| ID |

Date |

Author |

Subject |

|

121

|

Sun Nov 12 09:17:49 2017 |

CLW, PJW, TD | Run 107 | Header: 4.29MeV/u 59Cu20+ + (CH2)n #16

Ender:

====================================================

Run number : 107

Date : 12.11.17

Start time : 10.18

Stop time : 12:18:52

Trigger rate (MIDAS) : 5

Blocks written : 514

Run Scalers (approx rates)

0- Ungated : 4

1- Gated : 4

2- dE : 120k

3- E : 27

4- HI : 719

5- Pulser : 1

6- Clock : 969

Beam energy (MeV/u) : 4.4

Beam intensity (epA) :

Target : (CH2)n #16

Ladder position (mm) : 128.95*

HI Degrader foil (um) : 10 um Al

del_E voltage (V) : -40

del_E leakage (uA) : -0.78

E voltage (V) : -350

E leakage (uA) : -2.12

E_hi voltage (V) : -14

E_hi leakage (uA) : -2.71

PA power (Up, positive) (A) : 1.55

PA power (Up, negative) (A) : 0.55

PA power (Down, positive) (A) : 0.8

PA power (Down, negative) (A) : 0.25

Pressure (IMG1) (mbar) : 6.3E-06

Pressure (old gauge) (mbar) : 1.8E-05

Pressure (SEC) (mbar) : 3.5E-06

Temp (Chiller) deg : -10

Temp (chamber) deg : 5.8

Comments: Dimo cleans laser c. 10.20-10.35

====================================================

* target ladder reading by Tom 128.95, by Claudia 127.95 and Phil says ~128. True position depends how good the

marker is lining up with scale

|

|

120

|

Sun Nov 12 09:16:01 2017 |

CLW, PJW, TD | Run 106 | junk - ignore |

|

118

|

Sun Nov 12 06:23:36 2017 |

RG MB | Run 105 | Header: CH2 #30+25, beam energy 4.0 MeV/u

Ender: run ends OK to change beam energy from 4.0MeV/u to 4.29MeV/u

====================================================

Run number : 105

Date : 12/11/2017

Start time : 07:24

Stop time : 09:03

Trigger rate (MIDAS) : 4

Blocks written : 422

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Run Scalars (approx rates)

0- Ungated : 4

1- Gated : 4

2- dE : 133020

3- E : 16

4- HI : 456

5- Pulser : 1

6- Clock : 968

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Beam energy (MeV/u) : 4.0

Beam intensity (epA) : 1.25

Target : CH2 30+25

Ladder position (mm) : 67.26

HI Degrader foil (um) : 10 um Al

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

del_E voltage (V) : -40

del_E leakage (uA) : 0.7

E voltage (V) : -350

E leakage (uA) : 2.11

E_hi voltage (V) : -14

E_hi leakage (uA) : 2.7

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

PA power (Up, positive) (A) : 1.55

PA power (Up, negative) (A) : 0.55

PA power (Down, positive) (A) : 0.8

PA power (Down, negative) (A) : 0.3

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Pressure (IMG1) (mbar) : 6.4E-06

Pressure (old gauge) (mbar) : 1.8E-05

Pressure (SEC) (mbar) : 3.5E-06

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Temp (Chiller) deg : -10

Temp (chamber) deg : 5.7

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Comments: Proton current at GPS smaller (1.7 uA compared to 2.0 uA in previous run)

==================================================== |

|

117

|

Sun Nov 12 04:22:57 2017 |

RG MB | Run 104 | Header: CH2 #30+25, beam energy 4.0 MeV/u

Ender:

====================================================

Run number : 104

Date : 12/11/2017

Start time : 05:21

Stop time : 07:23

Trigger rate (MIDAS) : 5

Blocks written : 526

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Run Scalars (approx rates)

0- Ungated : 6

1- Gated : 5

2- dE : 142604

3- E : 17

4- HI : 472

5- Pulser : 1

6- Clock : 968

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Beam energy (MeV/u) : 4.0

Beam intensity (epA) : ~2

Target : CH2 30+25

Ladder position (mm) : 67.26

HI Degrader foil (um) : 10 um

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

del_E voltage (V) : -40

del_E leakage (uA) : 0.7

E voltage (V) : -350

E leakage (uA) : 2.11

E_hi voltage (V) : -14

E_hi leakage (uA) : 2.67

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

PA power (Up, positive) (A) : 1.55

PA power (Up, negative) (A) : 0.6

PA power (Down, positive) (A) : 0.8

PA power (Down, negative) (A) : 0.26

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Pressure (IMG1) (mbar) : 6.4E-06

Pressure (old gauge) (mbar) : 1.8E-05

Pressure (SEC) (mbar) : 3.6E-06

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Temp (Chiller) deg : -9.9

Temp (chamber) deg : 5.8

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Comments:

==================================================== |

|

116

|

Sun Nov 12 01:46:23 2017 |

RG MB | Run 103 | Header: CH2 #30+25, beam energy 4.0 MeV/u

Ender: Run stopped as the beam went off. Noticed on the HI det scalar

====================================================

Run number : 103

Date : 12/11/2017

Start time : 02:42

Stop time : 04:17

Trigger rate (MIDAS) : 4

Blocks written : 415

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Run Scalars (approx rates)

0- Ungated : 4

1- Gated : 4

2- dE : 140503

3- E : 18

4- HI : 767

5- Pulser : 1

6- Clock : 968

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Beam energy (MeV/u) : 4.0 MeV/u

Beam intensity (epA) : 2.0

Target : CH2 30+25

Ladder position (mm) : 67.26

HI Degrader foil (um) : 10 um Al

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

del_E voltage (V) : -40

del_E leakage (uA) : 0.69

E voltage (V) : -350

E leakage (uA) : 2.1

E_hi voltage (V) : -14

E_hi leakage (uA) : 2.64

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

PA power (Up, positive) (A) : 1.55

PA power (Up, negative) (A) : 0.6

PA power (Down, positive) (A) : 0.8

PA power (Down, negative) (A) : 0.29

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Pressure (IMG1) (mbar) : 6.5E-06

Pressure (old gauge) (mbar) : 1.9E-05

Pressure (SEC) (mbar) : 3.7E-06

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Temp (Chiller) deg : -10.0

Temp (chamber) deg : 5.9

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Comments:

==================================================== |

|

115

|

Sun Nov 12 01:28:26 2017 |

RG MB | Run 102 - Junk | Header: CH2 #30+25, Beam energy 4.0 MeV/u

Ender: Run stopped short as the RF cavity tripped

====================================================

Run number : 102

Date : 12/11/2017

Start time : 02:29

Stop time : 02:35

Trigger rate (MIDAS) : 2 Hz

Blocks written : 23

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Run Scalars (approx rates)

0- Ungated : 1

1- Gated : 1

2- dE : 145957

3- E : 17

4- HI : 3

5- Pulser : 2

6- Clock : 968

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Beam energy (MeV/u) :

Beam intensity (epA) : 0.05

Target :

Ladder position (mm) :

HI Degrader foil (um) :

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

del_E voltage (V) :

del_E leakage (uA) :

E voltage (V) :

E leakage (uA) :

E_hi voltage (V) :

E_hi leakage (uA) :

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

PA power (Up, positive) (A) :

PA power (Up, negative) (A) :

PA power (Down, positive) (A) :

PA power (Down, negative) (A) :

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Pressure (IMG1) (mbar) :

Pressure (old gauge) (mbar) :

Pressure (SEC) (mbar) :

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Temp (Chiller) deg :

Temp (chamber) deg :

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Comments:

==================================================== |

|

114

|

Sat Nov 11 23:30:25 2017 |

RG MB | Run 101 |

Header: CH2 #30+25, Beam energy 4.0 MeV/u

Ender:

====================================================

Run number : 101

Date : 12/11/2017

Start time : 00:27

Stop time : 02:29

Trigger rate (MIDAS) : 6

Blocks written : 484

——————————————————————————————

Run Scalars (approx rates)

0- Ungated : 4

1- Gated : 4

2- dE : 146151

3- E : 16

4- HI : 654

5- Pulser : 1

6- Clock : 968

——————————————————————————————

Beam energy (MeV/u) : 4.0

Beam intensity (epA) : 1.75

Target : CH2 30+25

Ladder position (mm) : 67.26

HI Degrader foil (um) : 10 um Al

——————————————————————————————

del_E voltage (V) : -40

del_E leakage (uA) : 0.69

E voltage (V) : -350

E leakage (uA) : 2.1

E_hi voltage (V) : -14

E_hi leakage (uA) : 2.64

——————————————————————————————

PA power (Up, positive) (A) : 1.55

PA power (Up, negative) (A) : 0.6

PA power (Down, positive) (A) : 0.8

PA power (Down, negative) (A) : 0.28

——————————————————————————————

Pressure (IMG1) (mbar) : 6.6E-06

Pressure (old gauge) (mbar) : 1.9E-05

Pressure (SEC) (mbar) : 3.7E-06

——————————————————————————————

Temp (Chiller) deg : -10

Temp (chamber) deg : 5.9

——————————————————————————————

Comments:

==================================================== |

|

113

|

Sat Nov 11 20:27:28 2017 |

TD, DK, RG, MB | Run 100 | Header: Continue CH2 at 4.0 MeV/u

Ender:

====================================================

Run number : 100

Date : 11 / 11 / 2017

Start time : 21:28

Stop time : 00:27

Trigger rate (MIDAS) : 6

Blocks written : 784

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Run Scalars (approx rates)

0- Ungated : 4

1- Gated : 4

2- dE : 150k

3- E : 20

4- HI : 556

5- Pulser : 1

6- Clock : 968

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Beam energy (MeV/u) : 4.0 MeV/u (nominal)

Beam intensity (epA) : 1.75

Target : CH2 30+25

Ladder position (mm) : 67.26

HI Degrader foil (um) : 10 um Al

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

del_E voltage (V) : -40

del_E leakage (uA) : 0.68

E voltage (V) : -350

E leakage (uA) : 2.10

E_hi voltage (V) : -14

E_hi leakage (uA) : 2.59

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

PA power (Up, positive) (A) : 1.55

PA power (Up, negative) (A) : 0.55

PA power (Down, positive) (A) : 0.8

PA power (Down, negative) (A) : 0.25

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Pressure (IMG1) (mbar) : 6.8 x 10^-6

Pressure (old gauge) (mbar) : 1.9 x 10^-5

Pressure (SEC) (mbar) : 3.8 x 10^-6

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Temp (Chiller) deg : -9.9

Temp (chamber) deg : 6.0

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Comments: At 21:57, we are notified by RILIS team that they would like to do some cleaning and laser maintenance before leaving for the night. It should take 15 minutes. We

will watch the scalars but continue the run. 22:14 beam is off. 22:18 the laser tuning is finished.

==================================================== |

|

106

|

Sat Nov 11 17:08:50 2017 |

RG, DK, CL, TD, AM, MD | Run 96 | Header: Continue with 4.0 MeV/u Empty Frame

Ender:

====================================================

Run number : 96

Date : 11 / 11 / 2017

Start time : 18:09:43

Stop time : 18:40

Trigger rate (MIDAS) :

Blocks written : 0 blocks written, it says.

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Run Scalars (approx rates)

0- Ungated : 0 (actually ~0.1 Hz)

1- Gated : 0 (actually ~0.1 Hz)

2- dE : 150k

3- E : 30

4- HI : 37

5- Pulser : 2

6- Clock : 968

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Beam energy (MeV/u) : Nominal 4.0 MeV/u

Beam intensity (epA) :

Target : Empty Frame

Ladder position (mm) : 52.09

HI Degrader foil (um) : 10 um Al

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

del_E voltage (V) : -40

del_E leakage (uA) : 0.67

E voltage (V) : -350

E leakage (uA) : 2.10

E_hi voltage (V) : -14

E_hi leakage (uA) : 2.57

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

PA power (Up, positive) (A) : 1.55

PA power (Up, negative) (A) : 0.55

PA power (Down, positive) (A) : 0.79

PA power (Down, negative) (A) : 0.25

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Pressure (IMG1) (mbar) : 6.9 x 10^-6

Pressure (old gauge) (mbar) : 2.0 x 10^-5

Pressure (SEC) (mbar) : 3.9 x 10^-6

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Temp (Chiller) deg : -10.0

Temp (chamber) deg : 5.9 ~ 6.0

覧覧覧覧覧覧覧覧覧覧覧覧覧覧覧

Comments: Increased pulser rate to 250 Hz after the run, to flush the previous buffer in the Tape Server.

See run 97

==================================================== |

|

62

|

Thu Nov 9 08:20:21 2017 |

Claudia | Restarting Target Current & Line Current | 0) If target or line drop, STOP THE BEAM!!

1) If you SEE target or line current go down (top right window of monitors next to the corridor):

Use Knobs open application (monitor below); remember set value; type 0 in set window; click Mode - Reset; click Mode - On. increase current in steps of 100 A

2) If Target or line current off and it happened a while ago

Use Knobs open application (monitor below); type 0 in set window; click Mode - Reset; click Mode - On Use Isolde Target heating GPs application (in monitor below); |

|

87

|

Fri Nov 10 16:32:19 2017 |

Claudia | RAL Amplitude Thresholds | Thresholds of RAL amplifiers set to: dE 30mV; E 20 mV, HI 20 mV |

|

211

|

Tue Nov 20 16:06:09 2018 |

dk | Projected Inventory of ISOLDE | (To be confirmed / finalized)

==Rack Electronics==

Two (2) 19" electronics racks

=Rack #1=

2 (Two) RAL Amp crate (1 full with modules, 1 with five (5) modules)

21 RAL 109 modules in total. (NB: Extras are borrowed from Miniball)

Two (2) NIM Fans

Four (4) Cable patch boxes

Ribbon cables for patch

Two (2) Preamp power supplies

+/-15 Volt type, up to several Amperes

=Rack #2=

VME crate, with power cable

Seven (7) Silena ADCs

One (1) S9418 ACQ controller

Two (2) CAEN V767 TDC

One (1) CAEN 560

One (1) MVME 24XX Motorola crate Controller

26 ribbon cables

Twelve (12) for analog

Twelve (12) for discrim

Two (2) extra

Camac crate

Five (5) Logic Shaped Outputs (CAMAC)

Two (2) CAMAC / VME converter

One (1) LeCroy 622 Quad Logic (NIM)

One (1) Ortec 566 TAC (NIM)

One (1) Lecroy 222 dual GDG

One (1) Ortec 459 bias supply

NIM crate

One (1) BNC PB-5 digital pulse generator

One (1) BNC PB-4 analog pulse generator -- returned to Edinburgh 2018.12

One (1) Analog ratemeter 4678

One (1) ECL-NIM-ECL EC 1601

One (1) Silena Quad Bias Supply 7710 -- swapped with functional unit 2018.11 from problems in 59Cu

Two (2) LeCroy 419A Logic FI/FO

One (1) Ortec 572 Amplifier

One (1) LeCroy Quad Discriminator 821

One (1) NIM Cooknell homebrew PA Power Supply

One (1) Cooknell Preamplifier

4 (Four) additional Long ribbon cables

2x spare HVBNC cables

BNC to Lemo

Lemo to Ribbon box

lemo cables

==Preamp setup==

2 Preamp feedthrough

Bolts and washers

2 O-Rings + 1 spare

16way BNC multicore

o-ring for ribbon feedthroughs

Julabo Chiller & Insulated External Chiller Lines

Swagelok nylon and brasss ferrels for gas line / coolant piping

spare straight and right angle swagelok fittings

thin green polymer tubing (gas lines, cooling system)

thermometer

thermocouple cable

1 thermocouple vacuum gauge

==Generic Power Connections==

3 Power Bars

20x IEC leads

2x Swiss to UK leads

==Vacuum systems==

Chamber, sliding mount

Scrolling pump

Backflow interlock

Large TMP from TUDA

Controller

Small TMP

Controller

TMP bolts (large and small)

Two (2) vacuum hoses

Valve for TP 1 & 2

vacuum clamps

Two (2) inverse magnetron ion gauges

Multi gauge reader

Old inv magnetron vac gauge meter

Upstream beamline pipe

Gate valve, nipple, adaptor flange to SEC

N2 pipe with valve

Mechanical pressure gauge and "plus" type connector

Blanking kindey plate

bellows

bellow cage

TMP/gauge mounting pipe

==Silicon Detectors and Components==

Two (2) Micron S2-type 1000 um SSDs

Three (3) Micron S2-type 75 um SSDs

dummy detectors

20 ~1 cm spacers for SSD mounting

9 ~2 cm spacers for SSD mounting

Degrader Foils

Irises and controller box

Al heavy ion degraders of various thicknesses.

3 Hamamatsu Photodiodes

1 PCB for Hamamatsu Photodiodes

3 degrader foils (10, 15 20 um Al)

==Beam Diagnostics==

Faraday cup

current integrator for FC

cctv camera power lead

ZnS (or similar) scint screen

==Computer==

Sun Microsystems Tower

Dell monitor

Sun keyboard

Sun mouse

Ethernet hub

==Misc==

alignment plugs for chamber

2 ch oscilloscope

2 (two) basic voltmeters

middle foot sections of blue frame

6 feet for chamber stand

All bolts for chamber stand

Spacers

3 large O-Rings for chamber (spare)

Bolts, nuts and spacers for chamber end flanges and center

short bits of blue frame

braces off blue frame

Wheels for frame

Tools

Safety boots and helmets-

-Daid

-Toby

-Mirco

-Claudia

-Sarah

-Conor

==In Edinburgh==

Target ladder and components |

|

157

|

Tue Nov 14 14:30:51 2017 |

SL | Photos inside chamber (detectors, IRIS, etc) | |

| Attachment 1: OneDrive-2017-11-14_2.zip

|

|

190

|

Thu Sep 27 11:14:34 2018 |

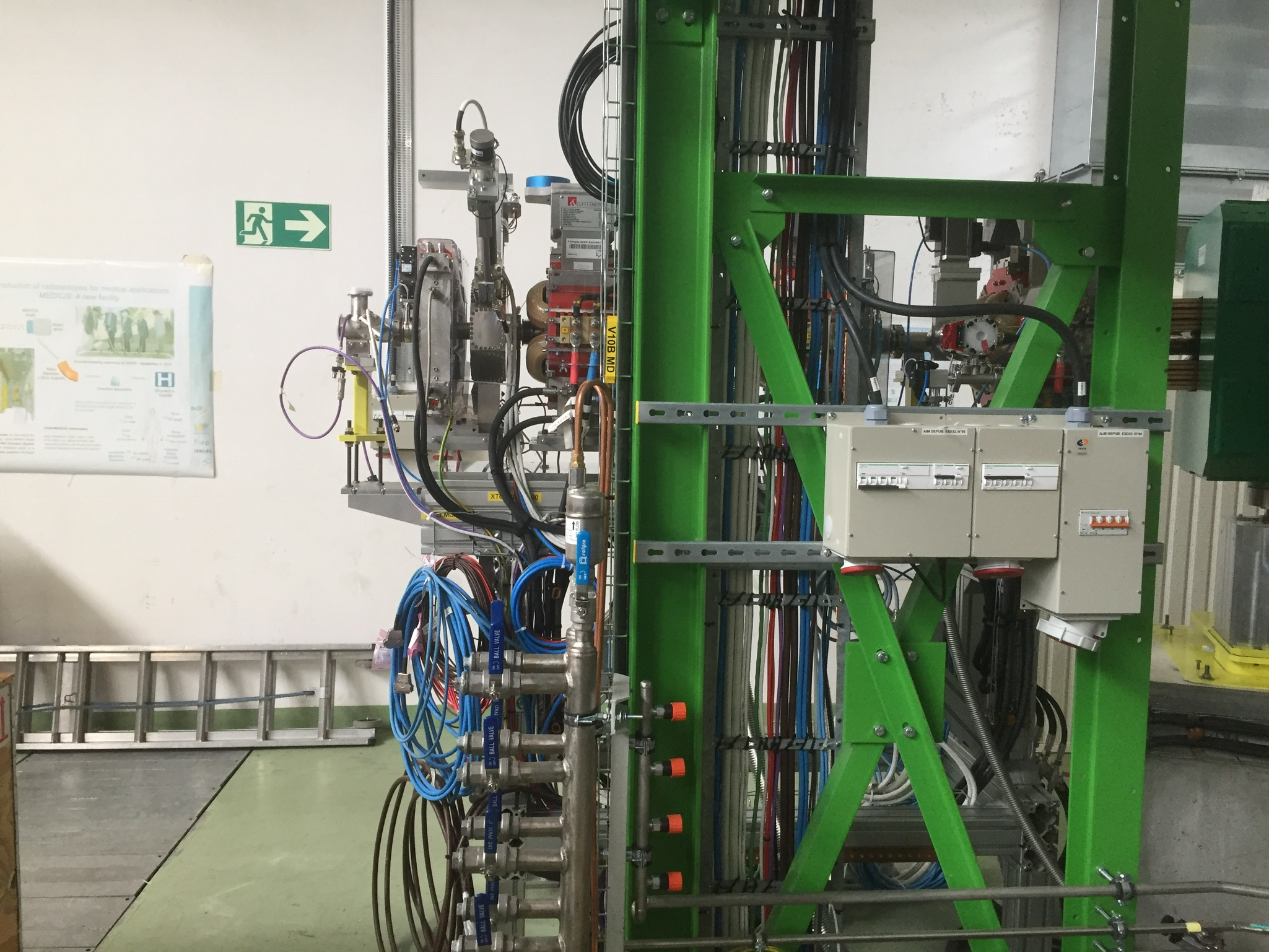

CBH | Photos and Measurements from August CERN Trip | Chamber frame width=65cm

Chamber frame height=146cm

Chamber frame length=230cm

Centre of mass of chamber (from ground)=173cm

Wheel span=160cm

SEC to wall=124cm

Ventilation box to container (to get to garage)=121cm

Photos of broken ends of struts attached. |

| Attachment 1: 20180823_082444199_iOS.jpg

|

|

| Attachment 2: 20180823_082445833_iOS.jpg

|

|

| Attachment 3: 20180823_082457574_iOS.jpg

|

|

| Attachment 4: 20180823_082505693_iOS.jpg

|

|

|

35

|

Mon Oct 30 09:46:04 2017 |

Peter Black | Notes on iris install/operation | The iris mounts have 2 superimposed constellations of 3mm mounting holes on them that correspond to those of the S2 detector, however the 85x85 square is missing one hole and the 110x40 rectangle is rotated by 45°. Either constellation may be used. Fixing is intended with M3x16 bolts into 10mm standoffs used to attach the detector to its mount.

Electrical connection is by a 5 pin DuPont connector. A feedthrough with flying tail ribbon cable inside and M12 5 pin A-coded industrial sensor connector outside for each iris is supplied that should fin in the same flange as the cooling pipes. The connection between the ribbon and the actuator is to be made with the red coded wire on the ribbon to the yellow wire on the actuator such that the visible metallic portion on the pins is visible on the same side of both the male and female connectors when matted.

The control box needs to be mounted outside the chamber and the cables connected to the feedthroughs.

Power is supplied from the 12v PSU provided.

Twiddle knob to make iris open and close...

Notes:

- When handling the irises it is advisable to leave them in the open position.

- Don’t get grease on the irises or they will jam up and the actuator is strong enough to destroy them.

- The actuators contain a small quantity of grease, if this turns out to be an issue with the vacuum I will strip them down and degrease them.

- The controllers are “tuned” to the actuators so try not to muddle them up. (U and D)

- When not in use I would suggest removing power from them as they will potentially radiate some RF noise and just made your signals noisier.

- Datasheet for controller https://s3.amazonaws.com/actuonix/Actuonix+LAC+Datasheet.pdf

- They have been roughly set so that closed is a 20mmm orifice. If you need to adjust them open the control box and twiddle the pot next to the one next to the USB port (P2 right if you look at the data sheet). Cycle the power and to open and close it again, repeat until the desired orifice is achieved.

- Pins 1, 4 and 5 of X2 are the feedback potentiometer for the actuators so if you want to know where the actuators are (you think they may have jammed etc.) you can simply measure the voltage between 1 and 4 with the power on or the resistance with the power off

|

|

1

|

Fri Jan 27 11:02:03 2017 |

DK, PB | Notes from visit to CERN | Here I am simply digitizing my notes from our visit to CERN 17~18 January 2017. They may not be perfectly linear or organized, but may be searchable.

==ISOLDE Hall Info==

*Safety shoes and hard hats are required for everyone. We need to buy our own in the future and bring them with us.

The 'general purpose scattering chamber' seems to in fact be named the Scattering Experiments Chamber (SEC).

Contact Joakim Cederkall at Lund University in Sweden joakim.cederkall@cern.ch (DK has collaborated with him before in 2012)

Secondary contact olof.tendblad@cern.ch

2 meters downstream of SEC we see the SAND neutron detector array.

Contact Ismael Martel at University of Huelva in Spain ismael.martel.bravo@cern.ch

Array structure is on wheels, but needs to be moved before our experiment, presumably by someone from that collaboration

Of course, we don't know after the SEC relocation from station 2 to station 3 that SAND will be installed in the same relative position or not

SEC has eight (8) transverse ports evenly spaced about its circumference

We need adapters to connect to this

The nominal ISOLDE beamline pipe is 50 mm diameter

Chamber itself is about 1 meter in diameter, about 70 cm tall. Shape is a cylindrical prism with hemispheres on top and bottom

Calculated volume about 0.55 cubic meters

Support structure is about 1 x 1 square meter footprint, about 125 cm tall

2 large-volume pumps in parallel.

TMP: PTM 5400 ALCATEL CORP x2

Oil roughing pumps Edwards 12 x2

According to Karl, its pressure is in the low 10^-6 mbar region, but everything seemed off when we visited so cannot confirm precise value

Presumably it requires the overhead crane to open it

Not many people have the license

Although we don't need to access it very often if at all

Karl said they are arguing to install a small fixed crane for that purpose after relocation which wouldn't need a license

SEC is being disconnected over the weekend (21~22 Jan)

Alignment in ISOLDE Hall (not very sensible to write w/o diagram)

POT1, POT2 are on the wall downstream of the beam lines

POT3 and POTREX are on the beam-right side before it is turned and delivered to the target stations

Geodetic survey points -- though we don't really know how they are used

Downstream of station 3 (under construction) is XT03 which is a crosshair on the wall

Presume it was used for alignment of the steering magnet base

Bases are installed but the quadrupoles are still off to the side

There is no port on the station 2 bending magnet to offer a straight line of sight down to the target station

How was the alignment performed?

We assume station 3 will be installed in a similar manner, unfortunately.

Station 3

Expected to be complete by the end of February

Station 2

HELIOS-type device will be installed at station 2

This is presently called ISS and is mainly being done by the Swedish group (Lund?)

Footprints were drawn on the ground downstream of the present SEC point

How much space will the fence to prohibit near-approach for B-field safety be?

Distances around the stations

From the target positions to the far wall is over 10m, though a lot of equipment and storage lines the wall area

Beam-right wall from station beam-line 3 is about 180 cm

7 m to station 2 -> ~5 m between station 2 and 3

End of station #2 to the end of the SEC including the beam pipe is ~210 cm

At some point, we must provide a list of items ot be imported and used so it can be approved by the CERN Safety groups

==Meeting notes with Karl Johnston==

HIE-ISOLDE may begin physics around the last week of June (say 24~25th)

A MINIBALL experiment is usually prioritized first, given the track record and existing infrastructure and experience.

From the end of April there will be about 2 months of commissioning, ideally

Though, in years past, the timeline was too tight and commissioning was basically not performed during this period

They will start the cryogenics on Tuesday, 24th January

ISS will start to be installed in May for about 3 weeks (? hand writing and detail of notes is poor on this point)

Anytime in mid-March should be okay for the Edinburgh group to ship

59Cu is a candidate for an early run this year

As soon as early July perhaps in an ideal world |

|

Draft

|

Wed May 24 15:21:37 2017 |

MD | Notes from visit of ISOLDE at 23rd May 2017 | Status of Beamline XT03 at HIE-ISOLDE:

Scattering chamber (1m*1m) will be put in place in next two weeks. They are just waiting for separate crane, which will be mounted on the wall.

(Reason is, that the roof crane can only go down in the middle for XT03, because it is the end of the hall)

The scattering chamber will take place at the gray surface with all tube connector.

The end of scattering chamber is ISO 100. Do we have the right adapter for the tube to connect?

The scattering chamber, with a lot of electronics inside, has a pressure of something E-06 mbar, so our pressure should fit well.

Our faraday cup was asked to have the possibility to monitor if we getting beam or not.

Behind the scattering chamber there will be a setup for Neutron Time of Flight experiment on C15 in the end of august and on 9/10Li in the end of October 2017.

The setup length will be additional 5-6 meters (close to left end of the poster/wooden box on picture).

Offline Setup:

Offline Setup next to parallel wall will probably not be possible due to the other setup, but there is at least 2-3m*4-5m space on the wall, where the beam line points to (corner). We just have to leave some space that people can access the crane ladder.

No specific time was discussed, because the current setup has to first installed.

Alignment:

The Tools are mounted at the wall (2 points) and are setup in the corner (stand from bottom). It is an electronic system, no further details from Karl, but contact has been established.

Beam Height:

Beam height is 1.75m. We will bring our own metal frame for support. What is our height (range) at the moment?

For Offline test we can have an alpha source.

Power plug: SWISS standard à need ADAPTERs

3 normal plugs per grounded access point (with C16 fuse). For offline testing we can easily use 1-2 access points, which would be enough.

Near the installation place at the beamline are also 2 access points, which we will share with the scattering chamber. In case we also use extension to the offline ones, although safety regulation allow no cables on the floor, so we always have to use cable guides above. (I´m not sure how they deal with power cables…)

Next point: cables guide are used, so we have to bring longer BNC cables and the other long ribbon cables.

No camacs crates are spotted at the moment by Karl, which we could use.

No OIL pumps are allowed anymore at HIE – ISOLDE. Our roughing pump and Turbo pump are working without oil, aren´t they?

Grounded crates??

Expectations:

They want to have a drawing of our setup (chamber including metal frame, crates, vacuum pipes, water cooling, … maybe add work place with PC)

And all the SAFETY Regulation papers should be prepared.

Important!!! Everything is temporary:

There are daily changes in the setup at XT03 with scattering chamber and neutron TOF setup in the next week and when ISS chamber will be installed, the odds and ends near the wall and the corner will hopefully disappear, so we will have a better picture how much space in the end will be there.

I will visit ISOLDE in the beginning of June again to see the progress.

Forgot to ask:

Any special placement for water cooling or can we still use shortest possible distance to chamber? |

|

Draft

|

Wed May 24 16:09:10 2017 |

MD | Notes from visit of ISOLDE at 23rd May 2017 | Status of Beamline XT03 at HIE-ISOLDE:

Scattering chamber (1m*1m) will be put in place in next two weeks. They are just waiting for separate crane, which will be mounted on the wall.

(Reason is, that the roof crane can only go down in the middle for XT03, because it is the end of the hall)

The scattering chamber will take place at the gray surface with all tube connector.

The end of scattering chamber is ISO 100. Do we have the right adapter for the tube to connect?

The scattering chamber, with a lot of electronics inside, has a pressure of something E-06 mbar, so our pressure should fit well.

Our faraday cup was asked to have the possibility to monitor if we getting beam or not.

Behind the scattering chamber there will be a setup for Neutron Time of Flight experiment on C15 in the end of august and on 9/10Li in the end of October 2017.

The setup length will be additional 5-6 meters (close to left end of the poster/wooden box on picture).

Offline Setup:

Offline Setup next to parallel wall will probably not be possible due to the other setup, but there is at least 2-3m*4-5m space on the wall, where the beam line points to (corner). We just have to leave some space that people can access the crane ladder.

No specific time was discussed, because the current setup has to first installed.

Alignment:

The Tools are mounted at the wall (2 points) and are setup in the corner (stand from bottom). It is an electronic system, no further details from Karl, but contact has been established.

Beam Height:

Beam height is 1.75m. We will bring our own metal frame for support. What is our height (range) at the moment?

For Offline test we can have an alpha source.

Power plug: SWISS standard à need ADAPTERs

3 normal plugs per grounded access point (with C16 fuse). For offline testing we can easily use 1-2 access points, which would be enough.

Near the installation place at the beamline are also 2 access points, which we will share with the scattering chamber. In case we also use extension to the offline ones, although safety regulation allow no cables on the floor, so we always have to use cable guides above. (I´m not sure how they deal with power cables…)

Next point: cables guide are used, so we have to bring longer BNC cables and the other long ribbon cables.

No camacs crates are spotted at the moment by Karl, which we could use.

No OIL pumps are allowed anymore at HIE – ISOLDE. Our roughing pump and Turbo pump are working without oil, aren´t they?

Grounded crates??

Expectations:

They want to have a drawing of our setup (chamber including metal frame, crates, vacuum pipes, water cooling, … maybe add work place with PC)

And all the SAFETY Regulation papers should be prepared.

Important!!! Everything is temporary:

There are daily changes in the setup at XT03 with scattering chamber and neutron TOF setup in the next week and when ISS chamber will be installed, the odds and ends near the wall and the corner will hopefully disappear, so we will have a better picture how much space in the end will be there.

I will visit ISOLDE in the beginning of June again to see the progress.

Forgot to ask:

Any special placement for water cooling or can we still use shortest possible distance to chamber? |

| Attachment 1: XT03_beamline_corner-panorama.jpg

|

|

| Attachment 2: scattering_chamber-not_in_place.jpg

|

|

|

9

|

Wed May 24 16:18:22 2017 |

MD | Notes from visit of ISOLDE at 23rd May 2017 | Status of Beamline XT03 at HIE-ISOLDE:

Scattering chamber (1m*1m) will be put in place in next two weeks. They are just waiting for separate crane, which will be mounted on the wall.

(Reason is, that the roof crane can only go down in the middle for XT03, because it is the end of the hall)

The scattering chamber will take place at the gray surface with all tube connector.

The end of scattering chamber is ISO 100. Do we have the right adapter for the tube to connect?

The scattering chamber, with a lot of electronics inside, has a pressure of something E-06 mbar, so our pressure should fit well.

Our faraday cup was asked to have the possibility to monitor if we getting beam or not.

Behind the scattering chamber there will be a setup for Neutron Time of Flight experiment on C15 in the end of august and on 9/10Li in the end of October 2017.

The setup length will be additional 5-6 meters (close to left end of the poster/wooden box on picture).

Offline Setup:

Offline Setup next to parallel wall will probably not be possible due to the other setup, but there is at least 2-3m*4-5m space on the wall, where the beam line points to (corner). We just have to leave some space that people can access the crane ladder.

No specific time was discussed, because the current setup has to first installed.

Alignment:

The Tools are mounted at the wall (2 points) and are setup in the corner (stand from bottom). It is an electronic system, no further details from Karl, but contact has been established.

Beam Height:

Beam height is 1.75m. We will bring our own metal frame for support. What is our height (range) at the moment?

For Offline test we can have an alpha source.

Power plug: SWISS standard à need ADAPTERs

3 normal plugs per grounded access point (with C16 fuse). For offline testing we can easily use 1-2 access points, which would be enough.

Near the installation place at the beamline are also 2 access points, which we will share with the scattering chamber. In case we also use extension to the offline ones, although safety regulation allow no cables on the floor, so we always have to use cable guides above. (I´m not sure how they deal with power cables…)

Next point: cables guide are used, so we have to bring longer BNC cables and the other long ribbon cables.

No camacs crates are spotted at the moment by Karl, which we could use.

No OIL pumps are allowed anymore at HIE – ISOLDE. Our roughing pump and Turbo pump are working without oil, aren´t they?

Grounded crates??

Expectations:

They want to have a drawing of our setup (chamber including metal frame, crates, vacuum pipes, water cooling, … maybe add work place with PC)

And all the SAFETY Regulation papers should be prepared.

Important!!! Everything is temporary:

There are daily changes in the setup at XT03 with scattering chamber and neutron TOF setup in the next week and when ISS chamber will be installed, the odds and ends near the wall and the corner will hopefully disappear, so we will have a better picture how much space in the end will be there.

I will visit ISOLDE in the beginning of June again to see the progress.

Forgot to ask:

Any special placement for water cooling or can we still use shortest possible distance to chamber? |

| Attachment 1: XT03_beamline_corner-panorama.jpg

|

|

| Attachment 2: scattering_chamber-not_in_place.jpg

|

|

| Attachment 3: corner-possible_offline_setup-1.jpg

|

|

| Attachment 4: power_supply_near_beam-1.jpg

|

|

|

206

|

Thu Nov 8 10:01:32 2018 |

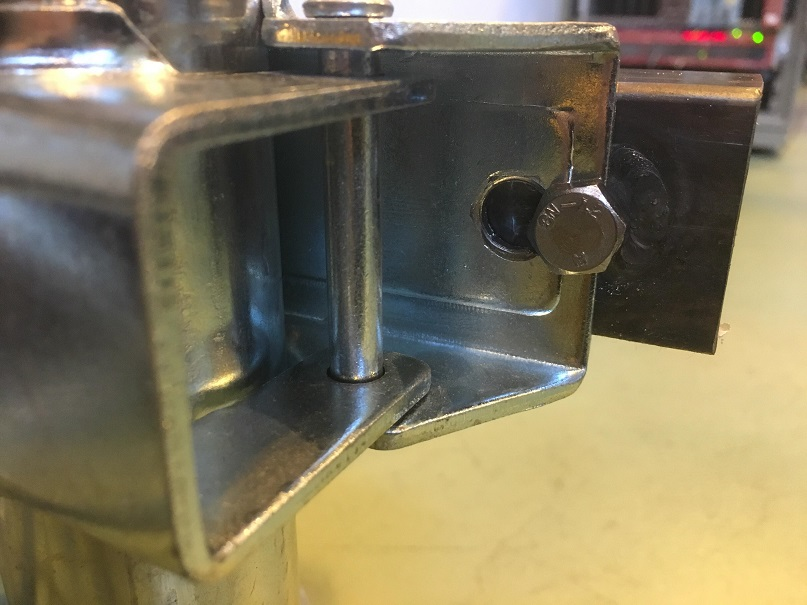

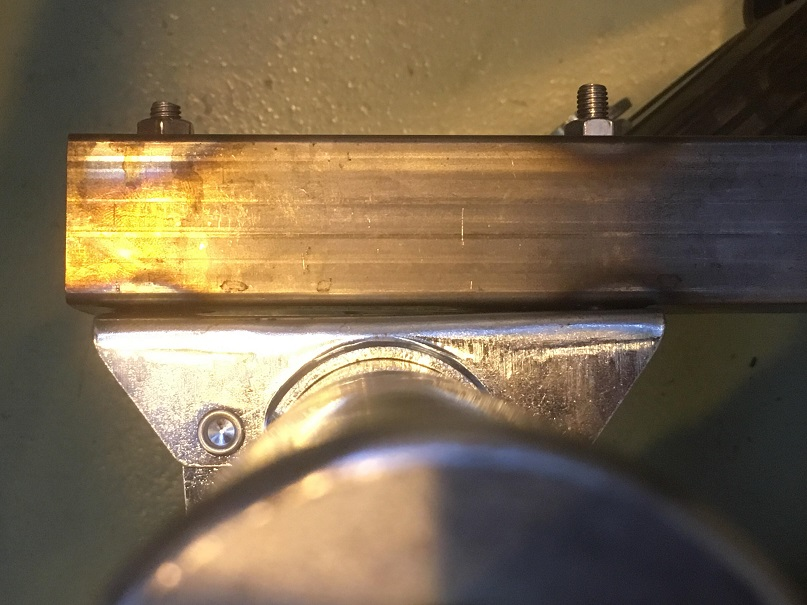

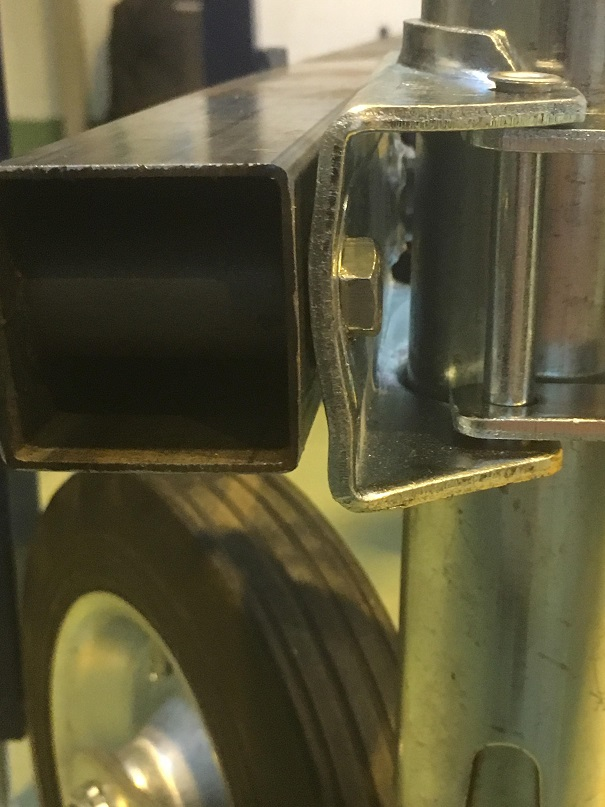

CBH, DK | New Struts Installation | Struts arrived and were installed on Wednesday. The holes on one side of each of the struts to connect the wheels to were slightly too wide (11.5 cm vs 10.5 cm).

We've taken away part of the wheel holders and now they seem to be fitting in.

See attached photos:

1. First wheel with wide holder holes

2. Close up of work done

3. Second wheel with wide holder holes (on opposite corner of chamber)

4. Close up of work done

5. Wheel holder that was warped previously

6. Wheel holder that was warped previously, other perspective

7. What chamber looks like as of Wednesday afternoon

8. Lead sheets to make chamber a little bit more secure. |

| Attachment 1: 45572519_266919730834791_8330124242079186944_n.jpg

|

|

| Attachment 2: 45627614_274796576508889_3500579035514142720_n.jpg

|

|

| Attachment 3: 45542395_2324689780898515_4518857653308358656_n.jpg

|

|

| Attachment 4: 45719087_191203315125224_4710983944323989504_n.jpg

|

|

| Attachment 5: 45617345_565825447222151_5971399735796301824_n.jpg

|

|

| Attachment 6: 45552489_494879210995766_5851766338049015808_n.jpg

|

|

| Attachment 7: 45558766_318380375425399_6225540243555090432_n.jpg

|

|

| Attachment 8: 45640419_2077469132528080_1562399133942153216_n.jpg

|

|

|