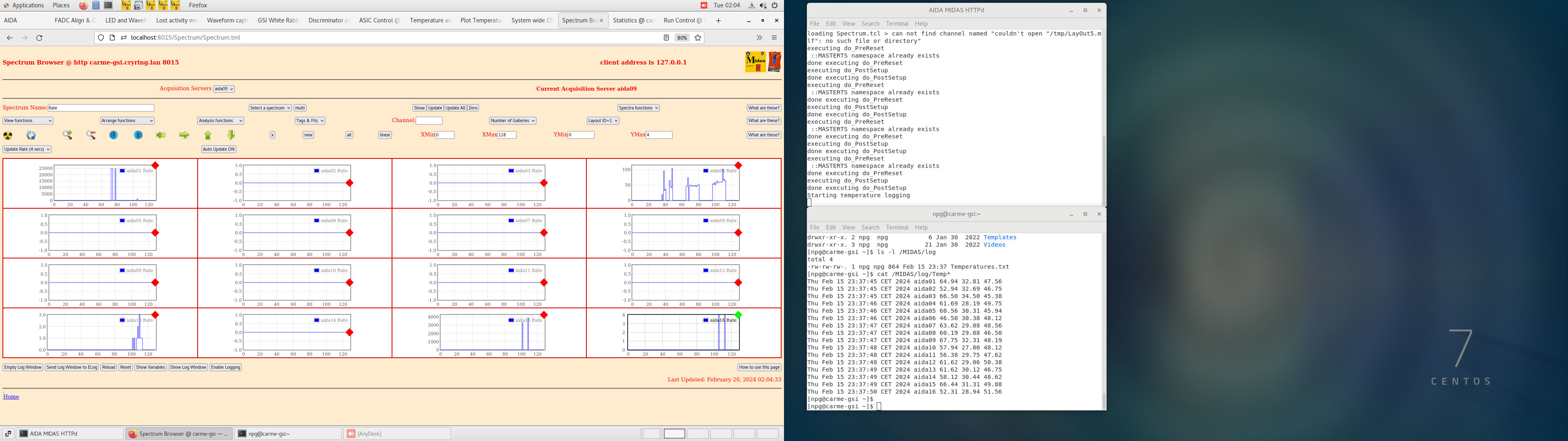

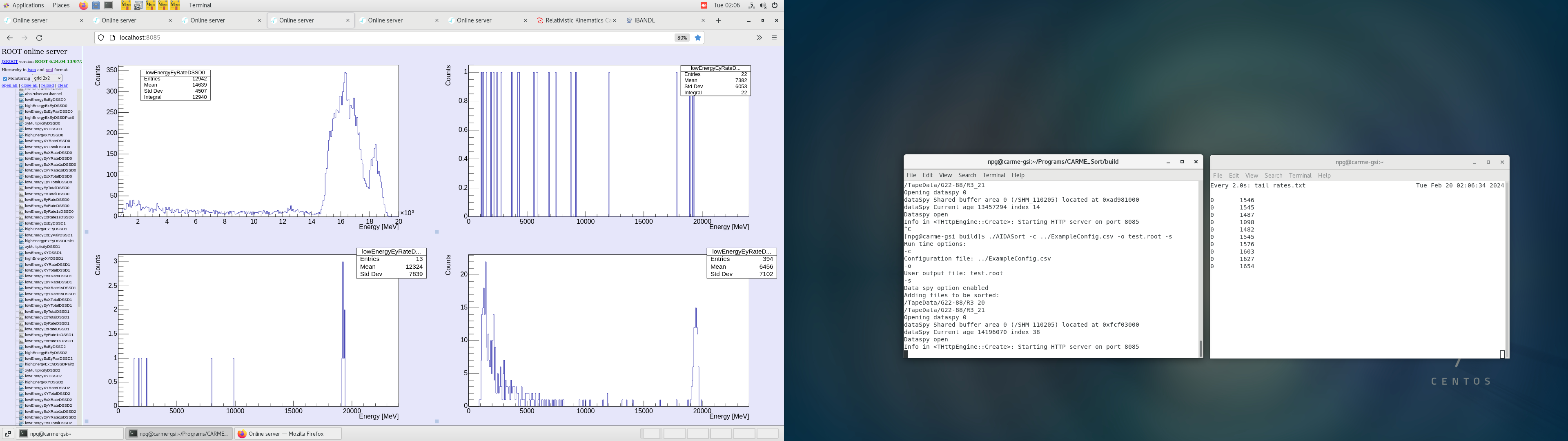

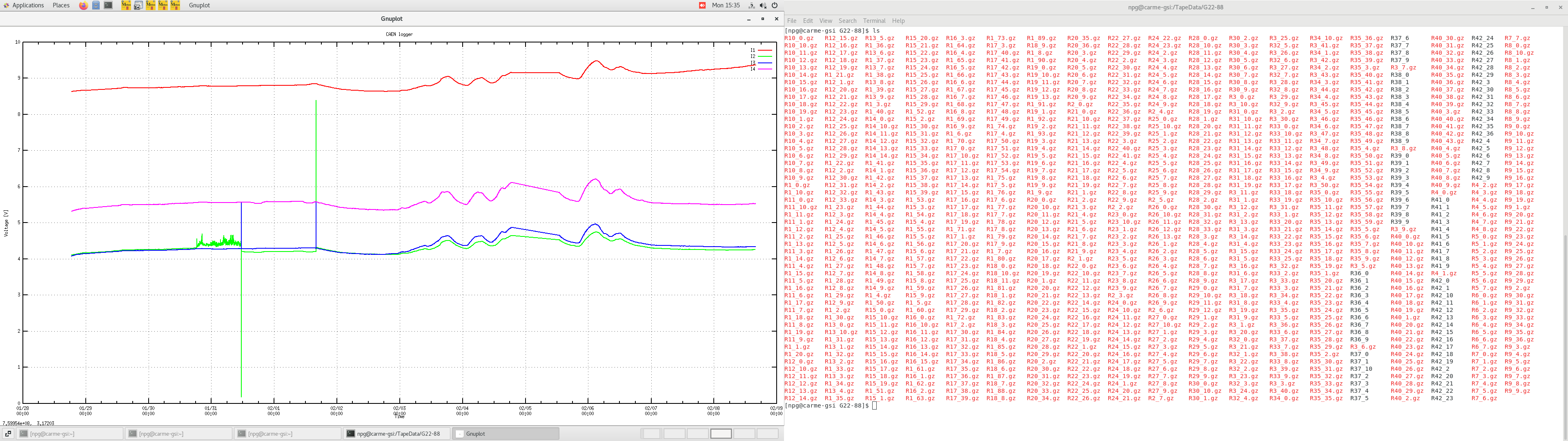

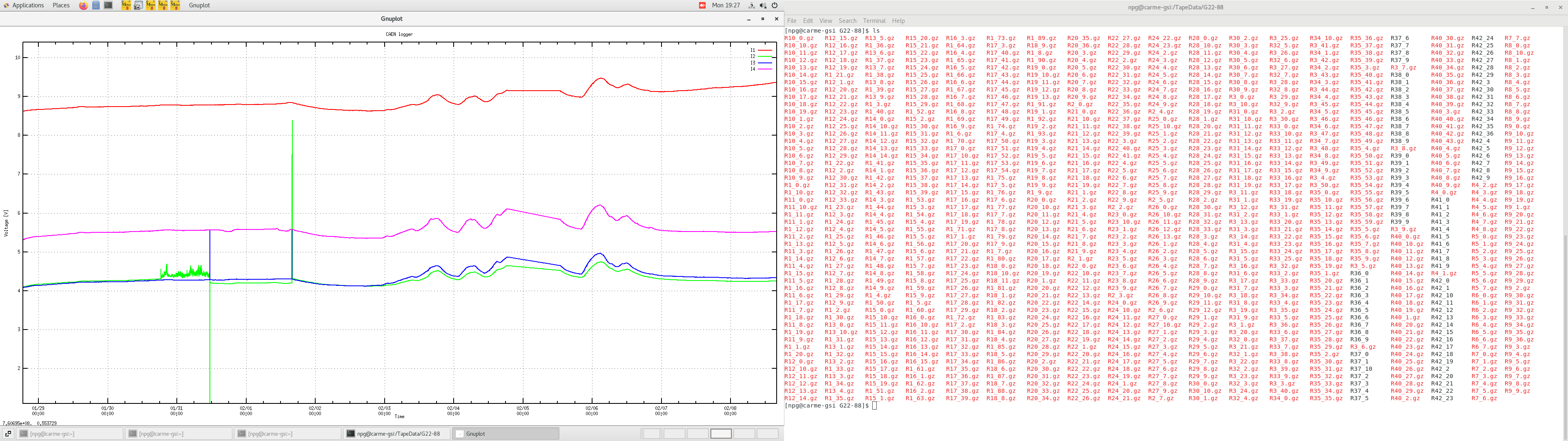

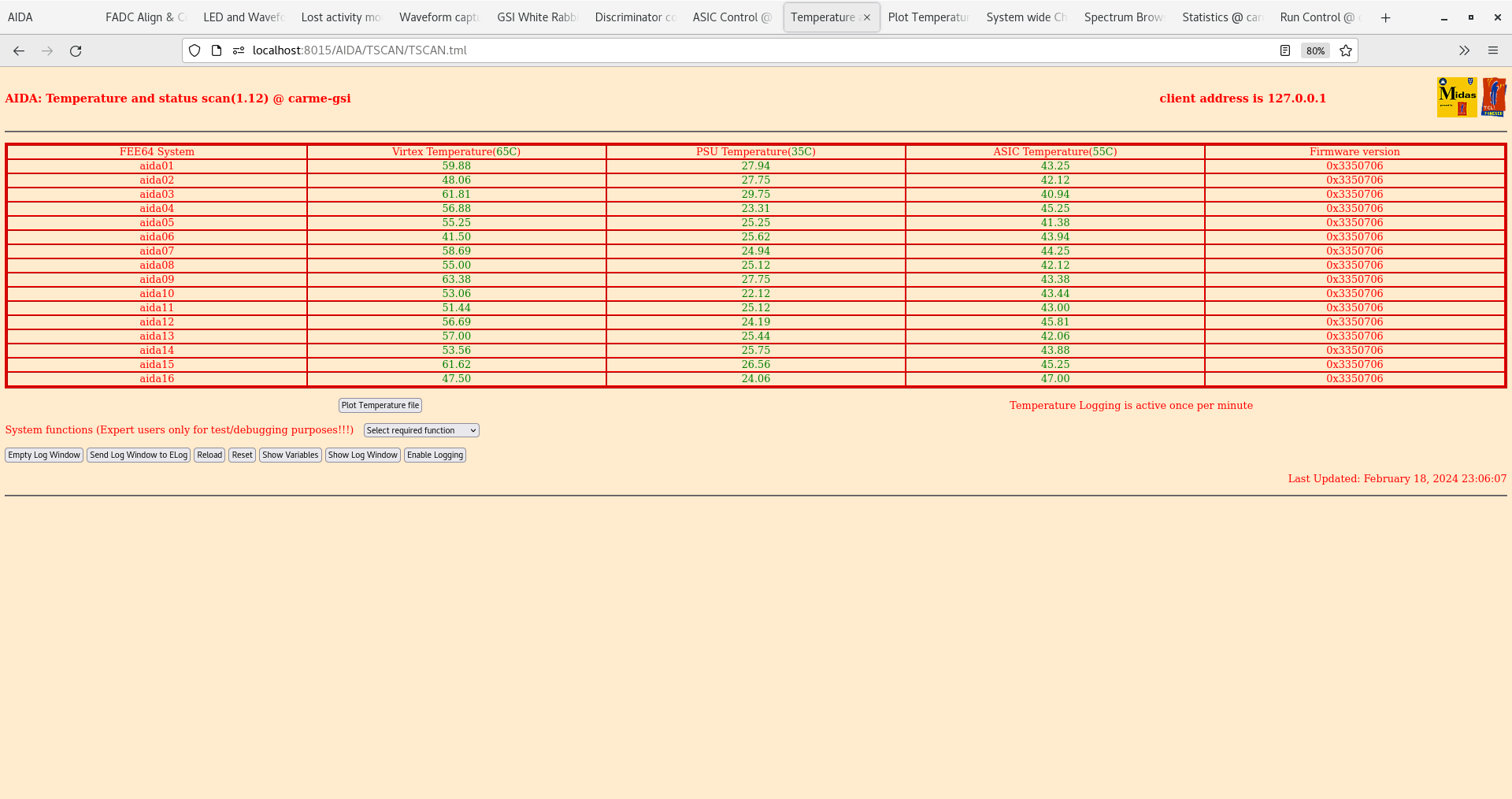

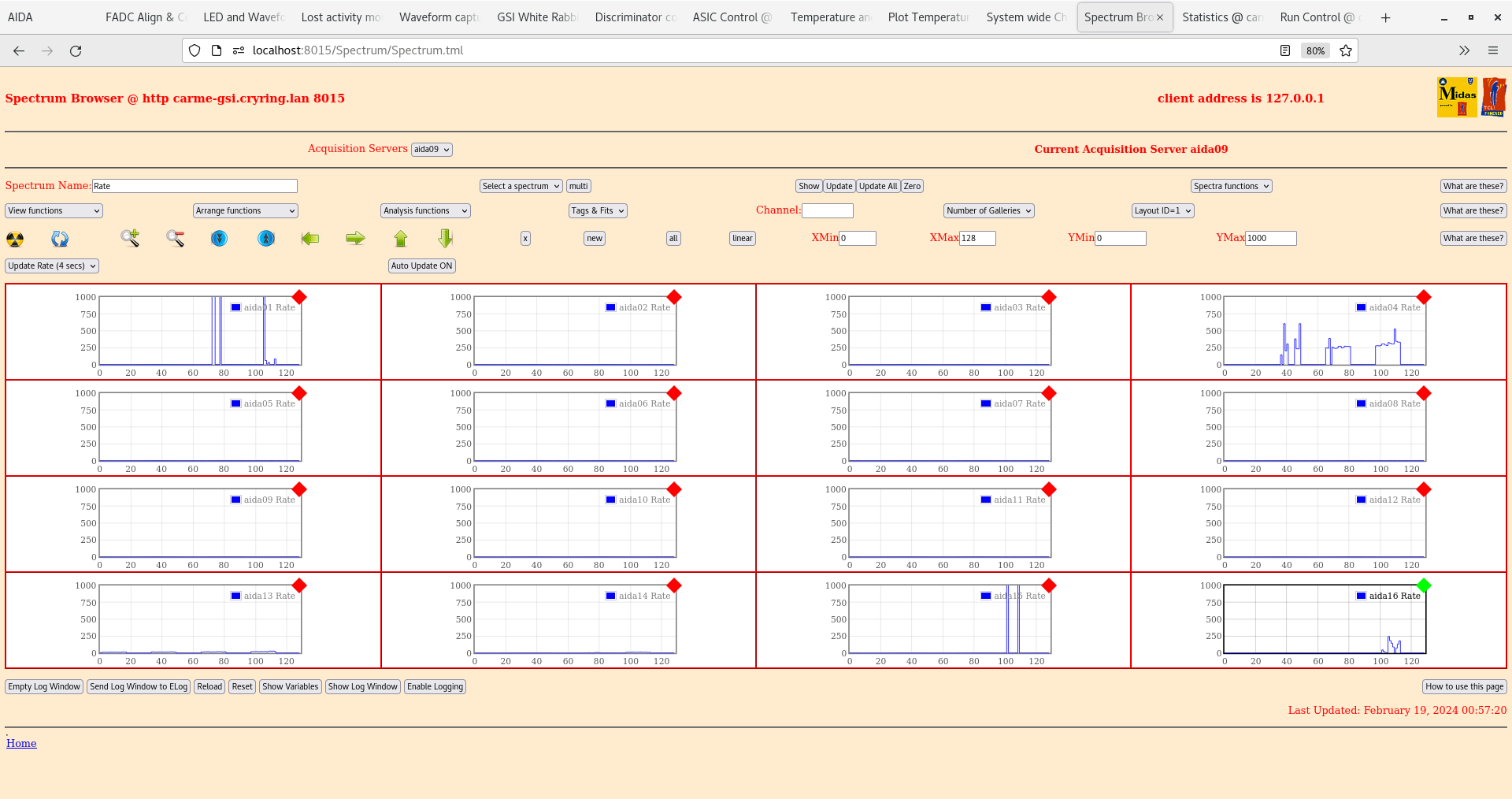

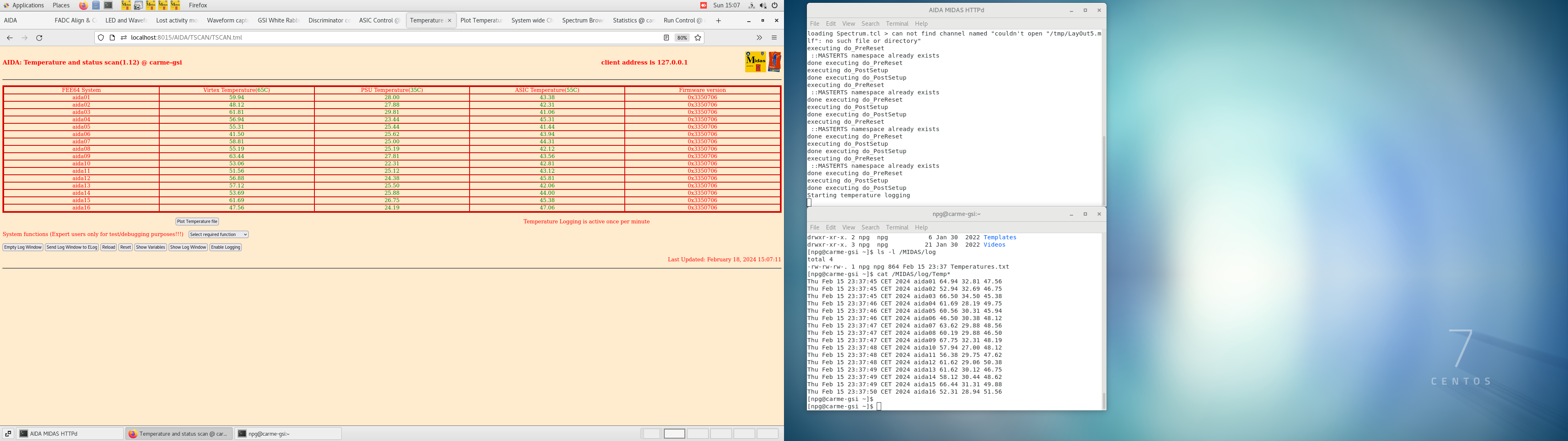

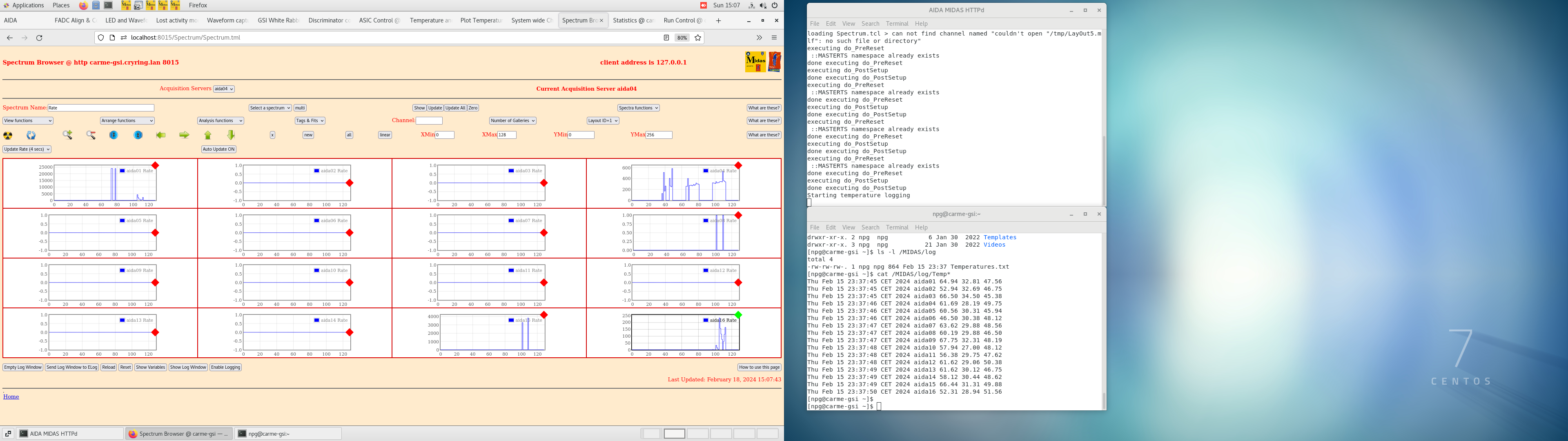

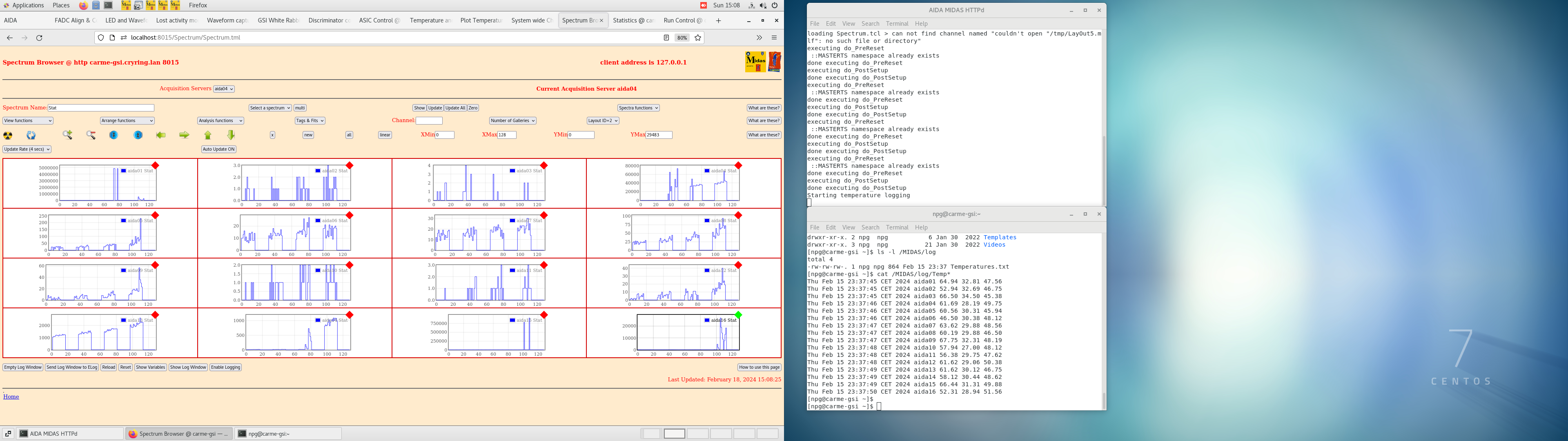

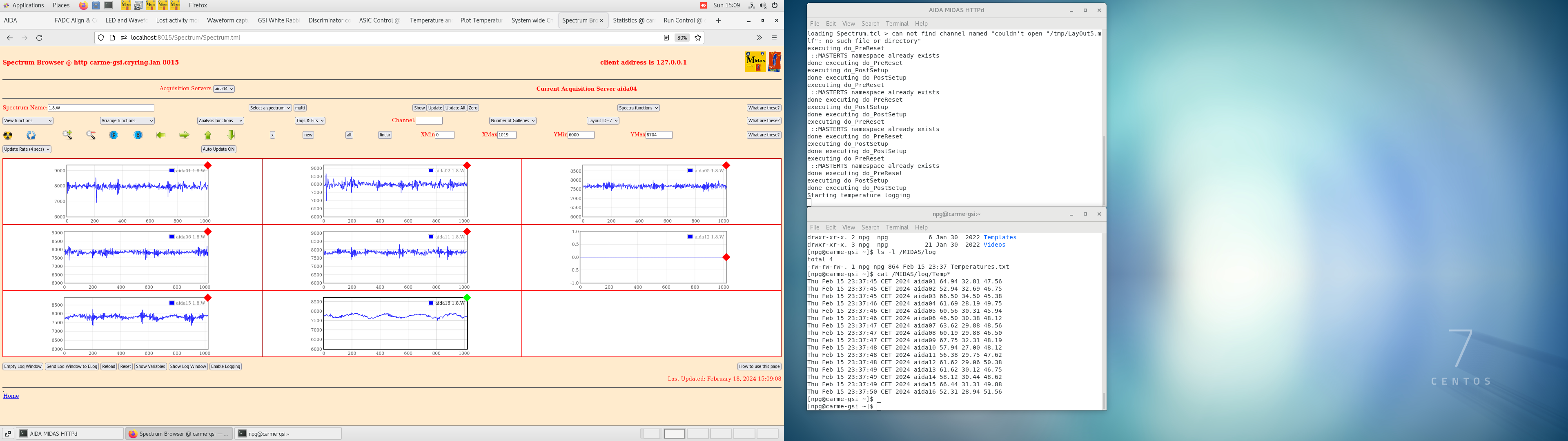

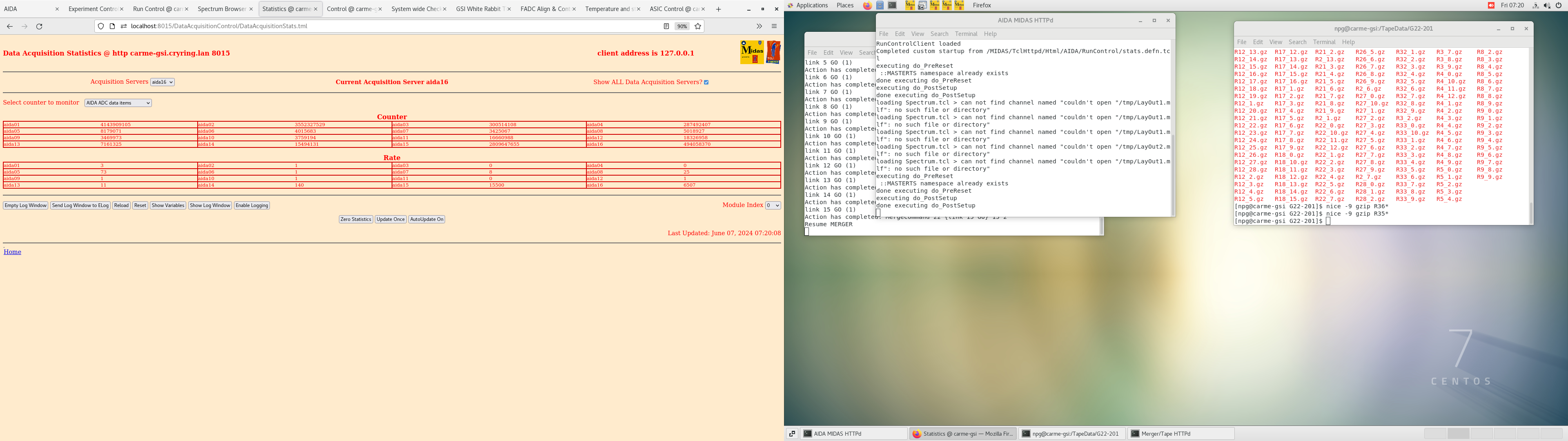

| Attachment 1: Screenshot_from_2024-02-20_02-02-14.png

|

|

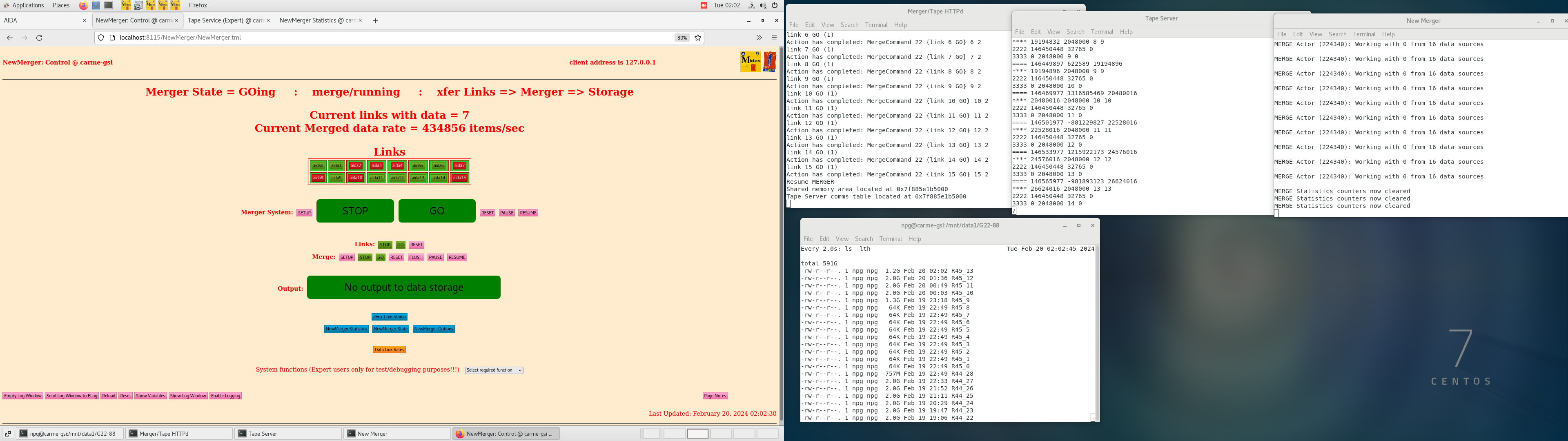

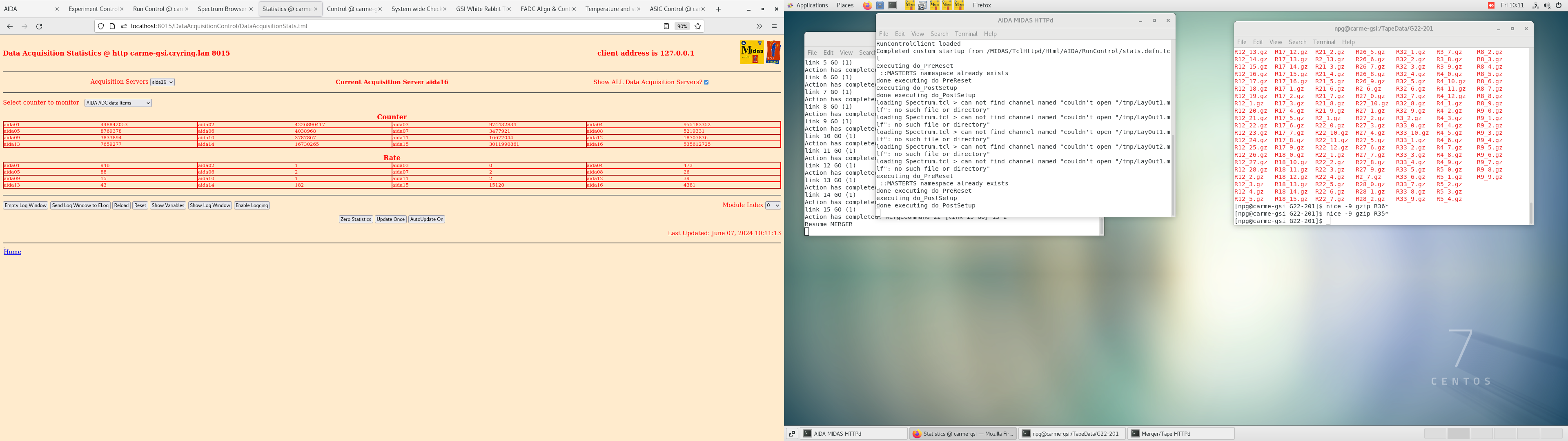

| Attachment 2: Screenshot_from_2024-02-20_02-02-47.png

|

|

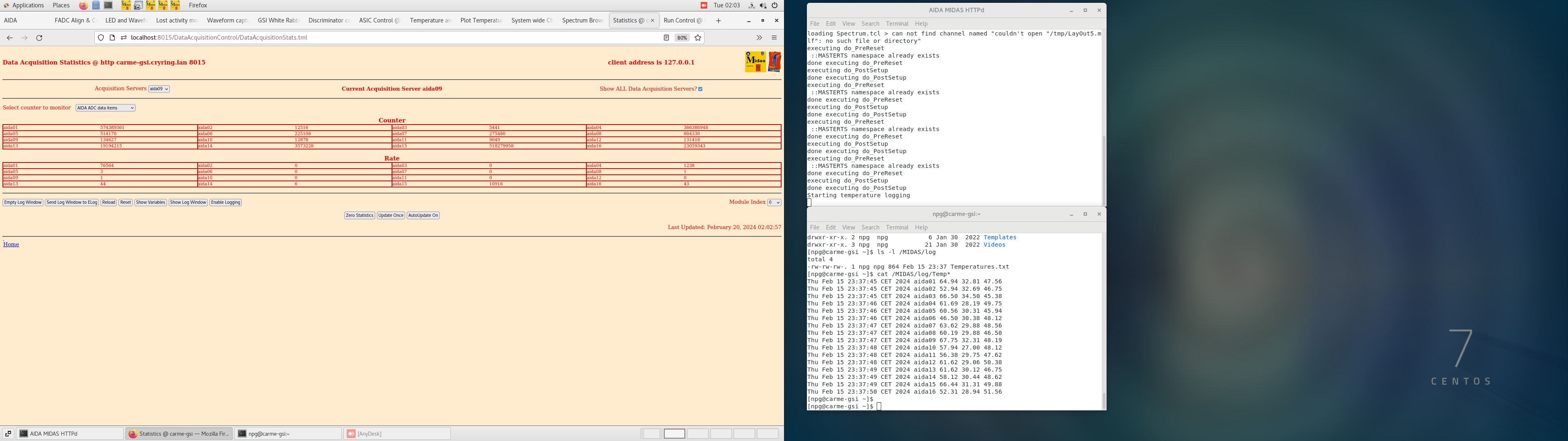

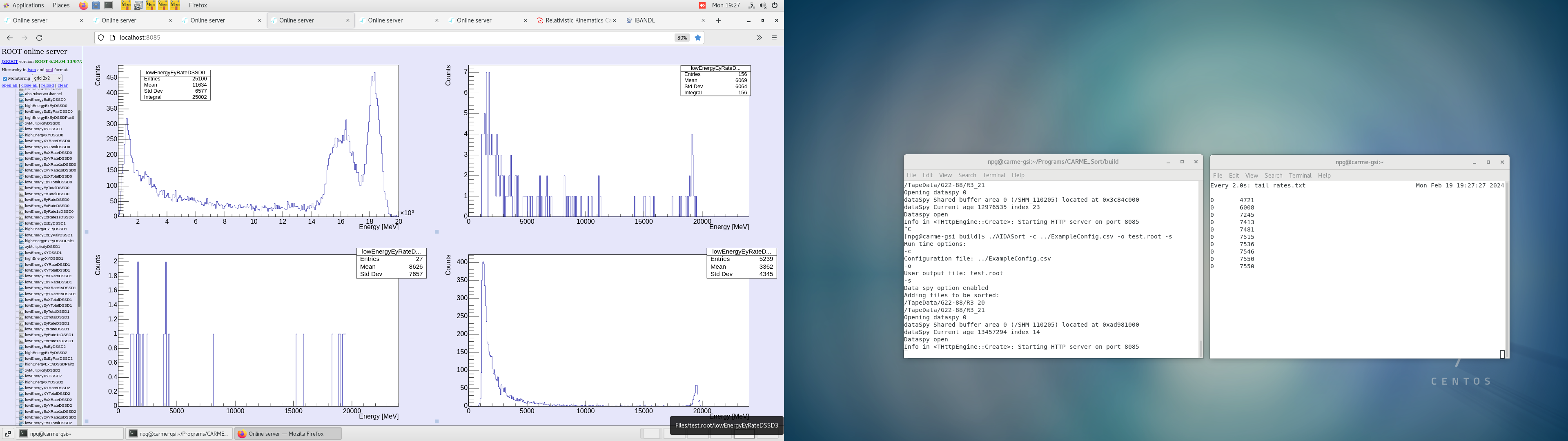

| Attachment 3: Screenshot_from_2024-02-20_02-03-07.png

|

|

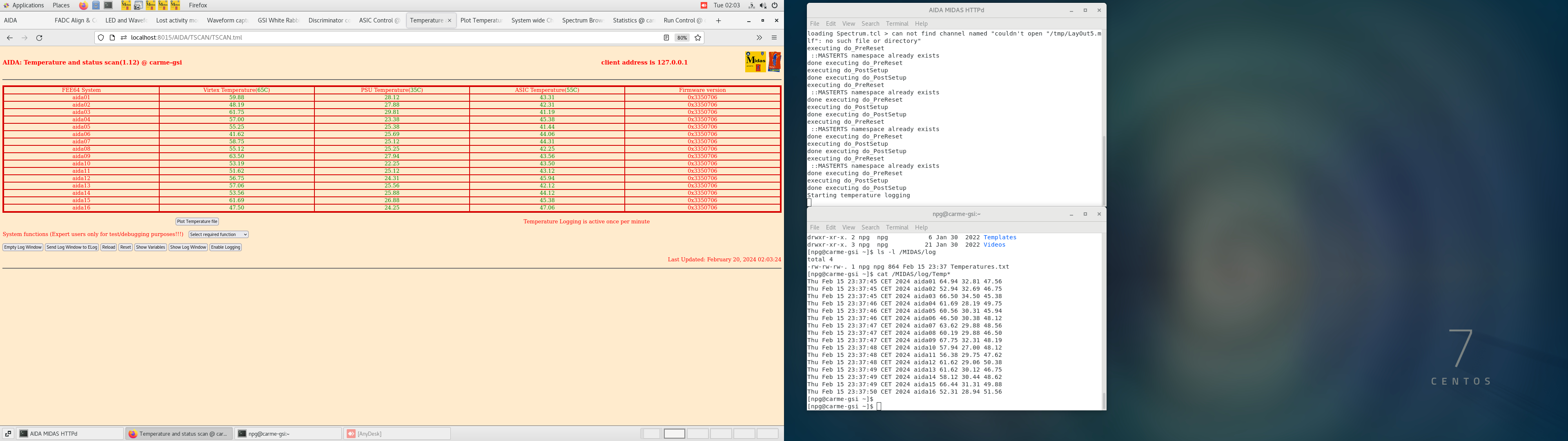

| Attachment 4: Screenshot_from_2024-02-20_02-03-31.png

|

|

| Attachment 5: Screenshot_from_2024-02-20_02-04-40.png

|

|

| Attachment 6: Screenshot_from_2024-02-20_02-06-37.png

|

|

| Attachment 7: Beam_intensity.png

|

|

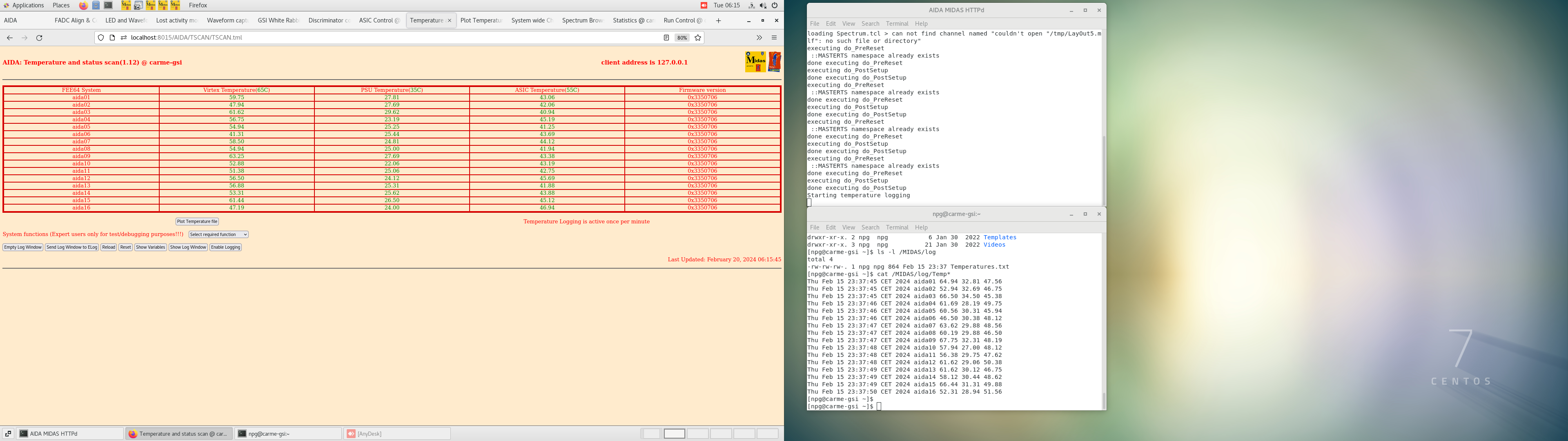

| Attachment 8: Screenshot_from_2024-02-20_06-15-54.png

|

|

| Attachment 9: Screenshot_from_2024-02-20_06-16-09.png

|

|

| Attachment 10: Screenshot_from_2024-02-20_06-16-39.png

|

|

| Attachment 11: Screenshot_from_2024-02-20_06-17-11.png

|

|

| Attachment 12: Screenshot_from_2024-02-20_06-17-35.png

|

|

| Attachment 13: Screenshot_from_2024-02-20_06-18-29.png

|

|

| Attachment 14: Screenshot_from_2024-02-20_06-18-58.png

|

|

|

714

|

Mon Jun 2 17:48:07 2025 |

JG, AG | Run 44 scraper tests |

Same settings are Run 43 but with coasting beam and scrapers set to: 30 / - 30 mm.

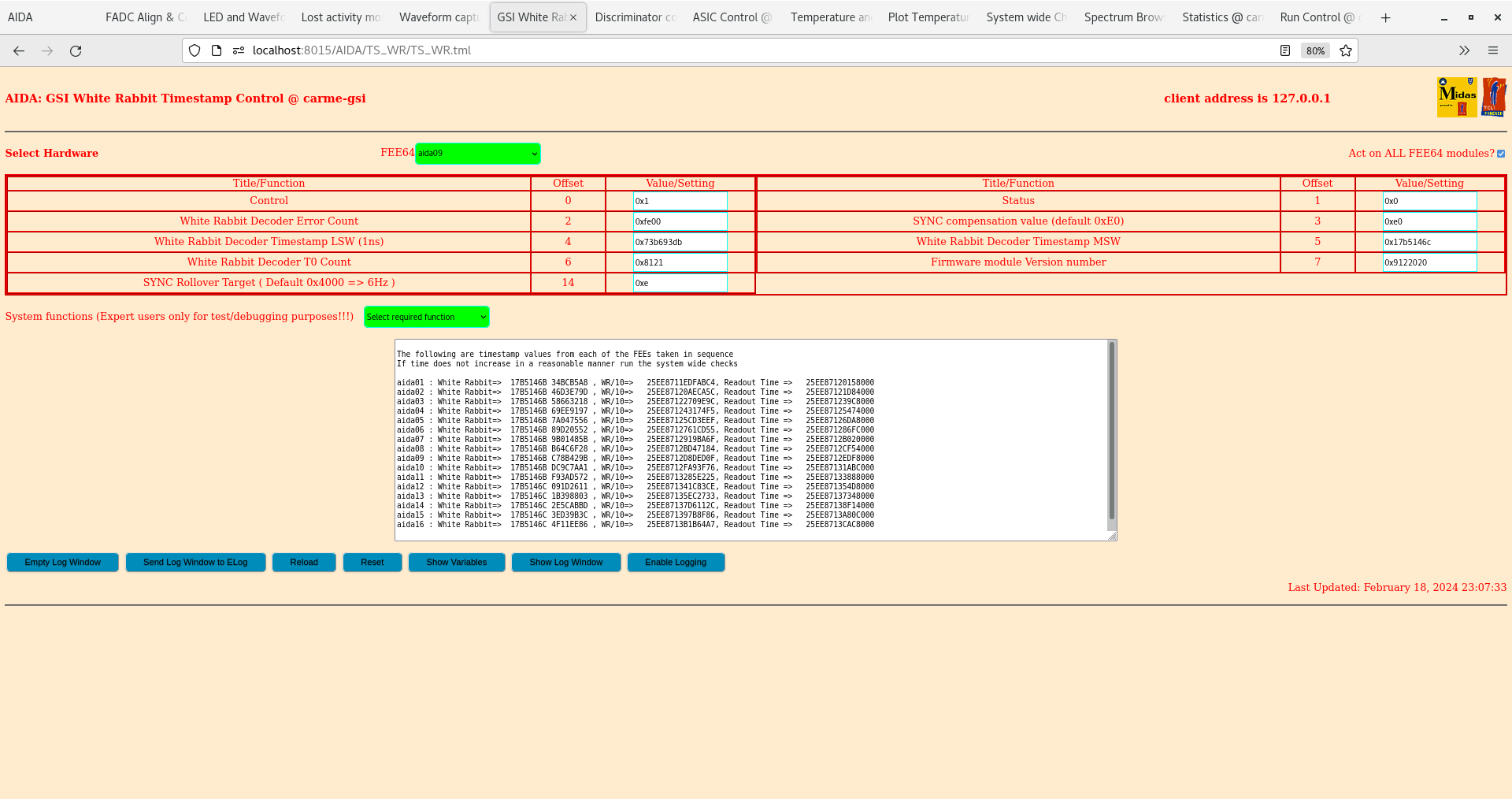

all checks ok, but WR timestamp error, see attached

19:28 the Run 44 has been stopped. |

| Attachment 1: Screenshot_from_2025-06-02_18-51-24.png

|

|

| Attachment 2: Screenshot_from_2025-06-02_19-27-31.png

|

|

|

531

|

Mon Feb 19 08:45:22 2024 |

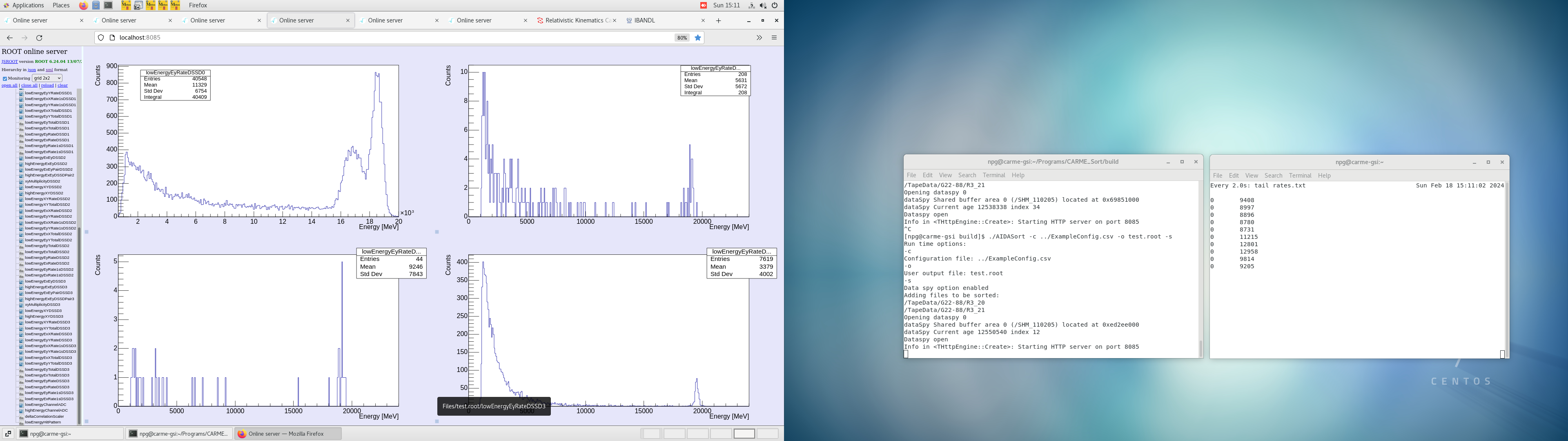

JM, JG, SHB, EM, EH | Run 44 - cooled beam on target |

09:43

Run 44 started cooled beam on target

Detectors IN (left arm pot =36.5 mm, right arm pot = 70.49 mm). Stationary. Same as previous runs

Electron cooler voltage 751.4 V this corresponds to 1.3436 MeV/u. This should be back on the peak of the resonance.

Target density is 5.2e11 at/cm2, ring pressure looks OK YR09 1.72e-10 mbar. Target density is not very stable and requires small corrections in the x position to maintain a target

Horizontal beam position is -7.5 mm, vertical beam position is 0.0 mm. Same as previous run

Beam is in the ring for 6 seconds and total cycle time between injections is 10 seconds. Notice this is different than previous runs. Aim is to have a few different cycle time configurations to see effect on halo

Statistics, merger statistics, histograms all zero'd

10:05

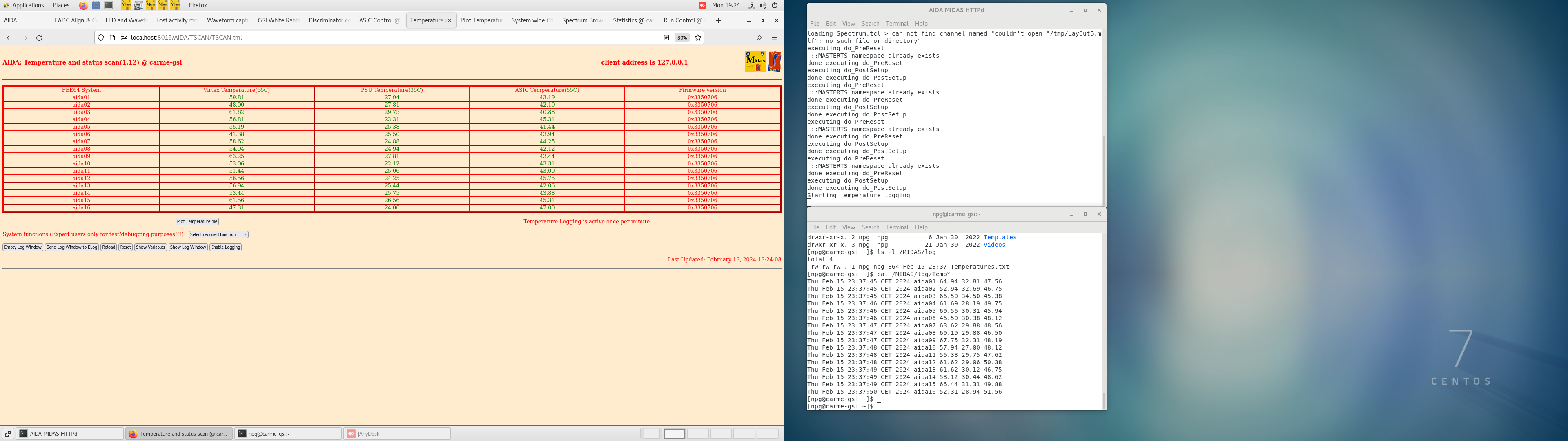

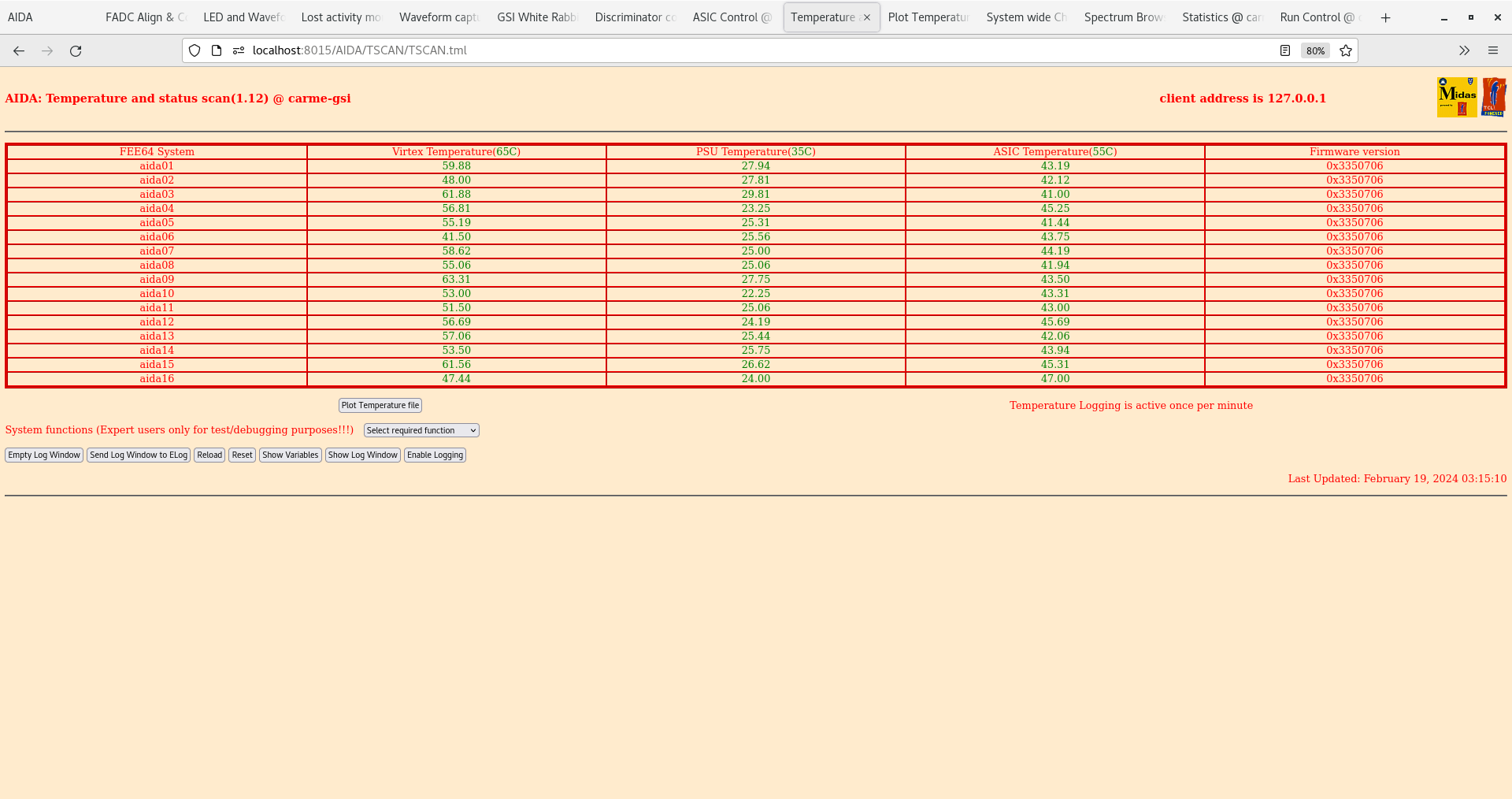

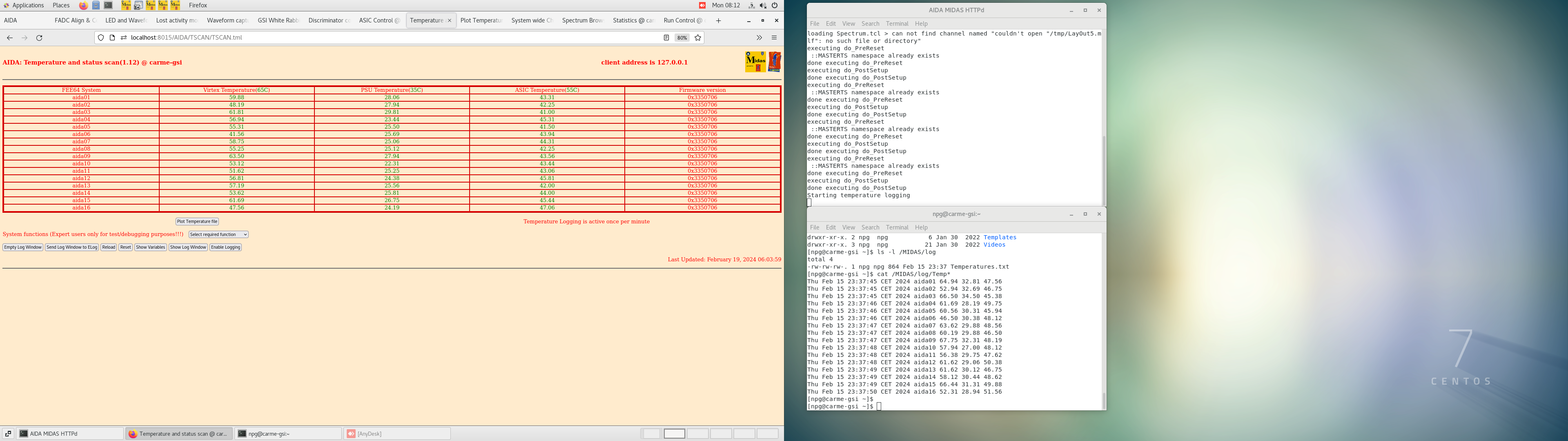

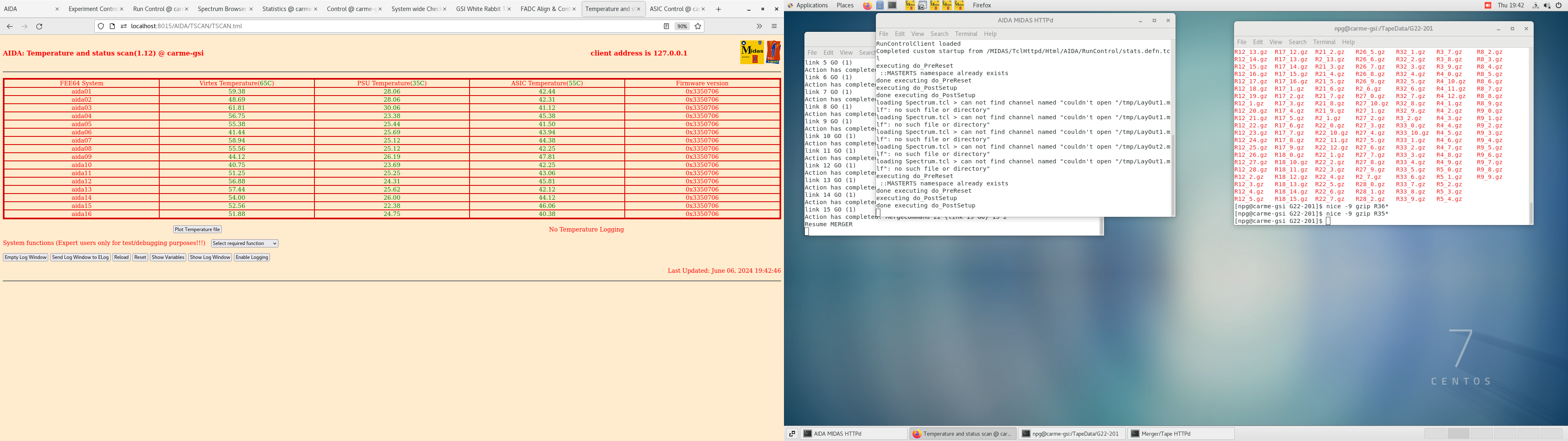

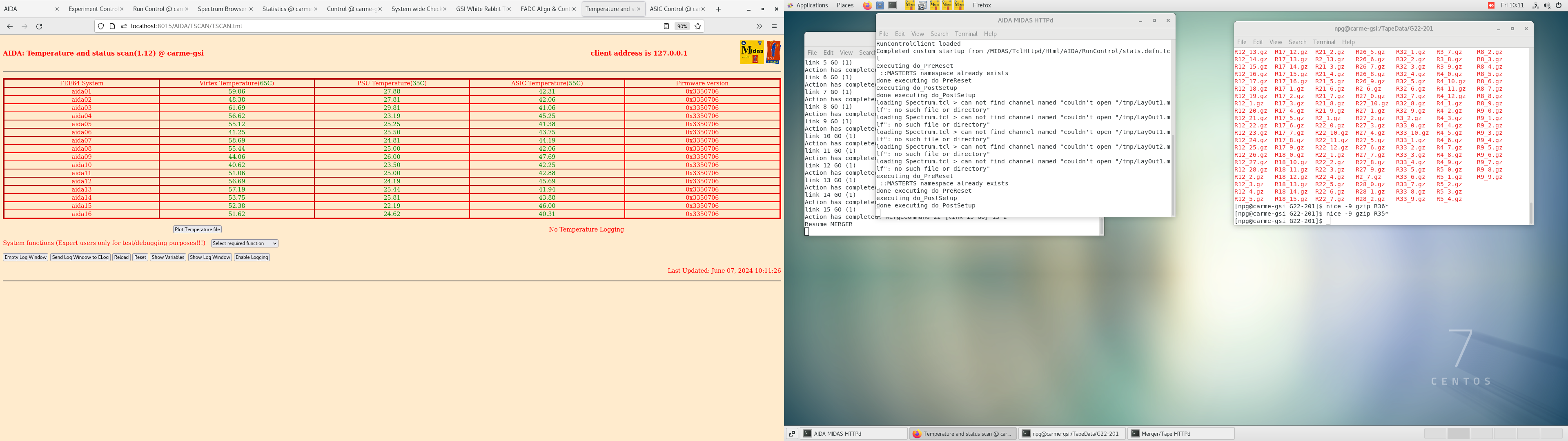

FEE temps OK

System checks OK

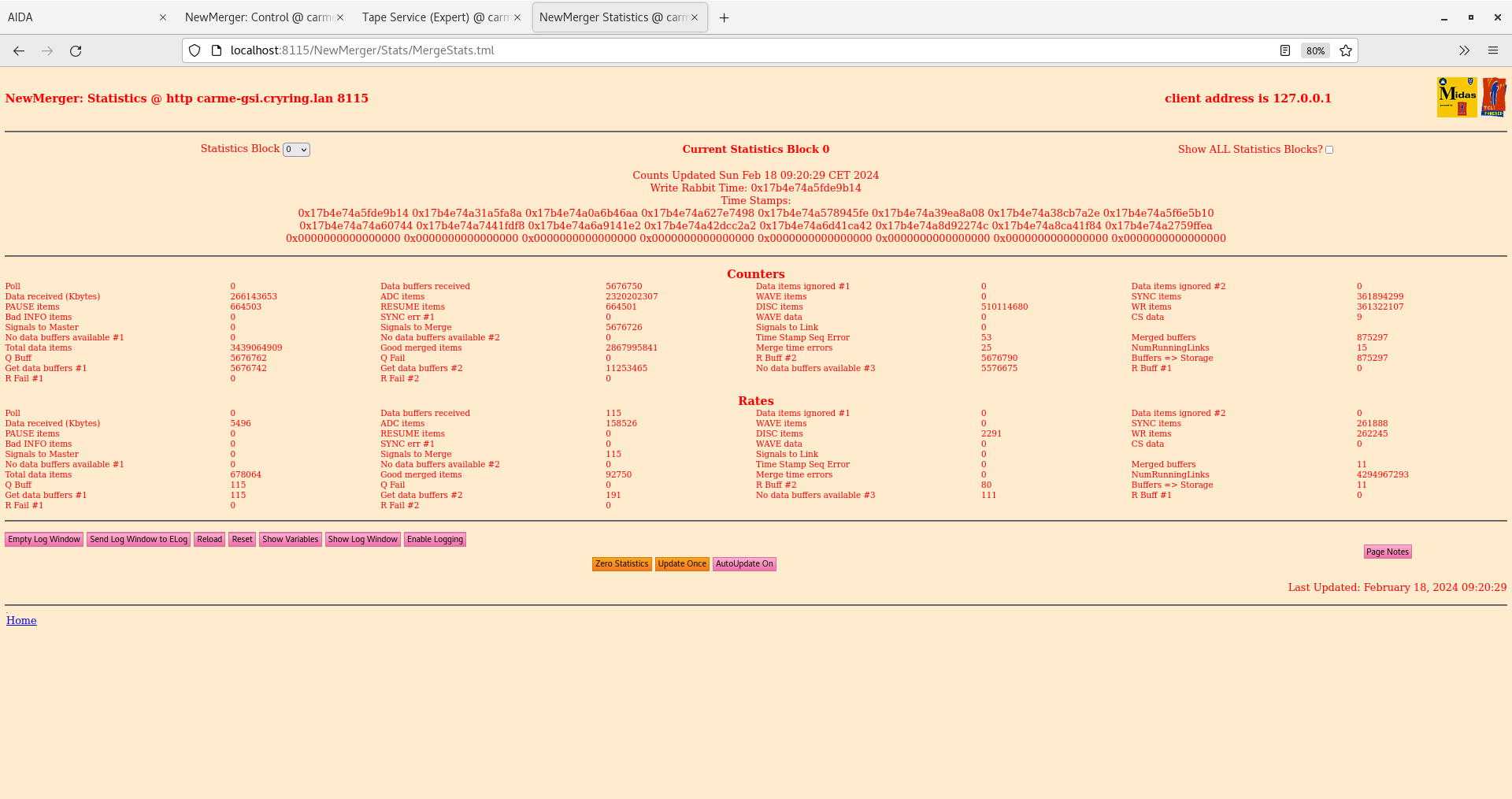

Merger OK, tape server OK

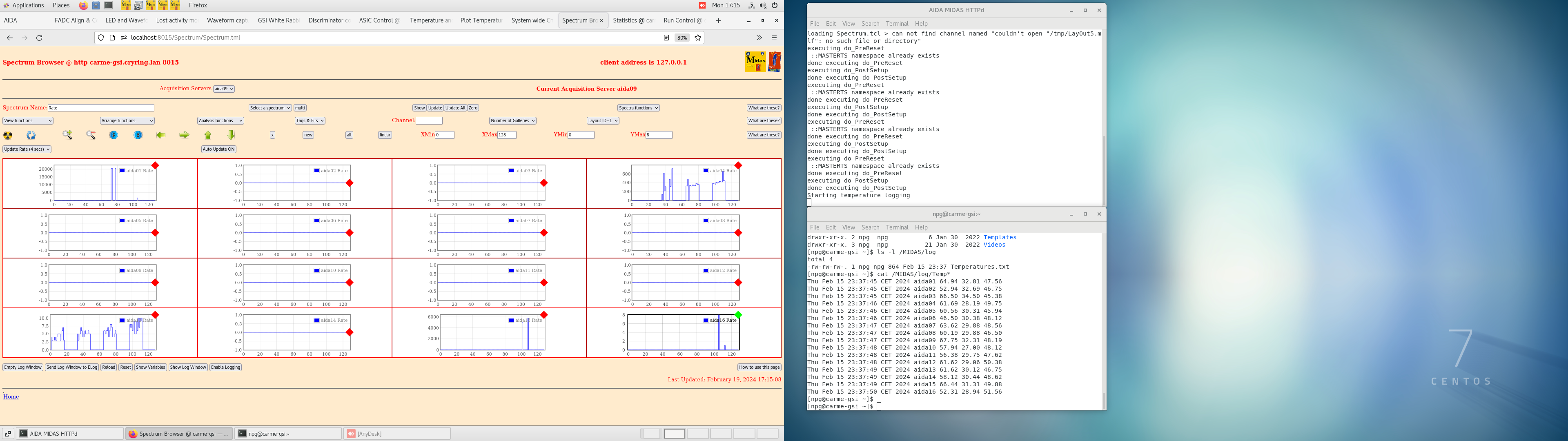

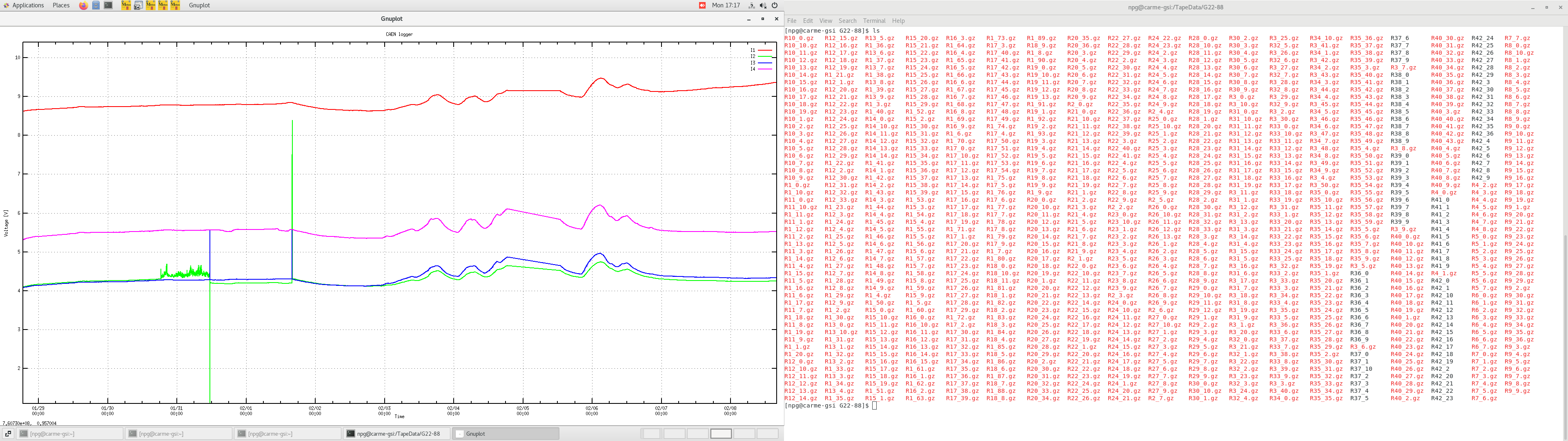

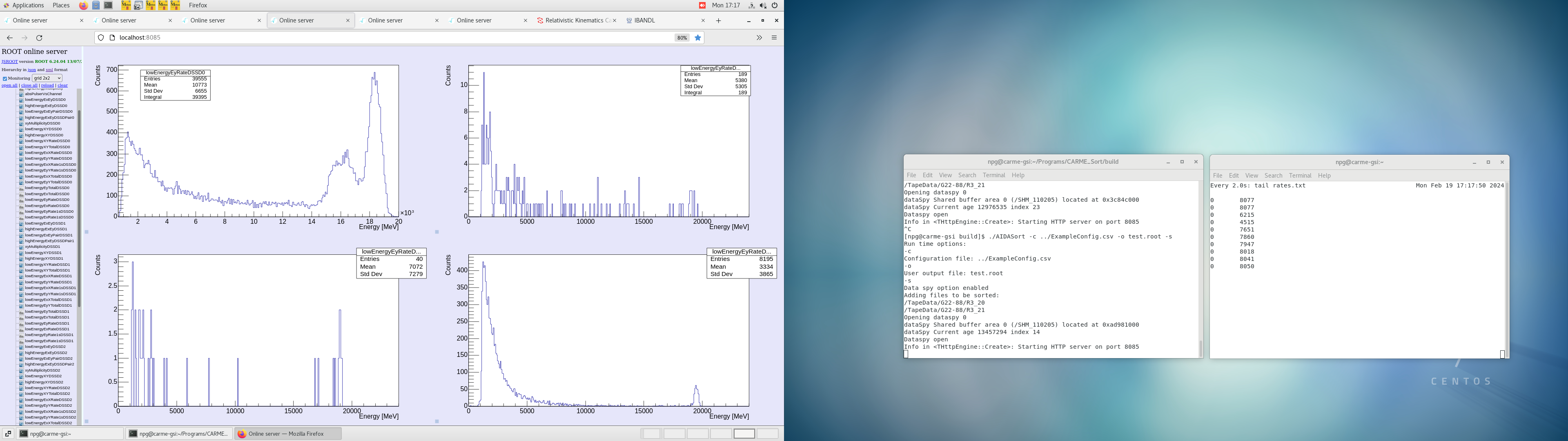

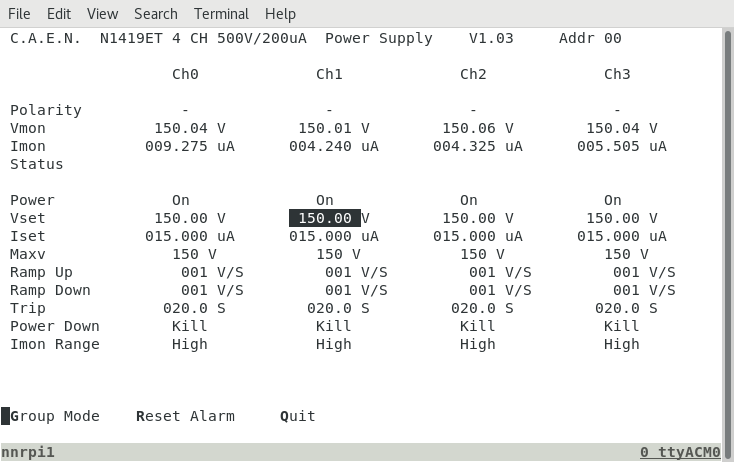

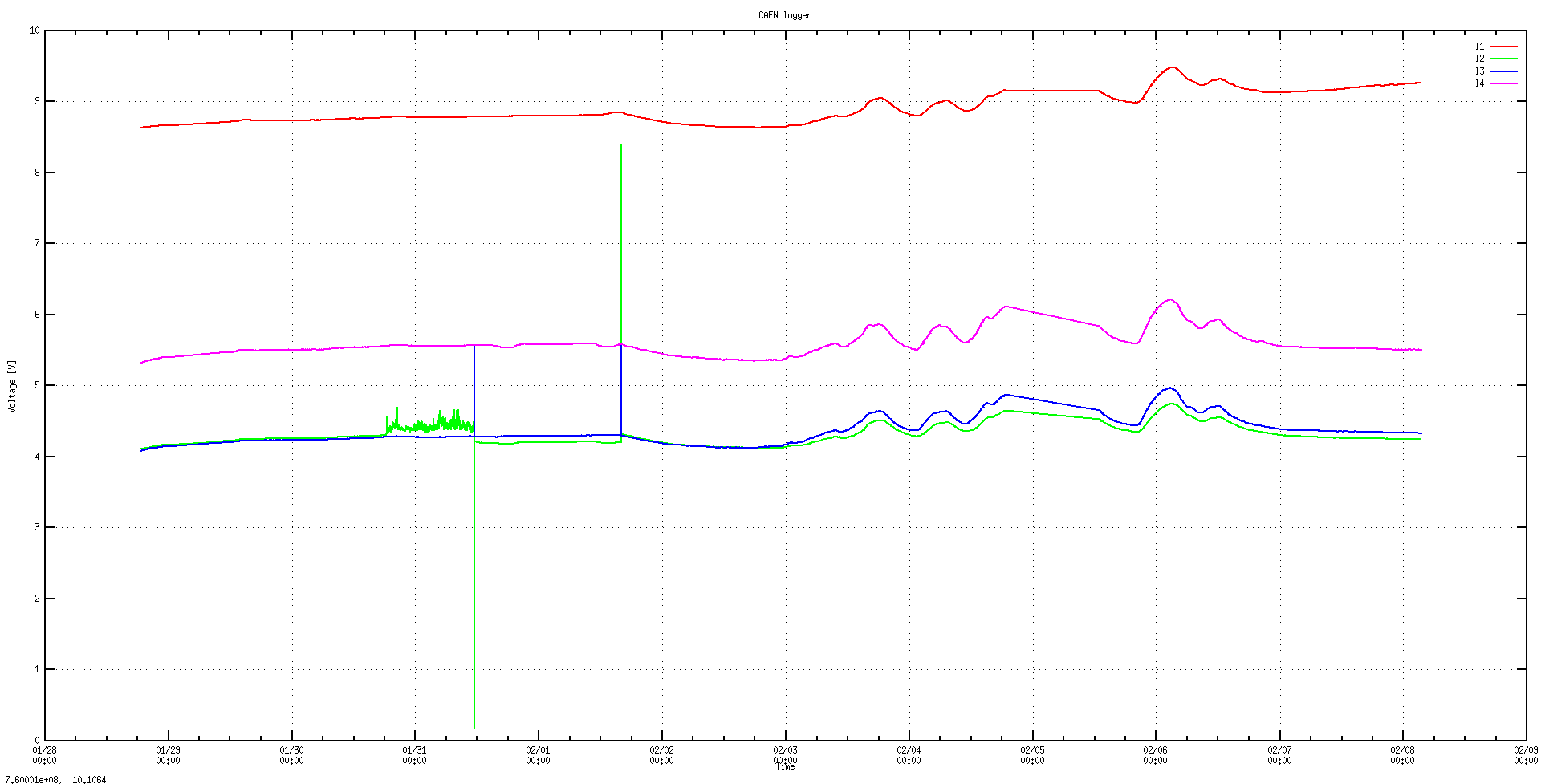

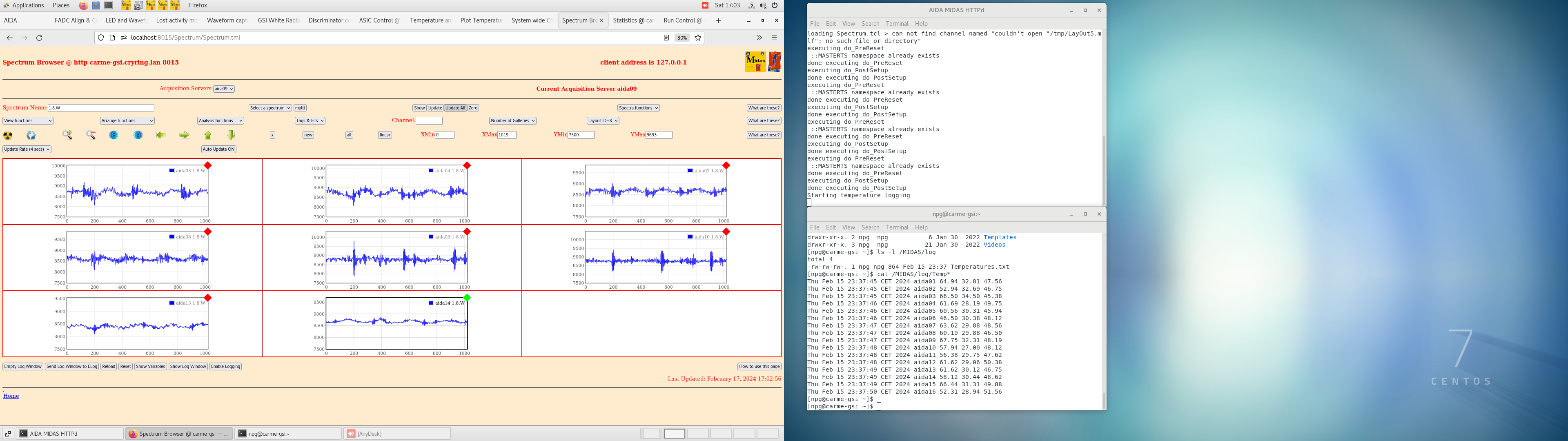

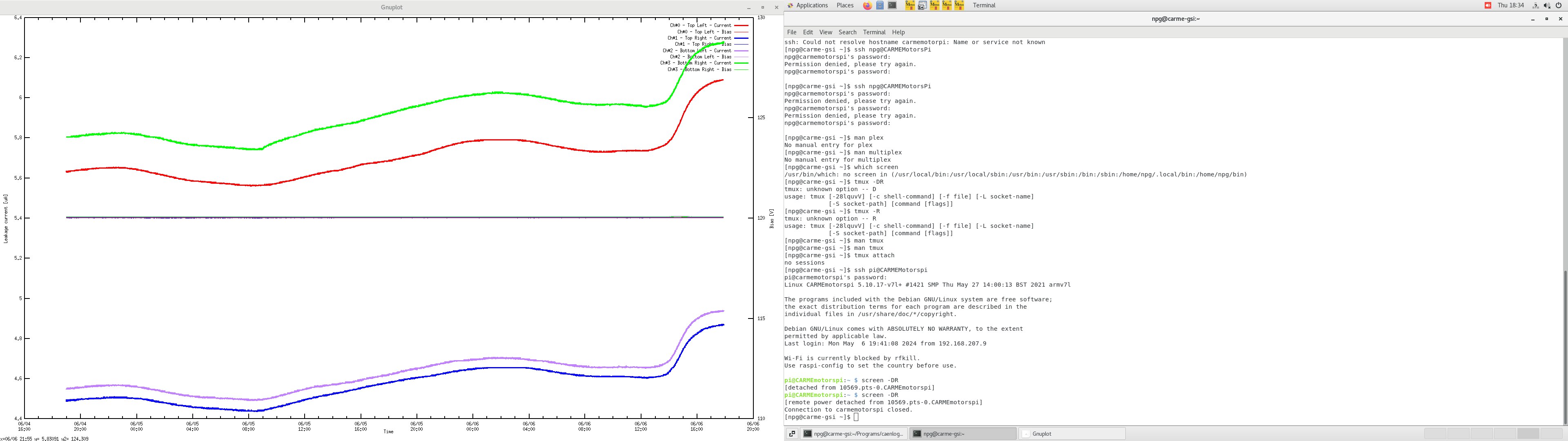

Leakage current plot attachment 1

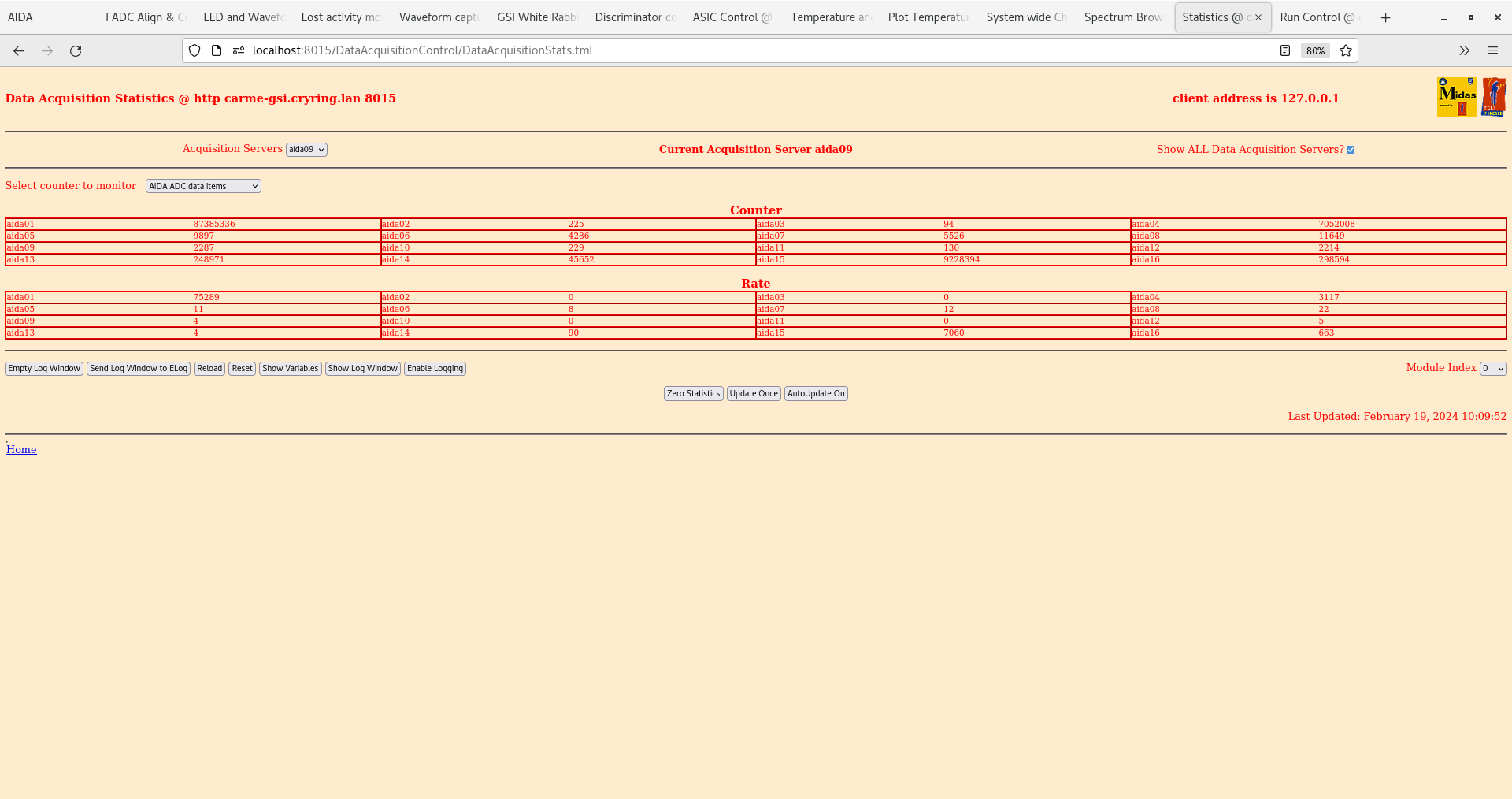

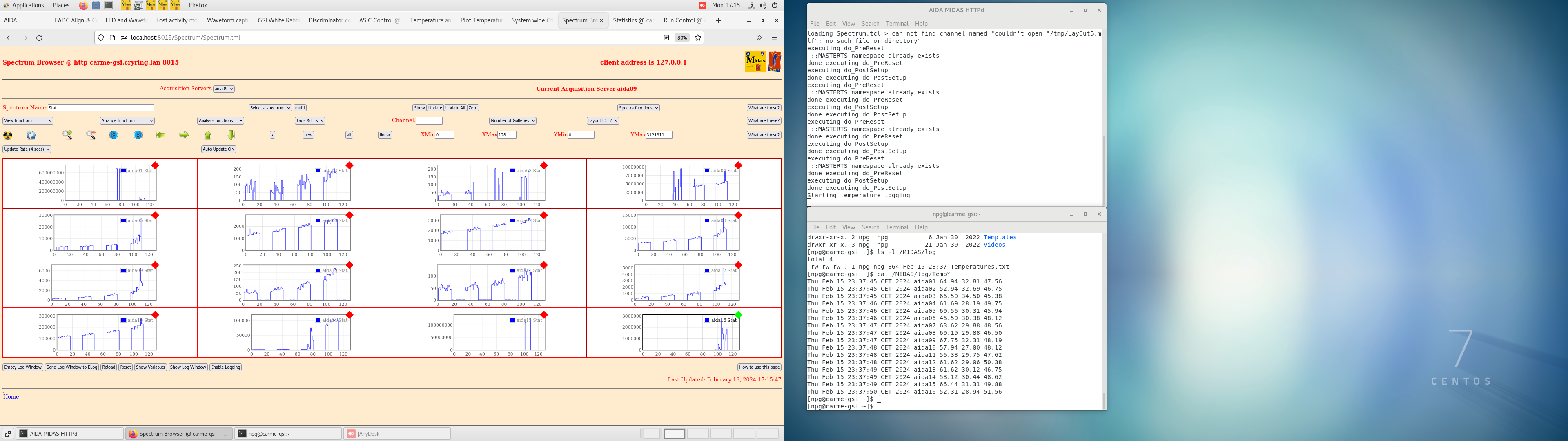

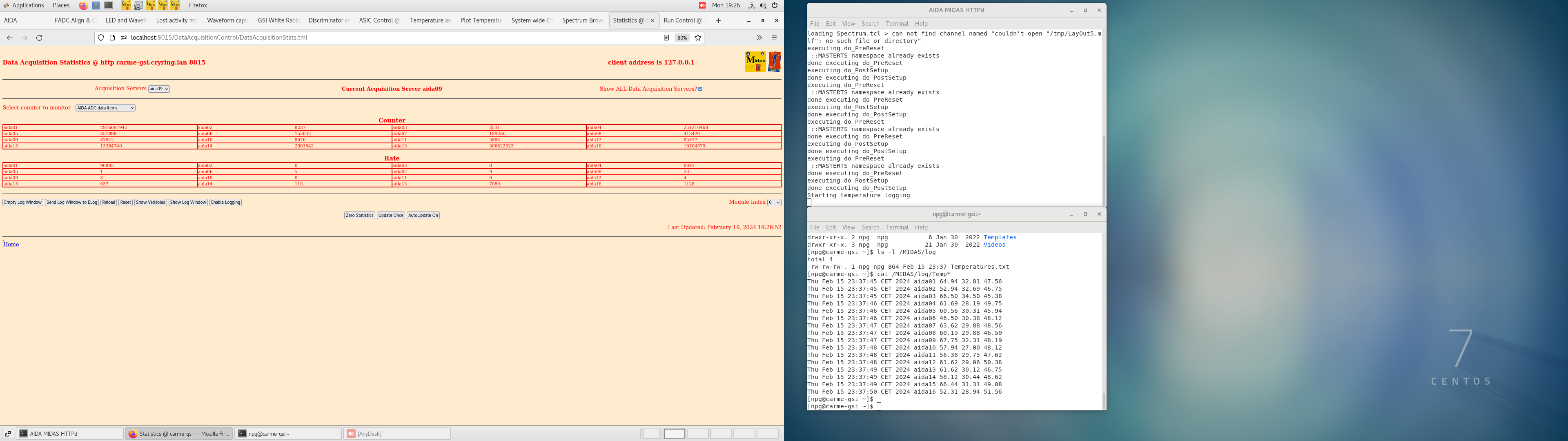

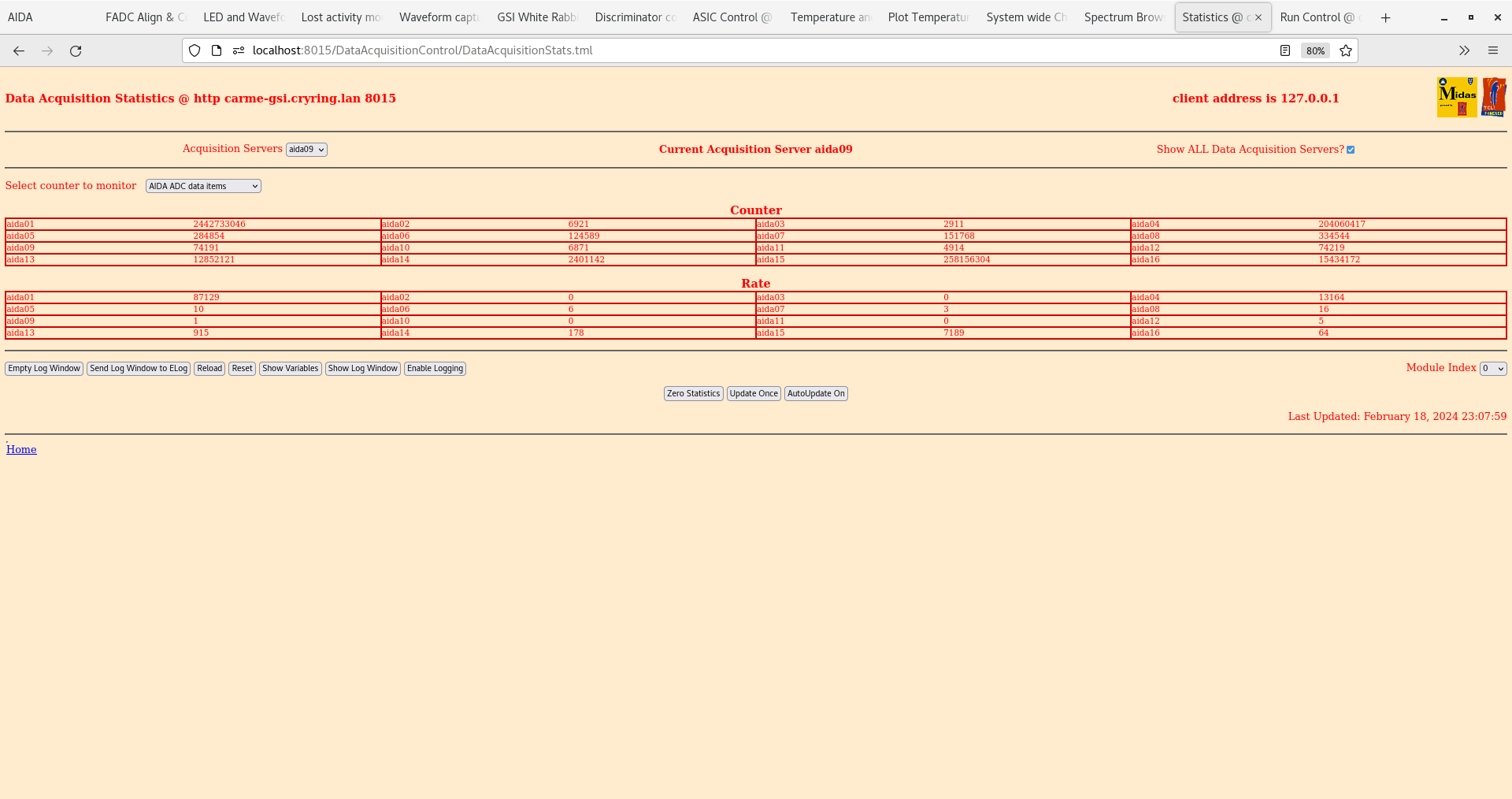

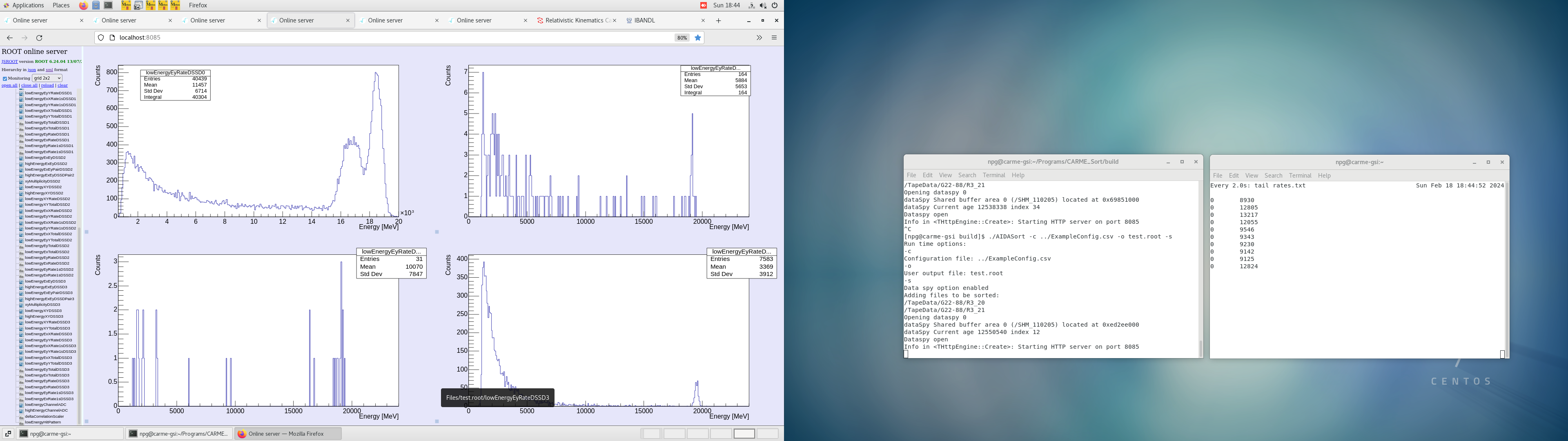

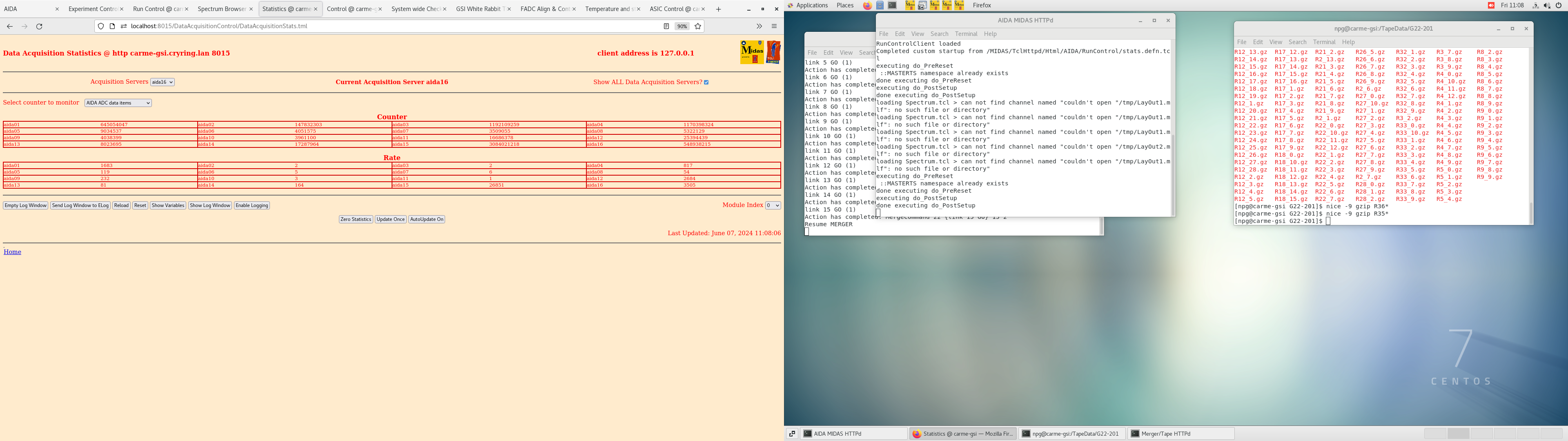

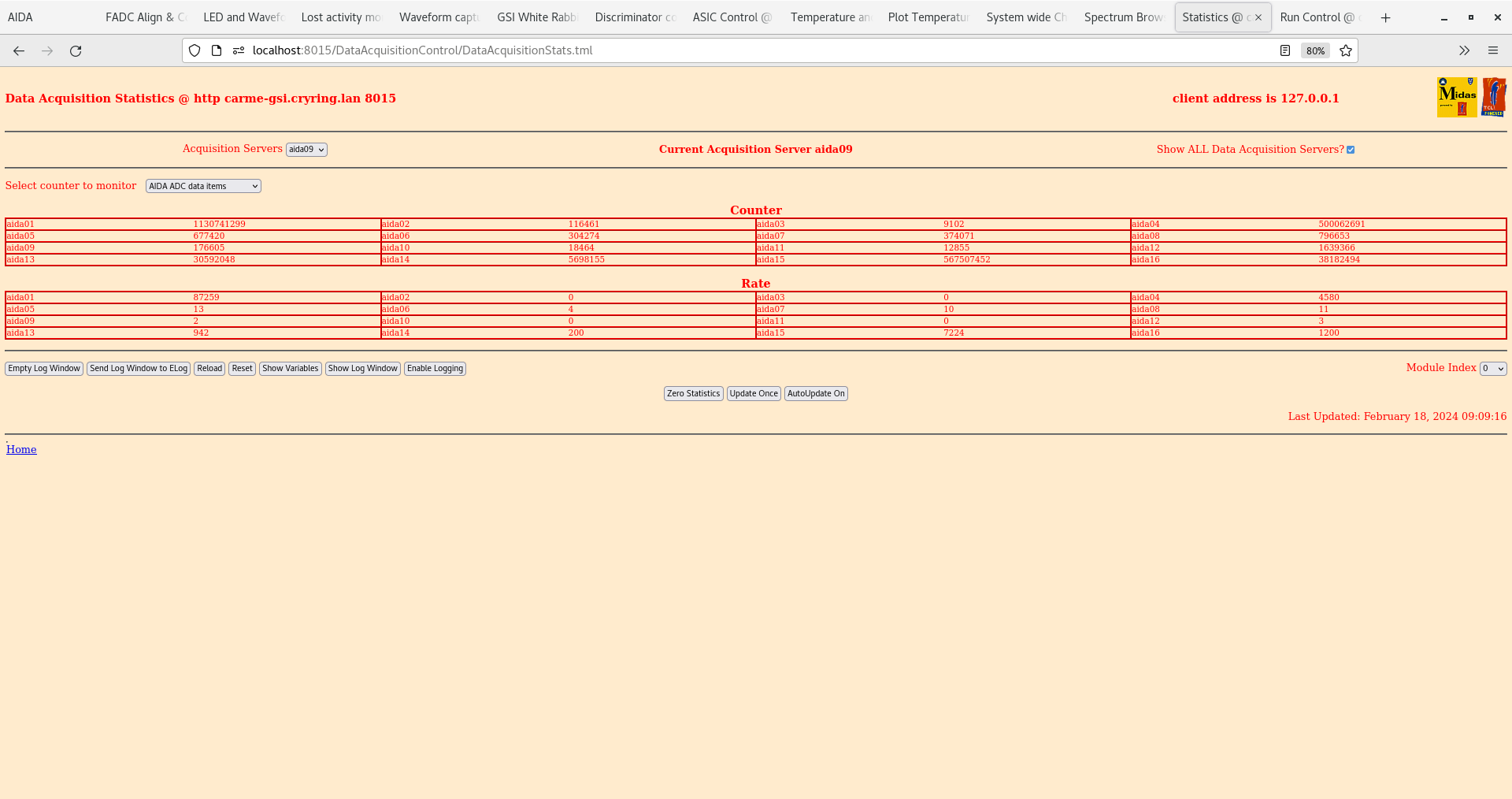

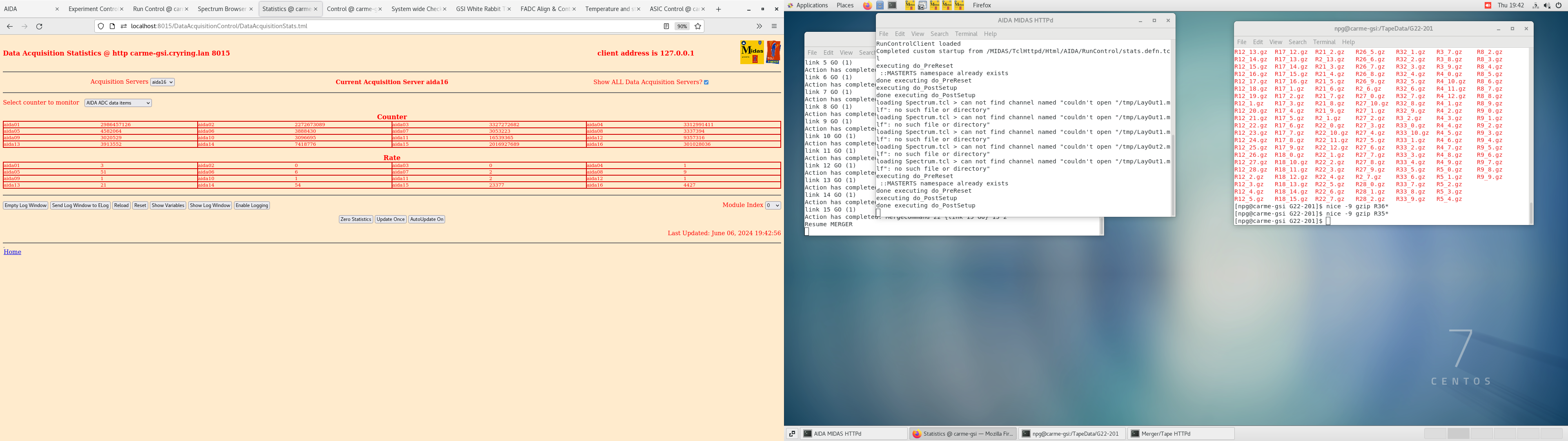

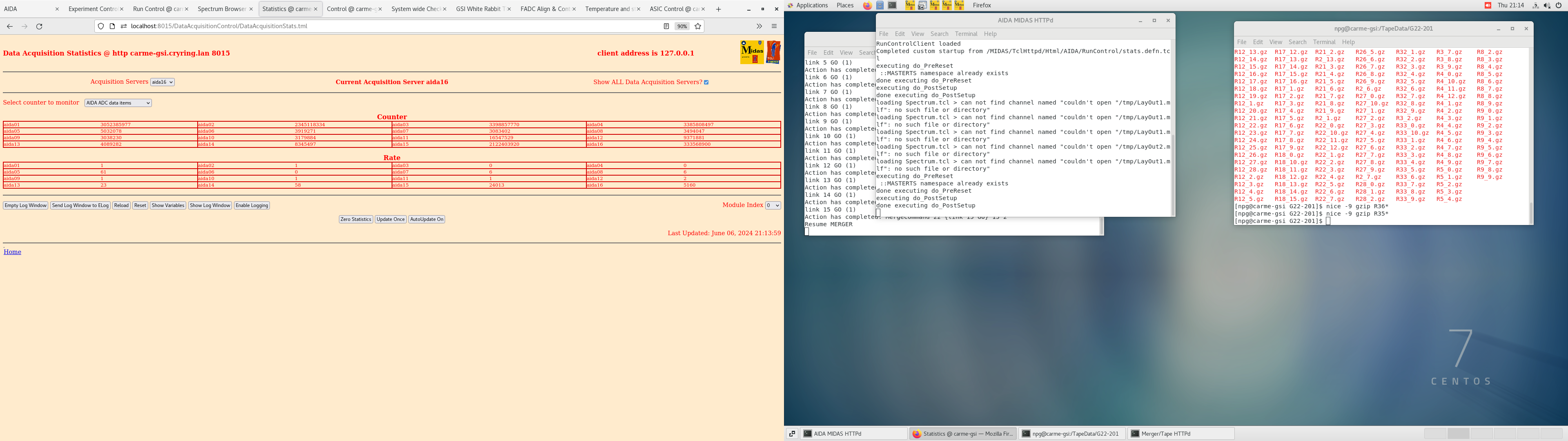

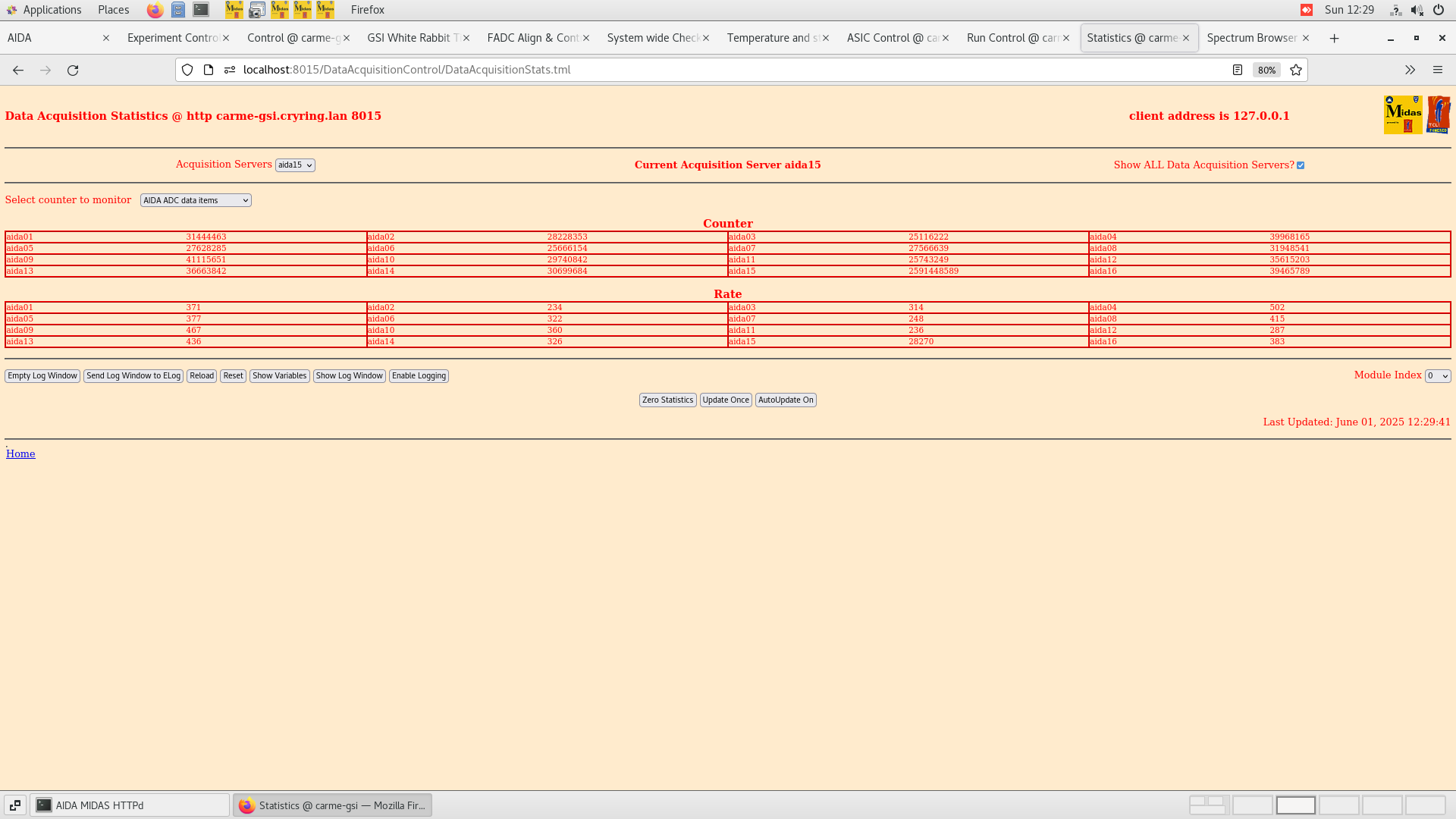

ADC data items stats attachment 2

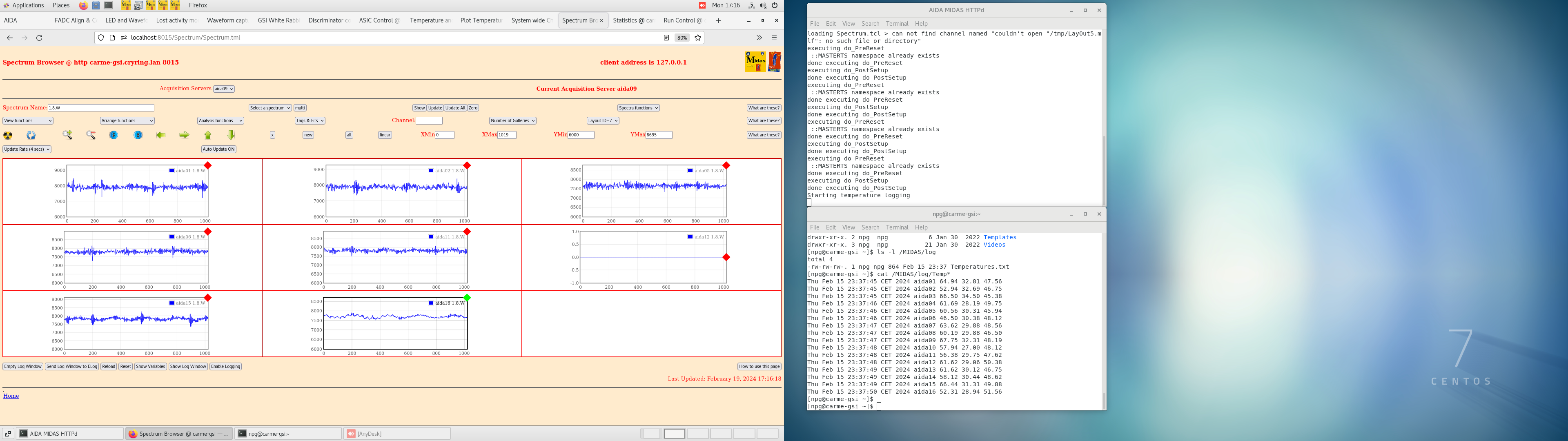

Monitoring code rates attachment 3

11:08

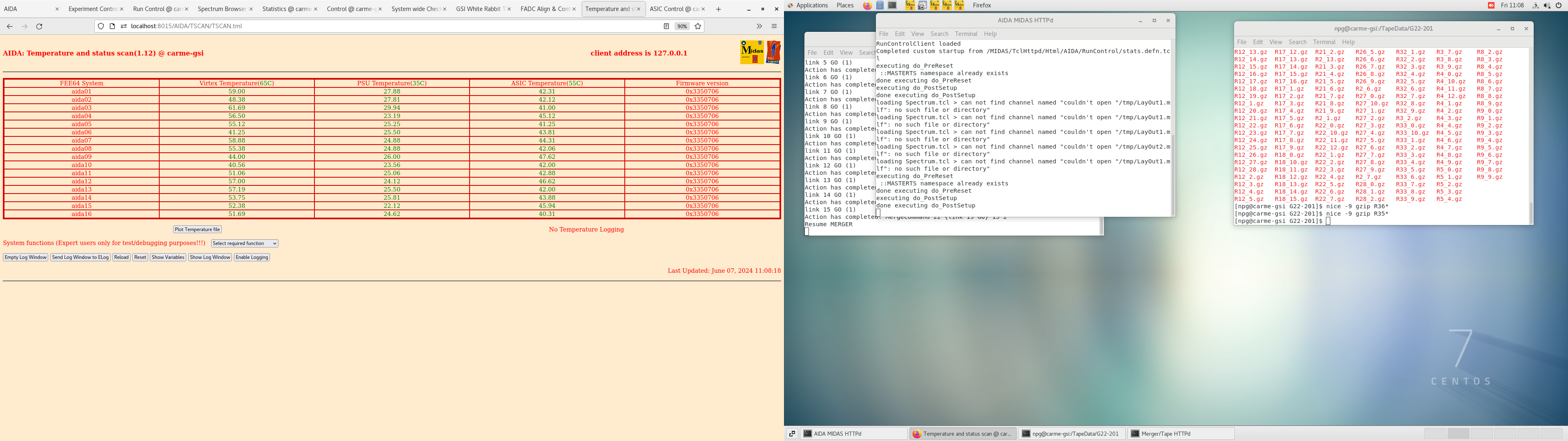

FEE temps OK

System checks OK

Merger OK, tape server OK

Leakage current OK

ADC data items stats OK

Online spectra OK

12:30

FEE temps OK

System checks OK

Merger OK, tape server OK

Leakage current OK

ADC data items stats OK

Online spectra OK

14:03

FEE temps OK

System checks OK

Merger OK, tape server OK

Leakage current OK

ADC data items stats OK

Online spectra OK

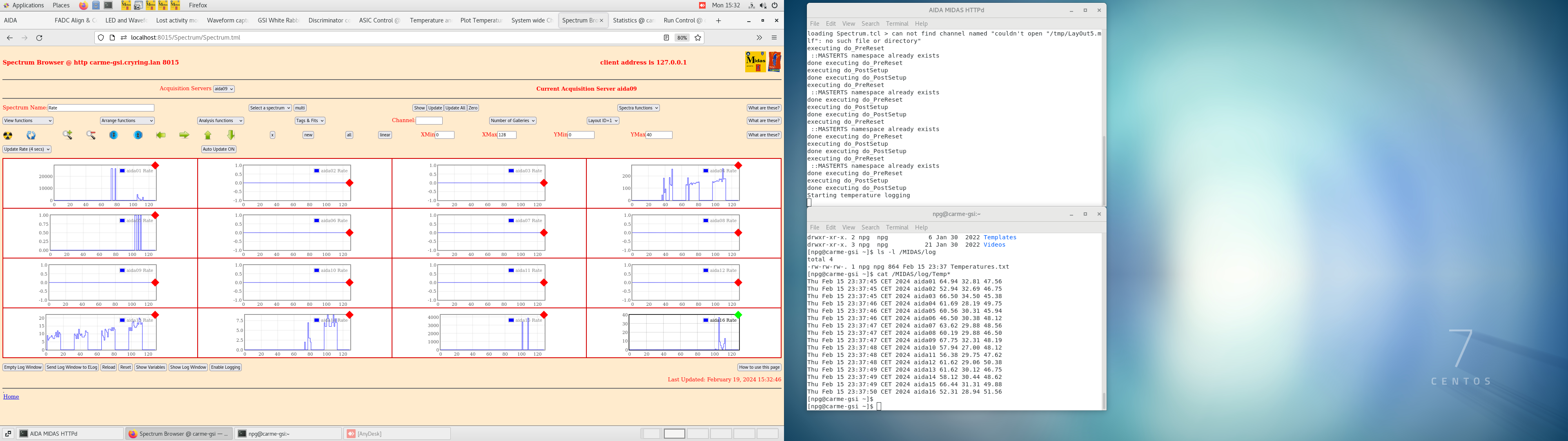

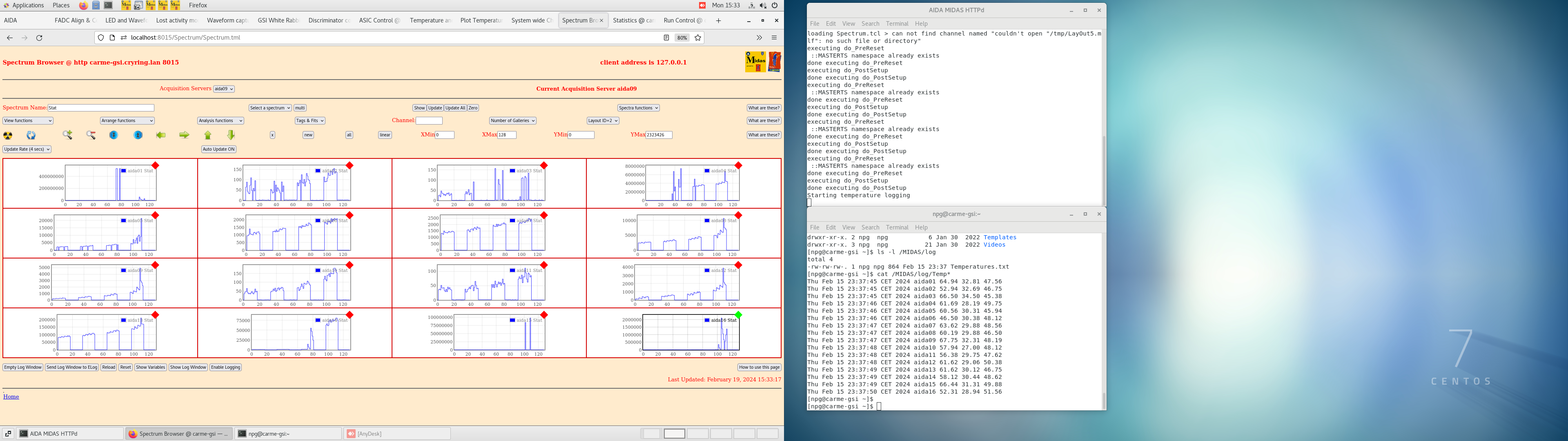

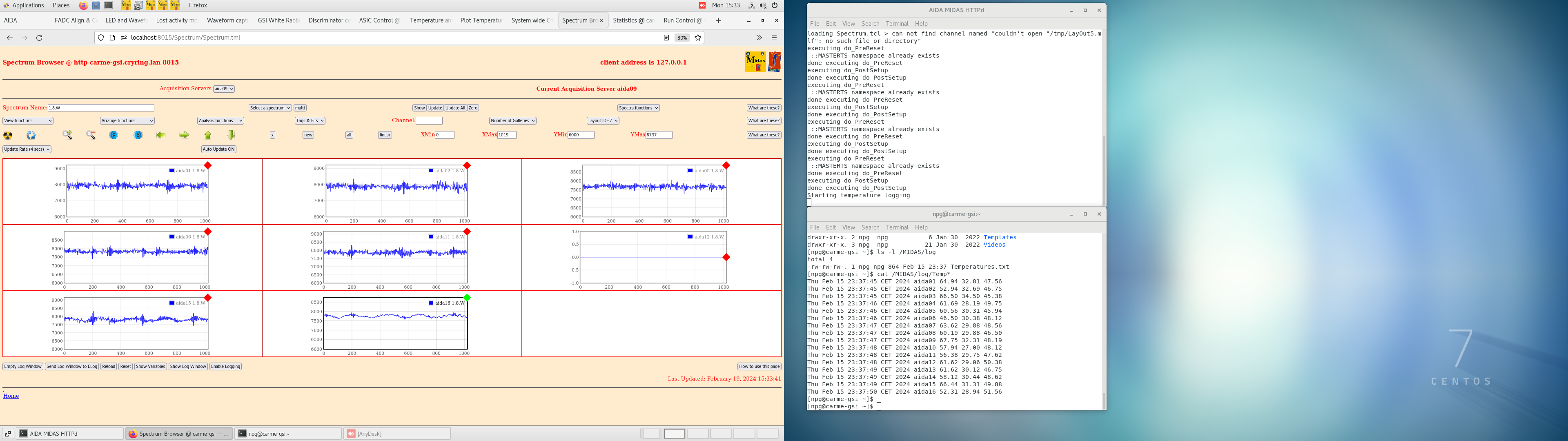

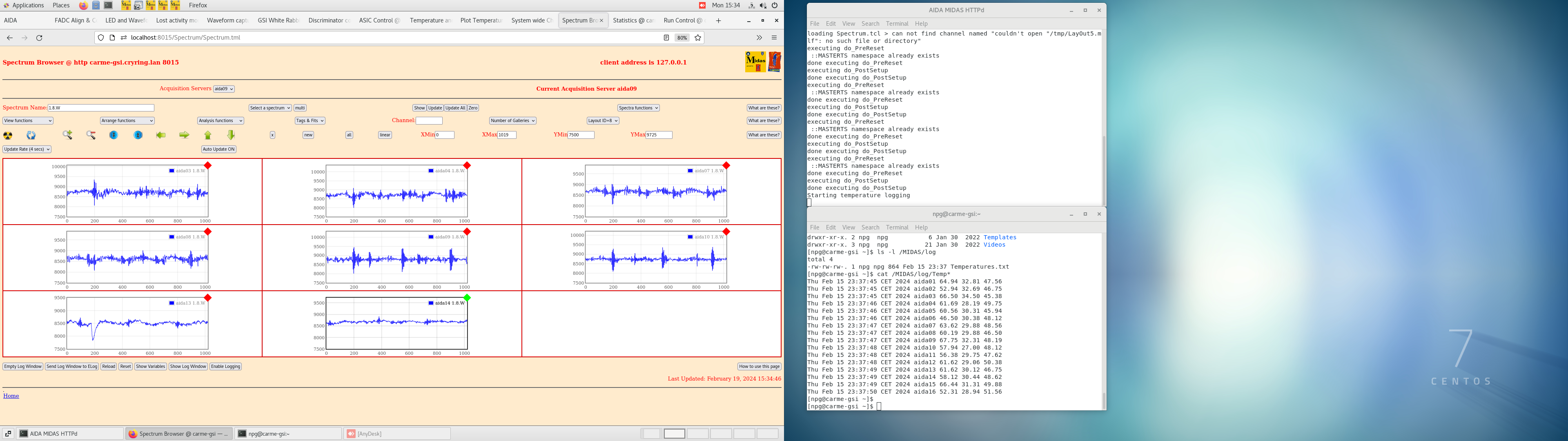

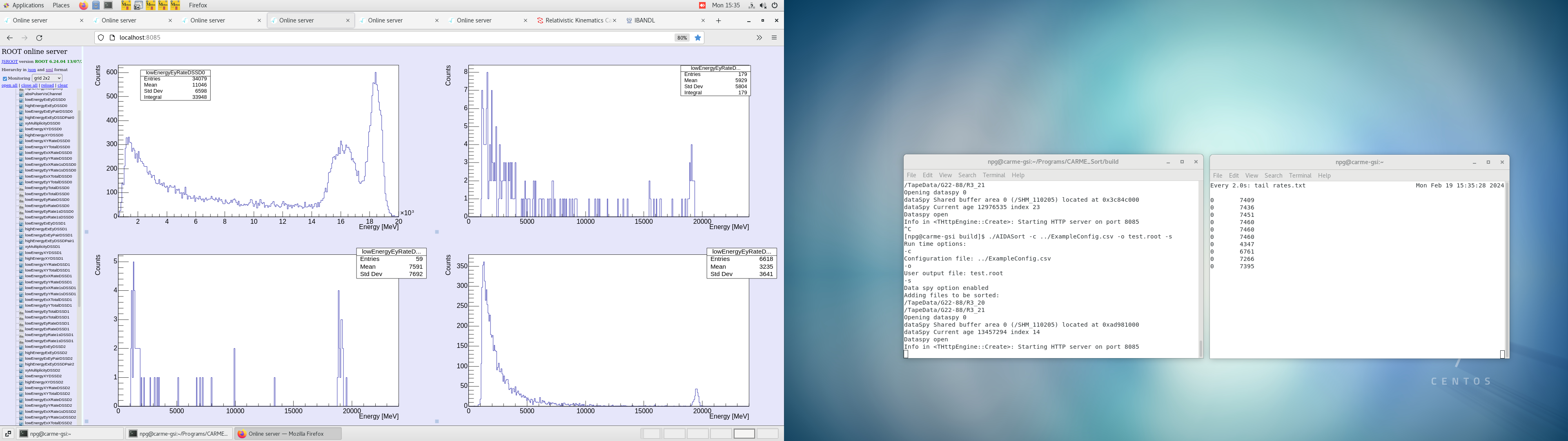

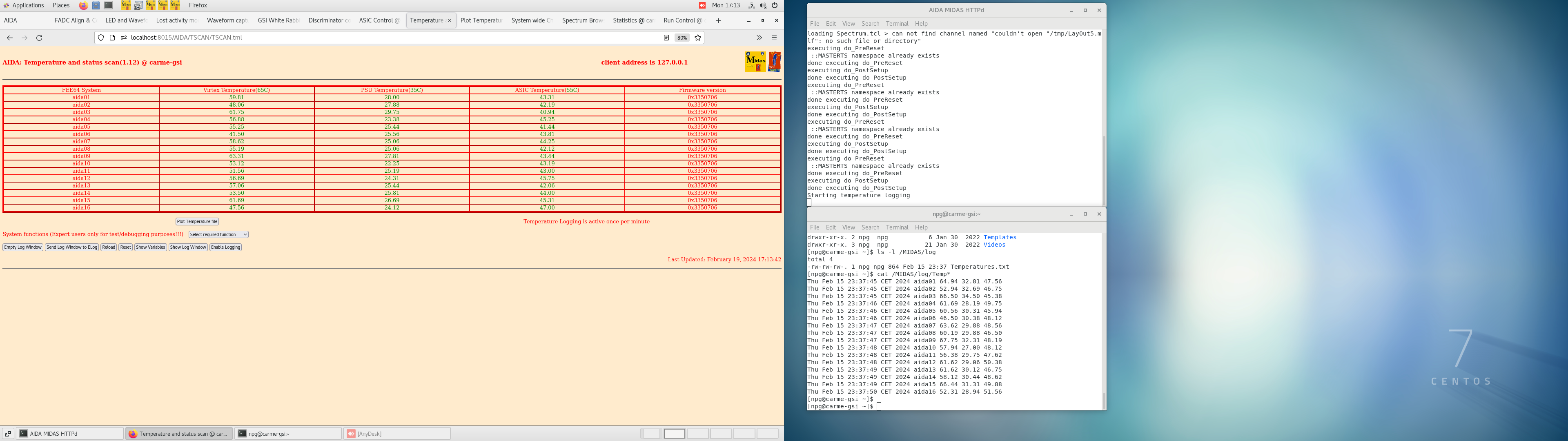

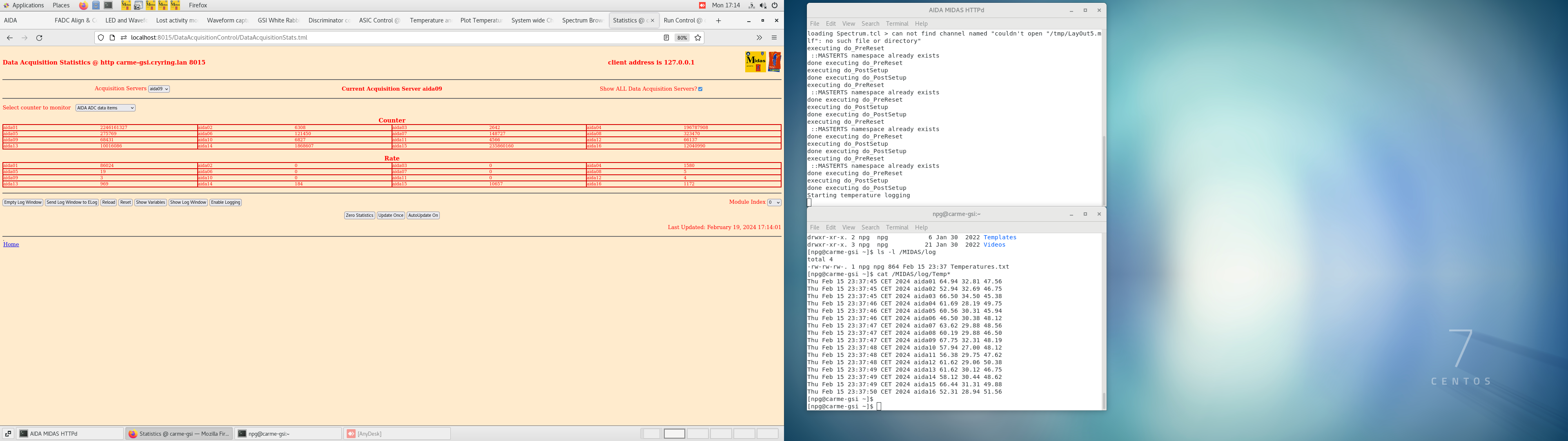

15:36

FEE temps OK, system checks OK, merger OK,

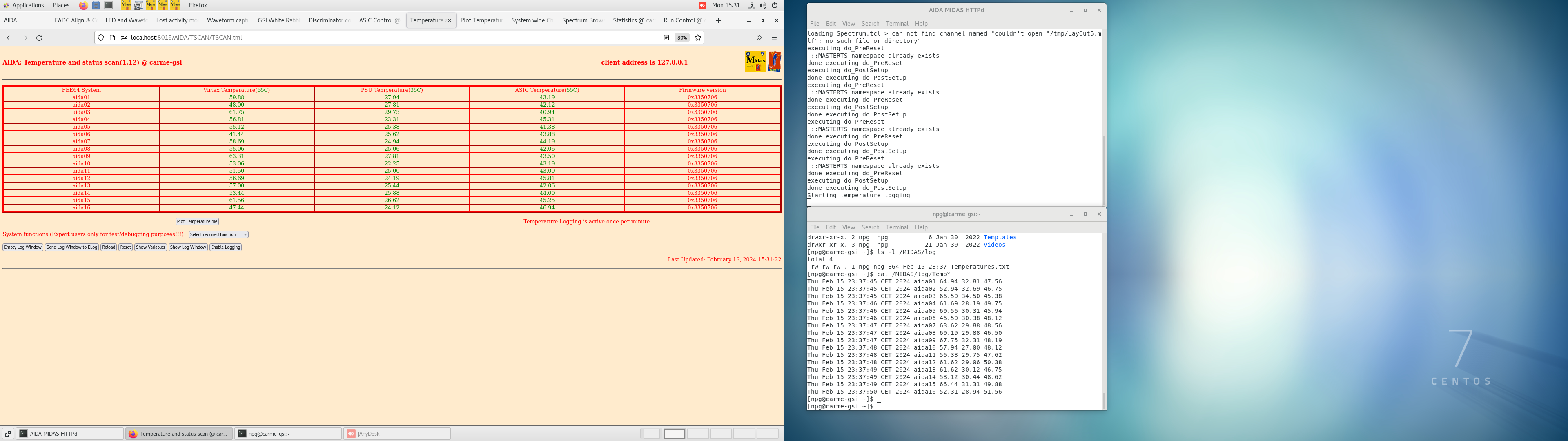

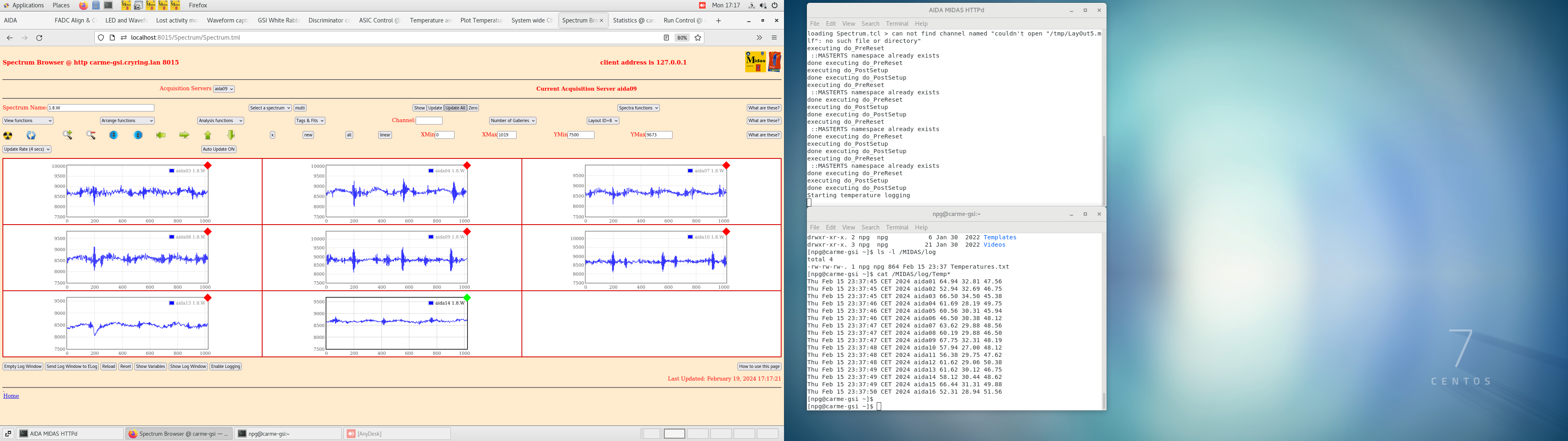

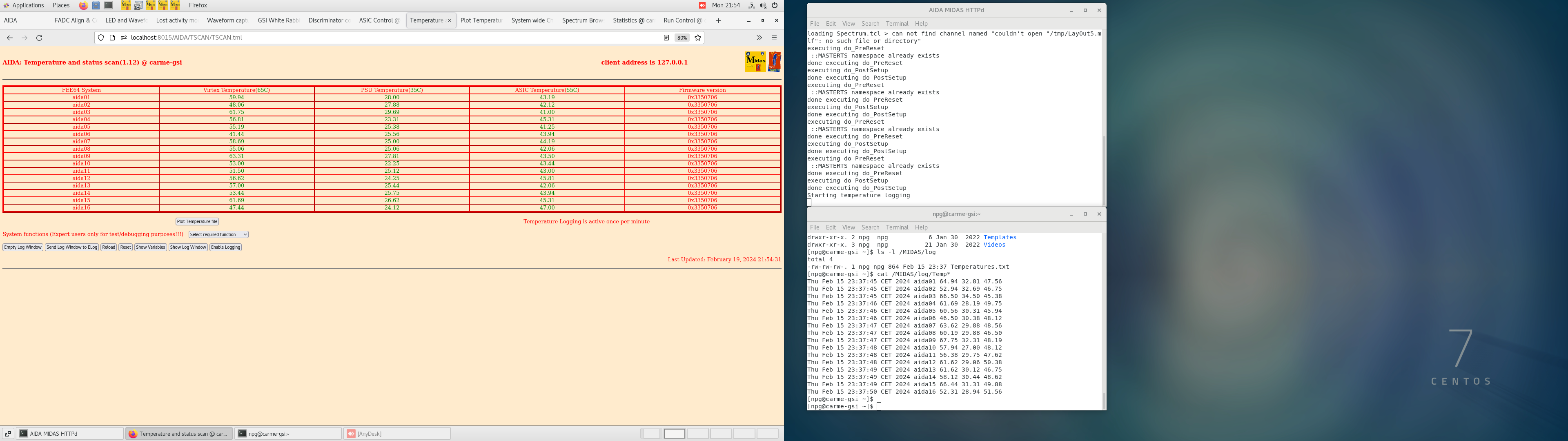

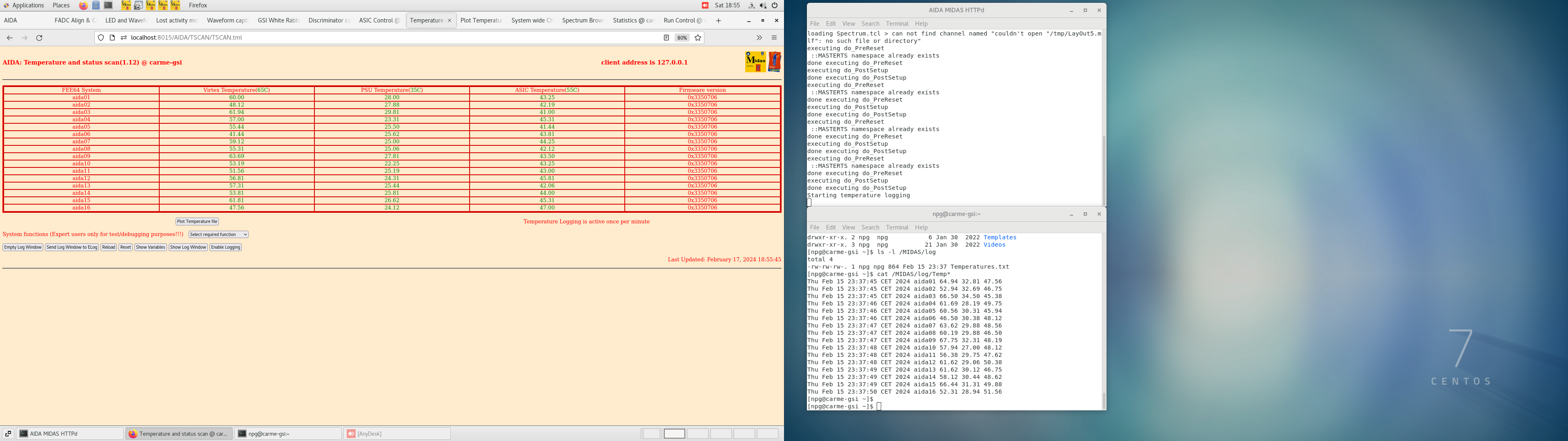

Screenshot 4: temperatures

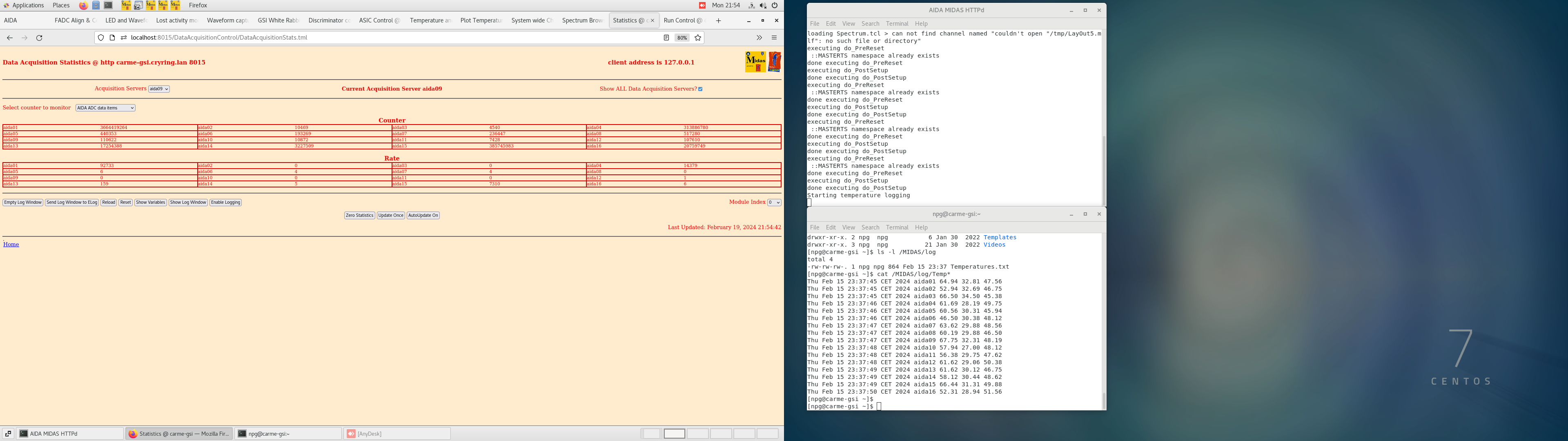

Screenshot 5: statistics

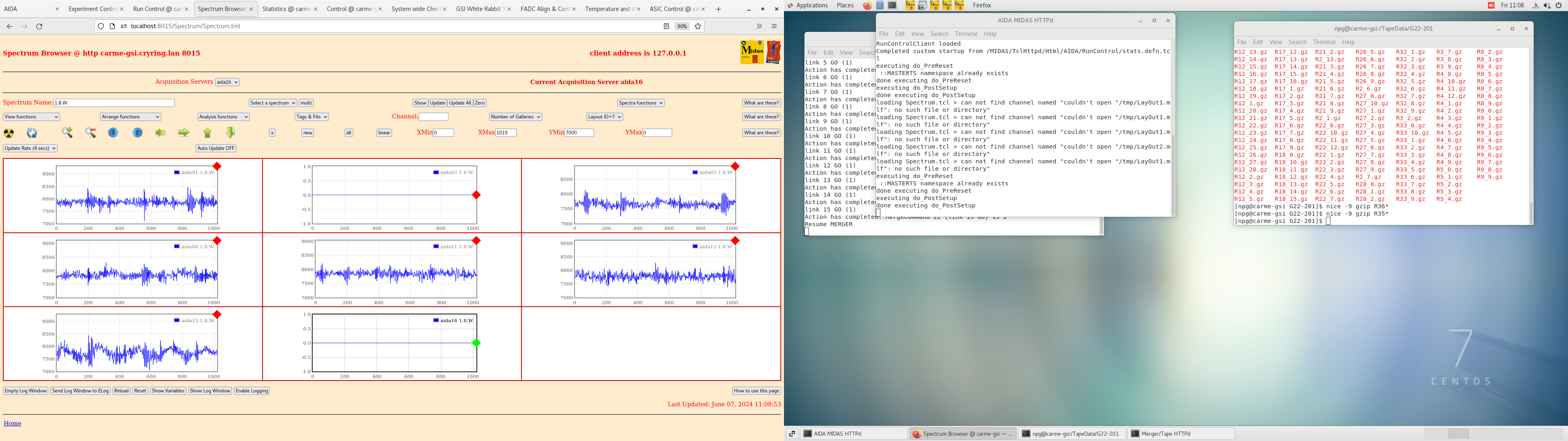

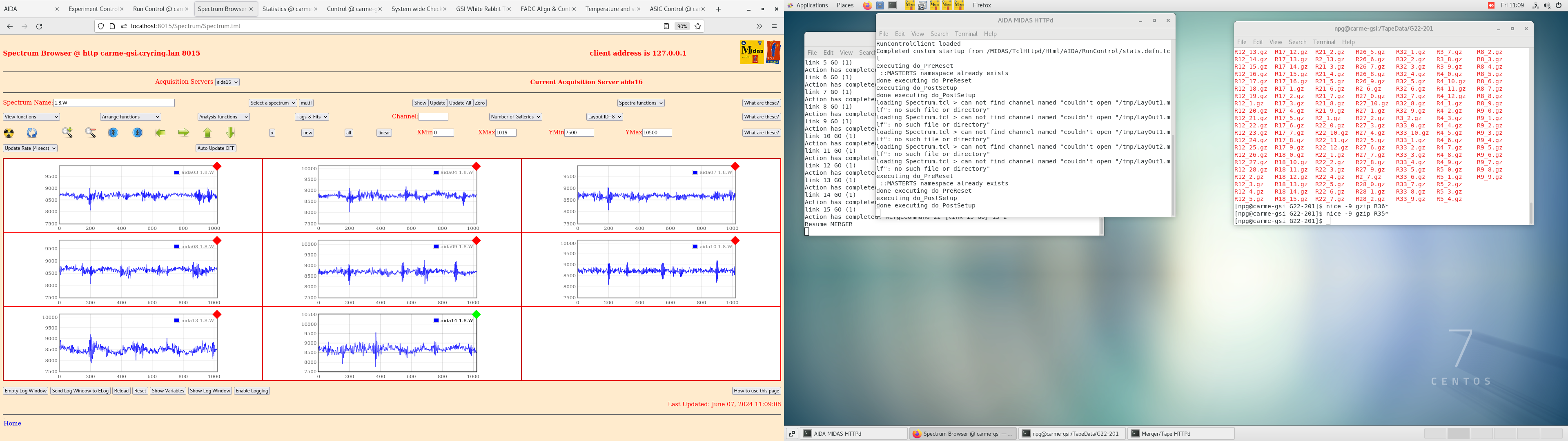

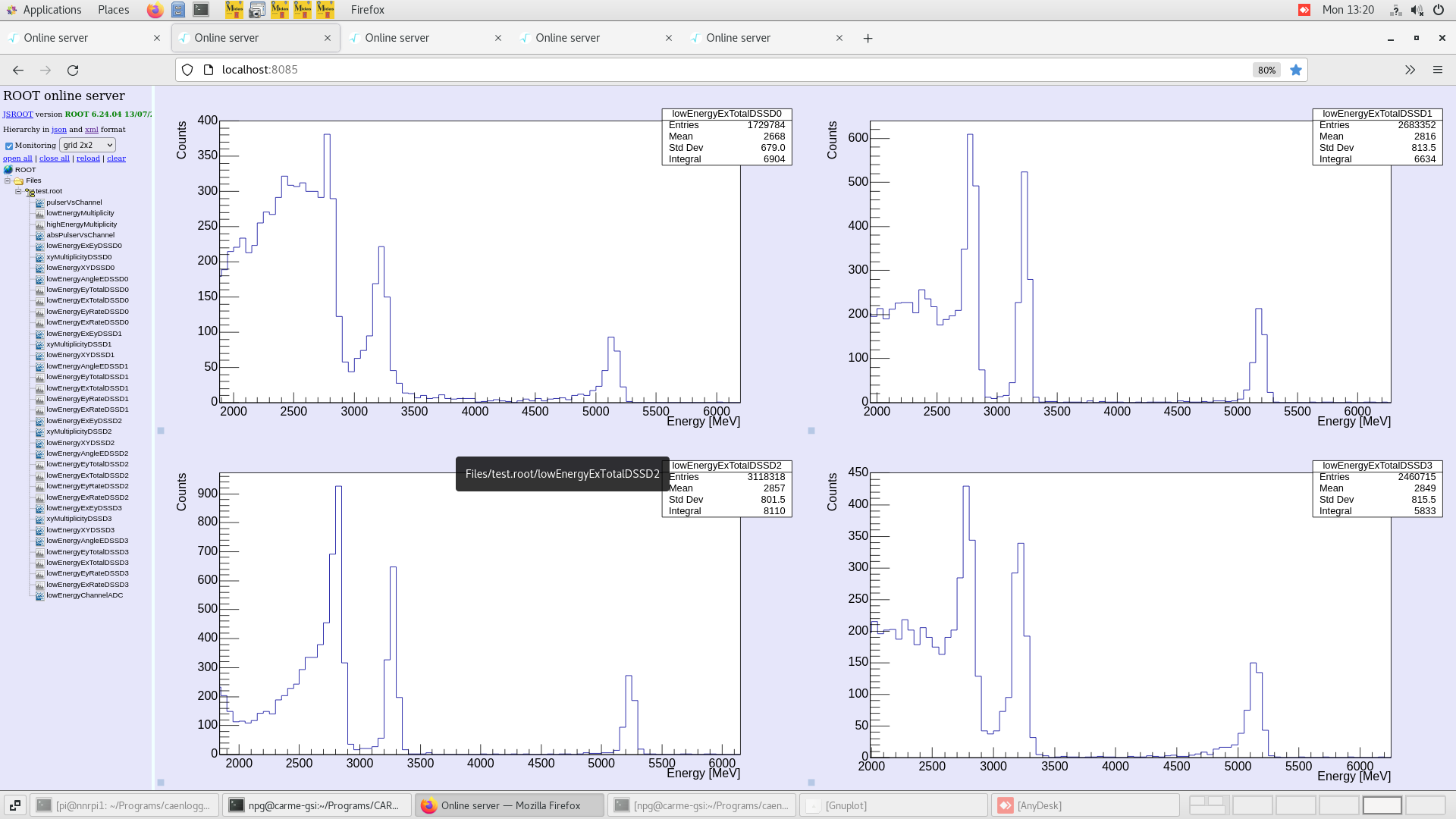

Screenhot 6 - 9: spectra (there is a persistent peak in aida13 in Layout8)

Screenshot 10: leakage current (current 1 seems to be going up slowly but steadily)

Screenshot 11: spectrum

17:18

FEE temps OK, system checks OK, merger OK,

Screenshot 12: temperatures

Screenshot 13: statistics

Screenhot 14 - 17: spectra (we still see a peak in aida13 in Layout8, but not always)

Screenshot 18: leakage current (current 1 seems to be going up slowly but steadily)

Screenshot 19: spectrum

19:27

FEE temps OK, system checks OK, merger OK,

Screenshot 20: temperatures

Screenshot 21: statistics

Screenhot 22 - 25: spectra (we still see a peak in aida13 in Layout8, but not always)

Screenshot 26: leakage current (current 1 seems to be going up slowly but steadily)

Screenshot 27: spectrum

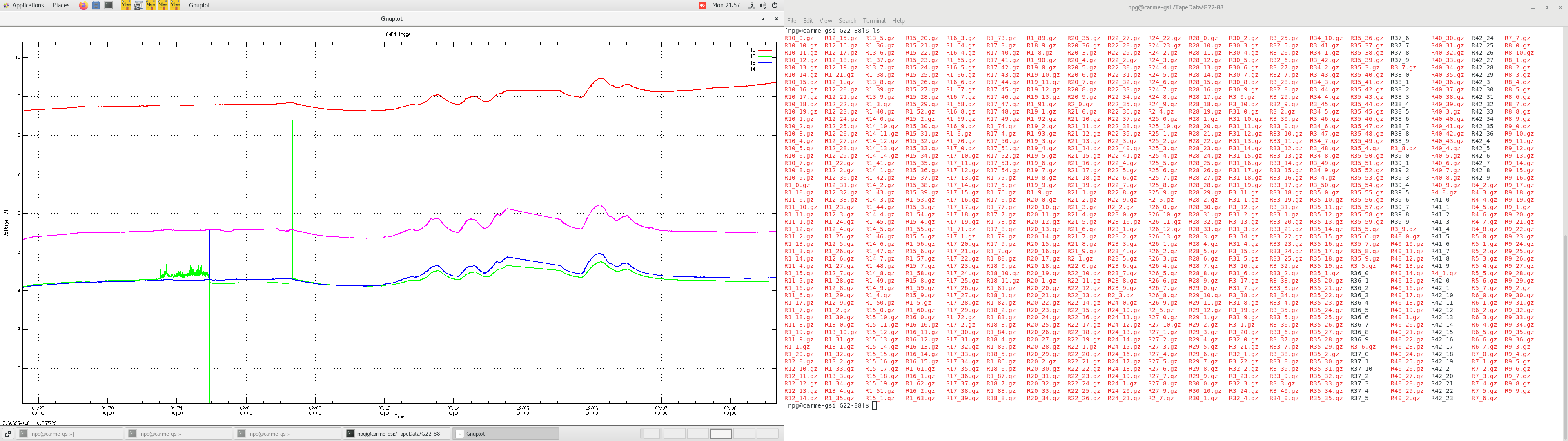

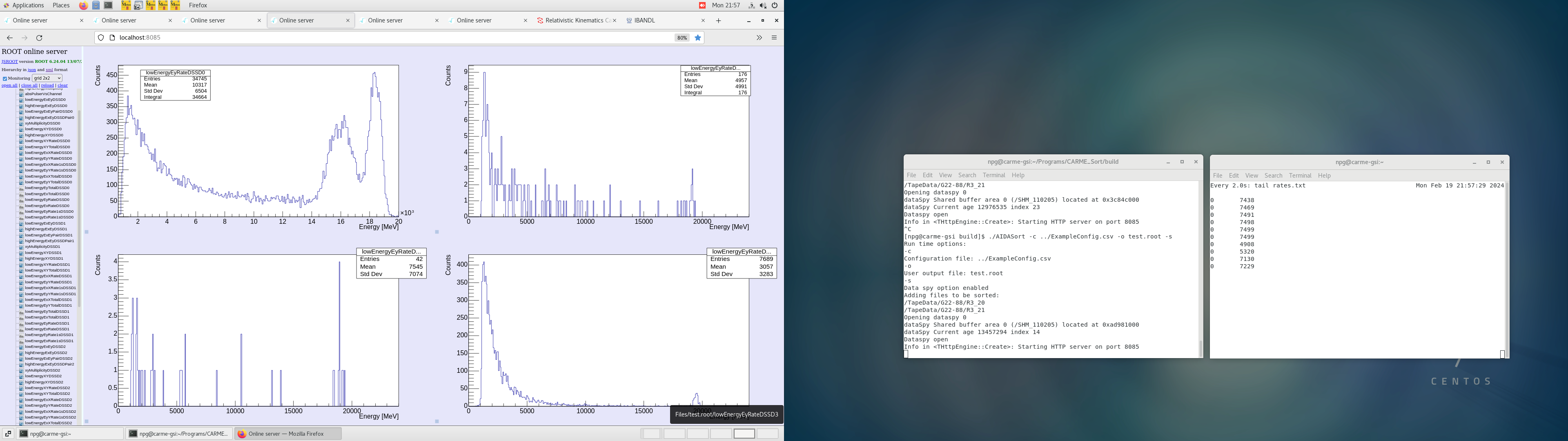

21:57

FEE temps OK, system checks OK, merger OK,

Screenshot 28: temperatures

Screenshot 29: statistics

Screenhot 30 - 33: spectra (we still see a peak in aida13 in Layout8, but not always)

Screenshot 34: leakage current

Screenshot 35: spectrum

|

| Attachment 1: Screenshot_from_2024-02-19_10-07-26.png

|

|

| Attachment 2: Screenshot_from_2024-02-19_10-10-24.png

|

|

| Attachment 3: Screenshot_from_2024-02-19_10-10-50.png

|

|

| Attachment 4: Screenshot_from_2024-02-19_15-31-30.png

|

|

| Attachment 5: Screenshot_from_2024-02-19_15-31-47.png

|

|

| Attachment 6: Screenshot_from_2024-02-19_15-32-57.png

|

|

| Attachment 7: Screenshot_from_2024-02-19_15-33-22.png

|

|

| Attachment 8: Screenshot_from_2024-02-19_15-33-46.png

|

|

| Attachment 9: Screenshot_from_2024-02-19_15-34-51.png

|

|

| Attachment 10: Screenshot_from_2024-02-19_15-35-23.png

|

|

| Attachment 11: Screenshot_from_2024-02-19_15-35-29.png

|

|

| Attachment 12: Screenshot_from_2024-02-19_17-13-45.png

|

|

| Attachment 13: Screenshot_from_2024-02-19_17-14-05.png

|

|

| Attachment 14: Screenshot_from_2024-02-19_17-15-12.png

|

|

| Attachment 15: Screenshot_from_2024-02-19_17-15-52.png

|

|

| Attachment 16: Screenshot_from_2024-02-19_17-16-24.png

|

|

| Attachment 17: Screenshot_from_2024-02-19_17-17-25.png

|

|

| Attachment 18: Screenshot_from_2024-02-19_17-17-44.png

|

|

| Attachment 19: Screenshot_from_2024-02-19_17-17-51.png

|

|

| Attachment 20: Screenshot_from_2024-02-19_19-24-13.png

|

|

| Attachment 21: Screenshot_from_2024-02-19_19-26-55.png

|

|

| Attachment 22: Screenshot_from_2024-02-19_19-24-59.png

|

|

| Attachment 23: Screenshot_from_2024-02-19_19-25-21.png

|

|

| Attachment 24: Screenshot_from_2024-02-19_19-25-51.png

|

|

| Attachment 25: Screenshot_from_2024-02-19_19-26-41.png

|

|

| Attachment 26: Screenshot_from_2024-02-19_19-27-22.png

|

|

| Attachment 27: Screenshot_from_2024-02-19_19-27-29.png

|

|

| Attachment 28: Screenshot_from_2024-02-19_21-54-34.png

|

|

| Attachment 29: Screenshot_from_2024-02-19_21-54-46.png

|

|

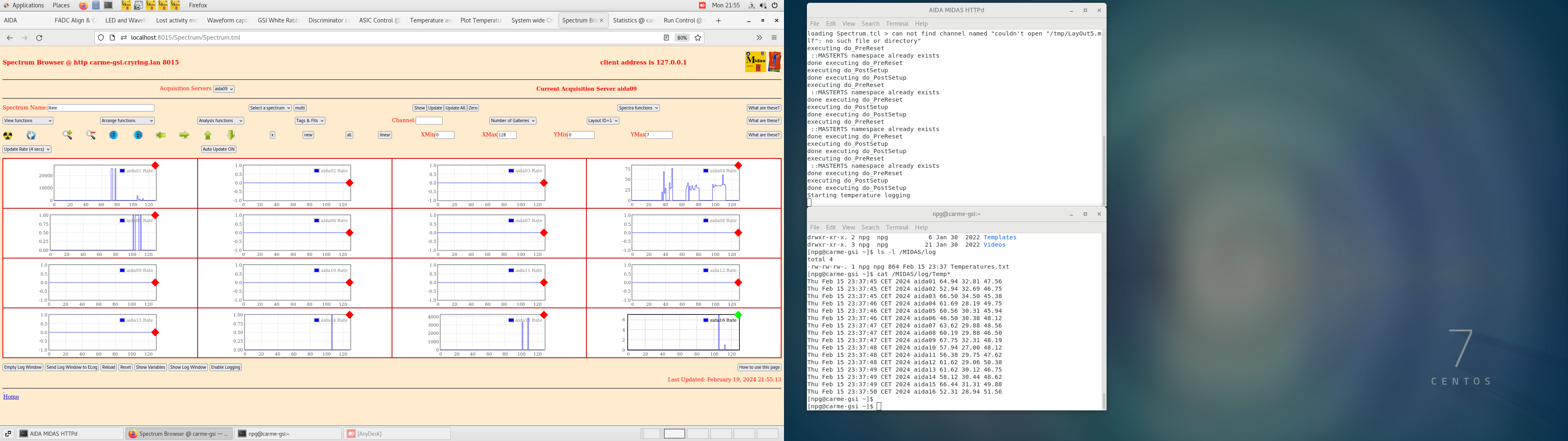

| Attachment 30: Screenshot_from_2024-02-19_21-55-17.png

|

|

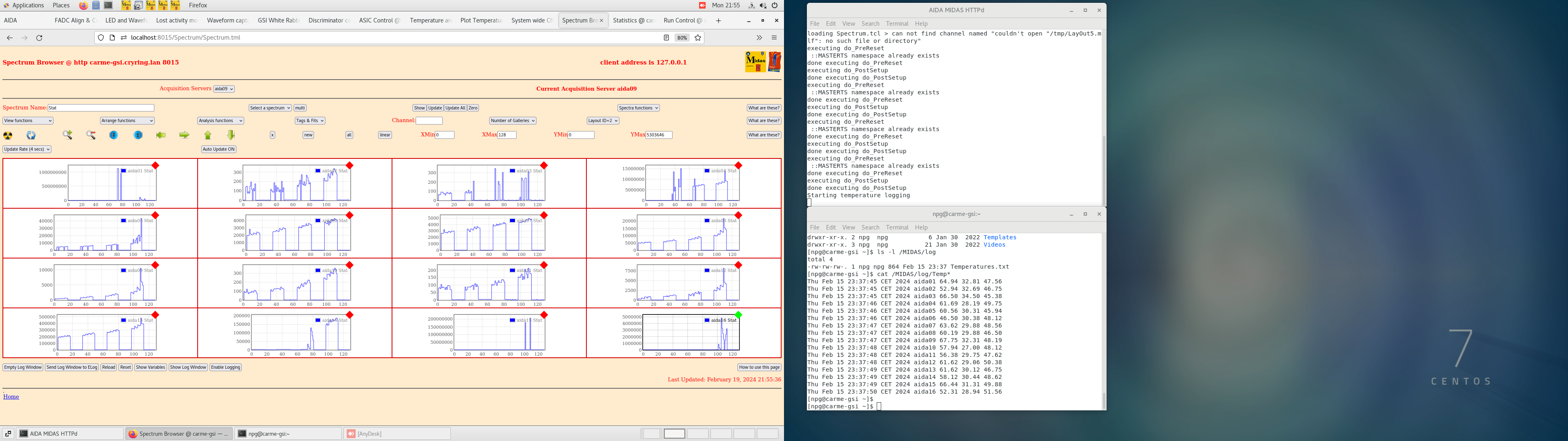

| Attachment 31: Screenshot_from_2024-02-19_21-55-41.png

|

|

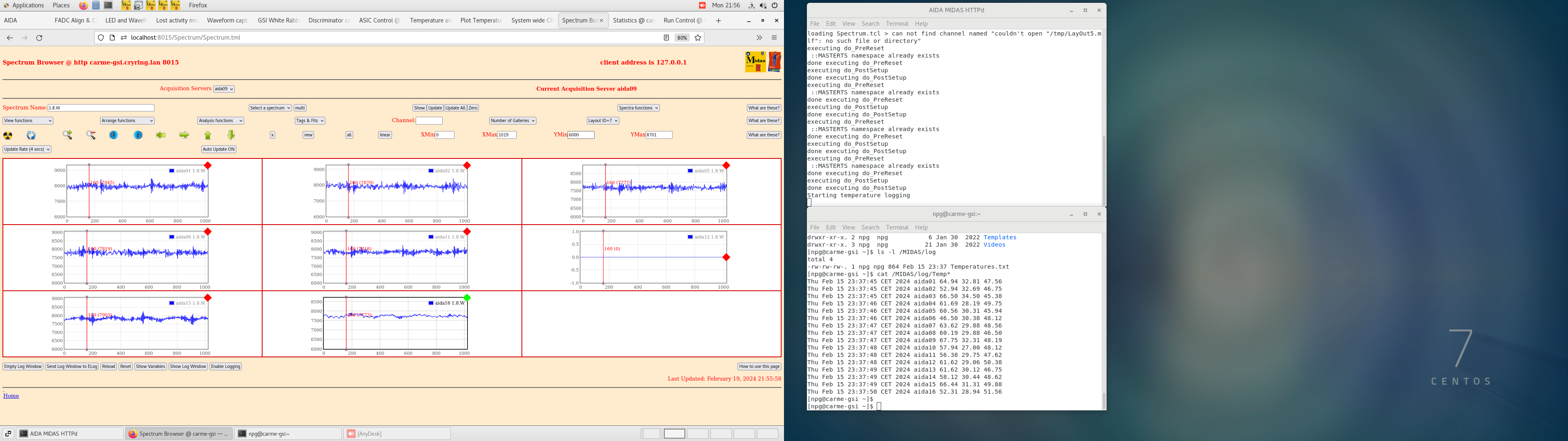

| Attachment 32: Screenshot_from_2024-02-19_21-56-02.png

|

|

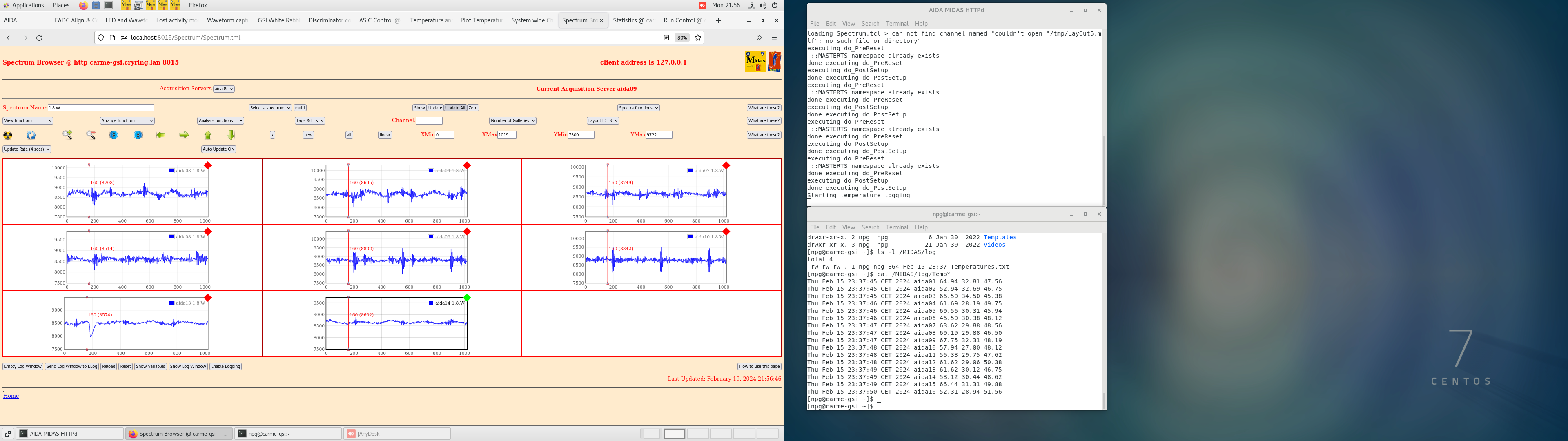

| Attachment 33: Screenshot_from_2024-02-19_21-56-50.png

|

|

| Attachment 34: Screenshot_from_2024-02-19_21-57-23.png

|

|

| Attachment 35: Screenshot_from_2024-02-19_21-57-30.png

|

|

|

596

|

Fri Jun 7 14:09:04 2024 |

JM, CB, DR, CN, LB | Run 44 - 15N Data Taking |

15:35

Electron cooler voltage set point = 244.3 V

Electron cooler voltage readout = 243.75 V

Collector current = 4.29 mA

All system checks OK

Cycle time = 6 s

Detector positions: left = 36.54 mm, right = 64.60 mm

Target density = 2.5e11

Injection = 3 - 4 e7 pps

15:50

Injection intensity dropped to 1e7 pps

15:54

Injection intensity back to ~4e7 pps

17:30

All system checks OK

Target at 3.7e11

Beam dropped to 1e7 pps

17:34

Beam back to 3-4 e7 pps

19:10

Beam started varying between 1e7 and 4e7. The operators briefly closed the Faraday cup (~30 seconds), the beam is now back to ~5e7

19:25

All system checks OK

Target at 2.6e11

Beam at 5e7

21:25

All system checks OK

Target at 2.7e11

Beam at 4-5 e7

|

|

713

|

Mon Jun 2 17:25:31 2025 |

JG, AG | Run 43 scraper tests |

Same settings are Run 42 but bunched beam and scrapers set to: 30 / - 30 mm.

|

|

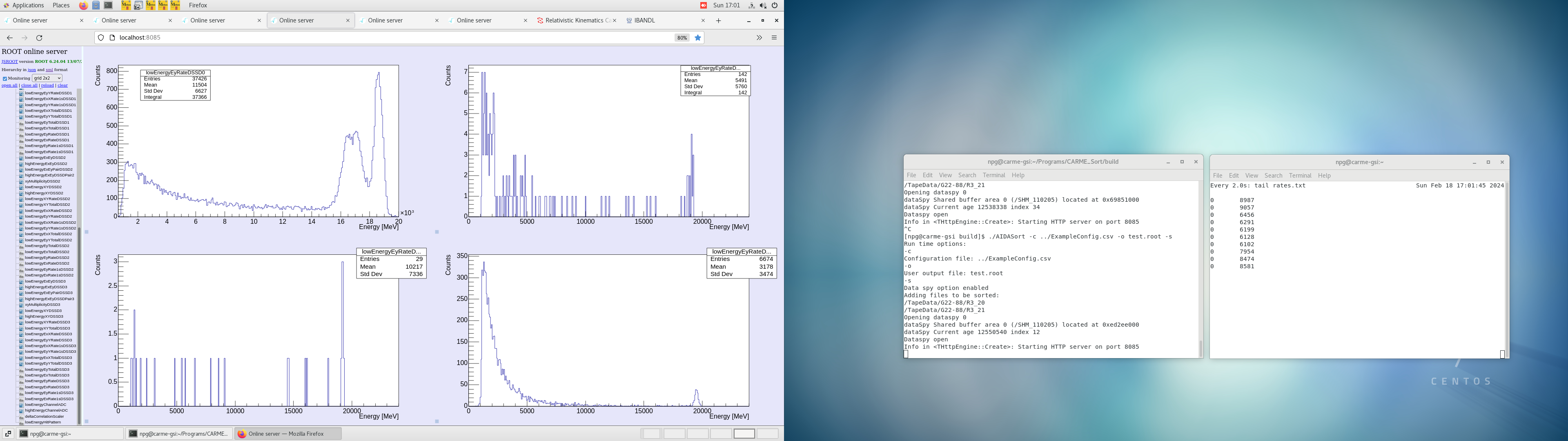

202

|

Wed Feb 16 21:41:11 2022 |

JM | Run 43 Alpha Background |

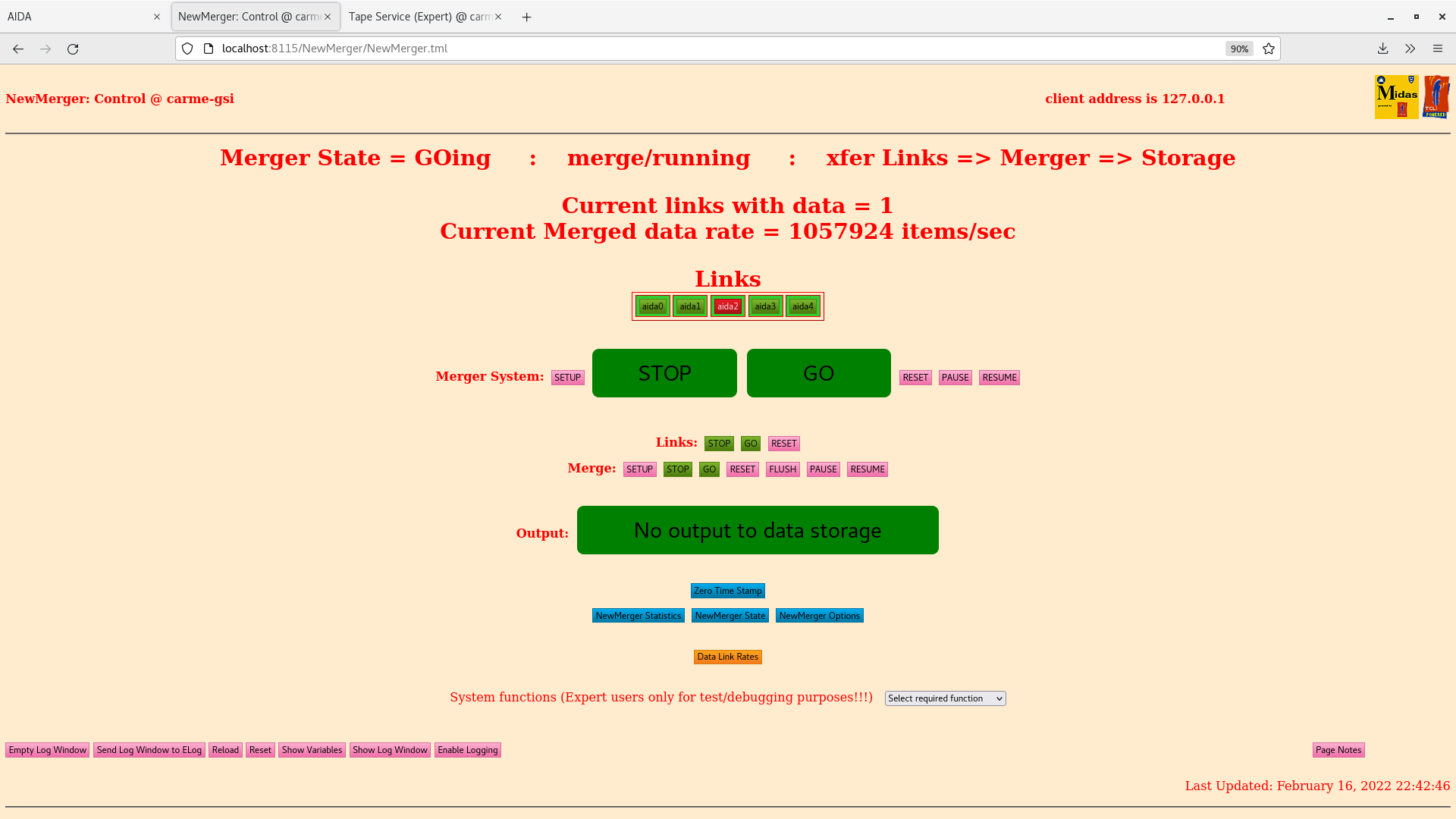

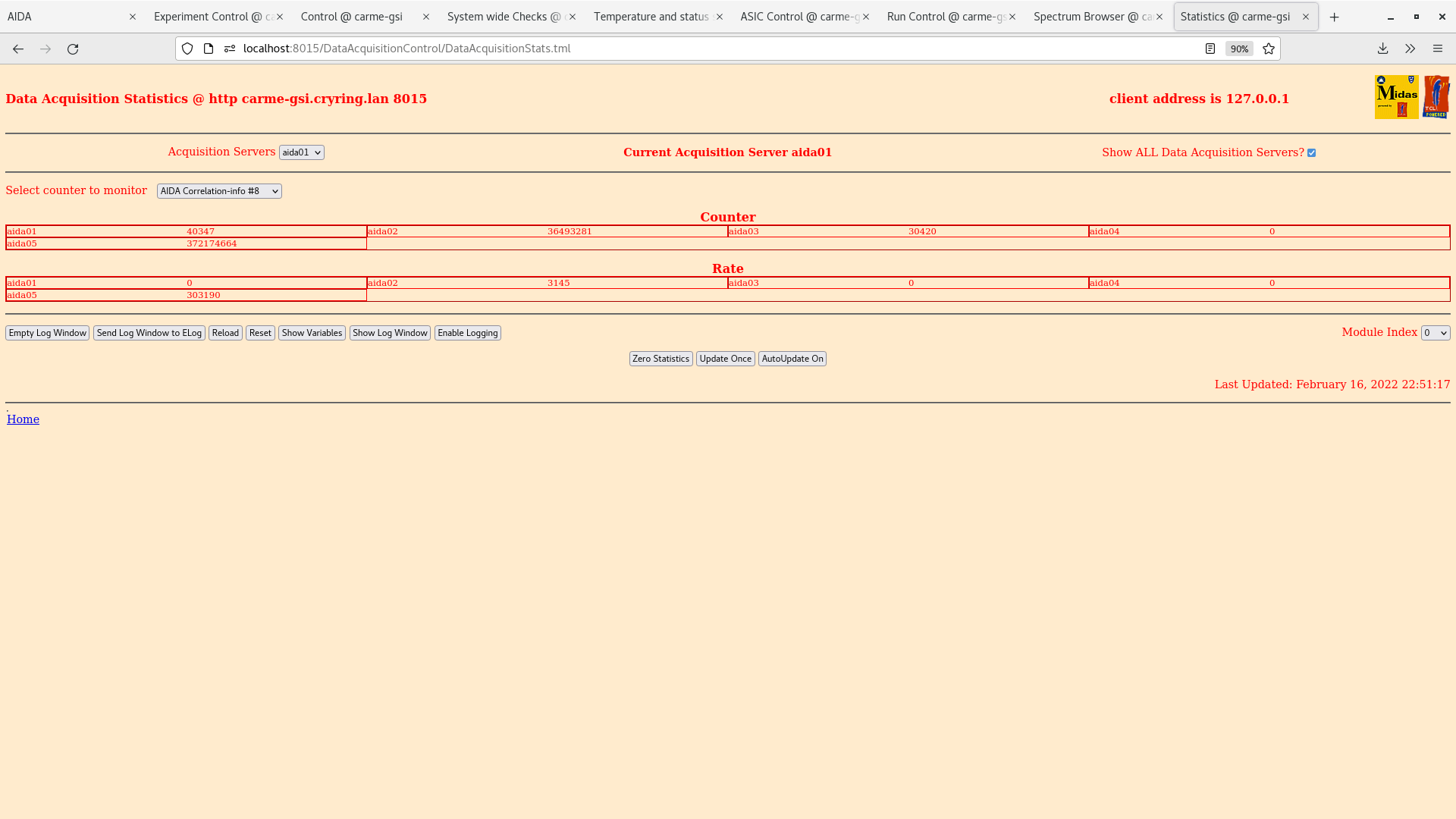

22:41

Check Leakage current: (see attachment 1) = 10.01 uA and falling

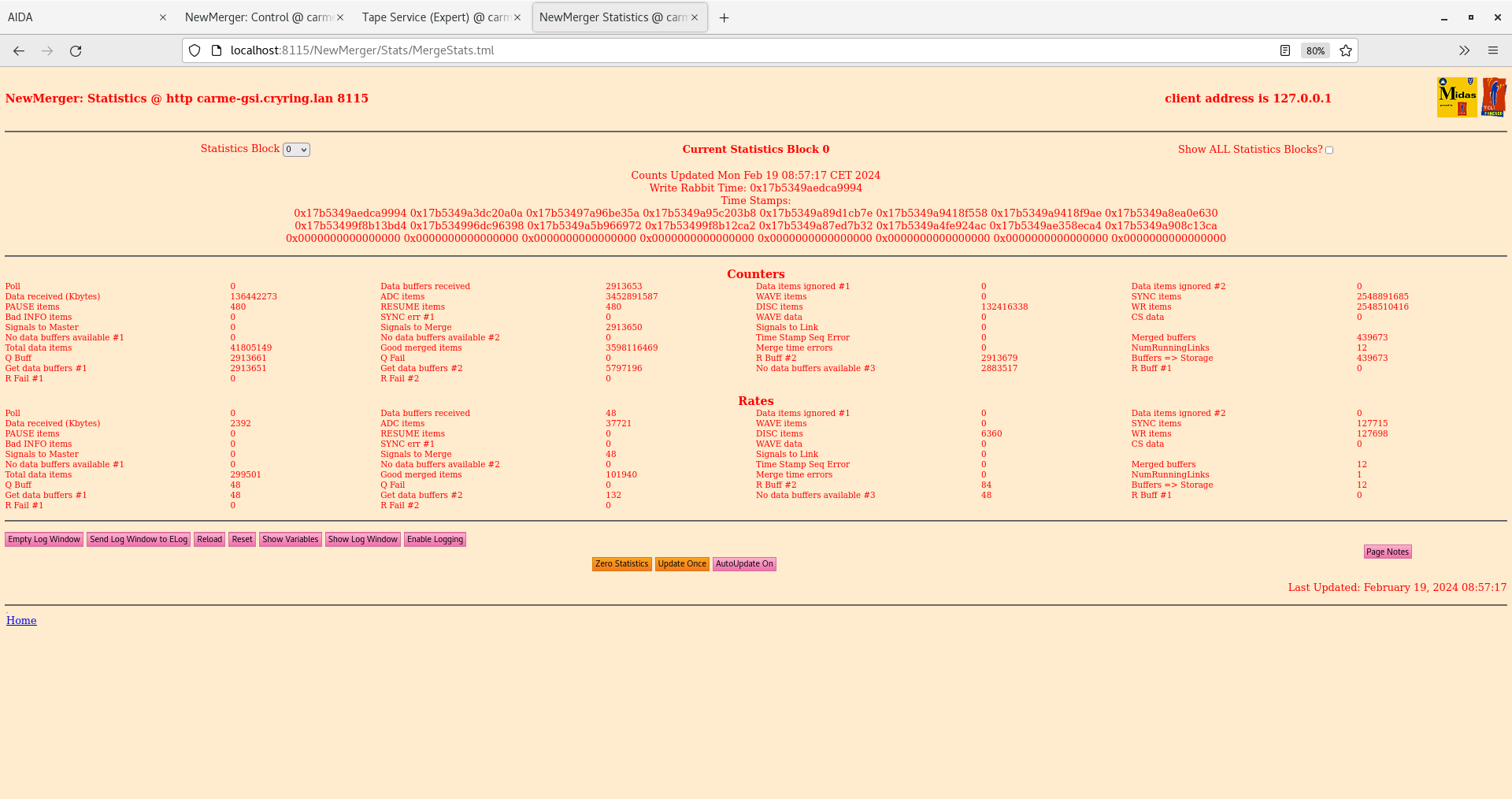

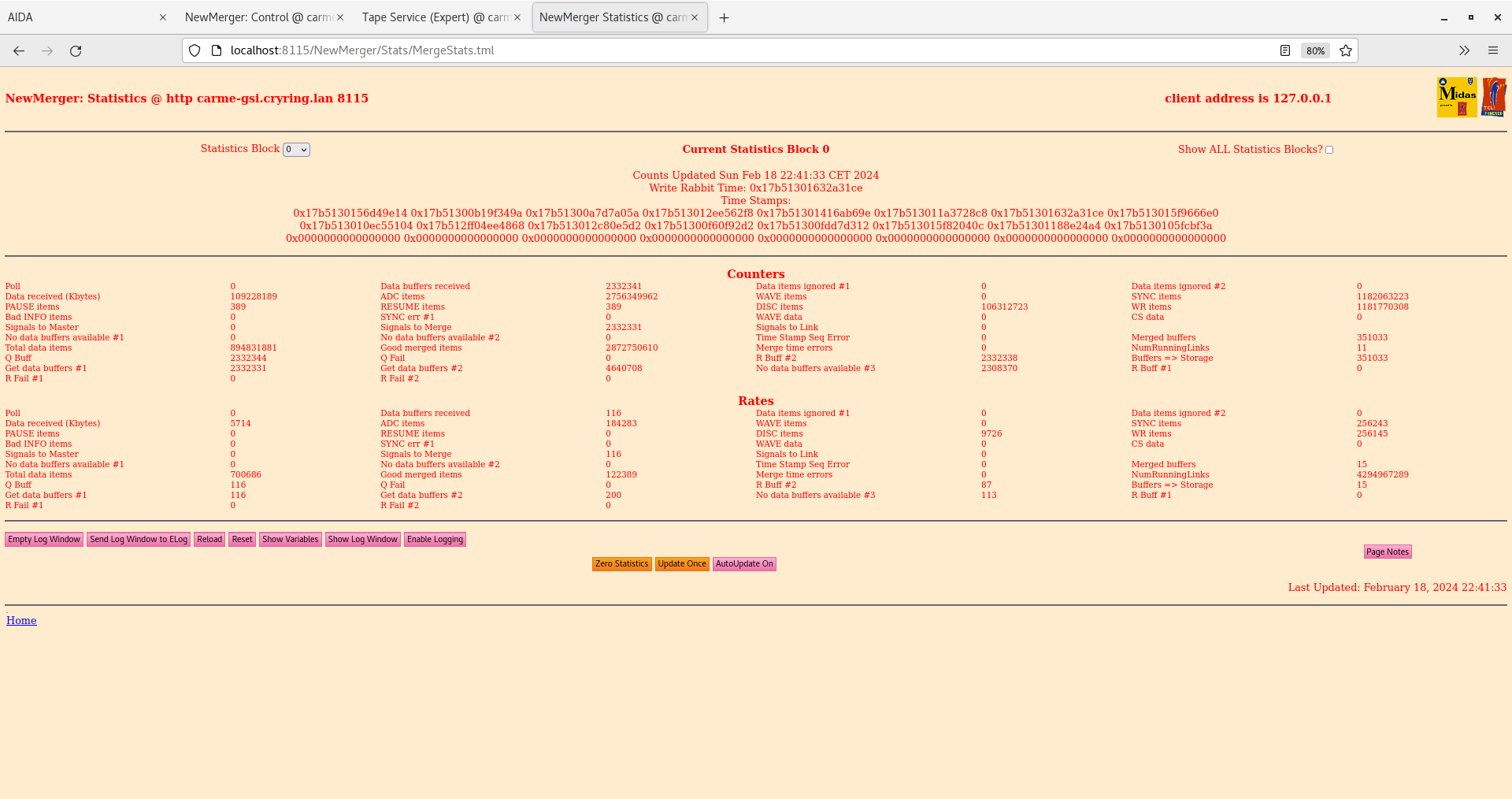

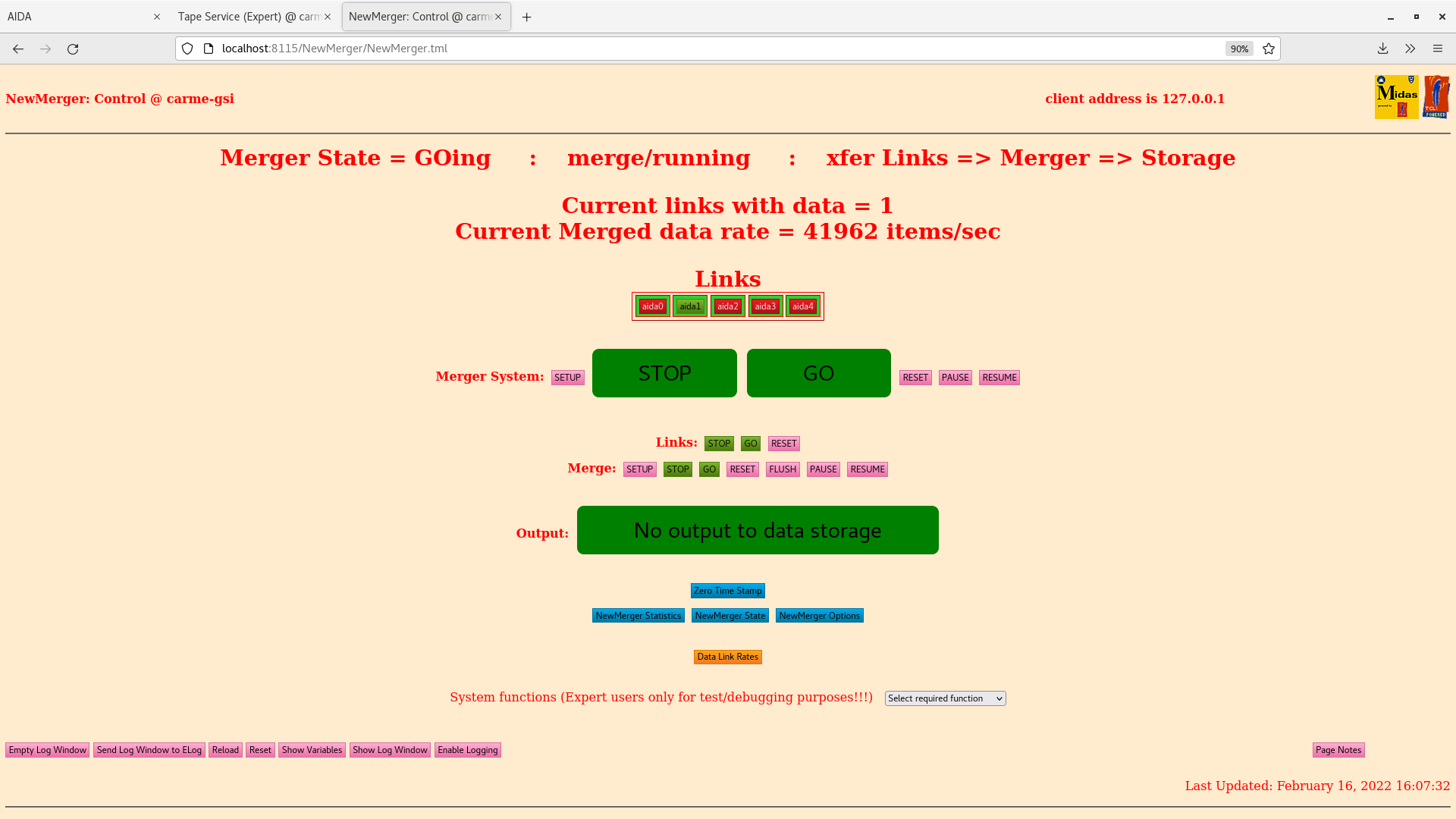

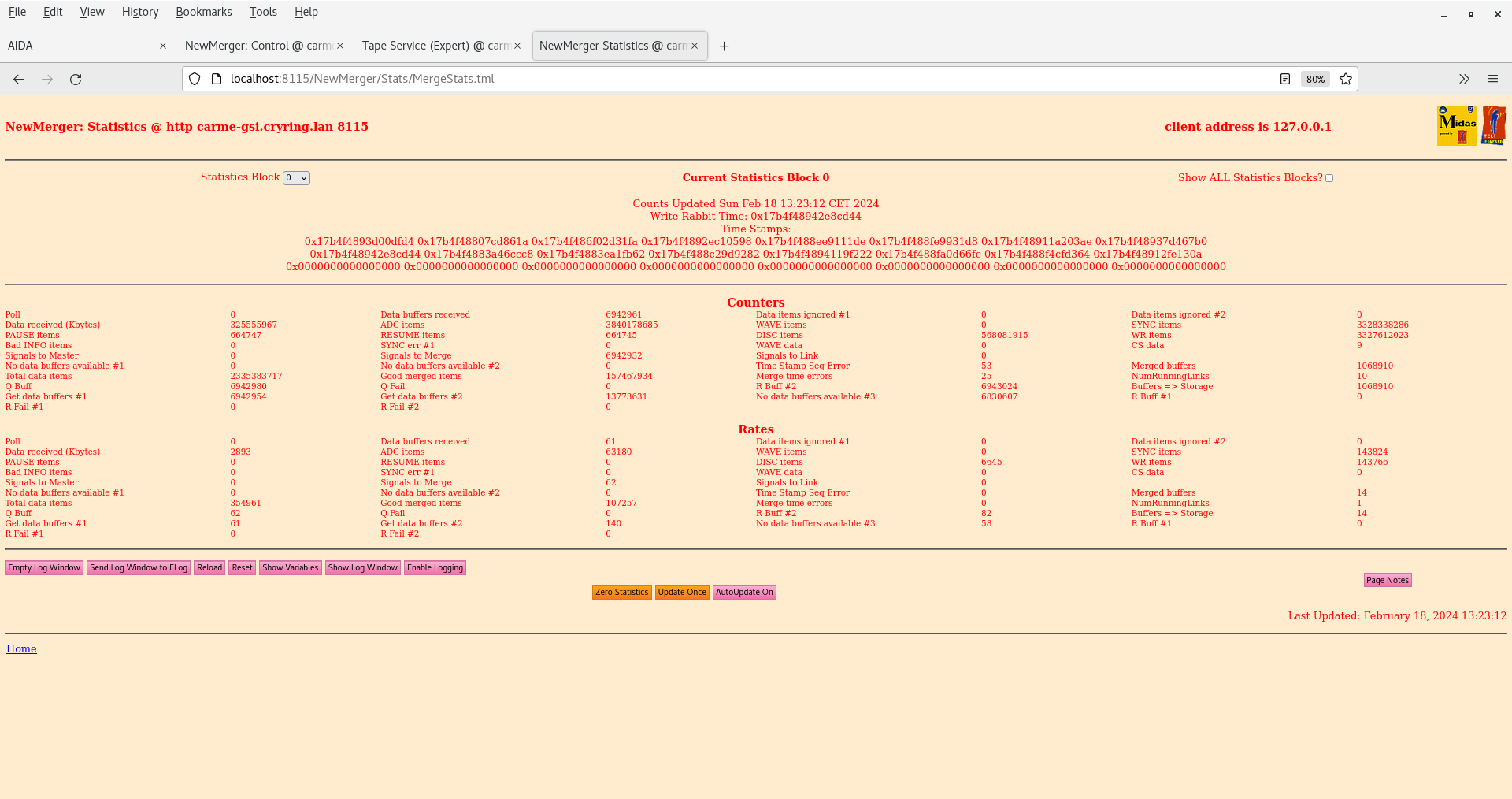

Check NewMerger tab: (see attachment 2)

Check Tape Server: (see attachment 3) Writing ~2500 kb/s

Check Fee temperatures: all green

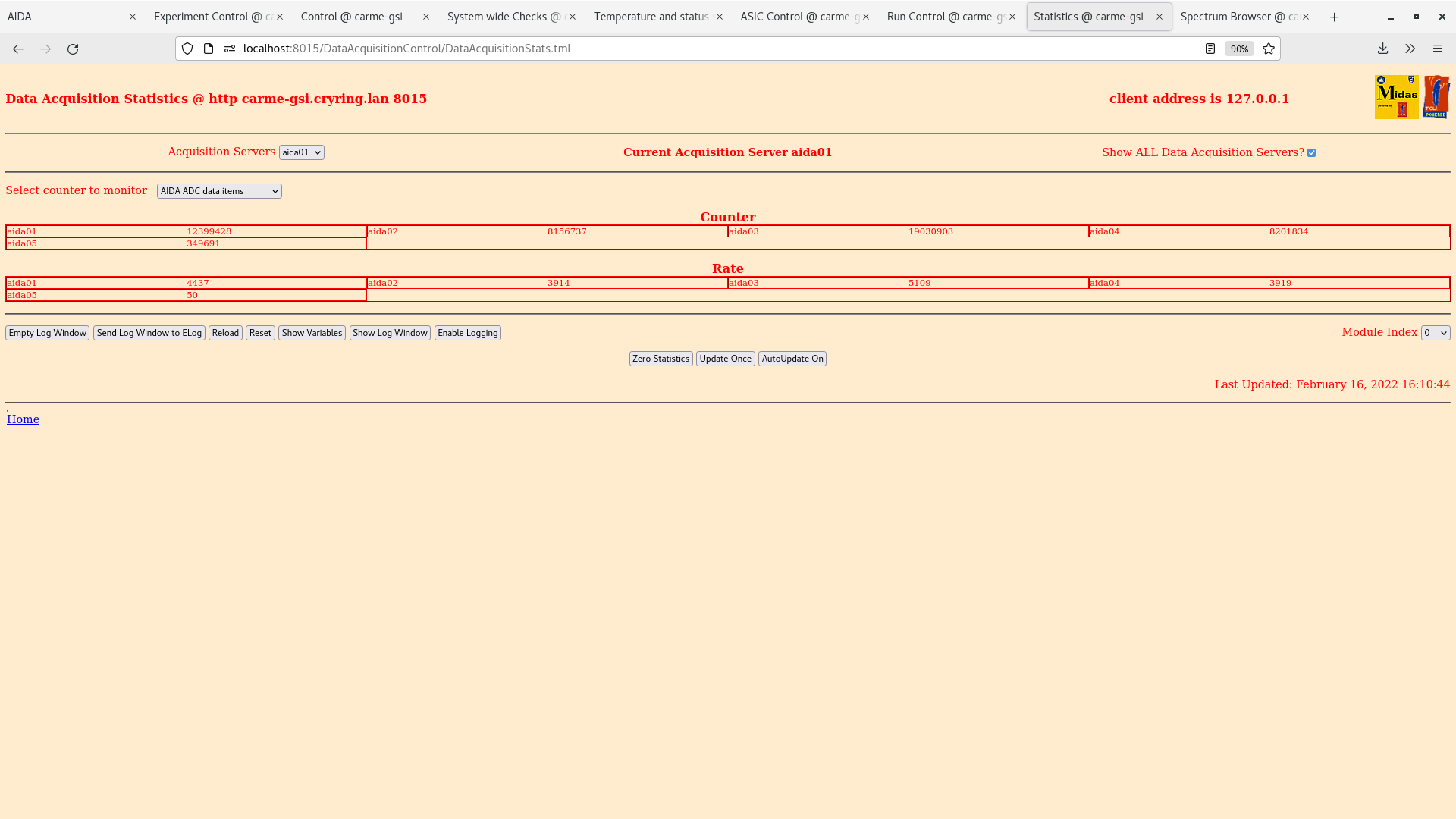

Check statistics tab: ADC data items (see attachment 4) -aida3 and aida4 reading zero. Appears to be low noise as stat histogram shows counts as does Ey and Ex low energy histograms

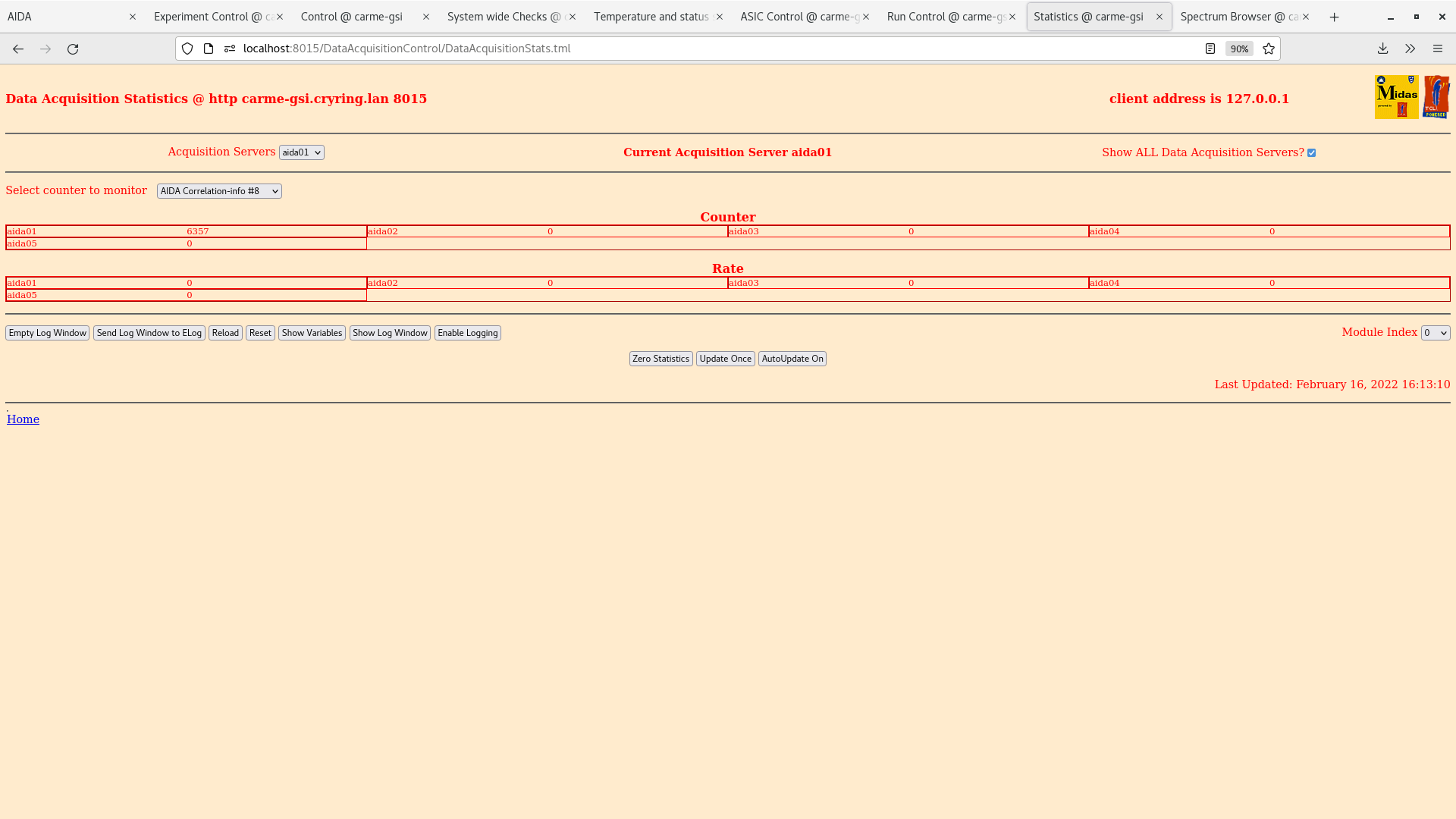

ADC coincidence-info #8 (see attachment 5) aida1,2,5 correlation #8 signals counted. Do not see aida3 correlation 8 signals. was 70-90 previously (elog201)

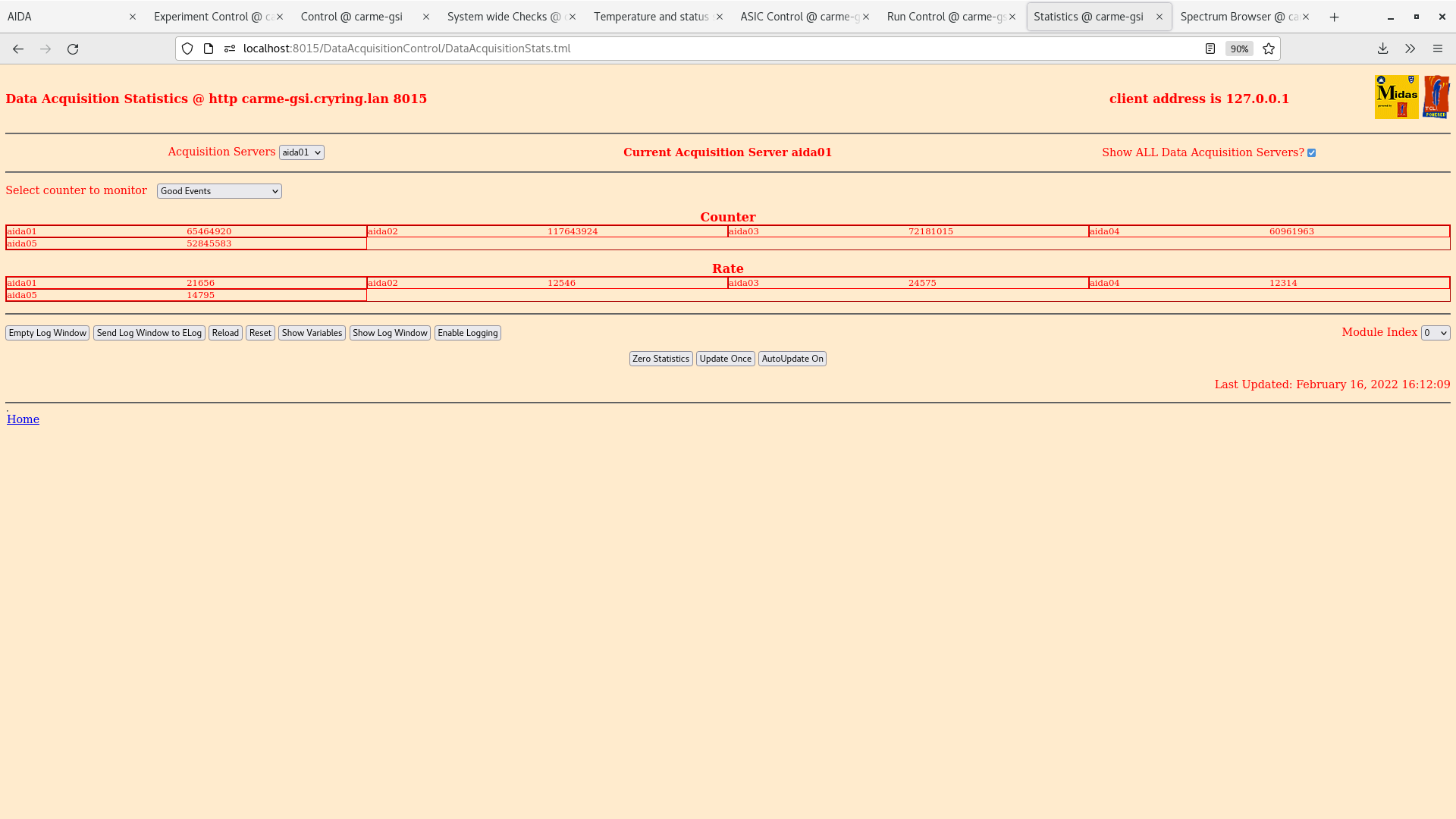

Good events (see attachment 6) see 10-20k on aida1-4.

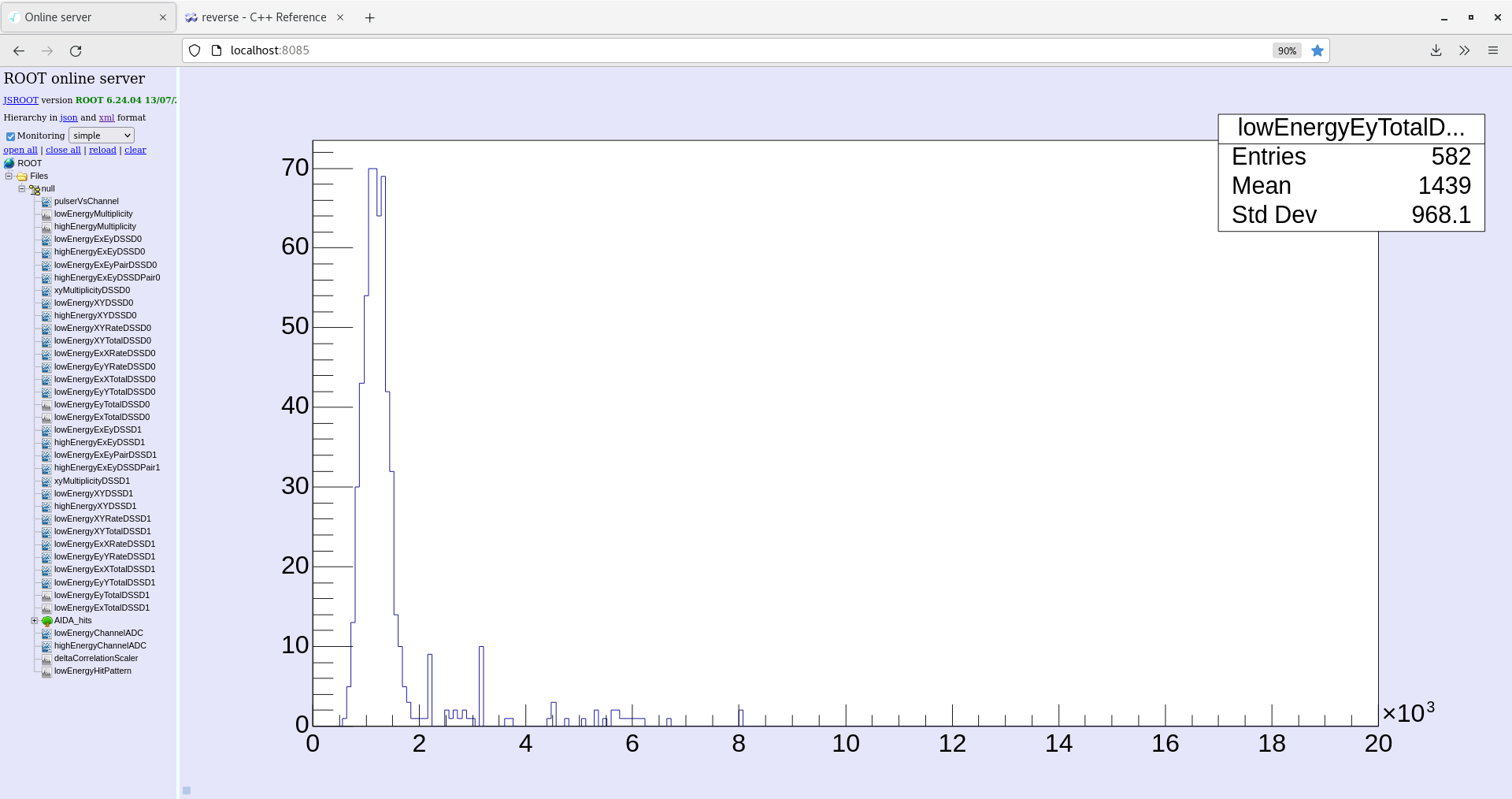

Low energy histograms Ex, Ey (attachemnts 7,8)

Noise appears lower across all fees. Aida1 channels for asic 1 and 3 (noisiest) checked against elog 197, same channels are hot but at lower rate to elog 197.

|

| Attachment 1: 2022-02-16_22-45-51-Leakage-Current.png

|

|

| Attachment 2: 2022-02-16_22-43-15-NewMerger.png

|

|

| Attachment 3: 2022-02-16_22-43-50-TapeServer.png

|

|

| Attachment 4: 2022-02-16_22-49-51-ADC-data-items.png

|

|

| Attachment 5: 2022-02-16_22-51-40-AIDA-correlation8.png

|

|

| Attachment 6: 2022-02-16_22-48-47-GoodEvents.png

|

|

| Attachment 7: 2022-02-16_22-52-51-lowenergyEx.png

|

|

| Attachment 8: 2022-02-16_22-57-35-lowenergyEy.png

|

|

|

529

|

Mon Feb 19 05:10:48 2024 |

TD | Run 42 night shift contd. |

06.03 DAQ continues file G22-86/R42_32

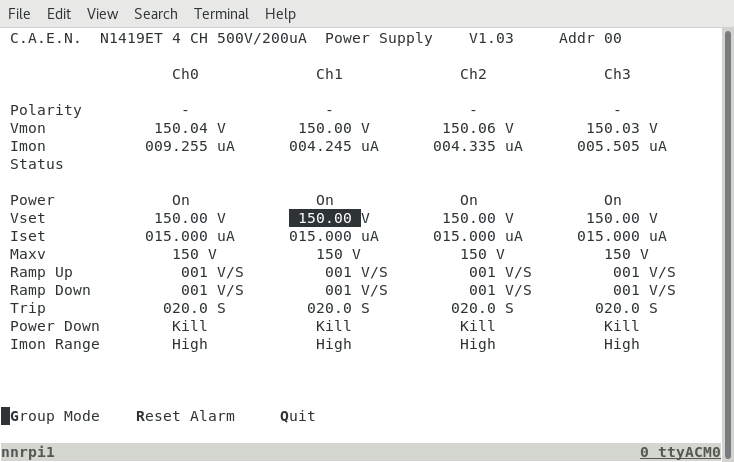

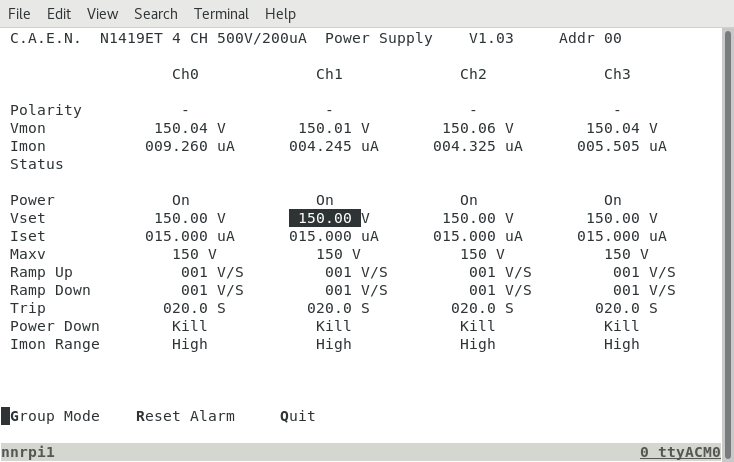

DSSSD bias & leakage current - attachments 1-2

DSSSD #0 trending upwards , DSSSD #1-3 trending downwards with decreasing ambient temperature

FEE64 temperatures OK - attachments 3-4

ADC data item stats - attachment 5

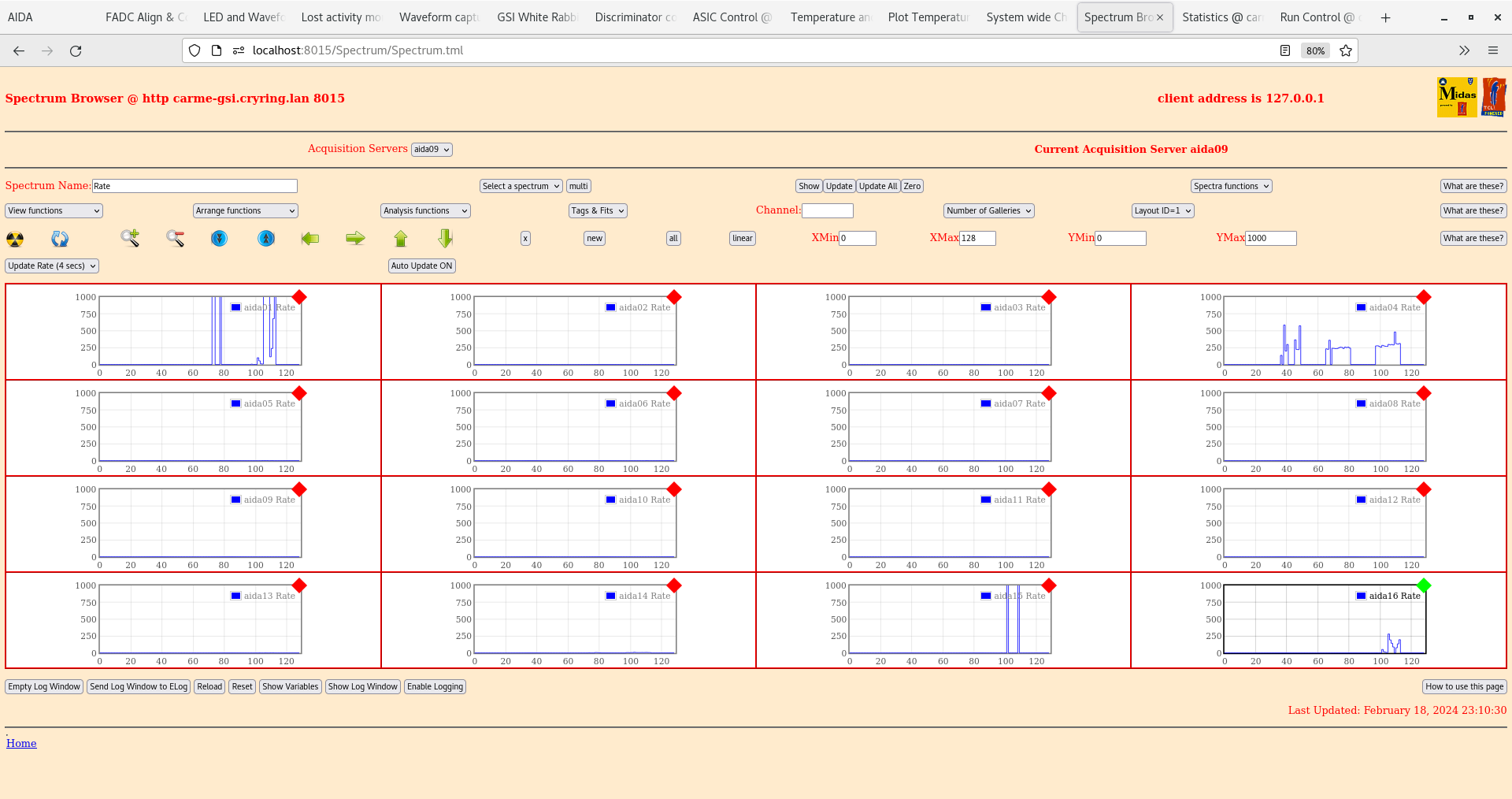

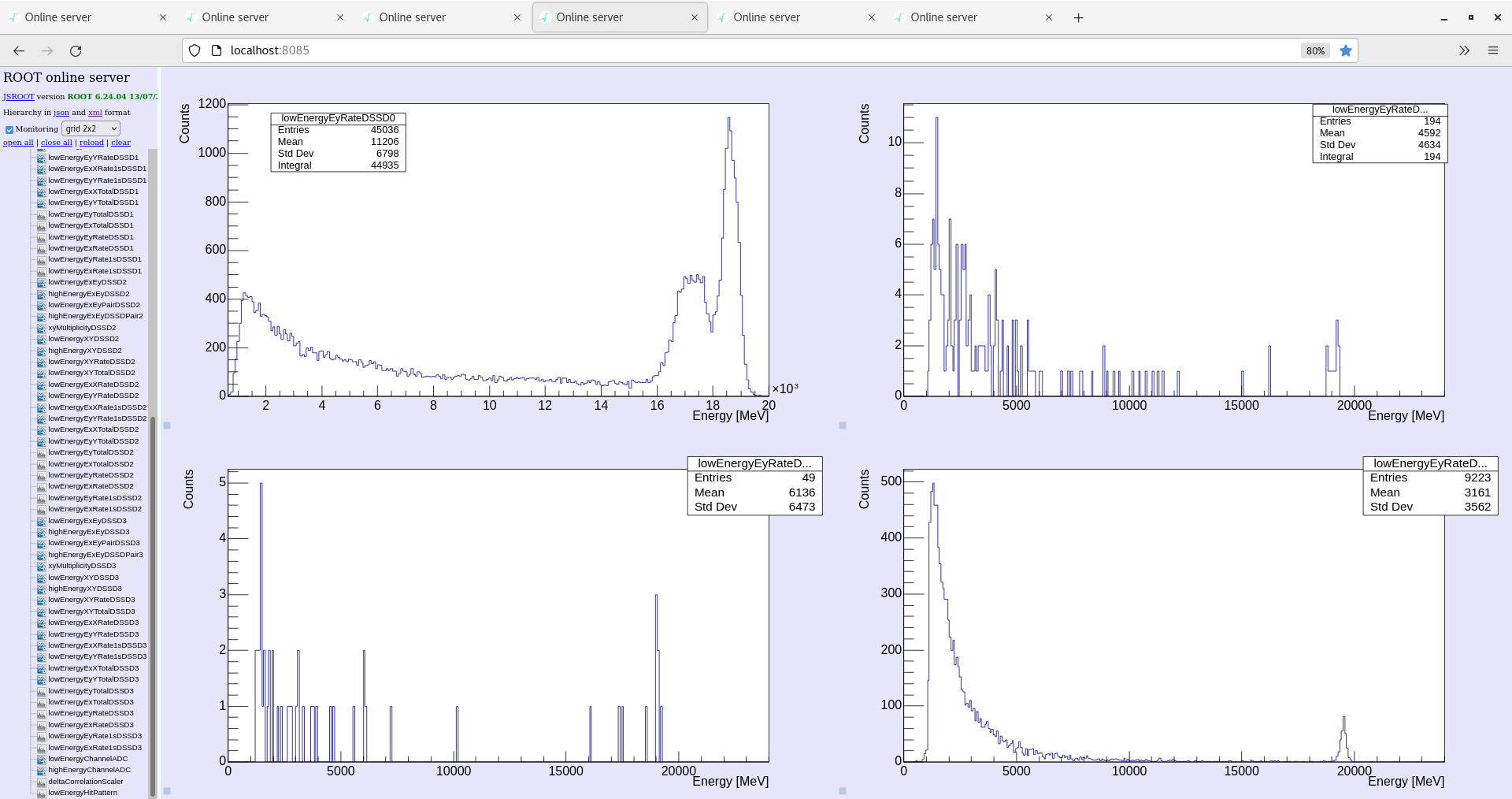

per FEE64 Rate spectra - attachments 6

target density 5.27e+11/cm2

beam stable for last 3 hours ( cannot read scale with X2Go ) |

| Attachment 1: Screenshot_from_2024-02-19_06-03-26.png

|

|

| Attachment 2: Screenshot_from_2024-02-19_06-03-41.png

|

|

| Attachment 3: Screenshot_from_2024-02-19_06-04-07.png

|

|

| Attachment 4: Screenshot_from_2024-02-19_06-05-27.png

|

|

| Attachment 5: Screenshot_from_2024-02-19_06-05-51.png

|

|

| Attachment 6: Screenshot_from_2024-02-19_06-06-15.png

|

|

|

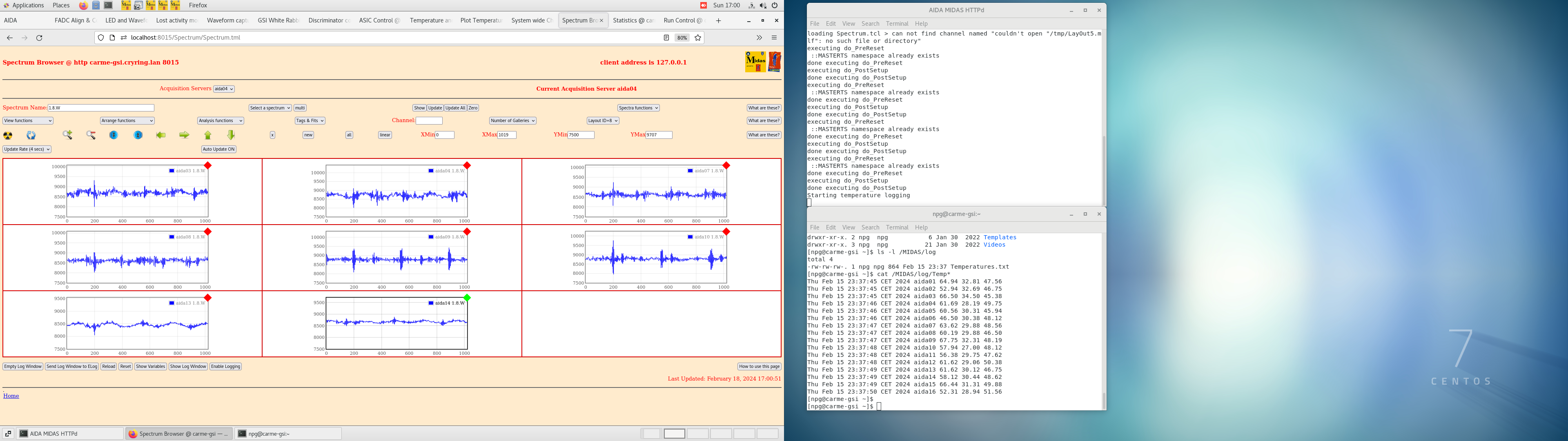

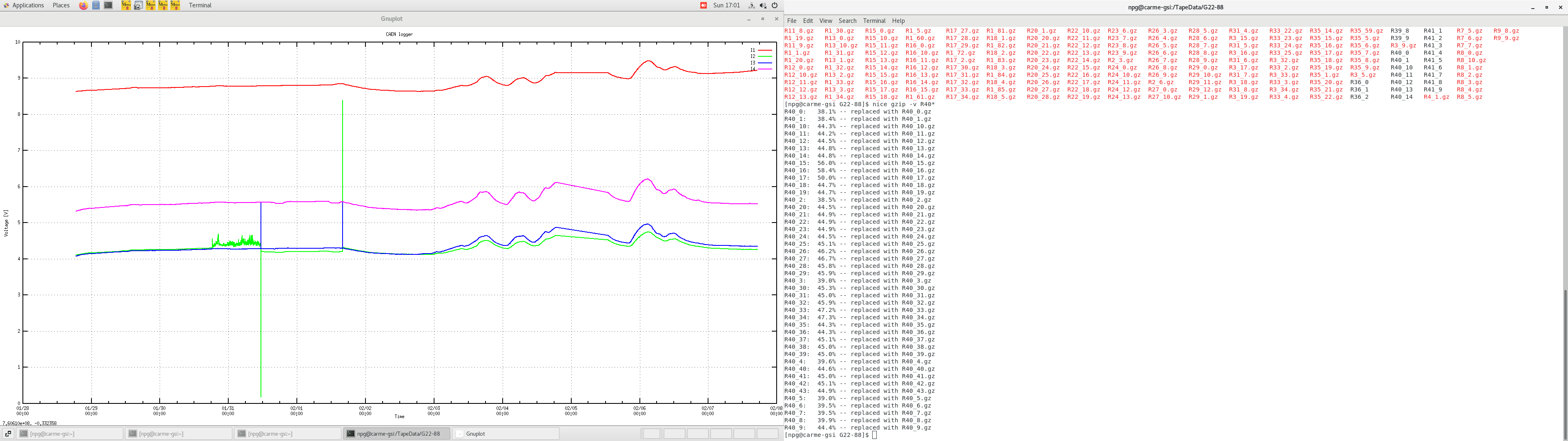

528

|

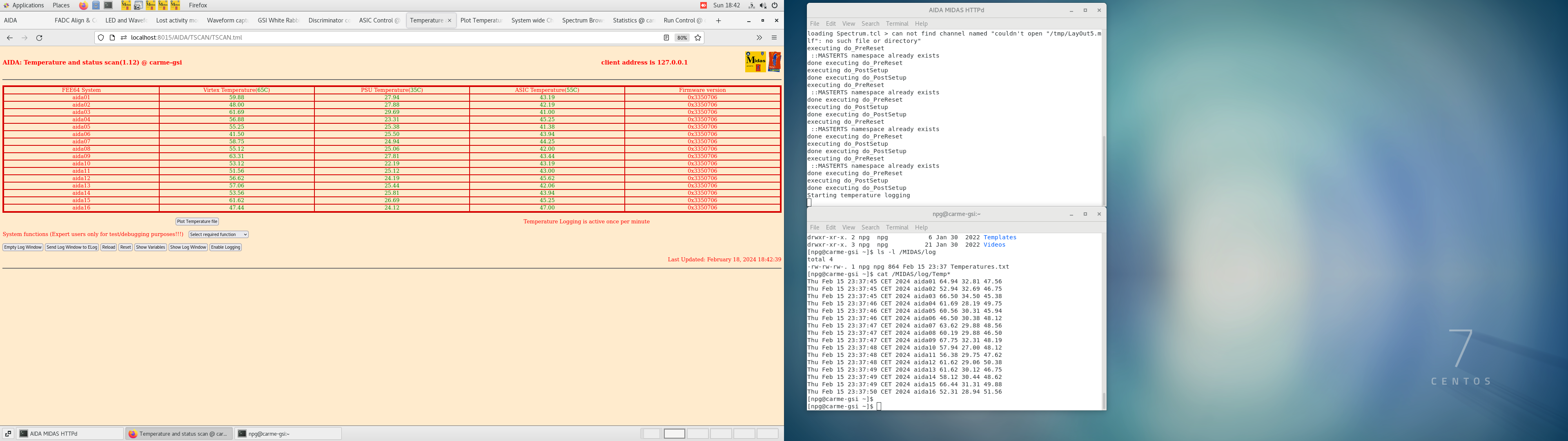

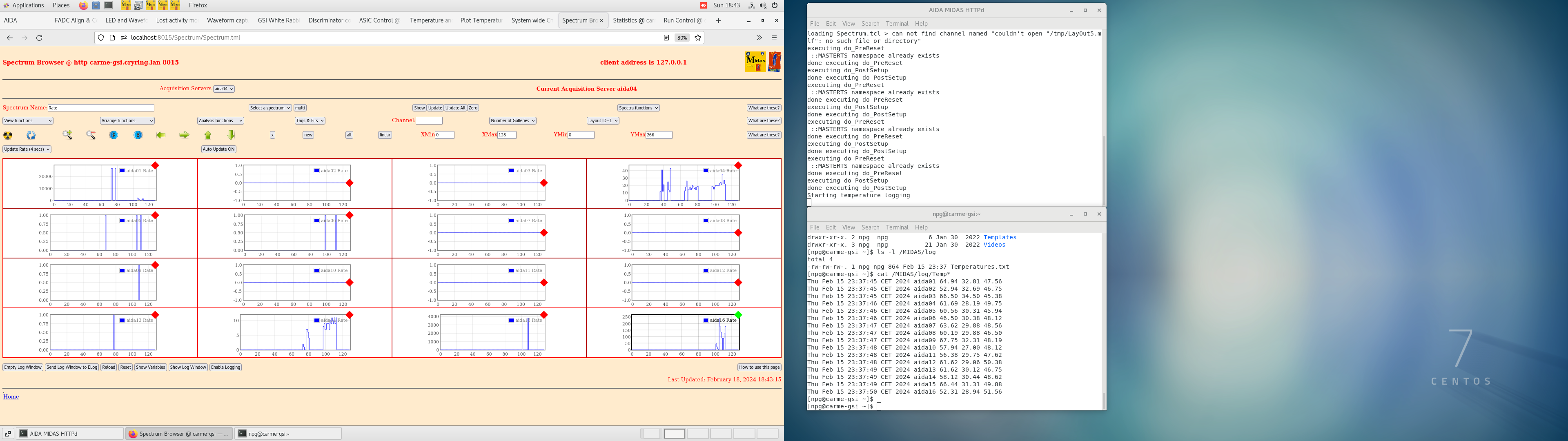

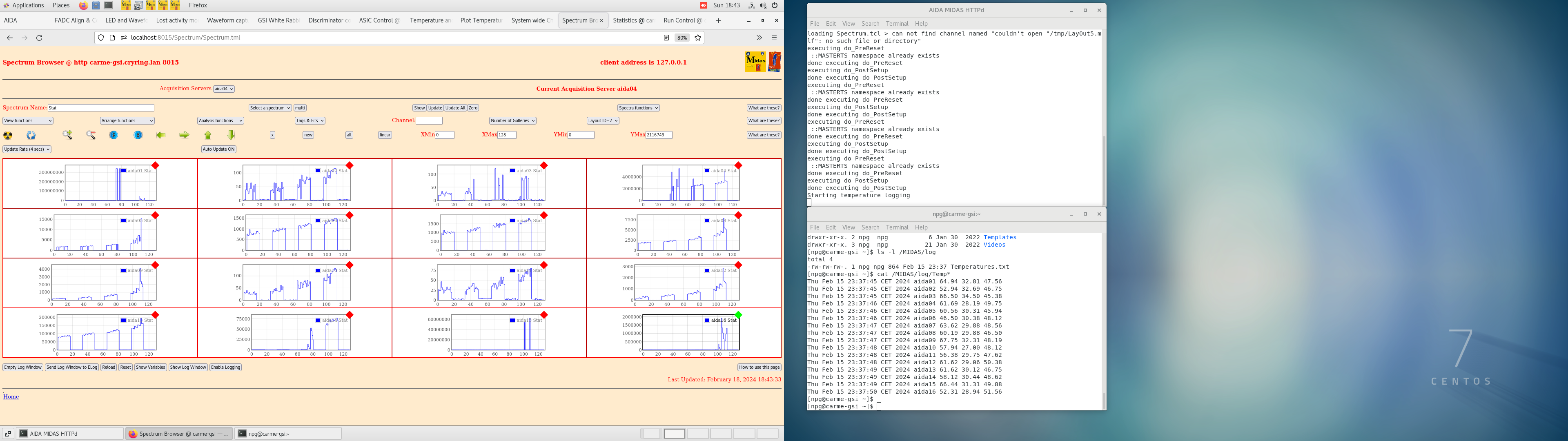

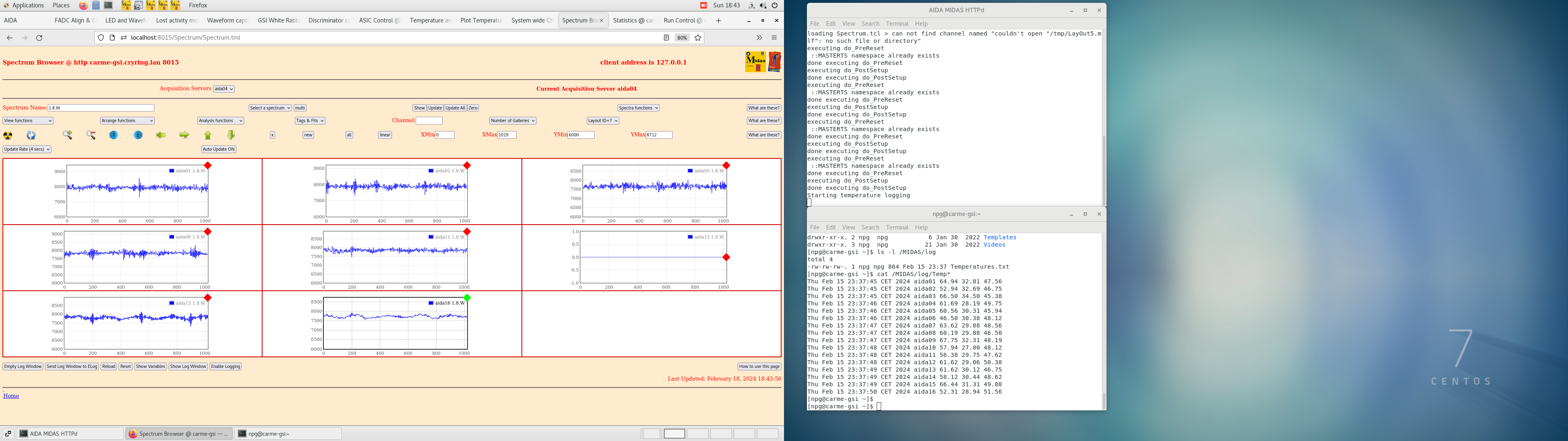

Sun Feb 18 22:03:56 2024 |

TD | Run 42 night shift |

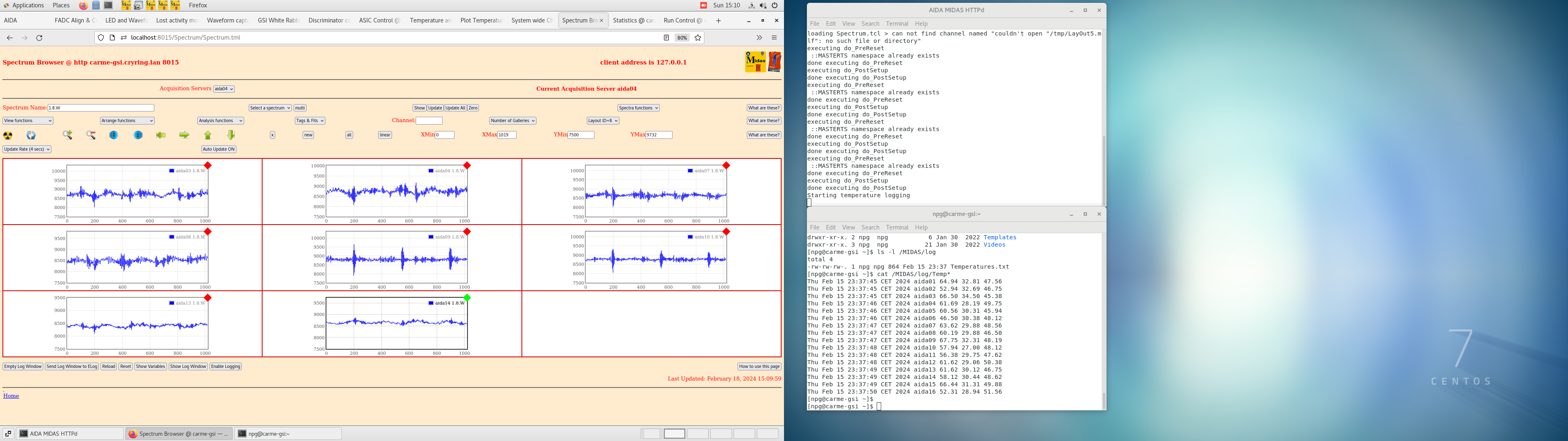

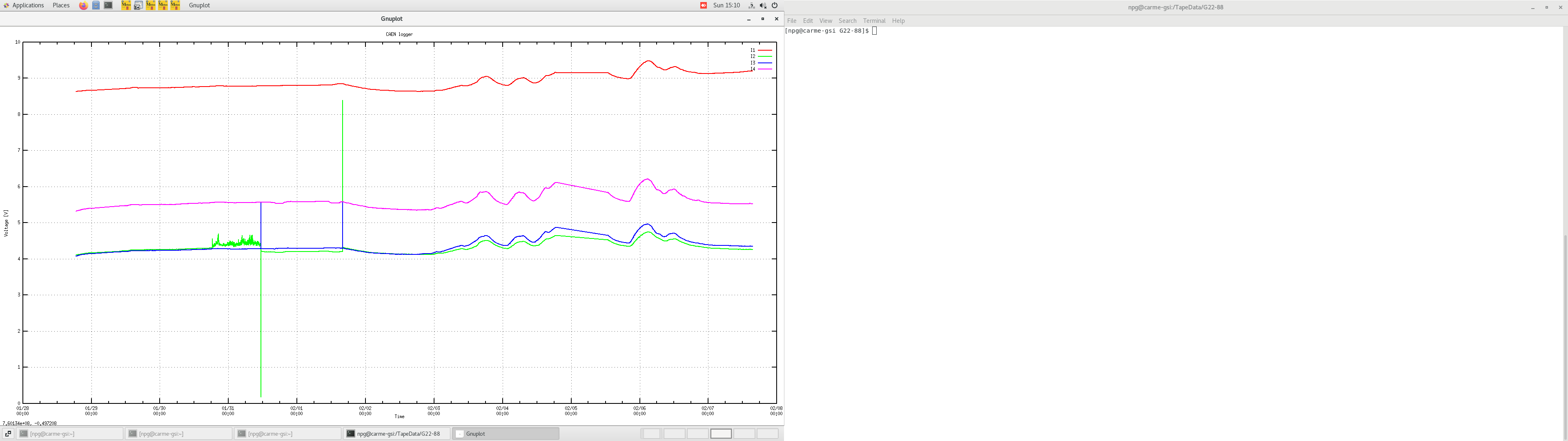

23.03 DAQ continues file G22-86/R42_21

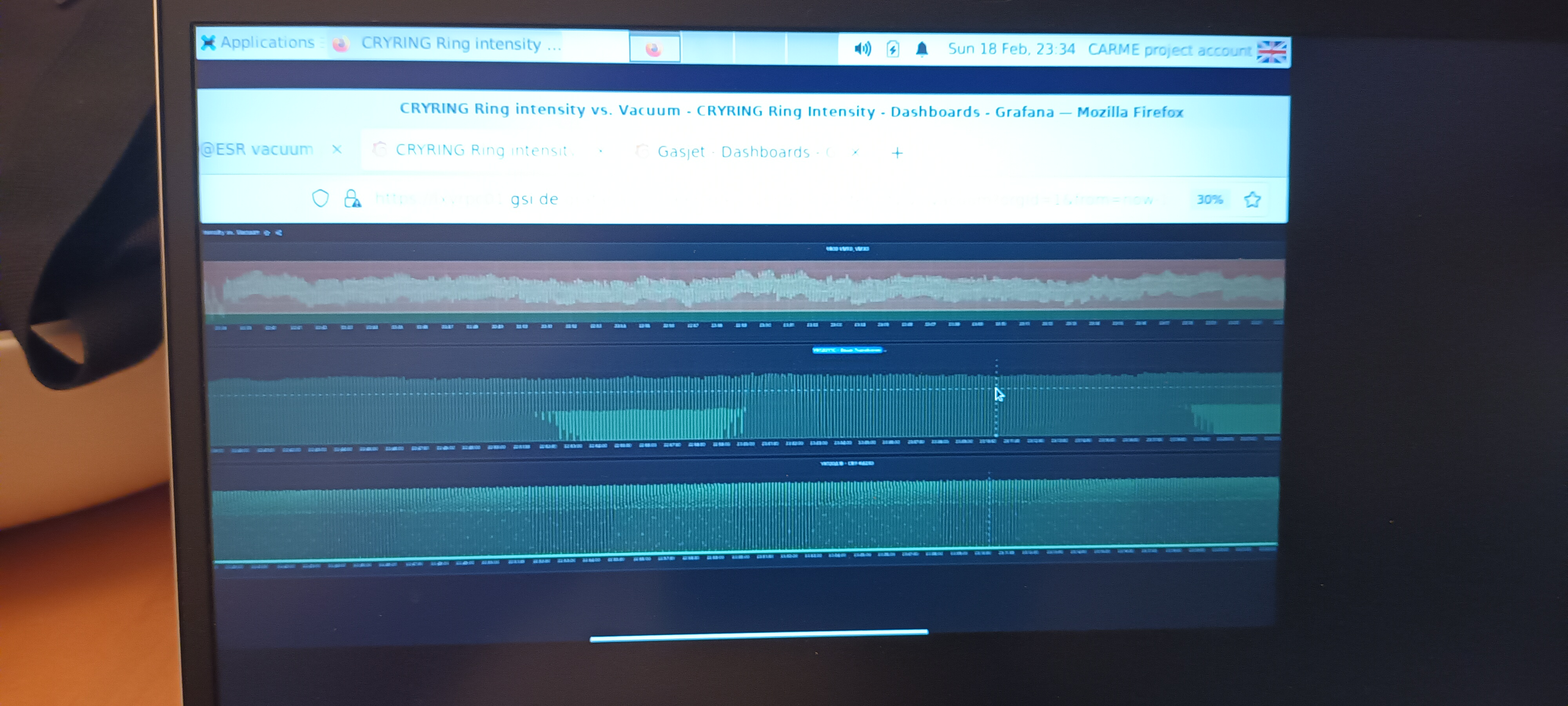

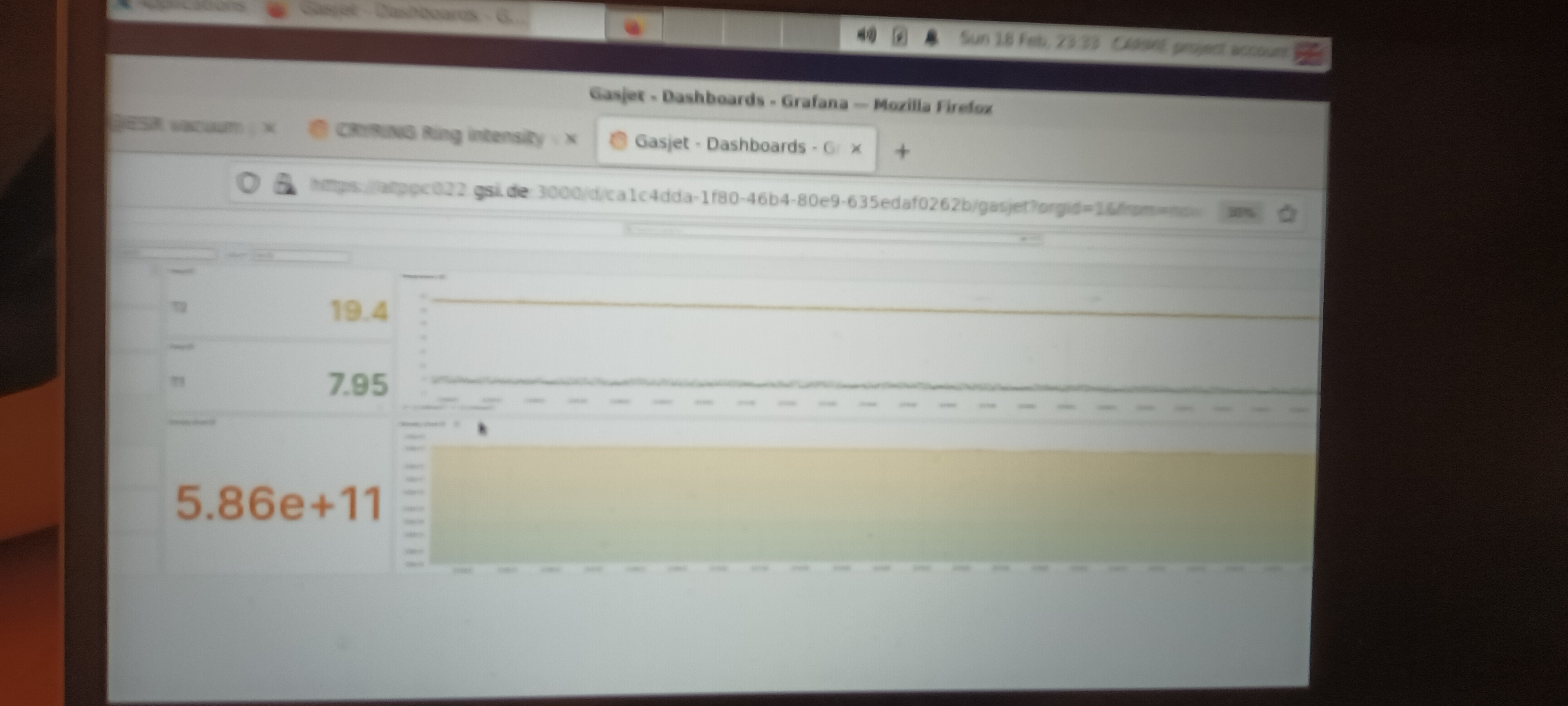

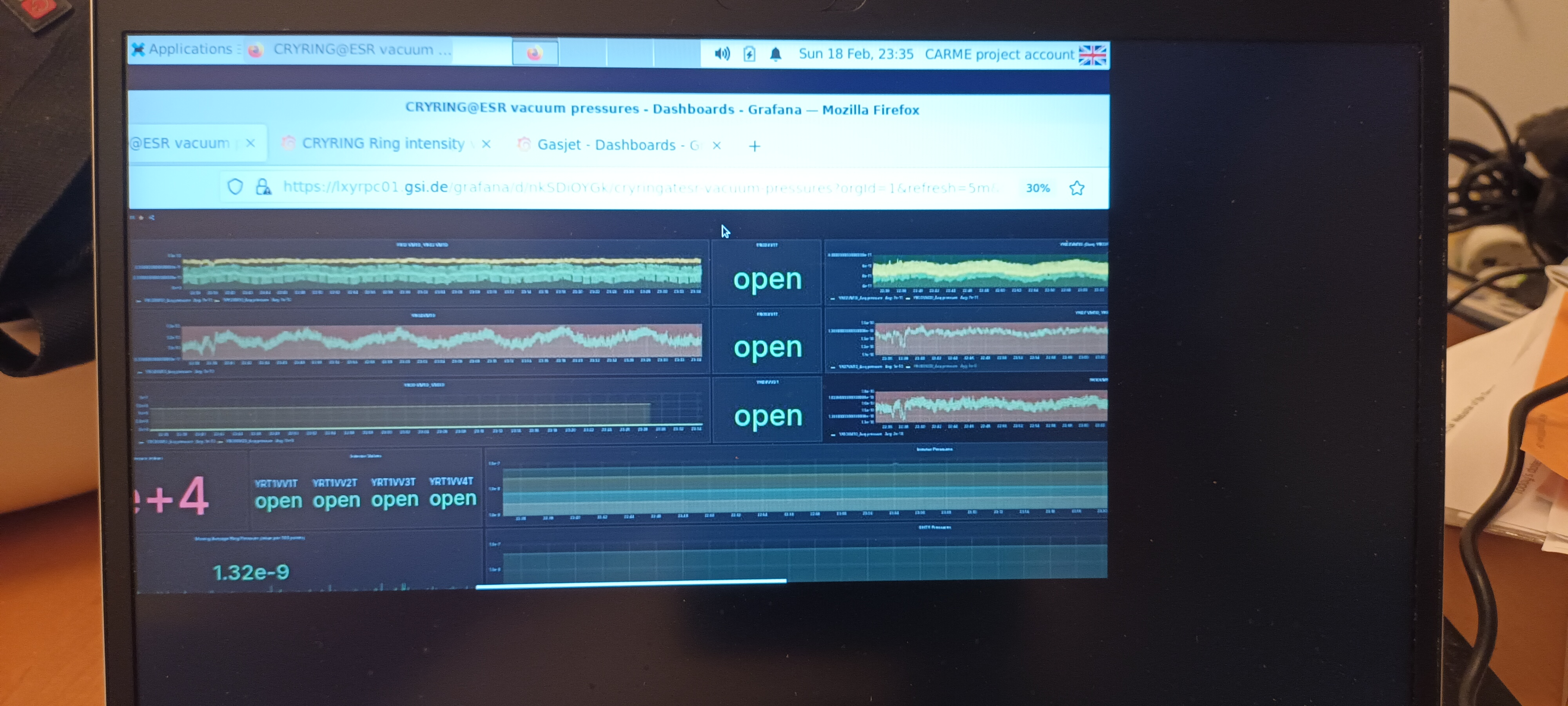

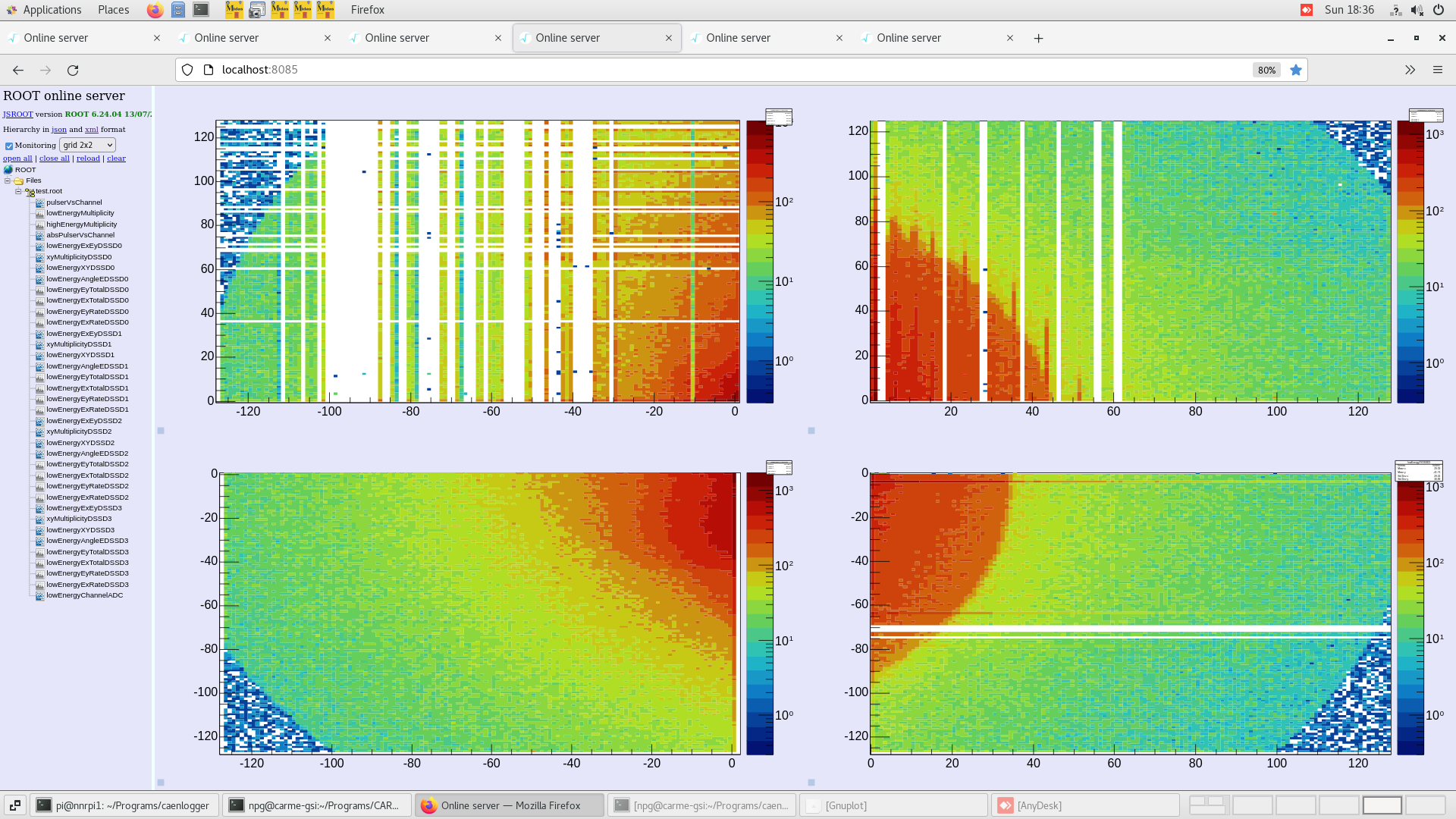

ML CRYRING ambient temperature and vacuum - attachments 1 & 2

DSSSD bias & leakage current - attachments 3 & 24

DSSSD #0 trending upwards , DSSSD #1-3 trending downwards with decreasing ambient temperature

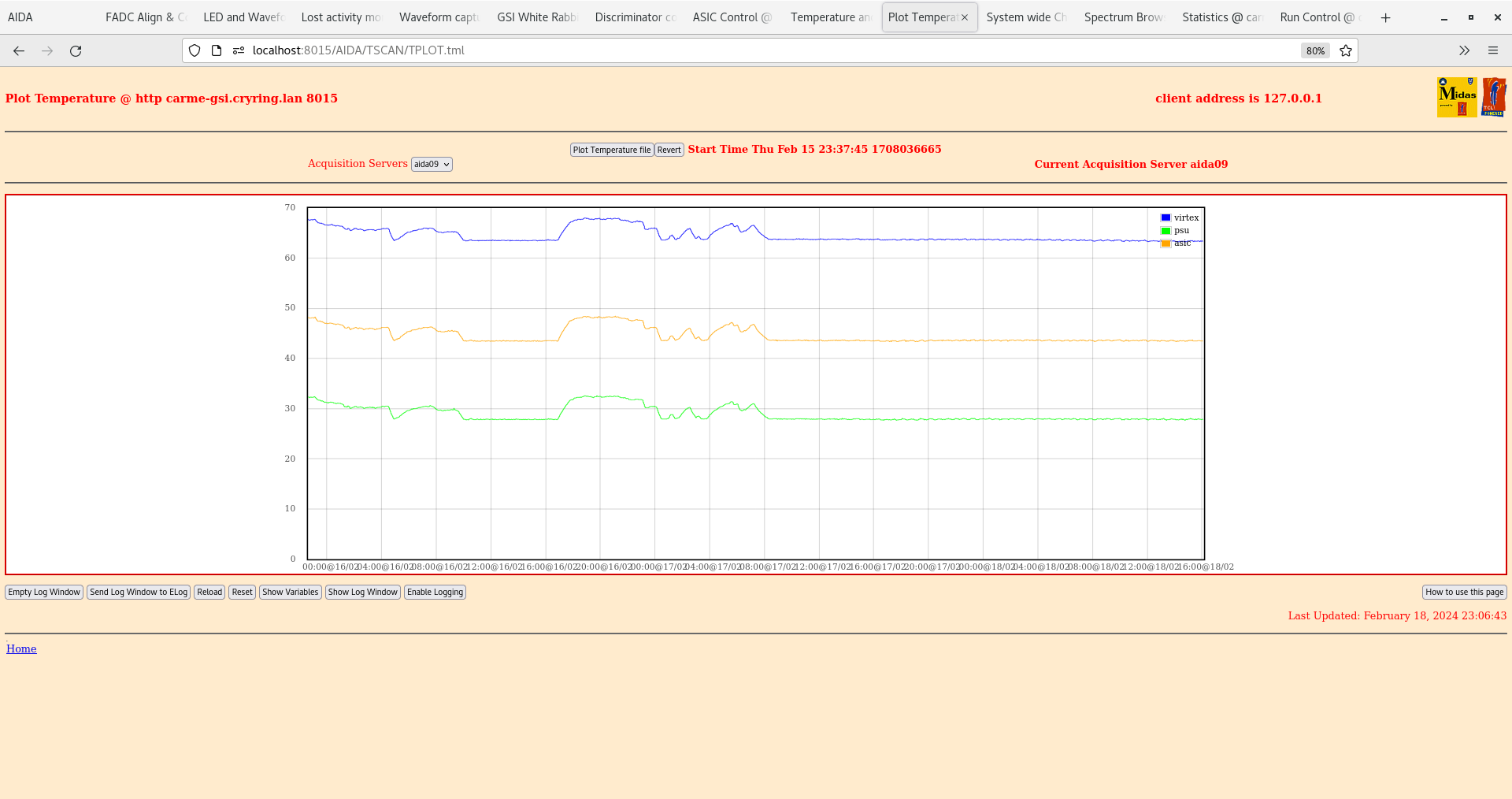

FEE64 temperatures OK - attachments 4-5

23.07 All system wide checks OK

WR timestamps OK - attachment 6

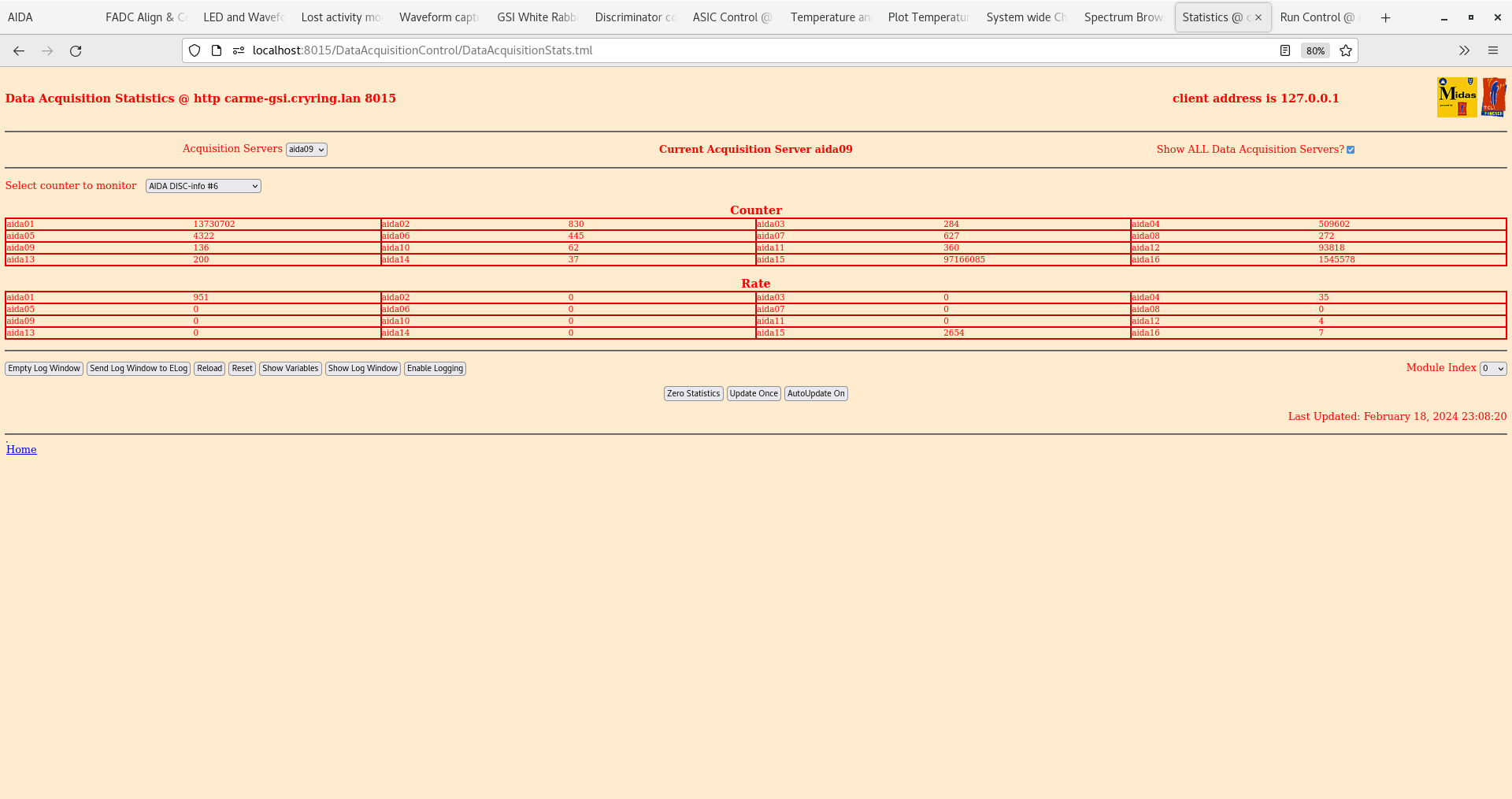

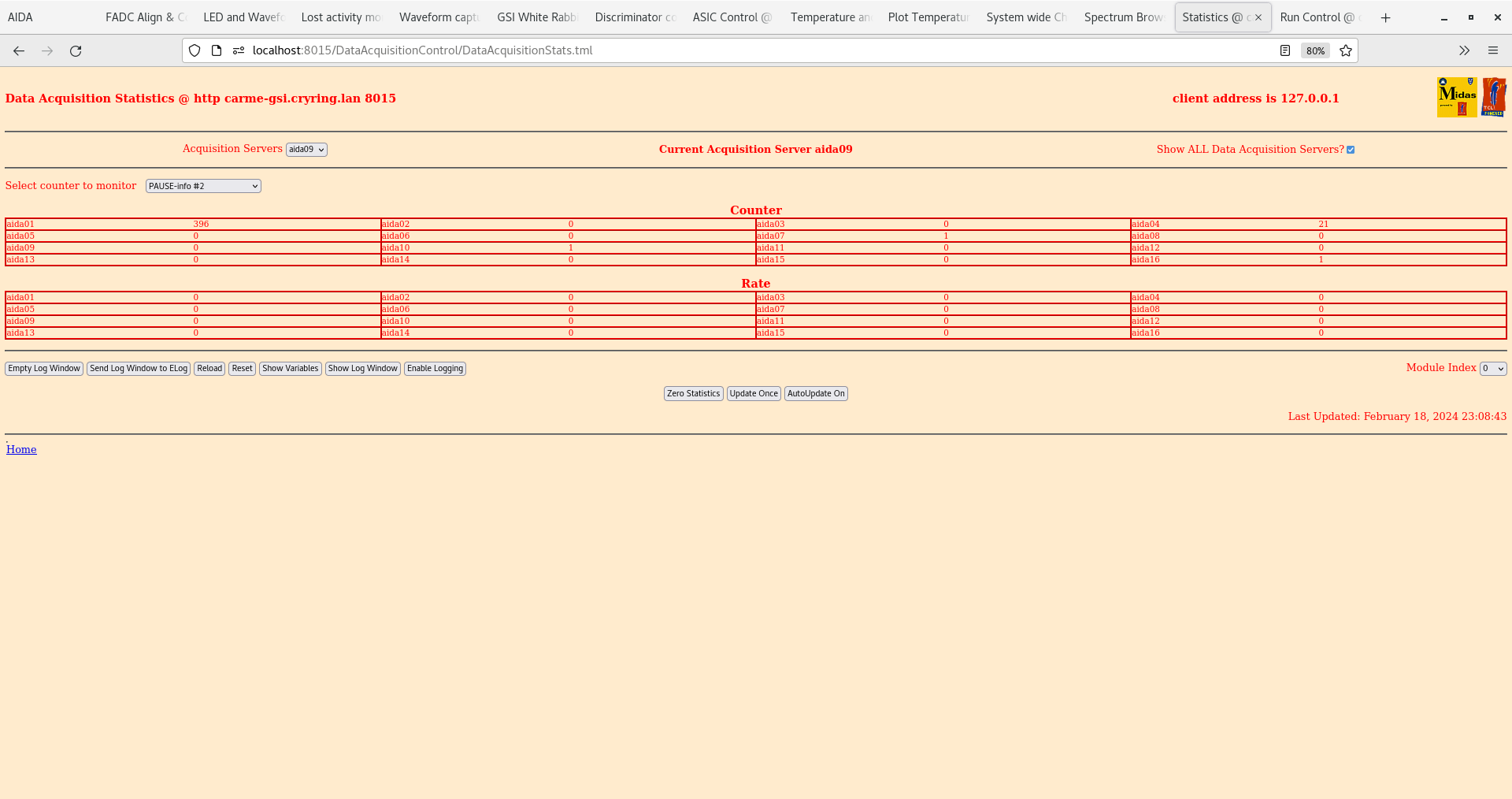

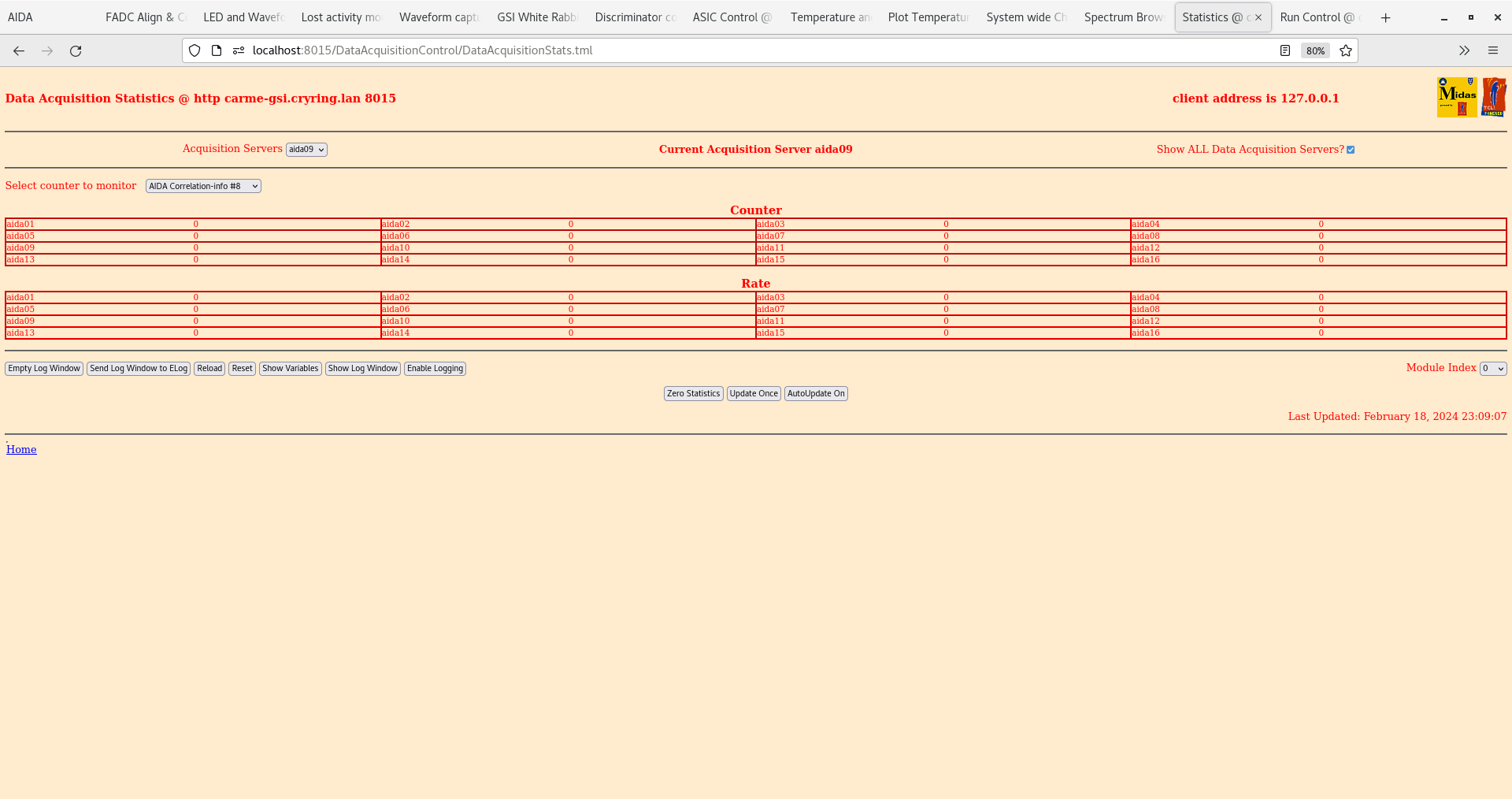

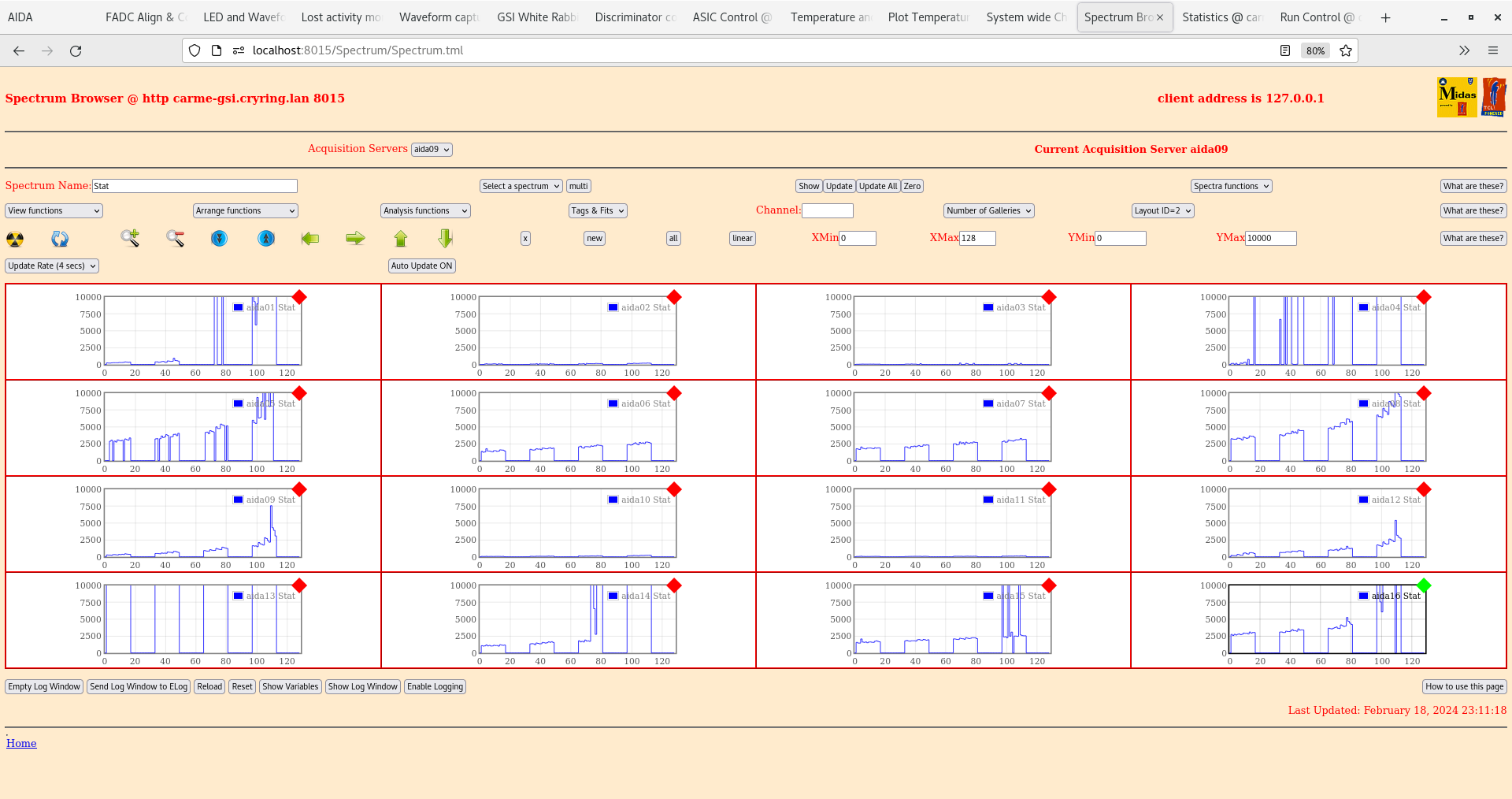

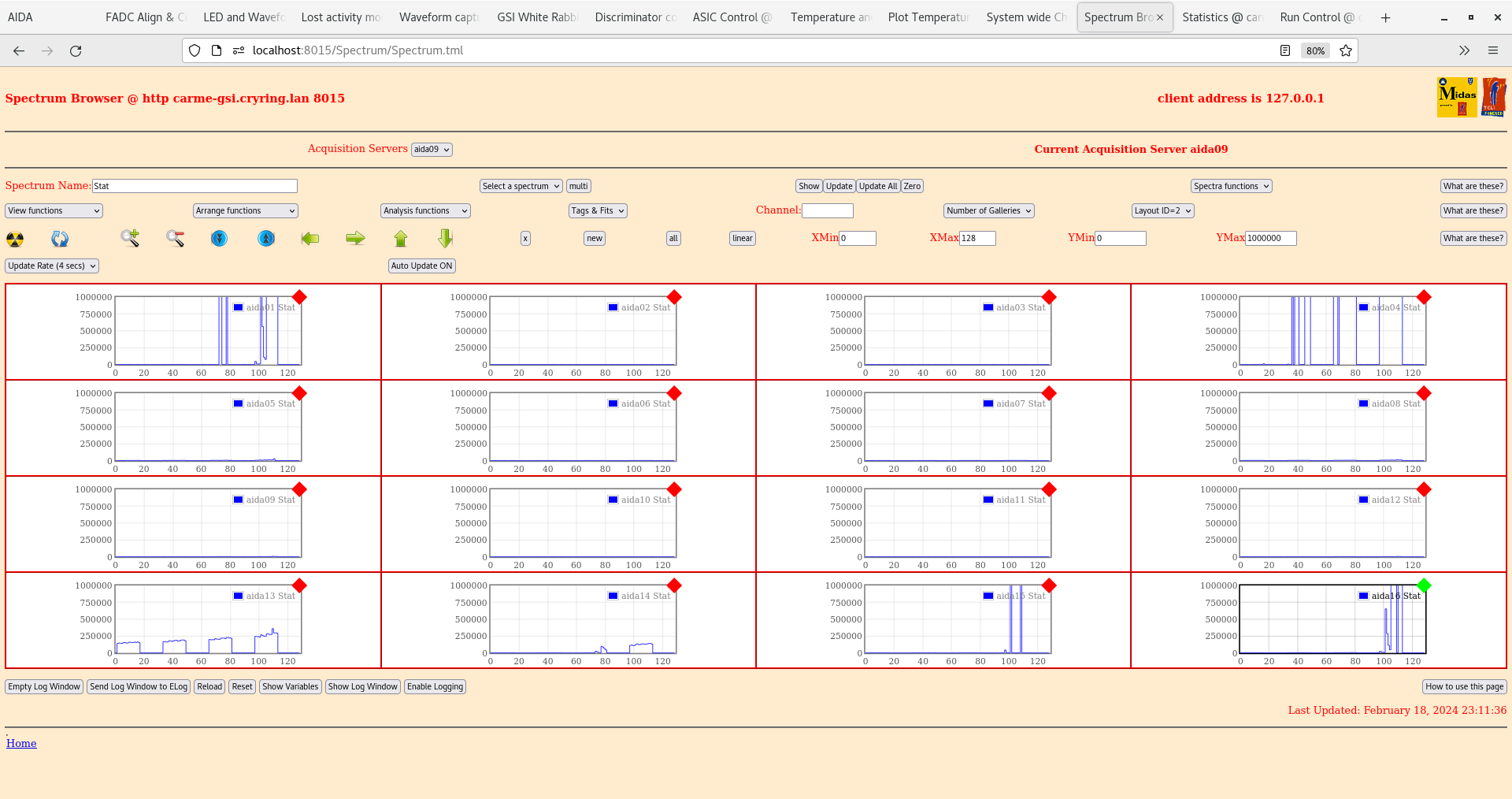

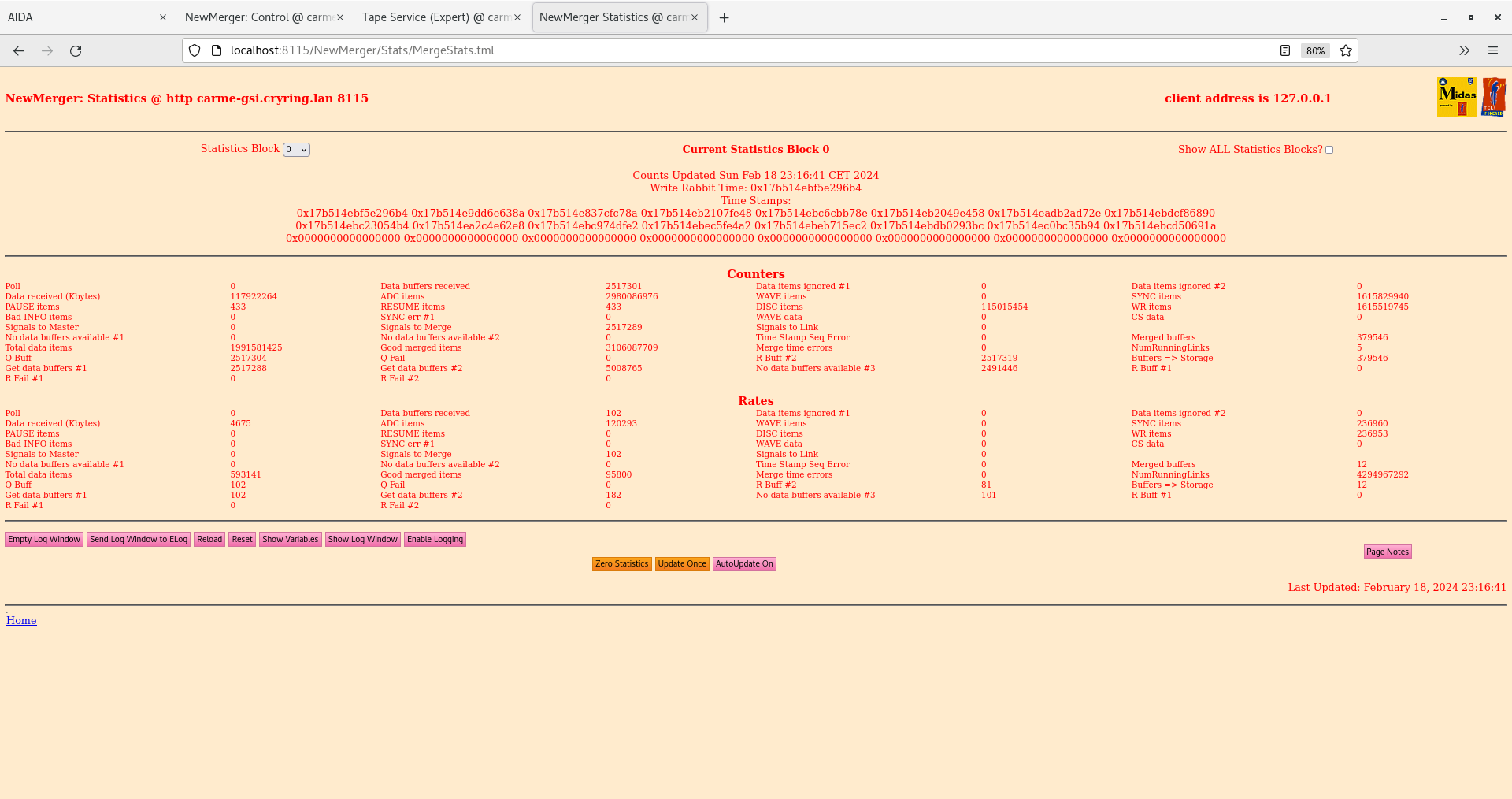

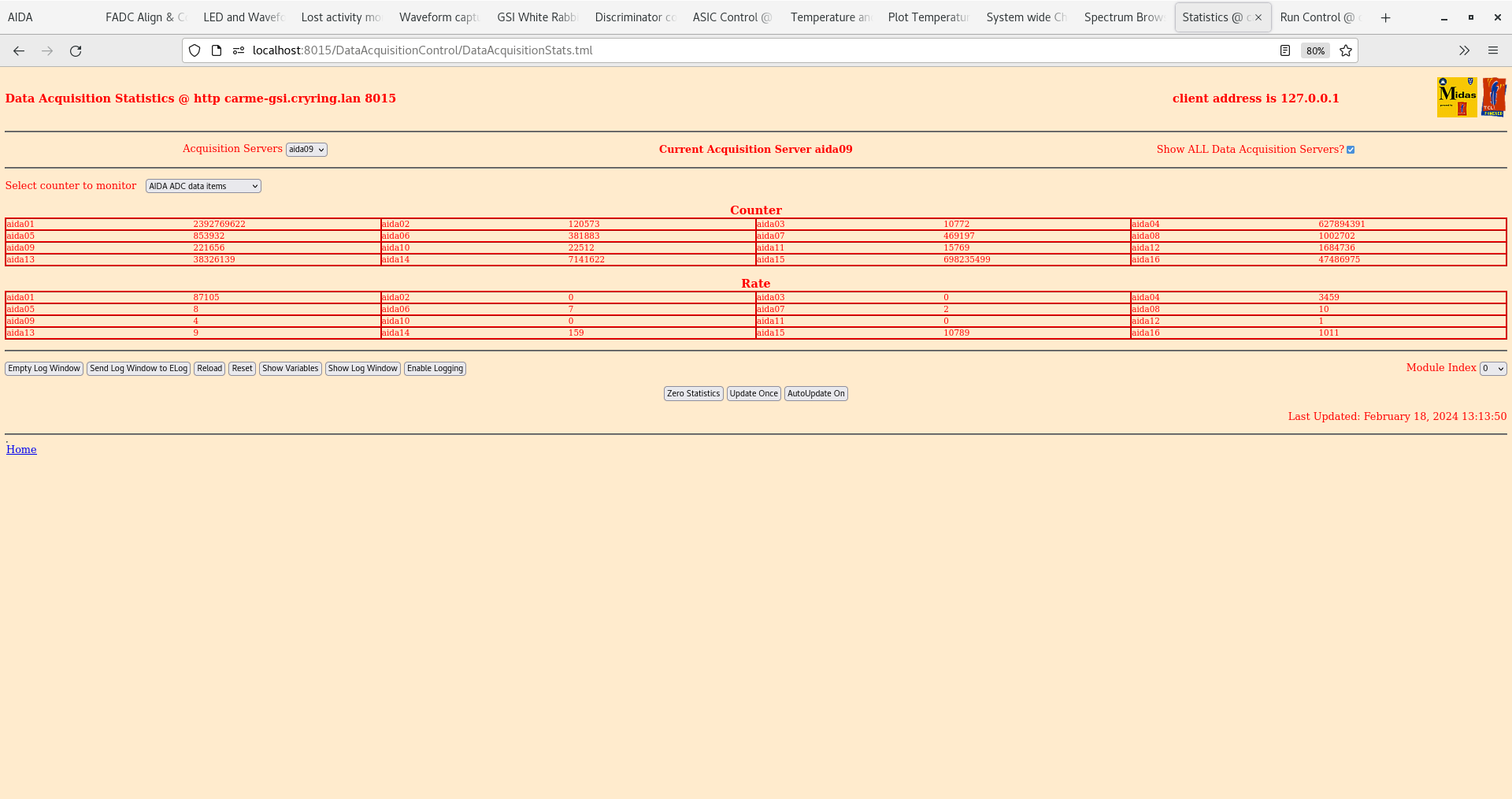

ADC, DISC, PAUSE and correlation stats OK - attachments 7-10

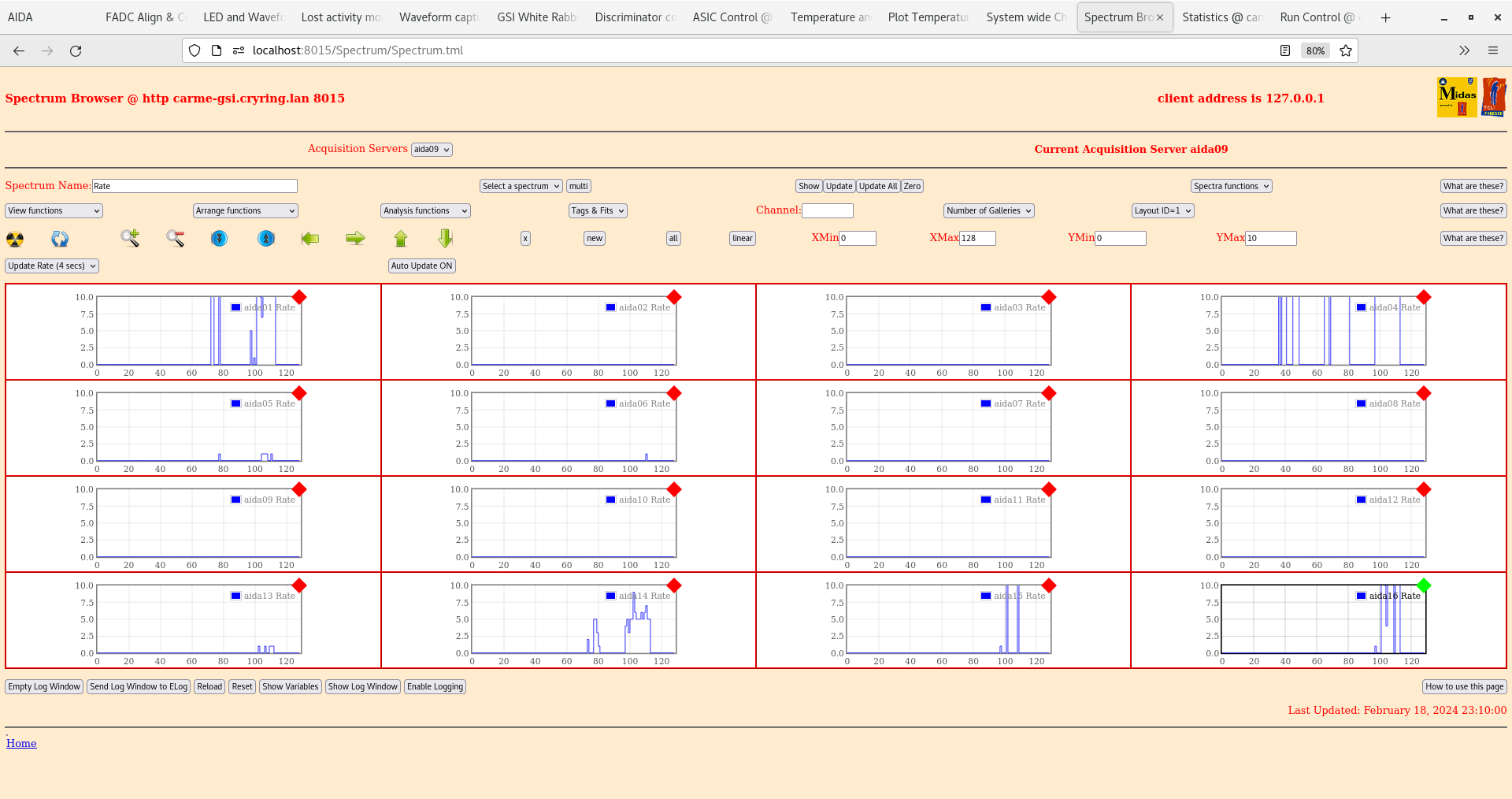

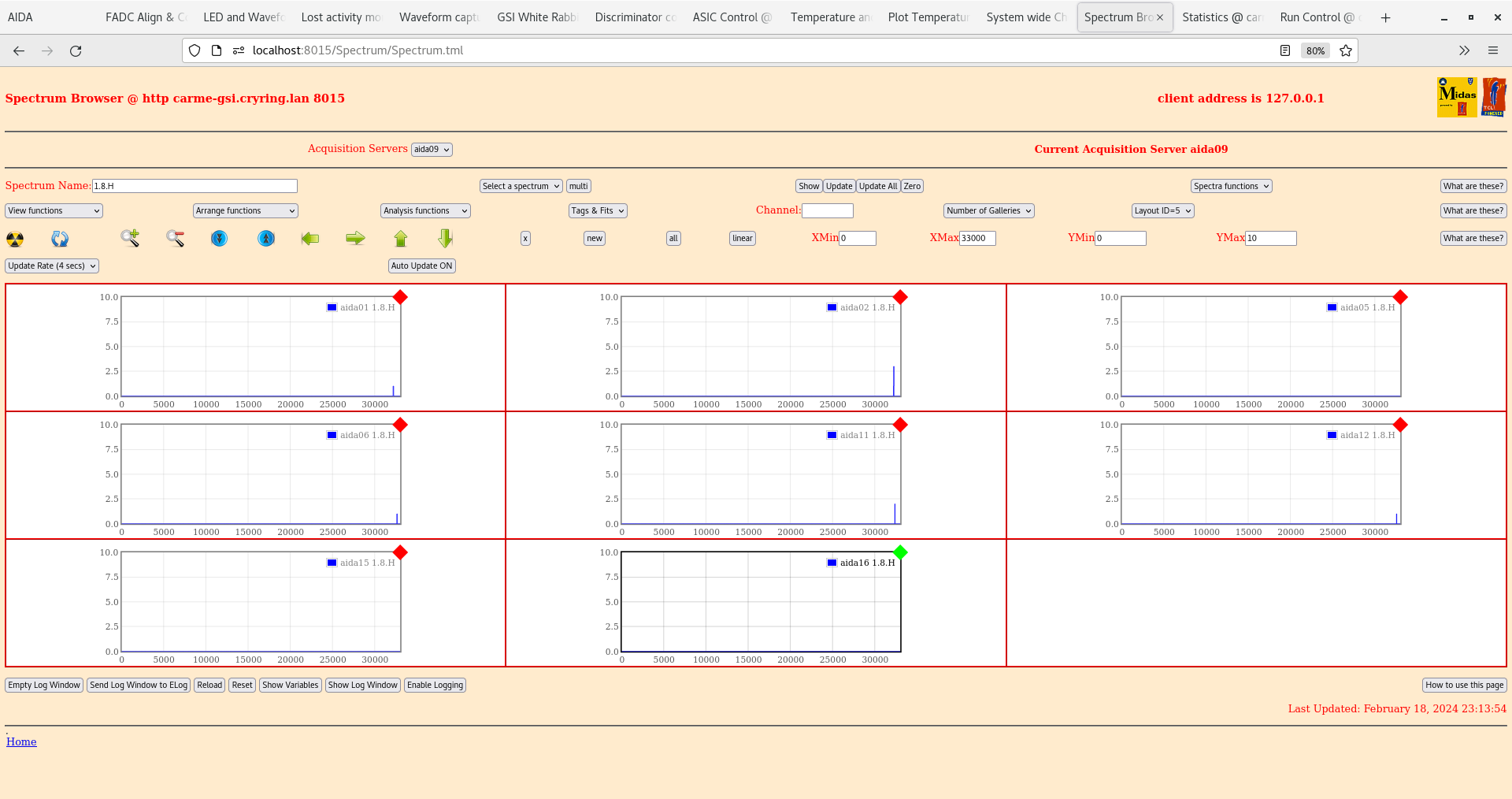

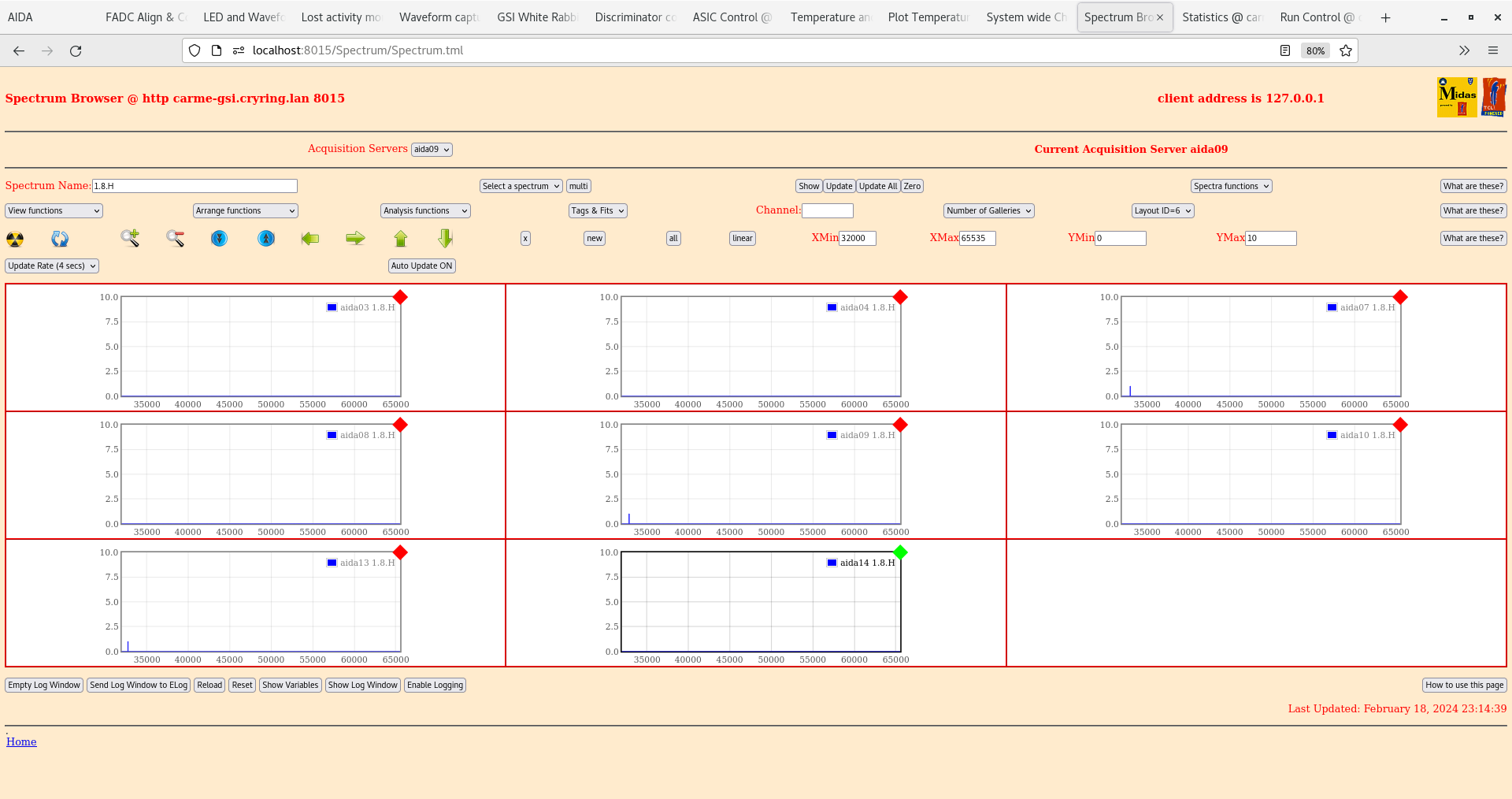

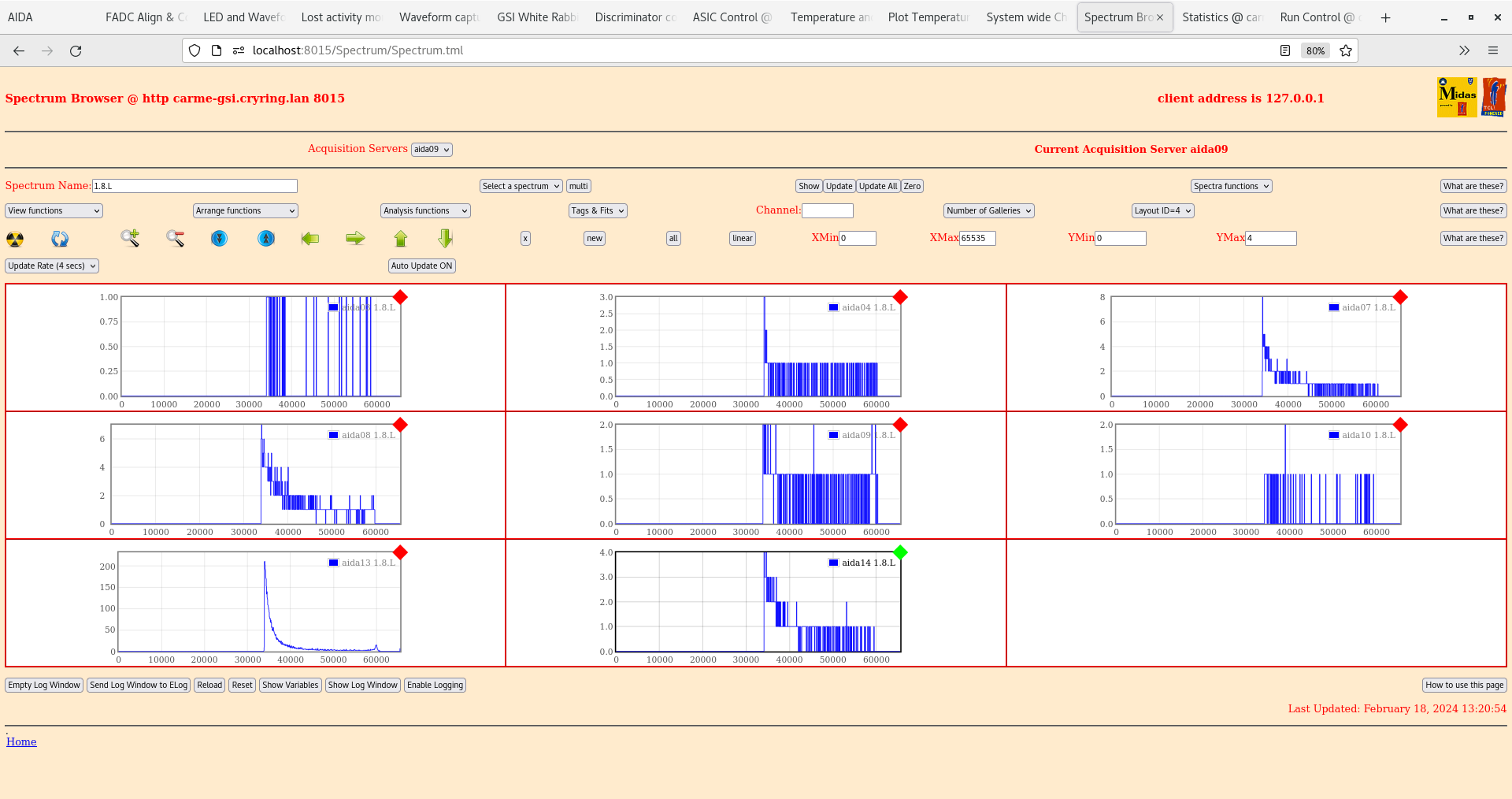

per FEE64 Rate spectra - attachments 11-12

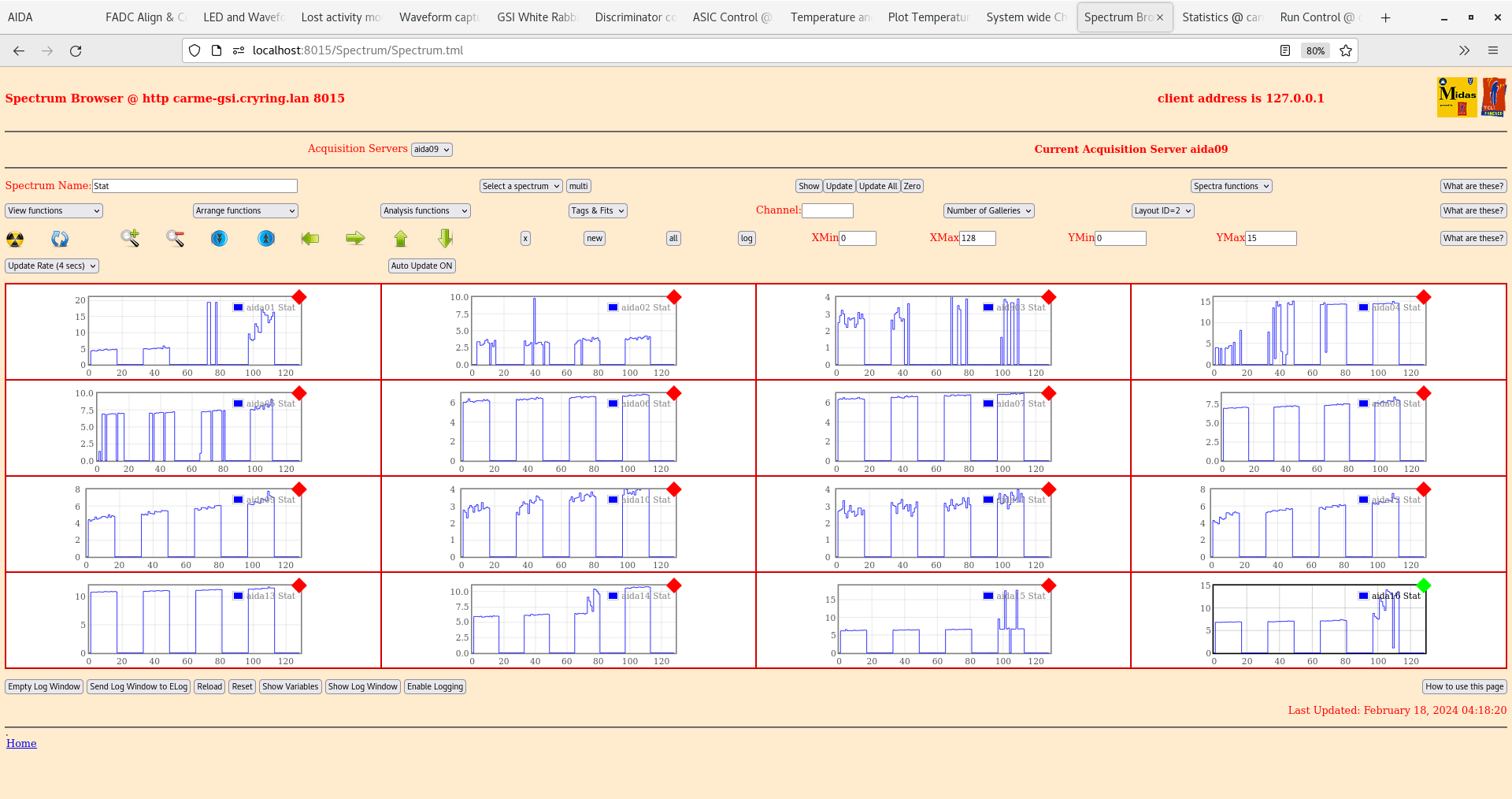

per FEE64 Stat spectra - attachments 13-14

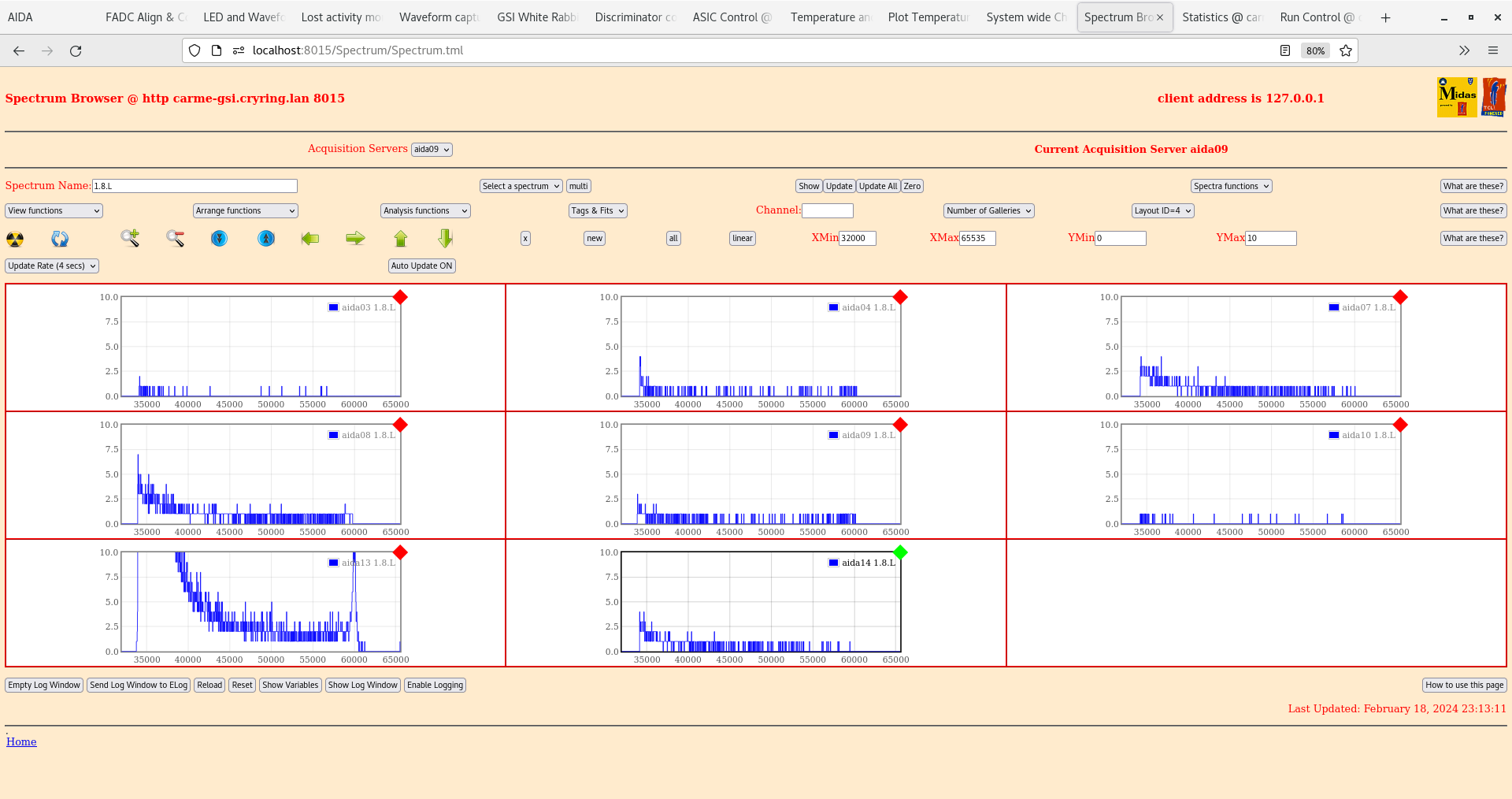

per FEE64 1.8.L, 1.8.H and 1.8.W 20us FSR spectra - attachments 15-20

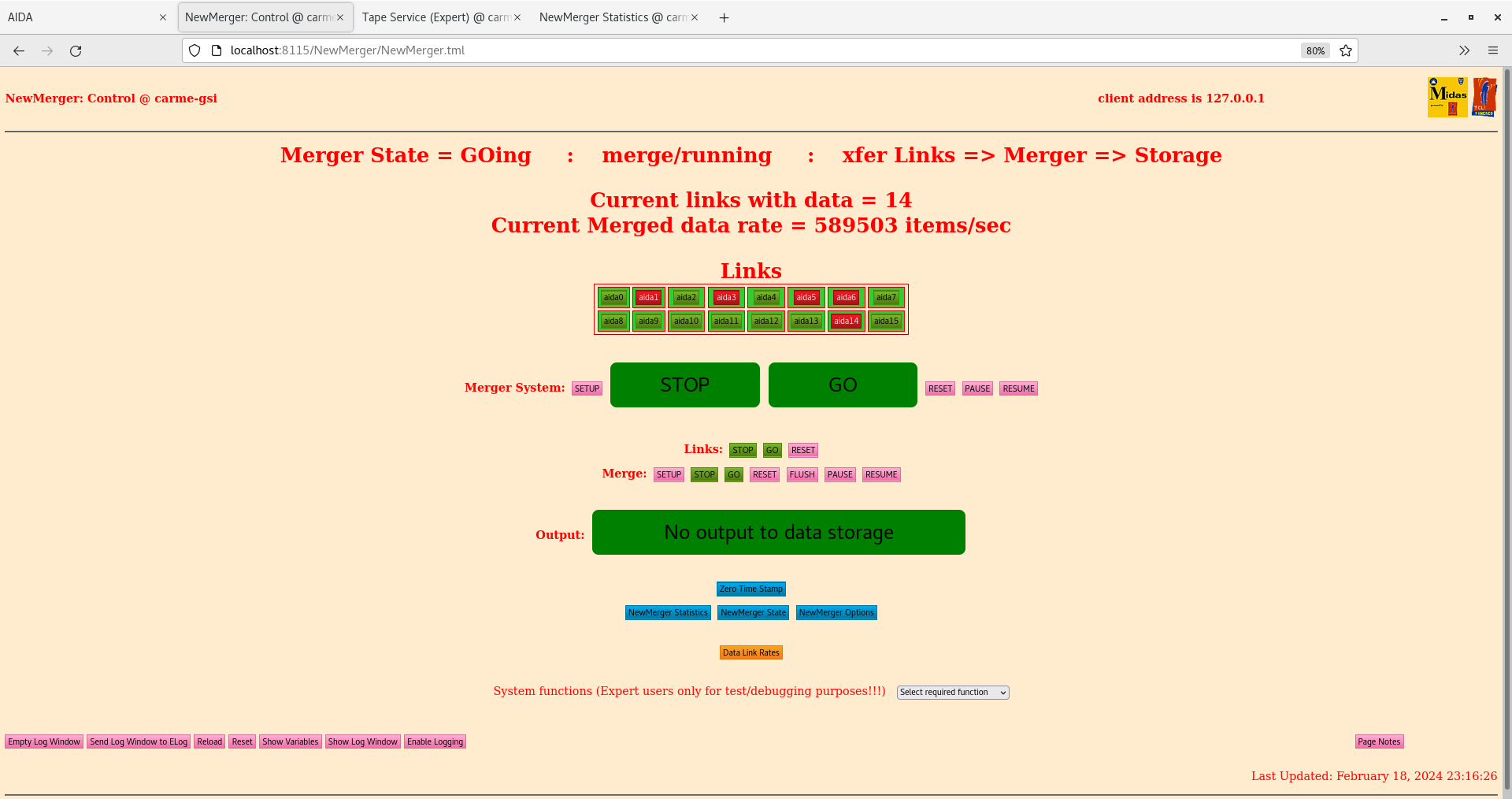

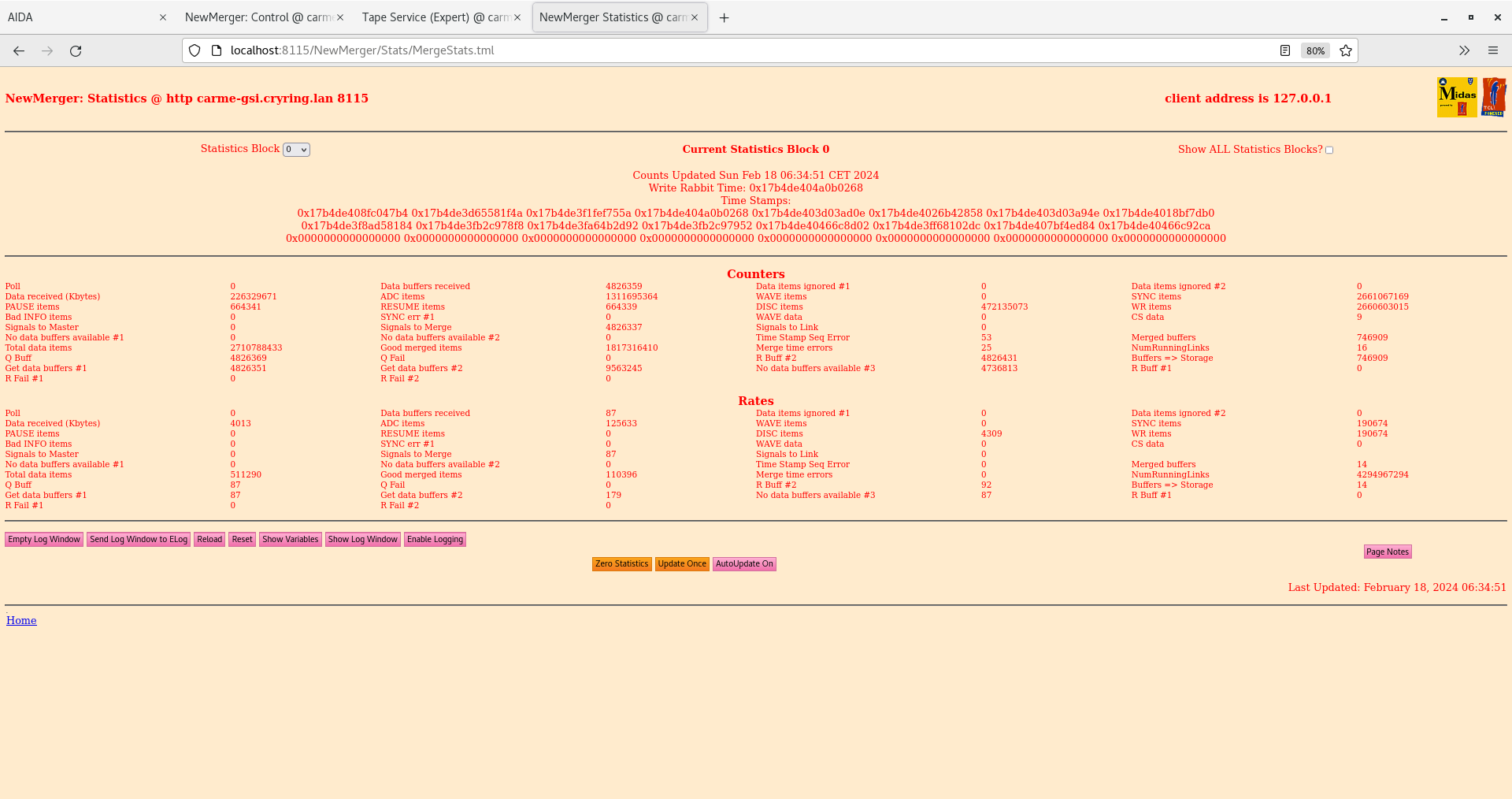

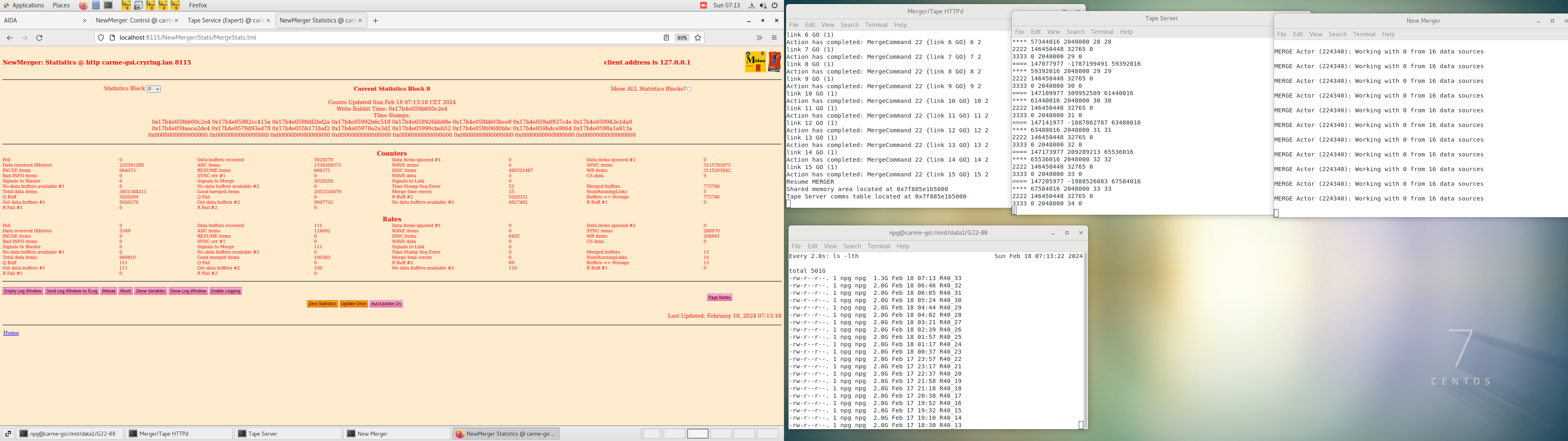

Merger, Merger stats and TapeServer OK - attachments 21-23

online analysis spectra - attachments 25-30

23.28 all histograms, stats, Merger stats zero'd

online analysis restarted

23.35 target density 5.83e+11/cm2

beam no change in last 3 hours ( cannot read scale with X2Go )

see attachments 31-33

00.58 DAQ continues file G22-86/R42_24

DSSSD bias & leakage current - attachments 34-35

DSSSD #0 trending upwards , DSSSD #1-3 trending downwards with decreasing ambient temperature

FEE64 temperatures OK - attachments 36-37

ADC data item stats - attachment 38

per FEE64 Rate spectra - attachments 39

target density 5.75e+11/cm2

beam no change in last 3 hours ( cannot read scale with X2Go )

03.14 DAQ continues file G22-86/R42_28

DSSSD bias & leakage current - attachments 40-41

DSSSD #0 trending upwards , DSSSD #1-3 trending downwards with decreasing ambient temperature

FEE64 temperatures OK - attachments 42-43

ADC data item stats - attachment 44

per FEE64 Rate spectra - attachments 45

target density 5.91e+11/cm2

beam decreased in last 3 hours ( cannot read scale with X2Go )

see attachments 46-47

03:30 beam recovered

online analysis rates DSSSD#0 recovered to values observed at start of shift |

| Attachment 1: Capture.PNG

|

|

| Attachment 2: Capture_2.PNG

|

|

| Attachment 3: Screenshot_from_2024-02-18_23-05-47.png

|

|

| Attachment 4: Screenshot_from_2024-02-18_23-06-14.png

|

|

| Attachment 5: Screenshot_from_2024-02-18_23-06-56.png

|

|

| Attachment 6: Screenshot_from_2024-02-18_23-07-42.png

|

|

| Attachment 7: Screenshot_from_2024-02-18_23-08-07.png

|

|

| Attachment 8: Screenshot_from_2024-02-18_23-08-29.png

|

|

| Attachment 9: Screenshot_from_2024-02-18_23-08-53.png

|

|

| Attachment 10: Screenshot_from_2024-02-18_23-09-16.png

|

|

| Attachment 11: Screenshot_from_2024-02-18_23-10-18.png

|

|

| Attachment 12: Screenshot_from_2024-02-18_23-10-41.png

|

|

| Attachment 13: Screenshot_from_2024-02-18_23-11-31.png

|

|

| Attachment 14: Screenshot_from_2024-02-18_23-11-48.png

|

|

| Attachment 15: Screenshot_from_2024-02-18_23-12-38.png

|

|

| Attachment 16: Screenshot_from_2024-02-18_23-13-20.png

|

|

| Attachment 17: Screenshot_from_2024-02-18_23-14-03.png

|

|

| Attachment 18: Screenshot_from_2024-02-18_23-14-45.png

|

|

| Attachment 19: Screenshot_from_2024-02-18_23-15-21.png

|

|

| Attachment 20: Screenshot_from_2024-02-18_23-15-58.png

|

|

| Attachment 21: Screenshot_from_2024-02-18_23-16-33.png

|

|

| Attachment 22: Screenshot_from_2024-02-18_23-16-49.png

|

|

| Attachment 23: Screenshot_from_2024-02-18_23-17-01.png

|

|

| Attachment 24: Screenshot_from_2024-02-18_23-18-10.png

|

|

| Attachment 25: Screenshot_from_2024-02-18_23-18-26.png

|

|

| Attachment 26: Screenshot_from_2024-02-18_23-18-38.png

|

|

| Attachment 27: Screenshot_from_2024-02-18_23-18-48.png

|

|

| Attachment 28: Screenshot_from_2024-02-18_23-18-59.png

|

|

| Attachment 29: Screenshot_from_2024-02-18_23-19-18.png

|

|

| Attachment 30: Screenshot_from_2024-02-18_23-19-39.png

|

|

| Attachment 31: 20240218_223433.jpg

|

|

| Attachment 32: 20240218_223341.jpg

|

|

| Attachment 33: 20240218_223509.jpg

|

|

| Attachment 34: Screenshot_from_2024-02-19_00-54-56.png

|

|

| Attachment 35: Screenshot_from_2024-02-19_00-55-14.png

|

|

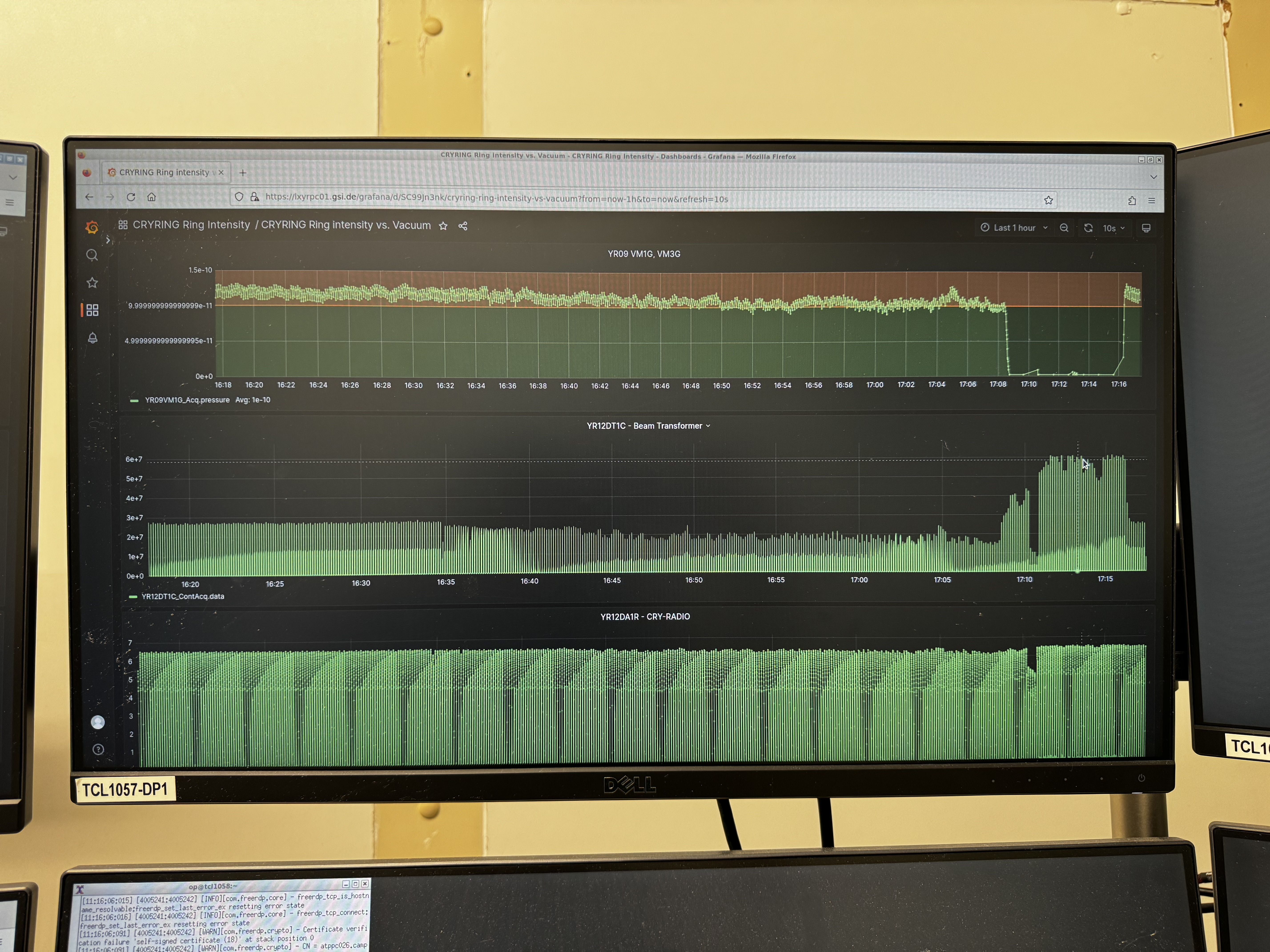

| Attachment 36: Screenshot_from_2024-02-19_00-55-44.png

|

|

| Attachment 37: Screenshot_from_2024-02-19_00-56-14.png

|

|

| Attachment 38: Screenshot_from_2024-02-19_00-56-42.png

|

|

| Attachment 39: Screenshot_from_2024-02-19_00-57-31.png

|

|

| Attachment 40: Screenshot_from_2024-02-19_03-14-25.png

|

|

| Attachment 41: Screenshot_from_2024-02-19_03-14-48.png

|

|

| Attachment 42: Screenshot_from_2024-02-19_03-15-18.png

|

|

| Attachment 43: Screenshot_from_2024-02-19_03-15-43.png

|

|

| Attachment 44: Screenshot_from_2024-02-19_03-16-04.png

|

|

| Attachment 45: Screenshot_from_2024-02-19_03-16-50.png

|

|

| Attachment 46: 20240219_022309.jpg

|

|

| Attachment 47: 20240219_022316.jpg

|

|

|

530

|

Mon Feb 19 06:01:17 2024 |

SHB, JM, JG | Run 42 morning shift |

07:00

Observed reduction in YR09 presure over last few hours in ML online plot. Beam intensity looks OK but target density was fluctuating quite a lot. Current value was 1.5e11.

Changed the nozzle position slightly which increased target density to 5.5e11. Pressure in YR09 looks OK.

I accidently scrolled slightly with the target code (only by 100 but am not sure). Target looks stable but I will not touch remotely again for fear of losing total target position.

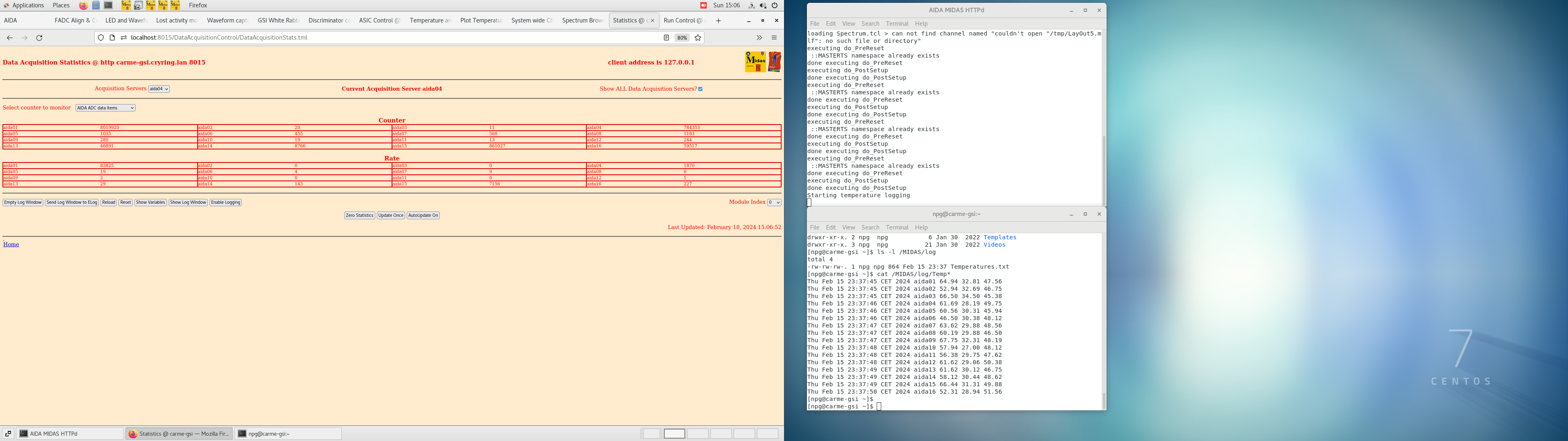

Rates in ADC data items statistics and in the monitoring code look consistent with beam on target.

08:56

Target density reduced again to 1.5e11. Changed the nozzle position slightly in X and recovered 5.5e11 at/cm2

Beam intensity looks OK

FEE temps OK

System checks OK

Merger and tape server OK

Statistics ADC data items and spectrum browser rates OK

Merger stats attachement 5

leakage current plot attachment 6

Online monitoring code rates OK

09:33

Run stopped to change beam energy

|

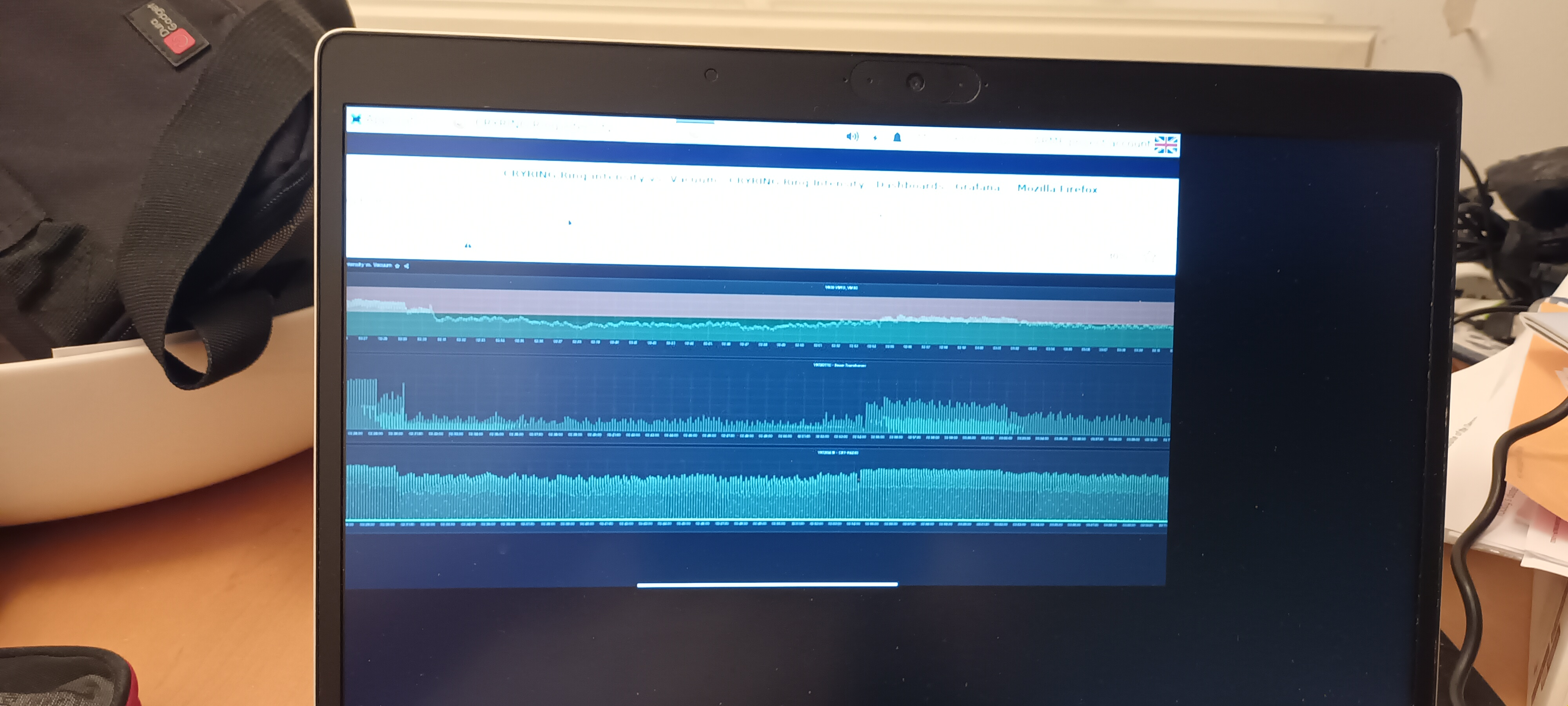

| Attachment 1: Screenshot_from_2024-02-19_08-11-42.png

|

|

| Attachment 2: Screenshot_from_2024-02-19_08-12-02.png

|

|

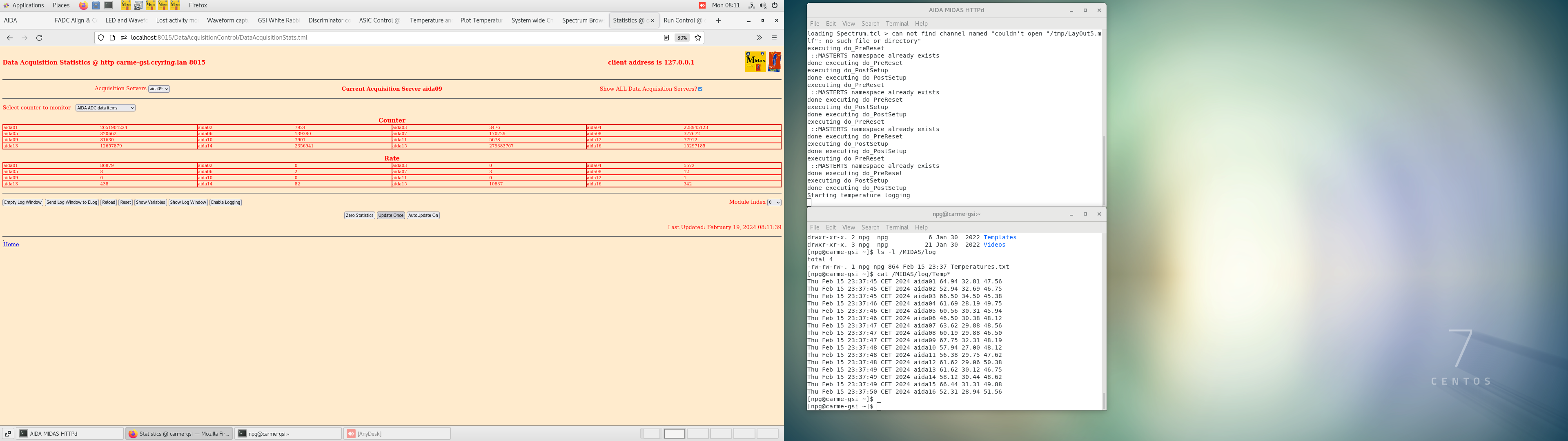

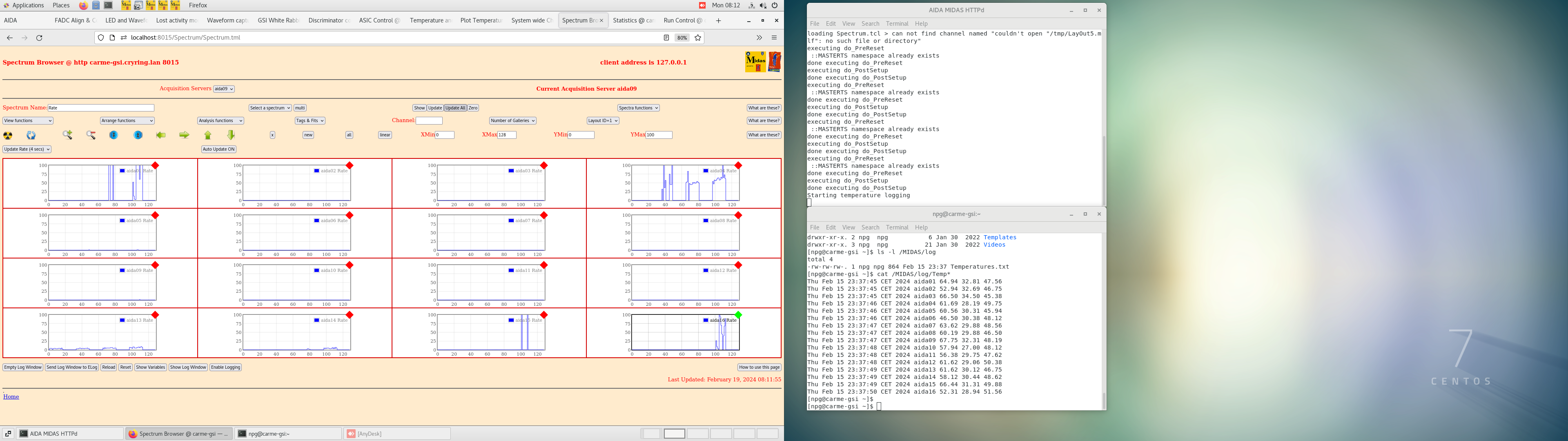

| Attachment 3: Screenshot_from_2024-02-19_08-12-27.png

|

|

| Attachment 4: Screenshot_from_2024-02-19_08-12-47.png

|

|

| Attachment 5: Screenshot_from_2024-02-19_08-57-23.png

|

|

| Attachment 6: Screenshot_from_2024-02-19_08-59-08.png

|

|

|

712

|

Mon Jun 2 16:35:35 2025 |

EW, AG | Run 42 and scraper tests |

17:00

Scraper tests conducted. We tried moving in the scrapers both at a fixed position throughout and also moving with the injection cycle.

We were unable to find a good position with the scrapers that did not produce significant scattering in the detectors.

Therefore we have moved the scrapers back to the fully out position.

Run 42 started.

We have increased the storage time to 10 reps (1 minute) in order to investigate the shoulders on the 3He peaks online and whether it is likely from injection. I think it is likely just a calibration issue

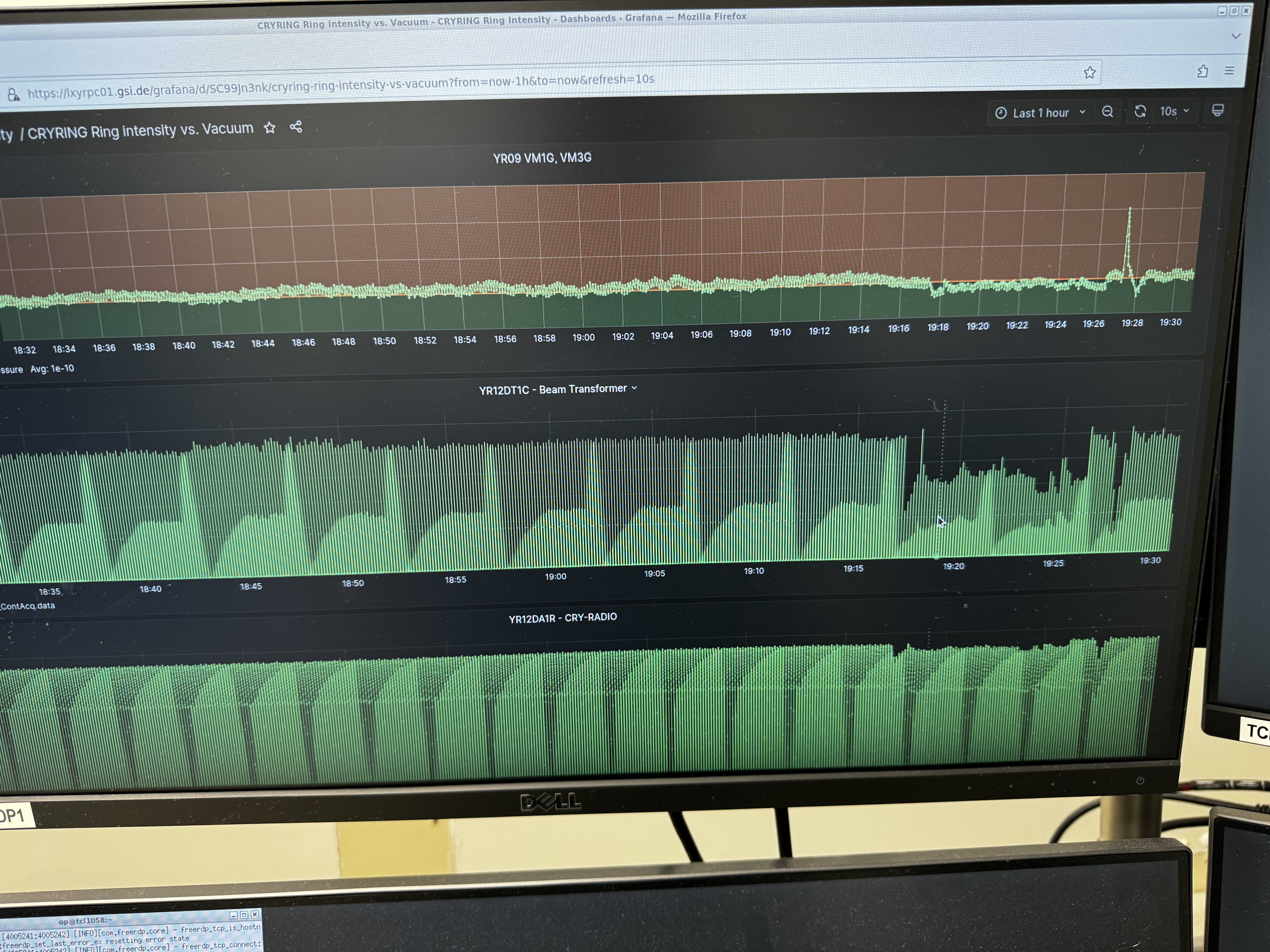

D+ beam deuterium target. D+ beam energy is 0.75 MeV/u. (beam calc calculation is 0.7619 MeV/u). See previous entry for beamcalc.

Beam calc - Attachment 1

Target density is about 2e12 at/cm2

All four detectors positioned fully out and stationary.

Left potentiometer = 18.86 mm

Right potentiometer = 19.8 mm

Ring cycle time is 60 seconds. Note we see some hydrogen in in the spectrum, this disapears after a few seconds.

Target T1=30.0K, T2=31.6K.

Nozzle position x=-2.96, z=1.72 mm

YR09-Etarget pressure = 2.0e-10 mbar.

Cooler set value = 439 V, 15 mA. Read value = 439.81 V, 12.88 mA

All leakage currents look good

Beam position. Vertical =0.0mm , Horizontal=-1.5 mm

Beam intensity ~6e8 on bunched beam, 6e8 on coasting.

Data rate ~ 416kB/s

slow comparator threshold to 0x24 (360 keV) |

| Attachment 1: Screenshot_from_2025-06-02_17-44-07.png

|

|

| Attachment 2: Screenshot_from_2025-06-02_17-44-50.png

|

|

|

527

|

Sun Feb 18 13:58:33 2024 |

AR, OF, JM | Run 42 - cooled beam on target |

Run 42 - 15:00

Detectors IN (left arm pot =36.54 mm, right arm pot = 70.49 mm). Stationary. Same as run 40

Electron cooler voltage 751.89 V this corresponds to 1.3444 MeV/u. This should be on the right of the peak of the resonance.

Target density is 5.03e11 at/cm2, ring pressure looks OK YR09 2.36e-10 mbar.

Horizontal beam position is -7.5 mm, vertical beam position is 0.0 mm. Same as run 40.

Beam is in the ring for 4 seconds and total cycle time between injections is 8 seconds. Notice this is the samet as run 40, different to run 35.

Statistics, merger statistics, histograms all zero'd

System wide checks ok. Temperatures ok. Leakage current ok. Merger ok.

Attatchment 1: Stats

Attatchment 2: Temperatures

Attatchments 3-6: Waveforms

Attatchment 7:Leakage current

Attatchment 8: Monitoring code rates

15.35 DSSSD #0 leakage current trending somewhat upwards cf. somewhat downwards for DSSSD #1-3

ML CRYRING hall ambient temprature c. 17.7. deg C and on downward trend.

Probably indicates radiation damage/surface charging of DSSSD #0 - leave DSSSD #0 biased for 24-48h following run and monitor leakage current

15:46

Seeing some beam intensity drops occasionally. Small drop that instantamnously went back up around 15:20 and then stbale beam unitl around 15:44 and then two small-time beam drops within 2 minutes. See attatchment 9. Continuing to monitor. Target density remains stable at 5e11.

16:45

Beam dropping again and continuing to drop (began at 16:35). Target density 4.7e11. Called HKR and they will try to increase the intensity. See attatchment 10.

17:00

System checks ok. Temperatures ok. Leakage current plot okay. Merger ok. Beam intensity still reduced to same amount as in attatchment 10). Target density approx 5e11.

Attatchment 1:1 Stats

Attatchment 12: Temperatures

Attatchments 13-16: Waveforms

Attatchment 17:Leakage current

Attatchment 18: Monitoring code rates

17:10

HKR cryring asked for target to be removed to check intensity. Target was removed.

17:17

Target back in, intensity back to around 2.5e7. Stable. Target desity 5e11.

18:42

All system checks and tempeatures ok. Beam stable. Target 2.3e11.

Leakage current: red line still trending upwards but slowly. See image 24.

10:30

Beam went down about 21:45. Called HKR and they were able to almost immediately restore the beam. Beam intensity ~2.5e7.

Target density 5.6e11 at/cm2, pressure in YR09 ~2.5e-10 mbar.

FEE temps and system check OK

Merger and tape server OK

Merger stats (attachment 25)

All rates in spectrum browser look OK

Monitoring code rates indicate beam on target.

|

| Attachment 1: Screenshot_from_2024-02-18_15-06-55.png

|

|

| Attachment 2: Screenshot_from_2024-02-18_15-07-13.png

|

|

| Attachment 3: Screenshot_from_2024-02-18_15-07-56.png

|

|

| Attachment 4: Screenshot_from_2024-02-18_15-08-32.png

|

|

| Attachment 5: Screenshot_from_2024-02-18_15-09-10.png

|

|

| Attachment 6: Screenshot_from_2024-02-18_15-10-02.png

|

|

| Attachment 7: Screenshot_from_2024-02-18_15-10-44.png

|

|

| Attachment 8: Screenshot_from_2024-02-18_15-11-03.png

|

|

| Attachment 9: IMG_7922.jpg

|

|

| Attachment 10: IMG_7932.jpg

|

|

| Attachment 11: Screenshot_from_2024-02-18_16-58-04.png

|

|

| Attachment 12: Screenshot_from_2024-02-18_16-58-17.png

|

|

| Attachment 13: Screenshot_from_2024-02-18_16-59-30.png

|

|

| Attachment 14: Screenshot_from_2024-02-18_17-00-01.png

|

|

| Attachment 15: Screenshot_from_2024-02-18_17-00-32.png

|

|

| Attachment 16: Screenshot_from_2024-02-18_17-00-53.png

|

|

| Attachment 17: Screenshot_from_2024-02-18_17-01-32.png

|

|

| Attachment 18: Screenshot_from_2024-02-18_17-01-45.png

|

|

| Attachment 19: IMG_7934.jpg

|

|

| Attachment 20: Screenshot_from_2024-02-18_18-42-41.png

|

|

| Attachment 21: Screenshot_from_2024-02-18_18-43-16.png

|

|

| Attachment 22: Screenshot_from_2024-02-18_18-43-35.png

|

|

| Attachment 23: Screenshot_from_2024-02-18_18-43-58.png

|

|

| Attachment 24: Screenshot_from_2024-02-18_18-44-24.png

|

|

| Attachment 25: Screenshot_from_2024-02-18_18-44-44.png

|

|

| Attachment 26: Screenshot_from_2024-02-18_18-44-52.png

|

|

| Attachment 27: Screenshot_from_2024-02-18_22-42-10.png

|

|

|

595

|

Fri Jun 7 10:05:40 2024 |

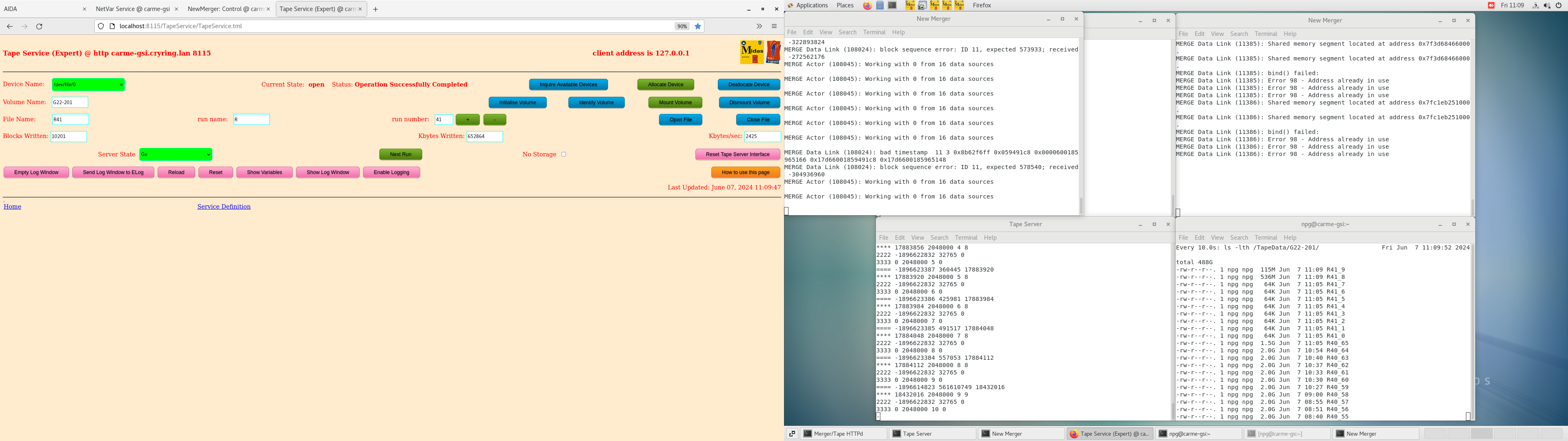

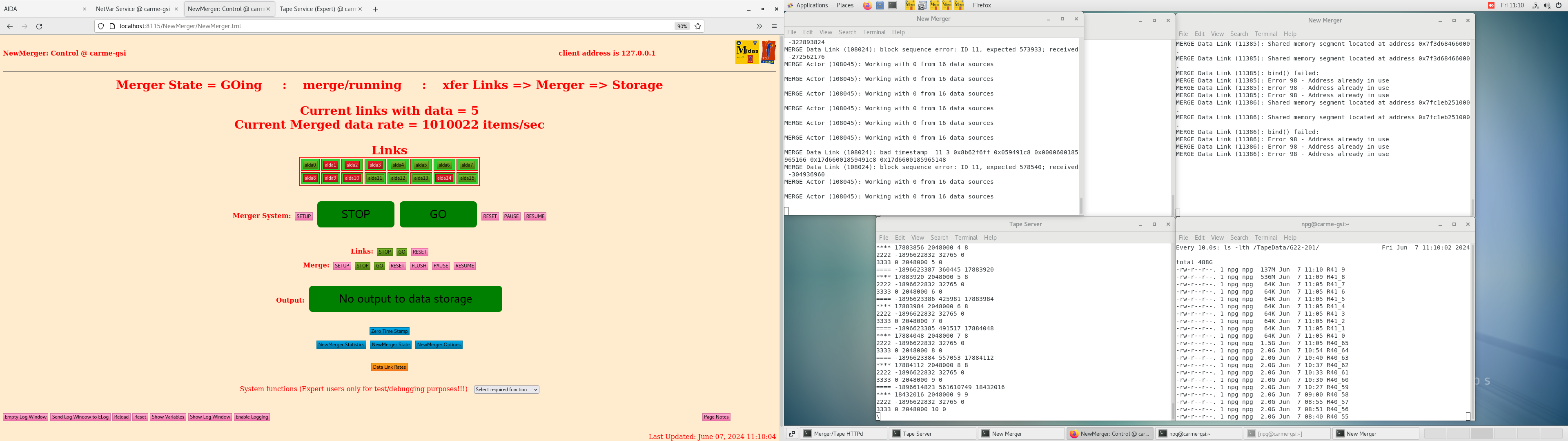

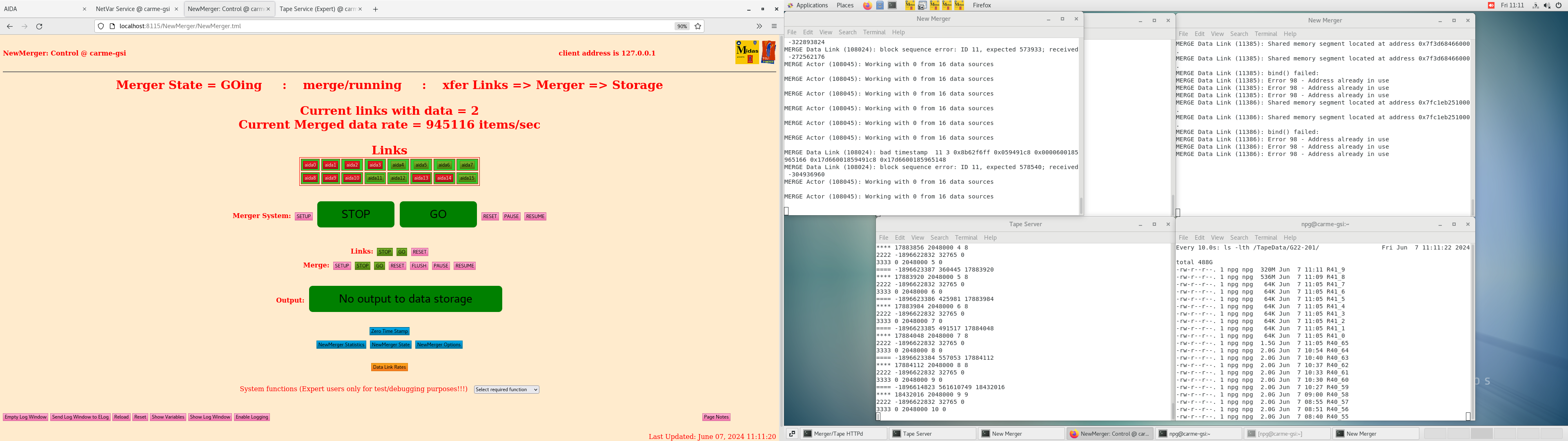

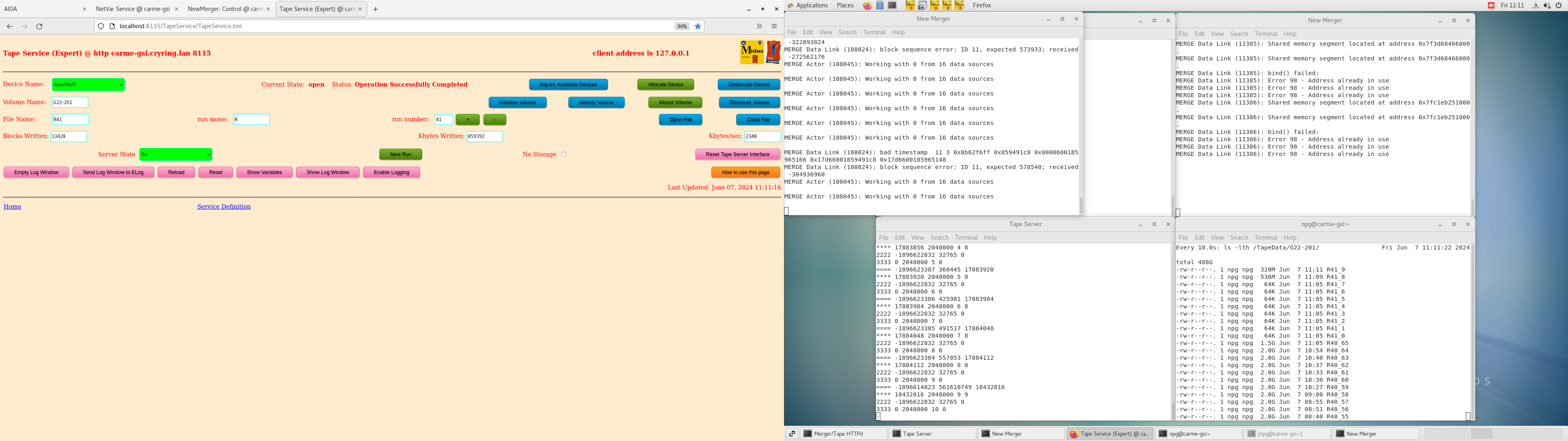

CB | Run 41/42/43 - 15N data taking start |

11:05

Confirmed overlap is at 4 mm under new settings.

For unclear reasons, the bottom-left detector is not seeing the halo anymore since around 10:00. Rutherford still visible and if the left arm is moved in the counts at 5 MeV become apparent.

l s by 20 mm, r p in -> 36.5 mm / 64.6 mm

Target thickness 3E11 atoms/cm2. Beam intensity few E7 at injection. Coasting beam mode.

Data rate x10 compared with earlier. Stats as before - the reason is unclear.

Temps & Merger OK. We should be able to tolerate these rates.

Moved detectors in/out to make sure we were not clipping the beam. A few seconds of data may be present in R41_9

11:30

Checkloaded. Detector 2 is now counting more.

Moved to run 42. No other changes.

13:00

Realised cooler voltage was being read via fault g35 divider. Beam stopped

15:00

Switched to F20. Beam back on. Moved to run 43

Electron cooler voltage = 243.155 V

Collector current = 4.29 mA

Beam energy was slightly off, will try again |

| Attachment 1: Screenshot_from_2024-06-07_11-08-08.png

|

|

| Attachment 2: Screenshot_from_2024-06-07_11-08-21.png

|

|

| Attachment 3: Screenshot_from_2024-06-07_11-08-57.png

|

|

| Attachment 4: Screenshot_from_2024-06-07_11-09-10.png

|

|

| Attachment 5: Screenshot_from_2024-06-07_11-09-56.png

|

|

| Attachment 6: Screenshot_from_2024-06-07_11-10-05.png

|

|

| Attachment 7: Screenshot_from_2024-06-07_11-11-23.png

|

|

| Attachment 8: Screenshot_from_2024-06-07_11-11-26.png

|

|

|

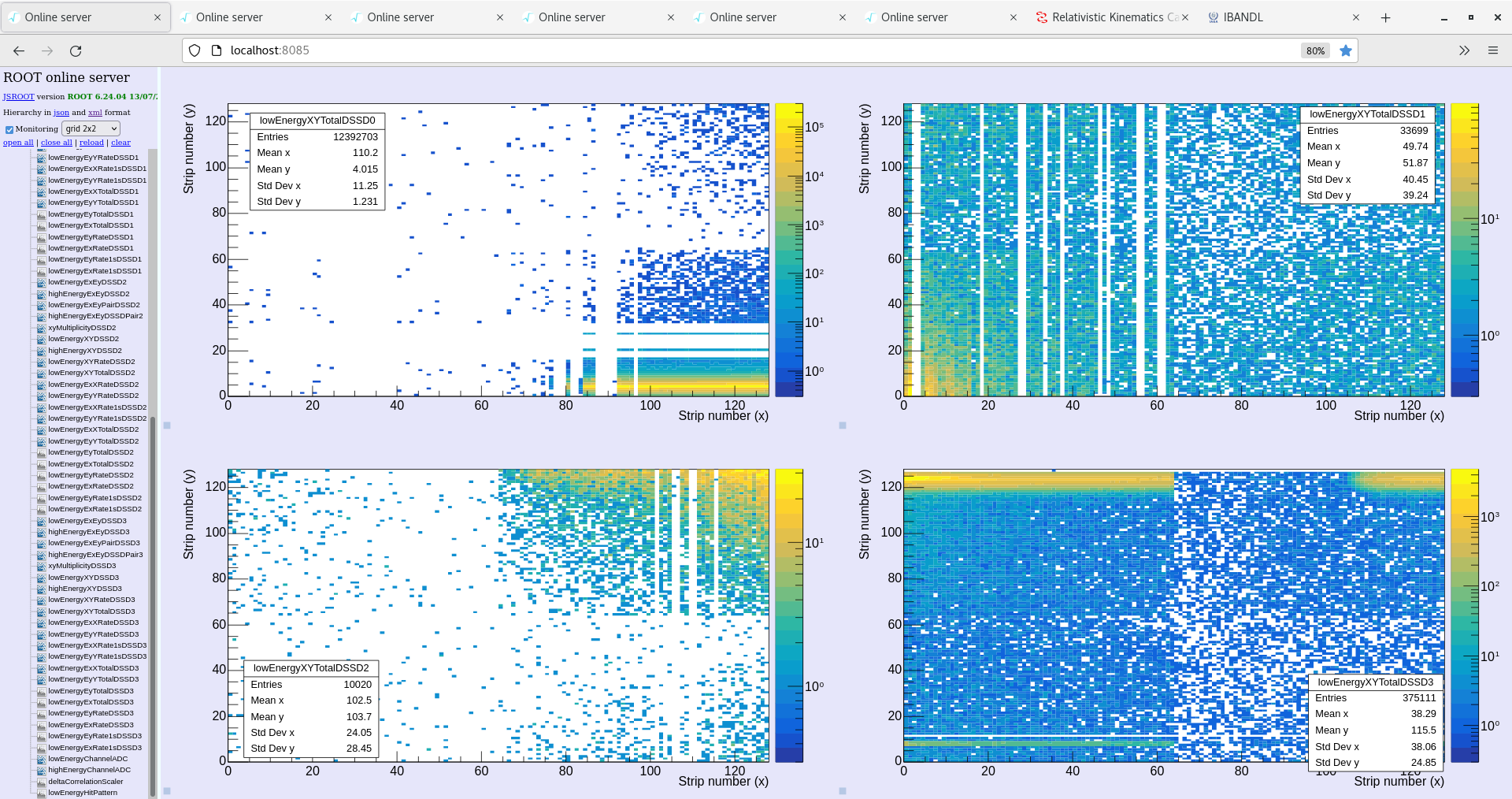

200

|

Wed Feb 16 15:27:53 2022 |

EM, JM | Run 41 Pulser tests |

16:30

NOTE: Pulser is ON!

Check Leakage current: (see attachment 1)

Check NewMerger tab: (see attachment 2)

Check Fee temperatures: all green (see attachment 3)

Check statistics tab: ADC data items (see attachment 4)

ADC coincidence-info #8 (see attachment 5)

Good events (see attachment 6)

Check Spectrum Browser tab: (see attachment 7)

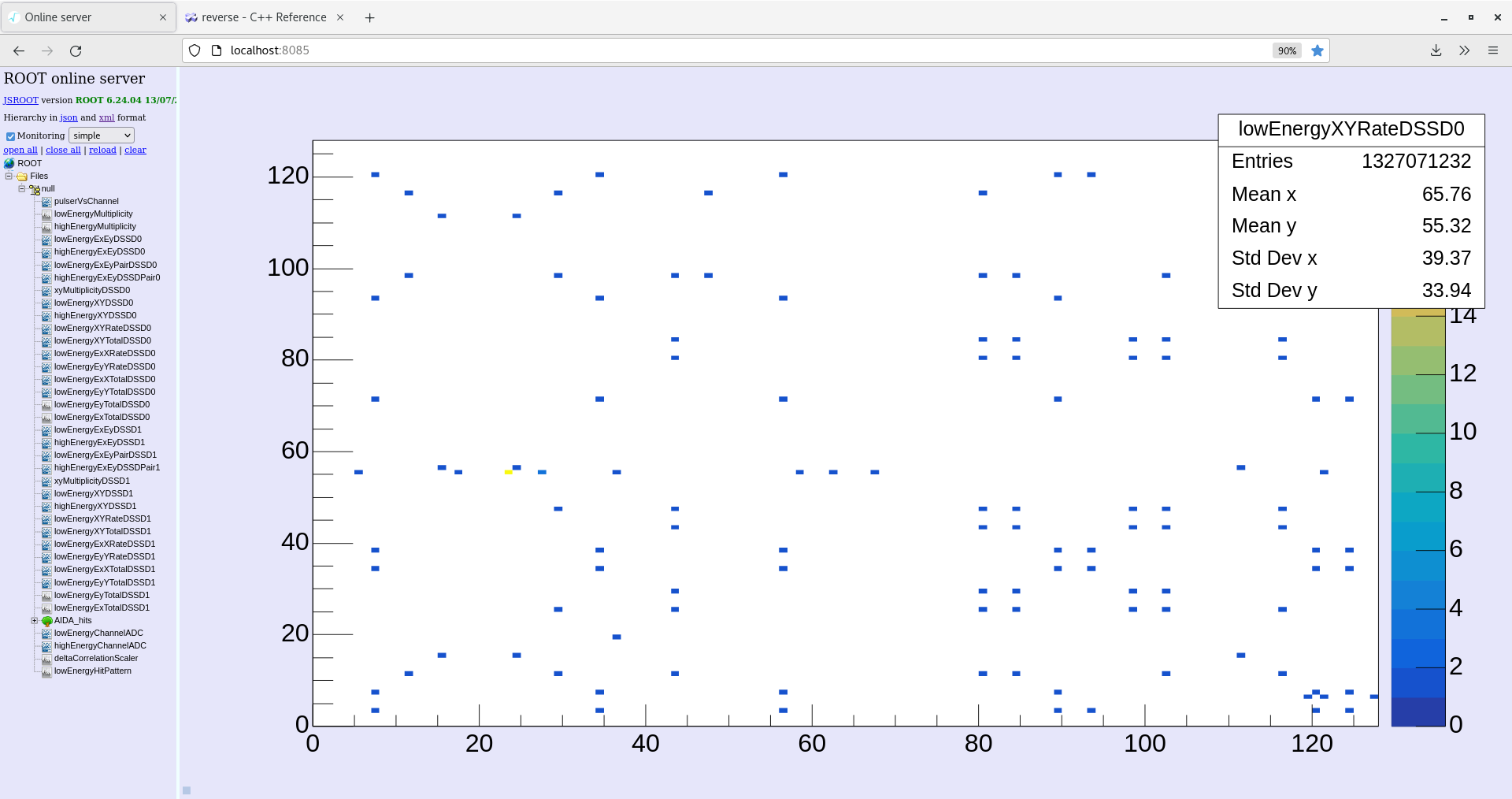

Check the following plots: LowEnergyXYRateDSSD0 (see attachment 8)

LowEnergyXYTotalDSSD0 (see attachment 9)

LowEnergyExTotal (see attachment 10)

LowEnergyEyTotal (see attachment 11)

Check system wide checks tab: all okay.

All is good. |

| Attachment 1: 2022-02-16_16-05-20_leakagecurrent.png

|

|

| Attachment 2: 2022-02-16_16-08-00_newmerger.png

|

|

| Attachment 3: 2022-02-16_16-09-05_feetemperatures.png

|

|

| Attachment 4: 2022-02-16_16-11-10_aida_adc_data.png

|

|

| Attachment 5: 2022-02-16_16-12-20_aida01_goodevents.png

|

|

| Attachment 6: 2022-02-16_16-13-29_aida01_correlationinfo.png

|

|

| Attachment 7: 2022-02-16_16-16-43_spectrumbrowser.png

|

|

| Attachment 8: 2022-02-16_16-21-39_lowenergyXYrate.png

|

|

| Attachment 9: 2022-02-16_16-23-56_lowenergyXYtotal.png

|

|

| Attachment 10: 2022-02-16_16-25-16_lowenergyEytotal.png

|

|

| Attachment 11: 2022-02-16_16-25-53_lowenergyExtotal.png

|

|

|

711

|

Mon Jun 2 09:30:38 2025 |

JM, EW, ST | Run 41 |

Run 41 started.

D+ beam deuterium target. D+ beam energy is 0.75 MeV/u. (beam calc calculation is 0.7619 MeV/u). See previous entry for beamcalc.

Beam calc - Attachment 1

Target density is about 3e12 at/cm2

All four detectors positioned fully out and stationary.

Left potentiometer = 18.86 mm

Right potentiometer = 19.8 mm

Ring cycle time is 25 seconds. Note we see some hydrogen in in the spectrum, this disapears after a few seconds.

Target T1=30.0K, T2=31.9K.

Nozzle position x=-2.96, z=1.72 mm

YR09-Etarget pressure = 2.0e-10 mbar.

Cooler set value = 439 V, 15 mA. Read value = 439.81 V, 12.88 mA

All leakage currents look good

Beam position. Vertical =0.0mm , Horizontal=-1.5 mm

Beam intensity ~3e8 on bunched beam, 3e8 on coasting. Gleb has increased the intensity this morning.

Data rate ~ 403kB/s

Lowered slow comparator threshold to 0x24 (360 keV)

13:20 Run stopped

Wolfgang tuning next beam energy

All checks fine

Total stats: 7827,4085,1821

OFFLINE CHECK

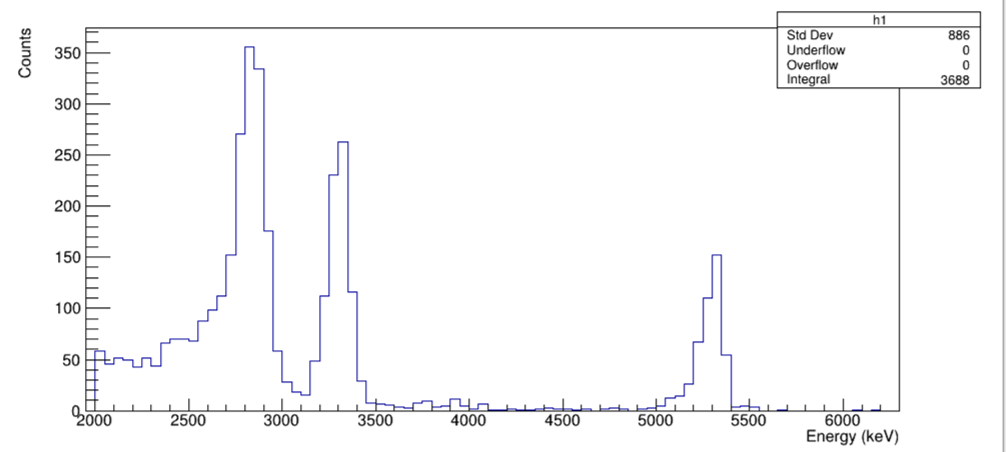

I have check Run41 and applied the gain calibration from 2024 in addition to a tigher EyEx energy cut (600 keV from 3 MeV for the online script). We no longer see the larger hump to the side of the 3He peak in DSSD1. See final attachment for comparison.

Note no time cuts have been applied to this spectra.and a more rigourous gain calibration using the igher energy D+ runs will likely improve things further. |

| Attachment 1: Screenshot_from_2025-06-02_10-37-39.png

|

|

| Attachment 2: Screenshot_from_2025-06-02_10-38-36.png

|

|

| Attachment 3: Screenshot_from_2025-06-02_13-21-06.png

|

|

| Attachment 4: Screenshot_from_2025-06-02_13-20-36.png

|

|

| Attachment 5: Screenshot_from_2025-06-02_13-20-19.png

|

|

| Attachment 6: DSSD1-Ey.png

|

|

|

525

|

Sun Feb 18 07:53:51 2024 |

HW AG | Run 40 Morning Shift |

08:57 Doing morning check. Checked the leakage currents, all ok. Attachment 1

Tempritures of, attchment 2

System wide check, all correct.

Statistics ok, aida 4 was a little high, carlo oked it attachment 3 and 4 (hist)

Spectrum brozer, ok, attachment 5 and 6

Waveforem atachment 7 and 8

Checked merger, spinner spinning...

Attached screenshot of merger 9

11:15 Beam current is around 2.5E7 and the target dencity is 5.3E11 cm2, there was small isntability (dips) from the beam, reason unknown, all detectors stable.

Check leakage current, is stable, attachment 1

Tempreture ok, attachment 2

System wide check, all pass

Statistics checked, attachment 3, aida 4 is still high, histograms attachment 4

Spectrum browser ok, attachment 5 and 6

Waveforms attachment 7 and 8

Checked merger, ok, spinner is spinning,

Attachment 9 is the merger info

12:21 Targer intencity started dropping quite dramatically. The beam position X value was adjusted to -11000, we got back above 4E11 /cm2

13:08 Beam current is around 2.5E7 pretty stable, target is working, 61E11 /cm2, stable

Checked leakage current, stable, attachment 1

Temp. stable, atatchment 2

System wide chack, all pass

Statistics checked, attachemnt 3, aida 4 should be checked, histogram of rates 4 attached

Spectrum browser, attached 5 and 6

Waveform attached 7 and 8

Merger ok, spinner is pinning,

Attached 9 merger info

|

| Attachment 1: Screenshot_from_2024-02-18_08-58-55.png

|

|

| Attachment 2: Screenshot_from_2024-02-18_09-02-22.png

|

|

| Attachment 3: Screenshot_from_2024-02-18_09-09-25.png

|

|

| Attachment 4: Screenshot_from_2024-02-18_09-11-15.png

|

|

| Attachment 5: Screenshot_from_2024-02-18_09-14-10.png

|

|

| Attachment 6: Screenshot_from_2024-02-18_09-14-41.png

|

|

| Attachment 7: Screenshot_from_2024-02-18_09-15-52.png

|

|

| Attachment 8: Screenshot_from_2024-02-18_09-16-34.png

|

|

| Attachment 9: Screenshot_from_2024-02-18_09-20-35.png

|

|

| Attachment 10: Screenshot_from_2024-02-18_11-17-59.png

|

|

| Attachment 11: Screenshot_from_2024-02-18_11-18-31.png

|

|

| Attachment 12: Screenshot_from_2024-02-18_11-20-03.png

|

|

| Attachment 13: Screenshot_from_2024-02-18_11-21-37.png

|

|

| Attachment 14: Screenshot_from_2024-02-18_11-23-10.png

|

|

| Attachment 15: Screenshot_from_2024-02-18_11-24-12.png

|

|

| Attachment 16: Screenshot_from_2024-02-18_11-24-59.png

|

|

| Attachment 17: Screenshot_from_2024-02-18_11-25-49.png

|

|

| Attachment 18: Screenshot_from_2024-02-18_11-28-06.png

|

|

| Attachment 19: Screenshot_from_2024-02-18_13-09-43.png

|

|

| Attachment 20: Screenshot_from_2024-02-18_13-11-14.png

|

|

| Attachment 21: Screenshot_from_2024-02-18_13-14-48.png

|

|

| Attachment 22: Screenshot_from_2024-02-18_13-18-19.png

|

|

| Attachment 23: Screenshot_from_2024-02-18_13-20-35.png

|

|

| Attachment 24: Screenshot_from_2024-02-18_13-21-01.png

|

|

| Attachment 25: Screenshot_from_2024-02-18_13-21-26.png

|

|

| Attachment 26: Screenshot_from_2024-02-18_13-21-54.png

|

|

| Attachment 27: Screenshot_from_2024-02-18_13-23-21.png

|

|

|

524

|

Sun Feb 18 00:16:55 2024 |

JM CB | Run 40 - night shift |

01:17

Run 40 continues.

Beam intensity looks OK. Oscillates between just below 2.5e7 and just below 3e7. (attachment 1)

Target density 4.3e11, YR09 pressure 1.54e-10 mbar.

Rates in monitoring code show beam on target.

FEE temperatures all OK - plot over time (attachment 2)

System check OK

Leakage current OK -trending down (attachment 3)

Tape server and merger OK. Merger stats (attachment 4)

ADC data items looks OK, spectrum browser rates OK

Spectrum browser stat (attachment 7 LOG scale) - looks like some HEC were firing previously. Spec browser histograms zero'd to monitor

pn + nn waveforms (attachments 5+6)

Monitoring code energy histograms (attachment 8)

02:40

X2go screen size has decreased further -> cannot see target density but can view beam intensity. Will use ML vac plot to help gauge beam on target

Beam intensity has decreased over the last hour but has now stabilised and is now ~2e7 at injection. Pressure in YR09 has decreased slightly accordingly from ML online but not significantly (still >1e-10 mbar)

Monitoring code rate plots indicate beam on target

All daq checks OK

Will continue to monitor beam intensity

04:14

Ring intensity has increased and appears stable back at 2.5e7.

Target density has slightly decreased to 3e11, ring pressure YR09 stable at 1.5e-10 mbar. I am reluctant to try and move the nozzle while my x2go screen is not 100%.

FEE temps OK

System checks OK

Merger and tape server OK

Rates in all FEEs look OK

Spectrum browser stats (attchment 9) no HEC firing

Monitoring code rates look OK -> beam on target (attachment 10)

05:14

Beam intensity looks OK, Target density 3.11e11. Ring pressure YR09 2e-10 mbar.

All checks OK

Monitoring code rate looks OK -> beam on target

06:20

Beam intensity OK, Target density 3.1e11. Pressure YR09 1.9e-10 mbar.

FEE temps OK

System checks OK

Statistics and rates of all FEEs OK

Merger and Tape server OK

Monitoring code rates look OK -> beam on target

Merger statistics (attachment 11)

7:15

Beam intensity 2E7, target density getting bad 2eE11. WIll fix it from the lab.

FEE temps OK

System checks OK

Merger OK

Stats OK |

| Attachment 1: 20240218_011615.jpg

|

|

| Attachment 2: Screenshot_from_2024-02-18_01-23-04.png

|

|

| Attachment 3: Screenshot_from_2024-02-18_01-25-06.png

|

|

| Attachment 4: Screenshot_from_2024-02-18_01-26-35.png

|

|

| Attachment 5: Screenshot_from_2024-02-18_01-36-02.png

|

|

| Attachment 6: Screenshot_from_2024-02-18_01-36-38.png

|

|

| Attachment 7: Screenshot_from_2024-02-18_01-32-12.png

|

|

| Attachment 8: Screenshot_from_2024-02-18_01-39-29.png

|

|

| Attachment 9: Screenshot_from_2024-02-18_04-18-35.png

|

|

| Attachment 10: Screenshot_from_2024-02-18_04-21-02.png

|

|

| Attachment 11: Screenshot_from_2024-02-18_06-35-40.png

|

|

| Attachment 12: Screenshot_from_2024-02-18_07-12-05.png

|

|

| Attachment 13: Screenshot_from_2024-02-18_07-12-44.png

|

|

| Attachment 14: Screenshot_from_2024-02-18_07-13-08.png

|

|

| Attachment 15: Screenshot_from_2024-02-18_07-13-25.png

|

|

|

523

|

Sat Feb 17 14:29:03 2024 |

JM, CB, AR, AB | Run 40 - cooled beam on target |

15:27

Run 40 started cooled beam on target

Detectors IN (left arm pot =36.5 mm, right arm pot = 70.49 mm). Stationary. Same as run 35

Electron cooler voltage 751.095 this corresponds to 1.338 MeV/u. This should be on the left of the peak of the resonance.

Target density is 4e11 at/cm2, ring pressure looks OK YR09 1.43e-10 mbar.

Horizontal beam position is -7.5 mm, vertical beam position is 0.0 mm. Same as run 35.

Beam is in the ring for 4 seconds and total cycle time between injections is 8 seconds. Notice this is different than run 35.

Statistics, merger statistics, histograms all zero'd

15:39

System wide checks ok. Merger ok. Temperatures ok.

Attatchment 1: statistics

Attatchment 2: Temperatures

Attatchment 3-6: Waveforms. Layout 2 - (attach 4) had a strnageish waveform for aida11, stays after reload.It was the HEC firing so did an ASIC control and Zero'd histograms and all is okay.

Attatchment 7: Leakage current

17:04

System wide checks ok. Merger ok. Temperatures ok. The beam is on target and everything runs smoothly.

Attatchment 8: statistics

Attatchment 9: Temperatures

Attatchment 10-13: Waveforms. Everything looks ok.

Attatchment 14: Leakage current

18:55

System wide checks ok. Merger ok. Temperatures ok. The beam is on target and everything runs smoothly.

Beam transformer shows a small decrease in beam intensity, not drastic but small slow decrease, see attachment 22. Target density 4e11. Vacuum pressue ok.

Attatchment 15: Statistics

Attatchment 16: Temperatures

Attatchment 17-20: Waveforms

Attatchment 21: Leakage current

19:28

Run40 - Beam dropped intesntiy at 19:17, moved detectors out, called gleb. Beam intensity started increasing again - not sure whats happenig at present (see image 23).

20:26

Around 19:50 beam decreased again and stayed down for a while. Beam not stable. Gleb was called, target turned off, beam restabilied - around 2.5e7 ish. Unsure if it will remain stable during the night (image 24).

20:35

detectors moved back in. Target back in, stable at 4e11.

Potentiometer Left: 36.54 mm

Potentiometer Right: 70.49 mm

Beam stable at the moment (image 25).

System checks 20:40

Base Current Difference

aida03 fault 0x0 : 0x1 : 1

aida04 fault 0x0 : 0x1 : 1

aida05 fault 0x0 : 0x1 : 1

aida06 fault 0x0 : 0x1 : 1

aida07 fault 0x0 : 0x1 : 1

aida08 fault 0xe : 0xf : 1

aida09 fault 0xb : 0xc : 1

aida10 fault 0x0 : 0x1 : 1

aida13 fault 0x0 : 0x1 : 1

aida14 fault 0x0 : 0x1 : 1

FPGA Timestamp error counter test result: Passed 6, Failed 10

If any of these counts are reported as in error

The ASIC readout system has detected a timeslip.

That is the timestamp read from the time FIFO is not younger than the last

System wide checks ok except the FPGA timestamps - see error above - collected them and it went away. Merger ok. Temperatures ok. The beam is on target and everything runs smoothly for now.

Attatchment 26: Temperatures

Attatchment 27-30: Waveforms

Attatchment 31: Leakage current

21:50

FEE temperatures OK

System wide checks OK

Statistics and spectrum browser rate look OK

Merger and tape server OK

Monitoring code rates are consistent with beam on target

X2go seems to not be loading full screen for me - may be my laptop misbehaving?

Can see ring intensity has been stable for the last hour, target density is 4.33e11 and YR09 pressure is 1-2e-10 mbar.

23:22

Target density 4.3e11, beam intensity stable.

Monitoring code rates are consistent with beam on target

Fee temps all OK

System checks OK

Statistics and FEErates OK.

Merger and tape server OK

|

| Attachment 1: Screenshot_from_2024-02-17_15-39-50.png

|

|

| Attachment 2: Screenshot_from_2024-02-17_15-40-05.png

|

|

| Attachment 3: Screenshot_from_2024-02-17_15-40-49.png

|

|

| Attachment 4: Screenshot_from_2024-02-17_15-43-04.png

|

|

| Attachment 5: Screenshot_from_2024-02-17_15-44-12.png

|

|

| Attachment 6: Screenshot_from_2024-02-17_15-44-36.png

|

|

| Attachment 7: Screenshot_from_2024-02-17_15-45-02.png

|

|

| Attachment 8: Screenshot_from_2024-02-17_16-58-47.png

|

|

| Attachment 9: Screenshot_from_2024-02-17_16-59-18.png

|

|

| Attachment 10: Screenshot_from_2024-02-17_17-00-48.png

|

|

| Attachment 11: Screenshot_from_2024-02-17_17-01-41.png

|

|

| Attachment 12: Screenshot_from_2024-02-17_17-02-26.png

|

|

| Attachment 13: Screenshot_from_2024-02-17_17-03-01.png

|

|

| Attachment 14: Screenshot_from_2024-02-17_17-03-51.png

|

|

| Attachment 15: Screenshot_from_2024-02-17_18-55-13.png

|

|

| Attachment 16: Screenshot_from_2024-02-17_18-55-48.png

|

|

| Attachment 17: Screenshot_from_2024-02-17_18-56-55.png

|

|

| Attachment 18: Screenshot_from_2024-02-17_18-57-26.png

|

|

| Attachment 19: Screenshot_from_2024-02-17_18-57-54.png

|

|

| Attachment 20: Screenshot_from_2024-02-17_18-58-27.png

|

|

| Attachment 21: Screenshot_from_2024-02-17_18-58-44.png

|

|

| Attachment 22: IMG_7902.jpeg

|

|

| Attachment 23: IMG_7903.jpeg

|

|

| Attachment 24: IMG_7906.jpeg

|

|

| Attachment 25: IMG_7907.jpeg

|

|

| Attachment 26: Screenshot_from_2024-02-17_20-38-37.png

|

|

| Attachment 27: Screenshot_from_2024-02-17_20-42-41.png

|

|

| Attachment 28: Screenshot_from_2024-02-17_20-43-17.png

|

|

| Attachment 29: Screenshot_from_2024-02-17_20-43-50.png

|

|

| Attachment 30: Screenshot_from_2024-02-17_20-55-50.png

|

|

| Attachment 31: Screenshot_from_2024-02-17_20-45-30.png

|

|

|

710

|

Sun Jun 1 15:33:50 2025 |

EW, JM, CB | Run 40 |

16:30

Run 40 started.

D+ beam deuterium target. D+ beam energy is 0.75 MeV/u. (beam calc calculation is 0.7619 MeV/u)

Beam calc - Attachment 1

Target density is about 1e12 at/cm2

All four detectors positioned fully out and stationary.

Left potentiometer = 18.86 mm

Right potentiometer = 19.8 mm

Ring cycle time is 30 seconds. Note we see some hydrogen in in the spectrum, this disapears after a few seconds.

Target T1=30.1K, T2=31.9K.

Nozzle position x=-2.96, z=1.72 mm

YR09-Etarget pressure = 2.55e-10 mbar.

Cooler set value = 439 V, 15 mA. Read value = 439.81 V, 12.88 mA

All leakage currents look good

Beam position. Vertical =0.0mm , Horizontal=-1.5 mm

Beam intensity ~1e8 on bunched beam, 1e7 on coasting. This is less intensity than higher energies, may require an increase in the morning.

Data rate ~ 403kB/s

Lowered slow comparator threshold to 0x24 (360 keV) since we decreased beam energy.

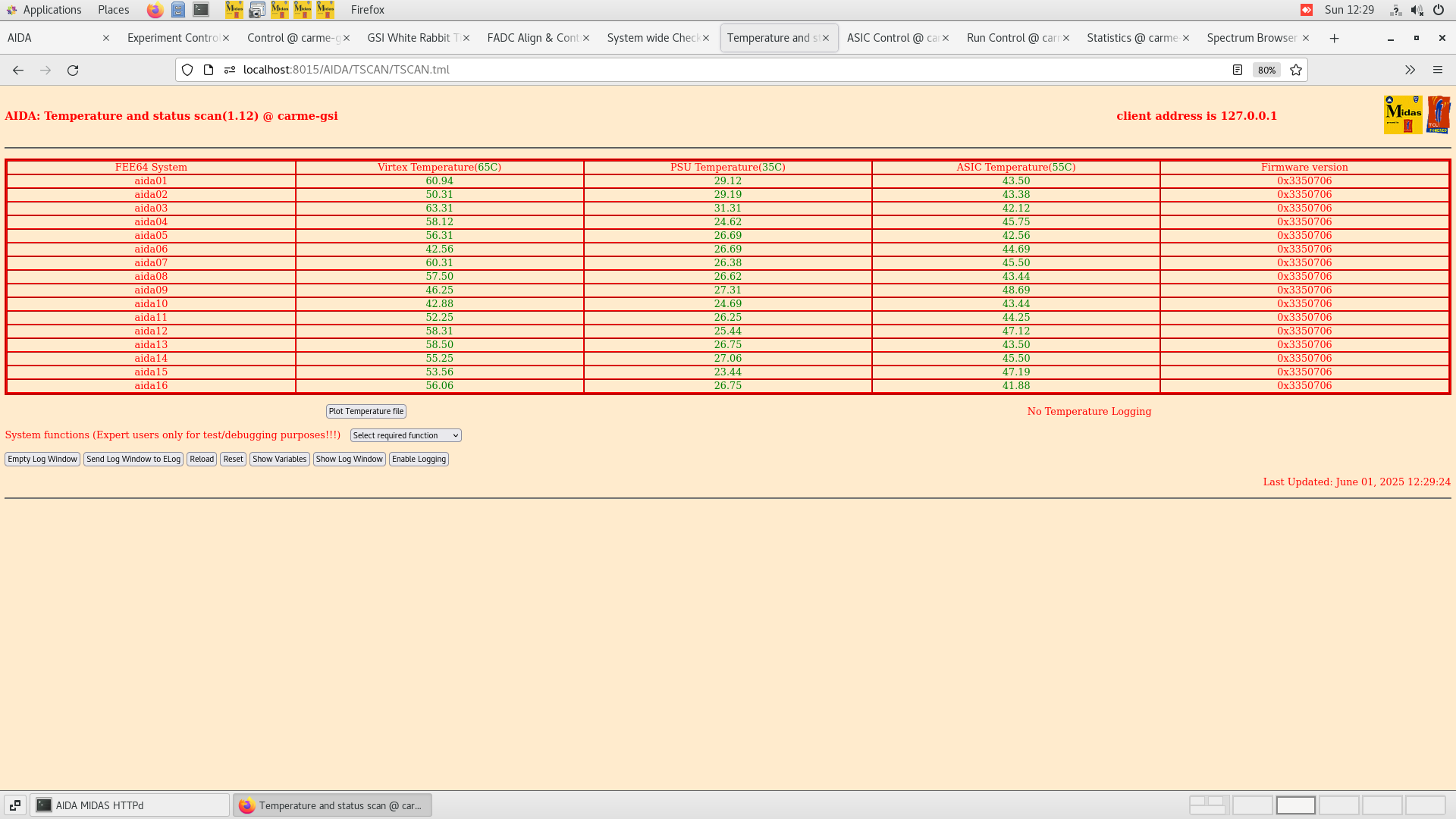

18:36

Temps OK - attached

Rates OK - attached

Merger OK - attached.

Spectra appear to have a flat background to the right of Rutherford that was not there at higher energies.

The xy plot also does not seem to be as centered.

21:17

Tems OK

Stats OK

Merger OK

Leakage current stable

Run continues OK

Ring vacuum 2E-10 mbar, likely getting less target.

02:00

Temps OK

Stats OK

Merger OK

Leakage current OK

Run continues - attached

Ring vacuum as before

04:20

Temps OK

Stats OK

Merger OK

L. current stable

Run continues

Ring vacuum as before

07:00

All checks OK

Leakage currents remain stable.

We have accumulated good statistics. 3He peak does seem a bit off. Cooling could be slightly off. Problem is not so bad looking at Ey compared to Ex. Online code uses pulser calibration only so may be a bit off depending on Ey/Ex.

Target density has been stable in the 1e12-2e12 at/cm2 range overnight. A bit more would be good.

Will ask on call operator to check cooling and try to increase intensity.

Run stopped gas target off.

07:30

Note during the tuning process we observed the same structure at 2.5 MeV in DSSD 1 as we did overnight that may overlap with the 3He peak. Perhaps it can be removed offline. See final attachment

|

| Attachment 1: Screenshot_from_2025-06-01_16-38-55.png

|

|

| Attachment 2: beamCalc-D4.png

|

|

| Attachment 3: Screenshot_from_2025-06-01_18-33-17.png

|

|

| Attachment 4: Screenshot_from_2025-06-01_18-33-35.png

|

|

| Attachment 5: Screenshot_from_2025-06-01_18-34-06.png

|

|

| Attachment 6: Screenshot_from_2025-06-01_18-36-19.png

|

|

| Attachment 7: Screenshot_from_2025-06-01_18-36-26.png

|

|

| Attachment 8: Screenshot_from_2025-06-02_02-03-19.png

|

|

| Attachment 9: Screenshot_from_2025-06-02_07-16-07.png

|

|

| Attachment 10: Screenshot_from_2025-06-02_07-37-04.png

|

|

|

594

|

Thu Jun 6 16:23:10 2024 |

LB CB JM | Run 39 - Run 40 15N |

Started run 39.

We have the 15N+ beam with 426 keV/nucleon. We see a peak in detector top left (mostly) and bottom right, at 4600 keV. We think it is the beam (nominally 6400 keV) after going through silicon dead layer, which however seems to be thicker than expected (expected 0.7 um, but given 1.4 MeV/um energy loss it seems to be > 1 um).

To understand what was going on we first played with detector and beam position.

At 17:28 detectors are fully out, while we are playing with the electron cooler to try to remove this beam halo hitting the detector.

Detector DSSD0 top left periodically seems to get noisier (statistics up to >2E5) and we need to move the detector in and out to go back to normal operations.

------------------

The beam halo in top left detector, as the detector gets moved in, gets elongated in the y direction instead of the x direction, as expected and previosuly observed.

Run 40 started.

18:36

Merger OK, Tape server OK

ADC data item statistics looks as before. OK

FEE temperatures look OK

System checks OK

Leakage current stable

Attachments 1-4

19:43

Merger OK, Tape server OK

ADC data item statistics looks as before. OK

FEE temperatures look OK

System checks OK

Leakage current stable

Attachments 5-8

21:15

Merger OK, Tape server OK

ADC data item statistics looks as before. OK

FEE temperatures look OK

System checks OK

Leakage current stable

Attachments 9-11

00;25

Merger OK, Tape server OK

ADC data item statistics looks as before. OK

FEE temperatures look OK

System checks OK

Leakage current stable

-----------------------------------

Movements and observation in xy plot:

- Move right servo in by 20 mm and we see the halo in the top right moving accordingly (attachment 12)

-Move right pneumatic in, saw big increase on bottom right (attachment 13)

-moved beam position down vertical -6 mm and we see reduced beam spot on top left and more on bottom left

-----------------------------------

Beam - target overlap:

We have yet to obtain an overlap

We cannot do this using the beam lifetime as from beam calc the lifetime from the ring is comparable to the lifetime with a target of 1e11 at/cm2

We have tried using Rutherford. However, we will have to move the detectors IN further as the Rutherford peaks at ~3.8 deg.

Possibly we may require other overlap detections from the ring?

I also think the beam requires some optimisation, electron cooler voltage seems to be fluctuating a lot and we see some features on the detectors when moving the beam / detectors as mentioned above.

02:25

The beam intensity has decreased signficantly (by about a factor of five) since about an hour. Operators tried different things, also consulted with Frank Herfurth, but they could not solve the problem.

There is no device which indicates malfunction.

So, during the rest of the night shift we will continue searching for the overlap (of the beam with the target) with the available beam intensity.

03:30

The beam intensity has improved without any aparent intervention.

We have started a new search for the overlap with 20 minute runs per horiznotal beam position.

Merger OK, Tape server OK

ADC data item statistics looks as before. OK

FEE temperatures look OK

System checks OK

Leakage current stable

03:40

After changing the horizontal beam position from 0 mm to 1 mm, the bottom right detector lost the Rutherford peak and its position spectrum looks to be half empty.

Moving it OUT and IN again did not change the situation.

There is no reason to think that this behavior has been caused by moving the beam by just 1 mm.

04:10

The beam intensity has dropped again without any apparent reason. So, at the moment we can not continue search for the overlap.

The bottom right detector seems to be counting normally again (also without any apparent reason).

06:45

Merger OK, Tape server OK

ADC data item statistics looks as before. OK

FEE temperatures look OK

System checks OK

Leakage current stable

07:18

Lost beam again. Gleb is looking for it. Moved right detector out temporarily.

System wide checks as before.

Merger OK, Tape Server OK.

Temperatures OK.

Rates currently OK.

Leakage current decreasing.

10:10

Beam is back. Target is unusually thick at 3-5E11

Checking beam overlap.

Merger & tape server OK.

Temps OK.

Rates OK, a bit higher in 01 and 04. |

| Attachment 1: Screenshot_from_2024-06-06_18-33-41.png

|

|

| Attachment 2: Screenshot_from_2024-06-06_18-34-15.png

|

|

| Attachment 3: Screenshot_from_2024-06-06_18-34-35.png

|

|

| Attachment 4: Screenshot_from_2024-06-06_18-34-49.png

|

|

| Attachment 5: Screenshot_from_2024-06-06_19-42-49.png

|

|

| Attachment 6: Screenshot_from_2024-06-06_19-42-57.png

|

|

| Attachment 7: Screenshot_from_2024-06-06_19-43-10.png

|

|

| Attachment 8: Screenshot_from_2024-06-06_21-14-02.png

|

|

| Attachment 9: Screenshot_from_2024-06-06_21-14-17.png

|

|

| Attachment 10: Screenshot_from_2024-06-06_21-14-48.png

|

|

| Attachment 11: Screenshot_from_2024-06-06_23-28-29.png

|

|

| Attachment 12: Screenshot_from_2024-06-06_23-42-18.png

|

|

| Attachment 13: Screenshot_from_2024-06-07_07-20-12.png

|

|

| Attachment 14: Screenshot_from_2024-06-07_10-11-17.png

|

|

| Attachment 15: Screenshot_from_2024-06-07_10-11-27.png

|

|

|

709

|

Sun Jun 1 07:46:34 2025 |

JM, EM, CB | Run 39 |

08:45

Run 39 started.

D+ beam deuterium target. D+ beam energy is 1.0 MeV/u. (beam calc calculation is 1.0151 MeV/u)

Beam calc - Attachment 1

Target density is about 5e12 at/cm2

All four detectors positioned fully out and stationary.

Left potentiometer = 18.86 mm

Right potentiometer = 19.8 mm

Ring cycle time is 1 minute. Note we see some hydrogen in in the spectrum, this disapears after a few seconds.

Target T1=30.1K, T2=31.9K.

Nozzle position x=-2.96, z=1.72 mm

YR09-Etarget pressure = 2.55e-10 mbar.

Cooler set value = 575 V, 15 mA. Read value = 575.8 V, 12.9 mA

All leakage currents look good

Beam position. Vertical =0.0mm , Horizontal=-1.25 mm

Beam intensity ~1e8. We appear to lose intensity when reducing energy. It is still sufficient to for our purposes.

09.38

CRYRING vacuum and ambient temperature - attachments 2-3

09:58

All checks OK.

Target density is ~7e12 at/cm2

Data rate ~300kB/sec

All leakage currents look OK

After 1 hour we have 3671, 2515 and 1064 in each peak respectively. This is also logged on the google docs form in same tab as elog.

10:36

Temps OK

Data rate OK 326 kB/sec

Leakage currents stable

12:30

Temps ok - attach

Rates ok - attach

Merger ok - attach

14:20

Run stopped for energy change. |

| Attachment 1: screenshot-2025-06-01_08-48-132701843244570721227.png

|

|

| Attachment 2: Capture.PNG

|

|

| Attachment 3: Capture_2.PNG

|

|

| Attachment 4: Screenshot_from_2025-06-01_12-29-30.png

|

|

| Attachment 5: Screenshot_from_2025-06-01_12-29-48.png

|

|

| Attachment 6: Screenshot_from_2025-06-01_12-30-11.png

|

|

| Attachment 7: Screenshot_from_2025-06-01_14-18-29.png

|

|