| ID |

Date |

Author |

Subject |

|

266

|

Thu Feb 24 07:25:53 2022 |

OH (Remote) | Recover of system after crash |

08:00 Woke up to message from Carlo explaining the server had crashed.

Anydesked into the machine.

Merger was showing just data transfer it was not showing Transfer => Merger

Went through the steps detailed in https://elog.ph.ed.ac.uk/DESPEC/36 to recover it.

After following these steps was again able to forward data from the merger.

Tested and it now sends on data again.

Setup the screen session for the caen bias and restarted the logger program.

Restarted the gnuplot script to plot leakage current

Started the online monitoring software and browser.

Have posted in the chat that the DAQ is now running again. |

|

265

|

Thu Feb 24 05:09:47 2022 |

CB, PE, EM | Inlet valve at target closed + problems with turbopump |

The turbo pump E1 is continuing to draw too much current and the rotation frequency has steadily decreased from 817 Hz at the beginning of the night shift to 800 Hz now. The frequency recovered after the temperature was increased.

Both of the valves (inlet and dump) have been closed to improve the vacuum in the ring. |

|

264

|

Thu Feb 24 04:17:35 2022 |

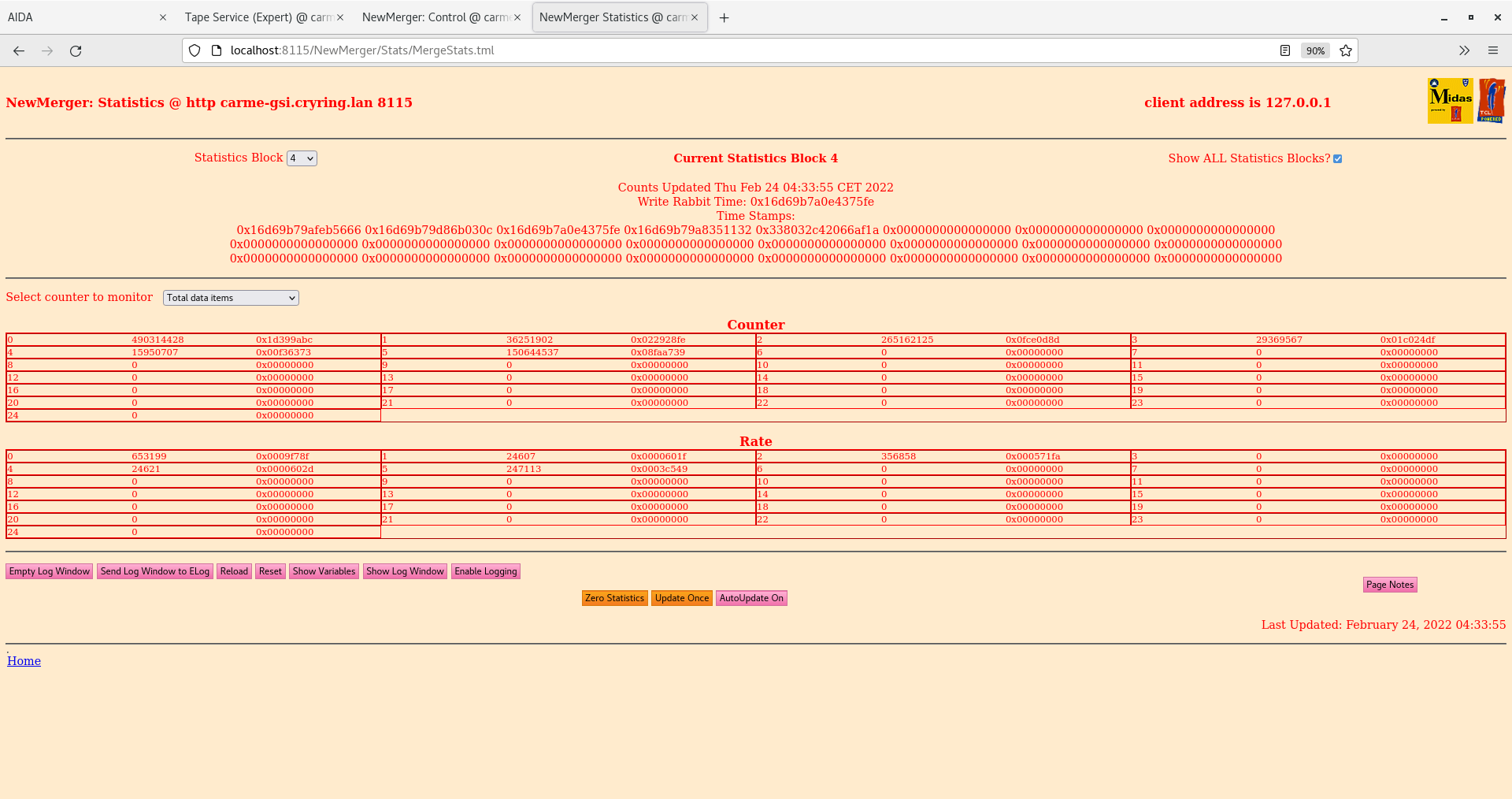

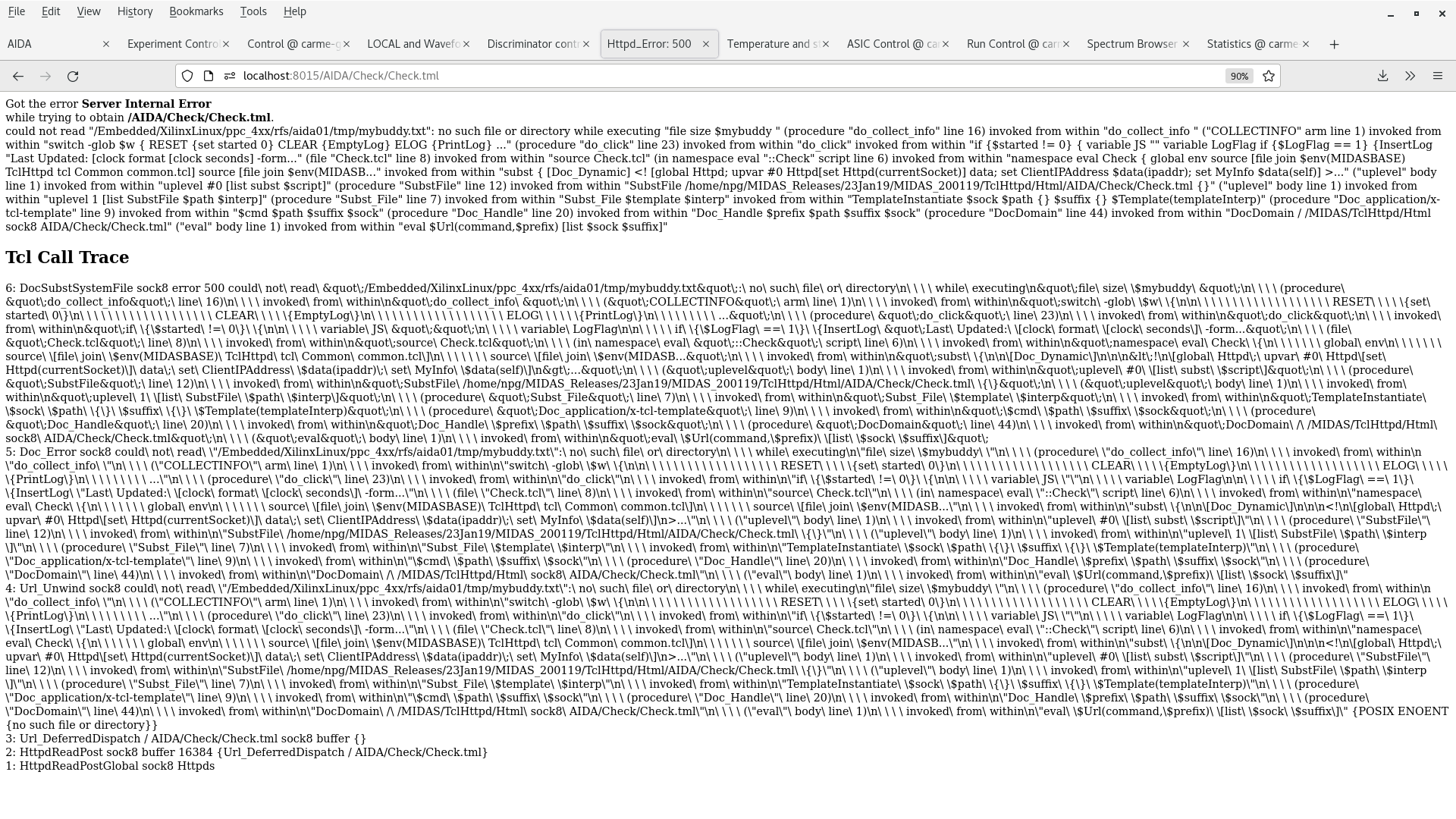

CB, TD (remotely) | MIDAS DAQ no longer working |

DAQ server crashed around 24:00

Rebooted server but could not could not rescue remotely - could not contact raspberry pi in control of FEE bias.

Entered cave, rebooted raspberry pi. Would not accept remote connections.

Had to manually start DHCP service on carme-gsi using

systemctl start dhcpd

Raspi could then be connected.

Started DAQ, TapeServer and Merger as per usual. Tapeserver refuses writing to disk.

Checked merged - very odd timestamp situation. See attached. Timestamp look OK in the GSI WR tab. See attached.

Power cycled server and FEES

Timestamp issue solved. All are now reading 0x16 etc.

However tapeserver still does not write to disk. Reasons unclear. Possibly Merger is not merging and not passing data on?

Have to stop data collection until solved.

|

| Attachment 1: Bad_Time_2022-02-24_04-34-12.png

|

|

| Attachment 2: BadTime_WRTime_2022-02-24_04-34-53.png

|

|

|

263

|

Wed Feb 23 22:29:50 2022 |

PE, EM, CB (remotely) | check - 23:30 |

Motor position ok

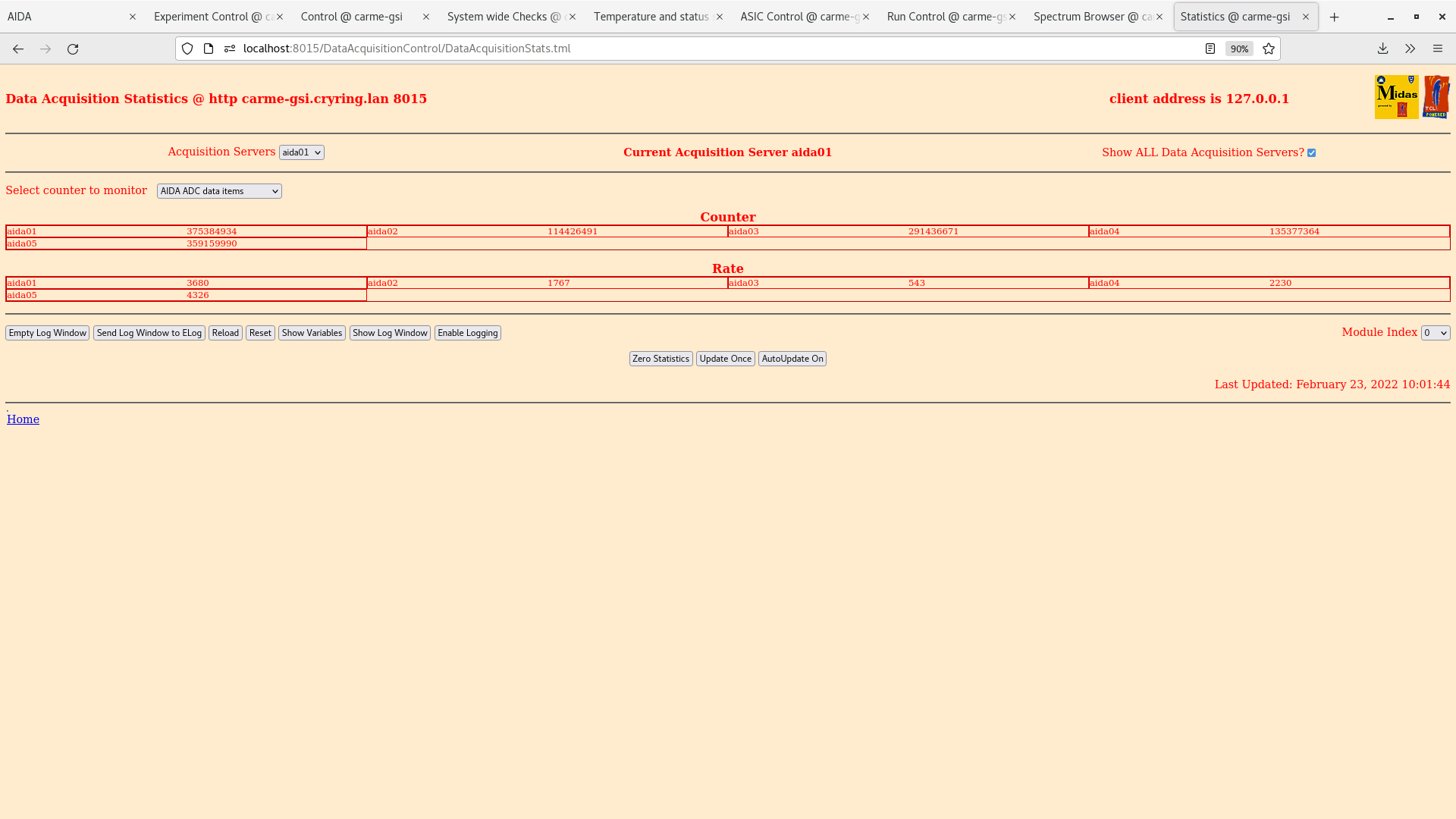

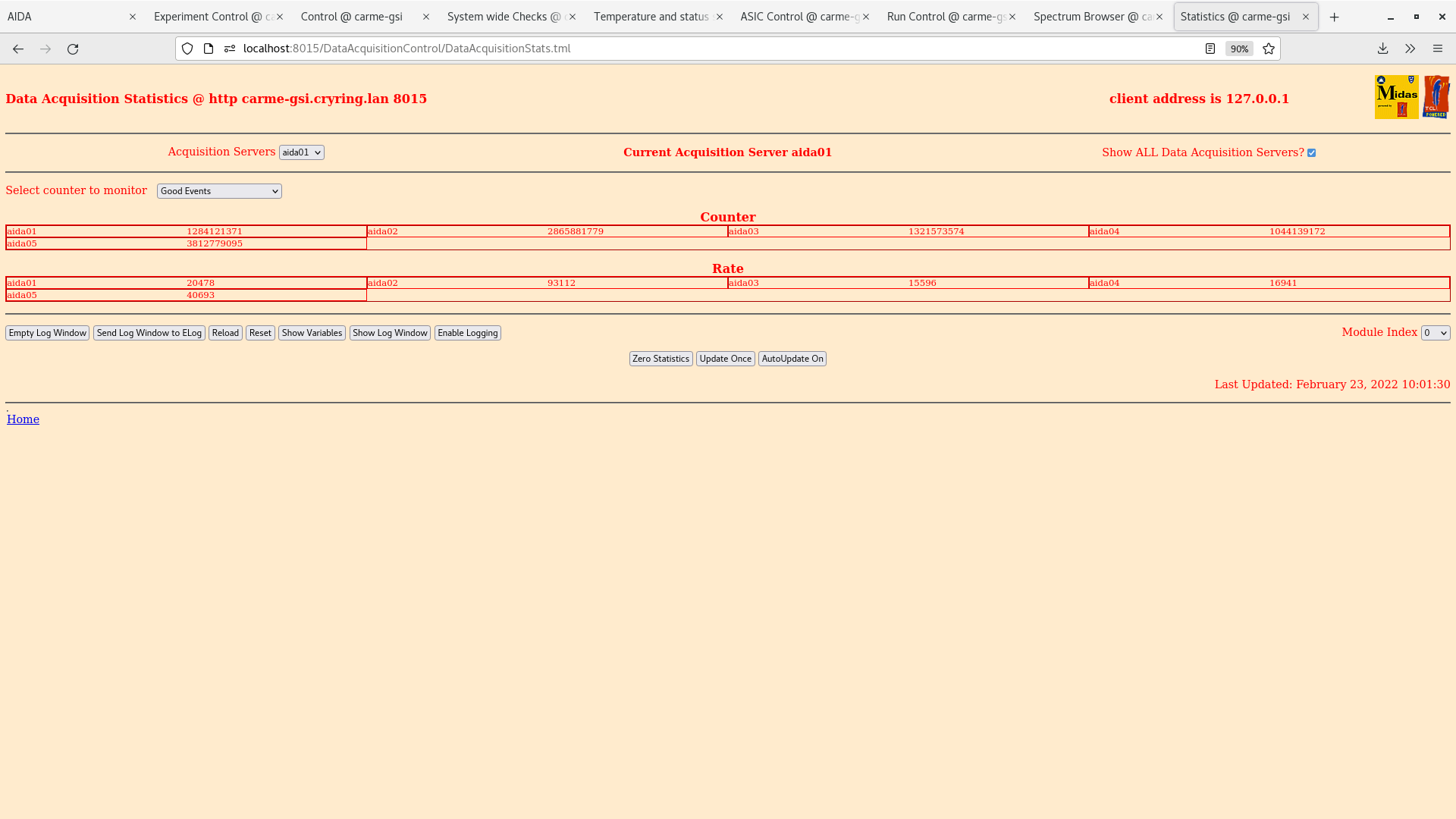

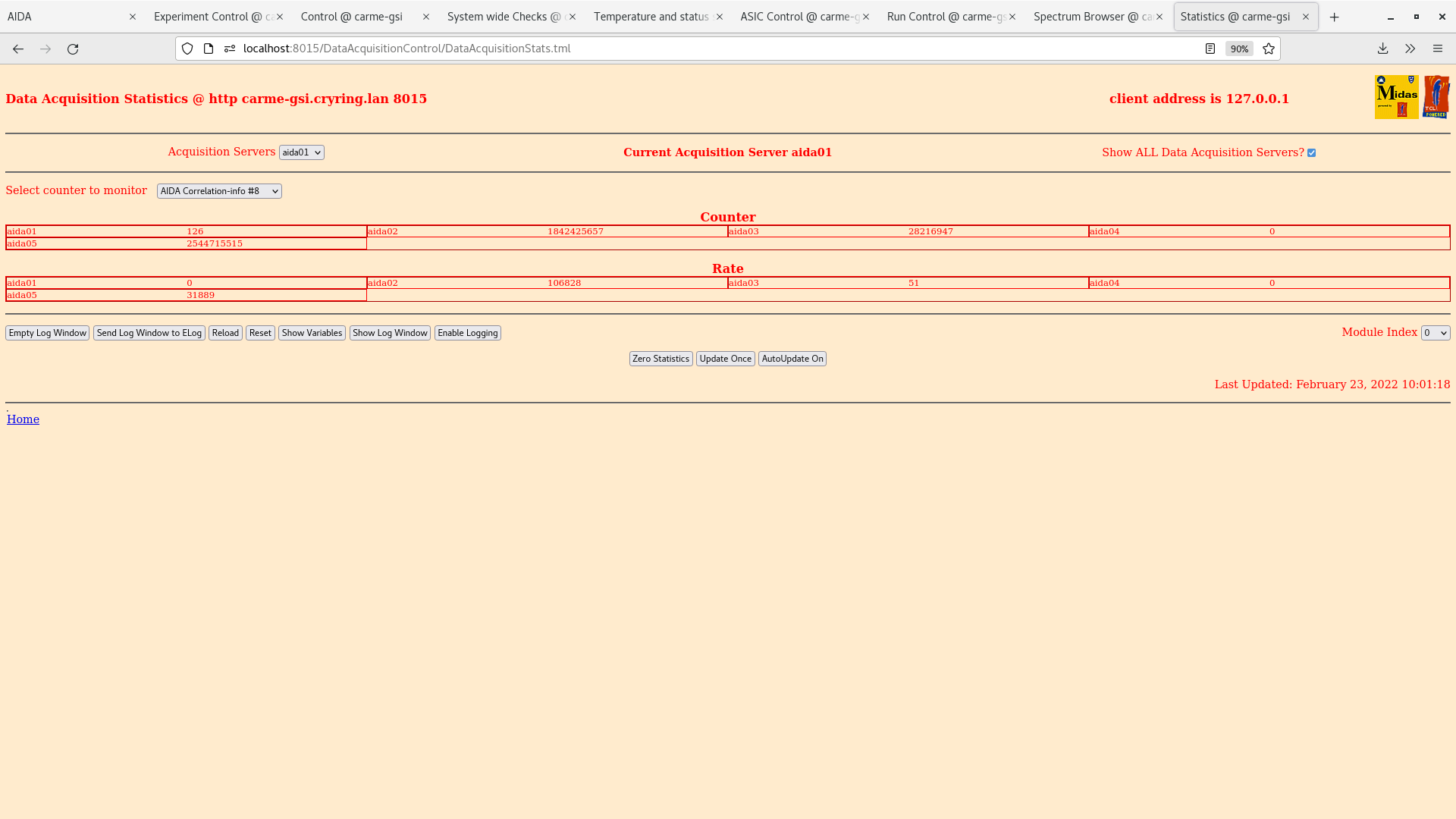

Data rate: 1030kbytes/s

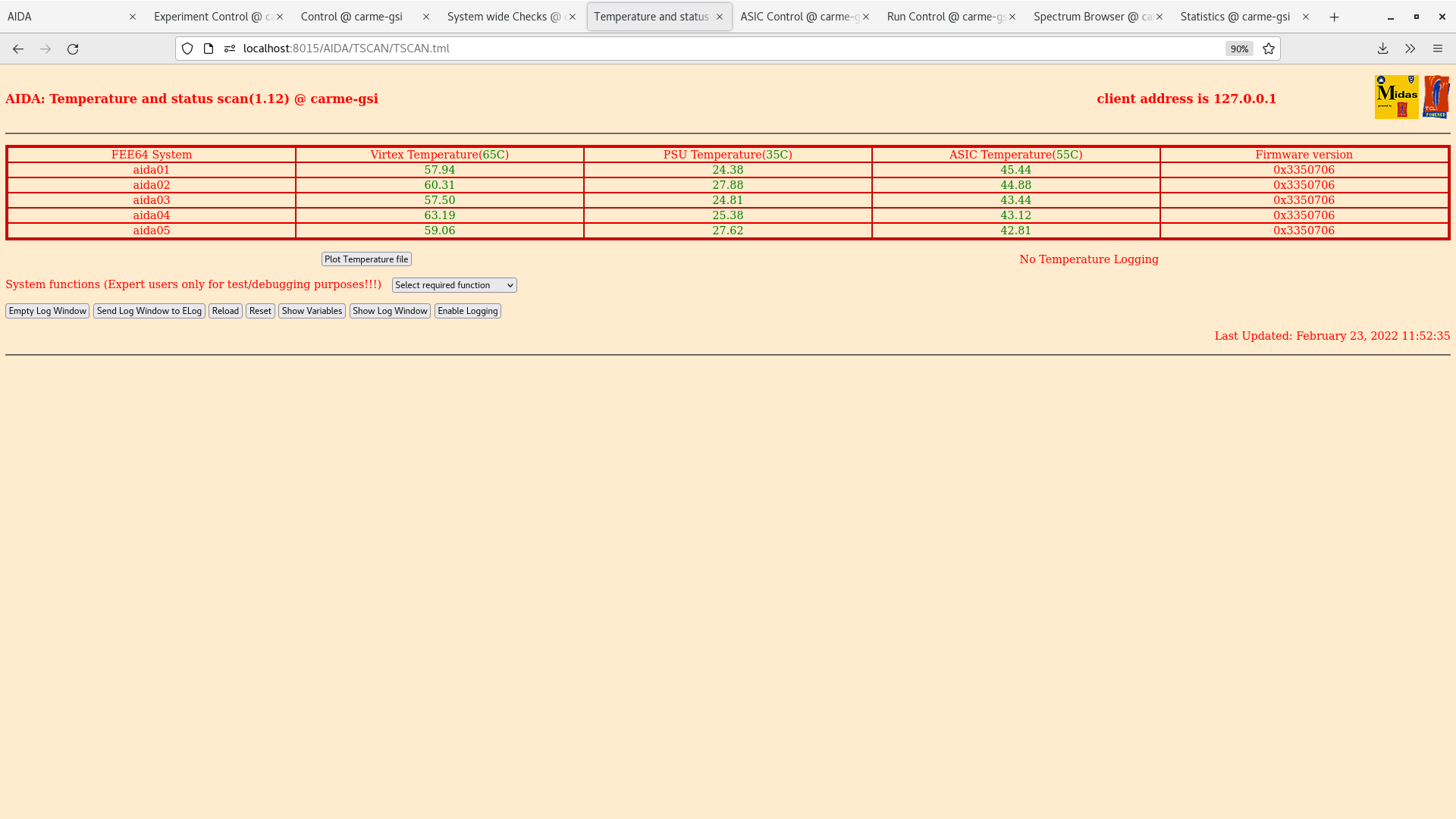

T ok

System wide check ok

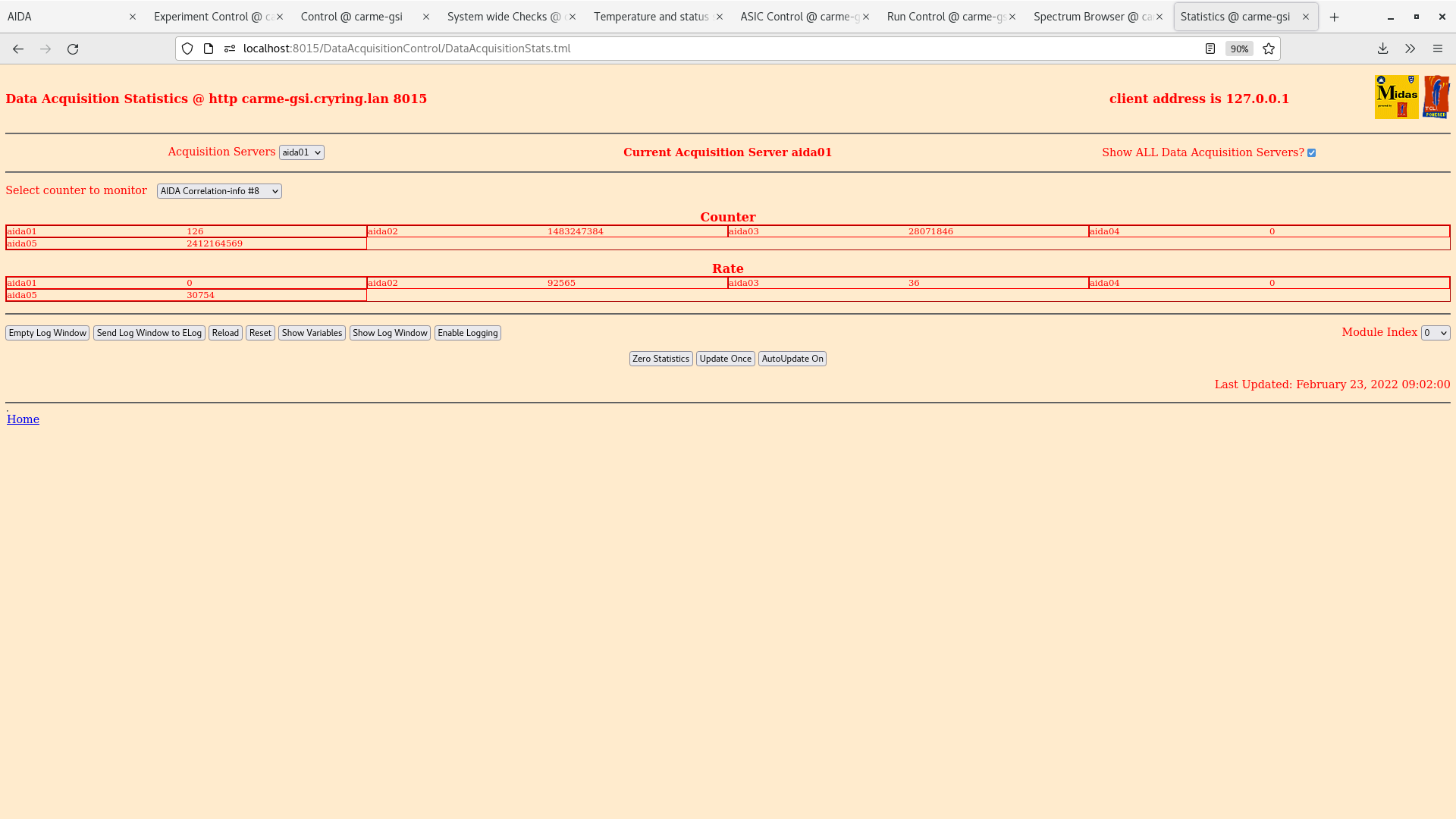

plots uploaded

DAQ crashed soon afterwards |

|

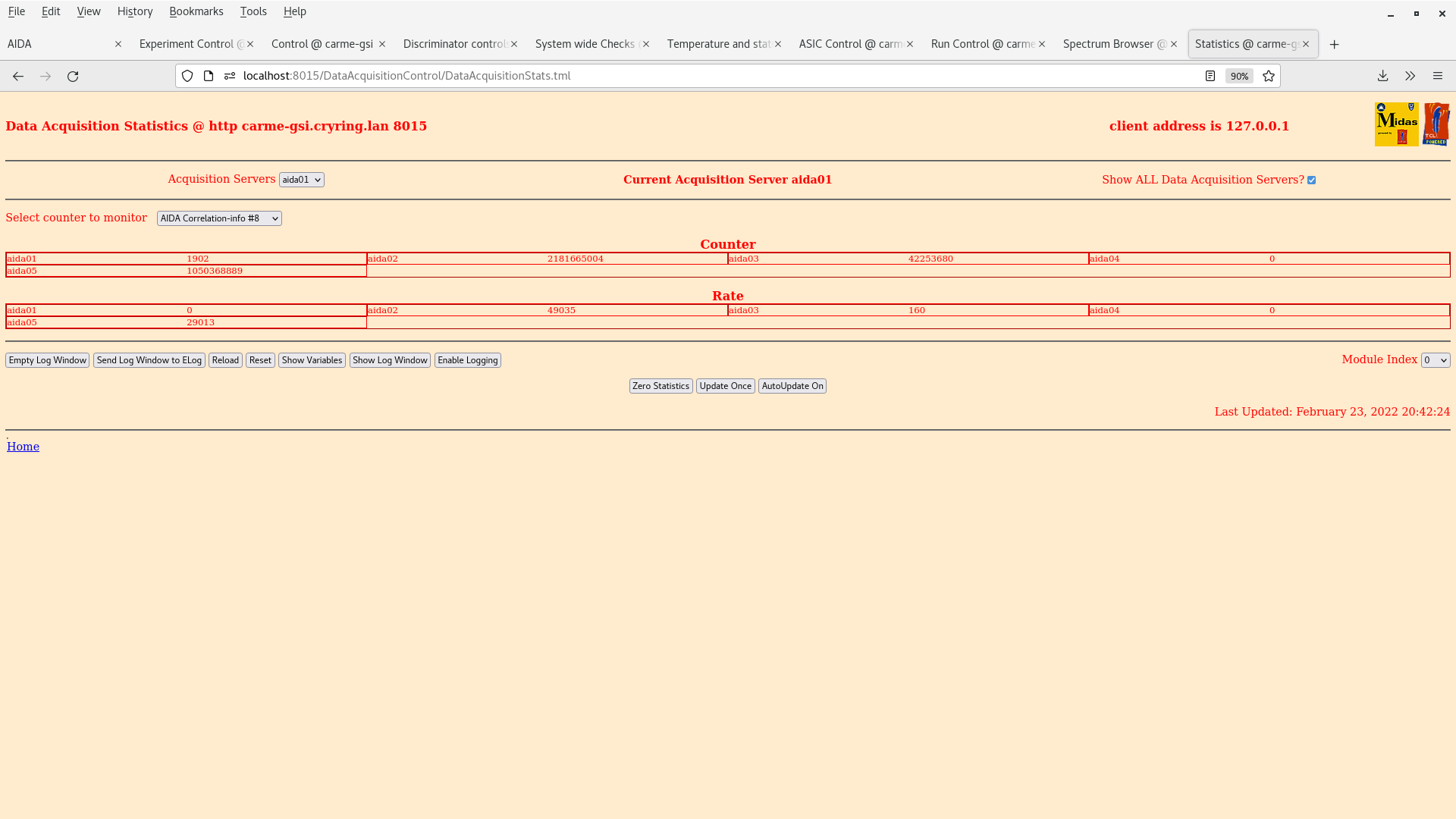

262

|

Wed Feb 23 21:27:29 2022 |

TD, CN | check |

Motor position ok

Data rate: 1030kbytes/s

T ok

System wide check ok

plots uploaded

|

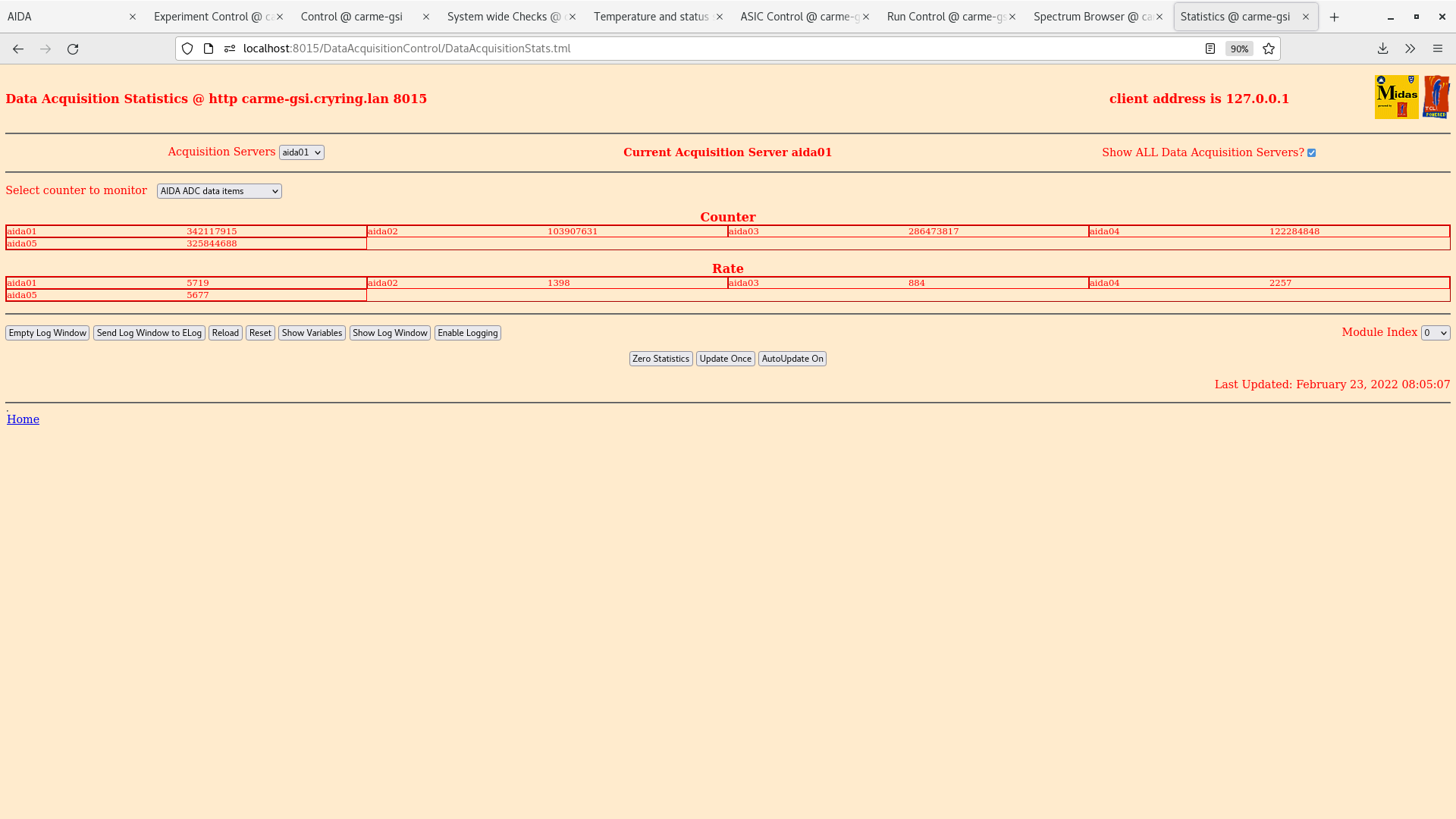

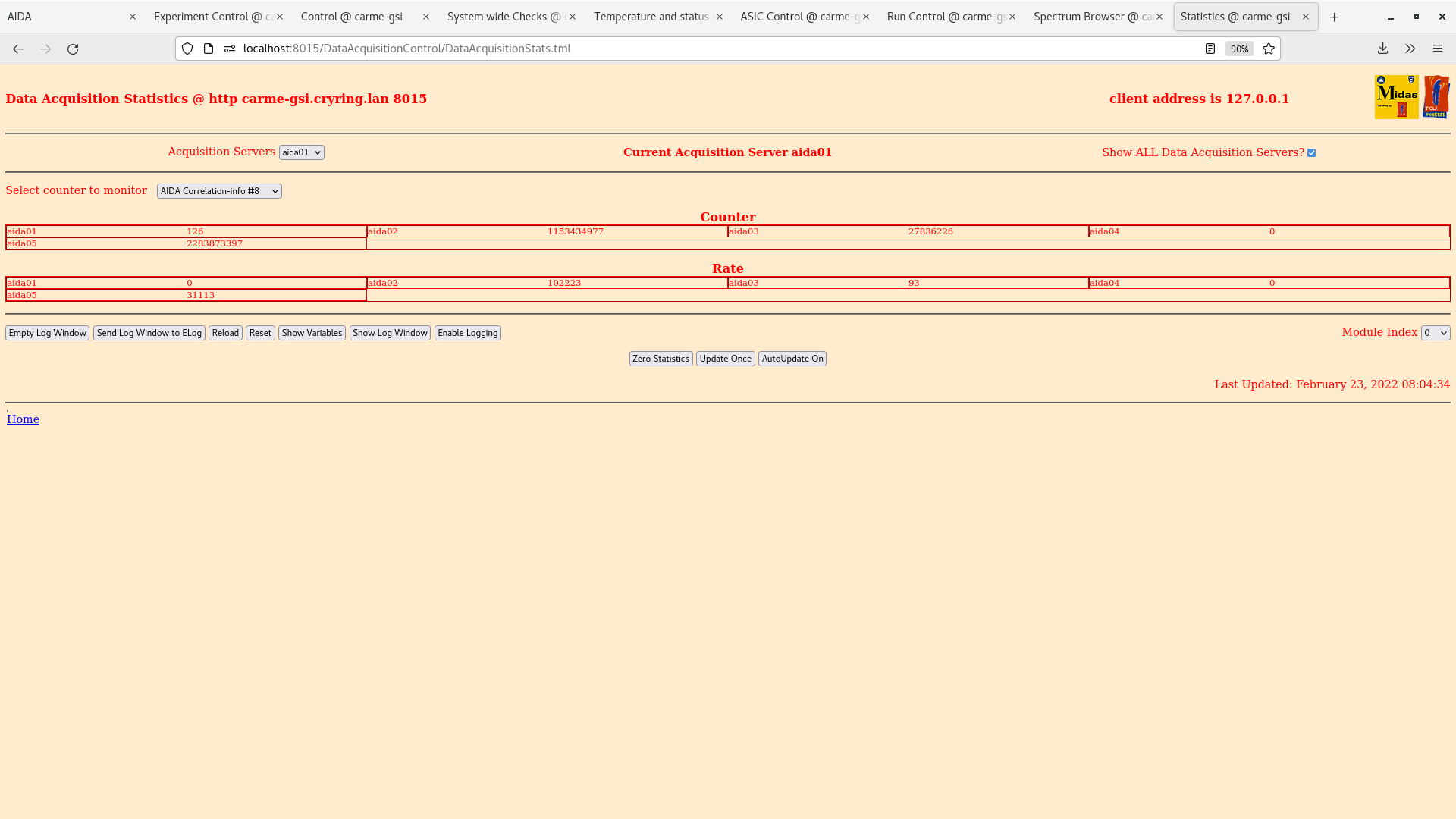

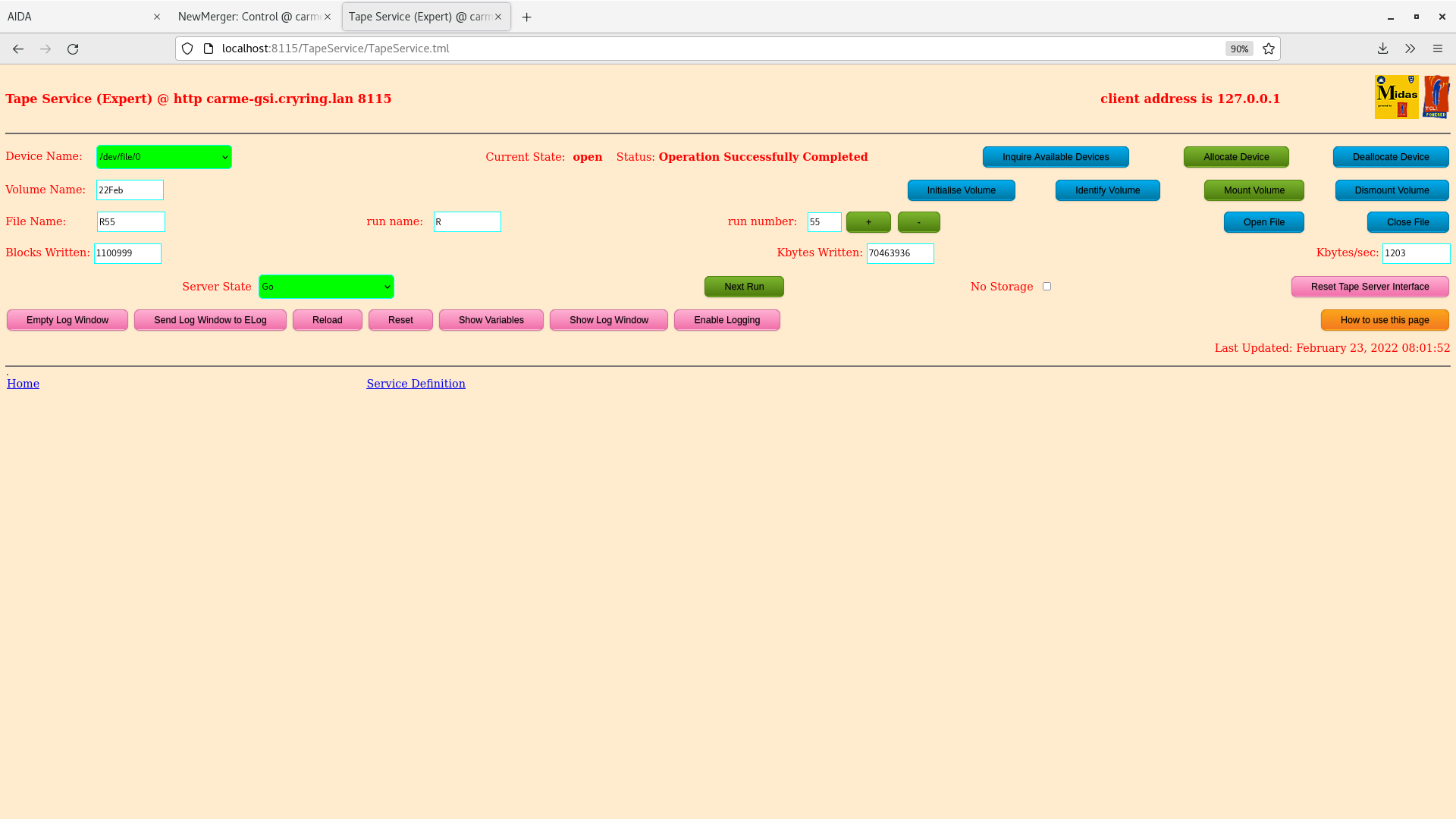

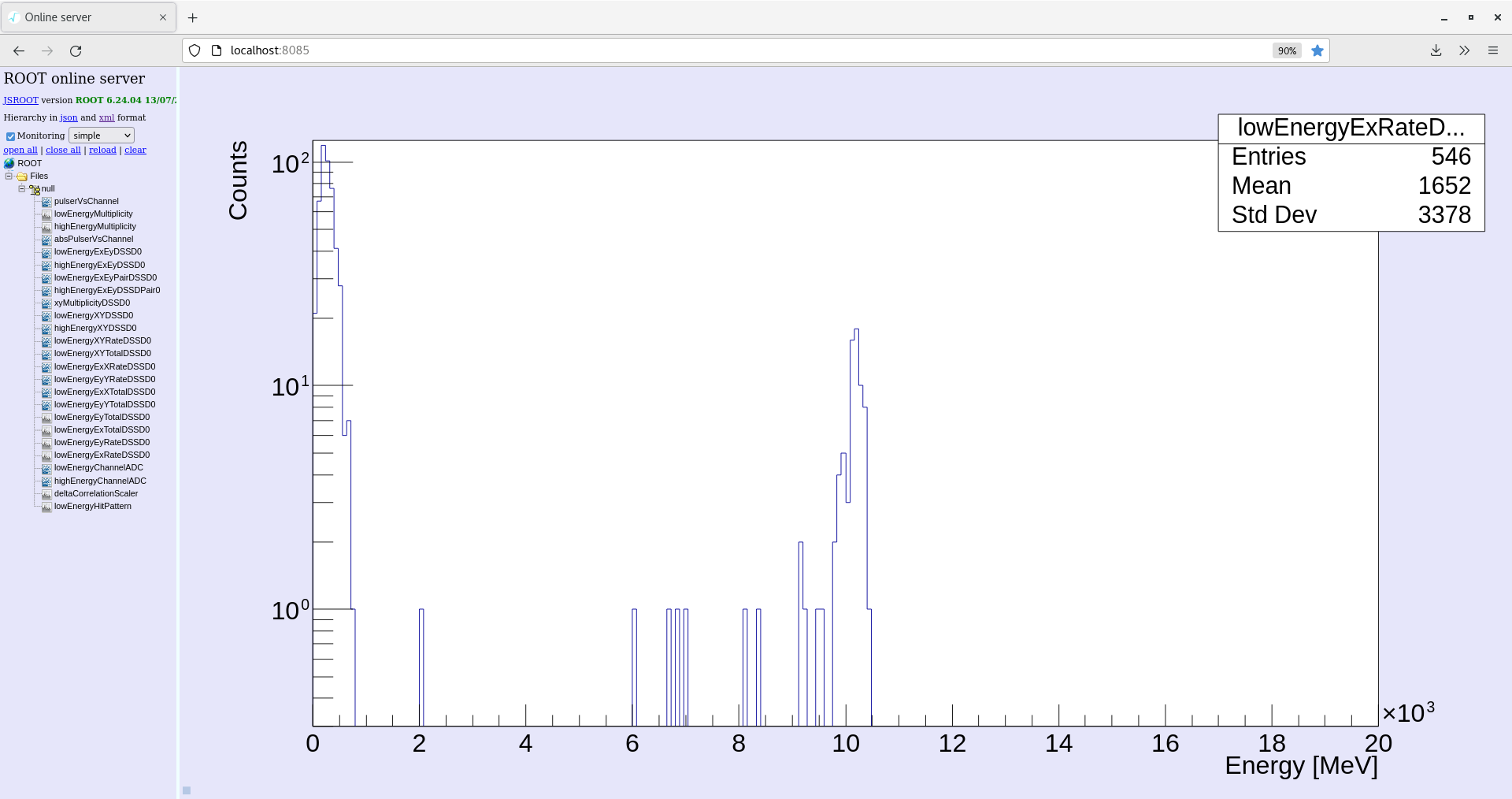

| Attachment 1: Screenshot_from_2022-02-23_22-29-36.png

|

|

| Attachment 2: Screenshot_from_2022-02-23_22-30-24.png

|

|

| Attachment 3: Screenshot_from_2022-02-23_22-33-23.png

|

|

| Attachment 4: Screenshot_from_2022-02-23_22-36-57.png

|

|

| Attachment 5: Screenshot_from_2022-02-23_22-37-22.png

|

|

| Attachment 6: Screenshot_from_2022-02-23_22-39-50.png

|

|

| Attachment 7: Screenshot_from_2022-02-23_22-41-08.png

|

|

| Attachment 8: Screenshot_from_2022-02-23_22-42-51.png

|

|

| Attachment 9: Screenshot_from_2022-02-23_22-43-16.png

|

|

| Attachment 10: Screenshot_from_2022-02-23_22-43-39.png

|

|

| Attachment 11: Screenshot_from_2022-02-23_22-46-52.png

|

|

|

261

|

Wed Feb 23 20:52:56 2022 |

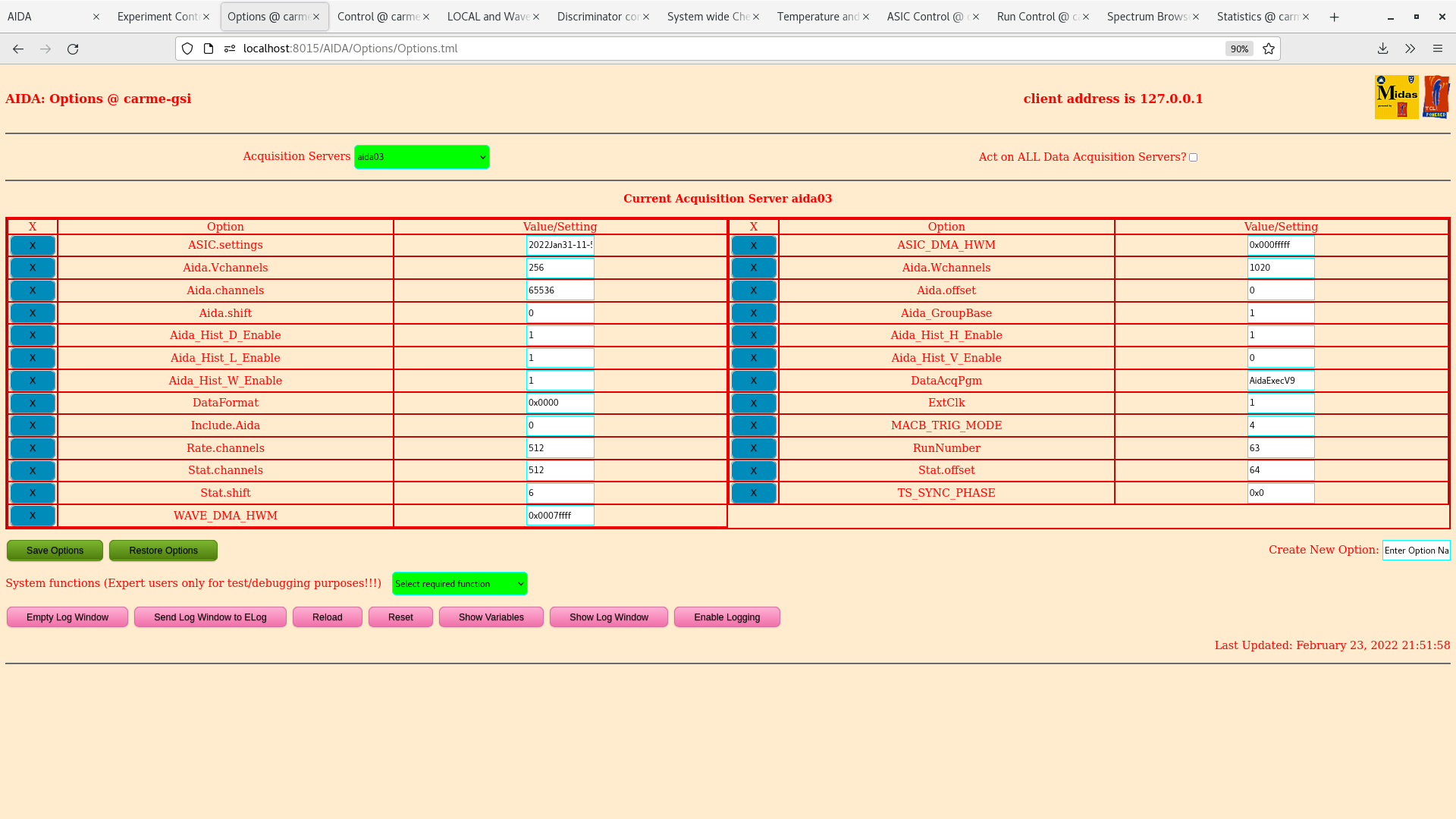

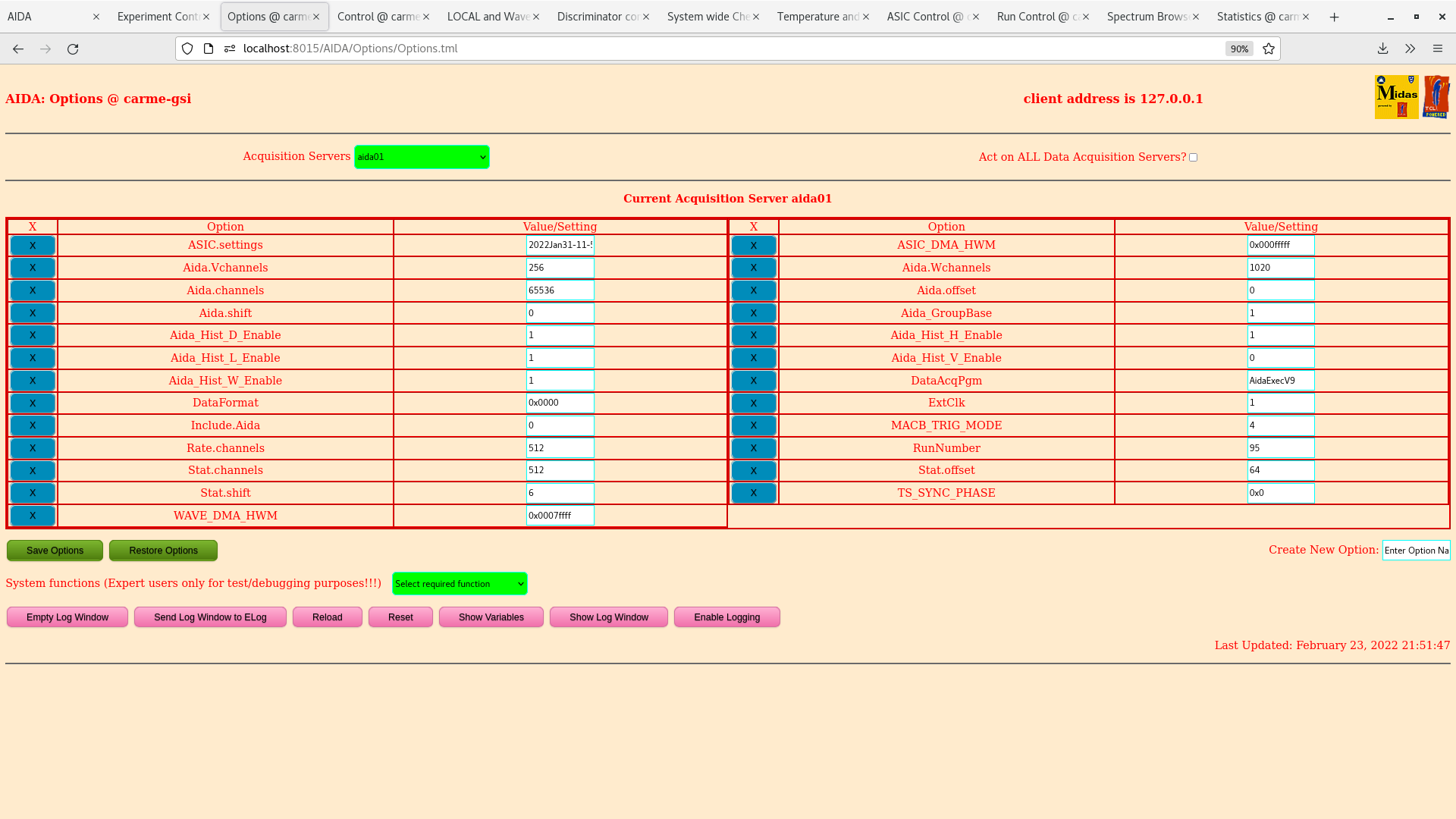

CN, TD | System wide checks |

Attachments 1-5 aida01-aida05 options

System wide checks

Attachment 6 - changes to options files - differences reported but none observed (attachments 1-5)

Attachment 7 - collect memory info from FEE64 Linux

Attachment 8 - collect FPGA timestamp errors

Attachment 9 - WR decoder status

Attachment 10 - ADC calibration

Attachment 11 - Clock status |

| Attachment 1: Screenshot_from_2022-02-23_21-52-10.png

|

|

| Attachment 2: Screenshot_from_2022-02-23_21-52-05.png

|

|

| Attachment 3: Screenshot_from_2022-02-23_21-52-00.png

|

|

| Attachment 4: Screenshot_from_2022-02-23_21-51-55.png

|

|

| Attachment 5: Screenshot_from_2022-02-23_21-51-50.png

|

|

| Attachment 6: Screenshot_from_2022-02-23_21-51-35.png

|

|

| Attachment 7: Screenshot_from_2022-02-23_21-51-20.png

|

|

| Attachment 8: Screenshot_from_2022-02-23_21-51-08.png

|

|

| Attachment 9: Screenshot_from_2022-02-23_21-51-02.png

|

|

| Attachment 10: Screenshot_from_2022-02-23_21-50-56.png

|

|

| Attachment 11: Screenshot_from_2022-02-23_21-50-49.png

|

|

|

260

|

Wed Feb 23 20:06:43 2022 |

TD CN | E141 kinematics |

Assuming DSSSD is 1000um thick we can expect to observe protons for E_lab=11MeV as follows

14N(d,p)15N(gs) E_p=5.4MeV

14N(d,p)15N(5.3) E_p=8.0MeV |

| Attachment 1: E141_kinematics.txt

|

________________________________________________________________________________

Reaction: 14N(2H,1H)15N

A: 14 2 1 15

Z: 7 1 1 7

Mass(amu): 14.003074 2.014102 1.007825 15.000109

Error(keV): 0.001 0.000 0.000 0.001

Origin:

Status:

Q = 8.6087 +/- 0.0000 MeV

________________________________________________________________________________

Enter reaction: 14n(2h,4he)

________________________________________________________________________________

Reaction: 14N(2H,4He)12C

A: 14 2 4 12

Z: 7 1 2 6

Mass(amu): 14.003074 2.014102 4.002603 12.000000

Error(keV): 0.001 0.000 0.000 0.000

Origin:

Status:

Q = 13.5742 +/- 0.0000 MeV

________________________________________________________________________________

Medium: si

density: 2.33000 g/cm**3

Molecule:

1 atom(s) of charge: 14.0 mass: 28.0860 amu

Average ionization potential: 0.172253E-03 MeV

Electron density: 0.699429 *10**24/cm**3

Average charge: 14.0000

Ion: 1h

charge: 1.0 mass: 1.0000 amu

Energy(MeV) dE/dx(MeV/mm) dE/dx(MeV.cm**2/mg) Range(mm) Range(mg/cm**2)

1.00000 41.7638 0.179244 0.168683E-01 3.93032

2.00000 26.4413 0.113482 0.479716E-01 11.1774

3.00000 19.8139 0.850383E-01 0.920942E-01 21.4580

4.00000 16.0296 0.687967E-01 0.148410 34.5796

5.00000 13.5554 0.581779E-01 0.216350 50.4095

6.00000 11.7994 0.506413E-01 0.295737 68.9066

7.00000 10.4828 0.449906E-01 0.385601 89.8451

8.00000 9.69841 0.416241E-01 0.486197 113.284

9.00000 8.85218 0.379922E-01 0.594047 138.413

10.0000 8.15487 0.349994E-01 0.712066 165.911

11.0000 7.56942 0.324868E-01 0.839325 195.563

12.0000 7.07026 0.303445E-01 0.976032 227.415

13.0000 6.63918 0.284943E-01 1.12211 261.451

14.0000 6.26279 0.268789E-01 1.27739 297.632

15.0000 5.93105 0.254552E-01 1.44140 335.846

16.0000 5.63627 0.241900E-01 1.61476 376.239

17.0000 5.37246 0.230577E-01 1.79614 418.501

18.0000 5.13484 0.220380E-01 1.98680 462.925

19.0000 4.91963 0.211143E-01 2.18570 509.269

20.0000 4.72370 0.202734E-01 2.39308 557.587

Medium: si

density: 2.33000 g/cm**3

Molecule:

1 atom(s) of charge: 14.0 mass: 28.0860 amu

Average ionization potential: 0.172253E-03 MeV

Electron density: 0.699429 *10**24/cm**3

Average charge: 14.0000

Ion: 4he

charge: 2.0 mass: 4.0000 amu

Energy(MeV) dE/dx(MeV/mm) dE/dx(MeV.cm**2/mg) Range(mm) Range(mg/cm**2)

1.00000 257.862 1.10670 0.382916E-02 0.892195

2.00000 217.610 0.933946 0.970542E-02 2.26136

3.00000 184.248 0.790762 0.147204E-01 3.42986

4.00000 159.425 0.684229 0.205680E-01 4.79233

5.00000 140.613 0.603489 0.272616E-01 6.35195

6.00000 125.944 0.540534 0.347858E-01 8.10510

7.00000 114.206 0.490155 0.431299E-01 10.0493

8.00000 104.603 0.448940 0.522753E-01 12.1802

9.00000 96.5996 0.414591 0.622123E-01 14.4955

10.0000 89.8241 0.385511 0.729664E-01 17.0012

11.0000 84.0110 0.360562 0.844573E-01 19.6786

12.0000 78.9663 0.338911 0.967262E-01 22.5372

13.0000 74.5447 0.319934 0.109668 25.5527

14.0000 70.6356 0.303157 0.123440 28.7614

15.0000 67.1531 0.288211 0.137756 32.0971

16.0000 64.0297 0.274806 0.152904 35.6267

17.0000 61.2114 0.262710 0.168794 39.3289

18.0000 58.6547 0.251737 0.185593 43.2431

19.0000 56.3239 0.241733 0.202664 47.2208

20.0000 54.1897 0.232574 0.220839 51.4555

______________________________________________________________________________________________________________________________

Reaction: 14N(2H,2H)14N

A: 14 2 2 14

Z: 7 1 1 7

Mass(amu): 14.003074 2.014102 2.014102 14.003074

Error(keV): 0.001 0.000 0.000 0.001

Origin:

Status:

Q(gs): 0.0000 +/- 0.0001 MeV

Projectile lab energy: 11.000 MeV

CM energy: 9.614 MeV

Excitation energy: 0.000 MeV

Reaction Q-value: 0.000 MeV

Reaction threshold: 0.000 MeV

Particle 3 Particle 4 Non-relativistic Jacobians

( scattered/ejectile ) ( recoil ) Ejectile Ejectile

Ejectile Recoil dOmega/ dOmega/

Lab CM Lab Lab Lab dOmega Lab CM Lab Lab Lab dOmega dOmega dOmega Recoil Recoil

Angle Angle Energy Beta ToF Lab/CM Angle Angle Energy Beta ToF Lab/CM Lab/CM Lab/CM dOmega dOmega

(deg) (deg) (MeV) (ns/cm) ratio (deg) (deg) (MeV) (ns/cm) ratio Lab/Lab CM/Lab

0.00 0.00 11.000 0.1078 0.309 0.0000 NaN 180.00 0.000 NaN NaN NaN 0.0000 NaN NaN NaN

10.00 11.44 10.952 0.1076 0.310 0.7665 84.28 168.56 0.048 0.0027 12.281 2.5089 0.7665 2.5084 0.3056 0.3987

20.00 22.83 10.810 0.1069 0.312 0.7758 78.58 157.17 0.190 0.0054 6.183 1.2631 0.7758 1.2628 0.6144 0.7919

30.00 34.14 10.582 0.1058 0.315 0.7915 72.93 145.86 0.418 0.0080 4.169 0.8516 0.7915 0.8515 0.9295 1.1744

40.00 45.33 10.281 0.1043 0.320 0.8134 67.33 134.67 0.719 0.0105 3.176 0.6488 0.8134 0.6487 1.2539 1.5416

50.00 56.36 9.920 0.1024 0.326 0.8416 61.82 123.64 1.080 0.0129 2.592 0.5294 0.8415 0.5294 1.5897 1.8891

60.00 67.19 9.517 0.1003 0.332 0.8758 56.40 112.81 1.483 0.0151 2.212 0.4518 0.8757 0.4518 1.9384 2.2135

70.00 77.80 9.089 0.0981 0.340 0.9158 51.10 102.20 1.911 0.0171 1.949 0.3981 0.9157 0.3980 2.3005 2.5123

80.00 88.18 8.654 0.0957 0.348 0.9610 45.91 91.82 2.346 0.0190 1.759 0.3593 0.9609 0.3593 2.6748 2.7835

90.00 98.31 8.228 0.0933 0.357 1.0107 40.84 81.69 2.772 0.0206 1.618 0.3305 1.0106 0.3304 3.0584 3.0263

100.00 108.18 7.822 0.0910 0.366 1.0636 35.91 71.82 3.178 0.0221 1.511 0.3086 1.0635 0.3086 3.4459 3.2402

110.00 117.80 7.448 0.0888 0.375 1.1181 31.10 62.20 3.552 0.0233 1.430 0.2919 1.1181 0.2919 3.8300 3.4256

120.00 127.18 7.113 0.0868 0.384 1.1724 26.41 52.82 3.887 0.0244 1.367 0.2791 1.1724 0.2791 4.2008 3.5832

130.00 136.35 6.825 0.0851 0.392 1.2242 21.82 43.65 4.175 0.0253 1.319 0.2693 1.2242 0.2693 4.5465 3.7140

140.00 145.33 6.585 0.0836 0.399 1.2711 17.34 34.67 4.415 0.0260 1.282 0.2619 1.2711 0.2619 4.8542 3.8189

150.00 154.14 6.398 0.0824 0.405 1.3107 12.93 25.86 4.602 0.0266 1.256 0.2565 1.3107 0.2565 5.1107 3.8993

160.00 162.83 6.263 0.0815 0.409 1.3408 8.58 17.17 4.737 0.0269 1.238 0.2528 1.3408 0.2528 5.3039 3.9559

170.00 171.44 6.182 0.0810 0.412 1.3596 4.28 8.56 4.818 0.0272 1.228 0.2507 1.3596 0.2507 5.4241 3.9896

180.00 180.00 6.155 0.0808 0.413 0.0000 0.00 0.00 4.845 0.0272 1.224 0.0000 0.0000 0.0000 5.4649 *******

______________________________________________________________________________________________________________________________

Reaction: 14N(2H,2H)14N

A: 14 2 2 14

Z: 7 1 1 7

Mass(amu): 14.003074 2.014102 2.014102 14.003074

Error(keV): 0.001 0.000 0.000 0.001

Origin:

Status:

Q(gs): 0.0000 +/- 0.0001 MeV

Projectile lab energy: 3.000 MeV

CM energy: 2.623 MeV

Excitation energy: 0.000 MeV

Reaction Q-value: 0.000 MeV

Reaction threshold: 0.000 MeV

Particle 3 Particle 4 Non-relativistic Jacobians

( scattered/ejectile ) ( recoil ) Ejectile Ejectile

Ejectile Recoil dOmega/ dOmega/

Lab CM Lab Lab Lab dOmega Lab CM Lab Lab Lab dOmega dOmega dOmega Recoil Recoil

Angle Angle Energy Beta ToF Lab/CM Angle Angle Energy Beta ToF Lab/CM Lab/CM Lab/CM dOmega dOmega

(deg) (deg) (MeV) (ns/cm) ratio (deg) (deg) (MeV) (ns/cm) ratio Lab/Lab CM/Lab

0.00 0.00 3.000 0.0565 0.591 0.0000 NaN 180.00 0.000 0.0000 Inf NaN 0.0000 NaN NaN NaN

10.00 11.43 2.987 0.0564 0.592 0.7672 84.28 168.57 0.013 0.0014 23.541 2.5099 0.7672 2.5098 0.3057 0.3984

20.00 22.82 2.948 0.0560 0.596 0.7765 78.59 157.18 0.052 0.0028 11.851 1.2636 0.7765 1.2635 0.6146 0.7915

30.00 34.13 2.886 0.0554 0.602 0.7921 72.93 145.87 0.114 0.0042 7.991 0.8519 0.7921 0.8519 0.9298 1.1738

40.00 45.31 2.804 0.0546 0.611 0.8139 67.34 134.69 0.196 0.0055 6.087 0.6490 0.8139 0.6490 1.2541 1.5408

50.00 56.33 2.706 0.0537 0.622 0.8420 61.83 123.67 0.294 0.0067 4.967 0.5296 0.8420 0.5296 1.5899 1.8882

60.00 67.16 2.596 0.0526 0.635 0.8761 56.42 112.84 0.404 0.0079 4.239 0.4520 0.8761 0.4520 1.9384 2.2126

70.00 77.78 2.480 0.0514 0.649 0.9160 51.11 102.22 0.520 0.0089 3.735 0.3982 0.9160 0.3982 2.3003 2.5113

80.00 88.15 2.361 0.0501 0.665 0.9611 45.92 91.85 0.639 0.0099 3.371 0.3594 0.9610 0.3594 2.6742 2.7826

90.00 98.28 2.245 0.0489 0.682 1.0106 40.86 81.72 0.755 0.0108 3.100 0.3305 1.0105 0.3305 3.0572 3.0254

100.00 108.15 2.135 0.0477 0.700 1.0633 35.92 71.85 0.865 0.0115 2.896 0.3087 1.0632 0.3087 3.4442 3.2393

110.00 117.78 2.033 0.0465 0.717 1.1177 31.11 62.22 0.967 0.0122 2.739 0.2920 1.1176 0.2920 3.8277 3.4248

120.00 127.16 1.941 0.0455 0.734 1.1718 26.42 52.84 1.059 0.0127 2.618 0.2791 1.1717 0.2791 4.1977 3.5824

130.00 136.33 1.863 0.0445 0.749 1.2234 21.83 43.67 1.137 0.0132 2.526 0.2693 1.2234 0.2693 4.5427 3.7132

140.00 145.31 1.797 0.0437 0.763 1.2701 17.34 34.69 1.203 0.0136 2.457 0.2619 1.2701 0.2619 4.8497 3.8183

150.00 154.13 1.746 0.0431 0.774 1.3096 12.94 25.87 1.254 0.0139 2.406 0.2565 1.3096 0.2565 5.1056 3.8987

160.00 162.82 1.710 0.0427 0.782 1.3396 8.59 17.18 1.290 0.0141 2.372 0.2528 1.3396 0.2528 5.2984 3.9553

170.00 171.43 1.688 0.0424 0.787 1.3583 4.28 8.57 1.312 0.0142 2.352 0.2507 1.3583 0.2507 5.4183 3.9890

180.00 NaN 1.680 0.0423 0.789 NaN 0.00 NaN 1.320 0.0142 2.345 NaN NaN NaN NaN NaN

______________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________

Reaction: 14N(2H,1H)15N

A: 14 2 1 15

Z: 7 1 1 7

Mass(amu): 14.003074 2.014102 1.007825 15.000109

Error(keV): 0.001 0.000 0.000 0.001

Origin:

Status:

Q(gs): 8.6087 +/- 0.0001 MeV

Projectile lab energy: 11.000 MeV

CM energy: 9.614 MeV

Excitation energy: 0.000 MeV

Reaction Q-value: 8.609 MeV

Reaction threshold: 0.000 MeV

Particle 3 Particle 4 Non-relativistic Jacobians

( scattered/ejectile ) ( recoil ) Ejectile Ejectile

Ejectile Recoil dOmega/ dOmega/

Lab CM Lab Lab Lab dOmega Lab CM Lab Lab Lab dOmega dOmega dOmega Recoil Recoil

Angle Angle Energy Beta ToF Lab/CM Angle Angle Energy Beta ToF Lab/CM Lab/CM Lab/CM dOmega dOmega

(deg) (deg) (MeV) (ns/cm) ratio (deg) (deg) (MeV) (ns/cm) ratio Lab/Lab CM/Lab

0.00 0.00 19.605 0.2012 0.166 0.0000 0.00 180.00 0.004 0.0008 43.955 0.0000 0.0000 0.0000 NaN NaN

10.00 10.72 19.562 0.2010 0.166 0.8712 67.67 169.28 0.047 0.0026 12.887 -4.9755 0.8712 -4.9759 -0.1751 -0.2010

20.00 21.42 19.435 0.2004 0.166 0.8767 70.68 158.58 0.173 0.0050 6.697 0.2448 0.8767 0.2446 3.5841 4.0882

30.00 32.08 19.231 0.1994 0.167 0.8858 68.27 147.92 0.378 0.0074 4.534 0.5498 0.8858 0.5496 1.6117 1.8195

40.00 42.67 18.956 0.1980 0.168 0.8984 64.47 137.33 0.653 0.0097 3.451 0.5224 0.8984 0.5223 1.7199 1.9144

50.00 53.18 18.623 0.1963 0.170 0.9143 60.13 126.82 0.986 0.0119 2.808 0.4645 0.9142 0.4644 1.9686 2.1533

60.00 63.60 18.244 0.1943 0.172 0.9331 55.55 116.40 1.365 0.0140 2.387 0.4130 0.9330 0.4129 2.2595 2.4218

70.00 73.90 17.834 0.1922 0.174 0.9544 50.86 106.10 1.775 0.0159 2.093 0.3717 0.9543 0.3717 2.5676 2.6905

80.00 84.09 17.406 0.1899 0.176 0.9778 46.13 95.91 2.202 0.0178 1.879 0.3393 0.9777 0.3393 2.8820 2.9477

90.00 94.15 16.977 0.1876 0.178 1.0027 41.39 85.85 2.632 0.0194 1.719 0.3138 1.0026 0.3138 3.1954 3.1870

100.00 104.09 16.558 0.1854 0.180 1.0284 36.67 75.91 3.051 0.0209 1.596 0.2937 1.0283 0.2937 3.5015 3.4050

110.00 113.90 16.161 0.1832 0.182 1.0541 31.98 66.10 3.447 0.0222 1.502 0.2778 1.0540 0.2778 3.7938 3.5995

120.00 123.59 15.798 0.1812 0.184 1.0789 27.32 56.41 3.810 0.0233 1.429 0.2653 1.0788 0.2653 4.0660 3.7690

130.00 133.18 15.477 0.1794 0.186 1.1019 22.70 46.82 4.131 0.0243 1.372 0.2556 1.1018 0.2556 4.3114 3.9129

140.00 142.67 15.206 0.1778 0.188 1.1222 18.11 37.33 4.403 0.0251 1.329 0.2481 1.1222 0.2481 4.5233 4.0308

150.00 152.07 14.989 0.1766 0.189 1.1391 13.55 27.93 4.620 0.0257 1.297 0.2426 1.1390 0.2426 4.6955 4.1224

160.00 161.42 14.831 0.1757 0.190 1.1516 9.02 18.58 4.777 0.0261 1.276 0.2388 1.1516 0.2388 4.8228 4.1878

170.00 170.72 14.736 0.1751 0.190 1.1594 4.51 9.28 4.873 0.0264 1.263 0.2366 1.1594 0.2366 4.9010 4.2270

180.00 NaN 14.704 0.1749 0.191 NaN 0.00 NaN 4.905 0.0265 1.259 NaN NaN NaN NaN NaN

______________________________________________________________________________________________________________________________

Reaction: 14N(2H,1H)15N

A: 14 2 1 15

Z: 7 1 1 7

Mass(amu): 14.003074 2.014102 1.007825 15.000109

Error(keV): 0.001 0.000 0.000 0.001

Origin:

Status:

Q(gs): 8.6087 +/- 0.0001 MeV

Projectile lab energy: 3.000 MeV

CM energy: 2.623 MeV

Excitation energy: 0.000 MeV

Reaction Q-value: 8.609 MeV

Reaction threshold: 0.000 MeV

Particle 3 Particle 4 Non-relativistic Jacobians

( scattered/ejectile ) ( recoil ) Ejectile Ejectile

Ejectile Recoil dOmega/ dOmega/

Lab CM Lab Lab Lab dOmega Lab CM Lab Lab Lab dOmega dOmega dOmega Recoil Recoil

Angle Angle Energy Beta ToF Lab/CM Angle Angle Energy Beta ToF Lab/CM Lab/CM Lab/CM dOmega dOmega

(deg) (deg) (MeV) (ns/cm) ratio (deg) (deg) (MeV) (ns/cm) ratio Lab/Lab CM/Lab

0.00 NaN 11.547 0.1554 0.215 NaN 180.00 NaN 0.062 0.0030 11.216 NaN NaN NaN NaN NaN

10.00 10.48 11.530 0.1553 0.215 0.9119 146.83 169.52 0.079 0.0034 9.951 8.3535 0.9119 8.3535 0.1092 0.1197

20.00 20.94 11.481 0.1550 0.215 0.9158 122.63 159.06 0.128 0.0043 7.793 4.4681 0.9158 4.4681 0.2050 0.2238

30.00 31.37 11.400 0.1544 0.216 0.9221 105.93 148.63 0.208 0.0055 6.108 2.5075 0.9221 2.5074 0.3678 0.3988

40.00 41.77 11.292 0.1537 0.217 0.9308 93.50 138.23 0.317 0.0067 4.956 1.5952 0.9308 1.5951 0.5836 0.6269

50.00 52.10 11.160 0.1528 0.218 0.9417 83.43 127.90 0.449 0.0080 4.163 1.1310 0.9417 1.1309 0.8327 0.8842

60.00 62.38 11.009 0.1518 0.220 0.9546 74.75 117.62 0.599 0.0093 3.601 0.8690 0.9545 0.8690 1.0985 1.1508

70.00 72.58 10.845 0.1507 0.221 0.9690 66.96 107.42 0.764 0.0105 3.190 0.7077 0.9690 0.7077 1.3691 1.4130

80.00 82.70 10.672 0.1495 0.223 0.9847 59.76 97.30 0.937 0.0116 2.880 0.6016 0.9846 0.6016 1.6368 1.6623

90.00 92.75 10.496 0.1483 0.225 1.0012 52.99 87.25 1.112 0.0126 2.644 0.5281 1.0011 0.5281 1.8958 1.8936

100.00 102.70 10.324 0.1471 0.227 1.0180 46.52 77.30 1.285 0.0136 2.460 0.4754 1.0180 0.4753 2.1416 2.1037

110.00 112.58 10.160 0.1459 0.229 1.0347 40.29 67.42 1.449 0.0144 2.316 0.4365 1.0347 0.4365 2.3704 2.2909

120.00 122.38 10.008 0.1449 0.230 1.0506 34.24 57.62 1.601 0.0151 2.204 0.4075 1.0506 0.4075 2.5783 2.4541

130.00 132.10 9.872 0.1439 0.232 1.0653 28.34 47.90 1.736 0.0158 2.116 0.3857 1.0653 0.3857 2.7618 2.5925

140.00 141.76 9.757 0.1431 0.233 1.0782 22.55 38.24 1.852 0.0163 2.049 0.3696 1.0782 0.3696 2.9175 2.7060

150.00 151.37 9.665 0.1424 0.234 1.0887 16.84 28.63 1.944 0.0167 2.000 0.3579 1.0887 0.3579 3.0422 2.7943

160.00 160.94 9.597 0.1419 0.235 1.0966 11.19 19.06 2.012 0.0170 1.966 0.3500 1.0966 0.3500 3.1334 2.8573

170.00 170.48 9.556 0.1416 0.236 1.1015 5.59 9.52 2.053 0.0171 1.946 0.3454 1.1015 0.3454 3.1889 2.8951

180.00 NaN 9.542 0.1415 0.236 NaN 0.00 NaN 2.067 0.0172 1.940 NaN NaN NaN NaN NaN

______________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________

... 144 more lines ...

|

|

259

|

Wed Feb 23 19:22:55 2022 |

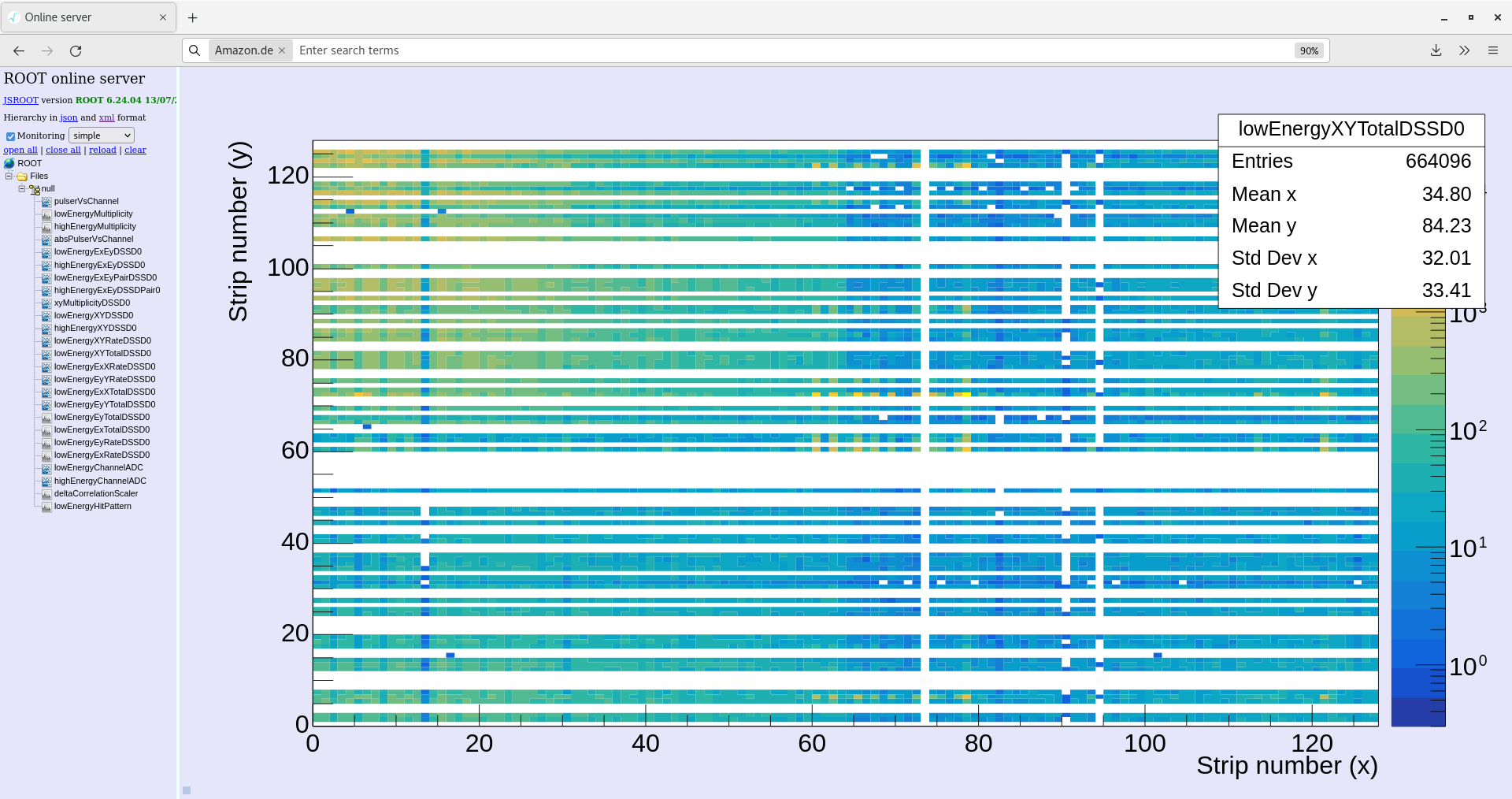

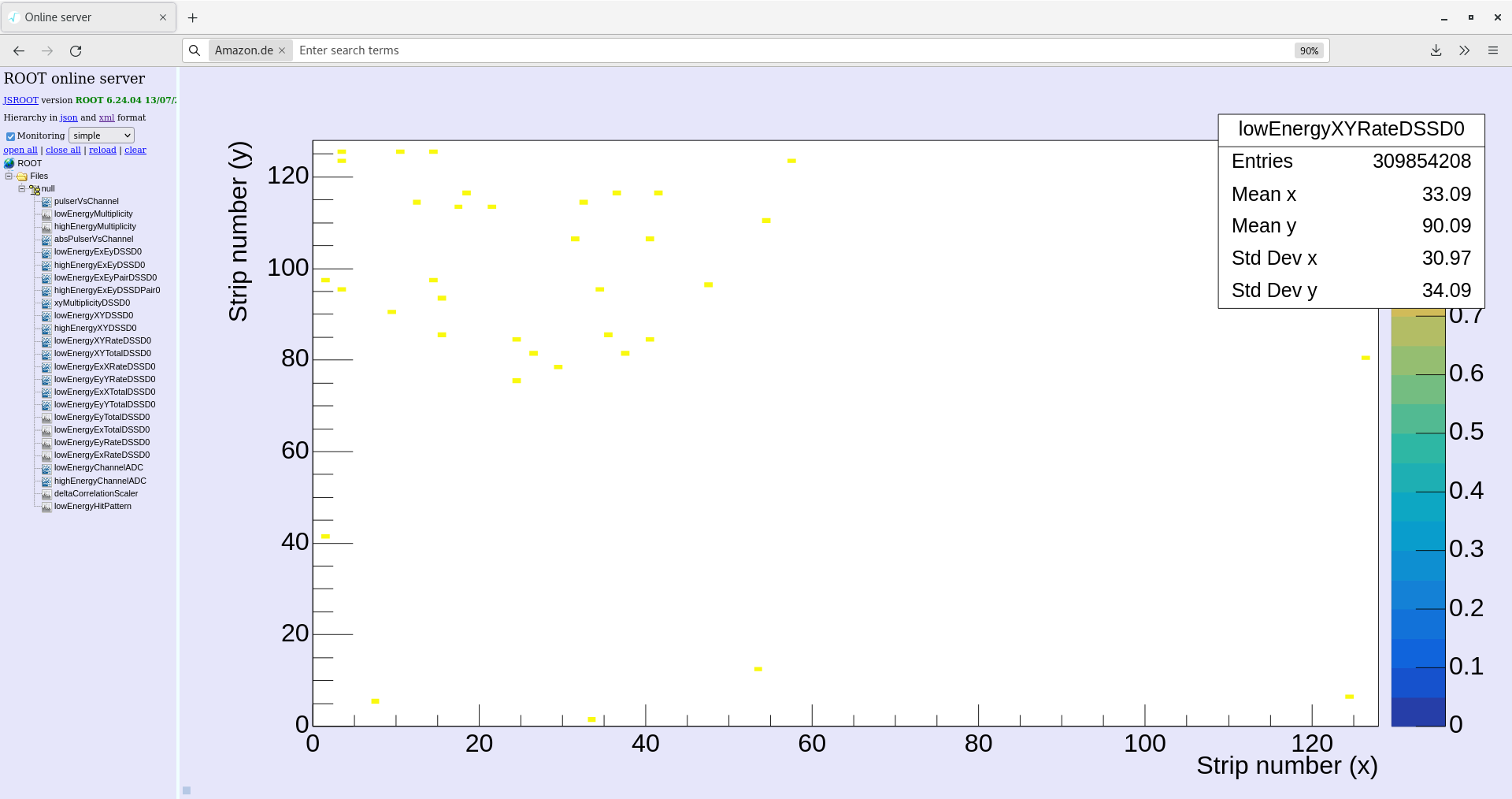

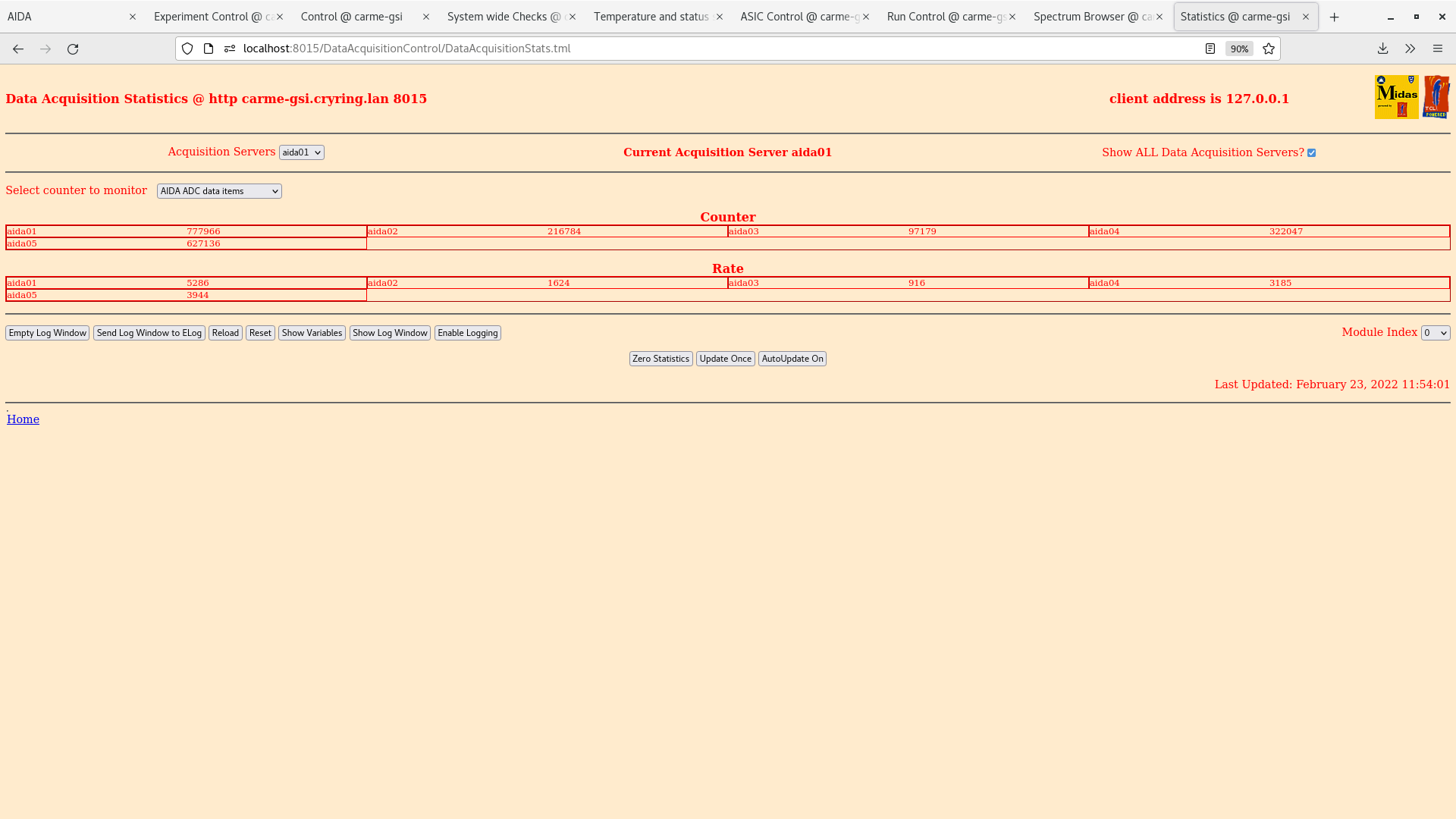

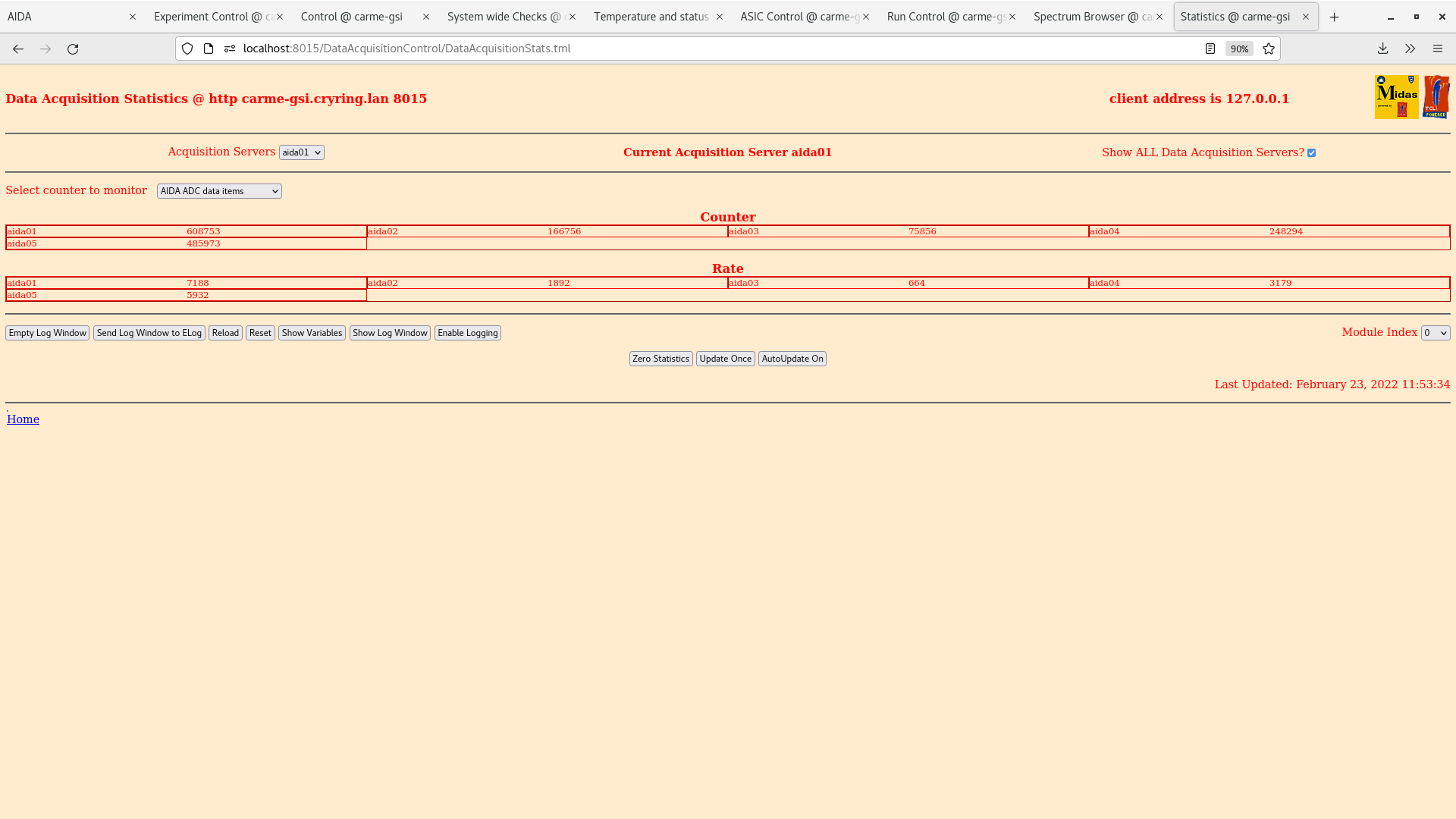

CN, TD | check |

- Motor checked , OK

SW3

- Merger OK

- Screenshot uploaded

- Data rate : 755 kbytes/s

SW4

- current plot uploaded

SW2

- T OK

- system wide check OK

- Statistics ok

- Spectra ok

SW5

4 plots uploaded

|

| Attachment 1: Screenshot_from_2022-02-23_20-27-38.png

|

|

| Attachment 2: Screenshot_from_2022-02-23_20-33-16.png

|

|

| Attachment 3: Screenshot_from_2022-02-23_20-35-15.png

|

|

| Attachment 4: Screenshot_from_2022-02-23_20-41-50.png

|

|

| Attachment 5: Screenshot_from_2022-02-23_20-42-53.png

|

|

| Attachment 6: Screenshot_from_2022-02-23_20-44-43.png

|

|

| Attachment 7: Screenshot_from_2022-02-23_20-48-47.png

|

|

| Attachment 8: Screenshot_from_2022-02-23_20-50-12.png

|

|

| Attachment 9: Screenshot_from_2022-02-23_20-51-10.png

|

|

| Attachment 10: Screenshot_from_2022-02-23_20-51-54.png

|

|

|

258

|

Wed Feb 23 18:58:12 2022 |

TD CN | Wednesday 23 February 15.00-23.00 shift |

Assorted screenshots of the CARME, CRYRING and gas jet target control systems in operation

Attachment 1 - detector motion controls

Attachment 2 - gas jet target pressures (blue proxy for target density, red proxy for gas load to CRYRING)

Attachment 3 - Schottky probe monitor of beam

Attachment 4 - CRYRING controls monitor

Attachment 5 - CRYRING vacuum pressures

Attachment 6 - CRYRING beam position and profile monitor |

| Attachment 1: 20220223_195402.jpg

|

|

| Attachment 2: 20220223_195349.jpg

|

|

| Attachment 3: 20220223_195208.jpg

|

|

| Attachment 4: 20220223_195203.jpg

|

|

| Attachment 5: 20220223_195142.jpg

|

|

| Attachment 6: 20220223_195133.jpg

|

|

|

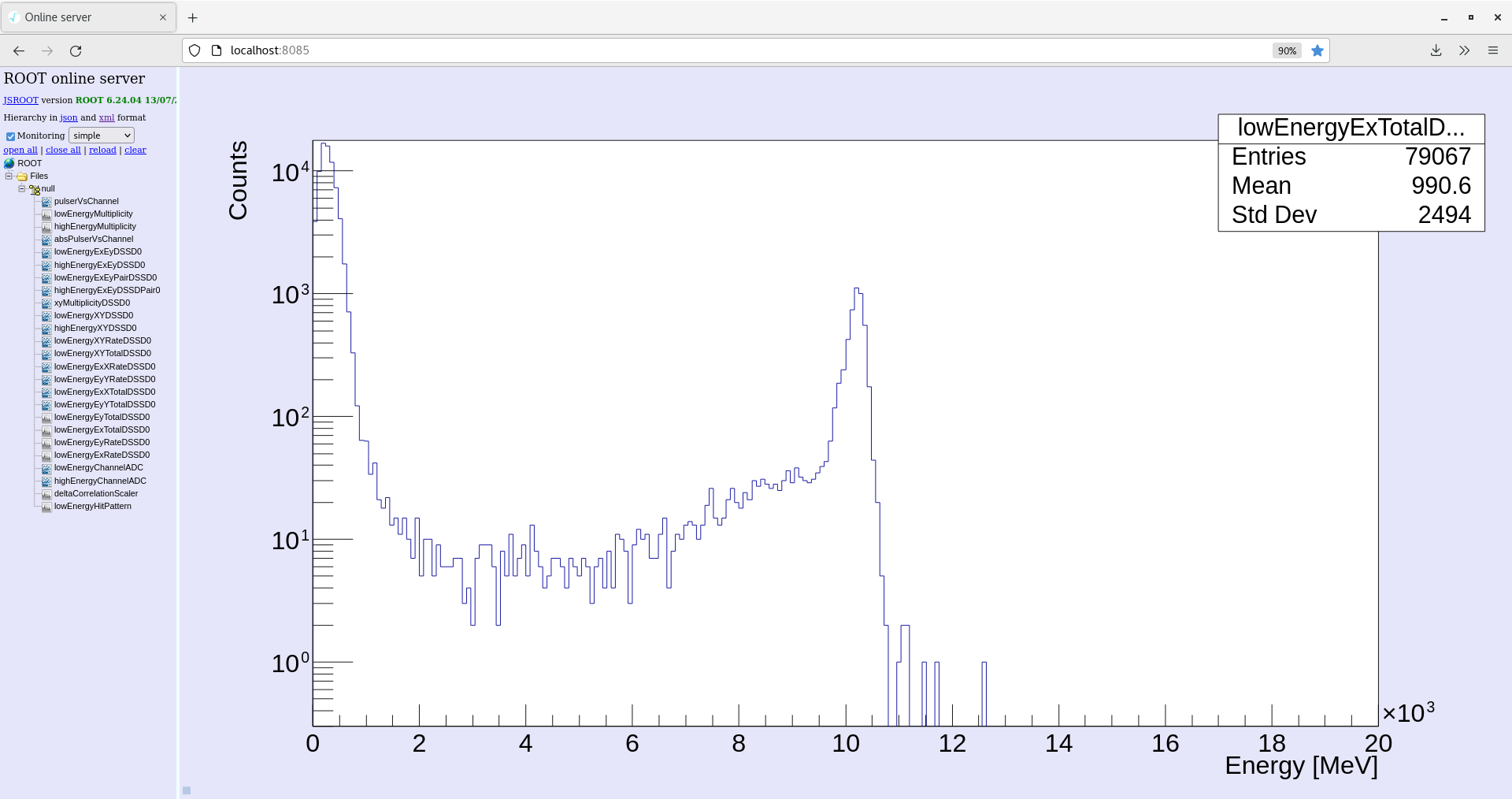

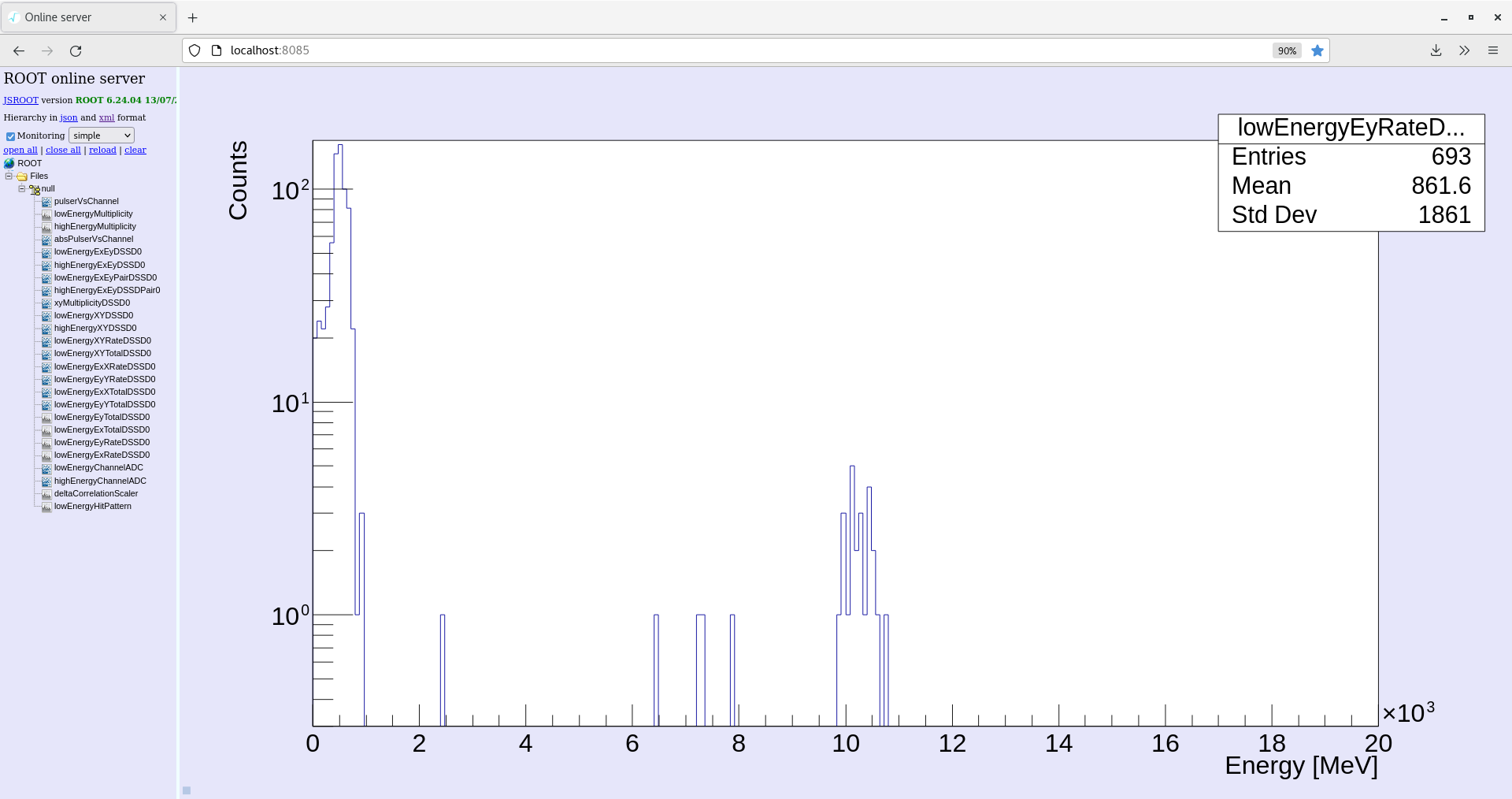

257

|

Wed Feb 23 16:57:35 2022 |

CB, CN | Optimising motor motion |

Optimised motor motion during run R58

Moved 2 mm in (20.3 potentiometer)

29.47 potentiometer

36.5 potentiometer

(started moving pneumatic)

64.36 potentiometer

74.03 potentiomater (servo in by 10 mm)

Moved in, collected counts for 5 minutes, moved out, waited for re-injection.

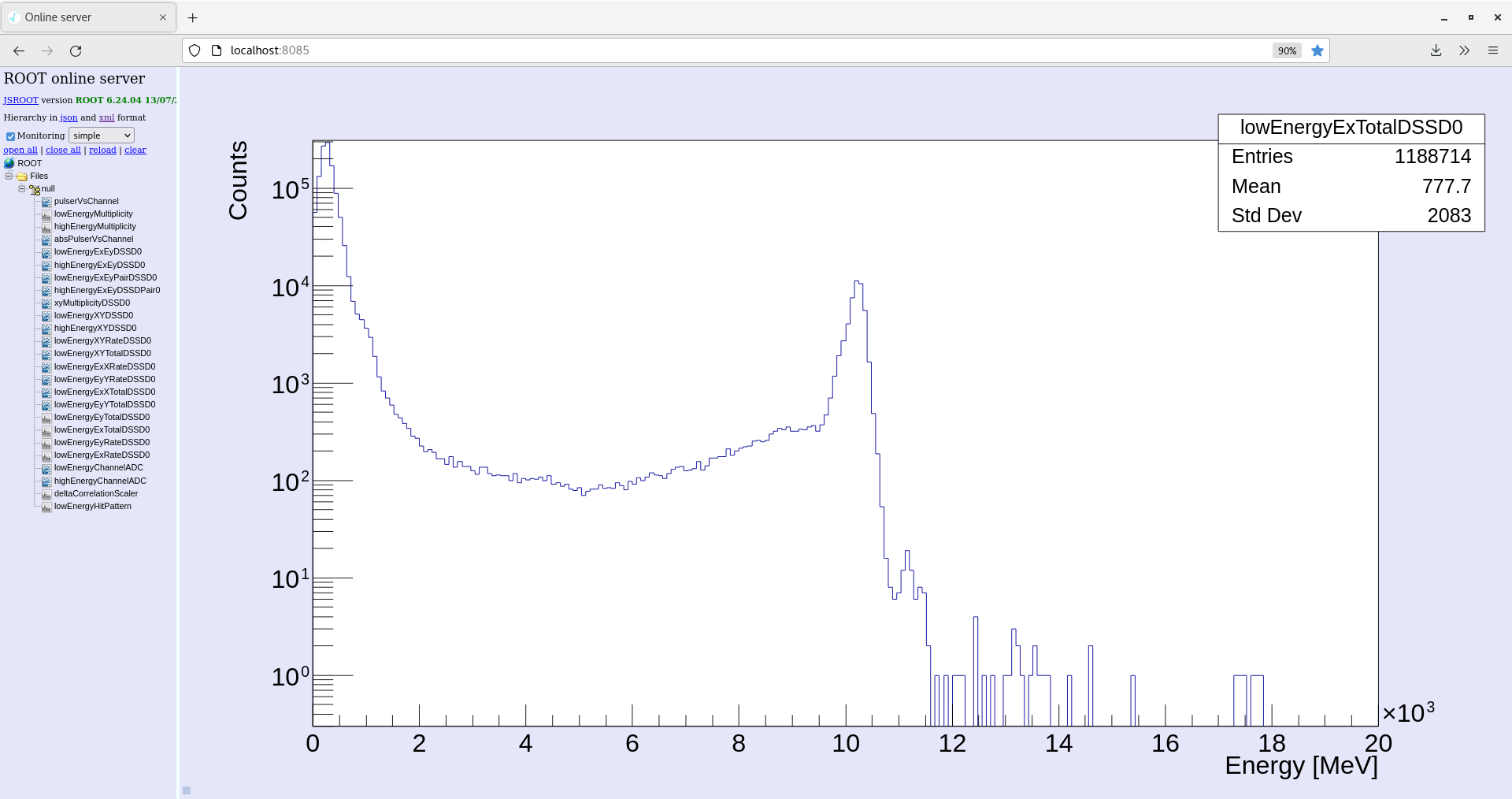

20.3 - 400 counts on the Rutherford peak, bins 125-131 on lowEnergyExTotalDSSD0

20.47 - 646

36.5 - 827

64.36 - 3900

74.03 - 10040

Based on Rutherford rate ratio, estimated we are 40-50 mm away from interaction point, i.e. beam roughly 1-2 cm on outer half of ring which may be consistent with BPM measurement in YR08

Decided to use 74.03 mm for data collection.

Started data acquisition on R59 at 17:27

Beam 3E7 at injection, 600 second storage, 3 second between cycles

Target pressure 1.3E12 based on 8.21E18 x S1=1.6E-8 |

|

256

|

Wed Feb 23 10:56:06 2022 |

Laszlo, Thanassis | Current status |

11:55

Temps OK

System Check OK

White Rabbit fail diff: 102

Write Speed: ~1.2Mb/s

Leakage Current: ~3.47uA

Cryo Temp = 129.2K setpoint (unchanged)

Pressures stable

AVG Pressures:

YR07: 1.99e-10mbar

YR08: 2.6e-9mbar

YR09: 1.03e-9mbar

YR10: 1.7e-10mbar |

| Attachment 1: Screenshot_from_2022-02-23_11-55-28.png

|

|

| Attachment 2: Screenshot_from_2022-02-23_11-55-08.png

|

|

| Attachment 3: Screenshot_from_2022-02-23_11-54-49.png

|

|

| Attachment 4: Screenshot_from_2022-02-23_11-54-37.png

|

|

| Attachment 5: Screenshot_from_2022-02-23_11-54-26.png

|

|

| Attachment 6: Screenshot_from_2022-02-23_11-54-07.png

|

|

| Attachment 7: Screenshot_from_2022-02-23_11-53-51.png

|

|

| Attachment 8: Screenshot_from_2022-02-23_11-53-38.png

|

|

| Attachment 9: Screenshot_from_2022-02-23_11-53-26.png

|

|

| Attachment 10: Screenshot_from_2022-02-23_11-52-51.png

|

|

|

255

|

Wed Feb 23 09:50:19 2022 |

Laszlo, Thanassis | Moving detector in |

We are moving the detector in run 56 |

|

254

|

Wed Feb 23 08:58:30 2022 |

Laszlo, Thanassis | Current status |

10:00

Temps OK

System Check OK

White Rabbit fail diff: 102

Write Speed: ~1.2Mb/s

Leakage Current: ~3.47uA

Cryo Temp = 129.2K setpoint (unchanged)

Pressures stable

AVG Pressures:

YR07: 1.93e-10mbar

YR08: 2.64e-9mbar

YR09: 1.13e-9mbar

YR10: 1.55e-10mbar |

| Attachment 1: Screenshot_from_2022-02-23_10-03-03.png

|

|

| Attachment 2: Screenshot_from_2022-02-23_10-02-49.png

|

|

| Attachment 3: Screenshot_from_2022-02-23_10-02-18.png

|

|

| Attachment 4: Screenshot_from_2022-02-23_10-01-48.png

|

|

| Attachment 5: Screenshot_from_2022-02-23_10-01-33.png

|

|

| Attachment 6: Screenshot_from_2022-02-23_10-01-21.png

|

|

| Attachment 7: Screenshot_from_2022-02-23_09-59-58.png

|

|

| Attachment 8: Screenshot_from_2022-02-23_09-59-39.png

|

|

| Attachment 9: Screenshot_from_2022-02-23_09-59-14.png

|

|

| Attachment 10: Screenshot_from_2022-02-23_09-58-59.png

|

|

|

253

|

Wed Feb 23 07:58:38 2022 |

Laszlo, Thanassis | Current status |

09:00

Temps OK

System Check OK

White Rabbit fail diff: 101

Write Speed: ~1.2Mb/s

Leakage Current: ~3.47uA

Cryo Temp = 129.2K setpoint (unchanged)

Pressures stable

AVG Pressures:

YR07: 1.88e-10mbar

YR08: 2.28e-9mbar

YR09: 9.15e-10mbar

YR10: 1.52e-10mbar |

| Attachment 1: Screenshot_from_2022-02-23_09-03-08.png

|

|

| Attachment 2: Screenshot_from_2022-02-23_09-02-35.png

|

|

| Attachment 3: Screenshot_from_2022-02-23_09-02-20.png

|

|

| Attachment 4: Screenshot_from_2022-02-23_09-02-04.png

|

|

| Attachment 5: Screenshot_from_2022-02-23_09-01-50.png

|

|

| Attachment 6: Screenshot_from_2022-02-23_09-01-36.png

|

|

| Attachment 7: Screenshot_from_2022-02-23_09-01-15.png

|

|

| Attachment 8: Screenshot_from_2022-02-23_09-00-35.png

|

|

| Attachment 9: Screenshot_from_2022-02-23_08-59-04.png

|

|

| Attachment 10: Screenshot_from_2022-02-23_08-58-46.png

|

|

|

252

|

Wed Feb 23 06:58:19 2022 |

Laszlo, Thanassis | Current status |

08:00

Temps OK

System Check OK

White Rabbit fail diff: 99

Write Speed: ~1.0Mb/s

Leakage Current: ~3.47uA

Cryo Temp = 129.2K setpoint (unchanged)

Pressures stable

AVG Pressures:

YR07: 2.06e-10mbar

YR08: 2.71e-9mbar

YR09: 1.06e-9mbar (up from previous check)

YR10: 1.78e-10mbar |

| Attachment 1: Screenshot_from_2022-02-23_08-08-36.png

|

|

| Attachment 2: Screenshot_from_2022-02-23_08-08-16.png

|

|

| Attachment 3: Screenshot_from_2022-02-23_08-07-48.png

|

|

| Attachment 4: Screenshot_from_2022-02-23_08-07-21.png

|

|

| Attachment 5: Screenshot_from_2022-02-23_08-05-30.png

|

|

| Attachment 6: Screenshot_from_2022-02-23_08-05-11.png

|

|

| Attachment 7: Screenshot_from_2022-02-23_08-04-42.png

|

|

| Attachment 8: Screenshot_from_2022-02-23_08-04-01.png

|

|

| Attachment 9: Screenshot_from_2022-02-23_08-02-57.png

|

|

| Attachment 10: Screenshot_from_2022-02-23_08-02-19.png

|

|

| Attachment 11: leakage-2022-02-23_08-00-38.png

|

|

|

251

|

Wed Feb 23 06:00:25 2022 |

Jordan, George | Current status |

07:00

Pressure Stable

Temps OK

System Check OK

White Rabbit fail diff: 90

Write speed: ~1Mb/s

Leakage Current: 3.47uA

Cryo Temp Setpoint: 129.2K (unchanged)

AVG Pressures:

YR07: 1.66e-10mbar

YR08: 1.93e-9mbar

YR09: 7.63e-10mbar

YR10: 1.26e-10mbar |

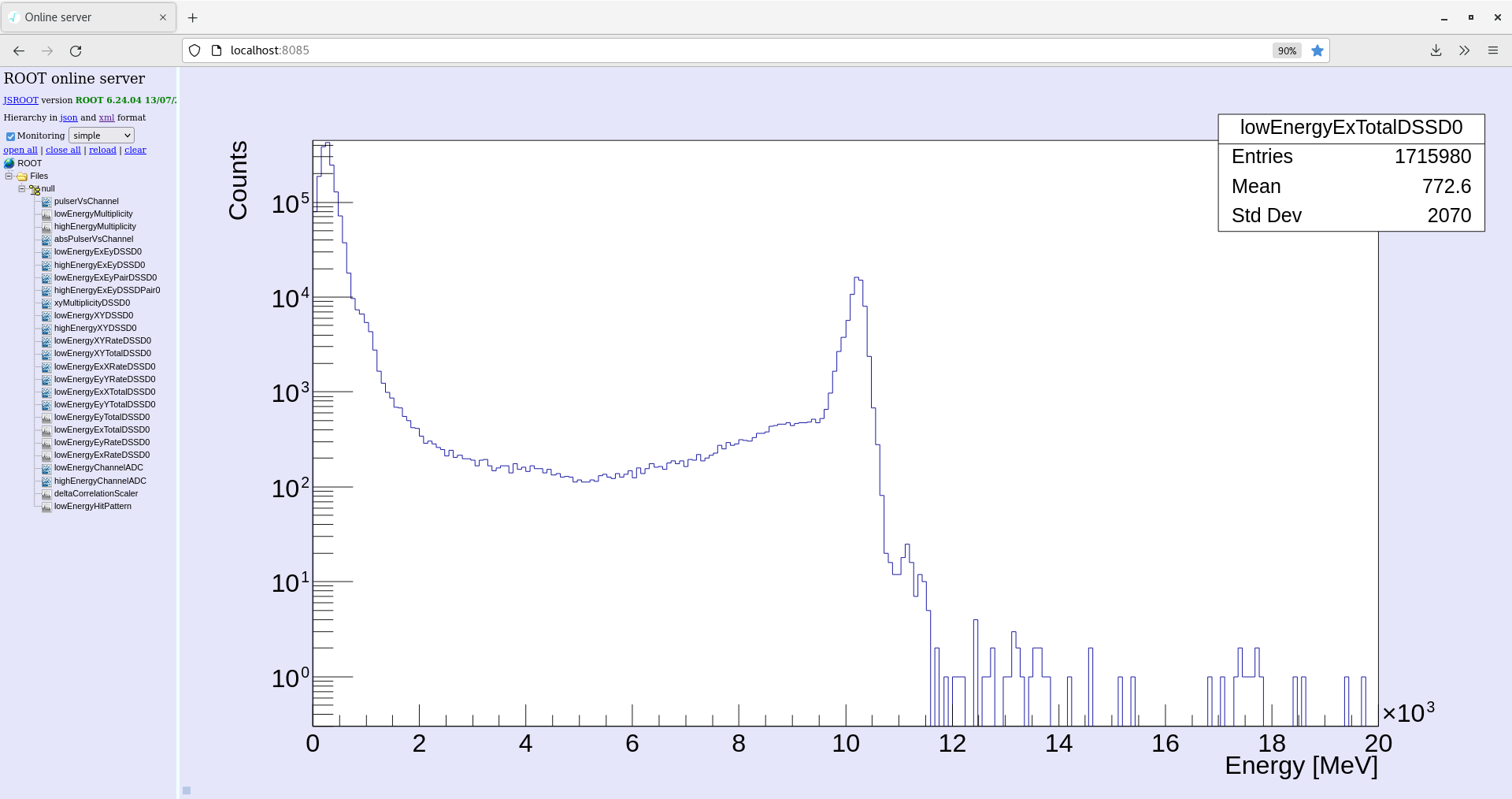

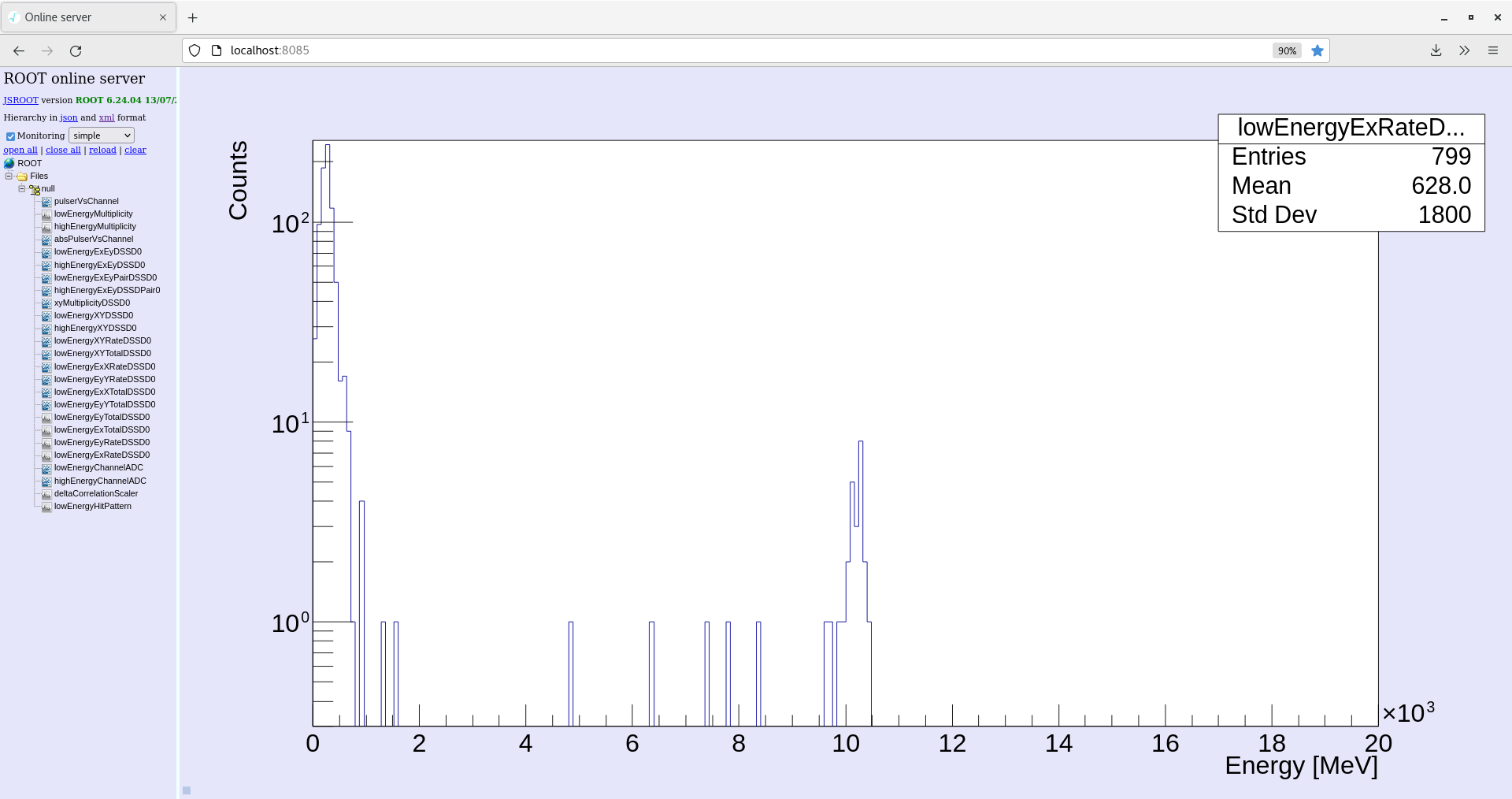

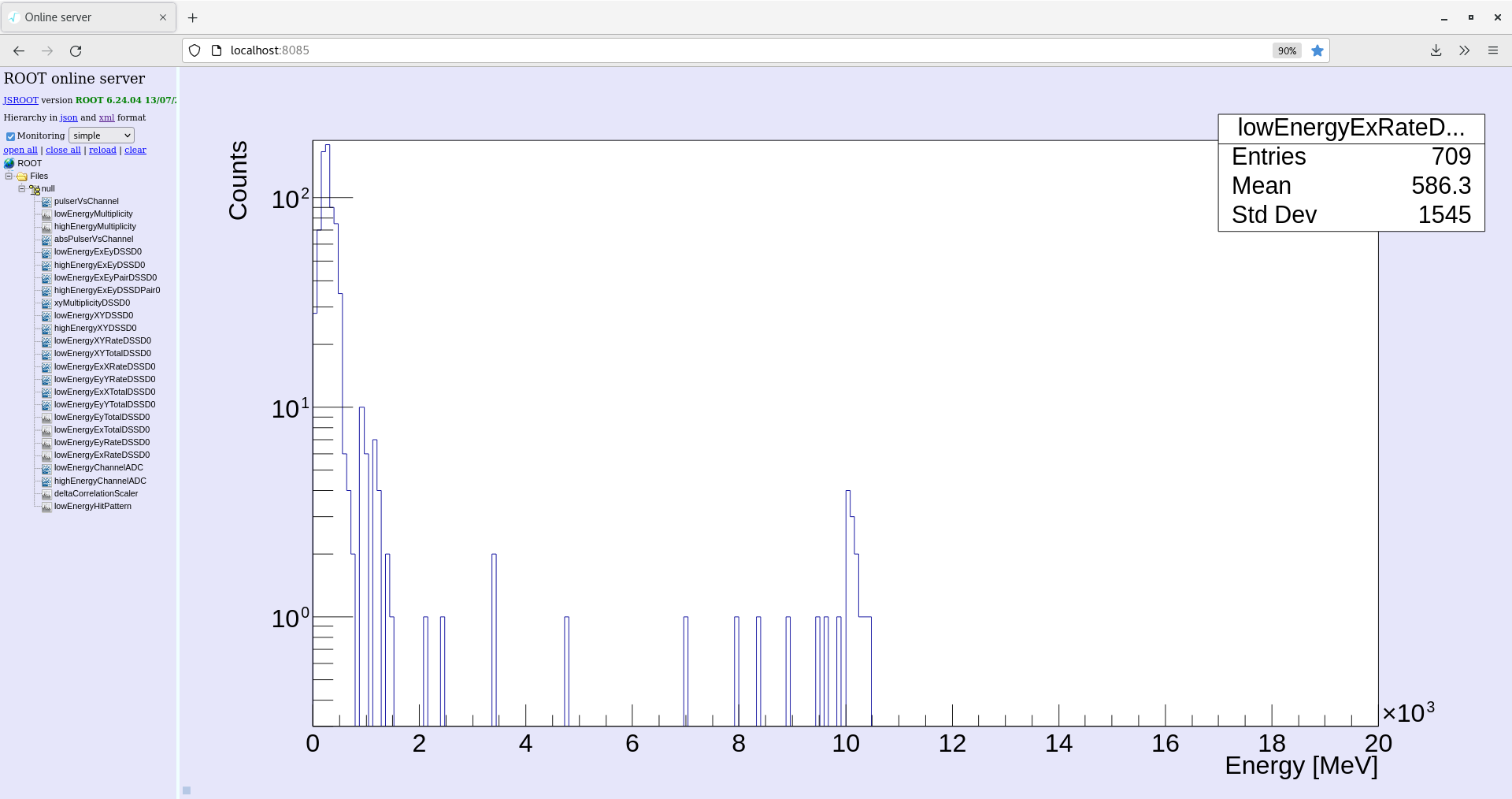

| Attachment 1: 2022-02-23_07-06-36exRate.png

|

|

| Attachment 2: 2022-02-23_07-06-11exTotal.png

|

|

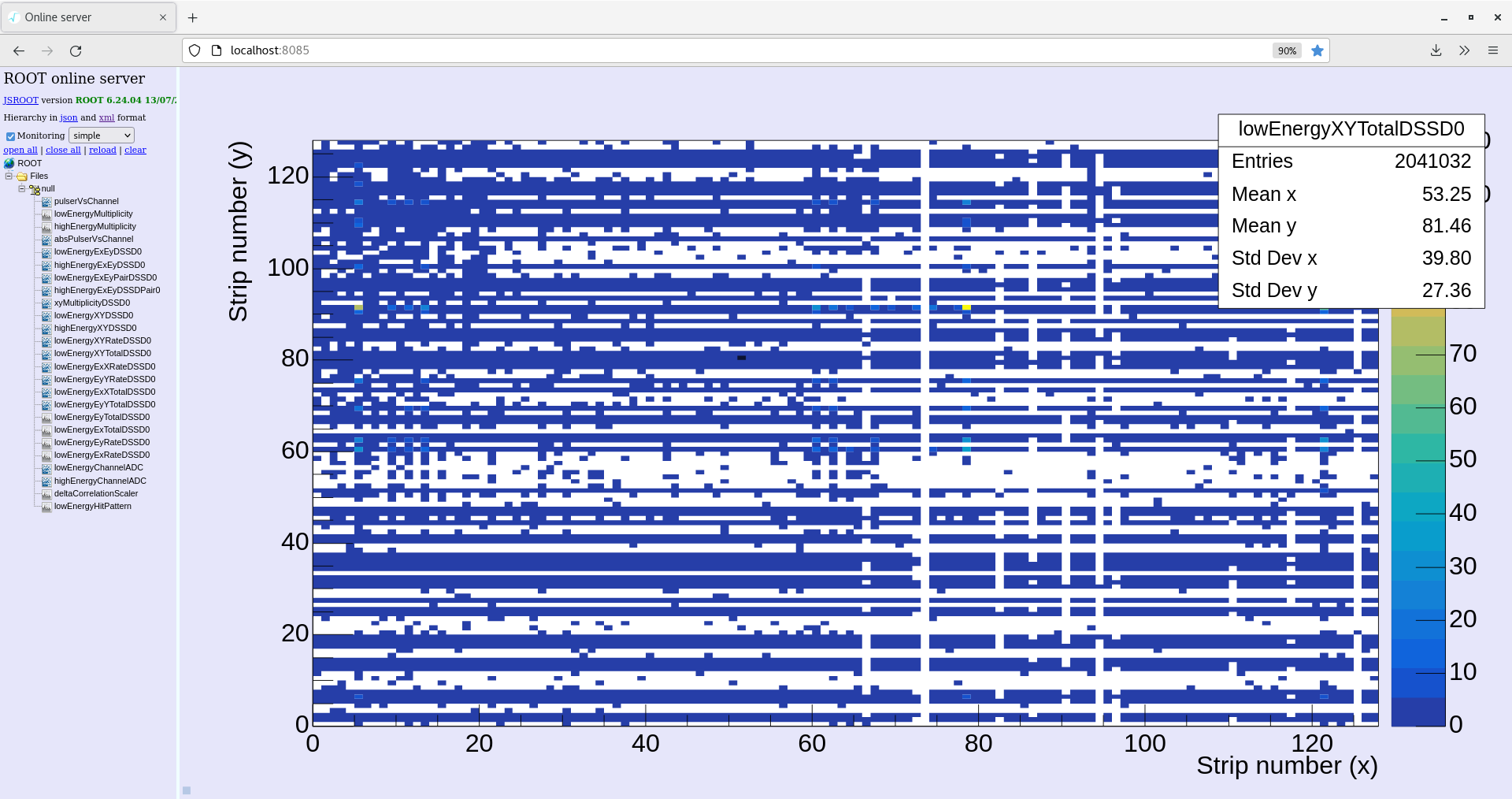

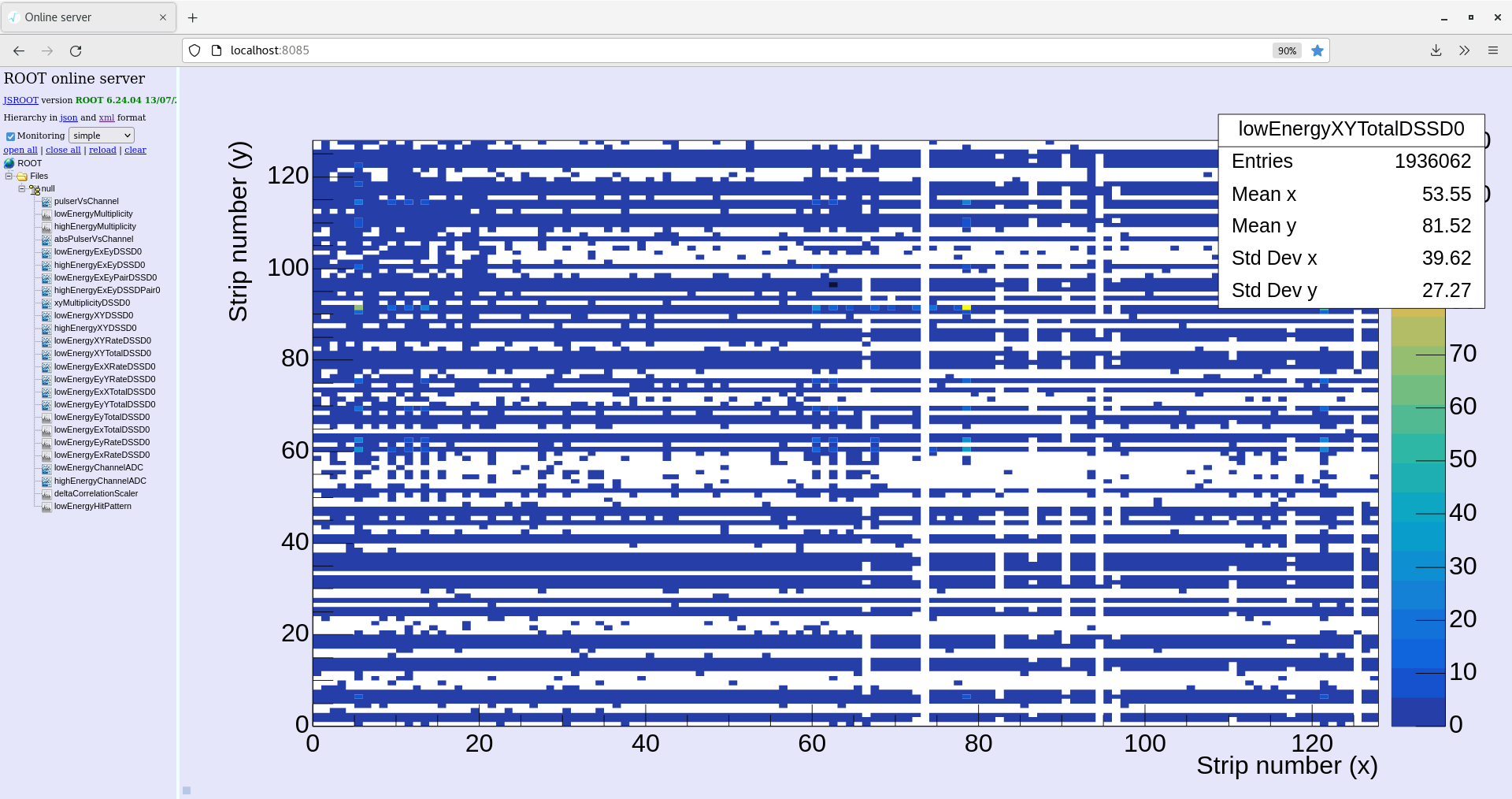

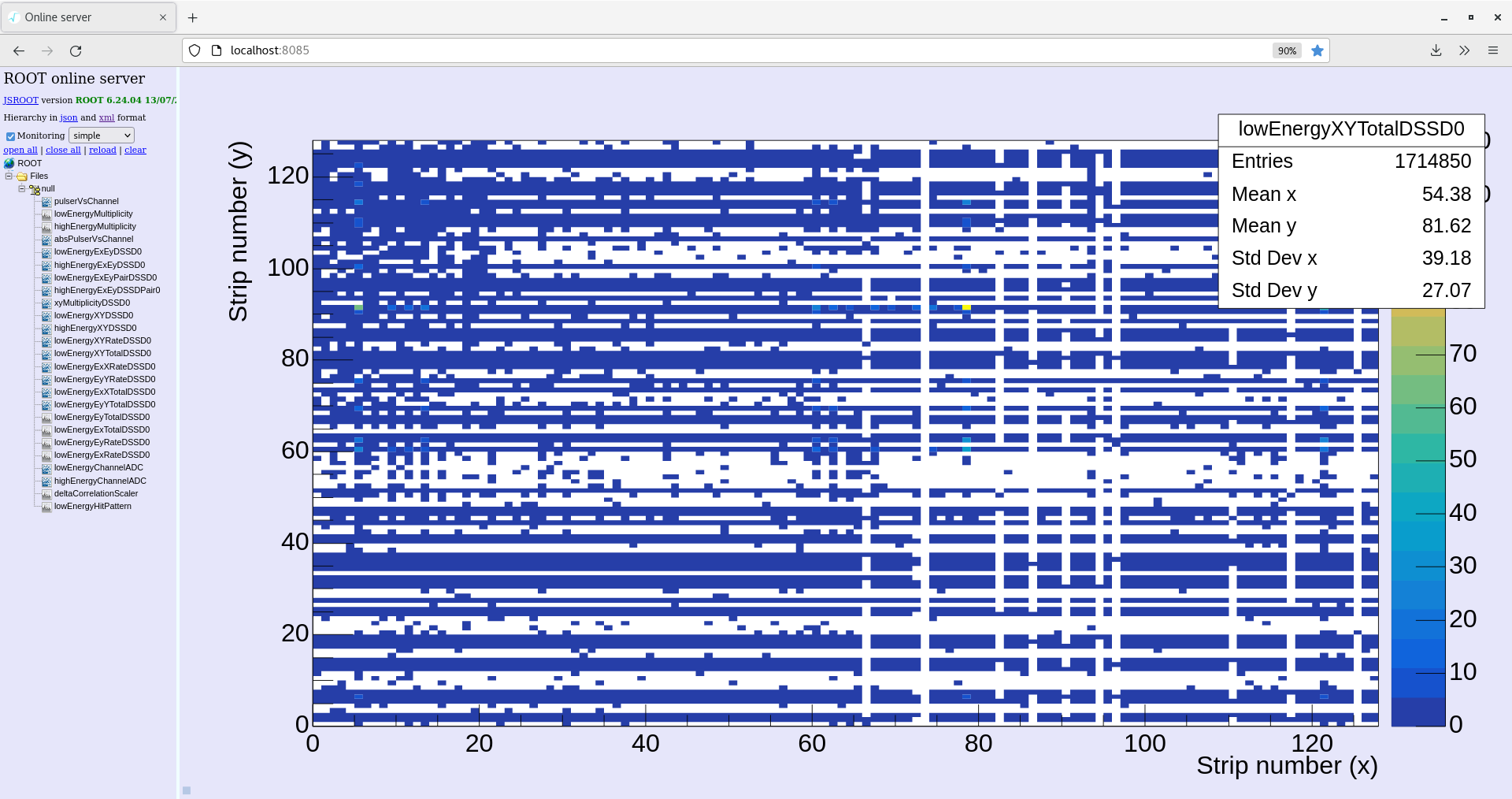

| Attachment 3: 2022-02-23_07-05-42xyTotal.png

|

|

|

250

|

Wed Feb 23 04:55:48 2022 |

Jordan, George | Current status |

05:55

Temps OK

System Check OK

White Rabbit fail diff: 90

Write Speed: ~1.0Mb/s

Leakage Current: ~3.47uA

Cryo Temp = 129.2K setpoint (unchanged)

Pressures stable

AVG Pressures:

YR07: 1.79e-10mbar

YR08: 2.21e-9mbar

YR09: 8.64e-10mbar

YR10: 1.36e-10mbar |

| Attachment 1: 2022-02-23_06-00-29xyTotal.png

|

|

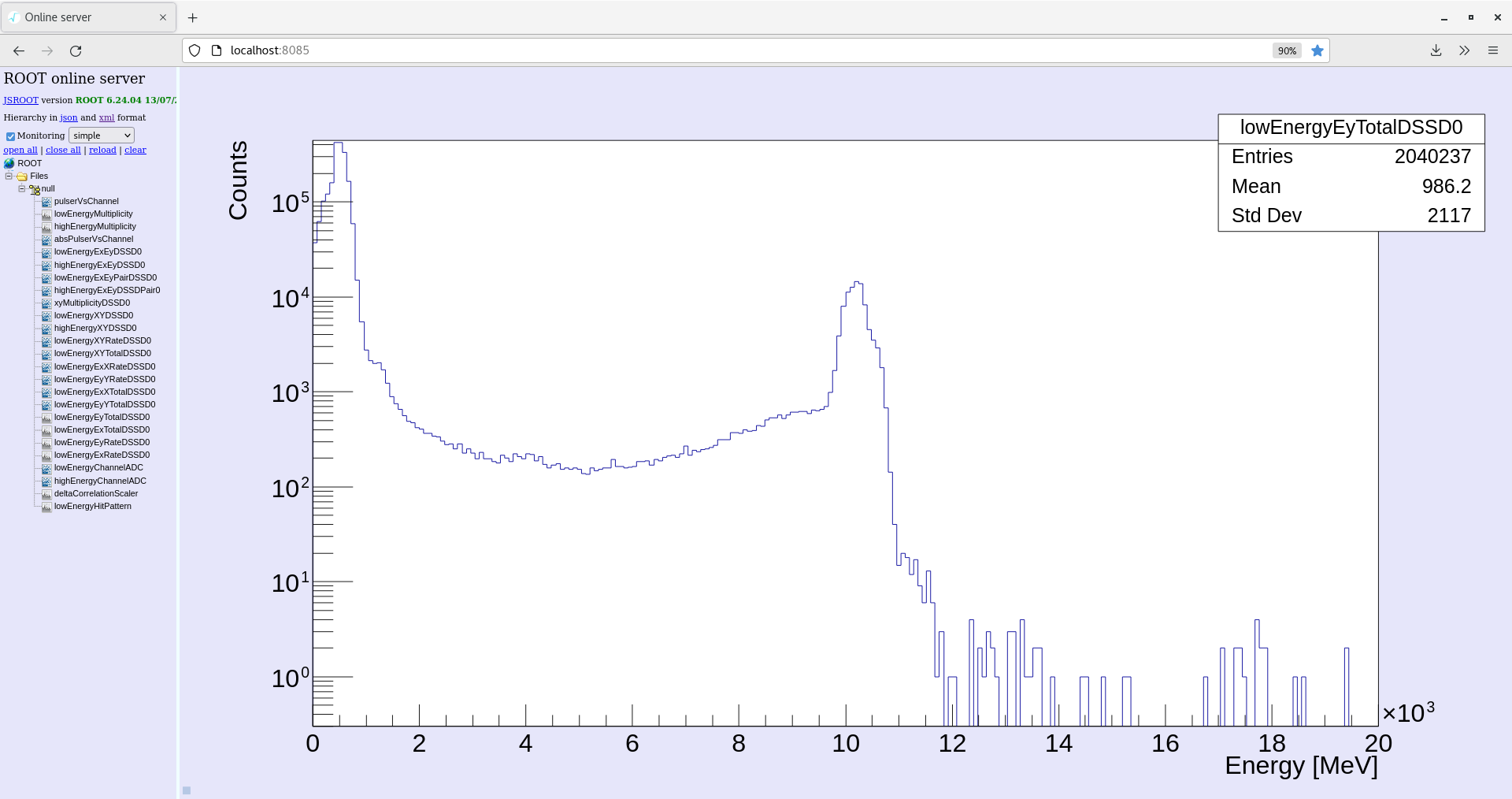

| Attachment 2: 2022-02-23_05-59-36exRate.png

|

|

| Attachment 3: 2022-02-23_05-59-05exTotal.png

|

|

|

249

|

Wed Feb 23 03:52:13 2022 |

Jordan, George | Current status |

04:52

Pressure seems to be climbing a little but still stable (just peaked at end of check)

Temps OK

Write Speed: ~1.0Mb/s

System Checks OK

White Rabbit fail diff: 90

Leakage Current: 3.47uA

Cryo Temp: 129.2K (unchanged)

AVG Pressures:

YR07: 1.79e-10mbar

YR08: 2.3e-9mbar

YR09: 9.46e-10mbar

YR10: 1.41e10mbar

Avg pressures plots for last hour and last 6 hours attached. |

| Attachment 1: 2022-02-23_04-58-19-XYtotal.png

|

|

| Attachment 2: 2022-02-23_04-57-17-Ex-total-hist.png

|

|

| Attachment 3: 2022-02-23_04-56-36-Ex-rate-hist.png

|

|

| Attachment 4: pressures-1hour.jpg

|

|

| Attachment 5: pressure-6hours.jpg

|

|

|

248

|

Wed Feb 23 02:52:09 2022 |

Jordan, George | Current status |

03:52

Temps OK

System Checks OK

White rabbit diff: 90

Data rate: 1.2Mb/s

Leakage Current: 3.474uA

Cryo temp = 129.2K (unchanged)

Pressures stable

AVG Pressures:

YR07: 1.74e-10mbar

YR08: 2.15e-9mbar

YR09: 8.61e-10mbar

YR10: 1.32e-10mbar |

| Attachment 1: 2022-02-23_03-58-03xyTotal.png

|

|

| Attachment 2: 2022-02-23_03-57-34exTotal.png

|

|

| Attachment 3: 2022-02-23_03-56-52exRate.png

|

|

|

247

|

Wed Feb 23 01:56:59 2022 |

Jordan, George | Current status |

02:56

Temps OK

write speed ~1.2Mb/s

System check OK

White rabbit diff - 89

Leakage Current ~3.472uA

Pressures stable

Beam intensity ~3.0e7

cryostat setpoint 129.2K (unchanged)

AVG Pressures:

YR09: 8.48e-10mbar

YR10: 1.28e-10mbar

YR07: 1.71e-10mbar

YR08: 2.1e-9mbar

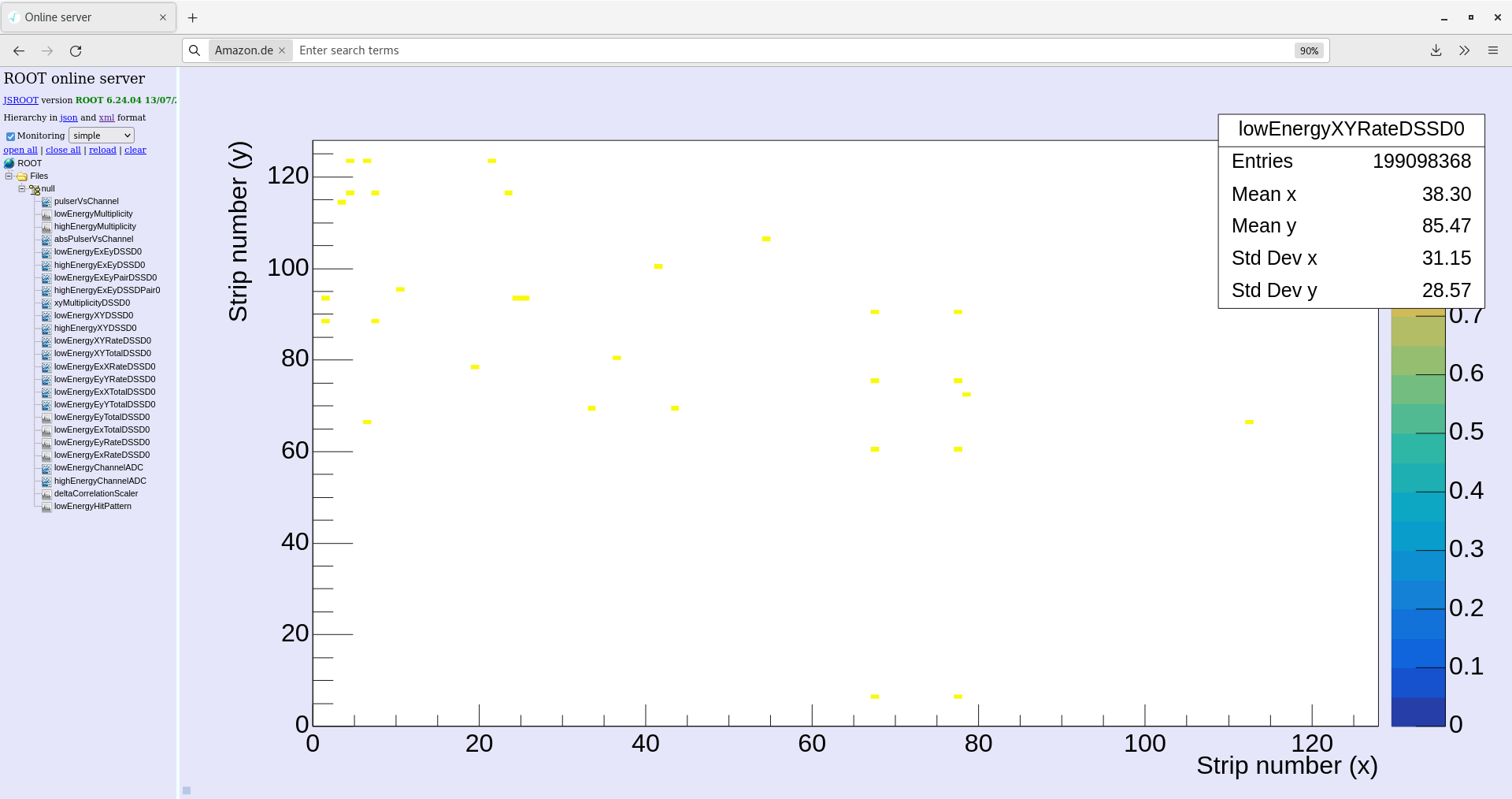

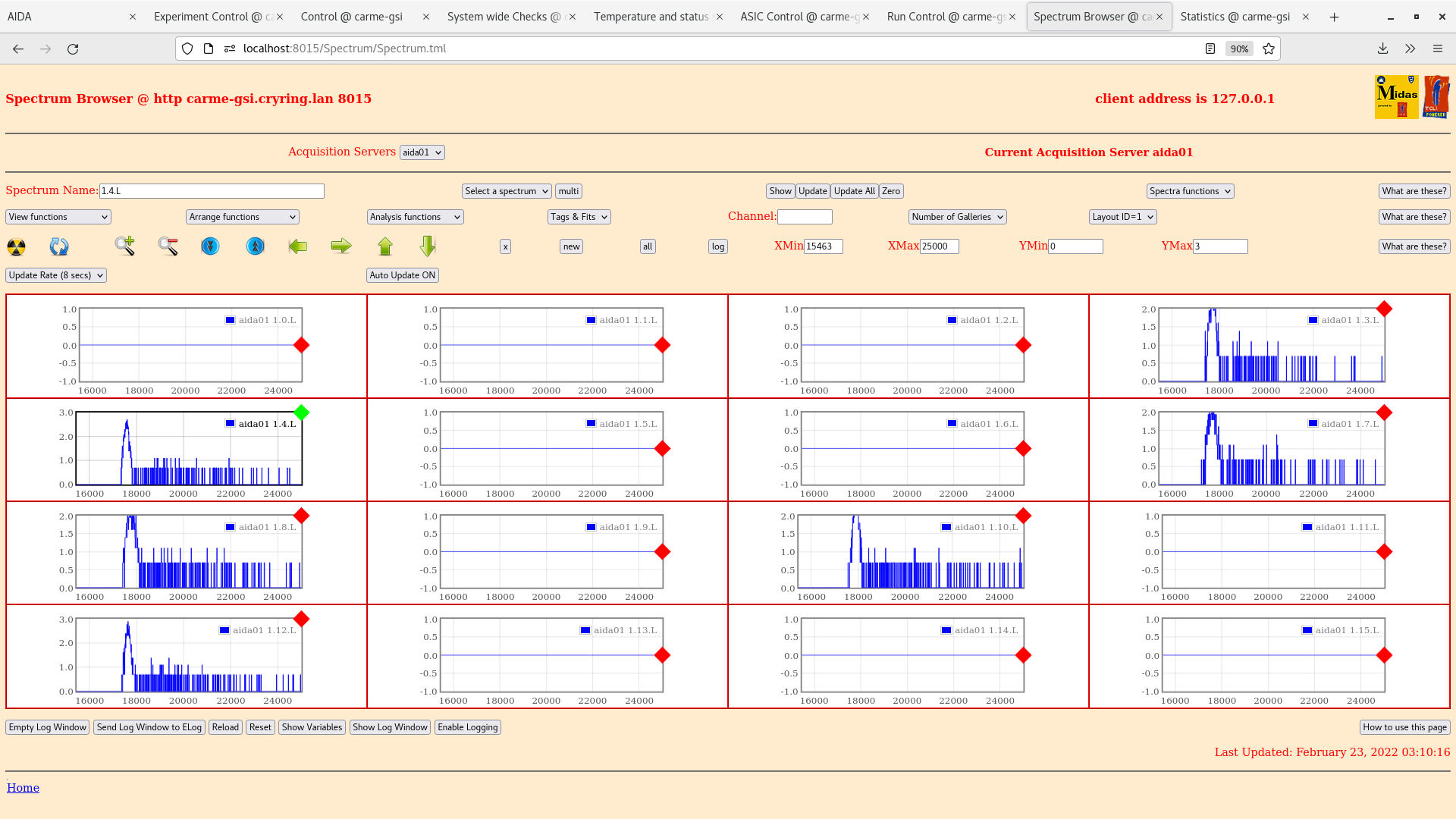

Aida 1 1*L plot attached. Some channels appear missing. Width of rutherford peaks ~280-300 channels. |

| Attachment 1: 2022-02-23_03-01-54xyTotal.png

|

|

| Attachment 2: 2022-02-23_03-00-54exTotal.png

|

|

| Attachment 3: 2022-02-23_03-00-11exRate.png

|

|

| Attachment 4: 2022-02-23_03-10-45-aida1-1*L.png

|

|